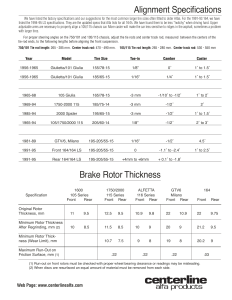

REPAIRMANUAL2003-2008 950/990 ADVENTURE 990 SUPER DUKE/R 950/990 SUPERMOTO/R 950 SUPER ENDURO REPARATURANLEITUNG MANUALE DI RIPARAZIONE MANUEL DE RÉPARATION ART.NR.: 3.206.056-E MANUAL DE REPARACIÓN REPAIRMANUAL2003-2008 950/990 ADVENTURE 990 SUPER DUKE/R 950/990 SUPERMOTO/R 950 SUPER ENDURO KTM Group Partner 1 SERVICE-INFORMATIONS 2 GENERAL INFORMATION 3 REMOVING AND REFITTING ENGINE 4 DISASSEMBLING ENGINE 5 SERVICING INDIVIDUAL COMPONENTS 6 ASSEMBLING ENGINE 7 ELECTRICAL / INJECTION 8 FUEL SYSTEM 9 TROUBLE SHOOTING 10 CHASSIS 11 TECHNICAL SPECIFICATIONS 12 PERIODIC MAINTENANCE SCHEDULE 13 WIRING DIAGRAMS 14 15 16 I MPORTANT I NFORMATION /U PDATING INSTRUCTIONS To be able to continue using the existing loose-leaf repair instructions, simply print the following pages and insert them in the existing repair instructions: 1,3,7,9,13,43-75,78-80,83,128,134,135-196,219,220,223,224,227,228,230,233,247256,258,261,263,267-285,287-446 Remove pages (s) 3-1 3-12 to 3-20 4-2 to 4-4 4-7 6-16 6-22 7-1 to 7-55 10-2 to 10-3 10-6 to 10-7 10-10 to 10-11 10-13 11-1 11-14 to 11-20 12-1 12-4 12-6 12-10 to 12-26 13-2 to 13-141 Replace by page (s) 3-1 3-12 to 3-44 4-2 to 4-4 4-7 6-16 6-22 7-1 to 7-61 10-2 to 10-3 10-6 to 10-7 10-10 to 10-11 10-13 11-1 11-14 to 11-23 12-1 12-4 12-6 12-10 to 12-28 13-2 to 13-159 Insert page (s) after page KTM REPAIR MANUAL IN LOOSE-LEAF FORM STORING THE REPAIR MANUAL IN THE BINDER – Put the index into the binder. – Put the front page of the repair manual (210x297 mm) into the transparent pocket provided for this purpose on the outside of the binder. – Put the spine label (170x45 mm) into the transparent pocket provided for this purpose on the spine of the binder. – Put the summary list of contents (150x297 mm) into the transparent pocket provided for this purpose on the inside of the binder or insert this page on the beginning of the manual. – Then insert the individual chapters of the manual between the sheets of the index according to the page number printed in the right bottom corner of each page. Example: page no. 3-5; 3 = chapter 3; 5 = page 5 All pages with a page number that begins with the digit 3, for example, must be put under the index heading „Chapter 3“. – Index sheets that have not been marked with a certain chapter are for your personal convenience. The respective headings can be entered in the list of contents. EXPLANATION - UPDATING 3.206.009-E Repair Manual LC8 Basicversion Modelyear 2003 4/2003 3.206.016-E Updating of Rep.Manual 3.206.009-E Modelyear 2004 (Engine number with first digit “4“) 11/2003 3.206.025-E Updating of Rep.Manual 3.206.009-E Modelyear 2005 (Engine number with first digit “5“) 01/2005 3.206.035-E Updating of Rep.Manual 3.206.009-E Modelyear 2005/06 (Engine number with first digit “5“ and “6”) 01/2006 3.206.044-E Updating of Rep.Manual 3.206.009-E Modelyear 2007 (Engine number with first digit “7“) 02/2007 3.206.056-E Updating of Rep.Manual 3.206.009-E Modelyear 2008 (Engine number with first digit “8“) 7/2008 technical details, technical data, technical specifications, wiring diagrams Edition: 07/2008 INTRODUCTION This repair manual offers extensiv repair-instructions and is an up-to-date version that describes the latest models of the series. However, the right to modifications in the interest of technical improvement is reserved without updating the current issue of this manual. A description of general working modes common in work shops has not been included. Safety rules common in the work shop have also not been listed. We take it for granted that the repairs are made by qualified profesionally trained mechanics. Read through the repair manual before beginning with the repair work. WARNING STRICT COMPLIANCE WITH THESE INSTRUCTIONS ESSENTIAL TO AVOID DANGER TO LIFE AND LIMB. ! CAUTION IS ! NON-COMPLIANCE WITH THESE INSTRUCTIONS CAN LEAD TO DAMAGE OF MOTORCYCLE COMPONENTS OR RENDER MOTORCYCLES UNFIT FOR TRAFFIC ! „NOTE” POINTS OUT USEFUL TIPS. Use only ORIGINAL KTM SPARE PARTS when replacing parts. The KTM high performance engine is only able to meet user expectations if the maintenance work is performed regularly and professionally. In accordance with the international quality management ISO 9001 standard, KTM uses quality assurance processes that lead to the highest possible product quality. KTM Sportmotorcycle AG reserves the right to modify any equipment, technical specifications, colors, materials, services offered and rendered, and the like so as to adapt them to local conditions without previous announcement and without giving reasons, or to cancel any of the above items without substituting them with others. It shall be acceptable to stop manufacturing a certain model without previous announcement. In the event of such modifications, please ask your local KTM dealer for information. KTM Sportmotorcycle AG 5230 Mattighofen, Austria All design and assembly modification rights reserved. C by KTM SPORTMOTORCYCLE AG, AUSTRIA All rights reserved REPLY FAX FOR REPAIR MANUALS We have made every effort to make our repair manuals as accurate as possible but it is always possible for a mistake or two to creep in. To keep improving the quality of our repair manuals, we request mechanics and shop foremen to assist us as follows: If you find any errors or inaccuracies in one of our repair manual – whether these are technical errors, incorrect or unclear repair procedures, tool problems, missing technical data or torques, inaccurate or incorrect translations or wording, etc. – please enter the error(s) in the table below and fax the completed form to us at 0043/7742/6000/5349. NOTE to table: – Enter the complete item no. for the repair manual in column 1 (e.g.: 3.206.056-E). You will find the number on the cover page or in the left margin on each right page of the manual. – Enter the corresponding page number in the repair manual (e.g.: 5-7) in column 2. – Enter the current text (inaccurate or incomplete) in column 3 by quoting or describing the respective passage of the text. If your text deviates from the text contained in the repair manual, please write your text in German or English if possible. – Enter the correct text in column 4. Your corrections will be reviewed and incorporated in the next issue of our repair manual. Item no. of repair manual Page Current text Correct text Additional suggestions, requests or comments on our Repair Manuals (in German or English): Name mechanic/shop foreman Company/work shop 2-1 GENERAL INFORMATION Repair manual KTM LC8 Art.-No. 3.206.056-E INDEX OIL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2 AIR INTAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3 SLS-SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4 COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5 ABS-SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6 SPECIAL TOOLS – ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7 SPECIAL TOOLS – CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9 BLEEDING THE CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10 RESETTING THE CONTROL UNIT AFTER REPLACING/REPAIRING THE ENGINE . . .2-11 ADJUSTING THE THROTTLE CABLE FOR MODELS WITH FUEL INJECTION . . . . . . .2-12 ECU-SOFTWARE UPDATE/MAPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13 BLEEDING THE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . .SEE CHAPTER 12 CHECKING THE OIL PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15 2 2-2 Oil system Pressure pump 1 draws engine oil from oil tank 2 through oil filter 3 and the oil return valve 4 and pumps it past the pressure relief valve 5 through the oil filter 6 into the annular groove 7. The main bearing 8, the conrod bearings 9 and the spraying nozzle bk (front timing chain) are supplied with oil through holes in the crankshaft. An oil duct leads to spraying nozzle bl (piston cooling), the timing chain tensioner bm, the camshaft bn and the oil pressure switch bo in the front cylinder. Another oil duct leads from the annular groove to a distributor groove bp in the clutch cover. From there an oil duct leads to the spraying nozzle bq (piston cooling). Another oil duct supplies the timing chain tensioner br, the spraying nozzle bs (timing chain) and the camshaft bt on the rear cylinder with oil. 2 3 4 bn Another oil duct leads to the oil injection tube ck which lubricates the transmission gears. Oil is conducted to the pushrod and to the clutch through the injection tube, another oil duct and the reducing jet. bo bl bk Art.-No. 3.206.056-E bm The suction pump cl draws the oil from the oil sump cn through the screen cm into the oil tank 2. 9 8 NOTE: each piston is lubricated and cooled by 2 jets starting with the 2005 model. 7 br 8 bq bp bs bt 1 Repair manual KTM LC8 cl 5 cm 6 cn ck 2-3 Intake system Fresh air is drawn into the filter box through the intake snorkel 1, past the carburetors 2 and through the air filter 3. The cleaned air is conducted to the combustion chamber through the carburetors and intake ports. The diagram for the injection engine is similar; the air flows to the intake ports through the throttle body instead of through the carburetor. 1 2 3 3 2-4 Secondary air system The secondary air system supplies fresh air to the emissions in the exhaust port, resulting in the afterburning (oxidation) of the emissions. A line leads from the filter box 1 to the control valve 2 which opens as soon as the throttle valves 3 are opened. The line continues to the reed valves 4 in the cylinder heads which are actuated by the pressure pulsation in the exhaust system. As a result, cleansed fresh air arrives in the exhaust port. The oxygen content in the air and the high exhaust gas temperature cause the emissions to oxidize. If the throttle valves are closed and the engine goes into an overrun condition, the underpressure in the intake port will rise and the control valve will close. This prevents exhaust backfire (combustion of the unburned fuel/air mixture). The secondary air system operates in a similar manner in models equipped with an injection engine; a solenoid valve controlled by the control unit is used instead of the control valve. 1 2 Repair manual KTM LC8 Art.-No. 3.206.056-E 3 4 3 4 4 2-5 Cooling system 3 2 2 1 Closed thermostat The thermostat is closed if the temperature of the cooling liquid drops below 75° C. The water pump 1 pumps the cooling liquid through the cylinder and cylinder heads 2 and the thermostat 3. 5 6 7 4 3 2 2 1 Open thermostat The thermostat 3 opens at 75° C. The water pump 1 pumps the cooling liquid through the cylinder and cylinder heads 2, the aluminum cooler 4 and the thermostat. The pressure in the cooling system (max. 1.4 bar) is regulated by a valve in the radiator cap 5. The cooling liquid level in the compensating tank 6 must be between the MIN and MAX marks when the engine is cold. The fan 7 switches on at 102° C. 2-6 ABS (antilock brake system) The ABS is a safety system that prevents the wheels from locking when driving straight ahead without the influence of lateral forces. The ABS unit 1, consisting of a hydraulic unit, an electronic control unit and the electric pump motor, is located under the seat. Sensors 2 on the front and rear wheel send pulses to the control unit to indicate how fast the wheel is turning. 2 The KTM 990 Adventure ABS operates with two independent brake circuits (front and rear wheel brake). During normal service the brake system works just like a conventional brake without the ABS. The ABS control phase sets in when the control unit detects that one of the wheels is starting to lock. It releases the pressure in the respective brake circuit and prevents the wheel from locking. You can feel the control function as a slight pulsing in the brake lever. The ABS warning lamp 3 must light up when the ignition is switched on and go out at a speed of approx. 5 KPH after you drive off. If it stays on or lights up while driving, the ABS is defective. The ABS can be switched off with the ABS button 4. ! 1 2 Art.-No. 3.206.056-E ! NOT MOUNT WHEELS WITH A DIFFERENT RIM DIAMETER. THE ABS FUNCTION CAN NO LONGER BE GUARANTEED. THE ABS IS DESIGNED TO BE USED WITH THE TIRES AUTHORIZED BY KTM. THE ABS FUNCTION CANNOT BE GUARANTEED IF OTHER TIRES ARE USED. MAXIMUM ABS CONTROL CAN NO LONGER BE GUARANTEED IF THE TIRE PRESSURE IS INCORRECT. THE ABS SYSTEM IS DESIGNED FOR THE 990 ADVENTURE MODEL AND MAY NOT BE INSTALLED IN THE 990 ADVENTURE S SINCE THE 990 ADVENTURE S MODEL HAS A DIFFERENT CENTER OF GRAVITY; 990 ADVENTURE S FORKS/SHOCK ABSORBERS MAY NOT BE MOUNTED ON 990 ADVENTURE MODELS WITH ABS. ALL OTHER MODIFICATIONS THAT DISPLACE THE MOTORCYCLE'S CENTER OF GRAVITY (E.G. LOWERING) JEOPARDIZE THE PROPER FUNCTIONING OF THE ABS SYSTEM. – DO – – – – ABS warning lamp The ABS warning lamp 3 must light up when the ignition is switched on and go out at a speed of approx. 5 KPH after you drive off. If it stays on or lights up while driving, the ABS is defective. The ABS is no longer active and the wheels can lock when braking. 3 4 Repair manual KTM LC8 CAUTION NOTE: – The brake system will still function but ABS control will no longer be active. – The ABS warning lamp can also light up if there is a large deviation between the speed of the front and rear wheel in extreme driving situations, e.g. during a wheelie or if the rear wheel slips when accelerating on loose ground. The ABS will no longer be active and the wheels can lock when braking. To activate the ABS again, stop and switch the ignition off/on. If the warning lamp goes off again at a speed of approx. 5 KPH after you drive off, the ABS is active and fully operative. ABS button The ABS button 4 switches off the ABS. To switch off the ABS, stop the motorcycle and press the ABS button for at least 3 seconds with the engine running. Let go of the ABS button as soon as the ABS warning lamp starts blinking fast. The ABS warning lamp will blink slowly to indicate that the ABS is switched off. To switch the ABS on again, stop and switch off the ignition. The ABS will be active again when you switch on the ignition. See the KTM ABS training documents for a detailed description of the ABS system. 2-7 SPECIAL TOOLS – ENGINE FIG 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 PART NO 309098 0113 080802 151.12.017.000 451.29.075.000 503.29.050.000 560.12.001.000 584.29.059.000 585.29.005.000 590.29.019.000 590.29.021.044 590.29.026.006 590.29.041.000 6 899 785 600.29.002.000 600.29.003.000 600.29.005.000 600.29.006.000 600.29.009.000 600.29.009.010 600.29.009.110 600.29.010.000 600.29.011.000 600.29.012.000 600.29.015.000 600.29.016.000 600.29.018.000 600.29.031.000 600.29.033.000 600.29.041.000 600.29.043.010 600.29.043.020 600.29.043.030 600.29.043.040 600.29.043.050 600.29.043.060 600.29.044.050 600.29.046.028 600.29.050.000 600.29.051.000 600.29.058.000 600.29.073.000 600.29.075.000 600.29.081.000 600.29.082.000 600.29.083.000 610.29.094.000 625.29.093.000 DESCRIPTION Seal Three-Bond Crankshaft locking bolt Gear puller Tachometer Bleeding syringe for hydraulic clutch Universal-engine work stand Loctite 648 green 20 ml Protection sleeve for shaft seal ring of water pump Valve spring mounter Puller Limit plug gauge 6,05 mm Feeler gauge for valve clearance Loctite 243 blu 10 ml Engine holder for engine work stand Clutch holder Protection sleeve for shaft seal ring of output shaft Oil pressure adapter Magneto extractor Pressure screw for magneto extractor up to the 2004 model Pressure screw for rotor extractor from the 2005 model Degree wheel Carburator synchronisation tool Plastigauge-measuring strips Piston ring mounting tool Setting gauge for float level Internal gear puller 28 mm Protection sleeve for crankshaft (for pulling of the primary gear) Puller for primary gear Valve spring mounter insert Pressing tool for seal of clutch release shaft Pressing tool for seal of output shaft Pressing tool for seal and bearing of shifting shaft Pressing tool for seal of water pump Pressing tool for seal of balancer shaft Pressing tool for bearing of water pump Pressing tool for main bearings (In/out) Pressing tool for supporting bearing (In) Pretensioning tool - lower part Pretensioning tool - hook wrench Puller for spreader components Spark plug wrench 16 mm Special nut for conrod Special tool for cylinder head nuts Holder for water pump wheel Special nut for cylinder head nuts EFi-tool for pressure check Intermediate adapter for ignition cable 2-8 bo 6 4 2 1 3 5 bn 8 bp LOCTITE 243 7 bq br bs bt 8 Art.-No. 3.206.056-E 64 bk 9 Repair manual KTM LC8 cr cq bl ck bm cn co cp cs ct dk dl dm dn do ds dt ek el dq cm cl dp em en eo 2 4 0 dr ep 3 1 BAR 5 2-9 SPECIALTOOLS – CHASSIS 6 4 3 2 1 7 5 8 9 bk bp bl bm bn bo FIG 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 PART NO 151.12.017.000 584.29.086.000 584.29.089.000 584.29.091.000 584.29.092.000 600.03.022.000 600.10.013.000 600.29.018.000 600.29.020.000 600.29.055.000 600.29.055.100 600.29.056.000 600.29.057.000 600.29.057.100 625.29.055.000 DESCRIPTION Gear puller Pressing tool for swing arm bearing Chassis tool holder Press-in tool for bearing seat / rear wheel bearing Knock-out tool for bearing seat Center stand Sleeve for pressing tool for swim arm bearing Internal gear puller 28 mm Chain rivet tool Center stand lock Floor jack attachment Anvil dolly (for 584.29.086.000) Pliers for Öttiker clamps Pliers for spring-loaded band-type clamp Assembly stand 2-10 Checking the oil level of the hydraulic clutch - 950/990 Adventure, 950 Supermoto/R 1 To check the oil level in the master cylinder of the clutch remove the cover. For this purpose, remove bolts and cover together with the rubber boot 1. The oil level in the horizontal-standing master cylinder should be 4 mm below the upper edge. If necessary add SAE 10 biodegradable hydraulic oil (e.g. Motorex Kupplungs-Fluid 75). ONLY ! SAE 10 CAUTION ! USE BIODEGRADABLE HYDRAULIC OIL TO REFILL THE MASTER CYLINDER. NEVER USE BRAKE FLUID NOR MIX BIODEGRADABLE HYDRAULIC OILS WITH MINERAL OILS! Checking the oil level of the hydraulic clutch - 990 Super Duke/R The oil level in the horizontal-standing master cylinder should be between the "MIN" and "MAX" marks. If necessary, add SAE 10 biodegradable hydraulic oil (Motorex Kupplungsfluid 75). ! CAUTION ! USE SAE 10 BIODEGRADABLE HYDRAULIC OIL TO FILL THE MASTER CYLINDER. DO NOT USE BRAKE FLUID AND DO NOT MIX WITH HYDRAULIC MINERAL OIL. ONLY Art.-No. 3.206.056-E Bleeding of the hydraulic clutch For bleeding, the cover of the master cylinder of the clutch needs to be removed. For this purpose, remove bolts and take off cover together with rubber bellows 1. At the slave cylinder of the clutch, remove the bleeder nipple. At its place, mount the bleeder syringe 2 which is filled with biodegradable hydraulic oil (e.g. Motorex Kupplungs-Fluid 75). 2 Refill oil, until oil is discharged from the bore A of the master cylinder in a bubble-free state. Make sure that the oil does not overflow. ! Repair manual KTM LC8 A CAUTION ! HAVING COMPLETED THE BLEEDING PROCEDURE, YOU HAVE TO VERIFY THAT THE OIL LEVEL IN THE MASTER CYLINDER IS CORRECT. FOR FILLING OF THE MASTER CYLINDER, USE SAE 10 BIODEGRADABLE HYDRAULIC OIL ONLY (EX. MOTOREX KUPPLUNGS-FLUID 75); NEVER USE BRAKE FLUID NOR MIX BIODEGRADABLE HYDRAULIC OILS WITH MINERAL OILS. 2-11 Resetting the control unit after replacing/repairing the engine NOTE: the control unit must be reset after replacing the engine or after engine repair if replacing a piston, cylinder or cylinder head. The engine may have a poor idle behavior if the control unit is not reset. – Connect the KTM diagnostics tool, turn the ignition switch on and start the program. – Select "Extend" 1. 1 – Select "Device operation" 2. 2 – Enter your password. – Select "All reference reset operation" 3 and move to the right window with the arrow 4. 4 – Acknowledge with "Execute" 5 to "Reset" the control unit. – Wait until the "Reset" process is completed, exit the program, turn the ignition switch off and disconnect the KTM diagnostics tool. 3 5 – Allow the vehicle to idle for 15 minutes. Do not open the throttle during this time, observe the coolant temperature, stop if the engine is likely to overheat. 2-12 Adjusting the throttle cable for models with fuel injection NOTE: to adjust the throttle cable clearance, the throttle valves must be closed. To close, retract the idle speed control stepper motor all the way using the KTM diagnostics tool. If this step is omitted, the throttle cable clearance cannot be correctly adjusted. – Connect the KTM diagnostics tool, turn the ignition switch on and start the program. – Select "Extend" 1. 1 – Select "Device operation" 2. 2 Art.-No. 3.206.056-E – Enter your password. – Select "Idle speed control stepper motor" 3 and move to the right window with the arrow 4. 4 3 – Acknowledge with "Execute" 5. The idle speed control stepper motor will be completely retracted and the throttle valves completely closed. – Remove the left side cover on the air filter box and check whether the throttle valves are completely closed. 5 – Switch the ignition switch off and adjust the throttle cable clearance as follows: Repair manual KTM LC8 – Loosen the counter nut 6, turn the adjusting screw 7 as needed and tighten the counter nut again. 6 7 NOTE: – You should be able to feel 3-5 mm play in the throttle grip when you start to turn it. – Make sure the throttle grip returns to the neutral position automatically when released. – Turn the ignition switch on again, exit the program, turn the ignition switch off and disconnect the KTM diagnostics tool. To check whether the setting is correct, start the engine, steer left and right all the way to the stop. The idle speed should not change. 2-13 ECU software update/mapping 1 2 NOTE: – ECU software update or mapping means that the software for the injection system control unit has been modified. The software can be downloaded from KTM's dealer.net site; the software is transferred to the control unit via the KTM diagnostics tool (FAN). – Some exhaust systems require new "mapping". If these exhaust systems are replaced by the production system again, the "mapping" will need to be reverted to the original version. ! CAUTION ! NOT USE THE MODIFIED MAPPING WITH PRODUCTION EXHAUST SYSTEMS. THIS CAN LEAD TO ENGINE DAMAGE AND YOU WILL RUN THE RISK OF BURNING/INJURING YOURSELF. DO Downloading the software: – Log into dealer.net. – Select "Parts and Hard Equipment" 1. – Select "Fichefinder" 2. 5 3 – Select the model year, model type and model 3 and click "Start search" 4. – Select "Technical documentation" 5. 4 – Select the required mapping 6. – Click "Save" 7. 7 6 – Select the storage location 8. 8 9 NOTE: – Save the file onto your "Desktop" to make it easier to locate. – This can take a little time, depending on your Internet connection and the size of the mapping file. – The downloaded file is compressed and needs to be extracted with "winzip". – Double click the downloaded file 9. – Click "I agree" in the "winzip" window bk. – Mark the extracted file with the cursor and drag to your "Desktop". bk 2-14 Starting the DMT (Data Maintenance Tool): – Double click "DMT" 1 to start the DMT program. 2 1 8 NOTE: – If the DMT is not installed yet, install with the KTM diagnostics tool CD. – If the program is already installed but the DMT icon does not appear on your screen, start the program under "Start" (in the task bar at the bottom of the screen) by clicking "Programs". – Click the field in the DMT window with the 3 dots 2. – Select the storage location of the downloaded mapping file in the selection window ("Desktop") 3. 3 – Click "update" in the DMT window 4. 4 – Confirm "update" selection with "Yes" 5. 5 Art.-No. 3.206.056-E – End "update" with "OK" 6. 6 – Confirm that you are ending the "update" with "YES" 7. 7 Starting the FAN (Flash Download System): – Double click on "FAN" 8 to start the FAN program. Reparaturanleitung KTM LC8 9 bk NOTE: – If the FAN is not installed yet, install with the KTM diagnostics tool CD. – If the program is already installed but the DMT icon does not appear on your screen, start the program under "Start" (in the task bar at the bottom of the screen) by clicking "Programs". – Connect the motorcycle to the diagnostics adapter, switch on the ignition. – Click the mapping file 9 to be transferred to the ECU and confirm with "Execute". – Enter the password (Adapter number) and click "OK" to confirm. 2-15 – The mapping file will be transferred to the ECU. ! CAUTION ! DO NOT SWITCH OFF THE IGNITION OR DISCONNECT THE DIAGNOSTICS CABLE WHILE THE FILE IS BEING TRANSFERRED ("FLASHING"). THIS CAN DAMAGE THE ECU. 1 NOTE: – All of the indicator lamps in the digital speedometer will light up while the file is being transferred. – The bar 1 will show download progress. – Click "OK" to confirm when the operation is completed. – End the program, switch off the ignition and disconnect the diagnostics cable. – Start the engine and allow to idle for 15 minutes. NOTE: the engine must run in idle for 15 minutes after each mapping operation (Mapping initializing). Do not accelerate during this time, observe the coolant temperature and abort if the engine threatens to overheat. Checking the oil pressure – Remove the plug from the timing chain tensioner 2. 2 – Screw on the oil pressure adapter 3 600.29.006.000 and tighten. – Connect the EFI pressure gauge 610.29.094.000 (without the Tfitting) to the oil pressure adapter, tighten the banjo bolt. 3 ! CAUTION – CONNECT ALL LOOSENED OIL AND FUEL LINES AGAIN ENGINE. – CHECK THE OIL LEVEL AND CORRECT IF NECESSARY. ! BEFORE STARTING THE – Allow the engine to warm up and check the oil pressure with the engine at operating temperature: min. 0.8 bar at 1500 rpm min. 2.4 bar - max. 3.5 bar at 6000 rpm NOTE: the engine is at operating temperature when the engine oil in the oil tank is approx. 100ºC. – Remove the special tools again, screw the plug in the timing chain with a new gasket and tighten to 20 Nm. 3-1 REMOVING AND REFITTING ENGINE INDEX 950 ADVENTURE REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7 Art.-No. 3.206.056-E 990 ADVENTURE REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12 REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17 990 SUPER DUKE REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24 REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25 990 SUPER DUKE R REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32 REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25 Repair manual KTM LC8 950 SUPERMOTO/R REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34 REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34 990 SUPERMOTO REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35 REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40 3 3-2 Removing the engine - 950 Adventure – Screw the center stand 600.03.022.000 onto the frame 1 and jack up the motorcycle on a firm, even surface. – Remove the left bump rubber and lock the center stand with the lock 600.29.055.000 2. 2 NOTE: if available, use the center stand already on the bike. 1 1 – Unlock the seat lock with the ignition key and remove. – Remove the bolts 3 on the left and right of the front side covers, disconnect the front turn signal, pull the tank vent hoses off of the fuel tank and remove the side covers. 3 4 3 3 Art.-No. 3.206.056-E 4 – Remove the bolts 5 on the lower tank compartment and the fuse box, take the cover off the fuse box and dismount the lower tank compartment. – Close the fuel cocks, disconnect the gasoline hoses, unscrew the upper 6 and lower 7 fixing bolts on both fuel tanks and remove the tanks together with the lower vent hoses. 5 5 6 6 5 5 7 Repair manual KTM LC8 NOTE: it is easier to disconnect the gasoline hoses if you remove the front bolts on the underride protection and fold the engine guard down. – Drain the engine oil from the oil tank and the engine: see Chapter 12. – Remove the 4 bolts 8 on the underride protection and take off the underride protection. – Remove both bolts 9 on the front cover and take off the cover. 9 8 – Open the tank cover, unscrew the fixing bolts 4 and remove the upper tank compartment. 8 – Open the lid on the battery compartment and disconnect the battery terminals bk (starting with the negative pole). – Take out the battery and remove the upper battery cover. bk bk 3-3 2 3 – Unscrew the bolts 1 and remove the intake snorkel 2 together with the frame from the air filter box. – Disconnect the vent hose and the EPC hose and remove the upper half of the air filter box. – Turn the intake trumpet 3 in a clockwise direction and remove. Remove air filter. 1 – Unbolt both side covers on the lower air filter box and remove the clamps on the carburetor connection boot. – Detach the EPC hoses 4 from both carburetors and pull the hoses out of the lower air filter box. – Remove both vent hoses from the carburetors. – Lift both carburetors, carefully draw the cable for the idle speed adjustment and the gasoline hose through the openings in the lower air filter box. – Detach the fuel hoses from the carburetors. – Pull the carburetor connection boots off of the intake manifolds. 4 4 5 – Detach the SLS valve 5 from the lower air filter box, pulling the thin hose from the intake manifold and the thick hose from the valve. Remove the valve. – Remove the EPC valve 6 from the lower air filter box and disconnect. – Tilt up the carburetors and fasten to the handlebar with a wire or rubber band. They do not need to be completely dismounted. – Take the lower air filter box out of the frame. NOTE: cover the intake ports with a cloth to prevent any parts from falling inside. 6 7 8 – Unscrew both nuts 7 on the front exhaust manifold flange on the cylinder head, loosen the exhaust clamp 8 on the front exhaust manifold, pull the front exhaust manifold out of the rear exhaust pipe and remove. – Unscrew the rear exhaust manifold from the cylinder head. 3-4 2 – Disconnect the electric connections from the fan motor and the temperature switch 1. – Drain the cooling liquid from the radiator and engine: see Chapter 12. – Detach the water hoses from the radiator (special pliers 600.29.057.100) and unscrew the radiator 2 . 2 1 NOTE: fan and radiator shield do not need to be dismounted from the radiator. 2 – Pull off the oil lines from the oil tank to the valve covers 3 and the return line 4 (special pliers 600.29.57.100), unscrew the oil lines from the oil terminal 5 and pull out. Remove the O-rings. 4 6 3 Art.-No. 3.206.056-E – Loosen the fixing bolts 6 on the oil tank, remove the oil tank and carefully pull out the oil line. 5 6 8 – Disconnect the side stand switch 7 and take the cable out of the cable clips. – Loosen the two bolts and the nut 8 and remove the side stand. Repair manual KTM LC8 7 – Unscrew the clutch slave cylinder 9 and the chainguard bk and pull the locking pin out of the pushrod. – Dismount the chain roller and chain securing guide. 9 bk 3-5 – Unscrew the nut on the wheel spindle, pull out the rear wheel spindle, take the chain off of the rear sprocket and place over the side of the bracket 1. Remove the chain from the engine sprocket. 1 – Detach the connector 2. – Remove the engine vent hose 3, discarding the hose clamp. 2 2 3 2 5 6 4 – Unscrew the positive starter engine cable and draw out the wiring harness. – Detach connector 4 on the starter relay. – Pull out the gasoline pump vent hose 5 towards the bottom. – Unscrew the ground connection 6. 4 – Disconnect the fuel hose 7. – Loosen the bolts on the side support 8 and the nut on the bolt 9, pull out the bolt and remove support together with the battery case. 8 8 7 9 – Unscrew the front oil line bk. bk 3-6 – Use the trolley jack to position the attachment 600.29.055.100 on the engine, insert the bolt 1 through the front of the engine bracket and fasten with the nut. Screw one of the bolts 2 on the rear of the side stand fixture and slightly lift the engine. 1 2 – Remove the bolt 3 and tilt the foot brake pedal to the side. 3 Art.-No. 3.206.056-E – Unscrew the ground wire connection 4. – Detach the connector from the pulse generator 5. 4 5 6 8 – Detach the connector from the oil pressure switch 6, the temperature sensor 7 and from the front 8 and rear ignition coil. Remove any cable clips necessary. Repair manual KTM LC8 7 – Pull the bolt 9 out of the lower support (if necessary, raise or lower the engine slightly). bk – Loosen the nut on the swing arm pivot bk and knock out the swing arm pivot with a suitable pipe. – Pull the engine towards the front with the trolley jack, lower and pull away towards the side. – Disconnect all hoses and lines from the engine. 9 3-7 Refitting the engine - 950 Adventure – Before mounting the engine, attach the water, SLS and vacuum hoses (Öttiger clamps - special pliers 600.29.057.000 or springloaded band-type clamps - special pliers 600.29.057.100) – Position the swing arm and fix with the swing arm pivot on the right and a suitable pipe on the left. – Lift the engine into the frame with the trolley jack, insert the sealing washer in the rear exhaust flange and secure with copper paste if necessary. – Guide the chain along the side of the pinion and insert the swing arm pivot 1, screw on the nut but do not tighten yet. – Insert the bolt 2 in the lower support (raise or lower the engine slightly if necessary). – Remove the trolley jack attachment 600.29.055.100 from the engine. 1 2 3 – Plug the connector on the oil pressure switch 3, the temperature sensor 4 and the front and rear ignition coil 5. Use cable clips to fasten the wiring harnesses. 5 4 – Screw on the ground wire connection 6. – Attach the pulse generator connector 7. 6 7 – Position the foot brake pedal, apply Loctite 243 to the bolt 8 and tighten to 25 Nm. 8 3-8 – Mount the front oil line 1 inserting new O-rings. Tighten the bolts. NOTE: up to engine number 2-600-1186 a washer must be used to preload the O-rings on the oil terminal. 1 3 3 – Align the side supports and battery case against the engine, insert the bolt 2 and mount the nut. – Mount the bolts 3 (M10x23), lifting the engine slightly if necessary. Tighten the nut and bolts to 45 Nm. – Tighten the nut on the swing arm pivot to 130 Nm. – Connect the fuel hose 4 and fasten with a cable clip. 4 Art.-No. 3.206.056-E 2 6 7 5 – Run the positive starter cable to the starter and screw on the starter engine. Run the starter ground to the battery case. – Attach both starter relay connectors 5. – Run the gasoline pump vent hose 6 upwards along the wiring harness to the engine bracket and back down, forming an arch see Technical Information, Chapter 1. ! CAUTION ! YOU RUN THE HOSE STRAIGHT UP WITHOUT AN ARCH, WATER WILL BE ABLE TO PENETRATE, CAUSING THE GASOLINE PUMP TO BE SOILED AND DAMAGED. IF – Screw on the ground wire 7 from the regulator. 5 – Attach the connector 8. – Slip on the hose from the engine ventilation 9 and mount the new Öttiker clamp with the special pliers 600.29.057.000. Repair manual KTM LC8 8 8 8 9 3-9 1 1 – Place the chain over the pinion and rear sprocket, lift the rear wheel and slide the wheel spindle through. – Press the rear wheel towards the front to apply the chain tensioner 1 and tighten the nut on the wheel spindle to 90 Nm. – Actuate the foot brake pedal to apply the brake shoes against the brake disk. – Check the chain tension, see owners manual. – Mount the chain securing guide and the chain roller. – Insert the locking pin in the pushrod and mount the clutch slave cylinder 2. Screw on the chainguard 3. 2 3 – Position the side stand and tighten the two bolts and the nut 4 to 45 Nm (with Loctite 243). – Mount the side stand switch 5 and fasten the cable with the cable clips. 4 5 – Carefully install the oil line, mount the oil tank and tighten the fixing bolts 6. 7 – Connect the return line 7 to the oil tank and mount the springloaded band-type clamp with the special pliers 600.29.057.100. – Attach the oil lines from the oil tank to the valve covers 8 (special pliers 600.29.057.100). 6 6 – Mount both oil lines on the oil terminal 9 with new O-rings, insert the bolts (M6x20) in the retaining brackets bk and tighten to 10 Nm. NOTE: – up to engine number 2-600-1186 a washer must be used to preload the O-rings on the oil terminal. – to allow the oil pump to build up the oil pressure faster, remove the suction line (left) from the oil tank and fill with engine oil. – Check the hose part of the suction line for cracks. 8 bk 9 bk 3-10 – Screw on the radiator together with the fan and the radiator shield 1, tighten the bolts to 10 Nm. – Connect the water hoses on the radiator (special pliers 600.29.057.100) 1 – Attach the electric connections for the fan motor and the temperature switch 2. 1 2 1 – Screw the rear exhaust manifold on to the cylinder head. – Insert the front exhaust manifold in the rear exhaust pipe, mount to the front cylinder head together with the sealing washer and tighten the exhaust nuts 3. 4 3 NOTE: the exhaust nuts should be tightened evenly without bending the metal sheet. – Tighten the exhaust clamp 4 on the front manifold. Art.-No. 3.206.056-E 6 – Mount the lower air filter box on the intake ports, connect the drain hose and push the fuel hose and the cable for the idle speed adjustment down through the opening in the lower air filter box. NOTE: if the carburetors are equipped with transparent vent hoses, the vent hoses must be replaced with reinforced vent hoses. ! CAUTION ! – MAKE – 5 SURE THERE ARE NO KINKS IN THE CARBURETOR VENT HOSES AND RUN THEM DOWN BEHIND THE STARTER ENGINE WITHOUT FORMING AN UPWARD ARCH. REMOVE THE CLOTH USED TO COVER THE INTAKE PORTS. – Mount the EPC valve 5 on the lower air filter box and connect. – Mount the secondary air system valve 6 on the lower air filter box, connecting the thin hose to the intake manifold and the thick hose directly to the valve. – Attach the carburetor connection boots to the intake manifold. NOTE: the clamps on the carburetor connection boots must be aligned so that they can be tightened through the openings in the side covers. – Connect the fuel hoses to the carburetors. Repair manual KTM LC8 8 7 8 NOTE: to make it easier to connect the fuel hoses, disconnect the fuel hose from the connecting piece (on the side of the engine brace) and pull the fuel hose up. Reconnect after mounting the carburetor. – Insert the carburetor in the carburetor connection boots, tighten the clamps on the carburetor connection boots and screw both side covers on the lower air filter box. – Connect both vent hoses to the carburetors and fasten the choke cable 7 with a cable clip (see photo). – Insert the EPC hoses 8 in the corresponding openings in the lower air filter box and connect to the carburetors. bk 9 – Mount the air filter, position the intake trumpet 9 and turn in a counter-clockwise direction. – Mount the intake snorkel bk with the frame to the filter housing. – Screw on the upper air filter box half. Connect the vent hose and the EPC hose. 3-11 – Fit the upper battery cover and place a battery with battery cover into the battery compartment. – Fit the front battery compartment lid and connect both battery cables 1 together to the connections on the front lid (start with the positive cable). – Close the front battery compartment lid. 1 1 – Mount the underride protection, apply Loctite 243 to the 4 bolts 2 (M8x14 collar bolts) and tighten to 25 Nm. – Mount the front cover, apply Loctite 243 to both bolts 3 (M8x16) and tighten to 25 Nm. 3 2 2 – Mount the lower tank compartment and screw on the fuse box 4. Mount the fuse box cover. 4 4 – Fill cooling liquid into the radiator, compensating tank and engine: see Chapter 12. 5 5 4 4 – Fill engine oil: see Chapter 12. 7 – Connect the fuel sender to the right tank. Connect the gasoline and vent hoses and mount the tanks. – Screw in the upper 5 (M8x40) and lower 6 (M8x55) or 7 (M8x50) fixing bolts and open the fuel cocks. 6 – Connect the front turn signal and attach the vent hoses to the tanks. Fasten both side covers with the bolts 8 and tighten. 8 8 8 9 – Mount the upper tank compartment and fasten with the bolts 9. – Close the tank compartment lid and mount the seat. 9 – Remove the center stand lock bk 600.29.055.000, remount the left bump rubber and remove the center stand bl. bk – Check all hose connections for leakage before you take a trial run. – Check all hoses, lines and cables for a proper fit. bl 3-12 Removing the engine - 990 Adventure – Screw the center stand 600.03.022.000 onto the frame 1 and jack up the motorcycle on a firm, even surface. – Remove the left bump rubber and lock the center stand with the lock 600.29.055.000 2. 2 NOTE: if available, use the center stand already on the bike. 1 1 – Unlock the seat lock with the ignition key and remove. – Remove the bolts 3 on the left and right of the front side covers, disconnect the front turn signal, pull the tank vent hoses off of the fuel tank and remove the side covers. 3 4 3 Art.-No. 3.206.056-E 4 – Remove the bolts 5 on the lower tank compartment and the fuse box, take the cover off the fuse box and dismount the lower tank compartment. – Close the fuel cocks, disconnect the tank line, unscrew the upper 6 and lower 7 fixing bolts on both fuel tanks and remove the tanks together with the lower vent hoses. 5 5 6 6 5 5 – Drain the engine oil from the oil tank and the engine: see Chapter 12. 7 – Remove the 4 bolts 8 on the underride protection and take off the underride protection. – Remove both bolts 9 on the front cover and take off the cover. Repair manual KTM LC8 9 8 – Open the tank cover, unscrew the fixing bolts 4 and remove the upper tank compartment. 8 – Open the lid on the battery compartment and disconnect the battery terminals bk (starting with the negative pole). – Take out the battery and remove the upper battery cover. bk bk 3-13 2 3 – Unscrew the bolts 1 and remove the intake snorkel 2 together with the frame from the air filter box. – Disconnect the vent hose and the EPC hose and remove the upper half of the air filter box. – Turn the intake trumpet 3 in a clockwise direction and remove. Remove air filter. 1 – Disconnect the plug-in connection 4 of the SLS valve 5 and take the SLS valve off of the lower section of the air filter box. 4 5 – Pull the drain hose off of the lower section of the air filter box. – Unbolt both side covers on the lower air filter box. – Remove the fuel line 6 (special pliers 600.29.57.100) and loosen the hose clamps 7. – Take the plug-in connection 8 of the throttle body off of the holder and disconnect it. – Fold the throttle body up toward the front and secure it on the handlebar using a wire or rubber band; the throttle body does not need to be removed completely. – Take off the intake sleeves. 6 8 7 NOTE: The lower section of the air filter box must be raised slightly to make room for the plug-in connection 8 of the throttle body. – Take the lower section of the air filter box off of the intake flange. NOTE: cover the intake ports with a cloth to prevent any parts from falling inside. – Disconnect the plug-in connections of the manifold pressure sensors 9, remove the manifold pressure sensors 9 from the holders and set them down on the engine. 9 9 – Unscrew the heat shield bk at the front of the exhaust pipe and remove it. bk 3-14 – Expose the electric lines of the lambda probes at the front and rear and disconnect plug-in connections 1. 1 1 3 Art.-No. 3.206.056-E 2 5 5 4 – Disconnect the electric connections from the fan motor and the temperature switch 4. – Drain the cooling liquid from the radiator and engine: see Chapter 12. – Detach the water hoses from the radiator (special pliers 600.29.057.100) and unscrew the radiator 5 . NOTE: fan and radiator shield do not need to be dismounted from the radiator. 5 7 Repair manual KTM LC8 – Unscrew both nuts 2 on the front exhaust manifold flange on the cylinder head, loosen the exhaust clamp 3 on the front exhaust manifold, pull the front exhaust manifold out of the rear exhaust pipe and remove. – Unscrew the rear exhaust manifold from the cylinder head. – Pull off the oil lines from the oil tank to the valve covers 6 and the return line 7 (special pliers 600.29.57.100), unscrew the oil tank valve 8 on the oil tank and remove the seal ring. 9 6 9 8 – Loosen the fixing bolts 9 on the oil tank, remove the oil tank and carefully pull out the oil line. 3-15 23 – Disconnect the side stand switch 1 and take the cable out of the cable clips. – Loosen the two bolts 2 and the nut 3 and remove the side stand. 1 – Unscrew the clutch slave cylinder 4 and the chainguard 5. 4 5 7 – Remove the adapter for the clutch slave cylinder 6 and the chain securing guide 7. – Take off the adapter for the hydraulic coupling 8. – Pull the locking pin out of the pushrod. 8 6 – Unscrew the nut on the wheel spindle. – Take the chain off of the rear sprocket and place over the side of the bracket 9. – Remove the chain from the engine sprocket 9 – Detach the connector bk. bk – Remove the engine vent hose bl, discarding the hose clamp. bk bl 3-16 – Take off the positive starter cable cover 1. Unscrew the positive starter engine cable 2 and draw out the wiring harness. 2 1 3 – Detach connector 3 on the starter relay. – Unscrew the ground connection 4. – Pull off the cover 5 from the positive terminal, unscrew the nut beneath it and remove the lines from the stud. – Pull the battery cable with the lock 6 from the holder. 5 6 4 – Loosen the bolts on the side support 7 and the nut on the bolt 8, pull out the bolt and remove support together with the battery case. Art.-No. 3.206.056-E NOTE: When removing the lateral supports with the battery box, ensure that the lines of the locks are not pinched. 7 8 Repair manual KTM LC8 9 – Use the trolley jack to position the attachment 600.29.055.100 on the engine, insert the bolt 9 through the front of the engine bracket and fasten with the nut. – Remove the retaining pin bk by removing the lock on the retaining pin bk. – Detach the return spring of the brake lever. – Remove the bolt bl and tilt the foot brake pedal to the side. bl bk 3-17 1 – Unscrew the ground wire connection 1. – Detach the connector from the pulse generator 2. 2 1 3 5 – Detach the connector from the oil pressure switch 3, the temperature sensor 4 and from the front 5 and rear ignition coil. Remove any cable clips necessary. 4 – Pull the bolt 6 out of the lower support (if necessary, raise or lower the engine slightly). – Loosen the nut on the swing arm pivot 7 and knock out the swing arm pivot with a suitable pipe. 7 – Pull the engine towards the front with the trolley jack, lower and pull away towards the side. – Disconnect all hoses and lines from the engine. 6 3-18 Refitting the engine - 990 Adventure – Before mounting the engine, attach the water, SLS and vacuum hoses (Öttiger clamps - special pliers 600.29.057.000 or springloaded band-type clamps - special pliers 600.29.057.100) – Position the swing arm and fix with the swing arm pivot on the right and a suitable pipe on the left. – Lift the engine into the frame with the trolley jack, insert the sealing washer in the rear exhaust flange and secure with copper paste if necessary. – Guide the chain along the side of the pinion and insert the swing arm pivot 1, screw on the nut but do not tighten yet. – Insert the bolt 2 in the lower support (raise or lower the engine slightly if necessary). – Remove the trolley jack attachment 600.29.055.100 from the engine. 1 2 Art.-No. 3.206.056-E 3 – Plug the connector on the oil pressure switch 3, the temperature sensor 4 and the front and rear ignition coil 5. Use cable clips to fasten the wiring harnesses. 5 4 6 – Screw on the ground wire connection 6. – Attach the pulse generator connector 7. Repair manual KTM LC8 7 6 – Position the foot brake pedal, apply Loctite 243 to the bolt 8 and tighten to 25 Nm. – Attach the return spring to the foot brake pedal. – Install the retaining pin 9 by installing the lock on the retaining pin. 9 8 3-19 – Align the side supports and battery case against the engine, insert the bolt 1 and mount the nut. – Mount the bolts 2 (M10x23), lifting the engine slightly if necessary. Tighten the nut and bolts to 45 Nm. – Tighten the nut on the swing arm pivot to 130 Nm. 2 1 – Run the positive starter cable to the starter and screw on the starter motor 3 and mount the positive starter cable cover 4. 3 4 7 6 – Attach the locks 5 to the holder and connect the lines to the stud of the positive terminal. – Tighten the nut of the positive terminal with 4 Nm and mount the cover 6 onto the stud of the positive terminal. – Plug in the connector 7 of the starter relay. – Screw on the ground wire 7 of the regulator. 5 8 – Attach the connector 9. 9 – Slip on the hose from the engine ventilation bk and mount the new Öttiker clamp with the special pliers 600.29.057.000. 9 bk bl bl – Place the chain over the pinion and rear sprocket. – Tighten the chain using the chain adjuster bl; see the owner's manual. – Tighten the nut on the wheel spindle to 90 Nm. 3-20 – Insert the locking pin in the pushrod. – Mount the adapter for the hydraulic clutch 1. – Mount the chain securing guide 2 and the adapter for the clutch slave cylinder 3. 2 1 3 – Screw on the clutch slave cylinder 4 and the chainguard 5. 4 5 – Position the side stand. – Tighten the two bolts 6 and the nut 7 to 45 Nm (with Loctite 243). – Mount the side stand switch 8 and fasten the cable with the cable clips. Art.-No. 3.206.056-E 67 8 – Mount the oil tank and tighten the fixing bolts 9. 9 – Connect the return line bk to the oil tank and mount the springloaded band-type clamp with the special pliers 600.29.057.100. – Attach the oil lines from the oil tank to the valve covers bl (special pliers 600.29.057.100). Repair manual KTM LC8 – Mount the oil line onto the oil tank bm with a new O-ring, mount the screws and tighten with 10 Nm. NOTE: – to allow the oil pump to build up the oil pressure faster, remove the suction line (left) from the oil tank and fill with engine oil. – Check the hose part of the suction line for cracks. bm bk bl 9 3-21 – Screw on the radiator together with the fan and the radiator shield 1, tighten the bolts to 10 Nm. – Connect the water hoses on the radiator (special pliers 600.29.057.100) 1 – Attach the electric connections for the fan motor and the temperature switch 2. 1 1 2 4 3 – Screw the rear exhaust manifold on to the cylinder head. – Insert the front exhaust manifold in the rear exhaust pipe, mount to the front cylinder head together with the sealing washer and tighten the exhaust nuts 3. NOTE: – on a stud, a washer must be mounted as a spacer between the clamping plate and the cylinder. – the exhaust nuts should be tightened evenly without bending the metal sheet. – Tighten the exhaust clamps 4 of the front and rear manifolds. – Attach the heat shield 5 on the exhaust pipe at the front and screw tight. NOTE: Lubricate the screws of the heat shield 5 with copper paste. 5 – Route the electric lines of the lambda probes at the front and rear, secure them with cable binders and create plug-in connections 6. 6 6 – Attach the manifold pressure sensors 7 to the holders and create the plug-in connections. 7 7 3-22 – Place the lower section of the air filter box onto the intake flange. 3 ! REMOVE CAUTION ! THE CLOTH USED TO COVER THE INTAKE PORTS. – Place the throttle body into the lower section of the air filter box. NOTE: The lower section of the air filter box must be raised slightly to make room for the plug-in connection 1 of the throttle body 2 – Connect the drain hose to the lower section of the air filter box. – Connect the lower section of the air filter box to the intake flange. – Attach the sleeves of the throttle body to the intake flange. 1 NOTE: the clamps on the carburetor connection boots must be aligned so that they can be tightened through the openings in the side covers. – Insert the throttle body into the sleeves and tighten the hose clamps 2 of the sleeves. – Connect the fuel hose 3 to the throttle body. – Create the plug-in connection 1 of the throttle body. 4 – Mount the SLS valve 4 on the lower section of the air filter box and create the plug-in connection. Art.-No. 3.206.056-E 6 5 – Mount the air filter, position the intake trumpet 5 and turn in a counter-clockwise direction. – Mount the intake snorkel 6 with the frame to the filter housing. – Screw on the upper air filter box half. Connect the vent hose and the EPC hose. – Fit the upper battery cover and place a battery with battery cover into the battery compartment. – Fit the front battery compartment lid and connect both battery cables 7 together to the connections on the front lid (start with the positive cable). – Close the front battery compartment lid. Repair manual KTM LC8 7 7 – Mount the underride protection, apply Loctite 243 to the 4 bolts 8 (M8x14 collar bolts) and tighten to 25 Nm. – Mount the front cover, apply Loctite 243 to both bolts 9 (M8x16) and tighten to 25 Nm. 8 9 9 3-23 – Fill cooling liquid into the radiator, compensating tank and engine: see Chapter 12. – Fill engine oil: see Chapter 12. 2 2 – Attach both tanks and fix them with the screws 1 (M8x40). – Connect the tank line. 1 1 2 2 – Mount the lower tank compartment and screw on the fuse box 2. Mount the fuse box cover. 4 3 – Connect the tank gauge sender to the right tank and connect the vent hoses. – Mount screws 3 (M8x55) and 4 (M8x50) and open the fuel taps. – Connect the front turn signal and attach the vent hoses to the tanks. Fasten both side covers with the bolts 5 and tighten. 5 5 5 6 – Mount the upper tank compartment and fasten with the bolts 6. – Close the tank compartment lid and mount the seat. 6 – Remove the center stand lock 7 600.29.055.000, remount the left bump rubber and remove the center stand 8. 7 – Check all hose connections for leakage before you take a trial run. – Check all hoses, lines and cables for a proper fit. 8 3-24 Dismounting the engine - 990 Super Duke NOTE: the procedure for dismounting the engine is the same as the procedure used for the 950 Adventure; the only deviations are in the preparatory work: – Remove the spoiler and tank side covers. – Disconnect the fuel hose connection (see Chapter 8), remove the front tank screw, pull off the vent line and fold up the tank. – Dismounting the throttle body: remove both side covers on the air filter box, loosen the clamps 1 on the throttle body and dismount the fuel line 2. Art.-No. 3.206.056-E 2 1 1 Repair manual KTM LC8 – Pull the throttle body up, disconnect the wiring harness, remove both throttle cables and lift out the throttle body. 3 4 – Unscrew the ball joints from the shift rod and the foot brake lever, remove both footrest screws on the left and right, screw the assembly stand 625.29.055.000 in the lower screw holes 3 and 4 and tighten. – Press down on the back of the assembly sand to jack up the motorcycle. 3-25 Mounting the engine - 990 Super Duke – Connect the water, SLS and vacuum hoses to the engine before mounting (Öttiger clamps - special pliers 600.29.057.000 or spring-loaded band-type clamps - special pliers 600.29.057.100). – Position the exhaust system under the motorcycle according to the installation position. – Position the swing arm and hold in place with the swing arm bolt on the right and a suitable pipe on the left. – Lift the engine into the frame with a floor jack, insert the sealing washer in the rear exhaust flange and, if necessary, secure with a small amount of copper paste. – Run the chain along the side of the pinion and push the swing arm bolt 1 through the chain, screw on the nut but do not tighten yet. – Insert the bolt 2 for the lower support through the chain (raise or lower the engine if necessary). – Remove the floor jack attachment 600.29.055.100 from the engine. 1 2 3 5 – Connect the connectors for the oil pressure switch 3, the temperature sensor 4 and the front 5 and rear ignition coil. Secure the wiring harnesses with cable clips. 4 – Screw on the ground cable terminal 6. 6 7 8 – Insert the short manifold pipe into the exhaust with a new gasket. – Position the front and rear exhaust manifold on the cylinder head and slightly tighten the nuts 7 and 8; do not screw tight. 3-26 – Mount the exhaust pipe clamp 1 between the manifold and the main silencer and slightly tighten. – Slightly tighten the exhaust pipe clamp 2 on the rear manifold. 1 NOTE: – Do not tighten the screw connections until the exhaust system is completely installed and mounted stress-free. – Tighten the exhaust nuts evenly without bending the sheet. – Tightening torque for clamp 1: 35 Nm and clamp 2: 12 Nm. 2 4 – Position the side stays on the engine, insert the bolt 3 and mount the nut. – Turn in the screws 4 (M10x24), lifting the engine if necessary. Tighten the nut and screws to 45 Nm. – Tighten the nut on the swing arm bolt to 130 Nm. 4 3 Art.-No. 3.206.056-E – Mount the battery case with the controller and horn, using the black screw 5 in the position shown. 5 Repair manual KTM LC8 – Run the positive starter cable 6 to the starter engine 7 and screw on, screw on the starter ground and run to the battery case. 6 7 3-27 – Place the battery in the battery case and attach the battery case cover. – Connect the positive starter relay cable to the positive pole on the battery. – Connect the two ground connections to the negative pole on the battery (2 green cables from the controller and 1 black cable from the starter engine). – Close the battery case cover and screw on, mount the starter relay. 1 2 4 3 – Run the wiring harness from above behind the side stay, through the recess 1 and to the starter relay. – Connect connector 2 on the starter relay (2 red/white cables), the regulator output 3 (2 red/white cables) and the generator 4 (3-pole connector). – Run the horn cable 5 in front of the controller, connect and fasten with the clip. 5 – Position the side stand and tighten both screws and the nut to 45 Nm (+ Loctite 243). NOTE: – Run cable 6 for the lambda probe, the side stand switch and the gear sensor behind the side stand console. – Fasten the lambda probe cable to the frame with a cable clip. 6 – Connect the connector for the lambda probe, the side stand switch and the gear sensor to the wiring harness. – Align the wiring harnesses in a loop as shown in the photo and fasten with clamp 7 and cable clips. 7 3-28 – Fasten the wiring harnesses and connector on the pulse generator 1 with cable clips. 1 2 2 – Run the chain over the pinion and rear sprocket, raise the rear wheel and push the wheel spindle through. – Push the rear wheel forward until the chain tensioner 2 rests against the stop screw and tighten the wheel spindle nut to 90 Nm. – Actuate the foot brake lever until the brake pads rest against the brake disk again. – Check the chain tension (see Owner's Manual). Art.-No. 3.206.056-E – Attach the lock pin to the pushrod and align with the recess in the chainguard. Mount the chain clip and the chainguard. – Mount the clutch slave cylinder 3 and screw on the chainguard 4. 3 4 – Mount the oil tank and tighten the fixing screws 5. – Mount the suction line 6 with a new O-ring. 5 7 – Connect the oil lines from the oil tank to the valve covers 7 (special pliers 600.29.057.100). Repair manual KTM LC8 – Connect the return line 8 to the oil tank and mount the springloaded band-type clamps with the special pliers 600.29.057.100. 5 6 8 5 3-29 1 2 1 1 – Screw on the radiator, the fan and the radiator shield 1, tighten the screws to 10 Nm. – Mount the water hoses on the radiator (special pliers 600.29.057.100) – Connect the electric connectors for the temperature switch 2 and fan motor 3. 1 3 – Connect the hose on the front vacuum sensor 4 and the connector on the front lambda probe 5; attach the connector to the frame with a cable clip. ! CAUTION ! – ALWAYS – 5 – 4 REPLACE THE VACUUM HOSES ON THE INTAKE MANIFOLD IF THEY WERE PULLED OFF. DO NOT USE SILICONE SPRAY WHEN MOUNTING THE VACUUM HOSES. IT CAN DAMAGE THE MANIFOLD AIR PRESSURE SENSORS. DO NOT EXCHANGE THE CONNECTIONS ON THE INTAKE MANIFOLD WITH THE CONNECTIONS ON THE 950 ADVENTURE OTHERWISE THE INJECTION SYSTEM IS LIKELY TO MALFUNCTION. – Place the lower air filter box on the intake ports, connect the drain hose and push the fuel hose down through the opening in the lower air filter box. ! REMOVE CAUTION ! THE CLOTH USED TO COVER THE INTAKE PORTS. – Slip the throttle body bellows over the intake manifolds. NOTE: align the clamps on the bellows so they can be tightened through the openings in the side cover. – Place the throttle body in the lower air filter box and mount the throttle cables - see throttle cable adjustment, chapter 2. – Insert the throttle body in the bellows and tighten the bellows clamps. – Connect the fuel hose to the throttle body. 3-30 – Mount the throttle cable duct 1. 1 – Screw on the left side cover of the lower air filter box together with the bracket 2 for the vacuum hose to the rear vacuum sensor. – Connect the hose on the rear vacuum sensor. 2 ! CAUTION ! – ALWAYS – – REPLACE THE VACUUM HOSES ON THE INTAKE MANIFOLD IF THEY WERE PULLED OFF. DO NOT USE SILICONE SPRAY WHEN MOUNTING THE VACUUM HOSES. IT CAN DAMAGE THE MANIFOLD AIR PRESSURE SENSORS. DO NOT EXCHANGE THE CONNECTIONS ON THE INTAKE MANIFOLD WITH THE CONNECTIONS ON THE 950 ADVENTURE OTHERWISE THE INJECTION SYSTEM IS LIKELY TO MALFUNCTION. Art.-No. 3.206.056-E – Screw on the right side cover of the lower air filter box together with the bracket 3 for the secondary air system hose. 3 – Mount the intake snorkel 4 and frame on the air filter housing and screw on. – Mount the air filter and the intake trumpet 5. 4 Repair manual KTM LC8 – Mount the upper air filter box half and screw on, connect the vent hose and SLS hose, attach the intake temperature sensor. – Mount the secondary air system valve on the lower air filter box and connect. 5 – Mount the radiator compensating tank, connect the short hose 6 to the radiator, run the longer hose 7 in front of the intake snorkel over the air filter box to the left side of the motorcycle and continue along the frame to behind the battery case. 7 6 3-31 – Run the tank vent hose down parallel to the overflow hose on the compensating tank, tilt the tank forward and screw on. Connect the tank vent hose and fuel connector. – Mount both tank side covers and the spoiler and tighten the screws. – Remove the assembly stand. – Apply Loctite 243 to the screws of the footrest support 1 and tighten to 25 Nm. – Mount the relay lever for the shift rod, apply Loctite 243 to screw 2 and tighten to 18 Nm. – Apply Loctite 243 to the screw on the shift rod 3 and tighten to 12 Nm. 1 2 3 5 – Apply Loctite 243 to the screws of the footrest support 4 and tighten to 25 Nm. – Apply Loctite 243 to the screw of the foot brake push rod 5 and tighten to 12 Nm. – Bleed the cooling system (see Chapter 12). 4 – Add engine oil (see chapter 12). – Check all hose connections for leakage before taking a test ride. – Check all hoses, lines and cables for a tight fit. 3-32 Dismounting the engine - 990 Super Duke R NOTE: the procedure for dismounting and mounting the engine is the same as the procedure used for the 950 Adventure; the only deviations are in the preparatory work: – Remove the spoiler and tank side covers. – Remove the holder for the seat. – Disconnect the fuel hose connection (see Chapter 8), remove the front tank screw, pull off the vent line – Disconnect the plug-in connections. – Disconnect the fuel supply line, loosen the tank fixation at the rear and take off the tank. ! CAUTION ! To prevent damage to the tank, place it on a surface covered with a cloth. – Take off both side covers of the air filter box, loosen the hose clamps 1 of the throttle body and remove the fuel line 2. – Expose the plug-in connection 3 of the throttle body and disconnect it. 2 Art.-No. 3.206.056-E – Fold the throttle body up toward the front and secure it on the handlebar using a wire or rubber band; the throttle body does not need to be removed completely. 1 3 Repair manual KTM LC8 4 4 NOTE: The lower section of the air filter box must be raised slightly to make room for the plug-in connection 3 of the throttle body. – Unscrew the ball joints from the shift rod and the foot brake lever, remove both footrest screws on the left and right. – Mount the fixing bolts of assembly stand 625.29.055.000 into the lower screw holes 4 and tighten. – Press down on the back of the assembly sand to jack up the motorcycle. – Drain the coolant out of the radiator and engine: see Chapter 12. – Drain the engine oil out of the oil tank and engine: see Chapter 12. 5 – Disconnect the coolant hoses at the joint 5 by loosening the hose clamps (special pliers 600.29.057.100). 5 5 3-33 – Expose the lines of the ignition coil connectors for the cylinder at the front and rear, take the plug-in connections off of the holder and disconnect the plug-in connections 1 for the cylinder at the front and rear. 1 – Unscrew the holder 2 of the front exhaust manifold from the engine. 2 – Loosen the exhaust clamps 3 of the front and rear exhaust manifold. 3 3 – Unscrew both nuts 4 of the front exhaust manifold flange from the cylinder head. – Pull the front exhaust manifold out of the rear exhaust pipe and remove it. – Unscrew both nuts 5 of the rear exhaust manifold from the cylinder head and remove them. 4 5 NOTE: – on a stud, a sleeve must be mounted as a spacer between the cylinder and the clamping plate. – the nuts 4 of the front exhaust manifold and the nuts 5 of the rear exhaust manifold must be tightened evenly without warping the clamping plate. – Assembly is performed in reverse order. 3-34 Dis-/Mounting the engine - 950 Supermoto/R NOTE: the procedure for dismounting the engine is the same as the procedure used for the 950 Adventure; the only difference is in the preparatory work: Jack up the motorcycle with the assembly stand 625.29.055.000: – Remove the footrests on each side and screw off the foot brake lever. – Mount the retaining bolt insert 1 on the assembly stand. – Raise the assembly stand in the back and slide the retaining bolts in the footrest support on each side. NOTE: if you have trouble sliding the retaining bolts into the footrest support, loosen the counternuts 2 and tighten again after the retaining bolts have been pushed in the footrest supports. – Press down on the back of the assembly stand to jack up the motorcycle. 2 Art.-No. 3.206.056-E 1 Removing the tank: – Remove the tank covers 3 (3 screws on left; 2 screws on right). – Remove both tank spoilers 4 (2 screws in the front and 2 from the outside). 4 3 – Close both fuel taps and disconnect the fuel hoses. – Disconnect the fuel connection by pressing lightly on the metal plate 5 and pulling the connection apart. – Remove the fuel hose 6 from the fuel pump. Repair manual KTM LC8 6 5 7 – Unscrew the tank retaining screw and pull the tank ventilation off the connector at the filling hole. – Disconnect the connector for the horn 7. – Disconnect the fuel sender and fuel pump connector 8. – Carefully lift off the tank. – To mount, proceed in the reverse order. – To bleed the cooling system: see chapter 12 – To add engine oil: see chapter 12 8 3-35 Removing the engine - 990 Supermoto – Jack up the motorcycle on the link fork using assembly stand 625.29.055.000. – Open the seat lock with the ignition key and take off the seat. 1 – Unscrew the screws 1 on the left and right of the side cover and take off the side cover. – Drain the coolant out of the radiator and engine: see Chapter 12. – Drain the engine oil out of the oil tank and engine: see Chapter 12. 1 – Close both fuel taps 2 and pull off the fuel hoses. – Disconnect the fuel connection by pressing lightly on the metal plate 3 and pulling the connection apart. – Disconnect the connection 4 of the gasoline pump and tank gauge sender. – Unscrew the tank fixing screws and pull the tank breather off of the connection at the filling hole. – Remove the tank carefully. 2 4 3 – – – – 5 6 Remove the side cover 5 on the left and right. Expose the line of the side stand and disconnect it. Remove the screws 6 and the nut 7. Remove the side stand. 7 – Expose the lines of the lambda probes and disconnect the plug-in connections 8. 8 8 – Loosen the exhaust clamps of the front and rear exhaust manifold. – Unscrew the holder 9 of the front exhaust manifold from the engine. 9 3-36 – Loosen the nuts 1 of the front exhaust manifold and take off the front exhaust manifold. – Loosen the nuts 2 of the rear exhaust manifold and take off the rear exhaust manifold. 1 1 2 2 – Remove the retaining pin 3 by remove the lock on the retaining pin. – Detach the return spring of the brake lever. – Remove the screw 4 and take off the foot brake pedal. – Remove the footrests on both sides. 4 3 Art.-No. 3.206.056-E – With the help of another person, jack up the motorcycle at the rear. – Mount the retaining pin insert 5 on the assembly stand. – Raise the assembly stand at the rear and slide the retaining pins on both sides into the footrest holder. NOTE: If the retaining pins are difficult to slide into the footrest holder, or cannot be slid in at all, loosen the counter nuts 6 and, after the retaining pins have been slid into the footrest holder, retighten them. – Push down the rear of the assembly stand to jack up the motorcycle. 6 Repair manual KTM LC8 5 – Disconnect the negative terminal of the battery. – Remove the vent hose 7 and the hose 8 of the SLS valve on the upper section of the air filter box (special pliers 600.29.57.100). – Disconnect the plug-in connection 9 of the intake air temperature sensor. – Unscrew the screws of the upper section of the air filter box and remove the upper section of the air filter box. 7 8 9 3-37 2 3 – Unscrew the screws 1 and take the intake snorkel 2 with the frame off of the air filter box. – Pull off the vent and EPC hoses and remove the top section of the air filter box. – Turn the intake trumpet 3 clockwise and take it off; remove the air filter. 1 – Disconnect the plug-in connection 4 of the SLS valve 5 and take the SLS valve off of the lower section of the air filter box. 4 5 – Disconnect the plug-in connection 6 of the generator. – Take the manifold pressure sensors 7 on the left and right off of the holder and disconnect the plug-in connections. – Take the plug-in connection 8 of the throttle body off of the holder and disconnect the plug-in connection 8. – Pull the drain hose off of the lower section of the air filter box. – Unscrew both side covers of the lower section of the air filter box. 6 7 7 8 – Remove the fuel line 9 (special pliers 600.29.57.100) and loosen the hose clamps bk. – Fold the throttle body up toward the front and secure it on the handlebar using a wire or rubber band; the throttle body does not need to be removed completely. 9 NOTE: The lower section of the air filter box must be raised slightly to make room for plug-in connection of the throttle body. – Take the lower section of the air filter box off of the intake pipe. bk NOTE: The intake channels should be closed off with a cloth to keep parts from falling out. – Disconnect the electrical plug-in connection of the horn. – Disconnect the electrical connections of the fan motor and temperature switch bl. – Remove the water hoses from the radiator (special pliers 600.29.057.100) – Remove the screws bm and take off the radiator. bm bl NOTE: The fan and radiator shield do not need to be removed from the radiator. bm 3-38 – Detach the oil line between the oil tank and the valve cover from the front of the oil tank (special pliers 600.29.57.100). – Unscrew the oil lines from the oil terminal 1 and pull them out; remove the O-rings. 2 1 – Loosen the retaining screws 2 at the oil tank and take off the oil tank. 4 – Expose the line of the gear position sensor. – Disconnect the plug-in connection 3 of the gear position sensor. – Disconnect the plug-in connection 4 of the ignition pulse generator. 3 2 Art.-No. 3.206.056-E – Loosen the screws 5 of the lateral supports and the nut 6 of the bolt, pull out the bolt and take off the supports. 5 6 8 – Unscrew the clutch slave cylinder 7 and chainguard 8. – Remove the chain roller and the chain securing guide. – Pull the locking pin out of the push rod. Repair manual KTM LC8 7 bk bl 9 – Remove the adapter for the clutch slave cylinder 9 and the chain securing guide bk. – Take off the adapter for the hydraulic coupling bl. – Pull the locking pin out of the push rod. 3-39 – – – – Loosen the chain adjuster. Loosen the nut of the wheel spindle. Push the wheel into the frontmost position. Remove the chain 1 from the rear sprocket and place it over the link fork. – Take the chain off of the engine sprocket. NOTE: To avoid damaging the link fork, place a cloth between the link fork and the chain 1. 1 – Position component 600.29.055.100 on the engine with the trolley jack, push the bolt 2 of the engine support through the front and raise the engine slightly. 2 – Unscrew the ground cable connections 3 and the positive cable from the starter. 3 3 – Disconnect the connectors of the oil pressure sensor 4, temperature sensor 5 and the front 6 and rear ignition coils. Remove the cable binders where necessary. 4 5 6 – Pull out the bolt 7 of the lower support (raising or lowering the engine slightly if necessary). – Loosen the nut of the swingarm pivot 8 and hammer out the swingarm pivot with a suitable pipe. – Using the trolley jack, pull the engine forward, lower it and move it out to one side. 7 8 – Remove all hoses and cables from the engine. 3-40 Refitting the engine - 990 Supermoto – Before mounting the engine, attach the water, SLS and vacuum hoses (Öttiger clamps - special pliers 600.29.057.000 or springloaded band-type clamps - special pliers 600.29.057.100) – Position the swing arm and fix with the swing arm pivot on the right and a suitable pipe on the left.. – Lift the engine into the frame with the trolley jack, insert the sealing washer in the rear exhaust flange and secure with copper paste if necessary. – Guide the chain along the side of the pinion and insert the swing arm pivot 1, screw on the nut but do not tighten yet. – Insert the bolt in the lower support (raise or lower the engine slightly if necessary). – Remove the trolley jack attachment 600.29.055.100 from the engine. 1 – Plug the connector on the oil pressure switch 2, the temperature sensor 3 and the front and rear ignition coil 4. Use cable clips to fasten the wiring harnesses. Art.