336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 1 de 22

Pantalla anterior

Bienvenido: r405jap

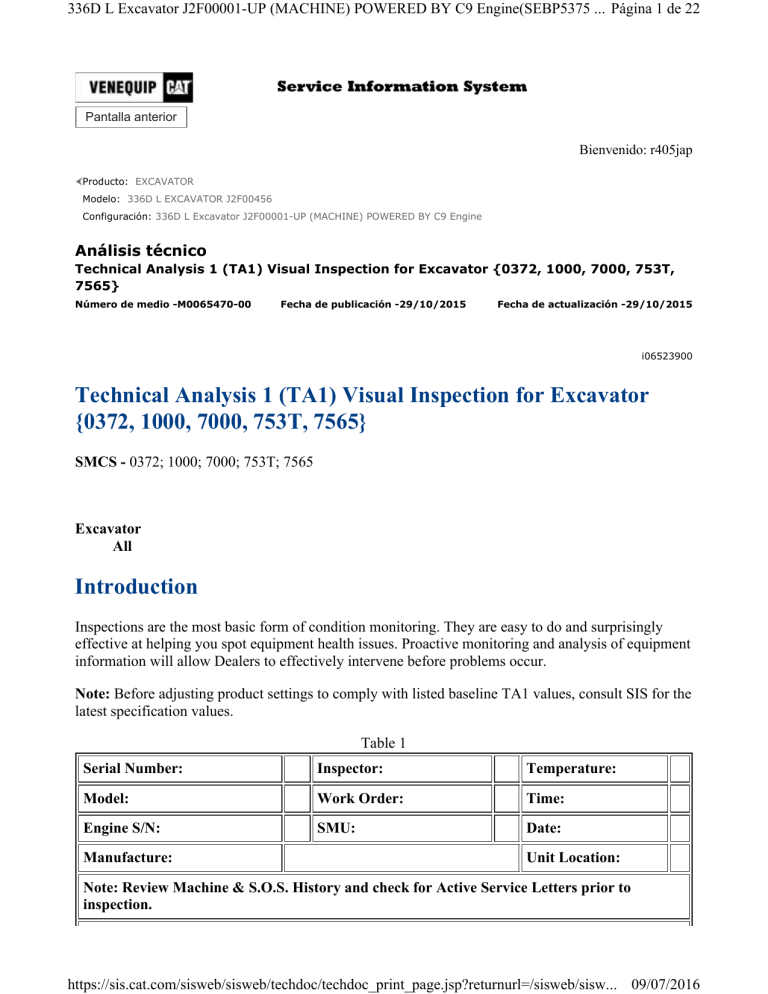

Producto: EXCAVATOR

Modelo: 336D L EXCAVATOR J2F00456

Configuración: 336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine

Análisis técnico

Technical Analysis 1 (TA1) Visual Inspection for Excavator {0372, 1000, 7000, 753T,

7565}

Número de medio -M0065470-00

Fecha de publicación -29/10/2015

Fecha de actualización -29/10/2015

i06523900

Technical Analysis 1 (TA1) Visual Inspection for Excavator

{0372, 1000, 7000, 753T, 7565}

SMCS - 0372; 1000; 7000; 753T; 7565

Excavator

All

Introduction

Inspections are the most basic form of condition monitoring. They are easy to do and surprisingly

effective at helping you spot equipment health issues. Proactive monitoring and analysis of equipment

information will allow Dealers to effectively intervene before problems occur.

Note: Before adjusting product settings to comply with listed baseline TA1 values, consult SIS for the

latest specification values.

Table 1

Serial Number:

Inspector:

Temperature:

Model:

Work Order:

Time:

Engine S/N:

SMU:

Date:

Manufacture:

Unit Location:

Note: Review Machine & S.O.S. History and check for Active Service Letters prior to

inspection.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 2 de 22

Status of the Machine(1)

The status recommendation of your Excavator is:

(1)

N = Normal, D = Down Machine, M = Monitor/Needs Attention

Creating an Electronic Copy

Use the following procedure to create an editable electronic copy from SIS web.

