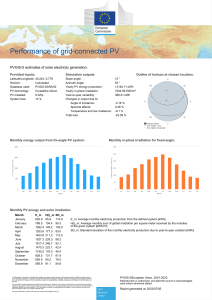

Renewable Energy 36 (2011) 2177e2188 Contents lists available at ScienceDirect Renewable Energy journal homepage: www.elsevier.com/locate/renene Earth-to-air heat exchangers for Italian climates Fabrizio Ascione a, Laura Bellia b, Francesco Minichiello b, * a b DING, University of Sannio, P. zza Roma 21, 82100 Benevento, Italy DETEC, University of Naples Federico II, P. le Tecchio 80, 80125 Napoli, Italy a r t i c l e i n f o a b s t r a c t Article history: Received 15 July 2010 Accepted 12 January 2011 Available online 21 February 2011 The European Energy Efficiency Building Directive 2002/91/CE, as well as other acts and funding programs, strongly promotes the adoption of passive strategies for buildings, in order to achieve indoor thermal comfort conditions above all in summer, so reducing or avoiding the use of air conditioning systems. In this paper, the energy performances achievable using an earth-to-air heat exchanger for an airconditioned building have been evaluated for both winter and summer. By means of dynamic building energy performance simulation codes, the energy requirements of the systems have been analysed for different Italian climates, as a function of the main boundary conditions (such as the typology of soil, tube material, tube length and depth, velocity of the air crossing the tube, ventilation airflow rates, control modes). The earth-to-air heat exchanger has shown the highest efficiency for cold climates both in winter and summer. The possible coupling of this technology with other passive strategies has been also examined. Then, a technical-economic analysis has been carried out: this technology is economically acceptable (simple payback of 5e9 years) only in the cases of easy and cheap moving earth works; moreover, metallic tubes are not suitable. Finally, considering in summer a not fully air-conditioned building, only provided with diurnal ventilation coupled to an earth-to-air heat exchanger plus night-time ventilation, the possible indoor thermal comfort conditions have been evaluated. ! 2011 Elsevier Ltd. All rights reserved. Keywords: Ground cooling Heat exchanger Earth-to-air Energy saving Building Dynamic simulation 1. Introduction An earth-to-air heat exchanger (EAHX) consists in one or more tubes lied under ground in order to cool (in summer) or pre-heat (in winter) air to be supplied in a building. This air is often outdoor air necessary for ventilation, but also useful to partially or totally handle the building thermal loads. The physical phenomenon is simple: the ground temperature is commonly higher than the outdoor air temperature in winter and lower in summer, so it makes the use of the earth convenient as warm or cold sink, respectively. Normally, the soil temperature, at a depth of 5e8 m under the ground level, remains almost constant throughout the year; its temperature profile as a function of the depth depends on several factors, such as the physical properties of the soil, the sky covering and the climate conditions [1]. Givoni [2] identified two macro-groups of earth tubes, those with open and closed loop; in this paper, the first typology has been considered. Typical buried tube lengths are 30e60 m, usually posed * Corresponding author. Tel.: þ39 081 2538665; fax: þ39 081 2390364. E-mail address: [email protected] (F. Minichiello). 0960-1481/$ e see front matter ! 2011 Elsevier Ltd. All rights reserved. doi:10.1016/j.renene.2011.01.013 at 2e4 m under ground level. The tubes are located in almost horizontal position, with a slight inclination to remove possible condensed water. A physical model to simulate the EAHX was developed and validated by Mihalakakou et al. [3,4]. Benkert et al. [5] underlined the lack of optimisation criteria; moreover, they developed the computer tool GAEA, based on a physical model and then experimentally validated with good results. The EAHXs are characterised by high energy saving potential and require low maintenance. Moreover, Pfafferot [6] underlined that in winter the re-heating of the air downstream of the EAHX is however necessary before supplying air in the building, while in summer indoor comfort conditions are sometimes achievable also without an active re-cooling. However, few research investigations [7,8] have been carried out to evaluate the energy performances of the EAHX as a function of the main boundary conditions, above all for Italian climates. Thus, in this paper an extended parametric analysis on EAHXs is presented, starting from a validated physical-mathematical model. This investigation has been carried out by using appropriate dynamic simulation codes, especially Energy Plus [9] and Calculation Soil Temperature [10]; some modelling conditions adopted in 2178 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 these codes have been calculated also by means of the above mentioned GAEA code. Three different Italian climates (cities of Naples, Rome, Milan) and an air-conditioned building have been analysed for both winter and summer. The energy requirements of these systems have been evaluated as a function of the main boundary conditions (such as the typology of soil, tube material, tube length and depth, velocity of the air crossing the tube, ventilation airflow rates, control modes). Then, the possible coupling of this technology with other passive strategies has been examined, and a technical-economic analysis has been performed. Finally, considering in summer a not fully air-conditioned building, only provided with diurnal ventilation coupled to an earthto-air heat exchanger plus night-time traditional ventilation, the possible indoor thermal comfort conditions have been evaluated. 