-No. 3.206.056-E 2 3 4 – Screw the ground cable connections 5 and the positive cable onto the starter. Repair manual KTM LC8 5 5 – Place the chain over the pinion and rear sprocket. – Tension the chain using the chain adjuster 6, see the owner's manual. – Tighten the nut on the wheel spindle to 90 Nm. 6 6 3-41 – Insert the locking pin in the pushrod. – Mount the adapter for the hydraulic clutch 1. – Mount the chain securing guide 2 and the adapter for the clutch slave cylinder 3. 2 1 3 5 – Screw on the clutch slave cylinder 4 and the chainguard 5. 4 – Align the side supports and battery case against the engine, insert the bolt 6 and mount the nut. – Mount the bolts 7 (M10x23), lifting the engine slightly if necessary. Tighten the nut and bolts to 45 Nm. – Tighten the nut on the swing arm pivot to 130 Nm. 7 6 – Carefully install the oil line, mount the oil tank and tighten the fixing bolts 8. – Connect the return line to the oil tank and mount the spring-loaded band-type clamp with the special pliers 600.29.057.100. – Mount both oil lines on the oil terminal 9 with new O-rings, screw in the screws (M6x20) with the holding plates and tighten with 10 Nm. 8 8 NOTE: – To ensure that the oil pump can build up oil pressure more quickly, the intake line (left) should be removed from the oil tank and prefilled with engine oil. – Check the hose section of the intake line for tearing - see Technical Information. bl 9 bk – Create the plug-in connection bk of the gear position sensor and secure the line with cable binders. – Create the plug-in connection of the ignition pulse generator bl. 3-42 – Screw on the radiator together with the fan and the radiator shield 1, tighten the bolts to 10 Nm. – Connect the water hoses on the radiator (special pliers 600.29.057.100) – Create the electrical plug-in connection of the horn, fan motor and temperature switch 2. 1 1 2 – Mount the lower air filter box on the intake ports. ! 5 REMOVE CAUTION ! THE CLOTH USED TO COVER THE INTAKE PORTS – Place the throttle body into the lower section of the air filter box. NOTE: The lower section of the air filter box must be raised slightly to make room for the plug-in connection 3 of the throttle body. – Connect the drain hose to the lower section of the air filter box. – Connect the lower section of the air filter box to the intake flange. – Attach the sleeves of the throttle body to the intake flange. 4 Art.-No. 3.206.056-E NOTE: the clamps on the carburetor connection boots must be aligned so that they can be tightened through the openings in the side covers. – Insert the throttle body in the bellows and tighten the bellows clamps 4. – Connect the fuel hose 5 to the throttle body. 7 6 6 3 – Create the plug-in connection 3 of the throttle body and attach it to the holder. – Attach both side covers of the lower section of the air filter box and screw them on tightly. – Attach the manifold pressure sensors 6 to the holder and create the plug-in connections. – Create the plug-in connection 7 of the generator. – Put the air filter in place, position the intake trumpet 8 and turn counterclockwise. – Mount the intake snorkel 9 with the frame on the air filter housing. 9 Repair manual KTM LC8 8 – Position the upper section of the air filter box, screw it in place and connect the vent hose. – Create the plug-in connection of the intake air temperature sensor bk. – Mount the vent hose bl and the hose bm of the SLS valve (special pliers 600.29.57.100). bl bm – Connect the negative terminal of the battery. bk 3-43 – Take down the motorcycle with the help of a second person and take the assembly stand 1 out of the footrest holder. – Jack up the motorcycle on the link fork. – Mount the footrests on both sides. 1 – Position the foot brake pedal and tighten the screw 2 with 25 Nm (+ Loctite 243). – Attach the return spring to the foot brake pedal. – Mount the retaining pin 3 by installing the lock on retaining pin. 2 3 – Position the rear exhaust manifold and fix it with the nuts 4, but do not tighten the nuts yet. – Position the front exhaust manifold and fix it to the holder with the screw 6. – Tighten the nuts 5 of the front exhaust manifold and the nuts of the rear exhaust manifold. 4 4 5 5 NOTE: – in each case, one of the studs must be mounted with a sleeve that acts as a spacer between the cylinder and the clamping plate. – the exhaust nuts should be tightened evenly without warping the clamping plate. – Tighten the exhaust clamps of the front and rear exhaust manifolds. – Tighten the screw 6 of the holder of the front exhaust manifold. 6 – Route the lines of the lambda probe, secure them with cable binders and create the plug-in connections 7. 7 7 3-44 3 1 – Position the side stand. – Tighten the screw 1 and the nut 2 with 45 Nm (+ Loctite 243). – Create the plug-in connection of the side stand switch and secure the cable with cable binders. – Mount both side covers 3. 2 – Fill coolant into the radiator, compensating reservoir and engine: see Chapter 12. – Fill in engine oil: see Chapter 12. – Position the tank on the motorcycle and screw it in place. – Create the connection 4 of the gasoline pump and tank gauge sender. – Create the fuel connection 5 by connecting the two lines. – Mount the fuel hoses and open the fuel taps 6. 6 5 4 – Position the side covers and screw them in place 7. Repair manual KTM LC8 Art.-No. 3.206.056-E – Mount the seat and take down the motorcycle. – Before taking a test ride, check all hose connections for tightness. – Check that all hoses, lines and cables are correctly seated. 7 4-1 DISASSEMBLING THE ENGINE Repair manual KTM LC8 Art.-No. 3.206.056-E INDEX VALVE COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2 SPARK PLUG SHAFT INSERTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2 STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2 SETTING CYLINDER REAR TO TDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3 CAMSHAFTS CYLINDER REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3 CHAIN TENSIONER CYLINDER REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4 TIMING CHAIN CYLINDER REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4 DOUBLE TIMING GEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5 CYLINDER HEAD REAR WITH CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5 SETTING CYLINDER FRONT TO TDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5 CAMSHAFTS CYLINDER FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6 OIL PRESSURE SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6 CHAIN TENSIONER CYLINDER FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6 TIMING CHAIN CYLINDER FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7 CYLINDER HEAD FRONT WITH CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7 WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8 OIL SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8 CLUTCH COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8 CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9 PRIMARY PINION AND CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10 GENERATOR COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11 ROTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11 FREEWHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12 BALANCER SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12 SHIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12 ENGINE CASE HALF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13 TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14 OIL PUMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15 4 4-2 Clean the engine thoroughly on the outside prior to disassembling. – Clamp the engine in the work stand using the special tool 600.29.002.000. Valve covers 1 – – – – 990 Super Duke R only: remove screw 1. Pull out the spark plug connectors.. Unscrew the spark plugs using the special tool 600.29.073.000. Remove the bolts 1 on the valve covers, remove both valve covers. – Dismount the gaskets of the bolts, the valve covers and the spark plug shafts 2. 2 2 Art.-No. 3.206.056-E 2 3 Spark plug shaft inserts – Pull the spark plug shaft inserts out of the spark plug shafts (pry out carefully with 2 screwdrivers if necessary), remove the O-rings 3 (2 pieces for each spark plug shaft) and discard. Repair manual KTM LC8 4 Starter motor – Remove both bolts 4 and pull the starter motor out of the case. The starter motor is sealed off with an O-ring on the case side. 5 5 4-3 Setting cylinder rear to TDC – Unscrew the plug 1 from the generator cover to be able to turn the crankshaft. 1 – Turn the crankshaft in a counterclockwise direction until the rear cylinder is in the TDC position. The marks 2 (points as of model year 2007) must coincide with the flat outer surface of the cylinder head at the camshaft gears. NOTE: the camshaft gears are identical for both cylinders but have marks for cylinders rear and front. Match the respective mark to the respective cylinder, i.e. the crosses for cylinder rear and the circles for cylinder front. 2 2 – Remove the case bolt and screw in the special tool 0113 080802 3 to block the crankshaft. 3 Camshafts cylinder rear – Check and note down the valve clearance before you dismount the camshafts. Valve clearance (at 20ºC): intake 0.10 - 0.15 mm exhaust 0.25 - 0.30 mm – Loosen the bolts on the camshaft bearing bridge from the rear cylinder and carefully remove the camshaft bearing bridge. ! CAUTION ! TIGHTENING THE BOLTS OF THE CAMSHAFT BEARING BRIDGE, MAKE SURE THAT THE VALVES ARE NOT ACTUATED BY THE CAMSHAFT (SEE ILLUSTRATION), OTHERWISE THE BEARING BRIDGE WILL BREAK. WHEN – Remove the camshafts from the cylinder head without tilting. 4-4 Chain tensioner cylinder rear – Remove the bolt from the chain tensioner 1. 1 NOTE: measure the preload on the chain tensioner element before dismounting: – Apply the chain tensioner bolt to the chain tensioner element without compressing the spring. – Measure the distance between the sealing washer and the cylinder head. The measured value should be between 6 mm and 11 mm. If the value is lower, the tensioning rail could be worn or the timing chain excessively elongated. If it is higher, the engine was turned to TDC against the running direction. – Remove the sealing washer. – Pull out the chain tensioner element 2. Art.-No. 3.206.056-E NOTE: the housing and the tensioning piston on the chain tensioner element are compression molded. If they fall apart during disassembly, the chain tensioner element must be replaced. 2 Timing chain cylinder rear Repair manual KTM LC8 NOTE: Valid up to and including model year 2006 – Loosen the bearing bolt 3 on the double timing gear and pull out of the cylinder head together with the needle bearing. The double timing gear will slide down slightly, relieving the timing chain. NOTE: Valid as of model year 2007 – Remove the screw of the bearing bolt 4 and carefully press out the bearing bolt 4 with a screwdriver. The timing gear slips down easily and the timing chain loosens. 3 4 A 5 6 7 – Remove the O-ring on the bearing bolt. – Use a wire hook A which you can bend from a piece of welding wire to lift the side of the chain 5 towards the inside from the chain teeth 6 over the gear teeth 7 of the double timing gear. Hold the double timing gear towards the outside by inserting your finger through the hole for the bearing bolt. 4-5 Double timing gear – Lift the double timing gear out of the cylinder head, letting the chain fall into the slot. 1 2 Cylinder head rear with cylinder – Remove the outer nut 1. – Loosen the cylinder-head nuts crosswise. 600.29.083.000 is required for the inside nuts 2. Special nut – Pull the cylinder head and cylinder up until the piston-pin retainer can be lifted out of the groove on the generator side with a suitable screwdriver. NOTE: the piston-pin retainer can easily be removed if the piston is held in place by the cylinder. – Press the piston pins out of the piston by hand and remove the cylinder together with the piston. – Discard the cylinder-base gasket. Setting cylinder front to TDC Loosen the crankshaft locking bolt and continue to turn the engine towards the front cylinder's TDC position, keeping the timing chain on the rear cylinder slightly tensioned and holding the conrod in the center of the opening in the case. ! CAUTION ! YOU DO NOT HOLD THE CHAIN, IT MAY GET JAMMED BETWEEN THE TIMING GEAR OF THE BALANCER SHAFT AND THE TENSIONING RAIL. IF THE CONROD IS NOT POSITIONED IN THE CENTER OF THE OPENING IN THE CASE, THE CONROD BOTTOM WILL BLOCK ON THE BALANCER SHAFT AND PREVENT THE CRANKSHAFT FROM TURNING. – IF – – Turn the crankshaft until the front cylinder is in the TDC position. The marks 3 (circles) must coincide with the flat outer surface of the cylinder head at the camshaft gears. 3 3 – The same camshaft gears are used in both cylinders but they have marks for cylinder rear and front. Use the camshaft gear marked with a cross for cylinder rear and the camshaft gear marked with a circle for cylinder front cylinder. – Block the crankshaft again. 4-6 Camshafts cylinder front – Check and note down the valve clearance before you dismount the camshafts. Valve clearance (at 20ºC): intake 0.10 - 0.15 mm exhaust 0.25 - 0.30 mm – Loosen the bolts on the camshaft bearing bridge from the front cylinder and carefully remove the camshaft bearing bridge. ! CAUTION ! TIGHTENING THE BOLTS OF THE CAMSHAFT BEARING BRIDGE, MAKE SURE THAT THE VALVES ARE NOT ACTUATED BY THE CAMSHAFT (SEE ILLUSTRATION), OTHERWISE THE BEARING BRIDGE WILL BREAK. WHEN – Remove the camshafts from the cylinder head without tilting. Oil pressure switch – Loosen the oil pressure switch 1 and unscrew. Discard sealing washer. 1 Chain tensioner cylinder front Art.-No. 3.206.056-E – Remove the bolt on the chain tensioner 2. NOTE: measure the preload on the chain tensioner element before dismounting: – Apply the chain tensioner bolt to the chain tensioner element without compressing the spring. – Measure the distance between the sealing washer and the cylinder head. 2 The measured value should be between 6 mm and 11 mm. If the value is lower, the tensioning rail could be worn or the timing chain excessively elongated. If it is higher, the engine was turned to TDC against the running direction. Repair manual KTM LC8 – Remove the sealing washer. – Pull out the chain tensioner element 3. NOTE: the housing and the tensioning piston on the chain tensioner element are compression molded. If they fall apart during disassembly, the chain tensionerelement must be replaced. 3 4-7 Timing chain cylinder front 1 NOTE: Valid up to and including model year 2006 – Loosen the bearing bolt 1 on the double timing gear and pull out of the cylinder head together with the needle bearing. The double timing gear will slide down slightly, relieving the timing chain. NOTE: Valid as of model year 2007 – Remove the screw of the bearing bolt 2 and carefully press out the bearing bolt 4 with a screwdriver. The timing gear slips down easily and the timing chain loosens. 2 3 A – Remove the O-ring on the bearing bolt. – Use a wire hook A which you can bend from a piece of welding wire to lift the side of the chain 3 towards the inside from the chain teeth 4 over the gear teeth 5 of the double timing gear. Hold the double timing gear towards the outside by inserting your finger through the hole for the bearing bolt. 4 – Lift the double timing gear out of the cylinder head, letting the chain fall into the slot. 5 6 7 Cylinder head front with cylinder – Remove the outer nut 6. – Loosen the cylinder-head nuts crosswise. 600.29.083.000 is required for the inside nuts 7. Special nut – Pull the cylinder head and cylinder up until the piston-pin retainer can be lifted out of the groove on the clutch side with a suitable screwdriver. NOTE: the piston-pin retainer can easily be removed if the piston is held in place by the cylinder. – Press the piston pins out of the piston by hand and remove the cylinder together with the piston. – Discard the cylinder-base gasket. 4-8 Water pump – Remove the water pump cover 1, discard the O-ring gasket. NOTE: also remove the 2 dowel pins used to keep the water pump cover in a central position. 1 – Hold the water pump wheel with special tool 600.29.082.000, remove the bolt 2 and pull the water pump wheel 3 off of the shaft. 2 NOTE: – The bolt and the water pump wheel only need to be removed if the water pump will be serviced. They do not need to be removed if you are only dismounting the clutch cover. – If the water pump wheel cannot be removed because it is being held by residual thread adhesive, the water pump shaft and the water pump wheel can be pressed out from the inside later. ! 3 CAUTION ! IF YOU TRY TO LOOSEN THE BOLT ON THE WATER PUMP WITHOUT USING SPECIAL TOOL 600.29.082.000, YOU MAY BREAK THE DRIVER ON THE BALANCER SHAFT OR WATER PUMP SHAFT. Oil screen Art.-No. 3.206.056-E – Remove the oil screen cover 4. – Carefully pull the oil screen 5 out of the clutch cover with a pair of pliers. 5 4 Clutch cover 6 – Remove the bolts and detach the inner clutch cover together with the outer clutch cover. Be careful not to lose the dowel pins. Repair manual KTM LC8 NOTE: – The outer clutch over can remain on the inner clutch cover if you also remove the bolt 6 on the outer clutch cover. – If the case bolt for the blocking hole is still mounted, it must also be removed. – A vibration damper 7 is mounted in the outer clutch cover from the 2005 model; do not loosen the screw 8. ! CAUTION ! THE SCREW ON THE VIBRATION DAMPER IS LOOSENED, A NEW OUTER CLUTCH COVER WITH A VIBRATION DAMPER OR THE OLD CLUTCH COVER WITHOUT THE VIBRATION DAMPER MUST BE USED SINCE THE SELF-CUTTING SCREW 8 CANNOT BE ADEQUATELY SECURED. IF YOU REMOUNT THE VIBRATION DAMPER WITH THE SCREW, THE SCREW CAN BECOME LOOSE AND DAMAGE THE ENGINE. IF 7 8 4-9 Clutch – Remove the bolts on the clutch springs crosswise and lift off the pressure cap. – Pull out the clutch push rod. – Insert a wire hook in the recess in the clutch disks and pull all of the clutch disks out of the clutch hub. NOTE: leave the spring washer and supporting ring in the clutch. They will be detached together with the inner clutch hub, at which time they can be easily removed. A – Slip on the holder for the inner clutch hub A 600.29.003.000, counteract the inner clutch hub and loosen the nut (32 mm). – Pull off the inner clutch hub together with the clutch pressure booster and the underlying washer, which usually adheres to the inner clutch hub. NOTE: you do not need to dismount the primary pinion if you are only replacing the outer clutch hub: – Remove the engine locking bolt 0113 080802. – Continue turning the crankshaft until the flat part of the pickup ring 1 coincides with the teeth on the outer clutch hub. 1 2 – Pull the needle bearing 2 out of the outer clutch hub with a suitable screwdriver, carefully pushing the outer clutch hub back and forth. – Press the outer clutch hub away from the primary pinion and remove. NOTE: the gear for the oil pump drive is located on the back of the outer clutch hub and can easily fall down. 4-10 Primary pinion and clutch 3 2 1 If you are completely dismounting the engine, the primary pinion must be detached before you remove the clutch. – Mount the special tool 0113 080802 (engine locking bolt) and hold the crankshaft in the rear or front cylinder's TDC position. – Unscrew the pickup 1. – Loosen the nut 2 of the primary pinion (46 mm, LH thread) and remove together with the washer. – Loosen the nut 3 of the balancer shaft (30 mm) and remove together with the washer. – Pull the outer clutch hub away from the housing until the pickup ring 4 can be removed. It is secured by a pin. – Completely remove the outer clutch hub together with the needle bearing. NOTE: – The gear for the oil pump drive is located on the back of the outer clutch hub and can easily fall down. – Remove the spacing washer inserted between the gear for the oil pump drive and the bearing which may adhere to the bearing. 4 Art.-No. 3.206.056-E Up to the 2004 model: – Pull off the gear on the balancer shaft 5. 5 – From the 2005 model: – Remove the spring washer 6. – Use the special tool 600.29.050.000 to turn the tensioning wheel 7 in a counterclockwise direction until the tensioning wheel and the drive wheel are retained by each other S. Repair manual KTM LC8 – Remove the tensioning wheel 7, tension spring 8 and drive wheel 9 together. S NOTE: – If the spreader components do not need to be serviced, the tensioning wheel, tension spring and drive wheel do not need to be taken apart. – If the spreader components are removed and separated, they must be preassembled before remounting (see Chapter 5). – If you cannot remove the drive wheel from the balancer shaft, pull it off using the extractors 590.29.021.044 and 600.29.058.000 evenly, do not tilt! 6 7 8 9 4-11 2 – Insert the pressure tool 600.29.031.000 1 in the crankshaft bore, turn the balance weight up and pull the primary pinion 2 off the crankshaft with the puller 600.29.033.000. 1 – Remove the balance weight 3 from the balancer shaft; carefully pry the woodruff key out of the shaft groove with a screwdriver. – Slip off the timing chain and pull the engine sprocket off of the balancer shaft. – Unscrew the chain tensioning rail 4. 4 NOTE: – if you intend to reuse the timing chain, engine sprocket and chain tensioning rail, mark the running direction and the cylinder allocation. – If you cannot remove the balance weight from the balancer shaft, pull it off using the extractors 590.29.021.044 and 600.29.058.000. 3 Generator cover 5 6 – Loosen all of the bolts on the generator cover except the bolt on the starter idler shaft 5 and remove the generator cover, being careful not to lose the dowel pins. Discard the gasket. NOTE: the rotor's magnetic retaining force will prevent the cover from being removed easily. – Bend up the lock washer, unscrew the nut 6 and remove the engine sprocket together with the lock washer. Rotor 7 – Remove the upper starter idler gear 7. – Remove the rotor bolt 8 and the washer. 8 – Screw the pressure screw 9 600.29.009.010 (up to the 2004 model) or 600.29.009.110 (from the 2005 model) into the crankshaft. ! 9 CAUTION ! HOLE IN THE CRANKSHAFT HAS A FINE THREAD FROM THE 2005 MODEL. IF YOU USE THE PRESSURE SCREW 600.29.009.010 YOU WILL DESTROY THE THREAD. THE – Pull the rotor off of the crankshaft using the puller 600.29.009.000 bk; remove the pressure bolt and the engine locking bolt. bk 4-12 Freewheel – Remove the freewheel lock 1 and lift the freewheel 2 of the crankshaft. – Pull the lower starter idler gear 3 from the balancer shaft. 3 2 1 Balancer shaft – Gently tap the balancer shaft off on the clutch side with a rubber hammer. ! MAKE CAUTION ! SURE THE TIMING CHAIN DOES NOT GET CAUGHT. NOTE: a stop disk is located on the outside of the roller bearing on the balancer shaft (on the clutch side) which should be removed before the balancer shaft is dismounted. – Remove the timing chain and unscrew the tensioning rail. NOTE: if you intend to reuse the timing chain and chain tensioning rail, mark the running direction and the cylinder allocation. Art.-No. 3.206.056-E Shift mechanism – Push the shift rail 4 away from the shift locating drum and pull out the shift shaft 5. – Remove the bolt 6 from the shift locating drum. 5 4 Repair manual KTM LC8 8 7 6 – Press the locking lever 7 down to relieve the shift locating drum 8, remove the shift locating drum. – Loosen the bolt and remove the locking lever 9 (not required for further engine removal). 4-13 Engine case half – Remove the gear shift sensor 1 with the pin and spring. Unscrew the oil filter cover 2, discarding the gasket on the oil filter cover and the oil filter. – Unscrew all HH bolts accessible from the generator side. 2 1 – Tilt the case horizontally with the generator side up. – Lift the case half of the generator side while lightly tapping the drive shaft with a rubber hammer. If necessary, tap the drive shaft downwards. ! CAUTION DO ! NOT USE A SCREWDRIVER OR SIMILAR TOOL TO PRY THE CASE HALVES APART SINCE THIS MAY DAMAGE THE SEALING AREAS. – Discard the case gasket. – Remove the crankshaft from the case. 4-14 Transmission 1 – Remove the oil rail 1 for the transmission lubrication. It is secured at the bottom to keep it from twisting. NOTE: the oil rail is sealed with 2 O-rings from the 2005 model which should be replaced. – Pull out the shift rails 2 together with the upper shift rail springs. 2 2 3 3 5 – Tilt the shift forks 3 to the side; watch the shift rollers 4 while you remove the shift drum 5. – Remove the shift forks and the lower springs of the shift rails. 4 4 43 Art.-No. 3.206.056-E – Bring the engine into a vertical position (mounting position) and remove the lock ring 6 and washer from the countershaft. 6 – Simultaneously pull both transmission shafts out of the bearing seats. Repair manual KTM LC8 NOTE: also remove the spacing washer on the countershaft which often adheres to the bearing. 4-15 Oil pumps – Remove the lock ring 1 from the oil pump shaft; remove the spacing washer 2 and oil pump gear 3. – Pull the needle roller 4 out of the pump gear and remove the washer underneath. 1 3 2 4 – Loosen the bolts on the outer oil pump 5 (pressure pump) and remove the oil pump housing. 5 NOTE: the centering pins are usually retained in the oil pump housing; if they are retained, pull them out with pliers. – Remove the inner oil pump 6 (suction pump). 6 – Remove the suction pump's inner and outer rotor (7 and 8) from the oil pump shaft. – Pull the needle roller 9 out of the oil pump shaft. 7 8 9 – Pull the oil pump shaft and the two pressure pump rotors out of the engine housing. – Remove both rotors from the oil pump shaft and pull out the needle roller. 5-1 SERVICING INDIVIDUAL COMPONENTS Repair manual KTM LC8 Art.-No. 3.206.056-E INDEX ROLLER BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2 MAIN BEARINGS - GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3 REPLACING BEARING SHELLS, OUTPUT END . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4 REPLACING BEARING SHELLS, GENERATOR END . . . . . . . . . . . . . . . . . . . . . . . .5-4 REPLACING THE CONROD BEARINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5 SELECTING THE BEARING SHELLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5 REPLACING THE SUPPORTING BEARINGS IN THE CLUTCH COVER . . . . . . . . . . . .5-6 OVERHAULING THE WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7 CHECKING THE SUCTION PUMP FOR WEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8 CHECKING THE PRESSURE PUMP FOR WEAR . . . . . . . . . . . . . . . . . . . . . . . . . .5-8 BYPASS VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8 DISASSEMBLING THE CYLINDER HEAD AND CHECKING PARTS FOR WEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9 CHECKING THE PISTONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10 ASSEMBLY INSTRUCTIONS FOR PISTON RINGS . . . . . . . . . . . . . . . . . . . . . . . .5-10 CHECKING THE PISTON RING END GAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10 MEASURING PISTONS + CYLINDERS, ESTABLISHING THE PISTON MOUNTING CLEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10 PISTON AND CYLINDER IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11 ASSEMBLING THE CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11 GENERATOR COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13 TORQUE LIMITER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13 VALVE GEAR – CHECKING PARTS FOR WEAR . . . . . . . . . . . . . . . . . . . . . . . . . .5-13 PREASSEMBLING THE SPREADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14 CLUTCH – CHECKING PARTS FOR WEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15 SHIFT MECHANISM – CHECKING PARTS FOR WEAR . . . . . . . . . . . . . . . . . . . . .5-16 PREASSEMBLING THE SHIFT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16 GENERAL INFORMATION ON SERVICING THE TRANSMISSION . . . . . . . . . . . . . .5-17 ASSEMBLING THE MAIN SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17 ASSEMBLING THE COUNTERSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18 CHECKING THE FREEWHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19 REPLACING THE FREEWHEEL HUB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19 STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19 5 5-2 Replacing the roller bearing 1 A 1 – Remove all bearing locking bolts 1 from both case halves. NOTE: – Additional oil jets are installed from the 2005 model; they should also be removed to prevent them from being bent. – the output-end antifriction bearing on the countershaft mounted by KTM does not have a sealing from the 2005 model. An antifriction bearing with a one-sided sealing is provided for repair; to keep it from blocking the lubrication, the open side must point towards the inside (towards the center of the housing). A A 1 Art.-No. 3.206.056-E 1 2 – Remove all shaft seal rings and the dowel pins from the case halves. Heat both case halves evenly in an oven at 150° C; the roller bearings will fall out of the case by themselves. If any roller bearings should be left in the case, tap the case lightly on a flat wooden surface. NOTE: the shift shaft bearing 2 must be pressed out with the pressing tool 600.29.043.030, although this bearing is usually highly resistant to wear. 4 – Replace all of the roller bearings. The new roller bearings can be inserted by hand until flush as soon as the case temperature has reached approx. 150° C. The roller bearings should fit tightly after cooling down. Use a mandrel to carefully press in any bearings that are not flush with the surface. 3 Repair manual KTM LC8 NOTE: the shift shaft bearing 2 must be pressed in flush with the pressing tool 600.29.043.030. 5 – Press in the shaft sealing ring 3 for the push rod until flush using the special tool 600.29.043.010. – Press in the shaft sealing ring for the countershaft 4 until flush using the special tool 600.29.043.020. – Press in the shaft sealing ring for the shift shaft 5 until flush using the special tool 600.29.043.030. – Apply Loctite 243 to all bearing locking bolts 1 and tighten to 6 Nm. 6 7 – Remove all of the oil jets, blow compressed air through the oil ducts and screw the oil jets back on. NOTE: – Size "60" jets are used to lubricate the timing chains, size "90" jets for the piston cooling. – Starting with engine number 2-600-02549, a size "30" reducing sleeve 6 is screwed into the outer bore 7 on the outside of the left housing half to supply the clutch and the pushrod with oil. This jet should be retrofitted in all engines of an earlier make. 5-3 Replacing the main bearings-general information NOTE: – The bearing shells for the friction bearings are pressed in and out in a cold state. – Mark the position of the bearing end gap 1 on the engine case with a felt-tip pin to facilitate reassembly. 1 2 NOTE: the main bearing shells have retaining brackets to hold them in position from the 2005 model; they must be removed before the main bearing shells are pressed out and mounted again after the main bearing shells are remounted; apply Loctite 243 to the screws and tighten to 6 Nm. – Press the main bearing shells out of both engine case halves from the inside to the outside using the press mandrel 600.29.044.050 2. Before you select the bearing shells you must measure the crankshaft. – Measure the diameter of the two main bearing pins at 3 points that are 120° apart using a micrometer gauge. This only applies to crankshafts that you will continue to use. Diameter of main bearing pin: 49.965 mm – 49.975 mm (yellow) 49.976 mm – 49.985 mm (blue) 49.986 mm – 49.995 mm (red) NOTE: – Use the bearing color indicated for the respective measurement. – The crankshaft must be replaced if the measurement falls short of the minimum diameter or if the crankshaft is worn. – New crankshafts do not need to be measured. Use new bearings according to the colored circles 3 marked on the crankshaft web of the new crankshaft. 3 NOTE: – there are 2 types of bearings for each bearing color – the grooved bearing shell (with the lubricating groove and oil bore) is pressed into the top of the case half of the generator end and the smooth bearing shells (without lubricating groove) are pressed into the bottom of the case half of the generator end and into the case half of the output end - applicable for models up to the 2004 model. – Bearing shells with grooves on the top and bottom (with lubricating groove and lubrication bore) are mounted on the generator end of the housing half from the 2005 model. – A new crankshaft comes with 2 grooved bearing shells. They can also be installed in engines preceding the 2004 model. ! CAUTION ! IF YOU MOUNT A BEARING SHELL THAT IS SMOOTH ON THE BOTTOM ON THE GENERATOR END OF THE ENGINE FROM THE 2005 MODEL, THE WATER JET TO COOL THE PISTON WILL NOT BE SUPPLIED WITH LUBRICATING OIL AND WILL LEAD TO DAMAGE. – Measure the bearing bores with a micrometer to ensure that the bearing shells are seated firmly in the engine case after being pressed in. Nominal dimension: 54.000 mm – 54.015 mm NOTE: if the bearing bores are too big, the engine case must be replaced. Measure the inner diameter of the bearings after they are pressed in to ensure that the bearing clearance is correct. NOTE: the inner diameter of the bearings must be measured at a 90° angle to the bearing end gap. The diameter of the main bearing pin must be deducted from the inner diameters of the bearings, the difference is the radial clearance of the main bearing. Setpoint value for the radial clearance of the main bearing: 0.025 mm – 0.055 mm Wear limit: 0.080 mm Example: Inner bearing diameter measured 50.020 mm Main bearing pin measured 49.980 mm 50.020 – 49.980 = 0.040 mm radial clearance 5-4 Replacing bearing shells, output end – Center the new bearing shells (both smooth) with the assembling sleeve 600.29.044.050 1. The assembling sleeve is beveled on one side so the bearing shells can be pushed in easily. The bearing shells should protrude 1-2 mm on the other side of the assembling sleeve to make it easier to position them in the engine case. 1 – Position the bearing shells on the output end of the case such that the end gap on the bearing shells points to the marks 2 made when disassembling. 2 Art.-No. 3.206.056-E – Press in the bearings from the outside to the inside through the assembling sleeve up to the stop using the press mandrel 600.29.044.050 3. ! 3 – – CAUTION ! ALWAYS PRESS IN BEARING SHELLS FROM THE OUTSIDE TO THE INSIDE OTHERWISE THEY WILL NOT BE POSITIONED CORRECTLY AND THE BEARING RADII OF THE CRANKSHAFT WEBS WILL PRESS AGAINST THE BEARING SHELLS. THIS IS WHY THE BEARING SHELLS ARE SEATED 2 MM BELOW THE EDGE OF THE BEARING BORE. THE ASSEMBLING SLEEVE SERVES AS A STOP. IT IS NOT REMOVED UNTIL THE BEARING SHELLS ARE SEATED IN THE CORRECT POSITION. Replacing bearing shells, generator end – Center the new bearing shells (smooth on the bottom, grooved on top up to the 2004 model, both grooved from the 2005 model) with the assembling sleeve 600.29.044.050 – same procedure as for the bearing shells, output end (see above). – Position the bearing sleeves at the generator end of the case with the bearing shell end gap pointing to the marks 4 made when disassembling. Do not cover the oil bore. – Press the bearings into the engine case half from the outside to the inside through the assembling sleeve up to the stop using the special tool 600.29.044.050. Repair manual KTM LC8 ! – – – – 4 CAUTION ! ALWAYS PRESS IN BEARING SHELLS FROM THE OUTSIDE TO THE INSIDE OTHERWISE THEY WILL NOT BE POSITIONED CORRECTLY AND THE BEARING RADII OF THE CRANKSHAFT WEBS WILL PRESS AGAINST THE BEARING SHELLS. THIS IS WHY THE BEARING SHELLS ARE SEATED 2 MM BELOW THE EDGE OF THE BEARING BORE. THE ASSEMBLING SLEEVE SERVES AS A STOP. IT IS NOT REMOVED UNTIL THE BEARING SHELLS ARE SEATED IN THE CORRECT POSITION. IF THE BEARING SHELLS ARE INCORRECTLY ALIGNED OR IF SMOOTH BEARING SHELLS ARE PRESSED IN ON TOP, THE OIL SUPPLY TO THE SPRAYING NOZZLES TO COOL THE PISTONS AND LUBRICATE THE TIMING CHAIN WILL BE INTERRUPTED, LEADING TO SERIOUS ENGINE DAMAGE. IF A SMOOTH BEARING SHELL IS INSTALLED ON THE GENERATOR END IN ENGINES STARTING WITH THE 2005 MODEL, THE WATER JET TO COOL THE PISTONS WILL NOT BE SUPPLIED WITH LUBRICATING OIL AND WILL LEAD TO DAMAGE. NOTE: – After replacing all friction and roller bearings, dismount the spraying nozzles and oil nozzles and clean the oil ducts with compressed air to make sure they are not clogged. – Coat the friction bearings with Molycote grease. Apply Loctite 243 to the spraying nozzles and oil nozzles and tighten to 6 Nm. 5-5 Replacing the conrod bearings – Clamp each conrod in a vise using protective jaws. – Loosen the bolts 1 on the conrod bearing covers with the special wrench socket 600.29.075.000 and remove the bearing covers. 1 NOTE: mark the conrod caps to ensure that each cap is mounted to the same conrod when it is measured and assembled. – Remove the conrod caps. – Clean the crankshaft and blow compressed air through the lubrication bores. Selecting the bearing shells Before you select the new bearing shells you must measure the conrod journal. – Measure the diameter of the conrod journal at 3 points that are 120° apart using a micrometer gauge. Diameter of the conrod journal: 41.978 mm – 41.989 mm (yellow) 41.990 mm – 42.000 mm (blue) 42.001 mm – 42.011 mm (red) NOTE: – Use the bearing color indicated for the respective measurement. – The crankshaft must be replaced if the measurement falls short of the minimum diameter or if the crankshaft is worn. – Clamp each conrod in a vise, insert new bearing shells, position the crankshaft with a plastigauge measuring strip A (600.29.012.000) on top and mount the conrod caps with the old bolts, as described below. ! – – CAUTION ! INSERT THE PLASTIGAUGE MEASURING STRIPS AT A 90° ANGLE TO THE BEARING END GAP. DO NOT TURN THE CONRODS ON THE CONROD JOURNAL. – Unclamp the conrods and compare the width of the plastigauge measuring strip with the information on the packing. The width of the plastiguage measuring strip is equivalent to the bearing clearance. A Setpoint value of the conrod bearing clearance: 0.030 mm – 0.060 mm Wear limit: 0.080 mm – Clamp each conrod in a vise using protective jaws, apply a thin layer of Molycote grease to the bearing shells, position the crankshaft and mount the conrod caps with new bolts. 2 2 ! CAUTION ! THE BEARING SHELLS SHOULD BE MOUNTED IN AN OFFSET POSITION IN THE CONROD TO ALLOW ROOM FOR THE CRANKSHAFT RADIUS 2. IF THE CONRODS ARE MOUNTED BACKWARDS, THE BEARING SHELLS WILL EXERT PRESSURE ON THE RADIUS AND BLOCK THE CONRODS. – Tighten the conrod bearing bolts with the special wrench socket 600.29.075.000 to 25 Nm (1st stage). The tighten to 30 Nm (2nd stage) and finally by another 60° (3rd stage). 3 NOTE: use a degree wheel 3 (600.29.010.000) to make sure the conrod bearing bolts are tightened correctly. 5-6 Replacing the supporting bearings in the clutch cover – Pull the bearing shells out of the clutch cover using the puller 151.12.017.000 and the internal extractor 600.29.018.000 1. 1 – Measure the diameter of the bearing pin at 3 points that are 120° apart using a micrometer gauge. Diameter of the supporting bearing pin: 27.985 mm – 28.000 mm NOTE: The crankshaft must be replaced if the measurement falls short of the minimum diameter or if the crankshaft is worn. Art.-No. 3.206.056-E – Center the new bearing shells with the assembling sleeve 600.29.046.028 2. The assembling sleeve is beveled on one side so the bearing shells can be pushed in easily. The bearing shells should protrude 1-2 mm on the other side of the assembling sleeve to make it easier to position them in the clutch cover. 2 Repair manual KTM LC8 3 – Place the bearing shells on the clutch cover with the assembling sleeve and press in the bearing shells to the stop using the press mandrel 600.29.046.028 3. 5-7 Overhauling the water pump – Remove the washer 1 from the water pump shaft and pry the shaft sealing ring 2 out of the case. NOTE: if the water pump wheel cannot be removed because it is being held by residual thread adhesive, the water pump shaft and the water pump wheel can be pressed out from the inside after the lock ring 4 is removed. 2 1 4 – Remove the outer lock ring 3 from the water pump shaft using suitable pliers. – Press the water pump shaft out of the bearing from the outside to the inside. The inner lock ring 4 does not need to be removed. – Heat the case evenly in an oven at 150° C; the old bearing will fall out of the bearing seat by itself and the new bearing can easily be pressed into the bearing seat by hand. The bearing should fit flush and tightly after it cools down. If not, press in with the pressing tool 600.29.043.060. – Insert the water pump shaft in the new bearing from the inside to the outside. 3 NOTE: the recess in the water pump shaft should point towards the inside. – Mount the lock ring 3. 5 – Place the protective sleeve 5 585.29.005.000 on the pump shaft and press in a new shaft sealing ring 2 until flush using the pressing tool 600.29.043.040. Mount the washer 1. NOTE: To replace the water pump seal ring see Technical Information, Chapter 1. 2 5-8 A A Checking the suction pump for wear – Insert both suction pump rotors in the housing. – Use a feeler gauge A to check the clearance between the inner and outer rotor: Setpoint value: 0.1 mm Wear limit: 0.2 mm – Use a feeler gauge A to check the clearance between the outer rotor and the housing: Setpoint value: 0.2 mm Wear limit: 0.4 mm – Use a feeler gauge A and a straight edge B to check the axial clearance: B Setpoint value: 0.04 mm – 0.09 mm Wear limit: 0.25 mm A Art.-No. 3.206.056-E A A Checking the pressure pump for wear – Insert both pressure pump rotors in the case. – Use a feeler gauge A to check the clearance between the inner and outer rotor: Setpoint value: 0.1 mm Wear limit: 0.2 mm – Use a feeler gauge A to check the clearance between the outer rotor and the case: Setpoint value: 0.2 mm Wear limit: 0.4 mm – Use a feeler gauge and a straight edge to check the axial clearance: Setpoint value: 0.04 mm – 0.09 mm Wear limit: 0.25 mm Bypass valve 1 – Remove the lock ring 1 on the bypass valve using suitable pliers and take the individual bypass valve parts out of the housing. Repair manual KTM LC8 NOTE: the spring is pretensioned. – Check parts for visible wear and damage. – Measure the length of the pressure spring: Minimum length of pressure spring: 42.0 mm – Clean parts, oil the pistons and insert in the bore. Position the spring, place a washer on the spring and mount the lock ring in the groove using suitable pliers. NOTE: different pistons were installed starting with engine number 2-600-00773. Engines of an earlier make must be converted; see Technical Information, Chapter 1. 5-9 Disassembling the cylinder head and checking parts for wear NOTE: the illustration shows the font cylinder. The procedure for the rear cylinder is identical. 1 – Pull all of the bucket tappets 1 out of the cylinder head. NOTE: – Note down the mounting position to ensure that the same bucket tappet is inserted in the same bore during installation. – The compensating washers 2 for the valve clearance (shims) usually adhere to the bottom of the bucket tappets and should be set aside together with the bucket tappets. 2 – Invert the cylinder and cylinder head and remove the three Allen bolts 3 and nuts. – Remove the cylinder and pistons from the cylinder head and discard the cylinder head gasket. – Unscrew the chain guide. 3 3 3 – Press the valve springs together using the valve assembling tool (590.29.019.000 with the attachment 600.29.041.000 4) and remove the valve spring key from the valve shaft. Relieve the springs and remove from the cylinder head. 4 NOTE: note down the mounting position of the valves to ensure that the valves are mounted in the same position during installation. – Pull the valve shaft seal off the valve shaft with pliers and remove the valve spring washer. NOTE: a washer (14x30x2) is located under the spring retainers for the exhaust valve springs to increase the spring preload. – Repeat the above procedure for the other valves. – Clean all parts. Sealing area Check the spark plug thread and valve seats for damage or cracks. Use a straight edge A and a feeler gauge B to check the sealing area to the cylinder for distortion. Max. distortion: 0.05 mm. A B Valve seats The valve seats may not be impacted. Width of sealing seat: intake max. 1.8 mm; outlet max. 2.0 mm. Reseat the valves if necessary. Valves Check the valve disk for wear and runout. The valve disk runout should not exceed 0.03 mm. The valve seat may not be impacted. The sealing area should be in the middle of the valve seat. The valve shaft is hardchrome-plated. Wear usually occurs at the valve guide. C Valve guides The valve guides are checked with the limit plug gauge C 590.29.026.006 (Ø 6.05 mm). If the limit plug gauge can easily be pushed into the valve guide, the valve guide needs to be replaced at a special workshop. Valve springs Check the valve springs for fractures or other wear. Measure the spring length with a sliding caliper in an unloaded condition: Minimum length of inner spring: 38.0 mm (950) or 37.0 (990) Maximum length of outer spring: 41.3 mm (950) or 41.2 (990) 5-10 Checking the pistons – Mark the position of the piston arrow in the cylinder to facilitate reassembly and to ensure that the same piston is mounted in the same cylinder again. – Press the piston up out of the cylinder. – Replace the piston if oil consumption is high or the piston skirt is excessively grooved. – If the piston is to be reinstalled: 1. Check the piston bearing surface for damage. 2. Piston ring grooves: the piston rings must move freely in the groove. Use old piston rings or sandpaper (400 grit) to clean the piston ring grooves. 3. Check the piston rings for damage and end gap. 4. The piston pins must move freely in the bolt hole when mounted. Replace piston pins that are badly discolored or have visible running marks. Place the piston pin in the conrod and check for clearance. Maximum clearance in the conrod eye: 0.08 mm. A NOTE: the piston pin may not have any clearance when mounted and should be easy to move when applying slight counterpressure. Checking the piston ring end gap – Insert the piston ring in the cylinder and align with the piston (approx. 10 mm under the upper edge of the cylinder). – Measure the end gap with a feeler gauge A. Piston ring end gap: max. 0.50 mm If the end gap is larger than indicated above, check the cylinder for wear. If the cylinder wear is within the tolerance limits, replace the piston ring. Art.-No. 3.206.056-E Assembly instructions for piston rings – Mount the oil scraper ring in the lower piston ring groove with the mark facing the piston head. – Mount the compression ring in the middle piston ring groove with the mark facing the piston head. – Mount the compression ring in the upper piston ring groove with the mark facing the piston head. Measuring pistons and cylinders, establishing the piston mounting clearance – To establish cylinder wear, use a micrometer to measure the cylinder in the middle of the bearing surface. – Measure the X and Y axis of the cylinder diameter to establish any ovality. x Repair manual KTM LC8 y – Measure the piston at the piston skirt across the piston pin, 9 mm from the lower edge. 950: 990: Piston size I: 99.953 mm – 99.967 mm Piston size II: 99.963 mm – 99.977 mm Wear limit: 99.930 mm Piston size I: 100.943 mm – 100.957 mm Piston size II: 100.953 mm – 100.967 mm Wear limit: 100.930 mm – The piston mounting clearance is the difference between the smallest cylinder diameter and the piston diameter. Piston mounting clearance 950: 0.04 mm – 0.06 mm Wear limit: 0.10 mm Piston mounting clearance 990: 0.05 mm – 0.07 mm Wear limit: 0.10 mm 5-11 Piston and cylinder identification The cylinder size 1 is impressed in the bottom of the cylinder near the chain tunnel; 1 is size I, 2 is size II. 1 The piston size 2 is impressed in the top of the piston; 1 is size I, 2 is size II. 2 Assembling the cylinder head – Slide the valve spring washers 3 over the valve guides and mount new valve shaft seals 4. – Lubricate the valve shafts and insert the valves in their original position in the valve guides. 7 6 5 4 3 NOTE: – A washer to increase the spring preload is located under the spring retainers. – A washer with a thickness of 1 mm was installed up to engine number 2-600-00070. – Two washers with a thickness of 1 mm were installed in the engines with the engine number 2-600-00071 to 2-600-00124 – A washer with a thickness of 2 mm (14x30x2) was installed in engine number 2-600-00125. It can also be used for earlier engines. – Mount the inner and outer valve springs 5 with the spring retainers 6 and compress the springs using the valve assembling tool (590.29.019.000 with the attachment 600.29.041.000). – Grease the valve spring keys 7 and position on the valve shafts. Relieve the valve springs. – Tap the valve spring retainers to set the keys. 5-12 – Place the lubricated piston on the cylinder and clamp the piston rings together with the piston ring clamping band 600.29.015.000 1. – Use a plastic hammer to tap lightly on the top of the piston ring clamping band until it is flush with the cylinder. 1 – Use the hammer handle to carefully tap the piston into the cylinder, making sure the piston rings do not get caught. ! CAUTION ! IF THE PISTON RINGS ARE PROPERLY CLAMPED BY THE PISTON RING CLAMPING BAND AND THE CLAMPING BAND IS FLUSH WITH THE CYLINDER, IT SHOULD BE EASY TO PUSH THE PISTON INTO THE CYLINDER BY TAPPING LIGHTLY WITH THE HAMMER HANDLE. APPLYING MORE FORCE WILL ONLY DAMAGE THE PISTON RINGS. Art.-No. 3.206.056-E – Invert the cylinder head, mount a new cylinder head gasket and put the cylinder into position. NOTE: the cylinder and the cylinder head are marked at the exhaust flange 2. One or two circles are impressed on both parts 2 2 Repair manual KTM LC8 3 3 – Secure with Loctite 243 and tighten the three Allen bolts 3 to 18 Nm (1st stage) and 23 Nm (2nd stage). – Mount the chain guide rail, apply Loctite 243 to the bolt and tighten (15 Nm). Check the chain rail guide for mobility. 3 – Mount the bucket tappets 4 and the valve shims 5 in their original positions in the cylinder head. 4 NOTE: if the valve clearance was incorrect when measured or if the valves and valve seats were serviced or parts of the valve gear were replaced, the thickness of the valve shims must be corrected. 5 5-13 Generator cover 5 4 3 1 1 – Loosen the three bolts 1 on the stator. – Tilt the cable retaining bracket 2 away from the cable with long nose pliers A (see small arrow) and pull out of the housing. Take the cable duct out of the generator cover and remove the stator. – Pry the shaft sealing ring on the balancer shaft 3 out of the generator cover and discard. – Remove the lock ring 4 and pull the idler with the disk and the bearing from the bearing bolt. – Heat the housing to 150° C. The bearing 5 will fall out of the housing by itself. – Press in a new bearing 5 until flush. Slide the new bearing on the bearing bolt, slide on the idler and disk and mount the lock ring 4. – Use the special tool 600.29.043.050 to press in the new shaft sealing ring on the balancer shaft 3, open side first. – Position the stator, press the cable duct in the generator cover. – Push the retaining bracket in the recess of the housing and fit into place. Apply Loctite 243 to the stator bolts and tighten to 10 Nm. Torque limiter NOTE: a torque limiter is used to avoid damage to the engine if the engine "blows back" when started. Check the flange on the center gear and the cam surfaces for wear. Valve gear – checking parts for wear Check the teeth of the balancer shaft 6 for wear. Check the rollers and links of the timing chain 7 for wear, damage and smooth operation. 2 A Check the timing chain guides 8 for wear. Check the timing chain tensioning rails 9 for wear. Check the teeth on both double timing gears bk and the camshaft gears bl for wear. Check the camshafts and camshaft bearing positions for wear and seizing marks. bl bk 8 bm bn NOTE: the spring preload cannot be checked directly; if the tension spring is worn, the balancer shaft drive will become loud. 7 9 bo bp 6 8 bl 7 bk 9 Check the spreader components for wear and damage, particularly around the spreader wheel centering: spring washer bm, tensioning wheel bn, tension spring bo and drive wheel bp. 5-14 Preassembling the spreader drive NOTE: – The tension spring bolts must be attached as illustrated. – The other holes 1 are used to block the spreader drive. 1 1 – Attach the tension spring bolts 2 in the drive wheel 3 and press the tension spring into the recess of the drive wheel. 3 2 Art.-No. 3.206.056-E 4 – Mount the tensioning wheel so that the tension spring bolts engage in the right hole 4 and then press the two gears together. NOTE: gently press together with your fingers. Repair manual KTM LC8 – Mount the preassembled spreader drive on the lower part of the pretensioning tool 600.29.050.000, making sure the pin on the tool engages in the groove in the drive wheel. – Screw on the nut and washers for the balancer shaft to prevent the spreader drive from falling apart. – Clamp the lower part 600.29.050.000 with the flat areas in a vise. – Apply the pretensioning tool hook wrench 600.29.051.000 to the tensioning wheel and turn against the spring until the pin can be inserted in the hole. NOTE: the preload is approximately one tooth gap. 5-15 3 1 4 5 9 6 8 2 7 Clutch – checking parts for wear Check the thrust bearing 1 for wear. Check the front end of the pushrod 2 for wear and blow compressed air through the holes. NOTE: the pushrod is made of nitride steel from the 2005 model. If you are repairing an engine older than the 2004 model, replace the old pushrod with the newer version. Clutch springs 3 must have a minimum length of 29.0 mm (new 30.77 mm). If necessary, replace all 6 at the same time. The clutch disks must be even. 10 steel lamella 4 – may not have any recesses. 11 lining disks 5, wear limit 2.65 mm Inner clutch hub 6 – check the outer and inner teeth for wear. Needle bearing 7 – check for wear. Springs in the outer clutch hub 8 Springs dampen the drive train from the primary drive to the clutch. Check these springs in addition to performing the regular wear tests. Try to turn the outer clutch hub when the engine is blocked – you should not feel any backlash. NOTE: the outer clutch hub must have a supporting ring with a thickness of 1 mm - see Technical Information, Chapter 1. Check the sides of the clutch pressure booster 9 for wear. 5-16 Shift mechanism – checking parts for wear 1 Shift forks 1 Check the leaf for wear. Check the driving bolt 2 for the shift drum for wear. Shift rolls 3 Check the shift rolls for hair cracks and pressure marks. It should be easy to turn the shift rolls on the driving bolts 2 of the shift forks. 1 1 3 3 Shift drum 4 Check the shift grooves for wear. Check both grooved ball bearings in the shift drum for wear. 2 6 5 B 8 7 4 9 Art.-No. 3.206.056-E bk Shift rail 5 Check for wear at the points of contact. Check the return surface B on the shift rail for wear (replace if excessively grooved). Guide bolts 6 Check for a tight fit and wear. Guidance Check play (play max. 0.7 mm). between guide bolts and slider Preassembling the shift shaft 7 – Mount the shift rail on the shift shaft by engaging the guide bolt 6. – Attach the spring 7 and slide on the plastic sleeve 8. 5 NOTE: the noses on the plastic sleeve will engage in the opening in the shift rail and the shift shaft and hold the spring in place. 8 9 bk Repair manual KTM LC8 – Mount the return spring 9 such that the offset A runs towards the shift quadrant. – Slide the disk bk onto the shift shaft. A 5-17 General information on servicing the transmission – Clamp the main shaft in the vise (use protective jaws) and remove the gears. – Clean and check all parts. Use new lock rings whenever you repair the transmission. Check the tooth profile on the transmission shafts and sliding gears for wear. Place the sliding gears on the transmission shafts and check whether they run smoothly on the teeth. Check the bearing positions on the transmission shafts. Mount the idler gear with bearings on the transmission shaft and check for clearance. Check the needle bearings in the idler gears. bk 9 8 7 6 5 4 3 2 1 Assembling the main shaft – Clamp the main shaft in the vise (use protective jaws) with the gear facing down. – Mount the needle bearing 1 and slide the 5th gear idler 2 over the needle bearing with the claws pointing up. – Mount the stop disk 3 (28.3 x 35.75 x 1.5 mm) and the lock ring 4 with the sharp edge facing up. – Mount the 3rd and 4th gear sliding gear 5 with 4th gear (larger outer diameter) facing down. – Mount the stop disk 6 (22.2 x 30,2 x 1.5 mm). – Slip on the needle bearing 7 and slide the 6th gear idler 8 over the needle bearing with the claws pointing down. – Slip on the 2nd gear fixed gear 9 with the collar facing down and mount the stop disk bk (20.2 x 28 x 1.5 mm). Check all gear wheels for smooth operation. 5-18 General information on servicing the transmission – Clamp the main shaft or countershaft in the vise (use protective jaws) and remove the gears. Pull off the bearing ring. – Clean and check all parts. Use new lock rings whenever you repair the transmission. Check the tooth profile on the transmission shafts and sliding gears for wear. Place the sliding gears on the transmission shafts and check whether they run smoothly on the teeth. Check the bearing positions on the transmission shafts. Mount the idler gear with bearings on the transmission shaft and check for clearance. Check the needle bearings in the idler gears. Mount the bearing ring using a suitable tube. Assembling the countershaft – Clamp the countershaft in the vise (use protective jaws) with the collar facing down. bs br Art.-No. 3.206.056-E 9 8 bq bp 7 bo 6 bl Repair manual KTM LC8 – Slide the 2nd gear idler 2 with the groove facing up over the needle bearing. – Mount the stop disk 3 (30.2 x 39 x 1.5 mm) and the lock ring 4 with the sharp edge facing up. 5 – Mount the 6th gear sliding gear 5 with the shift groove facing up. – Mount the lock ring 6 with the sharp edge facing down and the stop disk 7 (26.2 x 36 x 1.5 mm). – Mount the needle bearing 8 and 9 and slide the 3rd gear idler bk over the needle bearing with the collar facing up. bn bm bk – Oil the needle bearing 1 and mount. 4 3 1 2 – Slip on the 4th gear idler bl with the collar facing down. – Mount the stop disk bm (26.2 x 36 x 1.5 mm) and lock ring bn with the sharp edge facing up. – Mount the 5th gear sliding gear bo with the shift groove facing down and the stop disk bp (24.3 x 35.75 x 1.0 mm). – Mount the 1st gear idler bq with the groove facing down, the needle bearing br and the stop disk bs (20.2 x 34 x 1.0 mm). Check all gear wheels for smooth operation. 5-19 Checking the freewheel 2 – Insert the freewheel gear 1 in the freewheel. – You should be able to turn the freewheel gear in a counterclockwise direction. – The freewheel gear should block without backlash in a clockwise direction. – Check the reduction gear 2 and the needle bearings 3 for wear, replace if necessary. 3 3 1 Replacing the freewheel hub – Remove the 6 bolts, tap the side of the freewheel hub with a plastic hammer and remove the freewheel hub. 4 – Hold the components of the freewheel 4 together. – Check the segments in the freewheel for wear. – Check the freewheel hub 5 at the freewheel running surface for wear. – Apply Loctite 648 to the flange areas on the rotor and the freewheel hub. – Mount the freewheel hub on the rotor. – Apply Loctite 648 along the entire thread length of the screws and tighten crosswise to 15 Nm - see Technical Information, Chapter 1. 5 ! ALWAYS USE NEW LOCTITE 648. BOLTS CAUTION (QUALITY GRADE 12.9) ! AND COAT BOLT THREAD WITH – Generously oil the freewheel and insert in the freewheel hub. Starter 6 – Since the starter will show little wear after 10,000 starts and the replacement of individual parts is uneconomical, these steps will not be described in detail at this point. – Replace the O-ring 6 on the starter flange. 6-1 ASSEMBLING THE ENGINE Repair manual KTM LC8 Art.-No. 3.206.056-E INDEX OIL PUMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2 AXIAL CLEARANCE OF THE MAIN SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3 TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4 CASE HALF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5 SHIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6 ALIGNING THE RETURN SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6 BALANCER SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7 FREEWHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7 ROTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7 GENERATOR COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8 TIMING CHAIN AND BALANCING WEIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8 PRIMARY PINION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9 OUTER CLUTCH HUB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9 CLUTCH DISKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10 CLUTCH COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11 OIL SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12 WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12 CYLINDER HEAD REAR WITH TIMING CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . .6-13 CHAIN TENSIONER CYLINDER REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15 CAMSHAFTS CYLINDER REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16 SETTING CYLINDER FRONT TO TDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17 CYLINDER HEAD FRONT WITH TIMING CHAIN . . . . . . . . . . . . . . . . . . . . . . . . .6-17 CHAIN TENSIONER CYLINDER FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19 OIL PRESSURE SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19 CAMSHAFTS CYLINDER FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20 STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21 SPARK PLUG SHAFT INSERTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22 VALVE COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22 6 6-2 Clean all parts thoroughly before reassembling. 1 – Clamp the output-end engine case on the engine work stand and move into a vertical position (installation position). Oil pumps NOTE: lubricate the oil pump rotors and the oil pump shaft prior to installation. – Slide the outer rotor of the pressure pump into the bore with the mark 1 facing the engine case. 4 3 – Insert the needle roller 2 on the pressure pump in the oil pump shaft and slide on the inner rotor 3 of the pressure pump. The mark 4 on the inner rotor of the pressure pump must point to the groove 5 in the oil pump shaft. – Insert the oil pump shaft and inner rotor of the pressure pump into the engine case. NOTE: contrary to common practice, the two marks for the outer and inner rotor of the pressure pump are not on the same side. Art.-No. 3.206.056-E 2 5 – Mount the pressure pump case 6 and fix with the short bolt 7 (M6x20) (apply Loctite 243 to the bolt but do not tighten yet). Do not forget the centering pins on the pressure pump housing. 6 7 Repair manual KTM LC8 bk bl 8 – Insert the needle roller in the oil pump shaft and slide on the inner rotor 8 of the suction pump. Mount the outer rotor 9 such that the mark bk is visible on the outside. NOTE: the marks for the outer and inner rotors (bk and bl) of the suction pump are on the same side. 9 – Hold the outer rotor in place while you slide the suction pump housing bm over the rotor. Do not forget the centering pins. – Replace the O-ring and lubricate. bm 6-3 – Apply Loctite 243 to the three remaining oil pump bolts (M6x40) and screw in. Tighten bolts to 10 Nm. 4 1 2 – Slide on the disk, insert the needle roller 1 and mount the oil pump gear 2 with the collar facing the rear. – Slide on the spacer washer 3 and mount the lock ring 4 on the oil pump shaft. – Check the oil pump for smooth operation by turning the oil pump gear. 3 Axial clearance of the main shaft – Slide the main shaft in den bearing seat and mount the 2nd housing half with a new gasket. – Screw both housing halves together, tighten the screws to 10 Nm (see page 6-5). – Position the test gauge holder on the engine case and measure the axial clearance of the mainshaft. Axial clearance: 0.01 - 0.13 mm ! CAUTION ! YOU ARE USING A CONVENTIONAL DIAL GAUGE SUPPORT, IT MUST BE SCREWED ONTO THE ENGINE CASE; IF YOU ARE USING A MAGNETIC SUPPORT, IT MUST BE ATTACHED TO A STEEL PLATE SCREWED ONTO THE ENGINE CASE (SEE PHOTO). ALWAYS MOVE THE MAIN SHAFT BY HAND, DO NOT USE ANY TOOLS. CAREFULLY MEASURE THE AXIAL CLEARANCE; IF THE CLEARANCE IS TOO SMALL, THE BEARINGS WILL PRELOAD AND THIS CAN LEAD TO ENGINE DAMAGE. – IF – – – Correct the axial clearance if the measured value does not correspond to the setpoint value. – To correct, remove the main shaft and add or remove compensating disks on the generator side. NOTE: – If the axial clearance is too large, use a thicker compensating washer. – If the axial clearance is too small, use a thinner compensating washer. – Always mount the compensating washer on the generator side. – Finally, check the axial clearance again. 6-4 Transmission – Simultaneously push both transmission shafts into the bearing seats. NOTE: pay attention to the spacing washer on the countershaft. – Slide the washer on the counter shaft and mount the lock ring 1. – Move the engine into a horizontal position. Art.-No. 3.206.056-E 1 2 2 4 3 3 – Insert the lower gearshift rail springs in the bores with the tapered ends down. – Position the shift forks 2 in the shift grooves and tilt aside, paying attention to the shift rollers 3 – fix with grease if necessary. Mount the shift drum 4 and allow the shift forks to engage in the shift drum. NOTE: since 3 different shift forks are used they cannot be confused with each other. 2 3 – Mount the gearshift rails 5, paying attention to the lower gearshift rail springs. Insert the upper gearshift rail springs in the gearshift rails with the tapered ends up. 6 NOTE: the longer gearshift rail is used for the countershaft shift forks. Repair manual KTM LC8 – Insert the oil rail for transmission lubrication 6 in the bore and turn to engage the locking pin. 5 5 NOTE: the oil rail is sealed with 2 O-rings from the 2005 model which should be replaced. 6-5 – Insert the crankshaft in the friction bearing. NOTE: – The crankshaft end with the thread for the primary pinion bolt connection must point down. – The conrod for the rear cylinder 1 must face up. Both conrods should be in the position shown in the illustration. 1 – Mount the case dowel pins and put a new case gasket in place. NOTE: additional housing dowels are used for items 19 and 21 (see photo below) starting with the 2005 model. Case half – Slide the protective sleeve 600.29.005.000 over the countershaft. – Slip on the generator-end case half. Tap lightly on the countershaft with a rubber hammer if necessary. ! DO M6x65/75 (19) M6x65/70 (21) M6x65 (18) M6x65/75 (20) M6x65 (17) – Screw in all HH case bolts (see illustration for bolt lengths) and tighten to 10 Nm. M6x40 (5) M6x40 (6) M6x90 (4) M6x90 (3) NOTE: – the bolts should be tightened in the order shown in the illustration (numbers in parentheses). – Screws item 19 and 20 were changed from M6x65 to M6x75 and screw item 21 to M6x70 starting with model year 2005. – Move the case into a horizontal position with the generator side facing up. M6x40 (7) M6x75 (12) ! NOT TRY TO DRAW THE TWO CASE HALVES TOGETHER WITH THE CASE BOLTS. M6x90 (2) M6x65 (16) CAUTION M6x90 (1) M6x60 (15) M6x75 (14) M6x40 (8) M6x60 (13) M6x60 (11) M6x60 (10) M6x60 (9) – Position the pin and spring in the shifting drum. Mount the gear sensor 2 with 2 M5x10 bolts. Tighten bolts to 4 Nm. – Slide in a new oil filter and mount the oil filter cover 3 with a new gasket. Tighten M5x16 bolts to 6 Nm. 3 2 6-6 Shift mechanism 2 – Mount the locking lever 1 with the spring. Apply Loctite 243 to the M5x20 bolt and tighten to 6 Nm. – Press the locking lever down and mount the shift locating drum 2. NOTE: the flat parts of the shift locating drum are off center. 1 – Apply Loctite 243 to the M6x30 bolt 3 and tighten to 10 Nm. – Slide the shift shaft 4 in the bearings, push the shift rail 5 away from the shift locating drum and press the shift shaft towards the case to the stop; let go of the shift rail. 4 3 5 Aligning the return spring Art.-No. 3.206.056-E – Engage second or third gear. – Check the backlash of the shift rail and the clearance of the shift bolt. – The backlash of the shift rail is the distance the rail travels until the shift shaft begins to move. You should be able to feel the pressure of the return spring. Relative to the basic position, this backlash A should be equal towards the top and towards the bottom. – The backlash can be corrected by aligning the return spring. Repair manual KTM LC8 6 B – To align, dismount the shift shaft and bend the return spring as needed at the bends B using a pair of pliers. Remount the shift shaft. When the shift shaft is installed, the return spring must rest against the shift bolt 6 and the dolly of the shift mechanism support. – Bend the return spring again if necessary. 6-7 – Screw on the generator-end timing chain tensioning rail 1. Apply Loctite 243 to the bolt and tighten to 20 Nm. ! CAUTION ! SURE NO LOCTITE THREAD ADHESIVE IS ON THE PIVOT AREA OF THE BOLT. THIS COULD CAUSE THE TIMING CHAIN TENSIONING RAIL TO BLOCK AND BREAK. MAKE Balancer shaft – Heat the generator-end bearing of the balancer shaft evenly with a heat gun (up to model 2004). 1 NOTE: a roller bearing without an inner ring is used instead of the ball bearing starting with the 2005 model; these bearings no longer need to be warmed. – Fit the timing chain on the generator end (pay attention to the running direction if the chain has already been used) and slide into the balancer shaft 2. The timing chain must be placed over the rear sprocket. – Check the balancer shaft for smooth operation. 1 2 Freewheel – Slip the freewheel 3 on the crankshaft and attach the locking device 4 with 2 M6x16 bolts. Apply Loctite 243 to the bolts and tighten to 10 Nm. – Attach the lower starter idler gear 5 to the balancer shaft with the collar on the inside. 5 3 4 Rotor – Hold the freewheel with your finger while mounting the rotor, turning it in a counterclockwise direction. 7 6 – Mount the rotor bolt 6 with disk, apply Loctite 243 to the bolt and tighten to 180 Nm (M16) or 150 Nm (M16x1.5). NOTE: – to prevent the crankshaft from turning, block it with the engine lock bolt. – Check the force fit of the rotor on engines that do not have a woodruff key fixture - see Technical Information, Chapter 1. – Mount the upper starter idler gear 7 on the journal. 6-8 Generator cover – Mount dowel pins on the engine case and put a new gasket in place. Position the generator cover and tighten the generator cover bolts to 10 Nm (see illustration for bolt lengths). M6x30 M6x30 (A) M6x30 (A) M6x35 NOTE: the bolts marked with an A must be mounted with new copper sealing washers (6x10x1); the bolt marked with a B is used to attach a cable clip. M6x30 M6x35 M6x30 M6x30 M6x30 M6x35 (B) – Mount the engine sprocket with the lock washer and tighten the nut 1 to 100 Nm, bend over the lock washer. Art.-No. 3.206.056-E 1 Timing chain and balancing weight – Screw the output-end timing chain tensioning rail 2. Apply Loctite 243 to the bolt and tighten to 20 Nm. 2 ! 4 3 Repair manual KTM LC8 CAUTION ! SURE NO LOCTITE THREAD ADHESIVE IS ON THE PIVOT AREA OF THE BOLT. THIS COULD CAUSE THE TIMING CHAIN TENSIONING RAIL TO BLOCK AND BREAK. MAKE – Insert the woodruff key for the chain sprocket in the shaft groove and push the chain sprocket onto the balancer shaft. Fit the timing chain (pay attention to the running direction if the chain has already been used). – Insert the woodruff key for the balancing weight in the shaft groove and mount the balancing weight 3 with the aperture 4 towards the front. 6-9 Primary pinion – Mount the woodruff key for the primary pinion in the shaft groove (if dismounted). – Mount the primary pinion 1 with the longer collar towards the rear. The bore for the pickup ring must face towards the outside. 1 4 2 – Mount the gear wheel of the balancer shaft 2 with the collar facing the back (up to the 2004 model). – From the 2005 model: slide on the preassembled spreader drive, making sure the drive wheel and tensioning wheel do not fall apart; pull out the pin. ! CAUTION ! TURN THE BALANCER SHAFT UNTIL THE MARKS ON GEARS FOR THE CRANKSHAFT 3 AND BALANCER SHAFT 4 COINCIDE AS SHOWN IN THE ILLUSTRATION. MAKE SURE THE TIMING CHAINS DO NOT GET CAUGHT. 3 NOTE: when the marks coincide the first cylinder of the engine is in the TDC position. – Slide a 30.3 x 50 x 2 mm spacer washer 5 and a needle bearing 6 on the clutch shaft. – Mount the gear for the oil pump drive on the back of the outer clutch hub. The gear is secured by 3 needle rollers. 5 6 Outer clutch hub – When slipping the outer clutch hub onto the shaft, leave enough room for the pickup ring 7 which is held in place by a pin. ! CAUTION ! – THE PIN ON THE PICKUP RING MUST ENGAGE IN THE HOLE OF THE PRIMARY PINION. – THE PICKUP RING IN CARBURATOR AND INJECTION MODELS ARE DIFFERENTIATED BY THE POSITION OF THE "TOOTH GAP"; THEY CANNOT BE INTERCHANGED. – After mounting the ring gear on the crankshaft, push the outer clutch hub up to the stop, moving the oil pump wheel back and forth to make the procedure easier. – Mount a 33.2 x 46 x 2 disk and nut 8 (46 mm) on the primary pinion (LH thread). Apply Loctite 243 to the nut and tighten to 130 Nm. – Mount a 20.2 x 33 x 1.5 mm disk and nut 9 on the balancer shaft. Apply Loctite 243 to the nut and tighten to 150 Nm (up to the 2004 model). 7 9 – Mount the washer 20.2x34x1 mm and the spring washer 30.5x46.5x0.6-1.5, apply Loctite 243 to the nut 9 (A/F 30 mm) on the balancer shaft and mount, tighten the nut to 120 Nm (from the 2005 model). ! 