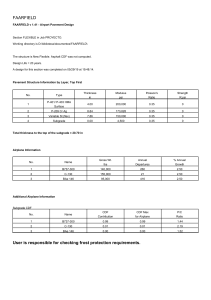

U.S. Department of Transportation Federal Aviation Administration Subject: Airport Pavement Design and Evaluation Advisory Circular Date: 9/30/2009 Initiated by: AAS-100 AC No: 150/5320-6E Change: 1. PURPOSE. This advisory circular (AC) provides guidance to the public on the design and evaluation of pavements at civil airports. 2. CANCELLATION. This AC cancels AC 150/5320-6D, Airport Pavement Design and Evaluation, dated July 7, 1995. 3. APPLICATION. The FAA recommends the guidelines and standards in this AC for airport pavement design and evaluation. In general, use of this AC is not mandatory. However, use this AC is mandatory for all projects funded with federal grant monies through the Airport Improvement Program (AIP) and with revenue from the Passenger Facility Charge (PFC) Program. See Grant Assurance No. 34, “Policies, Standards, and Specifications,” and PFC Assurance No. 9, “Standards and Specifications. 4. RELATED READING MATERIAL. The publications listed in Appendix 4 provide further guidance and detailed information on the design and evaluation of airport pavements. 5. UNITS. Through this AC, customary English units will be used with soft conversion to metric units for tables and figures and hard conversion for the text. Michael O’Donnell Director of Airport Safety and Standards 9/30/2009 AC 150/5320-6E This page intentionally blank. ii 9/30/2009 AC 150/5320-6E TABLE OF CONTENTS TABLE OF CONTENTS iii LIST OF TABLES vi LIST OF FIGURES vii FOREWORD viii CHAPTER 1. AIRPORT PAVEMENTS— 1 THEIR FUNCTION AND PURPOSES 1 100. 101. 102. 103. GENERAL SPECIFICATIONS AND STANDARDS SPECIAL CONSIDERATIONS STAGED CONSTRUCTION OF AIRPORT PAVEMENTS CHAPTER 2. SOIL INVESTIGATIONS AND EVALUATION 200. 201. 202. 203. 204. 205. 206. 207. 208. GENERAL SOIL INVESTIGATIONS SURVEYING AND SAMPLING SOIL TESTS UNIFIED SOIL CLASSIFICATION SOIL STRENGTH TESTS SUBGRADE STABILIZATION SEASONAL FROST PERMAFROST 1 1 1 2 3 3 3 4 5 6 9 10 10 11 CHAPTER 3. PAVEMENT DESIGN FOR AIRPLANES WEIGHING 13 MORE THAN 30,000 POUNDS 13 SECTION 1. DESIGN CONSIDERATIONS 300. SCOPE 301. DESIGN PHILOSOPHY 302. REPORTING PAVEMENT STRENGTH 303. BACKGROUND 304. PAVEMENT DESIGN USING FAARFIELD 305. TRAFFIC DISTRIBUTION 306. TYPICAL SECTIONS 307. FROST AND PERMAFROST DESIGN 13 13 13 13 13 14 20 20 21 SECTION 2. FLEXIBLE PAVEMENT DESIGN 308. GENERAL 309. HOT MIX ASPHALT SURFACING 310. BASE COURSE 311. SUBBASE 312. SUBGRADE 313. SWELLING SOILS 314. SELECTION OF DESIGN CBR VALUE 315. FLEXIBLE PAVEMENT DESIGN 316. DESIGN EXAMPLE 317. STABILIZED BASE AND SUBBASE 318. FULL-DEPTH ASPHALT PAVEMENTS 319. FROST EFFECTS 24 24 24 24 24 25 27 27 28 30 32 32 32 iii AC 150/5320-6E 9/30/2009 SECTION 3. RIGID PAVEMENT DESIGN 320. GENERAL 321. CONCRETE PAVEMENT 322. SUBBASE 323. SUBBASE QUALITY 324. STABILIZED SUBBASE. 325. SUBGRADE 326. DETERMINATION OF MODULUS (E VALUE) FOR RIGID PAVEMENT SUBGRADE 327. DETERMINATION OF CONCRETE SLAB THICKNESS 328. USE OF FAARFIELD FOR NEW RIGID PAVEMENT DESIGN 329. CRITICAL AND NONCRITICAL AREAS 330. DESIGN EXAMPLE 331. FROST EFFECTS 332. JOINTING OF CONCRETE PAVEMENTS 333. SPECIAL JOINTING CONSIDERATIONS FOR POSSIBLE FUTURE EXPANSION 334. JOINTING STEEL 335. JOINT SEALANTS AND FILLERS 336. JOINT LAYOUT 337. CONCRETE PAVEMENT CONTAINING EMBEDDED STEEL FOR CRACK CONTROL 338. TYPE AND SPACING OF EMBEDDED STEEL BARS 339. AMOUNT OF EMBEDDED STEEL. 340. DIMENSIONS AND WEIGHTS OF EMBEDDED STEEL 341. WELDED WIRE FABRIC 342. JOINTING OF EMBEDDED STEEL CONCRETE PAVEMENTS 343. CONTINUOUSLY REINFORCED CONCRETE PAVEMENT 344. CRCP JOINTING 345. CRCP TERMINAL TREATMENT 346. CRCP DESIGN EXAMPLE 347. PRESTRESSED CONCRETE PAVEMENT 33 33 33 33 33 33 34 34 34 35 36 36 36 38 42 43 44 44 44 44 46 46 47 48 48 51 51 54 55 CHAPTER 4. AIRPORT PAVEMENT OVERLAYS AND RECONSTRUCTION 57 400. 401. 402. 403. 404. 405. 406. 407. 408. 409. GENERAL CONDITION OF EXISTING PAVEMENT MATERIAL SELECTION CONSIDERATIONS OVERLAY DESIGN OVERLAYS OF EXISTING FLEXIBLE PAVEMENTS OVERLAYS OF EXISTING RIGID PAVEMENTS THICKNESS DESIGN FOR RUBBLIZED CONCRETE PAVEMENTS PREPARATION OF THE EXISTING SURFACE FOR THE OVERLAY MATERIALS AND METHODS NEW OVERLAY MATERIALS CHAPTER 5. PAVEMENT DESIGN FOR AIRPLANES WEIGHING LESS THAN 30,000 POUNDS 500. 501. 502. 503. 504. 505. 506. 507. 508. 509. iv GENERAL REPORTING PAVEMENT STRENGTH TYPICAL SECTIONS FLEXIBLE PAVEMENT MATERIALS FLEXIBLE PAVEMENT DESIGN RIGID PAVEMENT MATERIALS RIGID PAVEMENT THICKNESS AGGREGATE TURF OVERLAYS HELIPORT/VERTIPORT DESIGN 57 57 57 57 59 61 68 69 70 70 71 71 71 71 71 72 75 76 81 81 82 9/30/2009 AC 150/5320-6E CHAPTER 6. PAVEMENT EVALUATION 600. 601. 602. 603. 604. 605. 606. 607. PURPOSES OF PAVEMENT EVALUATION EVALUATION PROCESS FLEXIBLE PAVEMENTS APPLICATION OF FLEXIBLE PAVEMENT EVALUATION PROCEDURES RIGID PAVEMENTS APPLICATION OF RIGID PAVEMENT EVALUATION PROCEDURES USE OF RESULTS REPORTING PAVEMENT STRENGTH CHAPTER 7. PAVEMENT DESIGN FOR AIRFIELD SHOULDERS 700. 701. 702. 703. 704. 705. 706. 707. 708. PURPOSE APPLICATION BACKGROUND PURPOSE OF DESIGN PROCEDURE REPORTING PAVED SHOULDER DESIGN DESIGN PROCEDURE PAVEMENT LAYER THICKNESS AND MATERIAL REQUIREMENTS EMERGENCY AND MAINTENANCE VEHICLE CONSIDERATIONS AREAS SUSCEPTIBLE TO FROST HEAVE 83 83 83 84 84 86 87 88 88 89 89 89 89 89 89 89 90 90 90 APPENDIX 1. ECONOMIC ANALYSIS 91 APPENDIX 2. ORDER 5300.7 95 APPENDIX 3. DESIGN OF STRUCTURES FOR HEAVY AIRPLANES 105 APPENDIX 4. RELATED READING MATERIAL 107 APPENDIX 5. AIRFIELD PAVEMENT DESIGN SOFTWARE 110 APPENDIX 6. FAARFIELD INTERNAL AIRPLANE LIBRARY 111 v AC 150/5320-6E 9/30/2009 LIST OF TABLES TABLE 2-1. TABLE 2-2. TABLE 2-3. TABLE 3-1. TYPICAL SUBSURFACE BORING SPACING AND DEPTH FOR NEW CONSTRUCTION SOIL CHARACTERISTICS PERTINENT TO PAVEMENT FOUNDATIONS SOIL FROST GROUPS STANDARD NAMING CONVENTION FOR COMMON AIRPLANE GEAR CONFIGURATIONS TABLE 3-1. STANDARD NAMING CONVENTION FOR COMMON AIRPLANE GEAR CONFIGURATIONS (CONTINUED) TABLE 3-2. PAVEMENT REMAINING LIFE BASED ON CDF VALUE TABLE 3-3. REDUCED SUBGRADE STRENGTH RATINGS TABLE 3-4. SUBGRADE COMPACTION REQUIREMENTS FOR FLEXIBLE PAVEMENTS TABLE 3-5. DENSITIES FOR SUBGRADE IN EXAMPLE TABLE 3-6. COMPACTION REQUIREMENTS FOR EXAMPLE TABLE 3-7. RECOMMENDED TREATMENT OF SWELLING SOILS TABLE 3-8. LAYER TYPES IN FAARFIELD TABLE 3-9. MINIMUM AGGREGATE BASE COURSE THICKNESS TABLE 3-10. AIRPLANE TRAFFIC MIX EXAMPLE TABLE 3-11. PAVEMENT STRUCTURE INFORMATION FOR DESIGN EXAMPLE TABLE 3-12. ADDITIONAL AIRPLANE INFORMATION FOR DESIGN EXAMPLE TABLE 3-13. AIRPLANE MIXTURE INPUT DATA TABLE 3-14. PAVEMENT LAYER INPUT DATA TABLE 3-15. PAVEMENT JOINT TYPES TABLE 3-16. RECOMMENDED MAXIMUM JOINT SPACINGS - RIGID PAVEMENT WITH OR WITHOUT STABILIZED SUBBASE TABLE 3-17. DIMENSIONS AND SPACING OF STEEL DOWELS TABLE 3-18. YIELD STRENGTHS OF VARIOUS GRADES OF REINFORCING STEEL TABLE 3-19. DIMENSIONS AND UNIT WEIGHTS OF DEFORMED STEEL REINFORCING BARS NOMINAL DIMENSIONS TABLE 3-20. SECTIONAL AREAS OF WELDED FABRIC TABLE 3-21. AIRPLANE MIX DATA FOR CRCP DESIGN EXAMPLE TABLE 4-1. RIGID PAVEMENT DISTRESS TYPES USED TO CALCULATE THE STRUCTURAL CONDITION INDEX, SCI TABLE 5-1. SUBGRADE COMPACTION REQUIREMENTS FOR LIGHT LOAD FLEXIBLE PAVEMENTS vi 4 8 11 15 16 18 21 26 26 27 27 28 30 31 31 32 36 36 41 41 44 46 47 47 54 61 72 9/30/2009 AC 150/5320-6E LIST OF FIGURES FIGURE 2-1. TYPICAL BORING LOG FIGURE 2-2. RELATIONSHIP BETWEEN AIR THAWING INDEX AND THAW PENETRATION INTO GRANULAR, NON-FROST SUSCEPTABLE SUBGRADE SOIL FIGURE 3-1. TWO EFFECTIVE TIRE WIDTHS - NO OVERLAP FIGURE 3-2. ONE EFFECTIVE TIRE WIDTH – OVERLAP FIGURE 3-3. EXAMPLE OF CDF CONTRIBUTION FOR AIRPLANE MIX FIGURE 3-4. TYPICAL PLAN AND CROSS SECTION FOR RUNWAY PAVEMENT FIGURE 3-5. FAARFIELD SCREENSHOT SHOWING FINAL PAVEMENT THICKNESS DESIGN FIGURE 3-6. STRUCTURE WINDOW IN FAARFIELD FIGURE 3-7. AIRPLANE WINDOW IN FAARFIELD FIGURE 3-8. RIGID PAVEMENT JOINT TYPES AND DETAILS FIGURE 3-9. RIGID PAVEMENT JOINT TYPE DETAILS FIGURE 3-10. TYPICAL JOINT LAYOUT PATTERN FOR RUNWAY, PARALLEL TAXIWAY, AND CONNECTOR FIGURE 3-11. JOINTING IN RIGID PAVEMENT WITH EMBEDDED STEEL FIGURE 3-12. CONTINUOUSLY REINFORCED CONCRETE PAVEMENT – JOINT DETAILS FIGURE 3-13. CONTINUOUSLY REINFORCED CONCRETE PAVEMENT – JOINT DETAILS FIGURE 3-14. CONTINUOUSLY REINFORCED CONCRETE PAVEMENT – WIDE FLANGE BEAM TERMINAL JOINT FIGURE 3-15. COMPUTED SLAB THICKNESS, CRCP EXAMPLE FIGURE 4-1. TYPICAL OVERLAY PAVEMENTS FIGURE 4-2. DESIGN EXAMPLE OF FLEXIBLE OVERLAY ON EXISTING FLEXIBLE PAVEMENT FIGURE 4-3. DESIGN EXAMPLE OF RIGID OVERLAY ON EXISTING FLEXIBLE PAVEMENT FIGURE 4-4. CDFU COMPUTATION USING FAARFIELD FIGURE 4-5. DESIGN EXAMPLE OF FLEXIBLE OVERLAY ON EXISTING RIGID PAVEMENT WITH SCI 70 FIGURE 4-6. DESIGN EXAMPLE OF FLEXIBLE OVERLAY ON EXISTING RIGID PAVEMENT WITH SCI 100 FIGURE 4-7. DESIGN EXAMPLE OF RIGID OVERLAY ON EXISTING FULLY UNBONDED RIGID PAVEMENT FIGURE 5-1. TYPICAL SECTIONS FOR PAVEMENTS SERVING LIGHT AIRPLANES FIGURE 5-2. FAARFIELD AIRPLANE WINDOW – LIGHT LOAD PAVEMENT DESIGN FIGURE 5-3. CALCULATION OF SUBBASE LAYER THICKNESS FIGURE 5-4. JOINTING TYPES FOR LIGHT-LOAD RIGID PAVEMENT FIGURE 5-5. JOINTING DETAILS FOR LIGHT-LOAD RIGID PAVEMENT FIGURE 5-6. JOINTING LAYOUT PATTERNS FOR LIGHT-LOAD RIGID PAVEMENT – 60 FEET WIDE FIGURE 5-7. JOINTING LAYOUT PATTERNS FOR LIGHT-LOAD RIGID PAVEMENT – 50 FEET WIDE FIGURE 5-8. DESIGN EXAMPLE FOR AGGREGATE TURF PAVEMENT. FIGURE 6-1. EXAMPLE OF A FLEXIBLE PAVEMENT STRUCTURE FOR EVALUATION FIGURE 6-2. EXAMPLE OF A RIGID PAVEMENT STRUCTURE FOR EVALUATION 7 12 19 19 20 23 31 37 37 39 40 45 50 51 52 53 54 58 59 61 63 64 65 67 73 74 75 77 78 79 80 81 85 87 vii AC 150/5320-6E 9/30/2009 FOREWORD This AC provides guidance on the structural design and evaluation of airport pavements. Although airplane landing gears play a role in airport pavement design and evaluation, this AC does not dictate any facet of landing gear design. In 1958, the FAA adopted a policy of limiting maximum Federal participation in airport pavements to a pavement section designed to serve a 350,000-pound (158 757 kg) airplane with a DC-8-50 series landing gear configuration. The intent of the policy was to ensure that future airplanes were equipped with landing gears that would not stress pavements more than the referenced 350,000-pound (158 757 kg) airplane. Throughout the 20th century, airplane manufacturers accepted and followed the 1958 policy and designed airplane landing gears that conformed to it—even though airplane gross weights have long exceeded 350,000 pounds (158 757 kg). Despite increases in airplane weights, manufacturers were able to conform to the policy by increasing the number and spacing of landing gear wheels. Unfortunately, adding extra wheels and landing gears does not contribute to efficiency, and airplane manufacturers are focusing on designing airplane gear configurations to optimize the efficiency of the airplanes. With this change in philosophy and increasing airplane weights, airfield pavements must be designed to withstand increased loading conditions. Historical pavement design guidance presented in previous versions of this AC was based on methods of analysis that resulted from empirical research and field performance. Although it may have been possible to adjust these methods to address new gear configurations and increased pavement loading, newer design procedures, such as the layered elastic and finite element procedures discussed in Chapter 3, were better adapted for this challenge The pavement design guidance presented in this AC implements layered elastic theory for flexible pavement design and three-dimensional finite element theory for rigid pavement design. The FAA adopted these methodologies to address the impact of new landing gear configurations and increased pavement load conditions. These procedures are robust and can address future gear configurations without modifying their underlying design procedures. Chapter 6 presents the pavement evaluation portion of this AC. An airplane operator could be penalized unfairly if an existing facility was evaluated using a method different from that employed in the original design. A slight change in pavement thickness can have a dramatic effect on the payload or range of an airplane. Since a new pavement design methodology might produce different pavement thicknesses, an evaluation of an existing pavement using the new methodology could result in incompatible results. To avoid this situation, airport operators should base the evaluation, whenever possible, on the same methodology as was used for the design. Where new airplanes are added to the traffic mix at an existing facility, it may not be possible to evaluate the pavement with the original design procedure. For example, when adding a new airplane with a unique gear configuration to the traffic mixture at a facility, it may be impossible to assess the impact of the new airplane using the original design procedures. In these instances, it is necessary to evaluate the pavement with a design procedure capable of addressing the new traffic mixture. viii 9/30/2009 AC 150/5320-6E CHAPTER 1. AIRPORT PAVEMENTS— THEIR FUNCTION AND PURPOSES 100. GENERAL. Airport pavements are constructed to provide adequate support for the loads imposed by airplanes and to produce a firm, stable, smooth, all-year, all-weather surface free of debris or other particles that may be blown or picked up by propeller wash or jet blast. In order to satisfactorily fulfill these requirements, the pavement must be of such quality and thickness that it will not fail under the load imposed. In addition, it must possess sufficient inherent stability to withstand, without damage, the abrasive action of traffic, adverse weather conditions, and other deteriorating influences. To produce such pavements requires a coordination of many factors of design, construction, and inspection to assure the best possible combination of available materials and a high standard of workmanship. a. Types of Pavement. Pavements discussed in this circular are flexible, rigid, hot mix asphalt overlays, and rigid overlays. Various combinations of pavement types and stabilized layers result in complex pavements classified between flexible and rigid. The design and evaluation guidance in this circular can be adapted to any pavement type. b. Economic Analysis and Design Selection. With proper design and construction, any pavement type (rigid, flexible, composite, etc.) can provide a satisfactory pavement for any civil airplane. However, some designs may be more economical than others and can still provide satisfactory performance. The engineer is required to provide a rationale for the selected design in the engineer’s report (see AC 150/5300-9, Predesign, Prebid, and Preconstruction Conferences for Airport Grant Projects). Engineers often base this rationale on economic factors derived from evaluating several design alternatives. Use life-cycle cost analysis if the design selection is based on least cost. Appendix 1 demonstrates an example of a life-cycle cost analysis of alternatives for pavement rehabilitation. Research report FAA-RD-81/078, Economic Analysis of Airport Pavement Rehabilitation Alternatives – An Engineering Manual, provides more details on life-cycle cost analysis. Many new developments in construction have evolved, such as recycling, that can significantly affect pavement costs. Alternate construction bids are appropriate in instances where no clear cost advantage is established in the design process. Economic factors do not always control the design selection. Operational constraints, funding limitations, future expansion, and other issues can override economic factors in the design selection. The engineer’s report should address these considerations. c. Pavement Courses. (1) Surface. Surface courses include Portland cement concrete (PCC), hot mix asphalt (HMA), sand-bituminous mixture, and sprayed bituminous surface treatments. (2) Base. Base courses consist of a variety of different materials, which generally fall into two main classes, treated and untreated. An untreated base consists of crushed or uncrushed aggregates. A treated base normally consists of a crushed or uncrushed aggregate mixed with a stabilizer such as cement, bitumen, etc. (3) Subbase. Subbase courses consist of a granular material, a stabilized granular material, or a stabilized soil. (4) Geosynthetics. The term geosynthetics describes a range of manufactured synthetic products used to address geotechnical problems. The term is generally understood to encompass four main products: geotextiles, geonets/geogrids, geomembranes and geocomposites. The synthetic nature of the materials in these products makes them suitable for use in the ground where high levels of durability are required. These products have a wide range of applications, including use as a separation between subbase aggregate layers and the underlying subgrade. The need for geosynthetics within a pavement section is dependent upon subgrade soil conditions, groundwater conditions, and the type of overlying pavement aggregate. 101. SPECIFICATIONS AND STANDARDS. a. Specifications. Reference is made by Item Number throughout the text to construction material specifications contained in AC 150/5370-10, Standards for Specifying Construction of Airports. b. Geometric Standards. AC 150/5300-13, Airport Design, presents geometric standards for pavement lengths, widths, grades, and slopes. 102. SPECIAL CONSIDERATIONS. Airport pavements should provide a skid resistant surface that will provide good traction during any weather conditions. AC 150/5320-12, Measurement, Construction, and Maintenance of Skid Resistant Airport Pavement Surfaces, presents information on skid resistant surfaces. 1 AC 150/5320-6E 9/30/2009 STAGED CONSTRUCTION OF AIRPORT PAVEMENTS. In some instances, it may be necessary to 103. construct the airport pavement in stages; that is, to build up the pavement profile, layer by layer, as the traffic using the facility increases in weight and number. Lateral staging, i.e., planning for future widening of pavements, is sometimes advantageous to accommodate larger airplanes. If stage construction is to be undertaken, the need for sound planning cannot be overemphasized. It is important to design the complete pavement prior to the start of any stage and to assure that each stage provides an operational surface. The planning of a stage-constructed pavement should recognize a number of considerations. a. Adequacy of Each Stage. Design each stage to adequately accommodate the traffic that will use the pavement until the next stage is constructed. b. Drainage. Design and construct the underlying layers and drainage facilities of a pavement constructed in stages to the standards required for the final cross-section. Providing the proper foundation and drainage facilities in the first stage is mandatory, as the underlying layers will not be readily accessible for upgrading in the future. 2 9/30/2009 AC 150/5320-6E CHAPTER 2. SOIL INVESTIGATIONS AND EVALUATION 200. GENERAL. The importance of accurate identification and evaluation of pavement foundations cannot be overemphasized. Although it is impossible to explore the entire field of soil mechanics in a publication such as this, the following text will highlight those aspects that are particularly important to the airport paving engineer. a. Classification System. Use the Unified Soil Classification (USC) system in engineering matters concerning civil airport pavements. To avoid misunderstanding, certain terms employed are defined below: (1) SOIL Definition. For engineering purposes, and particularly as it applies to airports, soil includes all natural deposits that can be moved with earth moving equipment, without requiring blasting under unfrozen conditions. Harder materials are considered to be rock. (2) Conditions and Properties. Soil conditions include such items as the elevation of the water table, the presence of water bearing strata, and the field properties of the soil. Field properties of the soil include the density, moisture content, and frost penetration. (3) Profile. The soil profile is the vertical arrangement soil layers, each of which possesses different physical properties from the adjacent layer. (4) Subgrade. Subgrade soil is the soil that forms the foundation for the pavement. It is the soil directly beneath the pavement structure. b. Subgrade Support. It should be remembered that the subgrade soil ultimately provides support for the pavement and the imposed loads. The pavement serves to distribute the imposed load to the subgrade over an area greater than that of the tire contact area. The greater the thickness of pavement, the greater is the area over which the load on the subgrade is distributed. It follows, therefore, that the more unstable the subgrade soil, the greater is the required area of load distribution and consequently the required thickness of pavement is greater. The soils having the best engineering characteristics encountered in the grading and excavating operations should be incorporated in the upper layers of the subgrade by selective grading. c. Drainage. In addition to the relationship that soil conditions bear to grading and paving operations, they determine the necessity for underdrains and materially influence the amount of surface runoff. Thus, they have a resulting effect on the size and extent of other drainage structures and facilities. (See AC 150/5320-5, Surface Drainage Design.) 201. SOIL INVESTIGATIONS. a. Distribution and Properties. To provide essential information on the various types of soils, investigations should be made to determine their distribution and physical properties. This information combined with data on site topography and area climatic records, provides basic planning material essential to the logical and effective development of the airport. An investigation of soil conditions at an airport site will include— (1) Subsurface Soil Profile. An investigation of subsurface soil properties to determine the arrangement of different layers of the soil with relation to the proposed subgrade elevation. (2) Sampling. Collection of representative samples of the layers of soil. (3) Testing. Testing of samples to determine the physical properties of the various soil materials with respect to in-place density and subgrade support. (4) Availability. A review to determine the availability of materials for use in construction of the subgrade and pavement. b. Procedures. With respect to sampling and surveying procedures and techniques, American Society for Testing and Materials (ASTM) D 420, Standard Guide to Site Characterization for Engineering Design and Construction Purposes, is most frequently used. This method is based entirely on the soil profile. In the field, ASTM D 2488, Standard Practice for Description and Identification of Soils (Visual-Manual Procedures), is commonly used to identify soils by such characteristics as color, texture, structure, consistency, compactness, cementation, and, to varying degrees, chemical composition. 3 AC 150/5320-6E 9/30/2009 Maps. Department of Agriculture soils maps, United States Geodetic Survey (USGS) (1) geologic maps, and USGS engineering geology maps can prove valuable aids in the study of soils at and in the vicinity of the airport. Although the pedological classification, determined from these maps, does not treat soil as an engineering or construction material, data so obtained are extremely useful to the agronomist in connection with the development of turf areas on airports and to the engineer concerned with preliminary investigations of site selection, development costs, and alignment. (2) Aerial Photography. The practice of determining data on soils with aerial photographs is established and commonly acceptable. Relief, drainage, and soil patterns may be determined from the photographs, and an experienced photo interpreter can define differences in characteristics of soils. By employing this method of investigation, it is possible to expedite soil studies and reduce the amount of effort required to gather data. 202. SURVEYING AND SAMPLING. a. Subsurface Borings. The initial step in an investigation of subsurface conditions is a soil survey to determine the quantity and extent of the different types of soil, the arrangement of soil layers, and the depth of any subsurface water. These profile borings are usually obtained with a soil auger or similar device. Washed borings are not recommended due to inaccuracies of depth determinations. The intent of the borings is to determine the soil or rock profile and its lateral extent. Inasmuch as each location presents its particular problems and variations, the spacing of borings cannot always be definitely specified by rule or preconceived plan. Suggested criteria for the location, depth, and number of borings for new construction are given in table 2-1. Wide variations in these criteria can be expected due to local conditions. Nondestructive testing (NDT), as described in AC 150/5370-11, Use of Nondestructive Testing Devices in the Evaluation of Airport Pavement, can be used for computing subgrade strength and to locate soil borings and sampling locations for evaluation of existing pavements. Also, boring logs from original construction and prior evaluations can be used. TABLE 2-1. TYPICAL SUBSURFACE BORING SPACING AND DEPTH FOR NEW CONSTRUCTION AREA SPACING DEPTH Runways and Taxiways Random Across Pavement at 200Cut Areas - 10' (3 m) Below Finished Grade foot (60 m) Intervals Fill Areas - 10' (3 m) Below Existing Ground1 Other Areas of Pavement 1 Boring per 10,000 Square Feet Cut Areas - 10' (3 m) Below Finished Grade (930 sq m) of Area Fill Areas - 10' (3 m) Below Existing Ground1 Borrow Areas Sufficient Tests to Clearly Define To Depth of Borrow Excavation the Borrow Material 1 For deep fills, boring depths must be sufficient to determine the extent of consolidation and/or slippage the fill may cause. b. Number of Borings, Locations, and Depths. Obviously, the locations, depths, and numbers of borings must be such that all important soil variations can be determined and mapped. Whenever past experience at the location in question has indicated that settlement or stability in deep fill areas may be a problem or, if in the opinion of the engineer, additional investigations are warranted, more or deeper borings may be required in order to determine the proper design, location, and construction procedures. Conversely, where uniform soil conditions are encountered, fewer borings may be acceptable. c. Boring Log. A graphic log of soil conditions can be of great value in assessing subgrade conditions. It is recommended that the graphic log be developed, which summarizes the results of the soil explorations. A typical graphic log is included as figure 2-1. The graphic log should include— 4 (1) Location (2) Date performed (3) Type of exploration (4) Surface elevation (5) Depth of materials 9/30/2009 AC 150/5320-6E (6) Sample identification numbers (7) Classification (8) Water table (9) Standard penetration test (SPT) d. Soil Survey Areas. The soil survey is not confined to soils encountered in grading or necessarily to the area within the boundaries of the airport site. Possible sources of locally available material that may be used as borrow areas or aggregate sources should be investigated. e. Undisturbed Samples. Samples representative of the different layers of the various soils encountered and various construction materials discovered should be obtained and tested in the laboratory to determine their physical and engineering properties. In-situ properties such as in-place density, shear strength, consolidation characteristics, etc. may necessitate obtaining “undisturbed” core samples. ASTM D 1587, Standard Practice for Thin-Walled Tube Sampling of Soils for Geotechnical Purposes, describes a method of obtaining “undisturbed” soil samples. Because the results of a test can only be as good as the sampling, it is of utmost importance that each sample be representative of a particular type of soil material and not be a careless and indiscriminate mixture of several materials. f. Inplace Testing. Pits, open cuts, or both may be required for making in-place bearing tests, taking undisturbed samples, charting variable soil strata, etc. This type of supplemental soil investigation is recommended for situations that warrant a high degree of accuracy or when in-situ conditions are complex and require extensive investigation. 203. SOIL TESTS. a. Physical Soil Properties. To determine the physical properties of a soil and to provide an estimate of its behavior under various conditions, it is necessary to conduct certain soil tests. A number of field and laboratory tests have been developed and standardized. Detailed methods of performing soil tests are completely covered in publications of the ASTM. b. Testing Requirements. Soil tests are usually identified by terms indicating the soil characteristics that the tests will reveal. Terms that identify the tests considered to be the minimum or basic requirement for airport pavement, with their ASTM designations and brief explanations, follow: (1) Standard Practice for Dry Preparation of Soil Samples for Particle-Size Analysis and Determination of Soil Constants (ASTM D 421). The dry method should be used only for clean, cohesion-less granular materials. (2) Standard Test Method for Particle-Size Analysis of Soils (ASTM D 422). This analysis provides a quantitative determination of the distribution of particle sizes in soils. (3) Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils (ASTM D 4318). The plastic and liquid limits of soil define in a standard manner the lowest moisture content at which a soil will change from a semisolid to a plastic state and at which a solid passes from a plastic to a liquid state, respectively. The plasticity index is the numerical difference between the plastic limit and the liquid limit. It indicates the range in moisture content over which a soil remains in a plastic state prior to changing into a liquid. The plastic limit, liquid limit, and plasticity index of soils are used in engineering classification in accordance with the Unified Soil Classification System (ASTM D 2487). In conjunction with particle size analysis, natural moisture content, and other soil properties or conditions, the limits may be used to estimate engineering properties or behavior of soils such as shrink/swell potential, consolidation characteristics, construction/stabilization characteristics, permeability, and strength characteristics. Moisture-Density Relations of Soils . For purposes of compaction control during (4) construction, tests to determine the moisture-density relations of the different types of soils should be performed. (i) Heavy Load Pavements. For pavements designed to serve airplanes weighing 60,000 pounds (27 216 kg) or more, use ASTM Method D 1557, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)). 5 AC 150/5320-6E 9/30/2009 (ii) Light Load Pavements. For pavements designed to serve airplanes weighing less than 60,000 pounds (27 216 kg), use ASTM Method D 698, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ftlbf/ft3 (600 kN-m/m3)). (5) Standard Test Method for CBR (California Bearing Ratio) of Laboratory-Compacted Soils (ASTM D 1883). This test is used to assign a CBR (California Bearing Ratio) value to subgrade soils for use in the design of flexible pavements. (6) Modulus of Soil Reaction (AASHTO T 222). This test is used to determine the modulus of soil reaction, k, for use in the design of rigid pavements. c. Supplemental Tests. In many cases, additional soil tests will be required over those listed in paragraph 203b above. It is not possible to cover all the additional tests that may be required; however, a few examples are presented below. This list should not be considered all-inclusive. (1) Test Method for Shrinkage Factors of Soils by the Mercury Method (ASTM D 427). This test may be required in areas where swelling soils might be encountered. (2) Standard Test Method for Permeability of Granular Soils (Constant Head) (ASTM D 2434). This test may be needed to assist in the design of subsurface drainage. (3) Determination of Organic Material in Soils by Wet Combustion (AASHTO T-194). This test may be needed in areas where deep pockets of organic material are encountered or suspected. (4) Standard Test Method for CBR (California Bearing Ratio) of Soils in Place (ASTM D4429-04). Field bearing tests can be performed when the on site conditions satisfy density and moisture conditions that will exist under the pavement being designed. The method is also described in Manual Series No. 10, Soils Manual (The Asphalt Institute). 204. UNIFIED SOIL CLASSIFICATION. The standard method of classifying soils for engineering purposes is ASTM D 2487, commonly called the Unified System. Table 2-2 provides general soil characteristics pertinent to pavements. 6 9/30/2009 AC 150/5320-6E FIGURE 2-1. TYPICAL BORING LOG 7 TABLE 2-2. SOIL CHARACTERISTICS PERTINENT TO PAVEMENT FOUNDATIONS AC 150/5320-6E 8 9/30/2009 9/30/2009 AC 150/5320-6E 205. SOIL STRENGTH TESTS. Soil classification for engineering purposes provides an indication of the probable behavior of the soil as a pavement subgrade. This indication of behavior is, however, approximate. Performance different from that expected can occur due to a variety of reasons such as degree of compaction, degree of saturation, height of overburden, etc. The possibility of incorrectly predicting subgrade behavior can be largely eliminated by measuring soil strength. The strength of materials intended for use in flexible pavement structures is measured by the CBR tests. Materials intended for use in rigid pavement structures are tested by the plate bearing method. Each of these tests is discussed in greater detail below. Resilient modulus is used for rigid pavement design because of the variable stress states. Elastic modulus is estimated from CBR and k using the correlations E = 1500 CBR and E = 26 k1.284 a. California Bearing Ratio. The CBR test is basically a penetration test conducted at a uniform rate of strain. The force required to produce a given penetration in the material under test is compared to the force required to produce the same penetration in a standard crushed limestone. The result is expressed as a ratio of the two forces. Thus a material with a CBR value of 15 means the material in question offers 15 percent of the resistance to penetration that the standard crushed stone offers. Laboratory CBR tests should be performed in accordance with ASTM D 1883, Bearing Ratio of Laboratory-Compacted Soils. Field CBR tests should be conducted in accordance with the ASTM D 4429, Standard Test Method for Bearing Ratio of Soils in Place. (1) Laboratory. Laboratory CBR tests are conducted on materials that have been obtained from the site and remolded to the density that will be obtained during construction. Specimens are soaked for 4 days to allow the material to reach saturation. A saturated CBR test is used to simulate the conditions likely to occur in a pavement that has been in service for some time. Pavement foundations tend to reach nearly complete saturation after about 3 years. Seasonal moisture changes also dictate the use of a saturated CBR design value since traffic must be supported during periods of high moisture such as spring seasons. (2) Field. Field CBR tests can provide valuable information on foundations that have been in place for several years. The materials should have been in place for a sufficient time to allow for the moisture to reach an equilibrium condition. An example of this condition is a fill that has been constructed and surcharged for a long period of time prior to pavement construction. (3) Gravelly Materials. CBR tests on gravelly materials are difficult to interpret. Laboratory CBR tests on gravel often yield CBR results that are too high due to the confining effects of the mold. The assignment of CBR values to gravelly subgrade materials may be based on judgment and experience. The FAA pavement design procedure recommends a maximum subgrade E value of 50,000 psi (345 MPa) (CBR=33.3) for use in design. (4) Number of Tests. The number of CBR tests needed to properly establish a design value cannot be simply stated. Variability of the soil conditions encountered at the site will have the greatest influence on the number of tests needed. As an approximate “rule of thumb”, three CBR tests on each different major soil type should be considered. The preliminary soil survey will reveal how many different soil types will be encountered. The design CBR value should be conservatively selected. Common paving engineering practice is to select a value that is one standard deviation below the mean. As a rule, a design CBR value of 3 is the lowest practical value that should be assigned. In instances where the subgrade strength is lower than CBR equals 3, the subgrade should be improved through stabilization or other means to raise the design CBR value. The following formula can be used to convert CBR to k value for the subgrade. However, this is only an approximate relationship and it is the recommended appropriate testing to establish design values. 1500 CBR k 26 0.7788 , (k in pci) (5) Lime Rock Bearing Ratio. Some areas of the country use the lime rock bearing ratio (LBR) to express soil strength. To convert LBR to CBR, multiply LBR by 0.8. b. Plate Bearing Test. As the name indicates, the plate bearing test measures the bearing capacity of the pavement foundation. The result, k value, can be envisioned as the pressure required to produce a unit deflection of the pavement foundation. The plate bearing test result, k value, has the units of pounds per cubic inch (Mega-Newton per cubic meter). Plate bearing tests should be performed in accordance with the procedures contained in AASHTO T 222. 