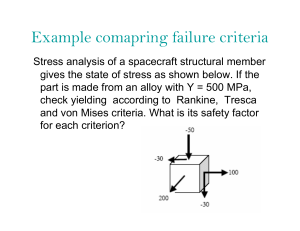

Powder Technology 199 (2010) 111–119 Contents lists available at ScienceDirect Powder Technology j o u r n a l h o m e p a g e : w w w. e l s e v i e r. c o m / l o c a t e / p o w t e c Strength and breakage of activated sludge flocs Yuan Yuan, Ramin R. Farnood ⁎ Department of Chemical Engineering and Applied Chemistry, University of Toronto, 200 College St., Toronto, Ontario, Canada M5S 3E5 a r t i c l e i n f o Article history: Received 18 November 2008 Received in revised form 11 October 2009 Accepted 27 November 2009 Available online 3 December 2009 Keywords: Floc breakage Floc strength Binding force Taylor–Couette flow Activated sludge a b s t r a c t The breakage of activated sludge flocs under turbulent shear conditions was investigated as a function of floc size. Municipal activated sludge flocs were fractionated by sieving to narrow size fractions. Shear stress distribution functions for the breakage of activated sludge floc samples were obtained. It was found that by increasing the floc size, this distribution was skewed towards smaller shear stress values and became broader. Results of experiments showed that the median shear stress, τ50, required for floc breakage reduced by about 23% from 3.9 Pa for 45–63 μm sieve fraction to 3 Pa for the 150–180 μm sieve fraction. Under steady conditions, the median shear stress for the breakage of fragments that formed due to the breakage of larger flocs was as much as three times larger than that of the original flocs. © 2009 Elsevier B.V. All rights reserved. 1. Introduction Better understanding of the breakage of activated sludge flocs under hydrodynamic stress could help improve the performance of solid/ liquid separation and disinfection processes in wastewater treatment systems. Floc breakage depends on its strength in tension, compression, and shear. To quantify floc strength, various methods have been developed such as hydrodynamic stress, sonication methods, and micromechanical and micromanipulation techniques. A comprehensive comparison of these methods could be found in a recent review paper [1]. In particular, techniques that are based on hydrodynamic stress utilize a variety of different flow conditions to break up the flocs [2– 19,43]. The change in the floc size is then monitored either directly using particle size analyzers [10], microscopy [8], or high speed imaging [4,20]; or indirectly by measuring changes in the turbidity of the sample [9,21]. Experimental and theoretical studies suggest that larger flocs break more readily than the smaller ones under shear stress [22,23]. Tambo and Hozumi [15] investigated the breakage of kaolin–aluminum sulfate flocs and concluded that the maximum diameter of such a floc in turbulent flow is a function of the mean effective dissipation energy. Parker et al. [24] found that the relationship between maximum stable floc diameter, dmax, and the mean velocity gradient, G, can be expressed by dmax =cG− n. Similar results reported by other investigators indicate that the power n varies between 0.4 and 4 for turbulent flow and various aggregate types [25]. It has been proposed that as floc size increases the floc density is reduced, and reduction in the mass concentration within ⁎ Corresponding author. Tel.: + 1 416 946 7525; fax: + 1 416 978 8605. E-mail address: [email protected] (R.R. Farnood). 0032-5910/$ – see front matter © 2009 Elsevier B.V. All rights reserved. doi:10.1016/j.powtec.2009.11.021 flocs will decrease the number of bonds per unit volume of floc and therefore decrease the floc strength [3,23]. The breakage of flocs may occur due to three different mechanisms: 1— large-scale fragmentation where a floc is broken into two or more smaller flocs, 2— surface erosion where single primary particles or their small aggregates are eroded off the floc [21], and 3— chipping due to impact upon solid surfaces. For example, in studying wood fiber flocs, Lee and Brodkey [26] reported that a shear stress of 2 Pa would result in floc breakage through massive fragmentation and small-scale erosion. Fragmentation will cause a shift in the particle size distribution towards smaller particles without any change in the number of primary particles while erosion will create a large number of primary particles. Based on the floc breakage mechanisms, several theoretical models have been reported to rationalize the floc strength and breakage process under hydrodynamic shear [7,8,13,15,17,20]. The available data on floc breakage deals with suspensions of polydispersed flocs with a wide size distribution. This, at best, provides only average strength value and masks critical information regarding floc breakage process. Furthermore, the majority of previous research is focused on the synthetic flocs that differ significantly from activated sludge flocs encountered in the wastewater treatment processes. Therefore the objectives of this study were: (1) to quantify the strength of activated sludge flocs as a function of the floc size, and (2) to investigate the activated sludge floc breakage process. In particular, the focus of this work was the large particle fractions that survive exposure to hydrodynamic shear. This is particularly important for the performance of downstream treatment processes such as disinfection systems. To achieve these objectives, activated sludge flocs were sieved to a narrow size fraction and were subjected to hydrodynamic shear stress using a Taylor–Couette flow cell. Changes in the particle size distribution were analyzed to estimate the shear sensitivity of activated sludge flocs. 