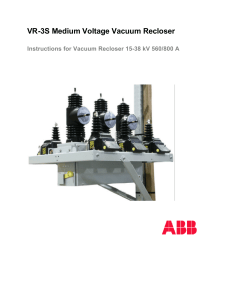

Eaton’s Cooper Power Systems catalog Reclosers and controls Reclosers and controls Catalog information Reclosers and controls catalog Technical Data Effective August 2014 Reclosers and controls catalog contents Contents Description Page Smart single-phase automation and protection solutions (B280-13004). . . . . . . . . . . . . . . . . . . 3 General ratings information and catalog guide for single-phase and three-phase reclosers (280-05). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Types E, 4E, V4E, H, 4H, V4H, L, V4L, single-phase and 6H, V6H threephase reclosers (280-10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Types D and DV single-phase hydraulically controlled recloser (280-20). . . . . . . . . . . . . . . . . . 33 Types W, WV27, WV38X, VW, VWV27, and VWV38X, three-phase hydraulically controlled reclosers (280-30). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 Types VWE, VWVE37, VWVE38X, WE, WVE27, and WVE38X, three-phase electronically controlled reclosers (280-40). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 NOVA15, NOVA27, and NOVA38 three-phase, microprocessorcontrolled recloser (280-42) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A; three-phase; air-insulated; electronically controlled recloser (280-45). . . . . . . . . . . . . . . . . . . . 93 Type VSO three-phase electronically controlled recloser (280-57) . . . . . . . . . . . . . . . . . . . . . 105 MET electronic recloser control tester (280-76) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 SPEAR™ single-phase recloser system (280-101) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 Form 4D microprocessor-based recloser control and accessories (280-104). . . . . . . . . . . . . 143 www.cooperpower.com SPEAR™ Single-Phase Recloser System Smart single-phase automation and protection solutions Utilizing field-proven recloser technology and the industry leading ProView™ NXG platform, the SPEAR™ single-phase recloser and control hosts a complete set of protection, automation, metering, and data acquisition functionality to maximize system performance and reduce customer outages. With full system protection, the SPEAR recloser system is perfect for multiple grid applications, up to 38 kV. Improve customer reliability and lower total life-cycle costs The SPEAR recloser design is based on field-proven NOVA™ recloser technology. The encapsulated axial-magnetic vacuum interrupter, and a lightweight, solid cycloaliphaticepoxy design make the SPEAR recloser a durable and flexible single-phase choice for demanding application requirements. Environmentally preferred Using Cooper Power Systems™ NOVA solid-insulation system, SPEAR reclosers are designed and manufactured to be SF6 gas-free and oil-free. NOVA solid insulation eliminates the need for insulating gas or liquid; thereby, greatly reducing the recloser life-cycle maintenance costs, and reducing user’s environmental concerns. Reduce maintenance costs SPEAR recloser technology provides durable service and reliability: • Solid Outdoor Cycloaliphatic Epoxy—no gas, oil, or foam to check and maintain, and no noxious by-products to dispose • Vacuum Interruption with AxialMagnetic Field—extended contact and mechanical life • Magnetic-Actuator Operated Mechanism—low power mechanism provides reliable operation, year after year Reduce installation time The SPEAR recloser, with its compact size and narrow profile, simplifies pole installation which reduces total installation time. Operators can be confident with handle, indicator and control functions being similar in look and feel to decades of installed electronic reclosers from Cooper Power Systems. B280-13004-1 Adding intelligent single-phase Cooper Power Systems SPEAR reclosers and controls to distribution lines can meet today's system reliability needs and easily transition for future Smart Grid applications. SPEAR single-phase recloser control The new microprocessor-based SPEAR recloser control integrates real-time valuable grid and outage data to be ported to your SCADA or feeder automation system. Complete with a separate regulated power supply, the control is automation-ready for your choice of radio. Also, tailor your digital communications performance with the user- configurable mapping of protocol DNP3. The control can be easily configured through the simple front panel display or with a laptop through a USB port on the front panel. • Smart Grid ready Protection flexibility The two separate protection profiles include: • • • • Overcurrent protection including 54 standard timecurrent curves available Time current curve modifiers—including minimum response time adder High-current trip and highcurrent lockout sequence coordination Cold load pickup • Hot-line tag • Fast trip disabled • Reclose retry • Improve customer reliability Metering data • Lower total life-cycle costs • Easy operation • Greater application flexibility • Full metering The SPEAR recloser control has instantaneous and demand metering with programmable integration intervals for system loading and planning: • Data acquisition • Remote monitoring • Simple, intuitive programming • Common look and feel to other Cooper Power Systems controls • CBC-8000 capacitor control • F4D recloser control • CL-7 regulator control • Demand power • Demand current • Instantaneous current and voltage • Energy and power factor • Frequency • Power metering Table 1. SPEAR Ratings Voltage - kV Continuous - A 400 630 15 800 400 27 630 800 400 38 630 800 Interrupting - kA 8 BIL - kV 12.5 110 8 12.5 125 8 12.5 170 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States CooperPower.com © 2013 Eaton All Rights Reserved Printed in USA Publication No. B280-13004 August 2013 B280-13004-1 Eaton, Cooper Power Systems, SPEAR, NOVA, and ProView are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the Eaton Trademarks without the prior written consent of Eaton. All other trademarks are property of their respective owners. Data acquisition To prevent future outages and improve grid performance, numerous data acquisition features are standard: • Data Profiler, user configurable with memory of 21 days for 10 analogs • Event Recorder with a 1000 event memory Receive real-time system data: • Metering • Sequence of events • Data profiler • Active control data • Recloser status • Hot-line tag • Non-reclosing • Alternate profile • Battery test voltage and current Technical Data 280-05 Effective August 2013 Supersedes October 2012 General ratings information and catalog guide for single-phase and three-phase reclosers Contents Description Page Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Temporary faults . . . . . . . . . . . . . . . . . . . . . . . . . . Recloser classifying features. . . . . . . . . . . . . . . . . Recloser: single-phase or three-phase . . . . . . . . . Single-phase reclosers. . . . . . . . . . . . . . . . . . . . Three-phase reclosers . . . . . . . . . . . . . . . . . . . . Recloser ratings summary.. . . . . . . . . . . . . . . . . Single-phase tripping. . . . . . . . . . . . . . . . . . . . Three-phase tripping. . . . . . . . . . . . . . . . . . . . Controls: hydraulic or electronic . . . . . . . . . . . . . . Hydraulic controls. . . . . . . . . . . . . . . . . . . . . . . . Electronic controls.. . . . . . . . . . . . . . . . . . . . . . . Current sensing . . . . . . . . . . . . . . . . . . . . . . . . . Microprocessor-based controls . . . . . . . . . . . . . 2 2 2 2 2 2 3 4 4 4 4 4 4 4 Description Page Interrupting medium: oil or vacuum . . . . . . . . . . . 5 Oil interrupters. . . . . . . . . . . . . . . . . . . . . . . . . . 5 Vacuum interrupters. . . . . . . . . . . . . . . . . . . . . . 5 Recloser application. . . . . . . . . . . . . . . . . . . . . . . . 5 Application criteria . . . . . . . . . . . . . . . . . . . . . . . 5 Coordination with other devices. . . . . . . . . . . . . 6 Dual timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Distribution circuit with reclosers diagram. . . . . 6 Recloser operating sequence of fault. . . . . . . . . 7 Ratings Tables Ratings for single-phase, hydraulically controlled reclosers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Ratings for single-phase, electronically controlled reclosers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Ratings for three-phase, hydraulically controlled reclosers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Ratings three-phase, electronically controlled reclosers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 280-05-1 Technical Data 280-05 General ratings and catalog guide for single-and three-phase reclosers Effective August 2013 Description Recloser: single-phase or three-phase Automatic circuit reclosers are recognized by electric utilities throughout the world as an essential device for achieving their prime goal: providing maximum continuity of electric service to their customers simply and economically. Both single- and three-phase reclosers are available to satisfy application requirements. Reclosers sense and interrupt fault currents and automatically restore service after momentary outage. Single-phase reclosers, as shown in Figure 1 and 2, are used to protect single-phase lines such as branches or taps of a three-phase feeder. They can also be used on three-phase circuits where the load is predominantly single-phase. Thus, when a permanent phase-toground fault occurs, one phase can be locked-out while service is maintained to the remaining two-thirds of the system. The automatic circuit recloser is essentially a self-contained device with the necessary intelligence to sense overcurrents to time and interrupt fault currents and to re-energize the line by reclosing automatically. If a fault is permanent, the recloser locks open after a preset number of operations (usually three or four), isolating the faulted section from the main part of the system. Single-phase reclosers Three-phase reclosers Two types of three-phase reclosers are available: Temporary faults Extensive studies of overhead distribution systems have established that approximately 80 to 95 percent of all system faults are temporary in nature and, at most, last from only a few cycles to a few seconds. • Single-Phase tripping • Three-Phase tripping Typical causes of these temporary faults are: • Windblown conductors touching one another. • Lightning surges flashing over an insulator. • Birds, reptiles, or small animals bridging between an energized line and a grounded surface. • Tree branches touching energized lines. • Switching surges that flash over an insulator. Based on statistics and observations, the need for a trip-and-reclose function was readily recognized; that is, if the line could be tripped open momentarily, a subsequent reclosure very likely would be successful because, by then, the cause of the fault would be gone. Thus, the automatic circuit recloser, in providing this trip-and-reclose function, virtually eliminates prolonged outages on distribution systems due to temporary faults or transient overcurrent conditions. Recloser classifying features Figure 2. SPEAR™ single-phase, electronically controlled recloser. Major classifying features of automatic circuit reclosers are: • Single-phase or three-phase • Control: hydraulic or electronic • Interrupters: oil or vacuum • Insulation: oil, air, or epoxy Table 1 contains a detailed listing of reclosers currently manufactured by Eaton’s Cooper Power Systems. Figure 3. NOVA™ triple-single, electronically controlled recloser. Figure 1. Type H single-phase, hydraulically controlled recloser. 280-05-2 www.cooperpower.com Technical Data 280-05 General ratings information and catalog guide for single-and three-phase reclosers Effective August 2013 Table 1. Recloser Ratings Summary (See Tables 2–5 for more detailed ratings data) Voltage Rating (kV) Single-Phase 2.4 - 14.4 24.9 24.9 - 34.5 Max. Cont. Current Rating (A) Interrupting Rating (sym A at max. voltage) Interrupting Medium Control Recloser Type 50 100 200 280 280 560 400 630 800 100 280 280 400 630 800 560 400 630 800 1250 2000* 2000* 4000* 6000 10000* 8000 12500 12500 2500 4000 6000 8000 12500 12500 8000 8000 12500 12500 Oil Oil Vacuum Oil Vacuum Oil Vacuum Vacuum Vacuum Oil Oil Vacuum Vacuum Vacuum Vacuum Oil Vacuum Vacuum Vacuum Hydraulic Hydraulic Hydraulic Hydraulic Hydraulic Hydraulic Electronic Electronic Electronic Hydraulic Hydraulic Hydraulic Electronic Electronic Electronic Hydraulic Electronic Electronic Electronic H 4H V4H L V4L D SPEAR15-8 SPEAR15-12 SPEAR15-12 E 4E V4E SPEAR27-8 SPEAR27-12 SPEAR27-12 DV SPEAR38-8 SPEAR38-12 SPEAR38-12 100 200 400 560 560** 560 560 560** 600 630** 800 800 800 630** 630** 1200 400 560 560** 560 560** 560 630** 630** 630** 400 560 560** 560 560** 560** 560** 630** 630** 630** 2000* 2000* 8000 10000* 10000* 12000 12000 12000 12000 12500† 12000 16000 20000 12500† 12500† 20000 8000 8000 8000 12000 12000 12000 12500† 12500† 12500† 8000 8000 8000 12000 12000 12000 16000 12500 12500 12500 Oil Oil Vacuum Oil Oil Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Oil Oil Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Oil Oil Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Vacuum Hydraulic Hydraulic Electronic Hydraulic Electronic Hydraulic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Hydraulic Electronic Hydraulic Electronic Electronic Electronic Electronic Electronic Electronic Hydraulic Electronic Hydraulic Electronic Electronic Electronic Electronic Electronic Electronic 6H V6H NOVA-TS-15-8 W WE VW PWE*** VWE VSA12B NOVA™ 15 VSA12 VSA16 VSA20 NOVA-TS-15-12 NOVA STS-15 VSA20A NOVA-TS-27-8 WV27 WVE27 VWV27 VWVE27 PWVE*** NOVA 27 NOVA-TS-27-12 NOVA STS-27 NOVA-TS-38-8 WV38X WVE38X VWV38X VWVE38X VSO12 VSO16 NOVA 38 NOVA-TS-38-12 NOVA STS-38 Three-Phase 2.4 - 14.4 24.9 34.5 * Interrupting rating will be higher at lower voltage as shown in expanded tables. ** Continuous current rating can be extended to 800 A with an accessory. *** For pad-mounted installation. † 16.0 kA option is also available. www.cooperpower.com 280-05-3 Technical Data 280-05 Effective August 2013 General ratings and catalog guide for single-and three-phase reclosers Figure 4. NOVA™ STS single-tank, triple-single electronically controlled recloser Single-phase tripping The triple-single reclosers, shown in Figures 3 and 4, have three modes of operation: • • • Three-phase trip and three-phase lockout. All three phases simultaneously trip on an overcurrent, reclose and sequence together. Single-phase trip and three-phase lockout. Each phase operates independently for overcurrent tripping and reclosing. If any phase sequences to lockout condition (due to permanent fault), or if “lockout” is locally or remotely asserted, the other two phases trip open and lock out. Thus, extended single-phase energization of three-phase loads is prevented. Single-phase trip and single-phase lockout. Each individual phase trips and sequences to lockout independent of each other. This is primarily for residential loads and/or where single-phasing of three-phase loads is protected by other means. Another configurable option is also available to trip and lockout all three phases in the event of a phase-to-phase or three-phase fault. Should a phase-to-phase or three-phase fault be detected on the system, all three reclosers will trip and lockout whenever any one phase sequences to lockout. Three-phase lockout occurs if a multiple phase fault is present as the recloser advances to lockout. Three-phase tripping There are various types of three-phase tripping reclosers available to improve system reliability. The recloser selection is based upon electrical ratings required, interrupting and insulation medium, and the selection of hydraulic or electronic control. • Three-phase trip and three-phase lockout. Larger reclosers such as the units shown in Figures 5 and 6, use this mode. For any fault—single-phase-to-ground, phase-to-phase, or three-phase—all contacts open simultaneously for each trip operation. The three phases, mechanically linked together for tripping and reclosing, are operated by a common mechanism. Controls: hydraulic or electronic The intelligence that enables a recloser to sense overcurrents, select timing operation, time the tripping and reclosing functions, and finally lockout is provided by its control. There are two basic types of control schemes used: an integral hydraulic control or an electronic control located in a separate cabinet. Hydraulic controls Hydraulic recloser control is used in most single-phase reclosers and in three-phase recloser types 6H, V6H, W, VW, WV27, VWV27, WV38X, and VWV38X. It is built as an integral part of the recloser. With this type of control, an overcurrent is sensed by a trip coil 280-05-4 www.cooperpower.com Figure 5. NOVA™ three-phase, electronically controlled recloser. Figure 6. Type VSA20A vacuum, three-phase, air-insulated, electronically controlled recloser. that is connected in series with the line. When the overcurrent flows through the coil, a plunger is drawn into the coil to trip open the recloser contacts. Timing and sequencing are accomplished by pumping oil through separate hydraulic chambers or ducts. For smaller reclosers, the reclosing energy is provided by springs that are charged by the series trip-coil plunger during overcurrent operation. Larger reclosers are closed from a separate closing solenoid that is energized by line potential from the source side of the recloser. Electronic controls Eaton’s Cooper Power Systems electronic recloser controls are used in most three-phase reclosers and in the single-phase SPEAR recloser control. Compared with the hydraulic control, they are more flexible, more easily customized and programmed, and many have advanced protection, metering, and automation functionality. The electronic control is housed in