(3$&

(3$&

1XPHULFDOGLVWDQFHUHOD\ZLWKLQWHJUDWHG

DXWRPDWLFDQGFRQWUROHTXLSPHQW

,QVWDOOHU·V*XLGH

*,

P-2

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

P-3

GI 1.6882

EPAC 3100/3500

PREFACE

Dear reader,

We are continuously endeavoring to improve the standard of quality of our brochures. This form

has been designed to enable you to send in your remarks and comments. Please return the form,

duly filled in, to the following address. Thank you in advance.

-----------------------------------------------------------------------------Address:

ALSTOM P & C

Marketing Department

Avenue de Figuières

F-34975 LATTES CEDEX

Have you found any errors in the brochure ? If so, please indicate where they are.

Did you find the brochure comprehensible and well set out ?

Please indicate here any proposals for improvement.

Have we supplied you with sufficient information to permit the understanding of the product

presented here ?

If not, what is missing and at what points should we supply additional indications ?

Name:

Position:

Date:

Utility or company:

Address:

Telephone:

Post/Zip Code :

City:

Country:

Concerning the item:

P-4

EPAC 3100/3500

GI 1.6882

INTRODUCTION

The documentation covering the EPAC 3100/3500 Distance Protection is subdivided into 3

documents. Each document provides its recipient with the information needed for the performance of his or her tasks. The following table summarizes the titles of the documents, their

recipients and the supply date.

Document Title

Recipient

Supply date

Installer’s Guide

Installer of Equipment

Delivered with each

equipment

User's Guide

Expert in charge

of equipment

On order

Commissioning and

Maintenance Guide

Agent specializing

in commissioning equipment

and in preventive maintenance

On order

P-5

GI 1.6882

EPAC 3100/3500

REASON FOR UP-DATES

GI 1.6882

INSTALLER'S GUIDE

First edition: 06/97

Indice

Updating

date

Updating subject

EPAC 3100/3500

P-6

EPAC 3100/3500

GI 1.6882

STATE OF UP-DATES

EPAC 3100/3500

Index

A

B

C

D

E

F

G

H

I

J

K

L

M

N

Updating

date

INSTALLER'S GUIDE

No.

AMENDED

PAGE INDEX

PRELIMARY PAGES

P-1

P-2

P-3

P-4

P-5

P-6

P-7

P-8

TEXT AND DRAWING PAGES

GI 1.6882

No.

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

CHAP 1

APPEND.

1-1

1-2

1-3

1-4

A-1

A-2

A-3

A-4

CHAP 2

2-1

2-2

2-3

2-4

2-5

2-6

CHAP 3

3-1

3-2

3-3

3-4

3-5

3--6

CHAP 4

4-1

4-2

4-3

4-4

CHAP 5

5-1

5-2

AMENDED

PAGE INDEX

P-7

GI 1.6882

EPAC 3100/3500

GENERAL CONTENT

CHAPTER 1 - TRANSPORTATION AND STORAGE CONDITIONS ______________________________ 1-1

1.1.

1.2.

1.2.1

1.2.2

TRANSPORTATION____________________________________________________________

STORAGE ON SITE OR IN A WAREHOUSE _______________________________________

Normal Storage Conditions ____________________________________________________

Long-Term Storage Conditions __________________________________________________

1-3

1-4

1-4

1-4

CHAPTER 2 - UNPACKING _____________________________________________________________ 2-1

2.1.

2.2.

UNPACKING _________________________________________________________________ 2-3

REPACKING _________________________________________________________________ 2-5

CHAPTER 3 - MECHANICAL CHARACTERISTICS AND INSTALLATION CONDITIONS ______________ 3-1

3.1.

3.2.

3.3.

OVERALL DIMENSION _________________________________________________________ 3-3

WEIGHT ____________________________________________________________________ 3-4

ASSEMBLY __________________________________________________________________ 3-5

CHAPTER 4 - ELECTRICAL CONDITIONS __________________________________________________ 4-1

4.1.

4.2.

ELECTRIC POWER SUPPLY ______________________________________________________ 4-3

GROUNDING ________________________________________________________________ 4-4

CHAPTER 5 - EXTERNAL CONNECTIONS _________________________________________________ 5-1

5.1.