112 Y. Yuan, R.R. Farnood / Powder Technology 199 (2010) 111–119 2. Theory Flocs exposed to hydrodynamic stress break up if stresses acting on them exceed the floc strength over a sufficiently long period of time. However, the floc strength is commonly considered to be a deterministic function of its size. This is an oversimplification since similar size flocs exhibit a large spectrum of shapes and structures and therefore respond differently under similar shear stress levels. The strength distribution of flocs can be monitored by subjecting them to rising levels of hydrodynamic stress and monitoring the number of broken flocs. By increasing the level of stress, a growing number of flocs that are weaker than the applied hydrodynamic force would break up. At steady state, the floc size distribution reaches a stable level. For a sufficiently dilute suspension, the kinetics of this process is dominated by floc breakage and the net change in the number of flocs within a specific size range is equal to the difference between “death” caused by the breakage of aggregates within this size range and “birth” due to the breakage of larger flocs [10]. However, if flocs are mono-dispersed with characteristic length within [d, d + δ] where δ ≪ d, the birth rate can be neglected and the change in the number of flocs can be exclusively attributed to the floc death due to breakage. After breakage, the number of surviving flocs within [d, d + δ] represents the “cumulative” number of flocs that are “stronger” than the hydrodynamic stress exerted on them. Therefore, the fractional reduction in the concentration of large flocs at various shear stress levels will represent the cumulative distribution of shear stress required for floc breakage. Fractionation can be used to narrow the size distribution of suspended aggregates, but fractionated aggregates have a polydispersed size distribution, schematically shown by curve 1 in Fig. 1. Upon the application of shear, weaker flocs break to give birth to a large number of smaller particles. The result is a bimodal size distribution similar to curve 2 in Fig. 1. However, in order to calculate the number of broken flocs based on the change in the particle size distribution, the effect of birth on the floc count should be minimized if not eliminated. This can be achieved by monitoring change in the total number of flocs that are larger than a threshold size: the larger the threshold floc size, the smaller the contribution of “birth” to the total number of flocs that are larger than this threshold value. To examine this idea, activated sludge flocs were subjected to hydrodynamic shear stress in a Taylor–Couette flow cell. Under such conditions, suspended flocs will be exposed to a mixture of shear flow with high vorticity, irrotational strains; rotational flow within eddies, and streams with no distortion or rotation [4]. Because of the complex nature of such systems, the root mean square of velocity gradient is commonly used to characterize the turbulent shear rate [1]: G= ð1Þ where ɛ is the energy dissipation rate and ν is the kinematic viscosity. In turbulent Taylor–Couette flow, the total energy dissipation can be expressed in terms of torque [27]: ε= TΩ 2πρLða2o −a2i Þ: ð2Þ Here T is the torque, Ω is the rotational speed, ρ is the fluid density, L is the length of annulus, and ai and ao are the radii of inner and outer cylinder, respectively. To determine the total dissipation rate, the value of torque is required. Here, we use Wendt's expressions to estimate the torque [28]: θ = 1:45 η3 = 2 1:5 Re ð1−ηÞ7 = 4 for 4 × 102 b Re b 104 = 0:23 η3 = 2 1:7 Re ð1−ηÞ7 = 4 for 104 b Re b 105 ð3Þ where θ(=T/ρν2L) is the dimensionless torque, η is the ratio of the radius of inner cylinder to the radius of the outer cylinder, and Re is the Reynolds number defined by: Re = Ωai ðao −ai Þ : ν ð4Þ Using Eqs. (1) to (3), an estimation of the turbulent shear rate, G, can be obtained, and then used to calculate the turbulent shear stress according to [7]: τ = μG: ð5Þ Turbulent shear stress given by Eq. (5) has reportedly been used to approximate the hydrodynamic shear stress acting on a floc [4]. However, it is important to recognize that in reality the shear stress exerted on a floc under turbulent conditions is a complex function of turbulent flow field and the floc–fluid interactions. In this study, we adopt the maximum shear stress criteria, i.e. it is assumed that flocs will break if the turbulent shear stress exceeds a critical value that is considered to be the floc strength [29]. Therefore, the cumulative number of broken flocs as a function of the turbulent shear stress is related to the floc strength distribution. However, it should be noted that due to the spatial distribution of turbulent stresses within the fluid, various flocs will have a different shear stress history depending on their trajectory in the flow cell. Here, we use the average “global” r.m.s velocity gradient given by G = (ε/ν)1/2 to obtain an estimation of the average shear stress exerted on flocs. It has been suggested that the breakage mechanism of flocs is controlled by the Kolmogorov microscale, λ [30]: λ= Fig. 1. Schematic diagram showing the size distribution of fractionated activated sludge flocs before (curve 1) and after (curve 2) exposure to hydrodynamic shear stress. rffiffiffi ε ν ν3 ε !1 = 4 ð6Þ where ν is the kinematic viscosity of fluid. It is proposed that under inertial subrange conditions (d NN λ), flocs are more likely to break by large-scale fragmentation, while surface erosion is proposed to dominate the break up in viscous subrange (d bb λ). Y. Yuan, R.R. Farnood / Powder Technology 199 (2010) 111–119 3. Experimental 