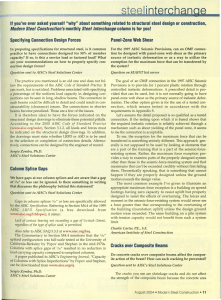

Recent changes in spaecification and Code requirements for conection design

Anuncio

RECENT CHANGES IN SPECIFICATION AND CODE REQUIREMENTS FOR CONNECTION DESIGN IN THE UNITED STATES Charles J. Carter, S.E., P.E. Director of Engineering and Continuing Education American Institute of Steel Construction, Chicago, IL, USA Nestor R. Iwankiw, P.E. Vice President of Engineering and Research American Institute of Steel Construction, Chicago, IL, USA ABSTRACT Many new specifications and codes have been introduced in the United States in the past few years. This paper provides a summary of recent changes in the current specifications and codes that are applicable in steel building design and construction. INTRODUCTION Many new specifications and codes have been introduced in the United States in the past few years. Following is a summary of the current specifications and codes that are applicable in steel building design and construction: x 1999 AISC Load and Resistance Factor Design Specification for Structural Steel Buildings (1) x 1997 AISC Seismic Provisions for Structural Steel Buildings (2) with 2000 AISC Seismic Provisions Supplement No. 2 (3) (note: this supplement replaced 1999 AISC Seismic Provisions Supplement No. 1 (4) in its entirety) x 1997 AISC Specification for the Design of Steel Hollow Structural Sections (5) x 1993 AISC Specification for Load and Resistance Factor Design of SingleAngle Members (6) x 2000 AWS D1.1 Structural Welding Code – Steel (7) x 2000 RCSC Specification for Structural Joints Using ASTM A325 or A490 Bolts (8) Changes have been made in most of these specifications and codes that affect the design and/or construction of connections. Following is a summary of the changes that have been made in each of these specifications and a more detailed look at a few of the more important ones in the 2000 RCSC Specification. The connection requirements for seismic design are still being developed as a part of the 1997 AISC Seismic Provisions and 2000 Supplement No. 2. Additionally, at the time of writing this paper, the SAC Joint Venture is finalizing the Guidelines documents that will be published by the Federal Emergency management Agency (FEMA). The reader is referred to those sources 1 for information on changes in connection design and construction requirements for seismic design. It has been assumed in the writing of this paper that the reader will have a copy of the above specifications and codes for reference. GENERAL SUMMARY OF CHANGES The following major changes have been made in requirements for the design and construction of welded joints: x Limitations on effective length of fillet welds have been clarified and revised. The new provisions focus the applicability of the limitation to end-loaded fillet welds and provide a straightforward means to calculate the effective length as a function of the actual length and the weld size. x The requirements for fillet weld terminations in Section J2.2b of the 1999 AISC LRFD Specification have been revised and clarified. x Notch-toughness requirements have been added in Section J2.6 of the 1999 AISC LRFD Specification. Filler metal with a specified minimum Charpy V-notch (CVN) toughness of 20 ft-lbs at 40 degrees F is required for: x Complete-joint-penetration groove welded T- and corner joints subject to tension normal to the effective area when backing bars are to be left in place (exception: a lesser CVN rating is permitted if the joint is treated as a partial-joint-penetration groove weld) x Complete-joint-penetration groove welded splices subject to tension normal to the effective area in Group 4 and 5 shapes and built-up shapes with plates more than 2 in. thick. x A more detailed listing of other major changes in the 2000 edition of AWS D1.1 can be found in the Foreword to that document. Additionally, a system of underlining and/or vertical line marking in the margin has been used throughout the 2000 edition of AWS D1.1 to indicate specific changes that have been made. The following major changes have been made in requirements for the design and construction of bolted joints: x New provisions have been added in the 1999 AISC LRFD Specification and 2000 RCSC Specification allowing the use of snug-tightened ASTM A325 bolts in applications involving static tensile loading. x Provisions covering the design of bolts in combined shear and tension in Section J3.7 and Appendix J3.7 in the 1999 AISC LRFD Specification and Section 5.2 in the 2000 RCSC Specification have been revised. x Slip-critical joint design provisions have been swapped in Section J3.8/J3.9 and Appendix J3.8/J3.9 in the 1999 AISC LRFD Specification. x Bearing strength calculations in Section J3.10 of the 1999 AISC LRFD Specification and Section 5.3 of the 2000 RCSC Specification have been modified to a clear-distance basis. x As has been the case before, it is occasionally indicated in the 2000 RCSC Specification that information is required to be shown on the design drawings or in other contract documents. Similarly, it is indicated in the 2000 RCSC Specification when the approval of the Engineer of Record is required for some aspect of a bolted joint. As a convenience to the user, a summary of the drawing information and approvals required from the Engineer of 2 x x x x x x x x Record has been added in Section 1.4 in the 2000 RCSC Specification. This subject is discussed in greater detail later in this article. Explicit