2. Case study and results 2.1. The complex building-system and the used physical model In Fig. 1, the modelled office building is shown: it is well thermally insulated, with efficient heating and cooling systems. The main characteristics of the building and systems are reported in Table 1. Several authors studied the physical model governing the earthto-air heat exchange: the Krarti’s model [11] is here used. A full description of the model, as well as the model validation, is reported in Reference [7], while in the following only the main characteristics of the model are shown. The heat transfer mechanisms around the earth tube are quite complex, so some assumptions have been made: - the pipe has a uniform internal/external diameter in the axial direction; - the soil around the pipe is homogeneous and its thermal conductivity has a constant value; - the soil temperature near the pipe is not influenced by the pipe, so the surface temperature of the pipe is uniform in the axial direction; - the convective flow inside the pipe is thermally and hydrodynamically developed. The annual TMEAN Equation (1): SURF of the soil is calculated by means of the he ¼ hs $ð1 þ 0:0168$a$f Þ (2) hr ¼ hs $ð1 þ 0:0168 $a $RH$f Þ (3) So, he and hr represent the convective heat transfer coefficient at the soil surface, increased taking into account, respectively, the fraction of evaporation rate (he) and the fraction of evaporation rate plus the relative humidity of the ambient air (hr). The phase angle difference between the air and the soil surface temperature trends, the amplitude of the soil surface temperature variation (As), and the related phase constant (t0) are then determined. Considering a soil characterised by uniform thermal diffusivity as, the Equation (4) provides the ground temperature as a function of depth and time. i h TGROUND ðz;tÞ ¼TMEAN SURF &As exp &zðp=365,as Þ1=2 n io h $cos ð2p=365Þ$ t &t0 &ðz=2Þð365=p,as Þ1=2 ð4Þ The main equations describing the heat exchange between soil, buried tubes and crossing air are: Rconv ¼ 1=ð2p$r1 $L$hc Þ (5) % & '( % ( Rcond&tube ¼ 1= 2p$L$kp $ln ðr1 þ r2 Þ=r1 (6) Rcond&tube=soil ¼ ½1=ð2p$L$ks Þ'$ln½ðr1 þ r2 þ r3 Þ=ðr1 þ r2 Þ' (7) The distance between the tube external surface and the undisturbed soil (r3) is assumed equal to the radius of the tube. hc ¼ Nu$kair =2$r1 (8) Ut ¼ 1=Rtot (9) Rtot ¼ Rconv þ Rcond&tube þ Rcond&tube=soil (10) The heat transfer between the air inside the tube and the soil is characterised by the following equation: TMEAN SURF ¼ ð1=he Þ$½hr $TMEAN AIR & 3$DR þ bs $Sm & 0:0168$hs $f $bð1 & RHÞ' As regards he and hr, both are related to the convective heat transfer coefficient at the soil surface, hs, as described in the Equations (2) and (3), with a ¼ 103 Pa/( C. (1) _ a ca ½dTa ðyÞ' Ut dy½Ta ðyÞ & TGROUND ðz; tÞ' ¼ &m Fig. 1. The modelled building: volumetric scheme, plan of the ground floor and thermal zones. (11) 2179 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 Table 1 Main characteristics of the modelled office building and systemsa. Dimensions of the office building and boundary design conditions Width (NeS direction) Height Surface to volume ratio Tsummer-set-point (no cooling during no occupancy periods) Uwindows Uroof Cooling efficiency (fan coils þ water chiller) Electric energy cost Type of soil a 12.8 m 8.0 m (two floors) 0.47 m&1 26 ( C 1.1 W/m2 K 0.17 W/m2 K hel ) SEER ¼ 0.36 ) 3.00 ¼ 1.08 0.20 €/kWh heavy and wet clay Length Plan area and volume Ventilation airflow rate Twinter-set-point (16 ( C during no occupancy periods) Uwalls Ubasement floor Heating efficiency (fan coils þ gas condensing boiler) Natural gas cost 32.30 m 413 m2e3304 m3 21.6 m3/h per person 20 ( C 0.29 W/m2 K 0.29 W/m2 K hOVERALL ¼ 0.76 0.65 €/Nm3 A hourly scheduling is fixed with reference to occupancy, lighting and other electric equipments installed. By solving this equation, the temperature of the air leaving the earth tube and entering the building, Ta (L), is finally obtained as follows: - if Ta ðLÞ ¼ TGROUND ðz; tÞ þ eA Tam > TGROUND ðz; tÞ (12) - if Tam ¼ TGROUND ðz; tÞ Ta ðLÞ ¼ TGROUND ðz; tÞ (13) temperature variation equal to 9 ( C, mean solar irradiance equal to 117 W/m2, clayey soil and grassy-moist surface); - the second one (figure on the right) refers to the values calculated by the authors using the numerical model of Krarti [11] and the weather data of Wien. The results are obviously different when varying the depth, the considered mid-European city and the kind of soil, but a quite satisfactory accordance of the model with respect to typical literature data is confirmed. 2.2. EAHX cooling potential: parametric analysis for summer conditions - if Ta ðLÞ ¼ TGROUND ðz; tÞ & eA Tam < TGROUND ðz; tÞ (14) where A ¼ ) ) _ a ca ln))Tam & TGROUND ðZ; TÞ)) & UL m (15) _ a ca m Table 2 describes the main design characteristics of the EAHX simulated. Fig. 2 shows a satisfactory accordance between the two following soil temperature trends, both related to the depth of 1 m: - the first one (figure on the left, line related to the depth of 1 m) is relative to the literature values reported in Reference [13], with reference to a typical mid-European weather (mean temperature of the ambient air equal to 10 ( C, amplitude of the Table 2 Earth tube base model: design characteristics. Whole Office Building Design volumetric airflow rate (for each zone) Design volumetric airflow rate (for the entire building) and fan position Tube depth and length Tube material and thickness Tube radius and soil conditions Buried tube: pressure drop and air speed Building ducts: pressure drop and air speed Fan absorbed electrical power 2 x 0.096 m3/s for Zones 1 & 3 2 x 0.144 m3/s for Zones 2 & 4 2 x 0.088 m3/s for Zones Y & X 2361 m3/h ( ¼ 0.66 m3/s) Exhaust fan Depth ¼ 3.0 m; length ¼ 50 m (horizontal) + 5 m (vertical) PVC: k ¼ 0.16 W/(mK); thickness ¼ 5 mm 165 mm e Heavy and damp soil 2 Pa/m - 7.7 m/s 2 Pa/m - 4 O 6 m/s 1250 W In the following, various parameters have been varied; when not specified, the values are those reported in Table 2. 