3.1. Samples Activated sludge samples were obtained from the Ashbridge Bay Municipal Wastewater Treatment Plant, Toronto, Canada. These samples were collected from the effluent channel of the aeration tank and carried using a sealed 20 L plastic tank. During stationary operation, the aeration tank VSS was 1500–2000 mg/L with a sludge age of 6.5 days and an average effluent BOD5 of 10 mg/L. Samples were fractionated in the laboratory immediately after receiving based on the procedure described below. All experiments were started immediately after fractionation and were completed within 48 h. 3.2. Size fractionation and particle sizing Activated sludge flocs were separated into narrow size fractions using a set of eight sieve trays with mesh sizes of 45 μm, 63 μm, 75 μm, 90 μm, 106 μm, 125 μm, 150 μm, and 180 μm (VWR, stainless steel). These sieves were vertically assembled with smaller sieve trays at the bottom and wastewater sample was gently added to the top sieve. To achieve better particle separation and to minimize floc breakage during fractionation, each fraction was washed carefully using a gentle flow of water for at least 20 min. Six sieve size fractions, namely 45–63, 63–75, 75–90, 90–106, 106–125, and 150–180 μm, were collected and a stock suspension of each size fraction was prepared by dispersing the collected flocs in deionized water. The floc size distribution for each fraction was determined using a Coulter particle size analyzer (Multisizer 3, Beckman Coulter, Miami, US) with a 280 μm aperture was used for measuring the size distribution of flocs. To achieve the desired particle concentration for the size analysis, 10 mL of the activated sludge floc suspension was added to 60–80 mL of the electrolyte. A measurement time of 60 s was used to ensure a constant volume of sample is analyzed in all tests. 113 Table 1 The turbulent shear rate and shear stress as a function of the rotational speed, calculated based on Eq. (5). N (rpm) Shear rate (s− 1) Turbulent shear stress (Pa) 1000 2000 3000 4000 5000 6000 2120 5040 8560 12,600 17,100 21,800 2.1 5.0 8.6 12.6 17.1 21.9 3.3. Shear experiments The experimental apparatus for shear breakage is depicted in Fig. 2. The flow cell was a custom-made device consisted of a stainless steel spindle (4.0 cm in diameter and 4.0 cm in length) and a transparent acrylic cup (4.4 cm diameter and 6.5 cm long). The gap between the spindle and the cup was 0.2 cm. The spindle was driven by a variable speed motor (Servodyne 50003-04, Cole-Parmer Instruments Co.) and its rotational speed was adjusted between 500 and 6000 rpm using a digital controller. The turbulent shear rate and shear stress as a function of the rotational speed, calculated based on Eq. (5), are given in Table 1. For each experiment, the flow cell was filled with 10 mL of fractionated activated sludge floc suspension with a volume concentration between 10− 4 and 10− 3 mL/mL. The floc suspension was exposed to the target rotational speed and was allowed to reach steady breaking conditions. The suspension was then removed for particle size analysis. This procedure was repeated at various speeds from 500 to 6000 rpm for each of the six size fractions. 4. Results and discussion 4.1. Initial floc size distribution The Coulter size distributions of 45–63 μm, 75–90 μm, 106– 125 μm, and 150–180 μm sieve fractions prior to breakage experiments are shown in Fig. 3, for clarity 63–75 μm fraction is not shown in this figure. The mode sizes for these fractions were 29, 43, 61, and 78 μm; respectively, that were less than the corresponding sieve size ranges. This is expected since Coulter particle size analyzer is based on the electrozone sensing that measures the solid volume of particles. Hence, the high porosity of activated sludge flocs leads to the undersizing of these flocs by a factor of about 2 [31]. In this study, Coulter particle sizing was used to determine the relative changes in the floc size distribution, therefore the underestimation of the absolute floc size does not affect the quantitative analysis of data. Fig. 2. Schematic diagram of the Taylor–Couette flow cell used in this study. Fig. 3. Coulter size distributions of fractionated activated sludge samples. 114 Y. Yuan, R.R. Farnood / Powder Technology 199 (2010) 111–119 Fig. 5. Effect of shear rate on floc size. Fig. 4. Effect of shear time on the median floc size, d50. 4.2. Shear time A set of experiments was conducted to study the time needed to reach the steady state floc size distribution in the Taylor–Couette flow cell. A suspension of 106–125 μm activated sludge floc size fraction was exposed to 1500 rpm for 5, 10, 15, 20, 25 and 30 min. The results summarized in Fig. 4 showed that the median floc size, d50, decreased steadily with time and reached a plateau level after about 15 min. Therefore, to ensure steady state floc size distribution, all the shear experiments in this study were performed for 20 min. 4.3. Floc binding force As discussed earlier, floc breakage data is commonly represented in terms of a power law relationship, d = cG− n, where G is the average shear rate and d is the floc size. The exponent, n, provides information about the sensitivity of floc to increase in the shear rate. This parameter is related to the floc strength [1,22]. Table 2 provides a list of several earlier studies reported in the literature for various types of flocs. The G–d diagrams from these studies are plotted in Fig. 5. The value of exponent n in Table 2 varies between 0.16 and 0.81, depending on the floc type and hydrodynamic shearing conditions. In the present study, the value of n for 45–63, 63– 75, and 75–90 