8 bk CAUTION ! THE GEAR WHEEL AND BALANCER SHAFT ARE PRESTRESSED STARTING WITH THE 2005 MODEL; THE NUT ON THE BALANCER SHAFT MAY ONLY BE TIGHTENED TO 120 NM OTHERWISE THE SPREADER DRIVE WILL BE DAMAGED. – Screw on the pickup bk. Apply Loctite 243 to the bolts (M6x16) and tighten to 10 Nm. Press the cable duct into the recess in the case. NOTE: the gap between the pickup and the pickup ring must be between 0.6 and 1.0 mm (950) or between 0.4 and 0.6 mm (990). 6-10 – Slide the 25 x 48 x 6.5 mm disk and inner clutch hub together with the clutch pressure booster onto the main shaft teeth. NOTE: the two clutch pressure booster parts are marked with coinciding circles. – Attach the holder for the inner clutch hub A 600.29.003.000. Mount the 22 x 37 x 3 mm disk. Apply Loctite 243 to the nut (32 mm) and tighten to 130 Nm. Remove support. – Turn the inner clutch hub to check for smooth operation. B A 2 Art.-No. 3.206.056-E Clutch disks 4 3 Repair manual KTM LC8 – First mount the supporting plate 1 and then the spring washer 2 with the open side facing outwards (see illustration). – Starting with the lining disk 3 with the largest inner diameter, alternately insert 11 lining disks and 10 clutch disks. B 2 1 NOTE: – Thoroughly oil all disks. – The clutch lining on the first and last clutch disks have a different color since these two disks run on aluminum on one side. – The first clutch disk has a larger inner diameter to hold the support and lining disk. – The clutch disks are punched out. The sharp edges on all of the disks must point in the same direction. The round recesses (for demounting) must be in the same meshing. – The last lining disk must be turned one meshing further. – Push the clutch pushrod into the transmission main shaft. – The marks B on the pressure cap and inner clutch hub must coincide when the pressure cap is mounted. – Mount the pressure springs with disks and bolts (M6x16). Tighten the bolts crosswise to 10 Nm. 6-11 Clutch cover – A vibration damper 1 is mounted in the outer clutch cover from the 2005 model, screw 2 may not be loosened. ! CAUTION ! THE SCREW ON THE VIBRATION DAMPER IS LOOSENED, A NEW OUTER CLUTCH OVER WITH A VIBRATION DAMPER OR THE OLD CLUTCH OVER WITHOUT THE VIBRATION DAMPER MUST BE USED SINCE THE SELF-CUTTING SCREW 2 CANNOT BE ADEQUATELY SECURED. IF YOU REMOUNT THE VIBRATION DAMPER WITH THE SCREW, THE SCREW CAN BECOME LOOSE AND DAMAGE THE ENGINE. IF 1 2 – Mount the dowel pins on the engine case and put a new clutch cover gasket in place. M6x30 NOTE: remove the locking bolt to make it easier to mount the clutch cover. M6x85 M6x35 M6x30 M6x30 M6x30 M6x30 M6x30 M6x30 M6x30 – Turn the water pump shaft 3 until the recess fits over the driver 4 of the balancer shaft when the clutch cover is mounted. 3 4 – Mount the inner clutch cover together with the outer clutch cover, inserting the bolts as illustrated. Tighten to 10 Nm. – Screw the locking bolt back in. 6-12 Oil screen – Insert the oil screen 1 in the opening in the case. 1 NOTE: the oil screen has a TOP marking 2 which must point up. – Mount the oil screen cover; tighten the two M6x35/M6x40 bolts to 10 Nm. 2 Water pump Art.-No. 3.206.056-E – Mount the water pump wheel 3 and disk on the shaft. Hold with the holding spanner 600.29.082.000, secure the bolt 4 M6x15 with Loctite 243 and tighten to 10 Nm. 4 3 Repair manual KTM LC8 – Mount the dowel pins and replace the O-ring gasket. – Mount the water pump cover 5 with 4 M6x60 bolts. Tighten to 10 Nm. 5 6-13 Cylinder head rear with timing chain – Remove the M10x161 stud bolts, strength class 10.9, and replace with stud bolts in class 12.9. 1 NOTE: you can tell the two strength classes apart by their thread length. Stud bolts in class 12.9 have a thread length of 26 mm; stud bolts in any other length must be replaced. – Mount a new base gasket. NOTE: make sure the crankshaft is blocked in the cylinder rear TDC position. – Fit the timing chain and chain tensioning rail in the cylinder. NOTE: – The chain guide is mounted on the exhaust side of cylinder rear. – The timing chain should be drawn up and held in the chain tunnel with a thin welding wire 1 or a rubber band. – Push the cylinder head and cylinder over the stud bolts until the piston pin can be pressed into the piston by hand from the output end. Insert a new piston pin retainer with a screwdriver into the piston groove. ! CAUTION ! – DO – – NOT PULL THE PISTON OUT OF THE CYLINDER UP TO THE OIL SCRAPER RING SINCE THE PISTON RING WILL BE DAMAGED BY THE LOWER EDGE OF THE CYLINDER. THE OPENING TOWARDS THE CRANKSHAFT SHOULD BE COVERED WITH A CLOTH TO PREVENT THE PISTON PIN RETAINER FROM FALLING OUT OF THE ENGINE CASE. THE PISTON PIN RETAINER 2 MUST BE IN THE POSITION SHOWN IN THE ILLUSTRATION. 2 Push the cylinder head and cylinder down. Oil the cylinder head nuts and mount with the washer - see Technical Information. The cylinder head nuts are tightened in 2 stages. 5 3 4 1st stage: – Tighten the cylinder head nuts crosswise. Use the special nut 600.29.083.000 for the internal nuts 3 and the special wrench 600.29.081.000 for the outer nut 4. ! CAUTION ! – THE TIGHTENING TORQUE FOR THE 1ST STAGE IS 25 NM. SINCE THE SPECIAL WRENCH 600.29.081.000 IS USED FOR NUT 4, IT MUST BE TIGHTENED TO 23 NM. – THE TORQUE WRENCH USED MUST BE USED IN LINE WITH THE SPECIAL WRENCH 600.29.081.000 (SEE ILLUSTRATION). 5 – Tighten the two outer nuts 5 to 8 Nm. 2nd stage: – Tighten the cylinder head nuts crosswise. ! – CAUTION ! TIGHTENING TORQUE FOR THE 2ND STAGE IS 38 NM. SINCE THE SPECIAL WRENCH 600.29.081.000 IS USED FOR NUT 4, IT MUST BE TIGHTENED TO 34 NM. THE TORQUE WRENCH USED MUST BE USED IN LINE WITH THE SPECIAL WRENCH 600.29.081.000 (SEE ILLUSTRATION). – THE 6-14 – Push the double timing gear down into the chain tunnel draw the timing chain along the side on the inside. A 2 – Use the wire hook A to lift the side of the chain on the inside over the gear teeth 1 onto the chain teeth 2 of the double timing gear. Hold the double timing gear towards the outside by inserting your finger through the hole in the bearing bolt. Repair manual KTM LC8 Art.-No. 3.206.056-E 1 – Mount and grease a new O-ring on the bearing bolt 3 of the double timing gear. – Lift the double timing gear, insert the bearing bolt on the double timing gear and the needle bearing into the cylinder head and tighten to 30 Nm. 3 6-15 Chain tensioner cylinder rear – Insert the chain tensioner element 1 in the cylinder head bore. NOTE: the housing and tensioning piston of the chain tensioner are compression molded. If the two parts cannot be separated, the chain tensioner must be replaced. 1 – Apply the chain tensioner bolt and new sealing washer to the chain tensioner element without compressing the spring. – Measure the distance 2 between the sealing washer and the cylinder head. 2 The measured value has to be between 6 mm and 11 mm. If the value is lower, the tensioning rail could be worn or the timing chain excessively elongated. If it is higher, the engine was turned to TDC against the running direction. – Mount the chain tensioner bolt 3 with a new sealing washer and tighten to 20 Nm. 3 6-16 Camshafts cylinder rear – Insert the two camshafts marked "in re" (rear intake camshaft) and "ex re" (rear exhaust camshaft) into the bearings without tilting. The marks on the camshaft gears must coincide with the flat outer surface of the cylinder head (see illustrations). Art.-No. 3.206.056-E 1 NOTE: – The same camshaft gears are used in both cylinders but they have marks for cylinder rear and front. Use the camshaft gear marked with a cross 1 (points as of 2007) and for cylinder rear and the camshaft gear marked with a circle for cylinder front. – The cams 2 of both camshafts on the cylinder rear will point towards the inside in the TDC position. – The camshaft bearing bridges 3 and the cylinder heads 4 have coinciding marks to ensure that the same camshaft bearing bridge is mounted on the same cylinder head. 1 2 – Place plastigauge measuring strips 5 (600.29.012.000) on the camshaft bearing positions. – Carefully mount the camshaft bearing bridge and tighten the bolts in the camshaft bearing bridge to 10 Nm (M8) in the first stage. – Tighten to 18 Nm (M8) and 10 Nm (M6) in the second stage. 3 Repair manual KTM LC8 4 ! CAUTION ! TIGHTENING THE BOLTS OF THE CAMSHAFT BEARING BRIDGE, MAKE SURE THAT THE VALVES ARE NOT ACTUATED BY THE CAMSHAFT (SEE ILLUSTRATION), OTHERWISE THE BEARING BRIDGE WILL BREAK. WHEN NOTE: do not turn the camshafts. – Remove the camshaft bearing bridge again and compare the width of the plastigauge measuring strip 6 with the information on the packing. The width of the plastiguage measuring strip is equivalent to the bearing clearance. Camshaft bearing clearance: 0.020 mm – 0.061 mm Wear limit: 0.09 mm 5 6 – Carefully mount the camshaft bearing bridge and tighten the bolts in the camshaft bearing bridge to 10 Nm (M8) in the first stage. – Tighten to 18 Nm (M8) and 10 Nm (M6) in the second stage. 6-17 Setting cylinder front to TDC – Loosen the crankshaft locking bolt and turn the engine counterclockwise 1 rotation and then 75° towards the front cylinder's TDC position, keeping the timing chain on the cylinder rear slightly tensioned and holding the conrod in the center of the opening in the case. ! CAUTION ! CRANKSHAFT MUST BE TURNED 1 ROTATION AND 75° IN A COUNTERCLOCKWISE DIRECTION, OTHERWISE THE IGNITION INTERVAL WILL NOT BE CORRECT AND THE MOTOR WILL NOT RUN. IF YOU DO NOT HOLD THE CHAIN, IT MAY GET JAMMED BETWEEN THE TIMING CHAIN ON THE CRANKSHAFT AND THE TENSIONING RAIL. IF THE CONROD IS NOT POSITIONED IN THE CENTER OF THE OPENING IN THE CASE, THE CONROD BOTTOM WILL BLOCK ON THE BALANCER SHAFT AND PREVENT THE CRANKSHAFT FROM TURNING. – THE – – – Screw the crankshaft locking bolt back in. 75º Cylinder head front with cylinder and timing chain – Remove the M10x161 stud bolts, strength class 10.9, and replace with stud bolts in class 12.9. 1 NOTE: you can tell the two strength classes apart by their thread length. Stud bolts in class 12.9 have a thread length of 26 mm; stud bolts in any other length must be replaced. – Mount a new base gasket. NOTE: make sure the crankshaft is blocked in the cylinder front TDC position. – Fit the timing chain and chain tensioning rail in the cylinder. Tilt the chain tensioning rail 1 towards the chain to allow it to engage in the chain tunnel of the engine case. NOTE: – The chain guide is mounted on the intake side of cylinder front . – The timing chain should be drawn up and held in the chain tunnel with a thin welding wire or a rubber band. – Push the cylinder head and cylinder over the stud bolts until the piston pin can be pressed into the piston by hand from the output end. Insert a new piston pin retainer with a screwdriver into the piston groove. ! – DO – – 2 CAUTION ! NOT PULL THE PISTON OUT OF THE CYLINDER UP TO THE OIL SCRAPER RING SINCE THE PISTON RING WILL BE DAMAGED BY THE LOWER EDGE OF THE CYLINDER. THE OPENING TOWARDS THE CRANKSHAFT SHOULD BE COVERED WITH A CLOTH TO PREVENT THE PISTON PIN RETAINER FROM FALLING OUT OF THE ENGINE CASE. THE PISTON PIN RETAINER 2 MUST BE IN THE POSITION SHOWN IN THE ILLUSTRATION. 6-18 2 – Push the cylinder head and cylinder down. Oil the cylinder head nuts and mount with the washer - see Technical Information. The cylinder head nuts are tightened in 2 stages. 1st stage: – Tighten the cylinder head nuts crosswise. Use the special nut 600.29.083.000 for the internal nuts 1 and the special wrench 600.29.081.000 for the outer nut 3. 1 ! 3 2 CAUTION ! – THE TIGHTENING TORQUE FOR THE 1ST STAGE IS 25 NM. SINCE THE SPECIAL WRENCH 600.29.081.000 IS USED FOR NUT 3, IT MUST BE TIGHTENED TO 23 NM. – THE TORQUE WRENCH USED MUST BE USED IN LINE WITH THE SPECIAL WRENCH 600.29.081.000 (SEE ILLUSTRATION). – Tighten the two outer nuts 2 to 8 Nm. 2nd stage: – Tighten the cylinder head nuts crosswise. ! CAUTION ! TIGHTENING TORQUE FOR THE 2ND STAGE IS 38 NM. SINCE THE SPECIAL WRENCH 600.29.081.000 IS USED FOR NUT 3, IT MUST BE TIGHTENED TO 34 NM. THE TORQUE WRENCH USED MUST BE USED IN LINE WITH THE SPECIAL WRENCH 600.29.081.000 (SEE ILLUSTRATION). – THE – Art.-No. 3.206.056-E – Push the double timing gear down into the chain tunnel draw the timing chain along the side on the inside. A 5 4 6 Repair manual KTM LC8 – Use the wire hook A to lift the side of the chain on the inside over the gear teeth 4 onto the chain teeth 5 of the double timing gear. Hold the double timing gear towards the outside by inserting your finger through the hole in the bearing bolt. – Mount and grease a new O-ring on the bearing bolt 6 of the double timing gear. – Lift the double timing gear, insert the bearing bolt on the double timing gear and the needle bearing into the cylinder head and tighten to 30 Nm. 6-19 Chain tensioner cylinder front – Insert the chain tensioning element 1 in the cylinder head bore. NOTE: the housing and tensioning piston of the chain tensioner are compression molded. If the two parts cannot be separated, the chain tensioner must be replaced. 1 – Apply the chain tensioner bolt and new sealing washer to the chain tensioner element without compressing the spring. – Measure the distance 2 between the sealing washer and the cylinder head. 2 The measured value should be between 6 mm and 11 mm. If the value is lower, the tensioning rail could be worn or the timing chain excessively elongated. If it is higher, the engine was turned to TDC against the running direction. – Mount the chain tensioner bolt 3 and tighten to 20 Nm. 3 Oil pressure switch – Mount the oil pressure switch 4 with a new sealing washer and tighten to 10 Nm. 4 6-20 Camshafts cylinder front – Insert the two camshafts marked "in fr" (front intake camshaft) and "ex fr" (front exhaust camshaft) into the bearings without tilting. The marks on the camshaft gears must coincide with the cylinder head surface (see illustrations). Art.-No. 3.206.056-E 1 NOTE: – The same camshaft gears are used in both cylinders but they have marks for cylinder rear and front. Use the camshaft gear marked with a cross for cylinder rear and the camshaft gear marked with a circle 1 for cylinder front. – The cams 2 of both camshafts on the cylinder front will point towards the outside in the TDC position. – The camshaft bearing bridges 3 and the cylinder heads 4 have coinciding marks to ensure that the same camshaft bearing bridge is mounted on the same cylinder head. 1 2 – Place plastigauge measuring strips 5 (600.29.012.000) on the camshaft bearing positions. – Carefully mount the camshaft bearing bridge and tighten the bolts in the camshaft bearing bridge to 10 Nm (M8) in the first stage. – Tighten to 18 Nm (M8) and 10 Nm (M6) in the second stage. 3 Repair manual KTM LC8 4 ! CAUTION ! TIGHTENING THE BOLTS OF THE CAMSHAFT BEARING BRIDGE, MAKE SURE THAT THE VALVES ARE NOT ACTUATED BY THE CAMSHAFT (SEE ILLUSTRATION), OTHERWISE THE BEARING BRIDGE WILL BREAK. WHEN NOTE: do not turn the camshafts. – Remove the camshaft bearing bridge again and compare the width of the plastigauge measuring strip 6 with the information on the packing. The width of the plastiguage measuring strip is equivalent to the bearing clearance. 5 6 Camshaft bearing clearance: 0.020 mm – 0.061 mm Wear limit: 0.09 mm – Carefully mount the camshaft bearing bridge and tighten the bolts in the camshaft bearing bridge to 10 Nm (M8) in the first stage. – Tighten to 18 Nm (M8) and 10 Nm (M6) in the second stage. 6-21 NOTE: – Check the position of the camshafts on cylinder front in the TDC position of cylinder rear. The cams on the exhaust camshaft 1 point towards the inside and push open the exhaust valves, the cams on the intake camshaft 2 also point towards the inside, the bucket tappets are not actuated. If the camshafts are in a different position, check the timing and reset. – Check valve clearance (see Chapter 12) 2 1 – Remove the crankshaft blocking tool 3. Insert the case bolt (M8x60) with a new sealing washer and tighten to 10 Nm. – Screw the plug 4 into the generator cover. 3 4 Starter motor – Insert the starter motor into the opening in the case with a new O-ring (greased). Insert both bolts 5 (M6x25) and tighten to 10 Nm. 5 5 6-22 Spark plug shaft inserts – Mount new O-rings 1 on the spark plug shafts and grease. Push the spark plug shaft inserts all the way in. 1 – Mount the valve cover gaskets 2 and spark plug shaft gaskets 3. 3 2 Art.-No. 3.206.056-E Valve cover – Mount the valve cover. Insert bolts 4 with the sealing washers and tighten to 10 Nm. 4 4 4 – Screw in the spark plugs with special tool 600.29.073.000 and tighten to 12 Nm (950, M10) or 20 Nm (990, M12x1.5). – Connect the spark plug connectors. – 990 Super Duke R only: mount and tighten screw 5. Repair manual KTM LC8 5 7-1 ELECTRICAL Repair manual KTM LC8 Art.-No. 3.206.056-E INDEX CHECKING FOR LOSS OF CURRENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3 DISMOUNTING THE BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3 CHARGING THE BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3 JUMP START . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.3 CHECKING THE CHARGING VOLTAGE/ RECTIFIER REGULATOR . . . . . . . . . . . . . . .7-3 CHECKING THE GENERATOR COILS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3 ELECTRIC STARTER SYSTEM 950 ADVENTURE . . . . . . . . . . . . . . . . . . . . . . . . .7-4 ELECTRIC STARTER SYSTEM 990 SUPER DUKE/R . . . . . . . . . . . . . . . . . . . . . . .7-5 ELECTRIC STARTER SYSTEM 950 SUPERMOTO/950 SUPER ENDURO . . . . . . . . .7-6 ELECTRIC STARTER SYSTEM 990 ADVENTURE -2007 . . . . . . . . . . . . . . . . . . . .7-7 ELECTRIC STARTER SYSTEM 990 ADVENTURE 2007- . . . . . . . . . . . . . . . . . . . .7-8 ELECTRIC STARTER SYSTEM 990 SUPERMOTO . . . . . . . . . . . . . . . . . . . . . . . . .7-9 CHECKING THE AUXILIARY STARTER RELAY . . . . . . . . . . . . . . . . . . . . . . . . . .7-10 FUNCTIONAL CHECK OF THE AUXILIARY STARTER RELAY . . . . . . . . . . . . . . . . .7-11 CHECKING THE DIODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12 CHECKING THE STARTER RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13 CHECKING THE STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13 CHECKING THE CLUTCH SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14 CHECKING THE TIP SWITCH AND THE EMERGENCY OFF SWITCH . . . . . . . . . . .7-15 TROUBLESHOOTING IN THE STARTER SYSTEM . . . . . . . . . . . . . . . . . . . . . . . .7-15 IGNITION SYSTEM, ECU 950 ADVENTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16 IGNITION SYSTEM, ECU 950 SUPERMOTO . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17 IGNITION SYSTEM, ECU 950 SUPER ENDURO . . . . . . . . . . . . . . . . . . . . . . . . .7-18 CHECKING THE ECU 950 ADVENTURE/950 SUPERMOTO/SUPER ENDURO . . . . .7-19 CHECKING THE PULSE GENERATOR 950 ADVENTURE/SUPERMOTO/SUPER ENDURO . .7-19 CHECKING THE FUEL PUMP RELAY 950 ADVENTURE/SUPERMOTO/SUPER ENDURO . .7-20 CHECKING THE IGNITION COILS (CARBURETTOR MODELS ONLY) . . . . . . . . . . . .7-20 TROUBLESHOOTING IN THE IGNITION SYSTEM 950 ADVENTURE/ SUPERMOTO/SUPER ENDURO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21 THE EPC SYSTEM 950 ADVENTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22 THE EPC SYSTEM 950 SUPERMOTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23 THE EPC SYSTEM 950 SUPER ENDURO . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24 7 7-2 ELECTRICAL Repair manual KTM LC8 Art.-No. 3.206.056-E INDEX CHECKING THE SOLENOID VALVE FOR THE EPC 950 ADVENTURE/950 SUPERMOTO . .7-25 CHECKING THE GEAR SENSOR 950 ADVENTURE/950 SUPERMOTO . . . . . . . . . .7-25 CARBURETOR HEATER 950 ADVENTURE/950 SUPERMOTO/950 SUPERMOTO . .7-26 INJECTION/IGNITION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-27 ESTABLISHING THE INJECTION PERIOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-27 CORRECTION SENSORS AND INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-27 SYSTEM DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-28 BASIC DESCRIPTION OF THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-29 WIRING DIAGRAM 990 SUPER DUKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-30 WIRING DIAGRAM 990 SUPER DUKE R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-31 WIRING DIAGRAM 990 ADVENTURE -2007 . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32 WIRING DIAGRAM 990 ADVENTURE 2007- . . . . . . . . . . . . . . . . . . . . . . . . . . .7-33 WIRING DIAGRAM 990 SUPERMOTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34 BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-35 DESCRIPTION OF THE ELECTRIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-35 DESCRIPTION OF THE COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-37 SAFETY AGAINST FAILURE/EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . .7-43 COMPONENT TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-44 ERROR CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-55 ABBREVIATIONS, LIMIT VALUES 990 SUPER DUKE . . . . . . . . . . . . . . . . . . . . .7-56 ABBREVIATIONS, LIMIT VALUES 990 ADVENTURE / 990 SUPERMOTO . . . . . . .7-57 ALARM SYSTEM 990 SUPER DUKE/R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-58 ORDER FOR ADDITIONAL HAND-HELD TRANSMITTERS . . . . . . . . . . . . . . . . . . .7-59 ADAPTING THE HAND-HELD TRANSMITTER . . . . . . . . . . . . . . . . . . . . . . . . . . .7-59 STARTING WITH THE EMERGENCY CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-60 ABS-SYSTEM 990 ADVENTURE CHECKING THE FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-61 CHECKING THE ABS FAULT MEMORY USING THE KTM DIAGNOSTICS TOOL . . . .7-61 CHECKING THE ABS SENSOR WITH THE KTM DIAGNOSTICS TOOL . . . . . . . . . . .7-61 7 7-3 Checking for loss of current Check for loss of current before you check the rectifier regulator. – Switch off the ignition and disconnect the ground wire from the battery. – Connect an ammeter between the ground wire and the negative pole on the battery. Set point value: max. 2 mA – If the value is higher, look for the current consumers. For example: – a defective regulator/rectifier – a defective multifunctional digital speedometer – Creepage current in the socket connectors or in the ignition lock NOTE: you will need to set the clock on the multifunctional digital speedometer after the battery is connected. Dismounting/replacing the battery see Chapter 3 0,00 Charging the battery see Owner's Manual Jump start see Owner's Manual Checking the charging voltage / rectifier regulator Art.-No. 3.206.056-E NOTE: the following figures only apply to fully charged batteries. – Connect a voltmeter to both battery terminals. – Start the engine and switch on the low beam. – Rev the engine up to 5000 rpm and read the voltage. Set point value: 14.0 – 15.0 V If the measured value deviates significantly from the set point value: – Check the socket connectors from the stator to the regulator rectifier and from the regulator rectifier to the cable tree. – Check the generator coils – Replace the regulator rectifier Checking the generator coils – Disconnect the socket connector 1 and measure the 3 cables (yellow) to the generator back to back for resistance. 1 Set point value: max 1,0 Ω bei 20º C Repair manual KTM LC8 – Check all three cables for short circuit to ground. – Check both connectors for damage. 7-4 30 30 3 1 2 7 3th 3fuse C_BB/9 C_AB/9 N orange 1 8 10 A 3 1 2 C_AI1/2 yellow 0.5 7 1 diode bm 2 3 31 C_AT2/2 C_AM3/3 A page 7/9 1 C_AL C_AR/2 brown 0.5 brown 0.5 1 pink 0.5 green-black 0.5 diode brown 0.5 bl starter motor yellow 0.5 bn M 2 C_AI/2 B page 4/9 sidestand switch 8 clutch switch brown 0.5 4 pink 0.5 C_AF/4 2 C_BF1/1 red 0.5 yellow 0.5 C_BA1/1 31 red 4 6 1 5 battery black-orange 0.5 orange 0.5 start auxillary relay 1 red 0.5 30 orange 0.5 3 C_AR/3 C_AM2/3 C_AE/4 4 neutral switch (N) / 2nd gear / 3th gear 2 2nd bk red 4 start-relay ignition switch 4 9 start/stop switch 31 Electric starter system 950 Adventure NOTE: the starter system is equipped with a safety feature. You will only be able to start under the following conditions: – If the gnition lock is in the ON position – If the emergency OFF switch is in the ON position – If the transmission is shifted to neutral or the clutch is pulled How the starter system operates: Battery voltage travels from the battery 1 through the ignition lock 2, fuse 3 and the emergency OFF switch 4 to the coil of the auxiliary starter relay 5 . The ground supply to the coil of the auxiliary starter relay takes place if at least one of the following conditions are met: – Transmission is shifted to neutral (neutral switch 6 is closed, current can flow through diode 7 and the neutral switch against the ground) – Clutch is pulled (clutch switch 8 is closed, the current can flow through the clutch switch against the ground) NOTE: if these conditions are met, the load contact from the coil is closed (nonrecurring "click “). When the tip switch 9 is actuated, battery voltage flows through the closed load contact of the auxiliary start relay 5 to the coil of the start relay bk and from there against the ground. This causes the load contact on the start relay to close and battery voltage to flow via the start relay contact to the starter engine bl . The diode bm is one of the electric starter system's important safety features which prevents the starter engine from being actuated although a gear is engaged and the clutch is not pulled. The diode does not allow current to flow when the side stand is folded down, in other words, the auxiliary starter relay will not have a ground connection via the side stand switch. If the clutch is released with the engine running and a gear engaged although the side stand is folded down (driving off with the side stand folded down) the ECU will not have a ground connection through the pink cable, the voltage will increase to over 2.5 volts and the ECU will break the ignition, immediately causing the engine to stall. An alarm system (accessory) can be connected to the BA/BF bn connectors. The two connectors must be connected together if no alarm system is installed. 7-5 re-wh C o nnector for optional alarm system 18 18 17 17 U 8 8 7 7 9 re-wh 4 br re-wh re-wh M 3 G 8 9 6 6 5 5 bl 4 4 bl 3 3 2 2 1 1 1 2 7 diode start auxillary relay 4 8 C_AI1/2 C_AI2/2 1 2 2 ye-wh 1 2 A 3 p a ge 6 1 re-wh diode bn 1 generator 6 3 ignition 9 gn-bl 10 fuse 10 A C_BB/9 C_AB/9 ye-wh re-wh 3 C_BI/2 2 C_AU/2 C_AE1/4 30 A start relay starter motor C_DK/18 11 10 bl bm C_DJ/18 11 regulator-rectifier gn re-wh 12 ye gn 1 1 13 ye-wh 1 o r a nge 1 15 C_AF2/4 battery 13 12 4 5 16 2 14 or-bl 16 15 14 start/stop switch re-bl bk re-bl Dummy plug 30 ignition switch 30 2 3 C_AL1/2 C_AM2/3 C_AT1/2 C_AR2/3 9 2 nd 3 th N 7 clutch switch neutral switch (N) / 2nd gear / 3rd gear Art.-No. 3.206.056-E 31 Electric starter system 990 Super Duke/R NOTE: The starting system is equipped with security features. The motorcycle can only be started under the following conditions: – – – – Ignition lock in the ON position Emergency-off switch in the ON position Transmission in the idle position or the clutch pulled Alarm system deactivated (if installed) 990 Super Duke starting system - mode of operation: Battery voltage flows from the battery 1 via the ignition lock 2, fuse 3 and the emergency-off switch 4 to the tip switch 5. The coil of the auxiliary start relay 6 is supplied with ground if at least one of the following conditions are met: – Transmission in the idle position (neutral switch 7 closed, current can flow via the diode 8 and the neutral switch to chassis) – clutch pulled (clutch switch 9 closed, current can flow via the clutch switch to chassis) Repair manual KTM LC8 By pressing the tip switch 5, battery voltage will flow to the coil of the auxiliary start relay 6 (via the bridge connector bk or the alarm system - if installed; for accessories, see alarm system) which picks up the load contact, as well as to the coil of the start relay bl via the closed load contact and from there to chassis. This causes the contact on the start relay to close and battery voltage to flow via the contact on the start relay to the starter engine bm. The diode bn is one of the starting system's important safety components. It prevents the starter engine from being actuated even if a gear is engaged and the clutch is not pulled. If the clutch is released with the engine running and a gear engaged although the side stand is folded down (driving off with the side stand folded down) the ECU will interrupt the ignition and injection and immediately cause the engine to stall. 7-6 re-wh Dummy plug battery 30 A C_AF3/4 start relay 1 re-wh 2 re-wh 3 re-bu 4 br 3 18 17 17 16 16 15 15 14 13 C_DK/18 18 12 C_DJ/18 U red-white 1 regulator-rectifier bk Connector for optional alarm system 8 3 2 13 12 11 10 10 9 9 8 8 7 7 C_BB/9 C_AB/9 8 6 6 5 5 9 4 4 bl 3 3 bl 2 2 1 1 C_BC/6 1 2 C_AC/6 7 5 4 diode bn diode diode 6 9 C_AF/4 A A A A A A 8 re-ye re-wh ye-bl bl-wh ye orange 0.5 2 C_AI1/2 bm 1 1 2 pink 0.5 J-page3/8 yellow 0.5 2 green-black 0.5 3 1 1 ye-bu or-bl red 0.5 4 f us e bo x A 2 10 10 10 10 1 0 1 0 15 1 0 A orange-white 0.5 1 1 C_AI2/2 C_AI/2 1 2 C_AL3/2 C _AM1/3 C_AT3/2 C_AR1/3 5 D-pa ge 4/8 G- pag e 6 /8 F-pag e6/8 3 7 2 4 1 brown 0.5 C-page 5/8 bo C_AF2/4 H-p age 6/8 B-page 5/8 red-white 1 light system relay A-page3/8 I-page6/8 3 re-bl red-blue 0.5 brown 0.5 16 start auxillary relay 4 or re-wh or re-wh or re-wh or bl re-wh starter motor M generator ignition switch 14 11 G 30 start/stop switch orange-white 0.5 red-white 1 red-white 1 red-white 1 red-white 1 30 2nd 3th N clutch switch E-page3/8 neutral switch (N) / 2nd gear / 3rd gear 31 Electric starter system 950 Supermoto/R, 950 Super Enduro NOTE: – The electric starter system is equipped with a safety feature. – The 950 Super Enduro model does not have an alarm system, dummy plug or emergency off switch. You will only be able to start under the following conditions: – If the ignition switch is in the ON position – If the emergency OFF switch is in the ON position – If the transmission is shifted to neutral or the clutch is pulled How the electric starter system operates: Battery voltage travels from the battery through the fuse 1, the ignition switch 2 and the emergency OFF switch 3 (950 Supermoto only) to the coil of the auxiliary starter relay 4. The ground supply to the coil of the auxiliary starter relay takes place if at least one of the following conditions are met: – Transmission is shifted to neutral (neutral switch 5 is closed, current can flow through diode 6 and the neutral switch against the ground) – Clutch is pulled (clutch switch 7 is closed, the current can flow through the clutch switch against the ground) NOTE: if these conditions are met, the load contact from the coil is closed (nonrecurring "click "). When the tip switch 8 is actuated, battery voltage flows through the control unit of the alarm system (if installed, otherwise through the dummy switch 9 - 950 Supermoto only), the closed load contact of the auxiliary start relay 4 to the coil of the start relay bk and from there against the ground. This causes the load contact on the start relay to close and battery voltage to flow via the start relay contact to the starter engine bl . If a gear is engaged when the engine is running and the clutch is released although the side stand is folded down (driving off with the side stand folded down), the ECU will no longer have contact to the ground via the diode bm and the pink cable, the voltage will increase to over 2.5 volts and the ECU will interrupt the ignition, immediately causing the engine to stall. The diode bn is a freewheeling diode that is used to reduce peak voltages and thus protect the electronic components. The light system relay bo is used to stop the power supply to the light system, relieving the battery. 7-7 30 red-white 1 red-white 1 red-white 1 red-white 1 re-wh start/stop switch 4 re-wh 3 re-bu 4 br 3 G generator 2 C_ AC/6 7 4 5 diode diode bk 6 R-page3/9 C_AI1/2 10 10 10 fus e box A A A A A A re-wh re-gn bl-wh ye-bu 2 green-black 0.5 3 1 I-page6/9 2 C_ AL 3/2 1 ye bl-ye 8 A 1 yellow-white 0.5 2 C_AT3/2 re-ye A 4 5 10 C_AF/4 10 C_AI1/2 1 red 0.5 1 9 15 10 re-bl red-blue 0.5 brown 0.5 16 10 s t a r t a ux i l l ar y r e l ay re-wh gn re-wh gn 1 re-wh 9 gn gn 2 re-wh starter motor M 8 C_ BC/6 1 red -black 0.5 30 A re-wh 2 2 3 8 1 ignition switch C_BB/9 C_AB/9 battery U red-white 1 regulator-rectifier start relay 30 I-page3/9 light system relay C-page 5/9 D-page 5/9 G-page7/9 F-page7/9 7 2 4 1 brown 0.5 B-page 6/9 C_AF2/4 H-page7/9 red-white 1 3 J-page3/9 A-page3/9 clutch switch E-page3/9 Art.-No. 3.206.056-E 31 Electric starter system 990 Adventure -2007 NOTE: The electric starter system is equipped with a safety feature. You will only be able to start under the following conditions: – If the ignition switch is in the ON position – If the emergency OFF switch is in the ON position – If the transmission is shifted to neutral or the clutch is pulled How the electric starter system operates: Battery voltage travels from the battery through the fuse 1, the ignition switch 2 and the emergency OFF switch 3 to the tip switch 4. By pressing the tip switch, the coil and load contact of the auxiliary start relay 5 are supplied with battery voltage. The ground supply to the coil of the auxiliary starter relay 6 takes place if at least one of the following conditions is met: – Transmission is shifted to neutral (neutral switch is closed, current can flow through the diode [6] and the neutral switch against the ground); – Clutch is pulled (clutch switch 7 is closed, the current can flow through the clutch switch against the ground). Repair manual KTM LC8 When the coil of the auxiliary starter relay closes the load contact, battery voltage will flow to the starter relay 8, causing the contact on the starter relay to close and the starter engine 9 to turn. The diode bk is one of the electric starter system's important safety features. It prevents the starter engine from being actuated although a gear is engaged and the clutch is not pulled. If the clutch is released with the engine running and a gear engaged although the side stand is folded down (driving off with the side stand folded down) the ECU will interrupt the ignition and injection, immediately causing the engine to stall. 7-8 30 red-white 1 red-white 1 red-white 1 red-white 1 start/stop switch 4 red-white 1 U re-wh 3 re-bu 4 br 3 G generator 2 7 C_AC/6 4 5 5 10 10 10 10 10 4 C_AF/4 10 15 10 fuse box A A A A A A A 3 re-wh re-gn bl-wh ye-bu 1 ye bl-ye 8 SAR-page3/9 2 re-ye A red 0.5 re-wh 1 9 re-bl red-blue 0.5 16 brown 0.5 start auxillary relay re-wh gn re-wh 1 gn gn 7 gn R-page3/9 re-wh starter motor M 6 C_BC/6 1 red -black 0.5 30 A re-wh 2 2 3 8 1 ignition switch C_BB/9 C_AB/9 battery C_BI/2 C_AU/2 regulator-rectifier start relay 30 re-wh light system relay B-page 6/9 C-page 5/9 D-page 5/9 G-page7/9 F-page7/9 2 C_AF2/4 H-page7/9 red-white 1 3 J-page3/9 A-page3/9 4 1 E-page3/9 31 Starting system 990 Adventure 2007NOTE: The starting system is equipped with security features. The motorcycle can only be started under the following conditions: – Ignition lock in the ON position – Emergency-off switch in the ON position – Transmission in the idle position or the clutch pulled How the electric starter system operates: The battery voltage flows from the battery to the fuse 1, ignition switch 2, emergency OFF switch 3, and finally to the tip switch 4. By pressing the tip switch, the coil and load contact of the auxiliary start relay 5 are supplied with battery voltage. The coil of the auxiliary start relay 6 is supplied with ground if at least one of the following conditions are met: – Transmission in the idle position (neutral switch 7 closed, current can flow via the diode 8 and the neutral switch to chassis) – clutch pulled (clutch switch 9 closed, current can flow via the clutch switch to chassis) When the coil of the start auxiliary relay closes the load contact, the battery voltage flows to the starter relay 6, the contact of the starter relay is closed and the starter motor 7 turns. The diode bn is one of the starting system's important safety components. It prevents the starter engine from being actuated even if a gear is engaged and the clutch is not pulled. If the clutch is released with the engine running and a gear engaged although the side stand is folded down (driving off with the side stand folded down) the ECU will interrupt the ignition and injection and immediately cause the engine to stall. Components not named here, such as the neutral switch, clutch switch, etc., can be found in the wiring diagram of the engine electronics in Chapter 13. 7-9 start/stop switch diode Immobilizer 4 5 6 7 8 48 1 28,29 /2.B2 10A 2 10A 2 -M1 M 8 1 gn battery -G1 30 A regulator-rectifier gn C_AF/4 4 3 2 1 gn 2 58 1 59 2 U re-wh re-wh -N1 30 CAN-L ALA-A2 10A /3.B2 /3.B2 /2.A2 175,143 -X12-P1 CAN-H -F1 -F5 -F6 start relay 55 21 23 22 157 159 155 158 1 1 7 -K1 C_BI/2 3 156 153 -X12 splice 154 4 137 3 2 2 45,46 42 2 60,61 1 61,135,136,175,143 2 1 136 1 1 C_AI/2 52 C_DV/2 6 135 4 153 2 29,137 5 C_BK/4 C_BR/4 154 3 51,52 1 C_EL/2 starter motor -X1 splice C_DO/8 C_BC/6 C_AC/6 C_AU/2 C_DN/8 40 -A2 57 3 -V1 56 5 -S2 56,57 2 58,59 antenna immobilizer ignition switch -S1 -A1-X5 /2.C1 3 G generator 5,13,20,38,50,54,55,63,65,197 -X2 splice ACC /3.B2 5,13,20,38,76,197,159 GND-X14 fuel-A2 fue-P1 Art.-No. 3.206.056-E 6 5 7 8 9 10 11 12 13 14 C_EF/14 -A1 C_EG/14 60 alarm system dummy plug Connector for optional alarm system STR-A3 /3.A5 1 3 4 42,43 2 41 4 43 3 40 1 53 2 45 30 4 54 49 1 48 2 50 3 /2.C1 /2.B5 /3.B2 51 1 47 47 2 77 46 4 76 44 Antenna 6 66 4 31 3 9 2 7 1 65 64 2 28 /3.E6 /3.E6 /3.B2 lig-X19 64 66 ALA-A1 63 7 flaR-X200 for optional alarm system 9 flaL-X200 /2.E5 2 1 3 1 C_BS/2 C_BV/2 C_EB/4 C_EB/4 C_EB/4 3 C_EB/4 4 C_AM/3 C_AR/3 -K2 -S3 seat surveillance fuel pump relay M fuel pump -K4 -K3 -M2 light relay power relay -K5 start auxillary relay Starting system 990 Supermoto NOTE: The starting system is equipped with security features. The motorcycle can only be started under the following conditions: – Ignition lock in the ON position – Emergency-off switch in the ON position – Transmission in the idle position or the clutch pulled How the electric starter system operates: The battery voltage flows from the battery to the fuse 1, ignition switch 2, emergency OFF switch 3, and finally to the coil of the start auxiliary relay 4. The coil of the auxiliary start relay is supplied with ground if at least one of the following conditions are met: – Transmission in the idle position (neutral switch closed, current can flow via the diode and the neutral switch to chassis) – clutch pulled (clutch switch closed, current can flow via the clutch switch to chassis) Repair manual KTM LC8 NOTE: If these conditions are met, the load contact is closed by the coil ("clicks" once). When the tip switch 5 is actuated, battery voltage flows to the control unit of the alarm system (if present, otherwise via the dummy connector 6), to the closed load contact of the start auxiliary relay 4, to the coil of the starter relay 7, and from there to ground. The load contact of the starter relay is closed and battery voltage flows via the contact of the starter relay to the starter motor 8. If the clutch is released with the engine running and a gear engaged although the side stand is folded down (driving off with the side stand folded down) the ECU will interrupt the ignition and injection and immediately cause the engine to stall. The diode is a free wheeling diode; it is used to protect electronic components by reducing voltage peaks. The light relay 9 is used to interrupt the power supply to the lighting system during the start procedure to relieve the battery. Components not named here, such as the neutral switch, clutch switch, etc., can be found in the wiring diagram of the engine electronics in Chapter 13. 7-10 Checking the auxiliary starter relay – Dismount the auxiliary starter relay 1 (950 Adventure). 1 NOTE: orange, yellow, red and white/red cable colors. – Dismount the auxiliary starter relay 1 (990 Adventure -2007). NOTE: red/black (2x), yellow/white, red/blue cable colors. – Dismount the auxiliary starter relay 1 (990 Adventure 2007-). NOTE: red/black (2x), yellow/white, green/orange und red/blue – Dismount the auxiliary starter relay 2 (990 Super Duke/R). 2 NOTE: red/black (2x), yellow/white, red/white cable colors – Dismount the auxiliary starter relay 3 (950 Supermoto/R, 990 Supermoto). NOTE: orange, yellow, red and white/red cable colors. 3 A B – Connect the auxiliary starter relay (see drawing) to a 12 V battery, making sure you hear the relay switch (nonrecurring "click"). NOTE: the 12 V battery must be connected to the two terminals to which the orange and yellow cable colors (950 Adventure/950 Supermoto) or red/black and yellow/white (990 Adventure/Super Duke) are connected when the plug is connected. – Use an ohmmeter to measure the continuity between terminals A and B. Reading: max 1 Ω OK Reading: ∞ Ω defective 7-11 Functional check of the auxiliary starter relay (950 Adventure) – Pull the auxiliary starter relay out of the bracket. – Connect an ohmmeter or continuity tester to the cable of the auxiliary starter relay (red and red/white cables). – Perform the tests in the specified order. The auxiliary starter relay must switch under the following 2 conditions: – Slowly pull the clutch lever with the gear engaged. The auxiliary starter relay should switch at half of the lever travel (ignition and kill switch on). If not, check the clutch switch. Observe the idle indicator lamp, it may not light up. If it does, check the diode. – Switch the transmission to neutral with the clutch released. The auxiliary starter relay should switch on and switch off when the gear is engaged. If not, check the diode and neutral switch NOTE: You will hear a faint click when the auxiliary starter relay switches. The ohmmeter or the continuity tester will display the continuity when the auxiliary starter relay is switched on. Functional check of the auxiliary start relay (990 Adventure/ 990 Super Duke/R) Art.-No. 3.206.056-E – Pull the auxiliary start relay out of the holder. – Connect the voltmeter to the red/blue (990 Adventure) or red/white (990 Super Duke/R) cable of the auxiliary start relay and measure the voltage to chassis. – Perform the tests in the specified order. The auxiliary start relay must switch under the following conditions (the voltmeter will display the on-board voltage): – Slowly pull the clutch lever with a gear engaged and the tip switch pressed. The auxiliary start relay switch will switch around half the distance of the lever travel(ignition and emergency-off switch on!). NOTE: if the starting system is working, the starter engine will start up and start the engine. If not, check the clutch switch. Watch the idle control lamp, it should not light up. If it does, check the diode. – Shift the transmission to neutral without pulling the clutch. The auxiliary start relay should switch on and off again if the gear is engaged. If not, check the diode and the neutral switch. Functional check of the auxiliary start relay (950 Supermoto/R, 990 Supermoto) Repair manual KTM LC8 – Pull the auxiliary start relay out of the holder. – Connect the voltmeter to the red/blue cable of the auxiliary start relay and measure the voltage to chassis. – Perform the tests in the specified order. The auxiliary start relay must switch under the following conditions (the voltmeter will display the on-board voltage): – Slowly pull the clutch lever with a gear engaged and the tip switch pressed. The auxiliary start relay switch will switch around half the distance of the lever travel(ignition and emergency-off switch on!). NOTE: if the starting system is working, the starter engine will start up and start the engine. If not, check the clutch switch. Watch the idle control lamp, it should not light up. If it does, check the diode. – Shift the transmission to neutral without pulling the clutch. The auxiliary start relay should switch on and off again if the gear is engaged. If not, check the diode and the neutral switch. 7-12 Checking the diodes NOTE: Diodes only conduct the current in one direction. They block in the other direction. 1 Diodes can have 2 defects: – the diode has no continuity. – the diode has continuity in both directions. Various malfunctions can occur, depending on the type of defect. Each diode 1 (950/990 Adventure), 2 (990 Super Duke/R) and 3 (950 Supermoto/R, 990 Supermoto) is plugged into a bipolar connector (connector AI) 1 Functional check: – Connect a suitable ohmmeter to the diode and check the diode for continuity. – Connect the ohmmeter in the other direction and check if the diode is blocked. 2 3 7-13 Checking the starter relay – Disconnect the negative pole from the battery and dismount the start relay. – Connect the starter relay to a 12 V battery, making sure you hear the relay switch (nonrecurring "click"). 1 NOTE: the 12 V battery must be connected to the terminals to which the connectors with following cable colors . 950 Adventure: white/red 1 and brown 2 990 Adventure: red/blue 1 and brown 2 990 Super Duke: white red 3 and brown 4 950 Supermoto: red/blue 5 and brown 6 2 3 – Check the continuity between the two screw terminals with an ohmmeter. Reading: max. 1 Ω OK Reading: ∞ Ω defective 4 Art.-No. 3.206.056-E – Remove the fuse for the start relay and check for continuity. 6 5 Repair manual KTM LC8 Checking the starter motor – Switch off the ignition. – Disconnect the negative pole of the battery and remove the electric starter motor. – Clamp starter motor in a vise. – Connect the negative pole of a 12 V battery to the housing of the E starter motor and briefly connect the positive pole of the battery to connection of the electric starter motor (use thick cables). – The starter must turn as soon as the circuit is closed. – If this is not the case, replace the starter. 7-14 Checking the clutch switch – Disconnect the clutch switch connector from the cable tree. – Connect an ohmmeter to the bipolar connector AT2 1 (950 Adventure) or AT1 1 (990 Adventure) or AT1 2 (990 Super Duke/R) or AT3 3 (950 Supermoto/R, 990 Supermoto) of the clutch switch and slowly pull the clutch lever. – The switch should close around 2/3 of the lever travel. 1 2 3 Reading: max. 1 Ω when the clutch lever is pulled Reading: ∞ Ω when the clutch lever is not pulled 7-15 Checking the tip switch and emergency OFF switch 1 – Disconnect the four-terminal connector BB 1 (950/990 Adventure), 2 (990 Super Duke/R) or 3 (950 Supermoto/R, 990 Supermoto) on the tip switch / emergency OFF switch from the cable tree. – Check both switches with an ohmmeter. Tip switch: between pin 1 and pin 8 Reading: max. 1 Ω when the tip switch is actuated Reading: ∞ Ω when the tip switch is not actuated Emergency OFF switch: between pin 2 and pin 7 Reading: max. 1 Ω when the emergency OFF switch is switched on Reading: ∞ Ω when the emergency OFF switch is switched off – Afterwards check all lines for short circuit to ground. Art.-No. 3.206.056-E 2 3 Repair manual KTM LC8 start/stop switch C_BB/9 Pin 8 Pin 1 Pin 2 Pin 7 Troubleshooting in the starter system If you actuate the tip switch but the starter engine does not run, check the following points: – Is the ignition lock in the ON position? – Is the emergency OFF switch in the ON position? – Does the idle indicator lamp light up when the ignition is switched on? – Can you start the engine when the clutch is pulled? – Is the battery charged? – Has the main fuse blown? – Has the fuse for the electric starter system and ignition blown? – Check the auxiliary starter relay – Check the starter relay – Check the E-starter engine 7-16 30 3 orange 1 pick up 5 2 9 throttle position sensor 1 2 7 orange 0.5 C_AR1/2 C_AT/2 C_AL1/2 black-orange 0.5 2 orange 0.5 C_AM/3 3 2 1 yellow-black 1 C_BB/9 C_AB/9 7 1 B page 2/9 blue 0.5 10 yellow 0.5 1 black 0.5 8 blue-grey 0.5 6 13 pink 0.5 4 1 C page 7/9 blue-white 0.5 7 black-brown 0.5 4 yellow-brown 0.5 11 grey 0.5 19 violet-white 0.5 25 C_AO/26 2 C_AF1/4 16 3 black-blue 0.5 U yellow-white 0.5 brown-white 0.5 26 red-green 0.5 orange 0.5 1 2 2 C_AS1/2 orange 1 brown 0.5 C_AW/2 C_AW1/2 EPC 1 EPC 2 31 1 C_AS/2 1 6 C_AR/3 C_AM2/3 1 bk C_BA/1 ignition coil 2 1 2 C_BF/1 1 2nd front 8 2 1 18 3th N octane selector fuel pump 31 E C yellow-blue 0.5 3 brown 0.5 4 20 2 2 1 C_AT/2 M brown 0.5 30 fuel pump relay battery 1 orange 1 fuse 5A fuse 10 A brown 0.5 start/stop switch ignition switch 30 rear neutral switch (N) / 2nd gear / 3th gear 31 Ignition system, ECU 950 Adventure NOTE: this is a digital battery ignition system with the current supplied by the battery. Battery voltage from the battery 1 flows to the ECU (control unit) 4 through the switched on ignition lock 2 and the switched on emergency OFF switch 3. The pulse generator 5 reports the crankshaft position to the ECU 4. The ECU uses this signal to calculate the ignition point for each cylinder. Battery voltage is supplied to both ignition coils 6 via the emergency OFF switch, the ground is switched by the ECU. The coil on the fuel pump relay 7 obtains battery voltage from the ECU. After the ignition is switched on, the fuel pump relay switches on for a few seconds and switches off again. If you start with the engine running, the fuel pump relay will stay on. The fuel pump 8 obtains battery voltage from the battery through the switched on ignition lock 2 , via the fuse and the contact on the fuel pump relay. The throttle potentiometer (TPS) 9 reports the position of the carburetor throttle valves to the ECU via the yellow cable (on connector AM or AR). The TPS is supplied with 5 volts of supply voltage (blue cable on connector AM or AR) by the ECU. The black cable (on connector AM or AR) supplies the ground. NOTE: See page 8-11 for the adjustment of the TPS. The ECU receives a ground signal via the connected octane selector bk (connector BA and BF) and uses the stored ignition curve for fuel with a minimum octane number of 95 (ROZ 95). If the octane selector is disconnected (connectors BA and BF pulled apart) the engine can be operated with fuel with a minimum quality of ROZ 80. 7-17 30 30 start/stop switch A-page2/8 7 5 sidestand switch 1 E-page2/8 throttle position sensor 9 red 0.5 C_AT/2 C_AR/3 C_AL/2 C _A M /3 2 1 2 1 C _AM 2 /3 C_AR2/3 3 1 3 7 2 fuel pump relay 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 11 11 12 12 13 13 14 14 4 yellow 0.5 4 black 0.5 C 1 blue-gr e y 0.5 8 pink 0.5 U 18 black-brown 0.5 16 yellow-brown 0.5 10 grey 0.5 2 violet-white 0.5 3 brown-white 0.5 20 re d -g ree n 0 .5 7 brown 0.5 2 2 18 1 orange 1 2 1 C_ A W /2 2 C_ A W 1 /2 2 1 C_AS/2 6 C_ AM 1 / 3 C_AR1/3 2nd f r o nt 3th N C_AL2/2 M 8 rear EPC 1 EPC 2 31 Art.-No. 3.206.056-E 1 C_AS1/2 1 C_AT2/2 2 1 17 K-page6/8 1 J-page2/8 ignition coil C_DJ/18 18 blue 0.5 E 16 C_DK/18 17 19 11 15 16 yellow-white 0.5 brown 0.5 15 2 26 black-blue 0.5 3 3 yellow-blue 0.5 C_AF1/4 2 4 yellow-orange 0.5 fuel pump 2 or 0.5 13 25 brown 0.5 1 C_AO/26 alarm system dummy plug 1 3 yellow-orange 0.5 Connector for optional alarm system yellow-black 1 2 pick up brown 0.5 ignition switch C_BB/9 C_AB/9 1 orange-black 0.5 2 neutral switch (N) / 2nd gear / 3rd gear 31 Ignition system, ECU 950 Supermoto NOTE: this is a digital battery ignition system with the current supplied by the battery. Battery voltage from the battery flows to the ECU (control unit) 4 through the switched on ignition switch 1, the switched on emergency OFF switch 2 and the alarm system control unit (if installed, otherwise through the dummy plug 3). The pulse generator 5 reports the crankshaft position to the ECU. The ECU uses this signal to calculate the ignition point for each cylinder. Battery voltage is supplied to both ignition coils 6 via the emergency OFF switch, the ground is switched by the ECU. The coil on the fuel pump relay 7 obtains battery voltage from the ECU. After the ignition is switched on, the fuel pump relay switches on for a few seconds and switches off again. If you start with the engine running, the fuel pump relay will stay on. The fuel pump 8 obtains battery voltage from the battery through the fuse and the contact on the fuel pump relay (continuous positive polarity). The throttle potentiometer (TPS) 9 reports the position of the carburetor throttle valves to the ECU via the yellow cable (on connector AM or AR). The TPS is supplied with 5 volts of supply voltage (blue cable on connector AM or AR) by the ECU. The black cable (on connector AM or AR) supplies the ground. Repair manual KTM LC8 NOTE: See Chapter 8 for the adjustment of the TPS. 7-18 30 30 A-page2/8 start bottom 4 orange-black 0.5 o-page5/8 engi n e s t op r el ay E-page2/8 C_ BR/4 3 2 1 8 1 throttle position sensor sidestand switch C_ AF4/4 3 3 red 0.5 2 4 1 C_AT/2 C_ AL /2 2 yellow-white 0.5 19 bl ue 0.5 6 3 C_AM2/3 3 C_ AR2/3 1 2 3 2 4 C_AF1/4 26 11 y e l l ow 0.5 4 b l ac k 0 .5 2 C 1 blue-grey 0.5 8 pi nk 0.5 18 black-brown 0.5 1 16 yellow-brown 0.5 10 grey 0.5 2 violet-white 0.5 3 brown-white 0.5 20 red-green 0.5 7 brown 0.5 black-blue 0.5 J-page2/8 1 orange 1 2 1 brown 0.5 C _ AW/ 2 2 C _ AW1 / 2 1 C_ AS/2 ignition coil C_ AS1/2 1 2 5 C_AM1/3 C_ AR1/3 2nd front 7 2 1 2 3th N fuel pump C_AO/26 fuel pump relay C_AM/3 1 2 yellow-blue 0.5 E U C_ AR/3 1 yellow-orange 0.5 brown 0.5 13 25 yellow-black 1 C_BK1 /4 2 1 C_AT2/2 C_ AL 2/2 M brown 0.5 ignition switch black pick up rear EPC 1 EPC 2 31 neutral switch (N) / 2nd gear / 3rd gear 31 Ignition system, ECU 950 Super Enduro NOTE: this is a digital battery ignition system with the current supplied by the battery. Battery voltage from the battery flows through the switched on ignition switch 1 to the ECU (control unit) 2. The pulse generator 3 reports the crankshaft position to the ECU. The ECU uses this signal to calculate the ignition point for each cylinder. The ignition switch supplies the coil of the engine stop relay 4 with current, the ground is supplied by the emergency off switch, i.e. the load contact closes when the emergency off switch is actuated. The engine stop relay is connected in parallel to the pulse generator, which it short circuits when the emergency off switch is actuated, immediately causing the engine to stall. Battery voltage is supplied to both ignition coils 5 via the ignition switch, the ground is switched by the ECU. The coil on the fuel pump relay 6 obtains battery voltage from the ECU. After the ignition is switched on, the fuel pump relay switches on for a few seconds and switches off again. If you start with the engine running, the fuel pump relay will stay on. The fuel pump 7 obtains battery voltage from the battery through the fuse (continuous positive polarity) and the contact on the fuel pump relay. The throttle potentiometer (TPS) 8 reports the position of the carburetor throttle valves to the ECU via the yellow cable (on connector AM or AR). The TPS is supplied with 5 volts of supply voltage (blue cable on connector AM or AR) by the ECU. The black cable (on connector AM or AR) supplies the ground. NOTE: see Chapter 8 for the adjustment of the TPS. 7-19 ECU 950 Adventure/Supermoto/Super Enduro Check the cables and socket connectors on the ECU 1 (950 Adventure) and 2 (950 Supermoto/Super Enduro). A functional check of the ECU can only be performed on an ignition test stand. 1 – Check the ignition coil control: remove the ignition coil connector and apply the measuring tips of the peak voltage adapter to the pins of the connector AS (see checking the ignition coils). – Actuate the tip switch and let the starter engine run for a few seconds Multimeter reading: 12 volts ! CAUTION ! TEST THE ECU WITH A CONVENTIONAL MEASURING DEVICE. THIS MAY DESTROY HIGHLY SENSITIVE ELECTRONIC COMPONENTS. NEVER 2 Checking the pulse generator 950 Adventure/950 Supermoto Art.-No. 3.206.056-E – Disconnect the connectors AL and AT and apply the measuring tips of the peak voltage adapter to the connector AT 3 (yellow/blue and yellow/white cable colors). – Actuate the tip switch and run the starter engine for a few seconds. Digital multimeter reading: 4.0 volts +/- 0.5 volts NOTE: make sure the battery is fully charged. 3 – If the measured value deviates from the set point value, measure the resistance of the pulse generator: 190 - 300 Ω at 20°C NOTE: if the resistance figure is correct but the signal voltage deviates, check the distance between the pulse generator and the pulse generator wheel (see Chapter 6). Repair manual KTM LC8 3 7-20 Checking the fuel pump relay 950 Adventure/950 Supermoto – Dismount the fuel pump relay 1 (950 Adventure) and 2 (950 Supermoto). NOTE: black/blue, blue/gray, yellow/black and brown cable colors 1 – Connect the fuel pump relay to a 12 V battery as shown, making sure you hear the relay switch (nonrecurring "click"). NOTE: the 12 V battery must be connected to the two terminals to which the blue/gray and brown cable colors are connected when the plug is connected. – Use an ohmmeter to measure the continuity between the terminals A and B. 2 Reading: max. 1 Ω OK Reading: ∞ Ω defective A B Checking the ignition coils 950 Adventure/Supermoto/Super Enduro 3 – Disconnect and remove the ignition coil 3. – Use an ohmmeter to obtain the following measurements: Resistance of the primary coil (measured between the terminals): 1.0 – 1.6 Ω at 20°C Resistance of the secondary coil (measured between one terminal and the spark plug connector: 9.4 – 17.6 KΩ at 20°C NOTE: – Repeat the measurement for the other ignition coil. – Replace the respective ignition coil if the measurement deviates significantly from the set point value. 7-21 Troubleshooting in the ignition system 950 Adventure/950 Supermoto Before checking the ignition, make sure: – the ignition lock is in the ON position – the emergency OFF switch is in the ON position (does not apply to the 950 Super Enduro) – the battery is charged – the main fuse is OK – the fuse for the electric starter system and ignition is OK Check whether there is an ignition spark upon starting: – Pull of the ignition coil and remove the spark plug. – Hold the spark plug and the ignition coil against the ground (engine case). – A strong spark should be visible when the starter is actuated. If not, try a new ignition coil or new spark plug. If no spark is visible during the first test, perform the following tests: – Is battery voltage being applied to the ECU (orange cable color at connector AO) and to the ignition coils (orange cable colors to both connectors AS)? – Check the ignition control. Are the coils being controlled? – If not, check the ignition lock, emergency OFF switch and the corresponding parts on the cable tree and the fuse for the ignition and electric starter system, for the 950 Super Enduro, also check the emergency off switch and the engine stop relay (relay should not attract). If – – – the ignition is being supplied with voltage but no spark is visible, check: the ground from the ECU the cable from the ECU to the ignition coil the pulse generator Repair manual KTM LC8 Art.-No. 3.206.056-E NOTE: the ECU cannot be tested with simple devices. It can only be tested on an ignition test stand. 7-22 30 30 3 ignition switch 2 pick up throttle position sensor fuse 10 A 1 2 7 orange 0.5 C_AL1/2 2 orange 0.5 C_AM/3 3 2 1 1 blue 0.5 10 yellow 0.5 1 black 0.5 8 blue-grey 0.5 6 13 pink 0.5 4 1 C page 7/9 blue-white 0.5 7 black-brown 0.5 4 yellow-brown 0.5 11 grey 0.5 19 violet-white 0.5 25 C_AO/26 2 C_AF1/4 16 3 black-blue 0.5 U yellow-white 0.5 brown-white 0.5 26 red-green 0.5 2 orange 0.5 1 2 2 C_AS1/2 brown 0.5 C_AW/2 31 1 C_AW1/2 EPC 1 EPC 2 5 C_AS/2 1 C_BA/1 ignition coil 2 1 2 orange 1 C_AR/3 C_AM2/3 1 C_BF/1 1 2nd front rear 1 C_AT/2 2 1 18 3th N 6 octane selector fuel pump 31 E C yellow-blue 0.5 3 B page 2/9 brown 0.5 4 20 2 M brown 0.5 30 fuel pump relay battery 1 C_AR1/2 C_AT/2 black-orange 0.5 fuse 5A yellow-black 1 C_BB/9 C_AB/9 orange 1 7 brown 0.5 start/stop switch orange 1 neutral switch (N) / 2nd gear / 3th gear 31 The EPC system 950 Adventure Mode of operation: Battery voltage from the battery 1 is conducted to the ECU (control unit) 4 through the switched on ignition lock 2 and the switched on emergency OFF switch 3. The EPC valves 5 are supplied with battery voltage via the emergency OFF switch, the ground (red/green cable) is switched by the ECU. The ECU receives a ground from the gear sensor 6 via the grey (2nd gear) or via the violet/brown (3rd gear) cable if one of the two gears is engaged. If the throttle grip is opened all the way (which the ECU recognizes via the TPS 7) at a certain speed (or a certain number of revolutions) in 2nd or 3rd gear, the ECU activates the ground control of the EPC valves. Subsequently, the EPC valves will open an air connection to the carburetor diaphragm covers. A controlled amount of fresh air can be sucked into the space above the diaphragm, reducing the vacuum over the carburetor diaphragm. This causes the carburetor slides to open more slowly resulting in a lower air-gap area to be sucked in through the engine. The engine performance and noise are significantly reduced. NOTE: if the EPC valves are disconnected, this will not influence the other systems. 7-23 30 30 start/stop switch A-page2/8 7 sidestand switch 1 E-page2/8 throttle position sensor 7 red 0.5 C_AT/2 C_AR/3 C_AL/2 C _A M /3 2 1 2 1 C _AM 2 /3 yellow-black 1 2 pick up C_AR2/3 3 1 3 2 fuel pump relay 3 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 11 11 12 12 13 13 14 14 yellow 0.5 4 black 0.5 C 1 blue-gr e y 0.5 8 pink 0.5 U 18 black-brown 0.5 16 yellow-brown 0.5 grey 0.5 2 violet-white 0.5 3 brown-white 0.5 20 re d -g ree n 0 .5 7 brown 0.5 2 1 C_AS1/2 18 1 orange 1 2 1 17 31 1 J-page2/8 10 K-page6/8 Art.-No. 3.206.056-E 4 2 1 C_ A W /2 2 C_ A W 1 /2 5 2 1 C_AS/2 ignition coil C_DJ/18 18 blue 0.5 E 16 C_DK/18 17 19 11 15 16 yellow-white 0.5 brown 0.5 15 4 2 26 black-blue 0.5 2 3 yellow-blue 0.5 C_AF1/4 2 or 0.5 yellow-orange 0.5 2nd f r o nt 6 2 3th 1 C_AT2/2 C_ AM 1 / 3 C_AR1/3 N fuel pump 1 C_AO/26 1 13 25 brown 0.5 3 yellow-orange 0.5 alarm system dummy plug Connector for optional alarm system C_AL2/2 M brown 0.5 ignition switch C_BB/9 C_AB/9 1 orange-black 0.5 2 rear EPC 1 EPC 2 neutral switch (N) / 2nd gear / 3rd gear 31 The EPC system 950 Supermoto/R Mode of operation: Battery voltage from the battery flows to the ECU (control unit) 4 through the switched on ignition switch 1, the switched on emergency OFF switch 2 and the alarm system control unit (if installed, otherwise through the dummy plug 3). The EPC valves 5 are supplied with battery current via the emergency OFF switch, the ground (red/green cable) is switched by the ECU. The ECU receives a ground from the gear sensor 6 via the grey (2nd gear) or via the violet/brown (3rd gear) cable if one of the two gears is engaged. If the throttle grip is opened all the way (which the ECU recognizes via the TPS 7) at a certain speed (or a certain number of revolutions) in 2nd or 3rd gear, the ECU activates the ground control of the EPC valves. Subsequently, the EPC valves will open an air connection to the carburetor diaphragm covers. A controlled amount of fresh air can be sucked into the space above the diaphragm, reducing the vacuum over the carburetor diaphragm. This causes the carburetor slides to open more slowly resulting in a lower air-gap area to be sucked in through the engine. The engine performance and noise are significantly reduced. Repair manual KTM LC8 NOTE: if the EPC valves are disconnected, this will not influence the other systems. 7-24 30 30 A-page2/8 start bottom o-page5/8 orange-black 0.5 engi n e s t op r el ay E-page2/8 C_BK1 /4 C_ BR/4 3 2 1 5 1 throttle position sensor sidestand switch C_ AF4/4 3 2 4 1 yellow-black 1 red 0.5 C_AT/2 C_ AL /2 2 13 25 yellow-blue 0.5 26 yellow-white 0.5 19 bl ue 0.5 11 E y e l l ow 0.5 4 b l ac k 0 .5 2 C 1 blue-grey 0.5 8 pi nk 0.5 18 black-brown 0.5 3 C_AM2/3 3 C_ AR2/3 2 3 2 4 C_AF1/4 1 1 yellow-brown 0.5 grey 0.5 2 violet-white 0.5 3 brown-white 0.5 20 red-green 0.5 7 brown 0.5 2 1 C_ AS1/2 orange 1 2 1 brown 0.5 C _ AW/ 2 2 C _ AW1 / 2 3 1 C_ AS/2 C_AM1/3 C_ AR1/3 4 ignition coil 1 2 2nd front 1 C_AT2/2 2 1 2 3th N fuel pump 16 black-blue 0.5 J-page2/8 10 31 fuel pump relay C_AM/3 1 2 brown 0.5 C_AO/26 U C_ AR/3 1 yellow-orange 0.5 C_ AL 2/2 M brown 0.5 ignition switch black pick up rear EPC 1 EPC 2 neutral switch (N) / 2nd gear / 3rd gear 31 EPC system 950 Super Enduro Mode of operation: Battery voltage from the battery is conducted through the switched on ignition switch 1 to the ECU (control unit) 2. The EPC valves 3 are supplied with battery voltage via the ignition switch, the ground (red/green cable) is switched by the ECU. The ECU receives a ground from the gear sensor 4 via the gray (2nd gear) or via the violet/brown (3rd gear) cable if one of the two gears is engaged. If the throttle grip is opened all the way (which the ECU recognizes via the TPS 5) at a certain speed (or a certain number of revolutions) in 2nd or 3rd gear, the ECU activates the ground control of the EPC valves. Subsequently, the EPC valves will open an air connection to the carburetor diaphragm covers. A controlled amount of fresh air can be sucked into the space above the diaphragm, reducing the vacuum over the carburetor diaphragm. This causes the carburetor slides to open more slowly resulting in a lower air-gap area to be sucked in through the engine. The engine performance and noise are significantly reduced. NOTE: if the EPC valves are disconnected, this will not influence the other systems. 7-25 Checking the solenoid valve for the EPC 950 Adventure, 950 Supermoto/R, 950 Super Enduro – To check, disconnect connector AW 1 from the solenoid valve. – Connect a 12-V battery with the two terminals on the solenoid valve. 1 – You should hear a click in the solenoid valve (the diaphragm opening) when the circuit is closed. – If you don't hear a click, the solenoid valve needs to be replaced. – Repeat the procedure for the second valve 2. ! CAUTION ! THE RETAINING CLIP FOR THE FRONT EPC VALVE IS BENT, THE EPC VALVE WILL BE ABLE TO TOUCH THE FRAME. THE ENGINE VIBRATIONS CAN CAUSE IT TO OPEN SLIGHTLY, RESULTING IN A LACK OF POWER FOR THE ENTIRE SPEED RANGE. IF 2 Art.-No. 3.206.056-E Checking the gear sensor 950 Adventure, 950 Supermoto/R, 950 Super Enduro 3 – Use a digital multimeter to measure the voltage between the blue/green cable (neutral) and the ground on connector AM/AR 3 (950 Adventure) and 4 (950 Supermoto/Super Enduro) with the cables connected. Multimeter reading: 0 - 2.5 volts with the transmission in neutral Multimeter reading: over 2.6 volts with a gear engaged – Measure the voltage between the gray cable (2nd gear) and the ground. Multimeter reading: 0 - 2.5 volts with the transmission in 2nd gear Multimeter reading: over 2.6 volts with the transmission not in 2nd gear – Measure the voltage between the yellow/brown cable (3rd gear) and the ground. Repair manual KTM LC8 4 Multimeter reading: 0 - 2.5 volts with the transmission in 3rd gear Multimeter reading: over 2.6 volts with the transmission not in 3rd gear 3 1 2 2 C_BF1/1 start auxillary relay re-wh 3 re 1 4 or 2 C_AF/4 ye re-wh or ye-re diode diode rear brake switch re br ye-bl C_BH/6 C_AP/6 4 5 6 C_AK2/2 ye-re 3 C_AI/2 2 1 gn-bl C_AI1/2 2 pi C_AH1/2 2 1 ye 1 gn-wh re-wh 1 ye-bu re-wh 2 re re-wh 3 or or or ye-re A A bl-bu f u se box ye 2 Q re-wh ye-re A bl-wh ye-bl 10 15 10 A y e - bu 2 10 10 10 10 10 A ye A b l - or AL/2 A AT2/2 A 1 C_AT1/2 br-re C_AL2/2 ACC1 always ON br ignition switch fuel level sensor C_BA1/1 2 3 ye-bl ch switch C_AF1/4 b u - gr rn 2 re-wh 4 br 4 ACC2 switched 1 re-wh C_AE/4 f ue l p um p r e l a y re-wh 3 ye 6 wh ye-br 9 bl-or 2 7 re-wh C_AU1/2 C_BI1/2 M C_AT/2 30 A M 1 or 1 f u e l pum p 1 4 battery br 2 C_AH4/2 C_AB/9 8 start relay starter motor carb body carb heater 2 1 bl-bu wh re-ye ye-wh 0 bl bl-wh bl-bu 1 C_BB/9 re G or r ela y or 2 carb heater 1 light switch start/stop switch temperature switch 7-26 g n - gr Adventure carburetor heater 950 Adventure, 950 Supermoto/R, 950 Super Enduro 1 Mode of operation: to prevent the carburetor from icing at low outdoor temperatures and high humidities, both carburetors are heated by one heating element 1 each. The air temperature must be below 3-9ºC and the ignition on for the heaters to operate. Current flows via the ignition switch 2 and a 10-ampere fuse 3 to the temperature switch 4 under the headlight mask. From there it continues to both heating elements 1 at a temperature of less than 39ºC. Checking the heating elements Use a digital multimeter to measure the resistance of the heating elements. Set-point value: 5 - 10 Ω at 20ºC NOTE: if the resistance is higher, replace the heating element. Checking the temperature switch Disconnect the connector 4 and use a digital multimeter to measure the resistance of the temperature switch (between the 2 yellow cables). 4 Set-point value: less than 1 Ω at temperatures of less than 3ºC Set-point value: 8 Ω at temperatures of more than 16ºC NOTE: – If the resistance is ∞ Ω under 3ºC, replace the temperature switch. – The temperature switch will switch on between 3ºC and 9ºC and off between 10ºC and 16ºC. – if no error was found and the carburetor heater still won't work, check the ground supply to the carburetor by using a digital multimeter to check the resistance between the carburetor and the negative pole on the battery. The measured resistance should be less than 1 Ω. 7-27 INJECTION/IGNITION SYSTEM Establishing the injection period (injection volume) Generally, the injection volume, i.e. the quantity of injected fuel, is dependent on the fuel pressure and the time the injection valve is open. Since the fuel pressure regulator keeps the fuel pressure constant, the quantity of fuel injected is controlled by the time the injection valve is open. The basic injection rate is determined by the engine speed and manifold air pressure or throttle valve position; the opening period is directly dependent on the engine load (manifold air pressure/throttle valve signal); fuel is injected every 720° crank angle (every other rotation). Additional sensors establish the operating conditions and driving conditions (e.g.: coolant and air temperature, ambient air pressure, battery voltage, etc.); the basic injection rate is corrected based on the signals received from these sensors. Control unit (ECU) Manifold air pressure sensors/ throttle valve sensor Basic injection rate Pulse generator Correction Corrective sensors/inputs Art.-No. 3.206.056-E Actual injection rate Injection valves CORRECTION SENSORS AND INPUTS SENSOR/INPUTS INFORMATION Coolant temperature sensor The injection time must be prolonged and the idle speed increased for a cold start and during the warming-up phase (required for starting enrichment and a steady warming-up). Throttle valve sensor The quantity injected is dependent on the TPS position in the upper Repair manual KTM LC8 load/speed range, it also influences the ignition. Air temperature sensor The injection time is prolonged at a lower intake air temperature and reduced at a high temperature. Ambient air pressure sensor The injection time is reduced at a low ambient air pressure (e.g.: uphill driving) and prolonged at a high ambient air pressure (the oxygen level of the intake air drops as the altitude increases). Lambda probes The oxygen level in the emission (rich-mixture combustion results in less residual oxygen, lean combustion in more residual oxygen). Battery voltage The injection time is prolonged at a low battery voltage. 7-28 SYSTEM DIAGRAM CLUTCH: Clutch switch CRK: Pulse generator ECU: Control unit EXAI: Secondary air valve FLPR: Fuel pump relay FUEL PUMP: Fuel pump GP2: 2nd gear switch GP3: 3rd gear switch HEGO: Lambda probes IGN: Ignition coils IGP: Battery INJ: Injection valves ISC: Idle control motor K-LINE: Diagnostics connector MIL: Error lamp MR: Main relay NLSW: Neutral switch PA: Ambient air pressure sensor PM: Manifold air pressure sensors PRESSURE REGULATOR: Pressure regulator PVC: Carbon canister purge valve (USA) ROLL: Roll angle sensor SSTAND: Side stand switch TA: Air temperature sensor TAC: Control motor for 2nd throttle valve TACHO: Tachometer TAP2: Sensor for 2nd throttle valve TH: Throttle valve sensor TW: Coolant temperature sensor FUEL PUMP PRESSURE REGULATOR FLPR IGP MR MIL TACHO ECU PVC K-LINE TA PA ISC EXAI TAP2 TH INJ2 INJ1 TAC PM2 PM1 IG N1 N2 IG TW HEGO2 CRK HEGO1 ROLL SSTAND NLSW GP2 GP3 CLUTCH 7-29 BASIC DESCRIPTION OF THE SYSTEM Fuel system: Fuel is drawn in by the fuel pump via the fuel screen and pumped through the fuel filter to the pressure regulator. All of these components are located in the tank. Since the fuel pump's flow rate and flow pressure are considerably higher than required by the injection system, a constant pressure of 343 kPa (3.5 bar) is selected by means of the pressure regulator. The excess fuel returns to the fuel tank unpressurized. The pressurized fuel flows from the pressure regulator to the injection valves and is injected into the induction manifold when the injection valves are opened (induction manifold or indirect injection). The system does not require an external return line since the pressure regulator is installed in the tank. Injection: The injection nozzles are controlled by the control unit based on the pressure conditions in the induction manifold (manifold air pressure sensors) and the rotational speed (pulse generator), taking the corrective injection periods into account (see above) this applies to the lower load/speed range. The opening of the injection nozzles is calculated according to the speed and throttle valve signals at higher loads or speeds. The injection is sequential, i.e. each injection nozzle is individually controlled and the fuel injected into the intake port of the respective cylinder. Ignition: The ignition is also controlled by the ECU using a conventional transistor ignition system. Both the ignition timing and the closing angle are calculated according to a stored map. The ignition timing is established based on the following information: rotational speed, position of the throttle valve, the coolant temperature and the operating condition (idle/not in idle). The ignition timing is also reduced if the two octane selector connectors are not connected (when using low-octane fuel). Idle control: Art.