2.2.1. Influence of the climate and soil composition The soil typologies reported in Table 3 have been considered. The results are reported in Fig. 3 (required specific thermal energy in Fig. 3A, required specific primary energy in Fig. 3B). Compared to the reference case (without EAHX), the best energy performances have been obtained for wet and heavy soil and cold winter climates (Milan) e maximum savings of about 44% in terms of thermal energy, about 37% for primary energy. In fact, in these climates, the time constant of the ground at the design depth (3 m) makes the soil particularly apt as cold sink in summer (the ground is colder compared to other cities). Anyway, even the less suitable kind of soil (light and dry) allows significant savings: in terms of thermal energy, these are about 25% for Naples, 30% for Rome, 34% for Milan (Fig. 3A). Note that the high water content of some soil typologies improves the EAHX performances. As regards the material surrounding the buried tube, a good contact between soil and tubes has to be ensured, by means of compacted clay or sand. These kinds of soil are also suitable for a correct tube installation. In terms of primary energy requirements (Fig. 3B), all the savings obtained are minor because of the electric energy required by the fans. Heavy and wet clay has been considered in the following analyses. 2.2.2. Influence of the tube material The thermal conductivity of the tube material appears in the Equation (6) and therefore in the Equation (9). The obtained results (Fig. 4) show that concrete, plastic or metallic materials lead to very similar energy performances. In fact, due to the small thickness of the tubes (5 mm in the case of PVC, 7 mm for the metallic material, 7 cm for the concrete), the different thermal conductivity values scarcely influence the heat exchange, if the right depths and lengths are used. 2180 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 Fig. 2. Under ground soil temperature: literature values [13] for mid-European weather and values calculated using the Krarti’s model with reference to Wien weather. Note that the concrete tubes require a further internal coating to avoid possible radon infiltrations; furthermore, hygienic conditions inside the tubes must be assured, for example by using antimicrobial coatings. 2.2.3. Influence of the tube length The thermal exchange between the ground and the air crossing the tube increases with the length of the buried tubes (Fig. 5aec). In Fig. 5d, the specific energy requests for summer cooling are reported. It can be inferred that, for all the considered climates, lengths of about 10 m are unsatisfactory, while significant advantages do not occur for lengths over 70 m, according to Reference [7]. In this last case, the further minimal air temperature reduction at the tube outlet does not compensate the higher energy required by fans (due to major necessary heads). Thus, for the climates here considered, lengths of about 50 m are preferable, which optimise heat exchange and first costs. With reference to Fig. 5d, compared to the base system without ground cooling, an EAHX of 50 m allows primary energy savings of about 12.5 kWh/m2a for Naples (the primary energy required for the base case is equal to 55.3 kWh/m2a), 14.2 kWh/m2a for Rome (52.2 kWh/m2a for the base case), 13.0 kWh/m2a for Milan (41.3 kWh/m2a for the base case). 2.2.4. Influence of the tube depth The ideal depth of buried tubes is about 8 m under the ground level. In fact, in this case the time lag is approximately 6 months, so the ground is characterised by the lowest yearly temperatures in summer and the highest in winter (Fig. 2B); thus, the thermal recovery is optimal in both the seasons. The depth of 6e9 m is also preferable compared to major depths characterised by ground temperature almost constant during the year. Fig. 6 shows that the depth of 3 m under the ground level implies a better thermal exchange compared to the depth of 1 m (not satisfactory depth), while a further deepness (4 m) allows only a minimal improvement. Thus, if the excavation costs are low Table 3 Thermal-physical properties of the considered soil. Albedo: 0.1 for wet soil, 0.2 for moderate soil, 0.3 for dry soil Dry density kg/m3 Conductivity W/(m K) Diffusivity m2/day Soil Heavy clay (15% water) Heavy clay (5% water) Light sand (15% water) Light sand (5% water) 1925 1925 1285 1285 1.4 1.0 1.0 0.9 0.042 0.047 0.047 0.055 O O O O 1.9 1.4 2.1 1.9 O O O O 0.061 0.061 0.093 0.120 (unleashed soils), a deeper tube can be useful, while, in presence of rock, a depth of 3 m is the best compromise. In Fig. 6, also a different air velocity inside the tubes has been considered (high velocity). The reference air velocity into the buried tubes is 7.7 m/s (Table 2) and this determines