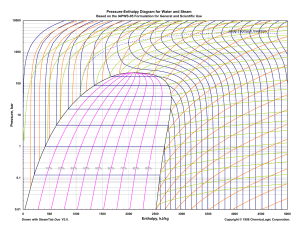

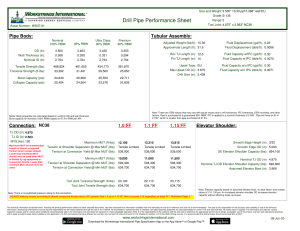

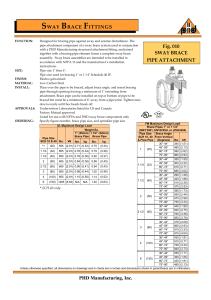

Calculating Condensate Loads Warm Up Load ( Heating Loss ) This is the amount of condensate which forms at starting up a power plant to raise the temperature of the metal of pipes, fittings, etc. to the operating temperature without including the normal radiation loss. As far as calculating the condensation load during the warming up period the required time is extremely important for sizing steam traps. Less warm up time increases the necessary capacity per trap. Allowing more time for warm up permits the use of smaller traps in smaller quantity. W x (T-t) x Sp. Heat x 60 Q = ————————————— Lxm Where Q = Quantity of Condensate ( Lbs/hr ) W = Total weight of pipes in LBS T = Saturation Steam Temp ( °F ) t = initial temp of pipe ( °F ) usually surrounding air temp m = minutes to heat up system L = Latent heat of steam ( BTU’s/Hr ) www.velansteamtraps.com 1-800-860-0233 [email protected] Normal Condensate Load ( Radiation Loss ) Once the system is heated up steam condenses due to normal radiation losses to the surrounding air. These losses depend of course on the size and length of the pipe, on the pressure of steam and its latent heat and mainly on the type and thickness of insulation. The equation from which a normal regulation load can be calculated is: F x HL ( T - t ) Q = —————————— L Where F = Length of Pipe (ft) HL ( T – t ) = Heat loss/foot of pipe at the temperature differential between steam and air Above Table L = Latent heat of steam ( BTU’s/Hr. ) www.velansteamtraps.com 1-800-860-0233 [email protected] Condensation Load for Sizing Steam Traps The condensation load builds up from 0 to maximum at the point where the warming up load drops to 0. It is assumed, therefore, that the peak is achieved halfway through the warming up period. Therefore, for sizing of steam traps, we take the maximum amount of condensate during the warming up period plus half of the radiation load. Qt= QW + .5QR Where Qt = Total condensation load at peak (LBS/Hr) QW = Condensation load during warm up (LBS/Hr) QR = Condensation load due to normal radiation loss (LBS/Hr) Condensate in LBS/Hr created in steam mains 1” to 24” and pressure of 600 to 2500 PSI based on the warm up period of 1 hour and 100 feet of pipe, and based on the above assumption is shown in tables. For shorter or longer heating up time, multiply by 60/m where m is the warm up time in minutes. www.velansteamtraps.com 1-800-860-0233 [email protected] Properties of Saturated Steam Heat in BTU/lb Gauge Temp Sens Pressure °F ible PSIG 25 134 102 20 162 129 179 147 15 192 160 10 203 171 5 212 180 0 215 183 1 219 187 2 222 190 3 224 192 4 227 195 5 230 198 6 232 200 7 233 201 8 237 205 9 239 207 10 244 212 12 248 216 14 16 252 220 18 256 224 20 259 227 22 262 230 24 265 233 268 236 26 271 239 28 274 343 30 277 346 32 279 248 34 282 251 36 284 253 38 286 256 40 289 258 42 291 260 44 293 262 46 295 264 48 298 267 50 300 271 55 307 277 60 65 312 282 70 316 286 75 320 290 80 324 294 85 328 298 331 302 90 335 305 95 338 309 100 341 312 105 344 316 110 347 