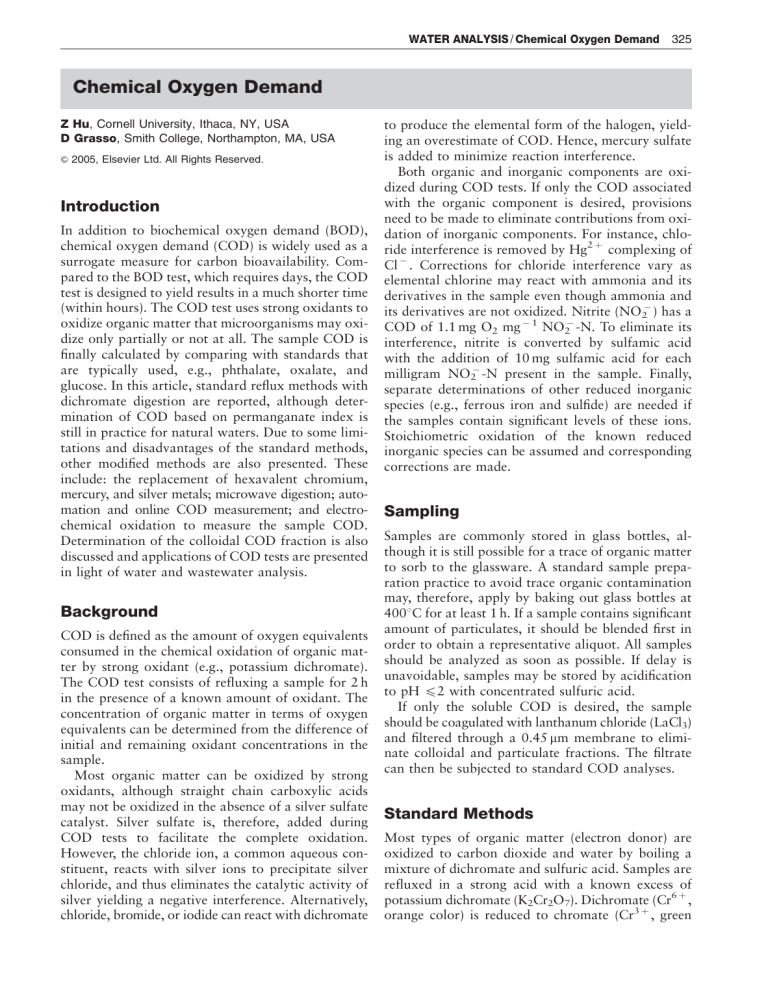

WATER ANALYSIS / Chemical Oxygen Demand 325 Chemical Oxygen Demand Z Hu, Cornell University, Ithaca, NY, USA D Grasso, Smith College, Northampton, MA, USA & 2005, Elsevier Ltd. All Rights Reserved. Introduction In addition to biochemical oxygen demand (BOD), chemical oxygen demand (COD) is widely used as a surrogate measure for carbon bioavailability. Compared to the BOD test, which requires days, the COD test is designed to yield results in a much shorter time (within hours). The COD test uses strong oxidants to oxidize organic matter that microorganisms may oxidize only partially or not at all. The sample COD is finally calculated by comparing with standards that are typically used, e.g., phthalate, oxalate, and glucose. In this article, standard reflux methods with dichromate digestion are reported, although determination of COD based on permanganate index is still in practice for natural waters. Due to some limitations and disadvantages of the standard methods, other modified methods are also presented. These include: the replacement of hexavalent chromium, mercury, and silver metals; microwave digestion; automation and online COD measurement; and electrochemical oxidation to measure the sample COD. Determination of the colloidal COD fraction is also discussed and applications of COD tests are presented in light of water and wastewater analysis. Background COD is defined as the amount of oxygen equivalents consumed in the chemical oxidation of organic matter by strong oxidant (e.g., potassium dichromate). The COD test consists of refluxing a sample for 2 h in the presence of a known amount of oxidant. The concentration of organic matter in terms of oxygen equivalents can be determined from the difference of initial and remaining oxidant concentrations in the sample. Most organic matter can be oxidized by strong oxidants, although straight chain carboxylic acids may not be oxidized in the absence of a silver sulfate catalyst. Silver sulfate is, therefore, added during COD tests to facilitate the complete oxidation. However, the chloride ion, a common aqueous constituent, reacts with silver ions to precipitate silver chloride, and thus eliminates the catalytic activity of silver yielding a negative interference. Alternatively, chloride, bromide, or iodide can react with dichromate to produce the elemental form of the halogen, yielding an overestimate of COD. Hence, mercury sulfate is added to minimize reaction interference. Both organic and inorganic components are oxidized during COD tests. If only the COD associated with the organic component is desired, provisions need to be made to eliminate contributions from oxidation of inorganic components. For instance, chloride interference is removed by Hg2 þ complexing of Cl . Corrections for chloride interference vary as elemental chlorine may react with ammonia and its derivatives in the sample even though ammonia and its derivatives are not oxidized. Nitrite (NO2 ) has a COD of 1.1 mg O2 mg 1 NO2 -N. To eliminate its interference, nitrite is converted by sulfamic acid with the addition of 10 mg sulfamic acid for each milligram NO2 -N present in the sample. Finally, separate determinations of other reduced inorganic species (e.g., ferrous iron and sulfide) are needed if the samples contain significant levels of these ions. Stoichiometric oxidation of the known reduced inorganic species can be assumed and corresponding corrections are made. Sampling Samples are commonly stored in glass bottles, although it is still possible for a trace of organic matter to sorb to the glassware. A standard sample preparation practice to avoid trace organic contamination may, therefore, apply by baking out glass bottles at 4001C for at least 1 h. If a sample contains significant amount of particulates, it should be blended first in order to obtain a representative aliquot. All samples should be analyzed as soon as possible. If delay is unavoidable, samples may be stored by acidification to pH p2 with