9 AC 150/5320-6E 9/30/2009 (1) Test Conditions. Plate bearing tests must be conducted in the field and are best performed on test sections that are constructed to the design compaction and moisture conditions. A correction to the k value for saturation is required to simulate the moisture conditions likely to be encountered by the in-service pavement. (2) Number of Tests. Plate bearing tests are relatively expensive to perform and thus the number of tests that can be conducted to establish a design value is limited. Generally only two or three tests can be performed for each pavement feature. The design k value should be conservatively selected. (3) Plate Size. The rigid pavement design presented in this circular is based on the elastic modulus (E) or k value. The k value can be determined by a static plate load test using a 30-inch (762 mm) diameter plate. Use of a plate of smaller diameter will result in a higher k value than is represented in the design and evaluation curves. c. Additional Soil Strength Tests. Where stability of the underlying section is questionable, additional soil strength tests may be necessary. Direct shear tests (ASTM D 3080) or field vane tests (ASTM D 2573) may be required to adequately design the pavement structure. 206. SUBGRADE STABILIZATION. Subgrade stabilization should be considered if one or more of the following conditions exist: poor drainage, adverse surface drainage, frost, or need for a stable working platform. Subgrade stabilization can be accomplished through the addition of chemical agents or by mechanical methods. a. Chemical Stabilization. Different soil types require different stabilizing agents for best results. The following publications are recommended to determine the appropriate type and amount of chemical stabilization for subgrade soils: Unified Facilities Criteria (UFC) Manual Pavement Design for Airfields, UFC 3-260-02; Soil Cement Construction Handbook, Portland Cement Association; and The Asphalt Institute Manual Series MS-19, Basic Asphalt Emulsion Manual (see Appendix 4). b. Mechanical Stabilization. In some instances, subgrades cannot be adequately stabilized through the use of chemical additives. The underlying soils may be so soft that stabilized materials cannot be mixed and compacted over the underlying soils without failing the soft soils. Extremely soft soils may require bridging in order to construct the pavement section. Bridging can be accomplished with the use of thick layers of shot rock or cobbles. Thick layers of lean, porous concrete have also been used to bridge extremely soft soils. Geosynthetics should be considered as mechanical stabilization over soft, fine-grained soils. Geosynthetics can facilitate site access over soft soils and aid in reducing subgrade soil disturbance due to construction traffic. Geosynthetics will also function as a separation material to limit long-term weakening of pavement aggregate associated with contamination of the aggregate with underlying fine-grained soils. FHWA-HI-95-038, Geosynthetic Design and Construction Guidelines, provides more information about construction over soft soils using geosynthetics (see Appendix 4). 207. SEASONAL FROST. The design of pavements in areas subject to seasonal frost action requires special consideration. The detrimental effects of frost action may be manifested by non-uniform heave and in loss of soil strength during frost melting. Other related detrimental effects include possible loss of compaction, development of pavement roughness, restriction of drainage, and cracking and deterioration of the pavement surface. Detrimental frost action requires that three conditions be met simultaneously: first, the soil must be frost susceptible; second, freezing temperatures must penetrate into the frost susceptible soil; third, free moisture must be available in sufficient quantities to form ice lenses. a. Frost Susceptibility. The frost susceptibility of soils is dependent to a large extent on the size and distribution of voids in the soil mass. Voids must be of a certain critical size for the development of ice lenses. Empirical relationships have been developed correlating the degree of frost susceptibility with the soil classification and the amount of material finer than 0.02 mm by weight. Soils are categorized into four groups for frost design purposes: Frost Group 1 (FG-l), FG-2, FG-3, and FG-4. The higher the frost group number, the more susceptible the soil, i.e., soils in FG-4 are more frost susceptible than soils in frost groups 1, 2, or 3. Table 2-3 defines the frost groups. b. Depth of Frost Penetration. The depth of frost penetration is a function of the thermal properties of the pavement and soil mass, the surface temperature, and the temperature of the pavement and soil mass at the start of the freezing season. In determining the frost penetration depth, primary consideration should be given to local engineering experience. Residential construction practice, including the experience of local building departments, is generally the best guide to frost penetration depth. c. Free Water. The availability of free water in the soil mass to freeze and form ice lenses is the third consideration that must be present for detrimental frost action to occur. Water can be drawn from considerable depths 10 9/30/2009 AC 150/5320-6E by capillary action, by infiltration from the surface or sides, or by condensation of atmospheric water vapor. Generally speaking, if the degree of saturation of the soil is 70 percent or greater, frost heave will probably occur. For all practical purposes, the designer should assume that sufficient water to cause detrimental frost action will be present. d. Frost Design. The design of pavements to offset seasonal frost effects is presented in Chapter 3. A more detailed and rigorous discussion of frost action and its effects can be found in Research Report No. FAA-RD-74030, Design of Civil Airfield Pavement for Seasonal Frost and Permafrost Conditions (see Appendix 4). TABLE 2-3. SOIL FROST GROUPS FROST GROUP FG-1 FG-2 FG-3 FG-4 KIND OF SOIL Gravelly Soils Gravelly Soils Sands Gravelly Soils Sands, except very fine silty sands Clays, PI above 12 Very fine silty sands All Silts Clays, PI = 12 or less Varved Clays and other fine grained banded sediments PERCENTAGE FINER THAN 0.02 mm BY WEIGHT 3 to 10 10 to 20 3 to 5 Over 20 Over 15 Over 15 - GW, GP, GW-GM, GP-GM GM, GW-GM, GP-GM, SW, SP, SM, SW-SM, SP-SM GM, GC SM, SC CL, CH SM ML, MH CL, CL-ML - CL, CH, ML, SM SOIL CLASSIFICATION 208. PERMAFROST. In arctic regions, soils are often frozen at considerable depths year round. Seasonal thawing and refreezing of the upper layer of permafrost can lead to severe loss of bearing capacity and/or differential heave. In areas with continuous high-ice-content permafrost at shallow depths, satisfactory pavements are best ensured by restricting seasonal thawing to the pavement and to a non-frost susceptible base course. This approach is intended to prevent degradation (thawing) of the permafrost layer. a. Susceptibility. The frost susceptibility of soils in permafrost areas is classified the same as given above in paragraph 207. b. Depth of Thaw Penetration. Pavement design for permafrost areas must consider the depth of seasonal thaw penetration. Although the Modified Berggren equation (see reference 18, Appendix 4) can theoretically be used with local climatic data to approximate the depth of thawing in permafrost, there are currently no software programs available to do this. However, the depth to which thawing temperatures penetrate into permafrost may be estimated using figure 2-2. Use of figure 2-2 requires inputs of air thawing index, average wind speed during the thaw period, pavement type, and density of the permafrost layer. The air thawing index is expressed in degree days and is the difference between average daily temperature and 32 degrees Fahrenheit (0 degrees Celsius) multiplied by the number of days the temperature exceeds freezing. The thawing index used for design (design thawing index) should be based on the three warmest summers in the last 30 years of record. If 30-year records are not available, data from the warmest summer in the latest 10-year period may be used. c. Muskeg. Muskeg is sometimes encountered in arctic areas. Muskeg is a highly organic soil deposit that is essentially a swamp. Every effort should be made to avoid pavement construction on this material. If construction in areas of muskeg is unavoidable and the soil survey shows the thickness of muskeg is less than 5 feet (1.5 m), the muskeg should be removed and replaced with granular fill. If the thickness of muskeg is too great to warrant removal and replacement, a 5-foot (1.5 m) granular fill should be placed over the muskeg. These thicknesses are based on experience and it should be anticipated that differential settlement will occur and considerable maintenance will be required to maintain a smooth surface. Use of a geosynthetic between the muskeg surface and the bottom of granular fill is recommended to prevent migration of the muskeg up into the granular till. In this application, the geosynthetic is considered to perform the function of separation. Additional information on the design and construction of geosynthetics performing the separation function within pavement sections is provided in FHWA-HI-95-038 (see Appendix 4). d. Permafrost Design. Design of pavements in areas of permafrost is discussed in Chapter 3. Further information on permafrost can be found in Research Report No. FAA-RD-74-030 (see Appendix 4). 11 FIGURE 2-2. RELATIONSHIP BETWEEN AIR THAWING INDEX AND THAW PENETRATION INTO GRANULAR, NON-FROST SUSCEPTABLE SUBGRADE SOIL AC 150/5320-6E 12 9/30/2009 9/30/2009 AC 150/5320-6E CHAPTER 3. PAVEMENT DESIGN FOR AIRPLANES WEIGHING MORE THAN 30,000 POUNDS SECTION 1. DESIGN CONSIDERATIONS. 300. SCOPE. This chapter provides pavement design guidance for airfield pavements intended to serve airplanes with gross weights in excess of 30,000 pounds (13 608 kg). Chapter 5 discusses the design of pavements serving lighter airplanes with gross weights under 30,000 pounds (13 608 kg). 301. DESIGN PHILOSOPHY. The foreword of this AC describes the FAA policy of treating the design of airplane landing gear and the design and evaluation of airport pavements as three separate entities. The design of airport pavements is a complex engineering problem that involves a large number of interacting variables. This chapter presents pavement mechanistic design procedures that are implemented in the FAA Rigid and Flexible Iterative Elastic Layer Design (FAARFIELD) program. FAARFIELD implements both layered elastic-based and three-dimensional finite element-based design procedures for new and overlay designs of flexible and rigid pavements, respectively. Because of thickness variations, the evaluation of existing pavements should be performed using the same method employed for design. Chapter 6 describes in detail procedures to use when evaluating pavements. Details on the development of the FAA method of design are as follows: a. Flexible Pavements. For flexible pavement design, FAARFIELD uses the maximum vertical strain at the top of the subgrade and the maximum horizontal strain at the bottom of the asphalt surface layer as the predictors of pavement structural life. FAARFIELD provides the required thickness for all individual layers of flexible pavement (surface, base, and subbase) needed to support a given airplane traffic mix over a particular subgrade. b. Rigid Pavements. For rigid pavement design, FAARFIELD uses the maximum horizontal stress at the bottom edge of the PCC slab as the predictor of pavement structural life. The maximum horizontal stress for design is determined using an edge loading condition. FAARFIELD provides the required thickness of the rigid pavement slab needed to support a given airplane traffic mix over a particular subgrade/subbase. 302. REPORTING PAVEMENT STRENGTH. When designing new pavements, summarize all pavement designs on FAA Form 5100-1, Airport Pavement Design, which is considered part of the Engineer’s Design Report. Submit the Engineer’s Design Report for FAA review and approval along with initial plans and specifications. 303. BACKGROUND. An airfield pavement and the airplanes that operate on it represent an interactive system that must be addressed in the pavement design process. Design considerations associated with both the airplanes and the pavement must be recognized in order to produce a satisfactory design. Producing a pavement that will achieve the intended design life will require careful construction control and some degree of maintenance. Pavements are designed to provide a finite life and fatigue limits are anticipated. Poor construction and a lack of preventative maintenance will shorten the service life of even the best-designed pavement. a. Variables. The determination of pavement thickness requirements is a complex engineering problem. Pavements are subject to a wide variety of loading and climatic effects. The design process involves a large number of interacting variables, which are often difficult to quantify. Despite considerable research on this subject, it has been impossible to arrive at a direct solution for thickness requirements. For this reason, pavement engineers must base pavement thickness on a theoretical analysis of load distribution through pavements and soils, the analysis of experimental pavement data, and a study of the performance of pavements under actual service conditions. The FAA developed the FAARFIELD program using failure models based on full-scale tests conducted from the 1940s until the present. Pavements designed and constructed in accordance with FAA standards are intended to provide a minimum structural life of 20 years that is free of major maintenance if no major changes in forecast traffic are encountered. Rehabilitation of surface grades and renewal of skid-resistant properties may be needed before 20 years because of destructive climatic effects and the deteriorating effects of normal usage. b. Structural Design. The structural design of airport pavements consists of determining both the overall pavement thickness and the thickness of the component parts of the pavement. There are a number of factors that influence the thickness of pavement required to provide satisfactory service. These include the magnitude and character of the airplane loads to be supported, the volume of traffic, the concentration of traffic in certain areas, and the strength of the subgrade soil and quality of materials that make up the pavement structure. 13 AC 150/5320-6E 304. 9/30/2009 PAVEMENT DESIGN USING FAARFIELD. a. Purpose. The design procedure presented in this chapter provides a method of design based on layered elastic and three-dimensional finite element-based structural analysis developed to calculate design thicknesses for airfield pavements. Layered elastic and three-dimensional finite element-based design theories were adopted to address the impact of new complex gear and wheel arrangements. The design method is computationally intense, so the FAA developed a computer program called FAARFIELD to help pavement engineers implement it. b. Application. The procedures and design software identified in this chapter are intended to provide pavement thickness design standards for all airfield pavements. To aid in the design review, the summary information from the design software should be printed and included with the pavement design submittal. The summary information can be printed from the FAARFIELD Notes Window by clicking the ‘Save XML’ button. FAARFIELD then saves the information into an Extensible Markup Language (XML) format file for future import into FAA Form 5100-1. FAARFIELD is based on the cumulative damage factor (CDF) concept, in which the contribution of each airplane in a given traffic mix to total damage is separately analyzed. Therefore, the FAARFIELD program should not be used to compare individual airplane pavement thickness requirements with the design methods contained in previous versions of the AC that are based on the “design aircraft” concept. Likewise, due care should be used when using FAARFIELD to evaluate pavement structures originally designed with the thickness design curves in previous versions of this AC. Any comparison between FAARFIELD and the design curve methodology from previous versions of this AC must be performed using the entire traffic mix. c. Computer Program. The structural computations are performed by two subprograms within FAARFIELD. These subprograms are called LEAF and NIKE3D_FAA. LEAF is a layered elastic computational program implemented as a Microsoft WindowsTM dynamic link library written in Visual BasicTM 2005. NIKE3D_FAA is a three-dimensional finite element computational program implemented as a dynamic link library written in FORTRAN. NIKE3D_FAA is a modification of the NIKE3D program originally developed by the Lawrence Livermore National Laboratory (LLNL) of the U.S. Department of Energy and is distributed in compiled form under a software sharing agreement between LLNL and the FAA. (1) Airplane Considerations. A wide variety of airplanes with pertinent pavement design characteristics are stored in the program library. The FAARFIELD internal airplane library is divided into six airplane groups: Generic, Airbus, Boeing, Other Commercial, General Aviation, and Military. The designer has considerable latitude in selecting and adjusting airplane weights and frequencies. (i) Load. The pavement design method is based on the gross weight of the airplane. The pavement should be designed for the maximum anticipated takeoff weight of the airplane at the anticipated facility. The design procedure assumes 95 percent of the gross weight is carried by the main landing gears and 5 percent is carried by the nose gear. FAARFIELD provides manufacturer-recommended gross operating weights for many civil and military airplanes. The FAA recommends using the maximum anticipated takeoff weight, which provides some degree of conservatism in the design. This will allow for changes in operational use and forecast traffic. The conservatism is offset somewhat by ignoring arriving traffic. (ii) Landing Gear Type and Geometry. Gear type and configuration dictate how airplane weight is distributed to a pavement and how the pavement will respond to airplane loadings. Table 3-1 shows typical gear configurations and new gear designations in accordance with FAA Order 5300.7, Standard Naming Convention for Aircraft Landing Gear Configurations (Appendix 2). (iii) Tire Pressure. Tire pressure varies depending on gear configuration, gross weight, and tire size. Tire pressure has significantly more influence on strains in the asphalt surface layer than at the subgrade. Tire pressures in excess of 221 psi (1.5 MPa) may be safely exceeded if the pavement surface course and base course meet the minimum design requirements for pavement loading along with a high stability asphalt surface. (iv) Traffic Volume. Forecasts of annual departures by airplane type are needed for pavement design. Information on airplane operations is available from Airport Master Plans, Terminal Area Forecasts, the National Plan of Integrated Airport Systems, Airport Activity Statistics, and FAA Air Traffic Activity Reports. Pavement engineers should consult these publications when developing forecasts of annual departures by airplane type. 14 9/30/2009 AC 150/5320-6E TABLE 3-1. STANDARD NAMING CONVENTION FOR COMMON AIRPLANE GEAR CONFIGURATIONS Gear Designation Gear Designation Airplane Example Sngl Whl-45 S Single B737-100 D Dual 2S C-130 2 Singles in Tandem 2D B767-200 2 Duals in Tandem 3D B777-200 3 Duals in Tandem C-17A 2T Two Triple Wheels in Tandem 15 AC 150/5320-6E 9/30/2009 TABLE 3-1. STANDARD NAMING CONVENTION FOR COMMON AIRPLANE GEAR CONFIGURATIONS (CONTINUED) Gear Designation Gear Designation Airplane Example DC10-30/40 2D/D1 Two Dual Wheels in Tandem Main Gear/Dual Wheel Body Gear A340-600 std 2D/2D1 2D/2D1 Two Dual Wheels in Tandem Main Gear/Two Dual Wheels in Tandem Body Gear 2D/2D2 B747-400 Two Dual Wheels in Tandem Main Gear/Two Dual Wheels in Tandem Body Gear A380-800 2D/3D2 Two Dual Wheels in Tandem Main Gear/Three Dual Wheels in Tandem Body Gear 5D An-124 Five Dual Wheels in Tandem Main Gear 16 9/30/2009 AC 150/5320-6E (2) Units. The program may be operated with U.S. customary or metric dimensions. (3) Availability. FAARFIELD can be downloaded from the Office of Airport Safety and Standards website (http://www.faa.gov/airports/). (4) Related Reference Material. The internal help file for FAARFIELD contains a user’s manual, which provides detailed information on proper execution of the program. The manual also contains additional technical references for specific details of the FAARFIELD design procedure. (5) Airplane Traffic Mixture. FAARFIELD was developed and calibrated specifically to produce pavement thickness designs consistent with previous methods based on a mixture of different airplanes rather than an individual airplane. If a single airplane is used for design, a warning will appear in the Airplane Window indicating a non-standard airplane list is used in the design. This warning is intended to alert the user that the program was intended for use with a mixture of different airplane types. Nearly any traffic mix can be developed from the airplanes in the program library. Solution times are a function of the number of airplanes in the mix. The FAARFIELD design procedure deals with mixed traffic differently than did previous design methods. Determination of a design aircraft is not required to operate FAARFIELD. Instead, the program calculates the damaging effects of each airplane in the traffic mix. The damaging effects of all airplanes are summed in accordance with Miner’s law. When the cumulative damage factor (CDF) sums to a value of 1.0, the design conditions have been satisfied. d. Pavement Design Considerations. There are distinct differences between the previous FAA design methodology and the methodology contained in FAARFIELD. These differences, along with some common design assumptions between the two methods, are discussed below. (1) Design Life. The FAA design standard for pavements is based on a 20-year design life. The computer program is capable of considering other design life time frames, but the use of a design life other than 20 years constitutes a deviation from FAA standards. (2) Traffic Mix. The design procedures in previous versions of this AC required the traffic mixture to be converted into a single design aircraft and all annual departures converted to equivalent annual departures of the design aircraft. The design aircraft was determined by selecting the most damaging airplane based on the anticipated gross weight and the number of departures for each airplane. As noted in 303c(5), the FAARFIELD design program does not convert the traffic mixture to equivalent departures of a design aircraft. Instead, it analyzes the damage to the pavement for each airplane and determines a final thickness for the total cumulative damage. FAARFIELD considers the placement of each airplane’s main gear in relationship to the pavement centerline. It also allows the pavement damage associated with a particular airplane to be completely isolated from one or more of the other airplanes in the traffic mixture. (3) Pass-to-Coverage Ratio. As an airplane moves along a pavement section it seldom travels in a perfectly straight path or along the exact same path as before. This lateral movement is known as airplane wander and is modeled by a statistically normal distribution. As an airplane moves along a taxiway or runway, it may take several trips or passes along the pavement for a specific point on the pavement to receive a full-load application. The ratio of the number of passes required to apply one full load application to a unit area of the pavement is expressed by the passto-coverage (P/C) ratio. It is easy to observe the number of passes an airplane may make on a given pavement, but the number of coverages must be mathematically derived based upon the established P/C ratio for each airplane. By definition, one coverage occurs when a unit area of the pavement experiences the maximum response (stress for rigid pavement, strain for flexible pavement) induced by a given airplane. For flexible pavements, coverages are a measure of the number of repetitions of the maximum strain occurring at the top of subgrade. For rigid pavements, coverages are a measure of repetitions of the maximum stress occurring at the bottom of the PCC layer (see Report No. FAA-RD-77-81, Development of a Structural Design Procedure for Rigid Airport Pavements). Coverages resulting from operations of a particular airplane type are a function of the number of airplane passes, the number and spacing of wheels on the airplane main landing gear, the width of the tire-contact area, and the lateral distribution of the wheel-paths relative to the pavement centerline or guideline markings (see Report No. FAA-RD-74-036, Field Survey and Analysis of Aircraft Distribution on Airport Pavements). In calculating the P/C ratio, FAARFIELD uses the concept of effective tire width. For rigid pavements, the effective tire width is defined at the surface of the pavement and is equal to a nominal tire contact patch width. For flexible pavements, for the failure mode of shear in the subgrade layer, the effective tire width is defined at the top of the subgrade. “Response lines” are drawn at a 1:2 slope from the edges of the contact patches to the top of the subgrade, as illustrated in figures 3-1 and 3-2. Tires are considered to be either separate or combined, 17 AC 150/5320-6E 9/30/2009 depending on whether the response lines overlap. Figures 3-1 and 3-2 are shown for information only. All effective tire width and P/C ratio calculations are performed internally within the FAARFIELD program. (4) Annual Departures and Traffic Cycles. Airport pavement design using FAARFIELD considers only departures and ignores the arrival traffic when determining the number of airplane passes. This is because in most cases airplanes arrive at an airport at a significantly lower weight than at takeoff due to fuel consumption. During touchdown impact, remaining lift on the wings further alleviates the dynamic vertical force that is actually transmitted to the pavement through the landing gears. The FAA has defined a standard traffic cycle (TC) as one takeoff and one landing of the same airplane. In the situation described above, one traffic cycle produces one pass of the airplane which results in a pass-to-traffic cycle ratio (P/TC ) of 1. To determine annual departures for pavement design purposes multiply the number of departing airplanes by the P/TC. For most airport pavement design purposes, a P/TC of 1 may be used. In cases where the landing weight is not significantly less than the take off weight or in a case where the airplane must travel along the pavement more than once, it may be appropriate to adjust the number of annual departures used for thickness design to reflect a different pass-to-traffic cycle (P/TC) ratio. For example, in the case of a runway with a central taxiway configuration the airplane is required to traffic a large part of the runway during the taxi movement. In this case the airplane must travel along the same portion of the runway pavement two times during the take off operation. For this scenario a P/TC ratio of 2 would be used (assuming that the airplane obtains fuel at the airport), and the number of annual departures used for design should accordingly be increased by a factor of 2. Additional definitions and guidance on determining the P/TC ratio may be found in AC 150/5335-5, “Standardized Method of Reporting Airport Pavement Strength – PCN,” Appendix 1. (5) Cumulative Damage Factor. In FAARFIELD, the “design aircraft” concept has been replaced by design for fatigue failure expressed in terms of a cumulative damage factor (CDF) using Miner’s rule, CDF is the amount of the structural fatigue life of a pavement that has been used up. It is expressed as the ratio of applied load repetitions to allowable load repetitions to failure. For a single airplane and constant annual departures, CDF is expressed as— CDF number of applied load repetition s number of allowable repetition s to failure CDF annual departures life in years pass coverages to failure coverage ratio or or CDF applied coverages coverages to failure Table 3-2 describes pavement condition for different values of CDF. TABLE 3-2. PAVEMENT REMAINING LIFE BASED ON CDF VALUE CDF value 1 <1 >1 Pavement Remaining Life The pavement has used up all of its fatigue life. The pavement has some life remaining, and the value of CDF gives the fraction of the life used. The pavement has exceeded its fatigue life. In the program implementation, CDF is calculated for each 10-inch (254 mm) wide strip along the pavement over a total width of 820 inches (20 828 mm). Pass-to-coverage ratio is computed for each strip based on a normally distributed 18 9/30/2009 AC 150/5320-6E airplane wander pattern with standard deviation of 30.435 inches (773 mm) (equivalent to airplane operation on a taxiway) and used in the above equation for Miner’s rule. The CDF for design is taken to be the maximum over all 82 strips. Even with the same gear geometry, therefore, airplanes with different main gear track widths will have different pass-to-coverage ratios in each of the 10-inch (254 mm) strips and may show little cumulative effect on the maximum CDF. Removing the airplanes with the lowest stress or strain may then have little effect on the design thickness, depending on how close the gear tracks are to each other and the number of departures. FIGURE 3-1. TWO EFFECTIVE TIRE WIDTHS - NO OVERLAP FIGURE 3-2. ONE EFFECTIVE TIRE WIDTH – OVERLAP 19 AC 150/5320-6E 9/30/2009 Example: To illustrate the results of CDF calculations, an existing taxiway pavement composed of the following section was assumed: the subgrade k-value is 141 pci (38.4 MN/m3), equivalent to an E modulus of 15,000 psi (103.42 MPa), the PCC surface course is 15.2 inches (386 mm) thick, the P-306 econocrete base course is 6 inches (152 mm) thick, and the P-209 crushed aggregate subbase course is 6 inches (152 mm). The pavement is designed for the following airplane mix: B747-200B Combi Mixed weighing 836,000 pounds (379 203 kg) at an annual departure level of 1,200, B777-200 ER weighing 657,000 pounds (298 010 kg) at an annual departure level of 1,200, and DC8-63/73 weighing 358,000 pounds (162 386 kg) at an annual departure level of 1,200. The CDF contributions for each individual airplane and the cumulative CDF across the pavement section are shown on figure 3-3. Values of individual airplane contributions depend on several factors of which the most important are annual departure level and airplane gross weight. FIGURE 3-3. EXAMPLE OF CDF CONTRIBUTION FOR AIRPLANE MIX (6) Materials. In the FAARFIELD design procedure, pavement layers are assigned a thickness, elastic modulus, and Poisson’s ratio. The same layer properties are used in layered elastic and finite element analysis mode. Layer thicknesses can be varied, subject to minimum thickness requirements. Elastic moduli are either fixed or variable, depending on the material. The permissible range of variability for elastic moduli is fixed to ensure reasonable values. Poisson’s ratio for all materials is fixed. Materials are identified by their corresponding FAA specification designations; for example, crushed stone base course is identified as Item P-209. The list of materials contains an undefined layer with variable properties. If an undefined layer is used, a warning will appear in the Structure Window stating that a non-standard material has been selected and its use in the structure will require FAA approval. (7) Minimum Layer Thickness. When used in accordance with the user’s manual, FAARFIELD will automatically establish the minimum layer thickness for each layer, as required. However, it is recommended that the user consult the applicable paragraphs of this AC for design of new flexible, new rigid, and overlaid pavements to assure that the minimum thickness requirements are obtained. 305. TRAFFIC DISTRIBUTION. Research studies have shown that airplane traffic is distributed laterally on runways and taxiways according to statistically normal (bell-shaped) distribution. FAA Report No. FAA-RD-74-036 contains research information on traffic distribution. The design procedures presented in this AC incorporate the statistically normal distribution in the departure levels. In addition to the lateral distribution of traffic across pavements, it also considers traffic distribution and the nature of loadings for aprons and high-speed turnoffs. 306. TYPICAL SECTIONS. Airport pavements are generally constructed in uniform, full-width sections. Runways may be constructed with a transversely variable section, if practical or economically feasible. A variable section permits a reduction in the quantity of materials required for the upper paving layers of the runway. However, more complex construction operations are associated with variable sections and are usually more costly. The additional construction costs may negate any savings realized from reduced material quantities. Typical plan and section drawings for transversely variable section runway pavements are shown in figure 3-4. Deviations from these typical sections will be common due to the change inherent in staged construction projects where runways are extended and the location of 20 9/30/2009 AC 150/5320-6E taxiways is uncertain. As a general rule-of-thumb the designer should specify full pavement thickness where departing traffic will be using the pavement; pavement thickness designed using arrivals weight and estimated frequency where traffic will be arrivals such as high speed turnoffs; and pavement thickness designed using departure weight and 1 percent of estimated frequency where pavement is required but traffic is unlikely such as along the extreme outer edges of the runway. Note that the full-strength keel section is 50 feet (15 m) on the basis of the research study discussed in paragraph 305. 307. FROST AND PERMAFROST DESIGN. The design of an airport pavement must consider the climatic conditions that will act on the pavement during its construction and service life. The protection of pavements from the adverse effects of seasonal frost and permafrost effects are considered in the design of airport pavements as discussed below. a. Seasonal Frost. The adverse effects of seasonal frost are discussed in Chapter 2. The design of pavements in seasonal frost areas may be based on either of two approaches. The first approach is based on the control of pavement deformations resulting from frost action. Under this approach, sufficient combined thickness of pavement and non-frost-susceptible material must be provided to eliminate, or limit to an acceptable amount, frost penetration into the subgrade and its adverse effects. The second approach is based on providing adequate pavement load carrying capacity during the critical frost melting period. The second approach provides for the loss of load carrying capacity due to frost melting but ignores the effects of frost heave. Three design procedures that encompass the above approaches have been developed and are discussed below. (1) Complete Frost Protection. Complete frost protection is accomplished by providing a sufficient thickness of pavement and non-frost-susceptible material to totally contain frost penetration. This method is intended to prevent underlying frost susceptible materials from freezing. To use the complete protection method, the depth of frost penetration is determined by local experience or engineering analysis following the procedure given in Chapter 2. The thickness of pavement required for structural support is compared with the depth of frost penetration computed. The difference between the pavement thickness required for structural support and the computed depth of frost penetration is made up with non-frost susceptible material. Depending on grades and other considerations, provision for complete protection may involve removal and replacement of a considerable amount of subgrade material. Complete frost protection is the most positive, and is usually the most costly, method of providing frost protection. (2) Limited Subgrade Frost Penetration. The limited subgrade frost penetration method is based on holding frost heave to a tolerable level. Frost is allowed to penetrate a limited amount into the underlying frost susceptible subgrade. Sixty-five percent of the depth of frost penetration is made up with non-frost-susceptible material. Use of the method is similar to the complete protection method. Additional frost protection is required if the thickness of the structural section is less than 65 percent of the frost penetration. The limited subgrade frost penetration method allows a tolerable (based on experience) amount of frost heave. (3) Reduced Subgrade Strength. The reduced subgrade strength method is based on the concept of providing a pavement with adequate load carrying capacity during the frost melting period. This method does not consider the effects of frost heave. Use of the reduced subgrade strength method involves assigning a subgrade strength rating to the pavement for the frost melting period. The various soil frost groups, as defined in Chapter 2, should be assigned strength ratings as shown below: TABLE 3-3. REDUCED SUBGRADE STRENGTH RATINGS Frost Group FG-1 FG-2 FG-3 FG-4 Flexible Pavement CBR Value Rigid Pavement k-value 9 50 7 40 4 25 Reduced Subgrade Strength Method Does Not Apply The required pavement thicknesses are determined using FAARFIELD, using the reduced subgrade strength value from table 3-3 in lieu of the nominal subgrade CBR or k-value determined by testing. Pavement thicknesses thus established reflect the requirements for the subgrade in its weakened condition due to frost melting. b. Applications. Due to economic considerations, the maximum practical depth of frost protection that should be provided is normally 72 inches (1 829 mm). The recommended applications of the three methods of frost protection discussed above are as follows. In addition to these recommended applications, local experience should be given strong consideration when designing for frost conditions. 