µm fractionated activated sludge samples were found to be 0.47 (0.37–0.55), 0.60 (0.38–0.82), and 0.54 (0.29–0.79), respectively, where numbers in parenthesis represent the confidence intervals. However, differences among these values were not statistically significant, suggesting that the dominant breakage mechanism is likely the same for the above fractionated samples. Several theoretical models have been proposed for the stable floc diameter as a function of shear rate. These theoretical models are based on either force balance or energy balance; i.e. floc breakage occurs when the external forces (or energy) acting on a floc exceed the floc binding force (or binding energy). Furthermore, these models are typically classified into viscous subrange and inertial subrange depending on the relative size of flocs with respect to the turbulence microscale. Fig. 5 shows that in the present study, the average size of activated sludge flocs remained larger than the turbulence microscale. A list of theoretical models that are suitable for such conditions is given in Table 3. Models 1 and 3, proposed by Parker et al. [24] and Kobayashi et al. [7], predicted that floc size was proportional to G− 1/2. On the other hand, Bache et al. [3] and Tambo and Hozumi [15] used a floc size–density function and found that exponent n was a function of the floc-size density exponent, Kp, that is related to the fractal dimension of the floc according to Kp = 3 − DF. Considering the fractal dimension of activated sludge flocs is of the order of 2, both model 2 and model 4 predict that stable floc diameter is approximately proportional to G− 1. Based on the above discussion, the values of exponent n for the fractionated activated sludge samples were close to the theoretical predictions of Parker et al. [24] and Kobayashi et al. [7] (models 1 and 3 in Table 3). In fact, using regression analysis, the G–d data for the fractionated floc samples could be expressed by: −1 = 2 dw;avg = C1 G : ð7Þ The values of coefficient C1 were 2.6 × 10− 3, 3.9 × 10− 3, and 3.5 × 10− 3 m/s1//2 for the 45–63 µm, 63–75 µm, and 75–90 µm fractions, respectively. The average relative error of Eq. (7) for the experimental data in the present study is 13%. Table 2 Value of exponent n for various types of flocs reported in the literature. Floc type Activated sludge Clay + Al2(SO4)3 Clay + Al2(SO4)3 Latex + NaCl Humic acid + Al2(SO4)3 Latex + KCl Sonicated activated sludge Latex + KCl Clay + PAM/Al2(SO4)3 Sediment + alum/cPAM/chitosan Activated sludge 1 Strain rate1 (s− 1) 1 2 10 –10 102–103 102–103 101–102 102–103 101–103 101–102 101–103 101–102 102–103 103–104 Estimated shear stress, 2Approximate floc size range. Floc size2 (μm) Exponent, n Technique Source 1000–5000 150–1500 100–500 10–50 120–240 10–100 150–300 10–100 60–500 30–90 45–180 0.17–0.37 0.16–0.19 0.43–0.61 0.19–0.26 0.44 0.54 0.27 0.37–0.41 0.37–0.60 0.33–0.81 0.47–0.60 Mixer Paddle mixer Paddle mixer Couette flow Multi-grid mixer Paddle mixer Paddle mixer Orifice flow Paddle mixer Paddle mixer Couette flow [24] [15] [22] [41] [3] [7] [36] [16] [42] [2] This study Y. Yuan, R.R. Farnood / Powder Technology 199 (2010) 111–119 Table 3 Theoretical models for stable floc size under inertial subrange. Model Stable floc size1 Reference 1 1 3 dmax ∝ðAf σÞ =8 G− =2 [24] 2 3 4 dmax ∝σ =8 G 1 3 dmax ∝ðfNc Þ =8 G− =2 −1=Kp 1 dmax ∝ðβφÞ =K G [15] [7] [3] 3 −2=ð1þKp Þ p 1 σ: tensile strength of floc, Af: cross sectional area of fragments, Kp: exponent of floc density function, f: cohesive force between primary particles, Nc: number of contacts between clusters, β: proportion of broken bonds, φ: bond energy. According to Parker et al. [24], the breakage of activated sludge flocs by filament fracture may be idealized as the breakage of two identical spherical primary particle clusters separated by a filamentous strand. The forces accelerating these clusters act in opposite directions and are resisted by the tensile strength of the floc as determined by the floc binding forces. Furthermore, in the inertial subrange, the hydrodynamic forces accelerating these clusters may be approximated by the acceleration of eddies that are in the order of the cluster size. Based on these assumptions and using force balance, authors showed that the value of coefficient C1 could be estimated as: 8=3 C1 = 3Bg πρp βν2 = 3 !3 = 8 ð8Þ where B is the floc binding force at the plane of rupture (=σAf), g is the ratio of cluster diameter to floc diameter, ρp is the floc density, ν is the dynamic viscosity of fluid, and β is the mean-square velocity constant in the inertial subrange that experimentally is found to be 1.5 [32]. Using Eq. (8) it is possible to estimate an average value for floc binding force. Assuming that g ∼ 0.5, ν ∼ 10− 6 m2/s, ρp ∼ 103 kg/m3, and using the values of exponent n given in Table 2, the binding force of the fractionated activated sludge flocs are estimated to be about 130 to 380 nN. In general, B depends on the floc characteristics; however, the value of B has been reported to be in the order of 10− 1–103 nN for various floc types (Table 4). It is worth noting that; with the exception of the micromechanical measurements of Yeung and Pelton [44], the binding force of activated sludge flocs is generally 1–3 orders of magnitude larger than the reported values for similar size synthetic flocs listed in Table 4. Higher binding force of activated sludge flocs compared to these weaker synthetic flocs may be explained based on the differences in the dominant type of intra-floc binding forces. In the case of weak synthetic flocs, primary particles are held together by electrostatic, Table 4 Estimated floc binding force for various types of flocs as reported in the literature. Floc type Floc binding force, nN Technique Source Humic acid + Al2(SO4)3 Latex + KCl Silica + FeCl3 Latex + KCl CaCO3 + dual component polymeric flocculant Clay + PAM/Al2(SO4)3 Polymeric particles + alum/PAM Clay + Al2(SO4)3 Activated sludge Activated sludge 45–63 µm 63–75 µm 75–90 µm 3–5 0.5–5 4–70 0.5–20 15–270 Multi-grid mixer Converging flow Straining flow Converging flow Micromanipulations [3] [17] [38] [16] [44] 2–4 1–20 Paddle mixer Orifice flow [42] [39] 200a 2000–3000a Paddle mixer Mixer [22] [24] 120a 380a 280a Couette flow This study a Estimated using Eq. (6). 