concentrated sulfuric acid. If only the soluble COD is desired, the sample should be coagulated with lanthanum chloride (LaCl3) and filtered through a 0.45 mm membrane to eliminate colloidal and particulate fractions. The filtrate can then be subjected to standard COD analyses. Standard Methods Most types of organic matter (electron donor) are oxidized to carbon dioxide and water by boiling a mixture of dichromate and sulfuric acid. Samples are refluxed in a strong acid with a known excess of potassium dichromate (K2Cr2O7). Dichromate (Cr6 þ , orange color) is reduced to chromate (Cr3 þ , green 326 WATER ANALYSIS / Chemical Oxygen Demand color) via the following reaction: 3þ þ Cr2 O2 þ 7H2 O 7 þ 6e þ 14H -2Cr ½1 By using a titrimetric method, the remaining dichromate is back-titrated with ammonium iron(II) sulfate (ferrous ammonium sulfate (FAS)) to determine the amount of Cr2O27 consumed: 2þ Cr2 O2 þ 14Hþ -2Cr3þ þ 6Fe3þ þ 7H2 O 7 þ 6Fe ½2 The amount of oxidized organic matter is calculated in terms of oxygen equivalents (1 equivalent weight electron equals 8 g of oxygen) with the following equation: COD as mg O2 l1 ¼ ðA BÞ M 8000=V ½3 where A ¼ FAS used for blank (ml), B ¼ FAS used for sample (ml), M ¼ molarity of FAS, and V ¼ sample volume (ml). By using a colorimetric method, the formation of Cr3 þ (green color) is quantified as the oxidation proceeds and the absorbance is read at 600 nm. Alternatively, the disappearance of the orange Cr6 þ can be determined at 420 nm. The sample COD is determined colorimetrically at 600 and 420 nm, respectively, based on standard COD calibration curves. Most organic compounds are oxidized with the dichromate reflux method under standard procedure, but ammonia and organic nitrogen are not oxidized by dichromate in the absence of significant concentration of elemental chlorine. Hence, the dichromate reflux method is preferred over procedures using other oxidants because of its superior oxidation ability. There are, however, several potential sources of limitation in the test including the following: * * * Pyridine and related aromatic compounds resist oxidation. Straight chain aliphatic compounds are not oxidized in the absence of AgSO4 and may not be completely destroyed even in the presence of AgSO4. Volatile organic compounds may escape and are oxidized only to the extent that they remain in contact with the oxidant. milliliter concentrated H2SO4) while gently mixing to dissolve use HgSO4 and avoid possible loss of volatile organic components. Add 25.00 ml of 0.0417 mol l 1 K2Cr2O7 and mix. Attach the flask to a condenser and turn on cooling water. While continuously stirring, add the remaining 70 ml sulfuric acid–silver sulfate mixture through the open end of the condenser. Heat the sample for 2 h in the flask under reflux conditions. Wash down the condenser with de-ionized (DI) water into the flask and cool to room temperature. Titrate excess K2Cr2O7 with standard 0.25 mol l 1 FAS using two to three drops ferroin indicator to determine the volume of FAS utilized. Acquire a blank sample (50 ml DI water) through the same procedure to determine the value of A. For quality assurance and quality control purpose, conduct a test on a standard potassium hydrogenphthalate (KHP) solution (500 mg O2 l 1). The above procedure is suitable for a sample with a COD in the range of 0–900 mg O2 l 1. For high COD (41000 mg O2 l 1) samples, dilution may be necessary. Selection of a dilution ratio can be determined from the color after mixing the sample with dichromate and sulfuric acid. If the sample solution becomes bluish green or green within a few minutes, a 10-fold dilution is suggested. Solutions showing predominantly orange color with little change within minutes should not require dilution. For low COD (o50 mg O2 l 1) samples, the standard procedure is still valid by using dichromate and FAS at 1/10 the concentration given above (i.e., 0.00417 mol l 1 K2Cr2O7 and 0.025 mol l 1 FAS). Great care must be taken with this procedure because even slight