coverage of the material and geometric requirements for washer-type indicating devices, twist-off-type tension-control bolt assemblies and alternative design fasteners has been added in Sections 2.6, 2.7 and 2.8, respectively, in the 2000 RCSC Specification. Explicit coverage of ASTM F1852 twist-off-type tension-control bolt assemblies has been included throughout the 2000 RCSC Specification. These fastener assemblies were previously covered in general under the alternative-design fastener provisions. Provisions allowing the thermal cutting of bolt holes with the approval of the Engineer of Record have been added in Section 3.3 in the 2000 RCSC Specification. Previously silent on this subject, the new RCSC Specification allows the use of flame cutting, plasma cutting and other thermal cutting processes if approved by the Engineer of Record. New information has been added in Section 4 of the 2000 RCSC Specification to address the applicability and suitability of the various joint types: snug-tightened joints, pretensioned joints and slip-critical joints. The requirements in this Section also serve to identify the applicable design, installation and inspection requirements for each of the joint types. This item is discussed in greater detail later in this paper. In Section 5.5 in the 2000 RCSC Specification, the limitation on prying force for applications that involve tensile fatigue has been reduced from 60 percent of the total applied load to 30 percent. This change was made based upon review of the available research and engineering judgment. Provisions for pre-installation verification of fastener assemblies have been clarified in Section 7 in the 2000 RCSC Specification. These provisions apply as they are invoked in Section 8.2 for pretensioned joints and slip-critical joints. The intent and applicability of the installation requirements and inspection requirements have been simplified, clarified and expanded significantly in Sections 8 and 9, respectively, in the 2000 RCSC Specification. These topics are discussed in greater detail later in this article. Arbitration provisions to be used in the case of a dispute for pretensioned joints and slipcritical joints have been clarified in Section 10 in the 2000 RCSC Specification. The following major changes have been made in requirements for the design and construction of connecting elements: x Revised Provisions for Block Shear Rupture – The provisions in 1999 AISC LRFD Specification Section J4.3 have been modified to account for the possibility in block shear rupture that the block can tear out in a rupture/rupture mode. That is, block shear rupture strength is now checked for three possible modes of failure: x Shear rupture in combination with tension yielding when the rupture strength of the shear plane(s) exceeds the rupture strength of the tension plane(s) x Tension rupture in combination with shear yielding when the rupture strength of the tension plane(s) exceeds the rupture strength of the shear planes(s) x Shear rupture in combination with tension rupture when this total strength is less than the controlling combination in the forgoing two options x Revised Provisions for Fatigue – A significant revision has been made to the fatigue provisions in 1999 AISC LRFD Specification Appendix K3. In lieu of the step-function approach taken in previous editions of this specification, fatigue design in this new edition is based upon calculation of design stress range based upon the number of cycles anticipated in design and the type of detail used. Additionally, the number of fatigue cases covered has been significantly expanded. 3 NEW DRAWING INFORMATION REQUIREMENTS IN THE 2000 RCSC SPECIFICATION As a convenience to the user, Section 1.4 in the 2000 RCSC Specification contains a summary of the information that is needed from the Engineer of Record. The section name “Drawing Information” implies that this information should be shown in the design drawings. However, the letter of the requirements in that section indicates that the information can be included in any of the contract documents, at the discretion of the Engineer of Record. The required information has also been simplified significantly. The ASTM designation and type of bolt to be used and the joint type (see the next section in this article) must be indicated. If a slip-critical joint is specified, two additional requirements may apply. First, the required class of slip resistance (i.e., Class A, Class B or Class C) must be indicated. Second, if the connections are to be selected and/or completed by someone other than the engineer of record for subsequent review and approval by the engineer of record, it must be indicated whether slip resistance is to be checked at the factored-load level or the service-load level. The Commentary on this section also provides a summary of the several cases where the approval of the Engineer of Record would be required to do something. Such approval is required for: x The reuse of non-galvanized ASTM A325 bolts; x The use of washer-type indicating devices other than those covered by ASTM F959; x The use of fastener assemblies other than those with bolts covered by ASTM A325, A490 or F1852; x The use of faying-surface coatings in slip-critical joints with a slip coefficient that is intermediate between 0.33 (Class A) and 0.5 (Class B); x The use of thermal cutting in the production of bolt holes; x The use of oversized, short-slotted or