-No. 3.206.056-E The control unit controls the idle speed depending on the cooling liquid temperature by opening the throttle valve wider or less wide with the idle speed control motor. Trailing throttle fuel cutoff: If the driver closes the throttle valve with the engine running at operating temperature at a speed of at least 5000 rpm (overrun condition, i.e. the motorcycle is driving the engine), the control unit will interrupt the control of the injection valves until the minimum speed drops below 5000 rpm. Purpose: to save fuel and improve exhaust emissions. Speed limitation: To avoid damage to the engine, the control of the injection nozzles is cut off at speeds exceeding 9600 rpm and the ignition coils cut off at speeds exceeding 10100 rpm. Secondary air control: Fresh air is introduced into the exhaust through a valve during the warm-up stage to improve the emission quality and to reduce the catalytic converter light-off time. Afterburning takes place. Lambda control: Repair manual KTM LC8 A lambda probe (one probe per cylinder) is used to find the ideal fuel/air ratio for the best possible combustion (at a mixture ratio of 1 kg fuel and 14.7 kg air). The catalytic converter installed in the exhaust can operate at maximum efficiency (at a maximum conversion rate). The goal is to obtain the maximum lambda 1 air ratio, i.e. to make the air volume actually drawn in by the engine equivalent to the air volume theoretically required (to burn the quantity of injected fuel). If the quantity of drawn-in air is smaller (i.e. air deficiency), the mixture is rich (lambda less than 1). If the quantity of drawn-in air is greater (i.e. excess air), the mixture is lean (lambda greater than 1). Electronic power control (EPC): Under certain operating conditions, the second throttle is controlled in accordance with the throttle valve position and speed. Error detection/elimination: An "FI" error lamp is installed in the multifunctional digital speedometer that lights up for 2 seconds after "Ignition on" (function indicator) and goes out if the control unit fails to detect any errors. The error lamp will stay on during operation if an error is detected; if the vehicle is standing (gear in neutral) the error lamp will start to blink according to the respective error code. The registered error codes can be read out through the diagnostics connector using the KTM diagnostics tool and deleted after the error has been eliminated. 31 4 5 s en so r rollover C_AP2/6 bl ye-re bu 6 re-gn or wh-bl br 3 L L rear t° p C_BZ1/3 3 2 2 1 1 2 3 p C_BZ/3 1 1 2 C_CM/2 t° 1 pu 3 p C_BZ2/3 2 bl 2 or br or-wh g n -re 1 3 C_AR3/3 C_AM3/3 2 P i c k up C_AT/2 C_AL/2 1 3 4 2 1 15 fuse 10 A 7 sidestand switch main relay ye-wh manifold pressure sensor rear atmospheric pressure sensor 990 Super Duke 05 lambda sensor´s f r ont t° C_CE/4 2 C_CE1/4 4 1 wh-or C_CA/4 3 bl C_CA1/4 4 1 2 bl C_AX/2 ye-bl gn-gr bu ye re-br or t° bl bl 2 water temperature sensor manifold pressure sensor front 1 bu re bl bl C_AL1/2 bu-bl air temperature sensor bu C_AF/4 bl C_AT1/2 ye-bu re-wh 2 C_AI/2 1 7 13 14 3 24 23 11 12 4 C_AO/26 2 10 9 22 6 20 25 26 19 15 18 17 1 diode 1 2 3 C_AM2/3 ye-re br or C_AR2/3 4 1 6 I page 6/9 C_BB/9 1 8 ECU 2 33 15 13 23 11 3 bl bl or C_CO/34 7 21 12 4 22 5 7 2 ye-or diagnostic c o nn e c to r C_AB/9 6 29 26 H 6/8 G 6 /8 C 6/8 gr ye-br gn-bl C_BH1/6 9 14 16 34 or ignition switch pi N 3th 2nd C_AP1/6 start/stop switch ignition coil bu 3rd gear or-bl or f r ont rear 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 fuse 10 A 14 10 8 4 5 11 bl-wh 9 o r 13 b l - gr pi bu-wh 3 gn-wh 7 b l - b r 15 wh-re 12 wh gn b l - o r 16 bu ye 2 exhaust air valve C_CK/2 1 2 or ye-wh 6 bl 9 1 re-wh C_CP/16 C_CQ/16 bl wh 610.41.012.000 3 f r ont 1 rear C_CL/2 2 1 C_CL1/2 2 bu-bl or pu ye bu re gr gr wh gn pu bu 2 C_AM/3 5 4 TPS 2 2 1 C_CA2/4 C_CE2/4 fuel pumprelay 3 2 C_AM4/3 C_AR4/3 2 M fuel pump 4 1 3 C_AE/4 1 B 6/8 Q f u e l pum p unit 3/8 ISC stepper motor s e c on d throttle stepper motor 3 4 C_AR1/3 1 3 3 2 C_AM1/3 C_AF1/4 1 13 fuse 10 A 2nd TPS C_AR/3 1 g n - re airbox harness 1 C_AS/2 2 1 C_AS1/2 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 or Connector for optional alarm system wh-br C_DK/18 or ignition switch alarm system dummy plug re-bl or-wh br gr bu-bl wh clutch switch E gn pu re-wh or-wh bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re ye ye-wh ye-bl re br ye-or ye pi gn-bl ye-br gr ye-re C C_DJ/18 wh-pu bu or bu-gr br br bu-wh wh bu-br or bu injector´s or bl bu-bl ye-bl wh ye 2nd gear neutral switch wh-or wh-bl re-bl bl-or gn wh wh-re bl-br gn-wh bu-wh pi bl-gr bl-wh wh-pu wh-br U gn-re or bu-gr pu bu-bl bu bl re gr br-re 30 31 30 7-30 WIRING DIAGRAM 990 SUPER DUKE fuel level sensor 1 225 2 -B2 6 4 C_AP/6 5 3 4 164,165 -X7 splice 133,139,50,141 /1.E8 -B15 hego sensor front t° 1 t° -B16 1 p C_DP/3 2 164 -B4 atmospheric pressure sensor 3 /3.B2 137 1 p C_DP/3 2 C_AR/2 -X101 205,209,210 205,206 1 p C_DP/3 2 -B18 GND-P1 168,204 manifold pressure sensor rear -B17 3 2 49 3 /1.D2 /3.B2 2 pick up C_AT/2 C_AL/2 1 1 /3.B6 2 3 4 5 6 C_AO/26 ECU -L3 /3.D4 GND-S5 -A2 -A2-P1 GND-H4 214,215,33 49,176,177,178 156,157,158 -X13 splice -X17 splice 206,223 -X2 splice GND-X2 4 1 C_AM/2 53,55,56,207,208,211,212,213 manifold pressure sensor front 3 /1.C7 -X8 splice 2 990 Superduke R 2008 hego sensor rear L 2 C_CE/4 3 C_CA/4 4 C_CE/4 1 C_CA/4 2 GND-X8 142,146,147,150,152,155,159,162,225 -X6 splice 132,133,134,135,136,137 -X15 splice 120,121,122,124,125,123 117,120,119,118 L rollover sensor -B7 50 -X16 splice air temp. sensor t° C_CM/2 145 159 -X11 splice 138 fue-P1 140 160 -X10 splice 165 156 134 161 115,116 149 -A1-X10 154 /1.D7 152 155 150 117 147 212 153 175 148 201 121 3 151 /3.B2 1 136 174 C_AR/3 132 tem-P1 139 211 122 2 167 1 168 C_AT/2 175 173 171 154 172 149 170 2 1 7 6 5 4 3 2 3 4 5 6 C_CO/34 1 8 214 /3.B2 /3.A8 178 Neu-P1 GND-X3 195 135 187 167 188 170 183 146 181 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 -A2-P1 313,314,315 319 312 310 308 305 304 300 306 303 320 316 311 309 307 1 C_CL/2 2 TAC-P1 1 ignition coil front C_EP/3 C_EO/3 3 /3.B2 2 1 C_CL/2 /3.B2 2 -Y4 3 2 1 M 1 -L5 MIL-P1 /3.B2 1 C_DU/2 1 2 M -M6 C_CE/4 C_CA/4 2nd throttle stepper motor 3 4 3 2 1 C_CK/2 611.11.175.000 610.41.012.000 main harness - 3 P. Page:2 -Y1 -Y2 purge valve exhaust air valve 2 2 -M5 C_AE/4 1 C_AM/3 C_AR/3 2nd throttle position sensor ISC stepper motor 3 -B14 4 ignition coil rear C_EP/3 C_EO/3 3 injection rear 2 -L6 -Y3 300,301,302 1 C_AR/3 C_AM/3 main throttle position sensor 316,317,318 -B13 injection front 2 313 -X310 splice -X309 splice /3.F2 -X308 splice 193 125 194 186 189 185 184 CLU-A2 179,180,181 -X18 splice 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 215 E C U 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 169 C_AL/2 174 200 126 157 STR-A3 145 3 141 176 2 179 1 158 C_EC/3 186 C_DO/8 187 C_DN/8 184 222 185 N 189 3th 191 2nd 188 C_AM/3 192 R 196 -A3 Starter Interlock Unit 190 180 /1.E7 140 -S11 148 169 151 -B11 138 -B3 163 6 194 4 193 1 195 C_AP/6 199 -X50 197 t° 198 -B9 t° 153 gear position switch 142 C_CP/16 -X307 C_CQ/16 sidestand sensor 160 9 87 65 4 3 2 1 16 15 14 13 12 11 10 173 162 309 fuel level sensor 163 317 315 C_BH/6 171 301 diagnostic connector 172 306 199 fuel-A2 182 320 177 /1.E4 183 314 196 304 water temp. sensor 123 305 197 308 Art.-No. 3.206.056-E 118 303 302 311 318 312 198 307 119 310 124 319 190 Repair manual KTM LC8 7-31 SCHALTPLAN 990 SUPER DUKE R 114 air temp. sensor t° C_CM/2 1 2 113 -B3 1 3 4 6 -X54 C_CZ/3 C_CY/3 2 -B5 t° 2 1 t° -B6 -X4 splice 2 1 p C_DP/3 -B7 1 3 2 1 p C_DP/3 -X101 -B8 manifold pressure sensor front 3 1 2 2 1 p C_DP/3 125 GND-P1 2 /3.B2 198,5,13 GND-X14 -X53 -B9 75 manifold pressure sensor rear 3 2.1 C_BJ/1 C_AY/1 1 89,179,186,126 pick up C_AT/2 C_AL/2 1 -X8 splice 184 74 2 3 4 5 6 152 C_AO/26 1 118 ECU -L3 -A4 /3.D6 -X6 splice 86,189,190 73,76,198,197,159 3 -X7 splice 19 125 122 96 87 7 6 5 4 3 2 1 1 2 3 4 5 6 C_CO/34 Neu-P1 192 17,157 /3.B2 97 110 104 106 108 102 100 98 -X301 splice 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 215 211 207 219 206 218 205 199 204 212 209 202 210 203 208 1 C_CL/2 176 ignition coil front 1 -L1 TAC-P1 MIL-P1 2 1 C_CL/2 injection rear 2 ignition coil rear -L2 1 /3.B2 /3.B2 C_AS/2 2 -Y3 215,216,217 1 C_AR/3 C_AM/3 1 M -M4 1 or 1 2 2 C_CK/2 1 main harness 626.11.076.000 210 1 M -M5 C_CE/4 C_CA/4 2 211 3 P. Page:2 2nd throttle stepper motor 3 4 3 -Y1 -Y2 purge valve exhaust air valve 2 2 C_AE/4 3 1 C_AM/3 C_AR/3 2nd throttle position sensor ISC stepper motor 4 -B13 C_DU/2 -Y4 3 main throttle position sensor 212,213,214 -B12 injection front 2 180 C_AS/2 2 199,200,201 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 /3.F1 -X302 splice -X303 splice 111 109 107 105 103 101 99 142 CLU-A2 -X11 splice -X10 splice 191 -X9 splice 179 158,16 8 E C U 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 124 C_AR/2 185 C_AM/2 126 1,3,14,53,68,70,93,104,127,185,155 -X5 splice 2 39 C_AR/3 83 186 C_AM/3 119 atmospheric pressure sensor 3 140 990 Supermoto 2008 hego sensor rear L 3 C_CE/4 4 C_CE/4 1 C_CA/4 2 C_CA/4 hego sensor front L rollover sensor -B4 C_AP/6 5 4 2.3 2.2 2.1 3 -X3 splice /3.B2 -X305 splice 18,228 129 228 GND-X14 76,5,13,20,38,197,159 53,155 16 -X304 splice 15,227 17 158 CAN-L /1.B5 128 115 -A1-X5 94 157 127 18 130 CAN-H 114 C_DN/8 187 /1.B4 121 90 15 tem-P1 80,91,95,97,113,116,120,129,138,150,184 /1.E8 80 152 20 93 /1.B7 81 151 194 120 91 14 150 193 83,90,109,117,119,139,151,183 139 73 74,75 117 3 116 2 138 124 38 39 118 1 123 C_DO/8 188 C_EC/3 92 N 107 3th 101 84 140 227 96 195 84,121,188 130 85 STR-A3 41 81 86 /1.E8 92 2nd 189 2 102 C_AT/2 190 -A3 Starter Interlock Unit 176 1 183 -S4 103 -B2 180 -X51 105 6 67 5 94 19 95 4 191 3 192 2 106 1 110 C_AP/6 82 85,142,187 111 -X50 88 t° 69 -B1 t° 123 218 gear position switch 122 203 sidestand sensor 2 -X300 C_CQ/16 87 fuel-A2 44 9 87 65 4 3 2 1 16 15 14 13 12 11 10 128 C_CP/16 70 88 98 202 89 100 108 /1.E5 99 200 82 219 CAN-BUS connector 68 205 213 201 69 204 3 216 2 206 214 207 1 208 217 209 diagnostic connector 67 water temp. sensor 7-32 WIRING DIAGRAM 990 SUPERMOTO 4 ye-re 5 bu 31 sensor rollover C_AP2 /6 bl 6 re-gn or wh-bl ye L L rear lambda sensor´s f ront t° t° C_CE/4 3 C_CE1 /4 2 2 3 1 3 2 p C_DP1 /3 1 octane selector br 1 2 C_CM/2 t° 3 p C_DP/3 1 2 bl atmospheric pressure sensor 990 Adventure p C_DP2 /3 ye-bl gn-gr bu 2 bl bl 1 C_AX/2 t° water temperature sensor manifold pressure sensor front br 4 1 wh-or C_CA/4 3 bl C_CA1 /4 4 1 2 bl re I-page 2/9 bu air temperature sensor bu 2 bu-bl br br-pu re-br or bl bl br-bl 2 ye-bu 21 1 3 C_AR3 /3 C_AM3/3 2 Pick up C_AT/2 C_ AL /2 1 or br or-wh gn-re sidestand sensor 3 4 2 1 bl 1 ye-wh C_AF/4 bu pi C_ AL 1/ 2 C_BF/1 manifold pressure sensor rear C_BA/1 pu power relay C_AI/2 2 1 7 13 14 3 2 4 2 3 11 12 4 2 10 9 2 2 C_AO/ 26 6 2 0 2 5 2 6 19 15 18 17 1 or EFI 2 8 1 2 3 9 14 16 3 4 P 6/8 O 6/8 K 6/8 gr ye-br gn-bl bu-gr br br bu-wh wh bu-br C_AR2/3 C_AM2/3 lbu br or 6 4 1 N 3th 2nd C_AP1/6 C_AT1/2 Q-page7/ 9 3 3 15 13 2 3 11 3 C_BH1/6 7 21 12 4 2 2 3rd gear neutral switch diagnostic connector 5 6 29 26 C_CO/ 34 1 f ront C_ AS1/ 2 2 J-page2/9 1 2 1 or-bl C_CW/2 14 8 5 ye-or 9 or 13 bl-gr ye-gn 11 bu-pi 3 gn-wh 7 br-gr 15 wh-re 12 bu-or 4 gn or-gn 16 bu 2 exhaust air valve C_ CK/2 1 6 2 pu-re 10 re-bl bl C_CQ/16 610.41.012.000 airbox harness rear C_AS/2 2 lbu gr R-page3/9 wh-pu diode or E-page2/9 1 bl wh 3 f ront 1 rear C_ CL /2 2 1 C_ CL 1/ 2 2 bu-bl or pu ye bu re gr gr wh gn pu bu gn-re 2 C_AM/3 C_AR/3 2nd TPS 4 2 C_AR1 /3 1 4 2 1 C_CA2 /4 C_CE2 /4 fuel pumprelay 2 Q 4 1 3 C_ AE/4 3/9 ISC stepper m ot or second throt tl e st epper m ot or 3 3 3 2 TPS C_AM1/3 C_AF1 /4 1 3 2 C_AM4/3 C_AR4 /3 M f uel pump fuel pump unit wh clutch switch E or br bu-bl gr 30 or-wh bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re pu-re re-bl ye-bl re br-pu or ye pi gn-bl ye-br gr lbu C wh-br bu C_CX/2 or wh ye bu or bl or-wh bu A-page2/9 bu-gr ye-bl pu bu-bl bl re gr 2nd gear wh-or wh-bl or-bl or-gn gn bu-or wh-re br-gr gn-wh bu-pi ye-gn bl-gr ye-or wh-pu wh-br U gn-re or bu-bl injector´s gn pu Art.-No. 3.206.056-E 30 31 fuel level sensor Repair manual KTM LC8 7-33 WIRING DIAGRAM 990 ADVENTURE -2007 C_CP/16 ignition coil 5 6 4 bl 31 sensor rollover C_AP2/6 ye-re bu 1 br br 2 C_AL1/2 C_AT1/2 ye wh-bl bl 3 L L rear lambda sensor´s front t° t° C_CE/4 2 C_CE1/4 4 1 wh-or C_CA/4 3 bl C_CA1/4 4 1 2 re-gn or 2 1 ye-bl gn-gr 3 bu 1 atmospheric pressure sensor 2 3 p C_DP1/3 1 octane selector br 1 2 C_CM/2 t° 2 3 p C_DP/3 1 br-bl 2 C_DF/2 PVC 1 990 Adventure (S) 2007-2008 p C_DP2/3 2 bl bl C_AX/2 water temperature sensor manifold pressure sensor front t° bu 2 or br 1 3 C_AR3/3 C_AM3/3 2 Pick up C_AT/2 C_AL/2 1 gn-re or-wh sidestand sensor 3 4 2 1 bl clutch switch bu-bl br br-pu re-br or re bl C_AF/4 pi ye-bu bu I-page 7/9 C_BF/1 bu air temperature sensor C_BA/1 or bl re-bl ye-wh bl power relay R-page3/9 21 1 7 13 14 3 24 23 11 12 4 2 10 9 22 E C_AO/26 6 20 25 26 19 15 18 17 8 1 or-bl 2 EFI 1 C_AR2/3 lbu br or C_AM2/3 P 6/8 O 6/8 K 6/8 gr ye-br 2 gn-bl 3 4 1 6 ASP-page7/9 SAR-page2/9 N 3th C_AI/2 or-wh br-bl bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re pu-re re-bl ye-bl re br-pu or ye pi gn-bl ye-br gr lbu pi-bu C pu manifold pressure sensor rear Q-page7/9 2 8 9 14 16 34 33 15 13 23 11 3 C_BH1/6 diagnostic connector 6 29 26 C_CO/34 7 21 12 4 22 5 or-gn 1 5 2 7 6 8 4 front C_AS1/2 1 3 C_DN/8 C_DO/8 Starter Interlock Unit 2 ignition coil 2nd C_AP1/6 ye or gn-bl 1 6 2 8 5 gr lbu C_AR/3 1 exhaust air valve 610.41.012.000 front C_CL1/2 2 bu-bl or pu ye bu re gr gr wh gn pu bu gn-re 2 C_CX/2 3 2nd TPS C_AM/3 1 bl wh 2 1 2 ye-or 9 or 13 bl-gr ye-gn 11 bu-pi 3 gn-wh 7 br-gr 15 wh-re 12 bu-or 4 gn or-gn 16 14 pu-re 10 bu C_CK/2 1 bl re-bl J-page2/9 airbox harness rear C_AS/2 2 or pi br-bu wh-pu pi-bu br or-bl diode C_CQ/16 bu wh-br bu E-page2/9 C_CP/16 or 2 4 1 rear C_CL/2 TPS 4 2 1 fuel pumprelay 3 2 C_AM4/3 C_AR4/3 M fuel pump 2 4 1 3 C_AE/4 Q fuel pump unit 3/9 ISC stepper motor second throttle stepper motor C_CE2/4 C_CA2/4 3 2 C_AR1/3 1 3 3 2 C_AM1/3 C_AF1/4 1 bu C_CW/2 or ye-bl wh ye bl or or-wh A-page2/9 bu-gr pu bu-bl bu bl re gr neutral switch 2nd gear 3rd gear bu-gr br br bu-wh wh bu-br re-bl bu-br wh-or wh-bl or-bl or-gn gn bu-or wh-re br-gr gn-wh bu-pi ye-gn bl-gr ye-or wh-pu wh-br U gn-re bu-bl injector´s wh br gr bu-bl gn pu 30 31 fuel level sensor 30 7-34 WIRING DIAGRAM 990 ADVENTURE 2007- 7-35 BLOCK DIAGRAM A Kill Switch Ignition Switch B Battery Power Relay Regulator / RECTA A.C Generator. Start button Starter Relay1 C A Starter Relay2 IGP Sidestand Switch MAP Sensor #2(FRONT) HEGO Sensor #1(REAR) HEGO Sensor #2(FRONT) Art.-No. 3.206.056-E Atmospheric press. sensor MAP Sensor #1(REAR) SSTAND(A/D) INJ#1 Fuel Injector #1(REAR) INJ#2 Fuel Injector #2(FRONT) IG#1 Ignition #1(REAR) IG#2 Ignition #2(FRONT) PM#2 HG#1 HGHT#1 HG#2 HGHT#2 PA PM#1 Throttle Position Sensor TH Inlet Air Temp. Sensor TA PVC Starter Motor Purge Valve EXAI Exhaust Air Injection B Fuel Pump Relay Water Temp. Sensor TW FLPR Fuel Pump Rollover sensor ROLL 2nd Throttle Position Sensor VCC TAP SG 2nd Throttle Actuator Control (stepper) ISC AP ISC AN ISC BP ISC BN TAC AP TAC AN TAC BP TAC BN Meter Assembly TACHO Crank Sensor Repair manual KTM LC8 Gear Position Switch3 Gear Position Switch2 Neutral Switch Idle Speed Control (stepper) CRKP CRKM Tachometer MIL Meter-Line (K-LINE2) GP#3 MIL Meter Communication GP#2 NLSW C Clutch Switch CLUTCH K-LINE LG LG PG#1 PG#2 Diagnostic Tool NEUTRAL indicator M 7-36 DESCRIPTION OF THE ELECTRIC SYSTEM Fuel pump relay: A positive charge travels to the start/stop switch via the ignition switch and a fuse (10 amperes), then via the diode to the relay coil (positive side). The ground for the relay coil is switched for several seconds by the control unit with the ignition on during the starting process. The control is maintained as long as the engine is running. If the engine fails to start, Stalls or is switched off, the control unit will immediately break the ground connection, also in case of a crash (roll sensor). The positive charge for the load contact on the fuel pump relay travels via the ignition switch and the fuse (10 amperes), the other side of the load contact leads to the fuel pump and from the fuel pump to the ground. Main relay: The positive charge travels to the start/stop switch via the ignition switch and a fuse (10 amperes), then via the diode to the relay coil (positive side). The 2nd side of the relay coil is directly connected to the ground. The positive charge for the load contact on the fuel pump relay travels via the ignition switch and the fuse (10 amperes); the other side of the load contact supplies the following components with on-board voltage (orange cable/or): control unit, heater for both lambda probes, both ignition coils, the secondary air valve and both injection nozzles. Sensors: All of the sensors (except the pulse generator) and both lambda probes are connected to the control unit ground by a black cable (bl). All of the sensors that have a 3-pole connector are supplied with control unit positive (5 volts) via a blue cable (bu). Sensor information is transmitted to the control unit via the 2nd cable (temperature sensors) or via the 3rd cable (3-pole sensors). The lambda probe signal is transmitted via the red/green cable (re/gn; front cylinder) and red/brown (re/br; rear cylinder), the control unit actuates the lambda probe heater through the ground circuit via the white/black (wh/bl; front cylinder) and white/orange (wh/or; rear cylinder); the positive charge for the lambda probe heater comes from the main relay. The pulse generator is an inductive sensor and directly connected to the control unit by 2 poles. Actuators: The ignition coils, injection nozzles and the valves for the secondary air system are ground-controlled, i.e. the respective component is actuated as soon as the control unit transmits the ground. The two stepping motors for the idle and the 2nd throttle valve each have 2 coils that are activated by the control unit until the desired position is reached; the throttle valve sensors emit a feedback signal for the position. Additional control unit outputs: Tachometer, cooling liquid temperature and "FI" error lamp 7-37 DESCRIPTION OF THE COMPONENTS Fuel pump 2 1 The vane-type pump mounted in the fuel tank is driven by an electric motor 1 whose rotor is rinsed and simultaneously cooled and lubricated with fuel. A back-pressure valve is installed in the outlet opening which closes when the ignition is switched off, stopping the pump in order to maintain the residual fuel pressure; this prevents vapor bubbles from forming in the fuel system. The fuel pump is also equipped with a pressure relief valve to avoid damage to the fuel pump if the pressure regulator 2 is defective. Pressure regulator The pressure regulator 2 mounted in the fuel tank operates like a pressure relief valve that opens upon exceeding a certain system pressure (343 kPa, 3.5 bar) and closes if this pressure is not achieved. A valve is mounted on the spring-loaded diaphragm which closes when the fuel pump stops. When the fuel pump starts up, the pressure in the system rises until the spring over the diaphragm can be pressed together; the diaphragm lifts the valve out of its seat, allowing fuel to flow back into the tank, the system pressure decreases again. When the pressure drops, the spring on the valve can close again and the control process starts over again. Art.-No. 3.206.056-E Injection valves The injection valves consist of a magnetic coil, a spring-loaded plunger, a needle valve and a filter. When the control unit triggers the injection valves, a magnetic field is created in the magnetic coil, attracting the plunger against spring force and thus lifting the needle valve from its seat. The fuel escapes through 8 injection jets and forms 2 conical jets. After injection, the control unit cuts off the circuit, the magnetic field breaks down and the spring can close the needle valve again. The filter prevents the tiny holes from becoming clogged with dirt. The injection valves are mounted in the throttle valve body. Coolant temperature sensor The coolant temperature sensor consists of a thermal resistor that changes its electric resistance depending on the temperature. The sensor is an NTC (Negative Temperature Coefficient) sensor, i.e. the resistance of the sensor drops if the temperature rises (but never reaches zero resistance) and rises if the temperature drops (but never reaches infinite resistance). Repair manual KTM LC8 The coolant sensor is positioned on the left side of the engine. Air temperature sensor The mode of action is the same as for the coolant temperature sensor. The air temperature sensor is located in the air filter box. 7-38 Manifold air pressure sensor The manifold air pressure sensors are mounted on the frame and connected to the intake port under the throttle valve with equally long vacuum hoses. Reducing jets with a 1 mm air hole are connected to the intake port. NOTE: If the vacuum hoses are damaged, they must be replaced with new, original KTM hoses. ! CAUTION ! – ALWAYS – – REPLACE THE VACUUM HOSES ON THE INTAKE MANIFOLD IF THEY WERE PULLED OFF. DO NOT USE SILICONE SPRAY WHEN MOUNTING THE VACUUM HOSES. IT CAN DAMAGE THE MANIFOLD AIR PRESSURE SENSORS. DO NOT EXCHANGE THE CONNECTIONS ON THE INTAKE MANIFOLD WITH THE CONNECTIONS ON THE CARBURATOR MODELS OTHERWISE THE INJECTION SYSTEM IS LIKELY TO MALFUNCTION. The intake pressure sensors convert the applied vacuum into an electric signal for the control unit. Each of the two intake pressure sensors is supplied with a 5-volt operating voltage and a ground from the control unit. The output signal increases with the pressure; i.e. the intake pressure sensor emits a low voltage signal when the throttle valve is closed and the pressure in the induction manifold is low (high vacuum due to the engine's suction effect). When the throttle valve is completely open, the induction manifold pressure is practically equivalent to the ambient air pressure and the voltage signal has a high value. The sensors must be mounted vertically and the hoses leading to the sensor inclining (due to condensate formation). Ambient air pressure sensor The mode of action is similar to the manifold air pressure sensor. Information is relayed to the control unit indicating under which ambient pressure (at which altitude) the vehicle is being driven. Installed position: under the headlight mask; a 5-cm hose is connected to the sensor to prevent splashed water from penetrating. Throttle valve sensor 1 The throttle valve sensor 1 is mounted on the side of the throttle valve shaft of the front throttle valve and operates like a variable resistor. The control unit determines the position of the throttle valve based on the output voltage. The information acquired is required for the acceleration enrichment, full-load enrichment, ignition timing and trailing throttle fuel cutoff. Sensor for the 2nd throttle valve Operates in the same manner as the throttle valve sensor but is mounted on the shaft of the rear 2nd throttle valve 2 through which the control unit controls the power development. 2 7-39 Pulse generator (crankshaft) 2 1 The pulse generator 1 is located under the clutch cover on the right side of the engine. It is an inductive sensor, i.e. the control unit calculates the speed and the crankshaft position based on the output signal. The pulse generator wheel 2 on the crankshaft is the counterpart of the pulse generator. The distance between its 22 teeth is equal with a larger gap between two teeth. Each tooth induces a signal; the large interval is caused by the gap in the teeth since the distance between 2 teeth is much larger in this position; this signal is used to determine the crankshaft position. ! CAUTION ! THE PICKUP RING FOR THE CARBURATOR AND INJECTION VERSIONS ARE DIFFERENTIATED BY THE POSITION OF THE "TOOTH GAP"; THEY CANNOT BE INTERCHANGED. Probe ceramics Electrodes Contact Housing contact Exhaust pipe Protective ceramic layer (porous) 7 Emission 8 Air Art.-No. 3.206.056-E 1 2 3 4 5 6 Lambda probes The lambda probes screwed into the exhaust after each cylinder measure the partial oxygen pressure in the emission compared to the ambient air, i.e. the sensors compare the oxygen content in the emission with the fresh air. A lambda probe basically consists of a ceramic body coated on both sides with a platinum layer. The platinum layer acts like an electrode. The outer layer comes into contact with the emission, the inner layer with the ambient air. The ceramic body becomes electro-conductive from a temperature of approx. 350º C; voltage is generated if the oxygen content between the ambient air (inner electrode) and emission (outer electrode) varies. The higher the difference in the oxygen level, the greater the voltage; the lambda probe voltage can lie between 0 and 1 volt in operation. Normally the lambda probe voltage will fall between 0.2 volt for a lean combustion and approx. 0.8 volt for a rich combustion. NOTE: – For lean mixtures (excess air) only part of the drawn in oxygen is required for combustion; a large share of oxygen remains in the emission - resulting in a low lambda probe voltage. – For rich mixtures (air deficiency) almost all of the oxygen is burned; hardly any oxygen remains in the emission - resulting in a high lambda probe voltage. The ideal operating temperature for a lambda probe is at approx. 600º C, although up to 950º C is possible for short durations. To reach the operating temperature as quickly as possible, the lambda probes used in this motorcycle are equipped with a heater switched on by the control unit. Repair manual KTM LC8 NOTE: The ceramic body of the lambda probe is very sensitive to shock which is why it is covered with a slotted sheet-metal sleeve. 7-40 Catalytic converter The catalytic converter is installed in the main silencer and transforms most of the main toxic constituents into non-toxic compounds. It is designed as a three-way catalytic converter and consists of a coiled metal support whose surface is coated with precious metals such as platinum and rhodium; the coating only weighs 1 to 2 grams. Similar to the lambda probe, the catalytic converter is not activated until a temperature of approx. 300º C is reached; it operates best between 400º C and 800º C. Thermal aging accelerates at a temperature of 800º C. Much higher temperatures occur if the ignition/injection system (e.g.: ignition faults) malfunctions, which can destroy the catalytic converter. The main constituents in the emissions are nitrogen (N2, not involved in combustion), carbon dioxide (CO2, the result of complete combustion) and water or steam (H2O, is bound in the fuel and released during combustion); together they comprise approx. 90% of emitted exhaust gas and are considered harmless. The rest mainly consists of carbon monoxide and hydrocarbon (CO and HC, both the result of incomplete combustion) and nitrogen oxide (NOx, the result of high combustion chamber temperature); all three are toxic. To effectively convert these 3 components into harmless carbon dioxide, water and nitrogen in the catalytic converter, the engine must be operated close to lambda 1, i.e. the efficiency of combustion is greatest close to lambda 1. But lambda 1 is almost impossible to achieve by control engineering, which is why the control unit continuously (several times each second) produces mixtures alternating between lambda 0.97 (rich mixture) and 1.03 (lean mixture). Under these conditions the voltage generated by the lambda probe varies between 0.2 volt and 0.8 volt depending on the exhaust gas composition. Idle speed control motor The idle speed control motor 1 is mounted to the throttle valve body; it is a stepper motor driven by the control unit to achieve a calculated speed setting. 1 Servomotor for the 2nd throttle valve The function, construction and installed position are the same as for the idle speed control motor; however, the stepper motor for the 2nd throttle valve 2 controls the position of the 2nd throttle valve. 2 7-41 Ignition coils The ignition coils are mounted directly on the spark plugs; the same ignition coils are used for the injection engine as for the carburetor engine. Fuel pump relay The fuel pump relay is installed under the seat. Each relay has a coil and at least one load contact; a magnetic field is created when the coil is supplied with current, which attracts a contact plate, closing the load contact. The control unit uses the fuel pump relay to switch the fuel pump on or off if the engine Stalls or a crash is imminent. Main relay The main relay is installed under the seat. Its mode of operation is similar to the fuel pump relay. The main relay supplies the control unit, heater for both lambda probes, both ignition coils, the secondary air valve and both injection nozzles with current. Art.-No. 3.206.056-E Secondary air valve The secondary air valve is attached to the air filter box. It consists of a coil and a valve. The control unit sets up a ground circuit during the warming-up phase, causing current to flow through the coil which causes a magnetic field to be created, causing the valve to open. Fresh air is drawn into the exhaust resulting in afterburning. Octane selector connections (990 Adventure only) If fuel having at least 95 octane (ROZ) is not available, you can easily activate the corresponding ignition curve by reducing the ignition timing. Repair manual KTM LC8 A plug and socket connection (brown/black cable) is located near the upper shock absorber holder. If the two connectors are joined, the ignition curve for fuel having at least 95 octane (ROZ) is activated. If you disconnect the plug and socket connection, the ignition curve for fuel having 80 - 94 octane (ROZ) will be activated. Although this will cause the engine to lose some of its power output, it will prevent knocking combustion from low-grade fuel that ultimately leads to engine damage. 7-42 Roll angle sensor A pendulum is positioned in the roll angle sensor that prompts the ECU to switch off the ignition and injection at an angle of 65º +/- 10º (from the vertical position); this prevents the engine from running after a crash. Installation: behind the headlight mask. Diagnostics connector 1 The diagnostics connector 1 is located under the seat. The diagnostics connector connects the KTM diagnostics tool and the control unit to read error codes or perform function tests. Side stand switch The side stand switch 2 is mounted on the side stand console and relays the position of the side stand to the ECU (for the safety start system). The side stand switch operates according to the Hall generator principle. 2 Clutch switch The clutch switch 3 is mounted on the clutch pickup instrument and relays the position of the clutch lever to the ECU (for the safety start system and idle speed control). The clutch switch is an on/off switch. 3 Gear switch The gear switch is mounted on the left side of the engine and relays the position of the shift roller to the ECU (for safety start system, idle speed control and EPC). The gear switch is a three-way on/off switch. The neutral, 2nd gear and 3rd gear positions are relayed. 7-43 SAFETY AGAINST FAILURE/EMERGENCY OPERATION Defective component Defect/Effect Backup value/ Spare sensor Possible to start engine? Possible to run vehicle? Fuel pump Total failure: will not start no no no Lack of pressure: power loss no yes limited Pressure regulator same as fuel pump no see above see above Injection valve Electric error no no no Coolant temperature sensor poor cold start/engine operation 80°C yes limited Air temperature sensor Hardly any restriction 25°C yes limited Manifold air pressure sensor Emergency operation program Throttle valve position yes limited Ambient air pressure sensor Hardly any restriction 97 kPa yes limited Throttle valve sensor Emergency operation program Manifold air pressure sensor yes limited Sensor for 2nd throttle valve Emergency operation program Closed yes limited Pulse generator No signal no no no Lambda probes No lambda control not necessary yes limited Catalytic converter No conversion no yes yes Clogged: lack of power no limited limited No idle control no limited limited no yes limited Misfire no limited limited Short circuit/interruption no no no Fuel pump relay Not functioning no no no Main relay Not functioning no no no Secondary air valve No lambda control no yes limited Roll angle sensor Engine does not switch off during crash no yes yes Repair manual KTM LC8 Art.-No. 3.206.056-E Idle speed control motor Stepper motor for 2nd throttle valve Throttle valve can easily be moved Ignition coil 7-44 COMPONENT TESTS NOTE: – Before injection system components are replaced, insure that none of the engine's mechanical components are defective. – Check all fuses. Make sure the control unit is being supplied with ground and positive voltage. Fuel pump and pressure regulator Checking the fuel presure Switch on the ignition, the pump will run for 2 seconds or switch on the pump with the KTM diagnostics tool. If not, perform the following tests: – Scan the fault memory with the KTM diagnostics tool. – Check whether the fuel pump relay is functioning (see page 7-44). – Check the ground and voltage on the fuel pump connector (AR4). NOTE: – If the fuel pump relay is not being controlled by the control unit, check the crash switch (see page 7-46). – The pressure should be 343 kPA (3.5 bar). If the pressure is lower, check the voltage and ground on the fuel pump connector (AR4). – If you cannot find a defect in the electric system, dismount the fuel pump / pressure regulator unit. Injection valves (output) The signal from the injection valves can be scanned with the KTM diagnostics tool Before replacing an injection valve, perform the following tests: – Check the positive supply (orange cable) at the injection valve connector (CL or CL1). – Check the wiring and the connector for continuity to the control unit (control unit disconnected). – Measure the resistance at the respective injection valve. Resistance of the injection valves at 20ºC: 11.7 Ω 7-45 Coolant temperature sensor (input) The signal from the coolant temperature sensor 1 can be scanned with the KTM diagnostics tool (see table for voltage figures). If the displayed value does not correspond to the actual temperature or if an error code is displayed, perform the following tests: – Ground supply (black cable) at the sensor connector AX. – Check the wiring and the connector for continuity to the control unit (control unit disconnected). – Measure the resistance of the coolant temperature sensor. 1 Resistance at -20º C: 15 kΩ +/- 1.5 kΩ Resistance at 20º C: 2.45 kΩ +/- 240 Ω Resistance at 80º C: 318 Ω +/- 31 Ω Sensor-characteristics TW TA 140 Art.-No. 3.206.056-E TW: Coolant temperature sensor 120 TA: Air temperature sensor 100 80 60 Temperature (ºC) 40 20 0 -20 Voltage (Volt) -40 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 Air temperature sensor (input) The signal from the air temperature sensor can be scanned with the KTM diagnostics tool (see table for voltage figures). Repair manual KTM LC8 If the displayed value does not correspond to the actual temperature or if an error code is displayed, perform the following tests: – Ground supply (black cable) at the sensor connector CM. – Check the wiring and the connector for continuity to the control unit (control unit disconnected). – Measure the resistance of the air temperature sensor. Resistance at -20º C: 18.8 kΩ +/- 2.3 kΩ Resistance at 40º C: 1.136 kΩ +/- 95 Ω Resistance at 100º C: 155.3 Ω +/- 7 Ω 7-46 Intake pressure sensors (input) The signal from the intake pressure sensors (1 mounted on the right side of the frame and 2 on the left side of the frame) can be scanned with the KTM diagnostics tool. Output signal in neutral, engine at operating temperature: 1.6 - 3.3 volt Output signal with the engine switched off (ignition on): approx. 3.5 volts 1 2 If the displayed value does not correspond to the actual pressure or if an error code is displayed, perform the following tests: NOTE: if the engine is switched off, both values must be equal to the value of the ambient air pressure sensor. If an intake pressure sensor breaks down, exchange the two and scan the values again with the KTM diagnostics tool - if the error is in the other position, replace the affected intake pressure sensor. If the position of the defective sensor has not changed, perform the following tests: – Apply the ground (black cable) and the 5-volt supply (blue cable) to the BZ or BZ1 connector with the ignition switched on. – Check the vacuum connection and vacuum lines from the induction manifold induction manifold to the intake pressure sensors for damage and continuity. – Check the signal cable (purple and blue/black cables) and the connector from the intake pressure sensors to the control unit for continuity (control unit disconnected). Ambient air pressure sensor (input) The signal from the ambient air pressure sensor 3 can be scanned with the KTM Diagnostics tool. Output signal: approx. 3.5 volts at approx. 37 KPa 3 In case of an error, perform the following tests: – Apply the ground (black cable) and the 5-volt supply (blue cable) to the BZ2 connector with the ignition switched on. – Measure the output signal directly on connector BZ2. – Check the signal cable (green/grey) and connector to the control unit for continuity (control unit disconnected). 7-47 Throttle valve sensor (input) The signal from the throttle valve sensor 1 can be scanned with the KTM diagnostics tool. 1 In case of an error, perform the following tests: – Apply the ground (black cable) and the 5-volt supply (blue cable) to the AR1 connector with the ignition on. – Measure the output signal directly on the AR1 connector: Output signal - throttle in idle, engine at operating temperature: approx. 0.6 volt Output signal - wide-open throttle, with the engine switched off (ignition on): approx. 3.8 volts NOTE: If the throttle is opened slowly, the output signal should change accordingly. – Check the signal cable (yellow/white cable) and the connector to the control unit for continuity (control unit disconnected). Art.-No. 3.206.056-E Sensor for 2nd throttle valve (input) The signal from the 2nd throttle valve sensor 2 can be scanned with the KTM diagnostics tool. In case of an error, perform the following tests: – Apply the ground (black cable) and the 5-volt supply (blue cable) to the AM connector with the ignition switched on. – Measure the output signal directly on connector AM: 2 Output signal throttle closed: approx. 1.0 volt Output signal throttle wide open: approx. 4.3 volts Repair manual KTM LC8 – Check the signal cable (green/red) and connector to the control unit for continuity (control unit disconnected). 7-48 Pulse generator (input) The signal from the pulse generator 1 can be scanned with the KTM diagnostics tool. In case of an error, perform the following tests: 1 – Check the pulse generator resistance between the two cables at connector AT (pulse generator). 190 - 290 Ω at 20ºC – Disconnect connectors AL and AT and check connector AL (yellow/blue and yellow/white cables) for continuity to the control unit (control unit disconnected). – If no error is found, check the distance between the pulse generator and the pulse generator wheel (see Chapter 6). ! CAUTION ! THE PICKUP RING FOR THE CARBURATOR AND INJECTION VERSIONS ARE DIFFERENTIATED BY THE POSITION OF THE "TOOTH GAP"; THEY CANNOT BE INTERCHANGED. Lambda probes (input) The signal from the lambda probes 2 can be scanned with the KTM diagnostics tool. 2 NOTE: – The engine must be at operating temperature in idle. – At speeds below approx. 5000 rpm the signal surges rapidly between 0.2 and 0.8 volt, at higher speeds the signal fluctuates slightly; if the signal fails to surge below 5000 rpm but is in the preset range, the injection system has an electrical defect. – Generally, the lambda probe signal must fall between 0.2 and 0.8 volt. In case of an error, perform the following tests: – Check the ground supply (black cable) from the sensor connector CA or CA1. – Check the wiring and the connector for continuity to the control unit (control unit disconnected). Lambda probe heater (output) The lambda probe heater can be tested and controlled with the KTM diagnostics tool. In case of an error, perform the following tests: – Check the positive supply (with the ignition on, orange cable) at sensor connector CA or CA1. – Check the wiring and the connector for continuity to the control unit (control unit disconnected). – Coil resistance of the lambda probe heater: 13 Ω at 20º C 7-49 Catalytic converter The effectiveness of the catalytic converter can only be tested with an emissions tester. Before replacing a catalytic converter suspected to be defective, take a test ride and use the KTM diagnostics tool to check the injection system for proper functioning. Idle speed control motor (output) The idle speed control motor 1 can be tested and controlled with the KTM diagnostics tool. 1 In case of an error, perform the following tests: Art.-No. 3.206.056-E – Check the wiring and connectors for continuity from the idle speed control motor to the control unit (control unit disconnected). – Check the coil resistance of the idle speed control motor (between the grey and purple or white and green cables). At 20ºC each of the two coils should have a resistance of approx. 8 Ω. Control motor for the 2nd throttle valve (output) Repair manual KTM LC8 2 The control motor 2 can be tested and controlled with the KTM diagnostics tool. In case of an error, perform the following tests: – Check the wiring and connectors for continuity from the idle speed control motor to the control unit (control unit disconnected). – Check the coil resistance of the control motor (between the blue and red or yellow and grey cables). At 20ºC each of the two coils should have a resistance of approx. 6.5 Ω 7-50 Ignition coil (output) Defective ignition coils can be tested and controlled with the KTM diagnostics tool. It allows you to establish which ignition coil is affected. Both ignition coils must be dismounted but stay connected. If an ignition coil breaks down, exchange the two and control again with the KTM diagnostics tool - if the error is in the other position, replace the affected ignition coil. If not, perform the following tests: – Check the positive supply (ignition on, orange cable) at the ignition coil connectors (AS or AS1). – Check the wiring and the connectors for continuity to the control unit (control unit disconnected), white/brown and white/violet cables). – Measure the resistance of the affected ignition coil: (measured between the terminals): 1.0 - 1.6 Ω at 20ºC (measured between one terminal and the spark plug connector): 9.4 - 17.6 KΩ at 20ºC 1 Fuel pump relay (output) The fuel pump relay 1 can be tested and controlled with the KTM diagnostics tool. If the fuel pump is not running, disconnect the control unit and apply the ground to Pin 2 on the wiring harness connector CO (blue/green cable). Switch on the ignition, the fuel pump relay should switch (click once) and the fuel pump should keep running. If not, perform the following tests: – Check the positive supply to the relay connector AF1 Pin 1 (yellow/black cable color) and Pin 2 (orange/white cable). – Check the wiring from connector AF1 to the control unit. NOTE: – If the fuel pump relay switches when actuated as described above but is not actuated by the control unit, check the crash switch - see page 7-46. – If the fuel pump relay switches but there is no positive voltage at the connector AF1 Pin 3 (blue/black cable), replace the relay. – The fuel pump relay is located on the instrument mount under the headlight mask in the 990 Adventure model. 7-51 Main relay 1 Switch on the ignition, the main relay 1 should switch on (audible click). If not, perform the following tests: – Check the positive voltage at connector AF Pin 2 (orange/white cable). – Check the ground supply at connector AF Pin 4 (Braun cable). If no error is detected, replace the main relay. NOTE: The fuel pump relay is located on the instrument mount under the headlight mask in the 990 Adventure model. If the main relay switches and no error is found during the above tests, perform the following tests: 2 – Check the positive voltage at connector AF Pin 1 (green/red cable). – There should be positive voltage at the connector AF Pin 3 (orange cable). If there is positive voltage at connector AF Pin 1 but not at Pin 3 with the ignition switched on, replace the main relay. Secondary air valve (output) The secondary air valve 2 can be tested and controlled with the KTM diagnostics tool. If the secondary air valve fails to switch, perform the following tests: Repair manual KTM LC8 Art.-No. 3.206.056-E – There should be positive voltage at connector CK Pin 2 (ignition on, orange cable). – Check the wiring from connector CO to connector CK for continuity. – The coil resistance of the secondary air valves must be 20 Ohm at 20ºC. 7-52 Roll angle sensor (input) The signal from the roll angle sensor 1 can be scanned with the KTM diagnostics tool. 1 Output signal "No crash detected": 0.4 - 1.4 volts Output signal "Crash detected": 3.7 - 4.1 volts In case of an error, perform the following tests: – Ground supply (black cable) at connector AP2. – 5-volt supply (blue cable) at connector AP2 with the ignition switched on. – Measure the output signal directly at connector AP2 Pin 6 (yellow/red cable). Side stand switch (input) The signal for the side stand switch 2 can be scanned with the KTM diagnostics tool. 2 Output signal up (folded up): 2-3 volts Output signal down (folded down): 4-5 volts In case of an error, perform the following tests: 3 – Ground supply (black cable) connected to connector AM3 3. – 5-volt supply (blue cable) connector AM3 with ignition switched on. – Measure the output signal directly at the connector AR3 Pin 3 (pink cable). 7-53 Clutch switch (input) The clutch switch 1 status can be scanned with the KTM diagnostics tool. NOTE: the clutch switch delivers a ground signal to the ECU when actuated, this function is especially important for the idle speed control. – Ground supply (brown cable) at connector AL1. – Check the wiring from connector AL1 to connector AO for continuity. 1 Art.-No. 3.206.056-E Gear sensor (neutral, 2, 3) (input) The current status of the gear sensor 2 can be scanned with the KTM diagnostics tool. 2 3 Respective gear engaged: max. 3.31 volts Respective gear not engaged: min. 4.14 volts In case of an error, perform the following tests: – Check the wiring from connector AM2 3 to connector AO for continuity. Repair manual KTM LC8 NOTE: This function is especially important for the idle speed control. Error lamp (output) The error lamp (FI) can be tested with the KTM diagnostics tool. NOTE: the error lamp must light up for 2 seconds and then go out after the ignition is switched on if no ignition error is detected by the ECU. If the error lamp does not switch on, perform the following tests: – There must be positive ouput voltage at connector CO Pin 16 (with the ignition on, white cable). – Check the wiring from connector CO to connector AA Pin 8 for continuity. 7-54 Speed signal (output) The tachometer output can be tested and controlled with the KTM diagnostics tool. If the tachometer fails to react, perform the following tests: – Check the wiring from connector CO Pin 14 cable colour blue/white to connector AG Pin 2 for continuity. Coolant temperature signal (output) The coolant temperature output can be tested and controlled with the KTM diagnostics tool. If the coolant temperature display does not react, perform the following tests: – Check the wiring from connector CO Pin 34 (orange/yellow cable) to connector AA Pin 12 for continuity. NOTE: the coolant temperature display will rise very slowly when controlled and will drop very slowly afterwards. Diagnostics line If there is not connection between the KTM diagnostics tool and the vehicle ECU, perform the following test: – Ground supply (brown cable) at connector AP1 Pin 6. – 12-volt supply (orange cable) at connector AP1 with the ignition switched on. – Check the wiring from connector AP1 to connector AO for continuity (yellow cable). 7-55 ERROR CODES Repair manual KTM LC8 Art.-No. 3.206.056-E DTC (Code) Blink code Signal/Component Description of error Engine P0201 33 Injection valve, rear cylinder Malfunction Stalls P0202 34 Injection valve, front cylinder Malfunction Stalls P0351 37 Ignition coil, rear cylinder Malfunction Stalls P0352 38 Ignition coil, front cylinder Malfunction Stalls P0335 02 Pick up Malfunction Stalls P0032 45 Lambda probe heater Short circuit to positive Continues to run P0031 45 Lambda probe heater Kurzschluß nach Masse Continues to run P0130 17 Lambda probe, rear cylinder Malfunction Continues to run P0052 46 Lambda probe heater, front cylinder Short circuit to positive Continues to run P0051 46 Lambda probe heater, front cylinder Short circuit to ground Continues to run P0150 18 Lambda probe heater, front cylinder Malfunction Continues to run P0122 06 Throttle position sensor Output signal too low (interruption) Continues to run P0123 06 Throttle position sensor Output signal too high (short circuit) Continues to run P0107 09 Manifold air pressure sensor, rear cylinder Output signal too low (interruption) Continues to run P0108 09 Manifold air pressure sensor, rear cylinder Output signal too high (short circuit) Continues to run P1106 68 Manifold air pressure sensor, rear cylinder Hose pulled off/defective, no vacuum Continues to run P1687 11 Manifold air pressure sensor, front cylinder Output signal too low (interruption) Continues to run P1688 11 Manifold air pressure sensor, front cylinder Output signal too high (short circuit) Continues to run P1105 69 Manifold air pressure sensor, front cylinder Hose pulled off/defective, no vacuum Continues to run P1107 14 Ambient air pressure sensor Output signal too low (interruption) Continues to run P1108 14 Ambient air pressure sensor Output signal too high (short circuit) Continues to run P0112 13 Air temperature sensor Output signal too low (interruption) Continues to run P0113 13 Air temperature sensor Output signal too high (short circuit) Continues to run P0117 12 Coolant temperature sensor Output signal too low (interruption) Continues to run P0118 12 Coolant temperature sensor Output signal too high (short circuit) Continues to run P1232 41 Fuel pump relay Short circuit to positive Stalls P1231 41 Fuel pump relay Short circuit to ground Stalls P0413 54 Secondary air valve Short circuit to positive Continues to run P0414 54 Secondary air valve Short circuit to ground or interruption Continues to run P0222 07 Sensor for 2nd throttle valve Output signal too low (interruption) Continues to run P0223 07 Sensor for 2nd throttle valve Output signal too high (short circuit) Continues to run P0638 72 Stepper motor for 2nd throttle valve Malfunction Continues to run P0505 49 Idle speed control motor Malfunction Continues to run P1631 15 Roll angle sensor Output signal too low (interruption) Continues to run P1632 15 Roll angle sensor Output signal too high (short circuit) Continues to run P0560 24 Control unit voltage supply Malfunction Continues to run P1590 25 Side stand switch Output signal too low (short circuit to ground) Continues to run P0603 65 EEPROM error Malfunction Continues to run 7-56 ABBREVIATIONS, LIMIT VALUES 990 SUPER DUKE/R Abbreviation Description THAD ATP PM1AD PM1M PAAD PA VBAT TWAD TW TAAD TA HEGO1AD HEGO2AD PM2AD PM2M TAPAD SidestandAD Throttle valve sensor voltage Throttle valve sensor signal Manifold air pressure, rear voltage Manifold air pressure, rear Ambient air pressure sensor voltage Ambient pressure Battery voltage Coolant temperature voltage Coolant temperature Air temperature voltage Air temperature Lamda probe, rear voltage Lamda probe, front voltage Manifold air pressure, front voltage Manifold air pressure, front 2nd throttle valve voltage Side stand switch voltage RolloverAD Roll angle sensor voltage MIL NCS Neutral FI lamp Number of errors influencing exhaust gas Neutral switch voltage Clutch Clutch switch voltage Side stand GP2 Rollover GP3 FLPR HGHT1 HGHT2 EXAI NE MHG1 CLV NETRG MHG2 TIOUT1 TIOUT2 IGLOG1 IGLOG2 IGDWELL1 IGDWELL2 THREF DTHREF MREFHG1 MREFHG1ID MREFHG2 MREFHG2ID ISCSTEP OSTEP 2ndTHAngle STHTRG STHADLL STHADHH Side stand switch voltage Switch for 2nd gear voltage Roll angle sensor Switch for 3rd gear voltage Fuel pump relay Lambda probe heater, rear Lambda probe heater, front SLS (Secondary air system) Engine speed Mixture correction 1 Calculated load value Desired idle speed Mixture correction 2 Injection valve, rear Opening time Injection valve, front Opening time Ignition timing, rear Ignition timing, front Dwell angle, rear Dwell angle, front Throttle reference value Throttle voltage reference value Mixture correction reference value 1 general Mixture correction reference value 1 idle Mixture correction reference value 2 general Mixture correction reference value 2 idle Idle speed control motor, actual Idle speed control motor set-point value 2nd throttle valve, actual steps 2nd throttle valve set-point value steps Min. initialization voltage 2nd throttle sensor Max. initialization voltage 2nd throttle sensor Min. limit value Max. limit value Unit 0.3 0 1 13.3 1 13.3 6.5 4.551 -20 4.629 -20 0 0 1 13.3 0.3 1 4.5 75-85 4.2 119.99 4.2 119.99 16 0.342 120 0.288 120 5 5 4.2 119.99 4.5 5 volts degrees volts KPa volts KPa volts volts ºC volts ºC volts volts volts KPa volts volts 0.4-1.4 3.7-4.1 volts on 0 max. 3.31 V (on) off 40 min. 4.14 V (off) volts actuated not actuated max. 3.31 V min. 4.14 V down (folded down) up (folded up) max. 3.31 V (on) min. 4.14 V (off) Normal Crash detected max. 3.31 V (on) min. 4.14 V (off) on off on off on off Valve open Valve closed 0 9600 0.65 1.25 0 100 0.65 1.25 0 20.25 0 20.25 0 54 0 54 0.966 4.000 0.966 4.000 13.8 20 -0.1 0.1 0.9 1.1 0.9 1.1 0.9 1.1 0.9 1.1 0 700 0 700 0 100 0 100 0.518 1.2 3.799 4.5 volts volts volts volts volts rpm % rpm msec msec º BTDC º BTDC msec msec º volts steps steps % % volts volts Remarks Completely closed 0.56-0.64 V Idle, engine min.80ºC: 36-40KPa rich: 0.8 V; lean: 0.1 V rich: 0.8 V; lean: 0.1 V Idle, engine 80ºC: 37-43KPa closed:1V; open: 4.3V Side stand up: 2-3 volts side stand down 4-5 volts Short circuit 0-1 volts Normal operation: 0.4-1.4 volts Crash detected: 3.7-4.1 volts Error: <0.352, >4.8 volts Cable break: 2-3 volts Number of codes on: idle/no gear engaged off: random gear engaged Actuated: clutch pulled Not actuated: clutch disengaged on: 2nd gear engaged on: 3rd gear engaged 13 Ohm at 20ºC 13 Ohm at 20ºC 20 Ohm at 20ºC 1400 rpm Normal value: 15-17º Normal value: +/-0.02 V 0 % in idle 0 % in idle Normal: approx.1V; Error: 0.518V Normal: approx.4.3V; Error: 3.799V 7-57 ABBREVIATIONS, LIMIT VALUES 990 ADVENTURE / 990 SUPERMOTO Repair manual KTM LC8 Art.-No. 3.206.056-E Abbreviation Description THAD ATP PM1AD PM1M PAAD PA VBAT TWAD TW TAAD TA HEGO1AD HEGO2AD PM2AD PM2M TAPAD SidestandAD Throttle valve sensor voltage Throttle valve sensor signal Manifold air pressure, rear voltage Manifold air pressure, rear Ambient air pressure sensor voltage Ambient pressure Battery voltage Coolant temperature voltage Coolant temperature Air temperature voltage Air temperature Lamda probe, rear voltage Lamda probe, front voltage Manifold air pressure, front voltage Manifold air pressure, front 2nd throttle valve voltage Side stand switch voltage RolloverAD Roll angle sensor voltage MIL NCS Neutral FI lamp Number of errors influencing exhaust gas Neutral switch voltage Clutch Clutch switch voltage Side stand GP2 Rollover GP3 FLPR HGHT1 HGHT2 EXAI NE MHG1 CLV NETRG MHG2 TIOUT1 TIOUT2 IGLOG1 IGLOG2 IGDWELL1 IGDWELL2 THREF DTHREF MREFHG1 MREFHG1ID MREFHG2 MREFHG2ID ISCSTEP OSTEP 2ndTHAngle STHTRG STHADLL STHADHH Side stand switch voltage Switch for 2nd gear voltage Roll angle sensor Switch for 3rd gear voltage Fuel pump relay Lambda probe heater, rear Lambda probe heater, front SLS (Secondary air system) Engine speed Mixture correction 1 Calculated load value Desired idle speed Mixture correction 2 Injection valve, rear Opening time Injection valve, front Opening time Ignition timing, rear Ignition timing, front Dwell angle, rear Dwell angle, front Throttle reference value Throttle voltage reference value Mixture correction reference value 1 general Mixture correction reference value 1 idle Mixture correction reference value 2 general Mixture correction reference value 2 idle Idle speed control motor, actual Idle speed control motor set-point value 2nd throttle valve, actual steps 2nd throttle valve set-point value steps Min. initialization voltage 2nd throttle sensor Max. initialization voltage 2nd throttle sensor Min. limit value Max. limit value Unit 0.3 0 1 13.3 1 13.3 6.5 4.551 -20 4.629 -20 0 0 1 13.3 0.3 1 4.5 75-85 4.2 119.99 4.2 119.99 16 0.2 140 0.288 120 5 5 4.2 119.99 4.5 5 volts degrees volts KPa volts KPa volts volts ºC volts ºC volts volts volts KPa volts volts 0.4-1.4 3.7-4.1 volts on 0 max. 3.31 V (on) off 40 min. 4.14 V (off) volts actuated not actuated max. 3.31 V min. 4.14 V down (folded down) up (folded up) max. 3.31 V (on) min. 4.14 V (off) Normal Crash detected max. 3.31 V (on) min. 4.14 V (off) on off on off on off Valve open Valve closed 0 9600 0.65 1.25 0 100 0.65 1.25 0 20.25 0 20.25 0 54 0 54 0.966 4.000 0.966 4.000 13.8 20 0 1 0.95 1.05 0.95 1.05 0.95 1.05 0.95 1.05 0 700 0 700 0 100 0 100 0.518 1.2 3.799 4.5 volts volts volts volts volts rpm % rpm msec msec º BTDC º BTDC msec msec º volts steps steps % % volts volts Remarks Completely closed 0.56-0.64 V Idle, engine min.80ºC: 36-40KPa rich: 0.8 V; lean: 0.1 V rich: 0.8 V; lean: 0.1 V Idle, engine 80ºC: 37-43KPa closed:1V; open: 4.3V Side stand up: 1-3 volts side stand down 4-5 volts Short circuit 0-1 volts Normal operation: 0.4-1.4 volts Crash detected: 3.7-4.1 volts Error: <0.352, >4.8 volts Cable break: 2-3 volts Number of codes on: idle/no gear engaged off: random gear engaged Actuated: clutch pulled Not actuated: clutch disengaged on: 2nd gear engaged on: 3rd gear engaged 13 Ohm at 20ºC 13 Ohm at 20ºC 20 Ohm at 20ºC 1450 rpm, Tw min.80ºC Normal value: 15-17º Normal value: 0,4-0,5 V 0 % in idle 0 % in idle Normal: approx.1V; Error: 0.518V Normal: approx.4.3V; Error: 3.799V 7-58 Alarm system for 990 Super Duke/R (optional) General information: a Power Parts alarm system is available for the KTM 990 Super Duke which should be retrofitted by your dealer (under the seat). The vehicle wiring harness is already equipped to accommodate the alarm system (see mounting instructions). The alarm system is deactivated/activated with a hand-held transmitter and comes with a separate battery and horn. If someone attempts to steal the bike, the alarm will be triggered even if the vehicle battery is disconnected. If the alarm system is activated, the alarm LED will light up on the instrument panel. The alarm system will react to the following manipulations: – Change of angle (max. 1.5 degrees/second) – Removal of seat – Ignition on/attempt to start the engine – Disconnection of vehicle battery – Disconnection of the alarm system The system reacts by: – Triggering an acoustic alarm (alarm system horn) – Triggering an optical alarm (flasher lights unless the alarm system is disconnected) – Double starter interlock (starting system and injection system are blocked) The engine cannot be started if the alarm system is activated even if the alarm system control unit is disconnected. Hand-held transmitter: transmits a radio signal that partially changes each time it is actuated (rolling code); the permanent changes make it impossible to copy the signal. If the alarm system receives a copied (i.e. identical) signal, it does not deactivate. If a hand-held transmitter is lost (2 are included in the scope of supply) a reprogrammed hand-held transmitter can be supplied by KTM, although the new hand-held transmitter must be adapted to the vehicle first. To reprogram the transmitter, the customer must present the code card for the alarm system which contains the programming code required for reprogramming. Up to 7 hand-held transmitters can be programmed simultaneously for each vehicle. If a hand-held transmitter is lost or defective, the motorcycle must be started with the other hand-held transmitter or (if not available) with an emergency start code. The emergency start code is also programmed on the code card and is different for each vehicle. The alarm will inevitably be triggered when the emergency start code is entered since the ignition must be switched on. If an alarm was triggered, the ignition will deliver a low humming noise when switched on, afterwards the alarm LED will indicate why the alarm was triggered as information for the driver or as a false alarm for troubleshooting: 1 x blink: Angle sensor (change in vehicle position) 2 x blink: Seat switch (manipulation of the seat) 3 x blink: Ignition switch (ignition was switched on) 4 x blink: Voltage at the vehicle battery (vehicle battery was disconnected) The alarm system inputs can be checked without triggering the alarm if the ignition is switched to ON, the vehicle is moved or the seat removed within 26 seconds after activation (neutral time); if the system is faultless, each step will be confirmed with an acoustic signal. Upon expiration of the neutral time, the normal alarm will be triggered. 7-59 Order for additional hand-held transmitters New hand-held transmitters 1 for the alarm system 2 will be delivered by KTM pre-programmed. Indicate the bar code 3 from the code card 4 and the next available programming space 5 when ordering. 4 2 Art.-No. 3.206.056-E 1 6 3 5 Adapting the hand-held transmitter NOTE: – A new hand-held transmitter must be "adapted" with the alarm system before it can be operated. – During the adapting process described below, all of the hand-held transmitters previously used will be blocked and must be "adapted" again together with the new hand-held transmitter. – If the ignition switch is switched ON and the OFF again with the alarm system deactivated, the alarm LED will blink the number of "adapted" hand-held transmitters. – Keep your code card 4 and emergency start code 6 handy. – Deactivate the alarm system (with the hand-held transmitter or the emergency code) and immediately turn the ignition switch ON 3x and OFF 2x (the ignition is now switched on). The alarm LED will light continuously now. – Switch the ignition OFF and watch the alarm LED; it will start to blink for the first digit of the emergency start code (in this case the 2 in code 26673). – After the alarm LED lights up 2x, immediately switch the ignition ON and OFF again. – The alarm LED will blink for the 2nd digit of the emergency start code (the 6 in our example). After the alarm LED lights up 6x, immediately switch the ignition ON and OFF again. – The alarm LED will blink for the 3rd digit of the emergency start code (the 6 in our example). After the alarm LED lights up 6x, immediately switch the ignition ON and OFF again. – The alarm LED will blink for the 4th digit of the emergency start code (the 7 in our example). After the alarm LED lights up 7x, immediately switch the ignition ON and OFF again. – Now the alarm LED will blink for the 5th digit of the emergency start code (the 3 in our example). After the alarm LED lights up 3x, immediately switch the ignition ON and leave it on - if the emergency start code was entered correctly, the alarm system will give an acoustic signal (2 high tones, 2 low tones). Now you can program all of the remote controls that are to be used: – Press the hand-held transmitter until the alarm LED lights up. – Press the hand-held transmitter again until the alarm LED extinguishes. You will hear an acoustic signal (1 high tone) to indicate that the hand-held transmitter was successfully "adjusted". – "Adjust" the other hand-held transmitters in the same manner. – Switch off the ignition to complete the programming. You will hear an acoustic signal (2 high tones, 2 low tones). Repair manual KTM LC8 – Check whether the hand-held transmitter is operative. – Mark the new digit 5 (the 3 in our example) with an asterisk. NOTE: also proceed as described above to block hand-held transmitters that were lost or stolen. 7-60 Starting with the emergency code NOTE: – Use the following procedure if no functioning hand-held transmitter is available to deactivate the alarm system. – This procedure must be repeated each time the engine is started since the engine lock is automatically activated 50 seconds after the ignition is switched off – Switch the ignition to ON. The alarm system will trigger an optical and acoustic alarm, the alarm LED will light up continuously. – Switch the ignition OFF and watch the alarm LED. The first digit of the emergency code will start to blink (in this case the 2 in code 26673). – After the alarm LED lights up 2x, immediately switch the ignition ON and OFF again. – The alarm LED will blink for the 2nd digit of the emergency start code (the 6 in our example). After the alarm LED lights up 6x, immediately switch the ignition ON and OFF again. – The alarm LED will blink for the 3rd digit of the emergency start code (the 6 in our example). After the alarm LED lights up 6x, immediately switch the ignition ON and OFF again. – The alarm LED will blink for the 4th digit of the emergency start code (the 7 in our example). After the alarm LED lights up 7x, immediately switch the ignition ON and OFF again. – The alarm LED will blink for the 5th digit of the emergency start code (the 3 in our example). After the alarm LED lights up 3x, immediately switch the ignition ON and leave it on. If the emergency start code was entered correctly, the alarm system is deactivated and you can start the engine. 7-61 ABS SYSTEM 990 ADVENTURE Checking the fuses NOTE: 2 fuses for the ABS are located under the starter relay. – Remove the protection covers and check fuse 1. Always replace a blown fuse with an equivalent fuse. 1 Checking the ABS fault memory using the KTM diagnostics tool – Connect the diagnostics plug, switch on the ignition and select "ABS-ECU" 2 in the KTM diagnostics tool. – Select "Show diagnostics menu" 3. 3 2 Art.-No. 3.206.056-E – Select "Show DTC/Freeze data" 4 in the diagnostics menu. 9 4 – Any errors will be listed 5 and a description provided 6 (e.g. "rear ABS sensor disconnected") and the error status displayed 7 (Error currently present). Repair manual KTM LC8 5 8 6 7 – After rectifying/eliminating the error, stored errors can be deleted with "Clear DTC in ECU" 8. NOTE: if extreme differences in the rotational speed of the front and rear wheels arise while driving (e.g. driving on loose ground) error 5032 or 5034 will be stored and can be deleted. Checking the ABS sensor with the KTM diagnostics tool bk bl – Select "Show Current data" 9 in the diagnostics menu. – Turn the front and rear wheel. NOTE: – The speed of the front ABS sensor will be displayed under "FWS" bk. – The speed of the rear ABS sensor will be displayed under "RWS" bl. 8-1 FUEL SYSTEM Repair manual KTM LC8 Art.-No. 3.206.056-E INDEX KEIHIN CARBURETOR CVRD 43 DESCRIPTION OF THE ACV (AIR CUT VALVE) SYSTEM . . . . . . . . . . . . . . . . . . . .8-3 DISASSEMBLING THE CARBURETOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4 ASSEMBLING THE CARBURETOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7 CHECKING THE FLOAT LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10 ADJUSTING THE MIXTURE CONTROL SCREW . . . . . . . . . . . . . . . . . . . . . . . . . .8-10 CHECKING THE THROTTLE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11 ADJUSTING THE THOTTLE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11 ADJUSTING THE CHOKE CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11 ADJUSTING THE THROTTLE CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11 SYNCHRONIZING THE CARBURETOR . . . . . . . . . . . . . . . . . . . . . . .SEE CHAPTER 12 ADJUSTING THE IDLE SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . .SEE CHAPTER 12 CARBURETOR HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-12 KEIHIN ELECTRONIC FUEL INJECTION ADJUSTING THE THROTTLE CABLE . . . . . . . . . . . . . . . . . . . . . . . . .SEE CHAPTER 2 DISMOUNTING/MOUNTING THE THROTTLE BODY . . . . . . . . . . . . . . . . . . . . . . .8-13 DISMOUNTING/MOUNTING THE FUEL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . .8-13 REPLACING THE FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13 CHECKING THE FUEL PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-14 8 Repair manual KTM LC8 Art.-No. 3.206.056-E 8-2 CARBURATOR - KEIHIN CVRD 43 8-3 Description of the ACV (air cut valve) system ACV stands for Air Cut Valve. 2 The ACV system enriches the mixture by reducing the idle-air quantity to prevent the exhaust from backfiring in an overrun condition or upon sudden closure of the throttle valve. 1 Normally the required idle-air reaches the mixture through two air jets, the idle air jet 1 (jet diameter 50) and the ACV jet 2 (jet diameter 80). 3 4 In an overrun condition or during upon sudden closure of the throttle valve, the momentary high under-pressure causes the diaphragm 3 of the ACV valve to close the air channel to the idle-air jet against the pressure of the ACV spring 4. Now the air can only be drawn in through the ACV jet 2, resulting in a richer mixture. The system needs no maintenance. No servicing is required other than an inspection of the components when the carburetor is overhauled. No adjustments can be made. 8-4 Disassembling the carburetor 2 – Loosen the throttle linkage arm 1 and remove together with the shims. – Unscrew the throttle sensor and cable for the idle setting. – Loosen the screws and remove both connecting rods 2. 2 NOTE: – The screws on the connecting rods are glued in. Place the carburetor on an aluminum plate and tap the screws carefully with a hammer to loosen. – The fuel connections must be turned aside before the connecting rods can be removed. 1 5 – Unscrew the connection for the electric starter system 3 and remove the starter piston and spring, unless already removed when the carburetor was dismounted. – Pull the fuel connection 4 out of the carburetor. – Remove the diaphragm cover 5. 3 4 – Remove the throttle slide spring 6 and pull the throttle slide 7 out of the carburetor together with the diaphragm. Art.-No. 3.206.056-E 6 5 7 Repair manual KTM LC8 8 bl bk – Press the jet needle holder 8 together in the direction of the arrows, carefully unclip from the jet needle and remove. NOTE: the spring 9 on the jet needle usually remains in the jet needle holder. – Check all parts for wear, especially the jet needle and the guide surfaces bk of the throttle slide. – Check the throttle slide diaphragm carefully for cracks or fractures. 9 NOTE: the tab of the throttle slide diaphragm contains a small air jet bl – be carefully not to lose it. 8-5 – Remove the float chamber 1 and discard the gasket. 1 – Loosen the fixing screw 2 on the float hinge pin 3 and remove the float 4 together with the hinge pin and the needle valve. – Check the needle valve for wear at the conical seat. 3 2 4 – Unscrew the ACV cover 5 and remove the spring 6 together with the diaphragm 7. 5 – Remove the O-ring 8 from the recess around the air jet 9. – Check the diaphragm 7 for cracks or other damage. – Use a needle or similar tool to press lightly on the ACV valve bk. The ACV valve should move down. The valve should close completely when you let go. 9 bk 6 8 7 8-6 – Unscrew the main air jet 1, the ACV jet 2 and the idle-air jet 3 with a suitable screwdriver. 2 1 3 5 4 6 7 – Unscrew the idle-air jet 4, the main jet 5 with the main jet holder and starter jet 6. – Before removing the idle-air mixture control screw 7, screw in to the limit. Count and note down the number of turns. Then remove the mixture control screw together with the O-ring, shim and spring. – Check the jets for damage and wear. – Clean all parts thoroughly and blow compressed air through all of the bores. ! CAUTION ! CAREFULLY BLOW THE AIR THROUGH THE ACT JET AIR DUCT FROM THE ACV VALVE SIDE TO AVOID DAMAGING THE ACV VALVE. – Hold the throttle valve against the light in a closed condition. No light should be visible on the side of the throttle valve. Art.-No. 3.206.056-E NOTE: if any light is visible, check the throttle valve and carburetor housing for wear. The throttle valve usually becomes worn on the side near the throttle shaft. 8 – Remove the screws 8. ! CAUTION ! HOLD A SUITABLE MANDREL AGAINST THE THROTTLE SHAFT TO KEEP IT FROM BENDING. NOTE: bore out the screws if you are unable to loosen them. – Remove the throttle valve. – Remove the lock ring 9 from the throttle shaft and pull the throttle shaft out from the side of the carburetor. – Check the throttle shaft for wear and deformation. Repair manual KTM LC8 9 8-7 Assembling the carburetor – Push the throttle shaft into the carburetor housing, fit the spring and mount the lock ring 1. 1 – Mount the throttle valve 2, tighten and caulk the screws. ! – Screw on the idle-air jet 3, main jet 4 with main jet holder and starter jet 5. – Screw the idle-air mixture control screw 6 with the O-ring, shim and spring in to the limit, unscrew the number of turns previously noted. 5 7 ! A SUITABLE MANDREL AGAINST THE THROTTLE SHAFT TO KEEP IT FROM BENDING. 2 4 3 CAUTION HOLD 6 See pages 8-10 to adjust the mixture control screw. – Mount the main air jet 7, ACV jet 8 and idle-air jet 9 with a suitable screwdriver. 8 9 8-8 – Place the O-ring 1 in the recess around the air jet. – Mount the ACV diaphragm so that the pin 2 presses on the ACV valve plate 3. 2 3 1 – Place the spring on the diaphragm and mount the ACV cover 4. Art.-No. 3.206.056-E 4 5 6 7 – Position the float 5 together with the needle valve and float hinge pin 6 in the carburetor housing. – Tighten the fixing screw 7 on the float hinge pin. See pages 8-10 to adjust the float level. – Mount the float chamber 8 with a new gasket. Tighten the screws. Repair manual KTM LC8 8 8-9 – Mount the lock ring 1 in the respective position on the jet needle 2 (2nd notch from the top – see technical specifications). 