contamination of organic compounds on glassware can lead to significant error. If a further increase of sensitivity is required, a large volume of sample may be concentrated to 150 ml (equivalent to the total volume in the standard procedure) after the addition of all reagents by boiling in the refluxing flask open to the atmosphere without the condenser attached. Before refluxing, the amount of chloride must be determined in order to add sufficient HgSO4 on the basis of a weight ratio of 10:1 for HgSO4:Cl . A blank should be carried out through the same procedure. Compared to ordinary evaporative concentration methods, this technique has the advantage of reducing losses of easily digested volatile organic compounds. Open Reflux Method For an open reflux method, the standard procedure follows: pipette 50 ml sample (for samples with COD higher than 900 mg O2 l 1, use a small sample portion diluted to 50 ml) in a 500 ml refluxing flask. Add 1 g HgSO4, and glass beads. Slowly add 5 ml sulfuric acid–silver sulfate mixture (10–15 g Ag2SO4 per Closed Reflux Methods Compared to the open reflux method, volatile organic compounds are more easily oxidized with closed reflux methods, because those compounds remain in contact with the oxidant in closed vessels. WATER ANALYSIS / Chemical Oxygen Demand 327 (o90 mg O2 l 1) values can be determined by measuring the decrease of absorbance at 420 nm, which directly correlates with Cr6 þ concentration. A calibration curve must be prepared before COD can be determined with this colorimetric method. At least 5 standards of KHP solution should be prepared to cover a range of sample COD values. Aliquots of standard KHP stock are diluted with DI water to the same volume for samples. A reference solution (blank) contains DI water only. The same reagent volumes, tube, and digestion procedure as for samples are followed (Table 1). Digestion vessels containing a blank, standards, and samples are placed on a block heater preheated to 1501C for 2 h. Samples are cooled to room temperature and their absorbances are measured against the blank. A linear calibration curve is created by measuring the difference between absorbencies of digested standards and the digested blank. COD values are determined based on calibration curves. Furthermore, closed reflux methods are preferred because fewer reagents are used, and therefore less hazardous wastes are generated. The methods are equivalent to ISO 15705–Determination of the chemical oxygen demand index (ST-COD) – Small-scale sealed-tube method. Closed reflux: titrimetric method The procedure is a scaled-down adaptation from the one described above with the same chemistry, and is applicable to samples with COD between 40 and 400 mg O2 l 1. Samples with higher COD values (4400 mg O2 l 1) must be diluted while those with lower COD values (o40 mg O2 l 1) may be determined by using more dilute dichromate and FAS solutions. Since small sample volumes are used, diluted dichromate (0.0167 mol l 1) and FAS (0.10 mol l 1) are prepared, and it is critical to obtain accurate volumes for samples and digestion solutions. Digestion vessels with premixed reagents and other accessories are commercially available. Otherwise, sample volumes and reagent quantities for various digestion vessels are suggested below. The digestion vessels are placed on a block heater preheated to 1501C for 2 h. The remaining K2Cr2O7 is determined by titrating with standard 0.10 mol l 1 FAS. A blank containing the water reagents and DI is examined the same way for samples and the COD is calculated using eqn [3]. Comparison of Chemical and Theoretical Oxygen Demand Ideally, COD values obtained from the standard reflux methods should equal the solution’s theoretical oxygen demand (ThOD), which is the amount of oxygen required to stoichiometrically oxidize compounds to end products, including CO2, NH3, and H2O. Examination of a database of 565 organic compounds has recently showed, however, that an average 85% of the ThOD value is obtained from COD tests due to