1. Click format to print.

2. Save the document as an HTML format.

3. Open the document with Microsoft Word.

Visual Inspection

1.0 Inspection Preparation

Refer to "1.0 Inspection Preparation" section in "Inspection Reference" for more information for

performing machine inspection preparation.

Table 2

Sl.No.

Status(1)

Description

1.1

Check with customer for operator complaints

1.2

Perform machine inspection preparation

1.3

Download Product Status Report

Comments

Check Product Link

Is machine equipped with Product Link

1.4

Is Product Link registered

Is Product Link reporting to Vision Link

(1)

1.5

Observe engine exhaust colors

1.6

Listen for unusual noises

1.7

Lockout / Tagout Machine

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

2.0 Lower-Level Inspection

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 3 de 22

Refer to "2.0 Lower-Level Inspections" section in "Inspection Reference" for more information for

performing lower-level inspection.

Table 3

Sl.No.

(1)

Status(1)

Description

2.1

Final drive & sprocket

2.2

Travel Motor & brake valve

2.3

Track adjuster

2.4

Carrier rollers

2.5

Track rollers

2.6

Front idlers

2.7

Track guides

2.8

Track shoes

2.9

Track links, pins & bushings

2.10

Track roller frame & carbody

2.11

Engine Oil Pan

Comments

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

3.0 Middle-Level Inspection

Refer to "3.0 Middle-Level Inspections:" section in "Inspection Reference" for more information for

performing middle-level inspection.

Table 4

Sl.No.

Status(1)

Description

3.1

Cab exterior

3.2

Cab interior

3.3

Steps & handrails

3.4

Work lights

3.5

Air cleaner

3.6

Batteries and battery cables

3.7

Radiator, oil cooler, condenser & aftercooler

3.8

Lower radiator & oil cooler hoses

Comments

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 4 de 22

(1)

3.9

Counterweight

3.10

Hydraulic pump compartment

3.11

Swing drive gear

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

4.0 Upper-Level Inspection

Refer to "4.0 Upper-Level Inspections:" section in "Inspection Reference" for more information for

performing upper-level inspection.

Table 5

Sl.No.

(1)

Status

Description

(1)

4.1

Hood & platform

4.2

Exhaust manifold

4.3

Turbocharger

4.4

Cylinder head & valve cover

4.5

Engine mounts

4.6

Pulleys, belts & compressor clutch

4.7

Fan guard & fan

4.8

Upper radiator, air inlet, oil cooler & after cooler lines

4.9

Radiator/oil cooler screen

4.10

Water pump

4.11

Radiator cap

4.12

Fuel priming pump, secondary fuel filter & fuel injection

pump

4.13

Engine wiring harness

4.14

Swing drive compartment

4.15

Swing drive

4.16

Main hydraulic control valve

Comments

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

5.0 Implement/Attachment Inspection

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 5 de 22

Refer to "5.0 Implement/Attachment Inspections:" section in "Inspection Reference" for more

information for performing implement/attachment inspection.

Table 6

Sl.No.

(1)

Status(1)

Description

Comments

5.1

Area around boom cylinders & swivel

5.2

Lower boom area

5.3

Boom cylinder

5.4

Area where boom attaches to stick

5.5

Stick cylinder

5.6

Bucket cylinder

5.7

Bucket linkage

5.8

Bucket wear plates

5.9

Side cutters

5.10

Tips & adapters

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Site Conditions

Table 7

Sl.No.