a cabinet separate from the recloser and conveniently permits changes to operational settings. A wide range of accessories is available to customize the basic operation, solving many application problems. Current sensing Line current is sensed by special sensing current transformers in the recloser. The recloser and control are connected by a multi-conductor control cable that carries sensing transformer secondary currents to the control and the necessary trip and close signals from the control to the recloser. Microprocessor-based controls Eaton’s Cooper Power Systems offers numerous electronic controls that can be used in conjunction with its broad line of electronically controlled reclosers. The Form 6 control, see Figures 7 and 8, provides maximum protective hardware design and simple interactive graphical interfaces for complete user customization. All standard control operating parameters, including minimum trip levels, time-current curve selection, and sequences of recloser operation, are keyboard programmable. This control utilizes a powerful PC-based interface software to configure control settings, record metering information, and establish communication parameters. It also provides analysis tools that include fault locating, event recording, and oscillography functions. General ratings information and catalog guide for single-and three-phase reclosers Technical Data 280-05 Effective August 2013 Figure 7. Form 6-TS pole-mount recloser control (left). Form 6 pole-mount recloser control (right). Figure 10. Eaton’s Cooper Power Systems vacuum interrupter. Vacuum interrupters Vacuum interrupters provide fast, low-energy arc interruption with long contact and interrupter life, low mechanical stress, and maximum operating safety. With arc interruption taking place in a vacuum, contact and interrupter life far exceeds other interrupting media. Figure 8. Form 6 rack-mount recloser control. Eaton’s Cooper Power Systems vacuum interrupters (Figure 10) are designed with a metal and ceramic housing for maximum strength and long-term vacuum integrity. The high-alumina ceramic has more than five times the strength of glass, which permits a higher processing temperature to develop maximum purity of the assembly, and is impervious even to helium penetration to sustain the vacuum level. With over 40 years of experience, Eaton’s Cooper Power Systems is a world leader in the design and manufacture of vacuum interrupters for use in distribution switchgear. A state-of-the-art vacuum interrupter clean room manufacturing facility ensures the production of very high quality interrupters that provide long and trouble-free operating life. Depending on type, a vacuum recloser may use either oil, air, or epoxy as the insulating medium. Recloser application Figure 9. SPEAR recloser control. For more information on the Form 6 control, refer to Bulletin B28008010 and for the SPEAR recloser control, refer to Bulletin B28013004. Interrupting medium: oil or vacuum Reclosers use either oil or vacuum as the interrupting medium. Oil interrupters Reclosers using oil for current interruption use the same oil for basic insulation. Most reclosers with hydraulic control (except the W-group reclosers) also use the same oil for timing and counting functions. Reclosers can be used anywhere on a distribution system where recloser ratings are adequate for system requirements. Locations for reclosers are: • In substations as the primary feeder protective device. • On distribution lines at a distance from a substation, to sectionalize long feeders and thus prevent outages of the entire feeder when a permanent fault occurs near the end of the feeder. • On important taps of main feeders to protect the main feeder from interruptions and outages due to faults on the taps. Application criteria To properly apply automatic circuit reclosers, five major factors must be considered: 1. System voltage. System voltage will be known. The recloser must have a voltage rating equal to—or greater than—system voltage. www.cooperpower.com 280-05-5 Technical Data 280-05 General ratings and catalog guide for single-and three-phase reclosers Effective August 2013 2. Maximum fault current available at the recloser location. Maximum fault current will be known or can be calculated. The recloser interrupting must be equal to—or greater than—the maximum available fault current at the recloser location. farther down the line is selected to coordinate with it as shown in Figure 11. 3. Maximum load current. The recloser continuous current rating must be equal to—or greater than—anticipated circuit load. For series-coil-type reclosers, the coil size can be selected to match the present load current, the anticipated future load current, or the substation transformer capacity. Minimum-trip current is nominally twice the coil continuous-current rating. Automatic circuit reclosers have dual-timing capabilities; that is, the first fault-current interruptions (one or more) are performed in accordance with a fast or instantaneous timing characteristic (no intentional time delay) and the remaining interruptions are performed in accordance with a predetermined time delay. Dual timing The first operations are as fast as possible in order to clear temporary faults before any line damage can occur. If the fault is permanent, the time-delay operation allows the down-line device— either another recloser or a fuse—to clear first. 4. For electronically controlled reclosers, minimum-trip current must be greater than any anticipated peak load. Generally, a trip-current value of at least twice the expected load current is used. 5. Minimum-fault current within the zone to be protected. Minimum fault current that might occur at the end of the line section must be checked to confirm that the recloser will sense and interrupt this current. Recloser-to-recloser coordination is achieved primarily by selecting different coil sizes or trip values with further coordination possible by different time delays or sequences. To coordinate a recloser with a downline fuse, the fuse link size should be selected to coordinate with the recloser fast and time-delay curves. 6. Coordination with other protective devices on both the source and the load sides of the recloser. Figure 12 shows a typical recloser operating sequence-to-lockout for a permanent fault. Coordination with other devices A recloser operating on its fast curve should clear a temporary fault before the fuse link can be damaged. When on its time-delay curve, a recloser operation should be more delayed than the fuse-link clearing time, allowing the fuse to clear permanent faults without tripping the recloser. After the first four application factors have been satisfied, coordination of the recloser with both the source- and the load-side devices must be determined. Proper selection of time delays and sequences is vital to assure that any momentary interruption or longer-term outage due to faults is restricted to the smallest possible section of the system. Generally, recloser timing and sequences are selected to coordinate with the source-side devices. After the size and sequence of the required recloser has been determined, the protective equipment SUBSTATION 3Ø A HIGH-SIDE FUSE THREE-PHASE LINES 3Ø 3Ø A 1Ø C B C D 3Ø 1Ø D D 1Ø Figure 11. Typical line diagram of distribution circuit showing application of reclosers. 280-05-6 www.cooperpower.com 1Ø D 3Ø TRANSFORMER 69 - 14.4 KV RECLOSERS: A. 3Ø RECLOSER PROTECTING FEEDER LEAVING SUBSTATION.* B. 3Ø LINE RECLOSER FOR SECTIONALIZING LONG LINE.* C. 3Ø RECLOSER FOR TAP WITH LARGER LOAD.* D. 1Ø RECLOSER FOR SMALLER 1Ø TAP. *1Ø reclosers may be substituted if system considerations permit 1Ø lockout. SINGLE-PHASE LINES 3Ø Technical Data 280-05 General ratings information and catalog guide for single-and three-phase reclosers FAULT CURRENT FAST OPERATIONS (CONTACTS CLOSED) Effective August 2013 TIME-DELAY OPERATIONS (CONTACTS CLOSED) LOAD CURRENT (CONTACTS CLOSED) RECLOSER LOCKOUT (CONTACTS OPEN) FAULT INITIATED RECLOSING INTERVALS (CONTACTS OPEN) TIME Figure 12. Recloser operating sequence when a permanent fault occurs. Table 2. Single-Phase, Hydraulically Controlled Reclosers Recloser Type Nominal Voltage (kV) BIL (kV) Max. Cont. Current Rating (A) Interrupting Medium For Detailed Description and Ordering Information See Catalog Section Trip-Coil Rating (cont. A) Min. Trip Rating (A) Interrupting Rating (rms sym A) 5 10 125 10 20 250 15 30 375 25 50 625 35 70 875 50 100 1250 4.8 kV 8.32 kV 14.4 kV 5 10 200 200 200 2.4 kV thru 14.4 kV H 4H V4H 24.4-14.4 2.4-14.4 2.4-14.4 95 110 110 50 100 200 Oil Oil Vacuum 10 20 400 400 400 15 30 600 600 600 25 50 1000 1000 1000 35 70 1400 1400 1400 50 100 2000 2000 2000 70 140 2800 2500 2000 100 200 3000 2500 2000 5 10 200 200 200 10 20 400 400 400 15 30 600 600 600 25 50 1000 1000 1000 35 70 1400 1400 1400 50 100 2000 2000 2000 70 140 2800 2500 2000 100 200 3000 2500 2000 140 280 3000 2500 2000 200 400 3000 2500 2000 Recloser Mountings 280-10 280-10 280-10 280-10 280-10 280-10 * Trip rating is 140% of X coil ratings, all others are 200%. www.cooperpower.com 280-05-7 Technical Data 280-05 General ratings and catalog guide for single-and three-phase reclosers Effective August 2013 Table 2. Single-Phase, Hydraulically Controlled Reclosers (continued) Recloser Type L V4L D Nominal Voltage (kV) 2.4 - 14.4 2.4 - 14.4 2.4 -14.4 BIL (kV) 110 110 110 Max. Cont. Current Rating (A) 280 280 560 Interrupting Medium Oil 50 70 100 140 200 280 400 560 Vacuum 25 35 50 70 100 140 170 200 280 50 70 100 140 200 280 340 400 560 Oil 70X 100 100X 140 140X 160 185 225 280 280X 400 400X 560 560X 100* 200 140* 280 200* 320 370 450 560 400* 800 560* 1120 750* 5 10 15 25 35 50 70 100 50 70 100 140 170 200 280 10 20 30 50 70 100 140 200 100 140 200 280 340 400 560 24.9 150 100 Oil 4E 24.9 150 280 Oil 280-05-8 www.cooperpower.com Min. Trip Rating (A) 25 35 50 70 100 140 200 280 E * Trip rating is 140% of X coil ratings, all others are 200%. Trip-Coil Rating (cont. A) For Detailed Description and Ordering Information See Catalog Section Interrupting Rating (rms sym A) 4.8 kV 8.32 kV 1500 1500 2100 2100 3000 3000 4200 4200 6000 5000 6000 5000 6000 5000 6000 5000 2.4 thru 14.4 kV 1500 2100 3000 4200 6000 6000 6000 6000 6000 4.8 kV 8.32 kV 3000 3000 6000 6000 4200 4200 8400 8400 6000 6000 9600 9600 11100 10000 12000 10000 12000 10000 12000 10000 12000 10000 12000 10000 12000 10000 12000 10000 24.9 kV 300 600 900 1500 2100 2500 2500 2500 3000 4000 4000 4000 4000 4000 4000 Recloser 14.4 kV 1500 2100 3000 4000 4000 4000 4000 4000 14.4 kV 3000 6000 4200 8400 6000 9600 10000 10000 10000 10000 10000 10000 10000 10000 Mountings 280-10 280-10 280-10 and Bulletin 89007 280-10 280-20 280-20 280-10 280-10 280-10 280-10 Technical Data 280-05 General ratings information and catalog guide for single-and three-phase reclosers Effective August 2013 Table 2. Single-Phase, Hydraulically Controlled Reclosers (continued) Recloser Type V4E DV Nominal Voltage (kV) 24.9 Max. Cont. Current Rating (A) BIL (kV) 150 24.9-34.5 280 150 560 Interrupting Medium Trip-Coil Rating (cont. A) Min. Trip Rating (A) Vacuum 15 25 35 50 70 100 140 170 200 280 30 50 70 100 1410 200 280 340 400 560 Oil 70X 100 100X 140 140X 160 185 225 280 280X 400 400X 560 560X 100* 200 140* 280 200* 320 370 450 560 400* 800 560* 1120 750* For Detailed Description and Ordering Information See Catalog Section Interrupting Rating (rms sym A) Recloser 24.9 kV 900 1500 2100 3000 4200 6000 6000 6000 6000 6000 24.9 thru 34.5 kV 3000 6000 4200 8000 6000 8000 8000 8000 8000 8000 8000 8000 8000 8000 Mountings 280-10 and Bulletin 91036 280-10 280-10 280-10 * Trip rating is 140% of X coil ratings, all others are 200%. Table 3. Single-Phase, Electronically Controlled Reclosers Recloser Type Nominal Voltage (kV) BIL (kV) Max. Cont. Current Rating (A) For Detailed Description and Ordering Information See Catalog Section Interrupting Medium SPEAR15-8 SPEAR15-12 SPEAR15-12 2.44-14.4 110* 400 630 800 Vacuum SPEAR27-8 SPEAR27-12 SPEAR27-12 24.9 125** 400 630 800 Vacuum SPEAR38-8 SPEAR38-12 SPEAR38-12 34.5 170 400 630 800 Vacuum Interrupting Rating (rms sym A) 2.4 thru 14.4 kV 8000 12500 12500 24.9 kV 8000 12500 12500 34.5 kV 8000 12500 12500 Recloser Electronic Control Mountings 280-101 280-101 S280-101-1 280-101 280-101 S280-101-1 280-101 280-101 S280-101-1 * 125 kV BIL accessory option available ** 150 kV BIL accessory option available www.cooperpower.com 280-05-9 Technical Data 280-05 General ratings and catalog guide for single-and three-phase reclosers Effective August 2013 Table 4. Three-Phase, Hydraulically Controlled Reclosers Recloser Type Nominal Voltage (kV) BIL (kV) Max. Cont. Current Rating (A) Interrupting Medium 6H* 2.4-14.4 110 100 Oil V6H* 2.4-14.4 110 200 Vacuum W 2.4-14.4 110 560 Oil Trip-Coil Rating (cont. A) 5 10 15 25 35 50 70 100 5 10 15 25 35 50 70 100 140 200 5 10 15 25 35 50 70 70X 100 100X 140 140X 160 160X 185 185X 200 225 225X 280 280X 400 400X 560 560X * Phases trip individually on overcurrent, but trip and lock out all three phases at the final step in sequence. Other reclosers operate all three phases simultaneously under all conditions. ** Trip rating is 140% of X coil ratings, all others are 200%. 280-05-10 www.cooperpower.com Min. Trip Rating (A) Interrupting Rating (rms sym A) 10 20 30 50 70 100 140 200 10 20 30 50 70 100 140 200 280 400 10 20 30 50 70 100 140 100** 200 140** 280 200** 320 225** 370 260** 400 450 315** 560 400** 800 560** 1120 750** 4.8 kV 200 400 600 1000 1400 2000 2800 3000 200 400 600 1000 1400 2000 2800 3000 3000 3000 300 600 900 1500 2100 3000 4200 3000 6000 4200 8400 6000 9600 6750 11100 7800 12000 12000 9450 12000 12000 12000 12000 12000 12000 8.32 kV 200 400 600 1000 1400 2000 2500 2500 200 400 600 1000 1400 2000 2500 2500 2500 2500 300 600 900 1500 2100 3000 4200 3000 6000 4200 8400 6000 9600 6750 10000 7800 10000 10000 9450 10000 10000 10000 10000 10000 10000 For Detailed Description and Ordering Information See Catalog Section Recloser 14.4 kV 200 400 600 1000 1400 2000 2000 2000 200 400 600 1000 1400 2000 2000 2000 2000 2000 300 600 900 1500 2100 3000 4200 3000 6000 4200 8400 6000 9600 6750 10000 7800 10000 10000 9450 10000 10000 10000 10000 10000 10000 Mountings 280-10 S280-85-1 280-10 S280-85-11 280-30 S280-85-1 S280-85-2 Technical Data 280-05 General ratings information and catalog guide for single-and three-phase reclosers Effective August 2013 Table 4. Three-Phase, Hydraulically Controlled Reclosers (continued) Recloser Type VW VW27 Nominal Voltage (kV) 2.4-14.4 24.9 BIL (kV) 110 150 Max. Cont. Current Rating (A) 560 560 Interrupting Medium Trip-Coil Rating (cont. A) Min. Trip Rating (A) Vacuum 5 10 15 25 35 50 70 70X 100 100X 140 140X 160 160X 185 185X 200 225 225X 280 280X 400 400X 560 560X 10 20 30 50 70 100 140 100** 200 140** 280 200** 320 225** 370 260** 400 450 315** 560 400** 800 560** 1120 750** Oil 5 10 15 25 35 50 70 70X 100 100X 140 140X 160 160X 185 185X 225 225X 280 280X 400 400X 560 560X 10 20 30 50 70 100 140 100** 200 140** 280 200** 320 225** 370 260** 450 315** 560 400** 800 560** 1120 750** Interrupting Rating (rms sym A) 14.4 kV 300 600 900 1500 2100 3000 4200 3000 6000 4200 8400 6000 9600 6750 11100 7800 12000 12000 9450 12000 12000 12000 12000 12000 12000 24.9 kV 300 600 900 1500 2100 3000 4200 3000 6000 4200 8000 6000 8000 6750 8000 7800 8000 8000 8000 8000 8000 8000 8000 8000 For Detailed Description and Ordering Information See Catalog Section Recloser Mountings 280-30 S280-85-1 S280-85-2 280-30 S280-85-1 S280-85-2 * Phases trip individually on overcurrent, but trip and lock out all three phases at the final step in sequence. Other reclosers operate all three phases simultaneously under all conditions. ** Trip rating is 140% of X coil ratings, all others are 200%. www.cooperpower.com 280-05-11 Technical Data 280-05 General ratings and catalog guide for single-and three-phase reclosers Effective August 2013 Table 4. Three-Phase, Hydraulically Controlled Reclosers (continued) Recloser Type Nominal Voltage (kV) BIL (kV) Max. Cont. Current Rating (A) Interrupting Medium Trip-Coil Rating (cont. A) Min. Trip Rating (A) Interrupting Rating (rms sym A) For Detailed Description and Ordering Information See Catalog Section Recloser Mountings 24.9 kV VWV27 VWV38X 24.9 34.5 125 150 560 560 Vacuum 5 10 15 25 35 50 70 70X 100 100X 140 140X 160 160X 185 185X 200 225 225X 280 280X 400 400X 560 560X 10 20 30 50 70 100 140 100** 200 140** 280 200** 320 225** 370 260** 400 450 315** 560 400** 800 560** 1120 750** Vacuum 5 10 15 25 35 50 70 70X 100 100X 140 140X 160 160X 185 185X 200 225 225X 280 280X 400 400X 560 560X 10 20 30 50 70 100 140 100** 200 140** 280 200** 320 225** 370 260** 400 450 315** 560 400** 800 560** 1120 750** * Phases trip individually on overcurrent, but trip and lock out all three phases at the final step in sequence. Other reclosers operate all three phases simultaneously under all conditions. ** Trip rating is 140% of X coil ratings, all others are 200%. 