5.2.

5.3.

5.4.

5.5.

ANALOG INPUT CONNECTIONS ________________________________________________ 5-3

INPUT AND OUTPUT CONTACTS CONNECTIONS __________________________________ 5-6

POWER SUPPLY CONNECTIONS _______________________________________________ 5-10

EQUIPMENT FAULT SIGNALLING CONNECTIONS _________________________________ 5-10

COMMUNICATION OPTION CONNECTIONS ____________________________________ 5-10

APPENDICES ________________________________________________________________________ A-1

FRONT PANEL CONNECTIONS AND REAR PANEL TERMINAL BLOCK CONNECTIONS ___________ A-3

FIBRE OPTIC CONNECTIONS ___________________________________________________________ A-3

SIMPLIFIED DIAGRAM EPAC 3132 ______________________________________________________ A-4

P-8

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

GI 1.6882

EPAC 3100/3500

CHAPTER 1

TRANSPORTATION AND STORAGE

CONDITIONS

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

1-1

GI 1.6882

EPAC 3100/3500

CONTENT

PAGE

1.1.

TRANSPORTATION____________________________________________________________ 1-3

1.2.

1.2.1

1.2.2

STORAGE ON SITE OR IN A WAREHOUSE _______________________________________ 1-4

Normal Storage Conditions ____________________________________________________ 1-4

Long-Term Storage Conditions __________________________________________________ 1-4

1-2

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

1-3

GI 1.6882

EPAC 3100/3500

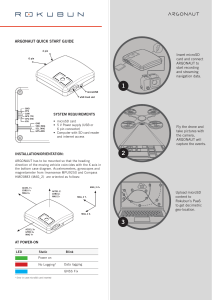

The EPAC is delivered in a cardboard box. The following equipment is contained inside the box:

-

the EPAC 3100/3500,

-

a plastic bag containing the installer’s guide,

-

the assembly kit screw-in or Faston connectors,

-

two floppy disk with the man machine interface sofware.

The EPAC 3100 is the frame mounted "L Case" EPAC.

The EPAC 3500 is the cabinet mounted "L Case" EPAC.

1.1.

TRANSPORTATION

The gross weight of the equipment in its packing is 12 kg. It can easily be moved by one person.

The precautions to be taken when transporting the package are those used for the transportation

of electronic equipment.

The cardboard box can withstand a weight of 100 kg without being deformed. You should

therefore avoid stacking more than 5 boxes of the same equipment or any other package

weighting more than 80 kg on top of it.

When handling the box, avoid dropping or knocking it. If the box falls more than 0.80 metres

on one of its surfaces, the equipment components (modules, connectors, board-guides, etc.) may

be damaged or distorted. If the box falls on its corner, the equipment may be damaged in the

same way. Great care must therefore be taken when handling the box.

The packing guarantees that the equipment will remain in good condition when submitted to

accelerations of less than 3 g (g = 9.81 m/s2) for all modes of transport (overland, railway, sea

and air).

The vibration resistance of the EPAC 3100/3500 is in conformance with the response curve

defined by the IEEE Seismic Testing of Relays standard.

1-4

EPAC 3100/3500

1.2.

STORAGE ON SITE OR IN A WAREHOUSE

1.2.1

Normal Storage Conditions

GI 1.6882

While the equipment is stored on site, it must be kept in its original packing.

The cardboard box must be put on a pallet so that it does not absorb any humidity from the ground.

1.2.2

Long-Term Storage Conditions

For long-term storage in a warehouse and for certain types of transport (overland, sea and

tropical), we recommend the use of moisture barriers in order to keep the level of humidity inside

the envelope at a level lower than 5 g of water per m3.

These packages contain dessicant pouches that must be renewed every 6, 12 or 24 months

depending on whether the packing is provided for overland, sea or tropical conditions. The

dessicant pouches are put inside the envelope but do not touch the equipment. Therefore the

equipment may be stored for 3 years in the following storage conditions (no tests are needed

during this period to check that the relay operates correctly):

-

stored in a sheltered area without air-conditioning,

-

temperature: - 40°C to 70°C,

-

relative humidity: less than 95% with no condensation.

