- Ninguna Categoria

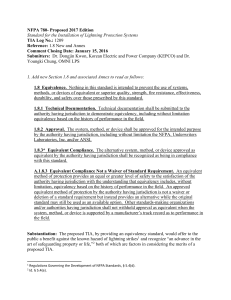

NFPA 780: Lightning Protection Systems Standard (1997)

Anuncio