the incomplete oxidation of some organic compounds by dichromate. Some halogenated aromatic and aliphatic hydrocarbons have especially low COD/ThOD ratios (as low as 0.03). The low COD/ThOD ratios also apply to many aliphatic alkane compounds with the lowest value down to 0.01. If a water or wastewater sample contains a large fraction of such refractory organic compounds, standard COD tests may be an inappropriate surrogate to Closed reflux: colorimetric method The colorimetric method is another standard method to quantify COD values based on the change of chromate and dichromate concentrations. The chromate ion absorbs strongly in the 600 nm region while the dichromate ion has almost zero absorption. Therefore, samples with high COD (100–900 mg O2 l 1) values convert sufficient amount of Cr6 þ to Cr3 þ , which can be determined in the 600 nm region. On the other hand, the dichromate ion absorbs strongly in the 420 nm region while the chromate ion absorbs weakly at this wavelength. Hence, samples with low COD Table 1 Suggested digestion vessels and sample and reagent volumes in COD tests Digestion vessel Sample volume (ml) H2SO4 volume (ml) K2Cr2O7 volume (ml) HgSO4 (g) 500- or 250-ml Erlenmeyer flasks 16 100 mm capped tube 20 150 mm capped tube 25 150 mm capped tube 50 75 25 1 2.5 3.5 1.5 0.05 5.0 7.0 3.0 0.1 6.0 0.2 10.0 14 328 WATER ANALYSIS / Chemical Oxygen Demand represent the degree of contamination. Alternatively, total organic carbon analyses may be performed to measure the total organic contents in the samples. Modifications of Standard Procedures In addition to the incomplete oxidation of some chemicals with the reflux methods, laboratory wastes generated from the standard COD tests contain hexavalent chromium, mercury, and silver metals, all of which are classified as hazardous wastes by the US Environmental Protection Agency and their disposal is regulated under Resource Conservation and Recovery Act. Consequently, various modifications of the standard procedures or alternative methods have been reported for the COD test. These include: the replacement of hexavalent chromium, mercury, and silver metals; microwave digestion; automation and online COD measurement; and electrochemical oxidation to measure the sample COD. Elimination of Mercury and Chromate Mercury is used in a standard COD test to suppress the chloride interference. Mercury sulfate can be used up for samples with chloride values as high as 2000 mg l 1. For samples containing more than 2000 mg l 1, however, various chloride removal methods may be considered. These include precipitation as silver chloride, ion exchange, addition of Cr3 þ as a complexing agent, and oxidation of Cl to chlorine by pentavalent bismuth (Bi5 þ ). Of these methods, the removal of chloride by Bi5 þ proposed by Miller et al. is novel and promising. In this method, solid sodium bismuthate containing pentavalent bismuth oxidizes the chloride rapidly without affecting sample organics according to the following reaction: 2Cl þ Bi5þ -Bi3þ þCl2 ½4 A special chloride removal cartridge containing a glass-fiber filter (upper cartridge, for removal of particulates) and a column packed with a mixture of solid sodium bismuthate and an inert, free-flow agent (lower cartridge) is used. The acidified sample is drawn through the chloride removal cartridge under carefully controlled conditions of contact time, flow rate, and acid strength to allow chloride and bismuthate to react effectively without destroying sample organics. Solid sodium bismuthate is not soluble in the acidified solution and remains in the cartridge. The by-product, trivalent bismuth (Bi3 þ ), dissolves in the acidified sample solution but has no effect on COD results. The glass-fiber filter containing particulates is removed from the top of the cartridge and combined with the treated liquid component in a COD reagent vial for total COD measurement. Alternatively, soluble and particulate COD can be determined separately by digesting only the sample component of interest. Permanganate (Mn7 þ ) and trivalent manganese (Mn3 þ ) have been proposed to replace hexavalent chromium as strong oxidants in COD analysis. In fact, the permanganate method is widely used in Japan to monitor organic pollution. Oxidation potentials of Mn3 þ –Mn2 þ and Mn7 þ –Mn2 þ half-reactions are 1.54 and 1.51 E1 (V), respectively, both of which are greater than that of Cr6 þ –Cr3 þ half-reaction (1.35E1 (V)). Trivalent manganese (Mn3 þ ) is a strong, noncarcinogenic chemical oxidant that changes quantitatively from purple to faint pink when it reacts with organic matter. Sample COD values are determined colorimetrically, and the color intensity is inversely proportional to the amount of COD in the sample. Unfortunately, the permanganate and trivalent manganese methods have relatively low oxidation power and poor reproducibility. Manganese (Mn3 þ ) in sulfuric acid can oxidize B80% of synthetic and naturally occurring organic compounds. Microwave Digestion The standard reflux methods require a long time (2 h) for the digestion step in the COD analysis. A rapid COD determination technique using microwave digestion has been developed. One of the advantages of using microwave digestion over the standard reflux method is that compounds such as pyridine and aromatic organic compounds are oxidized better. A special microwave with six individual magnetrons is designed to focus the microwave radiation on each sample in a 250 ml glass digestion tube. Each digestion tube is connected to a condenser circulating with cooling water to avoid any loss of volatile organic compounds in the sample. An aliquot (20 ml) of a sample is added in the glass digestion tube, followed by the addition of 0.5 g of mercuric sulfate, 10 ml of dichromate solution, and 5 ml of sulfuric acid. The tube is placed into the microwave and connected to a condenser. An additional volume (25 ml) of sulfuric acid is added to the top of the condenser. The mixture is digested in the microwave at 1501C for 8 min. Excess dichromate in the digestion tube is determined with the standard titrimetric or colorimetric procedure. COD determination of real water and wastewater samples indicates that the results obtained from both microwave digestion and closed reflux digestion are consistent. Automation and Online COD Measurement Standard reflux methods require 2 h of digestion, a length of time that would eliminate the benefits of WATER ANALYSIS / Chemical Oxygen Demand 329 online COD measurement. With the development of microwave digestion and innovative thermal oxidation techniques, attempts to automate COD analysis in continuous flow systems (also called flow-injection analysis, FIA) have shortened the analysis period to 15 min. One flow-injection method based on microwave digestion techniques is as follows. A sample is taken with an autosampler and mixed with reagents from a fast loop arrangement into a microwave heated chamber, where it is digested in an acid solution containing mercuric sulfate, dichromate solution, and sulfuric acid for 5–15 min. The process and system design ensures the constant sample volume and the reduced chromate (Cr3 þ ) with green color is determined colorimetrically to give accurate COD values. Other FIA methods have been developed by using innovative thermal oxidation techniques. The addition of a strong oxidizing agent, cerium(IV) sulfate, results in a high degree of sample oxidation. Potassium permanganate may also be used as both an oxidant and a colorimetric reagent during a segmented FIA to determine COD in aqueous environmental samples. But, it may not apply for analysis of samples containing abundant recalcitrant organic matter due to its limited oxidation power. COD Measurement with Electrochemical Oxidation COD may also be determined with electrochemical methods. An electrochemical cell with the capacity for electrochemical oxidation of organic matter into water and carbon dioxide might enable a fast method to measure the sample COD based on coulometry (the number of electrons consumed in