long-slotted holes in lieu of standard holes; and, x The use of a value of Du (pretension multiplier in LRFD) or D (slip probability factor in ASD) other than the default value of 1.13 or 0.80, respectively, in calculations of slip resistance. PROPER SPECIFICATION OF JOINT TYPE FOR BOLTED JOINTS Section 4 in the 2000 RCSC Specification provides a clear basis for the proper specification of joint type by the Engineer of Record, based upon the type of load that the fasteners in the joint transmit. For joints with fasteners that are loaded in shear or combined shear and tension, the joint type can be specified as snug-tightened, pretensioned or slip-critical. For joints with fasteners that are loaded in tension only, the joint can be specified as snug-tightened or pretensioned. Table 4.1 in the 2000 RCSC Specification provides a more detailed summary of the appropriate joint types given the type of load transmitted. Once the joint type is specified, the remaining requirements for design, as well as installation and inspection (see the next section in this paper), are also defined. Snug-Tightened Joints Snug-tightened joints are permitted except when pretensioned joints or slip-critical joints are required. Essentially, that means that most joints can be specified as snug tightened, except when pretensioned is required in the fasteners (with or without faying surfaces that are prepared to achieve slip resistance). 4 Bolts in snug-tightened joints must be designed to provide the required resistance in shear, tension or combined shear and tension on the fasteners and bearing on the connected material. Installation and inspection requirements are as described in the next section of this paper. It is also worthy of note that, with the 2000 RCSC Specification and based upon the historic usage of ASTM A307 bolts and recent research on high-strength fasteners, snug-tightened joints are also permitted for statically loaded applications involving ASTM A325 bolts and ASTM F1852 twist-off-type tension-control bolt assemblies in direct tension. However, snug-tightened installation is not permitted for these fasteners in applications involving non-static tensile loading, nor for tensile applications involving ASTM A490 bolts. Pretensioned Joints Pretensioned Joints are only required in the following applications: x Joints in which fastener pretension is required in the specification or code that invokes the 2000 RCSC Specification (1999 AISC LRFD Specification Section J1.11 and 1997 AISC Seismic Provisions Section I-7.2a, for example); x Joints that are subject to significant load reversal (near-full or full load in one direction followed by near-full or full load in the other direction, like is characteristic of seismic loads, but not wind loads); x Joints that are subject to fatigue load with no reversal of the loading direction (i.e., cycled loading that does not involve a change in the sign of the load); x Joints with ASTM A325 or F1852 bolts that are subject to tensile fatigue; and, x Joints with ASTM A490 bolts that are subject to tension or combined shear and tension, with or without fatigue. Bolts in pretensioned joints must be designed to provide the required resistance in shear, tension or combined shear and tension on the fasteners, bearing on the connected material and tensile fatigue, if applicable. Installation and inspection requirements are as described in the next section of this paper. Slip-Critical Joints Slip-Critical Joints are only required in the following applications involving shear or combined shear and tension (i.e., not applicable for applications involving tension only): x Joints that are subject to fatigue load with reversal of the loading direction (i.e., cycled load that does involve a change in the sign of the load); x Joints that utilize oversized holes; x Joints that utilize slotted holes, except those with applied load approximately normal (within 80 to 100 degrees) to the direction of the long dimension of the slot; and, x Joints in which slip at the faying surfaces would be detrimental to the performance of the structure. Bolts in slip-critical joints must be designed to provide the required slip resistance and the required resistance to shear or combined shear and tension on the fasteners, bearing on the connected material and tensile fatigue, if applicable. Installation and inspection requirements are as described in the next section of this paper. 5 INSTALLATION AND INSPECTION REQUIREMENTS FOR BOLTED JOINTS The requirements in the 2000 RCSC Specification for installation and inspection are invoked by the joint type specification. In all cases, proper storage of the fastener components is required. Snug-Tightened Joints For proper installation of fastener assemblies in snug-tightened connections, all bolt holes must be aligned so that the bolts are not damaged during insertion. Once bolts are placed with washers as required, and nuts, the assembly is used to compact the joint progressing systematically from the most rigid part of the joint, bringing the connected plies into firm contact. For proper inspection of snug-tightened bolted joints, it must be ensured that the proper fastener components were used, the connected elements were fabricated properly, and the bolted joint was drawn into firm contact. Because pretension is not required for the proper performance of a snug-tightened joint, the installed bolts should not be inspected to determine the actual installed