280-05-12 www.cooperpower.com 300 600 900 1500 2100 3000 4200 3000 6000 4200 8400 6000 9600 6750 11100 7800 12000 12000 9450 12000 12000 12000 12000 12000 12000 34.5 kV 300 600 900 1500 2100 3000 4200 3000 6000 4200 8400 6000 9600 6750 11100 7800 12000 12000 9450 12000 12000 12000 12000 12000 12000 280-30 S280-85-1 S280-85-2 280-30 S280-85-1 S280-85-2 Technical Data 280-05 General ratings information and catalog guide for single-and three-phase reclosers Effective August 2013 Table 4. Three-Phase, Hydraulically Controlled Reclosers (continued) Recloser Type VWV38X Nominal Voltage (kV) 34.5 BIL (kV) 170 Max. Cont. Current Rating (A) 560 Interrupting Medium Oil Trip-Coil Rating (cont. A) 5 10 15 25 35 50 70 70X 100 100X 140 140X 160 160X 185 185X 225 225X 280 280X 400 400X 560 560X Min. Trip Rating (A) Interrupting Rating (rms sym A) 10 20 30 50 70 100 140 100** 200 140** 280 200** 320 225** 370 260** 450 315** 560 400** 800 560** 1120 750** 34.5 kV 300 600 900 1500 2100 3000 4200 3000 6000 4200 8400 6000 8000 6750 8000 7800 8000 8000 8000 8000 8000 8000 8000 8000 For Detailed Description and Ordering Information See Catalog Section Recloser 280-30 Mountings S280-85-1 S280-85-2 * Phases trip individually on overcurrent, but trip and lock out all three phases at the final step in sequence. Other reclosers operate all three phases simultaneously under all conditions. ** Trip rating is 140% of X coil ratings, all others are 200%. www.cooperpower.com 280-05-13 Technical Data 280-05 General ratings and catalog guide for single-and three-phase reclosers Effective August 2013 Table 5. Three-Phase, Electronically Controlled Reclosers Recloser Type WE Nominal Voltage (kV) 2.4 - 14.4 BIL (kV) 110 Max. Cont. Current Rating (A) 560** For Detailed Description and Ordering Information See Catalog Section Interrupting Medium Oil Interrupting Rating (rms sym A) 4.8 kV 8.32 kV 14.4 kV 12000 10000 10000 Reclosers Electronic Control Mountings 280-40 Bulletin B280-08010 S280-85-1 S280-85-2 Bulletin B280-08010 Bulletin B280-08010 Bulletin B280-08010 Bulletin B280-08010 Bulletin B280-08010 Bulletin B280-08010 Bulletin B280-08010 Bulletin B280-08012 Bulletin B280-08010 Bulletin B280-08012 Bulletin B280-08012 Not Applicable S280-85-1 S280-85-2 2.4 thru 14.4 kV PWE* 2.4 - 14.4 95 560 Vacuum 12000 285-71 VWE 2.4 - 14.4 110 560** Vacuum 12000 280-40 VSA12B 2.4 - 14.4 110 600 Vacuum 12000 280-45 VSA12 2.4 - 14.4 110 800 Vacuum 12000 280-45 VSA16 2.4 - 14.4 110 800 Vacuum 16000 280-45 VSA20 2.4 - 14.4 110 800 Vacuum 20000 280-45 VSA20A 2.4 - 14.4 110 1200 Vacuum 20000 280-45 NOVA-TS-15-8 2.4 - 14.4 110 400 Vacuum 8000 S280-42-2 NOVA15 2.4 - 14.4 110 630** Vacuum 12500*** 280-42 NOVA-TS-15-12 2.4 - 14.4 110 630** Vacuum 12500*** S280-42-2 NOVA STS-15 2.4 - 14.4 110 630** Vacuum 12500*** S280-44-1 280-45 280-45 280-45 280-45 280-45 S280-42-2 S280-85-16 S280-85-17 S280-42-2 S280-44-1 24.9 kV NOVA-TS-27-8 24.9 125 400 Vacuum 8000 S280-42-2 NOVA 27 24.9 125 630** Vacuum 12500*** 280-42 PWVE* 24.9 125 560 Vacuum 12000 285-71 WVE27 24.9 150 560** Oil 8000 280-40 VWVE27 24.9 125 560** Vacuum 12000 280-40 NOVA-TS-27-12 24.9 125 630** Vacuum 12500*** S280-42-2 NOVA STS-27 24.9 125 630** Vacuum 12500*** S280-44-1 Bulletin B28008012 Bulletin B28008010 Bulletin B28008010 Bulletin B28008010 Bulletin B28008010 Bulletin B28008012 Bulletin B28008012 S280-42-2 Bulletin B28008012 Bulletin B28008010 Bulletin B28008010 Bulletin B28008010 Bulletin B28008010 Bulletin B28008010 Bulletin B28008012 Bulletin B28008012 S280-42-2 S280-85-16 S280-85-17 Not Applicable S280-85-1 S280-85-2 S280-85-1 S280-85-2 S280-42-2 S280-44-1 34.5 kV NOVA-TS-38-8 34.5 170 400 Vacuum 8000 S280-42-2 WVE38X 34.5 170 560** Oil 8000 280-40 VWVE38X 34.5 150 560** Vacuum 12000 280-40 VSO12 34.5 150 560** Vacuum 12000 280-57 VSO16 34.5 150 560** Vacuum 16000 280-57 NOVA38 34.5 170 630** Vacuum 12500 280-42 NOVA-TS-38-12 34.5 170 630** Vacuum 12500 S280-42-2 NOVA STS-38 34.5 170 630** Vacuum 12500 S280-44-1 * For pad-mounted installation. ** Continuous current rating can be extended to 800 A with an accessory. *** 16.0 kA option is also available. 280-05-14 www.cooperpower.com S280-85-1 S280-85-2 S280-85-1 S280-85-2 280-57 280-57 S280-85-16 S280-85-17 S280-42-2 S280-44-1 General ratings information and catalog guide for single-and three-phase reclosers Technical Data 280-05 Effective August 2013 www.cooperpower.com 280-05-15 Technical Data 280-05 General ratings information and catalog guide for singleand three-phase reclosers Effective August 2013 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2013 Eaton All Rights Reserved Printed in USA Publication No. 280-05 August 2013 280-05-16 Eaton, Cooper Power Systems, SPEAR, and NOVA are trademarks of Eaton in the U.S. and other countries. You are not permitted to use these trademarks without the prior written consent of Eaton. Effective May 2014 Supersedes June 1999 Technical Data 280-10 Types E, 4E, V4E, H, 4H, V4H, L, V4L, single-phase and 6H, V6H threephase reclosers Description Types E, 4E, V4E, H, 4H, V4H, L, and V4L singlephase reclosers and Types 6H and V6H threephase reclosers provide reliable, self-contained distribution-circuit overcurrent protection at low initial cost, and require minimal service. Because most line faults are temporary in nature, they will clear after only momentary circuit interruption; therefore, permanent outages usually are prevented. Automatic circuit reclosers both improve customer service and reduce operating costs. A summary of all available reclosers – ratings, basic characteristics, and applications – is included in Catalog 280-05, General Ratings Information and Catalog Guide for Single-Phase and Three-Phase Reclosers. Basic ratings and characteristic features Type L Reclosers in the E, H, and L groups include most of the single-phase reclosers produced by Eaton's Cooper Power Systems. The three-phase reclosers – Types 6H and V6H – are included in here because they adapt three single-phase interrupting structures with a common lockout mechanism. In operation, these reclosers sense line current in each phase individually and trip individually; however, if one phase sequences to lockout, all phases lock out. Reclosers can be installed on poles or in substations to protect lines requiring the ratings shown in Table 1. Type 6H Both single-phase and three-phase reclosers are hydraulically controlled. Tripping is initiated by a series-connected coil. Current-carrying and interrupting capacities vary with the operating coil’s rating, which is selected to meet circuit requirements. A choice of dual time-current characteristics permits coordination with other protective devices. A non-reclosing feature (Figure 1), standard on all Eaton's Cooper Power Systems reclosers, is set with a hookstick-operated lever for one operation to lockout without removing the recloser from service. Two types of interrupters are available: 1. In Types E, 4E, 4H, L, and 6H reclosers, current interruption takes place in oil. 2. Types V4H, V4L, V4E, and V6H reclosers are equipped with vacuum interrupters. A major advantage of vacuum interrupters is reduced maintenance frequency. 280-10-1 Technical Data 280-10 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Effective May 2014 Application Both single- and three-phase H-group and L-group reclosers are designed, tested, and rated for operation on 14.4 kV three-phase systems where the line-to-ground voltage is 8.32 kV. Bushing insulation strength and other line-to-ground insulation is designed for this 8.32 kV stress. The standard recloser (110 kV BIL) is not suitable for operation on single-phase taps of 14.4/24.9 kV systems. Operation on these higher voltage systems will stress the insulation at the 14.4 kV level, resulting in excessive radio influence voltage and deterioration of the insulation. Types E, 4E, and V4E reclosers can be used for operation on singlephase taps of a 20/34.5 kV system where the 150 kV BIL rating is satisfactory. The bushings and other line-to-ground insulation are adequate for the 20 kV line-to-ground voltage stress. Since the interrupting capability is 24.9 kV, application on this system is limited to single-phase taps only. Operation on the three-phase line can result in a single recloser attempting to interrupt the full 34.5 kV voltage, which is in excess of its rating. Surge protection Reclosers operate best when protected with surge arresters. On line applications, arrester protection is recommended on both sides of the recloser. If protection is to be provided on one side only, install the arrester on the source side. In substations, arresters are located on the load-side. Eaton's Cooper Power Systems distributionclass arresters provide excellent protection; see Catalog 235-99, UltraSIL™ Polymer-Housed Evolution™ Surge Arrester or Catalog 235-35, UltraSIL Polymer-Housed VariSTAR™ Surge Arrester for more information. Ordering information To order an E-, H-, or L-group recloser: Figure 1. The non-reclosing feature is set with a handle under the sleet hood (see arrow). When the handle Is down (top), the recloser will trip on overcurrent and lock out without reclosing. When the handle is up (bottom), the recloser will operate according to its internally set program. Constructing a catalog number 1. Use the chart below to construct a cata!og number that describes the required recloser. 2. From Tables 2 through 13, specify the catalog number that describe the required recloser accessories and mounting equipment. To order a basic Type 4H recloser with a l00-amp coil, time-current Curve B, and two fast and two retarded operations to lockout, the catalog number would be constructed as shown on following page. Table 1. Basic Ratings Nominal Voltage (kV) Max Continuous Current (amps) @ 2.4—4.8 kV @ 4.8—8.32 kV @ 8.32—14.4 kV @ 24.9 kV H 2.4—14.4 50 1250 1250 1250 — 4H 2.4—14.4 100 3000 2500 2000 — V4H 2.4—14.4 200 3000 2500 2000 — L 2.4—14.4 280 6000 5000 4000 — V4L 2.4—14.4 280 6000 6000 6000 — E 24.9 100 — — — 2500 4E 24.9 280 — — — 4000 V4E 24.9 280 — — — 6000 6H 2.4—14.4 100 3000 2500 2000 — V6H 2.4—14.4 200 3000 2500 2000 — Type Single-Phase Max Interrupting Current (symmetrical amps) Three-Phase 280-10-2 www.cooperpower.com Technical Data 280-10 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Effective May 2014 KH Basic letters for H-group reclosers; Accessories E-group reclosers: KE L-group reclosers: KL E-, H-, and L-group reclosers can be supplemented with factory- or fieldinstalled accessories. Select the accessories and mounting equipment required from Tables 2 through 13. 4 Recloser type: Omit for Types E or L; 1 for Type H; 4 for Type 4H or 4E; V4 for Type V4H, V4E, or V4L; 6 for Type 6H; V6 for Type V6H. 1. Shunt lockout mechanism (Types E, 6H, and V6H only) enables remote electrical trip and lockout. 2. Lockout-indicating switch (all types) provides remote indication of recloser lockout. 100 Continuous current rating of series-trip coil: Type E : 5, 10, 15, 25, 35, 50,70, or l00 amps; Type 4E: 50, 70, 100, 140, 200, or 280 amps; Type V4E : 15, 25, 35, 50, 70, 100, 140, 200, or 280 amps; Type H : 5, 10, 15, 25, 35, or 50 amps; Type 4H : 5, 10, 15, 25, 35, 50, 70,100,140, or 200 amps; Type 6H : 5, 10, 15, 25, 35, 50, 70, or 100 amps; Type V6H: 5, 10, 15, 25, 35, 50, 70, 100, 140, or 200 amps; Type L : 25, 35, 50, 70, 100, 140, 200, or 280 amps; B 3. Bushings with 17-in. creepage distance (all H-group and L-group) increase creepage distance from standard bushing distances of 10-3/8 in. for H; 10-7/8 in. for 4H, V4H, 6H, V6H; 11-3/4 in. for L and V4L. 4. Bushings with 26-1/2-in. creepage distances (Types E, 4E, and V4E) increase creepage distance from standard bushing distances of 13-5/8 in. for E and 17 in. for 4E and V4E. Delayed time-current curve: Types H, 4H, V4H, 6H, or V6H: B or C; Types E, 4E, V4E, or L: B, C, or D. If all fast operations are required, insert letter A. 2 Number of fast A-curve operations: 0, 1, 2, 3, or 4. 2 Number of delayed operations: 0, 1, 2, 3, or 4. KH 4 100 B 2 2 } Fast + delayed operations not to exceed 4. 5. Slip-on, multi-ratio bushing-current transformer kit for field installation (all types) is easily installed at low cost and is convenient for metering. Taps are available for 100, 150, 200, 250, 300, and 450:5 amp ratio; 5% accuracy. KH4100B22 is the catalog number for the required Basic Type 4H recloser. Accessories Types E, 4E, V4E, L, and V4L (Single-Phase) Reclosers Table 2. Shunt Lockout and Lockout Indication; Factory Installed Description Type E Type 4E Type V4E Type L Type V4L Shunt-lockout mechanism* KA193E — KA193E — KA193E Lockout-indicating switch.. KA194E** KA86L2 KA86L2 KA86L1 KA86L2 Description Type E Type 4E Type V4E Type L Type V4L 17-in.-creepage bushings.. — — — KA126L KA121V4L 261¼2-in.-creepage bushings KA188E KA149E4-1 KA149E4-1 — — Description Type E Type 4E Type V4E Type L Type V4L Two-bolt flat pad connectors; set of two — — — — KA146L1 * Specify operating voltage: 120 or 240 Vac ** Includes shunt-lockout mechanism. Table 3. Bushings; Factory-Installed Table 4. Hardware; Factory-Installed Table 5. Bushing Current Transformer for Field Installation Description Type E Type 4E Type V4E Type L Type V4L Slip-on bushing current transformer kit; one BCT per kit.. KA712L1 KA712L1 KA712L1 KA712L1 KA712L1 Description Type E Type 4E Type V4E Type L Type V4L Crossarm mounting hanger; two required for each recloser KA39H KA39H KA39H KA39H KA39H Table 6. Mounting Equipment www.cooperpower.com 280-10-3 Technical Data 280-10 Effective May 2014 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Accessories Types H, 4H, and V4H (Single-Phase) Reclosers Table 7. Lockout Indication; Factory-Installed Description Type H Type 4H Type V4H Lockout-indicating switch KA161H KA161H KA161H Description Type H Type 4H Type V4H 17-in.-creepage bushing KA193H KA60H4 KA51V4H Description Type H Type 4H Type V4H Crossarm mounting hanger KA39H* KA39H** KA39H** Description Type 6H Type V6H Lockout-indicating switch KA96H3-2 KA96H3-2 Shunt-lockout mechanism* KA1HS6 KA1HS6 Ground-fault lockout** KA123H3-2 KA123H3-2 Description Type 6H Type V6H 17-in.-creepage bushings KA31H6 KA51V6H Description Type 6H Type V6H Slip-on bushing current transformer kit; one BCT per kit KA712L1 KA712L1 Description Type 6H Type V6H Double crossarm bracket or substation hanger KA19H3 KA19H3 Substation mounting frame KA46H6 KA46H6 In-line broadside pole-mounting hanger KA116H3 KA116H3 Surge arrester mounting bracket KA126H3 KA126H3 Tank-lifting windlass for substation mounting frame KA584R2 KA584R2 Table 8. Bushings; Factory-Installed Table 9. Mounting Equipment * One required. ** Two required. Type 6H, V6H (Three-Phase) Reclosers Table 10. Lockout and Lockout Indication; Factory-Installed * Specify operating voltage 120 or 240 Vac; 12, 18, 20, 24, 36, 48, or 125 Vdc. ** Specify minimum-trlp current (5, 10, 20, 35, 50, 70, 100, 140, or 200 amps) and time delay (3,.5, 7, 9, or 11 seconds) Table 11. Bushings; Factory-Installed Table 12. Bushing Current Transformer for Field Installation Table 13. Mounting Equipment 280-10-4 www.cooperpower.com Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Technical Data 280-10 Effective May 2014 Features and detailed description mechanical and dielectric strength and moisture resistance. Construction features With the exception of Types V4E, V4H, V4L, and V6H, all reclosers described here have oil interrupters; Types V4E, V4H, V4L, and V6H are equipped with vacuum interrupters. Kits are available for field conversion of 4H and 6H reclosers from oil to vacuum interruption. Type L reclosers cannot be converted from oil to vacuum interruption. Basic features E-, H-, and L-group reclosers are designed for long service life with minimum maintenance. Figure 2 describes the parts of the singlephase reclosers. Heads are aluminum castings. Heavy-gage steel tanks are finished with an inhibiting epoxy prime coat and finish-coated with thermosetting acrylic paint. Finish color is light gray. Munsell 5BG 7.0/0.4. A Buna-N o-ring gasket assures an oil-tight seal between head and tank. The gasket is confined in a groove, providing controlled compression. Mechanisms have been thoroughly field-proven through many years of service. They are designed and built in accordance with ANSI® Standard C37.60. For more detailed information on construction of H-group reclosers, ask for Reference Data R280-10-1; for E-group and Type L reclosers, specify R280-10-2. Insulating supports connect the hydraulic mechanism to the head. Made of filament-wound glass epoxy, these supports provide high UNIVERSAL CLAMP TYPE TERMINALS Accept copper or aluminum conductors horizontally or vertically. COVER-CLAMPED BUSHINGS Wet-process porcelain; can be field replaced. NAMEPLATES Show complete recloser data. O-RING GASKET Forms positive moistureproof seal between head casting and tank. HYDRAULIC PUMP AND LOCKOUT PISTON Counts operations; resets operating program. INSULATING SUPPORTS Epoxy-fiberglass; provide mechanical and dielectric strength to support hydraulic and interrupting mechanisms. LIFTING STRAP Facilitates hoisting during installation and maintenance. OPERATIONS COUNTER Records all recloser trip operations; large, easy-toread figures. SLEET HOOD Houses manual operating handle, non-reclosing lever, and operations counter. NON-RECLOSING HANDLE Under sleet hood; switchstick operable; when pulled down, sets recloser to lockout after one operation. MANUAL OPERATING HANDLE Provides indication of locked-out recloser; permits manual opening and closing. BYPASS GAP Protects series-trip coil from lightning surges. INTERRUPTER ASSEMBLY Provides fast arc extinction. SERIES TRIP-SOLENOID Trips recloser when current greater than minimum-trip value flows. MOVING CONTACTS Provide double-break interruption; have long-life, copper-tungsten alloy tips. ARC SHIELD Protects operating coil from contact arcing and resultant gases. Figure 2. Untanked view of typical single-phase recloser (Type L shown). www.cooperpower.com 280-10-5 Technical Data 280-10 Effective May 2014 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Interrupter and contact construction Non-reclosing operation Oil interrupter All E-, H-, and L-group reclosers are equipped with a non-reclosing feature. Simply by moving an externally operable handle with a hookstick, the recloser can be set for one operation to lockout. The non-reclosing feature is a valuable tool when hot-line work is necessary. Should an overcurrent occur while the non-reclosing feature is activated, the recloser will trip according to the first time/ current curve programmed in its operating sequence and then lock out. When the feature is deactivated, the recloser will operate normally according to the internally programmed sequence. Contacts – silverplated copper-tungsten alloy to resist arc erosion – are arranged to give two breaks in series. Different interrupter and contact configurations are employed in the various recloser types but all oil interrupters are designed to provide fast arc extinction and self-cleaning of the contacts through a wiping action. Type H reclosers feature a wiping contact design; Types 4H, 6H, E, 4E, and L employ a bayonet contact design. Vacuum interrupter Arc interruption in Types V4H, V4L, V4E, and V6H reclosers is fast – arcing time is generally less than 1/2 cycle. Arc energy is low, minimizing mechanical stress. Also, contact erosion is substantially reduced, contributing to long service life without contact maintenance. Unaffected by ambient temperature, contaminants, humidity, or altitude, vacuum interruption provides maximum reliability. Because there are no arcing by-products to contaminate the insulating oil, inspections are fewer and maintenance costs are lower. The vacuum interrupter is fully interchangeable with the oil interrupter used in Type 4H and 6H reclosers. A replacement assembly is available for quick field installation. Figure 3. Untanked view of typical three-phase recloser (Type 6H shown). Basic operation Eaton's Cooper Power Systems E-, H-, and L-group reclosers are series-trip-solenoid-operated and hydraulically controlled. Series tripping provides simple and reliable operation since the tripping energy is taken directly from the fault itself. During tripping, the mechanism stores energy for reclosing. Hydraulic control permits accurate coordination with other protective equipment. The two three-phase reclosers in the H group – Types 6H and V6H – consist of three single-phase reclosers in one tank (Figure 3), mechanically interlocked for lockout operation. This permits initial independent operation of a single phase in the event of a fault on any one phase. Should the fault persist after the initial operation and the phase proceed to lockout, the mechanical interconnection opens and locks out the other two phases as well. A separate counter on each phase accumulates information for operating records. For more detailed information on operation of H-group reclosers, ask for Reference Data R280-10-1; for E-group and L-group reclosers, specify R280-10-2. 