21 AC 150/5320-6E 9/30/2009 (1) Complete Frost Protection. The complete frost protection method applies only to FG-3 and FG-4 soils, which are extremely variable in horizontal extent. These soil deposits are characterized by very large, frequent, and abrupt changes in frost heave potential. The variability is such that the use of transition sections is not practical. (2) Limited Subgrade Frost Penetration. This design method should be used for FG-4, soils except where the conditions require complete protection, see (1) above. The method also applies to soils in frost groups FG-1, FG-2, and FG-3 when the functional requirements of the pavement permit a minor amount of frost heave. Consideration should be given to using transition sections where horizontal variability of frost heave potential permits. (3) Reduced Subgrade Strength. The reduced subgrade strength method is recommended for FG-1, FG-2, and FG-3 subgrades, which are uniform in horizontal extent or where the functional requirements of the pavement will permit some degree of frost heave. The method may also be used for variable FG-1 through FG-3 subgrades for less sensitive pavements, which are subject to slow speed traffic and heave can be tolerated. c. Permafrost. The design of pavements in permafrost regions must consider not only the effects of seasonal thawing and refreezing, but also the effects of construction on the existing thermal equilibrium. Changes in the subsurface thermal regime may cause degradation of the permafrost table, resulting in severe differential settlements and drastic reduction of pavement load carrying capacity. Gravel surfaced pavements are rather common in permafrost areas and generally will provide satisfactory service. These pavements often exhibit considerable distortion but are rather easily regraded. The absence of a waterproof surface is not a great problem because these areas usually have low precipitation. Three design methods for asphaltic or concrete surfaced pavements are discussed below. (1) Complete Protection Method. The objective of the complete protection method is to ensure that the underlying permafrost remains frozen year-round. Seasonal thawing is restricted to non-frost-susceptible materials. This method is analogous to the complete frost protection method of design for seasonal frost. The thickness of pavement required for structural support is first determined. The depth of seasonal thaw is then computed as described in Chapter 2 or using information based on local experience. The difference between the depth of seasonal thaw and the thickness needed for structural support is the amount of non-frost-susceptible material that must be provided to fully contain the depth of seasonal thaw. The use of relatively high moisture retaining soils, such as uniformly graded sands, should be considered. If some heaving can be tolerated, the use of frost-susceptible soils in the FG-1 or FG-2 groups may also be considered. If FG-1 or FG-2 soils are used, they must be placed so as to be as uniform as possible. Normally, economic considerations will limit the depth of treatment to a maximum of 6 feet (1.8 m). (2) Reduced Subgrade Strength Method. If conditions are such that the complete protection method of design is not practical, the design may be based on the reduced subgrade strength method. The use of this method for permafrost design is identical to that presented in paragraph 307b(3) above. This method should provide a pavement with sufficient structural support during the seasonal permafrost thaw period but will likely result in differential heaving. If practical, it may be advisable to delay paving for 2 or 3 years to allow the embankment to reach equilibrium. (3) Insulating Panels. A third approach, which is not as common, is the use of insulating panels beneath the pavement structure to protect against degradation of the permafrost. This method can lead to problems if the insulating panels are crushed by the weight of the overburden or by the live loads. Crushing of the cell structure of the insulation results in loss of insulating properties and failure to serve its intended purpose. Pavements using this technique must be very carefully constructed and may be subject to load limitations because of the need to guard against crushing the insulating panels. A significant change in the weight of using airplanes may fail the insulating panels. Since the FAA has no standards or design criteria for the use of insulating panels, the FAA must approve their use on federally funded construction on a case-by-case basis. 22 9/30/2009 AC 150/5320-6E FIGURE 3-4. TYPICAL PLAN AND CROSS SECTION FOR RUNWAY PAVEMENT 23 AC 150/5320-6E 9/30/2009 SECTION 2. FLEXIBLE PAVEMENT DESIGN 308. GENERAL. Flexible pavements consist of a hot mix asphalt wearing surface placed on a base course and, when required by subgrade conditions, a subbase. The entire flexible pavement structure is ultimately supported by the subgrade. Definitions of the function of the various components are given in the following paragraphs. 309. HOT MIX ASPHALT SURFACING. The hot mix asphalt surface or wearing course must prevent the penetration of surface water to the base course; provide a smooth, well-bonded surface free from loose particles which might endanger airplanes or persons; resist the shearing stresses induced by airplane wheel loads; and furnish a texture of nonskid qualities, yet not cause undue wear on tires. To successfully fulfill these requirements, the surface must be composed of mixtures of aggregates and bituminous binders which will produce a uniform surface of suitable texture possessing maximum stability and durability. Since control of the mixture is of paramount importance, these requirements can best be achieved by use of a central mixing plant where proper control can be most readily obtained. A dense-graded hot mix asphalt concrete such as Item P-401 produced in a central mixing plant will most satisfactorily meet all the above requirements. Whenever a hot mix asphalt surface is subject to spillage of fuel, hydraulic fluid, or other solvents, such as at airplane fueling positions and maintenance areas, protection should be provided by a solvent resistant surface. 310. BASE COURSE. The base course is the principal structural component of the flexible pavement. It has the major function of distributing the imposed wheel loadings to the pavement foundation, the subbase and/or subgrade. The base course must be of such quality and thickness to prevent failure in the subgrade, withstand the stresses produced in the base itself, resist vertical pressures tending to produce consolidation and resulting in distortion of the surface course, and resist volume changes caused by fluctuations in its moisture content. The quality of the base course depends upon composition, physical properties and compaction. Many materials and combinations thereof have proved satisfactory as base courses. They are composed of select, hard, and durable aggregates. Specifications covering the quality of components, gradation, manipulation control, and preparation of various base materials for use on airports for airplane design loads of 30,000 pounds (13 608 kg) or more are as follows: (1) Item P-208 – Aggregate Base Course¹ (2) Item P-209 – Crushed Aggregate Base Course2 (3) Item P-211 – Lime Rock Base Course (4) Item P-219 – Recycled Concrete Aggregate Base Course (5) Item P-304 – Cement Treated Base Course (6) Item P-306 – Econocrete Subbase Course (7) Item P-401 – Plant Mix Bituminous Pavements (8) Item P-403 – HMA Base Course ¹The use of Item P-208, Aggregate Base Course, as base course is limited to pavements designed for gross loads of 60,000 lb (27 216 kg) or less. When Item P-208 is used as base course the minimum thickness of the hot mix asphalt surfacing should be 5 inches (127 mm). 2 The use of item P-209, Crushed Aggregate Base Course, as a base course is limited to pavements serving airplanes having gross loads of 100,000 lbs (45 359 kg) or less except as noted in paragraph 317. Rubblized Portland cement concrete can also be used as a base course for flexible pavement. Depending on their composition, these materials have been divided into two major types: stabilized (P-211, P-304, P306, P-401, and P-403) and unstabilized (P-208, P-209, P-219, and rubblized Portland cement concrete) base courses. Details on these materials are described in paragraph 315d. 311. SUBBASE. A subbase is included as an integral part of the flexible pavement structure in all pavements except those on subgrades with a CBR value of 20 or greater (usually GW or GP type soils). The function of the subbase is similar to that of the base course. However, since it is further removed from the surface and is subjected to lower loading intensities, the material requirements are not as strict as for the base course. In the development of pavement thickness requirements the CBR value of the subbase course is a variable. 24 9/30/2009 AC 150/5320-6E a. Quality. Specifications covering the quality of components, gradations, manipulation control, and preparation of various types of subbase courses for use on airports for airplane design loads of 30,000 pounds (13 608 kg) or more are as follows: (1) Item P-154 – Subbase Course (2) Item P-210 – Caliche Base Course (3) Item P-212 – Shell Base Course (4) Item P-213 – Sand Clay Base Course¹ (5) Item P-301 – Soil Cement Base Course¹ ¹ Use of Items P-213 and P-301 as subbase course is not recommended where frost penetration into the subbase is anticipated. Any material suitable for use as base course can also be used on subbase if economy and practicality dictate. b. Sandwich Construction. Pavements should not be configured such that a pervious granular layer is located between two impervious layers. This type of section is often called sandwich construction. Problems are often encountered in sandwich construction when water becomes trapped in the granular layer causing a dramatic loss of strength and results in poor performance. A rubblized concrete layer over a stabilized base layer is not considered as sandwich construction. 312. SUBGRADE. The subgrade soils are subjected to lower stresses than the surface, base, and subbase courses. Subgrade stresses attenuate with depth, and the controlling subgrade stress is usually at the top of the subgrade, unless unusual conditions exist. Unusual conditions such as a layered subgrade or sharply varying water contents or densities can change the location of the controlling stress. The ability of a particular soil to resist shear and deformation vary with its density and moisture content. Such unusual conditions should be revealed during the soils investigation. Specification Item P-152, Excavation and Embankment, covers the construction and density control of subgrade soils. Table 3-4 shows depths below the subgrade surface to which compaction controls apply. To use table 3-4, consider the mix of the airplanes that will be using the pavement feature under consideration. The airplane in the mix that should be used to determine compaction requirements is the airplane requiring the maximum compaction depth from table 3-4, regardless of the anticipated number of operations. a. Contamination. A loss of structural capacity can result from contamination of base or subbase elements with fines from underlying subgrade soils. This contamination occurs during pavement construction and during pavement loading. Aggregate contamination results in a reduced ability of the aggregate to distribute and reduce stresses applied to the subgrade. Fine grained soils are most likely to contaminate pavement aggregate. This process is not limited to soft subgrade conditions. Problematic soils may be cohesive or noncohesive and usually exhibit poor drainage properties. Chemical and mechanical stabilization of the subbase or subgrade can be effectively used to reduce aggregate contamination (refer to paragraph 206). Geosynthetics are effective at providing separation between finegrained soils and overlying pavement aggregates (FHWA-HI-95-038) (see Appendix 4). In this application, the geosynthetic is not considered to act as a structural element within the pavement. For separation applications the geosynthetic is designed based on survivability properties. Refer to FHWA-HI-95-038 (see Appendix 4) for additional information about design and construction using separation geosynthetics. b. Example. An apron extension is to be built to accommodate the following airplane mix: B767-200 (340,000 lbs./154 221 kg), B757-200 (256,000 lbs./116 1200 kg), and A310-200 (315,041 lbs./142 900 kg). A soils investigation has shown the subgrade will be noncohesive. In-place densities of the soils have been determined at even foot increments below the ground surface. Design calculations indicate that the top of subgrade in this area will be approximately 10 inches (254 mm) below the existing grade. Depths and densities may be tabulated as follows in table 3-5. 25 AC 150/5320-6E 9/30/2009 TABLE 3-4. SUBGRADE COMPACTION REQUIREMENTS FOR FLEXIBLE PAVEMENTS GEAR TYPE S D (incls. 2S) 2D (incls. B757, B767, A-300, DC10-10, L1011) 2D/D1, 2D/2D1 (incls. MD11, A340, DC10-30/40) 2D/2D2 (incls. B747 series) 3D (incls. B777 series) GROSS WEIGHT Lb. 30,000 50,000 75,000 50,000 100,000 150,000 200,000 100,000 200,000 300,000 400,000 – 600,000 500,000 – 800,000 NON-COHESIVE SOILS Depth of Compaction, inch 100% 95% 90% 85% 8 8-18 18-32 32-44 10 10-24 24-36 36-48 12 12-30 30-40 40-52 12 12-28 28-38 38-50 17 17-30 30-42 42-55 19 19-32 32-46 46-60 21 21-37 37-53 53-69 14 14-26 26-38 38-49 17 17-30 30-43 43-56 20 20-34 34-48 48-63 23 23-41 41-59 59-76 COHESIVE SOILS Depth of Compaction, inch 95% 90% 85% 80% 6 6-9 9-12 12-17 6 6-9 9-16 16-20 6 6-12 12-19 19-25 6 6-10 10-17 17-22 6 6-12 12-19 19-25 7 7-14 14-21 21-28 9 9-16 16-24 24-32 5 6-10 10-17 17-22 5 6-12 12-18 18-26 7 7-14 14-22 22-29 9 9-18 18-27 27-36 23 23-41 41-59 59-76 9 9-18 18-27 27-36 800,000 975,000 550,000 650,000 750,000 1,250,000 1,350,000 23 24 20 22 24 24 25 23-41 24-44 20-36 22-39 24-42 24-42 25-44 41-59 44-62 36-52 39-56 42-57 42-61 44-64 59-76 62-78 52-67 56-70 57-71 61-78 64-81 9 10 6 7 8 9 10 9-18 10-20 6-14 7-16 8-17 9-18 10-20 18-27 20-28 14-21 16-22 17-23 18-27 20-29 27-36 28-37 21-29 22-30 23-30 27-36 29-38 2D/3D2 (incls. A380 series) Notes: 1. Noncohesive soils, for the purpose of determining compaction control, are those with a plasticity index of less than 3. 2. Tabulated values denote depths below the finished subgrade above which densities should equal or exceed the indicated percentage of the maximum dry density as specified in Item P-152. 3. The subgrade in cut areas should have natural densities shown or should (a) be compacted from the surface to achieve the required densities, (b) be removed and replaced at the densities shown, or (c) when economics and grades permit, be covered with sufficient select or subbase material so that the uncompacted subgrade is at a depth where the in-place densities are satisfactory. 4. For intermediate airplane weights, use linear interpolation. 5. For swelling soils, refer to paragraph 313. 6. 1 inch = 25.4 mm, 1 pound. = 0.454 kg TABLE 3-5. DENSITIES FOR SUBGRADE IN EXAMPLE Depth Below Existing Grade 1′ (0.3 m) 2′ (0.6 m) 3′ (0.9 m) 4′ (1.2 m) 5′ (1.5 m) Depth Below Finished Grade 2″ (50 mm) 14″ (0.36 m) 26″ (0.66 m) 38″ (0.97 m) 50″ (1.27 m) In-Place Density 70% 84% 86% 90% 93% For this example, the B767-200 gives the maximum required compaction values from table 3-4. Using table 3-4 for non-cohesive soils and applying linear interpolation, obtain the following compaction requirements as shown in table 36. 26 9/30/2009 AC 150/5320-6E TABLE 3-6. COMPACTION REQUIREMENTS FOR EXAMPLE 100% 0-21 95% 21-37 90% 37-52 85% 52-68 Comparison of the tabulations show that for this example in-place density is satisfactory at a depth of 38 inches (0.97 m), being 90 percent within the required 90 percent zone. It will be necessary to compact an additional 1 inch (0.03 m) at 95 percent. Therefore, compact the top 21 inches (0.53 m) of subgrade at 100 percent density and the 21 to 38 inches at 95 percent density. 313. SWELLING SOILS. Swelling soils are clayey soils that exhibit significant volume changes brought on by moisture variations. The potential for volumetric change of a soil due to moisture variation is a function of the type of soil and the likelihood of moisture fluctuation. Airport pavements constructed on these soils are subject to differential movements causing surface roughness and cracking. The design of pavements in areas of swelling soils should incorporate methods that prevent or reduce the effects of soil volume changes. a. Soil Type. Only clayey soils containing a significant amount of particular clay minerals are prone to swelling. The clay minerals that cause swelling, in descending order of swelling activity, are: smectite, illite, and kaolinite. These soils usually have liquid limits above 40 and plasticity indexes above 25. b. Identification. Soils that exhibit a swell of greater than 3 percent when tested for the CBR (California Bearing Ratio), ASTM D 1883, require treatment. Experience with soils in certain locales is often used to determine when treatment is required. c. Treatment. Treatment of swelling soils consists of removal and replacement, stabilization, modified compaction efforts and careful control of compaction moisture. Provisions for adequate drainage are of paramount importance when dealing with swelling soils. Recommended treatments for swelling soils are shown in table 3-7. Local experience and judgment should be applied in dealing with swelling soils to achieve the best results. Care should be taken to minimize water flow along the contact plane between the stabilized / nonstabilized material. TABLE 3-7. RECOMMENDED TREATMENT OF SWELLING SOILS Swell Potential (Based on Experience) Low Percent Swell Measured (ASTM D 1883) 3-5 Medium 6-10 High Over 10 Potential for Moisture Fluctuation1 Low High Low High Low High Treatment Compact soil on wet side of optimum (+2% to +3%) to not greater than 90% of appropriate maximum density2. Stabilize soil to a depth of at least 6 in. (150 mm) Stabilize soil to a depth of at least 12 in. (300 mm) Stabilize soil to a depth of at least 12 in. (300 mm) Stabilize soil to a depth of at least 12 in. (300 mm) For uniform soils, i.e., redeposited clays, stabilize soil to a depth of at least 36 in. (900 mm) or raise grade to bury swelling soil at least 36 in. (900 mm) below pavement section or remove and replace with nonswelling soil. For variable soil deposits depth of treatment should be increased to 60 in. (1 500 mm). Notes: 1 Potential for moisture fluctuation is a judgmental determination and should consider proximity of water table, likelihood of variations in water table, as well as other sources of moisture, and thickness of the swelling soil layer. 2 When control of swelling is attempted by compacting on the wet side of optimum and reduced density, the design subgrade strength should be based on the higher moisture content and reduced density. d. Additional Information. Additional information on identifying and handling swelling soils is presented in FAA Reports No. FAA-RD-76-066, Design and Construction of Airport Pavements on Expansive Soils, and DOT/FAA/PM-85115, Validation of Procedures for Pavement Design on Expansive Soils. 314. SELECTION OF DESIGN CBR VALUE. Subgrade soils are usually rather variable and the selection of a design CBR value requires some judgment. The design CBR value should be equal to or less than 85 percent of all the 27 AC 150/5320-6E 9/30/2009 subgrade CBR values. This corresponds to a design value of one standard deviation below the mean. In some cases subgrade soils that are significantly different in strength occur in different layers. In these instances several designs should be examined to determine the most economical pavement section. It may be more economical to remove and replace a weak layer than to design for it. On the other hand, circumstances may be such that designing for the weakest layer is more economical. Local conditions will dictate which approach should be used. 315. FLEXIBLE PAVEMENT DESIGN. The design process for flexible pavement considers two modes of failure for flexible pavement: vertical strain in the subgrade and horizontal strain in the asphalt layer. Limiting vertical strain in the subgrade is intended to preclude failure by subgrade rutting. Limiting horizontal strain at the bottom of the asphalt surfacing layer guards against pavement failure initiated by cracking of the asphalt surface layer. By default, FAARFIELD computes only the vertical subgrade strain for flexible pavement thickness design. However, the user has the option of enabling the asphalt strain computation by deselecting the “No AC CDF” checkbox in the FAARFIELD options screen. In most cases the thickness design is governed by the subgrade strain criterion. The user has the option of performing the asphalt strain check for the final design, and it is good engineering practice to do so. a. Design Life. The FAA design standards for airport pavements use the 20 year structural design life criteria as a policy. FAARFIELD is capable of considering design life timeframes other than the 20 year life criteria, but they are considered a deviation from FAA standards. b. Traffic Mix. Input the complete air traffic mix into FAARFIELD. See paragraph 304c(5). c. Hot Mix Asphalt Surfacing. Hot mix asphalt surfacing should meet the requirements of FAA Item P-401. A minimum thickness of 4 inches (102 mm) of hot mix surfacing is required. A fixed modulus value for hot mix surfacing is set in the program at 200,000 psi (1 380 MPa). This modulus value was conservatively chosen and corresponds to a pavement temperature of approximately 90 ºF (32ºC). Two types of asphalt surface layers are available in FAARFIELD: asphalt surface and asphalt overlay. Both have the same properties, with modulus fixed at 200,000 psi (1 380 MPa) and Poisson’s ratio fixed at 0.35. The asphalt overlay type can be placed over asphalt surface or PCC surface types. The asphalt surface type can only be placed on the top of a structure, or under an asphalt overlay. d. Base Course. Two types of base courses are defined: stabilized and unstabilized (aggregate). A stabilized base course may be required as described in paragraph 317. (1) Stabilized Base Course. FAARFIELD includes two types of stabilized layers, classified as stabilized (flexible) and stabilized (rigid). Variable modulus types are provided as well as fixed modulus types corresponding to standard material items. The two stabilized flexible base options are designated P-401/P-403 and Variable. The word flexible is used to indicate that these bases have a higher Poisson’s ratio (0.35), act as flexible layers as opposed to rigid layers, and are not likely to crack. The standard FAA bituminous base is P-401/P-403, which has a fixed modulus of 400,000 psi (2 760 MPa). The variable stabilized flexible base can be used to characterize a stabilized base, which does not conform to the properties of P-401/P-403. It has a variable modulus ranging from 150,000 to 400,000 psi (1 035 to 2 760 MPa). Stabilized (rigid) bases, P-304, and P-306 may also be used as base courses in flexible pavements. Item P-301, Soil Cement Base, is not acceptable for use as a stabilized base course for flexible pavements. The properties of the various stabilized base layer types used in FAARFIELD are summarized in table 3-8. TABLE 3-8. LAYER TYPES IN FAARFIELD Base Layer Stabilized (flexible) Variable Minimum Variable Maximum P-401/403 Asphalt Stabilized (rigid) Variable Minimum Variable Maximum P-304 Cement Treated Base P-306 Econocrete Subbase Modulus, psi (MPa) 150,000 (1 035) 400,000 (2 760) 400,000 (2 760) 250,000 (1 720) 700,000 (4 830) 500,000 (3 450) 700,000 (4 830) Poisson’s Ratio 0.35 0.20 The above minimum and maximum modulus values were determined on the basis of producing thickness designs comparable with the CBR design procedures. Therefore, typical laboratory test data for stabilized materials should not 28 9/30/2009 AC 150/5320-6E be used in preparing input data for FAARFIELD designs. If it is necessary to establish a modulus for a variable base layer the following guidance should be used: For flexible pavement design, the minimum modulus value of 150,000 psi (1 034 MPa) corresponds to a base course equivalency factor of 1.2 and the maximum value of 400,000 psi (2 758 MPa) corresponds to a base course equivalency factor of 1.6 previously used in CBR method. The equivalency factor represents the ratio of the thickness of a standard aggregate base layer (Item P-208) to a base layer of higher quality in the CBR method. The choice of base course modulus value can have a significant effect on total thickness of a flexible pavement. When a variable modulus layer is first created, the modulus is automatically set to the minimum value. (2) Unstabilized (Aggregate) Base Course. The standard aggregate base course for flexible pavement design is Item P-209, Crushed Aggregate Base Course. In FAARFIELD, P-209 Crushed Aggregate corresponds to the standard material. Item P-208, Uncrushed Aggregate, is not suitable as a base course material. Item P-208, when used as a base course is subject to the restrictions in paragraph 310. The modulus of aggregate layers is computed automatically and cannot be changed manually. To compute the modulus of non-stablized layers, the “Modulus” procedure developed by the U.S. Army Corps of Engineers Waterways Experiment Station is followed with sublayering performed automatically (maximum sublayer thicknesses are 8 inches (203 mm) for uncrushed aggregate and 10 inches (254 mm) for crushed aggregate). The modulus values of the sublayers decrease with increasing depth of a sublayer within the aggregate layer and are also dependent on the modulus of the layer below the aggregate layer. Aggregate layers can be placed anywhere in the pavement structure except at the surface or subgrade. The following additional restrictions also apply: Only one crushed layer and one uncrushed layer may be present in a structure. This is for compatibility with the “Modulus” procedure. (Sublayering by the “Modulus” procedure accounts for thick layers, and multiple layers of a single aggregate type are not necessary.) The maximum number of aggregate layers that may be present in a structure is therefore two, one of each type. If crushed and uncrushed layers are adjacent, the crushed layer must be above the uncrushed layer (to be compatible with the “Modulus” procedure). The modulus value displayed in the structure table for an aggregate layer is the average value of the sublayer modulus values. The only exception is for newly created layers, in which case the modulus values of 75,000 psi (517 MPa) and 40,000 psi (276 MPa) are displayed for crushed and uncrushed respectively. These default modulus values are never used in calculations. (3) Minimum Base Course Thickness. FAARFIELD, by default, computes the structural thickness required for the base course. Since it is assumed that the subbase layer provides the equivalent bearing capacity of a CBR 20 subgrade, the structural base course thickness is computed as the thickness required to protect a subgrade of CBR 20. When an aggregate base course is used, the automatic base thickness design procedure in FAARFIELD consists of two steps: Step 1 Compute the aggregate base thickness structurally required to protect an assumed CBR 20 subgrade. Step 2 Compare the base thickness computed in step 1 against the minimum base thickness requirements in table 3-9. Select the thicker of the two values as the design base course thickness. For traffic mixtures with airplanes exceeding 100,000 pounds (45 400 kg), a stabilized base course is required as described in paragraph 317. The minimum stabilized base thickness is 5 inches (127 mm). When a stabilized base is used, an additional step is added to the automated base thickness design procedure. After the thickness of the aggregate base structurally required to protect a CBR 20 subgrade is computed (step 1 above), the required thickness of the stabilized base is obtained by dividing by 1.6. The required stabilized base thickness thus obtained is compared with the 5 inch (127 mm) minimum requirement, and the larger of the two values is selected as the design stabilized base course thickness. 29 AC 150/5320-6E 9/30/2009 TABLE 3-9. MINIMUM AGGREGATE BASE COURSE THICKNESS Minimum Base Course (P-209) Thickness lbs (kg) in. (mm) S 30,000 - 50,000 (13 600 – 22 700) 4 (100) 50,000 - 75,000 (22 700 – 34 000) 6 (150) D 50,000 - 100,000 (22 700 – 45 400) 6 (150) 100,000 - 200,000* (45 400 – 90 700) 8 (200) 2D 100,000 - 250,000* (45 400 – 113 400) 6 (150) 250,000 - 400,000* (113 400 – 181 000) 8 (200) 2D (B757, B767) 200,000 - 400,000* (90 700 – 181 000) 6 (150) 2D or 2D/D1 (DC10, L1011) 400,000 - 600,000* (181 000 – 272 000) 8 (150) 2D/2D2 (B747) 400,000 - 600,000* (181 000 – 272 000) 6 (150) 600,000 - 850,000* (272 000 – 385 600) 8 (200) 2D/D1 or 2D/2D1(A340) 568,000 – 840,400 (257 640 – 381 200) 10 (250) 2S (C130) 75,000 - 125,000 (34 000 – 56 700) 4 (100) 125,000 - 175,000* (56 700 – 79 400) 6 (150) 3D (B777) 537,000 – 777,000* (243 500 – 352 440) 10 (250) 3D (A380) 1,239,000 – 1,305,125* (562 000 – 592 000) 9 (230) *Values are listed for reference. However, when the traffic mixture contains airplanes exceeding 100,000 lbs. (45 400 kg) gross weight, a stabilized base is required. Gear Type Design Load Range d. Subbase Course. Subbases may be aggregate or stabilized materials. The minimum thickness of subbase for structural purposes is 4 inches (102 mm). Additional thickness might be required for practical construction limitations. Acceptable aggregate and stabilized materials are defined in paragraphs 309, 310, and 311. Use of Item P301 is limited to locations not subject to freeze-thaw cycles. More than one layer of subbase material may be used, i.e., P-209 over a layer of P-154. Layering must be done so as not to produce a sandwich (granular layer between two stabilized layers) section and to assure that material quality increases toward the top of the pavement section. For traffic mixtures with airplanes exceeding 100,000 pounds (45 359 kg), a stabilized base course is required as described in paragraph 317. When a stabilized base course is required, it is recommended that a higher quality material be used for the subbase. Acceptable materials for use as subbase with a stabilized base layer are: P-208 – Aggregate Base Course P-209 – Crushed Aggregate Base Course In addition, any material suitable for use as a base course can also be used as a subbase course with a stabilized base layer. e. Subgrade. The subgrade is assumed to be infinite in thickness and is characterized by either a modulus or CBR value. Subgrade modulus values for flexible pavement design can be determined in a number of ways. The procedure that will be applicable in most cases is to use available CBR values and substitute in the relationship: E 1500 CBR , (E in psi) This method will provide designs compatible with the previous FAA design procedure based on the CBR equation. Although FAARFIELD requires input of the material elastic modulus, direct input of CBR values is also acceptable. f. Seasonal Frost and Permafrost. Seasonal frost and permafrost effects should be considered by applying the techniques in Chapter 2 and section 306. 316. DESIGN EXAMPLE. As an example of the use of the FAARFIELD, assume a flexible pavement is to be designed for the airplane traffic mix in table 3-10. The subgrade CBR is 8 (E=12,000 psi). Since the traffic mix includes jet airplanes weighing 100,000 pounds (45 359 kg) or more, an asphalt stabilized base will be used. The pavement layer thicknesses obtained from the design software FAARFIELD are listed in table 3-11. 30 9/30/2009 AC 150/5320-6E TABLE 3-10. AIRPLANE TRAFFIC MIX EXAMPLE No. 1 2 3 4 5 6 7 8 9 10 11 Name A320-100 A340-600 std A340-600 std Belly A380-800 B737-800 B747-400 B747-400ER B757-300 B767-400 ER B777-300 ER B787-8 Gross Weight, lb 150,796 805,128 805,128 1,239,000 174,700 877,000 913,000 271,000 451,000 777,000 478,000 Annual Departures 600 1,000 1,000 300 2,000 400 300 1,200 800 1,000 600 Annual Growth, % 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 TABLE 3-11. PAVEMENT STRUCTURE INFORMATION FOR DESIGN EXAMPLE No. 1 2 3 4 Type P-401/ P-403 AC Surface P-401/ P-403 St (flex) P-209 Cr Ag Subgrade Thickness, in 5.00 11.06 18.78 0.00 Modulus, psi 200,000 400,000 51,440 12,000 Poisson’s Ratio 0.35 0.35 0.35 0.35 The screenshot from the design software showing final thickness design is shown below: FIGURE 3-5. FAARFIELD SCREENSHOT SHOWING FINAL PAVEMENT THICKNESS DESIGN 31 AC 150/5320-6E 9/30/2009 The pavement thickness design software also provides information on the damage caused by individual airplanes. This additional information is provided in the Notes and Airplanes Windows. For the given example, the additional airplane information is listed in table 3-12. Note that two fields are provided for CDF information. Each field contains different information. “CDF Contribution” lists the contribution of the airplanes to the total CDF calculated at the critical offset. This column should sum to 1.00 for a completed design, although due to rounding error and internal tolerances the sum may be slightly greater than or less than 1.00. “CDF Max for Airplanes” lists the maximum CDF over all offsets calculated for the airplanes, whether or not these occur at the critical offset. The sum of the values in this column should be greater than or equal to 1.00 for a completed design.” TABLE 3-12. ADDITIONAL AIRPLANE INFORMATION FOR DESIGN EXAMPLE No. 1 2 3 4 5 6 7 8 9 10 11 Name A320-100 A340-600 std A340-600 std Belly A380-800 B737-800 B747-400 B747-400ER B757-300 B767-400 ER B777-300 ER B787-8 CDF Contribution 0.00 0.04 0.00 0.01 0.00 0.01 0.01 0.00 0.04 0.86 0.03 CDF Max for Airplanes 0.00 0.05 0.03 0.01 0.00 0.01 0.02 0.00 0.05 0.86 0.03 P/C Ratio 1.21 0.59 0.57 0.42 1.22 0.57 0.57 0.73 0.60 0.40 0.57 Table 3-12 shows that the pavement thickness design in this example is controlled primarily by the B777-300 ER, which contributes 86 percent of the CDF. 317. STABILIZED BASE AND SUBBASE. Stabilized base and subbase courses are necessary for new pavements designed to accommodate jet airplanes weighing 100,000 pounds (45 359 kg) or more. Exceptions to the policy requiring stabilized base and subbase may be made on the basis of superior materials being available, such as 100 percent crushed, hard, closely graded stone. These materials should exhibit a remolded soaked CBR minimum of 100 for base and 35 for subbase. In areas subject to frost penetration, the materials should meet permeability and nonfrost susceptibility tests in addition to the CBR requirements. Other exceptions to the policy requiring stabilized base and subbase should be based on proven performance of a granular material such as lime rock in the state of Florida. Proven performance in this instance means a history of satisfactory airport pavements using the materials. This history of satisfactory performance should be under airplane loadings and climatic conditions comparable to those anticipated. 318. FULL-DEPTH ASPHALT PAVEMENTS. Full-depth asphalt pavements contain asphaltic cement in all components above the prepared subgrade. Alternate design procedures can be used to design full-depth asphalt pavements when approved by the FAA. 319. FROST EFFECTS. Frost protection should be provided in areas where conditions conducive to detrimental frost action exist. Details are given in Chapter 2, paragraph 207. Levels of frost protection are given in paragraph 307 of this document. Frost considerations may result in thicker subbase courses than the thicknesses needed for structural support. 32 9/30/2009 AC 150/5320-6E SECTION 3. RIGID PAVEMENT DESIGN 320. GENERAL. The design process considers one mode of failure for rigid pavement, cracking of the concrete slab. The cracking of the surface layer is controlled by limiting the horizontal stress at bottom of PCC slab. Failure of subbase and subgrade layers is not considered. FAARFIELD iterates on the concrete layer thickness until the CDF reaches a value of 1.0. Once a CDF of 1.0 is achieved, the section satisfies the design conditions. a. Structure. Rigid pavements for airports are composed of Portland cement concrete placed on a granular or treated subbase course that is supported on a compacted subgrade. b. Modeling. A three-dimensional finite element model is used to compute the stresses in concrete slabs. The three dimensional finite element model has the advantage of considering the critical stresses for slab design, which normally occur at slab edges, and also employs similar concepts for new rigid pavement design and rigid overlay design. Rigid overlay design is covered in Chapter 4. c. Applications. Refer to paragraph 304b. d. Seasonal Frost and Permafrost. Seasonal frost and permafrost effects should be considered by applying the techniques in Chapter 2. e. Jointing Details. Jointing details for rigid pavements are presented in this chapter, paragraph 332. 321. CONCRETE PAVEMENT. The concrete surface must provide a texture of nonskid qualities, prevent the infiltration of surface water into the subgrade, and provide structural support to the airplanes. The quality of the concrete, acceptance and control tests, methods of construction and handling, and quality of workmanship are covered in Item P-501, Portland Cement Concrete Pavement. 322. SUBBASE. The purpose of a subbase under a rigid pavement is to provide uniform stable support for the pavement slabs. A minimum thickness of 4 inches (102 mm) of subbase is required under all rigid pavements. 323. SUBBASE QUALITY. The standard FAA subbase for rigid pavements is 4 inches (100 mm) of Item P-154, Subbase Course. In some instances, it may be desirable to use higher-quality materials or thicknesses of P-154 greater than 4 inches (102 mm). The following materials are acceptable for use as subbase under rigid pavements: Item P-154 – Subbase Course Item P-208 – Aggregate Base Course Item P-209 – Crushed Aggregate Base Course Item P-211 – Lime Rock Base Course Item P-301 – Soil Cement Base Item P-304 – Cement Treated Base Course Item P-306 – Econocrete Subbase Course Item P-401 – Plant Mix Bituminous Pavements Item P-403 – HMA Base Course Rubblized Portland cement concrete can also be used as a subbase for rigid pavements. High-quality materials meeting state highway specifications can be substituted. Materials of higher quality than P-154 and/or greater thicknesses of subbase are considered in the design program FAARFIELD. The costs of providing the additional thickness or higher-quality subbase should be weighed against the savings in concrete thickness. 