pretension. Likewise, arbitration (described in 2000 RCSC Specification Section 10) is not appropriate. Pretensioned Joints There are four approved methods for proper installation of fastener assemblies: turn-of-nut pretensioning, calibrated wrench pretensioning, twist-off-type tension-control bolt pretensioning and direct-tension-indicator pretensioning. Although there are differences in how extensively the requirements apply, in each of these methods, the pre-installation verification requirements in 2000 RCSC Specification Section 7 must be met for pretensioned installation. Also, in each case, the snug-tightened condition is the starting point. When Joints are designated as pretensioned, they are not subject to the same faying-surfacetreatment inspection requirements as is specified for slip-critical joints. Turn-of-Nut Pretensioning: For installation, after snug-tightening the joint, the nut (or bolt head) rotation specified in the RCSC Specification must be applied to all fastener assemblies in the joint, progressing systematically from the most rigid part of the Joint in a manner that will minimize relaxation of previously pretensioned bolts. For inspection, in addition to meeting the inspection requirements for snug-tightened joints, the inspector should observe the pre-installation verification testing required. Subsequently, the inspector can either ensured by routine observation that the proper rotation is applied to the turned element or visually inspect match-marks after pretensioning Calibrated Wrench Pretensioning: For installation, after snug-tightening the joint, the calibrated installation torque (not a tabulated or assumed value) must be applied to all fastener assemblies in the joint, progressing systematically from the most rigid part of the joint in a manner that will minimize relaxation of previously pretensioned bolts. For inspection, in addition to meeting the inspection requirements for snug-tightened joints, the Inspector should observe the pre-installation verification testing required. Subsequently, the inspector should ensure by routine observation that the proper calibrated installation torque is applied to the turned element. Twist-Off-Type Tension-Control Bolt Pretensioning: For installation, after snug-tightening the joint without severing the splined end, the installation wrench must be applied to all fastener 6 assemblies in the joint, progressing systematically from the most rigid part of the joint in a manner that will minimize relaxation of previously pretensioned bolts. For inspection, in addition to meeting the inspection requirements for snug-tightened joints, the Inspector should observe the pre-installation verification testing required. Subsequently, the inspector should ensure by routine observation that the splined ends are properly severed during installation. Direct-Tension-Indicator Pretensioning: For installation, after snug-tightening the joint, the direct-tension-indicator gaps should be compressed, progressing systematically from the most rigid part of the joint in a manner that will minimize relaxation of previously pretensioned bolts. For inspection, in addition to meeting the inspection requirements for snug-tightened joints, the Inspector should observe the pre-installation verification testing required and that the appropriate feeler gage is accepted in at least half of the spaces between the protrusions of the direct tension indicator prior to pretensioning and that the protrusions are properly oriented away from the work. Subsequently, the inspector should ensured by routine observation that the appropriate feeler gage is refused entry into at least half of the spaces between the protrusions. In each of these methods, no further evidence of conformity is required. Furthermore, a pretension that is greater than the specified minimum pretension is not cause for rejection. Slip-Critical Joints Installation in slip-critical joints is identical to that for pretensioned joints. Inspection is also identical, except that the inspector should also verify that the faying surfaces of slip-critical joints meet the appropriate requirements. CONCLUSIONS Many new specifications and codes have been introduced in the United States in the past few years. This paper provided a summary of the changes that have been made in each of these specifications and a more detailed look at a few of the more important ones in the 2000 RCSC Specification. REFERENCES: (1) American Institute of Steel Construction, 1999, Load and Resistance Factor Design Specification for Structural Steel Buildings, AISC, Chicago, IL. (2) American Institute of Steel Construction, 1997, Seismic Provisions for Structural Steel Buildings, AISC, Chicago, IL. (3) American Institute of Steel Construction, 2000, Seismic Provisions Supplement No. 2, AISC, Chicago, IL. (4) American Institute of Steel Construction, 1999, Seismic Provisions Supplement No. 1, AISC, Chicago, IL. (5) American Institute of Steel Construction, 1997, Specification for the Design of Steel Hollow Structural Sections, AISC, Chicago, IL. 7 (6) American Institute of Steel Construction, 1993, Specification for Load and Resistance Factor Design of Single-Angle Members, AISC, Chicago, IL. (7) American Welding Society, 2000, AWS D1.1 Structural Welding Code – Steel, AWS, Miami, FL. (8) Research Council on Structural Connections, 2000, Specification for Structural Joints Using ASTM A325 or A490 Bolts, AISC, Chicago, IL. 8