Status

Description

(1)

Comments

Ambient Temperature

NORMAL: −18 to 32°C (0 to 90°F)

6.1

MONITOR: 32 to 46°C (90 to 115°F) or −18° to -29°C

(0 to -20°F)

ACTION: Above 46° C (115° F) or Below −29° C (−20° F)

Altitude

NORMAL: 0 to 1524 m (0 to 5000 ft)

6.2

MONITOR: 1524 to 3048 m (5000 to 10000 ft)

ACTION: Above 3048 m (10000 ft)

6.3

Haul Road Grade

NORMAL: Flat

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 6 de 22

MONITOR: Mild

ACTION: Steep

Haul Road Condition

6.4

NORMAL: Positive Banking, Gradual Turns, Good Erosion

Control

ACTION: Negative Banking, Sharp Turns, Poor Erosion

Control

Humidity

NORMAL: Below 25%

6.5

MONITOR: 25 to 60%

ACTION: Above 60%

Air Quality

NORMAL: No Dust

6.6

MONITOR: Light Dust

ACTION: Heavy Dust

Underfoot Condition

NORMAL: Dry Flat Surface

6.7

MONITOR: Moderate Grades, Mixture of Muddy / Dry

Surfaces

ACTION: Steep Grades, Muddy, Snow, Ice

Machine Utilization

6.8

NORMAL: 0 to 10 Hours

ACTION: Above 10 hours

Equipment Role

NORMAL: Utility

6.9

MONITOR: Support

ACTION: Production

6.10

Working Material

NORMAL: Uncompacted, Low Abrasion

MONITOR: Moderately Compacted, Moderate Abrasion

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 7 de 22

ACTION: High Abrasion, Compacted, Dense

Maintenance Practices

NORMAL: Excellent

6.11

MONITOR: Good

ACTION: Poor

6.12

(1)

Primary Industries

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Inspection Reference

Inspection Benefits:

• Minimizes downtime through scheduled maintenance

• Locates potential problems

• Finds overlooked problems

• Enables scheduled maintenance and repairs

• Lowers owning and operating costs

Guidelines

Wiring Harness Inspection Guidelines

Check for:

• Check for tubes, hoses, and wiring harnesses rubbing against:

- One another

- Sharp corners

- Bolt heads

• Check for tubes, hoses, and wiring harnesses not properly secured

- Missing clips and/or wire ties

- O-clips not attached

Harness Connector Inspection Guidelines

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 8 de 22

Check for connectors:

• Not properly secured in place

• Rubbing against machine frame

• Rubbing against sharp edges

Implement Linkage Pin Inspection Guidelines

Check for:

• Loose or broken flange mounting bolt

• Elongated bolt hole in flange (hole is located behind pin retaining bolt)

• Loose or missing pin retainer bolts

• Irregular shaped pin bores

Hydraulic Cylinder Inspection Guidelines:

Check for:

• Oil leaks indicated by dirt or oil buildup around the cylinder lip seal

• Oil leaks at hose connections

• Damage to cylinder rods

• Damage or wear to linkage pins (refer to "Pin Inspection Guidelines" for inspection procedure)

1.0 Inspection Preparation

1.1 Check with customer for operator complaints

1.2 Perform walk-around inspection

• Make sure no one is underneath the machine, around the machine, or on the machine. Be sure

that the area is free of personnel.

• Walk around the machine and inspect underneath the machine for visible signs of fluid leaks.

• Park the machine on a level surface in the recommended service position according to the

OMM.

• Check engine oil, hydraulic oil, swing drive oil, and engine coolant levels. If necessary, add oil

or coolant to reach minimum level.

1.3 Download Product Status Report

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP5375 ... Página 9 de 22

• Download Product Status Report using ET.

• If ET is not available, download fault codes using machine monitor.

