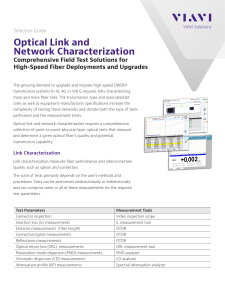

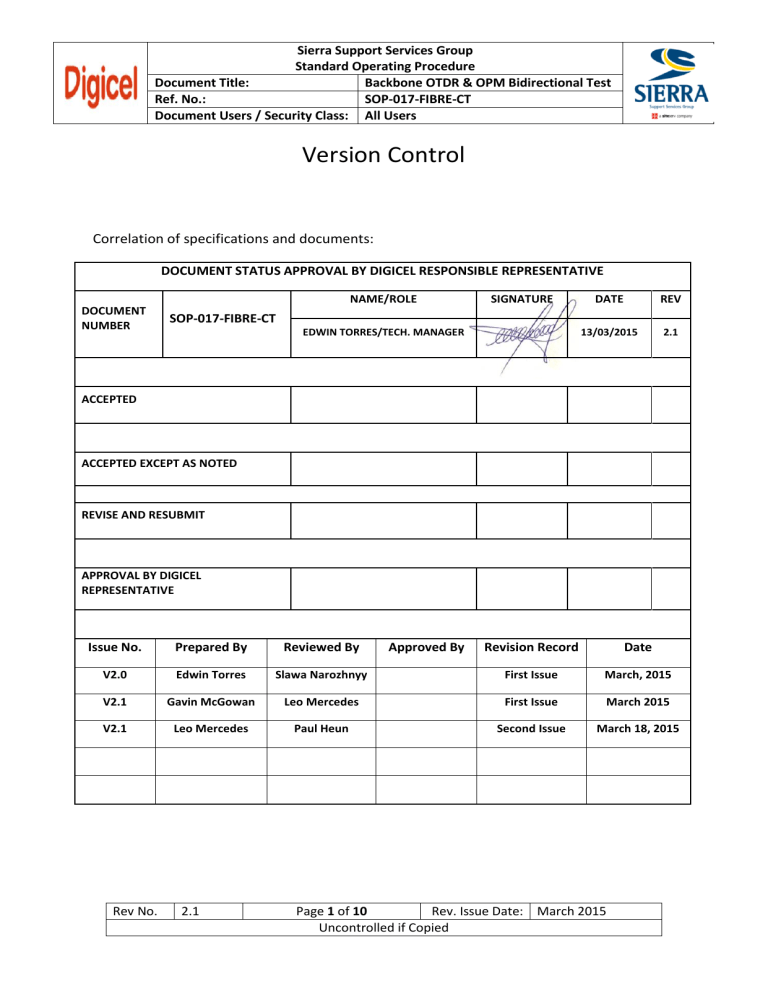

Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users Version Control Correlation of specifications and documents: DOCUMENT STATUS APPROVAL BY DIGICEL RESPONSIBLE REPRESENTATIVE NAME/ROLE DOCUMENT NUMBER SIGNATURE DATE REV 13/03/2015 2.1 SOP-017-FIBRE-CT EDWIN TORRES/TECH. MANAGER ACCEPTED ACCEPTED EXCEPT AS NOTED REVISE AND RESUBMIT APPROVAL BY DIGICEL REPRESENTATIVE Issue No. Prepared By Reviewed By V2.0 Edwin Torres V2.1 V2.1 Rev No. Revision Record Date Slawa Narozhnyy First Issue March, 2015 Gavin McGowan Leo Mercedes First Issue March 2015 Leo Mercedes Paul Heun Second Issue March 18, 2015 2.1 Approved By Page 1 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users OTDR Connection Diagram 1.- Testing diagram A-B Side Note: 1km Receive cable required at B-Side ODF 2.- Testing diagram B-A Side Note: 1km Receive cord required at A-Side ODF 3. Backbone SOP Test process Inspect - Clean Connect as per IEC 61300-3-35 Rev No. 2.1 Perform OTDR A-B and then B-A 1310/1550nm with Bi-directional Analysis Perform Insertion Loss Measurements A-B then B-A 1310/1550nm with Bi-directional Analysis Page 2 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users OTDR Settings 1. - Check the calibration certificate of the OTDR Machine and arrange the fibre spool for A-B and B-A testing 2. Set the OTDR parameters Recommended OTDR Configuration 1310nm & 1550nm Use the recommended parameters on Table 2.2 Range should be 1.3 times the FUT length or nearest setting available on the OTDR Acquisition time Use the recommended parameters on table 2.2 Refractive Index (IOR) Provided by cable manufacturer Backscattering Coefficient Provided by cable manufacturer Splice detection threshold 0.1 dB Table 2.1 – OTDR Configuration Wavelength Pulse width Range Cable Length < 1.5 Km 1.5 to 5 Km 5 to 10 Km 10 to 20 Km 20 to 40 Km 40 to 80 Km 80 to 120 Km 120 to 160 Km Recommended Parameters Pulse width / Acquisition time 5 ns / 30s 10 ns / 30s 10 ns / 45s 30 ns / 45s 100 ns / 60s 275 ns / 90s 1 µs / 90s 2.5 µs / 120s Table 2.2 – Recommended Parameters Note: The Pulse width settings above are a guideline and it is up to the discretion of the Tester to select a pulse width which provides a clean trace with optimum resolution. 3. Analysis settings a. Reflectance detection threshold= -72 dB b. End of fiber detection threshold= 5 dB 4. Event table settings: a. Splice loss= 0.3dB b. Connector loss= 0.5dB c. Reflectance= -55dB 5. Recommended Launch Lead: a. 1km launch & Receive cables required Rev No. 2.1 Page 3 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users Optical theoretical fibre link loss AT = AF x L T + AE x N E + AC x N C AT[dB]: Total loss (dB)(obtained from the test result) LT[Km]: Cable length (Km) AF[dB/Km]: Fibre loss per kilometre (dB/Km)(From cable manufacturer) AE[dB]: Splicing loss (dB)( maximum 0.3 dB) NE: Total # of splices (Full route) AC[dB]: Mated connector loss (dB)(maximum 0.5 dB) NC: Total # of Connectors (full route) Example: Wave Length: 1550nm LT[Km]: 10 Km AF[dB/Km]: 0.24 dB/Km AE[dB]: 0.3 dB NE: 2 AC[dB]: 0.5 dB NC: 2 AT = (0.24 x 10) + (0.3 x 2) + (0.5 x 2) => 4 dB Rev No. 2.1 Page 4 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users OTDR Testing Procedure 1. Calculate the Optical theoretical fibre link loss following the formula 2. Test from ODF to ODF 3. Protect the patch cord’s connector with the cover and keep it in safe manner during the test. 4. Clean all connectors and mating adapters as per IEC 61300-3-35 5. Run the OTDR test on both wavelengths 1310nm and 1550nm. 6. Save the test results from the OTDR as per the Digicel file name convention and repeat