GI 1.6882

EPAC 3100/3500

CHAPTER 2

UNPACKING

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

2-1

GI 1.6882

EPAC 3100/3500

CONTENT

PAGE

2.1.

UNPACKING _________________________________________________________________ 2-3

2.2.

REPACKING _________________________________________________________________ 2-5

2-2

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

2-3

GI 1.6882

2.1.

EPAC 3100/3500

UNPACKING

Procedure:

1.

Place the box on the ground or on a pallet, with the pictogram the right way up.

2.

Cut the adhesive tape width-wise using the blade of a sharp instrument, on the upper

right and left edges.

3.

Remove the tape to get access to the staples holding flaps.

4.

Remove the staples.

5.

Open the flaps by folding them back, as shown on the packing diagram.

6.

Remove the various elements from the cardboard box, and check that the contents correspond to the list given in chapter 1.

7.

Remove the packing blocks and put the EPAC on a table with the assembly kit and

documents.

8.

Put the packing blocks back into the box.

If the EPAC 3100/3500 is to be temporarily used on site,

keep the packing and re-use it to repack the equipment.

However, if the EPAC 3100/3500 is installed definitively,

the packing can be destroyed.

2-4

EPAC 3100/3500

GI 1.6882

Superior hand packing block

Product

Inferior hand packing block

UP

N

DOW

Card board

base

Figure 2.1a: Packing / Unpacking the EPAC 3100/3500

2-5

GI 1.6882

2.2.

EPAC 3100/3500

REPACKING

Procedure:

1.

Repeat the unpacking procedures in reverse order.

2.

Put installer guide in a plastic bag.

3.

Install the superior-hand and inferior-hand packing blocks on the rack.

4.

Put the assembly in the cardboard box.

5.

Put the plastic bags containing the documents and connection kit connectors on the

packed rack.

6.

Fold down the four flaps.

7.

Staple flaps.

8.

Use adhesive tape to close the box.

9.

10.

Clearly indicate the following information on the box:

-

the equipment version,

-

the serial number,

-

the purchase order and contract number,

-

the delivery address (workstation designation, person to be contacted, etc.).

Put the advice of dispatch in a plastic bag and stick the bag to the box.

2-6

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

GI 1.6882

EPAC 3100/3500

CHAPTER 3

MECHANICAL CHARACTERISTICS

AND INSTALLATION CONDITIONS

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

3-1

GI 1.6882

EPAC 3100/3500

CONTENT

PAGE

3.1.

OVERALL DIMENSION _________________________________________________________ 3-3

3.2.

WEIGHT ____________________________________________________________________ 3-4

3.3.

ASSEMBLY __________________________________________________________________ 3-5

3-2

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

3-3

GI 1.6882

3.1.

EPAC 3100/3500

OVERALL DIMENSION

The overall dimensions of the EPAC 3100/3500 depend on whether it is frame- or cabinetmounted.

304,3

412,50

177,00

Figure 3.1a: Rack dimensions when frame-mounted (EPAC 3100)

3-4

EPAC 3100/3500

GI 1.6882

304,3

483,0

88,9

177,0

57,1

15,5

Figure 3.1b: Rack dimensions when cabinet-mounted (EPAC 3500)

3.2.

WEIGHT

-

<12 kg.

3-5

GI 1.6882

3.3.

EPAC 3100/3500

ASSEMBLY

The frame-mounted EPAC 3100 is attached with 8 screws at the top and bottom of the front

panel, as shown in Figure 3.1c. The cabinet-mounted EPAC 3500 is attached with 4 screws on

the left and right of the front panel.

412

24,8

5,2

362,5

246

116,5

168,3

Figure 3.1c: Location of attachment points for frame mounting (EPAC 3100)

465,1 +1,6

450 mini

4 M6 tappings

101,6

38,1

Slides mandatory

37,5

Figure 3.1d: Location of attachment points for cabinet mounting (EPAC 3500)

177,8

3-6

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

GI 1.6882

EPAC 3100/3500

CHAPTER 4

ELECTRICAL CONDITIONS

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

4-1

GI 1.6882

EPAC 3100/3500

CONTENT

PAGE

4.1.

ELECTRIC POWER SUPPLY ______________________________________________________ 4-3

4.2.