1.4 Check Product Link

• Is machine equipped with Product Link

• Is Product Link registered

• Is Product Link reporting to Vision Link

1.5 Observe engine exhaust colors

• Start the machine and observe exhaust colors:

- White smoke after initial startup could indicate coolant in the engine cylinders

- Blue smoke during startup may indicate oil in the engine cylinders

- Continuous black smoke could indicate an improper air/fuel mixture

- Continuous gray smoke may indicate a fuel timing problem

1.6 Listen for unusual noises

• Excessive noise coming from hydraulic pump could indicate either:

- Pump cavitation

- A loose or failed bearing

• Excessive noise coming from engine compartment could indicate:

- Fuel injector damage

- Engine bearing damage

- Valve train damage

1.7 Lockout / Tagout Machine

Turn the key start switch to the OFF position, remove the key, also remove the battery disconnect key,

and tag the machine out for safety.

2.0 Lower-Level Inspections

2.1 Inspect final drives and sprockets

Check the oil level in the final drives

• If equipped, check the magnetic plug for metal particles.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 10 de 22

• If the oil level is low, check the following areas for leaks:

- Sealing surface between the cover and the ring gear

- Sealing surface between the ring gear and the housing

- Duo-cone seal located behind the sprocket

Inspect the sprockets

• Look for broken or chipped teeth

• Look for sharp edges on sprocket teeth; sharp edges on teeth indicate excessive sprocket wear

2.2 Inspect travel motors and brake valves

Check for oil leakage along the bottom surface of travel motor housing

• If oil is visible in this area, remove the cover and inspect the travel motor, brake valve, and oil

lines for leakage

2.3 Inspect track adjusters

• If track adjustment is necessary, inspect the track adjuster.

• Check for proper adjustment of track.

• Look for grease and dust buildup around the piston; leakage in this area indicates piston lip seal

or piston rod may be worn or damaged.

2.4 Inspect carrier rollers for:

• Excessive wear on the surface where the track link rides on the carrier roller.

• Oil leakage in the following areas:

- On the sealing surface between the front cover and the roller.

- From the duo-cone seal on the backside of the carrier roller.

2.5 Inspect track rollers for:

• Excessive wear on the surface where the track link rides on the track roller

• Oil leakage in the following areas:

- From the duo-cone seals on the front and backside of the track roller

- At each end of the track roller shaft; leakage in this area indicates the O-Ring seal on the track roller

shaft may worn or damaged

2.6 Inspect front idlers for:

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 11 de 22

• Excessive wear on the surfaces of the idler where the track link rides on the idler

• Oil leakage in the following areas:

- From the duo-cone seals on the front and backside of the idler

- At each end of the track idler shaft; leakage in this area indicates the O-ring seal on the shaft may be

worn or damaged

2.7 Inspect the track guides for:

• Damaged, missing, or loose bolts

• Damage to track guide

2.8 Inspect the track shoes for:

• Damaged, missing, or loose bolts

• Damaged or worn track shoes

2.9 Inspect track links, pins, and bushings for:

• Damaged or missing cotter pins in the master links

• Excessive wear on contact surface of track links

• Excessive noise in the track during machine operation

- If excessive noise is noticed, check for temperature variances between the pins. To do this, touch the

end of the pins with your hand or use an infrared thermometer. Large temperature variances may

indicate a dry joint in the link.

2.10 Inspect the track roller frames and carbody for:

• Damage to frame

• Structural cracks

• Cracked welds

2.11 Inspect engine oil pan for:

• Check the wiring harnesses and hoses located in the engine compartment for wear and/or

damage

• Oil accumulation on the bottom of the oil pan. If oil is found on the pan, remove the bottom

guard and inspect the following:

- Check for leaks around the oil pan mounting flange

- Check for leaks around the oil level sensor, drain valve, and the dipstick tube

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 12 de 22

3.0 Middle-Level Inspections:

3.1 Inspect the cab exterior for:

• Bent or damaged cab structure

• Cracked or broken glass

• Damaged or missing mirrors

• Worn or broken window wiper arm or wiper blade

3.2 Inspect the cab interior for:

• Excessive dirt in cab air filter

• Proper function of the seat and seat belt

• Wear or damage to seat belt

• Seat belt replacement date

• Proper function of door and latches

• Worn or broken window latches or slides

3.3 Inspect steps and handrails:

• Ensure that steps and handrails are in place and check for:

- Damaged, missing, or loose bolts

- Damage to steps or handrails

- Excessive dirt or debris

3.4 Inspect work lights for:

• Proper operation

• Cracked or broken lenses

• Damaged harnesses or electrical connectors

• Loose or damaged mounting brackets

3.5 Inspect air cleaner for:

• Dirt and/or debris in the air pre-cleaner

• Loose or damaged hose clamps on air inlet tube

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 13 de 22

3.6 Inspect battery and battery cables for:

• Corrosion on battery posts and/or cables

• Proper function and tightness of battery hold down

3.7 Inspect radiator, oil cooler, condenser, and aftercooler for:

• Plugged cores

• Plugged screens

• Damaged fins

3.8 Inspect lower radiator and oil cooler hoses for:

• Rubbing, cracked, or damaged hoses

• Loose or damaged hose clamps

3.9 Inspect counterweight for:

• Damaged, missing, or loose bolts

3.10 Inspect hydraulic pump compartment for:

• Leaks around hose connection points

• Rubbing, damaged, or worn hoses

• Rubbing, damaged, or worn wiring harnesses or connectors

• Loose or damaged hose clamps on main pump suction lines

3.11 Inspect swing drive gear for:

• Proper lubrication

• Wear on visible gear teeth

• Water in compartment

- If compartment is full of water, remove the drain plate located above the bottom guard in the center

of the carbody

4.0 Upper-Level Inspections:

4.1 Inspect hood and platform for:

• Proper function of hood and latches

• Debris or excessive dirt on service platform

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 14 de 22

4.2 Inspect exhaust manifold for:

• Cracks or other damage in the manifold housing

• Black soot around the sealing surface where the exhaust manifold bolts to the engine block,

which may indicate:

- Loose connection at the joint

- Loose or broken manifold bolts

4.3 Inspect turbocharger for:

• Oil leakage around the turbocharger oil line

• Loose or damaged hose clamp on air inlet tube

• Black soot around the areas where the turbocharger bolts to the exhaust manifold or to the pipe,

which would indicate:

- Loose connection at the joint

- Loose or broken mounting bolts

4.4 Inspect cylinder head and valve cover for:

• Fuel leaks around and below the protective guard located above the fuel lines. If fuel leaks are

present on the intake manifold, remove the guard and inspect fuel lines for leaks.

• Oil and dust buildup around the valve cover sealing surface, which could indicate:

- Loose connection at the joint

- Damaged gasket or seal

4.5 Inspect engine mounts for:

• Loose or damaged bolts

• Wear or damage to rubber mounts

4.6 Inspect belts, pulleys, and compressor for:

• Worn, cracked, or broken belts

• Proper belt tension

• Oil leaks around air conditioning compressor clutch

4.7 Inspect fan guard and fan for:

• Loose, damaged, or missing bolts

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 15 de 22

• Damaged wire fan guard

• Cracked or missing blades on the engine fan

4.8 Inspect upper radiator, air inlet, oil cooler, and aftercooler lines for:

• Rubbing, cracked, or damaged hoses

• Loose or damaged hose clamps

4.9 Inspect radiator/oil cooler screen for:

• Debris on the screen; clean if necessary

• Holes and/or tears in the screen

4.10 Inspect water pump for:

• Coolant leaks around water pump mounting flange

• Coolant leaks through the weep hole in the water pump housing

4.11 If the radiator cap is cool, check:

• Gaskets for wear or damage

4.12 Inspect fuel priming pump, fuel lines, and fuel injection pump for:

• Damaged, rubbing, or worn fuel lines

• Loose connections

4.13 Inspect engine harness for:

• Loose or damaged wires

4.14 Inspect swing drive compartment for:

• Leaks around hose connection points

• Rubbing, damaged, or worn hoses

• Rubbing, damaged, or worn wiring harnesses or connectors

4.15 Inspect swing drive:

• Check the swing drive oil level; if the oil level is low, check the following areas for leaks:

- Sealing surface between the cover and the ring gear.