115 van der Waals and DLVO [33] type forces. However, entanglement by EPS (extracellular polymeric substances) plays a key role in the cohesion forces within activated sludge flocs [34]. Using correlative microscopy, Droppo et al. [35] found that fibrilar EPS formed a framework within the activated sludge floc that provided structural stability. Further evidence regarding the role of polymer entanglement was provided by Biggs and Lant [36] who studied the strength of flocs formed from the primary particles obtained by the sonication of activated sludge aggregates. Flocs formed in this manner lacked the EPS entanglement and therefore their strength was of the same magnitude of mineral flocs listed in Table 4. Although the relatively higher binding force in Young and Pelton's experiments could be due to biased sampling of large strong flocs, in principle it is possible to prepare synthetic flocs with higher binding forces by proper selection of floc type and floccuant system. 4.4. Floc strength distribution Under turbulent flow conditions, floc size depends on the floc binding forces and turbulence dissipation rate [37]. The binding force of floc in turn is a function of floc characteristics and internal structure. However, as pointed out by Blaser [38], “because of the internal inhomogeneity, the binding force cannot be taken simply as a function, for example of the floc size”, but he added that floc binding force “has to be treated as a random variable; i.e. given a floc of a definite size, there is a certain probability that the floc breaks or not.” A similar argument has been made by Kramer and Clark [29] who stated that aggregates within the same size class have a distribution of bonding strength. In other words, the shear stress required for the breakage of activated sludge flocs is a stochastic variable. Despite the significant role of floc binding force and floc strength in floc breakage process, there is limited experimental data in the literature regarding the statistical distribution of these parameters. In studying the breakage of flocculated polymeric particles under straining flow conditions, Higashitani et al. [39] found that binding force of two-fold particles varied from about 1 nN to 20 nN and the probability of breakage of these particles exhibited a power law distribution. Similarly, using a multi-grid mixer, Bache et al. [40] determined the distribution of pressure forces for the breakage of latex and rice starch flocs. In the present study, changes in the floc size distribution after breakage were used to quantify the probability of breakage of activated sludge flocs at various hydrodynamic shear conditions. The number distribution curves for activated sludge samples prior to and after breakage at 1000, 2000, 3000, and 4000 rpm are shown in Fig. 6. Since the volume concentration of flocs in the Couette flow cell was low (10− 4–10− 3 mL/mL), changes in the floc size distribution were dominated by the floc breakage process. Furthermore, to minimize the effect of floc birth, a lower threshold size of dmode was used such that only flocs larger than dmode were considered in the analysis. Therefore, the fraction of broken flocs could be directly calculated from the floc size distribution data and the floc breakage ratio could be defined as: b= N0 −Nτ N0 ð9Þ where N0 and Nτ are the number of flocs larger than the mode floc size (d N dmode) under the steady state conditions before and after exposure to shear stress, τ, respectively. At a given level of turbulent shear stress, breakage ratio is the total (cumulative) fraction of flocs that are broken under the applied shear stress. Therefore, plot of τ versus b represents the cumulative distribution function (CDF) of the shear stress required for floc breakage, or equivalently the probability of breakage of a floc at a given shear stress. 116 Y. Yuan, R.R. Farnood / Powder Technology 199 (2010) 111–119 Fig. 7. Cumulative fraction of breakage of activated sludge flocs. (a) 45–63, 63–75 and 75–90 µm, and (b) 90–106, 106–125 and 150–180 µm. Data from Bache et al. [3] for latex and starch aggregates are also included. Fig. 7 shows the breakage ratio of activated sludge floc fractions as a function of the applied shear stress for rotational speed between 500 and 6000 rpm. The Reynolds number was in the range of 2600–31,000 that corresponds to turbulent flow regime. In general, the breakage ratio increased and asymptotically approached unity with increasing the shear stress. The median shear stress (τ50); i.e. the shear stress at which the number of flocs reduced by 50%, for various activated sludge floc size fractions are given in Table 5. According to this table, by increasing the floc size from 45–63 μm fraction to 150–180 μm fraction, τ50 decreased by 23% from 3.9 Pa to 3.0 Pa. For comparison, results for rice starch flocs (∼ 2200 µm) and latex flocs (∼ 600 µm) by Bache et al. [40] were 0.72 Pa and 1.4 Pa, respectively. Based on Fig. 7, synthetic flocs containing