319 115 350 322 120 353 325 125 356 328 130 361 333 140 363 336 145 Heat in BTU/lb Latent Total 1017 1001 990 982 976 970 968 966 964 962 960 959 957 956 954 953 949 947 944 941 939 937 934 933 930 929 927 925 923 922 920 918 917 915 914 912 909 903 901 898 895 891 889 886 883 880 878 875 873 871 868 866 861 859 1119 1130 1137 1142 1147 1150 1151 1153 1154 1154 1155 1157 1157 1157 1159 1160 1161 1163 1164 1165 1166 1167 1167 1169 1169 1272 1273 1173 1174 1175 1176 1176 1177 1177 1178 1179 1180 1180 1183 1184 1185 1185 1187 1188 1188 1189 1190 1191 1192 1193 1193 1194 1194 1195 www.velansteamtraps.com Specific Volume Cu. Ft./lb 142 73.9 51.3 39.4 31.8 26.8 25.2 23.5 22.3 21.4 20.1 19.4 18.7 18.4 17.1 16.5 15.3 14.3 13.4 12.6 11.9 11.3 10.8 10.3 9.85 9.46 9.10 8.75 8.42 8.08 7.82 7.57 7.31 7.14 6.94 6.68 6.27 5.84 5.49 5.18 4.91 4.67 4.44 4.24 4.05 3.89 3.74 3.59 3.46 3.34 3.23 3.12 2.92 2.98 Gauge Temp Sens Pressure °F ible PSIG 150 366 339 155 368 341 371 344 160 373 346 165 375 348 170 377 351 175 380 353 180 382 355 185 384 358 190 386 360 195 388 362 200 390 364 205 392 366 210 394 368 215 396 370 220 397 372 225 399 374 230 401 376 235 240 403 378 404 380 245 250 406 382 255 408 383 260 409 385 411 387 265 413 389 270 414 391 275 416 392 280 417 394 285 418 395 290 420 397 295 421 398 300 423 400 305 425 402 310 426 404 315 427 405 320 429 407 325 430 408 330 432 410 335 340 433 411 345 434 413 350 435 414 355 437 416 360 438 417 440 419 365 441 420 370 442 421 375 443 422 380 445 424 385 446 425 390 447 427 395 448 428 400 460 439 450 470 453 500 479 464 550 489 475 600 1-800-860-0233 Latent Total 857 855 853 851 849 847 845 843 841 839 837 836 834 832 830 828 827 825 823 822 820 819 817 815 814 812 811 809 808 806 805 803 802 800 799 797 796 794 793 791 790 789 788 786 785 784 783 781 780 778 777 766 751 740 728 1196 1196 1197 1197 1197 1198 1198 1198 1199 1199 1199 1200 1200 1200 1200 1200 1201 1201 1201 1202 1202 1202 1202 1202 1203 1203 1203 1203 1203 1203 1203 1203 1204 1204 1204 1204 1204 1204 1204 1204 1204 1205 1205 1205 1205 1205 1205 1205 1205 1205 1205 1205 1204 1204 1203 Specific Volume Cu. Ft./lb 2.74 2.68 2.60 2.54 2.47 2.41 2.34 2.29 2.29 2.19 2.14 2.09 2.05 2.00 1.96 1.92 1.89 1.85 1.81 1.78 1.75 1.72 1.69 1.66 1.63 1.60 1.57 1.55 1.53 1.49 1.47 1.45 1.43 1.41 1.38 1.36 1.34 1.33 1.31 1.29 1.28 1.26 1.24 1.22 1.20 1.19 1.18 1.16 1.14 1.13 1.12 1.00 .89 .82 .74 [email protected] Standard Dimensions for Schedule 40 Pipe Examples: Warm up loss Ambient Temp = 70°F Working Temp = 366°F (150psig) Warm up time = 720 minutes 1000 feet of 10 inch Schedule 40 pipe weighs = 40483 Latent heat = 857 40483 x (366-70) x .12 x 60 Q = ————————————— 857 x 720 Q = 472 lbs/hr www.velansteamtraps.com 1-800-860-0233 [email protected] Radiation loss Ambient Temp = 70°F Working Temp = 366°F (150psig) Differential temp = 294°F Differential multiplier = .98 1000 feet 10 inch Schedule 40 uninsulated pipe Latent heat = 857 1000 x 2600 ( .98 [factor for 296° diff] ) Q = —————————— 857 Q = 2973 lbs/hr Sizing for steam traps Qt= QW + .5QR .5QR = 1486.5 + QW = 472 = 1958.5 www.velansteamtraps.com 1-800-860-0233 [email protected]