280-10-6 www.cooperpower.com Series-trip solenoid Fault-current sensing is provided by a series-connected solenoid coil that carries line current. When a fault occurs, tripping is initiated by the solenoid plunger. The plunger, normally held at rest by the closing springs, is drawn into the coil by the magnetic force generated by the fault current. Downward travel of the plunger overtoggles springs in the contact assembly that open the recloser contacts. The same motion charges the closing springs in preparation for a reclosing operation. When the circuit is opened, the solenoid coil is deenergized, allowing the closing springs to close the contacts and simultaneously return the plunger to its original position. Technical Data 280-10 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Contact operating speeds – controlled entirely by the springs – are independent of the magnitude of the fault current. Total time to contact opening is proportional to the level of fault current passing through the series-trip solenoid. When the recloser operates to lockout, the hydraulic mechanism releases a lock-out spring and mechanism, preventing the plunger from returning and the contacts from reclosing. The series-trip coil is capable of withstanding forces caused by maximum-rated fault currents and is effectively shunted with a bypass gap for surge protection. Effective May 2014 Hydraulic control mechanism The hydraulic control mechanism provides selectivity in timing enabling flexibility in application and coordination with other equipment. All timing is governed by the hydraulic mechanism which: 1. controls the timing before contact opening; 2. establishes the time delay before the contacts reclose; 3. counts the number of operations; 4. causes the recloser to lock out when the preset number of trip operations has been completed. Variations of timing characteristics and sequences can be programmed for a maximum of four operations. When a recloser is programmed for both fast and retarded operations, the fast operations – involving no intentional time delay – occur first in the sequence according to the recloser’s A curve time-current characteristic. Retarded operations are according to the recloser’s B or C time-current curve (B, C, or D curve for Types E, 4E, and L). See Time Current Curves R280-91-10 for Type E reclosers; R280-91-8 for Type 4E; R280-91-1 for Type H; R280-91-2 for Types 4H, V4H, 6H, and V6H; R280-91-3 for Type L; and R280-91-15 for Types V4L and V4E. www.cooperpower.com 280-10-7 Technical Data 280-10 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Effective May 2014 Ratings Table 14. Single- and Three-Phase Recloser Ratings Trip-Coil Continuous Current (amps) Minimum Trip Current (amps) Interrupting Current (rms symmetrical amps) Type H Single-Phase; 50 Amps Maximum 5 10 10 20 15 30 25 50 35 70 50 100 Types 4H Single-Phase and 6H Three-Phase; 100 Amps Maximum @ 2.4 through 14.4 kV 125 250 375 625 875 1250 @ 4.8 kV 5 10 200 10 20 400 15 30 600 25 50 1000 35 70 1400 50 100 2000 70 140 2800 100 200 3000 Types V4H Single-Phase and V6H Three-Phase; 200 Amps Maximum 5 10 200 10 20 400 15 30 600 25 50 1000 35 70 1400 50 100 2000 70 140 2800 100 200 3000 140 280 3000 200 400 3000 Type L Single-Phase; 280 Amps Maximum 25 50 1500 35 70 2100 50 100 3000 70 140 4200 100 200 6000 140 280 6000 200 400 6000 280 560 6000 Type V4L Single-Phase; 280 Amps Maximum @ 2.4 through 14.4 kV 5 10 300 10 20 600 15 30 900 25 50 1500 35 70 2100 50 100 3000 70 140 4200 100 200 6000 140 280 6000 200 400 6000 280 560 6000 Type E Single-Phase; 100 Amps Maximum @ 24.9 kV 5 10 300 10 20 600 15 30 900 25 50 1500 35 70 2100 50 100 2500 70 140 2500 100 200 2500 280-10-8 www.cooperpower.com @ 8.32 kV 200 400 600 1000 1400 2000 2500 2500 @ 14.4 kV 200 400 600 1000 1400 2000 2000 2000 200 400 600 1000 1400 2000 2500 2500 2500 2500 200 400 600 1000 1400 2000 2000 2000 2000 2000 1500 2100 3000 4200 5000 5000 5000 5000 1500 2100 3000 4000 4000 4000 4000 4000 Technical Data 280-10 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Effective May 2014 Table 14. Single- and Three-Phase Recloser Ratings (continued) Trip-Coil Continuous Current (amps) Minimum Trip Current (amps) Interrupting Current (rms symmetrical amps) Type 4E Single-Phase; 280 Amps Maximum @ 24.9 kV 3000 4000 4000 4000 4000 4000 50 100 70 140 100 200 140 280 200 400 280 560 Type V4E Single-Phase; 280 Amps Maximum 15 30 25 50 35 70 50 100 70 140 100 200 140 280 170 340 200 400 280 560 900 1500 2100 3000 4200 6000 6000 6000 6000 6000 RATINGS Table 15. Duty Cycles Type H 4H, 6H V4H, V6H E % Interrupting Rating Maximum Circuit X/R Ratio Number Unit Operations 15-20 45-55 90-100 15-20 45-55 90-100 15-20 45-55 90-100 15-20 45-55 90-100 2 4 8 2 5 10 2 5 10 2 5 12 40 40 20 32 24 12 128 96 48 40 20 12 Total Unit Operations Type 100 4E 68 V4E 272 L 72 V4L % Interrupting Rating Maximum Circuit X/R Ratio Number Unit Operations 15-20 45-55 90-100 15-20 45-55 90-100 15-20 45-55 90-100 15-20 45-55 90-100 3 6 13 3 7 15 3 6 12 4 8 15 32 20 12 96 120 32 32 20 12 88 112 32 Total Unit Operations 64 248 64 232 SPECIFICATIONS Table 16. Specifications Recloser Type H 4H 6H V4H V6H L V4L E 4E V4E Nominal operating voltage (rms kV) 2.4—14.4 2.4—14.4 2.4—14.4 2.4—14.4 2.4—14.4 24.9 24.9 Maximum design voltage (rms kV) 15.0 15.5 15.5 15.5 15.5 27 27 Impulse withstand (BIL), 1.2 x 50 sec wave (crest kV) 95 110 110 110 110 150 150 60-Hz withstand (rms kV) Dry one minute Wet, ten seconds 35 30 50 45 50 45 50 45 50 45 60 50 60 50 Reclosing time (sec) 1 1-1/2 1-1/2 2 2 1-1/2 2 Bushing creepage distance (in.) 10-3/8 10-7/8 10-7/8 11-3/4 11-3/4 13-5/8 17 www.cooperpower.com 280-10-9 Technical Data 280-10 Effective May 2014 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Dimensions and weights Dimension (in.) Recloser Type 4H, V4H L V4L E 4E,V4E A 14 15 15 15 15-1/8 B 14-5/16 15-7/8 15-7/8 15-7/8 16 C 35-1/2 37-1/8 45-1/2 41-1/2 49 D 16-13/16 18-7/8 18-7/8 20-3/8 22-1/2 E 6-11/16 6-1/4 14-5/8 9-1/8 14-1/2 F 8-3/4 9-3/4 9-3/4 9-3/4 9-3/4 G 8-1/2 11 11 11 11-3/4 H 9-1/4 11-1/4 11-1/4 11-1/4 11-1/4 NNote: Dimensions shown are for general information only. For critical construction dimensions, refer to factory. Figure 4. Dimensions of Types 4H, V4H, L, V4L, E, 4E, and V4E reclosers. Figure 5. Dimensions of Type H reclosers. 280-10-10 www.cooperpower.com Technical Data 280-10 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Effective May 2014 Figure 6. Dimensions of Types 6H and V6H reclosers. Table 17. Weights and Oil Capacity Recloser Type H 4H, V4H 6H, V6H L V4L E 4E V4E Weight; dry (Ib) 55 76 236 106 142 107 142 147 Weight, with oil (Ib) 85 114 394 159 205 169 205 210 Oil capacity (gal) 4 5 21 7 9-1/2 8-1/4 9-1/2 9-1/2 www.cooperpower.com 280-10-11 Technical Data 280-10 Types E, 4E, 4E, V4E, H, 4H, V4H, L, V4L single-phase and 6H and V6H three-phase reclosers Effective May 2014 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-10 May 2014 280-10-12 Eaton, Cooper Power Systems, VariSTAR, UltraSIL, and Evolution are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. ANSI® is a registered trademark of American National Standards Institute. For Eaton’s Cooper Power Systems reclosers product information call 1-877-277-4636 or visit: www.cooperpower. com. Technical Data 280-20 Effective July 2014 Supersedes January 1990 Types D and DV single-phase hydraulically controlled recloser Types D and DV single-phase automatic circuit reclosers from Eaton’s Cooper Power Systems provide reliable, economical overcurrent protection for distribution systems. Designed for 15 kV (Type D) and 15-34.5 kV (Type DV) system applications such as sectionalizing single-phase branches of three-phase feeders, the reclosers’ high continuous current and interrupting capacity enables them to be used on heavily loaded circuits with high available fault currents. Types D and DV reclosers provide single-phase load protection, tripping, and automatic clearing of temporary faults to minimize downtime and simplify troubleshooting. They are compact and self-contained in operation, can be pole-mounted or installed in substations, and utilize the serviceproven Eaton’s Cooper Power Systems hydraulic control. Types D and DV reclosers can be easily coordinated with circuit breakers, sectionalizers, fuses, and other reclosers in the distribution system. Eaton’s Cooper Power Systems reclosers in a distribution system protection scheme offer significant user advantages. Their broad application capabilities permit the user to select exactly the right recloser for the protection required. When needed, Eaton’s Cooper Power Systems application expertise – backed by world-wide recloser application experience – is readily available. Knowledgeable design capability – based on 45 years of recloser manufacturing experience – provides the operating features required for effective overcurrent protection of complex distribution systems. Progressive development programs using the latest technologies have resulted in modern, efficient reclosers from Eaton’s Cooper Power Systems, designed and built in accordance with ANSI® Standard C37.60. Accessories are available for Types D and DV reclosers that permit tailoring a recloser to specific application requirements. Mounting equipment for pole and substation permits recloser installation precisely where system requirements demand its protection. 280-20-1 Technical Data 280-20 Types D and DV single-phase reclosers Effective July 2014 Basic ratings Type D reclosers protect systems rated 2.4 through 14.4 kV and Type DV reclosers protect systems rated through 34.5 kV. Table 1 summarizes the ratings of the Types D and DV reclosers. For basic ratings and application information for all reclosers from Eaton’s Cooper Power Systems, see Technical Data 280-05, General Ratings Information and Catalog Guide for Single-Phase and Three-Phase Reclosers. 4. Delayed time-current curve: B, C, D, or E (Refer to time-current curves in Reference Data R280-91-4). 5. Number of delayed operations: 0,1, 2, 3,or 4. 6. Closing coil voltage code (select from Table 2.) Table 2. Closing Coil Voltage Code Numbers Basic characteristics Types D and DV reclosers are hydraulically controlled protective devices in which tripping is initiated by a series-trip coil that releases the stored-energy trip mechanism when an overcurrent occurs. Current carrying and interrupting capacities depend on the current rating of the series trip coil. Minimum-trip current is 200% of the coil rating except X coil ratings which initiate tripping at 140%. A closing solenoid supplies the energy for contact closing and also stores energy in the trip mechanism. High-voltage closing solenoids are connected to the system on the source-side of the recloser. Solenoid voltage rating is based on the system operating voltage. Low-voltage closing solenoids can be used if auxiliary voltage is supplied to the recloser. Dual time-current characteristics permit coordinating Types D and DV reclosers with other protective devices on a distribution system. Fast-curve operations are followed by trip operations on a delayed curve. A choice of four delayed characteristics allows flexibility in system coordination. Oil interruption Types D and DV reclosers use oil as the arc-interrupting medium. Movable bridge-type contacts provide two breaks in series. Separate self-generating interrupter chambers at each of the two breaks effectively interrupt all current from minimum load to rated maximum fault. Surge protection Best operating results are achieved if reclosers are protected with surge arresters. On line applications, arrester protection is recommended on both sides of the recloser. (If protection is on one side only, it should be on the source-side.) In substations, arresters should be on the load-side. Arresters provide excellent protection and are available with mounting brackets to fit Eaton’s Cooper Power Systems reclosers; see Technical Data 235-99, UltraSIL™ PolymerHoused Evolution™ Surge Arrester or Technical Data 235-35, UltraSIL Polymer-Housed VariSTAR™ Surge Arrester for information. Phase-to-Grounded Neutral Closing Coil Operating Voltage ± 15% (kV) Code Number 2.4 21 4.16-4.8 22 7.2-7.62 23 8.0-8.32 24 14.4 27* 20.0 29* Low-Voltage Closing Coils** (Vdc) 125 26 250 28 * For Type DV reclosers only. ** When dc coils are selected also specify KA136D for installation. For ac closing, specify a rectifier accessory from Table 4 in place of KA136D. Example To order a basic Type D recloser with a 400-amp trip coil, minimumtrip current of 140% of continuous current rating, a B time-current curve, and two fast and two delayed operations before lockout for service on a 4.8-8.32-kV grounded-wye system, the catalog number should be constructed like this: KD Basic letters for a Type D recloser. Basic letters for a Type DV recloser: KDV. 400 Continuous current rating of series trip coil: 100, 140, 160, 185,225, 280,400 or 560 amps. (Minimum-trip is 200% of continuous ratings.) X B Table 1. Basic Ratings Delayed time-current curve desired: B, C, D, or E. If all fast operations are desired, insert letter A. 2 Recloser Type Normal Voltage (kV) Maximum Continuous Current (amps) Maximum Interrupting Rating at Normal Voltage (symmetrical amps) D 14.4 560 10000* DV 34.5 560 8000 * Ratings are higher at lower voltage; see Table 8. Ordering information To order a basic Type D and DV recloser, use the chart to the right and Table 2 to construct a catalog number that describes the required recloser. Order accessories and mounting equipment from Tables 3 through 5. Construction of catalog number requires: 1. Recloser type: D or DV. 2. Series trip-coil continuous current rating. 3. If 400- or 560-amp coil is used, choose trip current level of 140 or 200%. 280-20-2 Insert letter X only if 400- or 560-amp coil is to have minimum trip current approximately 140% of continuous rating; otherwise omit letter. (Minimumtrip current of 400X coil is 560 amps;minimum-trip of 560X coil is 750-amps.) www.cooperpower.com Number of fast A-curve operations: 0,1,2,3, or 4. 2 Number of delayed operations: 0,1,2,3, or 4. 