324. STABILIZED SUBBASE. Stabilized materials are required for subbase under rigid pavements serving airplanes weighing 100,000 pounds (45 359 kg) or more. Acceptable stabilized materials are P-304 (Cement Treated Base Course), P-306 (Econocrete Subbase Course), and P-401 and P-403 (Plant Mix Bituminous Pavements). The minimum thickness of subbase is 4 inches (102 mm). More than one layer of subbase may be used, i.e., P-306 over a layer of P-209. Layering must be done so as not to produce a sandwich (granular layer between two stabilized layers) section. Exceptions to the policy of using stabilized subbase are the same as those given in paragraph 317. 33 AC 150/5320-6E 9/30/2009 325. SUBGRADE. Subgrade materials under a rigid pavement must be compacted in accordance with table 3-4. Specification Item P-152, Excavation and Embankment, covers the construction and density control of subgrade soils. Swelling soils require special considerations. Paragraph 313 contains guidance on the identification and treatment of swelling soils. a. Contamination. In rigid pavement systems repeated loading might cause intermixing of soft subgrade soils and aggregate base or subbase. This mixing can create voids below the pavement in which moisture can accumulate causing pumping to occur. Chemical and mechanical stabilization of the subbase or subgrade can effectively reduce aggregate contamination (see paragraph 206). Geosynthetics have been found to be effective at providing separation between fine-grained subgrade soils and pavement aggregates (FHWA-HI-95-038). Geosynthetics should be considered for separation between fine-grained soils and overlying pavement aggregates. In this application, the geosynthetic is not considered to act as a structural element within the pavement. Therefore, the modulus of the base or subbase is not increased when a geosynthetic is used for stabilization. For separation applications, the geosynthetic is designed based on survivability properties. Additional information about design and construction using separation geosynthetics can be found in FHWA-HI-95-038. 326. DETERMINATION OF MODULUS (E VALUE) FOR RIGID PAVEMENT SUBGRADE. In addition to the soils survey and analysis and classification of subgrade conditions, the determination of the foundation modulus is required for rigid pavement design. The foundation modulus should be assigned to the subgrade layer; i.e., the layer below all structural layers. The foundation modulus can be expressed as the modulus of subgrade reaction k or as the elastic (Young’s) modulus E and can be input into the program directly in either form. However, all structural computations are performed using the elastic modulus E. If the foundation modulus is input as a k-value it is automatically converted to the equivalent E value using the following equation: E SG 26k 1.284 where: ESG k = Resilient modulus of the subgrade, in psi = Foundation modulus of the subgrade, in pci For existing pavements the E modulus can be determined in the field from non-destructive testing (NDT) such as falling-weight deflectometer (FWD) tests and this may be necessary if direct testing of the subgrade is impractical. If the subgrade is accessible then the k-value can be determined directly by plate-load testing. If the k-modulus can be determined by plate load testing, or is otherwise available, then the k-value should be input directly into the FAARFIELD program without first converting to E modulus. The preferred method of determining the subgrade modulus is by testing a limited section of representative subgrade, which has been constructed to the required specifications. The plate bearing test procedures are given in AASHTO T 222, Nonrepetitive Static Plate Load Test of Soils and Flexible Pavement Components, for Use in Evaluation and Design of Airport and Highway Pavements. If the construction and testing of a test section of embankment is impractical, the conversion from CBR to k-value for the subgrade can be achieved using the following formula: 0.7788 1500 CBR , (k in pci) k 26 The designer is cautioned that the obtained values are approximate and engineering judgment should be used in selecting a design value. 327. DETERMINATION OF CONCRETE SLAB THICKNESS. FAARFIELD designs the slab thickness based on the assumption of edge loading. The gear load is located either tangent or perpendicular to the slab edge, and the larger of the two stresses, reduced by 25 percent to account for load transfer through the joint, is taken as the design stress for determining the slab thickness. Use of the design program FAARFIELD requires five groups of design input data: concrete flexural strength, subgrade modulus, design life in years, structural layer data, and airplane mixture information. The program computes only the thickness of the concrete layer. The minimum slab thickness is six inches. Thicknesses of other layers of the rigid pavement structure must be selected by the user. a. Concrete Flexural Strength. The required thickness of concrete pavement is related to the strength of the concrete used for construction of the pavement. For pavement design, the strength of the concrete is characterized by the flexural strength, since the primary action and failure mode of a concrete pavement is in flexure. For FAA design 34 9/30/2009 AC 150/5320-6E purposes, concrete flexural strength is measured in accordance with the ASTM C78, Standard Test Method for Flexural Strength of Concrete, test method. Although the flexural strength required for the pavement design is related to the flexural strength required by the P-501 specification, the strengths used for the pavement design and the P-501 specification are not necessarily the same. Unless expedited construction requires early opening of the pavement to airplane traffic (e.g., less than 28 days), Item P-501 typically uses a 28-day strength as a practical construction measure. However, the long-term strength achieved by the concrete is normally expected to be at least 5 percent more than the strength measured at 28 days. To establish the flexural strength for the thickness design the designer needs to consider several factors, such as: Capability of the industry in a particular area to produce concrete at a particular strength Flexural strength vs. cement content data from prior projects at the airport The need to avoid high cement contents, which can affect concrete durability Whether early opening requirements necessitate using a lower strength than 28-day The FAA recommends a design flexural strength of 600 to 700 psi (4.14 to 4.83 MPa) for most airfield applications. Lower strength requirements allow balancing the components of the concrete mixture for performance but may result in slightly thicker pavement requirements. However, these conditions reduce the risk of early cracking, minimize curling and warping stresses, and provide increased performance with respect to fatigue. The strength used for thickness design should be reduced by 5 percent when stating the P-501 specification requirements for the 28-day flexural strength. b. Subgrade Modulus. The subgrade modulus can be input as either a k-value or an E-value, as described in paragraph 326. c. Design Life. The standard design life for pavement thickness design is 20 years. The FAARFIELD computer program is capable of considering other design life timeframes, but they are considered a deviation from FAA standards. d. Material Properties for Subbase Layers. Up to three base/subbase layers can be added to the pavement structure in FAARFIELD for new rigid design. The number of subbase layers is limited because experience shows that above three layers the effect on designed slab thickness is small and does not justify the additional computation time that would be required. The layer thickness must be entered for each base/subbase layer. For standard base/subbase materials, the modulus and Poisson’s ratio are internally set and cannot be changed by the user. However, the variable stabilized and undefined layers allow the user to directly input a modulus value. e. Airplane Mixture Information. The user inputs specific information for each airplane in the mix, including airplane type, gross weight, number of annual departures, and percentage of annual growth. 328. USE OF FAARFIELD FOR NEW RIGID PAVEMENT DESIGN. This design procedure for airport concrete pavements is based on the computer program FAARFIELD. The internal help file for the FAARFIELD program contains a user’s manual, which provides detailed information on proper execution of the computer program. The manual also contains additional technical references for specific details of the FAARFIELD design procedure. There are distinct differences between the design methodology in FAARFIELD and the design methodology contained in previous versions of this AC. These differences along with some common design assumptions between the two methods are discussed below. a. Design Life. As noted in paragraph 315a, the FAA design standard for pavements is a 20-year design life. The computer program FAARFIELD is capable of considering other design life timeframes. Use of a design life other than 20 years constitutes a deviation from FAA standards. b. Traffic Mix. Input the complete air traffic mix into FAARFIELD. See paragraph 304c(5). c. Materials. Concrete pavement surfacing should meet the requirements of Item P-501. The minimum concrete surfacing thickness is 6 inches (152 mm) for pavements intended to serve airplanes with gross weights above 30,000 pounds (13 608 kg). Elastic moduli are either fixed or variable depending on the material and layer position. A fixed modulus value for concrete is set in the program at 4,000,000 psi (27 580 MPa). This modulus value was chosen to produce results that closely matched thickness requirements for pavements designed with the Westergaard-based design curves for rigid pavement used in previous versions of this AC. Materials are identified by their corresponding FAA specification designations; for example, crushed stone base course is identified as Item P-209. The list of materials contains an undefined layer with variable properties. If an undefined layer is used, such as variable stabilized rigid and 35 AC 150/5320-6E 9/30/2009 variable stabilized flexible layer, a warning will appear in the Structure Window stating that a non-standard material has been selected and its use in the structure will require FAA approval. d. Minimum Layer Thickness. FAARFIELD will not design the thickness of pavement layers other than the PCC slab in rigid pavement structures, but will enforce the minimum thickness requirements for subbase layers as specified elsewhere in this AC. It is recommended that the user consult paragraphs 322 for granular subbase, 324 for stabilized subbase, and 327 for concrete surface layer to assure the minimum thickness requirements are met. 329. CRITICAL AND NONCRITICAL AREAS. The program FAARFIELD is used to determine the concrete slab thickness for the critical pavement areas shown in figure 3-4. See paragraph 306 for pavement thickness determination for noncritical areas. For the variable thickness section of the thinned edge and transition section, the reduction applies to the concrete slab thickness. The change in thickness for the transitions should be accomplished over an entire slab length or width. In areas of variable slab thickness, the subbase thickness must be adjusted as necessary to provide surface drainage from the entire subgrade surface. Pavement thicknesses should be rounded to nearest 0.5 inch or 1 cm. 330. DESIGN EXAMPLE. As an example of the use of FAARFIELD, assume that the input data listed in tables 313 and 3-14 are to be used to design a new rigid pavement. Detailed steps for using the FAARFIELD program can be found in the user’s manual. The user’s manual is available by mouse clicking on “Help” from any screen in FAARFIELD. TABLE 3-13. AIRPLANE MIXTURE INPUT DATA Airplane Name Adv. B727-200 Option B747-400 B777-200 ER Gross Taxi Weight, lb 210,000 877,000 657,000 Annual Departures 1200 800 1200 Annual Growth, % 0.0 0.0 0.0 TABLE 3-14. PAVEMENT LAYER INPUT DATA Layer Material PCC Surface Thickness, in. (Calculate) Flexural Strength, psi 700 P-306 Econocrete P-209 Crushed Aggregate Subgrade 6 6 Infinite N/A N/A N/A Modulus, psi Fixed (4,000,000) in FAARFIELD Fixed (700,000) Variable 15,000 (k = 141.4 pci) Using the above data, FAARFIELD produces a PCC thickness of 16.15 inches, which is rounded to the nearest 0.5 inches, or 16 inches. Screen shots showing the designed section and the airplane traffic are presented in figures 3-6 and 3-7. For comparison, if the subgrade modulus used is 80 pci rather than 141 pci, the resulting FAARFIELD PCC thickness is 17.47 inches, rounded to 17.5 inches. 331. FROST EFFECTS. As with flexible pavements, frost protection should be provided for rigid pavements in areas where conditions conducive to detrimental frost action exist. Frost protection considerations for rigid pavements are similar to those for flexible pavements. The determination of the depth of frost protection required is given in paragraph 307b. Local experience may be used to refine the calculations. 36 9/30/2009 AC 150/5320-6E FIGURE 3-6. STRUCTURE WINDOW IN FAARFIELD FIGURE 3-7. AIRPLANE WINDOW IN FAARFIELD 37 AC 150/5320-6E 9/30/2009 332. JOINTING OF CONCRETE PAVEMENTS. Variations in temperature and moisture content can cause volume changes and slab warping resulting in significant stresses. In order to reduce the detrimental effects of these stresses and to minimize random cracking, it is necessary to divide the pavement into a series of slabs of predetermined dimension by means of joints. These slabs should be as nearly square as possible when no embedded steel is used. a. Joint Categories. Pavement joints are categorized according to the function that the joint is intended to perform. The categories are isolation, contraction, and construction joints. All joints, regardless of type, should be finished in a manner that permits the joint to be sealed. Pavement joint details are shown in figures 3-8 and 3-9 and are summarized in table 3-15. These various joints are described as follows: (1) Isolation Joints (Types A, A-1). The function of isolation joints is to isolate intersecting pavements and to isolate structures from the pavement. Type A is used when conditions preclude the use of load transfer devices that span across the joint, such as where the pavement abuts a structure or where horizontal differences in movement of the pavements may occur. These joints are formed by increasing the thickness of the pavement along the edge of the slab. No dowel bars are provided. Type A-1 joints may be used as an alternate in cases where thickened edge joints are undesirable. (2) Contraction Joints (Types B, C, D). The function of contraction joints is to provide controlled cracking of the pavement when the pavement contracts due to decrease in moisture content or a temperature drop. Contraction joints also decrease stresses caused by slab warping. Details for contraction joints are shown as Types B, C, and D in figure 3-8. (3) Construction Joints (Type E). Construction joints are required when two abutting slabs are placed at different times, such as at the end of a day’s placement or between paving lanes. Details for construction joints are shown as Types E in figure 3-8. 38 9/30/2009 AC 150/5320-6E FIGURE 3-8. RIGID PAVEMENT JOINT TYPES AND DETAILS 39 AC 150/5320-6E 9/30/2009 FIGURE 3-9. RIGID PAVEMENT JOINT TYPE DETAILS 40 9/30/2009 AC 150/5320-6E TABLE 3-15. PAVEMENT JOINT TYPES TYPE A DESCRIPTION Thickened Edge Isolation Joint LONGITUDINAL Use at intersections where dowels are not suitable and where pavements abut structures. Consider at locations along a pavement edge where future expansion is possible. B Hinged Contraction Joint C Doweled Contraction Joint D Dummy Contraction Joint Doweled Construction Joint For all contraction joints in taxiway slabs < 9 inches (230 mm) thick. For all other contraction joints in slabs < 9 inches (230 mm) thick, where the joint is placed 20 feet (6 m) or less from the pavement edge. May be considered for general use. Consider for use in contraction joints in slabs > 9 inches (230 mm) thick, where the joint is placed 20 feet (6m) or less from the pavement edge. For all other contraction joints in pavement. All construction joints excluding isolation joints. E b. TRANSVERSE Use at pavement feature intersections when the respective longitudinal axis intersects at an angle. Use at free edge of pavements where future expansion, using the same pavement thickness is expected. Not used. May be considered for general use. Use on the last three joints from a free edge, and for three joints on either side of isolation joints. For all other contraction joints in pavement. Use for construction joints at all locations separating successive paving operations (“headers”). Joint Spacing. (1) Without Stabilized Subbase. A rule-of-thumb for joint spacing given by the Portland Cement Association is applicable for rigid pavements without stabilized subbase: As a rough guide, the joint spacing should not greatly exceed twenty four times the slab thickness, or, L 24t (valid for any unit system), where L is the joint spacing and t is the slab thickness. Table 3-16 shows the recommended maximum joint spacings. Shorter spacings may be more convenient in some instances and may be required to provide minimum clearance between pavement joints and in-pavement obstructions such as light bases. A maximum spacing of 20 feet (6.1 m) is recommended. The ratio of the longest side of a slab to the shortest side of a slab at two intersecting sides should not exceed 1.25 in nonreinforced pavements. TABLE 3-16. RECOMMENDED MAXIMUM JOINT SPACINGS RIGID PAVEMENT WITH OR WITHOUT STABILIZED SUBBASE Part I, without Stabilized Subbase Slab Thickness Joint Spacing1 Inches Millimeters Feet Meters 6 152 12.5 3.8 6.5-9 165-229 15 4.6 >9 >229 20 6.1 Part II, with Stabilized Subbase Slab Thickness Joint Spacing1 Inches Millimeters Feet Meters 8–10 203-254 12.5 3.8 10.5-13 267-330 15 4.6 13.5-16 343-406 17.52 5.32 >16 >406 20 6.1 41 AC 150/5320-6E 9/30/2009 Notes: 1. Transverse and longitudinal joint spacing. 2. For typical runway and taxiway geometries, the corresponding longitudinal joint spacing is 18.75 ft. (5.7 m). 3. Joint spacings shown in this table are maximum values that may be acceptable under ideal conditions. 4. Smaller joint spacings should be used if indicated by past experience 5. Pavements subject to extreme seasonal temperature differentials or extreme temperature differentials during placement may require shorter joint spacings. 6. See Chapter 5 for light-load rigid pavement jointing. (2) With Stabilized Subbase. Rigid pavements supported on stabilized subbase are subject to higher warping and curling stresses than those supported on unstabilized foundations. The recommended maximum joint spacings are listed in part II, table 3-16. In lieu of historical performance records, a maximum spacing of 20 feet (6.1 m) is recommended for slabs equal to or thicker than 16 inches (406 mm). The ratio of the longest side of a slab to the shortest side of a slab at two intersecting sides should not exceed 1.25 in non reinforced pavements. 333. SPECIAL JOINTING CONSIDERATIONS FOR POSSIBLE FUTURE EXPANSION. When a runway or taxiway is likely to be extended at some future date, it is recommended that a thickened edge joint (Type A in figure 3-8) be provided at that end of the runway or taxiway. Likewise, if any pavement will require an isolation joint in the future, a thickened edge should be provided at the appropriate edge. In pavements with drainable bases, thickened edge joints may create the potential to trap water beneath the pavement. In such cases, the engineer may consider using a reinforced isolation joint (Type A-1 in figure 3-8) as an alternative to a thickened edge joint. The amount of steel at the slab edge should be justified by structural calculations. Sufficient steel reinforcement should be provided at the bottom of the slab for the reinforced concrete section to resist the maximum bending moment caused by the critical aircraft loading the free edge of the slab, with an appropriate load factor applied. Steel reinforcement is not required at the top of the slab for structural capacity, but if embedded steel is placed at the top of the slab for crack control, it should conform to the requirements of paragraph 337. a. Reinforced Isolation Joint (Type A-1) Design Example. A new rigid pavement will be constructed for the following mix of airplanes: DC10-10, B747-200B Combi Mixed, B777-200ER. An isolation joint will be provided at the location of planned future expansion. Because of the potential for trapped water, a reinforced isolation joint is selected. Assume that the concrete compressive strength f c = 4,000 psi. Using FAARFIELD, the PCC design thickness for a 20-year life was determined to be 15.5 inches (394 mm). The maximum stress to be used for the joint design is determined using FAARFIELD as follows: (1) In the Options window, under “General Options,” uncheck the “No Out Files” box. (2) For the design section, and for each airplane in the traffic mix, run a “Life” computation. A separate computation should be performed for each airplane. (3) For each airplane, obtain the computed PCC slab horizontal (tensile) stress from the output file NikePCC.out, in the FAARFIELD working directory. (4) For the maximum stress found in step 3, calculate the free edge stress by dividing the PCC slab horizontal stress by 0.75. (Dividing by 0.75 is necessary because the FAARFIELD stress has already been reduced by 25% to account for assumed joint load transfer.) For this design example, the maximum PCC horizontal stress from the output file NikePCC.out was found to be 357.71 psi, for the B777-200ER. Therefore, the maximum (working) free edge stress for the concrete section design is calculated as 357.71/0.75 = 476.9 psi. The reinforced concrete section will be designed using the ultimate strength method. The dead load will be neglected. Assuming a live load factor of 1.7, calculate the ultimate bending moment Mu as: 15.5 in.3 12 in. 476.9 psi 12 edge I g M u 1.7 1.7 = 389,555 lb.-in. = 32.5 kip-ft. c 7.75 in. where: edge is the maximum edge stress based on FAARFIELD, Ig = the gross moment of inertia calculated for a 1- foot strip of the concrete slab, and c = the distance from the neutral axis to the extreme fiber, assumed to be one-half of the slab thickness. 42 9/30/2009 AC 150/5320-6E Assume the edge reinforcement will consist of No. 6 bars spaced at 6 inches at the bottom of the slab, as shown in igure 3-8. Calculate the flexural design strength using the following equation: M n As f y d 1 0.59 f y f c where: = stress reduction factor (= 0.90 for flexure without axial loading) As = steel area = 2 x 0.44 = 0.88 in2 for 1-ft. width fy = steel yield stress (assume fy = 60,000 psi) f c = concrete compressive strength d = depth to steel centroid A = steel ratio s bd b = section width = 12 in. For the minimum 3 in. (76.2 mm) clear cover on No. 6 bars, d = 12.13 in. (308 mm). Using the above values M n is calculated as 45.5 kip-ft. Since M U M n , the design is adequate for flexure. A check should also be performed for minimum and maximum steel ratio. The minimum steel ratio is given by: min 200 , where fy is in psi. From the above values, obtain min = 0.0033. The calculated steel ratio 0.0060 > fy 0.0033, hence the minimum steel ratio criterion is satisfied. The maximum steel ratio is determined from the equation: f 87000 max 0.75 b 0.75 0.85 1 c 0.0213 f y 87000 f y where: b is the balanced steel ratio, 1 = 0.85 (for f c = 4000 psi) and fy is in psi. Since the calculated steel ratio 0.0060 < 0.0213, the maximum steel ratio criterion is also satisfied. For the final design, provide four (4) no. 6 bars spaced at 6 inches (152 mm). 334. JOINTING STEEL. a. Tie Bars. Tie bars are used across certain longitudinal contraction joints to hold the slab faces in close contact. The tie bars themselves do not act as load transfer devices. By preventing wide opening of the joint, load transfer is provided by aggregate interlock in the crack below the groove-type joint. Tie bars should be deformed bars conforming to the specifications given in Item P-501. The bars should be 5/8 inch (16 mm) in diameter and 30 inches (762 mm) on center spacing. Do not use tie-bars such that areas of pavement with continuous tied joints greater than 75 feet (23 m) exist. b. Dowels. Dowels are used at joints to provide for transfer of load across the joint and to prevent relative vertical displacement of adjacent slab ends. Dowels permit longitudinal movement of adjacent slabs. (1) Where Used. Provision for load transfer by dowels is provided as described in table 3-15. Dowels for contraction joints should be provided at least three joints from a free edge. (2) Size Length and Spacing. Dowels should be sized such that they will resist the shearing and bending stresses produced by the loads on the pavement. They should be of such length and spacing that the bearing stresses exerted on the concrete will not cause failure of the concrete slab. Table 3-17 indicates the dowel dimensions and spacing for various pavement thicknesses. (3) Dowel Positioning. The alignment and elevation of dowels is extremely important in obtaining a satisfactory joint. Transverse dowels will require the use of a fixture, usually a wire cage or basket firmly anchored to the subbase, to hold the dowels in position. Supports on the baskets do not need to be cut. During the concrete placement operations, it is advisable to place plastic concrete directly on the dowel assembly immediately prior to passage of the paver to prevent displacement of the assembly by the paving equipment. An alternate procedure for placing dowels in the transverse joint is to use a paving machine equipped with an automated dowel bar inserter. 43 AC 150/5320-6E 9/30/2009 TABLE 3-17. DIMENSIONS AND SPACING OF STEEL DOWELS Thickness of Slab Diameter Length Spacing 6-7 in (152-178 mm) ¾ in1 (20 mm) 18 in (460 mm) 12 in (305 mm) 7.5-12 in (191-305 mm) 1 in1 (25 mm) 19 in (480 mm) 12 in (305 mm) 12.5-16 in (318-406 mm) 1 ¼ in1 (30 mm) 20 in (510 mm) 15 in (380 mm) 16.5-20 in (419-58 mm) 1 ½ in1 (40 mm) 20 in (510 mm) 18 in (460 m) 20.5-24 in (521-610 mm) 2 in1 (50 mm) 24 in (610 mm) 18 in (460 mm) 1 Dowels noted may be solid bar or high-strength pipe. High-strength pipe dowels must be plugged on each end with a tight-fitting plastic cap or mortar mix. 335. JOINT SEALANTS AND FILLERS. Sealants are used in all joints to prevent the ingress of water and foreign material in the joint. Premolded compressible filler are used in isolation joints to accommodate expansion of the slabs. Joint sealants are applied above the filler in isolation joints to prevent infiltration of water and foreign material. In areas subject to fuel spillage, fuel-resistant sealants should be used. Specifications for joint sealants are given in Item P605. 336. JOINT LAYOUT. Pavement joint layout is a matter of selecting the proper joint types and dimensions so that the joints can perform their intended function. Construction considerations are also vitally important in determining the joint layout pattern. Paving lane widths will often dictate how the pavement should be jointed. Generally speaking, it is more economical to keep the number of passes of the paving train to a minimum while maintaining proper joint function. Figure 3-10 shows a typical jointing plan for a runway end, parallel taxiway, and connector. In-pavement light fixtures may also affect joint spacing. Joints should be placed with respect to light fixtures in accordance with AC 150/5340-30B, Design and Installation Details for Airport Visual Aids. It is impossible to illustrate all of the variations that can occur at pavement intersections. Two important considerations in designing joint layouts for intersections are isolation joints and odd-shaped slabs. More discussion on these follows: a. Isolation Joints. Two intersecting pavements, such as a taxiway and runway, should be isolated to allow the pavements to move independently. Isolation can best be accomplished by using a Type A isolation joint between the two pavements. The isolation joint should be positioned such that the two pavements can expand and contract independently; normally this can be accomplished by using a Type A isolation joint where the two pavements abut. One isolation joint is normally sufficient to allow independent movement. b. Odd-Shaped Slabs. Cracks tend to form in odd-shaped slabs; therefore, it is good practice to maintain sections that are nearly square or rectangular in shape. Pavement intersections that involve fillets are difficult to design without a few odd-shaped slabs. In instances where odd-shaped slabs cannot be avoided, embedded steel is recommended. The embedded steel should consist of 0.050 percent steel in both directions in slabs where the length-towidth ratio exceeds 1.25 or in slabs that are not rectangular in shape. The embedded steel should be placed in accordance with the recommendations given in paragraph 338. Fillets may also be defined by constructing slabs to the normal, full dimensions and painting out the unused portion of the slab. 337. CONCRETE PAVEMENT CONTAINING EMBEDDED STEEL FOR CRACK CONTROL. Concrete slabs may contain embedded steel reinforcing bars or welded wire mats for crack control. The main benefit of embedded steel is that, although it does not prevent cracking, it keeps the cracks that form tightly closed so that the interlock of the irregular faces provides structural integrity and usually maintains pavement performance. By holding the cracks tightly closed, the steel minimizes the infiltration of debris into the cracks. The thickness requirements for reinforced concrete pavements are the same as plain concrete and are determined by the program FAARFIELD. Embedded steel allows longer joint spacing; thus the cost benefits associated with fewer joints must be considered in the decision to use plain or embedded steel concrete pavement. 338. TYPE AND SPACING OF EMBEDDED STEEL BARS. Embedded steel may be either welded wire fabric or bar mats installed with end and side laps to provide complete embedded steel throughout the slab. End laps should be a minimum of 12 inches (305 mm) but not less than 30 times the diameter of the longitudinal wire or bar. Side laps should be a minimum of 6 inches (152 mm) but not less than 20 times the diameter of the transverse wire or bar. End and side clearances should be a maximum of 6 inches (152 mm) and a minimum of 2 inches (51 mm) to allow for nearly complete embedded steel and yet achieve adequate concrete cover. Longitudinal members should be spaced not less than 4 inches (100 mm) nor more than 12 inches (305 mm) apart; transverse members should be spaced not less than 4 inches (100 mm) nor more than 24 inches (610 mm) apart. 44 FIGURE 3-10. TYPICAL JOINT LAYOUT PATTERN FOR RUNWAY, PARALLEL TAXIWAY, AND CONNECTOR 9/30/2009 AC 150/5320-6E 45 AC 150/5320-6E 339. 9/30/2009 AMOUNT OF EMBEDDED STEEL. a. The steel area required for an embedded steel concrete pavement is determined from the subgrade drag formula and the coefficient of friction formula combined. The resultant formula is expressed as follows: AS 3 .7 L Lt fS where: As L t fs = = = = area of steel per foot of width or length, square inches length or width of slab, feet thickness of slab, inches allowable tensile stress in steel, psi NOTE: To determine the area of steel in metric units: L should be expressed in meters t should be expressed in millimeters f s should be expressed in mega newtons per square meter The constant 3.7 should be changed to 0.64. As will then be in terms of square centimeters per meter. b. In this formula the slab weight is assumed to be 12.5 pounds per square foot, per inch of thickness (23.6 MN/m2). The allowable tensile stress in steel will vary with the type and grade of steel. It is recommended that allowable tensile stress be taken as two-thirds of the yield strength of the steel. Based on current specifications the yield strengths and corresponding design stresses (fs) are as listed in table 3-18. c. The minimum percentage of embedded steel should be 0.05 percent. The percentage of steel is computed by dividing the area of steel, As, by the area of concrete per unit of length (or width) and multiplying by 100. The minimum percentage of steel considered the least amount of steel that can be economically placed is 0.05 percent. Embedded steel allows larger slab sizes and thus decreases the number of transverse contraction joints. The costs associated with providing an embedded steel pavement must be compared with the savings realized in eliminating some of the transverse contraction joints to determine the most economical steel percentage. The equation in (a) may be reorganized to obtain the relationship between the percentage of steel and the required slab length: PS % 30 . 8 L L t fS For a 75 ft (23 m) long slab with 10 inch (254 mm) thickness and using fs = 27,000 psi (186 MPa), the required steel percentage would be 0.23 %. For the 75 ft (23 m) long slab with 20 inch (508 mm) thickness and using fs = 47000 psi (324 MPa), the required steel percentage would be 0.1. Both satisfy the minimum required percentage 0.05. They are also smaller than the minimum required steel percentage for CRCP (0.5, see item 342). For safety reasons, the maximum allowable slab length regardless of steel percentage is 75 feet (23 m) for normal concrete slabs containing embedded steel. TABLE 3-18. YIELD STRENGTHS OF VARIOUS GRADES OF REINFORCING STEEL ASTM Designation A 615 A 616 A 616 A 615 A 185 A 497 Type & Grade of Steel Deformed Billet Steel, Grade 40 Deformed Rail Steel, Grade 50 Deformed Rail Steel, Grade 60 Deformed Billet Steel, Grade 60 Cold Drawn Welded Steel Wire Fabric Cold Drawn Welded Deformed Steel Wire Yield Strength, psi (MN/m2) 40,000 (280) 50,000 (350) 60,000 (420) 60,000 (420) 65,000 (460) 70,000 (490) fs, psi (MN/m2) 27,000 (190) 33,000 (230) 40,000 (280) 40,000 (280) 43,000 (300) 47,000(330) 340. DIMENSIONS AND WEIGHTS OF EMBEDDED STEEL. Dimensions and unit weights of standard deformed reinforcing bars are given in table 3-19, and wire size number, diameters, areas, and weights of wires used in welded wire fabric are given in table 3-20. 46 9/30/2009 AC 150/5320-6E TABLE 3-19. DIMENSIONS AND UNIT WEIGHTS OF DEFORMED STEEL REINFORCING BARS NOMINAL DIMENSIONS No. 3 4 5 6 7 Diameter, in. (mm) 0.375 9.5 0.500 12.7 0.625 15.9 0.750 19.1 0.875 22.2 Area, in2 (mm2) 0.11 0.71 0.20 1.29 0.31 2.00 0.44 2.84 0.60 3.86 Perimeter, in. (cm) 1.178 3.0 1.571 4.0 1.963 5.0 2.356 6.0 2.749 7.0 Unit Weight, lb/ft (kg/m) 0.376 0.56 0.668 1.00 1.043 1.57 1.502 2.26 2.044 3.07 TABLE 3-20. SECTIONAL AREAS OF WELDED FABRIC Wire Size Smooth Number Deformed Nominal Diameter Inches Nominal Weight, lb/linear ft W31 D31 0.628 1.054 W30 D30 0.618 1.020 W28 D28 0.597 .952 W26 D26 0.575 .934 W24 D24 0.553 .816 W22 D22 0.529 .748 W20 D20 0.504 .680 W18 D18 0.478 .612 W16 D16 0.451 .544 WI4 D14 0.422 .476 W12 D12 0.390 .408 W11 D11 0.374 .374 W10.5 0.366 .357 WI0 D10 0.356 .340 W9.5 .348 .323 W9 D9 .338 .306 W8.5 .329 .289 W8 D8 .319 .272 W7.5 .309 .255 W7 D7 .298 .238 W6.5 .288 .221 W6 D6 .276 .204 W5.5 .264 .187 W5 D5 .252 .170 W4.5 .240 .153 W4 D4 .225 .136 Note: 1 inch = 2.54 cm, 1 lb/linear ft = 1.5 kg/m Area of Steel When Center-to-Center Spacing is (in inches) 4 .93 .90 .84 .78 .72 .66 .60 .54 .48 .42 .36 .33 .315 .30 .285 .27 .255 .24 .225 .21 .195 .18 .165 .15 .135 .12 6 .62 .60 .56 .52 .48 .44 .40 .36 .32 .28 .24 .22 .21 .20 .19 .18 .17 .16 .15 .14 .13 .12 .11 .10 .09 .08 8 .465 .45 .42 .39 .36 .33 .30 .27 .24 .21 .18 .165 .157 .15 .142 .135 .127 .12 .112 .105 .097 .09 .082 .075 .067 .06 10 .372 .36 .336 .312 .288 .264 .24 .216 .192 .168 .144 .132 .126 .12 .114 .108 .102 .096 .09 .084 .078 .072 .066 .06 .054 .048 12 .31 .30 .28 .26 .24 .22 .20 .18 .16 .14 .12 .11 .105 .10 .095 .09 .085 .08 .075 .07 .065 .06 .055 .05 .045 .04 341. WELDED WIRE FABRIC. The use of welded wire fabric requires some special design considerations to achieve the most economical design. The use of smooth welded wire fabric or deformed welded wire fabric is the option of the designer. The choice should be based on the difference in allowable design stresses, the availability of the desired sizes (smooth wire fabric is available in a wider range of sizes), and the costs associated with each style of fabric. It is recommended that the minimum size of longitudinal wire be W5 or D5. The minimum transverse wire should be no smaller than W4 or D4. In addition, should calculated area of longitudinal steel be less than 0.05 percent of the crosssectional area of slab, the size and spacing of the steel members (bars or wire) should be determined on the premise that the minimum area should not be less than 0.05 percent. This percentage applies in the case of steel having yield strength of 65,000 psi (480 MN/m2). If lower grades are used, the percentage should be revised proportionately upward. For example, table 3-20 shows that W10 wires, spaced 10 inches (255 mm) apart, furnish an area of 0.12 square inches (77 mm2), which satisfies the requirement for pavements up to 20 inches (508 mm) thick. Sizing of individual sheets of welded wire fabric is also important in providing an economical design. Not all fabricators supply all wire sizes in all 47 AC 150/5320-6E 9/30/2009 spacings. While nearly any fabric style can be produced on special order, it is generally more economical to specify a standard production configuration. Sheet and roll widths in excess of 8 feet (2.4 m) can result in higher shipping costs. 342. JOINTING OF EMBEDDED STEEL CONCRETE PAVEMENTS. Contraction joints in concrete pavements containing embedded steel meeting the requirements of paragraphs 338 – 340 may be spaced up to 75 feet (23 m) apart, and all joints should be provided with load transfer devices as shown in figure 3-11. Also, this figure presents other embedded steel details such as clearance at joints and edges of pavement and depth below the surface. The longer joint spacing allowed with pavements containing embedded steel will result in larger joint openings. The joints must be sealed carefully to accommodate the larger movements at the joints. 