GROUNDING ________________________________________________________________ 4-4

4-2

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

4-3

GI 1.6882

4.1.

EPAC 3100/3500

ELECTRIC POWER SUPPLY

Rated Auxiliary Power Supply:

48, 60, 110, 125, 220 and 250 VDC

Permitted Variations:

-20% to + 20%, -20% to + 15% for 250 V

Power consumption in the basic version:

25 W

Temperature Range in operation:

-20°C to + 55°C

Maximum permitted ripple:

< 12%

Relative Humidity:

less than 95% with no condensation

The rated value of the auxiliary supply must correspond to

the value given on the EPAC 3100/3500 front panel.

4-4

EPAC 3100/3500

4.2.

GI 1.6882

GROUNDING

The equipment is to be grounded to an earth network with a resistance that is always less than

3 ohms. Therefore, the distance between the equipment and the real grounding point must be

minimized.

The grounding braid is connected to the terminal at the rear of the EPAC 3100/3500 rack. It

is identified by the ground symbol. The following diagrams show the grounding braid

connections for the different EPAC 3100/3500 options.

X6

1

2

27

1

27

1

28

2

28

2

27

1

27

1

28

2

28

2

X2

X1

X4

X3

27

1

X5

27

X6

28

28

X1

X3

X2

X4

X5

2

X18

Current loop

To UR

Protection cable

Figure 4.2a: Grounding for current loop

X6

1

2

X1

27

1

27

1

28

2

28

2

27

1

27

1

28

2

28

2

X3

X2

X4

NC

D26

27

1

X5

27

28

X6

28

X1

X3

2

X2

X4

X5

KBus link

Protection cable

Figure 4.2b: Grounding for KBUS link

GI 1.6882

EPAC 3100/3500

CHAPTER 5

EXTERNAL CONNECTIONS

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

5-1

GI 1.6882

EPAC 3100/3500

CONTENT

PAGE

5.1.

ANALOG INPUT CONNECTIONS ________________________________________________ 5-3

5.2.

INPUT AND OUTPUT CONTACTS CONNECTIONS __________________________________ 5-6

5.3.

POWER SUPPLY CONNECTIONS _______________________________________________ 5-10

5.4.

EQUIPMENT FAULT SIGNALLING CONNECTIONS _________________________________ 5-10

5.5.

COMMUNICATION OPTION CONNECTIONS ____________________________________ 5-10

5-2

EPAC 3100/3500

GI 1.6882

PAGE NOT USED

5-3

GI 1.6882

5.1.

EPAC 3100/3500

ANALOG INPUT CONNECTIONS

The current and voltage inputs are wired to pins 1 to 28 of the X5 connector on the EPAC rear

panel as indicated in figure 5.1a.

To maintain suitable EMC Electro-Magnetic-Compatibility margins provided with this product,

a state-of-art wiring and grounding is required.

We recommend the use of one multiwire (4 to 8 depending on the number of inputs used and

external neutral connection) cable of 4 mm2 for the voltage circuit and one multiwire (4 to 8

depending on external neutral connection) câble of 4 mm2 for 1 A current circuit or 6 mm2 for

5A current.

The external diameter of the cables is recommended as less than 15 mm. If the cables are

connected to cubicle terminals no shielding is required. If the cables are going out, cubicle

shielding of low HF impedance copper is to be provided with short strip large cross section

connections to ground at both ends. Unused wires are to be grounded at both ends.

As far as possible avoid mixing the voltage and current wires and other groups of wires.

The following diagrams show the analog input connections for the different types of zero

sequence current acquisition.