a pressure drop of 2 Pa/m (fan power equal to 1250 W). Raising the air velocity to 20 m/s, a reduction of the tube costs is achieved, but two negative effects on performance occur: the higher pressure drop (19 Pa/m) imposes a major fan power (2600 W); the overall heat exchange is reduced due to the minor exchange surface (a higher velocity, with unvaried flow rate, implies a lower radius), even if the convective heat transfer coefficient rises with the air velocity. Globally, high air velocities are not energy convenient, as clearly shown in Fig. 6, above all in terms of primary energy. In order to better understand the results of Fig. 6, with reference to the comparison between low and high velocity of the air inside the tube, it can be useful to report the following known concepts. The fan electric power rises with the required pressure head, as shown in the Equation (18) reported in the following section. The pressure head of the fan is evaluated on the basis of the global pressure loss of the most unfavourable circuit in the total duct layout. The global pressure losses of an air distribution system are the sum of the frictional pressure losses and the dynamic pressure losses, calculated by means of the Equations (16) and (17), respectively. Dp ¼ l$L$ w2 r $ 2 dh Dp ¼ z$r $ w2 2 Frictional losses Dynamic losses (16) (17) So, the pressure losses depend on the terms L (length of the duct), l (Darcy friction factor), r (air density), dh (hydraulic diameter of the tube), z (dynamic loss coefficient) and the square-value of the air velocity (w2). Considering the Equations (16)e(18), it can be obtained that a high air speed, compared to the case of a low one, induces a higher air-duct global pressure loss, and, therefore, a major fan-required pressure head and, finally, a higher necessary fan electric power. 2.2.5. Influence of the fan position and airflow rate Earth-to-air heat exchangers can use intake fans, exhaust ones or both, depending on the complexity of the air ducts. The exclusively use of exhaust fans requires a careful sizing of the ventilation F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 2181 Fig. 3. Influence of the ground typology on the energy requests for summer cooling. system, so that the room extraction grilles can guarantee the correct incoming airflow rates in all the building zones. In this paper, only two different solutions have been considered: intake fans and exhaust fans. In Fig. 7A and B (on the left side), the influence of the fan position is shown. Considering the same ventilation airflow rate (i.e. 1 ACH), the energy request for building summer cooling is very similar in the two cases of intake fan and exhaust fan; when an intake fan is used, the energy required is higher of only about 0.4 kWh/m2a (in terms of thermal energy), as the increase of the air temperature due to the crossing of the fan is little (this increase depends on shape and rotational speed of the fan blades). In addition, different amounts of ventilation air (2 and 4 ACH) supplied into the building have been also considered (Fig. 7A and B, on the right side). Of course, in the considered climates, the achievable thermal energy savings increase when raising the airflow rate crossing the EAHX (Fig. 7A), as in summer the under ground soil temperature is usually lower than the indoor comfort temperature, independently of climate, ground composition, tube length, depth and material. Thus, using an earth tube, the increase of the ventilation air amount determines a reduction of the thermal energy requests for cooling. In terms of primary energy, the results are very different. In fact, the fan electric power grows with the airflow rate, according to Equation (18): Fan electric power ¼ðVolumetric flow rate$Pressure headÞ =hFAN ð18Þ Thus, when considering 1 or 2 ACH, the thermal energy requests are different (Fig. 7A), while the primary energy requirements are very similar (Fig. 7B). A further growth of the airflow amount (4 ACH) determines a further reduction of the thermal energy required (Fig. 7A), but also a significant growth of the primary energy (Fig. 7B). Moreover, it can be noted that the primary energy performances relative to the cases with 1 and 2 ACH are almost equivalent in summer (Fig. 7B), but not in winter. In fact, in winter, the EAHX ventilation can be used as pre-heating strategy, because the heat exchange between the soil and the outdoor air makes the ventilation energetically less disadvantageous (but, anyway, the ventilation remains disadvantageous). Therefore, contrary to what occurs in summer, in winter any rise of the supplied outdoor air over the necessary air-change induces an increase of the ventilation thermal load and of the energy requirements; furthermore, other energy disadvantages derive from higher fan needs. 2.2.6. Influence of the EAHX control mode Five different control modes of the EAHX have been considered, in which the daily working period has been varied (Table 4); all the results are reported in Fig. 8. It is clear that, despite higher fan energy requirements, the most convenient solution is the use of the EAHX during all the diurnal hours, and it is verified for all the considered climates. Thus, the first control mode (mode 1, e.g. 15 h/day) represents the best solution, with a cooling primary energy request (lines in Fig. 8B) equal to: for Naples, 42.8 kWh/m2a (vs. 55.3 kWh/m2a without the earth tube, i.e. &23%); for Rome, 38.0 kWh/m2a (vs. 52.2 kWh/m2a without the earth tube, i.e. &27%); for Milan, 28.3 kWh/m2a (vs. 41.3 kWh/m2a without the earth tube, i.e. &31%). 