343. CONTINUOUSLY REINFORCED CONCRETE PAVEMENT. A continuously reinforced concrete pavement (CRCP) is a Portland cement concrete pavement with continuous longitudinal embedded steel and no intermediate transverse isolation or contraction joints. Continuously reinforced concrete pavements normally contain from 0.5 to 1.0 percent longitudinal embedded steel. The main advantage of continuously reinforced concrete pavement is the elimination of transverse joints, which are costly to construct, require periodic resealing, and are often a source of maintenance problems. Continuously reinforced concrete pavements usually provide a very smooth riding surface. A properly designed CRCP will develop random transverse cracks at 2 to 10 feet (0.6 to 3 m) intervals. The resultant pavement is composed of a series of articulated short slabs held tightly together by the longitudinal reinforcing steel. A high degree of shear transfer across the cracks can be achieved because the cracks are held tightly closed. a. Foundation Support. The reinforcing steel in a CRCP provides continuity of load transfer. However, a good uniform foundation support must still be provided for satisfactory performance. The embankment and subbase requirements given earlier in this chapter for plain concrete pavements, also apply to CRCP. b. Thickness Design. The thickness requirements for CRCP are the same as plain concrete pavement. Design inputs are the same for concrete flexural strength, subgrade modulus, material properties for subbase layers and airplane mixture information. c. Longitudinal Steel Design. The design of embedded steel for CRCP is critical to providing a satisfactory pavement. The steel percentage must be properly selected to provide optimum crack spacing and crack width. Crack widths must be small to provide a high degree of shear transfer across the crack and to prevent the ingress of water through the crack. The design of longitudinal embedded steel must satisfy three conditions. The maximum steel percentage determined by any of the three following requirements should be selected as the design value. In no case should the longitudinal steel percentage be less than 0.5 percent. (1) Steel to Resist Subgrade Restraint. The longitudinal embedded steel required to resist the forces generated by the frictional restraint between the CRCP and the subbase should be determined by using the following formula: PS % 1.3 0.2 F ft fS where: Ps ft F fs = = = = embedded steel in percent tensile strength of concrete, in psi friction factor of subgrade allowable working stress in steel, in psi Use of the above formula requires three parameters: allowable working stress for steel, tensile strength of concrete and a friction factor for the subbase. The recommended working stress for steel is 75 percent of the specified minimum yield strength. The tensile strength of concrete may be estimated as 67 percent of the flexural strength. The recommended friction factor for stabilized subbase is 1.8. While not recommended as subbase for CRCP, friction factors for nonstabilized fine-grained soils and coarse-grained soils are usually assumed to be 1.0 and 1.5 respectively. (2) Steel to Resist Temperature Effects. The longitudinal embedded steel must be capable of withstanding the forces generated by the expansion and contraction of the pavement due to temperature changes. The following formula is used to compute the temperature embedded steel requirements. PS 48 50 f t f s 195T 9/30/2009 AC 150/5320-6E where: Ps ft fs T = = = = embedded steel in percent tensile strength of concrete, 67% of the flexural strength is recommended working stress for steel usually taken as 75% of specified minimum yield strength maximum seasonal temperature differential for pavement in degrees Fahrenheit Reinforcing steel should be specified on the basis of minimum yield strength. All deformed reinforcing steel bars should conform to ASTM A615 or A996. Deformed welded wire fabric should conform to ASTM A497. (3) Concrete to Steel Strength Ratio. The third consideration in selecting the amount of longitudinal embedded steel is the ratio of concrete tensile strength to the specified minimum yield strength of steel. The steel percentage is obtained by multiplying the ratio of the concrete strength to the yield strength of steel by 100. PS 100 f t fy where: Ps = embedded steel in percent ft = tensile strength of concrete fy = minimum yield strength of steel d. Transverse Steel Design. Transverse embedded steel is recommended for CRCP airport pavements to control “chance” longitudinal cracks, which sometimes form. It is also aids in construction by supporting and maintaining longitudinal embedded steel spacing. The following formula is used for determining transverse steel requirements: PS % WS F 100 2 fS where: Ps Ws F fs = embedded steel in percent = width of slab, in feet = friction factor of subgrade = allowable working stress in steel, in psi, 0.75 of yield strength recommended e. Steel Detailing. Longitudinal embedded steel should be located at mid-depth of the slab or slightly above. Transverse steel may be located either above or below the longitudinal steel. A minimum concrete cover of 3 inches (76 mm) should be maintained over all embedded steel. Longitudinal steel spacing should be 6 to 12 inches (152 to 305 mm). Transverse steel should be spaced at 12 inches (305 mm) or greater. The recommended overlap for splicing of reinforcing bars is 25 diameters or 16 inches (406 mm), whichever is greater. The recommended overlap for splicing deformed welded wire fabric is 32 diameters or 16 inches (406 mm), whichever is greater. When splicing longitudinal steel bar reinforcing it is recommended that the lap splices be made on a 60 degree skew from centerline or staggered such that not more than one-third of the bars are spliced on the same transverse plane. 49 AC 150/5320-6E FIGURE 3-11. JOINTING IN RIGID PAVEMENT WITH EMBEDDED STEEL 50 9/30/2009 9/30/2009 AC 150/5320-6E 344. CRCP JOINTING. Even though transverse contraction joints can be eliminated with CRCP, some joints will be needed to accommodate construction and to control warping stresses. The two types of joints are discussed below: a. Construction Joints. Two types of construction joints are necessary for CRCP. Because pavements are constructed in multiple lanes, a longitudinal construction joint is required between lanes. A transverse construction joint must be provided where paving ends and begins, such as at the finish of a day’s paving and the start of the next day’s paving. Typical construction joint details are shown in figure 3-12. b. Warping Joints. Warping joints or hinged joints are needed when the paving lane width exceeds the recommended maximum longitudinal joint spacings shown in table 3-16. Transverse steel is carried through the joint to provide continuity and positive aggregate interlock across the joint. Since carrying the steel through the joint eliminates any expansion or contraction capacity, the maximum width of tied pavement should not exceed 75 feet (23 m), see paragraph 334a. Typical warping joint details are shown in figures 3-12 and 3-13. FIGURE 3-12. CONTINUOUSLY REINFORCED CONCRETE PAVEMENT – JOINT DETAILS 345. CRCP TERMINAL TREATMENT. Since long slabs of CRCP are constructed with no transverse joints, provisions must be made to either restrain or accommodate end movements wherever the CRCP abuts other pavements or structures. Rather large end movements, up to 2 inches (51 mm), are experienced with CRCP due to thermal expansion and contraction. End movement is normally not a problem except where CRCP abuts another pavement or structure. Experience with highway CRCP shows that attempts to restrain end movement have not been too successful. More favorable results are achieved where end movement is accommodated rather than restrained. Joints designed to accommodate large movements are required where CRCP intersects other pavements or abuts another structures. Failure to do so may result in damage to the CRCP, pavement or other structure. Wide flange beam type joints or finger type joints can accommodate the movements. The wide flange beam type joint is recommended due to its relatively lower costs. A sketch of the wide flange beam joint is shown on figure 3-14. 51 AC 150/5320-6E 9/30/2009 FIGURE 3-13. CONTINUOUSLY REINFORCED CONCRETE PAVEMENT – JOINT DETAILS 52 9/30/2009 AC 150/5320-6E 10ft (3 m) FIGURE 3-14. CONTINUOUSLY REINFORCED CONCRETE PAVEMENT – WIDE FLANGE BEAM TERMINAL JOINT 53 AC 150/5320-6E 9/30/2009 346. CRCP DESIGN EXAMPLE. An example design for CRCP is given below. Assume a CRCP is to be designed to serve the following conditions: The following mix of airplanes is assumed: a. TABLE 3-21. AIRPLANE MIX DATA FOR CRCP DESIGN EXAMPLE Airplane B737-800 A320-100 B777-200 ER Gross Weight, lb 174,700 150,796 657,000 Annual Departures 10,000 750 8760 % Annual Growth 0 0 0 b. Subgrade E value is 25,000 psi (172 MPa) c. The lower (aggregate) subbase is P-154, 8 inches (203 mm) thick, and the upper (stabilized) subbase is P-306, 6 inches (152 mm) thick. d. Concrete Flexural Strength - 650 psi (4.5 MPa) e. Minimum Specified Yield Strength of Steel - 60,000 psi (414 MPa) (Longitudinal and Transverse) f. Paving Lane Width - 25 feet (7.6 m) Cement Stabilized Subbase g. Seasonal Temperature Differential - 100°F (38C) (1) Slab Thickness. Enter the input data listed in (a) to (d) in program FAARFIELD. The calculated slab thickness (15.61 inches) is shown in figure 3-15. Round this thickness to the closest 0.5 inch to obtain or 15.5 inches (394 mm). FIGURE 3-15. COMPUTED SLAB THICKNESS, CRCP EXAMPLE (2) Steel Design. The longitudinal reinforcing steel would be determined as described in paragraph 343c: (i) Subgrade Restraint. Using the formula in paragraph 342c(1) with the following inputs: Working stress = 75% 60,000 psi (414 MPa) = 45,000 psi (310 MPa) 54 9/30/2009 AC 150/5320-6E Friction factor = 1.8 Tensile strength of concrete = 67% of 650 psi (4.5 MPa) = 436 psi (3.0 MPa) The longitudinal steel required to withstand the forces generated by subgrade restraint is: PS 1.3 0.2 1.8 436 100 0.91% 45,000 (ii) Temperature Effects. The steel required to withstand the forces generated by seasonal temperature changes is computed using the formula given in paragraph 343c(2). PS 50 436 0.86% 45,000 195 100 (iii) Concrete to Steel Strength Ratio. The strength ratio between the concrete and steel is computed by the procedure given in paragraph 343c(3). PS (iv) 100 436 0.73% 60,000 Transverse Steel. The transverse reinforcing steel percentage would be determined using the formula in 342d: PS 25 1.8 100 0.05 2 45,000 This will yield a transverse steel requirement of 0.05 percent (v) Final Design. The final design would be a 15.5 inch (394 cm) thick concrete slab. Since the steel percentage necessary to satisfy the subgrade restraint condition is the largest steel percentage for longitudinal embedded steel, the value of 0.91 percent would be selected for design. The transverse steel requirement is 0.05 percent. The longitudinal steel requirement can be satisfied by using #7 reinforcing bars spaced at 4 inches (102 mm). The transverse steel requirement can be met by using #4 bars on 24 inch (610 mm) centers. 347. PRESTRESSED CONCRETE PAVEMENT. Prestressed concrete pavements have been used in airport applications in Europe and to a limited extent in the United States. Prestressed concrete airport pavements are usually post-tensioned with high strength steel strands. These pavements are usually considerably thinner than plain, jointed reinforced, or continuously reinforced concrete pavements yet provide high load carrying capacity. Slab lengths on the order of 400 to 500 feet (120 to 152 m) are generally used. A design procedure for prestressed airport pavements was developed under an FAA research effort and is reported in Research Report Number FAA-RD-74-34, Volume II. Use of prestressed concrete airport pavements on federally assisted projects will require FAA approval on a case by case basis. 55 AC 150/5320-6E 9/30/2009 THIS PAGE INTENTIONALLY LEFT BLANK. 56 9/30/2009 AC 150/5320-6E CHAPTER 4. AIRPORT PAVEMENT OVERLAYS AND RECONSTRUCTION 400. GENERAL. Airport pavement overlays or reconstruction may be required for a variety of reasons. A pavement may require an overlay or reconstruction because the original pavement has served its design life and it is simply “worn out.” A pavement may also require an overlay or rehabilitation due to surface conditions or materialrelated distresses. A pavement may have been damaged by overloading in such a way that it cannot be economically maintained at a serviceable level. Similarly, a pavement in good condition may require strengthening to serve heavier airplanes than those for which the pavement was originally designed. Generally, airport pavement overlays consist of either Portland cement concrete or hot mix asphalt concrete. Techniques and equipment are now available to recycle old pavement materials into reconstructed sections. Pavements that are severely distressed in the center portions can sometimes be economically rehabilitated by reconstructing the keel section. The reconstruction method can consider using recycled materials. 401. CONDITION OF EXISTING PAVEMENT. Assessment of the condition of the existing pavement is one of the most important and difficult steps in design of a reconstruction or overlay project. Measurement of the properties of the existing pavement should include the thickness, condition, and strength of each layer; the subgrade soil classification; and some estimate of foundation strength (CBR or subgrade modulus). An assessment of the structural integrity of the existing pavement is necessary. The overlay design procedures in this AC assume that the overlay is to be placed on a base pavement with significant structural integrity. Problems such as alkali-silica reactivity in existing rigid pavements should be addressed, and if necessary mitigated, prior to overlay. Severely distressed areas in the existing pavement should be carefully studied to determine the cause of the distresses and to determine potential mitigation. Subsurface drainage conditions should be assessed carefully and corrected if found to be deficient. In some instances, subsurface drainage corrections are best performed through reconstruction. Overlaying an existing pavement without correcting poor subsurface drainage will usually result in poor overlay performance. A valuable technique for assessing the structural condition of the existing pavement is nondestructive pavement testing (NDT) (see AC 150/5370-11, Use of Nondestructive Testing Devices in the Evaluation of Airport Pavement, Appendix 4). NDT can be used to estimate foundation strength, measure joint load transfer, and possibly detect voids in existing pavements. NDT can also be used to determine structural capacity, to assist with calculating PCN, and to assess areas of localized weakness. 402. MATERIAL SELECTION CONSIDERATIONS. Criteria are presented in this circular for both hot mix asphalt and concrete reconstruction or overlays. The selection of the material type should be made after careful consideration of many factors. The designer should consider the total life cycle cost of the reconstructed or overlay pavement (see DOT-FAA-RD-81/078, Appendix 4). Life cycle costs should include initial construction and maintenance costs over the design life of the pavement. Other considerations such as allowable downtime of the pavement and availability of alternate pavements to use during construction will have a significant impact on the material selected. 403. OVERLAY DESIGN. The remainder of this chapter is devoted to the design of overlay pavements. As previously mentioned, the design of reconstructed pavements is essentially the same as for new construction. a. Typical Overlay Cross Sections and Definitions. Typical overlay pavement cross sections are shown in figure 4-l. Definitions applicable to overlay pavements are as follows: (1) Overlay Pavement. Pavement that is constructed on top of an existing pavement. (2) Hot Mix Asphalt Overlay. Hot mix asphalt pavement placed on an existing pavement. (3) Concrete Overlay. Portland cement concrete pavement placed on an existing pavement. (4) Sandwich Pavement. Overlay pavement sections containing granular separation courses between the old and new impervious surfaces are called sandwich pavements. b. Sandwich Pavements. Regardless of the type of overlay, FAA criteria do not permit the construction of sandwich overlay pavements. They are not allowed because the granular separation course usually becomes saturated with water and provides poor or, at best, unpredictable performance. Saturation of the separation course can be caused by the infiltration of surface water, ingress of ground or capillary water, or the condensation of water from the atmosphere. In any event, the water in the separation course usually cannot be adequately drained. The trapped water drastically reduces the stability of the overlay. However, where an existing concrete surface layer over a stabilized 57 AC 150/5320-6E 9/30/2009 subbase is rubblized prior to placement of a HMA or PCC overlay, the overlaid structure should not be considered sandwich construction. FIGURE 4-1. TYPICAL OVERLAY PAVEMENTS 58 9/30/2009 AC 150/5320-6E c. FAARFIELD Overlay Design. The layered elastic and three-dimensional finite element methods as implemented in the FAARFIELD program allow a direct approach for overlay design. FAARFIELD calculates the thickness of overlay required to provide a 20-year life, which satisfies the layered elastic failure criteria for limiting stress or strain. The 20-year life thickness is defined as the design thickness. Report DOT-FAA-PM-87/19, Design of Overlays for Rigid Airport Pavements (see Appendix 4), describes the developed through an FAA-funded research effort design method for overlays of rigid pavement. Overlay pavements are grouped into four different types as follows: (1) (2) (3) (4) Hot Mix Asphalt Overlay of Existing Flexible Pavement Concrete Overlay of Existing Flexible Pavement Hot Mix Asphalt Overlay of Existing Rigid Pavement Concrete Overlay of Existing Rigid Pavement 404. OVERLAYS OF EXISTING FLEXIBLE PAVEMENTS. The design of an overlay for an existing flexible pavement is essentially the same as designing a new pavement. The existing flexible pavement is characterized by assigning the appropriate thicknesses and moduli of the existing layers. A qualified engineer should be consulted to characterize the existing pavement layers. a. Hot Mix Overlay of an Existing Flexible Pavement. A trial thickness of overlay is selected and the program iterates until a CDF of 1.0 is reached. The overlay thickness required to achieve a CDF of 1.0 is the design thickness. However, the minimum hot mix overlay of an existing flexible pavement is 2 inches (50 mm). FIGURE 4-2. DESIGN EXAMPLE OF FLEXIBLE OVERLAY ON EXISTING FLEXIBLE PAVEMENT (1) Example. To illustrate the procedure of designing HMA overlay, assume an existing taxiway pavement composed of the following section: the subgrade CBR is 10, (E is 15,000 psi (103.42 MPa)), the HMA surface course is 4 inches (102 mm) thick, the standard base course (P-209) is 10 inches (254 mm) thick, and the subbase (P-154) is 6 inches (152 mm) thick. Frost action is negligible. Assume the existing pavement is to be strengthened to accommodate the following airplane mix: DC10-10 weighing 458,000 pounds (207 745 kg) at an annual departure level of 2,263, B747-200B Combi Mixed weighing 873,000 pounds (395 986 kg) at an annual departure level of 832, a B777-200 ER weighing 634,500 pounds (287 804 kg) at an annual departure level of 425. The flexible pavement thickness required based on FAARFIELD for these conditions is— 59 AC 150/5320-6E 9/30/2009 P-401 asphalt overlay P-401 asphalt surface P-209 standard base P-154 standard subbase 7.78 inches (198 mm) 4.00 inches (102 mm) 10.00 inches (254 mm) 6.00 inches (152 mm) Total pavement thickness 27.78 inches (706 mm) The required overlay thickness of 7.78 inches (198 mm) will be rounded up to 8 inches (203 mm) as shown in figure 42. In this example the existing pavement structure does not require a stabilized base to accommodate airplanes weighting more than 100,000 pounds. The lack of stabilized base is compensated by designing thicker asphalt overlay than it would be required in case of stabilized base in place. (2) Summary. Structurally, an 8 inch (203 mm) thick overlay should satisfy the design conditions. The overlay thickness calculated from structural considerations should be compared with that required to satisfy geometric requirements. Geometric requirements include, for example, provision of drainage, correcting crown and grade, meeting grade of other adjacent pavements and structures, etc. The most difficult part of designing hot mix asphalt overlays for flexible pavements is the determination of the properties of the existing pavement. Subgrade and subbase properties can be measured by conducting NDT. The subgrade and subbase must be at the equilibrium moisture content when field tests are conducted. Normally, a pavement that has been in place for at least 3 years will be in equilibrium. Procedures for calculating properties from nondestructive tests are contained in AC 150/5370-11. b. Nonstructural Hot Mix Asphalt Overlays. In some instances overlays are required to correct nonstructural problems such as restoration of crown, improve rideability, etc. Thickness calculations are not required in these situations, as thickness is controlled by other design considerations or minimum practical overlay thickness. Although the overlay in this case is not necessary for structural requirements it may be included when computing pavement strength (PCN). Information concerning runway roughness correction can be found in FAA Report No. FAARD-75-110, Methodology for Determining, Isolating and Correcting Runway Roughness (see Appendix 4). c. Concrete Overlay of an Existing Flexible Pavement. The design of a concrete overlay on an existing flexible pavement is essentially the same as designing a new rigid pavement. The existing flexible pavement is characterized by assigning the appropriate thicknesses and moduli of the existing layers. A trial thickness of overlay is selected and the program iterates until a CDF of 1.0 is reached. The overlay thickness required to achieve a CDF of 1.0 is the design thickness. The design process is relatively simple; however, the characterization of the existing pavement layers requires judgment by a qualified engineer. The program assumes the interface between the concrete overlay and the existing flexible surface is frictionless. When frost conditions require additional thickness, the use of nonstabilized material below the rigid pavement overlay is not allowed, as this would result in a sandwich pavement. Frost protection must be provided by stabilized material. The minimum thickness for a concrete overlay of an existing flexible pavement should be 5 inches (130 mm). (1) Example. To illustrate the procedure of designing a concrete overlay, assume an existing taxiway pavement composed of the following section: the subgrade CBR = 10 (equivalent to E = 15,000 psi (103.4 MPa) or k = 141 pci (38.4 MN/m3) using the conversion formulas from paragraph 326), the HMA surface course is 4 inches (102 mm) thick, and the base course is 12 inches (305 mm) thick. Frost action is negligible. Assume the existing pavement is to be strengthened to accommodate the following airplane mix: DC10-10 weighing 458,000 pounds (207 745 kg) at an annual departure level of 2,263, B747-200B Combi Mixed weighing 873,000 pounds (395 986 kg) at an annual departure level of 832, and B777-200 ER weighing 634,500 pounds (207 804 kg) at an annual departure level of 425. The concrete overlay required based on FAARFIELD for these conditions is: PCC overlay on flexible P-401 asphalt surface P-209 base 15.41 inches (392 mm) 4.00 inches (102 mm) 12.00 inches (305 mm) Total pavement thickness 31.41 inches (789 mm) Figure 4-3 shows the required concrete overlay thickness is 15.41 inches (392 mm), which is rounded up to the nearest 0.5 inch, or 15.5 inches (381 mm). 60 9/30/2009 AC 150/5320-6E FIGURE 4-3. DESIGN EXAMPLE OF RIGID OVERLAY ON EXISTING FLEXIBLE PAVEMENT 405. OVERLAYS OF EXISTING RIGID PAVEMENTS. The design of overlays for an existing rigid pavement is complex because deterioration of the underlying pavement as well as deterioration of the overlay must be considered. The flexural strength of the existing rigid pavement can be determined using non-destructive testing (NDT), destructive methods or engineering judgment. The condition of the existing rigid pavement prior to overlay is important and is expressed in terms of the structural condition index (SCI) (see DOT-FAA-PM-87/19, Appendix 4). a. Structural Condition Index (SCI). The SCI is derived from the pavement condition index (PCI) and it is the summation of structural components from PCI. Additional guidance on deriving an SCI is provided in the FAARFIELD user’s manual. The PCI is a numerical rating indicating the operational condition of an airport pavement based on a visual survey. The scale ranges from a high of 100 to a low of 0, with 100 representing a pavement in excellent condition and 0 representing complete failure. The PCI is measured following ASTM D 5340, Standard Test Method for Airport Pavement Condition Index Survey (see Appendix 4). For rigid pavements, 15 different types of distresses are considered in measuring the PCI. These distress types all reduce the PCI of a pavement, depending on their severity and relative effect on performance. Not all distress types are indicative of structural distress. Report DOT-FAA-PM-87/19 identifies six distress types that are indicative of the structural condition of the pavement. Table 4-1 lists these six distress types. The SCI can be computed automatically with computer programs such as MicroPAVER, provided the distresses listed in table 4-1 are used to define the SCI. TABLE 4-1. RIGID PAVEMENT DISTRESS TYPES USED TO CALCULATE THE STRUCTURAL CONDITION INDEX, SCI Distress Severity Level Corner Break Low, Medium, High Longitudinal/Transverse/Diagonal Cracking Low, Medium, High Shattered Slab Low, Medium, High Shrinkage Cracks (cracking partial width of slab)a Low Spalling–Joint Low, Medium, High Spalling–Corner Low, Medium, High a Used only to describe a load-induced crack that extends only part of the way across a slab. The SCI does not include conventional shrinkage cracks due to curing or other non load-related problems. An SCI of 80 is the FAA definition of structural failure of a rigid pavement, and is consistent with 50 percent of slabs in the traffic area exhibiting a structural crack. The SCI allows a more precise and reproducible rating of a pavement’s condition than the previous FAA condition factor ratings, Cb and Cr. 61 AC 150/5320-6E 9/30/2009 SCI can be calculated by the following equation: SCI 100 a mS nj f(T , S i j , Dij ) i 1 j 1 where: a = adjustment factor (see ASTM D 5340) ms = total number of distress type related to the pavement structural failure = total number of severity levels for the ith distress nj f(Ti,Sj,Dij) = deduct value for distress type Ti, at the severity level Sj, existing at density Dij. b. Cumulative Damage Factor Used (CDFU). In the case when the SCI of the existing pavement is 100 (i.e., no visible distresses contributing to a reduction in SCI), the condition of existing pavement is described by the cumulative damage factor used (CDFU), which defines the amount of life that has been used by the existing pavement up to the time of the overlay. For aggregate base layers, and assuming that traffic on the pavement has been constant over time, a good estimate of CDFU can be obtained from: CDFU LU when LU 0.75 LD 0.75 LD 1 when LU 0.75 LD where: LU = LD = number of years of operation of the existing pavement until overlay design life of the existing pavement in years This equation was derived from the empirical relationship between traffic coverages and SCI given in Report No. DOTFAA-PM-87/19 and applies to pavements on conventional (aggregate) base. However, FAARFIELD implements a modification of this empirical relationship for higher quality base materials to account for the observed performance of rigid pavements on stabilized bases. This modification essentially increases the percent of design life remaining after the SCI starts to drop from 100 if the base and subbase layers are of higher quality than an 8-inch (203 mm) aggregate subbase (aggregate base thicker than 8 inches (203 mm) or stabilized base thicker than 4 inches (102 mm)). Hence, the simple relationship given above is not valid for such structures. In FAARFIELD, the percent CDFU is computed and displayed when the Life button is clicked in the STRUCTURE window. The procedure for computing percent CDFU for a rigid pavement with SCI = 100 follows: (1) Set up the structure based on the original design assumptions. (2) Estimate the traffic that has been applied to the pavement and enter it into the airplane design (3) Set “Design Life” to the number of years the pavement will have been in operation up to the (4) Run Life. list. time of overlay. The percent CDFU will be displayed when the computation is completed. Values of percent CDFU greater than 100 indicate that the procedure predicts that the SCI of the pavement should be less than 100. A value of 100 should then be entered for percent CDFU as input data for the overlay design. However, since the computation of percent CDFU will be based on estimated structure properties and traffic, the value is likely to be unreliable. An alternative procedure is to run Design Structure for the original structure with design life set to the actual design life, where actual design life is typically the 20 year design period. Then repeat the steps given above and use the new value of percent CDFU. If it is suspected that the pavement has been subjected to more or heavier traffic than assumed in the Life computation, percent CDFU should be increased from the computed value. Setting percent CDFU to 100 will give the most conservative design. 62 9/30/2009 AC 150/5320-6E For fully unbonded concrete overlay, the modulus of the base pavement varies as a function of the SCI of the base pavement when the SCI is less than 100. This computation is done automatically within FAARFIELD. The equations for the modulus reduction as a function of the SCI are given in Report No. DOT-FAA-PM-87/19. Example. The following steps illustrate the procedure for calculating CDFU: FIGURE 4-4. CDFU COMPUTATION USING FAARFIELD (1) Set up the structure based on the original design assumptions. Assume an existing taxiway pavement composed of: 15.3 inch (388 mm) thick PCC surface course; 6 inch (152 mm) thick stabilized base course, Item P-306 Econocrete; 6 inch (152 mm) thick subbase course, Item P-209 Crushed Aggregate. The subgrade k-value is 141 pci (38.4 MN/m3), equivalent to an E-modulus of 15,000 psi (103.4 MPa). The existing pavement was designed to accommodate the following airplane mix: 2263 annual departures of the DC10-10 (gross taxi weight 458,000 lbs (207 700 kg)), 832 annual departures of the B747-200B Combi Mixed (gross taxi weight 833,000 lbs (377 800 kg)), and 425 annual departures of the B777-200 ER (gross taxi weight 634,500 lbs (287 800 kg)). The design life was 20 years. (2) Estimate the traffic applied to the pavement and enter it into the airplane design list. Assume that the annual traffic levels actually applied to the pavement were: 1200 annual departures of the DC10-10, 300 annual departures of the B747, and 200 annual departures of the B777. (3) Set “Design Life” to the number of years the pavement will have been in operation up to the time of the overlay. Assume that at the time of the overlay the taxiway will have been in operation for 12 years. In the “Structure” window, click on “Design Life” and change to 12 years. Figure 4-4 shows that the design life has been adjusted to 12 years. (4) Run Life. The calculated percent CDFU will appear on the Structure screen, at the lower left of the pavement section. (See figure 4-4). For the above case, FAARFIELD calculates percent CDFU equal to 40.08. For overlay design, the value CDFU = 40 percent would be used. 63 AC 150/5320-6E 9/30/2009 Higher traffic levels, heavier airplanes, or a longer “design life” will result in a higher calculated value of %CDFU. In this example, if the higher traffic levels used in the original design had actually been applied to the pavement, the percent CDFU computed by FAARFIELD would increase to 87.21. c. Hot Mix Asphalt Overlays of Existing Rigid Pavements. The design process for hot mix overlays of rigid pavements considers two conditions for the existing rigid pavement to be overlaid: (1) SCI of the existing pavement less than 100; (2) SCI equal to 100. (1) Structural Condition Index Less Than 100. The most likely situation is one in which the existing pavement is exhibiting some structural distress, i.e., the SCI is less than 100. If the SCI is less than 100, the overlay and base pavement deteriorate at a given rate until failure is reached. FAARFIELD assumes an initial overlay thickness and iterates on the overlay thickness until a 20-year life is predicted. A 20-year predicted life satisfies the design requirements. (i) Example. To illustrate the procedure of designing a HMA overlay, assume an existing taxiway pavement composed of the following section: the subgrade k-value is 141 pci (38.4 MN/m3), equivalent to an E modulus of 15,000 psi (103.42 MPa), the PCC surface course is 14 inches (356 mm) thick, the stabilized base course is 6 inches (152 mm) thick, and the subbase course is 6 inches (152 mm). Based on a visual survey, the existing pavement is assigned an SCI of 70. Frost action is negligible. Assume the existing pavement is to be strengthened to accommodate the following airplane mix: DC10-10 weighing 458,000 pounds (207 745 kg) at an annual departure level of 2,263, B747-200B Combi Mixed weighing 873,000 pounds (395 986 kg) at an annual departure level of 832, and B777-200 ER weighing 634,500 pounds (207 804 kg) at an annual departure level of 425. The flexible pavement overlay required based on FAARFIELD for these conditions is: P-401 AC overlay PCC Surface P-304 Stabilized base P-209 Subbase 4.29 inches (109 mm) 14 inches (356 mm) 6 inches (152 mm) 6 inches (152 mm) Total pavement thickness 30.29 inches (770 mm) The required overlay thickness is 4.29 inches (109 mm) and will be rounded up to 4.5 inches (114 mm) (See figure 4-5). The thickness generated by FAARFIELD does not address reflection cracking. Additional guidance on reflection cracking is provided in paragraph 405c(5). FIGURE 4-5. DESIGN EXAMPLE OF FLEXIBLE OVERLAY ON EXISTING RIGID PAVEMENT WITH SCI 70 64 9/30/2009 AC 150/5320-6E (2) Structural Condition Index Equal to 100. An existing pavement with an SCI of 100 might require an overlay to strengthen the pavement in order to accept heavier airplanes. If the SCI of the base pavement is equal to 100, an additional input is required, the percent CDFU. FAARFIELD assumes the base pavement will deteriorate at one rate while the SCI is equal to 100 and at a different rate after the SCI drops below 100. As with case (1), a trial overlay thickness is input, and the program iterates on that thickness until a 20-year life is predicted. The design thickness is the thickness that provides a 20-year predicted life. (i) Example. To illustrate the procedure of designing an HMA overlay, assume an existing rigid taxiway pavement. The existing pavement section and airplane mix is the same as the example in (1) above. Frost action is negligible. The SCI is 100 (there are no visible structural distresses), but based on an analysis of the traffic that has been applied by the pavement to date, the % CDFU is estimated to be 50 percent. The flexible pavement overlay required based on FAARFIELD for these conditions is: P-401 AC overlay PCC Surface P-304 Stabilized base P-209 Subbase 3.25 inches (83 mm) 14.00 inches (356 mm) 6.00 inches (152 mm) 6.00 inches (152 mm) Total pavement thickness 29.25 inches (743 mm) The required overlay thickness (as shown in figure 4-6) is 3.25 inches (83 mm), which will be rounded up to 3.5 inches (89 mm). The required overlay thickness is 1 inch (25.4 mm) less than the example in (1), reflecting the fact that the PCC is in better condition. FIGURE 4-6. DESIGN EXAMPLE OF FLEXIBLE OVERLAY ON EXISTING RIGID PAVEMENT WITH SCI 100 (3) Previously Overlaid Rigid Pavement. The design of a hot mix asphalt overlay for a rigid pavement that already has an existing hot mix asphalt overlay is slightly different. The designer should treat the problem as if the existing hot mix asphalt overlay were not present, calculate the overlay thickness required, and then adjust the calculated thickness to compensate for the existing overlay. If this procedure is not used, inconsistent results will often be produced. The condition of the rigid pavement should be determined using engineering judgment. (4) Limitations. For hot mix asphalt overlay thickness, the FAARFIELD program assumes the existing rigid pavement will support load through flexural action. As the overlay thickness becomes greater, at some point the existing rigid pavement will tend to act more like a high quality base material. As the overlay thickness approaches the thickness of the rigid pavement, it may be more economical to treat the design as a new flexible 65 AC 150/5320-6E 9/30/2009 pavement design on a high quality base material. For the new flexible case, the existing PCC should be considered as a variable stabilized (flexible) base layer with the modulus determined by engineering judgment. Both cases (HMA on rigid overlay, and new flexible on high quality base) should be tried, and the more economical design selected. (5) Reflection Cracking In Hot Mix Asphalt Overlays. Reflection cracking is often a problem in hot mix asphalt overlays particularly overlays of rigid pavement. The thickness generated by FAARFIELD does not address reflection cracking. Numerous materials and techniques have been tried attempting to solve the problem with varying degrees of success. The following methods have met with some success: (i) Coarse Aggregate Binders. The use of coarse aggregate binder course is recommended where economically feasible. Use of the largest practical size coarse aggregate in the hot mix asphalt layer immediately above the existing pavement is recommended. This practice provides some measure of protection against reflection cracking. (ii) Rubblization of Existing PCC Pavement. If the condition of the existing rigid pavement is very poor (i.e., extensive structural cracking, joint faulting, “D” cracking, etc.), consideration may be given to using the rubblization technique. Subgrade support conditions must be considered, as weak subgrade support can cause difficulties in rubblizing the existing pavement and cause premature failures in the completed pavement. Rubblization involves purposely breaking the existing rigid pavement into small pieces and then rolling the broken pieces to firmly seat them in the foundation. A hot mix asphalt layer is then placed over the pavement. This type of section is designed as a flexible pavement, treating the broken rigid pavement as base course. Reflective cracking is reduced or eliminated with this type of construction (See AAPTP Report 04-01, Development of Guidelines for Rubblization, for additional information). (iii) Engineering Fabrics. Research studies and field performance have shown that fabric membranes may be effective in retarding reflection cracking. While fabrics will not eliminate reflection cracking altogether, they do provide some degree of waterproofing beneath reflection cracks, thus protecting the existing pavement and foundation. At present, the waterproofing capability of fabrics, assuming the capacity of the asphalt impregnated fabric to resist rupture is not lost, appears to be the most significant contribution provided in a hot mix asphalt overlay system. Existing pavements, whether flexible or rigid, that show evidence of excessive deflections, substantial thermal stresses, and/or poor drainage, probably will exhibit no improvement by including a fabric in a structural overlay. The following conditions are recommended for fabric usage: (iv) Fabric Properties. The fabric should have a minimum tensile strength of at least 90 pounds (41 kg) when tested in accordance with ASTM D 4632 and a density in the range of 3 to 5.5 ounces per square yard (70 to 130 grams per square meter). (v) Tack Coat. The proper amount of tack coat applied to the fabric is critical. Emulsified asphalt applied at a rate of from 0.15 to 0.30 gallons per square yard (0.7 to 1.4 liters per square meter) is recommended. The optimum amount of tack coat will depend on the type of fabric and the surface on which the fabric is placed. (vi) Crack and Seat. The crack and seat process involves cracking a PCC layer into pieces typically measuring 1.5 to 2 feet (0.46 m to 0.6 m) and firmly seating the pieces into the subgrade prior to overlaying with asphalt concrete. It is an alternative method and should be evaluated by FAA Headquarters on a caseby-case basis. (vii) Asphalt Reinforcement. Destructive tensile stresses in asphalt pavements may be reduced by incorporating a reinforcement material. Reinforcement materials are similar to fabric membranes except the reinforcement is either a woven fabric or a grid-shaped material. These materials have very high tensile strength and very low strain capacity. Products with a combination of fabric materials and reinforcement grids have been developed and appear to be successful in retarding reflective cracking. Depending upon the material type and the intended purpose, reinforcing materials may be applied across the full width of the pavement or may be limited to the immediate area around joints and cracks. FAARFIELD does not address asphalt reinforcement in the thickness design. d. Concrete Overlays of Existing Concrete Pavements. The design of a concrete overlay of an existing rigid pavement is the most complex type of overlay to be designed. Deterioration of the concrete overlay and existing rigid pavement must be considered as well as the degree of bond between the overlay and existing pavement. FAARFIELD considers two degrees of bond and addresses each one separately for thickness design. 