latex particles and rice starch granules were significantly “weaker” than the activated sludge flocs analyzed in the present work. This difference is likely due to differences in the floc Table 5 Median, 10%ile and 90%ile shear stress values for floc breakage, and coefficients of shear stress distribution function; Eq. (8), for various activated sludge floc samples. Fig. 6. Coulter particle size distributions for the activated sludge flocs before and after breakage at various rotational speeds given in rpm: (a) 75–90 μm; (b) 63–75 μm; and (c) 45–63 μm. Sieve size fraction (µm) τ50 (Pa) τ10 (Pa) τ90 (Pa) k (Pa− 1/2) a (Pa−1) θ m 45–63 63–75 75–90 90–106 106–125 150–180 Resieved 45–63 Resieved 75–90 1 1 1 1 1 1 2 2 3.9 3.9 3.4 3.6 3.2 3.0 9.8 7.8 2.4 2.2 1.4 1.0 1.0 0.7 6.6 5.3 13.3 7.8 9.5 8.2 8.4 8.3 22.6 17.4 0.63 0.83 0.74 0.83 0.77 0.72 0.62 0.71 0.86 0.67 0.54 0.33 0.45 0.29 0.38 0.46 2.90 2.34 1.52 0.95 1.08 0.53 3.34 3.29 Y. Yuan, R.R. Farnood / Powder Technology 199 (2010) 111–119 structure and composition. Similar results have been reported by Bache et al. [3] who found that synthetic alumino-humic flocs were significantly weaker than natural flocs found in turbid waters. Fig. 7 also shows a wide variation in the shear stress required for the breakage of activated sludge flocs: depending on the flocs size fraction, 10th percentile and 90th percentile shear stress values were 0.7–2.4 Pa and 8.2–13.3 Pa, respectively (Table 5). This wide variation is due to the variability in the internal floc structure and strength. To better quantify this variability, the G–b data provided in Fig. 7 was used to estimate the probability density function (PDF) of the shear stress for the breakage of activated sludge size samples. In order to do this, the experimental breakage data were first fitted to the following distribution function: 117 figure, by increasing the floc size from 45–63 μm to 150–180 μm, the distribution of shear stress was increasingly skewed towards smaller shear stress values and the distribution became broader. This means that by increasing the floc size, it is more likely to encounter weaker flocs while a small fraction of relatively stronger flocs remains in the population. In particular, the PDF for the largest floc size range, i.e. 150–180 μm, shows a more rapid initial increase compared to the smaller flocs, indicating that a larger number of bigger flocs break at a relatively lower levels of shear stress values. This difference is expected since larger flocs are significantly weaker than smaller ones. 4.5. Floc breakage process Using the above equation, the probability density of shear stress for floc breakage was obtained and plotted in Fig. 8. Based on this According to Fig. 5, the activated sludge flocs in the present study remained larger than the turbulent microscale. Therefore, shearing experiments were conducted under inertial subrange conditions and floc breakage process was likely dominated by large-scale fragmentation [30]. However, erosion and fragmentation likely occurred simultaneously [22], i.e. flocs that were of the order of or larger than the turbulent microscale broke into large fragments, and those fragments that were smaller than the turbulent microscale were further eroded into smaller flocs and primary particles. In addition, turbulent eddies have a wide size range. Hence, for a given size floc, eddies that are bigger than the floc size could cause surface erosion while small eddies may result in the fragmentation of floc. This concept is supported by the floc size distribution after exposure to hydrodynamic shear in Fig. 6. This figure shows that upon exposure to shear, larger flocs were broken to form a large number of intermediate-size fragments and as well as small flocs. Furthermore, the presence of these fragments under steady state conditions indicates that they resisted the hydrodynamic shear stress. In other words, fragments that were generated due to the floc breakage were “stronger” than the original flocs. Therefore, under steady state shear conditions, the breakage of larger flocs resulted in the formation of smaller flocs that could either further decrease in size by erosion or fragmentation, or resist the breakage all together. To further examine this concept, the intermediate-size fragments were isolated and tested for their shear sensitivity. A 90–106 µm sieve fraction sample was exposed to hydrodynamic shear stress at 5.0 Pa (i.e. 2000 rpm) for 20 min. The sheared sample was then removed and resieved to recover 45–63 µm and 75–90 µm fragment fractions. These samples were then examined using the procedure described earlier. The breakage ratios of the resieved fractions are given in Fig. 9. This figure shows that the breakage process was delayed until shear stress reached to about 5 Pa, i.e. the same shear level that the initial 90–106 µm sample was exposed to. Compared to the breakage ratio for fresh fractions given in Fig. 7a, the resieved fragments clearly Fig. 8. Probability density of shear stress for the breakage of various activated sludge floc size fractions. Fig. 9. Cumulative fraction of breakage of resieved activated sludge floc samples. Data for 106–125 µm is included for comparison. pffiffi −k τ m bðτÞ = f ðτÞð1−e Þ ð10:aÞ where f (τ) is given by: f ðτÞ = 1 τ + 1 = tanhðθÞ 1+ tanhðaτ−θÞ : 2 τ+1 ð10:bÞ The above PDF is merely a mathematical function that can accurately describe various features of experimental data shown in Fig. 7. Constants k, a, θ, and m were determined by non-linear optimization using Mathematica™ (version 6.0), and their values for various activated sludge samples are given in Table 