2.3. EAHX optimisation and coupling to other energy saving techniques for summer conditions Considering the results previously presented, the best of the configurations studied for the earth-to-air heat exchanger is characterised by the following conditions: depth ¼ 3 m, length ¼ 50 m, Fig. 4. Influence of the buried pipe material on the energy requests for summer cooling. 2182 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 Fig. 5. Influence of the tube length on the EAHX outlet air temperature (a, b, c) and on the energy requests for summer cooling (d). Fig. 6. Influence of the tube depth and air velocity on the energy requests for summer cooling. 2183 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 Fig. 7. Influence of the fan position and airflow rate on the energy requests for summer cooling. material ¼ PVC, ventilation airflow rate ¼ 1 ACH, air speed ¼ 7.7 m/s, exhaust fan use, control mode 1 (15 h/day). Up to now, the analysis has been carried out considering only the EAHX and no other passive techniques for energy saving in buildings. On the contrary, in this section, the EAHX is coupled to window shadings (outdoor blinds with horizontal slats) and nighttime ventilation, still with reference to summer conditions. In fact, as regards ventilation, it is suitable to use both the diurnal ventilation (fresh air supplied into the building) and the night-ventilation (in order to cool the building envelope and activate its mass). In Fig. 9 the energy requests for summer cooling are reported, in terms of thermal energy (Fig. 9A) and primary energy requirements (Fig. 9B). Adopting all the 3 passive techniques for the examined building, the reduction of the active cooling energy requests becomes more significant. In terms of thermal energy, the following requirements have been obtained: for Naples: 33 kWh/m2a (59 kWh/m2a in the base case with no energy saving technology, i.e. &44%); for Rome: 28 kWh/m2a (56 kWh/m2a in the base case, i.e. &50%); for Milan: 17 kWh/m2a (44 kWh/m2a in the base case, i.e. &61%). It can be noted that the current Italian rule [12] imposes a limit of 30 kWh/m2a (even if for the residential buildings) to the thermal needs for summer cooling. By using the 3 passive cooling solutions, the building respects the legal limit value for Rome (28 kWh/m2a) and Milan (17 kWh/m2a), but not for Naples (33 kWh/m2a). Note that the curve slopes in Fig. 9 seem to show that the highest energy saving potential is related to the use of the EAXH. 2.4. Energy efficiency ratios for the ventilation system with EAHX in summer conditions For the examined cities, the following energy efficiency ratios have been calculated for summer conditions: - energy efficiency ratio (EER) at the design conditions e Equation (19); - mean summer seasonal energy efficiency ratio (SEER) e Equation (20). _ EERDESIGN ¼ m$c$ðT external&air & TEAHX outlet&air Þ= Fan electric power ½kWthermal =kWelectric ' ð19Þ SEER ¼ Qground recovered =Fan seasonal electric request ½kWhthermal =kWhelectric ' ð20Þ These performance coefficients (the values are reported in Table 5) have been evaluated both for the total system (“TOTAL” as subscript in Table 5, i.e. considering the energy required by the fans for the whole ventilation system) and with reference to the only EAHX (pressure drops z 1/3 compared to the whole ventilation system). The highest energy efficiency ratios have been obtained for Milan, i.e. for the zone with the coldest winter (so, in summer the ground is colder compared to the other zones). Note that, also considering the seasonal performance coefficient referred to the whole ventilation system (SEERTOTAL), values about 10 Whthermal/ Whelectric are about three times higher than those obtainable using a typical and efficient cooling system for single room (split-system). It is also noteworthy that the obtained results are coherent with the evaluations reported in Reference [13]. 2.5. Energy saving potential obtainable using the EAHX in winter conditions In this section, the EAHX in winter conditions is examined, with reference to its optimal configuration described at the beginning of Section 2.3. In Fig. 10 the temperature of the outdoor air and that of the air at the EAHX exit have been reported for winter conditions; so, the EAHX pre-heating potential (proportional to the thermal energy recovery obtainable in winter) has been evaluated. In moderate climates (Naples and Rome), the outdoor air is heated of about 4 ( C Table 4 Analysed control modes for the EAHX (working period and time). Control mode 1 16/06 O 15/09 (15 h/day) Control mode 2 16/06 O 15/09 (13 h/day) Control mode 3 16/06 O 15/09 (11 h/day) Control mode 4 Control mode 5 16/06 O 15/09 (9 h/day) 16/06 O 30/06 (15 h/day) 01.07 O 31/08 (11 h/day) 01/09 O 15/09 (15 h/day) 2184 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 Fig. 8. Influence of the earth tube control modes on the energy requests for summer cooling. Fig. 9. Energy requests obtained coupling three passive solutions for summer cooling. through the EAHX, while in Milan the temperature increase is significantly higher (z10 ( C). In the case of building without EAHX, the thermal energy for winter heating is about 6.4 kWh/m2a for Naples, 7.5 kWh/m2a for Rome and 32.3 kWh/m2a for Milan. Results obtained using an earth tube for 9 h/day (8.00e13.00 and 15.00e19.00), in the period from November to March, for 5 days/week, are reported in the following. Naples: savings of about 1.9 kWh/m2a in terms of thermal energy and 2.5 kWh/m2a in terms of primary energy. As the fan primary energy consumption is equal to 4.9 kWh/m2a, the primary energy balance is negative (&2.4 kWh/m2a), so the use of the EAHX is not convenient. Rome: savings of about 2.1 kWh/m2a for thermal energy and 2.8 kWh/m2a for primary energy; the primary energy balance is negative also in this case (&2.1 kWh/m2a). Milan: savings of about 5.2 kWh/m2a for thermal energy and 6.9 kWh/m2a for primary energy; the primary energy balance is positive (þ2.0 kWh/m2a), so the use of the EAHX is suitable also in winter. Table 5 Ventilation system and EAHX energy efficiency ratios. EERtotal EEREAHX SEERtotal SEEREAHX kWth/kWel kWth/kWel kWhth/kWhel kWhth/kWhel Naples Rome Milan 10.4 25.3 7.5 18.3 10 24.3 8.9 21.8 12.9 31.4 12.4 30.2 Finally, a high efficiency and an energetic convenience of the EAHX in winter conditions have been obtained only in the case of cold climates. 2.6. Cost-benefit analysis The cost-benefit analysis is based on the costs reported in Table 6. Four different design solutions have been examined, as a function of the soil type (with the related excavation and refilling costs) and the EAHX material: 1) PVC tube, unleashed soil (excavation costs: 2.4 €/m3; refilling costs: 2.0 €/m3); 2) PVC tube, tender rock (excavation costs: 8.1 €/m3; refilling costs: 2.0 €/m3); 3) PVC tube, hard rock (excavation costs: 32.5 €/m3; manual refilling costs: 8.0 €/m3); 4) Metallic tube, unleashed soil (excavation costs: 2.4 €/m3; refilling costs: 2.0 €/m3). All these solutions (ventilation system with EAHX) have been compared with a traditional ventilation system without EAHX. In Table 7, a simple payback analysis is reported. On the basis of the results reported in Section 2.5, the savings obtainable in winter conditions have been considered only for Milan. Table 7 shows that the ground moving represents a relevant cost, equal or higher compared to the tube, according to Reference [13]; 2185 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 Fig. 10. EAHX winter pre-heating potential. Table 6 EAHX costs and moving earth costs (rough estimate). Excavation costs Open section excavation Unleashed rocks: sand, clay, gravel Tender rock €/m3 Refilling costs 2.4 Adopting mechanical devices and using the material previously moved off: 2.0 €/m3 8.1 EAHX costsb plastic, F ¼ 160 mm plastic, F ¼ 315 mm plastic, €/m 8.0 28.0 44.0 F ¼ 400 mm Hard rock 32.5 metallic, EAHX not suitable. In particular, the use of metallic material does not guarantee any benefit, as installation costs are much higher, while thermal performances are only slightly better compared to the PVC tubes (so, the differences of savings are neglected in Table 7). This analysis shows again that the highest benefits are obtained in climates with colder winter (Milan). Moreover, the economic suitability related to the use of an EAHX is more relevant for new buildings compared to the case of existing building energy refurbishment. 52.0 F ¼ 150 mm Force section excavation (not considered here) 2.9 Unleashed rocks: sand, claya Tender rock 9.1 Hard rock a b Manually executed refilling, using the material previously moved off: 8.0 €/m3 52.8 metallic, F ¼ 315 mm metallic, F ¼ 400 mm 170.0 concrete, F ¼ 300 mm concrete, F ¼ 400 mm 34.0 202.0 40.0 Over e 2 m, extra-cost of around 2 €/m3. Installation: extra-cost of about 20%. this is not true only for the case 4, as the metallic tube is very expensive. When the ground allows an easy moving work (cases 1 and 2), the earth tube represents a very suitable improvement of the ventilation system, with reduced payback periods (5e9 years). On the contrary, onerous ground moving works (hard rock, case 3) and/ or the use of expensive material (metallic tube, case 4) make the 2.7. Indoor thermal conditions in building provided only with ventilation and EAHX, in summer conditions In the previous sections, all the energy evaluations have been carried out considering a fully air-conditioned building and calculating the active cooling savings achievable in summer by using an EAHX coupled to the ventilation system. According to another approach, typical of the middle Europe climates, in this section the EAHX benefits have been estimated considering the possible indoor thermal comfort conditions for a not fully air-conditioned building; the building is provided only with diurnal ventilation coupled to EAHX, plus nocturnal ventilation: therefore, the indoor temperature varies. The indoor thermal comfort conditions have been fixed according to the EN Standard 15251 [14], as regards the adaptive thermal comfort criteria (Equations (21) and (22), Fig. 11 and Table 8). The Equations (21) and (22) are necessary to define the limits of each thermal environment category: Table 7 Simple payback analysis for the EAHX. 1 2 3 4 Saving in summer conditions (€) Saving in winter conditions (€) System extra-cost (€) Naples Rome Milan 633.9 720.1 659.3 e e 120.1 3513 Naples Rome Milan 633.9 720.1 659.3 e e 120.1 Naples Rome Milan 633.9 720.1 659.3 Naples Rome Milan 633.9 720.1 659.3 Payback (years) Component costs % 5.5 4.9 4.5 Solution 1: Ground moving Earth tube 50 50 5771 9.1 8.0 7.4 Solution 2: Ground moving Earth tube 69 31 e e 120.1 17809 28.1 24.7 22.8 Solution 3: Ground moving Earth tube 90 10 e e 120.1 12495 19.7 17.4 16.0 Solution 4: Ground moving Earth tube 14 86 2186 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 Fig. 11. Temperature limits of the thermal environment