the same procedure in an incremental manner for each port 1, 2, 3………48 etc. 7. OTDR test results after analysis should be filled onto the Bi-Directional Excel OTDR Report. This report involves: a. Splice Location b. Distance Km c. Fiber Nº/Port Nº d. (A-B) and (B-A) splice event values e. Average values f. Average Splice Loss less than or equal to 0.1dB g. Events Logs If the data overrun the reference value, highlight it. 8. Once completed (A-B) SIDE start a new test on (B-A) SIDE 9. Soft copy must be provided (all the data and OTDR graphics) Acceptable Bi-directional test results Fibre optic cable loss Connecting point Rev No. 1310nm 0.35 (dB/Km) 1550nm 0.25 (dB/Km) SC/APC Mated pair connectors ≤0.5 dB Fusion splicing point ≤0.1 dB Reflectance -55 dB Total Loss Less than the calculated theoretical fibre link loss 2.1 Page 5 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users Saving of OTDR Results OTDR traces should be saved and stored in the OTDR Vendor Neutral Telcordia (Bellcore) GR-196 & SR-4731 *.sor file formats. The OTDR trace file will be saved as an 8:3 file format using the following convention: AABBWNNN.SOR where; o AA is the first and last letter (number) of the Source address o BB is the first and last letter of the Destination address o W is wavelength: 3 is for 1310, 4 is for 1490, 5 is for 1550 & 6 is for 1625nm o NNN is the fibre number e.g. 1, 2, 3….144 etc. o Therefore an example of the above Trace name would be: AZZA3144.SOR These traces need to be saved in the appropriate Digicel Sharefolder using the Country/Backbone/Segment/Files in order to avoid trace name duplication. Therefore traces associated with the cable need to be saved in a Folder with that name. Also a master Folder for just the OTDR Files to be Stored using the Cable names as subfolders. OTDR test results after analysing should be filled into Excel OTDR Event Log Register. Finally ILM results & Certs should also be saved to the same folder. Rev No. 2.1 Page 6 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users ILM Test Diagram OPM/Light Source Calibration • Calibration Process: 1. Turn on Light Source, OPM and allow time to warm-up. 2. Clean all connectors and mating adapters (Outline in Cleaning Process). 3. Configure wavelength for the test at 1310nm and 1550nm for dual wavelength testers, if not you must calibrate at 1550nm. 4. Attach launch cable to source. This should remain connected to source for the duration of the test. 5. Set “0 dB” reference on the OPM holding the (REF) button for 3 seconds. 6. Check “0 dB Reference” periodically during testing. ILM test Procedure B - Side 1. Turn ON the OPM Tester and allow time to warm-up Rev No. 2.1 Page 7 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users 2. Clean all connectors and mating adapters (Outline in Cleaning Process) 3. Attach patch cord cable to the ODF port to test. This should remain connected to the OPM during the duration of the test 4. Configure OPM at the same wavelength as the light source output (1310nm and 1550nm) for dual wavelength testers, if not you must test first at 1310nm and after at 1550nm. 5. Confirm that no Laser signal indicated by OPM tester A-Side 6. 7. 8. 9. Disconnect OLT patch cord connected onto the ODF port to test Turn ON Light Source and allow time to warm-up Clean all connectors and mating adapters (Outline in Cleaning Process) Set-up light source at 1310 nm and 1550nm for dual wavelength testers, if not you must test first at 1310nm and after at 1550nm. 10. Connect OPM Light Source into the ODF port to test B-Side 11. 12. 13. 14. 