- Sealing surface between the ring gear and the housing.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 16 de 22

- Joint where the dipstick tube connects to the swing drive housing.

- If no leakage is found in these areas, leakage may be caused from a worn pinion shaft or bottom

cover seal. To service these seals, the swing drive must be removed.

4.16 Inspect the main hydraulic control valve for:

• Leaks around hose connection points

• Rubbing, damaged, or worn hoses

• Rubbing, damaged, or worn wiring harnesses or connectors

5.0 Implement/Attachment Inspections:

5.1 Inspect area around boom cylinders and swivel for:

• Leaks around hose connection points

• Rubbing, damaged, or worn hoses

• Rubbing, damaged, or worn wiring harnesses or connectors

• Boom cylinder linkage pin wear (refer to “Pin Inspection Guidelines” for inspection procedure)

5.2 Inspect lower boom area for:

• Leaks around hose connections

• Rubbing, damaged, or worn hoses

• Damaged or leaking grease lines

• Inspect boom foot pin (refer to “Pin Inspection Guidelines” for inspection procedure)

5.3 Inspect boom cylinder (refer to “Hydraulic Cylinder Inspection Guidelines” for inspection

procedure) for:

• Oil leaks indicated by dirt or oil buildup around the cylinder lip seal

• Oil leaks at hose connections

• Damage to cylinder rods

• Damage or wear to linkage pins (refer to “Pin Inspection Guidelines” for inspection procedure)

5.4 Inspect area where boom attaches to stick for:

• Leaks around hose connections

• Rubbing, damaged, or worn hoses

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 17 de 22

• Damaged or leaking grease lines

• Inspect boom to stick pin and bucket cylinder pin (refer to “Pin Inspection Guidelines” for

inspection procedure)

5.5 Inspect stick cylinder (refer to “Hydraulic Cylinder Inspection Guidelines” for inspection

procedure) for:

• Oil leaks indicated by dirt or oil buildup around the cylinder lip seal

• Oil leaks at hose connections

• Damage to cylinder rods

• Damage to wear to linkage pins (refer to “Pin Inspection Guidelines” for inspection procedure)

5.6 Inspect bucket cylinder (refer to “Hydraulic Cylinder Inspection Guidelines” for inspection

procedure) for:

• Oil leaks indicated by dirt or oil buildup around the cylinder lip seal

• Oil leaks at hose connections

• Damage to cylinder rods

• Damage to wear to linkage pins (refer to “Pin Inspection Guidelines” for inspection procedure)

5.7 Inspect bucket linkage for:

• Loose or broken flange mounting bolt

• Elongated bolt hole in flange (hole is located behind pin retaining bolt)

• Loose or missing pin retainer bolts

• Irregular shaped pin bores

5.8 Inspect bucket wear plates for:

• Excessive wear

5.9 Inspect side cutters for:

• Excessive wear

• Loose, damaged, or missing bolts.

5.10 Inspect bucket tips and adapters for:

• Excessive wear on the bucket tips

• Damage to the bucket tip adapter

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 18 de 22

• Damage or missing retainer pins

6.0 Site Conditions

6.1 Ambient Temperature

NORMAL: -18 to 32°C (0 to 90°F)

MONITOR: 32 to 46°C (90 to 115°F) or -18° to -29°C (0 to -20°F)

ACTION: Above 46° C (115° F) or Below -29° C (-20° F)

6.2 Altitude

NORMAL: 0 to 1524 m (0 to 5000 ft)

MONITOR: 1524 to 3048 m (5000 to 10000 ft)

ACTION: Above 3048 m (10000 ft)