categories for buildings without active cooling system, in summer (according to adaptive thermal comfort criteria - EN 15251). upper limit / TINDOOR MAX ¼ 0:33$TOUTDOOR MEAN MONTHLY þ 18:8 þ X ð21Þ lower limit / TINDOOR MIN ¼ 0:33$TOUTDOOR MEAN MONTHLY þ 18:8 & X ð22Þ thermal zone 2: 1st floor, south-exposed; thermal zone 3: ground floor, north-exposed. where: for category I (90% acceptation, 10% dissatisfied), X ¼ 2 ( C; for category II (80% acceptation, 20% dissatisfied), X ¼ 3 ( C; for category III (65% acceptation, 35% dissatisfied), X ¼ 4 ( C. In order to simplify the analysis, the mean monthly outdoor temperature of July has been considered for the whole summer season. Then, the indoor temperatures have been evaluated considering the building provided only with diurnal ventilation coupled to EAHX, plus nocturnal ventilation; the evaluation has been carried Table 8 Temperature limits of the thermal environment categories for buildings without active cooling system, for three Italian cities and summer conditions (according to adaptive thermal comfort criteria - EN 15251). Naples (mean July T w 26.7 ( C) Rome (mean July T w 25.7 ( C) Milan (mean July T w 25.1 ( C) out only for the summer diurnal hours during the working days and for each thermal zone (note that the room exposure is relevant in the evaluation of the temperature inside a building not fully airconditioned). Two different thermal zones have been considered here (the most and the less critical zone as regards the thermal loads): Category I (90% acceptation) Category II (80% acceptation) Category III (65% acceptation) 25.6e29.6 ( C 24.6e30.6 ( C 23.6e31.6 ( C 25.3e29.3 ( C 24.3e30.3 ( C 23.3e31.3 ( C 25.1e29.1 ( C 24.1e30.1 ( C 23.1e31.1 ( C The calculated indoor temperatures are reported in Table 9: the values represent the percentage time fraction in which thermal comfort conditions are obtained, with reference to the above specified categories. The following results can be highlighted. Thermal zone 2: despite the use of passive cooling solutions, thermal comfort conditions are rarely obtained, above all in the hottest climate (Naples e time periods between 10% and 23% of the summer working time). Also in the less critical climate (Milan), where both the night-time ventilation and the ground Table 9 Summer indoor thermal conditions in a building provided only with ventilation and EAHX for three Italian cities, subdivided with respect to the thermal environment categories reported in EN 15251. Naples Rome Milan Zone 2 (1st floor, south-exposed) Category I Category II 10.0% 13.0% 20.0% 26.1% 27.4% 36.5% Category III 23.0% 29.9% 42.7% Naples Rome Milan Zone 3 (ground floor, north-exposed) Category I Category II 35.6% 43.3% 50.1% 67.2% 80.3% 88.8% Category III 49.6% 74.4% 90.0% F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 2187 Fig. 12. Frequency and cumulative frequency of the summer indoor temperature values for the thermal zone 3 of an office building in Milan, and thermal environment evaluation according to EN 15251. cooling potentials are higher, partial comfort conditions (category III) are obtained only for 43% of the global diurnal working hours. With reference to Naples and Rome, even if the admitted indoor temperatures are higher compared to Milan (Fig. 11 and Table 8), the indoor conditions are worse. Thermal zone 3: the comfort conditions of category I are only partially achieved in Naples (36% of summer working time) and Rome (50%), while more interesting results are obtained for Milan (80%). Enlarging the admitted indoor temperature range (categories II and III), the building in Milan shows better performances (about 90%). Considering the comfort conditions of category III, minor results are achieved for Rome and Naples (respectively, 74% and 50%). The main results for Milan and thermal zone 3 are reported also in Fig. 12: so, for cold climates such as Milan, the achievable indoor thermal conditions are good (about 90% of the summer diurnal time characterised by indoor temperature lower than 30 ( C, as shown by the cumulative frequency curve). On the contrary, with reference to Naples and Rome, the indoor summer temperatures obtainable using EAHX coupled to ventilation aren’t fully satisfactory (Table 9); anyway, the use of the active cooling can be noticeably reduced. 3. Conclusions With reference to three localities, representative of the different Italian climates, the energy performances of a buried earth-to-air heat exchanger have been evaluated as a function of the main boundary conditions. In fact, the thermal requirements of a building can be significantly reduced by means of the pre-handling of the ventilation air through the heat transfer with the ground. The following conclusions of the analysis can be drawn as regards summer conditions: - the best energy performances have been obtained for wet/ humid soil and for the coldest climates (Milan) e maximum energy savings of about 44% in terms of thermal energy, about 37% for primary energy; - the influence of the tube material (usually, PVC, metal or concrete) on the energy performance is negligible; - as regards the tube length, values of about 10 m are unsatisfactory. Moreover, a length of nearly 50 m is a good compromise; in fact, adopting a tube longer than 50 m, the cooling energy reduction is negligible, while the electric energy requirements for fans increase significantly; - about the tube depth, a good compromise between energy performance and moving earth costs is achieved with a depth of about 