the degradation). The system includes a copper electrode, a potentiostat, and a personal computer. Copper in alkaline media can act as an electrocatalyst to oxidize organic matter. The potentiostat is used to maintain constant potentials during electrolysis. The data are recorded with a data acquisition system. The net charge, corresponding to the number of electrons consumed in the electrochemical oxidation, is correlated to the COD determined by standard reflux methods. The time required for a single sample COD measurement is B30 min, which is much less than the 2–4 h required by the standard methods. However, electrochemical methods may not provide sufficient oxidation power to completely electrolyze all the organic matter. Furthermore, the electrodes may be easily contaminated with significant fouling, especially in a sample containing high concentrations of humic acid. Applications COD is often used as a measurement of pollutants in water, wastewater, and aqueous hazardous wastes. One application of the COD test is to measure soluble COD in wastewater, since characterization of total COD in wastewater is critical for accurate modeling of biotransformation in wastewater treatment processes. Another application is to rapidly infer biodegradability of samples from the COD tests. This is commonly accomplished by establishing a correlation between COD and BOD. This method has been found successful when the proportions and types of materials in a wastewater remain relatively constant. For example, BOD in domestic wastewater samples from 5-day BOD tests can be approximated as BOD5 ¼ 0.476 COD. See also: Sample Dissolution for Elemental Analysis: Microwave Digestion. Sampling: Theory. Water Analysis: Overview; Seawater – Dissolved Organic Carbon; Industrial Effluents; Sewage; Biochemical Oxygen Demand. Further Reading APHA, AWWA, WEF (1998) Standard Methods for the Examination of Water and Wastewater. Washington, DC. American Society for Testing and Materials (1995) Standard Methods for Chemical Oxygen Demand (Dichromate Oxygen Demand) of Water. Philadelphia, PA. Baker JR, Milke MW, and Mihelcic JR (1999) Relationship between chemical and theoretical oxygen demand for specific classes of organic chemicals. Water Research 33: 327–334. Balconi ML, Borgarello M, Ferraroli R, and Realini F (1992) Chemical oxygen demand determination in well and river waters by flow-injection analysis using a microwave oven during the oxidation step. Analytica Chimica Acta 261: 295–299. Baumann FI (1974) Dichromate reflux chemical oxygen demand: A proposed method for chloride correction in highly saline waters. Analytical Chemistry 46: 1336–1338. Chen S, Tzeng J, Tien Y, and Wu L (2001) Rapid determination of chemical oxygen demand (COD) using focused microwave digestion followed by a titrimetric method. Analytical Sciences (Japan) 17: 551–553. Hu Z, Chandran K, Smets BF, and Grasso D (2002) Evaluation of a rapid physical-chemical method for the determination of extant soluble COD. Water Research 36: 617–624. ISO 6060 (1989) Water Quality – Determination of the Chemical Oxygen Demand. ISO 8467 (1993) Water Quality – Determination of Permanganate Index. ISO 15705 (2002) Water Quality – Determination of the Chemical Oxygen Demand Index (ST-COD) – Smallscale Sealed-tube Method. Korenga T, Zhou X, Okada K, Moriwake T, and Shinoda S (1993) Determination of chemical oxygen demand by a flow injection method using cerium(IV) sulfate as oxidizing agent. Analytica Chimica Acta 272: 237–244. 