5. Eq. (8) fitted the experimental data with r2 = 0.99. As discussed earlier, by definition, the above equation represents the cumulative distribution function of shear stress for the floc breakage. Therefore, the probability density function, PDF(τ), can be determined from: PDFðτÞ = d ½bðτÞ dτ ð11Þ that gives: pffiffi −k τ m PDFðτÞ = gðτÞð1−e Þ ð12:aÞ 2 gðτÞ = aðx + 1Þðx + cothθÞ sech ðax−θÞ−ðcothθ−1Þ tanhðax−θÞ 2ðx + 1Þ2 ð12:bÞ mk ðx + cothθÞ tanhðax−θÞ pffiffi + 1 : + pffiffiffi x+1 4 xð1−e−k τ Þ 118 Y. Yuan, R.R. Farnood / Powder Technology 199 (2010) 111–119 g m n Af B C1 G N0 Nτ Re T L β ε Fig. 10. Probability density of shear stress for the breakage of re-sieved activated sludge floc samples. For comparison, results for the 106–125 um size fraction are also included. exhibited a higher resistance to breakage. The median shear stress values for resieved fractions were more than twice larger than those for freshly sieved activated sludge floc samples of the same size fraction (Table 5). The shear stress distribution for the breakage of reseived 45–63 µm and 75–90 µm samples is given in Fig. 10. For comparison, the shear stress distribution of the original flocs; i.e. 90–106 µm size fraction, is also plotted on the same figure. This figure shows that smaller fragments (i.e. 45–63 µm and 75–90 µm resieved fractions) generated by the hydrodynamic breakage of larger flocs (i.e. 90–106 µm fraction) are significantly stronger. The shear stress distribution of the resieved fragments shifted to higher values such that the median shear stress was 2–3 times higher than that of the original 90–106 µm fraction. This result further emphasized on the heterogeneous nature of the floc internal structure and binding forces. In addition, compared to the original 45–63 µm and 75–90 µm (see Fig. 8), the strength distribution of the resieved fractions is significantly shifted towards larger values. 5. Conclusions The binding forces of fractionated activated sludge flocs with a narrow size distribution were estimated to be in the order of 102 nN. The hydrodynamic shear stress required for the breakage of activated sludge flocs within the same narrow size fraction exhibited a large variation. This emphasizes the variability in the internal floc structure and strength. Furthermore, by increasing the activated sludge floc size, the distribution of hydrodynamic shear stress required for the breakage of activated sludge flocs became broader and shifted towards smaller shear stress values. The median hydrodynamic shear stress for the breakage of activated sludge flocs was found to decrease with the floc size according to a power law relationship, τ50 ∼ d− 0.26, while τ10 was a stronger function of the floc size such that τ10 ∼ d− 1.2. Under steady shear conditions, the breakage of larger flocs resulted in the formation of smaller fragments that could resist the breakage all together. The median shear stress for the breakage of 45– 63 µm fragments formed by exposing a 90–106 µm sieve fraction to a hydrodynamic shear stress value of 5 Pa was three times larger than that of the initial sample. Nomenclature a Parameter in Eq. (10.b) ai Radius of spindle (m) ao Radius of the cup (m) b Breakage ratio defined by Eq. (9) d Floc diameter (m) f Auxiliary function defined by Eq. (10.b) η λ μ ν θ ρ ρp σ τ τ50 τ10 τ90 Ω Ratio of cluster diameter to floc diameter (–) Exponent in the breakage ratio function (Eq. (10)) Exponent of in G–d power law relationship Cross sectional area of filament (m2) Floc binding force (N) Constant Turbulent shear rate (s− 1) Initial number of flocs Number of flocs after exposure to shear stress τ Reynolds number Torque (N m) Length of annulus in Couette flow cell (m) Mean-square velocity constant in the inertial subrange (–) Turbulent energy dissipation rate per unit of mass (N m s− 1 kg− 1) =a/b Kolmogorov microscale (m) Viscosity (kg m− 1 s− 1) Kinematic viscosity (m2 s− 1) Dimensionless torque number (=T/ρν2L) Fluid density (kg/m3) Floc density (kg/m3) Floc tensile stress (N m− 2) turbulent shear stress (N m− 2) Median shear stress (N m− 2) 10th percentile shear stress (N m− 2) 90th percentile shear stress (N m− 2) Rotational speed of spindle (rad s− 1) Acknowledgements The support from Natural Science and Engineering Research Council of Canada (NSERC), Canada Foundation for Innovation (CFI), the government of Ontario, and University of Toronto is gratefully acknowledged. References [1] P. Jarvis, B. Jefferson, J. Gregory, S.A. Parsons, A review of floc strength and breakage, Water Research 39 (14) (2005) 3121–3137. [2] I.G. Droppo, K. Exall, K. Stafford, Effects of chemical amendments on aquatic floc structure, settling and strength, Water Research 42 (1–2) (2008) 169–179. [3] D.H. Bache, E. Rasool, D. Moffat, F.J. McGilligan, On the strength and character of alumino-humic flocs, Water Science and Technology 40 (9) (1999) 81–88. [4] M. Boller, S. Balser, Particles under stress, Water Science and Technology 37 (10) (1998) 9–29. [5] P.K. Jin, X.C. Wang, H. Chai, Evaluation of floc strength by morphological analysis and PDA online monitoring, Water Science and Technology 56 (10) (2007) 117–124. [6] S. Kao, S. Mason, Dispersion of particles by shear, Nature 253 (5493) (1975) 619–621. [7] M. Kobayashi, Y. Adachi, S. Ooi, Breakup of fractal flocs in a turbulent flow, Langmuir 15 (13) (1999) 4351–4356. [8] T. Matsuo, H. Unno, Forces acting on floc and strength of floc, Journal of Environmental Engineering 107 (EE3) (1981) 527–545. [9] L.H. Mikkelsen, K. Keiding, Equilibrium aspect of the effect of shear and solids content on aggregate deflocculation, Advances in Colloid and Interface Science 80 (2) (1999) 151–182. [10] S.J. Peng, R.A. Williams, Direct measurement of floc breakage in flowing suspensions, Journal of Colloid and Interface Science 166 (1994) 321–332. [11] M.G. Rasteiro, F.A.P. Garcia, P. Ferreira, A. Blanco, C. Negro, E. Antunes, Evaluation of flocs resistance and reflocculation capacity using the LDS technique, Powder Technology 183 (2) (2008) 231–238. [12] T. Serra, X. Casamitjana, Structure of the aggregates during the process of aggregation and breakup under a shear flow, Journal of Colloid and Interface Science 206 (2) (1998) 505–511. [13] R.C. Sonntag, W.B. Russel, Structure and breakup of flocs subjected to fluid stresses. I. Shear experiments, Journal of Colloid and Interface Science 113 (2) (1986) 399–413. [14] S.