1 2 5 4 3 6 – Insert the spring 3 in the jet needle holder 4 and position in the throttle slide together with the jet needle. Clip the jet needle holder into place. NOTE: a small air jet 5 should be mounted in the tab of the throttle slide diaphragm. – Insert the throttle slide and diaphragm 6 in the carburetor, pushing the jet needle in the needle jet (see arrow). – Mount the throttle slide spring and screw on the diaphragm cover 7. – Fit the starter cable in the piston and screw on the connection for the electric starter system 8. 7 See pages 8-11 to adjust the starter cable. – Insert the fuel connection 9 in the bore with new O-rings. 8 9 8-10 1 – Position both connecting rods 1, coat the thread of the screws with Loctite 243 and mount. NOTE: bend the fuel connections according to the recesses in the connecting rods before mounting the connecting rods. 1 2 – Mount the throttle linkage arm 2 with shims as shown in the drawing and secure with the pins. NOTE: slide the curved plastic shims 3 on the bolts first. 3 – Screw on the throttle sensor and cable for the idle setting. 2 See page 8-11 to adjust/check the throttle sensor. See Chapter 12 to adjust the idle speed. See Chapter 12 to synchronize the carburetor. See page 8-11 to adjust the throttle cable. Adjusting the float level 5 Art.-No. 3.206.056-E NOTE: it is not necessary to separate the two carburetors to adjust the float level. 4 – Remove the float chamber. – Turn the carburetor aside until the float 4 presses lightly against the needle valve. – Place the setting gauge 600.29.016.000 5 on the carburetor at the highest part of the float. The setting gauge should not press against the float but there should not be a gap between the setting gauge and the float. If necessary, bend the arm on the float and check again. – Mount the float chamber. Adjusting the idle mixture control screw NOTE: the idle mixture control screw can only be adjusted when the carburetor is dismounted. Repair manual KTM LC8 6 – Screw the mixture control screws in to the limit. – Screw out the mixture control screws 2 1/4 turns (see Technical Specifications). 8-11 Checking the throttle sensor NOTE: the adjustment must be made in a mounted condition with the cable connected and the ignition switched on. – Use a digital multimeter to measure the voltage between the black and yellow cables at the connector AM 1 (under the fuse box). ! CAUTION ! YOU MUST MEASURE WITH THE CONNECTOR ATTACHED, MAKE SURE TO CAREFULLY PUSH THE MEASURING TIPS ON THE MULTIMETER THROUGH THE SEALING FROM THE CABLE SIDE AND NOT TO DAMAGE ANY PART OF THE CONNECTOR. SINCE 1 – Reading with closed throttle (neutral position): 0.5 – 0.6 volts – Slowly open the throttle valve with the throttle grip, the measured voltage should increase uniformly up to the full load reading. – Reading with fully opened throttle grip (full throttle position): 3.6 – 3.7 volts Adjusting the throttle sensor 2 – Remove the carburetors from the air filter box: see Chapter 3. – Loosen the screw on the throttle sensor 2 and turn the throttle sensor until you reach the reading for the neutral position. NOTE: make sure that you still have enough throttle cable play when the carburetors are dismounted. – Tighten the screw on the throttle sensor and remount the carburetors (see Chapter 3). – Check the readings with the carburetors mounted (see above). Adjusting the choke cable 4 5 3 The choke cable should always have a play of approx. 3 mm. – Push back the protection cover 3; you should be able to lift the cable approx. 3 mm away from the adjusting screw 4. – Loosen the counter nut 5, turn the adjusting screw as needed, tighten the counter nut again and slide on the protection cover. ! CAUTION ! IF THERE IS NO CHOKE CABLE PLAY, THE HOLE IN THE COLD START SYSTEM WILL NOT BE ABLE TO CLOSE COMPLETELY. THIS WILL RESULT IN A HIGH FUEL CONSUMPTION, IRREGULAR ENGINE OPERATION AND EXTREME WEAR ON THE PISTONS AND CYLINDERS. Adjusting the throttle cable (Carburetor models only) You should be able to feel 3-5 mm play in the throttle grip when you start to turn it. – Loosen the counter nut 6, adjust the adjusting screw 7 as needed and tighten the counter nut again. 7 6 NOTE: the throttle grip will automatically return to the neutral position when released. Start the engine and steer to the left and right all the way to the stop. The idle speed should not change, otherwise the throttle cable play must be increased. 8-12 Carburetor heater – Pull the wiring harness connectors 1 from the carburetor heater elements. 1 1 – Unscrew the carburetor heater elements 2. 2 2 Repair manual KTM LC8 Art.-No. 3.206.056-E – Check the carburetor heater elements 2 for damage at the connectors, check the electrical resistance (see Chapter 7). – Tightening torque for the carburetor heater elements: 4 Nm 2 8-13 INJECTION SYSTEM Dismounting/mounting the throttle body (see Chapter 3) NOTE: never carry out any work on the throttle body; no adjustments are necessary. 1 Dismounting/mounting the fuel pump with pressure regulator and fuel level sensor – Disconnect the fuel line. To disconnect, press down lightly on the metal shim 1 and pull the connector off. – Remove the tank side covers, remove the front tank screw, disconnect the bleeder line and fold up the tank. – Disconnect connector 2, remove the lock ring 3 from the damper, loosen the screws 4 and lift off the tank. 5 – Loosen the screws 5 on the fuel pump and pull the fuel pump out of the tank. 2 4 3 – Remount in the reverse order, always replacing the O-rings 6 (lubricated with engine oil) for the fuel pump and fuel connector. 6 8 7 7 bk Replacing the fuel filter NOTE: no prescribed changing interval but recommended if soiled. – Remove the fuel pump (see above). – Press the retaining clip 7 towards the outside and pull off the upper part with the pressure regulator 8. – Remove and replace the fuel filter 9 and O-ring bk. – Position the spring bl in the upper part, mount on the fuel pump and press tightly until the retaining clip engages. 9 bl – Mount the fuel pump (see above). 8-14 Checking the fuel pressure – Disconnect the fuel connection (see page 8-13). 1 – Connect the EFI pressure gauge 610.29.094.000 and run the hose on the pressure manometer to the handlebar if taking a trial run. Hold in place with cable clips if necessary. ! DO CAUTION ! NOT BEND THE HOSES. – Start the engine. The fuel pressure should be approx. 3.5 bar, if not, replace the filter (see page 8-13); if the pressure has not changed despite the filter change, replace the fuel pump and pressure regulator (see page 8-13). 2 NOTE: the fuel pressure should also be 3.5 bar at a full engine load, i.e. if the fuel pressure is correct in neutral, take a trial run. Repair manual KTM LC8 Art.-No. 3.206.056-E – Remove the special tool and reconnect the fuel connection with a new O-ring. 9-1 TROUBLE SHOOTING INDEX Repair manual KTM LC8 Art.-No. 3.206.056-E TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2 9 Art.-No. 3.206.056-E 9-2 ERROR CAUSE REMEDY Engine does not start when the starter button is actuated Operating error Switch on the ignition, switch the transmission to neutral, switch on the emergency OFF switch Battery is dead Charge battery and look for cause of discharging; replace defective parts IGNITION fuse is blown Replace the IGNITION fuse in the fuse box Main fuse is blown Replace the main fuse in the starter relay Ignition lock or emergency OFF switch is defective Check the ignition lock and emergency OFF switch, replace any defective parts Back-up starter system is defective Repair the back-up starter system Engine only switches on when the clutch lever is pulled Back-up starter system is defective Repair the back-up starter system Engine switches on although a gear is engaged Back-up starter system is defective Repair the back-up starter system Engine is cranking but does not start Operating error Open the fuel taps, refuel, do not pull the chock, follow the starting instructions Fuel pump hose is blown Replace the FUEL PUMP fuse Plug and socket connector on the wiring harness is oxidizing Remove the covering and the fuel tank, clean the plug and socket connector and treat with contact spray Error in the (Super Duke) Error diagnosis with the KTM diagnostics tool, eliminate error Engine does enough power not Repair manual KTM LC8 Engine gets too hot have injection system Fuel supply partly interrupted Check the fuel taps, run the fuel lines without kinks Carburetors are leaking Check the vacuum hoses and vent hoses for a tight fit kinkfree installation Air filter is heavily soiled Replace the air filter Ignition curve for 80 octane is activated (950 Adventure only) Activate the ignition curve for 95 octane, provided 95 octane fuel is being used Error in the (Super Duke) system Error diagnosis with the KTM diagnostics tool, eliminate error Not enough coolant in the cooling system Add cooling liquid (see maintenance work), check the cooling system for leakage Air in the cooling system Bleed the cooling system (see Chapter 12) Radiator fins are heavily soiled Clean the radiator fins with a water jet Formation of foam in the cooling system Replace the cooling liquid, use brand-name antifreeze Kinked or damaged radiator hose Install the radiator hose correctly or replace Thermostat defective Have the thermostat checked (opening temperature 75°C) or replaced Fan fuse is blown Replace the FAN fuse Fan or thermoswitch for fan is defective Replace defective parts injection 9-3 ERROR CAUSE REMEDY Engine does not switch on EPC valve is not mounted correctly, opens through vibrations Check the position of the EPC valve (near the oil dipstick): may not rest against the frame Engine stalls while driving No fuel Refuel Operating error Open the fuel taps Fuel pump fuse is blown Replace the FUEL PUMP fuse Carburetor iced (moist, cold intake air) Fuse is blown, replace FI lamp is blinking/lights up Error in the injection system (Super Duke) Error diagnosis with the KTM diagnostics tool, eliminate error Poor idling after replacing the engine (EFi only) Control unit was not adapted to the new engine Delete preset values using the KTM diagnostics tool (see Chapter 3) and allow engine to run in neutral for 15 minutes Sudden loss of power in the mid-speed range (carburetor models only) Camshaft timing or ignition interval incorrectly adjusted Check/adjust camshaft position and timing High oil consumption Engine oil level is too high Check the oil level when the engine is warm and correct if necessary Engine oil is too thin (viscosity) Use a thicker engine oil; see "Engine oil" Chapter 11 Headlight and parking light do not light up Fuse is blown Replace the H/L BEAM POSITION fuse Turn signal, brake light, horn and multifunctional digital speedometer do not work Fuse is blown Replace the HORN BRAKE LIGHT SPEEDO fuse The time is not displayed or not displaced correctly Fuse is blown, interrupting the current supply Replace the CLOCK fuse and set the time Battery is dead The ignition (power consumer) was not switched off Charge the battery as specified The battery is not being charged by the generator Remove the left engine cowl and check the brown cable connector on the voltage regulator; check the voltage regulator and the generator; replace any defective parts No display in the multifunctional digital speedometer Fuse is blown Replace the HORN BRAKE LIGHT SPEEDO fuse The speed display in the multifunctional digital speedometer does not work Pickup cable is damaged or cable connector contacts are oxidizing Check the pickup cable for damage. ABS warning lamp lights up Driving situation with extremely deviating wheel speeds Stop, switch off the ignition, start again Fuse is blown Replace the ABS fuses (under the right engine cowl) Replace the ABS OPTIONAL fuse ABS sensors are loose or the cable damaged Check the ABS sensors for a tight fit and cables for damage; replace defective parts ABS sensor wheel is bent Replace defective parts Error in the ABS Error diagnosis with KTM diagnostics tool Wait briefly, start the engine again (if not installed, retrofit a carburetor heater 600.31.003.044) 10-1 CHASSIS Repair manual KTM LC8 Art.-No. 3.206.056-E INDEX DISMOUNTING/MOUNTING THE FRONT WHEEL . . . . . . . . . . . . . . . . . . . . . . . . 10-2 DISMOUNTING/MOUNTING THE REAR WHEEL . . . . . . . . . . . . . . . . . . . . . . . . . 10-3 REPLACING THE FRONT WHEEL BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4 REPLACING THE REAR WHEEL BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5 REPLACING THE FRONT BRAKE PADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6 REPLACING THE REAR BRAKE PADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7 REPLACING THE FORK LEGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8 REPLACING THE SHOCK ABSORBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-9 REPLACING THE STEERING HEAD BEARING . . . . . . . . . . . . . . . . . . . . . . . . . .10-11 REPLACING THE SWING ARM BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12 REPLACING THE CHAIN, PINION AND REAR SPROCKET . . . . . . . . . . . . . . . . . .10-13 CUTTING AND RIVETING THE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14 REPLACING THE ABS UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-15 REPLACING THE FRONT ABS SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-15 REPLACING THE REAR ABS SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-15 10 10-2 Dismounting/mounting the front wheel 950/990 Adventure: – Jack up the motorcycle with the center stand (use 600.03.022.000 if not available), unscrew the left bump rubber and block the center stand with the lock 600.29.055.000. – Put a weight on the rear end of the vehicle to lift the front wheel off the ground. 1 1 1 950 Supermoto/R, 990 Supermoto, 990 Super Duke/R: – Remove the footrests and jack up the motorcycle on a mounting rack 625.29.055.000, put a load on the back of the vehicle to lift the front wheel off the ground; you can also use a suitable commercial front wheel jack (see Owner's Manual). 1 3 3 2 2 Art.-No. 3.206.056-E – Remove the two screws 1 and pull the brake caliper off the brake disk towards the back. – Remove the collar screw 2 and loosen the clamp screws 3 on both fork leg axle passages. – Hold the front wheel and pull out the wheel spindle. Slightly turn one of the brake calipers towards the outside (950 Adventure) and take the front wheel out of the fork. 3 3 – Remove both distance bushings 4 from the shaft seal rings 5. A ! CAUTION ! – Do not actuate the hand brake if the front wheel is dismounted. – To avoid damage, make sure the brake disks do not have contact. – Mount both distance bushings. 4 Repair manual KTM LC8 NOTE: install the distance bushing with collar A on the left. 5 B – Lift the front wheel in the fork (pay attention to the rolling direction B), slightly turn one brake caliper towards the outside and slide the tire between the brake calipers. Insert the brake disks in the brake calipers (950/990 Adventure) and mount the wheel spindle. Mount the brake calipers, apply Loctite 243 to the screws and tighten to 25 Nm (M8) or 45 Nm (M10x1,25). – Mount the collar screw 2 and slightly tighten, tighten the clamp screws 3 on the right fork leg axle passage (in the direction of travel) to prevent the wheel spindle from turning and tighten the collar nut to 60 Nm. – Loosen the clamp screws on the right fork leg axle passage, take the motorcycle off the stand, actuate the front wheel brake and vigorously compress the fork a few times to align the fork legs. – Then tighten the clamp screws on both fork leg axle passages to 15 Nm. ! CAUTION – ALWAYS – ! ACTUATE THE HAND BRAKE AFTER MOUNTING THE FRONT WHEEL UNTIL YOU FEEL THE PRESSURE POINT. KEEP THE BRAKE DISKS FREE OF OIL AND GREASE OTHERWISE THE BRAKING ACTION WILL BE SIGNIFICANTLY REDUCED. – Finish assembling the motorcycle. 10-3 Dismounting/mounting the rear wheel 950/990 Adventure: – Place the motorcycle on the center stand to lift the rear wheel off the ground. 2 950 Supermoto/R, 990 Supermoto, 990 Super Duke/R: – Jack up the motorcycle with the assembly stand 625.29.055.000, see Chapter 3. 1 – Unscrew the collar nut 1, remove the chain tensioner 2, hold the rear wheel and pull out the wheel spindle 3. Push the rear wheel forward as far as possible, remove the chain from the rear sprocket and set it aside on the rear sprocket guard (950 Adventure only). Carefully lift the rear wheel out of the swing arm. A ! CAUTION ! ACTUATE THE FOOT BRAKE IF THE REAR WHEEL IS DISMOUNTED. SET THE WHEEL ASIDE WITH THE BRAKE DISK FACING UP OTHERWISE YOU MAY DAMAGE THE BRAKE DISK. IF YOU DISMOUNT THE WHEEL SPINDLE, THOROUGHLY CLEAN THE THREAD ON THE WHEEL SPINDLE AND COLLAR NUT AND REGREASE (MOTOREX LONG TERM 2000) TO PREVENT THE THREAD FROM SEIZING. – DO NOT – ALWAYS – 3 A NOTE: Check the rubber damping seal in the rear wheel hub when the rear wheel is dismounted. Before mounting the rear wheel, clean and grease the bearing surface of the bushing 4 and the shaft seal ring 5. Mount in the reverse order. Make sure the wheel spindle and chain tensioner are mounted with the tabs A facing towards the front. 4 Push the rear wheel forward before you tighten the collar nut to 90 Nm, to allow the chain tensioner to rest against the clamp screws. ! – ALWAYS – 5 CAUTION ! ACTUATE THE FOOT BRAKE AFTER MOUNTING THE REAR WHEEL UNTIL YOU FEEL THE PRESSURE POINT. KEEP THE BRAKE DISKS FREE OF OIL AND GREASE OTHERWISE THE BRAKING ACTION WILL BE SIGNIFICANTLY REDUCED. 10-4 Replacing the front wheel bearing – To dismount the front wheel, see page 10-2. 1 – Pull out both distance bushings 1, pry both shaft seal rings 2 out of the hub and take the lock ring 3 out of the hub with suitable pliers. – Push the bearing spacing tube 4 aside and knock the grooved ball bearing 5 out from the opposite side with a driver. – Take the bearing spacing tube out of the hub and knock out the second grooved ball bearing 6. 2 6 – Press a new grooved ball bearing 6 into the hub with a suitable tool. 4 ! CAUTION ! WHEN YOU PRESS IN THE BEARING, MAKE SURE TO PRESS THE OUTER RING ONLY. IF YOU PRESS THE INNER RING, THE BALLS OR THE BEARING SURFACES OF THE BALLS WILL BE DAMAGED. 5 3 2 1 – Insert the bearing spacing tube in the hub and press in the grooved ball bearing 5, again making sure that you only press the outer bearing ring. – Mount the lock ring 3, grease the new shaft seal rings 2 and press in with the back of 584.29.091.000 until flush. – Attach both distance bushings 1. NOTE: the collared bushing must be mounted on the left. Repair manual KTM LC8 Art.-No. 3.206.056-E – To remount the front wheel, see page 10-2. 10-5 1 2 3 Replacing the rear wheel bearing – Dismount the rear wheel (see page 10-3). – Remove the rear sprocket carrier from the rear hub and pull out the damper rubber. – Remove the distance bushing 1 and pry the shaft seal ring 2 out of the hub, then take the lock ring 3 out of the hub with suitable pliers. 4 5 7 6 – Pull the grooved ball bearing 4 out of the rear hub with the special tool 600.29.018.000 and the bearing puller 151.12.017.000. – Remove the distance bushing 5 from the hub. – Pull out the grooved ball bearing 6 with the special tool 600.29.018.000 and the bearing puller 151.12.017.000 and take the spacer ring 7 out of the hub. 6 4 – Insert the spacer ring 7 in the hub and tap in a new grooved ball bearing 6 with the back of special tool 584.29.091.000 A. – Slide the distance bushing 5 in the hub and tap a new grooved ball bearing 4 in the hub with the back of special tool 584.29.091.000 A. – Mount the lock ring 3 in the groove and check for a good fit. – Mount the shaft seal ring 2, grease and press in the distance bushing 1. A A 8 – Pull both distance bushings (8 and 9) out of the rear sprocket carrier bk with the special tool 600.29.018.000 and the bearing puller 151.12.017.000. – Remove the washer bl from the bearing. bk bm – Press out the grooved ball bearing bm from the rear sprocket carrier with the back of the special tool 584.29.091.000 A. bl 9 – Press a new grooved ball bearing bm together with a suitable pressing sleeve into the rear sprocket carrier until flush. ! CAUTION ! YOU PRESS IN THE GROOVED BALL BEARING, MAKE SURE TO PRESS THE OUTER RING ONLY. IF YOU PRESS THE INNER RING, THE BALLS OR THE BEARING SURFACES OF THE BALLS WILL BE DAMAGED. WHEN – Slide the washer bl on the distance bushing 9, mount both distance bushings (8 and 9). – Mount the damper rubber in the rear hub and insert the rear sprocket carrier in the rear hub. – Mount the rear wheel (see page 10-3). – Check the chain tension and adjust (see Owner's Manual). 8 A 10-6 Replacing the front brake pads (950/990 Adventure) – Press the brake caliper against the brake disk to move the brake pistons into the basic position. Remove the retainers 1, pull out the bolts 2 and take the brake pads out of the brake caliper. – Clean the brake caliper and brake caliper support with compressed air, check the bellows and guide bolt for damage and grease the guide bolt if necessary. 1 2 – Mount the right brake pad and fix with the bolt. Mount the left brake pad and slide the bolt in all the way to the stop. Mount the retainers. – When mounting the brake pads, make sure the shift rail 3 is correctly positioned in the brake caliper support and the leaf spring 4 is in place. ! CAUTION ! THE BRAKE DISK FREE OF OIL AND GREASE, OTHERWISE THE BRAKING ACTION WILL BE SIGNIFICANTLY REDUCED. AFTER MOUNTING, MAKE SURE THE RETAINERS ARE CORRECTLY FASTENED. AFTER WORKING ON THE BRAKE SYSTEM, ALWAYS ACTUATE THE HAND OR FOOT BRAKE LEVER TO PRESS THE BRAKE PADS AGAINST THE BRAKE DISK UNTIL YOU FEEL THE PRESSURE POINT. – KEEP – – 3 4 2 2 1 Art.-No. 3.206.056-E Replacing the front brake pads (950 Supermoto/R, 990 Supermoto, 990 Super Duke/R) 6 5 7 – Push the retaining clip 5 towards the brake caliper while pushing upwards, pull the securing bolt 6 out towards the rim. – Remove the retaining clips, press the brake pads 7 against the brake piston and take them out of the brake caliper. – Clean the brake caliper with compressed air. – Press the brake piston all the way back. – Mount the brake pads and fasten the retaining clips at the bottom. – Press the retaining clips towards the brake caliper while pushing upwards, mount the securing bolt. ! – KEEP – Repair manual KTM LC8 – 8 CAUTION ! THE BRAKE DISK FREE OF OIL AND GREASE OTHERWISE THE BRAKING ACTION WILL BE SIGNIFICANTLY REDUCED. AFTER MOUNTING, MAKE SURE THE RETAINING CLIPS ARE CORRECTLY POSITIONED IN THE GROOVE 8 OF THE SECURING BOLT. AFTER WORKING ON THE BRAKE SYSTEM, ALWAYS ACTUATE THE HAND OR FOOT BRAKE LEVER TO PRESS THE BRAKE PADS AGAINST THE BRAKE DISK UNTIL YOU FEEL THE PRESSURE POINT. 10-7 Replacing the rear brake pads (950/990 Adventure, 950 Supermoto/R, 990 Supermoto) – Press the brake caliper towards the rear sprocket to move the brake piston into the basic position. Remove the retainers 1, pull out the bolt 2 and remove the brake pads. Thoroughly clean the brake caliper with compressed air and check the guide bolt bellows for damage. 1 2 – Slide the left brake pad into the brake caliper and fix with the bolt. Slide in the right brake pad and push the bolt 2 all the way into the brake caliper. Mount the retainers 1. ! CAUTION ! – KEEP – – THE BRAKE DISK FREE OF OIL AND GREASE OTHERWISE THE BRAKING ACTION WILL BE SIGNIFICANTLY REDUCED. AFTER MOUNTING, MAKE SURE THE RETAINERS ARE CORRECTLY POSITIONED. AFTER WORKING ON THE BRAKE SYSTEM, ALWAYS ACTUATE THE HAND OR FOOT BRAKE LEVER TO PRESS THE BRAKE PADS AGAINST THE BRAKE DISK UNTIL YOU FEEL THE PRESSURE POINT. Replacing the rear brake pads (990 Super Duke/R) – Press the brake caliper towards the rear sprocket to move the brake piston into the basic position. Remove the retainer 3, knock out the bolt 4 from the outside towards the rim. – Remove the brake pads. Thoroughly clean the brake caliper with compressed air and check the guide bolt bellows for damage. 3 4 – Slide the left brake pad into the brake caliper and fix with the bolt. Slide in the right brake pad and push the bolt 4 all the way into the brake caliper. – Knock in the bolt towards the outside from the rim until the retainer 3 can be mounted. ! – KEEP – – CAUTION ! THE BRAKE DISK FREE OF OIL AND GREASE OTHERWISE THE BRAKING ACTION WILL BE SIGNIFICANTLY REDUCED. AFTER MOUNTING, MAKE SURE THE RETAINERS ARE CORRECTLY POSITIONED. AFTER WORKING ON THE BRAKE SYSTEM, ALWAYS ACTUATE THE HAND OR FOOT BRAKE LEVER TO PRESS THE BRAKE PADS AGAINST THE BRAKE DISK UNTIL YOU FEEL THE PRESSURE POINT. 10-8 Replacing the fork legs – Dismount the front wheel (see page 10-2). 1 – Unscrew the bracket 1 for the brake hose and the speed pickup cable and remove from the fender (950/990 Adventure only). – Remove all fender bolts 2 and then the fender. – Unscrew the speed pickup 3. 2 2 2 3 – Remove the bolts 4 on both brake calipers. 4 – Loosen the clamp bolts on both sides of the bottom 5 and top 6 triple clamps. – Pull both fork legs down out of the triple clamps. Art.-No. 3.206.056-E The new fork legs are mounted in the reverse order used to dismount. The upper edge of the fork legs must protrude approx. 5 mm from the top triple clamp 6. 6 Secure the bolts on the brake calipers with Loctite 243 and tighten to 25 Nm (M8) or 45 Nm (M10x1,25). Also secure the fixing screws on the speed pickup 3 with Loctite 243. 5 Repair manual KTM LC8 Tighten the clamp bolts on the top triple clamp to 12 Nm (990 Super Duke) or 20 Nm (950 Supermoto and 950/990 Adventure) and on the the bottom triple clamp to 15 Nm. – Mount the front wheel (see page 10-2). – Adjust the fork legs (see Technical Data). 10-9 Replacing the shock absorber (950/990 Adventure) – Jack up the motorcycle on the center stand 600.03.022.000, unscrew the left bump rubber and lock the center stand with the locking device 600.29.055.000. 2 – Unscrew the left side cover and the seat lock. 3 – Remove the lower shock absorber bolt 1 and press down on the back of the swing arm to release the shock absorber from the recess in the swing arm. – Remove the upper shock absorber bolt 2. 1 – Press the lower end of the shock absorber back against the splash protector 3, tilt the upper end of the shock absorber outwards and lift the shock absorber out of the frame. – Mount the new shock absorber in the same way it was dismounted and tighten the bolts to 80 Nm. NOTE: if you cannot press the shock absorber into the recess in the swing arm, proceed as follows: 4 – Dismount the rear wheel (see page 10-3) and the splash protector 3. – Lift the back of the swing arm and carefully tap the lower end of the shock absorber into the recess with a rubber hammer. – Tighten to bolt to 80 Nm. – Remount the rear wheel (see page 10-3) and the splash protector. – Adjust the chain tension (see Owner's Manual). NOTE: the holding clamps 4 for the brake hose must be open towards the outside. – Screw on the left side cover with the seat lock. To adjust the shock absorber: see Technical Data. 10-10 Replacing the shock absorber (950 Supermoto/R, 990 Supermoto, 990 Super Duke/R) 1 – Jack up the motorcycle and dismount the rear wheel (see page 10-3). – Remove the seat and the splash protector 1, loosen the tank and lift slightly in the rear (950 Supermoto only). – Remove the covering plugs for the upper 2 and lower 3 fork leg screw. 3 2 Art.-No. 3.206.056-E – Remove the lower fork leg screw and press the swing arm down to release the fork leg out of the recess in the swing arm. NOTE: if the lower fork leg bushing also turns, hold it in place with pliers. – Remove the upper fork leg screw. – Lift the fork leg out of the frame towards the rear. Repair manual KTM LC8 – Lift a new fork leg into the frame from the rear and mount the upper fork leg screw. – Lift the swing arm in the rear and press the lower end of the fork leg into the recess. – Apply Loctite 243 to both fork leg screws and tighten to 80 Nm. – Remount the splash protector and the rear wheel (see page 10-3). – Adjust the chain tension (see Owner's Manual). – Fix tank again (950 Supermoto only) and mount the seat. Fork leg adjustment: see Technical Specifications. 10-11 Replacing the steering head bearing 1 1 – Dismount the fork legs (see page 10-8). – Unscrew the brake hose guide from the lower and upper triple clamp (950/990 Adventure) or unscrew the mask support (990 Super Duke/R). – Remove the handlebar clamps 1 and lay the handlebar back. 3 2 NOTE: Protect the fairing components and tank from being damaged. – Loosen the clamp bolt on the steering stem 2, remove the blind bolt 3 on the steering stem, holding the bottom triple clamp 4 to prevent it from sliding out of the steering head. – Remove the top triple clamp 5 and pull the bottom triple clamp 4 and the steering stem down and out of the steering head. 5 6 7 8 bl – Remove the protective ring 6, seal 7 and the upper steering head bearing 8. – Pull the lower steering head bearing 9 off of the steering stem with a suitable puller and remove the seal bk. – Slide on a new seal and a new steering head bearing on the steering stem with a suitable tube. ! WHEN CAUTION ! YOU PRESS IN THE BEARING, MAKE SURE TO PRESS THE INNER RING ONLY. bm 9 bk 4 – Insert the special tool 584.29.092.000 with the collet 584.29.089.000 into the steering head from below and drive the outer ring bl on the upper steering head bearing out of the steering head. – Insert the special tool 584.29.092.000 with the collet 584.29.089.000 into the steering head from above and the drive the outer ring bm on the lower steering head bearing out of the steering head. – Drive the new outer ring on the upper steering head bearing bl into the steering head using the special tool 584.29.091.000 with the collet 584.29.089.000. – Drive the new outer ring on the lower steering head bearing bm into the steering head using the special tool 584.29.091.000 with the collet 584.29.089.000. NOTE: make sure the outer bearing rings do not cant when they are driven in. Assembly is in the reverse order as disassembly. To adjust the play of the steering head bearing, see Chapter 12. Tighten the clamp bolt on the steering stem and the collar bolts on the top triple clamp to 20 Nm (990 Super Duke/R 12 Nm!); tighten the collar bolts on the bottom triple clamp to 15 Nm. Tighten the collar bolts on the handlebar clamps to 20 Nm. Secure the AH bolts on the upper brake hose guide with Loctite 243 and tighten to 8 Nm. To mount the fork legs, see page 10-8. 10-12 4 7 6 8 7 5 9 9 Replacing the swing arm bearing 1 – Dismount the rear wheel (see page 10-3). – Dismount the splash protector 1. – Remove the lower shock absorber bolt 2 and press the swing arm down to release the shock absorber from the recess in the swing arm. – Remove the foot brake cylinder (950/990 Adventure only), pull the brake caliper back and out of the guide and fasten the foot brake cylinder again; do not tighten the bolts. – Tilt the brake caliper to the side and detach the brake hose from the brackets. – Loosen the nut on the swing arm bolt 3 and knock the swing arm bolt out with a suitable tube. Pull the swing arm back and remove. Art.-No. 3.206.056-E 2 3 – Remove the outer tappet for the shaft seal ring 4 and pull the inner tappet 5 and inner sleeve 6 out of the bearing. – Pry out both shaft seal rings 7. – Place the anvil dolly 600.29.056.000 A underneath and press the needle bearing 8 out of the swing arm using the special tool 584.29.086.000 B. B NOTE: the procedure for the second swing arm bearing is identical except that the stop disks 9 also need to be removed. Repair manual KTM LC8 A B C A – Place the anvil dolly 600.29.056.000 A underneath and press the new needle bearing into the swing arm with special tool 584.29.086.000 B and 600.10.013.000 C until flush. – Press in both shaft seal rings until flush. – Slide the inner tappet for the shaft seal ring 5 and the inner sleeve 6 into the bearing and press in the outer tappet. NOTE: the procedure for the second swing arm bearing is identical except that the stop disks 9 need to be mounted. – Position the swing arm on the motorcycle, knock in the swing arm bolt and tighten the nut to 130 Nm. – Press the shock absorber into the recess in the swing arm (see renewing the shock absorber), tighten bolt with 80 Nm. – Remove the bolts on the foot brake cylinder, push the brake caliper into the guide from behind and mount the foot brake cylinder again. Secure the bolts with Loctite 243 and tighten to 10 Nm (950/990 Adventure only). Press the brake hose into the bracket. – Remount the rear wheel (to remount, see page 10-3) and the splash protector. – Adjust the chain tension (see Owner's Manual). 10-13 Replacing the chain, pinion and rear sprocket – Unscrew the engine sprocket cover 1, bend up the lock washer 2 and loosen the engine sprocket nut 3. 2 – Open the chain with a cutting/riveting tool (see page 10-14) and remove the chain. – Remove the engine sprocket with the lock washer (+ Loctite 243!). – Slip on a new pinion with a lock washer and screw on the nut. 1 3 950/990 Adventure: – Loosen the rear sprocket nuts 4 and remove the rear sprocket from the sprocket carrier. – Position a new rear sprocket, secure the nuts with Loctite 243 and tighten to 50 Nm. 4 4 4 4 4 5 – Dismount the rear wheel (see page 10-3) and pull the rear sprocket carrier out of the rear wheel hub. 4 6 990 Super Duke/R, 950 Supermoto/R, 990 Supermoto – Loosen the jerk damper bolt 5 and remove the rear sprocket from the rear sprocket support. – Position a new rear sprocket, apply Loctite 243 to the jerk damper bolt and tighten to 50 Nm. NOTE: the nuts 6 on the jerk damper bolts must fit flush against the rear sprocket. – Place the rear sprocket carrier in the hub of the rear wheel and mount the rear wheel (see page 10-3). – Pull a new chain over the pinion and rear sprocket. – Rivet the chain with a cutting/riveting tool (see page 10-14). – Tighten the engine sprocket nut to 100 Nm, bend up the lock washer. – Screw on the engine sprocket cover. – Adjust the chain tension (see Owner's Manual). 10-14 Opening the chain with a separating/rivet tool 4 1 2 3 2 3 1 NOTE: an X-ring chain, type 525 HV (5/8 x 5/16“), is used for the KTM models with LC8-engine. You will need special tool 600.29.020.000 to separate or rivet the chain according to the manufacturer's specifications. This special tool consists of a bracket 1 with 2 marks (A and B), a pressing tool 2 with spindle and a locking screw, pressing pin 3 and the end plate 4. – Place bracket 1 over the chain from behind. The marks (A, B) should face up. – Insert pressing pin 3 with the larger diameter into the spindle of pressing tool 2 and turn spindle back. – Apply pressing tool 2 with pressing pin 3 to a chain link, the locking screw must face up. – Slide bracket 1 into pressing tool 2 from the side, positioning the bracket in such a way that the arrow on mark A points to the locking screw. – Screw in the locking screw to fix bracket 1 in position A. – Holding pressing tool 2 with a ring wrench (wrench size 27 mm), screw in the spindle of the pressing tool and press out the chain through the hole in the bracket. Art.-No. 3.206.056-E Riveting the chain 5 – Grease the connecting link 5, slide an X-ring 6 on each bolt and connect the ends of the chain. – Fasten another X-ring 6 to each bolt. 6 6 6 7 6 4 Repair manual KTM LC8 1 1 7 2 3 2 7 3 – Place bracket 1 over the chain from behind. The marks (A, B) must face up. – Slide pressing pin 3 with the smaller diameter into the spindle of pressing tool 2 and turn spindle back. – Insert the chain joint shim 7 in the end plate 4 and slide both into the pressing tool. – Apply pressing tool 2 with end plate 4 and the chain joint shim 7 to the connecting link 5 in such a way that the locking screw faces up; the hole on the back of the end plate will accommodate pressing pin 3. – Slide bracket 1 into pressing tool 2 fromt he side, positioning the bracket in such a way that the arrow on mark A points to the locking screw. – Screw in the locking screw to fix bracket 1 in position A. – Holding pressing tool 2 with a ring wrench (wrench size 27 mm), screw in the spindle of the pressing tool and press on the chain joint shim 7. – Loosen the locking screw, remove pressing tool 2 and end plate 4. – Apply pressing tool 2 to the chain again without end plate 4. The bracket 1 must be mounted in such a way that the arrow on mark B points to the locking screw. – Screw in the locking screw to fix bracket 1 in position B. – Holding pressing tool 2 with a ring wrench (wrench size 27 mm), screw in the spindle of the pressing tool and press both bolts of the connecting links together. – Completely remove the separating/riveting tool. 10-15 Replacing the ABS unit 1 – Gently actuate the hand brake lever and foot brake lever until you start to feel resistance; this closes the supply bore to the brake cylinder pistons and prevents the brake fluid from leaking out; fix in this position. NOTE: the fixation must be stiff; the position of the brake lever should not move when the brake lines are unscrewed. 2 1 4 NOTE: immediately wash off any spilled brake fluid with water. 4 3 – Unscrew all 4 brake lines. – Remove the 3 retaining screws 1, lift the ABS unit and disconnect the DL connector 2. – Remount the holder for the ABS unit and tighten the nuts to 8 Nm. – Position the ABS unit and connect the DL connector. – Screw in the 3 retaining screws and tighten. – Connect the banjo bolts (M10x1) for the brake line with new sealing washers and tighten to 25 Nm. – Bleed the brake system (see chapter 12). Replacing the front ABS sensor 4 – Remove the screw on the ABS sensor 3 and the left screws on the fender 4. – Remove the ABS sensor and the protective sleeve, remove the headlight mask and disconnect the DM1 connector (see chapter 13). – Unclip the ABS sensor cable and remove. – Run a new ABS sensor cable along the brake hose and clip on. Join the connectors. – Run the ABS sensor cable as illustrated and hold in place with cable clips. 5 – Mount the ABS sensor with the protective sleeve 5. The collar on the protective sleeve should face the ABS sensor (see photo). – Apply Loctite 243 to the screw on the ABS sensor 3 and tighten to 6 Nm. – Measure the air gap between the ABS sensor and the pulse generator wheel: max. 1.85 mm. Replacing the rear ABS sensor 6 – Remove the screw on the ABS sensor and remove the ABS sensor and the protective sleeve. Disconnect the connector DM (see chapter 13). – Unclip the ABS sensor cable and remove. – Mount a new ABS sensor and protective sleeve 6. The collar on the protective sleeve should face the ABS sensor (see photo). – Apply Loctite 243 to the screw on the ABS sensor and tighten to 6 Nm. – Run the ABS sensor cable along the brake hose and clip on. Join the connectors. – Measure the air gap between the ABS sensor and the pulse generator wheel: max. 1.85 mm. 11-1 TECHNICAL SPECIFICATIONS INDEX 950 ADVENTURE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3 Art.-No. 3.206.056-E 990 SUPER DUKE / SUPER DUKE R ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6 950 SUPERMOTO / SUPERMOTO R ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9 990 ADVENTURE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12 990 SUPERMOTO ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15 Repair manual KTM LC8 950 SUPER ENDURO ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-17 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-18 TOLERANCES, MOUNTING CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-20 TIGHTENING TORQUES ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-22 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-23 11 11-2 TECHNICAL SPECIFICATIONS – ENGINE 950 ADVENTURE Repair manual KTM LC8 Art.-No. 3.206.056-E Engine Design Displacement Bore / Stroke Compression ratio Fuel Valve timing Valve diameter Valve clearance, cold Crankcase bearing Conrod bearing Piston pin bearing Piston Piston rings Engine lubrication Engine oil Quantity of engine oil Primary drive Clutch Transmission Gear ratio Ignition system Ignition timing Generator Spark plug Electrode distance Cooling system Cooling liquid Starting aid LC8 Liquid-cooled, 2-cylinder 4-stroke engine with 75° V arrangement with balancer shaft and electric starter 942 cm3 100/60 mm 11.5:1 unleaded premium fuel with at least RON 95 (ROZ 80 - 94 for other ignition curve) 4 valves controlled over bucket tappet and 2 camshafts, camshaft drive with gears/chain Intake: 38 mm Exhaust: 33 mm Intake: 0,10 - 0,15 mm Exhaust: 0,25 - 0,30 mm Friction bearings (2 main bearings / 1 supporting bearing) Friction bearing Dual-fuel bearing Light alloy – forged 1 compression ring, 1 taper face ring, 1 single-piece oil scraper ring with spiral-type expander Dry sump with 2 trochoidal pumps (pressure pump and suction pump) SAE 5W/40, 10W-50 (f.ex. Motorex Power Synt 4T) approx. 3.0 liters during oil/filter change or approx. 3.3 liters for dry engine Straight-toothed spur wheels 35:67 Multi-disc clutch in oil bath 6-speed claw shifted 1st gear 12:35 2nd gear 15:32 3rd gear 18:30 4th gear 20:27 5th gear 24:27 6th gear 26:27 breakerless transistorized electronic ignition system with digital ignition advance 5° from TDC at 1200 rpm 12V 450W at 6000 rpm NGK CR 8 EK 0.7 mm liquid cooled, permanent circulation of cooling liquid through water pump 2.1 liters, 50% antifreeze, 50% destilled water, at least –25° C 0.9 kW electric starter BASIC CARBURETOR SETTING Type of carburetor Main jet Main air jet Idling jet Idle air jet Idle air cutoff jet Jet needle Needle position Mixture control screw open Starting jet 950 LC8 ADVENTURE CVRD 43 155 (front) / 160 (rear) 40 42 50 80 NDFB 2nd from top 2 1/4 turns 68 11-3 TECHNICAL SPECIFICATIONS – CHASSIS 950 ADVENTURE/ADVENTURE S Frame Fork Spring travel front Rear suspension Spring travel rear Front brake Rear brake Tires, front Air pressure Tires, rear Air pressure Fuel tank capacity Gear ratio – rear wheel Chain Lighting Battery Steering head angle Wheel base Seat height, unloaded Ground clearance, unloaded Dry weight Max. axle load, front Max. axle load, rear Max. total weight 950 ADVENTURE / 950 ADVENTURE S Tubular chrome-molybdenum-steel space frame, powder-coated White Power – Up Side Down 4860 MXMA (Multiadjuster) model year 2003/2004: ADVENTURE = 230 mm, ADVENTURE S = 265 mm model year 2005/2006: ADVENTURE = 210 mm, ADVENTURE S = 245 mm WP Progressive Damping System shock absorber with hydraulic preload adjuster, aluminum rear wheel swinging fork supported by needle bearings model year 2003/2004: ADVENTURE = 230 mm, ADVENTURE S = 265 mm model year 2005/2006: ADVENTURE = 210 mm, ADVENTURE S = 245 mm Disk brake, 2 perforated brake disks Ø 300 mm, floating brake calipers Disk brake, perforated brake disk Ø 240 mm, floating brake caliper Pirelli MT90 FRONT Scorpion A/T 90/90-21 M/C 54V TL (Metzeler MCE Karoo 2 FRONT 90/90-21 M/C 54R M+S max. 170 km/h) on road/alone 2,4 bar passenger 2,4 bar Pirelli MT90 Scorpion A/T 150/70 R18 M/C 70V TL (Metzeler MCE Karoo 150/70 R18 M/C 70R M+S TL max. 170 km/h) on road/alone 2,6 bar passenger 2,8 bar 22 liters, 4 liters reserve 17:42 525 HV (5/8 x 5/16”) X-ring, 118 rolls High beam headlight H3 12V 55W (PK22s base) Low beam headlight H7 12V 55W (PX26d base) High + low beam headlight H4 12V 60/55 W (P43t base) (USA) Front + rear parking light 12V 5W (W2,1x9.5d base) Instrument lights + indicator lamps LED Brake light 12V 21W (BA15s base) Turn signal 12V 10W (BA15s base) License plate illumination 12V 5W (W2,1x9.5d base) maintenance-free battery 12V 11.2 Ah 63,4° 1570 mm model year 2003/04: ADVENTURE = 880 mm, ADVENTURE S = 915 mm model year 2005/06: ADVENTURE = 860 mm, ADVENTURE S = 895 mm model year 2003/04: ADVENTURE = 281 mm, ADVENTURE S = 316 mm model year 2005/06: ADVENTURE = 261 mm, ADVENTURE S = 296 mm 206 kg 200 kg 240 kg 400 kg 11-4 STANDARD ADJUSTMENT – FORK 950 LC8 ADVENTURE WP USD 4860 MXMA 4,8 N/mm 100 mm SAE 5 (WP 4860.0211) Spring Air chamber length Fork oil STANDARD ADJUSTMENT – SHOCK ABSORBER 950 ADVENTURE / ADVENTURE S WP PDS 5018 PA 140/255 140/265 Spring STANDARD ADJUSTMENT – FORK AND SHOCK ABSORBER Repair manual KTM LC8 Standard adjustment Driver Sport Maximum load Driver comfort Maximum load Driver comfort Standard adjustment Driver Sport Maximum load – 8 1,5 12 6 – 6 1 10 8 – 6 1 10 18 20 15 15 15 – – – – – – – – 18 18 15 18 5 5 8 5 – 15 1,5 20 6 – 12 1,5 17 6 – 8 1 13 12 – 8 1 13 12 Driver Sport Driver comfort Standard adjustment Maximum load 950 ADVENTURE S FORK SHOCK ABSORBER – 12 1,5 17 6 Driver Sport Standard adjustment 950 ADVENTURE SHOCK ABSORBER Compression damping (clicks) 20 15 15 15 Compression damping, low speed (clicks) – – – – Compression damping, high speed (turns) – – – – Rebound (clicks) 18 18 15 18 Preload adjuster (turns) 5 5 8 5 Driver comfort Art.-No. 3.206.056-E FORK 11-5 TECHNICAL SPECIFICATIONS – ENGINE 990 SUPER DUKE / SUPER DUKE R Engine Design Displacement Bore / Stroke Compression ratio Fuel Valve timing Valve diameter Valve clearance, cold Crankcase bearing Conrod bearing Piston pin bearing Piston Piston rings Engine lubrication Engine oil Quantity of engine oil Primary drive Clutch Transmission Gear ratio Mixture preparation Ignition system Ignition timing Generator Spark plug Electrode distance Cooling system Cooling liquid Starting aid LC8 Liquid-cooled, 2-cylinder 4-stroke engine with 75° V arrangement with balancer shaft and electric starter 999.9 cm3 101/62.4 mm 11.8:1 unleaded premium fuel with at least RON 95 4 valves controlled over bucket tappet and 2 camshafts, camshaft drive with gears/chain Intake: 38 mm Exhaust: 33 mm Intake: 0.10 - 0.15 mm Exhaust: 0.25 - 0.30 mm Friction bearings (2 main bearings / 1 supporting bearing) Friction bearing Dual-fuel bearing Light alloy – forged 1 compression ring, 1 taper face ring, 1 single-piece oil scraper ring with spiral-type expander Dry sump with 2 trochoidal pumps (pressure pump and suction pump) SAE 5W/40, 10W-50 (f.ex. Motorex Power Synt 4T) approx. 3.1 liters during oil/filter change or approx. 3.3 liters for dry engine Straight-toothed spur wheels 35:67 Multi-disc clutch in oil bath 6-speed claw shifted 1st gear 14:36 2nd gear 16:30 3rd gear 20:30 4th gear 21:27 5th gear 23:26 6th gear 25:26 EFi (Electronic Fuel Injection) breakerless transistorized electronic ignition system with digital ignition advance map-controlled 12V 450W at 6000 rpm NGK CR 8 EK 0.8 mm liquid cooled, permanent circulation of cooling liquid through water pump 2.1 liters, 50% antifreeze, 50% destilled water, at least –25° C 0.9 kW electric starter 11-6 Art.-No. 3.206.056-E TECHNICAL SPECIFICATIONS – CHASSIS 990 DUKE / SUPER DUKE R CHASSIS 990 SUPER DUKE / R 2007 Frame Tubular chrome-molybdenum-steel space frame Fork WP Suspension – Up Side Down 4860 ROMA Spring travel front 135 mm (5.3 in) Rear suspension WP Suspension 4618 BAVP Spring travel rear Super Duke: 160 mm (6.3 in) Front brake Disk brake, 2 perforated brake disks Ø 320 mm (12.6 in), brake calipers radially bolted Rear brake Disk brake, perforated brake disk Ø 240 mm (9.4 in), floating brake caliper Authorized front tires * 120/70 ZR17 M/C 58W Air pressure front Road, driver only...............................................2.4 bar Road, with passenger / maximum payload ...........2.4 bar Authorized rear tires * 180/55 ZR17 M/C 73W Air pressure rear Road, driver only...............................................2.4 bar Road, with passenger / maximum payload ...........2.6 bar Fuel tank capacity 15 liters, 4 liters Reserve (-2006), 18.5 liters, 3.5 liters Reserve (2007-) Gear ratio – rear wheel 17:38 Chain 5/8 x 5/16” X-ring Lighting high beam ............................................H3 12V 55W (socket PK22s) low beam ..............................................H7 12V 55W (socket PX26d) USA: high beam + low beam ..................H4 12V 60/55 W (socket P43t) position light front ..................................12V 5W (socket W2,1x9,5d) indicator lamps .....................................LED position light rear ...................................12V WR5W (socket W2,1x9,5d), Super Duke R: LED USA: position light rear ...........................12V 5W (socket W2,1x9,5d), Super Duke R: LED stoplight ...............................................12V PR21W (socket BAW15s), Super Duke R: LED USA: stoplight .......................................12V 21W (socket BA15s), Super Duke R: LED flashers .................................................12V RY10W (socket BAU15s) licens plate illumination .........................12V 5W (socket W2,1x9,5d) Battery maintenance-free battery 12V 11.2 Ah Steering head angle Super Duke: 66.1° Wheel base 1450 ± 10 mm (57 ± 0.4 in) Seat height, unloaded Super Duke: 850 mm (33.5 in) Super Duke R: 860 mm (33.9 in) Ground clearance, unloaded Super Duke: 140 mm (5.5 in) Super Duke R: 150 mm (5.9 in) Dry weight 186 kg (410.6 lbs) Max. axle load front 180 kg (397.3 lbs) Max. axle load rear 250 kg (551.8 lbs) Max. total load 387 kg (854.2 lbs) Repair manual KTM LC8 * tire releases are available on the Internet at www.ktm.com Super Duke R: 150 mm (5.9 in) Super Duke R: 67.3° 11-7 Maximum Payload Super Duke R Spring 5 5 5 5 5 5 5 5 9.5 N/mm Air chamber length Fork oil 9.5 N/mm 110 mm (4.3 in) SAE 5 (WP 4860.0401) Super Duke R Compression adj. High Speed (turns) Rebound adjuster (clicks) Spring preload (mm) Spring Race course Basic Setting Driving Sport 25 20 10 10 20 16 10 16 Driving Sport Compression adj. Low Speed (clicks) Basic Setting BASIC SETTING SHOCK ABSORBER WP 4618 BAVP Driving Comfort Maximum Payload Super Duke Maximum Payload Spring preload (turns) Race course 20 15 10 10 16 16 12 16 Driving Sport Rebound adjuster (clicks) Basic Setting 20 15 10 10 18 18 14 18 Driving Sport Compression adjuster (clicks) Basic Setting BASIC SETTING FORK WP 4860 ROMA Driving Comfort Maximum Payload Super Duke 2 1.5 1 1 2.5 1.5 1 1.5 20 12 8 8 12 12 8 12 6 6 6 6 5 5 5 5 170/185 180/185 11-8 TECHNICAL SPECIFICATIONS – ENGINE 950 SUPERMOTO / SUPERMOTO R Repair manual KTM LC8 Art.-No. 3.206.056-E Engine Design Displacement Bore / Stroke Compression ratio Fuel Valve timing Valve diameter Valve clearance, cold Crankcase bearing Conrod bearing Piston pin bearing Piston Piston rings Engine lubrication Engine oil Quantity of engine oil Primary drive Clutch Transmission Gear ratio Ignition system Ignition timing Generator Spark plug Electrode distance Cooling system Cooling liquid Starting aid LC8 Liquid-cooled, 2-cylinder 4-stroke engine with 75° V arrangement with balancer shaft and electric starter 942 cm3 100/60 mm 11.5:1 unleaded premium fuel with at least RON 95 4 valves controlled over bucket tappet and 2 camshafts, camshaft drive with gears/chain Intake: 38 mm Exhaust: 33 mm Intake: 0,10 - 0,15 mm Exhaust: 0,25 - 0,30 mm Friction bearings (2 main bearings / 1 supporting bearing) Friction bearing Dual-fuel bearing Light alloy – forged 1 compression ring, 1 taper face ring, 1 single-piece oil scraper ring with spiral-type expander Dry sump with 2 trochoidal pumps (pressure pump and suction pump) SAE 5W/40, 10W-50 (f.ex. Motorex Power Synt 4T) approx. 3.0 liters during oil/filter change or approx. 3.3 liters for dry engine Straight-toothed spur wheels 35:67 Multi-disc clutch in oil bath 6-speed claw shifted 1st gear 12:35 2nd gear 15:32 3rd gear 18:30 4th gear 20:27 5th gear 24:27 6th gear 26:27 breakerless transistorized electronic ignition system with digital ignition advance 5° from TDC at 1200 rpm 12V 450W at 6000 rpm NGK CR 8 EK 0.7 mm liquid cooled, permanent circulation of cooling liquid through water pump 2.1 liters, 50% antifreeze, 50% destilled water, at least –25° C 0.9 kW electric starter BASIC CARBURETOR SETTING Type of carburetor Main jet Main air jet Idling jet Idle air jet Idle air cutoff jet Jet needle Needle position Mixture control screw open Starting jet 950 LC8 ADVENTURE CVRD 43 155 (front) / 160 (rear) 40 42 50 80 NDFB 2nd from top 2 1/4 turns 68 11-9 TECHNICAL SPECIFICATIONS – CHASSIS 950 SUPERMOTO / SUPERMOTO R Frame Fork Spring travel front Rear suspension Spring travel rear Front brake Front rear Tire, front Air pressure Tires, rear Air pressure Fuel tank capacity Gear ratio – rear wheel hain bulbs Battery Steering head angle Wheel base Seat height, unloaded Ground clearance, unloaded Dry weight Max. axle load, front Max. axle load, rear Max. total weight 950 SUPERMOTO / R Tubular chrome-molybdenum-steel space frame, powder-coated White Power – Up Side Down 4860 ROMA 200 mm WP 4618 BAVP 210 mm Disk brake, 2 perforated brake disks Ø 305 mm, fixed brake caliper Disk brake, perforated brake disk Ø 240 mm, floating brake caliper 120/70 ZR17 M/C 58W on road/alone 2.4 bar passenger 2.4 bar maximum load 2.4 bar 180/55 ZR17 M/C 73W on road/alone 2.4 bar passenger 2.6 bar maximum load 2.6 bar 17 liters (950 Supermoto), 14 liters (950 Supermoto R), 4 liters reserve 17:41 525 HV (5/8 x 5/16") X-Ring High/low beam headlight H4 12V 55/60W (base P43t) Front parking light 12V 5W (base W2,1x9,5d) Instrument lights+ indicator lamps LED Rear parking light 12V 5W (base W2,1x9,5d) Brake light 12V 21W (base BA15s) Turn signal 12V 10W (base BA15s) License plate illumination 12V 5W (base W2,1x9,5d) maintenance-free battery 12V 11,2 Ah 65.1 ° 1510 +/- 10 mm 865 mm 190 mm 191 kg 190 kg 250 kg 400 kg 11-10 STANDARD ADJUSTMENT – FORK 950 SUPERMOTO WP 4860 ROMA 5.6-450 110 mm SAE 5 (WP 4860.0401) Spring Air chamber length Fork oil STANDARD ADJUSTMENT – FORK 950 SUPERMOTO R WP 4860 ROMA 5.8-450 110 mm SAE 5 (WP 4860.0401) Spring Air chamber length Fork oil STANDARD ADJUSTMENT – SHOCK ABSORBER 950 SUPERMOTO / R WP 4618 BAVP 130/215 Spring Repair manual KTM LC8 Maximum load Driver comfort Standard adjustment Driver Sport Maximum load Compression damping (clicks) 20 15 10 15 Compression damping, low speed (clicks) – – – – Compression damping, high speed (turns) – – – – Rebound (clicks) 22 17 12 17 Preload adjuster (turns) 5 5 5 5 – 20 3 20 9 – 15 2 15 9 – 10 1 10 9 – 10 1 10 9 Driver Sport Standard adjustment 950 SUPERMOTO / R FORK SHOCK ABSORBER Driver comfort Art.-No. 3.206.056-E STANDARD ADJUSTMENT – FORK AND SHOCK ABSORBER 11-11 TECHNICAL SPECIFICATIONS – ENGINE 990 ADVENTURE Engine Design Displacement Bore / Stroke Compression ratio Fuel Valve timing Valve diameter Valve clearance, cold Crankcase bearing Conrod bearing Piston pin bearing Piston Piston rings Engine lubrication Engine oil Quantity of engine oil Primary drive Clutch Transmission Gear ratio Mixture preparation Ignition system Ignition timing Generator Spark plug Electrode distance Cooling system Cooling liquid Starting aid LC8 Liquid-cooled, 2-cylinder 4-stroke engine with 75° V arrangement with balancer shaft and electric starter 999.9 cm3 101/62.4 mm 11.8:1 unleaded premium fuel with at least RON 95 (ROZ 80 - 94 for other ignition curve) 4 valves controlled over bucket tappet and 2 camshafts, camshaft drive with gears/chain Intake: 38 mm Exhaust: 33 mm Intake: 0.10 - 0.15 mm Exhaust: 0.25 - 0.30 mm Friction bearings (2 main bearings / 1 supporting bearing) Friction bearing Dual-fuel bearing Light alloy – forged 1 compression ring, 1 taper face ring, 1 single-piece oil scraper ring with spiral-type expander Dry sump with 2 trochoidal pumps (pressure pump and suction pump) SAE 5W/40, 10W-50 (f.ex. Motorex Power Synt 4T) approx. 3.0 liters during oil/filter change or approx. 3.3 liters for dry engine Straight-toothed spur wheels 35:67 Multi-disc clutch in oil bath 6-speed claw shifted 1st gear 12:35 2nd gear 15:32 3rd gear 18:30 4th gear 20:27 5th gear 24:27 6th gear 26:27 EFi (Electronic Fuel Injection) breakerless transistorized electronic ignition system with digital ignition advance map-controlled 12V 450W at 6000 rpm NGK CR 8 EK 0.8 mm liquid cooled, permanent circulation of cooling liquid through water pump 2.1 liters, 50% antifreeze, 50% destilled water, at least –25° C 0.9 kW electric starter 11-12 TECHNICAL SPECIFICATIONS – CHASSIS 990 ADVENTURE/ADVENTURE S Frame Fork Spring travel front Rear suspension Spring travel rear Front brake Rear brake ABS (antilock brake system) Approved front tires Luftdruck Approved rear tires Repair manual KTM LC8 Art.-No. 3.206.056-E Luftdruck Fuel tank capacity Gear ratio – rear wheel Chain Lighting Battery Steering head angle Wheel base Seat height, unloaded Ground clearance, unloaded Dry weight Max. axle load, front Max. axle load, rear Max. total weight 990 ADVENTURE / 990 ADVENTURE S Tubular chrome-molybdenum-steel space frame, powder-coated White Power – Up Side Down 4860 MXMA (Multiadjuster) ADVENTURE = 210 mm, ADVENTURE S = 265 mm WP Progressive Damping System shock absorber with hydraulic preload adjuster, aluminum rear wheel swinging fork supported by needle bearings ADVENTURE = 210 mm, ADVENTURE S = 265 mm Disk brake, 2 perforated brake disks Ø 300 mm, floating brake calipers Disk brake, perforated brake disk Ø 240 mm, floating brake caliper Brembo/Bosch system with 2 independent brake circuits Pirelli MT90 90/90-21 M/C 54V up to a maximum of 160 KPH: Continental TKC80 90/90-21 M/C 54S TT M+S Straße solo 2,4 bar Straße Sozius 2,4 bar Pirelli MT90 150/70-18 M/C 70V up to a maximum of 160 KPH: Continental TKC80 150/70B18 M/C 70Q TT M+S Straße solo 2,6 bar Straße Sozius 2,8 bar 19.5 liters, 4 liters reserve 17:42 525 HV (5/8 x 5/16”) X-ring, 118 rolls High beam headlight H3 12V 55W (PK22s base) Low beam headlight H7 12V 55W (PX26d base) High + low beam headlight H4 12V 60/55 W (P43t base) (USA) Front + rear parking light 12V 5W (W2,1x9.5d base) Instrument lights + indicator lamps LED Brake light 12V 21W (BA15s base) Turn signal 12V 10W (BA15s base) License plate illumination 12V 5W (W2,1x9.5d base) maintenance-free battery 12V 11.2 Ah 63,4° 1570 mm ADVENTURE: 860 mm, ADVENTURE: 915 mm ADVENTURE: 261 mm, ADVENTURE: 316 mm ADVENTURE: 209 kg, ADVENTURE: 207 kg 200 kg 250 kg 430 kg 11-13 STANDARD ADJUSTMENT – FORK 990 ADVENTURE WP USD 4860 MXMA 4,8 N/mm 100 mm SAE 5 (WP 4860.0211) Spring Air chamber length Fork oil STANDARD ADJUSTMENT – SHOCK ABSORBER 990 ADVENTURE / ADVENTURE S WP PDS 5018 PA 140/255 140/265 Spring STANDARD ADJUSTMENT – FORK AND SHOCK ABSORBER Maximum load Driver comfort Maximum load Driver comfort Standard adjustment Driver Sport Maximum load – 20 1,5 15 6 – 15 1 10 10 – 15 1 10 18 20 15 10 10 – – – – – – – – 23 18 13 13 5 5 8 7 – 25 2 20 6 – 20 1,5 15 6 – 15 1 10 10 – 15 1 10 12 Driver Sport Driver Sport Standard adjustment Standard adjustment – 25 2 20 6 Driver Sport Driver comfort 990 ADVENTURE S FORK SHOCK ABSORBER Maximum load 990 ADVENTURE SHOCK ABSORBER Compression damping (clicks) 20 15 10 10 Compression damping, low speed (clicks) – – – – Compression damping, high speed (turns) – – – – Rebound (clicks) 23 18 13 13 Preload adjuster (turns) 5 5 8 7 Driver comfort Standard adjustment FORK 11-14 TECHNICAL SPECIFICATIONS – ENGINE 990 SUPERMOTO Repair manual KTM LC8 Art.-No. 3.206.056-E Engine Design Displacement Bore / Stroke Compression ratio Fuel Valve timing Valve diameter Valve clearance, cold Crankcase bearing Conrod bearing Piston pin bearing Piston Piston rings Engine lubrication Engine oil Quantity of engine oil Primary drive Clutch Transmission Gear ratio Mixture preparation Ignition system Ignition timing Generator Spark plug Electrode distance Cooling system Cooling liquid Starting aid LC8 Liquid-cooled, 2-cylinder 4-stroke engine with 75° V arrangement with balancer shaft and electric starter 999.9 cm3 101/62.4 mm 11.8:1 unleaded premium fuel with at least RON 95 (ROZ 80 - 94 for other ignition curve) 4 valves controlled over bucket tappet and 2 camshafts, camshaft drive with gears/chain Intake: 38 mm Exhaust: 33 mm Intake: 0.10 - 0.15 mm Exhaust: 0.25 - 0.30 mm Friction bearings (2 main bearings / 1 supporting bearing) Friction bearing Dual-fuel bearing Light alloy – forged 1 compression ring, 1 taper face ring, 1 single-piece oil scraper ring with spiral-type expander Dry sump with 2 trochoidal pumps (pressure pump and suction pump) SAE 5W/40, 10W-50 (f.ex. Motorex Power Synt 4T) approx. 3.0 liters during oil/filter change or approx. 3.3 liters for dry engine Straight-toothed spur wheels 35:67 Multi-disc clutch in oil bath 6-speed claw shifted 1st gear 12:35 2nd gear 15:32 3rd gear 18:30 4th gear 20:27 5th gear 24:27 6th gear 26:27 EFi (Electronic Fuel Injection) breakerless transistorized electronic ignition system with digital ignition advance map-controlled 12V 450W at 6000 rpm NGK CR 8 EK 0.8 mm liquid cooled, permanent circulation of cooling liquid through water pump 2.1 liters, 50% antifreeze, 50% destilled water, at least –25° C 0.9 kW electric starter 11-15 TECHNICAL SPECIFICATIONS – CHASSIS 990 SUPERMOTO CHASSIS 990 SUPERMOTO 2008 Frame tubular chrome-molybdenum-steel space frame Fork Wheel travel front WP Suspension – Up Side Down fork 4860 ROMA Rear suspension Wheel travel rear WP Suspension - Progressive Damping System shock absorber 4618 BAVP Front brake disk brake, 2 floating perforated brake disks Ø 305 mm (12 in), brake calipers radially bolted Rear brake disk brake, perforated brake disk Ø 240 mm (9.4 in), floating brake caliper Authorized front tires * PIRELLI Scorpion Sync 120/70 ZR17 M/C 58W Air pressure front road, driver only................................................2.2 bar (31 psi) road, with passenger / maximum payload ............2.4 bar (34 psi) Authorized rear tires * PIRELLI Scorpion Sync 180/55 ZR17 M/C 73W Air pressure rear road, driver only................................................2.2 bar (31 psi) road, with passenger / maximum payload ............2.5 bar (36 psi) Fuel tank capacity 19 liters / 5 USgal, 3.7 liters / 0.9 USgal reserve Gear ratio – rear wheel 17:41 Chain 5/8 x 5/16” X-ring Lighting headlight .........................................................H4 12V 60/55W (socket P43t) position light front ............................................12V 5W (socket W2,1x9,5d) indicator lamps ................................................LED position light rear..............................................12V WR5W (socket W2,1x9,5d) stoplight .........................................................12V PR21W (socket BAW15s) licens plate illumination ...................................12V 5W (socket W2,1x9,5d) flasher .............................................................12V RY10W (socket BAU15s) Battery 12V 11.2 Ah maintenance-free Steering head angle 65.1° Wheel base 1510 ± 10 mm (59.4 in) Seat height, unloaded 875 mm (34.4 in) Ground clearance, unloaded 195 mm (7.7 in) Dry weight 191 kg (421.6 lbs) Max. axle load, front 190 kg (419.4 lbs) Max. axle load, rear 250 kg (552 lbs) Payload 195 kg (430.5 lbs) Max. total weight 400 kg (883 lbs) 200 mm (7.9 in) 210 mm (8.3 in) * further tire releases are available on the Internet at www.ktm.com 11-16 FORK 990 SUPERMOTO 2008 Type 14187D20 WP Suspension Spring 6.2-450 Spring preload 5 mm (0.2 in) Air chamber lenght 110 mm (4.3 in) Fork oil SAE 5 (WP 4860.0401) SHOCK ABSORBER 990 SUPERMOTO 2008 Type 15187D15 WP Suspension Spring 130-215 Spring preload 11 mm (0.43 in) Repair manual KTM LC8 Art.-No. 3.206.056-E 990 Supermoto 2008 Compression Rebound Spring preload (turns) Compression Low Speed Compression High Speed Rebound Spring preload (mm) SHOCK SETTING FORK Comfort 20 22 7 20 2.5 20 11 Basic Setting 15 17 5 15 2 15 11 Sport 10 12 5 10 1 10 11 Max. payload 15 17 5 15 2 15 11 11-17 TECHNICAL SPECIFICATIONS – ENGINE 950 SUPER ENDURO Engine Design Displacement Bore / Stroke Compression ratio Fuel Valve timing Valve diameter Valve clearance, cold Crankcase bearing Conrod bearing Piston pin bearing Piston Piston rings Engine lubrication Engine oil Quantity of engine oil Primary drive Clutch Transmission Gear ratio Ignition system Ignition timing Generator Spark plug Electrode distance Cooling system Cooling liquid Starting aid LC8 Liquid-cooled, 2-cylinder 4-stroke engine with 75° V arrangement with balancer shaft and electric starter 942 cm3 100/60 mm 11.5:1 unleaded premium fuel with at least RON 95 4 valves controlled over bucket tappet and 2 camshafts, camshaft drive with gears/chain Intake: 38 mm Exhaust: 33 mm Intake: 0,10 - 0,15 mm Exhaust: 0,25 - 0,30 mm Friction bearings (2 main bearings / 1 supporting bearing) Friction bearing Dual-fuel bearing Light alloy – forged 1 compression ring, 1 taper face ring, 1 single-piece oil scraper ring with spiral-type expander Dry sump with 2 trochoidal pumps (pressure pump and suction pump) SAE 5W/40, 10W-50 (f.ex. Motorex Power Synt 4T) approx. 3.0 liters during oil/filter change or approx. 3.3 liters for dry engine Straight-toothed spur wheels 35:67 Multi-disc clutch in oil bath 6-speed claw shifted 1st gear 12:35 2nd gear 15:32 3rd gear 18:30 4th gear 20:27 5th gear 24:27 6th gear 26:27 breakerless transistorized electronic ignition system with digital ignition advance 5° from TDC at 1200 rpm 12V 450W at 6000 rpm NGK CR 8 EK 0.7 mm liquid cooled, permanent circulation of cooling liquid through water pump 2.1 liters, 50% antifreeze, 50% destilled water, at least –25° C 0.9 kW electric starter BASIC CARBURETOR SETTING Type of carburetor Main jet Main air jet Idling jet Idle air jet Idle air cutoff jet Jet needle Needle position Mixture control screw open Starting jet 950 LC8 ADVENTURE CVRD 43 155 (front) / 160 (rear) 40 42 50 80 NDFB 2nd from top 2 1/4 turns 68 11-18 TECHNICAL SPECIFICATIONS – CHASSIS 950 SUPER ENDURO Repair manual KTM LC8 Art.-No. 3.206.056-E Frame Fork Spring travel front Rear suspension Spring travel rear Front brake Rear brake Tires, front Air pressure Tires, rear Air pressure Fuel tank capacity Gear ratio – rear wheel Chain Lighting Battery Steering head angle Wheel base Seat height, unloaded Ground clearance, unloaded Dry weight Max. axle load, front Max. axle load, rear Max. total weight 950 SUPER ENDURO Tubular chrome-molybdenum-steel space frame, powder-coated WP Up Side Down 4860 MXMA PA (Multi/Preloadadjuster) 250 mm WP 4618 BAVP, aluminum rear wheel swinging fork supported by needle bearings 255 mm Disk brake, perforated brake disks Ø 300 mm, floating brake caliper Disk brake, perforated brake disk Ø 240 mm, floating brake caliper 90/90-21 M/C 54Q on road/alone 2.4 bar passenger 2.4 bar off road 1.7 bar 140/80-18 M/C 70Q on road/alone 2,5 bar passenger 2,8 bar off road 1.5 bar 14 liters, 4 liters reserve 17:45 525 HV (5/8 x 5/16”) X-ring, 118 rolls High + low beam headlight H4 12V 60/55 W (P43t base) Front + rear parking light 12V 5W (W2,1x9.5d base) Instrument lights + indicator lamps LED Brake light 12V 21W (BA15s base) Turn signal 12V 10W (BA15s base) License plate illumination 12V 5W (W2,1x9.5d base) maintenance-free battery 12V 11.2 Ah 64.4° 1577 mm +/- 10 mm 965 mm 330 mm 190 kg 190 kg 250 kg 400 kg 11-19 STANDARD ADJUSTMENT – FORK 950 SUPER ENDURO WP 4860 MXMA PA 5.9-450 100 mm SAE 5 (WP 4860.0401) Spring Air chamber length Fork oil STANDARD ADJUSTMENT – SHOCK ABSORBER 950 SUPER ENDURO WP 4618 BAVP (59) 140-215 Spring STANDARD ADJUSTMENT – FORK AND SHOCK ABSORBER Maximum load Driver comfort Standard adjustment Driver Sport Maximum load – 25 2 22 8 – 20 1.5 18 8 – 15 1 15 8 – 15 1 15 8 Driver Sport Compression damping (clicks) 25 20 15 20 Compression damping, low speed (clicks) – – – – Compression damping, high speed (turns) – – – – Rebound (clicks) 25 20 15 20 Preload adjuster (turns) 1 5 8 5 Driver comfort Standard adjustment 950 SUPER ENDURO FORK SHOCK ABSORBER 11-20 TOLERANCES AND FITTING CLEARANCES COMPONENT Valves Valve springs 950 Valve springs 990 Camshafts/cylinder head 950 Camshafts/cylinder head 990 Super Duke Camshafts/cylinder head 990 Adventure/SM Art.-No. 3.206.056-E Cylinder 950 Cylinder 990 Piston 950 Piston 990 Repair manual KTM LC8 Piston ring 950 Piston ring 990 Piston pin / piston MEASUREMENT/TEST . . . . . . . . . . . . . . . . . . . . . . .SETPOINT VALUE .TOLERANCE LIMIT Valve clearance (at 20ºC) intake . . . . . . . . . . . . . . . .0,10 mm - 0,15 mm Valve clearance (at 20ºC) exhaust . . . . . . . . . . . . . . .0,25 mm - 0,30 mm Valve shaft runout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .max. 0.1mm Sealing seat width, intake . . . . . . . . . . . . . . . . . . . . .1.2 mm – 1.8 mm Sealing seat width, exhaust . . . . . . . . . . . . . . . . . . . .1.5 mm – 2.0 mm Valve disk runout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .max. 0.03 mm Valve guide, inner diameter . . . . . . . . . . . . . . . . . .6.006 mm – 6.018 mm . . .max. 6.05 mm Valve shaft, outer diameter, intake . . . . . . . . . . . . .5.967 mm – 5.980 mm Valve shaft, outer diameter, exhaust . . . . . . . . . . . .5.973 mm – 5.987 mm Inner length, unloaded . . . . . . . . . . . . . . . . . . . . . . . . .new 39.4 mm . . . . . .min. 38.0 mm Outer length, unloaded . . . . . . . . . . . . . . . . . . . . . . . . .new 42.8 mm . . . . . .min. 41.3 mm Inner length, unloaded . . . . . . . . . . . . . . . . . . . . . . . . .new 37.8 mm . . . . . . .min.37.0 mm Outer length, unloaded . . . . . . . . . . . . . . . . . . . . . . . . new 42.0 mm . . . . . . .min.41.2 mm Cam height, intake . . . . . . . . . . . . . . . . . . . . . . . .37.80 mm – 37.90 mm Cam height, exhaust . . . . . . . . . . . . . . . . . . . . . . .36.45 mm – 36.55 mm Cam height, intake . . . . . . . . . . . . . . . . . . . . . . . .38.75 mm – 38.85 mm Cam height, exhaust . . . . . . . . . . . . . . . . . . . . . . .38.15 mm – 38.25 mm Cam height, intake . . . . . . . . . . . . . . . . . . . . . . . .36.96 mm – 37.04 mm Cam height, exhaust . . . . . . . . . . . . . . . . . . . . . . .36.96 mm – 37.04 mm Camshaft bearing bore . . . . . . . . . . . . . . . . . . . .24.000 mm – 24.021 mm Camshaft bearing journal . . . . . . . . . . . . . . . . . . .23.960 mm – 23.980 mm Camshaft bearing clearance . . . . . . . . . . . . . . . . . .0.020 mm – 0.061 mm . . .max. 0.09 mm Cylinder head distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .max. 0.05 mm Size I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100.000 mm – 100.012 mm Size II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100.013 mm – 100.025 mm Cylinder distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .max. 0.05 mm Size I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101.000 mm – 101.012 mm Size II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101.012 mm – 101.025 mm Cylinder distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .max. 0.05 mm Size I – 9 mm (from lower edge) . . . . . . . . . . . . .99.953 mm – 99.967 mm Size II – 9 mm (from lower edge) . . . . . . . . . . . . .99.963 mm – 99.977 mm . . . .99.930 mm Mounting clearance . . . . . . . . . . . . . . . . . . . . . . . .0.04 mm – 0.06 mm . . . . . . . .0.10 mm Size I – 9 mm (from lower edge) . . . . . . . . . . . .100.943 mm – 100.957 mm Size II – 9 mm (from lower edge) . . . . . . . . . . . .100.953 mm – 100.967 mm . .100.930 mm Mounting clearance . . . . . . . . . . . . . . . . . . . . . . . .0.05 mm – 0.07 mm . . . . . . . .0.10 mm Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.15 mm – 0.35 mm . . . . . . . . .0.5 mm Width of piston ring groove – 1st ring (L-ring) . . . . . .0.92 mm – 0.94 mm Width of piston ring groove – 1st ring (L-ring) . . . . . .1.80 mm – 1.84 mm . . . . . . . . . . . . . . Width of piston ring groove – 2nd ring . . . . . . . . . . .1.27 mm – 1.29 mm . . . . . . . . . . . . . . Width of piston ring groove – oil scraper ring . . . . . . .2.51 mm – 2.53 mm . . . . . . . . . . . . . . Thickness of 1st ring (L-ring) . . . . . . . . . . . . . . . . . .0.85 mm – 0.87 mm . . . . . . . . . . . . . . Thickness of 1st ring (L-ring) . . . . . . . . . . . . . . . . . .1.20 mm – 1.22 mm . . . . . . . . . . . . . . Thickness of 2nd ring . . . . . . . . . . . . . . . . . . . . . . .1.22 mm – 1.24 mm . . . . . . . . . . . . . . Thickness of oil scraper ring . . . . . . . . . . . . . . . . . .2.47 mm – 2.49 mm Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.15 mm – 0.35 mm . . . . . . . . .0.5 mm Width of piston ring groove – 1st ring (L-ring) . . . . . .0.92 mm – 0.94 mm Width of piston ring groove – 1st ring (L-ring) . . . . . .1.80 mm – 1.84 mm Width of piston ring groove – 2nd ring . . . . . . . . . . .1.25 mm – 1.29 mm Width of piston ring groove – oil scraper ring . . . . . . .2.50 mm – 2.53 mm Thickness of 1st ring (L-ring) . . . . . . . . . . . . . . . . . .0.85 mm – 0.88 mm Thickness of 1st ring (L-ring) . . . . . . . . . . . . . . . . . .1.20 mm – 1.27 mm Thickness of 2nd ring . . . . . . . . . . . . . . . . . . . . . . .1.22 mm – 1.24 mm Thickness of oil scraper ring . . . . . . . . . . . . . . . . . .2.47 mm – 2.49 mm Diameter of piston ring bore . . . . . . . . . . . . . . . .22.006 mm – 22.011 mm . . . .22.030 mm Diameter of piston pin . . . . . . . . . . . . . . . . . . . .21.996 mm – 22.000 mm . . . .21.980 mm 11-21 TOLERANCES AND FITTING CLEARANCE COMPONENT Crankshaft/conrod Oil pressure Oil consumption Pressure pump Suction pump Bypass valve Clutch Thermostat/radiator Transmission MEASUREMENT/TEST . . . . . . . . . . . . . . . . . . . . . .SETPOINT VALUE . .TOLERANCE LIMIT Diameter of crankshaft journal . . . . . . . . . . .49.965 mm – 49.975 mm (yellow) Diameter of crankshaft journal . . . . . . . . . . .49.976 mm – 49.985 mm (blue) Diameter of crankshaft journal . . . . . . . . . . . .49.986 mm – 49.995 mm (red) Mounting clearance of crankshaft journal . . . . . . .0.025 mm – 0.055 mm . . . . . . .0.08 mm Diameter of support bearing journal . . . . . . . . . .27.985 mm – 28.000 mm Mounting clearance of support bearing . . . . . . . . .0.030 mm – 0.070 mm . . . . . . .0.09 mm Axial clearance of crankshaft . . . . . . . . . . . . . . . . . .0.1 mm – 1.3 mm . . . . . . . . . .2.0 mm Diameter of conrod eye . . . . . . . . . . . . . . . . . . .22.010 mm – 22.020 mm . . . .22.040 mm Diameter of conrod journal . . . . . . . . . . . . .41.978 mm – 41.989 mm (yellow) Diameter of conrod journal . . . . . . . . . . . . . .41.990 mm – 42.000 mm (blue) Diameter of conrod journal . . . . . . . . . . . . . .42.001 mm – 42.011 mm (red) Mounting clearance of conrod bearing . . . . . . . . .0.030 mm – 0.060 mm . . . . . .0.080 mm Axial clearance of conrod eye on conrod journal . . .0.30 mm – 0.45 mm . . . . . . . .0.60 mm Width of conrod bottom . . . . . . . . . . . . . . . . . .21.948 mm – 22.000 mm Width of conrod journal . . . . . . . . . . . . . . . . . . .44.30 mm – 44.35 mm Oil pressure with engine at operating temperature (oil temperature 100ºC in oil tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .min. 0,8 bar at 1500 U/min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .min. 2,4 bar - max 3,5 bar at 6000 U/min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .max. 0,6 lt/1000 km Clearance between inner and outer rotor . . . . . . . . . . . . .0.1 mm . . . . . . . . . . . . .0.25 mm Clearance between outer rotor and case . . . . . . . . . . . . . .0.2 mm . . . . . . . . . . . . . .0.4 mm Axial clearance . . . . . . . . . . . . . . . . . . . . . . . . . .0.04 mm – 0.09 mm . . . . . . . .0.25 mm Clearance between inner and outer rotor . . . . . . . . . . . . .0.1 mm . . . . . . . . . . . . .0.25 mm Clearance between outer rotor and housing . . . . . . . . . . .0.2 mm . . . . . . . . . . . . .0.40 mm Axial clearance . . . . . . . . . . . . . . . . . . . . . . . . . .0.04 mm – 0.09 mm . . . . . . . .0.25 mm Length of spring, unloaded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .min. 41.5 mm Spring tension . . . . . . . . . . . . . . . . . . . . . .27 mm at a load of at least 3.5 kg Total height of disk package . . . . . . . . . . . . . . . .50.20 mm – 51.20 mm . . . .min. 48.0 mm Thickness of lining disks . . . . . . . . . . . . . . . . . . . .2.72 mm – 2.88 mm . . . . . . . .2.65 mm Thickness of steel disks . . . . . . . . . . . . . . . . . . . . . .1.95 – 2.05 mm . . . . . . . . . .1.85 mm Length of clutch springs, unloaded . . . . . . . . . . . . . . . .30.77 mm . . . . . . . . . . . .29.0 mm Spring tension . . . . . . . . . . . . . . . . . . . .19.0 at a load of at least 20 kg – 24 kg Opening temperature of thermostat . . . . . . . . . . . . . . .73° C – 77° C Opening stroke of thermostat . . . . . . . . . . . . . . . .over 7 mm at 100° C Discharge pressure of radiator cap . . . . . . . . . . . . . . . . . .1.4 bar Switch-on temperature of radiator fan switch . . . . . . . . . .102° C Axial clearance of the mainshaft . . . . . . . . . . . . . .0.05 mm - 0.15 mm Clearance between shift fork and groove . . . . . . . . .0.1 mm – 0.25 mm . . . . . . . . . .0.4 mm Width of shift fork groove . . . . . . . . . . . . . . . . . . .5.02 mm – 5.12 mm Thickness of shift fork . . . . . . . . . . . . . . . . . . . . .4.85 mm – 4.95 mm 11-22 Repair manual KTM LC8 Art.