330 WATER ANALYSIS / Oil Pollution Lee K-H, Ishikawa T, McNiven SJ, et al. (1999) Evaluation of chemical oxygen demand (COD) based on coulometric determination of electrochemical oxygen demand (EOD) using a surface oxidized c opper electrode. Analytica Chimica Acta 398: 161–171. Messenger AL (1981) Comparison of sealed chamber and standard method COD tests. Journal of the Water Pollution Control Federation 53: 232–236. Miller DG, Brayton SV, and Boyles WT (2001) Chemical oxygen demand analysis of wastewater using trivalent manganese oxidant with chloride removal by sodium bismuthate pretreatment. Water Environment Research 73: 63–71. Westbroek P and Temmerman E (2001) In line measurement of chemical oxygen demand by means of multipulse amperometry at a rotating Pt ring–Pt/PbO2 disc electrode. Analytica Chimica Acta 437: 95–105. Oil Pollution E Smith, University of Plymouth, Plymouth, UK & 2005, Elsevier Ltd. All Rights Reserved. Introduction Oils are very complex mixtures of hydrocarbons in which the boiling points of components can vary from a few to several hundred degrees. Crude oils vary in their physical and chemical composition depending on their geochemical derivation, but all crude oils consist of a complex mixture of compounds comprised mainly of hydrocarbons. The hydrocarbon components of crude oil consist of straight and branched chain alkanes, cycloalkanes, and aromatics, and the relative content of these groups of compounds varies from oil to oil. Compounds containing oxygen, nitrogen, and sulfur, and various metals (Ni, V, Fe, Zn, Cu, U) are also present in crude oil. The pollution of water and other matrices caused by the accidental leakage or chronic release of crude oil and refined products into the environment occurs each year. As the use and transportation of crude oil occurs on a large scale throughout the world, contamination of the environment with oil is an issue of concern. The amount of total hydrocarbons entering the oceans from all sources has been estimated at 2.35 million tons per year. Oil spills and hydrocarbons from land-based sources are usually limited to the coastal zone, but can be found even in the open oceans. The characterization of a spilled oil in a contaminated environmental sample can be important for the assessment of environmental damage, and also in the selection of appropriate response and cleanup measures. The identification of an oil spill source is also extremely important for settling any dispute relating to liability and compensation. Petroleum hydrocarbon analysis may also be required to determine the gradient of concentration around a point source, e.g., an oil platform, or provide baseline/benchmark and distribution concentrations. Oil or petroleum products spilled on water undergo a series of biotic and abiotic processes that in combination are termed weathering, and cause changes in the physical and chemical properties of the oil. Weathering processes occur at very different rates but begin immediately after oil is released into the environment. These processes include evaporation, dissolution, dispersion, photochemical oxidation, water–oil emulsification, microbial degradation, and adsorption onto suspended particles. The changes in chemical composition of spilled oil can affect the toxicity of the oil and its biological impact over time, and also further complicate the identification of residual oil in the impacted environment. These factors make it difficult to select the most appropriate analytical methods for evaluating environmental samples. A wide variety of instrumental and noninstrumental techniques are currently used in the analysis of oil hydrocarbons. These include gas chromatography (GC), gas chromatography coupled with mass spectrometry (GC–MS), infrared (IR) spectrometry, ultraviolet fluorescence spectroscopy (UVF) and gravimetry. Accurate and reliable analytical measurements are extremely important in order to unambiguously characterize spilled oil, to understand its fate and behavior, and to predict its long-term impact in environment. Despite advances in recent years in analytical technology, and in our understanding of the environmental fate of spilled oil, the complexity of oil means that there is no one method that can ‘do it all’ for the whole spectrum of oils and petroleum products that may be polluting an ecosystem. Each analytical technique measures only a subset of the complex mixture spilled or subsequently formed. This article gives a brief survey of several analytical techniques currently used for the analysis