6.3 Haul Road Grade

NORMAL: Flat

MONITOR: Mild

ACTION: Steep

6.4 Haul Road Condition

NORMAL: Positive Banking, Gradual Turns, Good Erosion Control

ACTION: Negative Banking, Sharp Turns, Poor Erosion Control

6.5 Humidity

NORMAL: Below 25%

MONITOR: 25 to 60%

ACTION: Above 60%

6.6 Air Quality

NORMAL: No Dust

MONITOR: Light Dust

ACTION: Heavy Dust

6.7 Underfoot Condition

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 19 de 22

NORMAL: Dry Flat Surface

MONITOR: Moderate Grades, Mixture of Muddy / Dry Surfaces

ACTION: Steep Grades, Muddy, Snow, Ice

6.8 Machine Utilization

NORMAL: 0 to 10 Hours

ACTION: Above 10 hours

6.9 Equipment Role

NORMAL: Utility

MONITOR: Support

ACTION: Production

6.10 Working Material

NORMAL: Uncompacted, Low Abrasion

MONITOR: Moderately Compacted, Moderate Abrasion

ACTION: High Abrasion, Compacted, Dense

6.11 Maintenance Practices

NORMAL: Excellent

MONITOR: Good

ACTION: Poor

Performance Inspection

Hydraulic Performance Checks

Travel on Level Ground

Table 8

Specification

Status(1)

Description

Actual

Comments

New Rebuild Service Limit

Travel Speed - Check

Travel Distance

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 20 de 22

High Forward

High Reverse

Low Forward

Low Reverse

Travel Deviation - Check

High Forward

High Reverse

Low Forward

Low Reverse

(1)

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Travel on Level Ground - Test (Optional Test)

Table 9

Specification

Status

(1)

Description

New Rebuild

Service

Limit

Actual

Comments

Travel Speed (Right Track) Check (With track raised)

High Forward

High Reverse

Low Forward

Low Reverse

Travel Speed (Left Track) Check (With track raised)

High Forward

High Reverse

Low Forward

Low Reverse

(1)

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Machine Drift on a Slope - Check

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 21 de 22

Table 10

Specification

Status

(1)

Description

New Rebuild

Service

Limit

Actual

Comments

Machine Drift on a Slope Check

(1)

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Swing Speed and Overswing on Level Ground - Check

Table 11

Specification

Status(1)

Description

Actual

Comments

Actual

Comments

New Rebuild Service Limit

Swing Speed (Right Swing)

Swing Speed (Left Swing)

Over Swing (Right Swing)

Over Swing (Left Swing)

(1)

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Swing Speed and Swing Drift on a Slope - Check

Table 12

Specification

Status(1)

Description

New Rebuild Service Limit

Swing Speed (Right Swing)

Swing Speed (Left Swing)

Swing Drift (Right Swing)

Swing Drift (Left Swing)

(1)

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Cylinder Drift - Check (Loaded Bucket)

Table 13

Status(1)

Description

Specification

Actual

Comments

New Rebuild Service Limit

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016

336D L Excavator J2F00001-UP (MACHINE) POWERED BY C9 Engine(SEBP53...

Página 22 de 22

Weight of Bucket Load

Boom Cylinder

Stick Cylinder

Bucket Cylinder

(1)

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Cylinder Drift - Check (Empty Bucket)

Table 14

Specification

Status(1)

Description

Actual

Comments

New Rebuild Service Limit

Boom Cylinder

Stick Cylinder

Bucket Cylinder

(1)

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Cylinder Speed - Check

Table 15

Specification

Status(1)

Description

Actual

Comments

New Rebuild Service Limit

Boom Extension

Boom Retraction

Stick Extension

Stick Retraction

Bucket Extension

Bucket Retraction

(1)

N = Normal, M = Monitor, A = Action, Blank = Not Applicable

Copyright 1993 - 2016 Caterpillar Inc.

Todos los derechos reservados.

Sat Jul 9 10:37:57 UTC+0200 2016

r405jap

Red privada para licenciados del SIS.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 09/07/2016