15. If Laser signal is indicated, continuity is confirmed Make loss measurement test Repeat this procedure for each ODF port one by one Fill out the Acceptance Test Report (ATP) with all the values Once completed (A-B) SIDE start a new test on (B-A) SIDE 16. Perform b-directional analysis of the results and issue Average ILM result for each wavelength on each fibre. Cleaning Process Rev No. 2.1 Page 8 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users Tools: One-Click Cleaner Cletop Cassette Cleaner Lint-Free Wipes One-Click Cleaner Process: 1. - Pull off the guide cap cover (A) 2. - Slide the connector into alignment sleeve (B) of the One-Click Cleaner and gently press the body of the OneClick Cleaner until an audible “click” is heard. 3. - Remove the One-Click Cleaner Dry Cleaning Cleaning connectors in OTDR, ODF, OPM, OLS, and VFL ports without removing adapters 1.- Remove the protective dust cover (C) from the tip of the One-Click Cleaner 2. - Insert the tip of the One-Click Cleaner into the optical port adapter and gently press the body of the One-Click Cleaner until an audible “click” is heard. 3. - Remove the One-Click Cleaner. Cletop Cassette Cleaner Process: 1. - Remove the protective end-cap and store it in a small resealable container. 2. - Press down and hold the thumb lever. The shutter slides back and exposes a new cleaning area. 3. - For single, non−APC fibre connectors, rotate the fibre once through a quarter turn, 90 degrees. 4. - For APC connector end-faces, hold cleaning area at the same angle as the end-face. 5. - Pull the fibre tip lightly down the exposed cleaning area in the direction of the arrow or from top to bottom. 6. - Release the thumb lever to close the cleaning window. 7. - Repeat the inspection and cleaning processes, as necessary. Tools: 99% isopropyl alcohol Lint-Free Wipes Wet Cleaning Rev No. Process: 1. - Remove the protective end-cap and store it in a small resealable container. 2. - Fold the wipe into a square, about 4 to 8 layers thick. 3. - Moisten one section of the wipe with one drop of 99% alcohol. Be sure that a portion of the wipe remains dry. 4. - Lightly wipe the ferrule tip in the alcohol moistened portion of the wipe with a figure 8 motion. Immediately repeat the figure 8 wiping action on the dry section of wipe to remove any residual alcohol. 5. - Properly dispose of the wipe. Never reuse a wipe 6. - Repeat the process as necessary. 2.1 Page 9 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied Sierra Support Services Group Standard Operating Procedure Document Title: Backbone OTDR & OPM Bidirectional Test Ref. No.: SOP-017-FIBRE-CT Document Users / Security Class: All Users Safety summary 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Keep all food and beverages out of the work area If fibre particles are ingested, they can cause internal haemorrhaging Wear disposable aprons to minimize fibre particles on your clothing Fibre particles on you clothing can later get into food, drinks, and ingested by other means Always wear safety glasses, suitable safety Helmet, safety belts and protective gloves Ground every metallic component to avoid electric hazards due to spark by power lines Suitable warning /Safety display board should be put on installation site Handle the fibre optic splinters similar to glass splinters Appropriate safety measures should be taken while working near the installation site Keep hands free from tools when climbing or getting down on pole or ladder Suitable accessories must be used during installation to ensure smooth and safe working Only skilled personnel should stay near the installation site to minimize risk of injury or death ------------------------------------------END OF DOCUMENT------------------------------------------- Rev No. 2.1 Page 10 of 10 Rev. Issue Date: March 2015 Uncontrolled if Copied