66 9/30/2009 AC 150/5320-6E (1) Fully Unbonded Concrete Overlay. An unbonded concrete overlay of an existing rigid pavement is one in which steps are taken to intentionally eliminate bonding between the overlay and existing pavement. Commonly, the bond is broken by applying a thin hot mix layer to the existing rigid pavement. The interface friction coefficient between the overlay and existing pavement is set to reflect an unbonded condition. The interface coefficient is fixed and cannot be changed by the user. As with hot mix asphalt overlays, an SCI is required to describe the condition of the existing pavement. A trial overlay thickness is input and FAARFIELD iterates until a 20-year service life is predicted. The thickness that yields a 20-year service life is the design thickness. However, the minimum thickness for a fully unbonded concrete overlay is 5 inches (130 mm). (i) Example. To illustrate the procedure of designing an unbonded concrete overlay, assume an existing taxiway pavement composed of the following section: SCI is 40 for the existing PCC surface, the subgrade k-value is 141 pci (38.4 MN/m3), corresponding to an E-modulus of 15,000 psi (103.42 MPa), the existing PCC surface course is 14 inches (102 mm) thick, the base course is 6 inches (305 mm) thick, and the subbase course is 6 inches (152 mm). Frost action is negligible. Assume the existing pavement is to be strengthened to accommodate the following airplane mix: DC10-10 weighing 458,000 pounds (207 745 kg) at an annual departure level of 2,263, B747200B Combi Mixed weighing 873,000 pounds (395 986 kg) at an annual departure level of 832, and B777-200 ER weighing 634,500 pounds (207 804 kg) at an annual departure level of 425. Assume that the PCC strength is 700 psi for both the overlay and the existing concrete. The overlay structure computed by FAARFIELD for these conditions is— PCC unbonded overlay Debonding layer PCC Surface P-304 Stabilized base P-209 Subbase 13.52 inches (343 mm) 1.00 inches (25 mm)¹ 14 inches (356 mm) 6 inches (152 mm) 6 inches (152 mm) Total pavement thickness 39.52 inches (1 004 mm) ¹Note: FAARFIELD does not include the debonding layer in thickness calculations. FIGURE 4-7. DESIGN EXAMPLE OF RIGID OVERLAY ON EXISTING FULLY UNBONDED RIGID PAVEMENT Figure 4-7 shows the required overlay thickness is 13.52 inches (343 mm), which will be rounded to the nearest 0.5 inches, or 13.5 inches (343 mm). (2) Bonded Concrete Overlays. Concrete overlays bonded to existing rigid pavements are sometimes used under certain conditions. By bonding the concrete overlay to the existing rigid pavement the new 67 AC 150/5320-6E 9/30/2009 section behaves as a monolithic slab. In FAARFIELD, a bonded overlay can be designed as a new rigid pavement by treating the existing concrete surface and the concrete overlay as a combined single layer. The flexural strength used in the FAARFIELD computation should be the strength of the existing concrete. The thickness of the bonded overlay required is computed by subtracting the thickness of the existing pavement from the total thickness of the required slab as computed by FAARFIELD: hc h he where: hc = h = he = required thickness of concrete overlay required slab thickness computed by FAARFIELD using the flexural strength of the existing concrete thickness of existing rigid pavement Bonded overlays should be used only when the existing rigid pavement is in good to excellent condition. The minimum thickness of concrete overlay that is bonded to an existing rigid pavement is 3 inches (75 mm). Defects in the existing pavement are more likely to reflect through a bonded overlay than other types of concrete overlays. The major problem likely to be encountered with bonded concrete overlays is achieving adequate bond. Elaborate surface preparation and exacting construction techniques are required to ensure the bond. (3) Jointing of Concrete Overlays. Where a rigid pavement is to receive the overlay, some modification to jointing criteria may be necessary because of the design and joint arrangement of the existing pavement. The following points may be used as guides in connection with the design and layout of joints in concrete overlays. (i) Joint Types. Joints need not be of the same type as in the old pavement except for some bonded overlay applications. (ii) Isolation Joints. It is not necessary to provide an isolation joint for each isolation joint in the old pavement; however, a saw cut or plane of weakness should be provided within 1 foot (0.3 m) of the existing isolation joint. (iii) Timing. The timing for sawing joints is extremely critical on concrete overlays to minimize curling and warping stresses and prevent random cracking. (iv) Contraction Joints. Contraction joints in unbonded overlays may be placed directly over or within 1 foot (0.3 m) of existing expansion, construction, or contraction joints. Joints in bonded overlays should be located within 0.5 inch (13 mm) of joints in the existing base pavement. Should spacing result in slabs too long to control cracking, additional intermediate contraction joints may be necessary. (v) Joint Pattern. If a concrete overlay with a leveling course is used, the joint pattern in the overlay does not have to match the joint pattern in the existing pavement. (vi) Reinforcement. Overlay slabs longer or wider than 20 feet (6.1 m) should contain embedded steel regardless of overlay thickness. 406. THICKNESS DESIGN FOR RUBBLIZED CONCRETE PAVEMENTS. Rubblization of deteriorated concrete pavements is becoming a popular method of pavement rehabilitation. The rubblization process destroys the slab action by breaking the concrete slab into 1- to 3-inch pieces at the top and 3- to 15-inch pieces at the bottom. The rubblized concrete layer behaves as a tightly keyed, interlocked, high-density non-stabilized base. The rubblized concrete base prevents the formation of reflective cracks in the asphalt concrete overlay and provides a sound base course. The thickness design procedure for asphalt concrete overlay over a rubblized concrete base is similar to the asphalt overlay on flexible pavement. A rubblized PCC layer is available in FAARFIELD. The recommended modulus values for the Rubblized PCC layer range from 100,000-psi to 400,000-psi. Engineering judgment is required for the selection of an appropriate modulus value. The following ranges are suggested for selecting a design modulus value of rubblized PCC on airfields: · For slabs 6 to 8 inches thick: Moduli from 100 to 135 ksi · For slabs 8 to 14 inches thick: Moduli from 135 to 235 ksi · For slabs >14 inches thick: 68 Moduli from 235 to 400 ksi 9/30/2009 AC 150/5320-6E The selected value is influenced by considerations such as level of conservatism in the design, exact slab thickness within the above ranges, pre-rubblized PCC modulus anticipated particle size, steel debonding conditions, and relevant historical data. For further insight into selecting a design modulus of rubblized PCC, reference AAPTP 04-01 . For a rigid overlay placed over rubblized PCC, the thickness design procedure is similar to that for a new rigid pavement. Some engineering judgment is required for the selection of an appropriate modulus value for the rubblized PCC layer. 407. PREPARATION OF THE EXISTING SURFACE FOR THE OVERLAY. Before proceeding with construction of the overlay, steps should be taken to correct all defective areas in the existing surface, base, subbase, and subgrade. Careful execution of this part of an overlay project is essential as a poorly prepared base pavement will result in an unsatisfactory overlay. Deficiencies in the base pavement will often be reflected in the overlay. a. Existing Flexible Pavements. Failures in flexible pavements may consist of pavement breakups, potholes and surface irregularities, and depressions. (1) Removal and Replacement. Localized areas of failed pavement will have to be removed and replaced with new pavement. This type of failure is usually encountered where the pavement is deficient in thickness, the subgrade consists of unstable material, or poor drainage has reduced the supporting power of the subgrade. To correct this condition, the subgrade material should be replaced with a select subgrade soil or by installation of proper drainage facilities; this is the first operation to be undertaken in repairing this type of failure. Following the correction of the subgrade condition, the subbase, base, and surface courses of the required thickness should be placed. Each layer comprising the total repair should be thoroughly compacted before the next layer is placed. (2) Irregularities and Depressions. Surface irregularities and depressions, such as shoving, rutting, scattered areas of settlement, and occasional “birdbaths” should be leveled by rolling or milling, where practical, or by filling with suitable hot mix asphalt mixtures. If the “birdbaths” and settlements are found to exist over extensive areas, a hot mix asphalt leveling course may be required as part of the overlay. The leveling course should consist of high-quality hot mix asphalt concrete. Scattered areas requiring leveling or patching may be repaired with hot mix asphalt patch mixtures. When placing a concrete overlay on an existing asphalt pavement serious asphalt distresses such as subgrade failure, potholes, shoving, and rutting in excess of 2 inches need to be addressed prior to the overlay. Less severe surface irregularities and depressions may be corrected within the overlay. If the surface irregularity will cause the concrete overlay thickness to be less than the design thickness then it must be corrected prior to the overlay. (3) Bleeding Surface. A bleeding surface may detrimentally affect the stability of the overlay and for this reason any excess hot mix asphalt material accumulated on the surface should be bladed or milled off, if possible. In some instances, a light application of fine aggregates may blot up the excess material, or a combination of the two processes may be necessary. Sweep after. (4) Cracks and Joints. For cracks, and joints, 3/8 inch (10 mm) or more in width, old joint and crack filler should be removed and, if vegetation is present, a sterilant applied. The cracks and joints should then be filled with a lean mixture of sand and liquid bituminous material. This mixture should be well tamped in place, leveled with the pavement surface, and any excess removed. The material should be allowed to dry to a hardened condition prior to overlay placement. For concrete overlays on existing asphalt pavement, joints and cracks may be cleaned and then filled as noted above or with a flowable fill material compatible with Item P-153, Controlled Low-Strength Material. (5) Potholes. Repair potholes prior to overlay. Repairs may require removal and replacement of unstable subgrade materials. Complete repairs with a suitable mixture of bituminous material and compact in place. (6) Grooves, Paint, Etc. It is not necessary to remove existing pavement grooves prior to an asphalt or concrete overlay. Paint must be removed or scarifed prior to an asphalt overlay to assure bonding of the overlay to the existing pavement. Paint does not require removal prior to a concrete overlay. (7) Porous Friction Courses (PFC). Existing PFC’s must be removed prior to any overlay. (8) Surface Contaminants. Surface contaminants that will prevent bonding of the surface overlay, e.g. oil spills, must be removed prior to an asphalt overlay. The FAA recommends that excessive amounts of rubber buildup be removed prior to an overlay; however, limited amounts of rubber may be tolerated. 69 AC 150/5320-6E 9/30/2009 b. Existing Rigid Pavements. In rigid pavements, narrow transverse, longitudinal, and corner cracks will need no special attention unless there is an appreciable amount of displacement and faulting between the separate slabs. If the subgrade is stable and no pumping has occurred, the low areas can be taken care of as part of the overlay and no other corrective measures are needed. On the other hand, if pumping has occurred at the slab ends or the slabs are subject to rocking under the movement of airplanes, subgrade support should be improved by pumping cement grout or specialized materials under the pavement to fill the voids that have developed. Pressure grouting requires considerable skill to avoid cracking slabs or providing uneven support for the overlay. (1) Slab Removal and Replacement. If the pavement slabs are badly broken and subject to rocking because of uneven bearing on the subgrade, the rocking slabs can be broken into smaller slabs to obtain a more firm seating. Badly broken slabs that do not rock will not require repairs since the criteria make adjustments for such a condition in the pavement thickness. In some cases, it may be desirable to replace certain badly broken slabs with new slabs before starting construction of the overlay. The decision in such cases will have to be made according to the merits of the individual project. (2) Leveling Course. Where the existing pavement is rough due to slab distortion, faulting, or settlement, a provision should be made for a leveling course of hot mix asphalt concrete before the overlay is commenced. Fractured slab techniques can also be used in these instances. (3) Cracks and Joints. Cracks, and joints, 3/8 inch (10 mm) or more in width, should be filled with a lean mixture of sand and liquid bituminous material. This mixture should be tamped firmly in place, leveled with the pavement surface, and any excess removed. (4) Surface Cleaning. After all repairs have been completed and prior to the placing of the overlay, the surface should be swept clean of all dirt, dust, and foreign material. Any extruding joint-sealing material should be trimmed from rigid pavements. (5) Bonded Concrete Overlays. Bonded concrete overlays will require special attention to insure bond with the existing pavement. Surface cleaning and preparation by shot peening or mechanical texturing by cold milling are two techniques that have been used to provide a surface that will allow bonding. Adequate bond has been achieved by placing the overlay directly on the dry prepared surface. In other instances, bond was achieved by placing a neat cement grout on the prepared surface immediately ahead of the overlay placement. If a bonding agent is used, care must be taken to apply it directly in front of the fresh concrete. If the bonding agent is allowed to cure before concrete placement, the bond will be broken. 408. MATERIALS AND METHODS. With regard to quality of materials and mixes, control tests, methods of construction, and workmanship, the overlay pavement components are governed by AC 150/5370-10, Standards for Specifying Construction of Airports (see Appendix 4). a. Tack Coat. If a hot mix asphalt overlay is specified, the existing pavement should receive a light tack coat (Item P-603) or fog coat immediately after cleaning. The overlay should not extend to the edges of the pavement but should be cut off approximately 3 inches (75 mm) from each edge. b. Forms. Should the existing pavement require drilling to provide anchorage for the overlay pavement forms, the size and number of holes should be the minimum necessary to accomplish that purpose. Holes should not be located close to joints or cracks. Location of holes for form anchors should be such as to avoid causing additional cracking or spalling. 409. NEW OVERLAY MATERIALS. In recent years, some new pavement overlay materials have been used with varying degrees of success. These materials include fibrous concrete, roller compacted concrete, and rubberized asphalt. Use of materials other than conventional Portland cement concrete (Item P-501) or Plant Mix Bituminous Surface (Item P-401) require special approval on a case-by-case basis. 70 9/30/2009 AC 150/5320-6E CHAPTER 5. PAVEMENT DESIGN FOR AIRPLANES WEIGHING LESS THAN 30,000 POUNDS 500. GENERAL. This chapter provides pavement design guidance for airfield pavements intended to serve only airplanes with gross weights less than 30,000 pounds (13 608 kg). Airplanes of this size are usually engaged in nonscheduled activities, such as agricultural, instructional, or recreational flying. Pavements designed to serve these airplanes may be flexible or rigid-type pavements. The design of pavements serving airplanes of 30,000 pounds (13 608 kg) gross weight or more should be based on the criteria contained in Chapter 3 of this publication. Some areas of airports serving light airplanes may not require paving. In these areas, the development of an aggregate-turf or turf surface may be adequate for limited operations of these light airplanes. Aggregate-turf surfaces are constructed by improving the stability of a soil with the addition of aggregate prior to development of the turf. Aggregate-turf construction is covered in some detail in the latter part of this chapter. Information on stabilization of soils can be found in Chapter 2 of this circular and in AC 150/5370-10, Standards for Specifying Construction of Airports. 501. REPORTING PAVEMENT STRENGTH. When designing pavements for light airplanes, summarize all pavement designs on FAA Form 5100-1, Airport Pavement Design, which is considered part of the Engineer’s Design Report. Submit the Engineer’s Design Report for FAA review and approval along with initial plans and specifications. 502. TYPICAL SECTIONS. Typical cross-sections for pavements serving light airplanes are shown in figure 5-1. No distinction is made between critical and noncritical pavement sections for pavements serving light airplanes. 503. FLEXIBLE PAVEMENT MATERIALS. Flexible pavements for light airplanes are composed of hot mix asphalt surfacing, base course, subbase, and prepared subgrade. The function of these layers and applicable specifications are discussed below. a. Hot Mix Asphalt Surfacing. The function of the hot mix asphalt surface or wearing course is the same as discussed earlier in Chapter 3. Specifications covering the composition and quality of hot mix asphalt mixtures are given in Item P-401, Plant Mix Bituminous Mixtures or Item P-403, Plant Mix Bituminous Pavements (Base, Leveling or Surface Course). In accordance with AC 150/5370-10, state highway specifications for hot mix asphalt mixtures may be used for pavements intended to serve aircraft weighing 12,500 pounds (5 670 kg) or less. b. Base Course. As in heavy loaded pavements, the base course is the primary load-carrying component of a flexible pavement. Specifications covering materials suitable for use as base courses for light-load pavements are as follows: (1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) Item P-208 – Aggregate Base Course Item P-209 – Crushed Aggregate Base Course Item P-210 – Caliche Base Course Item P-211 – Lime Rock Base Course Item P-212 – Shell Base Course Item P-213 – Sand-Clay Base Course Item P-219 – Recycled Concrete Aggregate Base Course Item P-301 – Soil-Cement Base Course Item P-304 – Cement-Treated Base Course Item P-306 – Econocrete Subbase Course Item P-401 – Plant Mix Bituminous Pavement Item P-403 – Plant Mix Bituminous Pavement (Base, Leveling or Surface Course) Note: Use of some of the above materials in areas where frost penetrates into the base course may result in some degree of frost heave and/or may require restricted loading during spring thaw. c. Subbase Course. A subbase course is usually required in flexible pavement except those on subgrades with CBR value of 20 or greater (usually GW or GP type soils). Materials conforming to specification Item P-154, Subbase Course, may be used as subbase course. Also any items listed above in paragraph 502b may be used as subbase course if economy and practicality dictate. Since the loads imposed on these pavements are much less than those on pavements designed for heavier airplanes, compaction control for base and subbase layers should be based upon ASTM D 698, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft3 (600 kN-m/m3)). 71 AC 150/5320-6E 9/30/2009 d. Stabilized Base and Subbase. Stabilized base and subbase courses may be used in light-load pavements. Reduced thicknesses of base and subbase may result. The discussions of stabilized materials are given in Chapter 3. e. Subgrade. Subgrade materials should be compacted in accordance with Item P-152 to the depths shown on Table 5-1. TABLE 5-1. SUBGRADE COMPACTION REQUIREMENTS FOR LIGHT LOAD FLEXIBLE PAVEMENTS Airplane Gross Weight (lbs.) Noncohesive Soils Depth of Compaction (in.) 100% 95% 90% 85% 6 6-9 9-18 18-24 8 8-12 12-24 24-36 Cohesive Soils Depth of Compaction (in.) 95% 90% 85% 4 4-8 8-12 6 6-9 9-12 80% 12,500 or less 12-15 12,501 or more 12-15 General Notes: 1. Noncohesive soils, for the purpose of determining compaction control, are those with a plasticity index of less than 3. 2. Tabulated values denote depths below the finished subgrade above which densities should equal or exceed the indicated percentage of the maximum dry density as specified in Item P- 152. 3. The subgrade in cut areas should have natural densities shown or should (a) be compacted from the surface to achieve the required densities, (b) be removed and replaced at the densities shown, or (c) when economics and grades permit, be covered with sufficient select or subbase material so that the uncompacted subgrade is at a depth where the in-place densities are satisfactory. 4. For swelling soils refer to paragraph 313. 5. 1 inch = 25.4 mm, 1 lb. = 0.454 kg 504. FLEXIBLE PAVEMENT DESIGN. Program FAARFIELD is used to determine the pavement thickness requirements for airplanes weighing up to 30,000 pounds (13 608 kg) gross weight. The pavement thickness determined by FAARFIELD should be used on all areas of the airport pavement. No reduction in thickness should be made for “noncritical” areas of pavements. For very light load pavements, the design should also consider the weight of aircraft rescue and firefighting vehicles, maintenance equipment and/or fueling equipment. It is possible that these types of equipment may require a thicker pavement section than the airplanes. a. Total Pavement Thickness. Use of the program FAARFIELD requires information on the CBR or modulus E value for the subgrade, airplane mix, gross weights, and annual departures of all airplanes. For traffic consisting of more than one airplane type, the entire mix should be entered, not equivalent departures of a “design aircraft”. The preferred method of establishing the subgrade CBR is by testing. The testing procedures described in Chapter 3 should also be applied to light load pavements. b. Thickness of Surfacing and Base. FAARFIELD calculates the thickness of the base layer automatically. Note that the minimum thickness of hot mix asphalt surfacing is 2 inches (50 mm) and the minimum base layer thickness is 3 inches (75 mm). Additional base thickness may be required to obtain construction density requirements. c. Thin Lifts. The reason for the minimum surfacing thickness is that layers thinner than 2 inches (50 mm) are difficult to place and compact on granular bases. Hot mix asphalt surfacing thickness of less than 2 inches (50 mm) is permissible on stabilized base materials if proper laydown and compaction can be achieved. The base course thicknesses range from 3 inches (75 mm) to 6 inches (152 mm) while the subbase thicknesses vary from 0-14 inches (0356 mm). In some instances, difficulties may be encountered in compacting thin bases or subbases. In these cases the base or subbase thicknesses may be increased to facilitate construction even though the additional thickness is not needed for structural capacity. 72 FIGURE 5-1. TYPICAL SECTIONS FOR PAVEMENTS SERVING LIGHT AIRPLANES 9/30/2009 AC 150/5320-6E 73 AC 150/5320-6E 9/30/2009 d. Example. As an example of the use of FAARFIELD, assume a pavement is to be designed for the following mix of airplanes: Airplane Name Citation-V Super King Air-300 Beech Jet-400 Learjet 35A/65 KingAir–B-100 Gross Weight, lbs (tonnes) 16,500 (7.5) 14,100 (6.4) 15,500 (7.0) 18,000 (8.2) 11,500 (5.2) Annual Departures 480 1,000 60 300 1,200 Also assume that the subgrade CBR = 5. The pavement will be designed assuming an HMA surface layer of 2 inches (51 mm). Figure 5-2 shows the airplane mix entered into the FAARFIELD Airplane Window. FIGURE 5-2. FAARFIELD AIRPLANE WINDOW – LIGHT LOAD PAVEMENT DESIGN After setting the HMA thickness to 2 inches, the subgrade CBR to 5, the base layer material to P-209 CrAg and the subbase layer material to P-154 UnCrAg, click “Design Structure”. As shown in figure 5-3, the section as designed by FAARFIELD consists of the 2 in (51 mm) of HMA surfacing, on 3.67 in (94 mm) of P-209 base, and 7.46 in (189 mm) of P-154 subbase. Since difficulties in compacting a base course of less than 4 inches (102 mm) may be anticipated, the P-209 layer will be increased to 4 in (102 mm). Re-running the FAARFIELD design with the 4 in (102 mm) P-209 layer (and disabling the automatic base design option) results in a designed subbase thickness of 7.07 in (180 mm). The final thickness design consists of 2 in (51 mm) P-401 HMA surface, 4 in (102 mm) P-209 base, and 7 in (178 mm) P-154 subbase. e. Omission of Hot Mix Asphalt Surfacing. Under certain conditions, it may be desirable to utilize a bituminous surface treatment on a prepared base course in lieu of hot mix asphalt. In such instances, the strength of the pavement is furnished by the base, subbase, and subgrade. Additional base course thickness will be necessary to make 74 9/30/2009 AC 150/5320-6E up for the missing surface course. Additional base should be provided at a ratio of 1.2 to 1.6 inches (30 to 41 mm) of base for each 1 inch (25.4 mm) of surfacing. f. Full-Depth Asphalt Pavements. Pavements to serve light airplanes may be constructed of full-depth asphalt using the criteria specified in paragraph 318. The Asphalt Institute has published guidance on the design of full depth asphalt pavements for light airplanes in Information Series No. 154, Full Depth Asphalt Pavements for General Aviation. Use of the Asphalt Institute method of design for full-depth asphalt pavements requires approval on a case-bycase basis. g. Local Materials. Since the base and subbase course materials discussed in Chapter 3 are more than adequate for light airplanes, full consideration should be given to the use of locally available, less-expensive materials. These locally available materials may be entirely satisfactory for light-load pavements. These materials may include locally available granular materials, soil aggregate mixtures, or soils stabilized with Portland cement, bituminous materials, or lime. The designer is cautioned, however, if the ultimate design of the pavement is greater than 30,000 pounds (13 608 kg), higher quality materials should be specified at the outset. FIGURE 5-3. CALCULATION OF SUBBASE LAYER THICKNESS 505. RIGID PAVEMENT MATERIALS. Rigid pavements for light airplanes are composed of Portland cement concrete surfacing, subbase, and prepared subgrade. The functions of these layers and applicable specifications are discussed below: a. Portland Cement Concrete. Specifications concerning the quality and placement of Portland cement concrete should be in accordance with Item P-501, Portland Cement Concrete Pavement. Local state highway specifications for paving quality concrete may be substituted for Item P-501 if desired. b. Subbase. Rigid pavements designed to serve airplanes weighing between 12,500 pounds (5 670 kg) and 30,000 pounds (13 608 kg) will require a minimum subbase thickness of 4 inches (102 mm) except as shown in table 3-9 of Chapter 3. No subbase is required for designs intended to serve airplanes weighing 12,500 pounds (5 670 kg) or less, except when soil types OL, MH, CH, or OH are encountered. When the above soil types are present, a 75 AC 150/5320-6E 9/30/2009 minimum 4-inch (102-mm) subbase should be provided. The materials suitable for subbase courses are covered in Item P-154, Subbase Course. c. Subgrade. Compact subgrade materials in accordance with Item P-152 to the following depths. For cohesive soils used in fill sections, compact the entire fill to 90-percent maximum density. For cohesive soils in cut sections, compacat the top 6 inches (152 mm) of the subgrade to 90-percent maximum density. For noncohesive soils used in fill sections, compact the top 6 inches (152 mm) of fill to 100-percent maximum density, and the remainder of the fill to 95-percent maximum density. For cut sections in noncohesive soils, compact the top 6 inches (152 mm) of subgrade to 100-percent maximum density and the next 18 inches (457 mm) of subgrade to 95-percent maximum density. For treatment of swelling soils refer to paragraph 313. 506. RIGID PAVEMENT THICKNESS. The use of FAARFIELD is not necessary for light-duty rigid pavement design. Rigid pavements designed to serve airplanes weighing 12,500 pounds (5 670 kg) or less should be 5 inches (127 mm) thick or 6 inches (152 mm) thick if doweled joints are used. Those designed to serve airplanes weighing between 12,501 pounds (5 670 kg) and 30,000 pounds (13 608 kg) should be 6 inches (152 mm) thick. Jointing of Light Load Rigid Pavements. The maximum spacing of joints for light-load rigid pavements should be 12.5 feet (3.8 m) for longitudinal joints and 15 feet (4.6 m) for transverse joints. Jointing types are shown in figure 5-4 and jointing details are shown in figure 5-5 for light-load rigid pavements. Note that several differences exist between light-load and heavy-load rigid pavement joints. For instance, butt-type construction joints are permitted when an asphalt or cement stabilized subbase is provided. Odd-shaped slabs should be reinforced with 0.05 percent steel in both directions. Odd-shaped slabs are defined as slabs that are not rectangular in shape or rectangular slabs with length-towidth ratios that exceed 1.25. Two recommended joint layout patterns are shown in figures 5-6 and 5-7 for 60 foot (18 m) and for 50 foot (15 m) wide pavements. The concept behind the jointing patterns shown is the creation of a “tension ring” around the perimeter of the pavement to hold joints within the interior of the paved area tightly closed. A tightly closed joint will function better than an open joint. The last three contraction joints and longitudinal joints nearest the free edge of the pavement are tied with #4 deformed bars, 20 inches (508 mm) long, spaced at 36 inches (914 mm) center to center. At the ends of the pavement and in locations where airplanes or vehicular traffic would move onto or off the pavement, a thickened edge should be constructed. The thickened edge should be 1.25 times the thickness of the slab and should taper to the slab thickness over a distance of 3 feet (0.9 m). Note that if a type “F” butt construction joint is used then a stabilized subbase is required as shown in figure 5-4. Alternatively, a type “E” doweled construction joint can be used at the locations shown in figures 5-6 and 5-7. If doweled joints are used, the rigid pavement thickness should be 6 inches (152 mm). The intent of this paragraph is to allow the use of the tension ring design but limit it to pavements less than 60 feet (18 m) in width. Pavements that do not use the tension ring design should be designed in a manner similar to Chapter 3. The general recommendations of table 3-15 may be employed for Chapter 5 pavements not using the tension ring concept; however, the designer should note that the joint designations and steel sizes and spacing discussed in Chapter 5 are different those in Chapter 3. 76 9/30/2009 AC 150/5320-6E FIGURE 5-4. JOINTING TYPES FOR LIGHT-LOAD RIGID PAVEMENT 77 AC 150/5320-6E 9/30/2009 FIGURE 5-5. JOINTING DETAILS FOR LIGHT-LOAD RIGID PAVEMENT 78 FIGURE 5-6. JOINTING LAYOUT PATTERNS FOR LIGHT-LOAD RIGID PAVEMENT – 60 FEET WIDE 9/30/2009 AC 150/5320-6E 79 FIGURE 5-7. JOINTING LAYOUT PATTERNS FOR LIGHT-LOAD RIGID PAVEMENT – 50 FEET WIDE AC 150/5320-6E 80 9/30/2009 9/30/2009 AC 150/5320-6E 507. AGGREGATE TURF. Aggregate-turf differs from normal turf in that the stability of the underlying soil is increased by the addition of granular materials prior to establishment of the turf. The objective of this type of construction is to provide a landing area that will not soften appreciably during wet weather and yet has sufficient soil to promote the growth of grass. Aggregate-turf should be considered only for areas designed to serve non jet airplanes having gross weights of 12,500 pounds (5 670 kg) or less. a. Materials. Construction details and material requirements are covered in Item P-217, Aggregate-Turf Pavement. Typically, aggregate-turf construction will consist of a soil seedbed layer (soil or soil/aggregate combination) over an aggregate stabilized base course. The aggregate stabilized base course consists of soil stabilized crushed stone, soil-stabilized gravel or soil-stabilized sand conforming to the requirements of P-217. b. Thickness. The thickness to be stabilized with the granular materials varies with the type of soil and the drainage and climatic conditions. The minimum thickness of aggregate stabilized soil can be computed from FAARFIELD using the CBR of the subgrade, as shown in the following example. The minimum thickness of the soil seedbed is not determined by structural considerations, but is the thickness required to support the growth of grass. c. Example. Assume that the airplane mix consists of the following: King Air B-100 (11,500 lbs, 1200 annual departures) and Citation 525 (10,500 lbs, 1200 annual departures). The subgrade CBR = 5. Figure 5-8 shows the use of FAARFIELD for determining the thickness of the aggregate stabilized base course layer. A minimum thickness of 2 inches (51 mm) is assigned to the turf seedbed, although the actual thickness of soil will be determined by growing requirements. The turf seedbed is represented as an undefined layer, with a nominal E-modulus of 3,000 psi (21 MPa). The design layer (aggregate stabilized base) is represented as P-154 uncrushed aggregate. In this example, the thickness required for the aggregate stabilized base course is 11.3 inches (287 mm), which will be rounded to 11.5 inches (300 mm). FIGURE 5-8. DESIGN EXAMPLE FOR AGGREGATE TURF PAVEMENT. 508. OVERLAYS. Overlays of pavements intended to serve light airplanes are designed in the same manner as overlays for heavy airplanes. 