-No. 3.206.056-E TIGHTENING TORQUES – ENGINE Hexagon nut on primary gear Multipoint head bolt on conrod caps Hexagon nut on balancer shaft Hexagon nut on balancer shaft preloaded (spreader) Hexagon nut on cylinder head AH bolts on cylinder head Hexagon nut on cylinder head Studs in engine case Studs in engine case Stud on exhaust flange Plug on front cylinder head Bolts to attach bearings Collar screws for bearing shell retaining brackets Crankshaft locking bolt Bearing bolts on tensioning rail Bearing bolts on guide rail Bearing bolts on double timing gear Bolt on chain tensioner AH bolts on camshaft bearing bridges AH bolts on camshaft bearing bridges HH bolts on valve covers HH bolts on engine case halves HH bolts on engine case halves AH bolts on freewheel support HH bolts on freewheel holder Oil plug (clutch lubrication) Oil drain plug Oil line screw connections HH bolts on oil pump cover Plug on oil filter housing Oil jets Oil jets bended Oil pressure switch AH bolt on shift locating drum HH bolt on shift locking lever HH bolt on the shift lever (Adventure) Hexagon nut on clutch clutch hub HH bolts on clutch pressure cap HH bolt on clutch cover HH bolt on clutch cover HH bolt on outer clutch cover AH bolt on ignition rotor AH bolt on ignition rotor HH bolt on generator cover Fixing bolts on the stator Plug on generator cover Bleeder flange on generator cover Bearing bolt on generator cover Fixing bolts on ignition pickup AH bolts on gear sensor Spark plugs Spark plugs Collar bolt on water pump wheel HH bolt on water pump cover Water temperature sensor Water connections for cylinder head HH bolt on the starter motor Vacuum connections for intake port Hexagon nut on chain sprocket AH screw for carburetor trumpet fixture Hose clamps for intake rubber Lambda probe Other engine bolts M33x1.5 left M10x1 M20x1.5 M20x1.5 M10 M8 M6 M6 M10 M8 M12x1.5 M5 M5 M8 M8 M8 M10 M16x1.5 M8 10.9 M6 10.9 M6 M6 M8 M6 10.9 M6 M10 M22x1.5 M6 M6 M14x1.5 M6x0.75 M4 M10x1 M6 M5 M6 M22x1.5 M6 M6 M8 M6 M16 M16x1.5 M6 M6 M24x1.5 M16x1.5 M6 M6 M5 M10x1.0 M12x1.5 M6 M6 M12x1.5 M20x1.5 M6 M6 M20x1.5 M4 M4 M18x1,5 M5 M6 Loctite 243 + 130 Nm 25 Nm/30Nm/60° Loctite 243 + 150 Nm Loctite 243 + 120 Nm lubricated, 25 Nm /38 Nm Loctite 243 + 18 Nm/23 Nm 8 Nm Loctite 243 + 10 Nm Loctite 243 + 20 Nm 15 Nm 25 Nm Loctite 243 + 6 Nm Loctite 243 + 6 Nm 10 Nm Loctite 243 + 20 Nm Loctite 243 + 15 Nm 30 Nm 20 Nm 10 Nm/18 Nm 10 Nm 10 Nm 10 Nm 20 Nm Loctite 648 + 13 Nm Loctite 243 + 10 Nm 15 Nm 35 Nm 10 Nm Loctite 243 + 10 Nm Loctite 243 + 15 Nm Loctite 243 + 4 Nm Loctite 243 + 6 Nm 10 Nm Loctite 243 + 10 Nm Loctite 243 + 6 Nm Loctite 243 + 10 Nm Loctite 243 + 130 Nm 10 Nm 10 Nm 15 Nm 10 Nm Loctite 243 + 180 Nm Loctite 243 + 150 Nm 10 Nm Loctite 243 + 10 Nm 8 Nm Loctite 243 + 10 Nm Loctite 243 + 10 Nm Loctite 243 + 10 Nm Loctite 243 + 3 Nm 12 Nm 20 Nm Loctite 243 + 10 Nm 10 Nm 12 Nm Loctite 577 + 10 Nm 10 Nm Loctite 243 + 5 Nm sheet retainer+Loctite 243+100 Nm 4 Nm 1.5 Nm 45 Nm 6 Nm 10 Nm 11-23 TIGHTENING TORQUES – CHASSIS Collar bolt on front wheel spindle (except 950 Super Enduro) Collar bolt on front wheel spindle (950 Super Enduro only) Collar nut wheel spindle rear AH bolt shock absorber top/bottom Collar nut for swing arm bolt AH bolts on subframe AH bolts on subframe AH bolts on back of footrest support Engine carrier bolts HH clamp bolts on top triple clamp (Super Duke) HH clamp bolts on top triple clamp (Adventure, Supermoto) HH clamp bolts on bottom triple clamp HH screw for steering head AH/HH clamp bolts on fork legs Collar bolts for handlebar clamps AH bolt for handlebar mount HH clamp bolts for steering stem Collar bolt brake disks Collar bolt brake disks HH bolts on front brake caliper HH bolts on front brake caliper HH bolts on handbrake cylinder HH bolts on footbrake cylinder AH bearing bolt for foot brake pedal, shift lever HH screw on cover plate for foot brake lever/shift mechanism Relay for shift shaft (on connecting support) Relay for shift shaft (on shift shaft) Gearshift rod attachment AH/HH bolt for brake-hose guide HH bolts on foot brake pedal surface AH bolts for side stand bracket - engine HH bolts for side stand fixture - side stand bracket HH bolts for side stand mounting HH bolt for spring rest on side stand HH bolt for side stand switch HH bolt for side stand switch HH nuts on rear sprocket bolts Drain plug on oil tank Exhaust nuts on manifold Exhaust clamps (except Adventure) Exhaust clamps (Adventure only) Exhaust clamps for ball joint HH bolts on exhaust suspension HH bolts for underride protection AH bolt on gas level indicator AH bolts on tank cover HH bolts on tank mounting AH bolts on tank mounting HH bolts for fuel taps Collar screws for in-tank pump Collar screw on retaining bracket for fuel pump (950 Supermoto) AH screw on arm for tank support Collar screw for gas pressure shock absorber Seat fixing plate Jerk damper bolt HH nut for seat lock Chainguard Chain sliding guard Spoke nipple Front spoiler Tail light Torx screw for front ABS sensor holder HH screw for ABS sensor Torx screw for rear ABS sensor cable guide Hexagon nut to mount ABS modulator Hexagon nut for positive terminal extension Other bolts on chassis Other collar nuts on chassis M24x1.5 M24x1.5 M25x1.5 M14x1.5 M19x1.5 M8 M10x1.25 M8 M10 M8 M8 M8 M20x1,5 M8 M8 M10 M8 M6 M8x1,25 M8 M10x1.25 M6 M6 M8 M6 M8 M6 M6 M6 M5 M10 M10 M10 M8 M4 M6 M10 M12x1.5 M8 M8 M8 M8 M6 M8 M5 M5 M6 M8 M6 M6 M6 M10 M6 M5 M10x1,25 M19x1 M5 M5 M5 M6 M6 M5 M6 M5 M6 M6 M6 M8 M10 M6 M8 M10 60 Nm 40 Nm 90 Nm 80 Nm 130 Nm Loctite 243 + 25 Nm Loctite 243 + 45 Nm Loctite 243 + 25 Nm 45 Nm 12 Nm 20 Nm 15 Nm 12 Nm 15 Nm 20 Nm 20 Nm 20 Nm Loctite 243 + 14 Nm Loctite 243 + 30 Nm Loctite 243 + 25 Nm Loctite 243 + 45 Nm 10 Nm Loctite 243 + 10 Nm Loctite 243 + 25 Nm Loctite 243 + 10 Nm Loctite 243 + 25 Nm Loctite 243 + 18 Nm Loctite 243 + 12 Nm Loctite 243 + 8 Nm Loctite 243 + 6 Nm Loctite 243 + 45 Nm Loctite 243 + 25 Nm Loctite 243 + 35 Nm Loctite 243 + 25 Nm Loctite 243 + 2 Nm Loctite 243 + 10 Nm Loctite 243 + 50 Nm 25 Nm evenly, do not bend sheet metal 8 Nm 12 Nm 35 Nm Loctite 243 + 12 Nm Loctite 243 + 25 Nm 3 Nm 5 Nm 6 Nm 25 Nm 6 Nm 6 Nm 6 Nm 15 Nm 6 Nm 4 Nm Loctite 243 + 50 Nm 8 Nm 5 Nm 5 Nm 4-6 Nm Loctite 243 + 10 Nm 8 Nm Loctite 243 + 4 Nm Loctite 243 + 6 Nm 3 Nm 8 Nm 4 Nm 10 Nm 25 Nm 45 Nm 15 Nm 30 Nm 50 Nm 12-1 PERIODIC MAINTENANCE SCHEDULE INDEX Repair manual KTM LC8 Art.-No. 3.206.056-E 950 ADVENTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2 990 SUPER DUKE/R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4 950 SUPERMOTO/R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6 990 ADVENTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-8 990 SUPERMOTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-10 950 SUPER ENDURO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-12 MAINTENANCE WORK CHANGING THE ENGINE OIL AND THE OIL FILTER . . . . . . . . . . . . . . . . . . . . . .12-14 CLEANING THE OIL SCREENS IN THE ENGINE AND OIL TANK . . . . . . . . . . . . . .12-14 CLEANING THE MAGNETS ON THE DRAIN PLUG FOR THE ENGINE AND OIL TANK . .12-14 REPLACING THE SPARK PLUGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-16 CHECKING AND ADJUSTING THE VALVE CLEARANCE . . . . . . . . . . . . . . . . . . .12-17 CHECKING THE CLUTCH LINING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-19 CHECKING THE CLUTCH PRESSURE BOOSTER SYSTEM . . . . . . . . . . . . . . . . .12-19 CLEAN THE OIL JET FOR THE CLUTCH LUBRICATION . . . . . . . . . . . . . . . . . . . .12-19 CARBURETOR SYNCHRONIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-21 IDLE ADJUSTMENT 950 ADVENTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-21 IDLE ADJUSTMENT 950 SUPERMOTO/SUPER ENDURO . . . . . . . . . . . . . . . . . .12-22 CHECK FAULT MEMORY WITH THE KTM DIAGNOSIS TOOL . . . . . . . . . . . . . . .12-22 PERFORM A STATUS CHECK USING THE KTM DIAGNOSIS TOOL . . . . . . . . . . .12-22 REPLACE THE O-RING OF THE FUEL HOSE CONNECTION . . . . . . . . . . . . . . . . .12-21 CHECKING THE COOLING SYSTEM FOR LEAKAGE AND ANTIFREEZE . . . . . . . . .12-22 CHECKING THE RADIATOR FAN FOR PROPER FUNCTIONING . . . . . . . . . . . . . .12-22 LUBRICATING THE CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-22 CHECKING THE AIR FILTER, REPLACING IF NECESSARY, CLEANING THE AIR FILTER BOX . .12-22 CHECKING THE BRAKE FLUID LEVEL, LINING THICKNESS, BRAKE DISKS . . . . .12-22 CHANGING THE BRAKE FLUID FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-23 CHANGING THE BRAKE FLUID REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-24 CHECKING THE BOLTS ON THE BRAKE SYSTEM FOR FORCE FIT . . . . . . . . . . . .12-24 CHECK ABS FAULT MEMORY WITH THE KTM DIAGNOSIS TOOL . . . . . . . . . . . .12-24 CLEANING THE DUST BOOTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-25 BLEEDING THE FORK LEGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-25 CHECKING THE SWING ARM SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-25 CHECKING/ADJUSTING THE STEERING HEAD BEARING . . . . . . . . . . . . . . . . . .12-25 CHECKING ALL CHASSIS BOLTS FOR FORCE FIT . . . . . . . . . . . . . . . . . . . . . . .12-25 CHECKING THE SPOKE TENSION AND RIM RUN-OUT . . . . . . . . . . . . . . . . . . .12-26 CHECKING THE CHAIN AND CHAIN GUIDES FOR WEAR, FORCE FIT AND TENSION . .12-26 CHECKING THE NUTS/BOLTS ON THE ENGINE SPROCKET AND THE REAR SPROCKET FOR THE SECURING AGENT AND A TIGHT FIT . . . . . . . . .12-26 CHECKING THE WHEEL BEARING AND JERK DAMPER FOR CLEARANCE . . . . . .12-26 SERVICING THE FORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-27 SERVICING THE SHOCK ABSORBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-27 CLEANING AND GREASING THE STEERING HEAD BEARING AND SEALING ELEMENTS . .12-27 CLEANING AND ADJUSTING THE CARBURETOR . . . . . . . . . . . . . . . . . . . . . . . .12-28 CHANGING THE COOLING LIQUID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-28 12 12-2 WHEELS CHASSIS BRAKES ADD-ON-PARTS CARBURETOR 15000 km or after 2 years 22500 km or after 3 years 30000 km or after 4 years 37500 km or after 5 years 45000 km or after 6 years 52500 km or after 7 years 60000 km or after 8 years Change engine oil and oil filter Clean oil screens of engine and oil tank Clean magnetic drain plugs of engine and oil tank Check oil lines for damage and kink-less arrangement Replace the oil line connection from the front valve cover to the oil tank Renew spark plugs Check the spark plug connector for a tight fit to the spark plug Check and adjust valve clearance Check engine fastening bolts for tight fit Check all engine bolts accessible from the outside for tight fit Check clutch linings Check the outer clutch hub and clutch drive for wear from the clutch disks Check clutch pressure booster system Clean the oil jet for the clutch lubrication Replace the water pump seal; check the water pump shaft for wear Check the pretensioning of the timing chain tensioner Check carburetor connection boots for cracks and leaks Check synchronisation of carburators using special tool, if necessary adjust Check idle setting (1400 rpm) Check bleeder hoses for damage and kink-free arrangement Check cooling system for leaks and antifreeze protection Check radiator fan for proper operation Check exhaust system for leaks and correct fit Check actuating cables for damage, smooth operation, and kink-less arrangement, adjust and lubricate Check the oil level in the hydraulic clutch reservoir Check air filter, renew if necessary, clean air filter box Check cables for damage and kink-less arrangement Check headlamp adjustment Check electrical system for function (low/high beams, stop light, turn indicators, headlamp flasher, tell-tale lamps, speedometer illumination, horn, sidestand switch, clutch switch, emergency-off switch) Make sure all bolts and nuts are tight Check brake fluid level, lining thickness and brake discs Change brake fluid Check brake lines for damage and leaks Check/adjust smooth operation, free travel of handbrake/footbrake levers Check the guide bolt on floating brake calipers for wear Check bolts of brake system for tight fit Check shock absorber and fork for leaks and proper operation Clean fork dust sleeves Bleed fork legs Check swingarm pivot Check/adjust steering-head bearing Check all chassis bolts for tight fit (fork clamps, fork leg, axle nuts/bolts, swinging arm pivot, shock absorber) Check spoke tension and rim joint Check tire condition and inflation pressure Check chain and chain guides for wear, force fit and tension Check bolts/nuts on pinion and chain sprocket for locking devices and a tight fit Lubricate chain Check wheel bearings and jerk damper for play Check the distance bushing and seal rings for damage or wear 7500 km or after 1 year ENGINE 950 ADVENTURE 1.Service after 1000 km PERIODIC MAINTENANCE SCHEDULE z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z IF MOTORCYCLE IS USED FOR COMPETITION 7500 KM SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE! SERVICE INTERVALLS SHOULD NEVER BE EXCEEDED BY MORE THAN 500 KM. MAINTENANCE WORK DONE BY KTM AUTHORISED WORKSHOPS IS NOT A SUBSTITUTE OF CARE AND CHECKS DONE BY THE RIDER! 12-3 PERIODIC MAINTENANCE SCHEDULE IMPORTANT MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENT ORDER at least once a year Perform complete fork maintenance Perform complete shock absorber maintenance Clean and lubricate steering-head bearing and sealing elements Clean and adjust the carburetors Treat the electrical contacts and switches with contact spray Treat battery connections with contact grease Change coolant fluid Check the wheel spindles/swing arm pivot; replace in case of damage to the surface or corrosion every 2 years or 15000 km every 4 years or 30000 km z z z z z z z z Perform a compression test 8 years/60000 km Repair manual KTM LC8 Art.-No. 3.206.056-E VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC Check oil level Check brake fluid level Check brake pads for wear Check lighting system for proper operation Check horn for proper operation Lubricate and adjust actuating cables and nipples Bleed fork legs in regular intervals Clean chain Lubricate chain Check chain tension, lubricate chain if necessary Check tire pressure and wear Check coolant level Check fuel lines for leaks Check all control elements for smooth running Check brake performance Treat exposed metal components (except for the braking and exhaust systems) with wax-based anti-corrosion agents Treat ignition/steering lock and light switch with contact spray before each start z z z z z after every cleaning every 1000 km or after off road use z z z z z z z z z z z z z z 12-4 PERIODIC MAINTENANCE SCHEDULE WHEELS CHASSIS BRAKES ADD-ON-PARTS INJECTION ENGINE 990 SUPER DUKE/R Change engine oil and oil filter Clean oil screens of engine and oil tank Clean magnetic drain plugs of engine and oil tank Check oil lines for damage and kink-less arrangement Renew spark plugs Check and adjust valve clearance Check engine fastening bolts for tight fit Check all engine bolts accessible from the outside for tight fit Check clutch linings Check clutch pressure booster system Clean the oil jet for the clutch lubrication Check rubber boot for cracks or leaks Check fault memory with the KTM diagnosis tool Perform a status check of neutral, clutch, 2nd/3rd gear and side stand switch using the KTM diagnosis tool Check the fuel hose, the vent hoses, hoses on the vacuum sensors and secondary air system hoses for correct installation, kink-free installation and damage Replace the O-ring on the fuel hose connection and check for leaks Check the wiring harness on the throttle body for proper installation and damage Check cooling system for leaks and antifreeze protection Check radiator fan for proper operation Check the exhaust system for leaks and correct suspension and the clamps for a tight fit Replace the graphite gasket in the rear exhaust manifold slide Check actuating cables for damage, smooth operation, and kink-less arrangement,adjust and lubricate Check the oil level in the hydraulic clutch reservoir Check air filter, renew if necessary, clean air filter box Check cables for damage and kink-less arrangement Check headlamp adjustment Check electrical system for function (low/high beams, stop light, turn indicators,headlamp flasher, tell-tale lamps, speedometer illumination, horn, side-stand switch, clutch switch, emergency-off switch) Make sure all bolts and nuts are tight Check brake fluid level, lining thickness, and brake discs Change brake fluid Check brake lines for damage and leaks Check/adjust smooth operation, free travel of handbrake/footbrake levers Check bolts of brake system for tight fit Check shock absorber and fork for leaks and proper operation Clean fork dust sleeves Bleed fork legs Check swingarm pivot Check/adjust steering-head bearing Check all chassis bolts for tight fit (fork plates, fork leg, axle nuts/bolts, swinging-fork pivot, reversing lever, shock absorber) Check rim joint Check tire condition and inflation pressure Check chain and chain guides for wear, force fit and tension Check bolts/nuts on pinion and chain sprocket for locking devices and a tight fit Lubricate chain Check wheel bearings and jerk damper for play 1. Service 7500 km 15000 km after or every or once 1000 km 2 years a year z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z IF MOTORCYCLE IS USED FOR COMPETITION 7500 KM SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE! SERVICE INTERVALLS SHOULD NEVER BE EXCEEDED BY MORE THAN 500 KM. MAINTENANCE WORK PERFORMED BY AN AUTHORIZED KTM WORKSHOP IS NOT A SUBSTITUTE FOR CARE AND MAINTENANCE BY THE DRIVER! 12-5 PERIODIC MAINTENANCE SCHEDULE IMPORTANT MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENT ORDER at least once a year Perform complete fork maintenance Perform complete shock absorber maintenance Clean and lubricate steering-head bearing and sealing elements Treat the electrical contacts and switches with contact spray Treat battery connections with contact grease Change coolant fluid every 2 years or 15000 km z z z z z z Repair manual KTM LC8 Art.-No. 3.206.056-E VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC Check oil level Check brake fluid level Check brake pads for wear Check lighting system for proper operation Check horn for proper operation Lubricate and adjust actuating cables and nipples Clean chain Lubricate chain Check chain tension, lubricate chain if necessary Check tire pressure and wear Check coolant level Check fuel lines for leaks Check all control elements for smooth running Grease the hand brake lever and clutch lever Check brake performance Treat exposed metal components (except for the braking and exhaust systems) with wax-based anti-corrosion agents Treat ignition/steering lock and light switch with contact spray before each start z z z z z after every cleaning every 1000 km z z z z z z z z z z z z z z 12-6 PERIODIC MAINTENANCE SCHEDULE WHEELS CHASSIS BRAKES ADD-ON-PARTS CARBURETOR ENGINE 950 SUPERMOTO/R Change engine oil and oil filter Clean oil screens of engine and oil tank Clean magnetic drain plugs of engine and oil tank Check oil lines for damage and kink-less arrangement Renew spark plugs Check and adjust valve clearance Check engine fastening bolts for tight fit Check all engine bolts accessible from the outside for tight fit Check clutch linings Check clutch pressure booster system Clean the oil jet for the clutch lubrication Check carburetor connection boots for cracks and leaks Check synchronisation of carburators using special tool, if necessary adjust Check idle setting (1400 rpm) Check bleeder hoses for damage and kink-free arrangement Check cooling system for leaks and antifreeze protection Check radiator fan for proper operation Check exhaust system for leaks and correct fit Replace the graphite gasket in the rear exhaust manifold slide Check actuating cables for damage, smooth operation, and kink-less arrangement,adjust and lubricate Check the oil level in the hydraulic clutch reservoir Check air filter, renew if necessary, clean air filter box Check cables for damage and kink-less arrangement Check headlamp adjustment Check electrical system for function (low/high beams, stop light, turn indicators,headlamp flasher, tell-tale lamps, speedometer illumination, horn, side-stand switch, clutch switch, emergency-off switch) Make sure all bolts and nuts are tight Check brake fluid level, lining thickness, and brake discs Change brake fluid Check brake lines for damage and leaks Check/adjust smooth operation, free travel of handbrake/footbrake levers Check bolts of brake system for tight fit Check shock absorber and fork for leaks and proper operation Clean fork dust sleeves Bleed fork legs Check swingarm pivot Check/adjust steering-head bearing Check all chassis bolts for tight fit (fork plates, fork leg, axle nuts/bolts, swinging-fork pivot, reversing lever, shock absorber) Check rim joint Check tire condition and inflation pressure Check chain and chain guides for wear, force fit and tension Check bolts/nuts on pinion and chain sprocket for locking devices and a tight fit Lubricate chain Check wheel bearings and jerk damper for play 1. Service 7500 km or 15000 km or after every once 1000 km 2 years a year z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z IF MOTORCYCLE IS USED FOR COMPETITION 7500 KM SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE! SERVICE INTERVALLS SHOULD NEVER BE EXCEEDED BY MORE THAN 500 KM. MAINTENANCE WORK DONE BY KTM AUTHORISED WORKSHOPS IS NOT A SUBSTITUTE OF CARE AND CHECKS DONE BY THE RIDER! 12-7 PERIODIC MAINTENANCE SCHEDULE IMPORTANT MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENT ORDER at least once a year Perform complete fork maintenance Perform complete shock absorber maintenance Clean and lubricate steering-head bearing and sealing elements Clean and adjust the carburetors Treat the electrical contacts and switches with contact spray Treat battery connections with contact grease Change coolant fluid every 2 years or 15000 km z z z z z z z Repair manual KTM LC8 Art.-No. 3.206.056-E VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC Check oil level Check brake fluid level Check brake pads for wear Check lighting system for proper operation Check horn for proper operation Lubricate and adjust actuating cables and nipples Bleed fork legs in regular intervals Clean chain Lubricate chain Check chain tension, lubricate chain if necessary Check tire pressure and wear Check coolant level Check fuel lines for leaks Check all control elements for smooth running Check brake performance Treat exposed metal components (except for the braking and exhaust systems) with wax-based anti-corrosion agents Treat ignition/steering lock and light switch with contact spray before each start z z z z z after every cleaning every 1000 km z z z z z z z z z z z z z z 12-8 PERIODIC MAINTENANCE SCHEDULE WHEELS CHASSIS BRAKES ADD-ON-PARTS INJECTION ENGINE 990 ADVENTURE Change engine oil and oil filter Clean oil screens of engine and oil tank Clean magnetic drain plugs of engine and oil tank Check oil lines for damage and kink-less arrangement Renew spark plugs Check and adjust valve clearance Check engine fastening bolts for tight fit Check all engine bolts accessible from the outside for tight fit Check clutch linings Check clutch pressure booster system Clean the oil jet for the clutch lubrication Check rubber boot for cracks or leaks Check fault memory with the KTM diagnosis tool Perform a status check of neutral, clutch, 2nd/3rd gear and side stand switch using the KTM diagnosis tool Check the fuel hose, the vent hoses, hoses on the vacuum sensors and secondary air system hoses for correct installation, kink-free installation and damage Replace the O-ring on the fuel hose connection and check for leaks Check the wiring harness on the throttle body for proper installation and damage Check cooling system for leaks and antifreeze protection Check radiator fan for proper operation Check exhaust system for leaks and correct fit Check actuating cables for damage, smooth operation, and kink-less arrangement,adjust and lubricate Check the oil level in the hydraulic clutch reservoir Check air filter, renew if necessary, clean air filter box Check cables for damage and kink-less arrangement Check headlamp adjustment Check electrical system for function (low/high beams, stop light, turn indicators,headlamp flasher, tell-tale lamps, speedometer illumination, horn, side-stand switch, clutch switch, emergency-off switch) Make sure all bolts and nuts are tight Check brake fluid level, lining thickness, and brake discs Change brake fluid Check brake lines for damage and leaks Check/adjust smooth operation, free travel of handbrake/footbrake levers Check bolts of brake system for tight fit Check ABS fault memory with the KTM diagnosis tool Check shock absorber and fork for leaks and proper operation Clean fork dust sleeves Bleed fork legs Check swingarm pivot Check/adjust steering-head bearing Check all chassis bolts for tight fit (fork plates, fork leg, axle nuts/bolts, swinging-fork pivot, reversing lever, shock absorber) Check spoke tension and rim joint Check tire condition and inflation pressure Check chain and chain guides for wear, force fit and tension Check bolts/nuts on pinion and chain sprocket for locking devices and a tight fit Lubricate chain Check wheel bearings and jerk damper for play 1. Service 7500 km or 15000 km or after every once 1000 km 2 years a year z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z IF MOTORCYCLE IS USED FOR COMPETITION 7500 KM SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE! SERVICE INTERVALLS SHOULD NEVER BE EXCEEDED BY MORE THAN 500 KM. MAINTENANCE WORK DONE BY KTM AUTHORISED WORKSHOPS IS NOT A SUBSTITUTE OF CARE AND CHECKS DONE BY THE RIDER! 12-9 PERIODIC MAINTENANCE SCHEDULE IMPORTANT MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENT ORDER at least once a year Perform complete fork maintenance Perform complete shock absorber maintenance Clean and lubricate steering-head bearing and sealing elements Treat the electrical contacts and switches with contact spray Treat battery connections with contact grease Change coolant fluid every 2 years or 15000 km z z z z z z Repair manual KTM LC8 Art.-No. 3.206.056-E VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC Check oil level Check brake fluid level Check brake pads for wear Check lighting system for proper operation Check horn for proper operation Lubricate and adjust actuating cables and nipples Bleed fork legs in regular intervals Clean chain Lubricate chain Check chain tension, lubricate chain if necessary Check tire pressure and wear Check coolant level Check fuel lines for leaks Check all control elements for smooth running Check brake performance Treat exposed metal components (except for the braking and exhaust systems) with wax-based anti-corrosion agents Treat ignition/steering lock and light switch with contact spray before each start z z z z z after every cleaning every 1000 km or after off road use z z z z z z z z z z z z z z 12-10 PERIODIC MAINTENANCE SCHEDULE WHEELS CHASSIS BRAKES ADD-ON-PARTS INJECTION ENGINE 990 SUPERMOTO Change engine oil and oil filter Clean oil screens of engine and oil tank Clean magnetic drain plugs of engine and oil tank Check oil lines for damage and kink-less arrangement Renew spark plugs Check and adjust valve clearance Check engine fastening bolts for tight fit Check all engine bolts accessible from the outside for tight fit Check clutch linings Check clutch pressure booster system Clean the oil jet for the clutch lubrication Check rubber boot for cracks or leaks Check fault memory with the KTM diagnosis tool Perform a status check of neutral, clutch, 2nd/3rd gear and side stand switch using the KTM diagnosis tool Check the fuel hose, the vent hoses, hoses on the vacuum sensors and secondary air system hoses for correct installation, kink-free installation and damage Replace the O-ring on the fuel hose connection and check for leaks Check the wiring harness on the throttle body for proper installation and damage Check cooling system for leaks and antifreeze protection Check radiator fan for proper operation Check exhaust system for leaks and correct fit Check actuating cables for damage, smooth operation, and kink-less arrangement,adjust and lubricate Check the oil level in the hydraulic clutch reservoir Check air filter, renew if necessary, clean air filter box Check cables for damage and kink-less arrangement Check headlamp adjustment Check electrical system for function (low/high beams, stop light, turn indicators,headlamp flasher, tell-tale lamps, speedometer illumination, horn, side-stand switch, clutch switch, emergency-off switch) Make sure all bolts and nuts are tight Check brake fluid level, lining thickness, and brake discs Change brake fluid Check brake lines for damage and leaks Check/adjust smooth operation, free travel of handbrake/footbrake levers Check bolts of brake system for tight fit Check shock absorber and fork for leaks and proper operation Clean fork dust sleeves Bleed fork legs Check swingarm pivot Check/adjust steering-head bearing Check all chassis bolts for tight fit (fork plates, fork leg, axle nuts/bolts, swinging-fork pivot, reversing lever, shock absorber) Check rim joint Check tire condition and inflation pressure Check chain and chain guides for wear, force fit and tension Check bolts/nuts on pinion and chain sprocket for locking devices and a tight fit Lubricate chain Check wheel bearings and jerk damper for play 1. Service 7500 km or 15000 km or after every once 1000 km 2 years a year z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z IF MOTORCYCLE IS USED FOR COMPETITION 7500 KM SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE! SERVICE INTERVALLS SHOULD NEVER BE EXCEEDED BY MORE THAN 500 KM. MAINTENANCE WORK DONE BY KTM AUTHORISED WORKSHOPS IS NOT A SUBSTITUTE OF CARE AND CHECKS DONE BY THE RIDER! 12-11 PERIODIC MAINTENANCE SCHEDULE IMPORTANT MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENT ORDER at least once a year Perform complete fork maintenance Perform complete shock absorber maintenance Clean and lubricate steering-head bearing and sealing elements Treat the electrical contacts and switches with contact spray Treat battery connections with contact grease Change coolant fluid every 2 years or 15000 km z z z z z z Repair manual KTM LC8 Art.-No. 3.206.056-E VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC Check oil level Check brake fluid level Check brake pads for wear Check lighting system for proper operation Check horn for proper operation Lubricate and adjust actuating cables and nipples Bleed fork legs in regular intervals Clean chain Lubricate chain Check chain tension, lubricate chain if necessary Check tire pressure and wear Check coolant level Check fuel lines for leaks Check all control elements for smooth running Check brake performance Treat exposed metal components (except for the braking and exhaust systems) with wax-based anti-corrosion agents Treat ignition/steering lock and light switch with contact spray before each start z z z z z after every cleaning every 1000 km or after off road use z z z z z z z z z z z z z z 12-12 PERIODIC MAINTENANCE SCHEDULE WHEELS CHASSIS BRAKES ADD-ON-PARTS CARBURETOR ENGINE 950 SUPER ENDURO Change engine oil and oil filter Clean oil screens of engine and oil tank Clean magnetic drain plugs of engine and oil tank Check oil lines for damage and kink-less arrangement Renew spark plugs Check and adjust valve clearance Check engine fastening bolts for tight fit Check all engine bolts accessible from the outside for tight fit Check clutch linings Check clutch pressure booster system Clean the oil jet for the clutch lubrication Check carburetor connection boots for cracks and leaks Check synchronisation of carburators using special tool, if necessary adjust Check idle setting (1400 rpm) Check bleeder hoses for damage and kink-free arrangement Check cooling system for leaks and antifreeze protection Check radiator fan for proper operation Check exhaust system for leaks and correct fit Check actuating cables for damage, smooth operation, and kink-less arrangement,adjust and lubricate Check the oil level in the hydraulic clutch reservoir Check air filter, renew if necessary, clean air filter box Check cables for damage and kink-less arrangement Check headlamp adjustment Check electrical system for function (low/high beams, stop light, turn indicators,headlamp flasher, tell-tale lamps, speedometer illumination, horn, side-stand switch, clutch switch, emergency-off switch) Make sure all bolts and nuts are tight Check brake fluid level, lining thickness, and brake discs Change brake fluid Check brake lines for damage and leaks Check/adjust smooth operation, free travel of handbrake/footbrake levers Check bolts of brake system for tight fit Check shock absorber and fork for leaks and proper operation Clean fork dust sleeves Bleed fork legs Check swingarm pivot Check/adjust steering-head bearing Check all chassis bolts for tight fit (fork plates, fork leg, axle nuts/bolts, swinging-fork pivot, reversing lever, shock absorber) Check spoke tension and rim joint Check tire condition and inflation pressure Check chain and chain guides for wear, force fit and tension Check bolts/nuts on pinion and chain sprocket for locking devices and a tight fit Lubricate chain Check wheel bearings and jerk damper for play 1. Service 7500 km or 15000 km or after every once 1000 km 2 years a year z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z z IF MOTORCYCLE IS USED FOR COMPETITION 7500 KM SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE! SERVICE INTERVALLS SHOULD NEVER BE EXCEEDED BY MORE THAN 500 KM. MAINTENANCE WORK DONE BY KTM AUTHORISED WORKSHOPS IS NOT A SUBSTITUTE OF CARE AND CHECKS DONE BY THE RIDER! 12-13 PERIODIC MAINTENANCE SCHEDULE IMPORTANT MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENT ORDER at least once a year Perform complete fork maintenance Perform complete shock absorber maintenance Clean and lubricate steering-head bearing and sealing elements Clean and adjust the carburetors Treat the electrical contacts and switches with contact spray Treat battery connections with contact grease Change coolant fluid every 2 years or 15000 km z z z z z z z VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC Repair manual KTM LC8 Art.-No. 3.206.056-E before each start Check oil level Check brake fluid level Check brake pads for wear Check lighting system for proper operation Check horn for proper operation Lubricate and adjust actuating cables and nipples Bleed fork legs in regular intervals Clean chain Lubricate chain Check chain tension, lubricate chain if necessary Check tire pressure and wear Check coolant level Check fuel lines for leaks Check all control elements for smooth running Check brake performance Treat exposed metal components (except for the braking and exhaust systems) with wax-based anti-corrosion agents Treat ignition/steering lock and light switch with contact spray Check spoke tension (sound test) Check the rims for damage and deformation Check exhaust system for leaks and correct fit Check air filter, renew if necessary, clean air filter box Check shock absorber and fork for leaks and proper operation Clean fork dust sleeves after every cleaning every 1000 after off road km use z z z z z z z z z z z z z z z z z z z z z z z z z z z z 12-14 Lubrication and maintenance work - engine Changing the engine oil and filter, cleaning the oil screens and magnets on the drain plugs NOTE: Change the engine oil when the engine is at operating temperature. WARNING THE ENGINE AND ENGINE OIL ARE VERY HOT AT OPERATING TEMPERATURE CAREFUL NOT TO BURN YOURSELF. – BE NOTE: before you start with the lubricating and maintenance work described below, remove the engine guard, seat and both tanks (950/990 Adventure), the seat, both tank covers and the front spoiler for the 990 Super Duke model or the seat, tank and the spoiler for the 950 Supermoto; also tilt up the tank for the 990 Super Duke (see Chapter 3). The vehicle must be jacked up with the corresponding special tool. After you finish, assemble the vehicle in the reverse order. 1 – Remove the oil drain plug on the engine 1 and allow the oil to drain into a receptacle. – Clean the magnet on the drain plug. – Mount a new seal ring on the drain plug, screw back in and tighten to 35 Nm. – Unscrew the oil drain plug 2 on the oil tank and allow the oil to drain into a receptacle. NOTE: dispose of the used oil properly. Do not pour the used oil into the sewer system. 1 liter of used oil will pollute 1,000,000 liters of water. – Clean the magnet on the drain plug. – Mount a new seal ring on the drain plug, screw back in and tighten to 25 Nm. 2 4 3 – Remove the oil screen cover 3 and carefully pull out the oil screen 4 with a pair of pliers. – Clean the oil screen, remount with the TOP mark facing up and mount the cover. – Remove the oil filter cover 5 and pull the engine out of the engine case with circlip pliers (upside-down). 5 – Insert a new oil filter in the engine case, grease the O-ring and mount the oil filter cover together with the O-ring. Tighten the bolts to 6 Nm. ! ONLY USE ORIGINAL FILTERS ARE USED. KTM CAUTION THE ENGINE OIL FILTERS. ! CAN BE DAMAGED IF OTHER 12-15 – Remove both bolts 1 from the oil tank connection 2 and tilt the oil tank aside together with the oil return valve. – Remove the screen and cleanse. Adventure/Super Duke 2 1 1 Supermoto 2 1 – Grease the seal ring and carefully slide the oil screen into the oil tank. Position the oil tank connection together with the oil return valve, mount the bolts and tighten to 10 Nm. Art.-No. 3.206.056-E Adventure/Super Duke Supermoto Repair manual KTM LC8 Engine oil JASO T903 MA TEMPERATUR 0°C 32°F 5W/40 10W/50 Automobile engine oil used to be used for four-stroke motorcycles before there were separate motorcycle specifications. Different technical developments made it necessary to have a separate specification for four-stroke motorcycles - the JASO T903 MA standard. Whereas car engines require long changing intervals, motorcycle engines require a higher power output at higher speeds. Most motorcycle engines also use the same oil to lubricate the transmission and the clutch. The JASO MA standard responds to these special requirements. Only use fully synthetic engine oils that meet the JASO MA quality requirements (see information on the can). KTM recommends Motorex Power Synt 4T in the 10W/50 viscosity (for temperatures over 0°C) or 5W/40 (for temperatures under 0°C). – Fill approx. 2.7 liters of engine oil into the oil tank. The oil tank will be filled up to the top. – Start the engine and allow to idle for about one minute without accelerating. – Switch off the engine and pour another 0.3 liters into the oil tank. Check the oil system for leakage. ! DO CAUTION ! NOT REV UP THE ENGINE RIGHT AFTER CHANGING THE OIL SINCE ALL OF THE LUBRICATING POINTS WILL NOT BE SUPPLIED WITH ENOUGH OIL YET. 12-16 Checking the engine oil level 1 Check the engine oil level when the engine is warm (at least 4 bars on the temperature indicator will light up). Place the motorcycle on a level surface (not on the side stand). Turn off the engine, unscrew the oil dipstick 1 and wipe off with a cloth. Screw the oil dipstick all the way back in and back out again. The oil level should fall between the lower end of the oil dipstick (MIN) and the MAX mark. The oil capacity between the MIN and MAX mark is 0.5 liters. For engines with an inspection pipe, the oil level should be between the MIN and MAX marks. Add more engine oil if necessary and check the engine for leakage. ! CAUTION ! ENOUGH ENGINE OIL OR LOW-QUALITY OIL WILL LEAD TO PREMATURE ENGINE WEAR. DO NOT EXCEED THE MAXIMUM LEVEL. DO NOT ALLOW TO FALL BELOW THE MINIMUM LEVEL. – NOT – – MAX MIN Replacing the spark plugs NOTE: the carburetors are dismounted during the 15000 km inspection to check/adjust the valve clearance. This work is described in Chapter 3 and will not be described in detail at this point. 2 – Disconnect the cable connectors (2 and 3) from both ignition coils. – Dismount the throttle body (see Chapter 3). – Pull the ignition coils out of the spark plug shafts. – Unscrew the spark plugs with the special tool 600.29.073.000. 3 – Check the new spark plugs for the correct electrode distance. The distance should be 0.7 mm (Carburator) and 0.8 (Injection). – Insert new spark plugs with the special tool 600.29.073.000 and tighten to 12 Nm (M10) or 20 Nm (M12x1.5). ! DO CAUTION ! NOT EXCEED THE FIXED TORQUE SINCE SPARK PLUGS BREAK EASILY. – Insert the ignition coils in the spark plug shafts and push to the stop by hand. NOTE: if you are checking the valve clearance, insert the ignition coils later. ! CAUTION ! – DO NOT INSTALL THE IGNITION COILS WITH A HAMMER OR SIMILAR TOOL. – TURN THE CONNECTIONS ON THE IGNITION COILS SO THEY DO NOT COME CLOSE TO THE VALVE COVER BOLTS (SEE PHOTOS) SINCE THIS COULD CAUSE ELECTROMAGNETIC INTERFERENCE. – Connect the cable connectors to both ignition coils. 12-17 Checking and adjusting the valve clearance NOTE: to make it easier to work on the front cylinder, remove the 4 radiator retaining bolts and pull the radiator forward. 2 1 1 2 – Pull the EPC valve on the front cylinder from the bracket. – Disconnect the ignition coil connectors 1 and pull the ignition coils out. – Push back the spring-loaded band-type clamps 2 with the special pliers 600.29.057.100 and pull the vent hoses from the valve cover connections. – Remove both valve covers and the gaskets. – Remove the plug 3, turn the crankshaft to the rear cylinder TDC position and lock with special tool 0113 080802 4. In the TDC position, the cams of the rear cylinder must point towards the inside and the crosses on the camshaft gears must coincide with the plane outer surface of the cylinder head (see Chapter 4). 3 4 Art.-No. 3.206.056-E – Check the valve clearance with the feeler gauge. The minimum clearance when the engine is cold should be 0.10 – 0.15 mm (intake) and 0.25 – 0.30 mm (exhaust). NOTE: if the valve clearance is incorrect for one or more valves, measure how large the deviation is. Use thinner or thicker compensating washers depending on whether the valve clearance is too small or too large. – Dismount the camshafts (see Chapter 4) and correct the thickness of the shims. NOTE: compensating shims from 1.85 mm to 3.20 mm are available in graduations of 0.05 mm – Unscrew the locking bolt, turn the engine to the TDC position of the front cylinder and lock again (see Chapter 4). – Check the valve clearance of the front cylinder and adjust if necessary - See table on page 12-16 and 12-17 for a list of the required shims. NOTE: the procedure for the front cylinder is the same as for the rear cylinder. Repair manual KTM LC8 – Mount the EPC valve. ! CAUTION ! THE RETAINING CLIP FOR THE FRONT EPC VALVE IS BENT, THE EPC VALVE WILL BE ABLE TO TOUCH THE FRAME. THE ENGINE VIBRATIONS CAN CAUSE IT TO OPEN SLIGHTLY, RESULTING IN A LACK OF POWER FOR THE ENTIRE SPEED RANGE. IF – Mount both valve covers. – Connect the vent hoses to the connections on the valve covers and attach the spring-loaded band-type clamps 1 with the special pliers 600.29.057.100. – Mount the ignition coils and connect the connector. – Screw the radiator back on. - - 0,06 - 0,10 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,95 3,00 3,05 3,10 3,15 3,20 3,00 3,05 3,10 3,15 3,20 3,05 3,10 3,15 3,20 3,10 3,15 3,20 3,15 3,20 3,20 0,21 - 0,25 0,26 - 0,30 0,31 - 035 0,36 - 0,40 0,41 - 0,45 0,46 - 0,50 0,51 - 0,55 0,56 - 0,60 0,61 - 0,65 0,66 - 0,70 0,71 - 0,75 0,76 - 0,80 0,81 - 0,85 0,86 - 0,90 0,91 - 0,95 0,96 - 1,00 1,01 - 1,05 1,06 - 1,10 1,11 - 1,15 1,16 - 1,20 1,21 - 1,25 1,26 - 1,30 1,31 - 1,35 1,36 - 1,40 1,41 - 1,45 1,46 - 1,50 New shim required: 2.55 mm Measured valve clearance: 0.48 mm Demounted shim: 2.20 mm Specified valve clearance: 0.10 - 0.15 mm NOTE to example: 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 Specified valve clearance - no correction required 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 - 0,16 - 0,20 0,10 - 0,15 Number/thickness of the demounted compensating washer(shim)in mm 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 0,00 - 0,05 Measured valve clearance (mm) INTAKE 12-18 - - - - - 0,06 - 0,10 0,11 - 0,15 0,16 - 0,20 0,21 - 0,25 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 - 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 - - 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 - - - 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,90 2,95 3,00 3,05 3,10 3,15 3,20 2,95 3,00 3,05 3,10 3,15 3,20 3,00 3,05 3,10 3,15 3,20 3,05 3,10 3,15 3,20 0,36 - 0,40 0,41 - 0,45 0,46 - 0,50 0,51 - 0,55 0,56 - 0,60 0,61 - 0,65 0,66 - 0,70 0,71 - 0,75 0,76 - 0,80 0,81 - 0,85 0,86 - 0,90 0,91 - 0,95 0,96 - 1,00 1,01 - 1,05 1,06 - 1,10 1,11 - 1,15 1,16 - 1,20 1,21 - 1,25 1,26 - 1,30 1,31 - 1,35 1,36 - 1,40 1,41 - 1,45 1,46 - 1,50 New shim required: 2.40 mm Measured valve clearance: 0.48 mm Demounted shim: 2.20 mm Specified valve clearance: 0,25 - 0,30 mm NOTE to example: 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 Specified valve clearance - no correction required 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 - - - - 0,31 - 035 0,25 - 0,30 Number/thickness of the demounted compensating washer(shim)in mm Art.-No. 3.206.056-E 1,85 1,90 1,95 2,00 2,05 2,10 2,15 2,20 2,25 2,30 2,35 2,40 2,45 2,50 2,55 2,60 2,65 2,70 2,75 2,80 2,85 2,90 2,95 3,00 3,05 3,10 3,15 3,20 0,00 - 0,05 Measured valve clearance (mm) EXHAUST Repair manual KTM LC8 12-19 12-20 Checking the clutch lining – Remove the lock clip on the foot brake lever bolt and pull out the bolt. – Loosen the bearing bolt on the foot brake lever and remove the foot brake lever. – Dismount the clutch lining (see Chapter 4). – Measure the total height of the clutch disk package (all of the lining disks and steel disks together) Wear limit: 48.0 mm – Check the clutch disks for damage (breakage, recesses). Checking the clutch pressure booster system – Check the outer and inner part for wear and breakage, especially near the pressure areas 1 and the toothing 2. 1 1 1 – Assemble the clutch again (see Chapter 6). 1 2 – Mount the foot brake lever, secure the bearing bolt with Loctite 243 and tighten to 25 Nm. – Mount the foot brake lever bolt and attach the lock clip. Cleaning the oil jet for the clutch lubrication – Remove the clutch cylinder, engine sprocket cover and chain securing guide. – Remove the AH plug 3 (6 mm) for the clutch lubrication. 3 4 – Unscrew the oil jet 4 with a suitable screwdriver. – Remove the oil jet from the hole with a pair of tweezers or compressed air. – Clean and blow compressed air through the oil jet. Check for damage and make sure it is not clogged. – Remount the oil jet and the AH plug (tightening torque 15 Nm). – Remount the clutch cylinder, engine sprocket cover and chain securing guide. 12-21 LUBRICATION AND MAINTENANCE WORK – CARBURETOR Check the carburetor synchronization with an vacuum gauge and adjust if necessary 2 – Disconnect the vacuum hoses from the air filter box 1 and from the secondary air system valve 2 and run up on the side between the frame and the air filter box. – Mount both tanks and connect the fuel lines, open the fuel taps. NOTE: before you use the special tool 600.29.011.000, always check both dial gauges for synchronism: – Connect both dial gauges to one cylinder with the vacuum hoses and a T-fitting. – Tighten the knurled nuts on the special tool by turning them in a clockwise direction almost to the stop. – Start the engine and unscrew the two knurled nuts until the dials barely begin to vibrate. You should still be able to read the gauge clearly. Both dial gauges should indicate the same value. If not, the special tool is damaged and should not be used. – Turn off the engine, disconnect the hoses and the T-fitting. 1 ! CAUTION ! THE FOLLOWING RULES ARE NOT OBSERVED, THE MEASURING MECHANISM IN THE SPECIAL TOOL WILL BE DAMAGED OR DESTROYED: – ADJUST THE DAMPING FIRST, THEN START THE ENGINE. – DO NOT DROP THE SPECIAL TOOL. – DO NOT RUN THE ENGINE WITH DEFECTIVE CARBURETORS (RISK OF THE ENGINE MISFIRING). IF Art.-No. 3.206.056-E – Connect each dial gauge on the special tool to a cylinder. You can also use the on-board hoses (see photo). – Tighten the knurled nuts again (also adjust stiff damping). – Start the engine and unscrew both knurled nuts until the dials barely begin to vibrate. You should still be able to read the gauge clearly. Both dial gauges should indicate the same value. If not, dismount the air filter and turn the synchronization screw 3 on the carburetor linkage until the dial gauges indicate a value of +/- 0.03 bar. 3 NOTE: before making the adjustment, make sure the cold-start system (choke) is completely closed and the engine is at operating temperature. Repair manual KTM LC8 – Remove the vacuum gauge and connect the vacuum hoses to the secondary air system valve or to the air filter box again. Checking the idle setting (950 Adventure) – Set the idle speed to 1400 rpm. 4 NOTE: – before make the adjustment, make sure the cold-start system (choke) is completely closed and the engine has reached operating temperature. – If the idle speed deviates from the set-point value, correct the value with the adjusting screw 4: turning in a clockwise direction will increase the idle speed, turning in a counterclockwise direction will decrease the idle speed. 12-22 Checking the idle setting (950 Supermoto/Super Enduro) – Pull the ignition coil for the rear cylinder from the spark plug. – Attach the intermediate adapter for the ignition cable 625.29.093.000 1 to the spark plug and ignition coil. – Measure the idle speed with the tachometer 451.29.075.000 2 or a shop tester and adjust to 1400 rpm. 2 1 NOTE: – before make the adjustment, make sure the cold-start system (choke) is completely closed and the engine has reached operating temperature. – If the idle speed deviates from the set-point value, correct the value with the adjusting screw: turning in a clockwise direction will increase the idle speed, turning in a counterclockwise direction will decrease the idle speed. LUBRICATION AND MAINTENANCE WORK - INJECTION Check the fault memory with the KTM diagnostics tool See KTM diagnostics tool operating instructions Scan the status of the neutral, clutch, 2nd/3rd gear and side stand switch using the KTM diagnostics tool See KTM diagnostics tool operating instructions Replacing the O-ring on the fuel hose connector 3 Disconnect the fuel hose connector (see Chapter 8), remove the O-ring 3, carefully mount a new O-ring and connect the hose connector again. Turn on the ignition , the fuel pump will start up and build up pressure. Check the connection for leakage. NOTE: Do not connect the hose connection until the tank no longer needs to be folded up for servicing. LUBRICATION AND MAINTENANCE WORK – ADD-ON PARTS Checking the cooling system for leakage and the antifreeze concentration – Check the cooling liquid level in the radiator and in the compensating tank. Fill up if necessary (see Owner's Manual). – Check the antifreeze concentration with a suitable gauge. The antifreeze concentration should be 50% antifreeze and 50% destilled water (at least -25ºC). NOTE: if the cooling liquid level is far below the minimum mark, check for leakage. Checking the radiator fan for proper functioning. – Following the test drive, let the engine run idle until the fan switches on. ! WATCH CAUTION ! THE TEMPERATURE INDICATOR FOR THE COOLING LIQUID TO AVOID ENGINE DAMAGE IN CASE THE RADIATOR FAN IS DEFECTIVE. Lubricating the cables NOTE: only use lubricants that are free of resin and acid otherwise they can destroy the inner cable coating and cause the cable to block. Do not use MoS2 spray. Checking the air filter, replacing if necessary, cleaning the air filter box – See Chapter 3 for dismounting the air filter. NOTE: the air filter insert cannot be cleaned and should be replaced when soiled. Do not use filter oil. – When mounting the filter, proceed in the reverse order used to dismount. LUBRICATION AND MAINTENANCE WORK - BRAKES Checking the brake fluid level, lining thickness, brake disks – See Owner's Manual 12-23 Changing the front brake fluid – Open the brake fluid reservoir 1. 1 – Use a syringe to extract the used brake fluid and add fresh DOT 5.1 brake fluid (Motorex Brake Fluid DOT 5.1). – Press the front brake caliper pistons all the way back (950/990 Adventure only). – Use a commercial extractor (shop equipment) to extract the used brake fluid out of the system through the bleeder screw 2 on the left brake caliper. Make sure the brake fluid reservoir is always filled with enough fresh brake fluid. – Tighten the bleeder screw again. Art.-No. 3.206.056-E 2 – Now extract the used brake fluid through the bleeder screw 3 on the right brake caliper, also making sure there is always enough fresh brake fluid in the brake fluid reservoir. – Tighten the bleeder screw again. 3 950/990 Adventure: – Move the hand brake cylinder into a horizontal position and add DOT 5.1 brake fluid (Motorex Brake Fluid DOT 5.1) up to 5 mm under the top edge of the reservoir. Remount the rubber boot, cover and screws. 950 Supermoto/990 Super Duke: – Fill the brake fluid reservoir up to the "max" mark 4 and close again. 5 mm – Wash off any overflowing or spilled brake fluid with water. ! CAUTION ! USE DOT 5 BRAKE FLUID. IT IS BASED ON SILICONE OIL AND DYED PURPLE. GASKETS AND BRAKE HOSES WILL BE DAMAGED IF DOT 5 BRAKE FLUID IS USED. BRAKE FLUID CAN CAUSE SKIN IRRITATIONS. AVOID COMING INTO CONTACT WITH THE SKIN OR EYES. IF BRAKE FLUID SPLASHES INTO YOUR EYES, RINSE THOROUGHLY WITH WATER AND CONSULT A DOCTOR. MAKE SURE NO BRAKE FLUID COMES INTO CONTACT WITH PAINTED PARTS SINCE BRAKE FLUID WILL CORRODE THE PAINTWORK. ONLY USE CLEAN, NEW BRAKE FLUID FROM TIGHTLY SEALED CONTAINERS. – NEVER Repair manual KTM LC8 – – – – Actuate the hand brake lever until you feel the point of pressure. 4 NOTE to the ABS system: allow at least 3 full brake fluid reservoirs to pump through to make sure no air is left in the system. 12-24 Changing the rear brake fluid 1 – Unscrew the cover on the brake fluid reservoirs 1 and remove together with the diaphragm 2. – Use a syringe to extract the used brake fluid and add fresh DOT 5.1 brake fluid (Motorex Brake Fluid DOT 5.1). – Press the brake caliper pistons all the way back. 2 3 12 mm – Use a commercial extractor (shop equipment) to extract the used brake fluid out of the system through the bleeder screw 3 on the brake caliper. Make sure the brake fluid reservoir is always filled with enough fresh brake fluid. – Tighten the bleeder screw again. – Add DOT 5.1 brake fluid (Motorex Brake Fluid DOT 5.1) up to 12 mm under the top edge of the reservoir. Remount the rubber boot, cover and screws. Wash off any overflowing or spilled brake fluid with water. ! CAUTION ! USE DOT 5 BRAKE FLUID. IT IS BASED ON SILICONE OIL AND DYED PURPLE. GASKETS AND BRAKE HOSES WILL BE DAMAGED IF DOT 5 BRAKE FLUID IS USED. BRAKE FLUID CAN CAUSE SKIN IRRITATIONS. AVOID COMING INTO CONTACT WITH THE SKIN OR EYES. IF BRAKE FLUID SPLASHES INTO YOUR EYES, RINSE THOROUGHLY WITH WATER AND CONSULT A DOCTOR. MAKE SURE NO BRAKE FLUID COMES INTO CONTACT WITH PAINTED PARTS SINCE BRAKE FLUID WILL CORRODE THE PAINTWORK. ONLY USE CLEAN, NEW BRAKE FLUID FROM TIGHTLY SEALED CONTAINERS. – NEVER – – – – Actuate the foot brake lever until you feel the point of pressure. NOTE to the ABS system: see Technical Information to replace the brake fluid /bleed the brake system. Checking the bolts on the brake system for force fit NOTE: check the bolts listed below with a torque wrench. If a bolt is not tightened to the specified torque (if it can easily be screwed in further), remove the bolt, clean, secure with Loctite 243 and tighten to the correct torque (see technical data). Check ABS fault memory with the KTM diagnosis tool see chapter 7 12-25 LUBRICATION AND MAINTENANCE WORK - CHASSIS Cleaning the dust boots – See Owner's Manual Bleeding the fork legs – See Owner's Manual Checking the swing arm support – Try to move the rear wheel to each side in an unloaded condition. You should not feel any clearance NOTE: – If you feel any clearance, check whether the swing arm support is worn or the wheel bearing is defective. – See Chapter 10 to replace the swing arm support or the wheel bearing. Checking/adjusting the steering head bearing Art.-No. 3.206.056-E – Try to move the fork back and forth in an unloaded condition. – If you feel any clearance, loosen the 5 clamp bolts on the top triple clamp and turn in the blind nut 1 until no clearance is left. 1 NOTE: do not tighten the blind nut since you may damage the bearing. – Gently tap on the top triple clamp with a plastic hammer to relieve any distortion and tighten the 5 clamp bolts (tigtening torques see technical data). Repair manual KTM LC8 Checking all chassis bolts for force fit NOTE: check the bolts listed below with a torque wrench. If a bolt secured with Loctite 243 is not tightened to the specified torque (if it can easily be screwed in further), remove the bolt, clean, secure with Loctite 243 and tighten to the correct torque. 12-26 LUBRICATION AND MAINTENANCE WORK - WHEELS Checking the spoke tension and rim run-out – Spoke nipple: 5 Nm – maximum radial/lateral run-out of the rim (without tires): 1.2 mm – maximum radial/lateral run-out of the rim (with tires): front 2.3 mm, rear 2.5 mm Checking the chain and chain guides for wear, force fit and tension. NOTE: – Replacing the drive elements: see Chapter 10. – Checking and adjusting the chain tension: see Owner's Manual Checking the nuts/bolts on the engine sprocket and the rear sprocket for the securing agent and a tight fit NOTE: check the nuts/bolts listed below with a torque wrench. If a nut secured with Loctite 243 is not tightened to the specified torque (if it can easily be screwed in further), remove, clean, secure with Loctite 243 and tighten to the correct torque. Hexagon nuts on the rear sprocket bolts: Loctite 243 + 50 Nm Hexagon nut on the engine sprocket: Loctite 243 + 100 Nm + sheet retainer Checking the wheel bearing and jerk damper for clearance – To check the wheel bearing: jack up the motorcycle, lifting the wheel to be inspected off the ground. Try to tilt the wheel to each side. You should not feel any clearance. If you feel any wheel bearing clearance, replace the wheel bearings (see Chapter 10). – To check the jerk damper: hold the rear wheel while you try to move the rear sprocket back and forth in the running direction. NOTE: the transmission should be switched to neutral. Maximum clearance: 5 mm (measured on the outside of the rear sprocket) To replace, see Owner's Manual. 12-27 LUBRICATION AND MAINTENANCE WORK – ADDITIONAL WORK Completely servicing the fork – Dismounting the fork legs: see Chapter 10 – Maintenance: see WP-documentation Completely servicing the shock absorber – Dismounting the shock absorber: see Chapter 10 – Maintenance: see WP-documentation Cleaning and greasing the steering head bearing and sealing elements 1 – Jack up the motorcycle until the front wheel no longer touches the ground. – Loosen the 5 clamp bolts on the upper triple clamp and remove the blind nut on the steering stem. – Move the upper triple clamp upwards but do not pull the triple clamp all the way off of the steering stem 1. The weight of the front wheel and the fork will give you access to the lower steering head bearing. – Clean the gasket element 2 and grease the lower steering head bearing 3. Art.-No. 3.206.056-E 3 2 – Lift the front wheel to have access to the upper steering head bearing. Clean the gasket element, raise the protection ring 4 and grease the upper steering head bearing 5. 4 – Place the front wheel on the ground, press the upper triple clamp down, screw the blind nut back in until the bearings have no clearance. NOTE: do not tighten the blind nut since you may damage the bearing. Repair manual KTM LC8 5 – Gently tap on the upper triple clamp with a plastic hammer to relieve any distortion and tighten the 5 clamp bolts on the top triple clamp (tigtening torques see technical data). 12-28 LUBRICATION AND MAINTENANCE WORK – ADDITIONAL WORK Cleaning and adjusting the carburetor – See Chapter 8 1 Changing the cooling liquid NOTE: change the cooling liquid after you have finished the general lubrication and maintenance work. ! CAUTION ! AVOID BURNING YOURSELF, ALWAYS DRAIN THE COOLING LIQUID WHEN THE ENGINE IS COLD. TO 3 5 2 – Open the radiator cap 1. – Remove the drain plug 2 on the engine and allow the cooling liquid to drain into a receptacle. Mount the oil drain plug with a new seal ring and tighten to 10 Nm. – Remove the compensating tank 3, open and drain the coolant into a receptacle. – Mount the compensating tank again. – Remove the drain plug 4 on the radiator and allow the cooling liquid to drain into a receptacle. Mount the drain plug again and tighten. – Fill approx. 2.1. liters of a mixture of 50% antifreeze (e.g. Motorex Antifreeze) and 50% destilled water (minimum protection -25ºC), into the radiator and compensating tank. 6 4 NOTE: to completely bleed the cooling system, the motorcycle must be raised approx. 50 cm in the front - see Technical Information. – Unscrew the bleeder screws on the water pump 5 and the radiators 6 until cooling liquid runs out without bubbles, tighten the screws again, close the radiator cap. ! CAUTION ! USE HIGH-GRADE ANTIFREEZE (E.G. MOTOREX ANTIFREEZE) TO AVOID THE RISK OF CORROSION AND FOAMING. USE DISTILLED WATER TO PREVENT CALCIFICATION, ESPECIALLY OF THE RADIATOR CAP AND THE ASSOCIATED, PREMATURE PRESSURE RELEASE. – ONLY – – Lower the motorcycle again, Start the engine and allow to run warm until the radiator fan switches on. – Allow the cooling system to cool down and add more coolant if necessary. 13-1 WIRING DIAGRAMS INDEX Repair manual KTM LC8 Art.-No. 3.206.056-E 950 ADVENTURE WIRING DIAGRAM 2003-2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6 EXPLANATION OF CONNECTORS, CABLE COLORS . . . . . . . . . . . . . . . . . . . . . . .13-7 WIRING DIAGRAM 2005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-8 EXPLANATION OF CONNECTORS, CABLE COLORS . . . . . . . . . . . . . . . . . . . . . . .13-9 START SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-10 CHARGING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-12 ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-14 FLASHER, HORN, COOLING FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-16 LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-18 LIGHTS USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-20 INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-22 GROUND CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-24 POSITIVE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-25 CONNECTOR LIST 950 ADVENTURE CONNECTOR AA - AF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-26 CONNECTOR AG - AH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-27 CONNECTOR AI - AK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-28 CONNECTOR AL - AM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-29 CONNECTOR AN - AR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-30 CONNECTOR AR - AT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-31 CONNECTOR AU - AW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-32 CONNECTOR AX - AZ, BA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-33 CONNECTOR BB - BG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-34 CONNECTOR BH - BK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-35 13 13-2 13 WIRING DIAGRAMS INDEX 990 SUPER DUKE / SUPER DUKE R WIRING DIAGRAM ((990 SUPER DUKE 2005/2006) . . . . . . . . . . . . . . . . . . . .12-36 EXPLANATION OF CONNECTORS, CABLE COLORS . . . . . . . . . . . . . . . . . . . . . .13-37 START/CHARGING SYSTEM (990 SUPER DUKE 2005/2006) . . . . . . . . . . . . . .13-38 START/CHARGING SYSTEM (990 SUPER DUKE/R 2007) . . . . . . . . . . . . . . . . .13-39 START/CHARGING SYSTEM (990 SUPER DUKE 2007/2008) . . . . . . . . . . . . . .13-42 START/CHARGING SYSTEM (990 SUPER DUKE R 2008) . . . . . . . . . . . . . . . . .13-43 ECU (990 SUPER DUKE 2005/2006) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-40 ECU (990 SUPER DUKE/R 2007) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-41 EFI (990 SUPER DUKE 2007/2008) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-46 EFI (990 SUPER DUKER R 2008) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-47 FLASHER, HORN, COOLING FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-42 LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-44 INSTRUMENTS (990 SUPER DUKE 2005/2006) . . . . . . . . . . . . . . . . . . . . . .13-46 INSTRUMENTS (990 SUPER DUKE/R 2007) . . . . . . . . . . . . . . . . . . . . . . . . .13-47 INSTRUMENTS (990 SUPER DUKE 2007/2008) . . . . . . . . . . . . . . . . . . . . . .13-54 INSTRUMENTS (990 SUPER DUKE R 2008) . . . . . . . . . . . . . . . . . . . . . . . . .13-55 GROUND CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-48 POSITIVE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-49 CONNECTOR LIST 990 SUPER DUKE / SUPER DUKE R CONNECTOR AA - AE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-50 CONNECTOR AF - AH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-51 CONNECTOR AI - AL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-52 CONNECTOR AM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-53 CONNECTOR AO - AR1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-54 CONNECTOR AR2 - AS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-55 CONNECTOR AT - AX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-56 CONNECTOR AY - AZ, BB - BD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-57 CONNECTOR BE - BI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-58 CONNECTOR BJ - BV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-59 CONNECTOR BZ, CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-60 CONNECTOR CC - CK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-61 CONNECTOR CL - CQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-62 CONNECTOR CR, DJ - DK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-63 13-3 WIRING DIAGRAMS INDEX Repair manual KTM LC8 Art.-No. 3.206.056-E 950 SUPERMOTO / SUPERMOTO R WIRING DIAGRAM (UP TO THE 2007 MODEL) . . . . . . . . . . . . . . . . . . . . . . . .12-64 WIRING DIAGRAM (STARTING WITH THE 2007 MODEL) . . . . . . . . . . . . . . . . .13-65 EXPLANATION OF CONNECTORS, CABLE COLORS . . . . . . . . . . . . . . . . . . . . . .13-66 START/CHARGING SYSTEM (UP TO THE 2007 MODEL) . . . . . . . . . . . . . . . . . .13-67 START/CHARGING SYSTEM (STARTING WITH THE 2007 MODEL) . . . . . . . . . .13-68 ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-69 FLASHER, HORN, COOLING FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-70 LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-72 INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-74 GROUND CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-76 POSITIVE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-77 CONNECTOR LIST 950 SUPERMOTO / SUPERMOTO R CONNECTOR AA - AF1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-78 CONNECTOR AF2 - AH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-79 CONNECTOR AI - AJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-80 CONNECTOR AK - AL2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-81 CONNECTOR AL3 - AM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-82 CONNECTOR AO - AR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-83 CONNECTOR AS - AT3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-84 CONNECTOR AT4 - AX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-85 CONNECTOR AY - AZ, BB - BG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-86 CONNECTOR BI - BS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-87 CONNECTOR BV - BW, CD, CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-88 CONNECTOR DI - DK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-89 NOTE: THE LIGHT IS SWITCHED OFF DURING THE STARTING PROCESS "UP TO THE 2007 MODEL" THE LIGHT IS NOT SWITCHED OFF DURING THE STARTING PROCESS "STARTING WITH THE 2007 MODEL" 13 13-4 13 WIRING DIAGRAMS INDEX 990 ADVENTURE WIRING DIAGRAM (2006/2007) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-90 WIRING DIAGRAM (2007) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-91 WIRING DIAGRAM (2007/2008) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-100 EXPLANATION OF CONNECTORS, CABLE COLORS . . . . . . . . . . . . . . . . . . . . . .13-92 START/CHARGING SYSTEM (2006/2007) . . . . . . . . . . . . . . . . . . . . . . . . . . .13-93 START/CHARGING SYSTEM (2007) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-94 START/CHARGING SYSTEM (2007/2008) . . . . . . . . . . . . . . . . . . . . . . . . . .13-104 EFI (-2006) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-95 EFI (2007-) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-106 FLASHER, HORN, COOLING FAN (-2006) . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-96 FLASHER, HORN, COOLING FAN (2007-) . . . . . . . . . . . . . . . . . . . . . . . . . . .13-108 LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-98 INSTRUMENTS (-2006) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-112 INSTRUMENTS (2007-) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-113 ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-101 GROUND CONNECTION (-2006) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-102 GROUND CONNECTION (2007-) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-116 POSITIVE CONNECTION (-2006) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-104 POSITIVE CONNECTION (2007-) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-118 CONNECTOR LIST 990 ADVENTURE CONNECTOR AA - AE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-119 CONNECTOR AF - AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-120 CONNECTOR AJ - AL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-121 CONNECTOR AM - AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-122 CONNECTOR AP - AR4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-123 CONNECTOR AR5 - AT2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-124 CONNECTOR AT3 - AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-125 CONNECTOR AZ, BA - BE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-126 CONNECTOR BF - BJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-127 CONNECTOR CA - CK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-128 CONNECTOR CL - CQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-129 CONNECTOR CR - CX, DL-DM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-130 CONNECTOR DN-DP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-131 NOTE: THE LIGHT IS SWITCHED OFF DURING THE STARTING PROCESS "UP TO THE 2007 MODEL" THE LIGHT IS NOT SWITCHED OFF DURING THE STARTING PROCESS "STARTING WITH THE 2007 MODEL" 13-5 WIRING DIAGRAMS INDEX Repair manual KTM LC8 Art.