22 Closing coil voltage code number selected from Table 2 for the system on which recloser is 22 to be used . B 2 2 KD 400 X Fast + delayed operations not to exceed four. KD400XB2222 is the catalog number for the required basic recloser. Table 3. Multi-Ratio Bushing-Current Transformers for Field Installation 600:5 for Metering Description Catalog Number Slip-on bushing current transformer kit; one CT per kit KA712L2 Technical Data 280-20 Types D and DV single-phase reclosers Effective July 2014 Table 4. Low Voltage Closing and Wiring Description Catalog Number Low voltage D.C. closing accessory KA136D 115-Vac rectifier to supply 125 Vdc coil KA137D1 230-Vac rectifier to supply 250 Vdc coil KA137D3 Low voltage cable, 20 feet KA139DV20* Table 5. Mounting Equipment Description Catalog Number Pole-mounting cluster-type frame for Three Type Reclosers DT8C1* * Refer to Catalog 280-85 for additional ordering information. Basic recloser design Eaton’s Cooper Power Systems Types D and DV hydraulically controlled, single-phase reclosers (Figures 1 and 2) are designed to protect circuits on systems operating through 34.5 kV. With the ratings available and the ability of these reclosers to coordinate with other protective devices – including lower-rated reclosers – they can be applied in a variety of protection schemes. The hydraulic control incorporates separate elements to govern time delay operations and regulate the number of operations to lockout. The basic design of the Types D and DV reclosers has been proven by more than 30 years of field service. Construction Like all the other reclosers from Eaton’s Cooper Power Systems, Types D and DV reclosers are designed for long service with little maintenance. Heads are aluminum castings and the tanks are constructed of heavy-gage steel. The tanks are treated with a corrosion inhibiting epoxy primer, followed by a finish coat of thermosetting acrylic paint. A Buna N o-ring gasket is confined in a groove in the head casting to assure an oil-tight seal between the head and the tank. The entire internal mechanism is suspended from the head casting so that the mechanism and the head assembly can be removed from the tank as a unit to simplify servicing. The head casting can be rotated with respect to the tank, in 60-degree increments, for optimum positioning of bushing terminals and manual operating handles. The insulating supports from which the interrupter and internal mechanism are suspended are constructed of filament wound glass epoxy for high electrical and mechanical strength and moisture resistance. Closing energy is supplied by a closing solenoid which simultaneously charges the opening springs in preparation for a tripping operation. Fault currents are sensed by a trip solenoid (connected in series with the recloser contacts) that initiates the tripping operation by releasing the opening springs. Series tripping provides simple and reliable operation since the energy to initiate the tripping operation is taken directly from the line. Types D and DV reclosers are self-contained; i.e., they require no external control or control power source. UNIVERSAL CLAMP TYPE TERMINALS Accept copper or aluminum conductors horizontally or vertically LIFTING STRAP Facilitates hoisting during installation and maintenance COVER-CLAMPED BUSHINGS Wet-process porcelain; can be field-replaced OPERATIONS COUNTER Records all recloser trip operations GROUND TERMINAL Provides easy connection to grounded neutral HEAD CASTING Supports bushings and operating mechanism; can be rotated in 60-degree increments to conveniently orient bushings and sleet hood. INFORMATION PLATE Provides recloser ratings SLEET HOOD Houses manual operating handle, non-reclosing lever, and operations counter MANUAL OPERATING HANDLE Provides indication of locked-out recloser; permits opening and closing to be manually initiated. NON-RECLOSING LEVER Provides one shot to lockout after fault interruption Figure 1. Construction features, operating levers, and indicators for Types D and DV reclosers. www.cooperpower.com 280-20-3 Technical Data 280-20 Types D and DV single-phase reclosers Effective July 2014 HEAD MECHANISM Includes opening springs and mechanical linkages TIME-DELAY UNIT Establishes delayed timecurrent characteristics SEQUENCE SELECTOR CAM Establishes sequence of fast and delayed operations CLOSING SOLENOID Operates recloser and charges opening springs SERIES-TRIP SOLENOID Senses overcurrents, inhales tripping HYDRAULIC INTEGRATOR Counts number of operations, initiates delayed operations and lockout after preset sequence Closing Solenoid Closing energy – as well as the energy to charge the opening springs – is supplied by a high-voltage closing solenoid Figures 3 and 4) connected phase-to-ground on the sourceside of the Type D and DV recloser. SOURCE RECLOSER HEAD LOAD CLOSING SOLENOID CONTACTOR CLOSING SOLENOID CLOSING SOLENOID CONTACTOR Momentarily energizes solenoid for closing operation FUSE Protects system in event of coil failure INSULATION SUPPORTS Fiberglass construction INTERRUPTERS Self-generating; vented for fast arc extinction SERIES TRIP COIL FUSE MAIN CONTACTS Figure 3. Phase-to-ground connection of high-voltage closing solenoid. MOVING CONTACTS Copper-tungsten alloy tips for long life Figure 2. Untanked view of Type D recloser (shown with head casting removed). Construction of Type DV is similar. Series-trip solenoid Sensing of fault currents in Types D and DV reclosers is provided by a trip solenoid which is connected in series with the recloser contacts and can carry line current up to its rating. Continuous current and minimum-trip values can be changed by replacing the coil. Coils used in Types D and DV reclosers are interchangeable (see Table 2). When fault current flows in excess of the minimum trip rating, the trip solenoid plunger – normally held at rest by the mechanism – is drawn into the coil by the magnetic effect generated by the fault current. Near the end of the downward stroke, a linkage connected to the solenoid plunger trips a latch which releases the charged opening springs and the recloser contacts are opened. The seriestrip coil is effectively surge-protected by a shunting bypass gap on reclosers with trip coils rated below 100 amps. Figure 4. High-voltage closing solenoid contactor. 280-20-4 www.cooperpower.com Technical Data 280-20 Types D and DV single-phase reclosers Effective July 2014 The aluminum cover casting is marked to designate bushings to aid in making the proper connections. The grounded side of the solenoid is connected to a connector on the cover. The phase-toground connection permits Types D and DV reclosers to function independently of outside control power, although application is limited to multigrounded-wye systems. A low-voltage closing solenoid, energized by an auxiliary ac or dc low-voltage source, is also available, permitting application of Types D and DV reclosers on other than grounded-neutral systems. RESETTING ARM AND PLUNGER Dumps oil from under lockout piston after lockout so recloser can immediately reset to begin another series of operations HYDRAULIC PUMP Acts as an accurate trip counter by pumping measured amount of oil under lockout piston When the recloser contacts are closed, the solenoid closing plunger is latched in the down position. This latch is tripped simultaneously with the release of the opening springs and as the solenoid plunger moves upward. A timing orifice in the bottom of the solenoid-plunger cylinder regulates the rate at which upward movement can take place as oil is drawn into the cylinder. As the solenoid plunger reaches the top of its stroke, the highvoltage line contactor energizes the closing solenoid, pulling the plunger down. The closing solenoid contactor opens de-energizing the coil and through the mechanical linkage, the main contactoperating rods are simultaneously moved upward to close the contacts. At the same time, the opening springs are charged in preparation for a tripping operation. LOCKOUT PISTON Advances to lockout according to presetting with each recloser trip Figure 5. Cutaway view of hydraulic integrator. Hydraulic control system operation The number and sequence of operations to lockout and time-delay operations of Types D and DV reclosers are controlled by two separate, sealed hydraulic mechanisms which are mechanically linked. These sealed units contain HFA hydraulic fluid and have extremely consistent and accurate operating characteristics. Hydraulic integrator − pump and lockout piston assembly The hydraulic integrator (Figure 5) containing the hydraulic pump and lockout piston, regulates the number of fast and delayed trip operations, counts the operations to lockout, and initiates lockout after a preset number of operations. The hydraulic pump (Figure 5) is linked to the closing-solenoid plunger and is pushed downward with each return operation of the plunger. With its downward stroke, the pump forces a measured amount of fluid under the lockout piston (Figure 5), causing it to rise one step. Ball-type check valves retain the charge. When the closing coil is energized, the recloser contacts close and the pump returns to its normal position. The integrator mechanism is linked to the time-delay unit through the cam shown in Figure 6. Upward movement of the lockout piston causes the cam to rotate counterclockwise. After the number of fast operations preset on the cam, it has advanced to engage the roller mechanism located at left of the cam. This brings the time-delay unit into operation. When the lockout piston reaches the top of its stroke, it trips the lockout latch through another set of linkages, and a spring locks out the recloser contacts. On the lockout operation, the resetting lever (Figure 5) raises the plunger to which it is linked. This releases the ball check-valve beneath the plunger, hydraulic fluid is withdrawn from beneath the lockout piston, and it quickly resets. After the recloser is reset from lockout, it is ready for another full sequence of operations. For temporary faults that are cleared before the recloser mechanism reaches lockout, the lockout piston resettles through a combination of spring action and fluid bleeding past the piston to reset the integrator mechanism. ROLLER ASSEMBLY SEQUENCE SELECTOR CAM TIME-DELAY UNIT LOCKOUT LEVER INTEGRATOR SERIES TRIP LINKAGE CLOSING SOLENOID PLUNGER Figure 6. Hydraulic integrator and time-delay linkage. Operating settings The required sequence of fast and delayed operations and the required number of operations to lockout are factory set per customer specification. Either or both settings are easily changed in the field; only partial untanking of the recloser is necessary and no special tools are needed. Internal settings for the number of operations to lockout permit the recloser to be programmed for two, three, or four trip operations before lockout. To set the number of operations to lockout, the lockout lever (Figure 6) is indexed to one of three holes in its assembly, corresponding to the number of desired operations. The number of fast operations in the sequence is established by indexing the sequence selector cam shown in Figure 6. The cam is simply rotated until the desired number of fast operations appears opposite an arrow above the cam. An indent holds the cam in the selected position. www.cooperpower.com 280-20-5 Technical Data 280-20 Types D and DV single-phase reclosers Effective July 2014 Setting the number of fast operations determines the number of delayed operations in the sequence to lockout; for example, if four operations to lockout have been selected and the cam has been adjusted for two fast operations, the sequence will be two fast, followed by two delayed operations. Programming for one operation to lockout is done with the external non-reclosing handle, located under the sleet hood. Moving the external non-reclosing handle down activates the non-reclosing feature (one operation to lockout). This overrides the internal setting, but does not change it physically. When the non-reclosing feature is deactivated (handle moved up), the number of operations to lockout automatically reverts to the internal setting, providing complete flexibility for testing or service without disturbing the programmed operations-to-lockout setting. TIME-DELAY ARM SOLENOID LINKAGE ENGAGEMENT ARM TIME-DELAY ARM PIN BRACKET THUMBSCREW BRACKET HOLES FOR ALTERNATE CURVE TIME-DELAY UNIT PIN Time-delay mechanism Delayed operations of the Types D and DV reclosers are established by the hydraulic time-delay mechanism which engages the series trip-solenoid linkage after the preset number of fast operations. The time-delay mechanism impedes the downward stroke of the series trip-solenoid linkage to provide the desired delayed time-current characteristic. The selected curve is established by the amount of engagement during the downward stroke of the time-delay mechanism. For a B or D curve, approximately half of the stroke is unimpeded; then the trip solenoid linkage engages the time-delay mechanism, impedes the remainder of the stroke and establishes the desired curve. With slower C or E curves, the amount of engagement is increased. The time-delay mechanism offers a choice of two characteristics: B and C, or D and E. The desired combination must be specified since one unit does not provide all four characteristics. Adjustment from one characteristic to the other is made by indexing a thumbscrew and bracket arrangement on the time-delay unit. This changes the curve by changing the amount of engagement (Figure 7). Establishing delayed operations Operation of the time-delay mechanism is initiated by the hydraulic integrator. As sequence selector cam (Figure 6) is rotated counterclockwise by the upward movement of the lockout piston, it engages the roller assembly causing the solenoid linkage engagement arm to pivot clockwise, placing its hook above the pin on the time-delay arm. When a delayed tripping operation occurs and the engagement arm moves downward with the trip-solenoid linkage, its hook engages a pin on the time-delay arm and the time-delay mechanism impedes the remainder of the stroke (Figure 7). 280-20-6 www.cooperpower.com Figure 7. Changing time-current characteristic to the alternate curve is accomplished by loosening the thumbscrew and indexing the pin on the time-delay unit to the bracket hole for the alternate curve. Figure 8. Schematic of time-delay mechanism. Technical Data 280-20 Types D and DV single-phase reclosers Effective July 2014 Operation The hydraulic time-delay mechanism piston (Figure 8) is pulled downward by the trip-solenoid linkage. A floating plate (retained by an open basket) at the bottom of the hollow piston functions as a one-way valve on the downstroke, sealing the bottom of the piston. Table 6. Electrical Ratings Description Type D Type DV Nominal system voltage (kV) 2.4 -14.4 24.9 - 34.5 On low-current operations, displaced oil is forced around the greased pin of the low-current timing valve and is allowed to return to the space above the piston. When a higher current fault is experienced, increased oil pressure raises the spring-loaded valve so that oil flows through both valves and the tripping operation is accelerated proportionately. The hydraulic time-delay mechanism has no effect on contact-opening speed – it only delays the moment at which the opening springs are released. Maximum rated voltage (kV) 15.5 38 Rated impulse withstand voltage (BIL) (kV crest) 110 150 Dry, one min 50 70 Wet, ten sec 45 60 Reclosing time (sec) 2 2 Oil interrupter construction Bushing creepage distance (in.) 11-5/8 17 Fast arc interruption (down to 2.7 cycles clearing) is achieved by bridge-type contacts that provide two current breaks in series. The bayonet-type moving contacts are silver-plated tungsten alloy for erosion resistance and good conductance. Table 7. Duty Cycle The stationary contact assemblies are tulip-type clusters of silverplated contact fingers held together by garter springs. The contacts are self-cleaned by the opening and closing wiping action. Each current break is provided with a self-generating-type arc interrupter structure (Figure 9) which includes a series of vented chambers. As the contacts open, the arc generates gap pressure in the upper chamber which blasts oil across the arc and out through the vents. As a result, arc extinction is fast and arc energy levels do not increase as fast at the higher fault-current levels. 60 Hz withstand (kV rms) % of Interrupting Rating Recloser Type D Maximum Circuit X/R Ratio 15-20 28 3 45-55 20 7 90-100 10 14 Total 58 DV Mounting equipment Types D and DV reclosers are furnished with two sets of mounting adapter plates for pole or substation mounting. For direct pole mounting, the curved plates are installed between the pole and the mounting brackets of the recloser. For mounting on a substation truss or pole-mounted channel, add the flat adapter plates between the curved plates and the mounting surface. An accessory clustertype frame for mounting three Type D reclosers is also available. See Table 5 on page 3 for ordering information. Number of Unit Operations 15-20 28 4 45-55 20 8 90-100 10 15 Total 58 Table 8. Interrupting Ratings Tripe Coil Ratings Continuous (amps) Minimum Trip Ratings (amps) Interrupting Ratings (rms symmetrical amps) Type D @4.8 kV Type DV @8.32 kV @14.4 kV @24.9-34.5 kV 100 200 6000 6000 6000 6000 140 280 8400 8400 8400 8000 160 320 9600 9600 9600 8000 185 370 11100 10000 10000 8000 225 450 12000 10000 10000 8000 280 560 12000 10000 10000 8000 400 800 12000 10000 10000 8000 400X 560 12000 10000 10000 8000 560 1120 12000 10000 10000 8000 560X 750 12000 10000 10000 8000 Figure 9. General construction of self-generating interrupter used on Types D and DV reclosers. www.cooperpower.com 280-20-7 Technical Data 280-20 Type D and DV single-phase reclosers Effective July 2014 Dimensions and weights Figure 10. Dimensions of Type D (left) and Type DV (right) reclosers. Table 9. Weights and Oil Capacities Type Weight with oil (lbs) Oil Capacity (gal) D 430 20 DV 556 30 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-20 July 2014 280-20-8 Eaton, Cooper Power Systems, UltraSIL, VariSTAR, and Evolution and are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. ANSI® is a registered trademark of American National Standards Institute. For Eaton’s Cooper Power Systems Types D and DV reclosers product information call 1-877-277-4636 or visit: www.cooperpower.com. Technical Data 280-30 Effective July 2014 Supersedes May 2003 Types W, WV27, WV38X, VW, VWV27, and VWV38X, three-phase hydraulically controlled reclosers Type VW 15.5 kV Type W 14.4 kV General W-group three-phase automatic, circuit reclosers from Eaton's Cooper Power Systems provide reliable, economical overcurrent protection for distribution circuits rated through 38 kV. Compact and self-contained in operations, these reclosers can be easily installed on poles and in substations. Employing the service-proven hydraulic control, the W-group reclosers can be readily coordinated with circuit breakers, sectionalizers, fuses, and other reclosers on the distribution system. Eaton's Cooper Power Systems reclosers in a distribution system protection scheme offer significant user advantages. Their broad application capabilities permit the user to select exactly the right recloser for the protection required. When needed, application expertise, backed by worldwide recloser application experience, is readily available. Knowledgeable design capability, based on over 60 solid years of recloser manufacturing experience, is the backbone of our dependable reclosers. Progressive development programs using the latest technologies have resulted in the modern, efficient reclosers from Eaton's Cooper Power Systems. W-group reclosers, like all reclosers from Eaton's Cooper Power Systems, are designed and built in accordance with ANSI C37.60. Six distinct types – W, WV27, WV38X, VW, VWV27, and VWV38X – within the W-group offer a broad range of voltage, continuous current, and interrupting ratings. Accessories permit tailoring a recloser to specific application requirements. Mounting equipment for both pole and substation facilitates installing a recloser precisely where system requirements demand its protection. Basic ratings W and VW reclosers protect systems rated 2.4 through 14.4 kV; WV27 and VWV27 reclosers protect systems rated through 24.9 kV; and WV38X and VWV38X reclosers protect systems rated through 34.5 kV. Table 1 summarizes the ratings of the W-group reclosers. For basic ratings and application information for all reclosers from Eaton's Cooper Power Systems, see Catalog Section 280-05. 