5-4

EPAC 3100/3500

P2

S2

GI 1.6882

P1

IL1

S1

P2

S2

P1

IL2

S1

P2

S2

IL3

P1

S1

UL1

P1 P2

S1

ILE1

ILS1 ILE2

ILS2 ILE3

ILS3

INS

INE

UL2

S2 S1

S2 S1

UL1 ULM

UL3

P1 P2

P1 P2

S2

UL2

UL3

To BCH

UbarreE

UbarreS ITMHE ITMHS

X5

Connector

IL1

IL2

IL3

IN

UL1

UL2

UBAR

UL3

TMH

Figure 5.1a: Analog input connections without zero sequence current transformer

Tore

P2

S2

P1

IL1

S1

P2

S2

P1

IL2

S1

P2

S2

IL3

P1

S1

UL1

P1 P2

UL2

P1 P2

UL3

P1 P2

To BCH

S1

ILE1

ILS1 ILE2

ILS2 ILE3

ILS3

INS

INE

UL1

S2 S1

ULM

S2 S1

UL2

S2

UL3

UbarreE

UbarreS ITMHE ITMHS

X5

Connector

IL1

IL2

IL3

IN

UL1

UL2

UL3

UBAR

TMH

Figure 5.1b: Analog input connections with zero sequence current transformer

5-5

GI 1.6882

EPAC 3100/3500

EPAC 3100/3500

TMH S

TMH E

U BarS

bar

U BarE

2

4

UL2

UL3

UN

UL1

6

8

10

12

16

INE

INS

INE

INS

18

IL E3

IL S3

If IN = 5A

20

IL E3

IL S3

If IN = 1A

22

IL E2

IL S2

If IN = 5A

24

26

IL

IL

IL

IL

28

IL E1

IL S1

14

X5

E2

S2

E1

S1

If IN = 5A

If IN = 1A

If IN = 1A

If IN = 5A

If IN = 1A

QTF Board

Screw-in

connector

Figure 5.1c: Analog input connections to the X5 connector

5-6

EPAC 3100/3500

5.2.

GI 1.6882

INPUT AND OUTPUT CONTACTS CONNECTIONS

Inputs and outputs contacts are connected to the screw-in LMI or ENTRELEC connectors at the

EPAC rear panel. The X1 and X2 connectors are used to connect the inputs/outputs of the

IO-1 board. The X3 and X4 connectors are used to connect the inputs/outputs of the additional

IO-1 or additional IO-2 board. To maintain suitable EMC margins provided with this product,

a state-of-art wiring and grounding is required.

The wire used must have a cross-section less than 2.5 mm2.

We recommend to use flexible multiwire (5 to 8 dependding on number of groups common)

cable of 1.5 or 2.5 mm2 for tripping contacts.

We recommend to use flexible multiwire (9 to 16 depending on number of groups common)

cable of 0.6 to 1.5 mm2 wire section for input contacts (for all pins of the X2 and X4 connectors

and pins 1 to 4 of the X1 and X3 connectors).

We recommend to use 1 or 2 multiwire (22 to 32 for 1 or 11 to 16 for 2 cables dependding

on number od groups common) cable of 0.6 to 1.5 mm2 wire section for signalling contacts (for

pins 13 to 28 of the X1 and X3 connectors).

The external diameter of cables is recommended as less than 15 mm.

If the cables are connected to cubicle terminals no shielding is required.

If the cables are going out cubicle shielding of low HF impedance copper is to be provide with

short strip large cross section connections to ground at both ends. Not used wires are to be

grounded at both ends.

5-7

GI 1.6882

EPAC 3100/3500

CONFIGURABLE

SIGNALLING

CONFIGURABLE

EPAC 3100/3500

CONTACTS (TC)

SIGNALLING

CONTACTS (TC)

2

TC 15

TC 01

2

4

TC 16

TC 02

4

6

Phase A tripping

TC 03

6

8

Phase B tripping

TC 04

8

10

Phase C tripping

TC 05

10

12

Closing by recloser

TC 06

12

14

TS 01

TC 07

14

16

TS 02

TC 08

16

18

TS 03

TC 09

18

20

TS 04

TC 10

20

22

TS 05

TC 11

22

24

TS 06

TC 12

24

26

TS 07

TC 13

26

28

TS 08

TC 14

28

CONFIGURABLE

LOGIC INPUTS (TS)

X1

IO-1 BOARD

Screw-in

Connector

X2

Screw-in

Connector

Figure 5.2a: Connections on the IO-1 Board

5-8

EPAC 3100/3500

GI 1.6882

CONFIGURABLE

SIGNALLING

EPAC 3100/3500

CONFIGURABLE

SIGNALLING

CONTACTS (TC)

CONTACTS (TC)