-S. Sung, S.-P. Ju, C. Hsu, A.S. Mujumdar, D.-J. Lee, Floc strength evaluation at alternative shearing with presence of natural organic matters, Drying Technology 26 (8) (2008) 996–1001. [15] N. Tambo, H. Hozumi, Physical characteristics of flocs—II. strength of floc, Water Research 13 (5) (1979) 421–427. Y. Yuan, R.R. Farnood / Powder Technology 199 (2010) 111–119 [16] Y. Adachi, M. Kobayashi, Y. Fukuhara, Break-up strength of floes analyzed using orifice converging flow, Nihon Reoroji Gakkaishi 35 (2) (2007) 69–72. [17] M. Kobayashi, Breakup and strength of polystyrene latex flocs subjected to a converging flow, Colloid and Surfaces A: Physicochemical and Engineering Aspects 235 (1–3) (2004) 73–78. [18] R.L. Powell, S.G. Mason, Dispersion by laminar flow, AIChE Journal 28 (2) (1982) 286–293. [19] R.C. Sonntag, W.B. Russel, Structure and breakup of flocs subjected to fluid stresses. III. Converging flow, Journal of Colloid and Interface Science 115 (2) (1987) 390–395. [20] L.A. Glasgow, P.J. Hsu, An experimental study of floc strength, AIChE Journal 28 (5) (1982) 779–785. [21] L.H. Mikkelsen, K. Keiding, The shear sensitivity of activated sludge: an evaluation of the possibility for a standardized floc strength test, Water Research 36 (12) (2002) 2931–2940. [22] R.J. Francois, Strength of aluminum hydroxide flocs, Water Research 21 (9) (1987) 1023–1030. [23] R.C. Sonntag, W.B. Russel, Structure and breakup of flocs subjected to fluid stresses. II. Theory, Journal of Colloid and Interface Science 115 (2) (1987) 378–389. [24] D.S. Parker, W.J. Kaufman, D. Jenkins, Floc breakup in turbulent flocculation process, ASCE Journal of the Sanitary Engineering Division 98 (SA1 Fe) (1972) 79–99. [25] J.C. Flesch, P.T. Spicer, S.E. Pratsinis, Laminar and turbulent shear-induced flocculation of fractal aggregates, AIChE Journal 45 (5) (1999) 1114–1124. [26] C.W. Lee, R.S. Brodkey, A visual study of pulp floc dispersion mechanisms, AIChE Journal 33 (2) (1987) 297–302. [27] T.H. Van den Berg, C.R. Doering, D. Lohse, D.P. Lathrop, Smooth and rough boundaries in turbulent Taylor–Couette flow, Physical Review E — Statistical, Nonlinear, and Soft Matter Physics 68 (32) (2003) 363071–363075. [28] D.P. Lathrop, J. Fineberg, H.L. Swinney, Transition to shear driven turbulence in Couette–Taylor flow, Physical Review A 46 (10) (1992) 6390–6405. [29] T.A. Kramer, M.M. Clark, Incorporation of aggregate breakup in the simulation of orthokinetic coagulation, Journal of Colloid and Interface Science 216 (1) (1999) 116–126. [30] D.N. Thomas, S.J. Judd, N. Fawcett, Flocculation modeling: a review, Water Research 33 (7) (1999) 1579–1592. 119 [31] Yuan Yuan, Jacques F. NdoutouMve, Mary Siew, Oanh Vo, Ramin Farnood, Sizing of wastewater particles using the electro-zone sensing technique, Particulate Science and Technology 27 (1) (2009) 50–56. [32] J.L. Lumley, Fundamental aspects of incompressible and compressible turbulent flows, in: T.B. Gatski, M. Yousuff Hussaini, J.L. Lumley (Eds.), Simulation and Modeling of Turbulent Flows, Oxford University Press, 1996, p. 8. [33] E.J.W. Verwey, J.Th.G. Overbeek, Theory of the Stability of Lyophobic Colloids, Elsevier, Amsterdam, 1948. [34] L.H. Mikkelsen, P.H. Nielsen, Quantification of the bond energy of bacteria attached to activated sludge floc surfaces, Water Science and Technology 43 (6) (2001) 67–75. [35] I.G. Droppo, Structural controls on floc strength and transport, Canadian Journal of Civil Engineering 31 (4) (2004) 569–578. [36] C.A. Biggs, P.A. Lant, Activated sludge flocculation: on-line determination of floc size and the effect of shear, Water Research 34 (9) (2000) 2542–2550. [37] J. Bridgeman, B. Jefferson, B. Parsons, Assessing floc strength using CFD to improve organics removal, Chemical Engineering Research and Design 86 (8) (2008) 941–950. [38] S. Blaser, Flocs in shear and strain flows, Journal of Colloid and Interface Science 225 (2) (2000) 273–284. [39] K. Higashitani, I. Nobufumi, T. Ochi, Floc breakup along centerline of contractile flow of orifice, Colloids and Surfaces 56 (C) (1991) 13–23. [40] D.H. Bache, C. Johnson, J.F. McGilligan, E. Rasool, A conceptual view of floc structure in the sweep floc domain, Water Science and Technology 36 (4) (1997) 49–56. [41] V. Oles, Shear-induced aggregation and breakup of polystyrene latex particles, Journal of Colloid and Interface Science 154 (2) (1992) 351–358. [42] T. Li, Z. Zhu, D. Wang, C. Yao, H. Tang, Characterization of floc size, strength and structure under various coagulation mechanisms, Powder Technology 168 (2) (2006) 104–110. [43] V. Oles, Shear-induced aggregation and breakup of polystyrene latex particles, Journal of Colloid and Interface Science 154 (2) (1992) 351–358. [44] A.K.C. Yeung, R. Pelton, Micromechanics: a new approach to study the strength and breakup of flocs, Journal of Colloids and Interface Science 184 (2) (1996) 579–585.