-No. 3.206.056-E 950 SUPER ENDURO WIRING DIAGRAM (UP TO THE 2007 MODEL) . . . . . . . . . . . . . . . . . . . . . . .12-117 WIRING DIAGRAM (STARTING WITH THE 2007 MODEL) . . . . . . . . . . . . . . . .12-118 EXPLANATION OF CONNECTORS, CABLE COLORS . . . . . . . . . . . . . . . . . . . . .13-119 START/CHARGING SYSTEM (UP TO THE 2007 MODEL) . . . . . . . . . . . . . . . . .13-120 START/CHARGING SYSTEM (STARTING WITH THE 2007 MODEL) . . . . . . . . .13-121 ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-122 FLASHER, HORN, COOLING FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-123 LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-125 INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-127 GROUND CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-129 POSITIVE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-130 CONNECTOR LIST 950 SUPER ENDURO CONNECTOR AA - AF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-131 CONNECTOR AH - AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-132 CONNECTOR AJ - AK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-133 CONNECTOR AL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-134 CONNECTOR AM - AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-135 CONNECTOR AR - AS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-136 CONNECTOR AT - AU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-137 CONNECTOR AV - AZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-138 CONNECTOR BA - BI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-139 CONNECTOR BJ - BT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-140 CONNECTOR BW, CD - CR, DI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-141 NOTE: THE LIGHT IS SWITCHED OFF DURING THE STARTING PROCESS "UP TO THE 2007 MODEL" THE LIGHT IS NOT SWITCHED OFF DURING THE STARTING PROCESS "STARTING WITH THE 2007 MODEL" 13 13-6 13-7 WIRING DIAGRAMS INDEX 990 SUPERMOTO Repair manual KTM LC8 Art.-No. 3.206.056-E START/CHARGING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-156 EFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-157 INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-158 13 n tachometer br-bl 3 bl-or 1 ye-bu 2 bu-wh br ye-bu 1 gn-re br-re 1 10 br 2 right front flasher ye-bl 7 19 left front flasher gn-gr re-wh ye-br ye 11 13 bl 12 pu ye-bu 4 bu 3 9 gn-bl 6 5 14 15 1 2 ye-bu pu br 4 1 2 3 br gn-wh bl 1 2 head light flascher gn-bl 2 1 C_BI/2 2 cooling fan M 1 7 3 8 1 ye-bu 2 temperature switch br 1 C_AU/2 2 2 4 9 6 C_AD/12 5 bu-bl 1 1 1 1 front C_AS1/2 2 1 rear C_AS/2 2 3 6 9 2 7 sidestand switch gn bl neutral switch 2nd gear 3rd gear 2nd 3th 3 2 C_AR3/3 C_AM1/3 1 2 C_AL/2 C_AT2/2 N C_AB/9 C_BB/9 8 clutch switch horn G flasher relay 950-Adventure 03-04 wh gn bu wh bu ye gn-re gn-br gn C_AN/4 C_AR2/2 C_BE/3 C_AG/3 C_AM2/3 handle bar switch for multi-func.-digitalspeedometer v front brake switch br-bl bl-or C_AK/2 multi-func.-digital-speedometer 3 C_AH3/2 speed sensor headlight 2 C_AC/6 C_AA/20 C_AH2/2 C_AK1/2 C_BC/6 ye C_BD/12 pu pi gr br-pi br br br C_AH/2 pi or re ye-br bl bl-or or wh ye-br ye-wh wh br-wh or bl-bu or bl-gn bl-wh or 0 br or 1 br 1 C_AO/26 3 16 10 2 br br-re 2 fuel pump relay 20 bu-gr 2 ye-bl 3 br 4 bl-bu1 M ye-bu bl-wh ye-bl re-wh ye-re re-bl fuse box ye bl-or 2 C_AT/2 1 bl-bu br fuel level sensor fuel pump 8 6 13 1 wiring diagram EPC 1 EPC 2 C_AW1/2 1 2 re-bl re-gn C_AW/2 2 ye-re or aditional instruments (roadbook;...) br pu-wh ye-br 1 C_AF1/4 br-wh re-gn C_AL2/2 light switch ye-br pu-wh 10 15 10 or or ye-re re-wh re-wh or re ye-re M re-wh sterter motor re-wh 1 2 2 C_BF/1 C_BA/1 1 2 600 11 092 000 3 3 2 wh gn-wh 1 1 w br 4 pu 2 3 1 bl br ye 2 C_AH1/2 C_AK2/2 oil pressure switch - TPS C_AR1/3 C_AU1/2 rear brake switch rear - 600 11 076 000 Pick up C_AT/2 ye pi 1 C_AI1/2 2 C_AI/2 2 or 1 2 C_BI1/2 start auxillary relay re-wh diode 4 ye br re-wh diode 1 re re-wh 3 2 1 gn-bl C_AM/3 1 2 C_AL1/2 1 6 4 5 battery C_AF/4 front - 600 11 075 000 octane selector 7 4 11 19 25 26 18 C_BH/6 C_AP/6 3 3 C_AE/4 4 ignition switch br 30 A start relay re-wh bu-re bl-wh br-bl ye-br or br-bl ye-bu A A A A A A A pi bl C_AV/2 ye-wh re-wh ye br br 1 ye-bl gn-gr 2 br 3 oil pressure sensor temperature sensor generator G U regulator-rectifier C_AX/2 C_BJ/1 re-wh re 5 10 5 5 5 bl A bu-wh bu-gr ye C_AM3/3 2 C_AY/1 re-ye ye ignition coil C_AT1/2 gr E ye Q or C bu U bl or ye-re ye-wh ye-bu t° start/stop switch C_BF1/1 ye-bu C_BA1/1 bu gr C_AR/3 br-bl br ye gn-wh C_AZ/4 C_BK/4 C_AJ/3 C_BG/3 1/9 left rear flasher licence plate lamp right rear flasher p gn-re rear light/brakelight high/low beam switch horn switch flasher switch 13-8 Repair manual KTM LC8 Art.-No. 3.206.056-E 13-9 Aditional instruments (roadbook;...) Battery Clutch switch Cooling fan Diode Flasher relay Flasher switch Front brake switch Fuel level sensor Fuel pump Fuel pump relay Fuse box Gear sensor Generator Handle bar switch for multi-func.-digital-speedometer Headlight High / low beam switch Horn Horn switch Ignition coil Ignition switch Left front flasher Left rear flasher Licence plate lamp Light switch Multi-func.-digital-speedometer Neutral switch Octane selector Oil pressure sensor Pick up Rear brake switch Rear light / brakelight Regulator-rectifier Right front flasher Right rear flasher Sidestand switch Speed sensor Start auxillary relay Start relay Start/stop switch Starter motor Tachometer Temperature sensor Temperature switch Throttle position sensor (TPS) Externe Instrumente Batterie Kupplungsschalter Lüftermotor Diode Blinkerrelais Blinkerschalter vorderer Bremslichtschalter Benzinstandgeber Kraftstoffpumpe Kraftstoffpumpenrelais Sicherungskasten Gangerkennung Generator Lenkerschalter für Multifunkt.Digitaltacho Scheinwerfer Auf-Abblendschalter Hupe Hornschalter Zündspule Zündschloss linker vorderer Blinker linker hinterer Blinker Kennzeichenbeleuchtung Lichtschalter Multifunktionsdigitaltacho Leerlaufschalter Oktananpassung Öldruckschalter Impulsgeber hinterer Bremslichtschalter hinteres Begrenzungslicht / Bremslicht Regelgleichrichter rechter vorderer Blinker Rechter hinterer Blinker Seitenständerschalter Geschwindigkeitssensor Starterhilfsrelais Startrelais Start / stop schalter Startermotor Drehzahlmesser Temperatursensor Temperaturschalter Vergaserpotentiometer NOTE to the connector designations: The connector designations are comprised of letters and numbers - e.g.: C_AA1/20 – The 1st position C stands for connector (connector). – The 2nd and 3rd positions AA stand for the connector type. – The 4th position numbers the same type of connector if the connector is used for different applications. – The 5th and 6th positions 20 specify the number of pins in the connector, in this case 20 poles. The 5th position is not required for connectors with less than 10 pins. Cable colours bl: black ye: yellow bu: blue gn: green re: red wh: white br: brown or: orange pi: pink gr: grey pu: purple b r - bl 1 3 bu g n -re br-re 13 1 10 n multi-func.-digital-speedometer tachometer handle bar switch for multi-func.-digitalspeedometer le f t f ro n t f l a s h e r 1 br 2 y e - bu pu br 4 1 2 3 br gn-wh bl 1 2 wh gn bu ye head light flascher gn-bl 1 2 3 8 1 y e - bu 2 1 1 2 sidestand switch gn bl neutral switch 2nd gear 3 r d gear 2nd 3th 3 2 C_AR3/3 C_AM1/3 1 2 C_AL/2 C_AT2/2 f r ont C_AS1/2 pu-wh 1 rear C_AS/2 2 2 1 3 6 wh 9 2 7 1 N C_AB/9 C_BB/9 bl-bu 8 clutch switch h o rn G flasher relay or 950-Adventure 05 c o o l i ng f an M C_BI/2 1 7 bu-bl t e m p e r a tu re sw it ch br 1 C_AU/2 2 2 4 9 6 5 C_AD/12 C_BD/12 wh ye gn-re gn-br bu bu-re pu pi gr br-pi br C_AN/4 C_AR2/2 C_BE/3 C_AG/3 C_AM2/3 right front flasher ye-bl 7 19 g n - gr re-wh y e- br ye 11 12 pu bl y e - bu 4 3 9 2 gn-bl 6 5 14 15 b l - or 1 y e - bu br y e - bu 3 C_AK/2 v front brake switch br-bl bl-or 2 bu-wh C_AH3/2 speed sensor headlight 2 C_AC/6 C_AA/20 C_AH2/2 C_AK1/2 C_BC/6 C_AH/2 pi bl-wh re ye-br br ye bl or bl-gn re-ye or bl-or or 0 or 1 ACC2 switched carb heater 1 3 16 10 C_AO/26 2 20 br-re ye-bl b u - gr carb heater 2 f u e l pum p 8 6 13 ye-re or re ye-re M 4 C_BH/6 re-wh 1 2 3 C_AE/4 30 A start relay 2 C_BF/1 C_BA/1 1 front rear carb heater battery 600 11 075 000 600 11 076 000 600 31 005 000 P i c k up C_AT/2 3 3 2 br wh gn-wh 1 1 wh 4 pu 2 3 1 bl br ye 2 C_AH1/2 C_AK2/2 rear brake switch oil pressure switch 600 11 092 000 TPS C_AR1/3 2 ye pi 1 C_AI1/2 2 1 2 C_BI1/2 start auxillary relay C_AI/2 2 or re-wh br re-wh diode 4 ye C_AF/4 diode 1 re re-wh 3 2 1 gn-bl C_AM/3 1 2 C_AL1/2 1 6 4 5 ignition switch br C_AP/6 3 o c t a ne s ele c tor 4 11 19 25 26 18 7 f u se box re-wh re-wh or or fuel level sensor f ue l p um p r e l a y 1 bl-bu ye-re re-wh ye-bl bl-wh y e - bu ye b l - or 1 2 2 3 4 1 1 2 wiring diagram EPC 1 EPC 2 C_AW1/2 1 2 C_AW/2 2 C_AH4/2 re-gn y e- br 1 ACC1 always ON or gn bl-wh br-wh ye-br or br-bl br ye-br C_AT/2 C_AF1/4 light switch re-gn C_AT1/2 bu-gr carb body pu-wh A A A A C_AL2/2 M Q 10 15 10 10 10 10 10 10 A A A A bu-wh pi bl C_AV/2 ye ye br ye-bu re-wh re-wh re-wh re ye-wh ye wh ye-br br-wh or ignition coil br-bl br ye-bu or ye-re ye-wh br C_AM3/3 2 C_BF1/1 ye-bu C_BA1/1 bu 1 ye-bl g n - gr 2 br 3 o i l p r e ss u r e s e n s o r temper ature s ensor generator G U regulator-rectifier C_AX/2 C_BJ/1 starter motor ye-wh bl bl-bu gr E or C bu U ye gr C_AR/3 br-bl br bl gn-wh t° start/stop switch C_AY/1 C_AU1/2 C_AZ/4 C_BK/4 C_AJ/3 C_BG/3 1/9 left rear flasher licence plate lamp right rear flasher p g n -re rear light/brakelight high/low beam switch horn switch flasher switch 13-10 temperature switch Repair manual KTM LC8 Art.-No. 3.206.056-E 13-11 Aditional instruments (roadbook;...) Battery Clutch switch Cooling fan Diode Flasher relay Flasher switch Front brake switch Fuel level sensor Fuel pump Fuel pump relay Fuse box Gear sensor Generator Handle bar switch for multi-func.-digital-speedometer Headlight High / low beam switch Horn Horn switch Ignition coil Ignition switch Left front flasher Left rear flasher Licence plate lamp Light switch Multi-func.-digital-speedometer Neutral switch Octane selector Oil pressure sensor Pick up Rear brake switch Rear light / brakelight Regulator-rectifier Right front flasher Right rear flasher Sidestand switch Speed sensor Start auxillary relay Start relay Start/stop switch Starter motor Tachometer Temperature sensor Temperature switch Throttle position sensor (TPS) Carb heater (Carburator heater element) Externe Instrumente Batterie Kupplungsschalter Lüftermotor Diode Blinkerrelais Blinkerschalter vorderer Bremslichtschalter Benzinstandgeber Kraftstoffpumpe Kraftstoffpumpenrelais Sicherungskasten Gangerkennung Generator Lenkerschalter für Multifunkt.Digitaltacho Scheinwerfer Auf-Abblendschalter Hupe Hornschalter Zündspule Zündschloss linker vorderer Blinker linker hinterer Blinker Kennzeichenbeleuchtung Lichtschalter Multifunktionsdigitaltacho Leerlaufschalter Oktananpassung Öldruckschalter Impulsgeber hinterer Bremslichtschalter hinteres Begrenzungslicht / Bremslicht Regelgleichrichter rechter vorderer Blinker Rechter hinterer Blinker Seitenständerschalter Geschwindigkeitssensor Starterhilfsrelais Startrelais Start / stop schalter Startermotor Drehzahlmesser Temperatursensor Temperaturschalter Vergaserpotentiometer Vergaserheizelement NOTE to the connector designations: The connector designations are comprised of letters and numbers - e.g.: C_AA1/20 – The 1st position C stands for connector (connector). – The 2nd and 3rd positions AA stand for the connector type. – The 4th position numbers the same type of connector if the connector is used for different applications. – The 5th and 6th positions 20 specify the number of pins in the connector, in this case 20 poles. The 5th position is not required for connectors with less than 10 pins. Cable colours bl: black ye: yellow bu: blue gn: green re: red wh: white br: brown or: orange pi: pink gr: grey pu: purple 31 battery r ed 4 M brown 0.5 3 30 31 red 4 r e d 0. 5 C_BF1/1 4 3 2 1 start auxillary relay C_AF/4 8 red 0.5 2 A page 7/9 1 orange 0.5 brown 0.5 950-Adventure starter motor 4 C_BA1/1 C_AE/4 orange 0.5 C_BB/9 C_AB/9 7 ignition switch black-orange 0.5 fuse 10 A yellow 0.5 start-relay 2 diode C_AI/2 1 o r a nge 1 green-black 0.5 start/stop switch 3 sidestand switch C_AM3/3 C_AR/2 1 yellow 0.5 start system brown 0.5 pink 0.5 C_AM1/3 C_AR3/3 2 B page 4/9 diode C_AI1/2 1 3 N 3th 2nd 1 clutch switch C_AT2/2 C_AL 2 yellow 0.5 30 brown 0.5 neutral switch (N) / 2nd gear / 3rd gear 2/9 31 30 13-12 pink 0.5 13-13 start switch ignition switch r-w r-w r-w o y-r r ON cable harness or cable switch blbu blor bl START OFF unpushed LOCKED Art.-No. 3.206.056-E kill switch sidestand switch cable harness re or cable harness br pi cable switch or blwh cable switch gn bl RUN folded up STOP folded down clutch switch switch position pulled Repair manual KTM LC8 unpulled ye br br 31 fuel pump clock page 4/9 page 7/9 950-Adventure red-black 0.5 yellow-red 0.5 1 10 A brake-horn-flasher-system 2 10 A 9 f an 10 A 10 page 5,6,7/9 page 6/9 3 4 10 A 11 5 10 A 12 6 10 A 13 7 15 A 14 8 10 A 15 1 2 3 5 6 4 C_BH/6 page 5/9 start system light page 2/9 fuse box orange 1 black-orange 0.5 16 yellow-red 1 yellow 1 battery red 1 yellow-blue 1 red-white 1 red-white 1 yellow-red 1 r ed 1 yellow-red 1 orange 1 black-white 1 C_AP/6 yellow-red 1 o r a nge 1 orange 1 black-yellow 1 30 31 red-white 1 red-white 1 red-white 1 red-white 0.5 red-white 1 ignition switch red-white 1 red-white 1 charging circuit aditional instruments (roadbook;...) main fuse 30 A C_AE/4 1 2 red-white 1 30 2 1 3 generator G 31 3/9 U regulator-rectifier 30 13-14 brown 1 C_AU1/2 C_BI1/2 13-15 ignition switch r-w r-w r-w ON OFF Repair manual KTM LC8 Art.-No. 3.206.056-E LOCKED o y-r r 30 31 31 C_BB/9 C_AB/9 battery 1 o r a nge 0.5 2 o r a nge 1 U 7 20 3 2 10 16 18 8 6 1 4 11 19 26 25 13 1 black 0.5 yellow 0.5 blue 0.5 2 1 o r a n g e 0. 5 brown-white 0.5 violet-white 0.5 EPC 1 EPC 2 C _ A W1 /2 1 2 C _ A W /2 2 r ed- gr een 0.5 yellow-white 0.5 yellow-blue 0.5 C_AT/2 C_AL1/2 ignition coil brown 0.5 blue-white 0.5 pink 0.5 b l u e- gr ey 0.5 1 2 1 front C_AS1/2 2 grey 0.5 r ear C_AS/2 2 1 C_AM/3 C_AR1/2 3 throttle position sensor yellow-brown 0.5 950-Adventure o r a nge 0.5 black-orange 0.5 E C 7 fuse 10 A C_AO/26 pick up 2 3 th N ECU neutral switch (N) / 2nd gear / 3rd gear 2 nd C_AM1/3 C_AR3/3 1 black-brown 0.5 1 C_BF/1 C_BA/1 1 B page 2/9 octane selector C page 7/9 fuel pump relay brown 0.5 o r a nge 1 C_AF1/4 fuel pump start/stop switch brown 0.5 1 1 M C_AT/2 2 4 2 3 ignition switch brown 0.5 31 o r a nge 1 30 4/9 fuse 10 A black-blue 0.5 30 13-16 13-17 ignition switch r-w r-w r-w o y-r ON OFF LOCKED Art.-No. 3.206.056-E start switch cable harness or cable switch blbu blor bl START unpushed kill switch cable harness re or cable switch or blwh RUN Repair manual KTM LC8 STOP r 31 E page 7/9 D page7/9 C_AH/2 4 1 C_AD/12 C_BD/12 7 flasher switch G v i ol et 0 .5 3 950-Adventure rear flasher light`s C_AZ/4 C_BG/4 2 1 2 1 2 4 C_AK1/2 violet 0.5 black 0.5 C_AH3/2 C_AH2/2 C_ A K / 2 fuse 10 A ignition switch brown 0.5 brown 0.5 yellow-blue 0.5 orange 0.5 8 horn brown 1 ignition switch black-white 1 o r a nge 1 2 1 2 temperature switch C_AV/2 1 fuse 10 A turn indicator system horn switch C_BD/12 C_AD/12 3 yellow-blue 0.5 r ed 1 grey 0.5 1 2 brown 0.5 brown-black 1 flasher relay right front flasher black 0.5 left-front-flasher M 31 30 5/9 cooling fan C_BI/2 30 13-18 C_AU/2 13-19 ignition switch r-w r-w r-w o y-r r ON OFF LOCKED Art.-No. 3.206.056-E flasher switch cable harness or gr br cable switch gn- bu- bupi br re bl brpi pu bl TURN L TURN R OFF Repair manual KTM LC8 horn switch cable harness gr br cable switch pi brpi HORN OFF 31 0 1 2 head light flasher HI LO low/high beam switch C_BD/12 C_AD/12 light switch 2 5 6 9 3 yellow 1 F page 7/9 white 0.5 fuse 10 A C_AB/9 front blue 1 g r een 1 brake switch r ear brake switch 1 2 C_BK/4 C_AZ/4 4 1 white 0.5 green-white 0.5 1 2 C_BG/3 C_AJ/3 1 white 0.5 3 2 3 rear light/brake ight C_BC/6 C_AC/6 light-brake system licence plate lamp 2 1 blue-yellow C_AH1/2 ignition switch ignition switch C_BB/9 950-Adventure 9 6 yellow 1 yellow-brown 1 fuse 15 A yellow-red 1 r ed 1 brown 0.5 head light 4 brown 0.5 30 brown 0.5 6/9 31 30 13-20 C_AK2/2 13-21 ignition switch r-w r-w r-w o y-r r ON OFF LOCKED light switch high/low beam switch cable harness yewh ye br cable harness bu gn yebr cable switch yewh wh cable switch wh ye gnre LIGHT OFF LO Art.-No. 3.206.056-E P. LIGHT HI LIGHT passing light brake switch cable harness gn- yewh bu cable harness ye cable switch bl cable switch gnwh bl pushed unpushed Repair manual KTM LC8 reye bl P. HORN OFF bu 31 head light flasher HI LO low/high beam switch 2 6 5 9 F page 7/9 yellow 1 white 0.5 fuse 10 A ignition switch ignition switch front r ear brake switch blue 1 g r een 1 brake switch 950 Adventure C_AB/9 3 6 9 yellow 1 yellow-brown 1 fuse 15 A yellow-red 1 r ed 1 brown 0.5 C_BK/4 C_AZ/4 4 1 white 0.5 green-white 0.5 C_BC/6 2 C_BG/3 C_AJ/3 1 white 0.5 3 2 3 rear light/brake light 1 C_AC/6 light system USA licence plate lamp 2 1 1 2 head light 4 brown 0.5 30 brown 0.5 6A/9 31 30 13-22 C_AH1/2 C_AK2/2 C_BD/12 C_AD/12 13-23 ignition switch r-w r-w r-w o y-r r ON OFF LOCKED light switch high/low beam switch cable harness yewh ye br cable harness bu gn yebr cable switch yewh wh cable switch wh ye gnre LIGHT OFF LO Art.-No. 3.206.056-E P. LIGHT HI LIGHT passing light brake switch cable harness gn- yewh bu cable harness ye cable switch bl cable switch gnwh bl pushed unpushed Repair manual KTM LC8 reye bl P. HORN OFF bu 31 3 black-brown 0.5 1 2 yellow-brown 0.5 yellow 0.5 3 green-red 0.5 2 7 19 1 6 2 9 p C_BJ/1 C _ AY /1 1 yellow-blue 0.5 oil pressure sensor gree n-gr ey 0.5 yellow-black 0.5 green-black 0.5 950-Adventure F page 6/9 E page 5/9 D page 5/9 violett 0.5 handlebar switch for multi-func.-digitalspeedometer C_AN/4 1 4 blue 0.5 red-white 0.5 speed sensor v black-orange 0.5 C_AM2/3 C_AR2/3 3 5 black 0.5 C_AA/20 10 15 14 11 12 13 4 brown 0.5 fuse 5A brown 0.5 brown 0.5 2 f u e l l e v el s e ns or Q C_AL2/2 C_AT1/2 1 instruments_tachometer t e mperature sensor 2 A page 2/9 t° C_AX/2 1 ignition switch fuse 10 A r ed 1 3 2 C_AG/3 C_BE/3 1 n tachometer yellow-blue 0.5 blue-white 0.5 multi-func.-digital-speedometer brown 0.5 30 31 7/9 C page 4/9 30 13-24 13-25 ignition switch r-w r-w r-w ON OFF Repair manual KTM LC8 Art.-No. 3.206.056-E LOCKED o y-r r left front flasher headlight right front flasher fuel pump relay handle bar switch tachometer M fuel pump ECU battery brown regulator ground connection sidestand switch temperature switch 30 A 950 Adventure clutch switch external instruments external instruments multi-func.-digital-speedometer horn switch s t a r t er m o t o r start relay rear flasher 8/9 rear light/brakelight octane selector f u e l l e v el se ns o r t e mperature sensor 13-26 tachometer front brake switch flasher relay speed sensor rear brake switch 950 Adventure multi-func.-digital-speedometer Fan A A A 10 15 10 fuel pump relay A A A A A battery fuse box yellow-red 10 10 10 10 10 o r ange red ignition switch 30 A positve connection black-orange start/stop switch light switch M yellow-black black-white horn high/low beam switch s t a r t er mo t o r yellow yellow-blue s t a r t relay red-white red-white Art.-No. 3.206.056-E red-black yellow-red Repair manual KTM LC8 9/9 external instruments external instruments carb heaters regulator 13-27 13-28 Connector AA 20-pole 1 11 1 1 Multifunctional digital speedometer Behind the functional speedometer 20 10 multidigital Connector AB 9-pole 2 3 1 9 2 Start/stop/light switch On the connector support under the multifunctional digital speedometer 4 Connector AC 6-pole 3 Front light 1 4 3 6 On the connector support under the multifunctional digital speedometer Connector AD 12-pole 4 3 1 7 12 Light/turn signal/horn switch On the connector support under the multifunctional digital speedometer Connector AE 4-pole 5 1 4 2 5 Starter relay On the right side on the battery case Connector AF 4-pole 6 1 42 Auxiliary start relay Connector AF 4-pole 7 Fuel pump On the connector support under the multifunctional digital speedometer 3 6 7 13-29 Connector AG 3-pole 1 Tachometer 1 3 On the connector support under the multifunctional digital speedometer 1 2 Connector AH 2-pole 2 Turn signal relay 1 2 On the connector support under the multifunctional digital speedometer Connector AH1 2-pole 3 3 Rear brake light switch Art.-No. 3.206.056-E Under the right rear side cover Connector AH2 2-pole 4 4 Left front turn signal Under the right front side cover Connector AH3 2-pole 5 Repair manual KTM LC8 Right front turn signal Under the left front side cover 5 Connector AH4 2-pole 6 Temperature switch of carburator heater element Behind the headlight 6 13-30 Connector AI 2-pole 1 2 1 Diode neutral switch 2 1 On the connector support under the multifunctional digital speedometer Connector AI1 2-pole 2 Diode side stand switch On the connector support under the multifunctional digital speedometer Connector AJ 3-pole 3 1 2 3 3 Rear lighting Under the right rear side cover Connector AK 2-pole 4 Rear brake light switch 1 2 4 Under the right rear side cover Connector AK1 2-pole 5 Right front turn signal Under the left front side cover 5 Connector AK2 2-pole 6 Left front turn signal Under the right front side cover 6 13-31 Connector AL 2-pole 1 1 Clutch switch 1 Behind the headlight under the connector support 2 Connector AL1 2-pole 2 2 Pick up Between the water pipe and the front cylinder head Connector AL2 2-pole 3 Fuel sender Art.-No. 3.206.056-E Between the left tank and the frame Connector AM 3-pole 4 1 3 Carburetor potentiometer 3 4 Under the fuse box Connector AM1 3-pole 5 Repair manual KTM LC8 Gear sensor 6 Connector AM2 3-pole 7 Speed sensor Behind the headlight under the connector support Connector AM3 3-pole 6 Side stand switch links am Motor vor dem Generatordeckel 7 5 13-32 Connector AN 4-pole 1 1 Tripmaster switch 1 2 4 Near the connector support under the multifunctional digital speedometer Connector AO 26-pole 2 20 14 8 ECU (control unit) 1 Under the fuse box behind the steering head 26 19 13 7 2 Connector AP 6-pole 3 Ignition lock 1 3 6 Under the fuse box 3 Connector AQ 1-pole Connector for auxiliary devices: Kl 15 (ignition) Kl 30 (battery) Kl 31 (ground) Behind the headlight under the connector support Connector AR 3-pole 4 Side stand switch 3 1 4 Connector AR3 3-pole 5 5 Gear sensor On the left side of the engine in front of the generator cover Connector AR1 3-pole 6 Carburetor potentiometer Under the fuse box 6 13-33 Connector AR 3-pole 1 Speed sensor 3 1 Behind the headlight under the connector support 1 Connector AS 2-pole 2 Rear ignition coil 1 2 2 Behind the air filter box Connector AS1 2-pole 3 Front ignition coil Art.-No. 3.206.056-E Behind the radiator 3 Connector AT 2-pole 4 Pick up 1 2 Between the water pipe and the front cylinder head 4 Connector AT1 2-pole 5 5 Repair manual KTM LC8 Fuel sender Between the left tank and the frame Connector AT2 2-pole 6 Clutch switch Behind the headlight under the connector support 6 13-34 Connector AU 2-pole 1 Radiator fan motor 21 1 On the right behind the radiator next to the fan Connector AU1 2-pole 2 Regulator On the right side of the battery case under the starter relay 2 Connector AV 2-pole 3 1 2 Temperature switch for the radiator fan On the right behind the radiator next to the compensating tank 3 Connector AW 2-pole 4 EPC front cylinder 2 1 On the right side of the frame 4 Connector AW1 2-pole 5 EPC rear cylinder Behind the air filter box 5 13-35 Connector AX 2-pole 1 Temperature sensor for the multifunctional digital speedometer 1 2 On the left side of the engine between the cylinders 2 1 Connector AY 1-pole 2 Oil pressure switch On the left side of the frame under the air filter box Connector AZ 4-pole 3 Art.-No. 3.206.056-E 1 2 3 4 Rear turn signal Connector BA 1-pole 4 Octane selector Behind the air filter box Repair manual KTM LC8 3 Under the right rear side cover 4 13-36 Connector BB 9-pole 1 1 3 7 9 1 Start/stop/light switch On the connector support under the multifunctional digital speedometer 2 3 Connector BC 6-pole 2 Front light 3 6 1 On the connector support under the multifunctional digital speedometer Connector BD 12-pole 3 3 1 10 12 Light/turn signal/horn switch On the connector support under the multifunctional digital speedometer Connector BE 3-pole 4 1 3 Tachometer 4 On the connector support under the multifunctional digital speedometer Connector BF 1-pole 5 Octane selector Behind the air filter box Connector BG 3-pole 6 1 2 3 Rear lighting Under the right rear side cover 5 6 13-37 Connector BH 6-pole 1 Ignition lock 1 3 6 Under the fuse box 1 Connector BI 2-pole 2 Radiator fan motor 2 1 On the right behind the radiator next to the fan 2 Connector BI1 2-pole 3 Regulator On the right side of the battery case under the starter relay Art.-No. 3.206.056-E 3 Connector BJ 1-pole 4 Oil pressure switch On the left frame under the air filter box 1 4 Repair manual KTM LC8 Connector BK 4-pole 5 1 1 2 3 Rear turn signal Under the right rear side cover 5 multi-func.-digital-speedometer headlight n front brake switch speed sensor 15 16 9 3 4 5 2 7 8 1 br left front flasher right front flasher br gn-gr wh r e- br br-bu gn-bl re-wh or-ye bl pu bu br-bl br ye ye-bu bl-or 1 3 5 4 bl or-ye 2 10 r e- br wh cooling fan M C_BI1/2 re-wh or-ye bl pu bu r e- br bu-br 11 gn-gr 3 br 12 wh 2 9 10 gn-bl 6 5 7 1 4 5 4 sensor rollover C_AP2/6 6 temperature switch C_AV/2 1 C_CI/12 2 gn-gr 11 1 br 12 7 bu-br gn-bl C_AU1/2 2 9 pu re-wh 6 bu C_CC/12 p C_AY/1 C_BJ/1 7 1 oil pressure sensor 1 2 L L rear t° 3 2 1 gr ye-bu 6 1 2 C_AX/2 4 2 ye -re or br 3 p C_BZ2/3 1 1 1 2 t° or C_AH2/2 C_BH1/6 h o rn p C_BZ1/3 2 3 1 1 2 C_CM/2 t° diode G flasher relay or 1 8 C_AB/9 C_BB/9 bl-bu 2 3 p C_BZ/3 1 wiring diagramm lambda sensor`s front t° C_CE/4 4 C_CA/4 3 C_CE1/4 2 diagnostic connector 3 8 C_CA1/4 4 1 990 Super Duke 2005/06 pu y e - br 6 wh gn 2 1 bu 3 br br bl or-ye 2 4 gn-wh br-bl 1 bl-or bu-re 12 6 C_BE/3 C_AH/2 LED red for optional alarm system tachometer clutch switch C_AK/2 10 C_BS/2 3 C_AC/6 v C_AT1/2 C_AM5/3 C_AG/3 C_AR5/2 1 2 C_BC/6 C_AA/20 C_BV/2 C_AL1/2 2 1 2 bl-wh 2 4 or br-bl head light flascher gn-bl ye re-gn wh-bl br-bl wh bu bu-re bl 1 bl ye gn gn-re gn-br ye-br or 9 or pu pi gr br-pi br wh-or bl-wh 2 7 9 2 1 3 C_AR3/3 C_AM3/3 2 C_AL/2 Pick up C_AT/2 1 sidestand switch 3 6 wh wh re-ye ye bu-bl bl re-br or-bl ye-bu 6 bu fuse box 1 2 A 3 2nd 2 1 9 A 4 6 5 5 3 6 7 A A A A A 10 10 10 10 10 3 4 C_BH/6 C_AP/6 8 2 gn-bl y e - br gr 1 0 1 1 12 13 14 1 5 16 A 10 15 10 or-bl or ye-bl C_AD/12 re bu-bl ye-bu ye-re re-wh C_BD/12 ye re re-gn 5 7 13 14 3 24 23 11 12 4 C_AO/26 2 10 9 22 6 20 25 26 19 15 18 17 C_CR/1 2 8 f uel pump M 3 2 C_CR1/1 9 14 16 34 alarm system d u mmy p l u g Connector for optional alarm system fuel pump module Q C_AR4/3 C_AM4/3 1 A CC starter motor M 33 15 13 23 11 3 6 29 26 C_CO/34 7 21 12 4 22 5 main harness - 610.11.075.000 1 1 re-wh br ye-bu manifold pressure sensor front br ye-re bu air temperature sensor bl bl br-re ye-wh ye-bu re-br 3 C_AR2/3 3th bu-bl br br 1 fuel level sensor bu-gr br br bu-wh wh bu-br 0 C_AM2/3 N 1 4 3 2 C_AE1/4 1 30 A start relay 2 1 C_BV1/2 C_BS1/2 battery C_DK/18 C_DJ/18 front exhaust air val ve 2 14 2 10 6 16 8 4 12 15 7 3 11 5 9 13 1 bu-gr 2 1 or-wh 2 1 C_AH1/2 C_AK1/2 2 main relay fuel pump relay C_AR/3 2 C_AM/3 1 re-wh re-wh start auxillary relay 1 2 1 rear C_CL/2 injector´s front C_CL1/2 3 2nd throttle position sensor rear brake switch re-gn 4 br or 3 4 1 or-wh ye-bl 3 2 bu-bl 2 4 re-bl re-bl 3 ye-wh re-wh 11.11..2004 rear ye-bu bu bl ye ye-wh bl-or gn wh wh-re bl-br gn-wh bu-wh pi bl-gr bl-wh or C_CK/2 1 1 C_AS/2 1 2 C_AS1/2 2 1 1 2 3 2 bu-wh 4 4 2 bl water temperature sensor C_AP1/6 atmospheric pressure sensor re-wh bl 5 5 C_AI3/2 bu ye-bl gn-gr bl bl or ye-or bl bl 2 6 6 bl ye-wh br 7 7 or bl re-bl bl 3 bl 8 8 or or-bl pi re-wh 9 9 ye-br bu re-bl pu bl re-wh bu-re bl bl re-wh bl 10 10 bl 11 11 or re-bl bu 13 13 ignition switch 1 3 2 1 4 2 gn-wh 3 br wh pu wh bl br 2 1 C_AR1/3 C_AM1/3 2 C_CE2/4 1 3 main throttle position sensor C_CA2/4 4 1 2 C_BI/2 2nd throttle stepper motor 3 ye light switch pu start/stop switch C_CP/16 4 1 C_AE/4 G 3 1/8 left raer flasher licence plate lamp right rear flasher 2 C_AI2/2 1 2 C_AI1/2 1 2 C_AI/2 1 diode generator diode 3 U diode re-wh regulator-rectifier ISC stepper motor 2 gn gn re-wh or-wh or bl pu manifold pressure sensor rear gn gn 14 14 seat surveillance for optional alarm system wh-br ignition coil`s 15 15 bl 16 bl 17 bl 18 17 wh-pu gn-wh C_CQ/16 ye-wh C_AF2/4 or gn-bl C_AF1/4 C_AF/4 bu bl-wh E or ye-wh re bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re ye ye-wh ye-bl re br ye-or ye pi gn-bl ye-br gr ye-re C bl Antenna 12 12 wh-or wh-bl re-bl bl-or gn wh wh-re bl-br gn-wh bu-wh pi bl-gr bl-wh wh-pu wh-br U bu 18 re-bl gn-re bu-bl C_AU/2 C_AU/2 bu re wh gr C_AZ/4 C_BK/4 C_AJ/3 C_BG/3 wh gn bl gr 16 or or pu ye high/low beam switch horn switch flasher switch 13-38 rear light/brakelight 3rd gear neutral switch 2nd gear br Repair manual KTM LC8 Art.-No. 3.206.056-E 13-39 Aditional instruments (roadbook;...) Battery Clutch switch Cooling fan Diode Flasher relay Flasher switch Front brake switch Fuel level sensor Fuel pump Fuel pump relay Fuse box Gear sensor Generator Headlight High / low beam switch Horn Horn switch Ignition coil Ignition switch Left front flasher Left rear flasher Licence plate lamp Light switch Multi-func.-digital-speedometer Oil pressure sensor Pick up Rear brake switch Rear light / brakelight Regulator-rectifier Right front flasher Right rear flasher Sidestand switch Speed sensor Start auxillary relay Start relay Start/stop switch Starter motor Tachometer Temperature sensor Temperature switch Fuel pump module Power relais Roll over sensor Diagnostic connector Water temperature sensor Air temperature sensor Front hego sensor Rear hego sensor Manifold pressure sensor front Manifold pressure sensor rear Atmospheric pressure sensor ECU Main throttle position sensor 2nd throttle position sensor Exhaust air valve Front injector Rear injector 2nd throttle stepper motor ISC stepper motor Cable colours bl: black ye: yellow bu: blue gn: green re: red wh: white br: brown or: orange pi: pink gr: grey pu: purple Externe Instrumente Batterie Kupplungsschalter Lüftermotor Diode Blinkerrelais Blinkerschalter vorderer Bremslichtschalter Benzinstandgeber Kraftstoffpumpe Kraftstoffpumpenrelais Sicherungskasten Gangerkennung Generator Scheinwerfer Auf-Abblendschalter Hupe Hornschalter Zündspule Zündschloss linker vorderer Blinker linker hinterer Blinker Kennzeichenbeleuchtung Lichtschalter Multifunktionsdigitaltacho Öldruckschalter Impulsgeber hinterer Bremslichtschalter hinteres Begrenzungslicht / Bremslicht Regelgleichrichter rechter vorderer Blinker Rechter hinterer Blinker Seitenständerschalter Geschwindigkeitssensor Starterhilfsrelais Startrelais Start / stop schalter Startermotor Drehzahlmesser Temperatursensor Temperaturschalter Kraftstoffpumpengruppe Hauptrelais Neigungssensor Diagnosestecker Wassertemperatursensor Lufttemperatursensor Lambdasensor vorne Lambdasensor hinten Ansaugkrümmerdrucksensor vorne Ansaugkrümmerdrucksensor hinten Außenluftdrucksensor Steuergerät Drosselklappenpositions-Hauptsensor 2. Drosselklappenpositionssensor Ventil für Sekundär-Luft-System vorderes Einspritzventil hinteres Einspritzventil 2. Drosselklappenstellmotor Leerlaufstellmotor NOTE to the connector designations: The connector designations are comprised of letters and numbers - e.g.: C_AA1/20 – The 1st position C stands for connector (connector). – The 2nd and 3rd positions AA stand for the connector type. – The 4th position numbers the same type of connector if the connector is used for different applications. – The 5th and 6th positions 20 specify the number of pins in the connector, in this case 20 poles. The 5th position is not required for connectors with less than 10 pins. 30 A M starter motor battery start relay re-wh re-wh re-wh br 1 2 3 4 3 generator G U regulator-rectifier 17 5 4 3 2 1 5 4 3 2 1 bl bl re-wh start auxillary relay 7 6 8 8 6 9 7 10 9 11 10 12 13 14 15 16 11 C_DK/18 12 13 14 15 C_DJ/18 C_BI/2 C_AU/2 990 Super Duke 2005/06 re-wh re-wh gn gn 17 16 C_AF2/4 ye-wh 1 2 7 1 clutch switch C_AR2/3 C_AT1/2 3 th 2 1 N 3 C_AI1/2 diode neutral switch (N) / 2nd gear / 3rd gear 2 nd C_AM2/3 2 o r a nge 1 C_AL1/2 1 2 C_AI2/2 diode 1 ignition 9 fuse 10 A ignition switch re-bl b a tte ry g e n e ra to r s ta rte r 3 4 2 1 8 C_BB/9 C_AB/9 start/stop switch re-bl 18 or-bl 18 ye-wh Dummy plug ye C o nnector for optional alarm system ye-wh re-wh gn-bl 30 A 2/8 31 p a ge 6 30 13-40 C_AE1/4 F E D 1 -A 1 C _ D K /1 8 3 4 6 7 8 9 8 9 A L A -P 1 /3 . C 5 /3 . D 2 /3 . D 6 C onne c tor for optiona l a la rm s ys te m pow-X 9 /3 . B 2 tlig-H 4 plig-S 2 10 11 12 13 14 15 16 17 18 a la rm s ys te m dummy plug 5 /3 . D 6 /3 . D 6 fla R -X 2 00 fla L -X 2 00 /2 . D 4 /3 . D 4 78,79 1 C _ A I /2 2 1 2 3 10A -F 1 -S 2 0 s eat s urve illa nc e C _ B V /2 C _ B S /2 2 -X 4 3 990 S U P E R D U K E (R ) 07 74 C _ D J /1 8 -A 2 -P 1 lig-S 7 7 116 -X31 9 6 2 5 1 4 126,127 -X32 11bl 10 bl 85,86 C 3 9 -X33 12 bl 8 65,66 2 -X34 13 bl 65 1 -X35 14 bl 83,54 76,166 203 48 C _ A B /9 66 C _ B B /9 -X36 15 bl 3 6 -X37 16 bl 2 5 -X38 17 bl 51 B 73 4 -X39 Antenna 19 bl 75 55 1 -X40 20 bl 128,129 67,68 C _ B H /6 -X41 21bl 56 26 73 C _ A P /6 2 1 70 2 2 2 10A 1 10A 1 1 2 1 3 C _ E B /4 -K 5 129 AC C B a t-P 1 /3 . A 6 3 1 fue l pump M C _ A R /3 C _ A M/3 2 -M2 /3 . B 2 4 4 5 1 3 -K 3 -M1 s ta rte r motor C _ E B /4 207 light re la y 2 ba tte ry, ge ne ra tor, s ta rte r fue l pump re la y 4 2 10A 10A 1 71 -F 5 -F 6 -F 7 -F 8 224 -X 1 s plic e 1,2 diode 52 -V 2 25 25 s ta rt/s top s witc h M -K 1 4 2 4 C _ A E /4 3 1 C _ E B /4 3 6 2 30 A s ta rt re la y powe r re la y 114 -S 2 68 ignition s witc h 23,24 74,75 6 5 69 113 113 114 fuel-A2 5 4 208 A -S 1 4 1 -G 1 -K 4 1 72 128 67 3 53 51 for optional alarm system 39,35 -X42 22 bl 2 115 2 4 G N D -X 2 ba tte ry 4 /2 . C 3 24 23 7 2 1 2 1 3 7 gn -K 2 1 15 , 1 16 C _ E B /4 7 s ta rt a ux illa ry re la y 5 1 213 C_BI/2 Art.-No. 3.206.056-E 224 130 /2.E5 182 /3.A5 lig-X4 27 /2.B5 STR-A3 200 C_AU/2 7,8 Repair manual KTM LC8 -A 1 -X 1 0 G ge ne ra tor /2 . C 1 3 -N 1 /2 . C 2 611. 11. 075 . 10 0 610. 41. 012. 000 8 ma in ha rne s s - G N D -X 8 53, 55, 56, 207, 208, 213 re -wh U re gula tor-re c tifie r re -wh gn gn 8 3 P. P a ge : 1 F E D C B A 13-41 F E D C B 1 -A1 73 1 4 C_DK/18 C_DJ/18 6 -A2-P1 5 3 2 3 1 2 74 -X31 116 -X32 126,127 11bl 6 7 2 3 lig-S7 4 8 9 ALA-P1 8 7 6 pow-X9 /3.B2 tlig-H4 plig-S2 /3.C5 /3.D2 /3.D6 2 3 990 Superduke 2007-2008 Connector for optional alarm system 9 10 11 12 13 14 15 16 17 18 /3.D4 5 78,79 alarm system dummy plug 5 4 /3.D6 /3.D6 flaR-X200 flaL-X200 /2.D4 1 9 C_AB/9 1 C_AI/2 66 C_BB/9 2 -X43 67,68 C_AP/6 -X35 14 bl 85,86 48 -X36 8 -X33 12 bl 65 15 bl 83,54 65,66 51 -X37 16 bl C_BV/2 C_BS/2 1 51 -S20 seat surveillance 2 10A -F1 2 1 10A 2 1 2 1 3 C_EB/4 -K5 129 ACC Bat-P1 /3.A6 3 1 fuel pump M C_AR/3 C_AM/3 2 -M2 /3.B2 -X1 splice 4 4 5 1 3 -K3 -M1 starter motor C_EB/4 207 1,2 light relay 2 battery, generator, starter fuel pump relay 4 10A 2 1 10A 2 1 10A 2 1 70 -F5 -F6 -F7 -F8 69 113 113 26 73 71 114 C_BH/6 25 25 diode 224 -V2 23,24 74,75 start/stop switch M -K1 4 2 4 C_AE/4 3 1 C_EB/4 3 6 2 30 A start relay power relay 114 -S2 68 ignition switch 5 6 4 208 75 -X40 55 -X41 56 21bl 5 -K4 1 -G1 4 GND-X2 battery 4 /2.C3 24 23 7 2 1 1 2 3 7 gn -K2 115,116 C_AU/2 C_EB/4 7 start auxillary relay 5 A -S1 4 1 3 2 115 72 67 128 fuel-A2 C_BI/2 2 213 76,166 -X39 203 -X38 17 bl 128,129 Antenna 19 bl 9 -X34 13 bl 10 bl 224 130 /2.E5 182 /3.A5 lig-X4 27 /2.B5 STR-A3 200 53 52 for optional alarm system 39,35 -X42 22 bl 20 bl 7,8 1 -A1-X10 G generator /2.C1 3 -N1 /2.C2 8 611.11.075.100 610.41.012.000 main harness - GND-X8 53,55,56,207,208,213 re-wh re-wh U regulator-rectifier gn gn 8 3 P. Page:1 F E D C B A 13-42 F E D C B 1 -A1 73 1 4 C_DK/18 C_DJ/18 6 -A2-P1 5 3 6 7 2 3 lig-S7 4 8 9 ALA-P1 8 7 6 pow-X9 /3.B2 tlig-H4 plig-S2 /3.C5 /3.D2 /3.D6 Connector for optional alarm system 9 10 11 12 13 14 15 16 17 18 /3.D4 5 alarm system dummy plug 5 4 /3.D6 /3.D6 flaR-X200 flaL-X200 /2.D4 1 C_AB/9 C_BB/9 78,79 1 C_AI/2 2 -X43 2 3 C_BV/2 C_BS/2 1 51 -S20 seat surveillance 2 10A -F1 2 1 10A 2 1 2 1 3 C_EB/4 -K5 129 ACC Bat-P1 /3.A6 3 1 fuel pump M C_AR/3 C_AM/3 2 -M2 /3.B2 4 4 5 1 3 -K3 -M1 starter motor C_EB/4 207 light relay 2 battery, generator, starter fuel pump relay 4 10A 2 1 10A 2 1 10A 2 1 70 -F5 -F6 -F7 -F8 -X1 splice 1,2 diode 66 990 Superduke R 2008 2 3 1 2 9 C_AP/6 74 -X31 116 -X32 126,127 11bl 67,68 C_BH/6 -X35 14 bl 85,86 48 -X36 8 -X33 12 bl 65 15 bl 83,54 65,66 51 -X37 16 bl 69 113 113 26 73 71 114 -V2 25 25 start/stop switch M -K1 4 2 4 C_AE/4 3 1 C_EB/4 3 6 2 30 A start relay power relay 114 -S2 23,24 74,75 6 68 ignition switch 224 75 -X40 55 -X41 56 21bl 5 5 A -S1 4 4 208 3 1 -G1 -K4 1 2 4 GND-X2 battery 4 /2.C3 24 23 7 2 1 2 1 3 7 gn -K2 115,116 C_AU/2 C_EB/4 7 start auxillary relay 5 1 2 115 72 67 128 fuel-A2 C_BI/2 Art.-No. 3.206.056-E 213 76,166 -X39 203 -X38 17 bl 128,129 Antenna 19 bl 9 -X34 13 bl 10 bl 224 130 /2.E5 182 /3.A5 lig-X4 27 /2.B5 STR-A3 200 53 52 for optional alarm system 39,35 -X42 22 bl 20 bl 7,8 Repair manual KTM LC8 -A1-X10 G generator /2.C1 3 -N1 /2.C2 8 611.11.175.000 610.41.012.000 main harness - GND-X8 53,55,56,207,208,213 re-wh re-wh U regulator-rectifier gn gn 8 3 P. Page:1 F E D C B A 13-43 31 4 5 bu s en so r rollover C_AP2/6 bl ye-re 6 wh-bl br 3 L L rear t° 2 1 p C_BZ1/3 3 2 1 C_AX/2 2 3 p C_BZ/3 1 1 2 C_CM/2 t° 1 2 pu 3 bl p C_BZ2/3 2 3 4 2 1 or br or-wh g n -re 15 fuse 10 A 7 1 3 2 C_AR3/3 C_AM3/3 sidestand switch P i c k up C_AT/2 C_AL/2 1 ye-wh manifold pressure sensor rear atmospheric pressure sensor 990 Super Duke 2005/06 lambda sensor´s f r ont t° C_CE/4 2 C_CE1/4 4 1 bl C_CA/4 3 wh-or C_CA1/4 re-gn or 4 1 2 bl t° ye-bl gn-gr bu 2 bl bl 1 water temperature sensor manifold pressure sensor front ye re-br or re C_AL1/2 bu air temperature sensor bu main relay ye-bu C_AT1/2 bu-bl bl bl bl re-wh 2 C_AI/2 1 7 13 14 3 24 23 11 12 4 C_AO/26 2 10 9 22 6 20 25 26 19 15 18 17 1 8 ECU 2 1 9 14 16 34 C_AM2/3 1 6 ye-re 4 br or C_AR2/3 I page 6/9 H 6/8 G 6 /8 C 6/8 gr ye-br 2 gn-bl 3 N 3th 2nd C_AP1/6 C_AF/4 pi 1 33 15 13 23 11 3 C_BH1/6 bl bl or 6 29 26 C_CO/34 7 21 12 4 22 5 7 2 ye-or diagnostic c o nn e c to r C_AB/9 C_BB/9 start/stop switch or ignition switch bu 3rd gear diode or bu-gr br br bu-wh wh bu-br 18 1 f r ont C_AS1/2 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 or C_DJ/18 rear C_AS/2 2 C_DK/18 14 10 4 8 11 bl-wh 9 o r 13 b l - gr 5 pi bu-wh 3 gn-wh 7 b l - b r 15 wh-re 12 wh gn b l - o r 16 bu ye 2 exhaust air valve C_CK/2 1 2 ye-wh 6 bl 9 C_CQ/16 C_AR/3 1 f r ont C_CL1/2 2 bu-bl or pu ye bu re gr gr wh gn pu bu 2 3 2 5 4 1 rear C_CL/2 2 C_AR1/3 1 4 2 1 C_CA2/4 C_CE2/4 fuel pumprelay 3 2 C_AM4/3 C_AR4/3 2 M fuel pump 4 1 3 C_AE/4 1 B 6/8 Q f u e l pum p unit 3/8 ISC stepper motor s e c on d throttle stepper motor 3 3 3 2 TPS C_AM1/3 C_AF1/4 1 13 fuse 10 A 2nd TPS C_AM/3 1 g n - re bl wh airbox harness 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 fuse 10 A 1 or C_CP/16 610.41.012.000 1 wh-pu ignition switch alarm system dummy plug re-bl or ignition coil bu or-bl or Connector for optional alarm system wh-br bu re-wh or wh ye br gr bu-bl wh clutch switch E gn pu re-wh or-wh bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re ye ye-wh ye-bl re br ye-or ye pi gn-bl ye-br gr ye-re C bu 2nd gear neutral switch wh-or wh-bl re-bl bl-or gn wh wh-re bl-br gn-wh bu-wh pi bl-gr bl-wh wh-pu wh-br U gn-re or injector´s bu-bl bl or bu-gr ye-bl pu bu-bl or-wh bl re gr br-re 31 30 fuel level sensor 30 13-44 F E D 2 -X 1 1 s plic e -B 2 6 4 1 rollove r s e n s or - B 7 -B 1 5 fue -P 1 1 he go s e ns or re a r t° -B 1 6 1 p C _ D P /3 2 164 -B 4 a tmos phe ric pre s s ure s e ns or 3 /3 . B 2 1 C _ A R /3 C _ A M/3 137 3 1 p C _ D P /3 2 C _ A R /2 -X 1 0 1 205, 209, 210 205, 206 1 p C _ D P /3 2 -B 1 8 G N D -P 1 1 68 , 2 04 ma nifold pre s s ure s e ns o r r e a r -B 1 7 3 2 2 3 49 3 /1 . D 2 /3 . B 2 2 pic k up C _ A T /2 C _ A L /2 1 1 ECU 4 2 3 C _ A O /2 6 4 /3 . D 4 G N D -S 5 -A 2 -L 3 -A 2 -P 1 G N D -H 4 214, 215, 33 /3 . B 6 49, 176, 177, 178 1 56, 157, 158 -X 1 3 s plic e -X 1 7 s plic e 206, 223 -X 2 s plic e G N D -X 2 4 1 C _ A M/2 53, 55, 56, 207, 208, 211, 212, 213 ma nifold pre s s ure s e ns or front 3 /1 . C 7 -X 8 s plic e 2 990 S U P E R D U K E (R ) 07 he go s e ns or front t° L 2 C _ C E /4 3 C _ C E /4 4 C _ C A /4 1 C _ C A /4 2 G N D -X 8 2 1 42, 146, 147, 150 , 152, 15 5, 159, 1 62, 225 -X 6 s plic e 3 L /1 . E 8 1 32, 13 3, 134, 135, 13 6, 137 4 1 64 , 1 65 -X 7 s plic e C _ A P /6 5 138 1 33, 139, 50, 141 -X 1 5 s plic e 1 20, 12 1, 122, 123, 12 4, 125 1 17, 11 8, 119 , 120 -X 1 0 s plic e 160 1 15 , 1 16 161 50 -X 1 6 s plic e a ir te mp. s e n s or t° C _ C M/2 1 225 159 -A 1 -X 1 0 165 C 145 /1 . D 7 149 B 147 1 140 117 /3 . B 2 154 te m-P 1 152 211 122 212 153 175 148 156 134 C _ A L /2 151 201 121 174 C _ A T /2 136 3 139 155 150 173 162 2 167 1 132 C _ E C /3 5 6 7 8 175 173 171 154 172 149 170 7 6 5 4 3 2 1 C _ D O /8 C _ D N /8 1 2 3 4 C _ C O /3 4 5 8 6 214 7 8 215 5 /3 . B 2 6 2. 1 2. 2 2. 3 2. 4 2. 5 2. 6 2. 7 2. 8 2. 9 2. 10 2. 11 2 . 12 2. 13 2. 14 2. 15 2. 16 -A 2 -P 1 3 20 3 16 3 11 3 09 3 07 3 06 3 03 ignition c oil front 1 7 -L 1 T A C -P 1 2 1 C _ C L /2 inje c tion re a r 2 1 C _ A R /3 C _ A M/3 ignition c oil re a r 1 -L 2 /3 . B 2 C _ A S /2 2 -Y 3 3 00, 30 1, 302 C _ C L /2 1 -B 1 3 1 -M5 M I L -P 1 1 2 1 3 4 3 8 ma in ha rne s s 611. 11. 075 . 20 0 610. 41. 012. 000 307 1 M -M6 C _ C E /4 C _ C A /4 2 319 3 P. P a ge : 2 2 nd throttle s te ppe r motor C _ C K /2 /3 . B 2 2 -Y 1 -Y 2 purge va lve e x ha us t a ir va lve 2 2 1 C _ A M/3 C _ A R /3 C _ A E /4 3 M 8 2 nd throttle pos ition s e ns or IS C s te ppe r motor 4 -B 1 4 C _ D U /2 -Y 4 3 ma in throttle pos ition s e ns or 3 16, 317, 318 7 inje c tion front 2 3 13 /3 . B 2 C _ A S /2 2 313, 314, 315 3 19 3 12 3 10 3 08 3 05 3 04 3 00 -X 3 1 0 s plic e -X 3 0 9 s plic e /3 . F 2 -X 3 0 8 s plic e 1 93 1 25 1 94 1 86 1 89 1 85 1 84 C L U -A 2 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 1 95 1 35 1 87 1 67 1 88 1 70 1 83 1 46 1 81 1 79, 180, 181 -X 1 8 s plic e /3 . A 8 1 7 8 N e u-P 1 G N D -X 3 E C U 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 174 N 176 3 th 168 -A 3 S ta rte r I nte rloc k U nit 141 126 2 nd 169 -S 1 1 151 -B 1 1 145 STR-A3 /1.E7 140 R 138 -B 3 163 6 179 200 158 157 186 222 184 180 185 169 187 4 189 1 191 C _ A P /6 188 -X 5 0 192 t° 190 -B 9 t° 148 A 194 ge a r pos ition s witc h 193 s ide s ta nd s e ns or 196 fue l le ve l s e ns or 195 C _ B H /6 199 6 197 5 198 dia gnos tic c onne c tor 142 -X307 C_CQ/16 4 160 9 8 7 6 5 4 3 2 1 16 15 14 13 12 11 10 153 wa te r te mp. s e n s or 171 309 3 163 317 2 172 305 199 fuel-A2 182 306 177 /1.E4 183 314 196 304 C_CP/16 123 310 1 190 Art.-No. 3.206.056-E 118 315 197 320 124 301 198 308 318 312 119 303 302 311 Repair manual KTM LC8 F E D C B A 13-45 F E D 2 159 -B2 6 4 1 rollover sensor -B7 C_AP/6 5 -B15 t° 1 t° fue-P1 -B16 1 p C_DP/3 2 164 1 -B4 atmospheric pressure sensor 3 /3.B2 137 3 1 p C_DP/3 2 2 C_AR/2 205,209,210 3 3 205,206 1 p C_DP/3 2 -B18 GND-P1 168,204 manifold pressure sensor rear -B17 -X101 2 49 3 /1.D2 /3.B2 2 pick up C_AT/2 C_AL/2 1 /3.D4 GND-S5 -A2 1 4 /3.B6 2 3 4 5 C_AO/26 ECU -L3 -A2-P1 GND-H4 214,215,33 49,176,177,178 156,157,158 -X13 splice -X17 splice 206,223 -X2 splice GND-X2 4 1 C_AM/2 53,55,56,207,208,211,212,213 manifold pressure sensor front 3 /1.C7 -X8 splice 2 990 Superduke 2007-2008 hego sensor rear L 2 C_CE/4 3 C_CE/4 4 C_CA/4 1 C_CA/4 2 GND-X8 2 142,146,147,150,152,155,159,162,225 -X6 splice hego sensor front L 3 4 164,165 -X7 splice /1.E8 132,133,134,135,136,137 -X15 splice 133,139,50,141 -X16 splice 120,121,122,123,124,125 117,118,119,120 -X10 splice 115,116 -X11 splice -A1-X10 air temp. sensor t° C_CM/2 1 225 160 50 1 140 161 138 C 145 /1.D7 165 B 154 /3.B2 152 175 148 212 153 211 122 201 121 tem-P1 149 156 134 117 147 155 150 C_AR/3 151 C_AM/3 163 C_AT/2 136 174 C_AL/2 139 173 162 3 167 2 138 1 132 C_EC/3 6 7 175 173 171 154 172 149 170 7 6 5 4 3 2 1 C_DO/8 C_DN/8 1 2 3 4 5 C_CO/34 8 6 214 7 5 /3.B2 /3.A8 178 Neu-P1 GND-X3 195 135 187 167 188 170 183 146 181 6 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 -A2-P1 320 316 311 309 307 306 303 ignition coil front 1 7 -L1 TAC-P1 2 1 C_CL/2 injection rear 2 1 C_AR/3 C_AM/3 ignition coil rear -L2 1 /3.B2 C_AS/2 2 -Y3 300,301,302 C_CL/2 1 -B13 1 -M5 MIL-P1 1 1 3 4 3 main harness - 8 611.11.075.100 610.41.012.000 307 1 M -M6 C_CE/4 C_CA/4 2 319 3 P. Page:2 2nd throttle stepper motor C_CK/2 /3.B2 2 2 -Y1 -Y2 purge valve exhaust air valve 2 2 1 C_AM/3 C_AR/3 C_AE/4 3 M 8 2nd throttle position sensor ISC stepper motor 4 -B14 C_DU/2 -Y4 3 main throttle position sensor 316,317,318 7 injection front 2 313 /3.B2 C_AS/2 2 313,314,315 319 312 310 308 305 304 300 -X310 splice -X309 splice /3.F2 -X308 splice 193 125 194 186 189 185 184 CLU-A2 179,180,181 -X18 splice 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 215 E C U 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 174 N 126 3th 151 2nd 168 -A3 Starter Interlock Unit 187 R 169 -S11 145 STR-A3 /1.E7 140 -B11 163 -B3 171 6 141 176 200 179 157 158 222 186 180 184 169 185 4 189 1 191 C_AP/6 188 A 192 C_BH/6 190 -X50 194 t° 196 -B9 t° 148 6 195 5 193 4 197 gear position switch 198 3 199 sidestand sensor 142 -X307 C_CQ/16 2 160 9 87 65 43 2 1 16 15 14 13 12 11 10 153 fuel level sensor 172 305 199 fuel-A2 182 314 196 306 177 /1.E4 183 309 C_CP/16 123 310 diagnostic connector 190 1 118 304 317 315 197 320 124 301 198 308 318 312 119 303 302 311 water temp. sensor F E D C B A 13-46 F E D 2 159 -B2 6 4 1 rollover sensor -B7 C_AP/6 5 -B15 t° 1 t° fue-P1 -B16 1 p C_DP/3 2 164 -B4 atmospheric pressure sensor 3 /3.B2 1 C_AR/3 C_AM/3 137 3 1 p C_DP/3 2 C_AR/2 205,209,210 3 205,206 1 p C_DP/3 2 -B18 GND-P1 168,204 manifold pressure sensor rear -B17 -X101 2 3 2 49 3 /1.D2 /3.B2 2 pick up C_AT/2 C_AL/2 1 1 4 /3.B6 2 3 4 5 C_AO/26 ECU -L3 /3.D4 GND-S5 -A2 -A2-P1 GND-H4 214,215,33 49,176,177,178 156,157,158 -X13 splice -X17 splice 206,223 -X2 splice GND-X2 4 1 C_AM/2 53,55,56,207,208,211,212,213 manifold pressure sensor front 3 /1.C7 -X8 splice 2 990 Superduke R 2008 hego sensor rear L 2 C_CE/4 3 C_CA/4 4 C_CE/4 1 C_CA/4 2 GND-X8 2 142,146,147,150,152,155,159,162,225 -X6 splice hego sensor front L 3 4 164,165 -X7 splice /1.E8 132,133,134,135,136,137 -X15 splice 133,139,50,141 -X16 splice 120,121,122,124,125,123 117,120,119,118 -X10 splice 115,116 -X11 splice -A1-X10 air temp. sensor t° C_CM/2 1 225 160 50 1 140 161 138 C 145 /1.D7 165 B 154 /3.B2 152 175 148 212 153 211 122 201 121 tem-P1 149 156 134 117 147 155 150 C_AT/2 139 174 C_AL/2 151 3 136 2 167 1 132 C_EC/3 6 7 175 173 171 154 172 149 170 7 6 5 4 3 2 1 C_DO/8 C_DN/8 1 2 3 4 5 C_CO/34 8 6 214 7 5 /3.B2 /3.A8 178 Neu-P1 GND-X3 195 135 187 167 188 170 183 146 181 6 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 -A2-P1 313,314,315 319 312 310 308 305 304 300 320 316 311 309 307 306 303 2 TAC-P1 1 7 ignition coil front C_EP/3 C_EO/3 3 /3.B2 2 1 C_CL/2 3 3 4 -B14 1 M /3.B2 3 2 C_EO/3 1 ignition coil rear C_EP/3 -L5 MIL-P1 /3.B2 1 C_DU/2 1 2 M -M6 C_CE/4 C_CA/4 2nd throttle stepper motor 3 4 3 2 1 C_CK/2 8 611.11.175.000 610.41.012.000 main harness - 3 P. Page:2 -Y1 -Y2 purge valve exhaust air valve 2 2 -M5 1 C_AM/3 C_AR/3 C_AE/4 2 8 2nd throttle position sensor ISC -Y4 stepper motor injection rear 2 1 C_AR/3 C_AM/3 -L6 -Y3 300,301,302 C_CL/2 1 -B13 main throttle position sensor 316,317,318 7 injection front 2 313 -X310 splice -X309 splice /3.F2 -X308 splice 193 125 194 186 189 185 184 CLU-A2 179,180,181 -X18 splice 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 215 E C U 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 174 N 126 3th 168 -A3 Starter Interlock Unit 151 2nd 169 -S11 145 STR-A3 /1.E7 140 -B11 187 R 138 -B3 163 6 141 176 200 179 157 158 222 186 180 184 169 185 4 189 1 191 C_AP/6 188 -X50 192 t° 190 -B9 t° 148 A 194 gear position switch 193 sidestand sensor 196 fuel level sensor 195 C_BH/6 197 6 198 5 199 diagnostic connector 142 C_CP/16 -X307 C_CQ/16 water temp. sensor 163 317 315 4 160 9 87 65 43 2 1 16 15 14 13 12 11 10 153 173 162 309 3 171 301 2 172 306 199 fuel-A2 182 320 177 /1.E4 183 305 197 314 196 304 1 123 308 Art.-No. 3.206.056-E 118 303 302 311 318 312 198 307 119 310 124 319 190 Repair manual KTM LC8 F E D C B A 13-47 31 E 6/8 D 6/8 1 or-bl orange 0.5 C_AH2/2 4 7 C_AD/12 C_BD/12 1 flasher switch G 3 1 2 3 right front flasher br left front flasher brown 0.5 990 Super Duke rear flasher light`s C_BK/4 C_AZ/4 1 7 C_CC/12 C_CI/12 pu 2 bl 1 diode C_AI3/2 2 8 horn switch C_BD/12 C_AD/12 3 yellow-blue 0.5 r ed 1 horn 12 4 re 2 1 2 temperature switch C_AV/2 1 fuse 10 A ignition switch br turn signal , horn , fan 11 fuse 10 A ignition switch br 3 gr flasher relay bl-wh red-white 1 br-bl red-white 1 M 31 30 4/8 cooling fan C_BI1/2 30 13-48 C_AU1/2 13-49 ignition switch r-w r-w r-w flasher switch o ON y-r r cable harness or gr br cable switch gn- bu- bupi br re bl brpi pu bl TURN L OFF TURN R LOCKED OFF Art.-No. 3.206.056-E start switch cable harness or cable switch blbu blor bl START horn switch cable harness gr br cable switch pi brpi HORN unpushed OFF stop switch cable harness Repair manual KTM LC8 cable switch RUN STOP or -bl or bl bl - bu clutch switch switch position pulled unpulled ye br 31 head light flasher HI LO low/high beam switch 2 1 0 light switch C_BD/12 C_AD/12 2 6 5 9 3 F 6/8 white 0.5 fuse 10 A ignition switch C_BB/9 11 3 r ed 1 front yellow-brown 1 blue 1 g r een 1 brake switch r ear brake switch 990 Super Duke 9 6 10 yellow-red 1 yellow 1 ignition switch fuse 15 A C_AB/9 2 yellow 1 yellow-brown 1 licence plate lamp green-white 0.5 1 3 1 2 white 0.5 C_BG/3 C_AJ/3 6 2 rear light/brakelight C_BC/6 C_AC/6 light-brake system 1 2 blue-yellow 2 1 head light 3 4 brown 1 C_AH/2 C_AH1/2 C_AK/2 C_AK1/2 30 brown 0.5 5/8 31 30 13-50 13-51 light switch ignition switch r-w r-w r-w o y-r r ON cable harness yewh ye br cable switch yewh wh reye LIGHT OFF OFF P. LIGHT LOCKED LIGHT high/low beam switch Art.-No. 3.206.056-E brake switch cable harness gn- yewh bu cable harness bu gn yebr cable switch bl cable switch wh ye gnre bl pushed LO unpushed HI Repair manual KTM LC8 passing light cable harness ye cable switch gnwh bl P. HORN OFF bu 31 bu-br white 0.5 F 5/8 7 1 6 2 9 p C _ AY /1 C_BJ/1 oil pressure sensor gree n-gr ey 0.5 green-black 0.5 990 Super Duke 2005/06 D E 4/8 violett 0.5 I G H B 3/8 3 5 blue 0.5 red-white 0.5 speed sensor v black-brown 0.5 C_AM5/3 C_AR5/3 2 or.ye black-orange 0.5 1 3 4 black 0.5 8 12 re-br C_AA/20 10 15 16 brown 0.5 14 ignition switch 11 r ed 1 A 2/8 3 2 C_AG/3 C_BE/3 1 n tachometer instruments-tachometer fuse 10 A 3 ye-bu 6 brown 0.5 fuse 10 A ye-bu multi-func.-digital-speedometer blue-white 0.5 30 C 3/8 6/8 31 30 13-52 F E D C B 1 C_ED/32 -S8 -H7 -B12 t° C_AH/2 94 109 110 96 95 1 10 97 98 1 11 92 93 89 90 99 1 01 1 00 1 05 1 03 1 08 1 02 1 81 221 91 107 81 82 166 78 220 1 11 1 12 108,112 -X304 splice C L U -A 2 1 81 203 1 61 178 1 92 204 203 T A C -P 1 te m-P 1 N e u-P 1 M I L -P 1 G N D -P 1 A L A -P 1 46,54 -S 7 7 8, 79 201 plig-S 2 219 80, 81 127 129 84, 85 1 91 1 61 178 2 02 1 92 204 129 1 91 B a t-P 1 127 -A 2 -P 1 8 C _ A D /1 2 1 38 HI 79 2 4 P . light 7 /1 . B 2 2 5 L 3 R 48 lig-S 7 be a m horn fla s he r s witc h LO C _ B D /1 2 80 990 S U P E R D U K E (R ) 07 /2 . A 6 /1 . B 3 1 04, 10 5, 106 , 109 87, 89 92 104 93 94, 95 96 90, 91 97 98 99 100 1 01 1 02 103 /2 . D 3 /1 . E 3 /2 . B 2 /2 . D 7 /1 . D 5 /2 . E 7 /2 . B 1 /2 . B 6 /2 . E 8 201 fue -P 1 46 6 84 3 C _ B J /1 2 G N D -H 4 1 C _ A Y /1 1 209, 210, 223 fla s he r re la y G -K 6 C _ A H /2 lig-X 4 1 C _ A I /2 diode 2 27 -X 4 s plic e -X 1 2 s plic e /1 . E 6 -V 1 1 1 10A 2 10A 10A 2 -F 2 -F 3 -F 4 2 1 4 5 1 C _ B L /2 M /1 . B 5 /1 . E 2 /1 . E 2 G N D -S 5 AC C 2 33 130 t C _ A V /2 1 32 1 -S 5 7 6, 166 85, 86 83, 54 tlig-H 4 fla L -X 2 00 fla R -X 2 00 6 37 te mpe ra ture s witc h -X 9 s plic e /1 . B 3 34, 39, 40 -M3 /2 . C 4 C _ C D /2 2 1 c ooling fa n 2 10A -F 9 6 1 a ditiona l c urre nt c onne c tion A C C 1 -X 2 1 C _ C R /1 -X 2 2 C _ C R /1 -H 5 216 5 ins trume nts -ta c home te r 9 /2 . C 4 1 2. 1 C _ E H /1 -X 5 1 -S 2 1 28 47 2 1 2 29 34 front brake switch flasher right front ambient temp. sensor multi-func.-digital-speedometer headlight C_CW/2 31 32 20 21 22 23 24 25 26 27 28 29 30 17 18 19 10 11 12 13 14 15 16 9 8 7 6 5 4 3 2 1 -P1 G -B8 speed sensor high low C_CX/2 C_CX/2 6 5 4 3 3 C_AM/3 C_AK/2 2 87 107 -X303 splice 3 2 1 2.1 2.2 2.3 2.10 2.11 2.12 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 C_BE/3 C_CI/4 2 1 9 10 11 12 8 7 6 5 4 3 2 C_AG/3 -X302 C_CC/4 -X301 1 218 106 42 82 209 83 86 77 ho r n 1 1 7 1 2 a ditiona l c urre nt c onne c tion A C C 2 -X 2 3 C _ C R /1 -X 2 4 C _ C R /1 60 59 58 57 1 C _ A H /2 C _ A K /2 2 re a r bra k e s witc h 7 -X 2 0 1 s plic e -S 6 131 oil pre s s ure s witc h 43 217 4 40 30 31 64 131 32 41 3 47,48 2 1 C_AC/6 C_CW/2 C_BC/6 C_CX/2 pos. clutch switch flasher left front -H201 -H6 -S9 45 2 2.4 2.3 2.2 2.1 1 C_AT/2 36 31 pow-X9 35,39 /1.E3 C_CW/2 2 1 C_AL/2 35 A 1 6 2 , 63 , 6 1 /2 . B 6 2 22 210 63 59 62 57 7 6, 77 216, 217, 218, 219, 220, 221, 223 -X 3 s plic e 3 6, 42 61 58 G N D -X 3 8 611. 11. 075 . 10 0 610. 41. 012. 000 8 ma in ha rne s s - C_DI/2 C_AR/3 Art.-No. 3.206.056-E C_CV/4 C_CX/2 C_CX/2 321 202 44 1 2 1 45 43,41 44 38 -X200 C_BY/4 37 1 2 3 4 1 2 1 C_CW/2 C_BG/3 1 2 -H8 -H4 -H9 2 3 1 2 C_AJ/3 C_CW/2 flasher right rear rear light/ brake light -H200 licence plate lamp 3 P. P a ge : 3 flasher left rear Repair manual KTM LC8 F E D C B A 13-53 F E D C 1 C_AH/2 94 109 110 96 95 110 97 98 111 92 93 89 90 99 101 100 105 103 322 108 102 181 221 91 107 81 82 166 78 220 111 112 87 108,112 -X304 splice /2.A6 103 C_BE/3 107 181 191 161 178 192 204 203 TAC-P1 tem-P1 Neu-P1 MIL-P1 GND-P1 ALA-P1 -S7 plig-S2 78,79 46,54 219 201 80,81 127 129 84,85 191 161 178 202 192 204 129 Bat-P1 203 127 -A2-P1 1 38 8 HI 2 2 80 4 P.light 7 /1.B2 5 lig-S7 L beam horn flasher switch LO C_BD/12 C_AD/12 79 -X303 splice 3 990 Superduke 2007-2008 CLU-A2 /1.B3 104,106,109,105,322 87,89 92 104 93 94,95 96 90,91 97 98 99 100 101 102 /2.D3 /1.E3 /2.B2 /2.D7 /1.D5 /2.E7 /2.B1 /2.B6 /2.E8 201 R 48 46 6 84 3 2 1 2 GND-H4 1 flasher relay G -K6 C_AH/2 209,210,223 1 C_AI/2 diode 2 27 -X4 splice -X12 splice lig-X4 -V1 10A 2 10A 10A 2 1 -F2 -F3 -F4 1 2 1 4 5 10A -F9 1 C_BL/2 M /1.B5 /1.E2 /1.E2 GND-S5 ACC 6 33 t C_AV/2 1 32 -S5 76,166 85,86 83,54 tlig-H4 flaL-X200 flaR-X200 6 37 temperature switch 2 130 1 1 -H5 216 aditional current connection ACC1 -X21 C_CR/1 -X22 C_CR/1 -X9 splice /1.B3 34,39,40 -M3 /2.C4 C_CD/2 2 1 cooling fan 2 instruments-tachometer 9 /2.C4 1 C_AY/1 C_BJ/1 2.1 1 /1.E6 29 47 P C_EH/1 -X51 -S21 28 34 front brake switch flasher right front ambient temp. sensor -S8 -H7 -B12 t° -P1 B C_ED/32 C_AM/3 multi-func.-digital-speedometer headlight G -B8 speed sensor high C_CW/2 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 9 8 7 6 5 4 3 2 1 3 C_CX/2 C_CX/2 6 5 4 2 321 202 30 31 64 131 32 C_AK/2 3 C_AG/3 2 C_AL/2 2.1 2.2 2.3 2.10 2.11 2.12 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3 1 9 10 11 12 8 7 6 5 4 3 2 -X302 C_CC/4 -X301 1 218 C_CI/4 fue-P1 82 209 83 86 77 horn 1 7 2 60 59 58 57 1 C_AH/2 C_AK/2 P 2 7 -X201 splice -S6 rear brake switch 1 1 aditional current connection ACC2 -X23 C_CR/1 -X24 C_CR/1 131 oil pressure switch 40 2 2 low pos. flasher left front clutch switch 43 31 pow-X9 35,39 /1.E3 217 5 2.4 2.3 2.2 2.1 1 1 36 106 42 47,48 2 1 C_AC/6 C_CW/2 C_BC/6 C_CX/2 35 4 62,63,61 /2.B6 222 210 63 59 62 57 76,77 216,217,218,219,220,221,223 -X3 splice 36,42 61 58 GND-X3 8 8 611.11.075.100 610.41.012.000 main harness - C_DI/2 41 3 45 2 C_CV/4 C_CX/2 C_CX/2 C_CW/2 2 1 C_AT/2 -H201 -H6 -S9 44 1 2 1 45 43,41 44 38 -X200 C_BY/4 37 1 2 3 4 1 2 1 C_CW/2 C_BG/3 1 2 -H8 -H4 -H9 2 3 1 2 C_AJ/3 C_CW/2 flasher right rear rear light/ brake light -H200 licence plate lamp 3 P. Page:3 flasher left rear A 1 F E D C B A 13-54 C_AR/3 F E D C 1 C_AH/2 94 109 110 96 95 110 97 98 111 92 93 89 90 99 101 100 105 103 322 108 102 181 221 91 107 81 82 166 78 220 111 112 87 108,112 -X304 splice 107 CLU-A2 181 191 161 178 192 204 203 TAC-P1 tem-P1 Neu-P1 MIL-P1 GND-P1 ALA-P1 -S7 plig-S2 78,79 46,54 219 201 80,81 127 129 84,85 191 161 178 202 192 204 129 -A2-P1 203 201 127 fue-P1 Bat-P1 1 38 8 HI 79 2 4 P.light 7 /1.B2 2 5 lig-S7 L beam horn flasher switch LO C_BD/12 C_AD/12 80 -X303 splice 3 990 Superduke R 2008 /2.A6 /1.B3 104,106,109,105,322 87,89 92 104 93 94,95 96 90,91 97 98 99 100 101 102 103 /2.D3 /1.E3 /2.B2 /2.D7 /1.D5 /2.E7 /2.B1 /2.B6 /2.E8 2 1 R 48 46 6 84 3 2 GND-H4 1 flasher relay G -K6 C_AH/2 209,210,223 1 C_AI/2 diode 2 27 -X4 splice -X12 splice lig-X4 -V1 10A 10A 2 1 10A 2 1 -F2 -F3 -F4 2 1 4 5 10A -F9 1 C_BL/2 M /1.B5 /1.E2 /1.E2 GND-S5 ACC 2 33 130 1 t C_AV/2 -S5 1 76,166 85,86 83,54 tlig-H4 flaL-X200 flaR-X200 6 37 temperature switch -X9 splice /1.B3 34,39,40 -M3 /2.C4 C_CD/2 2 1 cooling fan 2 instruments-tachometer 9 /2.C4 1 C_AY/1 C_BJ/1 2.1 1 /1.E6 6 32 -H5 1 aditional current connection ACC1 -X21 C_CR/1 -X22 C_CR/1 216 5 29 47 P C_EH/1 -X51 -S21 28 34 front brake switch flasher right front ambient temp. sensor -S8 -H7 -B12 t° -P1 B C_ED/32 C_AM/3 multi-func.-digital-speedometer headlight G -B8 speed sensor high C_CW/2 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 9 8 7 6 5 4 3 2 1 3 C_CX/2 C_CX/2 6 5 4 3 2 30 31 64 131 32 C_AK/2 3 C_AG/3 2 C_AL/2 2.1 2.2 2.3 2.10 2.11 2.12 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 C_BE/3 C_CI/4 1 9 10 11 12 8 7 6 5 4 3 2 -X302 C_CC/4 -X301 1 218 321 202 106 42 82 209 83 86 77 horn 1 7 2 60 59 58 57 1 C_AH/2 C_AK/2 P 2 7 -X201 splice -S6 rear brake switch 1 1 aditional current connection ACC2 -X23 C_CR/1 -X24 C_CR/1 131 oil pressure switch 40 2 2 low pos. flasher left front clutch switch 43 31 pow-X9 35,39 /1.E3 217 4 2.4 2.3 2.2 2.1 1 1 36 41 3 47,48 2 45 2 1 C_AC/6 C_CW/2 C_BC/6 C_CX/2 35 A 1 62,63,61 /2.B6 222 210 63 59 62 57 76,77 216,217,218,219,220,221,223 -X3 splice 36,42 61 58 GND-X3 8 8 611.11.175.000 610.41.012.000 main harness - C_DI/2 C_AR/3 Art.-No. 3.206.056-E C_CV/4 C_CX/2 C_CX/2 C_CW/2 2 1 C_AT/2 -H201 -H6 -S9 44 1 2 1 45 43,41 44 38 -X200 C_BY/4 37 1 2 3 4 1 2 1 C_CW/2 C_BG/3 1 2 -H8 -H4 -H9 2 3 1 2 C_AJ/3 C_CW/2 flasher right rear rear light/ brake light -H200 licence plate lamp 3 P. Page:3 flasher left rear Repair manual KTM LC8 F E D C B A 13-55 headlight tachometer LED red Alarm sytem M ECU ECU battery temperature switch 30 A 990 Super Duke clutch switch right-left front flasher multi-func.-digital-speedometer horn switch s t a r t er m o t o r start relay bl brown bl alarmsystem ground connection regulator 7/8 rear light/brakelight rear flasher main relay diagnostic connector fu e l pump module accesory 13-56 rear brake switch tachometer front brake switch flasher relay or multi-func.-digital-speedometer I 3/8 990 Super Duke speed sensor ye-bu bl -o r start/stop switch A A 9 5 6 7 A A A A A 8 10 11 12 13 14 15 16 A 4 10 10 10 10 10 3 fuel pump relay re-bl 30 A bl bl battery positive connection fan fuse box 2 10 15 10 1 ignition switch ye-bu horn ye bl-wh light switch M ye-bl high/low beam switch s t a r t er mo t o r ye re s t a r t relay gn-re Art.-No. 3.206.056-E re-wh Repair manual KTM LC8 power relay alarm system accesory regulator 8/8 13-57 13-58 Connector AA 20-pole 1 11 1 Multifunctional digital speedometer Behind the functional speedometer multidigital 20 10 1 Connector AB 9-pole 2 1 3 9 Start/stop/light switch Behind mask the headlight 3 2 Connector AC 6-pole 3 Front lighting 1 4 3 6 Behind mask the headlight Connector AD 12-pole 4 1 3 7 12 Turn signal, horn, high beam switch Behind mask the Connector AE 4-pole 5 1 4 2 4 headlight Idle speed control motor 5 On the throttle body Connector AE1 4-pole 6 Start relay/main fuse On the left next to the battery case 6 13-59 Connector AF 4-pole 1 Main relay 1 Under the seat 42 3 Connector AF1 4-pole 2 Fuel pump relay Under the seat Connector AF2 4-pole 3 Auxiliary starter relay Art.-No. 3.206.056-E Under the seat Connector AG 3-pole 4 Speedometer 1 3 Behind mask the 5 headlight 4 Connector AH 2-pole 5 Repair manual KTM LC8 Front brake light switch 1 2 Behind mask the headlight 6 Connector AH1 2-pole 6 Rear brake light switch In front of the fuse box Connector AH2 2-pole 7 Turn signal relay Behind mask the headlight 7 2 1 13-60 Connector AI, AI1, AI2 2-pole 1 2 1 Diodes Under the seat Connector AI3 2-pole 2 1 Diode Behind mask the headlight 2 Connector AJ 3-pole 3 1 2 3 Rear lighting Under the seat 3 Connector AK 2-pole 4 4 Front brake light switch 1 2 Behind mask the headlight Connector AK1 2-pole 5 Rear brake light switch In front of the fuse box 5 Connector AL 2-pole 6 Pick up 1 2 In front of the 2nd cylinder over the battery case 6 Connector AL1 2-pole 7 Clutch switch Behind mask the headlight 7 13-61 Connector AM 3-pole 1 1 3 Throttle sensor for the 2nd throttle 1 On the throttle body 2 Connector AM1 3-pole 2 Throttle sensor On the throttle body Connector AM2 3-pole 3 Gear sensor Art.-No. 3.206.056-E On the left next to the battery case 3 4 Connector AM3 3-pole 4 Side stand On the left next to the battery case Connector AM4 3-pole 5 Fuel pump Repair manual KTM LC8 In front of the fuse box 5 Connector AM5 3-pole 6 Speed sensor Behind mask the headlight 6 13-62 Connector AO 26-pole 1 20 14 8 1 ECU Behind head 26 19 13 the steering 7 1 Connector AP 6-pole 2 Ignition switch 1 3 6 Behind head the steering 2 Connector AP1 6-pole 3 Diagnosis connector Behind the fuse box 3 Connector AP2 6-pole 4 Rollover sensor Behind mask the headlight 4 Connector AR 3-pole 5 3 1 Throttle sensor for the 2nd throttle On the throttle body Connector AR1 3-pole 6 Throttle sensor On the throttle body 6 5 13-63 Connector AR2 3-pole 1 3 1 2 Gear sensor On the left next to the battery case 1 Connector AR3 3-pole 2 Side stand On the left next to the battery case Connector AR4 3-pole 3 Fuel pump Art.-No. 3.206.056-E In front of the fuse box Connector AR5 3-pole 4 Speed sensor Behind mask the 3 4 headlight Repair manual KTM LC8 Connector AS 2-pole 5 1 2 Rear ignition coil Behind the air filter box 5 Connector AS1 2-pole 6 Front ignition coil Behind the radiator 6 13-64 Connector AT 2-pole 1 Pick up 1 2 In front of the 2nd cylinder over the battery case 1 Connector AT1 2-pole 2 2 Clutch switch Behind mask the headlight Connector AU 2-pole 3 Regulator output 21 On the left next to the battery case 3 Connector AU1 2-pole 4 4 Fan motor Behind the radiator Connector AV 2-pole 5 1 2 Temperature switch On the right side of the radiator 5 Connector AX 2-pole 6 1 2 Coolant temperature sensor On the left between the cylinders 6 13-65 Connector AY 1-pole 1 Oil pressure switch 1 On the outer left side of the frame Connector AZ 4-pole 2 1 2 3 4 Rear blinker Under the seat 2 Art.-No. 3.206.056-E Connector BB 9-pole 3 1 3 7 9 Start/stop/light switch Behind mask the headlight 4 3 Connector BC 6-pole 4 Front lighting 1 3 6 Behind mask the headlight Connector BD 12-pole 5 Repair manual KTM LC8 1 10 3 Turn signal, horn, high beam switch Behind mask the headlight 12 5 13-66 Connector BE 3-pole 1 1 3 Speedometer Behind mask the headlight 1 Connector BG 3-pole 2 Rear lighting 1 2 3 Under the seat 2 Connector BH 6-pole 3 Ignition switch 1 3 6 Behind head the 3 steering Connector BH1 6-pole 4 Diagnosis connector Behind the fuse box 4 Connector BI 2-pole 5 Regulator output 2 1 On the left next to the battery case 5 Connector BI1 2-pole 6 Fan motor Behind the radiator 6 13-67 Connector BJ 1-pole 1 Oil pressure switch 1 On the outer left side of the frame 1 Connector BK 4-pole 2 1 1 2 3 Rear turn signal Under the seat 3 2 Connector BS 2-pole Alarm LED 1 2 Instrument panel (only for alarm systems) Connector BS1 Art.-No. 3.206.056-E Seat switch 3 Under the seat (only for alarm systems) Connector BV 2-pole 4 Alarm-LED 2 1 Instrument panel (only for alarm systems) Connector BV1 Seat switch Repair manual KTM LC8 Under the seat (only for alarm systems) 4 13-68 Connector BZ 3-pole 1 Pressure sensor for rear cylinder 1 On the left side of the frame 3 1 Connector BZ1 3-pole 2 Manifold air pressure sensor for front cylinder On the right side of the frame Connector BZ2 3-pole 3 2 3 Ambiant air pressure sensor Behind mask the headlight Connector CA 4-pole 4 Rear lambda probe 1 2 3 4 On the left next to the battery case 4 Connector CA1 4-pole 5 Front lambda probe On the right side of the frame 5 Connector CA2 4-pole 6 Control motor for the 2nd throttle On the throttle body 6 13-69 Connector CC 12-pole 1 Front wiring harness 3 1 Behind mask 7 the 1 headlight 12 Connector CE 4-pole 2 2 Rear lambda probe 1 2 3 4 On the left next to the battery case Connector CE1 4-pole 3 Front lambda probe 3 Art.-No. 3.206.056-E On the right side of the frame Connector CE2 4-pole 4 Control motor for 2nd throttle On the throttle body 4 Connector CI 12-pole 5 Repair manual KTM LC8 1 3 Front wiring harness Behind mask 7 the 5 headlight 12 Connector CK 2-pole 6 2 1 Secondary air system valve Behind the air filter box 6 13-70 Connector CL 2-pole 1 Rear injection valve 1 2 On the throttle body 1 Connector CL1 2-pole 2 Front injection valve On the throttle body 2 Connector CM 2-pole 3 Air temperature sensor 2 3 On the top of the air filter box 1 Connector CO 34-pole 4 26 18 10 1 ECU Behind the steering head 34 25 17 9 4 Connector CP 16-pole 5 4 1 Wiring harness EFI On the right side of the frame 6 16 5 Connector CQ 16-pole 6 1 4 Wiring harness EFI On the right side of the frame 16 13-71 Connector CR 1-pole 1 Connector for attachments: Kl 15 (ignition) Kl 31 (ground) 1 Under the seat next to the fuse box Connector DJ 20-pole 2 2 1 18 17 16 15 14 13 6 5 Connector for the alarm system control unit Under the seat Connector DK 20-pole 3 Art.-No. 3.206.056-E Repair manual KTM LC8 13 14 15 16 17 18 1 2 3 4 5 6 Connector (without alarm system) Under the seat 3 2 front brake switch C_AA/20 v C_BV/2 speed sensor clutch switch 2 7 2 1 bu-re left front flasher br gn-gr re-br br-bl ye-bl gn-bl re-wh ye-or bl pu bu ye-bu 1 2 gn-wh 1 2 1 3 2 br bl pu br br br br 1 1 C_BL1/2 M cooling fan M cooling fan C_CD1/2 2 C_BL/2 C_CD/2 2 temperature switch C_AV/2 1 2 wh C_AY/1 C_BJ/1 oil pressure sensor p 7 1 2 4 9 6 C_AD/12 C_BD/12 ye 5 950 SUPERMOTO 2005/06/07 wh gn bu br bl-or ye-or 2 1 br-bl 3 ye C_CR/1 bl-or C_AM3/3 br 15 1 19 6 10 9 3 4 5 right front flasher C_AH1/2 LED red for optional alarm system C_BS/2 16 C_AL3/2 multi-func.-digital-speedometer headlight positionlight C_AK1/2 C_AR3/2 1 C_DI/2 C_BW/3 2 C_AT3/2 C_CR1/1 bl-wh ye-re bl-wh head light flascher gn-bl ye gn-re gn-br gn bu-bl bu bu-re ye-br or gn-gr pu bl ye-bu 2 1 1 3 2 N t° C_AX/2 1 1 8 C_AB/9 C_BB/9 2 2 7 front C_AS1/2 1 2 r ear 0 9 1 C_AW1/2 2 3 C_AR2/3 C_AM2/3 2 ye-br 3 16 10 br-wh C_AO/26 20 2 sidestand switch 3 6 EPC 1 EPC 2 C_AW/2 2 1 1 C_AS/2 2 1 temperature sensor horn G flasher relay neutral switch 2nd gear 3rd gear 2nd C_AR1/3 C_AM1/3 1 3th fuel lev el sensor Q C_AL1/2 C_AT1/2 2 gr ye-bu 2 1 bl-or bl-or or wiring diagramm 3 8 pi gr br-pi br br br-bl br-bl re-br gr C_CR2/1 br-bl C_AI3/2 ye-br br C_AH3/2 br bl-gn or or-wh bl-wh or bl-bu or or 1 pi bl re wh wh re-ye ye ye-wh re-gn aditional current connection ACC1 2 pu-wh C_CR3/1 C_BC/6 5 C_AC/6 13 ignition switch or or A A A A 8 re-wh re-wh 9 2 1 A 2 1 br re fuse box temperature switch for carburetorheating C_AK2/2 C_AH2/2 1 A A 10 10 10 10 10 A 10 15 10 16 7 19 11 4 25 26 18 M 2 1 C_AT2/2 C_AL2/2 fuel pump heaterelement heaterelement M 2 Pick up C_AT/2 C_AL/2 1 2 1 TPS C_AR/3 C_AM/3 3 bu C_AL4/2 C_AT4/2 main harness - 625.11.075.000 8 1 4 starter motor 4 1 30 A 3 2 C_AF3/4 re-bu aditional current connection ACC2 ye-bu diode or bl re-gn or ye br or re-bl re-wh ye-bu ye or-bl bu bl-wh bl br re-wh re-bl re-wh ye-wh br-bl or pu-wh ye-bu re-ye br-bl bu-bl ye-wh ye-br bu or re-gn ye ye-bl br-wh ignition coil bu-gr re gr E pi bl-or ye-or C bl start relay re-wh light switch re-wh start/stop switch br high/low beam switch horn switch flasher switch ye-bu or-wh ye or re-bu ye-bl br bu- gr bu-bl or re re-bu re-wh 4 1 2 3 4 3 2 1 3 2 4 1 C_DJ/18 C_DK/18 20.02 .2005 alarm system dummy plug Connector for optional alarm system battery re-wh bl re-wh re-wh r ear brake switch start auxillary relay fuel pump relay light system relay gn 1 br bl wh gn-wh br wh pu 2 1 C_BV1/2 C_BS1/2 seat surv eillance for optional alarm system 2 3 3 2 1 4 2 1 3 or-wh C_AF2/4 C_AF1/4 C_AF/4 2 1 3 or ye-or gn-wh or-wh 4 4 bl 5 5 pu C_AK/2 G C_AI2/2 1/8 left rear flasher licence plate lamp right rear flasher 1 2 2 C_AI1/2 1 2 C_AI/2 1 diode diode generator diode 3 U regulator-rectifier ye ye-bl U C_AH/2 bu-re 6 6 bl 7 7 bl 8 8 bl 1 1 bl 9 9 bl 10 Antenna 11 11 10 bl 12 12 bl 13 13 bl bl C_AU/2 br 14 14 ye or C_AZ/4 C_BK/4 gn-bl C_AJ/3 C_BG/3 C_BI/2 br 15 15 bl 16 16 bl 17 17 bl bl 2 2 ye-bu bl 18 18 ye pi re-bl 13-72 rear light/brakelight front brake switch speed sensor C_AK1/2 C_AH1/2 1 2 left front flasher re-wh br gn-gr re-br br-bl ye-bl gn-bl ye-bu 1 2 gn-wh bl 2 1 pu br ye-re 1 C_BJ/1 C_AY/1 2 1 bl-or ye-bu 2 1 M cooling fan cooling fan 3th 3 N 8 1 t° C_AX/2 1 C_BB/9 C_AB/9 2 2 7 rear 9 1 2 EPC 1 EPC 2 2 3 C_AR2/3 C_AM2/3 sidestand switch 3 6 wh C_AW1/2 2 1 C_AW/2 1 1 C_AS/2 2 wiring diagramm front C_AS1/2 1 2 temperature sensor horn G flasher relay neutral switch 2nd gear 3rd gear 2nd C_AM1/3 M 1 fuel level sensor Q C_AL1/2 C_AR1/3 C_BL1/2 2 1 C_AT1/2 2 C_AI3/2 ye-bu gr bl-or or 1 3 8 C_CD1/2 oil pressure sensor p 7 1 2 4 9 6 C_AD/12 C_BD/12 5 2 C_BL/2 C_CD/2 2 temperature switch C_AV/2 1 2 950 Supermoto (R) 2007 950 Supermoto R 2008 br wh gn br bu 2 br br 1 3 br bl-or ye-or 2 1 br-bl 3 ye C_CR/1 ye-or bl pu bu bu-re C_AL3/2 C_CR1/1 bl-or C_AM3/3 br 2 7 15 1 19 6 10 9 3 4 5 right front flasher clutch switch LED red for optional alarm system C_BV/2 16 C_AT3/2 multi-func.-digital-speedometer headlight positionlight v C_AA/20 C_BS/2 C_AR3/2 1 2 C_BW/3 C_DI/2 wh bl-wh br bl-wh ye br-bl C_CR2/1 br-bl head light flascher gn-bl ye gn-re gn-br gn bu bu-re pu gn-gr ye-br or bu-bl bl br-pi gr pi br bl-bu or br-bl bl-wh or aditional current connection ACC1 re-gn wh re-ye ye 0 2 ye-br 3 16 10 br-wh C_AO/26 20 5 C_AC/6 C_BC/6 8 1 4 bl-or C_CR3/1 gr br-bl re-br ye-br br C_AH3/2 br bl-gn diode or 13 ignition switch 2 9 1 A 10 2 1 br re fuse box temperature switch for carburetorheating C_AK2/2 C_AH2/2 1 A A 10 re-wh 7 19 11 4 25 26 18 8 A A 10 10 A 10 A 15 10 A 10 16 re-wh or-bl br or or-wh or 1 2 1 C_AT2/2 C_AL2/2 M starter motor M 2 2 1 TPS C_AR/3 C_AM/3 3 bu C_AL4/2 C_AT4/2 main harness - 625.11.075.100 Pick up C_AT/2 C_AL/2 1 heaterelement heaterelement fuel pump 4 3 2 C_AF3/4 1 30 A start relay br light switch or or bu ye-wh ye-br bu re-gn pi pu-wh or ye ye-bu bl re-gn or ye-bu or re-bl re-wh re-wh ye-wh br re-wh ye-bl bl-wh ye re-bl re-ye br-bl bu-bl ye-bu ye-wh bl re or pu-wh bl ye-bl br-wh ignition coil pi bu-gr re gr E 2 re-wh start/stop switch re-wh high/low beam switch horn switch flasher switch re-bu re-bl 4 br ye-bu or-wh ye or re-bu ye-bl 4 1 2 3 4 3 2 1 bu-gr bu-bl 2 3 or re br re-wh 1 C_DJ/18 C_DK/18 6.6.2007 alarm system dummy plug Connector for optional alarm system battery re-wh re-wh rear brake switch start auxillary relay fuel pump relay light system relay gn 1 2 wh gn-wh br 2 1 C_BV1/2 C_BS1/2 wh pu br bl seat surveillance for optional alarm system 3 aditional current connection ACC2 4 4 ye C_AF2/4 C_AF1/4 5 5 Art.-No. 3.206.056-E or ye-or bl bl bl 2 1 1 C_AK/2 C_AF/4 2 1 bl 6 6 ye-or C re-wh or-wh bl 3 gn-wh or-wh C_AH/2 bu-re 7 7 bl U pu bl bl 2 bl 8 8 bl 9 9 Antenna 10 bl 11 11 bl bl C_AU/2 3 2 1 4 2 1 3 13 13 G 1/8 left rear flasher licence plate lamp right rear flasher 2 C_AI2/2 1 2 C_AI1/2 1 2 C_AI/2 1 diode diode generator diode 3 U regulator-rectifier ye C_AZ/4 or C_BK/4 C_AJ/3 gn-bl ye C_BG/3 C_BI/2 br 14 14 br 15 15 bl 16 16 bl 17 17 bl 12 12 10 ye-bu bl 18 18 ye pi Repair manual KTM LC8 13-73 rear light/brakelight 13-74 Aditional instruments (roadbook;...) Battery Carb heater (Carburator heater element) Clutch switch Cooling fan Diode Flasher relay Flasher switch Front brake switch Fuel level sensor Fuel pump Fuel pump relay Fuse box Gear sensor Generator Headlight High / low beam switch Horn Horn switch Ignition coil Ignition switch Left front flasher Left rear flasher Licence plate lamp Light switch Multi-func.-digital-speedometer Neutral switch Oil pressure sensor Pick up Rear brake switch Rear light / brakelight Regulator-rectifier Right front flasher Right rear flasher Sidestand switch Speed sensor Start auxillary relay Start relay Start/stop switch Starter motor Temperature sensor Temperature switch Throttle position sensor (TPS) Externe Instrumente Batterie Vergaserheizelement Kupplungsschalter Lüftermotor Diode Blinkerrelais Blinkerschalter vorderer Bremslichtschalter Benzinstandgeber Kraftstoffpumpe Kraftstoffpumpenrelais Sicherungskasten Gangerkennung Generator Scheinwerfer Auf-Abblendschalter Hupe Hornschalter Zündspule Zündschloss linker vorderer Blinker linker hinterer Blinker Kennzeichenbeleuchtung Lichtschalter Multifunktionsdigitaltacho Leerlaufschalter Öldruckschalter Impulsgeber hinterer Bremslichtschalter hinteres Begrenzungslicht / Bremslicht Regelgleichrichter rechter vorderer Blinker Rechter hinterer Blinker Seitenständerschalter Geschwindigkeitssensor Starterhilfsrelais Startrelais Start / stop schalter Startermotor Temperatursensor Temperaturschalter Vergaserpotentiometer NOTE to the connector designations: The connector designations are comprised of letters and numbers - e.g.: C_AA1/20 – The 1st position C stands for connector (connector). – The 2nd and 3rd positions AA stand for the connector type. – The 4th position numbers the same type of connector if the connector is used for different applications. – The 5th and 6th positions 20 specify the number of pins in the connector, in this case 20 poles. The 5th position is not required for connectors with less than 10 pins. Cable colours bl: black ye: yellow bu: blue gn: green re: red wh: white br: brown or: orange pi: pink gr: grey pu: purple 30 A M battery start relay red-white 1 br brown 0.5 4 red-white 1 1 A H-p age 6/8 f us e bo x F-pag e6/8 U red-white 1 red-white 1 red-white 1 red-blue 0.5 starter motor 8 7 8 7 2 1 2 1 bl bl start auxillary relay 4 3 4 3 6 9 9 5 10 10 6 11 5 12 13 14 15 16 17 18 1 4 2 3 light system relay 3 2 4 1 Connector for optional alarm system 11 C_DK/18 12 13 14 15 16 17 18 Dummy plug C_DJ/18 950 SUPERMOTO 2005/06/07 E-page3/8 D-pa ge 4/8 C-page 5/8 B-page 5/8 A-page3/8 9 G generator G- pag e 6 /8 A A A A A A 8 3 10 10 10 10 1 0 A 1 0 15 1 0 16 or or-bl re-bu re-wh ye 3 or ye-bu re-wh or bl-wh re-wh re-wh ye-bl 2 re-wh re-wh C_AR1/3 3th 1 2 C_AI1/2 diode 5 N 3 green-black 0.5 pink 0.5 neutral switch (N) / 2nd gear / 3rd gear 2nd C _AM1/3 C_AL3/2 1 C_AT3/2 2 2 1 C_AI2/2 C_AI/2 4 C_AC/6 C_BC/6 ignition switch diode 1 2 diode clutch switch yellow 0.5 7 re-wh start system 2 1 8 C_BB/9 C_AB/9 start/stop switch orange-white 0.5 regulator-rectifier or re-bl 1 re-wh re-ye orange 0.5 orange-white 0.5 30 C_AF/4 C_AF2/4 red 0.5 Art.