2

TC 15

TC 01

2

4

TC 16

TC 02

4

6

Phase A tripping

TC 03

6

8

Phase B tripping

TC 04

8

10

Phase C tripping

TC 05

10

12

Closing by recloser

TC 06

12

14

TS 01

TC 07

14

16

TS 02

TC 08

16

18

TS 03

TC 09

18

20

TS 04

TC 10

20

22

TS 05

TC 11

22

24

TS 06

TC 12

24

26

TS 07

TC 13

26

28

TS 08

TC 14

28

CONFIGURABLE

LOGIC INPUTS (TS)

X3

Additional IO-1 BOARD

Screw-in

Connector

X4

Screw-in

Connector

Figure 5.2b: Connections on the Additional IO-1 Board

5-9

GI 1.6882

EPAC 3100/3500

CONFIGURABLE

EPAC 3100/3500

SIGNALLING

CONFIGURABLE

SIGNALLING

CONTACTS (TC)

CONTACTS (TC)

2

TC 15

TC 01

2

4

TC 16

TC 02

4

6

Phase A tripping

TC 03

6

8

Phase B tripping

TC 04

8

10

Phase C tripping

TC 05

10

12

Closing by Recloser

TC 06

12

14

TC 07

14

16

TC 08

16

18

TC 09

18

20

TC 10

20

22

TC 11

22

24

TC 12

24

26

TC 13

26

28

TC 14

28

X3

IO-2 BOARD

Screw-in

Connector

X4

Screw-in

Connector

Figure 5.2c: Connections on the additional IO-2 Board

5-10

(ERRATUM)

EPAC 3100/3500

5.3.

GI 1.6882

POWER SUPPLY CONNECTIONS

The power supply PS is connected to the X6 screw-in connector on the rear panel. The wire

used must have a section less than 5 mm2. See 5.1. and 5.2. for wiring recommandations. Avoid

long distance wirings to DC source (less than 20-30 m) without special care.

27

28

- Power Supply

+ Power Supply

X6 Connector

Figure 5.3a: Power Supply Connections

5.4.

EQUIPMENT FAULT SIGNALLING CONNECTIONS

9

10

X6 Connector

15

16

X6 Connector

Figure 5.4a: Fault Signalling Connections

The equipment fault signal wires are connected to pins 9 and 10 of the X6 terminal block on

the IO-1 Board and to pins 15 and 16 of the X6 terminal block on the additional IO-1 Board

or the IO-2 Board.

5.5.

COMMUNICATION OPTION CONNECTIONS

The EPAC can be connected to three types of communication system:

-

Communication with an remote control system, either VDEW or KBUS-COURIER.

-

Reception of an external time synchronisation signal via an IRIG-B board.

-

Communication with the TPE system for disturbance event management. Communication is

by means of:

. a current loop for a link to a UR 2000 restitution unit,

. a Modem for a link to the TPE via the PSTN,

. RS232 for a direct link to the EPAC via the RS232 serial port on the EPAC front panel.

5-11

GI 1.6882

EPAC 3100/3500

Serial port for WinEPAC PC

Serial port for:

- WinV24

- or a local printer

Figure 5.5a: EPAC Front Panel Option Connections

X6

1

2

X1

X3

27

1

27

1

28

2

28

2

27

1

27

1

28

2

28

2

X5

27

28

27

1

X6

28

2

D24

X1

X3

X2

X4

X2

X4

X5

X30

D26

D25

X18

Current loop and

VDEW option

X20

Modem and

KBUS-COURIER

option

Figure 5.5b: EPAC Rear Panel Option Connections

X30 BNC connection

for IRIG-B time

synchronisation

signal

5-12

EPAC 3100/3500

Terminal

GI 1.6882

Description

Terminal

Description

X30 connector

X18 connector

BNC connector for

IRIG-B time

synchronisation

signal

Current loop

D24 connector

D26 connector

Ground

VDEW receiver

KBUS

D25 connector

X20 connector

VDEW transmitter

1

2

3

4

5

6

7

8

CD

RD

ED

DTR

0V

DSR

RTS

CTS

1

6

5

9

Modem

Figure 5.5c: Option Connector Connections

$

(3$&

abcd

3$*(12786('

(55$780

*,