3 m; - in spite of a minor heat transfer coefficient, low speeds (about 8 m/s) of the airflow inside the tubes are preferable, as the pressure drops and fan electric energy requirements decrease; the higher energy costs due to the use of intake fans instead of exhaust ones are negligible; - as regards the ventilation airflow rate, 1 or 2 ACH are equivalent and preferable in terms of total primary energy requirements; - about the control mode of the EAHX, the best solution consists in a long use. In winter, the minimum ventilation airflow rate necessary for an acceptable indoor air quality is preferable as regards energy requirements; moreover, the convenience of the EAHX in winter has been obtained only for cold climates (Milan). As regards the technical-economic analysis, the use of an EAHX is suitable (simple payback of 5e9 years) only when the moving earth works are easy and cheap (for example, this is not true for hard rock); otherwise, high moving earth costs or expensive tube materials (metals) induce too long payback values. Finally, considering in summer a not fully air-conditioned building, only provided with diurnal ventilation coupled to EAHX plus night-time ventilation, the possible indoor thermal comfort conditions have been evaluated for the diurnal hours during the working days. Only for building zones with low thermal loads and for the coldest climate (Milan), the achievable results are good (90% of the hours characterised by indoor temperature lower than 30 ( C and so by partial thermal comfort conditions). As regards the other building zones and the other cities (Naples and Rome), worse indoor thermal conditions have been obtained. 2188 F. Ascione et al. / Renewable Energy 36 (2011) 2177e2188 Nomenclature a A As b c dh f hc hs k L _ m Nu Q R RH Rtot r1 r2 r3 T Ta(y) Tam TGROUND t t0 Ut w Z constant (¼103 Pa/( C), Pa ( C&1 area, m2 amplitude of the soil surface temperature variation, ( C constant (609 Pa), Pa specific heat, kJ kg&1 K&1 hydraulic diameter of the tube, m fraction of evaporation rate, kJ convective heat transfer coefficient at the inner tube surface, W m&2 K&1 convective heat transfer coefficient at the soil surface, W m&2 K&1 thermal conductivity, W m&1 K&1 length of the tube or duct, m mass flow rate of the air crossing the EAHX, kg s&1 number of Nusselt thermal energy, kJ or kWh total thermal resistance, K W&1 ambient air relative humidity global total thermal resistance between the air in the tube and the soil, K W&1 inner radius of the tube, m thickness of the tube, m distance between the tube external surface and the undisturbed soil, m temperature( C air temperature inside the tube at the distance y from the tube inlet, ( C ambient air temperature, ( C (z, t) ground temperature at time t and depth z, ( C time passed from the begin of the year, days phase constant of the soil, days overall heat transfer coefficient, W m&2 K&1 air speed inside the duct, m s&1 depth of the tube section centre with respect to the ground level, m Greek letters as soil thermal diffusivity, m2 s&1 bs soil absorption coefficient (¼ 1esoil albedo) DR radiation constant (63 W/m2), W m&2 DP pressure loss, Pa 3 z l r hemispherical emittance of the ground surface dynamic loss coefficient Darcy friction factor air density, kg m&3 Acronyms EER energy efficiency ratio at the design conditions SEER mean summer seasonal energy efficiency ratio Subscripts a air (in the tube) air (outdoor ventilation) air cond conduction conv convection p pipe ¼ tube s soil SURF (soil) surface References [1] Argiriuou A. Ground cooling. In: Santamouris M, Asimakopoulos D, editors. Passive cooling of buildings; 2001. p. 360e401. [2] Givoni B. The earth as a cooling source for buildings. In: Givoni B, editor. Passive and low energy cooling of buildings. J. Wiley & Sons; 1994. p. 191e238. [3] Mihalakakou G, Santamouris M, Asimakopoulos DN. Modelling the thermal performance of earth-to air heat exchangers. Solar Energy 1994;53:301e5. [4] Mihalakakou G. On estimating soil surface temperature profiles. Energy and Buildings 2002;34:251e9. [5] Benkert S, Heidt FD, Scholer D. Calculation tool for earth heat exchangers GAEA. In: Proceeding of building simulation, vol. 2. Prague: Fifth International IBPSA Conference; 1997. [6] Pfafferott J. Evaluation of earth-to-air heat exchangers with a standardized method to calculate energy efficiency. Energy and Buildings 2003;35:971e83. [7] Lee KH, Strand RK. The cooling and heating potential of an earth tube system in buildings. Energy and Buildings 2008;40:486e94. [8] Lee KH, Strand RK. Implementation of an earth tube system into EnergyPlus program. IBPSA USA SimBuild Publications; 2006. [9] U.S. Department of Energy. EnergyPlus simulation software, version 2.0.0; 2007. [10] U.S. Department of Energy. Calculation of soil temperature, auxiliary program of EnergyPlus; 2007. [11] Krarti M, Lopez-Alonzo C, Claridge DE, Kreider JF. Analytical model to predict annual soil surface temperature variation. Journal of Solar Energy Engineering 1995;117:91e9. [12] Italian Presidential Decree n. 59/2009, Regolamento di attuazione del D.Lgs. 192 sul rendimento energetico in edilizia, 2009. [13] Pfafferott J, Walker-Hertkorn S, Sanner B. Ground cooling: recent progress. In: Santamouris M, editor. Advances in passive cooling; 2007. p. 190e227. [14] Standard EN 15251, Indoor environmental input parameters for design and assessment of energy performance of buildings addressing indoor air quality, thermal environment, lighting and acoustics, 2007.