-No. 3.206.056-E brown 0.5 Repair manual KTM LC8 2/8 31 I-page6/8 J-page3/8 30 13-75 red-white 1 C_AF3/4 30 A M battery start relay re-bu br 4 red-white 1 3 brown 0.5 re-wh or red-white 1 3 9 H-page6/8 fuse box F-page6/8 U red-white 1 red-white 1 red-white 1 red-blue 0.5 starter motor bl bl start auxillary relay 1 5 1 6 5 6 2 7 7 2 8 8 4 9 9 3 10 10 4 11 3 12 13 14 15 16 17 18 11 C_DK/18 12 13 14 15 16 17 C_DJ/18 3 2 4 1 1 4 2 3 light system relay 950 Supermoto (R) 2007 950 Supermoto R 2008 E-page3/8 D-page 4/8 1 A G generator G-page 6/8 A A A A 10 10 10 10 10 A C-page 5/8 B-page 5/8 A-page3/8 8 A A 10 15 10 16 or ye-bu re-wh or bl-wh 2 re-wh ye-bl 1 re-wh re-wh 8 C_AR1/3 3th 1 2 C_AI1/2 diode 5 N 3 green-black 0.5 pink 0.5 neutral switch (N) / 2nd gear / 3rd gear 2nd C_AM1/3 C_AT3/2 1 C_AL3/2 2 2 1 C_AI2/2 C_AI/2 4 C_AC/6 C_BC/6 ignition switch diode 1 2 diode clutch switch yellow 0.5 7 re-wh start system 2 1 C_BB/9 C_AB/9 start/stop switch orange 0.5 18 brown 0.5 regulator-rectifier or re-bl re-wh ye or-bl re-wh re-ye red 0.5 Connector for optional alarm system brown 0.5 Dummy plug C_AF/4 C_AF2/4 orange-white 0.5 orange-white 0.5 30 2/8 31 I-page6/8 J-page3/8 30 13-76 red-white 1 C_AF3/4 alarm system dummy plug 31 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 or 0.5 1 K-page6/8 yellow-orange 0.5 C_DJ/18 Connector for optional alarm system C_DK/18 C_BB/9 C_AB/9 2 red 0.5 yellow-blue 0.5 violet-white 0.5 brown-white 0.5 red-green 0.5 brown 0.5 2 3 20 7 yellow-brown 0.5 black-brown 0.5 18 grey 0.5 pink 0.5 8 10 blue-grey 0.5 1 16 yellow 0.5 black 0.5 11 4 blue 0.5 yellow-white 0.5 2 1 2 1 front C_AS1/2 2 2 1 1 rear C_AS/2 2 3th 2 N J-page2/8 ECU neutral switch (N) / 2nd gear / 3rd gear 2nd C_AM1/3 C_AR1/3 2 3 C_AR2/3 1 C_AM2/3 C_AR/3 1 sidestand switch C_AM/3 3 throttle position sensor EPC 1 EPC 2 C_AW1/2 2 1 C_AW/2 1 C_AL/2 C_AT/2 pick up yellow-orange 0.5 19 26 25 13 orange-black 0.5 950 Supermoto (R) 2007 950 Supermoto R 2008 orange 1 U C E 7 brown 0.5 ignition switch C_AO/26 A-page2/8 ignition coil start/stop switch fuel pump relay brown 0.5 30 C_AF1/4 fuel pump Art.-No. 3.206.056-E 1 black-blue 0.5 M C_AL2/2 C_AT2/2 2 1 4 2 3 30 3/8 31 E-page2/8 yellow-black 1 brown 0.5 Repair manual KTM LC8 13-77 orange 0.5 31 M-page6/8 L-page6/8 2 1 C_AH3/2 4 7 C_AD/12 C_BD/12 1 flasher switch G violet 0.5 black 0.5 violet 0.5 2 black 0.5 3 right front flasher brown 0.5 left front flasher 950 Supermoto (R) 2007 950 Supermoto R 2008 rear flasher light`s C_BK/4 C_AZ/4 1 1 8 horn switch C_BD/12 C_AD/12 3 horn brown 1 C_AV/2 1 D-page2/8 black-white 1 2 1 2 1 2 temperature switch turn indicator system diode C_AI3/2 2 yellow-blue 0.5 C-page2/8 grey 0.5 flasher relay brown 0.5 brown-black 1 black-orange 0.5 brown 0.5 C_CD/2 C_CD1/2 M 31 30 4/8 cooling fan M cooling fan C_BL/2 C_BL2/1 30 13-78 13-79 start switch cable harness or cable switch blbu Stop switch blor bl START cable harness re or cable switch or blwh RUN STOP unpushed ignition switch bl-or r-w re clutch switch r-w switch position ON ye br pulled unpulled Art.-No. 3.206.056-E OFF LOCKED flasher switch or gr cable switch gn- bu- bupi b r re b l TURN L Repair manual KTM LC8 horn switch cable harness TURN R OFF pu bl br cable harness gr br brpi cable switch pi brpi HORN OFF 31 0 1 2 head light flasher HI LO low/high beam switch 2 5 6 9 9 6 N-page6/8 yellow 1 C_BB/9 C_AB/9 white 0.5 blue 1 green 1 rear brake switch front brake switch 950 Supermoto (R) 2007 950 Supermoto R 2008 C_BD/12 C_AD/12 3 yellow 1 yellow-brown 1 light switch C-page2/8 brown 0.5 C_AK1/2 2 1 4 green-white 0.5 2 1 C_BG/3 C_AJ/3 3 white 0.5 2 rear light/brakelight 1 C_DI/2 positionlight light-brake system headlight C_BK/4 C_AZ/4 1 1 2 blue-yellow C_AH1/2 C_AH/2 C_AK/2 B-page2/8 1 3 C_BW/3 2 headlight brown 0.5 30 brown 0.5 5/8 31 30 13-80 13-81 light switch high/low beam switch cable harness yewh ye br cable switch yewh wh r eye cable harness bu gn yebr cable switch wh ye gnre LIGHT OFF LO P. LIGHT HI Art.-No. 3.206.056-E LIGHT brake switch cable harness cable switch pushed Repair manual KTM LC8 unpushed gn- yewh bu bl bl 31 3 yellow-orange 0.5 1 speed sensor v 2 black-brown 0.5 C_AM3/3 C_AR3/3 black-orange 0.5 1 yellow-black 0.5 19 3 5 7 M-page4/8 L-page4/8 9 4 2 N-page5/8 1 6 brown 0.5 temperature sensor brown-black 0.5 950 Supermoto (R) 2007 950 Supermoto R 2008 t° C_AX/2 2 10 15 16 violett 0.5 C_AA/20 multi-func.-digital-speedometer blue 0.5 p 1 C_BJ/1 C_AY/1 1 fuel level sensor Q C_AL2/2 C_AT2/2 2 brown 0.5 instruments-tachometer oil pressure sensor green-grey 0.5 red-brown 0.5 green-black 0.5 yellow-orange 0.5 K-page3/8 C_CR3/1 red-black 0.5 red-white 0.5 H-page2/8 C_CR2/1 aditional current connection ACC2 F-page2/8 black 0.5 G-page2/8 C_CR/1 C_CR1/1 yellow-red 0.5 I-page2/8 aditional current connection ACC1 30 brown 0.5 6/8 31 30 13-82 Repair manual KTM LC8 Art.-No. 3.206.056-E 13-83 left front flasher positionlight headlight right front flasher LED for alarmsystem ACC1 ACC2 M ECU C_AF3/4 regulator temperature sensor temperature switch 30 A 950 Supermoto (R) 2007 950 Supermoto R 2008 clutch switch carburetorheating fuellevelsensor right-left front flasher multi-func.-digital-speedometer horn switch starter motor battery ground connection brown start relay 7/8 alarmsystem rear light/brakelight main relay rear flasher fuel pump module 13-84 front brake switch flasher relay diode A Fan 8 A 9 1 A fuel pump relay A A A A 10 10 10 10 10 A 10 15 10 16 30 A battery positive connection fuse box rear brake switch 950 Supermoto (R) 2007 950 Supermoto R 2008 multi-func.-digital-speedometer yellow-blue ignition switch yellow yellow-blue horn red-white C_AF3/4 yellow-black black-white light switch M red-white high/low beam switch starter motor start relay red-black regulator green green alarmsystem ACC1 ACC2 carburetorheating 8/8 start auxillary relay C_AF/4 Art.-No. 3.206.056-E yellow black-orange Orange red-yellow Repair manual KTM LC8 13-85 13-86 Connector AA 20-pole 1 11 1 1 Multifunctional digital speedometer Behind the functional speedometer 20 10 multi digital Connector AB 9-pole 2 1 3 9 2 Start/stop/light switch Behind the functional speedometer multi digital 4 3 Connector AC 6-pole 3 Ignition switch 1 4 3 6 Behind the functional speedometer multi digital Connector AD 12-pole 4 1 3 7 12 Light/turn signal/horn switch Behind the functional speedometer multi digital Connector AF 4-pole 5 1 Auxiliary starter relay Under the seat 42 6 Connector AF1 4-pole 6 Fuel pump relay Under the seat 5 13-87 Connector AF2 4-pole 1 1 Lighting relay Under the seat 42 1 Connector AF3 2-pole 2 Start relay Under the seat 2 Connector AH 2-pole 3 Rear brake light switch Art.-No. 3.206.056-E 1 2 On the right side of the frame 3 Connector AH1 2-pole 4 Front brake light switch 4 Behind the headlight 5 Connector AH2 2-pole 5 Repair manual KTM LC8 Temperature switch for carburetor heater Behind the headlight Connector AH3 2-pole 6 Turn signal relay Behind the headlight 6 13-88 Connector AI 2-pole 2 1 Neutral switch diode Under the seat, next to the battery Connector AI1 2-pole Diode for side stand switch Under the seat, next to the battery Connector AI2 2-pole Diode for side stand switch Under the seat, next to the battery Connector AI3 2-pole 1 Diode for turn signal control Behind the headlight mask next to the turn signal relay Connector AJ 3-pole 2 Rear lighting system 1 2 3 Under the seat in the back of the storage compartment 1 2 13-89 Connector AK 2-pole 1 Rear brake light switch 1 2 On the right side of the frame 1 Connector AK1 2-pole 2 Front brake light switch 2 Behind the headlight 3 Connector AK2 2-pole 3 Temperature switch for carburetor heater Art.-No. 3.206.056-E Behind the headlight Connector AL 2-pole 4 Pick up 1 2 4 On the left between the oil tank and the generator cover Connector AL1 2-pole 5 Repair manual KTM LC8 Fuel sender On the front left next to the radiator Connector AL2 2-pole 6 Fuel pump On the front left next to the radiator 5 6 13-90 Connector AL3 2-pole 1 Clutch switch 1 Behind the headlight 1 6 2 Connector AL4 2-pole 2 Carburetor heater Behind the steering head and the ECU 3 2 Connector AM 3-pole 3 Throttle sensor 1 3 Behind the steering head and the ECU Connector AM1 3-pole 4 Gear sensor On the left between the oil tank and the generator cover Connector AM2 3-pole 5 Side stand switch On the left between the oil tank and the generator cover Connector AM3 3-pole 6 Speed sensor Behind the headlight 4 5 13-91 Connector AO 26-pole 20 14 8 1 ECU 1 Behind head 26 19 13 the 1 steering 7 Connector AR 3-pole 2 3 1 Throttle sensor Behind the steering head and the ECU Connector AR1 3-pole 3 Gear sensor Art.-No. 3.206.056-E On the left between the oil tank and the generator cover 2 4 3 Connector AR2 3-pole 4 Side stand switch On the left between the oil tank and the generator cover Connector AR3 3-pole 5 Speed sensor Repair manual KTM LC8 Behind the headlight 5 13-92 Connector AS 2-pole 1 1 2 Rear ignition coil 1 Behind the air filter box Connector AS1 2-pole 2 Front ignition coil Behind the radiator 2 Connector AT 2-pole 3 Pick up 1 2 On the left between the oil tank and the generator cover 3 Connector AT1 2-pole 4 Fuel sender On the front left next to the radiator 5 4 Connector AT2 2-pole 5 Fuel pump On the front left next to the radiator Connector AT3 2-pole 6 Clutch switch Behind the headlight 6 13-93 Connector AT4 2-pole 1 Carburetor heater 1 2 Behind the steering head and the ECU 1 Connector AU 2-pole 2 2 Controller outlet 21 Under the seat next to the battery case Connector AV 2-pole 3 Temperature switch 1 2 On the left side of the radiator Art.-No. 3.206.056-E 3 Connector AW 2-pole 4 Front EPC 2 1 On the right side of the frame 4 Connector AW1 2-pole 5 EPC rear Repair manual KTM LC8 Behind the air filter box 5 Connector AX 2-pole 6 1 2 Coolant temperature sensor On the left between the cylinders 6 13-94 Connector AY 1-pole 1 Oil pressure switch On the left side of the frame under the air filter box 1 Connector AZ 4-pole 2 Rear turn signal 1 2 3 4 Under the seat in the back of the storage compartment 2 Connector BB 9-pole 3 1 3 7 9 3 Start/stop/light switch 4 On the connector support under the multifunctional digital speedometer Connector BC 6-pole 4 Ignition switch 3 6 1 On the connector support under the multifunctional digital speedometer Connector BD 12-pole 5 3 1 10 12 Turn signal/horn/high beam switch On the connector support under the multifunctional digital speedometer Connector BG 3-pole 6 1 2 3 Rear lighting system Under the seat in the back of the storage compartment 5 6 13-95 Connector BI 2-pole 1 1 Controller outlet 2 1 Under the seat next to the battery case Connector BJ 1-pole 2 Oil pressure switch 1 On the left side of the frame under the air filter box Connector BK 4-pole 3 Art.-No. 3.206.056-E 1 1 2 3 3 Rear turn signal Under the seat in the back of the storage compartment Connector BL/BL1 2-pole 4 4 Radiator fan 1 2 2 Behind the left radiator Connector BS 2-pole 5 Alarm LED Repair manual KTM LC8 1 2 Instrument panel alarm system only) (for 5 Connector BS1 2-pole 6 Seat switch Under the seat alarm system only) (for 6 13-96 Connector BV 2-pole Alarm LED Instrument panel alarm system only) 2 1 (for Connector BV1 2-pole Seat switch Under the seat alarm system only) (for Connector BW 3-pole 1 1 Headlight Behind the headlight 1 3 Connector CD/CD1 2-pole 2 Radiator fan 1 2 2 Behind the left radiator Connector CR/CR1/CR2/CR3 1-pole Connector for attachments: Ground 3 Continuous positive polarity 4 Positive ignition 5 Behind the headlight 4 3 3 5 13-97 Connector DI 2-pole 1 Parking light 1 On the headlight Connector DJ 18-pole 2 1 18 17 16 15 14 13 6 5 Connector for the alarm ECU 2 Under the seat Connector DK 18-pole 3 Art.-No. 3.206.056-E Repair manual KTM LC8 13 14 15 16 17 18 1 2 3 4 5 6 Dummy plug (without alarm system) Under the seat 3 2 tachometer clutch switch 15 16 14 2 7 8 13 1 12 6 10 9 3 4 5 11 v n front brake switch speed sensor left fron t flas her right fron t flasher 1 2 adition al curr ent conn ec ti on ACC1 C_AM5/3 ye gn ye-br 2 6 br pu 2 1 5 4 sen sor rollover C_AP2/6 6 temp er atur e switch cool ing fan M C_BI1/2 C_ AU 1/ 2 2 1 C_AV/2 2 990 Adventure S 2006/07 p C_ AY/1 C_BJ/1 7 1 diag nos tic connector 2 L L t° 3 2 p C_DP2/3 3 or br lbu 2 1 1 1 6 4 t° gr ye- bu 2 1 C_AX/2 or p C_DP1/3 3 2 1 1 2 C_ CM /2 t° horn G flas her relay or 1 8 C_AB/9 C_BB/9 bl-bu C_AH2/2 C_BH1/6 3 2 p C_DP/3 1 wiring diagramm rear lam bd a s en sor `s front t° C_CA/4 1 C_CE/4 4 3 C_CA1/4 3 8 C_CE1/4 4 1 2 oil p res su re switch 990 Adventure 2006/07 wh bu 3 1 br br ye-re br re-bl 4 br 1 2 1 C_CR/1 bl C_CR2/1 C_CR1/1 br ye-br ye gn-r e br or- ye C_CR3/1 gn-r e br gn- gr wh ye re-br br- bu gn-bl re- wh or bl pu bu ye-br br-bl bl-or 4 3 2 1 1 wh ye C_AG/3 adition al curr ent conn ec ti on ACC2 C_AA/20 C_AT1/2 multi-func.-digital-speedometer headlight C_AL1/2 C_AN/4 C_CX1/2 C_BC/6 handle bar switch for multi-func.-digitalspeedometer C_BE/3 C_AR5/3 C_CW1/2 C_CW/2 bl-or bl-wh br-bl head light flascher gn-bl bu re-gn 2 or br-bl br-bl 2 4 wh-bl br ye-re bu 9 bl 3 bl ye gn bu-re pu gn-re gn-br ye-br or gr-gn 6 re-br C_AD/12 wh-or bu-bl bl br-pi br pi gr or ye-bu water temperature sensor C_AP1/6 C_BD/12 bl 5 bl ye- bu bu gn- w h re bu-bl 2 manifold pressure sensor front 1 2 7 2 1 0 9 2 1 3 C_AR3/3 C_ AM 3/ 3 2 Pick up C_AT/2 C_AL/2 1 sid estan d s ens or bl ye-bl bu air temperature sensor bl bl bl-wh or 3 6 wh wh re-ye ye ye- bu ye-wh br pu-br C_BF/1 C_ BA /1 2nd 3 C_AR2/3 2 1 gn-bl ye-br gr A 8 A 10 A 10 A 10 A 10 A 15 10 A 10 16 re- wh 5 C_ BH /6 C_AP/6 ye-bl bl re pi ye br ye-bu 1 A 10 9 2 7 13 14 3 24 23 11 12 4 ye-bl C_AO/26 2 10 9 22 6 20 25 26 19 15 18 17 re-br C_AL2/2 C_AT2/2 2 8 9 14 16 34 M 3 2 lbu to ABS harness gr 33 15 13 23 11 3 4 C_AE1/4 7 21 12 6 29 26 C_CO/34 4 22 5 1 30 A star t relay ABS connector fuel level sen sor light relay C_AF3/4 starter m otor main harness - 601.11.075.000 21 1 gn gn 3 ye-wh ye-br bu 3rd gear 2nd gear neutral switch ye-bu C_AM2/3 re-wh 1 3 gr re bl-wh ye-re re-gn 3th 1 2 re 2 bu-gr br br bu-wh wh bu-br re-bu 4 Q 2 1 re-wh N br 1 C_AT3/2 re-bl bu front fuel pump M 3 2 2 exhaust air valve C_CK/2 1 14 2 10 6 16 8 4 12 15 7 3 11 5 9 13 2 1 4 2 3 3 4 2 1 bu- bl or -w h bu- gr or br or -w h 2 2 1 C_ AH /2 C_AK/2 ye- bu re- gn power rel ay fuel pum p relay 2 C_A M /3 C_AR/3 1 2 1 rear C_CL/2 injec tor´s front C_CL1/2 3 2nd th rottle pos ition s ens or 1 re- wh re- wh start auxillary r elay rear brake switch 4 ye- wh ye-bl 1 re-bl 3 re-bl re- bu 07.12.2005 rear 1 bu bl pu- re re-bl or -gn gn bu- or wh -r e br-gr gn- w h bu- pi ye- gn bl-gr ye-or or fuel p um p m odu le Q C_AR4/3 C_ AM 4/ 3 battery C_AS/2 2 1 C_AS1/2 2 re-wh or re-bu ignition coil`s gn bu-bl C_AF1/4 ign iti on swi tch C_CQ/16 lig ht swi tch wh-pu C_AF2/4 or start/s top switch 3 bl br 3 2 1 4 2 1 gn- w h 3 br wh pu wh 2 1 C_AR1/3 C_ AM 1/ 3 2 C_CE2/4 1 3 mai n thr ottle pos ition s ens or C_CA2/4 4 1 2 2nd th rottle stepp er m otor ye hi gh /l ow b eam switch horn swi tch flash er switch pu bu-w h C_CP/16 C_AF/4 gn-wh bu bl gn-gr atmospheric pressure sensor bl 2 4 1 gn 3 1/9 left r aer fl ash er lic en ce p late lamp right rear flasher 2 C_AI2/2 1 2 C_AI1/2 1 2 C_AI/2 1 diode diode ISC stepp er m otor C_AE/4 G gen erator diode 3 U regu lator-rectifier ye-wh or-wh or bl pu manifold pressure sensor rear re-wh wh-br C_AC/6 C_CX/2 br-bl br or gn-bl re-bl E bu fuse box br br-bl bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re pu-re re-bl ye-bl re pu-br or ye pi gn-bl ye-br gr lbu C C_AL3/2 wh-or wh-bl or-bl or-gn gn bu-or wh-re br-gr gn-wh bu-pi ye-gn bl-gr ye-or wh-pu wh-br U fuel level sensor or gn-re bu-bl C_AU/2 bu re wh gr C_AZ/4 C_AJ/3 wh gn bl gr br or or-bl or pu ye ye-wh 2 13-98 rear light/brakelight octane selector tachometer additional cur rent connection AC C 1 n front brake switch C_CR/1 C_CR/1 speed sensor v 14 2 7 8 13 1 12 6 10 9 3 4 5 11 15 16 left front flasher right front flasher C_AI/2 2 1 4 3 2 1 1 2 3 ye-bu ye-br ye gn - re br or-ye 1 2 1 gn ye-br 2 6 1 c oo l i n g f an M C_BI1/2 C_AU1/2 2 5 4 s e n sor rollover C_AP2/6 6 t em p e r a t u r e s w i t c h C_AV/2 1 2 head light flascher ye p 2 4 9 C_BJ/1 C_AY/1 1 6 4 2 L L rear lambda sensor`s front t° 3 t° C_CA/4 C_CE/4 1 2 C_AX/2 t° C_CA1/4 4 1 3 br-pi C_CE1/4 2 8 3 di a g n o s t i c co n n e ct o r 4 1 bu-bl 7 1 oil pressure switch 6 C_AD/12 C_BD/12 wh 5 990 Adventure (S) 2007 br pu 2 wh bu 3 1 br br ye-re br 4 br bl 1 2 br ye C_EE/1 C_CR/1 C_EE/1 C_CR/1 C_CR2/1 re -b l br - bl b l-o r gn-wh C_CR3/1 gn -r e br gn-g r wh ye re-br br - bu gn- bl re-wh or bl pu bu ye-br br -b l b l-o r additional cur r ent connection ACC2 C_AT1/2 multi-func.-digital-speedometer headlight handlamp socket clutch switch C_AA/20 C_AG/3 C_CX1/2 C_AL1/2 C_AM5/3 C_AN/4 C_AC/6 handle bar switch for multi-func.-digitalspeedometer C_BE/3 C_AR5/3 C_CW1/2 C_CW/2 ye-bu bl-wh 1 br-bl br br-bl ye-re bu or br C_AI/2 2 1 3 2 p C_DP2/3 1 1 2 C_CM/2 t° gr ye-bu ye-bu C_AH1/2 8 1 2 3 2 p C_DP1/3 1 3 C_AR3/3 C_AM3/3 1 s i d e st a n d s e n s o r horn G fl as h er r elay wir in g diag ra mm lbu 2 1 ye-or or C_BB/9 C_AB/9 3 2 p C_DP/3 1 2 7 1 1 1 3 6 2 C_AL/2 Pick up C_AT/2 2 C_DF/2 0 9 PVC 2 light switch wh gn-bl ye gn-re gn-br gr-gn bu-re pu or re-bl bl-wh or ye-wh re-ye wh ye br bl br pu-br C_BF/1 C_BA/1 2nd 3 C_AR2/3 2 1 gn- bl ye-br gr A A 8 A 10 A 10 10 A 10 A 15 10 A 10 16 re-wh 5 C_BH/6 C_AP/6 9 1 A 10 2 ignition switch ye-bl gn or ye C_AM2/3 bu re-gn bl br water temperature sensor wh-or ye-bu ye-br or wh-bl bl C_BH1/6 bl ye-bl bl bl-wh pi gr C_AP1/6 or re-br air temperature sensor re re-gn 3 bl gn fuse box start/stop switch gr ye-bl high/low beam switch horn switch flasher switch 7 13 14 3 24 23 11 12 4 C_AO/26 21 1 2 10 9 22 6 20 25 26 19 15 18 17 8 re-br re l igh t r el ay C_EB3/4 starter motor 1 C_BV/2 C_BS/2 alarm LED 2 2 C_EG/14 C_EF/14 1 M f uel l e v e l s ens or ABS connector to ABS harness C_AT2/2 bu-wh bu bl bu atmospheric pressure sensor C_AL2/2 re-wh ye-re 4 Q rt-bu 1 2 C_AT3/2 re-wh 1 gn 3 2 1 2 C_AL3/2 br bl re or ye-wh diode pi re gn-gr bl bl bu-bl manifold pressure sensor front 8 9 14 16 34 31 32 33 15 13 23 11 3 main harness - C_CO/34 2 4 22 5 6 1 8 7 6 29 26 f ront 8 1 6 7 1 5 2 bu 1 4 2 bl pu-re 1 0 re-bl 6 or-gn 1 6 8 gn bu-or 4 wh-re 12 br-gr 15 gn-wh 7 bu- pi 3 ye-gn 11 bl-gr 5 ye-or 9 13 or 2 ex haus t air v al v e C_CK/2 1 2 C_AK/2 2 2 1 C_AH/2 ye-bu 2 3 p owe r r e la y fuel pum p re lay 2 C_AM/3 C_AR/3 1 2 rear C_CL/2 i n j e c tor ´ s front C_CL1/2 3 1 2nd throttle p o s i ti on s en s or 1 re-wh re-wh start auxillary relay rear brake switch 2 1 or-wh re-gn 4 or br 01.10.2006 rear C_AS/2 2 1 2 C_AS1/2 4 C_DN/8 2 3 bu-gr Connector for optional alarm system 1 S t a r t e r I n t e r l oc k U n i t 3 or-gn C_BV/2 C_BS/2 9 10 11 12 13 14 C_DO/8 4 or-wh 3 1 bu- bl ye-bl 4 2 1 or-gn re-bl re-bl 3 re-bu seat surveillance gn battery alarm system dummy plug 5 601.11.075.200 601.11.042.060 610.41.012.000 7 21 12 3 2 3 4 4 C_AE1/4 30 A start relay or ye-br re-bl ye-bu bu C_EB1/4 bl-bu bu manifold pressure sensor rear ye 3rd gear 2nd gear neutral switch pu wh-br or bu bl pu C_BC/6 C_CX/2 br-bl br rt-bu or 3th or gn-bl N br bu re-wh ye-rt re-wh bl re-bu Antenna ignition coil`s br C_EB2/4 or 2 C_AR4/3 re-bl E 3 3 2 1 4 2 1 gn-wh 3 wh br pu wh bl br 2 C_AI/2 d i od e 1 2 C_AR1/3 C_AM1/3 1 2 1 C_CE2/4 3 2 4 1 gn 3 3 G generator U regulator-rectifier ISC s te p p e r mo to r C_AE/4 fuel level sensor m ain t h rott le p o s i ti on s en s or C_CA2/4 4 1 2 C_BI/2 2nd throttle st e p pe r mo t o r ye Art.-No. 3.206.056-E C_CP/16 or br-bu or-bl for optional alarm system C_CQ/16 C_EB/4 gn-wh bu lbu br br-bl bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re pu-re re-bl ye-bl re pu-br or ye pi gn-bl ye-br gr lbu pi-bu C bl or-bl pi-bu wh-pu bu-bl bu-bl pi br br or br bu-gr br br bu-wh wh bu-br re-bl bu-br wh-or wh-bl or-bl or-gn gn bu-or wh-re br-gr gn-wh bu-pi ye-gn bl-gr ye-or wh-pu wh-br U bu bu C_AM4/3 pu C_AU/2 or wh re C_AZ/4 fuel pump or-wh M Q gr C_AJ/3 wh gn bl gr bu or fuel pump module pu octane selector Repair manual KTM LC8 1/9 left raer flasher li c e nc e pl a t e la m p right rear flasher 13-99 rear light/brakelight tachometer additional current connection ACC1 n front brake switch C_CR/1 C_CR/1 speed sensor v 14 2 7 8 13 1 12 6 10 9 3 4 5 11 15 16 left front flasher right front flasher C_AI/2 4 3 2 1 1 2 ye-bu ye-br ye gn-re br or-ye 1 2 1 1 2 2 br ye 1 pu gn 2 wh 1 cooling fan M C_BI1/2 C_AU1/2 2 5 4 sensor rollover C_AP2/6 6 temperature switch C_AV/2 1 2 990 Adventure (S) 2007-2008 ye-br bu 3 6 br br ye-re br 4 br br bl C_EE/1 C_CR/1 C_EE/1 C_CR/1 C_CR2/1 re-bl br-bl bl-or gn-wh C_CR3/1 gn-re br gn-gr wh ye re-br br-bu gn-bl re-wh or bl pu bu ye-br br-bl bl-or additional current connection ACC2 C_AT1/2 multi-func.-digital-speedometer headlight C_AL1/2 3 C_CX1/2 head light flascher ye wh C_BJ/1 C_AY/1 7 1 1 6 4 L L rear lambda sensor`s front t° 3 t° C_CE/4 2 C_CA/4 4 1 1 2 C_AX/2 t° C_CE1/4 2 3 C_CA1/4 4 1 8 3 diagnostic connector oil pressure switch p 2 4 9 6 5 C_AD/12 C_BD/12 gn-bl C_AG/3 C_AM5/3 C_AN/4 C_AC/6 handlamp socket clutch switch C_AA/20 handle bar switch for multi-func.-digitalspeedometer C_BE/3 C_AR5/3 C_CW1/2 C_CW/2 gn-re gn-br ye bu-re pu 2 bl-wh 1 br-bl br br-bl ye-re bu atmospheric pressure sensor 2 3 p C_DP2/3 1 1 2 C_CM/2 t° gr ye-bu 2 1 2 3 2 p C_DP1/3 1 3 C_AR3/3 C_AM3/3 1 sidestand sensor horn G flasher relay wiring diagramm or br lbu C_AI/2 ye-bu ye-or 1 or 2 C_AB/9 C_BB/9 bl-bu 8 1 3 2 p C_DP/3 1 2 7 1 1 6 9 2 C_AL/2 Pick up C_AT/2 2 C_DF/2 PVC 3 wh ye-bu manifold pressure sensor front or re-bl ye-wh re-ye wh ye bl-wh or 0 C_BF/1 C_BA/1 A 3 2 1 A A A 8 10 15 10 re-wh 10 16 ye 1 bl gn-bl ye-br gr ye-bu bu re-gn ye-bl 5 C_BH/6 C_AP/6 A A A 10 10 10 re re-wh gn gr-gn wh-bl 1 re-gn 1 A 10 9 2 ye-bl gn fuse box ye-br or or 2 gr bu-bl bl C_BH1/6 bl bl re-bl ye-re br C_AM2/3 ignition switch C_AR2/3 7 13 14 3 24 23 11 12 4 C_AO/26 21 1 2 10 9 22 6 20 25 26 19 15 18 17 8 re-br light relay C_EB3/4 starter motor C_BV/2 C_BS/2 1 alarm LED 2 2 C_EG/14 C_EF/14 1 M fuel level sensor ABS connector to ABS harness C_AT2/2 light switch C_AL2/2 br-pi water temperature sensor wh-or 8 9 14 16 34 31 32 33 15 13 23 11 3 main harness - C_CO/34 2 4 22 5 6 29 26 601.11.075.200 601.11.042.060 610.41.012.000 7 21 12 bu 4 5 3 2 6 7 1 8 pu battery 1 front C_AS1/2 2 or-gn 2 exhaust air valve C_CK/2 1 bu14 2 bl pu-re 10 re-bl 6 or-gn 16 8 gn bu-or 4 wh-re 12 br-gr 15 gn-wh 7 bu-pi 3 ye-gn 11 bl-gr 5 ye-or 9 13 or 6.6.2007 rear C_AS/2 2 1 1 5 2 7 6 8 4 C_DN/8 2 1 3 re-gn C_EB2/4 C_AK/2 1 C_AH/2 2 2 3 power relay fuel pump relay 1 2 1 rear C_CL/2 3 injector´s front C_CL1/2 2 2 C_AM/3 C_AR/3 2nd throttle position sensor 1 re-wh re-wh start auxillary relay rear brake switch 2 1 4 3 2 3 4 1 2 ye-bu or-wh br or ye-bl bu-gr or-wh bu-bl re-bl or-gn 4 re-bl re-bu Connector for optional alarm system Starter Interlock Unit C_DO/8 3 1 C_BS/2 C_BV/2 seat surveillance 9 10 11 12 13 14 rt-bu alarm system dummy plug 3 4 C_AE1/4 30 A start relay br start/stop switch octane selector C_AT3/2 pi gr br C_AP1/6 or re-br air temperature sensor bu ye-bl bl C_AH1/2 bl gn-gr re-wh 3 bu re-wh ye-rt high/low beam switch horn switch flasher switch bu-bl re bl bl bl br 1 2 re 2 C_AL3/2 re-wh 1 gn 3 2 1 4 Q bl re or ye-wh diode pi bu C_AR4/3 ye-br re-bl ye-bu 3rd gear 2nd gear neutral switch or ye or or bu bl pu manifold pressure sensor rear C_BC/6 C_CX/2 br pu-br br-bl br bu gn-bl 2nd 3th N re-bu ignition coil`s or-bl pi-bu br br Antenna or gn or br-bu or-bl pi or bl wh-br br bu wh-pu for optional alarm system C_CQ/16 C_EB1/4 C_EB/4 gn-wh or bl-wh E 2 C_AR1/3 C_AM1/3 1 2 1 C_CE2/4 3 4 1 3 3 G generator U regulator-rectifier ISC stepper motor 2 C_AE/4 fuel level sensor main throttle position sensor C_CA2/4 4 1 4 2 1 3 wh 2 gn-wh 3 br pu wh bl br 2 C_AI/2 diode 1 2 1 C_BI/2 2nd throttle stepper motor 3 ye bu-wh C_CP/16 br bl lbu br br-bl bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re pu-re re-bl ye-bl re pu-br or ye pi gn-bl ye-br gr lbu pi-bu C bu bu-bl or C_AU/2 bu re C_AM4/3 pu C_AZ/4 fuel pump or-wh Q C_AJ/3 wh or M wh gr rt-bu bu-gr br br bu-wh wh bu-br re-bl bu-br wh-or wh-bl or-bl or-gn gn bu-or wh-re br-gr gn-wh bu-pi ye-gn bl-gr ye-or wh-pu wh-br U gn gn bl gr bu bu-bl fuel pump module pu 2 1/9 left raer flasher licence plate lamp right rear flasher 13-100 rear light/brakelight Repair manual KTM LC8 Art.-No. 3.206.056-E 13-101 2nd throttle position sensor 2nd throttle stepper motor ABS connector to ABS harness Aditional current connection Air temperature sensor Atmospheric pressure sensor Battery Clutch switch Cooling fan Diagnostic connector Diode ECU Exhaust air valve Flasher relay Flasher switch Front brake switch Front injector Front lambda sensor Fuel level sensor Fuel pump module Fuel pump relay Fuse box Gear sensor Generator Handle bar switch for multi-func.-digital-speedometer Headlight High / low beam switch Horn Horn switch Ignition coil Ignition switch ISC stepper motor Left front flasher Left rear flasher Licence plate lamp Light relay Light switch Main throttle position sensor Manifold pressure sensor front Manifold pressure sensor rear Multi-func.-digital-speedometer Neutral switch Octane selector Oil pressure sensor Pick up Power relais Rear brake switch Rear injector Rear lambda sensor Rear light / brakelight Regulator-rectifier Right front flasher Right rear flasher Roll over sensor Sidestand sensor Speed sensor Start auxillary relay Start relay Start/stop switch Starter motor Tachometer Temperature switch Water temperature sensor 2. Drosselklappenpositionssensor 2. Drosselklappenstellmotor ABS-Steckverbindung zum ABS-Kabelstrang Stromversorgung für Zusatzgeräte Lufttemperatursensor Außenluftdrucksensor Batterie Kupplungsschalter Lüftermotor Diagnosestecker Diode Steuergerät Ventil für Sekundär-Luft-System Blinkerrelais Blinkerschalter vorderer Bremslichtschaltero vorderes Einspritzventil Lambdasensor vorne Benzinstandgeber Kraftstoffpumpengruppe Kraftstoffpumpenrelais Sicherungskasten Gangerkennung Generator Lenkerschalter für Multifunkt.Digitaltacho Scheinwerfer Auf-Abblendschalter Hupe Hornschalter Zündspule Zündschloss Leerlaufstellmotor linker vorderer Blinker linker hinterer Blinker Kennzeichenbeleuchtung Beleuchtungsrelais Lichtschalter Drosselklappenpositions-Hauptsensor Ansaugkrümmerdrucksensor vorne Ansaugkrümmerdrucksensor hinten Multifunktionsdigitaltacho Leerlaufschalter Oktananpassung Öldruckschalter Impulsgeber Hauptrelais hinterer Bremslichtschalter hinteres Einspritzventil Lambdasensor hinten hinteres Begrenzungslicht / Bremslicht Regelgleichrichter rechter vorderer Blinker Rechter hinterer Blinker Neigungssensor Seitenständerschalter Geschwindigkeitssensor Starterhilfsrelais Startrelais Start / stop schalter Startermotor Drehzahlmesser Temperaturschalter Wassertemperatursensor Cable colours bl: black ye: yellow bu: blue gn: green re: red wh: white br: brown or: orange pi: pink gr: grey pu: purple NOTE to the connector designations: The connector designations are comprised of letters and numbers - e.g.: C_AA1/20 – The 1st position C stands for connector (connector). – The 2nd and 3rd positions AA stand for the connector type. – The 4th position numbers the same type of connector if the connector is used for different applications. – The 5th and 6th positions 20 specify the number of pins in the connector, in this case 20 poles. The 5th position is not required for connectors with less than 10 pins. red-white 1 30 A M F-page7/9 G-page7/9 H-page7/9 J-page3/9 fus e box generator G U s t ar t a ux i l l ar y r e l ay 3 2 4 1 battery start relay 8 C_BB/9 C_AB/9 1 2 brown 0.5 red -black 0.5 2 clutch switch C_AT3/2 C_ AL 3/2 1 yellow-white 0.5 R-page3/9 7 re-wh starter motor 2 C_AI1/2 diode 1 4 5 1 2 C_AI1/2 diode C_ AC/6 C_ BC/6 31 I-page3/9 I-page6/9 30 2/9 green-black 0.5 ignition switch b a tte ry , g e n e ra to r, s ta r te r 1 4 2 3 light system relay 990 Adventure (S) 2006/07 E-page3/9 D-page 5/9 C-page 5/9 B-page 6/9 A-page3/9 8 1 A A A A 10 9 10 10 A 10 A 10 A 15 10 A 10 16 3 re-wh gn red-white 1 4 brown 0.5 br bl-ye re-bu re-wh ye re-wh gn gn ye-bu 3 gn bl-wh re-wh re-wh re-gn 2 re-bl 1 re-wh re-wh red-white 1 red-blue 0.5 regulator-rectifier red-white 1 re-ye red-white 1 C_AF/4 C_AF2/4 start/stop switch red 0.5 30 13-102 red-white 1 red-white 1 30 A M J-page3/9 H-page7/9 G-pag e7/9 1 A fu se bo x generator G U red-white 1 start auxillary relay 3 2 4 1 1 4 2 3 l igh t sys tem r elay 990 Adventure (S) 2007 E- pa ge 3/ 9 D-page 5/9 C-page 5/9 B-page 6/9 A-page3/9 A F -pag e7 /9 A A A A A 8 9 10 10 10 10 10 A 10 15 10 16 3 re-wh gn battery start relay red-white 1 br brown 0.5 4 bl-ye re-bu re-wh ye re-wh C_AU/2 ye-bu 3 gn bl-wh re-wh re-wh re-gn 2 re-wh re-wh 1 C_BI/2 gn gn red-white 1 red-blue 0.5 starter motor regulator-rectifier re-bl 30 C_AF/4 C_AF2/4 re-ye red-white 1 Art.-No. 3.206.056-E 8 C_BB/9 C_AB/9 1 R - p a g e 3 /9 7 re-wh St a rt s y st em 2 start/stop switch red 0.5 Repair manual KTM LC8 SA R - p a g e 3 / 9 4 C_AC/6 C_BC/6 5 igni tion switch 2/9 31 30 13-103 red -black 0.5 red-white 1 30 A M battery start relay red-white 1 br brown 0.5 4 red-white 1 A J-page3/9 H-page7/9 G-page7/9 1 A fuse box generator G U start auxillary relay 3 2 4 1 1 4 2 3 light system relay 990 Adventure (S) 2007-2008 E-page3/9 D-page 5/9 C-page 5/9 B-page 6/9 A-page3/9 9 F-page7/9 A A A A A 8 3 10 10 10 10 10 A 10 15 10 16 bl-ye re-bu re-wh ye re-wh C_AU/2 ye-bu 3 gn bl-wh re-wh re-wh re-gn 2 re-wh re-wh 1 re-wh gn re-bl C_BI/2 gn gn red-white 1 red-blue 0.5 starter motor regulator-rectifier red-white 1 re-ye red-white 1 C_AF/4 C_AF2/4 8 C_BB/9 C_AB/9 1 R-page3/9 7 re-wh Startsystem 2 start/stop switch red 0.5 30 SAR-page3/9 4 C_AC/6 C_BC/6 5 ignition switch 2/9 31 30 13-104 red -black 0.5 red-white 1 4 ye-re 5 bu 31 sensor rollover C_AP2 /6 bl 6 re-gn or wh-bl ye L L rear lambda sensor´s f ront t° t° C_CE/4 3 C_CE1 /4 2 2 3 1 3 2 p C_DP1 /3 1 octane selector br 1 2 C_CM/2 t° 3 p C_DP/3 1 2 bl atmospheric pressure sensor 990 Adventure p C_DP2 /3 ye-bl gn-gr bu 2 bl bl 1 C_AX/2 t° I-page 2/9 water temperature sensor manifold pressure sensor front br 4 1 wh-or C_CA/4 3 bl C_CA1 /4 4 1 2 bl re 2 bu air temperature sensor bu 1 bu-bl br br-pu re-br or bl bl br-bl 2 ye-bu 21 1 3 C_AR3 /3 C_AM3/3 2 Pick up C_AT/2 C_ AL /2 1 or br or-wh gn-re sidestand sensor 3 4 2 1 bl C_ AL 1/ 2 C_BF/1 manifold pressure sensor rear C_BA/1 pu power relay ye-wh C_AF/4 bu pi C_AT1/2 Q-page7/ 9 C_AI/2 2 1 7 13 14 3 2 4 2 3 11 12 4 2 10 9 2 2 C_AO/ 26 6 2 0 2 5 2 6 19 15 18 17 1 or EFI 2 8 1 2 3 9 14 16 3 4 P 6/8 O 6/8 K 6/8 gr ye-br gn-bl bu-gr br br bu-wh wh bu-br C_AR2/3 C_AM2/3 lbu br or 6 4 1 N 3th 2nd C_AP1/6 diode 3 3 15 13 2 3 11 3 C_BH1/6 7 21 12 4 2 2 3rd gear neutral switch diagnostic connector 5 6 29 26 C_CO/ 34 f ront gr lbu 1 1 2 or-bl C_CW/2 14 8 5 ye-or 9 or 13 bl-gr ye-gn 11 bu-pi 3 gn-wh 7 br-gr 15 wh-re 12 bu-or 4 gn or-gn 16 bu 2 exhaust air valve C_ CK/2 1 6 2 pu-re 10 re-bl bl C_CQ/16 610.41.012.000 airbox harness rear C_AS/2 2 1 C_ AS1/ 2 2 J-page2/9 R-page3/9 or E-page2/9 wh-br clutch switch E wh-pu 30 or-wh bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re pu-re re-bl ye-bl re br-pu or ye pi gn-bl ye-br gr lbu C or 1 bl wh 3 f ront 1 rear C_ CL /2 2 1 C_ CL 1/ 2 2 bu-bl or pu ye bu re gr gr wh gn pu bu gn-re 2 C_AM/3 C_AR/3 2nd TPS 4 2 C_AR1 /3 1 4 2 1 C_CA2 /4 C_CE2 /4 fuel pumprelay 4 1 3 C_ AE/4 2 3 2 C_AM4/3 C_AR4 /3 M Q fuel pump unit f uel pump 3/9 ISC stepper m ot or second throt tl e st epper m ot or 3 3 3 2 TPS C_AM1/3 C_AF1 /4 1 bu C_CX/2 or wh ye bu or bl or-wh bu A-page2/9 bu-gr ye-bl pu bu-bl bl re gr br bu-bl wh gr 2nd gear wh-or wh-bl or-bl or-gn gn bu-or wh-re br-gr gn-wh bu-pi ye-gn bl-gr ye-or wh-pu wh-br U gn-re or bu-bl injector´s gn pu Art.-No. 3.206.056-E 30 31 fuel level sensor Repair manual KTM LC8 13-105 C_CP/16 ignition coil 5 6 4 bl 31 sensor rollover C_AP2/6 ye-re bu 1 2 C_AL1/2 C_AT1/2 bl 3 L L rear lambda sensor´s front t° t° C_CE/4 2 C_CE1/4 4 1 wh-or C_CA/4 3 bl C_CA1/4 4 1 2 wh-bl 2 1 ye-bl gn-gr 3 bu 1 atmospheric pressure sensor 2 3 p C_DP1/3 1 octane selector br 1 2 C_CM/2 t° 2 3 p 2 3 4 2 gn-re or br or-wh 1 3 2 C_AR3/3 C_AM3/3 sidestand sensor Pick up C_AT/2 C_AL/2 1 br-bl 2 1 1 C_DP/3 PVC C_DF/2 990 Adventure (S) 2007-2008 p C_DP2/3 2 bl bl C_AX/2 t° bu br br water temperature sensor manifold pressure sensor front clutch switch bu-bl ye re-gn or re bl br br-pu re-br or bl I-page 7/9 C_BF/1 bu air temperature sensor C_BA/1 or bl re-bl ye-wh C_AF/4 bl ye-bu bu pi C_AI/2 21 1 7 13 14 3 24 23 11 12 4 2 10 9 22 C_AO/26 6 20 25 26 19 15 18 17 8 1 or-bl 2 EFI 1 C_AR2/3 lbu br or C_AM2/3 P 6/8 O 6/8 K 6/8 gr ye-br 2 gn-bl 3 4 1 6 ASP-page7/9 SAR-page2/9 N 3th C_BH1/6 2 8 9 14 16 34 33 15 13 23 11 3 diagnostic connector 6 29 26 C_CO/34 7 21 12 4 22 5 or-gn front C_AS1/2 1 1 5 2 7 6 8 4 2 3 ye C_DN/8 C_DO/8 Starter Interlock Unit gn-bl 1 6 2 14 8 5 gr lbu 1 bl wh exhaust air valve 1 610.41.012.000 front C_CL1/2 2 bu-bl or pu ye bu re gr gr wh gn pu bu gn-re 2 C_AM/3 C_AR/3 3 2nd TPS 1 2 2 ye-or 9 or 13 bl-gr ye-gn 11 bu-pi 3 gn-wh 7 br-gr 15 wh-re 12 bu-or 4 gn or-gn 16 bu C_CK/2 1 bl pu-re 10 re-bl J-page2/9 airbox harness rear C_AS/2 2 br or-bl 1 R-page3/9 Q-page7/9 ignition coil 2nd C_AP1/6 pi-bu or pi wh-pu br-bu or power relay E pu manifold pressure sensor rear or-wh br-bl bu bl ye-bu ye-wh pu bu-bl gn-gr re-br re-gn ye-re pu-re re-bl ye-bl re br-pu or ye pi gn-bl ye-br gr lbu pi-bu C or diode C_CQ/16 E-page2/9 C_CP/16 bu wh-br bu C_CW/2 or 2 4 1 rear C_CL/2 TPS 4 2 1 fuel pumprelay 3 2 C_AM4/3 C_AR4/3 M fuel pump 2 Q fuel pump unit 4 1 3 C_AE/4 3/9 ISC stepper motor second throttle stepper motor C_CE2/4 C_CA2/4 3 2 C_AR1/3 1 3 3 2 C_AM1/3 C_AF1/4 1 bu C_CX/2 bl or or-wh A-page2/9 ye-bl wh ye bl re gr bu-gr pu bu-bl bu neutral switch 2nd gear 3rd gear bu-gr br br bu-wh wh bu-br re-bl bu-br wh-or wh-bl or-bl or-gn gn bu-or wh-re br-gr gn-wh bu-pi ye-gn bl-gr ye-or wh-pu wh-br U gn-re bu-bl injector´s wh br gr bu-bl gn pu 30 31 fuel level sensor 30 13-106 31 M-page6/9 L-page6/9 2 1 C_AH3/2 4 7 C_AD/12 C_BD/12 1 flasher switch G fl as he r re la y v i ol et 0. 5 bl ac k 0.5 Yellow-blue 0.5 2 violet 0.5 2 3 black 0.5 rear flasher light`s C_BK/4 C_ AZ/4 1 right front flasher left front flasher 2 1 C_ CW 1/2 C_CX1/2 990 Adventure 1 C_CX/2 C_ CW /2 8 horn brown 1 C_ AV/2 1 D-page2/9 black-white 1 2 1 2 temperature switch turn signal, horn, fan horn switch C_BD/12 C_AD/12 3 yellow-blue 0.5 C-page2/9 brown-black 1 30 brown 0.5 grey 0.5 Art.-No. 3.206.056-E 30 M 5/9 31 cooling fan C_BI1/2 Repair manual KTM LC8 13-107 C_AU1/2 brown 0.5 brown 0.5 orange 0.5 31 M-page6/9 L-page6/9 2 1 1 C_AH1/2 C_AI/2 4 7 C_AD/12 C_BD/12 1 flasher switch G 2 violet 0.5 2 3 black 0.5 rear flasher light`s C_BK/4 C_AZ/4 1 right front flasher left front flasher 2 1 C_CW1/2 C_CX1/2 990 Adventure (S) 2007-2008 violet 0.5 black 0.5 1 C_CX/2 C_CW/2 8 horn brown 1 turn signal, horn, fan horn switch C_BD/12 C_AD/12 3 yellow-blue 0.5 grey 0.5 ye-or orange 0.5 C-page2/9 2 1 2 temperature switch C_AV/2 1 D-page2/9 black-white 1 2 brown 0.5 brown-black 1 diode flasher relay Yellow-blue 0.5 30 M 5/9 31 cooling fan C_BI1/2 30 13-108 C_AU1/2 brown 0.5 brown 0.5 13-109 ignition switch clutch switch o r-w r-w r-w y-r r ON switch position ye br pulled unpulled OFF LOCKED kill switch start switch cable harness or cable switch blbu blor bl START Art.-No. 3.206.056-E flasher switch Repair manual KTM LC8 cable switch or blwh horn switch or gr cable switch gn- bu- bupi b r re b l OFF or STOP cable harness TURN R re RUN unpushed TURN L cable harness pu bl br cable harness gr br brpi cable switch pi brpi HORN OFF 0 1 31 head light flasher HI LO low/high beam switch 2 2 5 6 9 white 0.5 C-page2/9 yellow 1 C_AB/9 C_BB/9 rear front brake switch yellow-brown 1 green 1 brake switch 990 Adventure 9 6 3 1 2 blue-yellow 2 C_AH1/2 B-page2/9 yellow 1 yellow-brown 1 light switch C_BD/12 C_AD/12 1 licence plate lamp green-white 0.5 1 3 1 2 white 0.5 C_BG/3 C_ AJ/3 6 2 rear light/brakelight C_ BC/6 C_ AC/6 light-brake system N-page7/9 head light 3 4 brown 1 30 brown 0.5 6/9 31 30 13-110 C_AK1/2 13-111 light switch high/low beam switch cable harness bu gn yebr cable switch wh ye gnre cable harness yewh ye br cable switch yewh wh LIGHT OFF LO P. LIGHT HI LIGHT brake switch cable harness cable switch Repair manual KTM LC8 Art.-No. 3.206.056-E pushed unpushed gn- yewh bu bl bl r eye 31 3 or.ye blue-brown 0.5 white 0.5 brown 0.5 brown 0.5 red-brown 0.5 violett 0.5 L-page4/9 1 fuel l ev e l s ens or Q C_ AL 2/2 C_AT2/2 2 green-grey 0.5 green-black 0.5 red-green 0.5 y e l l ow 0.5 yellow-brown 0.5 990 Adventure O P 3/8 2 9 11 p C_BJ/1 C_AY/1 I-page2/9 H-page2/9 G-page2/9 brown 0.5 C_CR/1 3 2 C_AG/3 C_BE/3 1 n tachometer instruments-tachometer oil pressure switch 1 2 3 4 handle bar switch for multi-func.-digitals pe ed om et er C_AN/4 F-page2/9 red-white 0.5 speed sensor v 2 black 0.5 M-page4/9 black-orange 0.5 C_AM5/3 C_ AR5/3 black-brown 0.5 1 blue 0.5 N-page5/9 7 13 1 6 red-black 0.5 3 5 yellow-red 0.5 8 12 14 4 yellow-blue 0.5 C_CR2/1 aditional current connection ACC2 C_AA/20 10 15 16 C_CR1/1 aditional current connection ACC1 C_CR3/1 C-page2/9 brown 0.5 Q-page3/9 ye-bu multi-func.-digital-speedometer blue-white 0.5 30 7/9 31 K-page 3/9 30 13-112 brown 0.5 31 additional current connection ACC1 handlamp socket C_AI/2 blue-brown 0.5 white 0.5 2 9 11 brown 0.5 red-brown 0.5 2 1 fuel level sensor Q C_AL2/2 C_AT2/2 2 green-grey 0.5 1 3 yellow 0.5 red-green 0.5 p or C_BJ/1 C_AY/1 1 C_BS/2 C_BV/2 H-page2/9 aditional current connection ACC2 G-page2/9 ASP-page 3/9 additional current connection ACC1 instruments-tachometer Alarm System 2 alarm LED oil pressure switch I-page3/9 handle bar switch for multi-func.-digitalspeedometer yellow-brown 0.5 4 green-black 0.5 990 Adventure (S) 2007-2008 O P 3/8 1 6 brown 0.5 red-white 0.5 speed sensor v 2 3 C_AM5/3 C_AR5/3 7 13 6 handlamp socket C_AI/2 7 8 or-bl C_CR2/1 F-page2/9 or.ye C_CR/1 3 5 red-black 0.5 black-brown 0.5 C_EE/1 C_CR/1 9 yellow-red 0.5 black-orange 0.5 C_EE/1 C_CR/1 C_CR/1 14 13 12 11 10 C_CR3/1 rt-bl C_EE/1 C_CR/1 C_CR/1 8 12 14 4 violett 0.5 L-page4/9 pu C_EE/1 C_CR/1 1 10 15 16 black 0.5 M-page4/9 ye-re bl 5 4 2 1 C_EF/14 C_EG/14 2 3 C_AG/3 C_BE/3 1 n tachometer 3 alarm system dummy plug br C_AA/20 blue 0.5 N-page5/9 Antenna C_CR/1 C_AN/4 brown 0.5 Connector for optional alarm system bu brown 0.5 Q-page3/9 brown 0.5 multi-func.-digital-speedometer ye-bu 30 K-page 3/9 2 31 7/9 C-page2/9 1 C_BS/2 C_BV/2 seat surveillance bu yellow-blue 0.5 30 for optional alarm system Art.-No. 3.206.056-E blue-white 0.5 br Repair manual KTM LC8 13-113 battery 30 31 2 2 1 or 1 re C_EA/1 or 2 br re-gn 2 1 C_AM5/3 C_ AR5/3 on main harness 2 C_ DL /2 6 4 1 990 Adventure re lbu 1 bl to s p eed s ens or c o nne c tor br C_ AL 3/2 ye-or bl-or C_AT3/2 or 3 18 11 3 7 5 6 8 4 A B S c o n t r ol l i g h t 1 C_DN/8 C_ DO/8 ye-or 25 A bl-or re-gn 40 A br lbu on main harness br 2 23 12 14 bu-wh ABS fuse box br wh 7 19 bl-wh gr AB S h a rne s s - 601.1 1 .079 . 000 ABS gr-bl 16 5 1 2 C_ DM1/2 front wheel revolution sensor gr t o A B S c o n n e c to r bl re gr-bl br ye-bl ye-bl A B 1 2 C_ DM/2 rear wheel revolution sensor wh bu-wh gn gn S wh-bl 30 4/9 31 30 13-114 left flasher right flasher headlight m ai n r el ay tachometer ACC1 ACC2 starter motor M battery ECU fuel pump regulator ground connection ECU temperature switch 30 A start relay Art.-No. 3.206.056-E 990 Adventure clutch switch handlebar switch right-left front flasher multi-func.-digital-speedometer horn switch Repair manual KTM LC8 8/9 rear light/brakelight rear flasher octane selector diagnostic connector fuel level sensor 13-115 left flasher right flasher headlight main relay tachometer ACC1 ACC2 clutch switch starter motor 990 Adventure (S) 2007-2008 handlebar switch right-left front flasher multi-func.-digital-speedometer horn switch M battery ECU alarm LED regulator ground connection ECU starter interlock fuel pump temperature switch 30 A start relay alarm system 8/9 seat surveillance rear light/brakelight rear flasher octane selector diagnostic connector fuel level sensor 13-116 rear brake switch tachometer front brake switch fl as he r re la y horn 990 Adventure multi-func.-digital-speedometer ye-bu ye fan A 10 A A A 10 10 A 15 10 fuel pump relay fus e box C_ AF3/4 A A A 10 ye-re re-bl re-wh 10 10 3 30 A start relay gr battery power relay positive connection ignition switch 1 light relay ye light switch ye-bl M ye-bu high/low beam switch starter motor bl-wh gn-re Art.-No. 3.206.056-E re-wh Repair manual KTM LC8 accesory accesory ABS regulator 9/9 13-117 rear brake switch tachometer front brake switch fl as he r re la y 990 Adventure multi-func.-digital-speedometer ye-bu fan A 10 A A A 10 10 A 15 10 fuel pump relay fus e box C_ AF3/4 A A A 10 ye-re re-bl re-wh 10 10 3 30 A start relay gr battery power relay positive connection ignition switch 1 ye horn ye light relay ye-bu light switch bl-wh gn-re high/low beam switch ye-bl M re-wh starter motor accesory accesory ABS regulator 9/9 13-118 13-119 Connector AA 20-pole 1 11 1 Multifunctional digital speedometer Behind the functional speedometer 1 multi digital 20 10 Connector AB 9-pole 2 3 1 9 2 Start/stop/light switch On the connector support under the multifunctional digital speedometer 4 Connector AC 6-pole 3 Front light Art.-No. 3.206.056-E 1 4 3 6 On the connector support under the multifunctional digital speedometer Connector AD 12-pole 4 1 3 7 12 Light/turn signal/horn switch On the connector support under the multifunctional digital speedometer Repair manual KTM LC8 Connector AE 4-pole 5 1 4 2 Idle speed control motor 5 On the throttle body Connector AE1 4-pole 6 Start relay On the right side of the battery case 3 6 13-120 Connector AF 4-pole 1 Main relay 1 Connector AF1 4-pole 2 42 1 Fuel pump relay 2 Connector AF2 4-pole 3 Auxiliary starter relay Connector AF3 4-pole 4 Lighting relay On the connector support under the multifunctional digital speedometer 4 3 Connector AG 3-pole 5 Tachometer 1 On the connector support under the multifunctional digital speedometer 3 5 Connector AH 2-pole 6 6 Rear brake light switch Under the right rear side cover 1 2 Connector AH1 2-pole 7 Turn signal relay On the connector support under the multifunctional digital speedometer 7 Connector AI, AI1, AI2 2-pole 8 Diodes 2 1 Behind mask the headlight 8 13-121 Connector AJ 3-pole 1 1 2 3 1 Rear lighting system Under the right rear side cover Connector AK 2-pole 2 2 Rear brake light switch 1 2 Under the right rear side cover Connector AL 2-pole 3 3 Pick up 1 Art.-No. 3.206.056-E 2 Between the water pipe and the front cylinder head Connector AL1 2-pole 4 4 Clutch switch Behind the headlight under the connector support Connector AL2 2-pole 5 Repair manual KTM LC8 Fuel sender Between the left tank and the frame Connector AL3 2-pole 6 ABS connection Under the seat next to the ABS unit 5 6 13-122 Connector AM 3-pole 1 1 3 Throttle sensor for the 2nd throttle 1 Connector AM1 3-pole 2 2 Throttle sensor On the throttle body Connector AM2 3-pole 3 Gear sensor 3 4 Connector AM3 3-pole 4 Side stand switch On the left side of the engine in front of the generator cover Connector AM4 3-pole 5 Fuel pump 5 Between the left tank and the engine Connector AM5 3-pole 6 Speed sensor 6 Behind the headlight under the connector support Connector AN 4-pole 7 7 Tripmaster switch 1 2 4 On the connector support under the multifunctional digital speedometer Connector AO 26-pole 8 20 14 8 1 ECU (Control unit) Under the headlight 26 19 13 7 8 13-123 Connector AP 6-pole 1 Ignition switch 1 3 6 Under the fuse box 1 Connector AP1 6-pole 2 2 Diagnosis connector Under the seat next to the ABS unit Connector AP2 6-pole 3 3 Rollover sensor Art.-No. 3.206.056-E Behind mask the headlight Connector AR 3-pole 4 3 1 Throttle sensor 2nd throttle Connector AR1 3-pole 5 4 5 Throttle sensor On the throttle body Connector AR2 3-pole 6 Repair manual KTM LC8 Gear sensor 6 Connector AR3 3-pole 7 7 Side stand switch On the left side of the engine in front of the generator cover Connector AR4 3-pole 8 Fuel pump Between the left tank and the engine 8 13-124 Connector AR5 3-pole 1 Speed sensor 3 1 Behind the headlight under the connector support 1 Connector AS 2-pole 2 1 2 2 Rear ignition coil Behind the air filter box Connector AS1 2-pole 3 3 Front ignition coil Behind the radiator Connector AT 2-pole 4 Pick up 1 2 Between the water pipe and the front cylinder head 4 Connector AT1 2-pole 5 Clutch switch Behind the headlight under the connector support 5 Connector AT2 2-pole 6 Fuel sender Between the left tank and the frame 6 13-125 Connector AT3 2-pole 1 1 ABS connection 1 2 Under the seat next to the ABS unit Connector AU 2-pole 2 Controller 21 On the right side of the battery case under the starter relay 2 Connector AU1 2-pole 3 Fan motor 3 Art.-No. 3.206.056-E Behind the radiator on the right side of the fan Connector AV 2-pole 4 1 2 Temperature switch for radiator fan Behind the radiator on the right side of the compensating tank 4 Repair manual KTM LC8 Connector AX 2-pole 5 1 2 Coolant temperature sensor 5 On the left between the cylinders Connector AY 1-pole 6 Oil pressure switch On the outer left side of the frame 6 13-126 Connector AZ 4-pole 1 1 2 3 4 Rear turn signal 1 Under the right rear side cover Connector BA 1-pole 2 Octane selector Behind the air filter box Connector BB 9-pole 3 1 3 7 9 2 3 Start/stop/light switch On the connector support under the multifunctional digital speedometer 5 Connector BC 6-pole 4 Front light 3 6 1 On the connector support under the multifunctional digital speedometer Connector BD 12-pole 5 3 1 10 12 Light/turn signal/horn switch On the connector support under the multifunctional digital speedometer Connector BE 3-pole 6 1 3 Tachometer On the connector support under the multifunctional digital speedometer 4 6 13-127 Connector BF 1-pole 1 Octane selector 1 Behind the air filter box Connector BH 6-pole 2 Ignition switch 1 3 6 Under the fuse box 2 Connector BH1 6-pole 3 Diagnosis connector Under the seat next to the ABS unit Art.-No. 3.206.056-E 3 Connector BI 2-pole 4 Controller 21 On the right side of the battery case under the starter relay 4 Connector BI1 2-pole 5 Fan motor 5 Repair manual KTM LC8 Behind the radiator on the right side of the fan Connector BJ 1-pole 6 Oil pressure switch 1 On the left side of the frame under the air filter box 6 13-128 Connector CA 4-pole 1 Rear lambda probe 1 2 3 4 On the left side of the air filter box 4 1 Connector CA1 4-pole 2 5 Front lambda probe On the right side of the frame 2 Connector CA2 4-pole 3 Control motor for the 2nd throttle On the throttle body 6 3 Connector CE 4-pole 4 Rear lambda probe 1 2 3 4 On the left side of the air filter box Connector CE1 4-pole 5 Front lambda probe On the right side of the frame Connector CE2 4-pole 6 Control motor for the 2nd throttle On the throttle body Connector CK 2-pole 7 SLS Valve 2 1 Behind the air filter box 7 13-129 Connector CL 2-pole 1 Rear injection valve 1 2 On the throttle body 1 Connector CL1 2-pole 2 Front injection valve On the throttle body 2 Connector CM 2-pole 3 3 Air temperature sensor 2 On the top of the air filter box Art.-No. 3.206.056-E 1 Connector CO 34-pole 4 26 18 10 1 ECU (Control unit) Under the headlight 34 25 17 4 9 Connector CP 16-pole 5 Repair manual KTM LC8 4 1 EFI wiring harness On the right side of the frame 6 16 5 Connector CQ 16-pole 6 1 4 EFI wiring harness On the right side of the frame 16 13-130 Connector CR 1-pole 1 Connector for attachments: Kl 15 (positive ignition) Kl 30 (continuous positive polarity) Kl 31 (ground) Behind the headlight under the connector support 1 Connector CW 2-pole 2 Left front turn signal 1 2 3 Connector CX 2-pole 3 Right front turn signal 2 Under the front left side cover Connector CW1 2-pole 4 5 Right front turn signal 2 1 Connector CX1 2-pole 5 Right front turn signal Under the front right side cover 4 Connector DL 26-pole 6 ABS-ECU (Control unit) 6 Under the seat Connector DM 2-pole 7 7 Rear ABS sensor In front of the ABS unit Connector DM1 2-pole 8 Front ABS sensor Behind the headlight 8 13-131 Connector DN 8-pole 1 ABS control lamp Behind the headlight 1 2 Connector DO 8-pole 2 ABS control lamp Behind the headlight Connector DP 3-pole 3 Manifold air pressure sensor for the rear cylinder Art.-No. 3.206.056-E On the left side of the frame 3 Connector DP1 3-pole 4 Manifold air pressure sensor for the front cylinder On the right side of the frame 4 Connector DP2 3-pole 5 Repair manual KTM LC8 Ambiant air pressure sensor Behind mask the headlight 5 multi-func.-digital-speedometer front brake switch v C_AK1/2 1 2 C_AA/20 speed sensor clutch switch 2 7 15 1 19 6 10 9 3 4 5 left fron t flas her right fron t flasher C_AH1/2 16 bu- br or bl pu bu gn- gr re-br br-bl ye-bl 1 2 gn- w h br ye 1 2 1 3 2 br bl C_AT3/2 wh br gn bu br C_BL1/2 M cool ing fan M cool ing fan C_CD1/2 1 2 6 5 C_ AY/1 C_BJ/1 ye-bl oil pr ess ur e s ens or p 2 3 1 4 wh temp er atur e switch C_BL/2 C_CD/2 1 2 1 C_AV/2 2 C_BC1/6 bu C_AC1/6 ye gn 950 Super Enduro 2006/07 pu br br bl-or or 2 1 br-bl bl-or C_AM3/3 gn-bl ye- bu C_AR3/2 C_AL3/2 3 br bl-wh br C_CR1/1 bl-wh C_ BA /1 C_BF/1 2 1 3 C_BT/3 C_AJ1/3 bl C_CR/1 br-bl br-bl or ye-re br-bl br gr gn-gr pu 1 3 2 N ye- bu gr t° C_AX/2 1 G flas her relay 2 front C_AS1/2 1 rear 1 2 EPC 1 EPC 2 3 C_AR2/3 C_ AM 2/ 3 2 ye-br 5 4 13 ignition switch 7 19 11 4 25 26 18 8 A A 10 A 10 A 10 A 10 A 15 10 A 10 16 9 1 A 10 ye- bu ye- wh ye-bl bl-or 2 Pick up C_AT/2 C_AL/2 1 2 1 C_AT2/2 C_AL2/2 M 1 4 2 3 M engi ne stop relay starter m otor C_AF4/4 fuel pump fuse box 2 TPS C_AR/3 C_A M /3 3 1 main harness - 630.11.075.000 8 1 C_AC/6 C_BC/6 3 16 10 br-wh C_AO/26 20 2 sid es tand switch 1 2 3 4 C_BR/4 C_BK1/4 C_AW1/2 2 1 C_AW/2 1 C_AS/2 2 horn 1 tem peratu re sens or 1 2 2 1 2 ye- bu bl-or bl-or or C_AH3/2 wiring diagramm neu tral s witch 2nd gear 3rd gear 2nd C_AR1/3 C_ AM 1/ 3 1 3th fuel level sen sor Q C_AL1/2 C_AT1/2 2 gr C_CR2/1 or adition al curr ent conn ec ti on ACC1 diode re-gn br bl-or black or-wh bu or re-wh or-bl br re re-gn or ye bu ye or pi or ye-bu ye-wh or re-bl or bl-wh br-bl C_CR3/1 br or re-gn re-br ye-br headlight positionlight bl pu-wh br bl-gn C_BW/3 C_DI/2 bu-bl ye-bu s t a r t b o t t om 4 3 2 C_AF3/4 1 30 A star t relay br flash er switch re-bu re-bl re-wh adition al curr ent conn ec ti on ACC2 re-wh hi gh /l ow b eam switch horn swi tch stop button pu-wh ye-wh br-bl or 2 1 br re C_AT4/2 4 1 2 4 3 3 bu- gr ye-bl re- bu ye- bu 1 2 re- wh re- wh rear brake switch start auxillary r elay fuel pum p relay lig ht sys tem relay gn heater el em en t heater el em en t 4 1 or -w h ye 2 or br 3 or bu- bl 2 re- bu re 1 re- wh 20.10.2005 temp er atur e switch for car buretor heating C_AK2/2 C_ AH 2/ 2 1 2 battery re-bl Art.-No. 3.206.056-E bu-gr bl C_AI3/2 or ignition coil pi ye ye-bl br-wh re gr E or C bu re-wh ye-bl U C_AH/2 C_AF2/4 C_AF1/4 C_AF/4 2 1 wh gn- w h br wh 3 1 2 4 2 3 1 br bl C_BI/2 pu G 1/8 left r ear fl ash er lic en ce p late lamp right rear flasher 2 C_AI2/2 1 2 C_AI1/2 1 2 C_AI/2 1 diode diode gen erator diode 3 U regu lator-rectifier ye C_AJ/3 C_BG/3 re-wh bu-br bl gn-wh C_AL4/2 ye or re-wh re-ye ye-bu C_AK/2 gn-bl C_AZ/4 C_BK/4 ye pi Repair manual KTM LC8 13-132 rear light/brakelight C_AU/2 handle bar switch for multi-func.-digitalspeedometer speed sensor v C_DB/4 C_AK1/2 2 4 3 C_AH1/2 1 2 C_AA/20 2 7 15 1 19 6 10 9 3 4 5 16 14 13 11 ye-br ye gn-re br left front flasher right front flasher clutch switch 1 br gn-gr re-br br-bl ye-bl gn-bl 1 2 gn-wh 1 2 pu bu 1 3 br ye-re 1 6 5 C_BJ/1 C_AY/1 C_BF/1 2 1 C_BT/3 3 2 M cooling fan M 3th 3 N gr ye-bu t° C_AX/2 1 G flasher relay 2 front C_AS1/2 1 rear 2 1 3 4 C_BR/4 C_BK1/4 1 2 EPC 1 EPC 2 2 3 C_AR2/3 C_AM2/3 sidestand switch C_AW1/2 2 1 C_AW/2 1 C_AS/2 2 horn 1 temperature sensor 1 2 2 1 2 ye-bu bl-or bl-or or wiring diagramm neutral switch 2nd gear 3rd gear 2nd C_AM1/3 1 C_AR1/3 C_BL1/2 1 fuel level sensor Q C_AL1/2 C_AT1/2 2 1 C_BA/1 C_CD1/2 oil pressure sensor p 2 3 C_AJ1/3 2 cooling fan C_BL/2 C_CD/2 2 temperature switch C_AV/2 1 2 4 1 C_AC1/6 C_BC1/6 950 Super Enduro 2007-2008 br wh gn br 2 br br bl bl-or or br br-bl 2 1 3 ye C_CR/1 bu-br or bl pu C_CR2/1 wh C_CR1/1 bl-or C_AM3/3 bu ye-bu C_AR3/2 C_AL3/2 multi-func.-digital-speedometer headlight C_AT3/2 ye gn bl-wh front brake switch positionlight ye-bl br-bl C_BW/3 C_DI/2 bu aditional current connection ACC1 bl-wh br-bl br br br-bl br gr gn-gr pu or bl re-br ye-br gr black or re C_CR3/1 2 ye-br 3 16 10 C_AO/26 20 5 8 1 C_AC/6 C_BC/6 4 13 bl-or aditional current connection ACC2 or br bl-gn C_AH3/2 C_AI3/2 or re gr or or 9 1 A 10 fuse box main harness - 7 19 11 4 25 26 18 8 A A A 10 A 10 10 A 10 A 15 10 A 10 16 or br ye-bu fuel pump 1 4 2 3 630.11.075.200 Pick up C_AT/2 C_AL/2 2 1 ye-wh ye-bl bl-or 2 1 C_AT2/2 C_AL2/2 M M engine stop relay starter motor C_AF4/4 TPS C_AR/3 C_AM/3 2 1 3 4 3 2 C_AF3/4 1 30 A start relay br start bottom re-wh flasher switch re-wh high/low beam switch horn switch stop button re-bu re-bl pu-wh diode re-gn or ye or-wh bu re-gn pi pu-wh bl re-gn br-bl or 2 1 br re C_AT4/2 24.05.2007 temperature switch for carburetorheating C_AK2/2 C_AH2/2 1 2 battery re-bl Art.-No. 3.206.056-E pi bu-gr ye-bl br-wh ignition coil br-wh E or ye-bu or-bl ye-bu or re-bl re-wh bl-wh ye bu bl br ye-wh bu-bl ye-bu ignition switch or C bl 2 4 3 3 bu-gr ye-bl re-bu ye-bu or-wh ye or 4 1 2 1 bu-bl br 3 2 4 1 or re br re-wh C_AF2/4 C_AF1/4 C_AF/4 2 1 2 re-wh re-wh rear brake switch start auxillary relay fuel pump relay light system relay gn heaterelement heaterelement 1 re-wh ye-bl U bu ye gn-wh C_AL4/2 re-wh bu-br ye-wh C_AH/2 re-wh re-ye br-bl C_AK/2 C_BI/2 2 wh gn-wh br 3 2 1 4 1 wh br 3 pu bl G 1/8 left rear flasher licence plate lamp right rear flasher 2 C_AI2/2 1 2 C_AI1/2 1 2 C_AI/2 1 diode diode generator diode 3 U regulator-rectifier ye C_AZ/4 or C_BK/4 C_AJ/3 gn-bl ye C_BG/3 ye pi Repair manual KTM LC8 13-133 rear light/brakelight C_AU/2 13-134 Aditional current connection Battery Carb heater (Carburator heater element) Clutch switch Cooling fan Diode ECU Engine stop relay Flasher relay Flasher switch Front brake switch Fuel level sensor Fuel pump Fuel pump relay Fuse box Gear sensor Generator Headlight High / low beam switch Horn Horn switch Ignition coil Ignition switch Left front flasher Left rear flasher Licence plate lamp Light system relay Multi-func.-digital-speedometer Neutral switch Oil pressure sensor Pick up Position light Rear brake switch Rear light / brakelight Regulator-rectifier Right front flasher Right rear flasher Sidestand switch Speed sensor Start auxillary relay Starter motor Stop button Temperature switch Throttle position sensor (TPS) Stromversorgung für Zusatzgeräte Batterie Vergaserheizelement Kupplungsschalter Lüftermotor Diode Steuergerät Motor-Stoprelais Blinkerrelais Blinkerschalter vorderer Bremslichtschalter Benzinstandgeber Kraftstoffpumpe Kraftstoffpumpenrelais Sicherungskasten Gangerkennung Generator Scheinwerfer Auf-Abblendschalter Hupe Hornschalter Zündspule Zündschloss linker vorderer Blinker linker hinterer Blinker Kennzeichenbeleuchtung Beleuchtungsrelais Multifunktionsdigitaltachol Leerlaufschalter Öldruckschalter Impulsgeber Begrenzungslicht hinterer Bremslichtschalter hinteres Begrenzungslicht / Bremslicht Regelgleichrichter rechter vorderer Blinker Rechter hinterer Blinker Seitenständerschalter Geschwindigkeitssensor Starterhilfsrelais Startermotor Stoptaster Temperaturschalter Vergaserpotentiometer NOTE to the connector designations: The connector designations are comprised of letters and numbers - e.g.: C_AA1/20 – The 1st position C stands for connector (connector). – The 2nd and 3rd positions AA stand for the connector type. – The 4th position numbers the same type of connector if the connector is used for different applications. – The 5th and 6th positions 20 specify the number of pins in the connector, in this case 20 poles. The 5th position is not required for connectors with less than 10 pins. Cable colours bl: black ye: yellow bu: blue gn: green re: red wh: white br: brown or: orange pi: pink gr: grey pu: purple 30 A M battery start relay red-white 1 br brown 0.5 4 red-white 1 1 A H-page6/8 fus e box F-page6/8 s t a r t a ux i l la r y r e l ay 3 2 4 1 1 4 2 3 light system relay 950 Super Enduro 2006/07 E-page3/8 D-page 4/8 C-page 5/8 B-page 5/8 A-page3/8 9 G generator G-page 6/8 A A 8 3 U red-white 1 red-white 1 red-white 1 red-blue 0.5 starter motor regulator-rectifier 10 10 A 10 A 10 A 10 A 15 10 A 10 16 or or-bl re-wh re-wh ye re-bu or ye-bu 3 or bl-wh re-wh re-wh ye-bl 2 re-wh bu-br 1 re-wh re-ye 4 2 1 clutch switch 3th 1 2 C_AI1/2 diode 5 N 3 green-black 0.5 pi nk 0.5 neutral switch (N) / 2nd gear / 3rd gear 2nd C_ AR1/3 1 C_AM1/3 2 2 C_AI2/2 C_AT3/2 1 2 diode 4 C_ AC/6 C_ BC/6 ignition switch C_ AL 3/2 y e l l ow 0 . 5 1 C_AI/2 diode re-wh start system 3 C_ BR/4 C_BK1 /4 start bottom orange-white 0.5 orange-white 0.5 black red 0.5 30 C_AF/4 C_AF2/4 or re-bl Art.-No. 3.206.056-E brown 0.5 Repair manual KTM LC8 2/8 31 I-page6/8 J-page3/8 30 13-135 red-white 1 C_AF3/4 starter motor 30 A M battery start relay red-white 1 br brown 0.5 4 red-white 1 3 9 1 A 10 F -pa ge 6 /8 G -pa ge 6 /8 H -pa ge 6 /8 fus e box ge ne ra tor G U red-white 1 red-white 1 s ta rt a ux illa ry re la y 3 2 4 1 1 4 2 3 light s ys te m re la y 950 Super Enduro 2007 E -pa ge 3 /8 D -pa ge 4 /8 C -pa ge 5 /8 B -pa ge 5 /8 A -pa ge 3 /8 8 A A 10 A 10 A 10 A 10 A 15 10 A 10 16 or or-bl re -bu re-wh ye re -wh or ye-bu 3 or bl-wh re -wh re-wh ye-bl 2 re-wh bu-br 1 re-wh re-ye or re-bl red-white 1 red-blue 0.5 4 2 1 c lutc h s witc h 3 th 2 C _ A I 1 /2 1 diode 5 N 3 gre e n-bla c k 0 . 5 pink 0 . 5 ne utra l s witc h ( N ) / 2 nd ge a r / 3 rd ge a r 2 nd C _ A R 1 /3 1 C _ A M1 /3 2 2 C _ A I 2 /2 C _ A T 3 /2 1 2 diode 4 C _ A C /6 C _ B C /6 ignition s witc h C _ A L 3 /2 ye llow 0 . 5 C _ A I /2 1 diode re -wh s ta rt s y s te m 3 C _ B R /4 C _ B K 1 /4 orange-white 0.5 orange-white 0.5 black red 0.5 re gula tor- re c tifie r C_AF/4 C_AF2/4 s ta rt bottom brown 0.5 30 2 /8 31 I -pa ge 6 /8 J -pa ge 3 /8 30 13-136 red-white 1 C_AF3/4 31 3 C_ BR/4 C_BK1 /4 2 1 black red 0.5 ignition switch C_AO/26 violet-white 0.5 brown-white 0.5 red-green 0.5 brown 0.5 2 3 20 7 yellow-brown 0.5 grey 0.5 18 10 black-brown 0.5 8 16 blue-grey 0.5 pi nk 0.5 1 1 2 2 EPC 1 EPC 2 C _ AW1 / 2 2 1 C _ AW/ 2 1 3 C_ AF4/4 1 1 front C_ AS1/2 2 4 engi n e s t op r el ay 950 Super Enduro orange 1 U C E y e l l ow 0.5 b l ac k 0 .5 11 4 bl ue 0.5 yellow-white 0.5 yellow-blue 0.5 yellow-orange 0.5 19 26 13 25 2 C_ AL /2 C_AT/2 pick up orange-black 0.5 ignition coil start bottom brown 0.5 A-page2/8 1 rear C_ AS/2 2 1 2 C_AM/3 C_ AR/3 2 3th 1 3 C_ AR2/3 C_AM2/3 N 2 sidestand switch J-page2/8 ECU neutral switch (N) / 2nd gear / 3rd gear 2nd C_AM1/3 C_ AR1/3 1 3 throttle position sensor o-page5/8 fuel pump relay brown 0.5 30 C_AF1/4 fuel pump Art.-No. 3.206.056-E 1 black-blue 0.5 M C_ AL 2/2 C_AT2/2 2 1 4 2 3 30 3/8 31 E-page2/8 yellow-black 1 brown 0.5 Repair manual KTM LC8 13-137 31 M-page6/8 L-page6/8 2 1 C_AH3/2 3 2 C_ BT/3 C_ AJ1/3 1 flasher switch G v i o l et 0. 5 bl ac k 0 . 5 violet 0.5 2 black 0.5 3 right front flasher brown 0.5 left front flasher 950 Super Enduro rear flasher light`s C_BK/4 C_ AZ/4 1 1 6 horn switch C_ B C1 / 6 C_ A C1 / 6 5 horn brown 1 C_ AV/2 1 D-page2/8 black-white 1 2 1 2 1 2 temperature switch turn indicator system diode C_AI3/2 2 yellow-blue 0.5 C-page2/8 grey 0.5 fl as he r re la y brown 0.5 brown-black 1 black-orange 0.5 brown 0.5 C_CD/2 C_CD1/2 M 31 30 4/8 cooling fan M cooling fan C_BL/2 C_BL2/1 30 13-138 orange 0.5 13-129 ignition switch bl-or r-w re clutch switch r-w switch position ON ye pulled unpulled OFF Repair manual KTM LC8 Art.-No. 3.206.056-E LOCKED flasher switch cable harness TURN L TURN R or pu horn switch bl cable color HORN OFF OFF gr br br 31 C_BF/1 C_BC1/6 C_BA/1 yellow 1 yellow 1 N-page6/8 bl ue 1 green 1 rear brake switch front brake switch 950 Super Enduro 4 1 3 2 5 white 0.5 C-page2/8 brown 0.5 C_AK1/2 C_AK/2 2 1 4 green-white 0.5 2 1 C_BG/3 C_ AJ/3 3 white 0.5 2 rear light/brakelight 1 C_DI/2 positionlight light-brake system headlight C_BK/4 C_ AZ/4 1 1 2 blue-yellow C_AH1/2 C_AH/2 B-page2/8 1 3 C_BW /3 2 headlight brown 0.5 30 brown 0.5 5/8 31 30 13-140 C_AC1/6 O-page3/8 high/low beam switch horn switch stop button 13-141 light switch high/low beam switch brake switch cable harness cable switch pushed unpushed gn- yewh bu bl bl cable color LIGHT OFF P.LIGHT LO HI Repair manual KTM LC8 Art.-No. 3.206.056-E P.LIGHT bu ye gn wh 31 3 orange 0.5 1 speed sensor v 2 black-brown 0.5 C_AM3/3 C_ AR3/3 black-orange 0.5 1 yellow-black 0.5 19 3 5 7 M-page4/8 L-page4/8 9 4 2 N-page5/8 1 6 brown 0.5 temperature sensor brown-black 0.5 950 Super Enduro t° C_ AX/2 2 10 15 16 violett 0.5 C_AA/20 multi-func.-digital-speedometer blue 0.5 p 1 C_BJ/1 C_AY/1 1 fuel l ev el s ens or Q C_ AL 2/2 C_AT2/2 2 brown 0.5 instruments-tachometer oil pressure sensor green-grey 0.5 red-brown 0.5 green-black 0.5 orange 0.5 K-page3/8 C_CR3/1 red-black 0.5 blue-brown 0.5 H-page2/8 C_CR2/1 aditional current connection ACC2 F-page2/8 black 0.5 G-page2/8 C_CR1/1 yellow-red 0.5 I-page2/8 aditional current connection ACC1 30 brown 0.5 6/8 31 30 13-142 C_CR/1 left front flasher positionlight headlight right front flasher ACC1 ACC2 M ECU C_ AF3/4 battery regulator temperature sensor temperature switch 30 A 950 Super Enduro clutch switch carburetorheating fuellevelsensor right-left front flasher multi-func.-digital-speedometer horn switch starter motor start relay Art.-No. 3.206.056-E ground connection brown Repair manual KTM LC8 7/8 rear light/brakelight m ai n r el ay rear flasher fuel pump module engine stop relay 13-143 front brake switch fl as he r re la y diode Fa n 8 A A 9 1 A 10 fuse box fuel pump relay A A 10 A 10 10 A 10 A 10 15 10 16 30 A battery positive connection ignition switch rear brake switch 950 Super Enduro multi-func.-digital-speedometer yellow-blue engine stop relay yellow yellow-blue horn red-white C_ AF3/4 yellow-black black-white light switch M blue-brown high/low beam switch yellow black-orange Orange red-yellow regulator green green ACC1 ACC2 carburetorheating 8/8 s ta r t a ux i l l a r y r e l ay C_AF/4 start relay red-black starter motor 13-144 13-145 Connector AA 20-pole 1 1 11 1 Multifunctional digital speedometer Behind the multi functional digital speedo meter 20 10 Connector AC 6-pole 2 Ignition switch 1 4 3 6 Behind mask the 3 headlight 2 Connector AC1 6-pole 3 Light/horn/stop switch Art.-No. 3.206.056-E Behind mask the headlight Connector AF 4-pole 4 1 42 Auxiliary starter relay Under the seat Connector AF1 4-pole 5 Fuel pump relay Under the seat Connector AF2 4-pole 6 Lighting relay Repair manual KTM LC8 Under the seat Connector AF3 2-pole 7 Starter relay Under the seat Connector AF4 2-pole 8 Engine stop relay Under the seat 6 458 7 13-146 Connector AH 2-pole 1 Rear brake light switch On the right side of the frame 1 2 Connector AH1 2-pole 2 Front brake light switch Behind mask the 1 6 headlight Connector AH2 2-pole 3 4 2 3 Temperature switch for the carburetor heater Behind mask the headlight Connector AH3 2-pole 4 Flasher relay Behind mask the headlight Connector AI 2-pole 5 2 1 Diode for neutral switch Under the seat Connector AI1 2-pole Diode for side stand switch Under the seat Connector AI2 2-pole Diode for side stand switch Under the seat Connector AI3 2-pole 6 Diode for flasher control Behind the headlight mask next to the flasher relay 5 13-147 Connector AJ 3-pole 1 1 2 3 Rear lighting Under the seat in the back of the storage compartment 1 Connector AJ1 3-pole 2 Flasher switch Behind mask the headlight 2 Connector AK 2-pole 3 Rear brake light switch Art.-No. 3.206.056-E 1 2 On the right side of the frame Connector AK1 2-pole 4 Front brake light switch Behind mask the headlight Connector AK2 2-pole 5 Temperature switch for carburetor heater Behind mask Repair manual KTM LC8 3 the headlight 5 4 13-148 Connector AL 2-pole 1 Pulse generator 1 2 1 On the left between the oil tank and the generator cover Connector AL1 2-pole 2 Fuel sender On the front left next to the radiator 2 3 Connector AL2 2-pole 3 Fuel pump On the front left next to the radiator Connector AL3 2-pole 4 4 Clutch switch Behind the headlight Connector AL4 2-pole 5 Carburetor heater Between the steering head and the ECU 5 13-149 Connector AM 3-pole 1 Throttle sensor 1 3 Between the steering head and the ECU 1 Connector AM1 3-pole 2 2 Gear sensor On the left between the oil tank and the generator cover 3 Connector AM2 3-pole 3 Side stand switch Art.-No. 3.206.056-E On the left between the oil tank and the generator cover Connector AM3 3-pole 4 Speed sensor Behind the headlight 4 Connector AO 26-pole 5 Repair manual KTM LC8 20 14 8 1 Control unit Behind head 26 19 13 7 the steering 5 13-150 Connector AR 3-pole 1 3 1 Throttle sensor Between the steering head and the ECU 1 Connector AR1 3-pole 2 Gear sensor 3 2 On the left between the oil tank and the generator cover Connector AR2 3-pole 3 Side stand switch On the left between the oil tank and the generator cover Connector AR3 3-pole 4 Speed sensor Behind the headlight 4 Connector AS 2-pole 5 1 2 Rear ignition coil 5 Behind the air filter box Connector AS1 2-pole 6 Front ignition coil Behind the radiator 6 13-151 Connector AT 2-pole 1 Pulse generator 1 2 On the left between the oil tank and the generator cover 1 Connector AT1 2-pole 2 Fuel sender On the front left next to the radiator 3 2 Connector AT2 2-pole 3 Fuel pump Art.-No. 3.206.056-E On the front left next to the radiator Connector AT3 2-pole 4 Clutch switch Behind the headlight 4 Connector AT4 2-pole 5 Carburetor heater Repair manual KTM LC8 Between the steering head and the ECU 5 Connector AU 2-pole 6 Controller output 21 Under the seat next to the battery case 6 13-152 Connector AV 2-pole 1 Temperature switch 1 2 On the left side of the radiator 1 Connector AW 2-pole 2 Front EPC cylinder 2 1 On the right side of the frame 2 Connector AW1 2-pole 3 Rear EPC cylinder Behind the air filter box 3 Connector AX 2-pole 4 Coolant temperature sensor 1 2 On the left between the cylinders 4 Connector AY 1-pole 5 Oil pressure switch On the left side of the frame under the air filter box 5 Connector AZ 4-pole 6 1 2 3 4 Rear flasher Under the seat in the back of the storage compartment 6 13-153 Connector BA 1-pole 1 Emergency off switch Behind mask the 3 headlight 4 1 Connector BC 6-pole 2 Ignition switch 3 6 1 Behind mask the headlight Connector BC1 6-pole 3 Light/horn/stop switch Art.-No. 3.206.056-E Behind mask the headlight Connector BF 1-pole 4 Emergency off switch Behind mask the headlight Repair manual KTM LC8 Connector BG 3-pole 5 1 2 3 Rear lighting Under the seat in the back of the storage compartment 5 Connector BI 2-pole 6 Controller outlet 2 1 Under the seat next to the battery case 6 2 13-154 Connector BJ 1-pole 1 Oil pressure switch 1 On the left side of the frame under the air filter box 1 Connector BK 4-pole 2 1 1 2 3 2 Rear flasher Under the seat in the back of the storage compartment Connector BK1 4-pole 3 Tip switch Behind mask the headlight 3 Connector BL/BL1 2-pole 4 Radiator fan On the left under the radiator hose 1 2 4 Connector BR 4-pole 3 Tip switch 1 Behind mask the headlight 4 Connector BT 3-pole 5 Flasher switch 1 3 Behind mask the headlight 5 13-155 Connector BW 3-pole 1 1 Headlight Behind mask 1 the headlight 3 3 Connector CD/CD1 2-pole 2 Radiator fan 1 2 On the left under the radiator hose 2 Art.-No. 3.206.056-E Connector CR/CR1/CR2/CR3 1-pole 3 Connector for attachments: Ground, continuous positive polarity, positive ignition Behind mask the headlight Connector DI 2-pole 4 Parking light Repair manual KTM LC8 On the headlight 4 51,52 -A1 5 2 C_EF/14 1 6 4 2 5 Antenna 6 31 7 9 8 1 2 C_BR/4 C_BK/4 42 66 9 10 11 12 13 14 7 3 4 /3.E6 /3.E6 /3.B2 -X12 splice Connector for optional alarm system 66 ALA-A1 7 flaR-X200 9 flaL-X200 136 1 C_AI/2 990 Supermoto 2008 alarm system dummy plug 3 153 1 60,61 C_EL/2 45,46 C_DV/2 65 4 29,137 C_EG/14 2 52 3 61,135,136,175,143 1 2 1 C_BV/2 C_BS/2 -S3 seat surveillance 2 175,143 -X12-P1 153 154 7 6 159 1 3 C_EB/4 fuel pump relay 2 137 44 28 4 5 8 -K2 3 47 1 77 fuel pump M C_AR/3 C_AM/3 2 -M2 fue-P1 fuel-A2 10A 10A 2 1 2 1 4 /3.B2 /2.E5 10A 2 1 -F1 -F5 -F6 21 1 3 49 -K1 /3.B2 /3.A5 M ACC -K3 lig-X19 -M1 starter motor C_EB/4 50 light relay 2 battery, generator, starter /3.B2 4 3 155 2 1 157 ALA-A2 C_AC/6 64 23 28,29 -X1 splice 56,57 C_DN/8 48 48 C_DO/8 58,59 51 Immobilizer 156 46 22 30 158 CAN-H /3.B2 /2.A2 47 CAN-L /2.B2 76 -A2 4 3 1 3 2 1 -G1 -K4 /2.C1 battery -A1-X5 -X2 splice C_EB/4 power relay 2 4 C_AF/4 30 A start relay 55 diode 40 54 C_BC/6 -V1 45 57 start/stop switch 63 for optional alarm system 56 53 -S2 5,13,20,38,50,54,55,63,65,197 -S1 30 4 1 2 1 3 C_AU/2 C_EB/4 43 start auxillary relay 2 59 58 gn re-wh re-wh 3 -K5 STR-A3 -N1 626.11.076.000 main harness - /2.B5 /2.C1 generator G U regulator-rectifier gn gn 5,13,20,38,76,197,159 GND-X14 C_BI/2 antenna immobilizer 40 154 64 41 135 60 42,43 ignition switch 3 P. Page:1 13-156 114 air temp. sensor t° C_CM/2 1 2 115 113 -B3 1 6 4 rollover sensor -B4 C_AP/6 5 -B5 t° 3 2 1 t° -B6 2 1 p C_DP/3 -B7 1 3 2 1 p C_DP/3 -X101 -B8 manifold pressure sensor front 3 1 2 125 2 1 p C_DP/3 GND-P1 2 /3.B2 198,5,13 GND-X14 -X53 -B9 75 manifold pressure sensor rear 3 2.1 C_BJ/1 C_AY/1 1 89,179,186,126 pick up C_AT/2 C_AL/2 1 2 3 152 4 C_AO/26 1 118 ECU -L3 -A4 /3.D6 -X6 splice 86,189,190 73,76,198,197,159 3 -X7 splice 74 5 -X8 splice 184 6 87 7 8 19 125 122 7 6 5 4 3 2 1 C_DN/8 1 2 3 4 C_CO/34 5 6 Neu-P1 192 7 8 /3.B2 97 98 110 104 106 108 102 100 -X301 splice 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 215 211 207 219 206 218 205 199 203 208 204 212 209 202 210 1 C_CL/2 176 ignition coil front 1 MIL-P1 -L1 TAC-P1 2 1 C_CL/2 injection rear 2 ignition coil rear -L2 1 /3.B2 /3.B2 C_AS/2 2 -Y3 215,216,217 1 C_AR/3 C_AM/3 1 M -M4 1 or 1 2 2 C_CK/2 1 main harness 626.11.076.000 210 1 M -M5 C_CE/4 C_CA/4 2 211 3 P. Page:2 2nd throttle stepper motor 3 4 3 -Y1 -Y2 purge valve exhaust air valve 2 2 C_AE/4 3 1 C_AM/3 C_AR/3 2nd throttle position sensor ISC stepper motor 4 -B13 C_DU/2 -Y4 3 main throttle position sensor 212,213,214 -B12 injection front 2 180 C_AS/2 2 199,200,201 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 /3.F1 -X302 splice -X303 splice 111 109 107 105 103 101 99 142 CLU-A2 -X11 splice -X10 splice 191 17,157 -X9 splice 179 158,16 8 E C U 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 96 C_AR/2 114 C_AM/2 126 1,3,14,53,68,70,93,104,127,185,155 -X5 splice 2 124 C_AR/3 119 atmospheric pressure sensor 3 140 990 Supermoto 2008 hego sensor rear L 4 C_CE/4 1 C_CA/4 2 C_CE/4 -X4 splice -X305 splice 18,228 C_CA/4 hego sensor front L 3 4 -X54 C_CZ/3 C_CY/3 2 2.3 2.2 2.1 3 -X3 splice 16 -X304 splice 15,227 17 158 CAN-L /1.B5 /3.B2 18 129 228 GND-X14 76,5,13,20,38,197,159 94 53,155 tem-P1 80,91,95,97,113,116,120,129,138,150,184 -A1-X5 152 20 93 157 128 15 130 CAN-H 123 C_DO/8 185 /1.B4 127 3 83,90,109,117,119,139,151,183 139 /1.E8 80 121 90 2 116 1 138 73 74,75 117 /1.B7 81 120 91 N 39 C_EC/3 92 124 38 39 118 14 150 193 151 194 83 186 3th 140 2nd 187 C_AM/3 101 84 92 227 96 195 84,121,188 130 85 81 STR-A3 41 /1.E8 86 188 2 189 C_AT/2 107 -A3 Starter Interlock Unit 102 1 105 -S4 190 -B2 176 -X51 183 6 103 5 180 19 95 4 67 3 94 2 191 1 192 C_AP/6 110 -X50 106 t° 82 85,142,187 111 -B1 t° 88 gear position switch 69 sidestand sensor 123 218 CAN-BUS connector 122 203 diagnostic connector 2 -X300 C_CQ/16 87 fuel-A2 44 987 65 43 2 1 16 15 14 13 12 11 10 128 C_CP/16 70 88 98 202 89 100 108 /1.E5 99 200 82 219 water temp. sensor 67 Art.-No. 3.206.056-E 68 205 213 201 69 204 3 216 2 206 214 207 1 208 217 209 Repair manual KTM LC8 13-157 -S5 -H9 -B10 t° -P1 C_AK/2 75 33 175 144 176 115 148 77 170 177 178 179 180 112 181 156 66 229 182 C_AH/2 C_CX/2 /2.B6 143 144 CLU-A2 142 141 163 162 166 168 167 164 165 75 GND-P1 8 HI 2 4 P.light 7 5 L R 6 3 164,171,172 79,146,147,198 1 C_AY/1 2 1 flasher relay G -K6 C_AH/2 12,34 C_AI/2 1 133,134 diode 2 24 2 -V2 34 2 1 -M3 1 C_AU/2 C_BI/2 M 2 79 2 /1.E3 9 flaR-X200 7 6,160,173,177 flaL-X200 -X18 splice /1.E3 -X17 splice 8,163,174,178 /2.C4 62,72 1 C_AV/2 t GND-X14 198,5,13 -X16 splice 35,133 10A 10A 10A 2 1 35 15A 2 1 36 instruments-tachometer 9 2.1 C_BJ/1 -X15 splice -X52 -X14 splice 141,161,162,165,168,169,181,229 beam horn flasher switch LO C_BD/12 C_AD/12 1 172 166,170 990 Supermoto 2008 -S7 -X13 splice 145,149,182 66 ALA-A1 156 180 MIL-P1 ALA-A2 77 179 fue-P1 115 tem-P1 Neu-P1 176 TAC-P1 1 C_EH/1 25 1 26 -F2 -F3 -F4 -F7 27 37 P /1.E6 36 2 1 2 145 148 149 160 175,143 -S8 -X21 32,33 1 C_CR/1 5 6,7 8,9 4 -X22 1 C_CR/1 -X23 226 224 220 225 1 C_CR/1 -X24 220,221,222,223 1 C_CR/1 aditional current connection ACC2 -X201 splice 2.4 2.3 2.2 2.1 aditional current connection ACC1 37 temperature switch -S9 146 cooling fan 78 -X19 splice 49 78 front brake switch flasher right front ambient temp. sensor multi-func.-digital-speedometer speed sensor position light G -B11 -H1 C_AR/3 C_DI/2 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 9 8 7 6 5 4 3 2 1 -X12-P1 71 2 C_CW/2 C_AL/2 C_CW/2 C_ED/32 C_AM/3 2 1 3 C_CW/2 /1.D6 /1.B4 /2.D7 /2.B2 /1.E5 /2.B6 /2.D7 /1.B4 /1.E3 /2.D4 169 161 167 32 171 ACC 173 62 10 72 71 1 C_AH/2 221 226 222 225 4,12 13 10,11 223 224 2 11 174 C_AK/2 1 1 2 134 132 2 1 C_BW/3 C_CX/2 C_AJ/3 626.11.076.000 main harness - C_CX/2 196 112 131 P C_DI/2 1 C_CX/2 3 2 1 2 headlight flasher left front clutch switch -H2 -H3 -S6 132 147 C_CV/4 -X200 C_BY/4 1 2 1 1 C_AT/2 131 1 2 3 4 C_CW/2 C_BG/3 C_CW/2 2 1 2 C_CX/2 3 1 2 lig-X19 -H8 1 2 -H4 -S10 -H5 -H6 horn rear brake switch flasher right rear rear light/ brake light -H7 licence plate lamp 3 P. Page:3 flasher left rear oil pressure switch 13-158