280-30-1 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Basic characteristics Vacuum interruption W-group reclosers are hydraulically controlled protective devices in which tripping is initiated by a series trip coil that releases the storedenergy trip mechanism when an overcurrent occurs. Current-carrying and interrupting capacities depend on the rating of the recloser series trip coil. Minimum-trip current is 200% of the coil rating, except X coil ratings which initiate tripping at approximately 140%. VW, VWV27, and VWV38X reclosers use vacuum as the arcinterrupting medium. Vacuum interruption not only means long contact life, it also offers considerably longer duty cycles than oil interruption. A single break on each phase is accomplished by separating contacts inside the vacuum interrupter. All arcing is contained within the vacuum envelope. Low-energy arc interruption in a vacuum results in far less shock and demonstration than interruption in oil, thus extending the vacuum recloser mechanism life. Because interruption within the vacuum envelope does not add contaminants to the insulating oil, recloser maintenance is minimized and intervals between oil changes can generally be extended. A closing solenoid supplies the energy for contact closing and also stores energy in the trip mechanism. High-voltage closing solenoids are connected to the system on the source side of the recloser. Solenoid phase-to-phase voltage rating is based on the system operating voltage. Low-voltage closing solenoids can be used if auxiliary voltage is supplied to the recloser. Surge protection Best operating results are achieved if reclosers are protected with surge arresters. On line applications, arrester protection is recommended on both sides of the recloser. (If protection is on one side only, it should be on the source-side.) In substations, arresters should be on the load-side. Eaton's Cooper Power Systems distribution-class arresters provide excellent protection and are available with mounting brackets to fit reclosers from Eaton's Cooper Power Systems; see Service Information S280-85-7, KA126H3 and KA847W Surge Arrester Mounting Brackets Assembly and Installation Instructions. Dual time–current characteristics permit coordinating W-group reclosers with other protective devices on a distribution system. Fast-curve trip operations are followed by trip operations on a delayed curve. A choice of four delayed characteristics allows flexibility in system coordination. Ground tripping is available as an accessory. A variety of operating, indicating, and service accessories extends a W-group recloser’s normal flexibility even further. Oil interruption W, WV27, and WV38X reclosers use oil as the arc-interrupting medium. Movable bridge-type contacts provide two breaks in series on each phase. Separate self-generating interrupter chambers at each of the two breaks effectively interrupt all currents from minimum load to rated maximum fault. Ratings and specifications Table 1. Basic Ratings Nominal Voltage (kV) Maximum Continuous Current (A) Maximum Interrupting Rating at Nominal Voltage (sym A) Interrupting Medium Recloser Type 14.4 560 10000 Oil W 14.4 560 12000 Vacuum VW 24.9 560 8000 Oil WV27 24.9 560 12000 Vacuum VWV27 34.5 560 8000 Oil WV38X 34.5 560 12000 Vacuum VWV38X Table 2. Electrical Ratings Types W and VW Description Type WV27 Type VWV27 Type VWV38X Type WV38X Nominal system voltage (kV) 2.4-14.4 24.9 24.9 24.9-34.5 24.9-34.5 Maximum rated voltage (kV) 15.5 27 27 38 38 Rated impulse withstand voltage (BIL) (kV crest) 110 150 125* 150 170 60 Hz withstand voltage (kV rms) Dry, one minute Wet, ten seconds 50 45 60 50 60 50 70 60 70 60 Rated maximum continuous current (A) 560 560 560 560 560 Reclosing time (seconds) 2 2 2 2 2 Bushing creepage distance (in.) 13 26-1/2 26-1/2 26-1/2 26-1/2 * Can be increased to 150 kV BIL with an accessory. Table 3. Definite Purpose Capacitor Switching Ratings Description VW VWV27 VWV38X* Isolated Bank (A rms) 400 400 250 Parallel Bank Current (A) Peak current (kA) 400 20 400 20 250 20 Transient inrush frequency (Hz) 4240 4240 6800 * Applies to solidly grounded bank applications. 280-30-2 www.cooperpower.com Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Table 4. Interrupting Ratings Trip Coil Rating Continuous A Minimum Trip A W @ 4.8 kV @ 14.4 kV VW 2.4–14.4 kV WV27 @ 24.9 kV VWV27 @ 24.9 kV WV38X 24.9–34.5 kV VWV38X 24.9–34.5 kV 5 10 15 25 35 50 70 100 140 160 185 200 225 280 400 560 70x 100X 140X 160X 185X 225X 280X 400X 560X 10 20 30 50 70 100 140 200 280 320 370 400 450 560 800 1120 100 140 200 225 260 315 450 560 750 300 600 900 1500 2100 3000 4200 6000 8400 9600 11100 12000 12000 12000 12000 12000 3000 4200 6000 6750 7800 9450 12000 12000 12000 300 600 900 1500 2100 3000 4200 6000 8400 9600 10000 10000 10000 10000 10000 10000 3000 4200 6000 6750 7800 9450 10000 10000 10000 300 600 900 1500 2100 3000 4200 6000 8400 9600 11100 12000 12000 12000 12000 12000 3000 4200 6000 6750 7800 9450 12000 12000 12000 300 600 900 1500 2100 3000 4200 6000 8000 8000 8000 8000 8000 8000 8000 8000 3000 4200 6000 6750 7800 8000 8000 8000 8000 300 600 900 1500 2100 3000 4200 6000 8400 9600 11100 12000 12000 12000 12000 12000 3000 4200 6000 6750 7800 9450 12000 12000 12000 300 600 900 1500 2100 3000 4200 6000 8000 8000 8000 8000 8000 8000 8000 8000 3000 4200 6000 6750 7800 8000 8000 8000 8000 300 600 900 1500 2100 3000 4200 6000 8400 9600 11100 12000 12000 12000 12000 12000 3000 4200 6000 6750 7800 9450 12000 12000 12000 NNote: Minimum-trip on "X" coils is approximately 140% of continuous ratings. Table 5. Duty Cycle Type W WV27 WV38X VW VWV27 VWV38X % of Interrupting Rating Number of Unit Operations Maximum Circuit X/R Value 15-20 45-55 90-100 28 20 10 Total 58 28 20 10 Total 58 28 20 10 Total 58 88 112 32 Total 232 88 112 32 Total 232 88 112 32 Total 232 3 7 14 15-20 45-55 90-100 15-20 45-55 90-100 15-20 45-55 90-100 15-20 45-55 90-100 15-20 45-55 90-100 4 8 15 4 8 15 4 8 15 4 8 15 4 8 15 www.cooperpower.com 280-30-3 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Features and detailed description Construction Basic recloser design Like all the other reclosers from Eaton's Cooper Power Systems, the W-group reclosers are designed for long service life with little maintenance. Heads are aluminum castings. Tanks are heavy-gage steel, finished with light gray polyester powder paint (ASA70). An o-ring gasket confined in a groove, for controlled compression, assures an oil-tight seal between the head and the tank. A 1/2-inch brass oil-sampling and drain valve near the bottom of the tank is standard. Eaton's Cooper Power Systems three-phase W-group reclosers are designed to protect circuits on systems operating through 34.5 kV. With the ratings available and the ability of these reclosers to coordinate with other protective equipment, including lower-rated reclosers, they can be applied in a variety of schemes. The range of protection can be extended by a ground-trip accessory, which provides protection against ground-fault currents that are less than the minimum-trip value of the series coils. Flexibility of application is greatly enhanced by accessories that enable remote control of the recloser. Closing energy is supplied by a closing solenoid that simultaneously charges the opening springs in preparation for a tripping operation. Fault currents are sensed by trip coils (connected in series with the recloser contacts) that initiate the tripping operation by releasing the opening springs. The entire internal mechanism is suspended from the head casting so that the mechanism and the head assembly can be removed from the tank as a unit. Reclosers are mounted by brackets that can be attached to the head casting. This permits easy access to the contacts and the mechanism in the field by lowering the tank with a wire-rope winch, which is available as an accessory. The insulating supports from which the three interrupters are suspended are filament-wound glass epoxy for high electrical and mechanical strength and moisture resistance. Series tripping provides simple and reliable operation because the energy to initiate the tripping operation is taken directly from the line. W-group reclosers are self-contained: they require no external control or control power source. The hydraulic control incorporates separate elements to govern timedelay operations and regulate the number of operations to lockout. The W-group basic design has been proven by more than 50 years of field service. Bushings Wet-process porcelain. Closing Solenoid Contactor Momentarily energizes solenoid for closing operation. Clamp-Type Terminals Accept 1/0 - 500 MCM cable in horizontal or vertical position. Closing Tool Port For manually closing deenergized recloser. Operations Counter Made entirely of noncorrosive parts; large numbers are easy to read. Time-Delay Units (3) One each phase: provide time-delayed tripping. Red Contact Lever Shown down to indicate open. Grey Non-Reclosing Lever (not shown) When down, restricts operation to one shot to lockout after fault interruption. Yellow Manual Handle (not shown) Up for manual close and down for manual open. Fuse Protects system in event of closing solenoid failure. Closing Solenoid Operates recloser and charges opening springs. Moving Contacts Copper-tungsten alloy tips for long life. Series Trip Coil Senses overcurrents, initiates tripping. Timing Orifice Regulates reclosing time at two seconds. Interrupters Self-generating; vented for fast arc-extinction. Figure 1. Untanked Type WV recloser shown from series trip coil side. Construction of Types WV27, WV38X, VW, VWV27, and VWV38X is similar except for the vacuum interrupters on VW, VWV27, and VWV38X; see Figure 2. 280-30-4 www.cooperpower.com Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Operation Series trip coil Fault current in the W-group is sensed by the three trip coils that are connected in series with the recloser contacts and can carry line current up to their rating. Coils of applicable ratings are interchangeable among the W-group reclosers. Continuous current and minimum trip ratings can be changed by replacing the coils. When fault current in excess of the minimum trip ratings flows on one or more phases, the trip solenoid plunger, which is normally held at rest by the mechanism, is drawn into the coil by the magnetic effect generated by the fault current. Near the end of the downward stroke, a linkage connected to the trip plunger trips a latch that releases the charged opening springs and the recloser contacts are opened. The series trip coil is surge-protected by a shunting bypass gap on reclosers with trip coils rated below 100 A. Independent fault detection on each phase is provided by separate trip coils. A common bar trips all three phases, preventing singlephase supply to three-phase loads. A trip coil carrying a higher fault current will override and cause faster tripping than a phase experiencing a lower fault current. Lifting Strap Used for hoisting mechanism out of tank. Oil Dipstick Simplifies checking oil level. Head Casting Supports bushings and operating mechanism. Sleet Hood Houses manual operating handle, non-reclosing handle, contact position indicator, and operations counter. O-Ring Gasket Provides weatherproof seal between head casting and tank under all operating conditions. Manual Operating Handle Indicates locked-out recloser; permits manual operation. Insulating Supports Filament wound glass epoxy construction. Vacuum Interrupters Have extended duty cycle; require no maintenance; are easily replaced. Hydraulic Pump Counts number of operations to lockout; moves linkages to change from fast to delayed tripping according to preset sequence. Figure 2. Untanked view of a VW recloser shown from hydraulic pump side. www.cooperpower.com 280-30-5 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Closing solenoid Main Contacts Closing Solenoid Fuse ØC 5 6 Closing Solenoid Contactor Operating Mechanism Closing Solenoid ØB 3 4 Source Terminal Bushing Load ØA 1 2 Series Trip Coil Figure 3. Phase-to-phase connection of high-voltage closing solenoid. Types W, WV27, VW, VWV27 reclosers Types WV38X and VWV38X reclosers with 30 kV, 33 kV, or 34.5 kV closing solenoid coil. Figure 4. High-voltage closing solenoid contactors. 280-30-6 www.cooperpower.com Closing energy – as well as the energy to charge the opening springs in the W-group reclosers – is supplied by a high-voltage closing solenoid, which is connected phase-to-phase and energized through a contactor. When the recloser contacts are closed, the solenoid plunger is latched in the down position. This latch is tripped simultaneously with the release of the opening springs and the solenoid plunger moves upward. A timing orifice in the bottom of the solenoid-plunger cylinder regulates the rate at which upward movement can take place as oil is drawn into the cylinder. As the solenoid plunger reaches the top of its stroke, the highvoltage line contactor energizes the closing solenoid, pulling the plunger down. The closing solenoid contactor opens, de-energizing the coil, and, through the mechanical linkage, the main contactoperating rods are simultaneously moved upward to close the contacts. At the same time, the opening springs are charged in preparation for a tripping operation. W, WV27, VW, and VWV27 reclosers – which are rated through 24.9 kV – are equipped with a high-voltage closing solenoid contactor with two breaks in series. The higher rated reclosers – WV38X and VWV38X – are equipped with a contactor with four breaks in series. Control of the upward travel of the plunger regulates reclosing time. Normal reclosing time for the W-group reclosers is two seconds. The first reclosing operation in the programmed sequence can be 30 or 45 cycles when the dual-reclosing accessory is used. Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Technical Data 280-30 Effective July 2014 Hydraulic control system operation The number and sequence of operations to lockout and the time-delay operations are controlled by two separate hydraulic mechanisms which are mechanically linked. Lockout Settings Pin Pump-and-Lockout-Piston assembly Lockout Bar The hydraulic pump, associated cam, and linkages regulate the number of fast and delayed operations, count the operations to lockout, and, after a preset number of operations, initiate lockout. The hydraulic pump (Figure 5) is linked to the closing solenoid plunger and pushed downward with each return operation of the plunger. With its downward stroke, the pump forces a measured amount of fluid under the lockout piston, causing it to rise one step. Ball-type check valves retain the charge. When the closing solenoid is energized, the recloser contacts close and the pump returns to its normal position. The lockout piston is linked to the sequence selector cam (Figure 6) and the lockout bar. Upward movement of the lockout piston causes the cam to rotate counterclockwise and the lockout bar to advance one step. The number of fast operations are preset on the cam. After these operations, the cam edge engages the roller and pushes it to the right. A mechanism arm attached to the roller engages the time-delay mechanism on each phase. Subsequent operations are then delayed. Roller Lockout Piston Linkage Sequence Selector Cam Figure 6. Recloser operating sequence is determined by the number of fast operations programmed on the sequence selector cam. The number of delayed operations will be the balance of operations to lockout. The setting on the sequence selector cam is easily changed in the field. When the lockout bar completes its travel, it trips the lockout latch through another set of linkages and springs lock the recloser contacts open. The reset rod and valve (Figure 5) are raised, releasing hydraulic fluid from beneath the lockout piston so that it resets quickly. The entire pump and sequencing mechanism are now ready for the next full sequence of operations. For temporary faults that are cleared before the recloser mechanism reaches lockout, the lockout piston resettles gradually (at a rate of approximately 90 seconds per operation at 25 °C) to reset the recloser mechanism. Hydraulic Pump Acts as an accurate trip counter by pumping measured amount of oil under lockout piston. Quick-Release Rod and Valve Dumps oil from under lockout piston after lockout so recloser can immediately reset to begin another fault tripping sequence. Lockout Piston Advances toward its lockout position with each recloser trip. Figure 5. Cross-section of hydraulic pump. www.cooperpower.com 280-30-7 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Operating settings The required sequence of fast and delayed operations and the required number of operations to lockout are factory set per customer specification. Either or both settings are easily changed in the field; only a partial untanking of the recloser is necessary and no special tools are needed. Lockout bar Lockout-setting pin Pin Engagement Arm Adjustment Bracket Figure 7. The internal setting for the number of operations to lockout (two, three, or four) is achieved by positioning the lockout-setting pin in one of three notches in the lockout bar. This setting is easily changed in the field. Internal settings for the number of operations to lockout permit the recloser to be programmed for two, three, or four trip operations to lockout. Programming for one operation to lockout is done with the external non-reclosing handle located under the sleet hood. The internal setting is easily changed by moving the horizontal lockout bar (Figure 7) to index the lockout-setting pin in the required notch. Moving the external non-reclosing handle down activates the nonreclosing feature (one operation to lockout); this overrides the internal setting but does not change it physically. When the nonreclosing feature is deactivated (handle moved up), the number of operations to lockout automatically reverts to the internal setting, providing complete flexibility for testing or service without disturbing the programmed operations-to-lockout setting. The timing of recloser trip operations can be fast (which includes no intentional time delay), delayed (which follows one of four slower time– current characteristics), or a sequence of fast followed by delayed. The recloser mechanism is programmed simply by setting the number of fast operations required in each sequence of operations to lockout, by indexing a notched cam to the required number (Figure 6). It is easily changed by lifting the flat spring tab away from the cam and rotating the cam until the desired number of fast operations is indicated. The setting for the number of fast operations determines the number of delayed operations in the sequence; for example, if four operations to lockout are selected and the cam is adjusted for two fast operations, the sequence will be two fast operations followed by two delayed. Time-delay mechanism Delayed operations in W-group reclosers are established by the hydraulic time-delay mechanism on each phase. The time-delay mechanism is engaged with time–current characteristic. The selected curve is established by the time of engagement of the time-delay mechanism. For the B and D curves, approximately half of the stroke is unimpeded, then the trip coil linkage engages the time-delay mechanism and the remainder of the stroke is impeded, establishing the desired curve. With the slower (C and E) curves, the time of engagement is earlier. 280-30-8 www.cooperpower.com Thumbscrew Figure 8. Changing time-current characteristics to the alternate curve is accomplished by loosening the thumbscrew and indexing the adjustment bracket to the proper hole. The time-delay mechanism permits a choice of two characteristics: B and C or D and E. The time-delay curves will be set at the factory as specified. Adjustment from one characteristic to the other is made by indexing a thumbscrew-and-bracket arrangement on the time-delay mechanism to change the curve by changing the time of engagement (Figure 8). Established delay operations Operation of the time-delay mechanism is initiated by the integrating mechanism. As the indexing cam (Figure 6) is rotated counterclockwise by the upward movement of the lockout piston, it engages a roller assembly, causing the solenoid linkage engagement arm to pivot clockwise, placing its hook above the pin on the timedelay arm. When an overcurrent occurs and the engagement arm moves downward with the trip coil linkage, the hook engages the pin on the time-delay arm and the time-delay mechanism impedes the remainder of the stroke. Operation The hydraulic time-delay mechanism piston is pulled downward by the trip coil linkage. A floating plate (retained by an open basket) at the bottom of the hollow piston functions as a one-way valve on the downstroke, sealing the bottom of the piston. On low-current operations, displaced oil is forced around the grooved pin in the low-current valve and is allowed to return to the space above the piston. When a higher current fault is interrupted, increased oil pressure raises the springloaded valve so that oil flows through both valves and the tripping operation is accelerated proportionately. The hydraulic time-delay mechanism has no effect on contactopening speed – it only delays the moment at which the opening springs are released. Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Technical Data 280-30 Effective July 2014 Interrupter construction Vacuum interrupters Oil interrupters Vacuum interrupters provide fast, low-energy arc interruption with long contact and interrupter life, low mechanical stress, and maximum operating safety. With arc interruption taking place in a vacuum, contact and interrupter life are several times greater than with interruption in oil, and interrupter maintenance is virtually eliminated. Because of the shorter contact stroke, mechanical stress and wear on the mechanism is substantially reduced. Fast arc interruption (down to 2-1/2 cycles clearing) is achieved by bridge-type contacts that provide two current breaks in series per phase. The bayonet-type moving contacts are silver-plated tungsten alloy for erosion resistance and good conductance. The stationary contact assemblies are tulip-type clusters of silver-plated contact fingers held together by garter springs. The contacts are self-cleaned by the opening and closing wiping action. Vacuum interrupters are designed with a metal and ceramic housing for maximum strength and long-term vacuum integrity. The highalumina ceramic has more than five times the strength of glass, permits a higher processing temperature to develop maximum purity of the assembly, and is impervious to helium penetration to sustain the vacuum level. Metal end-closures and the arcing chambers are of high-purity alloy to minimize contamination. Enclosed in the interrupter is a stationary and a moving contact assembly. The moving contact has a travel of approximately one-half inch, its shaft passing through a flexible bellows which maintains vacuum integrity. Contacts are made of a special non-welding alloy. Because the smallest amount of internal contamination can significantly shorten the life of a vacuum interrupter, a clean-room facility is used for interrupter production. Special care is taken to avoid even minute contamination from any source, whether it be dust particles, machining oils, or human body salts. Figure 9. General construction of a typical self-generating interrupter used in oil interrupting reclosers. Each current break is provided with a self-generating arc interrupter structure which includes a series of vented chambers. As the contacts open, the arc generates gas pressure in the upper chamber that blasts oil across the arc and out through the vents. As a result, arc extinction is fast and arc energy levels do not increase as fast at the higher fault-current levels. Figure 10. General construction of a typical vacuum interrupter used in vacuum interrupting reclosers. www.cooperpower.com 280-30-9 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Accessories Hydraulic ground-trip accessory W-group reclosers can be supplemented with a number of accessories to provide added application flexibility. Some accessories modify the normal operating functions while others increase operating versatility; still others provide indicating functions. For each accessory installed on a particular recloser, a data plate is mounted on the sleet hood of the recloser. Where required, accessory leads are brought into the recloser tank through a junction box mounted on the head casting. Bushing-type, multi-ratio current transformers Multi-ratio current transformers for operating meters or separate relays can be mounted on load-side bushings 2, 4, and 6 or the source-side bushings 1, 3, and 5 (Figure 11). These current transformers have only one primary turn – the bushing rod. They are available with secondary windings that provide primary/secondarycurrent ratios of either 600:5 or 1200:5. Different ratios can be obtained by connection to appropriate taps on their secondary windings. Ratios obtainable from 600:5 and 1200:5 transformers are shown in Table 6. Figure 12. Ground-trip coil mounted in recloser. If the rated minimum zero-sequence (ground) current is exceeded, the hydraulic ground-trip mechanism – an oil-dashpot-type solenoid connected to paralleled BCT secondaries – trips the recloser. The hydraulic ground-trip mechanism accessory enables the recloser to protect against ground-fault currents lower than the recloser’s minimum phase-trip setting. For currents above the minimum phase-trip setting, recloser opening is governed by either the phasetrip series coil or the ground-trip coil, whichever is faster. Refer to Reference Data R280-91-7 for available delay curves. The ground trip coil is operated from the bushing-type, multi-ratio current transformers mounted on the source-side bushings (1, 3, and 5) to produce the minimum ground-trip currents shown in Table 7. The current transformers must be ordered separately. Table 7. Ground-Trip Operating Data Bushing Current Transformer Ratio Figure 11. Multi-ratio current transformers mounted on the source-side bushings. Table 6. Bushing-Type Multi-Ratio Current Transformer Ratios and Terminal Connection Minimum Zero-Sequence Trip Current (primary A) Series Connected Coil Parallel-Connected Coil 50:5 N/A* N/A* 100:5 63.5 110 150:5 87 156 200:5 110 204 250:5 133 250 300:5 156 300 400:5 204 400 450:5 227 450 500:5 250 500 600:5 300 600 Ratio Ratio Terminal Connection 50:5 100:5 X2 - X3 100:5 200:5 X1 - X2 150:5 300:5 X1 - X3 200:5 400:5 X4 - X5 250:5 500:5 X3 - X4 * Not applicable: BCT output loo low to operate solenoid. 300:5 600:5 X2 - X4 Electronic ground-trip accessory 400:5 800:5 X1 - X4 450:5 900:5 X3 - X5 500:5 1000:5 X2 - X5 Self-contained, independent, sensitive ground-fault tripping is also available with an electronically controlled ground-trip accessory that includes the following: 600:5 1200:5 X1 - X5 280-30-10 www.cooperpower.com • Fifteen fault-timing characteristics including inverse and definitetime curves, or plug-in modules that are easily field changed. • Dual-timing capability. • Twelve minimum-trip levels, from 5 to 400 A. • Line powered; completely self-contained. • Precharging coil for consistent timings even when reclosing on a permanent fault. Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Technical Data 280-30 Effective July 2014 Circuit card with plug-in timing curves and minimum trip resistor Magnetic tripper If the system downline from the recloser is energized by other than electrical operation of the recloser (such as the closing of an upline recloser or breaker), control-circuit arming time must be added to the published time-current characteristic for proper TCC coordination. Further information that can be used in anticipating such circumstances is found with the published time-current characteristics on this accessory; refer to Eaton's Cooper Power Systems Reference Data R280-91-12 ,Types RX, RV, W, WV, VW, VWV Time-Current Curves. Ground-trip blocking switch A ground-trip blocking switch can be provided for either groundtrip accessory. The hotstick-operated blocking switch (Figure 14) is normally mounted on the recloser. The manual lever-operated blocking switch (Figure 16) is for remote mounting. Precharge element Dual-timing switch Figure 13. Components of electronic ground-fault trip accessory. Fault-timing characteristics and timing operations are independent and separate from the recloser’s phase fault timing and TCCs. Counting to lockout is integrated with phase operations. The dualtiming feature enables coordination with other protective apparatus on the system. Accessory control circuits are powered from the line through two current transformers mounted under the head casting on sourceside bushings (Figure 13). Five amperes of line current is all that is required to maintain circuit charge and supply the trip operation. Figure 15. Ground-trip blocking switch for remote manual operation. Zero-sequence (ground) current is sensed by three parallelconnected current-sensing transformers mounted beneath the head casting on the load-side bushings. When the ground current exceeds the selected minimum-trip level, the control circuits actuate the magnetic tripper to trip the recloser. Ground overcurrent timing is according to the time-current characteristics programmed with plugin modules on the accessory circuit board. When the recloser automatically recloses or is otherwise closed by electrical operation of its closing solenoid, an initial arming feature instantly charges the accessory control circuits. This enables the groundtrip accessory to respond immediately, according to its programmed time-current characteristic, should a ground fault be present. Figure 14. Ground-trip blocking switch; hotstick-operated. www.cooperpower.com 280-30-11 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Table 9. Interrupting Ratings of Auxiliary Switch Volts (ac or dc) Inductive ac (A) Non-Inductive ac (A) Inductive dc (A) Non-Inductive dc (A) 24 – – 15 20 48 – – 7.5 10 120 50 80 – – 125 – – 1.5 2 240 25 40 – – 250 – – 0.45 0.5 Low-voltage AC closing With the addition of a modified closing contactor equipped with a full-wave diode bridge (Figure 17), the dc closing solenoid can be operated from a low-voltage ac source. Current requirements for ac closing are 51 A at 120 Vac or 34 A at 240 Vac. Figure 16. Remote trip solenoid. Auxiliary switch Remote trip When energized from an external source, the remote trip accessory (Figure 16) trips the recloser, just as when the series trip coil operates. Normal automatic reclosing follows. Reclosing will occur even if the solenoid remains energized. Should this condition occur, the recloser will operate to lockout. The remote trip accessory leads are brought out of the recloser tank through a separately specified accessory junction box. Electrical ratings are shown in Table 8. Remote indication of recloser contact position or switching of other devices can be accomplished with an auxiliary switch. A three-stage switch is mounted on the recloser (Figure 18). Each stage has two independent contacts a and/or b. When the recloser’s main contacts are open, the a contacts are also open and the b contacts are closed. Table 10 shows the recloser/ auxiliary switch contact relationship. Switch contacts are insulated for 600 V and have a continuous current rating of 10 A. The interrupting ratings of the auxiliary switch contacts are shown in Table 9 above. NNote: The remote trip accessory cannot be installed on a recloser equipped with a ground-trip accessory (hydraulic or electronic) since both occupy the same space and operate the same trip-lever mechanism. Table 8. Electrical Ratings of Remote Trip Accessory; Intermittent Duty Only Rated Voltage (Vac) Operating Voltage Range (Vac) Steady-State Current at Rated Voltage (A) 120 95-125 1.3 240 190-250 0.65 Low-voltage DC closing By specifying a dc-closing solenoid from Table 17 and this accessory, the recloser can be closed by an externally controlled low-voltage dc power source rather than from the primary high-voltage source. A separately specified accessory junction box with input terminal block is also required. Low voltage is especially desirable in loop and loadtransfer schemes where the recloser can be operated regardless of which side of the unit is energized. Current requirements for dc closing are 55 A at 125 Vdc or 58 A at 48 Vdc. Figure 17. Low-voltage ac closing accessory. 