81 AC 150/5320-6E 9/30/2009 509. HELIPORT/VERTIPORT DESIGN. The guidance contained in paragraph 500 of this section is appropriate for pavements designed to serve rotary-wing airplanes. Where direct thermal effects of jet blast is a concern (e.g., at vertiports serving tiltrotor traffic), incorporation of unique pavement formulations specific to thermal resistance may be required. Any pavement that is subjected to the direct thermal effects of high temperature exhaust gases can become progressively damaged with repeated thermal cycles, resulting in surface spalling, a potential for foreign object damage (FOD), as well as subsequent deterioration of the affected slab. An example formulation for thermal resistant pavement can be found in TR-2079-SHR, Development of Mix Designs for F/A-18 Resistant Pavement Systems. 82 9/30/2009 AC 150/5320-6E CHAPTER 6. PAVEMENT EVALUATION 600. PURPOSES OF PAVEMENT EVALUATION. Airport pavement evaluations are necessary to assess the ability of an existing pavement to support different types, weights, or volumes of airplane traffic. The load carrying capacity of existing bridges, culverts, storm drains, and other structures should also be considered in these evaluations. Evaluations may be also necessary to determine the condition of existing pavements for use in the planning or design of improvements to the airport. Evaluation procedures are essentially the reverse of design procedures. This chapter covers the evaluation of pavements for all weights of airplanes. 601. EVALUATION PROCESS. The evaluation of airport pavements should be a methodical step-by-step process. The recommended steps in the evaluation process described below should be used regardless of the type of pavement. a. Records Research. A thorough review of construction data and history, design considerations, specifications, testing methods and results, as-built drawings, and maintenance history should be performed. Weather records and the most complete traffic history available are also parts of a usable records file. b. Site Inspection. The site in question should be visited and the condition of the pavements noted by visual inspection. This should include, in addition to the inspection of the pavements, an examination of the existing drainage conditions and drainage structures at the site. Evidence of the adverse effects of frost action, swelling soils, reactive aggregates, etc., should also be noted. The principles set forth in Chapter 2 of this circular and in AC 150/53205, Surface Drainage Design, apply. c. Sampling and Testing. The need for and scope of physical tests and materials analyses will be based on the findings made from the site inspection, records research, and type of evaluation. A complete evaluation for detailed design will require more sampling and testing than, for example, an evaluation intended for use in a master plan. Sampling and testing is intended to provide information on the thickness, quality, and general condition of the pavement elements. (1) Direct Sampling Procedures. The basic evaluation procedure for planning and design will be visual inspection and reference to the FAA design criteria, supplemented by the additional sampling, testing, and research, which the evaluation processes may warrant. For relatively new pavement constructed to FAA standards and without visible sign of wear or stress, strength may be based on inspection of the FAA Form 5100-1, Airport Pavement Design, and the as-constructed sections, with modification for any material variations or deficiencies of record. Where age or visible distress indicates the original strength no longer exists, further modification should be applied on the basis of judgment or a combination of judgment and supplemental physical testing. For pavements that consist of sections not readily comparable to FAA design standards, evaluation should be based on FAA standards after material comparison and equivalencies have been applied. (2) Nondestructive Testing. Several methods of nondestructive testing (NDT) of pavements are available. For purposes of this discussion, NDT means observing pavement response to a controlled dynamic load, as in the case of the falling-weight deflectometer (FWD), or other physical stimulus such as a mechanical wave. NDT provides a means of evaluating pavements that tends to remove some of the subjective judgment needed in other evaluation procedures. AC 150/5370-11, Use of Nondestructive Testing Devices in the Evaluation of Airport Pavements, contains guidance on nondestructive testing. The major advantages of nondestructive testing are: the pavement is tested in place under actual conditions of moisture, density, etc.; the disruption of traffic is minimal; and the need for destructive tests is minimized. Research efforts are continuing in the area of nondestructive testing to broaden its application. Several different NDT procedures are available in addition to that described in AC 150/537011. These other procedures may be used when approved by the FAA. The common NDT tools available to assist the evaluator include: FWD, ground penetrating radar (GPR), infrared thermography, etc. (i) Falling Weight Deflectometer. Falling weight deflectometers impart an impulse load to the pavement with a free-falling weight. The magnitude of the dynamic load depends on the mass of the weight and the height from which it is dropped. The resulting deflections of the pavement surface are typically measured using an array of sensors. The Heavy Falling Weight Deflectometer (HWD) uses a greater dynamic load than FWD and may be more suitable for some airport applications. FWD and HWD can be used in conjunction with appropriate software to estimate pavement layer properties. AC 150/5370-11 gives guidance for the use of FWD and HWD equipment. 83 AC 150/5320-6E 9/30/2009 (ii) Ground Penetrating Radar. Ground penetrating radar can be useful in studying subsurface conditions nondestructively. Ground penetrating radar depends on differences in dielectric constants to discriminate between materials. The technique is sometimes used to locate voids or foreign objects, such as, abandoned fuel tanks, tree stumps, etc. in embankments. (iii) Infrared Thermography. Infrared thermography is a nondestructive testing procedure whereby differences in infrared emissions are observed allowing certain physical properties of the pavement to be determined. Infrared thermography is purportedly capable of detecting delaminations in bonded rigid overlay pavements and in reinforced rigid pavements. d. Pavement Condition Index. The determination of the Pavement Condition Index (PCI) is often a useful tool in the evaluation of airport pavements. The PCI is a numerical rating of the surface condition of a pavement and is a measure of functional performance with implications of structural performance. PCI values range from 100 for a pavement with no defects to 0 for a pavement with no remaining functional life. The index is useful in describing distress and comparing pavements on an equal basis. AC 150/5380-6, Guidelines and Procedures for Maintenance of Airport Pavements, contains information on PCI surveys. The FAA recommends that airports follow ASTM D 5340, Standard Test Method for Airport Pavement Condition Index Surveys. e. Evaluation Report. The analyses, findings, and test results should be incorporated in an evaluation report, which becomes a permanent record for future reference. While evaluation reports need not be in any particular form, it is recommended that a drawing identifying limits of the evaluation be included. Analysis of information gained in the above steps should culminate in the assignment of load carrying capacity to the pavement sections under consideration. When soil, moisture, and weather conditions conductive to detrimental frost action exist, an adjustment to the evaluation may be required. 602. FLEXIBLE PAVEMENTS. Evaluation of flexible pavements requires, as a minimum, the determination of the thickness of the component layers, and the CBR of the subgrade. a. Layer Thicknesses. The thickness of the various layers in the flexible pavement structure must be known in order to evaluate the pavement. Thicknesses may be determined from borings or NDT. As-built drawings and records can also be used to determine thicknesses if the records are sufficiently complete and accurate. b. Subgrade CBR. Laboratory CBR tests should be performed on soaked specimens in accordance with ASTM D 1883, Bearing Ratio of Laboratory-Compacted Soils. Field CBRs should be performed in accordance with the procedure given in The Asphalt Institute Manual Series 10 (MS-10), Soils Manual. Field CBR tests on existing pavements less than 3 years old may not be representative unless the subgrade moisture content has stabilized. The evaluation process assumes a soaked CBR is and will not give reliable results if the subgrade moisture content has not reached the ultimate in situ condition. In situations where it is impractical to perform laboratory or field CBR tests, a back calculated subgrade elastic modulus value may be obtained from NDT test results. AC 150/5370-11 gives the procedures for obtaining the back calculated modulus value. The FAARFIELD program assumes that CBR is related to the subgrade modulus as E = 1500xCBR (E in psi), so that the back calculated modulus value can be input directly into FAARFIELD without manually converting to CBR. c. Layer Properties. As stated in paragraph 303, in FAARFIELD materials are designated by corresponding FAA specifications. Where flexible pavements have been constructed to FAA standards, each layer should be assigned a material type corresponding to the appropriate FAA specification. For example, where an existing flexible pavement consists of an HMA surface on a high-quality crushed aggregate base meeting FAA Item P-209, the base layer should be input as P-209 Crushed Aggregate in FAARFIELD. Where the quality of materials in a pavement structure to be evaluated differ significantly from the assumptions for FAA standard materials as given in AC 150/537010B, it may be necessary to use the “undefined” or “variable” layer types in FAARFIELD to input an appropriate modulus value or use lower quality material to model structure (e.g., P-154 for P-209). 603. APPLICATION OF FLEXIBLE PAVEMENT EVALUATION PROCEDURES. After all of the evaluation parameters of the existing flexible pavement have been established using the guidance given in the above paragraphs, the evaluation process is essentially the reverse of the design procedure. The FAARFIELD program can be used to determine the structural life of the existing pavement for a given traffic mix, or alternatively, the allowable load of an airplane on a pavement structure that will produce a 20-year life for a given number of annual departures. Required inputs are the subgrade CBR or modulus value, thicknesses of surfacing, base and subbase courses and annual departure levels for all airplanes using the pavement. 84 9/30/2009 AC 150/5320-6E a. Example 1. An existing taxiway pavement was constructed to FAA standards and consists of a 5 inch (127 mm) HMA surface layer (Item P-401), 9 inch (229 mm) HMA stabilized base layer (Item P-403), and 24 inch (610 mm) crushed aggregate subbase layer (Item P-209). The subgrade was previously evaluated by field CBR measurements and found to be CBR 7. The taxiway will serve the following mix of airplanes: Airplane Name DC10-10 B747-200B Combi Mixed B777-200 ER B737-800 A320-100 Gross Weight, lbs (tonnes) 458,000 (207.7) 873,000 (396.0) 634,500 (287.8) 174,700 (79.2) 150,796 (68.4) Annual Departures 2263 832 425 8000 4380 FAARFIELD will be used to determine the available structural life based on the above traffic mixture. Both total thickness and base thickness will be checked. The following steps are used: (1) Enter the above airplane list using the Airplanes screen. (2) In the Structure screen, enter the layer thickness and material type for each layer (figure 6-1). (3) Click the “Life” button. The predicted life for the given structure and traffic is 155.2 years, which exceeds the 20-year requirement. Next, the adequacy of the stabilized base layer should be checked. This should be done by designing the P-401/P-403 stabilized base course for the required life in accordance with the procedures given in Chapter 3. For the load carrying capacity to be met, the minimum base course thickness requirement should be less than the existing base course thickness. In this example, the design procedure requires a stabilized base thickness of 6.25 (11/1.6) inches (159 mm) for the 20-year life, which is less than the existing 9 inches (229 mm). Therefore, an overlay would not be required to serve the anticipated traffic mix. FIGURE 6-1. EXAMPLE OF A FLEXIBLE PAVEMENT STRUCTURE FOR EVALUATION 85 AC 150/5320-6E 9/30/2009 b. Example 2. For the pavement in Example 1, but with a subgrade CBR = 3, FAARFIELD will be used to determine the allowable gross weight of a B737-800 airplane for a 20-year life. Assume 10,000 annual departures of the B737-800. (1) In the Airplanes screen, remove all airplanes except the B737-800. For annual departures, enter 10,000.In the Structure screen, enter the layer thickness and material type for each layer (figure 6-1). (2) Click the “Life” button to compute the predicted Structural Life. (3) Continue to modify the airplane gross weight until Structural Life = 20.0 years. (4) In this example, the gross weight of the B737-800 producing the 20-year life is 152,950 lbs. (69.4 tonnes). (5) For this gross weight, check the adequacy of the base layer, using the stabilized base design procedure given in Chapter 3. In this example, the design procedure requires a stabilized base thickness of 9.0 inches, which agrees with the existing structure. To support 10,000 annual departures of the B737-800 on the existing pavement structure, the gross weight should be limited to 152,950 lbs. (69.4 tonnes). If the airplane is to be operated at higher weights, this may cause a reduction in the structural life. 604. RIGID PAVEMENTS. Evaluation of rigid pavements requires, as a minimum, the determination of the thickness of the component layers, the flexural strength of the concrete, and the subgrade modulus. a. Layer Thicknesses. The thickness of the component layers is sometimes available from construction records. Where information is not available or of questionable accuracy, thicknesses may be determined by borings or test pits in the pavement. b. Concrete Flexural Strength. The flexural strength of the concrete is most accurately determined from test beams sawed from the existing pavement and tested in accordance with ASTM C 78. Quite often this method is impractical as sawed beams are expensive to obtain and costs incurred in obtaining sufficient numbers of beams to establish a representative sample is prohibitive. Construction records, if available, may be used as a source of concrete flexural strength data. The construction data may require adjustment due to the age of the concrete. Correlations between concrete flexural strength and other concrete strength tests are available. It should be noted that correlations between flexural strength and other strength tests are approximate and considerable variations are likely. An approximate relationship between concrete flexural strength and tensile splitting strength (ASTM C 496) exists and can be computed by the following formula: R 1.02T 117 where: R T = = flexural strength, psi tensile split strength, psi Note: For conversions in metric units the above formula remains the same, except the + 117 psi constant should be changed to + 0.81 MPa. c. Subgrade Modulus. The modulus of subgrade reaction, k, is ideally determined by plate bearing tests performed on the subgrade. These tests should be made in accordance with the procedures established in AASHTO T 222. An important part of the test procedure for determining the subgrade reaction modulus is the correction for soil saturation, which is contained in the prescribed standard. The normal application utilizes a correction factor determined by the consolidation testing of samples at in situ and saturated moisture content. For evaluation of older pavement, where evidence exists that the subgrade moisture has stabilized or varies through a limited range, the correction for saturation is not necessary. If a field plate bearing test is not practical, the modulus of subgrade reaction may be estimated by the formula in paragraph 205a(4) of this circular. Alternatively, a backcalculated subgrade elastic modulus value may be obtained from NDT test results. AC 150/5370-11 gives the procedures for obtaining the backcalculated modulus value. The FAARFIELD program assumes that k is related to the subgrade modulus as E = 26 k1.284 (E in psi), so that the back calculated E modulus value can be input directly into FAARFIELD without manually converting to k. d. Layer Properties. As stated in paragraph 303, in FAARFIELD materials are designated by corresponding FAA specifications. Where rigid pavements have been constructed to FAA standards, each layer should 86 9/30/2009 AC 150/5320-6E be assigned a material type corresponding to the appropriate FAA specification. For example, where an existing rigid pavement consists of a PCC surface on a cement stabilized base meeting FAA Item P-304, the base layer should be input as P-304 CTB in FAARFIELD. Where the quality of materials in a pavement structure to be evaluated differ significantly from the assumptions for FAA standard materials as given in AC 150/5370-10, it may be necessary to use the “undefined” or “variable” layer types in FAARFIELD to input an appropriate modulus value. In FAARFIELD, the number of structural layers above the subgrade for a rigid pavement is limited to 4, including the PCC surface. If the actual rigid pavement structure to be evaluated consists of more than 4 distinct layers, two or more of the lower layers can be combined to reduce the total number of layers to 4 or fewer for analysis. Since rigid pavement evaluation is not highly sensitive to modulus properties of lower layers above the subgrade, the life computation should not be significantly affected. 605. APPLICATION OF RIGID PAVEMENT EVALUATION PROCEDURES. After all of the evaluation parameters of the existing rigid pavement have been established using the guidance given in the above paragraphs, the evaluation process is essentially the reverse of the design procedure. The FAARFIELD program can be used to determine the structural life of the existing pavement for a given traffic mix, or alternatively, the allowable load of an airplane on a pavement structure that will produce a 20-year life for a given number of annual departures. The FAARFIELD program allows the back calculated E modulus value to be input directly. a. Example. An existing taxiway was constructed to FAA standards and consists of a 16 inch (406 mm) PCC surface layer (Item P-501), 8 inch (203 mm) stabilized base (Item P-304), and 10 inch (254 mm) granular subbase (Item P-154). The current concrete flexural strength was estimated from compressive tests on cores as 700 psi (4.83 MPa). The subgrade was evaluated by NDT testing and found to have an E-modulus of approximately 13,000 psi (89.6 MPa). The anticipated traffic mix is the same as the example in paragraph 603. FAARFIELD is used to evaluate the structural life as follows: (1) Enter the airplane list, including gross weights and annual departures, using the Airplanes screen. (2) In the Structure screen, enter the layer thickness and material type for each layer (figure 6-2). (3) Click the “Life” control button. The predicted life for the given structure and traffic is 28.2 years, which exceeds the 20-year requirement. FIGURE 6-2. EXAMPLE OF A RIGID PAVEMENT STRUCTURE FOR EVALUATION 87 AC 150/5320-6E 9/30/2009 606. USE OF RESULTS. If the evaluation is being used for planning purposes and the existing pavement is found to be deficient in accordance with the design standards given in Chapter 3 or 5, the sponsor should be notified as to the deficiency and consideration should be given to corrective action. If the evaluation is being used a part of the design for a project to reconstruct or upgrade the facility, the procedures given in Chapters 3,4, or 5 should be used to design the reconstruction or overlay project. In this instance the main concern is not the load carrying capacity but rather the difference between the existing pavement structure and the section that is needed to support forecast traffic. 607. REPORTING PAVEMENT STRENGTH. The International Civil Aviation Organization (ICAO) developed a standardized method of reporting airport pavement strength known as the Aircraft Classification Number/Pavement Classification Number (ACN/PCN). This method of reporting is based on the concept of reporting strength in terms of a standardized equivalent single wheel load. While FAARFIELD can be used to establish allowable airplane loads based on a given structure and airplane departure level (see Example 2 in paragraph 603), it is recommended that PCN calculations be based on the same method adopted by ICAO for calculating ACN. For this purpose, the FAA developed a software program, COMFAA, which computes ACN following the procedures specified by ICAO. AC 150/5335-5, Standardized Method of Reporting Airport Pavement Strength – PCN, provides guidance on reporting PCN using the COMFAA software. 88 9/30/2009 AC 150/5320-6E CHAPTER 7. PAVEMENT DESIGN FOR AIRFIELD SHOULDERS 700. PURPOSE. This chapter provides a design procedure for paved airfield shoulders. 701. APPLICATION. The design procedure for paved or surfaced shoulders applies to all airports that accommodate Design Group III or higher airplanes. 702. BACKGROUND. The need for paved or surfaced shoulders is created due to erosion and generation of debris from jet blast. As airplanes grew in size, so did the size of the airplane engines and their respective increase in jet thrust or jet blast. Jet blast can cause problems with erosion of unprotected soil immediately adjacent to airfield pavements. To mitigate this problem, the FAA recommends paved shoulders for runways, taxiway, and aprons that will accommodate Group III and higher airplanes. In addition to providing protection from jet blast, the shoulder must be capable of safely supporting “occasional” passage of the most demanding airplanes as well as emergency and maintenance vehicles. 703. PURPOSE OF DESIGN PROCEDURE. The procedure for shoulder pavement thickness design is intended to provide a minimum pavement structure to support limited operations of airplanes. The design is intended to provide sufficient support for unintentional or emergency operations of an airplane on the shoulder pavement. Use standard airfield pavement design requirements to design all areas of pavement where airplanes regularly operate. The minimum section provided by the shoulder pavement design procedure will not perform in the same fashion as full strength airfield pavements. The shoulder pavement is intended to allow safe operation of the airplanes across the paved area without damage to the airplanes. Flexible shoulder pavement sections may experience noticeable vertical movements with each passage of an airplane and may require inspection and/or limited repair after each operation. Rigid shoulder pavement sections may experience cracking with each operation. 704. REPORTING PAVED SHOULDER DESIGN. Summarize all paved shoulder designs on FAA Form 51001, Airport Pavement Design, which is considered par of the Engineer’s Design Report. Submit the Engineer’s Design Report for FAA review and approval along with initial plans and specifications. 705. DESIGN PROCEDURE. The design procedure is based upon the FAA pavement design software (FAARFIELD) and utilizes a modified design procedure to determine the most demanding airplane (MDA) for shoulder pavement design purposes. Several of the procedural assumptions in the standard pavement design (traffic distribution, pass-to-coverage ratios, etc.) are not valid and are not used for the shoulder pavement design procedure. The procedure determines the minimum pavement section required for the MDA, assuming a total of 10 departures. A composite traffic mixture is not considered for the shoulder design. The shoulder pavement design procedure determines the MDA by calculating pavement thickness requirements for all airplanes utilizing or expected to utilize the airport. The airplane requiring the thickest pavement section is considered the MDA. The following steps are used to complete the design procedure: a. Use the FAARFIELD software to create a new job file and proposed pavement section for the shoulder design. Include all desired pavement layers, e.g. surface course, base course, stabilized course, subbase course, etc. Adjust layer thickness to observe minimum thickness requirements for shoulder design. NOTE: Due to minimum pavement layer requirements in the formal airfield pavement design procedure, it may be necessary to use the “undefined” pavement layer to represent the proposed shoulder pavement cross-section. b. Input one airplane from the traffic mixture for analysis. (1) (2) c. Adjust airplane operating weights as appropriate. Change annual departures to 1.0 departure. Return to the Structure screen and confirm that the design period is 10 years. NOTE: The intent of this design procedure is to design a pavement for 10 total departures of the most demanding airplane. By setting annual departures to 1 and the design period to 10, the total departures are 10. d. Confirm the composition and thickness of pavement layers and that the correct layer is designated for thickness iteration. The iteration layer will be shown with a small arrow along the left side. Drainage from the adjacent 89 AC 150/5320-6E 9/30/2009 airfield pavement should be considered in the total thickness of the shoulder pavement section to avoid trapping water under the airfield pavement. A thicker shoulder section or sub-drain may be appropriate. e. Click on the “Design Structure” button to establish the minimum pavement section for the individual airplane. f. Repeat steps 1 through 5 for all airplanes in the traffic mixture. The pavement section with the greatest thickness requirement is the design for the shoulder pavement. EVALUATION AID: To reduce the list of individual airplanes requiring evaluation, include all airplanes from the airport traffic mixture and set annual departures of all airplanes to 1,200 annual departures. Create the proposed shoulder pavement section in the structure screen, then click the “Life” button instead of the “Design Structure” button. Return to the airplane mixture, and scroll over to the column labeled “CDF Max for Airplanes”. The airplane with the highest CDF Max value will be the most demanding airplane in most instances and will control the shoulder design. However, the top few airplanes with the highest CDF Max values should be evaluated because the thickness of the pavement section being evaluated will influence which airplane is the most demanding. 706. PAVEMENT LAYER THICKNESS AND MATERIAL REQUIREMENTS. a. Asphalt Surface Course Materials. The minimum recommended thickness for asphalt surfacing material is 3 inches (76 mm). The material should be of high quality, similar to FAA Item P-401, and compacted to an average target density of 93 percent of maximum theoretical density. Material produced for use with high traffic volume highway pavement is acceptable provided the compaction specified for the highway application is obtained. b. Portland Cement Concrete Surface Course Materials. The minimum recommended thickness for rigid pavement design is 6 inches. Portland Cement Concrete (PCC) must be a high quality, durable material capable of resisting deterioration due to environmental factors. The PCC should be similar to FAA Item P-501, with a minimum design flexural strength of 600 psi (4.14 MPa). Material produced for use with high traffic volume highway pavement is acceptable provided that environmental durability is addressed. c. Base Course Materials. Base course materials must be high quality crushed stone or stabilized materials similar to FAA Items P-208, P-209, P-301, or P-304. Materials produced for use with high traffic volume highway pavement may be acceptable provided they possess qualities similar to the FAA specification items. Crushed stone material must possess a minimum CBR value of 80. The recommended minimum thickness of the base course material is 6 inches. The minimum base course thickness may be reduced to 4 inches (102 mm) by increasing the minimum asphalt thickness by 1 inch (25.4 mm). Place base course material in accordance with the appropriate standard from AC 150/5370-10 or in accordance with the applicable State Highway standard. Additional consideration should be given to frost heave susceptibility of the material when used in frost-susceptible zones. d. Subbase Course Materials. Subbase course material must provide a minimum CBR value of 20. Materials produced by State Highway standards are acceptable provided the minimum CBR value is obtained. Place subbase course material in accordance with AC 150/5370-10, Item P-154, or in accordance with the applicable State Highway standard. Additional consideration should be given to frost heave susceptibility of the material when used in frost susceptible zones. The minimum recommended thickness is 4 inches (102 mm). See paragraph 707 below. e. Subgrade Materials. Preparation of subgrade materials should be in accordance with AC 150/5370-10, Item P-152. 707. EMERGENCY AND MAINTENANCE VEHICLE CONSIDERATIONS. In most cases, the pavement design selected by the shoulder design procedure should provide sufficient strength for unlimited operations of maintenance and emergency vehicles. If high operations of these vehicles are anticipated, the shoulder design should be verified for all anticipated service other than airplane usage. 708. AREAS SUSCEPTIBLE TO FROST HEAVE. In areas prone to frost heave, it may be necessary to increase the thickness of the shoulder pavement to avoid differential frost heave. Additional thickness of the pavement beyond that necessary for structural design may be achieved with any material suitable for pavement construction. The material should possess a CBR value higher than the subgrade and have non-frost susceptible properties. Place the additional layer immediately on the subgrade surface below all base and subbase layers. The FAA recommends limited subgrade frost protection in accordance with paragraph 307a(2). 90 9/30/2009 AC 150/5320-6E APPENDIX 1. ECONOMIC ANALYSIS 1. BACKGROUND. The information presented in this appendix was developed from research report DOT/FAARD-81/078. The cost data used are probably not current. However, the principles and procedures are applicable. An example is given for illustrative purposes. 2. ANALYSIS METHOD. a. Present worth or present value economic analyses are considered the best methods for evaluating airport pavement design or rehabilitation alternatives. A discount rate of 4 percent is suggested together with an analysis period of 20 years. Residual salvage values should be calculated on the straight-line depreciated value of the alternative at the end of the analysis period. The initial cost and life expectancy of the various alternatives should be based on the engineer’s experience with consideration given to local materials, environmental factors, and contractor capability. b. The basic equation for determining present worth is shown below: n i m 1 1 PW C M i S 1 r 1 r i 1 z where: PW = Present Worth C = Present Cost of initial design or rehabilitation activity m = Number of maintenance or rehabilitation activities Mi = Cost of the ith maintenance or rehabilitation alternative in terms of present costs, i.e., constant dollars r = Discount rate (four percent suggested) ni = Number of years from the present of the ith maintenance or rehabilitation activity S = Salvage value at the end of the analysis period Z = Length of analysis period in years. The official FAA design period is 20 years. Design periods other than 20 years must be approved by the FAA. The term 1 1 r n is commonly called the single payment present worth factor in most engineering economic textbooks. From a practical standpoint, if the difference in the present worth of costs between two design or rehabilitation alternatives is 10 percent or less, it is normally assumed to be insignificant and the present worth of the two alternatives can be assumed to be the same. 3. STEP BY STEP PROCEDURE. The information presented in this appendix is intended to demonstrate how to calculate cost comparisons for airport pavement alternatives using the present worth method. The following is a step by step procedure illustrating the analysis method. a. Identify and record key project descriptions, such as— (1) (2) (3) (4) (5) b. Project Number and Location Type of Facility Design Aircraft Annual Departure of Design Aircraft Subgrade Strength If appropriate, determine the condition of existing pavement and record data, such as— (1) (2) Existing Pavement Layers (thicknesses, etc.) Condition of Pavement (description of distress, pavement condition index, PCI, see AC (3) (4) Skid Resistance Required Thickness of New Pavement 150/5380-6, etc.) c. Identify what feasible alternatives are available. 91 AC 150/5320-6E d. 9/30/2009 Determine costs associated with each feasible alternative in terms of present day costs. (1) (2) (3) e. f. alternative. Initial Cost Maintenance Future Rehabilitation Calculate life-cycle cost for each alternative to be evaluated. Summarize life-cycle costs, length of time required to perform and the chance for success for each g. Evaluated the most promising alternatives based on costs, time required, operational constraints, chance for success, etc. h. If the selection cannot be narrowed to one alternative in the evaluation process, the most promising alternatives should each be bid and the selection made on the basis of the lowest bid. 4. EXAMPLE PROBLEM – LIGHT-LOAD GENERAL AVIATION AIRPORT. An example problem is discussed below that illustrates the use of the present worth life-cycle costing techniques described above. a. A general aviation airport runway is in need of rehabilitation. The existing pavement contains alligator, transverse: and longitudinal cracking. The design aircraft for the facility has a gross weight of 24,000 pounds (10 890 kg). Using the procedures in Chapter 5 of this circular, a 3 inch (76 mm) thick bituminous overlay is required to rehabilitate the pavement. Pertinent data are presented in the Project Summary. PROJECT SUMMARY Location Design Aircraft Number - A.I.P Annual Departures of Design Aircraft: Type of Facility Runway Subgrade Strength Runway length Runway Width Muddville, TX 24,000 lbs. (10 890 kg) 12-34-567 3,000 General Aviation CBR = 4 3,200 ft (75 m) 75 ft (23 m) Existing Pavement: Layer and Type Thickness AC Surface 4 in. (102 mm) Untreated Base 10 in (254 mm) Condition of Existing Pavement Alligator cracking, moderate 15% of area Condition Survey Trans. cracking, moderate, 350’/station Long. cracking, moderate, 400’/station PCI = 35 Skid Resistance Good Required Thickness New Pavement Total Thickness Required 18 in. (487 mm) Surface Layer 2 in. (51 mm) Base Layer 5 in. (127 mm) Subbase Layer 11 in. (279 mm) Condition Poor Good b. Seven rehabilitation alternatives, including surface, in-place, and hot-mix recycling, are considered feasible. The alternatives under consideration are— (1) (2) (3) (4) (5) (6) (7) 92 Asphalt-rubber chip seal to delay overlay Full width 3-inch (76 mm) direct overlay Surface recycle l-inch (25 mm) deep + 2-inch (5 1 mm) overlay Asphalt-rubber interlayer + 3-inch (76 mm) overlay Fabric interlayer + 3-inch (76 mm) overlay Cold recycle with asphalt emulsion 6-inch (152 mm) deep + 2-inch (51 mm) overlay Hot recycle and re-work base 9/30/2009 c. AC 150/5320-6E The present day costs of various activities associated with these alternatives are estimated as shown in table 1. TABLE 1. COSTS OF REHABILITATION ACTIVITIES Rehabilitation Activity Asphalt-Rubber Chip Seal Asphalt-Rubber Interlayer Fabric Interlayer Surface Recycling Asphaltic Concrete - 1 in. (25 mm) Cold Recycle + 2 in. (5 1 mm) Overlay Hot Recycle + Rework Base $/yd 1.25 1.25 1.20 0.90 1.65 6.60 8.10 Cost $/m2 (1.50) (1.50) (1.44) (1.08) (1.97) (7.89) (9.69) d. The life-cycle costs for each alternative are calculated. This example shows the calculations for only one alternative, the asphalt-rubber chip seal. The calculations are shown in table 2. Some of the important aspects of this analysis are discussed further below. TABLE 2. PRESENT WORTH LIFE-CYCLE COSTING EXAMPLE 1. ALTERNATIVE 1. ASPHALT-RUBBER CHIP SEAL Year Cost $/yd2 Present Worth Factor 4% Present Worth Dollars 0 A-R Chip Seal 1.25 1.0000 1.25 1 0.9615 2 0.9246 3 Maintenance 0.25 0.8890 0.22 4 3” Overlay 4.95 0.8548 4.23 5 0.8219 6 0.7903 7 0.7599 8 0.7307 9 0.7026 10 Maintenance 0.10 0.6756 0.07 11 Maintenance 0.10 0.6496 0.06 12 Maintenance 0.10 0.6246 0.06 13 Maintenance 0.10 0.6006 0.06 14 Maintenance 0.25 0.5775 0.14 15 1-1/2″ Overlay 2.48 0.5553 1.38 16 0.5339 17 0.5134 18 0.4936 19 Maintenance 0.10 0.4746 0.05 20 Maintenance 0.15 0.4564 0.07 Sub Total 9.83 Salvage Value -0.71 0.4564 -0.32 Total 9.12 7.3 Note: To convert from $/yd2 to $/m2, divide by 0.8361 (1) The asphalt-rubber chip seal is estimated to delay the need for an overlay for 4 years. In the third year, the asphalt-rubber chip seal will need maintenance costing $0.25/yd2 ($0.29/m2). (2) In the fourth year, a 3-inch (76 mm) overlay will be required. This overlay will require maintenance starting in the 10th year and will require progressively more maintenance as time goes on. In the 14th year maintenance will reach $0.25/yd2 ($0.29/m2). (3) In the 15th year, a l.5-inch (38mm) leveling course will be required. This leveling course will not require maintenance until the 19th year. Maintenance costs begin to escalate again as time goes on. 93 AC 150/5320-6E 9/30/2009 (4) The 20th year marks the end of the analysis period. The salvage value of the leveling course is: the ratio of the life remaining/to how long it will last; multiplied by its costs. The leveling course, constructed in the 15th year, is expected to have a life of 7 years. It was used for only 5 years during the analysis period. Thus, the leveling course had 2 years of life remaining at the end of the analysis period. The salvage value is 2/7 x $2.48 = $0.71. Discounting the salvage value to the 20th year yields a salvage value of $0.32. Since the salvage value is an asset rather than a cost, it is shown as a negative cost in table 2. All other activities are assumed to have no salvage value since their useful lives have been exhausted during the analysis period. In this example, a discount rate of 4 percent was assumed. The present worth calculations for the other six alternatives should be calculated in a similar fashion. e. A final summary of all alternatives considered in this example is shown in table 3. This summary shows initial costs, life-cycle costs, construction times, and the probability for success in percent. This final summary is a convenient method of presenting all alternatives for evaluation. In this example a discount rate of 4 percent was used in all calculations. Maintenance and need for rehabilitation in future years are the engineer’s estimates. TABLE 3. SUMMARY OF ALTERNATIVES First Cost $/yd2 Alternatives #1 Asphalt-Rubber Chip Seal 1.25 #2 Asphalt-Rubber Interlayer 4.95 #3 Fabric Interlayer 4.20 #4 Surface Recycling 6.20 #5 Asphaltic Concrete - 1 in. (25 mm) 6.15 #6 Cold Recycle + 2 in. (5 1 mm) Overlay 6.60 #7 Hot Recycle + Rework Base 8.10 Note: To convert from $/yd2 to $/m2, divide by 0.8361 a. Present Worth Life Cycle $/yd2 7.30 7.29 6.22 7.39 7.74 7.41 8.46 Time 2 days 5 days 4 days 4 days 4 days 6 days 6 days Chance for Success % 90 95 97 97 97 97 99 Comparing and ranking the various alternatives shown in table 3 yields the following results: TABLE 4. COMPARATIVE RANKING OF ALTERNATIVES First Cost #1 #3 #2 #5 #4 #6 #7 Life-Cycle Cost #3 #2 #1 #4 #6 #5 #7 Time #1 #3 #4 #5 #2 #6 #7 Chance for Success #7 #3 #4 #5 #6 #2 #1 The average life-cycle cost of all 7 alternatives is $7.40/yd2 ($8.85/m2). Adding and subtracting 10 percent to the average lifecycle cost yields a range of $6.66/yd2 to $8.14/yd2 ($7.97/m2 to $9.74/m2). Alternative #3, surface recycling with an overlay, is lowest in life-cycle costs. Life-cycle costs for alternatives #1, 3, 4, 5, and 6 are within the 10 percent range of the average cost. Alternative #7 is the most costly and exceeds 10 percent of the average cots. Alternative #3 appears to be the most promising as it ranks high in three of the four categories considered. The decision to select alternative #3 must consider the availability of contractors capable of performing surface recycling and the time required for completion. 5. SUMMARY. This appendix presents an economic procedure for evaluating a wide variety of airport pavement design strategies. While the design example addresses a rehabilitation project, the principles are applicable to designs of new pavements as well. Cost data used in the example are out of date and should be updated with more current local costs before individual evaluations leading to strategy selection are undertaken. Whenever possible, local costs should be used in all alternative analyses as local conditions sometimes vary considerably from broad overall averages. 94 9/30/2009 AC 150/5320-6E APPENDIX 2. ORDER 5300.7 U.S. DEPARTMENT OF TRANSPORTATION FEDERAL AVIATION ADMINISTRATION ORDER 5300.7 Effective Date: October 6, 2005 SUBJ: Standard Naming Convention for Aircraft Landing Gear Configurations 1. Purpose of This Order. This Order establishes a standard convention for naming and characterizing aircraft landing gear configurations. Although this order is primarily directed at fixed wing airplanes, it is applicable to any aircraft using wheels for landing purposes. 2. Who This Order Affects. This Order impacts divisions in the Offices of Planning and Programming, Airport Safety and Standards, Air Traffic, Airway Facilities, and Flight Standards Services; the regional Airports, Air Traffic, Airway Facilities, and Flight Standards Divisions; and Airport District and Field Offices. It will also affect organizations and individuals external to the Federal Aviation Administration (FAA). A standardized naming convention will allow uniformity and consistency among Federal agencies and external entities when naming aircraft gear configurations. Pilots and airport operators will no longer need to learn multiple naming systems and will be able to use common aircraft landing gear names at all military and commercial facilities. 3. Background of This Order. Landing gear configuration and aircraft gross weight are an integral part of airfield pavement design and are often used to characterize pavement strength. Historically, most aircraft used relatively simple gear geometries such as a single wheel per strut or two wheels side by side on a landing strut. As aircraft became larger and heavier, they required additional wheels to prevent individual wheel loads from introducing excessively high stresses into the pavement structure. For economy and efficiency reasons, aircraft manufacturers added more wheels per landing strut whenever possible. This often led to groups of wheels placed side-by-side and in tandem configurations. a. Typical Gear Configurations. Up until the late 1980s, the majority of civilian and military aircraft used three basic gear configurations: the “single wheel” (one wheel per strut), the “dual wheel” (two wheels side by side on a strut), and the “dual tandem” (two wheels side by side followed by two additional side-by-side wheels). As aircraft continued to increase in gross weight, manufacturers attempted to limit the damage imparted to pavements by increasing the total number of wheels. This was typically done by adding additional landing struts to the aircraft. For example, McDonnell Douglas originally manufactured the DC-10 with two landing struts using the dual tandem gear configuration. When the company produced the heavier DC-10-30 variation of the aircraft, it added an additional landing strut, using a dual wheel configuration, to the center of the aircraft. Another example is the Boeing 747 aircraft. To reduce the impact to airfield pavements, Boeing used four landing struts with dual tandem configurations on the B-747. b. Complex Gear Configurations. The increasingly complex gear arrangements quickly outgrew the simple single, dual, and dual tandem descriptions. Additionally, other aircraft were developed with gear configurations that used numerous wheels in arrangements that could not be described by the three simple gear configurations. As the number and complexity of gear arrangements increased and with no coordinated effort to provide a uniform naming convention, the FAA, U.S. Air Force, and U.S. Navy developed different naming systems that were not easily crossreferenced. 4. Definitions Used in This Order. a. Main Gear. “Main gear” means the primary landing gear that is symmetrical on either side of an aircraft. When multiple landing gears are present and are not in line with each other, the outer most gear pair is considered the main gear. Multiples of the main gear exist when a gear is in line with other gears along the longitudinal axis of the aircraft. 95 AC 150/5320-6E 9/30/2009 b. Body/Belly Gear. “Body/belly gear” refers to an additional landing gear or gears in the center portion of the aircraft between the main gears. Body/belly gears may be of a different type than the main gear and may be nonsymmetrical. 5. Intended areas of use. The naming convention shown in Figure 1 is intended for use in all civilian and military applications. All FAA pavement design guidance and FAA databases and database publications, e.g. 5010 Master Record, Airport/Facilities Directory, etc., will hereafter use the described aircraft gear naming convention. The Air Force and Navy will also adopt this system in their pavement guidance and facilities databases. 6. Aircraft Gear Geometry Naming Convention. a. Basic Name for Aircraft Gear Geometry. Under the naming convention, abbreviated aircraft gear designations may include up to three variables: the main gear configuration, the body/belly gear configuration if body/belly gears are present, and an optional tire pressure code described below. Figure 1 illustrates the two primary variables. b. Basic Gear Type. Gear type for an individual landing strut is determined by the number of wheels across a given axle (or axle line) and whether wheels are repeated in tandem. There may exist, however, instances in which multiple struts are in close proximity and are best treated as a single gear, e.g. Antonov AN-124 (see Figure 14). If body/belly gears are not present, the second portion of the name is omitted. For aircraft with multiple gears, such as the B-747 and the A380, the outer gear pair is treated as the main gear. c. Basic Gear Codes. This naming convention uses the following codes for gear designation purposes (see Figure 2): S Single D Dual T Triple Q Quadruple d. Use of Historical Tandem Designation. Although the verbal description continues to use the term “tandem” to describe tandem gear configurations, the tandem designation “T” no longer appears in the gear name. “T” now indicates triple wheels. Body/Belly Gear Designation Main Gear Designation #X#/#X# Number of gear types in tandem Gear type, e.g. S, D, T, or Q Number of main gears in line on one side of the airplanes Total number of body/belly gears Gear type, e.g. S, D, T, or Q Number of gear types in tandem Figure 1. Aircraft Gear Naming Convention e. Main Gear Portion of Gear Designation. The first portion of the aircraft gear name comprises the main gear designation. This portion may consist of up to three characters. The first character indicates the number of tandem sets or wheels in tandem, e.g. 3D = three dual gears in tandem. (If a tandem configuration is not present, the leading value of “1” is omitted.) Typical names are S = Single, 2D = two dual wheels in Tandem, 5D = five dual wheels in tandem, and 2T = two triple wheels in tandem. (1) The second character of the gear designation indicates the gear code, e.g. S, D, T, or Q. 96 9/30/2009 AC 150/5320-6E (2) The third character of the gear designation is a numeric value that indicates multiples of gears. For the main gear, the gear designation assumes that the gear is present on both sides (symmetrical) of the aircraft and that the reported value indicates the number of gears on one side of the aircraft. A value of 1 is used for aircraft with one gear on each side of the airplane. For simplicity, a value of 1 is assumed and is omitted from the main gear designation. Aircraft with more than one main gear on each side of the aircraft and where the gears are in line will use a value indicating the number of gears in line. For example, the Ilyushin IL-76 has two gears containing quadruple wheels on each side of the aircraft and is designated as a Q2 (see Figure 20). f. Body/Belly Gear Portion of Gear Designation. The second portion of the aircraft gear name is used when body/belly gears are present. If body/belly gears are present, the main gear designation is followed by a forward slash (/), then the body/belly gear designation. For example, the B-747 aircraft has a two dual wheels in tandem main gear and two dual wheels in tandem body/belly gears. The full gear designation for this aircraft is 2D/2D2. The body/belly gear designation is similar to the main gear designation except that the trailing numeric value denotes the total number of body/belly gears present, e.g. 2D1 = one dual tandem body/belly gear; 2D2 = two dual tandem body/belly gears. Because body/belly gear arrangement may not be symmetrical, the gear code must identify the total number of gears present, and a value of 1 is not omitted if only one gear exists. g. Extension of Naming Convention. Future aircraft might require additional body/belly gears that are nonsymmetrical and/or nonuniform. In these instances, the body/belly gear designation will contain a hyphen to indicate the nonuniform gear geometry. For demonstration purposes, consider adding one dual wheel body/belly gear to the existing 2D/2D2 gear configuration. The resulting gear name would be 2D/2D2-D. h. Unique Gear Configurations. The Lockheed C-5 Galaxy has a unique gear type and is difficult to name using the proposed method. This aircraft will not be classified using the new naming convention and will continue to be referred to directly as the C5. Gear configurations such as those on the Boeing C-17, Antonov AN-124, and Ilusyin IL76 might also cause some confusion; see Figures 8, 14, and 20, respectively. In these cases, it is important to observe the number of landing struts and the proximity of the struts. In the case of the AN-124, it is more advantageous to address the multiple landing struts as one gear, i.e. 5D or five duals in tandem, rather than use D5 or dual wheel gears with five sets per side of the aircraft. Due to wheel proximity, the C-17 gear is more appropriately called a 2T as it appears to have triple wheels in tandem. In contrast, the IL-76 has considerable spacing between the struts and should be designated as a Q2. i. Examples of Gear Geometry Naming Convention. Figure 2 provides examples of generic gear types in individual and multiple tandem configurations. Figures 3 through 20 provide examples of known gear configurations. j. Comparison of Naming Convention to Historical Procedures. Table 3 demonstrates the proposed naming convention and references the historic FAA, U.S. Air Force, and U.S. Navy methods. The historic Air Force methodology also addresses the configuration of the aircraft nose gear. Due to the insignificance of the pavement load imposed by the nose gear, the proposed method does not address nose gear configuration. k. Inclusion of Tire Pressure Information. In addition to specifying gear geometry, the aircraft gear designation can also indicate the tire pressures at which the aircraft operates. Although tire pressure effects on airfield pavements are secondary to aircraft load and wheel spacing, they can have a significant impact on the ability of the pavement to accommodate a specific aircraft. (1) The Aircraft Classification Number (ACN) and the Pavement Classification Number (PCN) system created by the International Civil Aviation Organization (ICAO) has defined and categorized aircraft tire pressures into four groups for reporting purposes. Table 1 lists these groups and their assigned codes. Table 1. Standard Tire Pressure Categories Range Category High Medium Low Very Low psi No limit 146 - 217 74 - 145 0 - 73 MPa No Limit 1.01 - 1.5 0.51 - 1.0 0.0 - 0.5 Code Designation W X Y Z (2) To allow for the reporting of tire pressure, the gear naming convention includes a third variable. Using the codes identified by the International Civil Aviation Organization (ICAO), the tire pressure can be included in 97 AC 150/5320-6E 9/30/2009 parentheses after the standard gear nomenclature. Table 2 provides sample gear names with and without the additional tire pressure code. Table 2. Sample Gear Names With and Without Tire Pressure Codes Gear Name Without Tire Pressure S 2S 2D/2D1 Q2 2D/3D2 98 Gear Name With Tire Pressure S(W) 2S(X) 2D/2D1(Z) Q2(Y) 2D/3D2(Z) 9/30/2009 AC 150/5320-6E Table 3. Proposed Naming Convention with Historical FAA, U.S. Air Force, and U.S. Navy Nomenclatures 99 AC 150/5320-6E Single S 2 Singles in Tandem 2S 3 Singles in Tandem 3S 9/30/2009 Dual D 2 Duals in Tandem 2D 3 Duals in Tandem 3D Triple T 2 Triples in Tandem 2T 3 Triples in Tandem Quadruple Q 2 Quadruples in Tandem 2Q 3 Quadruples in Tandem Figure 2. Generic Gear Configurations. Increase numeric value for additional tandem axles. 100 9/30/2009 AC 150/5320-6E Figure 3. S - Single Wheel Main Gear with Single Wheel Nose Gear Figure 4. S - Single Wheel Main Gear with Dual Wheel Nose Gear Figure 5. D - Dual Wheel Main Gear with Single Wheel Nose Gear Figure 6. D - Dual Wheel Main Gear with Dual Wheel Nose Gear Figure 7. 2S - Two Single Wheels in Tandem Main Gear with Dual Wheel Nose Gear, Lockheed C-130 Figure 8. 2T - Two Triple wheels in Tandem Main Gear with Dual Wheel Nose Gear, Boeing C-17 101 AC 150/5320-6E Figure 9. 2D - Two Dual Wheels in Tandem Main Gear with Dual Wheel Nose Gear 9/30/2009 Figure 10. 2D/D1 - Two Dual Wheels in Tandem Main Gear/Dual Wheel Body Gear with Dual Wheel Nose Gear, McDonnell Douglas DC-10, Lockheed L1011 Figure 11. 2D/2D1 Two Dual Wheels in Tandem Main Gear/Two Dual Wheels in Tandem Body Gear with Dual Wheel Nose Gear, Airbus A340-600 Figure 12. 2D/2D2 - Two Dual Wheels in Tandem Main Gear/Two Dual Wheels in Tandem Body Gear with Dual Wheel Nose Gear, Boeing B-747 Figure 13. 3D - Three Dual Wheels in Tandem Main Gear with Dual Wheel Nose Gear, Boeing B-777 102 9/30/2009 Figure 14. 5D - Five Dual Wheels in Tandem Main Gear with Quadruple Nose Gear, Antonov AN-124 Figure 16. 2D/3D2 - Two Dual Wheels in Tandem Main Gear/Three Dual Wheels in Tandem Body Gear with Dual wheel Nose Gear, Airbus A380 AC 150/5320-6E Figure 15. 7D - Seven Dual Wheels in Tandem Main Gear with Quadruple Nose Gear, Antonov AN-225 Figure 17. C5 - Complex Gear Comprised of Dual Wheel and Quadruple Wheel Combination with Quadruple Wheel Nose Gear, Lockheed C5 Galaxy 103 AC 150/5320-6E Figure 18. D2 - Dual Wheel Gear Two Struts per Side Main Gear with No Separate Nose Gear (note that single wheel outriggers are ignored), Boeing B-52 Bomber David L. Bennett Director of Airport Safety and Standards 104 9/30/2009 Figure 20. Q2 - Quadruple Wheels Two Struts per Side with Quadruple Nose Gear, Ilyushin IL-76 9/30/2009 AC 150/5320-6E APPENDIX 3. DESIGN OF STRUCTURES FOR HEAVY AIRPLANES 1. BACKGROUND. Airport structures such as culverts and bridges are usually designed to last for the foreseeable future of the airport. Information concerning the landing gear arrangement of future heavy airplanes is speculative. It may be assumed with sufficient confidence that strengthening of pavements to accommodate future airplanes can be performed without undue problems. Strengthening of structures, however, may prove to be extremely difficult, costly, and time-consuming. Point loadings on some structures may be increased; while on overpasses, the entire airplanes weight may be imposed on a deck span, pier, or footing. 2. RECOMMENDED DESIGN PARAMETERS. a. Structural Considerations. For many structures the design is highly dependent upon the airplane landing gear configuration. Our assessment indicates that three basic configurations, shown in figure 1, will, if all are considered in the design of the bridge components, provide sufficient support for any airplane which may be forthcoming. These consist of two areas enclosing eight wheels each, or 16 wheels per airplane comprising the main gear. Nose gears, as such, are not considered, except as they occur in the static load. The “area” dimensions are 6 to 8 feet by 20 feet (2-3 m by 6 m) each supporting half of the airplane gross weight. Wheel prints are uniformly spaced within their respective areas. b. Foundation Design. Foundation design will vary with soil type and depth. No departure from accepted methodology is anticipated; except that for shallow structures, such as inlets and culverts, the concentrated loads may require heavier and wider spread footings than those presently provided by the structural standards in current use. For buried structures, such as culverts, the following guidance from AASHTO is recommended. (1) When the depth of fill is less than 2 feet, the wheel loads will be treated as concentrate loads. (2) When the depth of fill is 2 feet or more, wheel loads will be considered as uniformly distributed over a square with sides equal to l-3/4 times the depth of the fill. When such areas from several concentrations overlap, the total load will be uniformly distributed over the area defined by the outside limits of the individual areas, but the total width of distribution will not exceed the total width of the supporting slab. c. Loads. It should be noted that all loads discussed herein are to be considered as dead load plus live loads. The design of structures subject to direct wheel loads should also anticipate braking loads as high as 0.7 G (for no-slip brakes). d. Direct Loading. Decks and covers subject to direct heavy airplane loadings such as manhole covers, inlet grates, utility tunnel roofs, bridges, etc., should be designed for the following loadings: (1) Manhole covers for 100,000 lb. (45 000 kg) wheel loads with 250 psi (1.72 MPa) tire pressure. (2) For spans of 2 feet (0.6 m) or less in the least direction, a uniform live load of 250 psi (1.72 MPa). (3) For spans of 2 feet (0.6 m) or greater in the least direction, the design will be based on the number of wheels which will fit the span. Wheel loads of 50,000 to 75,000 pounds (22 700 to 34 000 kg) should be considered. (4) Special consideration will be given to structures that will be required to support both in-line and diagonal traffic lanes, such as diagonal taxiways or apron taxi routes. If structures require expansion joints, load transfer may not be possible. 105 AC 150/5320-6E FIGURE 1. TYPICAL GEAR CONFIGURATION FOR DESIGN OF STRUCTURES 106 9/30/2009 9/30/2009 AC 150/5320-6E APPENDIX 4. RELATED READING MATERIAL Electronic copies of the latest versions of the following FAA publications are available on the FAA website. Printed copies can be requested from the Department of Transportation, Subsequent Distribution Office, Ardmore East Business Center, 3341 Q 75th Ave, Landover, MD 20785. The Department of Transportation, however, will charge a fee for some of these documents. The following advisory circulars and orders are available for download on the FAA website (http://www.faa.gov): 1. AC 150/5300-9, Predesign, Prebid, and Preconstruction Conferences for Airport Grant Projects. 2. AC 150/5300-13, Airport Design. 3. AC 150/5320-5, Surface Drainage Design. 4. AC 150/5320-12, Measurement, Construction and Maintenance of Skid Resistance Airport Pavement Surfaces. 5. AC 150/5320-17, Airfield Pavement Surface Evaluation and Rating Manual. 6. AC 150/5335-5, Standardized Method of Reporting Airport Pavement Strength-PCN. 7. AC 150/5340-30, Design and Installation Details for Airport Visual Aids. 8. AC 150/5370-10, Standard for Specifying Construction of Airports. 9. AC 150/5370-11, Use of Nondestructive Testing Devices in the Evaluation of Airport Pavement. 10. AC 150/5370-14, Hot Mix Asphalt Paving Handbook. 11. AC 150/5380-6, Guidelines and Procedures for Maintenance of Airport Pavements. 12. Order 5300.7, Standard Naming Convention for Aircraft Landing Gear Configurations. Copies of the following technical reports may be obtained from the National Technical Information Service, 5285 Port Royal Road, Springfield, VA 22161 (http://www.ntis.gov): 13. DOT/FAA/AR-04/46, Operational Life of Airport Pavements, by Garg, Guo, and McQueen, December 2004. 14. FAA-RD-73-169, Review of Soil Classification Systems Applicable to Airport Pavement Design, by Yoder, May 1974; AD-783-190. 15. FAA-RD-73-198, Vol. 1, Comparative Performance of Structural Layers in Pavement Systems. Volume I. Design, Construction, and Behavior under Traffic of Pavement Test Sections, by Burns, Rone, Brabston , and Ulery, June 1974; AD-0785-024. 16. FAA-RD-73-198, Vol. 3, Comparative Performance of Structural Layers in Pavement Systems, Volume III: Design and Construction of MESL, by Hammitt, December 1974; ADA-005-893. 17. FAA-RD-74-030, Design of Civil Airfield Pavement for Seasonal Frost and Permafrost Conditions, by Berg, October 1974; ADA-006-284. 18. FAA-RD-74-033, Vol. 3, Continuously Reinforced Concrete Airfield Pavement. Volume III. Design Manual for Continuously Reinforced Concrete Pavement, by Treybig, McCullough, and Hudson, May 1974; AD0780-512. 19. FAA-RD-74-036, Field Survey and Analysis of Aircraft Distribution on Airport Pavements, by Ho Sang, February 1975; ADA-011-488. 20. FAA-RD-74-039, Pavement Response to Aircraft Dynamic Loads. Volume II. Presentation and Analysis of Data, by Ledbetter, September 1975, ADA-022-806. 21. FAA-RD-74-199, Development of a Structural Design Procedure for Flexible Airport Pavements, by Barker, and Brabston, September 1975; ADA-019-205. 107 AC 150/5320-6E 9/30/2009 22. FAA-RD-75-110, Vol. 2, Methodology for Determining, Isolating, and Correcting Runway Roughness, by Seeman, and Nielsen, June 1977; ADA-044-328. 23. FAA-RD-76-066, Design and Construction of Airport Pavements on Expansive Soils, by McKeen, June 1976; ADA-028-094. 24. FAA-RD-76-179, Structural Design of Pavements for Light Aircraft, by Ladd, Parker, and Pereira, December 1976; ADA-041-300. 25. FAA-RD-77-81, Development of a Structural Design Procedure for Rigid Airport Pavements, by Parker, Barker, Gunkel, and Odom, April 1979; ADA-069-548. 26. FAA-RD-81-078, Economic Analysis of Airport Pavement Rehabilitation Alternatives – An Engineering Manual, by Epps, and Wootan, October 1981; ADA-112-550. 27. FAA-PM-84/14, Performance of airport pavements under high traffic intensities. 28. DOT/FAA/PM-85115, Validation of Procedures for Pavement Design on Expansive Soils, by McKeen, July 1985; ADA-160-739. 29. FAA-PM-87/19, Design of Overlays for Rigid Airport Pavements, by Rollings, April 1988, ADA-194-331. Copies of ASTM standards may be obtained from the American Society for Testing and Materials, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, Pennsylvania, 19428-2959 (http://www.astm.org/): 30. ASTM D420, Standard Guide to Site Characterization for Engineering Design Construction Purposes. 31. ASTM D421,Standard Practice for Dry Preparation of Soil Samples for Particle-Size Analysis and Determination of Soil Constants. 32. ASTM D422, Standard Test Method for Particle-Size Analysis of Soils. 33. ASTM D427, Test Method for Shrinkage Factors of Soils by the Mercury Method. 34. ASTM D698, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). 35. ASTM D1557, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)). 36. ASTM D1587, Thin-Walled Tube Sampling of Soils for Geotechnical Purposes. 37. ASTM D1883, Standard Test Method for CBR (California Bearing Ratio) of Laboratory-Compacted Soils. 38. ASTM D2434, Standard Test Method for Permeability of Granular Soils (Constant Head). 39. ASTM D2487, Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). 40. ASTM D2488, Standard Practice for Description and Identification of Soils (Visual-Manual Procedure). 41. ASTM D2573, Standard Test Method for Field Vane Shear Test in Cohesive Soil 42. ASTM D3080, Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. 43. ASTM D4318, Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. 44. ASTM D4429, Standard Test Method for CBR (California Bearing Ratio) of Soils in Place. 45. ASTM D4632, Standard Test Method for Grab Breaking Load and Elongation of Geotextiles. 46. ASTM D5340, Standard Test Method for Airport Pavement Condition Index Surveys. 47. ASTM C39/C39M, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. 48. ASTM C78, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). 108 9/30/2009 AC 150/5320-6E 49. ASTM C496/C496M, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. 50. ASTM A185/A185M-06e1 Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete 51. ASTM A615/A615M-07, Standard Specification for Deformed and Plain Carbon Steel Bars for Concrete Reinforcement-AASHTO No. M 31 52. ASTM A996/A996M-06a Standard Specification for Rail-Steel and Axle-Steel Deformed Bars for Concrete Reinforcement 53. ASTM A497/A497M-06e1 Standard Specification for Steel Welded Wire Reinforcement, Deformed, for Concrete Copies of AASHTO standards may be obtained from the American Association of State Highway & Transportation Officials, 444 North Capitol Street N.W., Suite 249, Washington, DC 20001 (http://www.transportation.org/): 54. AASHTO T 194, Standard Method of Test for Determination of Organic Matter in Soils by Wet Combustion. 55. AASHTO T 222, Standard Method of Test for Nonrepetitive Static Plate Load Test of Soils and Flexible Pavement Components for Use in Evaluation and Design of Airport and Highway Pavements. Copies of Unified Facility Criteria (UFC) may be obtained from the US Department of Defense website (http://65.204.17.188//report/doc_ufc.html): 56. UFC 3-260-02, Pavement Design for Airfields, Unified Facility Criteria (UFC), June 2001 (Superseding U.S. Army and Air Force, Pavement design for seasonal frost conditions, U.S. Army and Air Force, TM 5-818-2, AFM 88-6 Chapter 4, U.S. Army, Air Force and NAVFAC TM 5-825-2/AFM 88-6 Chapter 2/DM 21.3, Flexible Pavement Design for Airfields, U.S. Army and Air Force, Technical Manual TM 5-824-3/AFM 88-6 Chapter 3, Rigid Pavements for Airfields Other than Army. Copies of the following publications are available from Asphalt Institute, 2696 Research Park Drive, Lexington, KY 40511-8480 (http://www.asphaltinstitute.org/): 57. MS-11, Thickness Design – Airports. 58. MS-10, Soils Manual. 59. MS-19, Basic Asphalt Emulsion Manual. 60. IS-154, Thickness Design-Asphalt Pavements for General Aviation. 61. SW-1 Asphalt Pavement Thickness Design Software. Miscellaneous 62. Soil Cement Construction Handbook, Portland Cement Association, 5420 Old Orchard Road, Skokie, Illinois 60077, 1995. 63. NIKE3D - A Nonlinear, Implicit, Three-Dimensional Finite Element Code for Solid and Structural Mechanics – User’s Manual, by Maker, B., Ferencz, R.M., and Hallquist, J.O., Lawrence Livermore National Laboratory, Livermore, California, Report No. UCRL-MA-105268 Rev.1, April 1995. 64. FHWA-HI-95-038, Geosynthetic Design and Construction Guidelines, 1995. 65. Berggren, W.P., Prediction of temperature distribution in frozen soils, Transactions of the American Geophysical Union, 24 (3), 71-77, 1943. 66. Development of Guidelines for Rubblization, Airfield Asphalt Pavement Technology Program (AAPTP) Report 04-01, by Buncher, M. (Principal Investigator), Fitts, G., Scullion, T., and McQueen, R., Draft Report, November 2007. 67. Best Practices for Airport Portland Cement Concrete Pavement Construction (Rigid Airport Pavement), Innovative Pavement Research Foundation (IPRF), Report IPRF-01-G-002-1, by Kohn, S. and Tayabji, S. (Principal Investigators), April 2003. 109 AC 150/5320-6E 9/30/2009 APPENDIX 5. AIRFIELD PAVEMENT DESIGN SOFTWARE 1. BACKGROUND. This appendix announces software to aid in the design of airfield pavements in accordance with the new design procedure presented in Chapters 3, 4 and 5 of this AC. The software is called FAARFIELD and incorporates two subprograms LEAF, implemented as a Microsoft WindowsTM dynamic link library written in Visual BasicTM 2005, which performs Layered Elastic Analysis (LEA) computations and NIKE3D_FAA, a three-dimensional finite element computational program implemented as a dynamic link library written in FORTRAN. NIKE3D_FAA is a modification of the NIKE3D software program originally developed by the US Department of Energy, Lawrence Livermore National Laboratory (LLNL), Livermore, California. NIKE3D and INGRID (3D mesh generation software for NIKE3D) are distributed in compiled form under the terms of a software sharing agreement between the FAA and LLNL. The remainder of the FAARFIELD program is written in Visual BasicTM 2005 and operates under Microsoft WindowsTM. Software for the previous design method as described in AC 150/5320-6D is also presented in this appendix and uses Microsoft Excel TM as a platform with Visual Basic TM for Applications (VBA) Macros to facilitate the design process. 2. AVAILABLE SOFTWARE AND SUPPORT MATERIAL. FAARFIELD implements both layered elastic-based and three-dimensional finite element-based design procedures for new and overlay designs of flexible and rigid pavements, respectively. For flexible pavement design, FAARFIELD uses the maximum vertical strain at the top of the subgrade, and the maximum horizontal strain at the bottom of the asphalt surface layer, as the predictors of pavement structural life. For rigid pavement design, FAARFIELD uses the maximum horizontal stress at the bottom edge of the PCC slab as the predictor of pavement structural life. The design method to determine pavement thickness as described in AC 150/5320-6D uses two programs (spreadsheets). Program F805FAA.XLS determines pavement thickness requirements for flexible pavement sections and bituminous overlays on existing flexible pavement sections. Program R805FAA.XLS determines pavement thickness requirements for rigid pavement sections and bituminous or Portland cement concrete overlays on existing rigid or flexible pavement sections. Reference manuals, which guide users through each step, are available for both programs. Pavement designs developed using the Frost Design feature of the spreadsheets are consistent with the Reduced Subgrade Strength method described in Chapter 3. The spreadsheets will produce thickness designs consistent with the nomographs used in AC 150/5320-6D. 3. ACCESS TO SOFTWARE. Design software and user manuals may be downloaded directly from the FAA Office of Airport Safety and Standards website (http://www.faa.gov/airports/engineering/design_software/). Updates or additions to the design software and manuals will be posted online, as well. 4. USE OF SOFTWARE. Numerical results from the programs may be used to complete FAA Form 5100-1, Airport Pavement Design. When used to develop the pavement design, the printed results of the software should be attached to Form 5100-1. Results from the program design summary and the airplane mixture data provide sufficient information to reproduce and review the pavement thickness design. Additional design information is required to complete Form 5100-1. 110 9/30/2009 AC 150/5320-6E APPENDIX 6. FAARFIELD INTERNAL AIRPLANE LIBRARY AIRPLANE LISTING BY GROUP TABLE 1. GENERIC AIRPLANE GROUP Airplane Name 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 SWL-50 Sngl Whl-3 Sngl Whl-5 Sngl Whl-10 Sngl Whl-12.5 Sngl Whl-15 Sngl Whl-20 Sngl Whl-30 Sngl Whl-45 Sngl Whl-60 Sngl Whl-75 Dual Whl-10 Dual Whl-20 Dual Whl-30 Dual Whl-45 Dual Whl-50 Dual Whl-60 Dual Whl-75 Dual Whl-100 Dual Whl-150 Dual Whl-200 Dual Tan-100 Dual Tan-150 Dual Tan-200 Dual Tan-300 Dual Tan-400 Gross Taxi Weight (lbs) 50,000 3,000 5,000 10,000 12,500 15,000 20,000 30,000 45,000 60,000 75,000 10,000 20,000 30,000 45,000 50,000 60,000 75,000 100,000 150,000 200,000 100,000 150,000 200,000 300,000 400,000 Gear Designation S S S S S S S S S S S D D D D D D D D D D 2D 2D 2D 2D 2D 111 AC 150/5320-6E 9/30/2009 TABLE 2. AIRBUS GROUP Airplane Name 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 112 A300-B2 SB A300-B2 std A300-B4 std A300-B4 LB A300-600 std A300-600 LB A310-200 A310-300 A318-100 std A318-100 opt A319-100 std A319-100 opt A320-100 A320-200 Twin std A320-200 Twin opt A320 Bogie A321-100 std A321-100 opt A321-200 std A321-200 opt A330-200 std A330-200 opt A330-300 std A330-300 opt A340-200 std A340-200 opt A340-300 std A340-300 opt A340-500 std A340-500 opt A340-600 std A340-600 opt A380-800 A380-800F Gross Taxi Weight (lbs) 315,041 315,041 365,747 365,747 380,518 380,518 315,041 315,041 124,341 150,796 141,978 150,796 150,796 162,922 172,842 162,922 183,866 188,275 197,093 207,014 509,047 515,661 509,047 515,661 568,563 575,176 608,245 611,552 813,947 840,402 805,128 840,402 1,239,000 1,305,125 Gear Designation 2D 2D 2D 2D 2D 2D 2D 2D D D D D D D D 2D D D D D 2D 2D 2D 2D 2D/D1 2D/D1 2D/D1 2D/D1 2D/2D1 2D/2D1 2D/2D1 2D/2D1 2D/3D2 2D/3D2 9/30/2009 AC 150/5320-6E TABLE 3. BOEING GROUP Airplane Name 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 B707-320C B720B B717-200 HGW B727-100C Alternate Adv. B727-200C Basic Adv. B727-200 Option B737-100 Adv. B737-200 Adv. B737-200 LP B737-300 B737-400 B737-500 B737-600 B737-700 B737-800 B737-900 ER B737 BBJ2 B747-100 SF B747-200B Combi Mixd B747-300 Combi Mixed B747-400 B747-400ER B747-SP B757-200 B757-300 B767-200 B767-200 ER B767-300 ER B767-400 ER B777-200 Baseline B777-200 ER B777-200LR B777-300 Baseline B777-300 ER B787-8 B787-9 Gross Taxi Weight (lbs) 336,000 235,000 122,000 170,000 Gear Designation 2D 2D D D 185,200 D 210,000 111,000 128,600 117,500 140,000 150,500 134,000 145,000 155,000 174,700 188,200 174,700 738,000 D D D D D D D D D D D D 2D/2D2 836,000 2D/2D2 836,000 2D/2D2 877,000 913,000 703,000 256,000 271,000 317,000 396,000 413,000 451,000 537,000 657,000 768,800 662,000 777,000 478,000 542,000 2D/2D2 2D/2D2 2D/2D2 2D 2D 2D 2D 2D 2D 3D 3D 3D 3D 3D 2D 2D 113 AC 150/5320-6E 9/30/2009 TABLE 4. OTHER COMMERCIAL AIRPLANES GROUP Airplane Name 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 An-124 An-225 BAe 146 Concorde DC3 DC4 DC8-43 DC8-63/73 DC9-32 DC9-51 DC10-10 DC10-30/40 Fokker F100 IL62 IL76T IL86 L-1011 MD11ER MD83 MD90-30 ER TU134A TU154B Gross Taxi Weight (lbs) 877,430 1,322,750 95,000 410,000 25,199 73,002 318,000 358,000 109,000 122,000 458,000 583,000 101,000 358,472 376,990 466,278 498,000 633,000 161,000 168,500 108,027 216,053 Gear Designation 5D 7D D 2D S D 2D 2D D D 2D 2D/D1 D 2D 3Q 2D/2D1 2D 2D/D1 D D 2D 3D TABLE 5. GENERAL AVIATION GROUP Airplane Name 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 114 Aztec-D Baron-E-55 BeechJet-400 BeechJet-400A Bonanza-F-33A Canadair-CL-215 Centurion-210 Challenger-CL-604 Chancellor-414 Chk.Arrow-PA-28-200 Chk.Six-PA-32 Citation-525 Citation-550B Citation-V Citation-VI/VII Citation-X Conquest-441 Gross Taxi Weight (lbs) 5,200 5,424 15,500 16,300 3,412 33,000 4,100 48,200 6,200 2,500 3,400 10,500 15,000 16,500 23,200 36,000 9,925 Gear Designation S S S S S S S D S S S S S S D D S 9/30/2009 AC 150/5320-6E TABLE 5. GENERAL AVIATION GROUP (cont.) Airplane Name 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 Conquest-441 DC-3 Falcon-50 Falcon-900 Falcon-2000 Fokker-F-28-1000 Fokker-F-28-2000 Fokker-F-28-4000 GrnCaravan-CE-208B Gulfstream-G-II Gulfstream-G-III Gulfstream-G-IV Gulfstream-G-V Hawker-800 Hawker-800XP KingAir-B-100 KingAir-C-90 Learjet-35A/65A Learjet-55 Malibu-PA-46-350P Navajo-C RegionalJet-200 RegionalJet-700 Sabreliner-40 Sabreliner-60 Sabreliner-65 Sabreliner-80 Sarat.PA-32R-301 Seneca-II Shorts-330-200 Shorts-360 Skyhawk-172 Skylane-1-82 Stationair-206 SuperKingAir-300 SuperKingAir-350 SuperKingAir-B200 Gross Taxi Weight (lbs) 9,925 26,900 38,800 45,500 35,000 66,500 65,000 73,000 8,750 66,000 70,200 75,000 90,900 27,520 28,120 11,500 9,710 18,000 21,500 4,118 6,536 47,450 72,500 19,035 20,372 24,000 23,500 3,616 4,570 22,900 27,200 2,558 3,110 3,612 14,100 15,100 12,590 Gear Designation S S D D D D D D S D D D D D D D S D D S S D D S S S D S S S S S S S D D D 115 AC 150/5320-6E 9/30/2009 TABLE 6. MILITARY GROUP Airplane Name 1 2 3 4 5 6 7 8 9 10 116 C-5 C-17A C-123 C-130 C-141 F-15C F-16C F/A-18C KC-10 P-3 Gross Taxi Weight (lbs) 769,000 585,000 60,000 155,000 345,000 68,000 42,300 56,000 583,000 142,000 Gear Designation Complex 2T S 2S 2D S S S 2D/D1 D