280-30-12 www.cooperpower.com Figure 18. Auxiliary switch (with cover removed). Table 10. Recloser/Auxiliary Switch Contact Positions Auxiliary Switch Recloser Contacts Contact A Contact B CLOSED CLOSED OPEN OPEN OPEN CLOSED Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Lockout-indicating switch Table 12. Electrical Ratings of Remote Lockout Accessory A lockout-indicating switch assembly can be added for remote indication of recloser lockout (Figure 19). The switch is particularly useful in load-transfer schemes. Consisting of two single-pole, double-throw switches in a weatherproof housing, the assembly is actuated by the recloser’s manual operating lever. A threaded opening for a one-half inch IPS conduit or cable grip is provided. Rated Voltage (Vac) Operating Voltage Range (Vac) Steady-State Current at Rated Voltage (A) 115 95-125 0.36 230 190-250 0.18 Electrical ratings of the lockout-indicating switch are shown in Table 11. Figure 21. Remote closing solenoid. Figure 19. Lockout-indicating switch. Table 11. Electrical Ratings of Lockout-Indicating Switch Accessory Interrupting Rating (A) Operating Voltage 10 120 Vac 5 240 Vac 0.5 125 Vdc 0.25 250 Vdc Remote lockout The remote lockout accessory (Figure 20) enables an external control to trip the recloser and operate the lockout mechanism. The remote lockout accessory leads are brought out of the recloser tank through a separately specified accessory junction box with terminal block. Remote close When energized from an external source, the remote close accessory closes a locked-out recloser by manually pulling the operating handle to the CLOSE position, actuating the high-voltage closing solenoid contactor to close the recloser. The external control circuit for this accessory requires a connection that includes a customer-furnished, normally open, momentary contact switch wired in series with the solenoid. Electrical ratings of the remote close of locked-out recloser accessory are shown in Table 13. NNote: When this accessory is added to a recloser, the recloser cannot lockout if the remote close accessory is held energized. Table 13. Electrical Ratings of Remote Close Accessory Rated Voltage (Vac) Operating Voltage-Range (Vac) Current at Rated Voltage (A) Inrush Steady-State 115 100-125 32-34 3.25 230 200-250 16-18 1.67 Electrical ratings of the remote lock-out accessory are shown in Table 12. NNote: To provide complete remote operation, the remote lockout accessory is usually employed with the remote close accessory. Figure 20. Remote lockout solenoid. www.cooperpower.com 280-30-13 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Remote block of closing The remote block of closing accessory enables remote control of closing (Figure 22). One type blocks closing when the solenoid is energized; the other blocks closing when the solenoid is de-energized. Electrical ratings of the remote block of closing accessory are shown in Table 14. Table 14. Electrical Ratings of Remote Block of Closing Accessory Rated Voltage (Vac) SteadyState Current (A) Operating Voltage Range (Vac) 115 95-125 0.2 230 190-250 0.1 115 95-125 0.2 230 190-250 0.1 Status Figure 22. Remote block of closing solenoid. Blocks when de-energized Blocks when energized Dimensions and weights H I I J NNote: For dimensions of reclosers with mountings, see Service Information S280-85-2 Recloser Mountings. G B Terminal Connectors 1/0—500 MCM C A Ground Connector 8 Sol—2/0 Str K E F Figure 23. Dimensions of W-group reclosers. 280-30-14 www.cooperpower.com D Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Table 15. Overall Dimensions mm (in.) Recloser Type W VW Without bushing current transformer accessory Standard 13 in. creepage or 17-in. extra-creepage bushings WV27 VWV27 WV38X Standard 26-1/2-in. creepage bushings VWV38X Recloser Type W VW With bushing current transformer accessory Dim A Dim B Dim C Dim D Dim E Dim F Dim G Dim H Dim I* Dim J Dim K 1057 41-5/8 283 11-1/8 79 3-1/8 333 13-/8 933 36-3/4 1076 42-3/8 435 17-1/8 1172 46-1/8 289 11-3/8 343 13-1/2 676 26-5/8 1114 43-7/8 283 11-1/8 79 3-1/8 333 13-1/8 933 36-3/4 1076 42-3/8 435 17-1/8 1172 46-1/8 289 11-3/8 343 13-1/2 733 28-7/8 1213 47-3/4 302 11-7/8 105 4-1/8 333 13-1/8 933 36-3/4 1076 42-3/8 435 17-1/8 1172 46-1/8 289 11-3/8 343 13-1/2 676 26-5/8 1270 50 302 11-7/8 105 4-1/8 333 13-1/8 933 36-3/4 1076 42-3/8 435 17-1/8 1172 46-1/8 289 11-3/8 343 13-1/2 733 28-7/8 1197 47-1/8 381 15 105 4-1/8 438 17-1/4 940 37 1083 42-5/8 540 21-1/4 1178 46-3/8 384 15-1/8 254 10 676 26-5/8 1254 49-3/8 381 15 105 4-1/8 438 17-1/4 940 37 1083 42-5/8 540 21-1/4 1178 46-3/8 384 15-1/8 254 10 733 28-7/8 Dim A Dim B Dim C Dim D Dim E Dim F Dim G Dim H Dim I* Dim J Dim K 1178 46-3/8 Standard 13 in. creepage or 17-in. extra-creepage bushings 1235 48-5/8 1334 52-1/2 WV27 VWV27 WV38X 1391 54-3/4 Standard 26-1/2-in. creepage bushings 1314 51-3/4 VWV38X 1375 54-1/8 302 79 333 933 1076 435 1172 289 343 676 11-7/8 3-1/8 13-1/8 36-3/4 42-3/8 17-1/8 46-1/8 11-3/8 13-1/2 26-5/8 302 79 333 933 1076 435 1172 289 343 733 11-7/8 3-1/8 13-1/8 36-3/4 42-3/8 17-1/8 46-1/8 11-3/8 13-1/2 28-7/8 321 105 333 933 1076 435 1172 289 343 676 12-5/8 4-1/8 13-1/8 36-3/4 42-3/8 17-1/8 46-1/8 11-3/8 13-1/2 26-5/8 321 105 333 933 1076 435 1172 289 343 733 12-5/8 4-1/8 13-1/8 36-3/4 42-3/8 17-1/8 46-1/8 11-3/8 13-1/2 28-7/8 403 105 438 940 1083 540 1178 397 241 676 15-7/8 4-1/8 17-1/4 37 42-5/8 21-1/4 46-3/8 15-5/8 9-1/2 26-5/8 403 105 438 940 1083 540 1178 397 241 733 15-7/8 4-1/8 17-1/4 37 42-5/8 21-1/4 46-3/8 15-5/8 9-1/2 28-7/8 * Dim. I is the distance between bushings (centerline-to-centerline.) Table 16. Weights and Oil Capacity Recloser Type Weight with Oil* kg (lb.) Oil Capacitor L (gal) W 356 (785) 144 (38) WV27 359 (790) 156 (41) WV38X 459 (1012) 201 (53) VW 384 (845) 156 (41) VWV27 384 (845) 171 (45) VWV38X 422 (930) 224 (59) * Add 11 kg (25 lb) for each bushing current transformer. www.cooperpower.com 280-30-15 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Constructing a catalog number To order a basic Type VW recloser with a 560 trip coil, a 750 A minimum-trip current, a B time-current curve, with two fast and two delayed operations to lockout for service on a 12.0-13.2 kV system, the catalog number would be constructed like this: KVW Basic letters for a Type VW recloser Basic letters for other reclosers: Type W: KW Type WV27 KWV27 Type WV38X KWVP Type VW KVW Type VWV27 KVWV27 Type VWV38X KVWVP 560 Continuous current rating of series-trip coils: 5, 10, 15, 25, 35, 50, 70, 100, 140, 160, 185, 200, 225, 280, 400, or 560 A. (Minimum-trip current is 200% of continuous rating.) X Insert letter X only if a type X series trip coil is used; otherwise omit letter. Continuous current rating of X series trip coils: 70, 100, 140, 160, 185, 225, 280, 400, or 560 A. (Minimumtrip current is 140% of continuous rating.) B Delayed time-current curve desired: B, C, D, or E. If all fast operations are required, insert letter A. Fast+delayed 2 Number of fast A-curve operations: 0, 1, 2, 3, or 4. operations not to exceed four 2 Number of delayed operations: 0, 1, 2, 3, or 4. 4 Closing solenoid voltage code number selected from Table 17 for the system on which the KVW recloser is to be used. 560 X B 2 2 4 KVW560XB224 is the catalog number for the required basic recloser. Ordering information To order a basic W-group recloser, use the chart above and Table 17 to construct a catalog number that describes the required recloser. Order accessories and mounting equipment from Tables 18 through 30. Table 17. Closing Solenoid Voltage Code Numbers Phase-to-Phase Closing Solenoid Operating Voltage ± 15% (kV) Code No. 2.4 1 3.3 10 4.16-4.8 2 1. Recloser Type: W, WV27, WV38X, VW, VWV27, or VWV38X. 6.0 6 2. Series trip coil continuous current rating. 7.2-8.32 3 3. Need for series trip coil with a minimum trip current rating other than 200% of continuous current rating. 11.0 9 12.0-13.2 4 14.4 5 17.0 12 20.0 11 23.0-24.9 13 34.5 14 Construction of a catalog number requires: 4. Delayed time-current curve; B, C, D, or E. 5. Number of operations on delayed curve: 0, 1, 2, 3, or 4. 6. Closing solenoid voltage code. Low-Voltage Closing Solenoid Operating Voltage (Vdc) 48 16* 125 7* 250 8* * Requires either low-voltage dc closing accessory (KA631R) or low-voltage ac closing accessory (KA742R). Order separately. 280-30-16 www.cooperpower.com Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Table 18. Multi-Ratio Bushing Current Sensing Transformers Factory-Installed on Load-Side Bushings 2, 4, and 6* Description Catalog Number** Types W and VW Three 600:5 BCTs on 13 in. creepage bushings Three 600:5 BCTs on 17 in. creepage bushings Three 1200:5 BCTs on 13 in. creepage bushings KA804W3X KA110W3X*** KA827W3X Types WV27 and VWV27 Three 600:5 BCTs on 26-1/2 in. creepage bushings Three 1200:5 BCTs 26-1/2 in. creepage bushings KA14WV3X KA24WV3X Types WV38X and VWV38X Three 600:5 BCTs on 26-1/2 in. creepage bushings Three 1200:5 BCTs on 26-1/2 in. creepage bushings KA82WV3X KA83WV3X * To specify accessory BCTs on source-side bushings, include the digit “9” after the “A” in the catalog number and specify source-side bushings in the order description. ** If factory wiring is ordered, replace the “X” in the catalog number with the ratio to be connected: 1200 = 1200:5; 1000 = 1000:5; 900 = 900:5; 800 = 800:5; 600 = 600:5; 500 = 500:5; 450 = 450:5; 400 = 400:5; 300 = 300:5; 250 = 250:5; 200 = 200:5; 150 = 150:5; 100 = 100:5; 50 = 50:5. ***Catalog number includes the extra-creepage bushings. Table 19. 600:5 Multi-Ratio Bushing Current Transformers for Field Installation Description Catalog Number Slip-on bushings current transformer kit; one BCT per kit KA712L2 Set of 3 BCTs KA712L2-3 Wiring kit for KA712L2-3 (one wiring kit required per recloser) Basic cable, no length. Replace X with number of feet. KA895R7-X Table 20. Service-Related; Hardware Description Catalog Number Junction box with terminal block; factory-installed KA187R Manual closing tool; de-energized recloser, factory-installed W, VW, WV27, and VWV27 WV38X, VWV38X KA476R KA66WV T-handle closing tool: de-energized recloser KA90R2 Oil-level sight gauge; factory-installed KA161W www.cooperpower.com 280-30-17 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Table 21. Automatic Tripping and Closing; Factory-Installed Description Catalog Number Hydraulic ground trip* KA510R2XXX** Electronic ground trip; minimum-trip current and timing curves must be specified*** Types W and WV27 Types VW and VWV27 Types W and WV27 with KA742, ac closing Types VW and VWV27 with KA742, ac closing Type WV38X Type VWV38X Type WV38X with KA742, ac closing Type VWV38X with KA742, ac closing KA1219R1 KA1219R2 KA1219R3 KA1219R4 KA62WV1 KA62WV2 KA62WV3 KA62WV4 Specify minimum-trip resistor Select minimum-trip current of 5, 10, 20, 30, 50, 70, 100, 140, 200, 280, 320, or 400 A Minimum-trip resistor____amperes. KA1197R__**** Specify constant time plug in first socket Select timing plug 1, 2, 3, 4, 5, 6, 7, 8, or 9 Timing plug______ KA1199R__-1__† Specify constant time plug in second socket Select timing plug 1, 2, 3, 4, 5, 6, 7, 8, or 9 Timing Plug______ KA1199R__-2__† -ORSpecify inverse time plug in first socket Select timing plug 1, 2, 3, 4, 5, or 6 Timing plug______ KA1200R__-1__† Specify inverse time plug in second socket Select timing plug 1, 2, 3, 4, 5, or 6 Timing plug______ KA1200R__-2__† Ground-trip blocking switch for KA510R, KA1219R, and KA62WV With manual switch handle. (Not mounted or wired. Generally used when recloser is mounted in KA89WV1 frame and switch is to be mounted on frame. Also for mounting remote from recloser.) KA813R1†† With pullring for hotstick (Mounted on recloser and wired to junction box. Cannot be used if recloser is mounted in KA89WV1 frame or in KA146W5 frame that has a KA146W2 windlass.) KA813R2†† With pullring for hotstick; for use when recloser is mounted in KA89WV1 frame or in KA146W5 frame that has a KA146W2 windlass. (Mounted on recloser and wired to junction box.) KA813R4††† Dual reclosing time First reclosing: 30 cycles First reclosing: 45 cycles KA547R1 KA547R2 * Requires KA187R junction box with terminal block, multi-ratio BCT accessory as shown in Table 3 and a KA843R, factory wiring, or KA850R, factory assembly, to complete wiring from multi-ratio BCTs to the ground trip mechanism. Hydraulic ground trip accessory cannot be used on a recloser that has a KA378R remote trip. ** Replace “Xs” in catalog number in following sequence from left to right: number of time-delay curve desired; number of fast operations (0, 1, 2, 3, or 4); and the numeral “1” for series-connected or the numeral “2” for parallel-connected coils. *** Note: Electronic ground trip accessory cannot be used on a recloser that has KA378R remote trip, KA631R dc closing, KA275R or KA276R remote block of closing, or KA1169R closing coil transfer switch. **** Complete the catalog number by specifying the selected value of the component. † Complete the catalog number by specifying the selected value for the component and the number of operations. †† Requires KA187R junction box with terminal block. ††† Junction box is included with accessory; do not order separately. 280-30-18 www.cooperpower.com Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Table 22. Remote Operation and Indication; Factory-Installed * Description Catalog Number Three-stage auxiliary switch with six independent contacts KA369R3 Lockout-indicating switch; dpdt contacts operated by recloser operating handle KA296R1 Remote trip 120 Vac 240 Vac 24 Vdc 48 Vdc 125 Vdc KA378R1* KA378R2* KA378R5* KA378R4* KA378R3* Remote lockout 120 Vac 240 Vac 24 Vdc 48 Vdc 125 Vdc KA475R1** KA475R2** KA475R3** KA475R4** KA475R5** Remote close 120 Vac 240 Vac 48 Vdc 125 Vdc KA486R1† KA486R2† KA486R4† KA486R3† Remote block of closing with coil de-energized 120 Vac 240 Vac or 125 Vdc KA275R1*** KA275R2*** Remote block of closing with coil energized 120 Vac 240 Vac or 125 Vdc KA276R1*** KA276R2*** Requires KA187R junction box with terminal block. Remote trip cannot be used on a recloser that has KA510R, KA62WV, or KA1219R ground trip accessories. ** Requires KA187R junction box with terminal block. *** Requires KA187R junction box with terminal block. Remote block of closing accessories cannot be used on a recloser that has a KA1219R or KA62WV electronic ground trip. † Can not be used on WV38X and VWV38X. Table 23. Low-Voltage Closing; Factory-installed Description Low-voltage dc closing, requires that recloser be ordered with dc closing coil 48 Vdc Types W, WV27, WV38X Types VW, VWV27, VWV38X 125 Vdc Types W, WV27, WV38X Types VW, VWV27, VWV38X 250 Vdc Types W, WV27, WV38X Types VW, VWV27, VWV38X Catalog Number KA631R11* KA631R13* KA631R1* KA631R5* KA631R2* KA631R6* Low-voltage ac closing; with KA1219 or KA62WV, electronic ground trip; requires that recloser be ordered with dc closing coil 120 Vac Types W, WV27, WV38X Types VW, VWV27, VWV38X 240 Vac Types W, WV27, WV38X Types VW, VWV27, VWV38X KA742R22** KA742R24** Low-voltage ac closing, without electronic ground trip, requires that recloser be ordered with dc closing coil 120 Vac Types W, WV27, WV38X Types VW, VWV27, VWV38X 240 Vac Types W, WV27, WV38X Types VW, VWV27, VWV38X KA742R1** KA742R5** KA742R23 KA742R25 KA742R2** KA742R6** * Requires KA187R junction box with terminal block. Dc closing accessory cannot be used on a recloser that has a KA1219R or KA62WV ground trip. ** Requires KA187R junction box with terminal block. www.cooperpower.com 280-30-19 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Table 24. Bushings and Terminals; Factory-Installed (set of six) Description Catalog Number 17-in. creepage standard length bushings Types W and VW KA25W Flat-pad terminals, two-hole Types W, VW with 13 in. or 17 in. creepage, standard or CT length bushings Types WV27, WV38X, VWV27, VWV38X with 261/2 in. creepage, standard length bushings Types WV27, WV38X, VWV27, VWV38X with 261/2 in. creepage, CT length bushings KA82W1 KA62RV3 KA62RV4 Flat-pad terminals, four-hole Types W, VW with 13 in. or 17 in. creepage, standard or CT length bushings Types WV27 and VWV27 with 261/2 in. creepage, standard length bushings Types WV27 and VWV27 with 261/2 in. creepage, CT length bushings KA156W1 KA61RV3 KA61RV4 Stud terminals, 11/8 12 UNF-2A Types W, VW with 13 in. or 17 in. creepage, standard or CT length bushings Types WV27, WV38X, VWV27, VWV38X with 261/2 in. creepage, standard length bushings Types WV27, WV38X, VWV27, VWV38X with 261/2 in. creepage, CT length bushings KA800W1 KA59RV3 KA59RV4 Table 25. Epoxy Bushings (set of six) and Required Terminals Description Catalog Number Epoxy bushing, standard length Types WV27, WV38X, VWV27, VWV38X KA67RV3 Epoxy bushing, BCT length Types WV27, WV38X, VWV27, VWV38X KA67RV4 Eyebolt terminals, 1/0 to 500 MCM cable Types WV27, WV38X, VWV27, VWV38X KA68RV2 Flat-pad terminals, two-hole Types WV27, WV38X, VWV27, VWV38X KA68RV3 Stud terminals, 1 1/8-12 UNF2 Types WV27, WV38X, VWV27, VWV38X KA68RV4 Flat-pad terminals, four-hole Types WV27 KA81RV5* Flat-pad terminals, four-hole Types WV38X, VWV27, VWV38X KA81RV7* * Limited to 125 kV BIL. Table 26. Factory Assembly of Recloser and Accessories in KA89WV1 Substation-Mounting Frame* Description Catalog Number Recloser on frame; no accessories with or without BCTs KA813W Factory assembly with ground trip and shorting switch KA850R * Includes factory assembly only; recloser, accessories, and mounting frame must be ordered separately. Table 27. Factory Assembly of Recloser in Pole-Mounting Frames* Description Catalog Number Recloser in KA146W5; with or without BCTs KA881R2 Recloser in KA706R1; with or without BCTs KA881R1 * Includes factory assembling only; recloser and mounting must be specified separately. 280-30-20 www.cooperpower.com Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Technical Data 280-30 Effective July 2014 Table 28. Mounting Equipment Description Catalog Number Substation-mounting equipment Basic mounting frame Hardware for attaching KA813R ground-trip blocking switch to KA89WV1 frame Removable tank-lifting windlass for KA89WV1 frame KA89WV1 KA89WV6 KA89WV2 Pole-mounting equipment Single-pole-mounting hanger End-mounted pole hanger KA146W5* KA706R3 Tank-lifting windlass for single-pole hanger KA146W2 Surge-arrester-mounting bracket Inboard (source) Outboard (load) KA126H3 KA847W * Requires KA883R, BCT conduit assembly, when recloser has source-side BCTs. Table 29. Factory Assembly of Conduit and Wiring* Description Catalog Number BCTs wired to KA510R2 hydraulic ground trip through KA187R junction box. If recloser is to be mounted with a KA146W5 frame and BCTs are on the pole side, a KA883R2 conduit kit must be specified Types W, VW, WV27, VWV27 Types WV38X, VWV38X KA843R KA80WV * Includes factory assembling only; recloser, accessories, and mounting must be specified separately. Table 30. Training-Related; Equipment Maintenance and Operation Aids Description Catalog Number General Maintenance and Inspection Procedures for Reclosers DVD (28 min.) KSPV1A Mechanical Operation, Service and Testing for Three-Phase Hydraulic Reclosers DVD (28 min.) KSPV5A www.cooperpower.com 280-30-21 Technical Data 280-30 Effective July 2014 280-30-22 www.cooperpower.com Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Technical Data 280-30 Effective July 2014 www.cooperpower.com 280-30-23 Technical Data 280-30 Types W, WV27, WV38X, VW, VWV27, and VWV38X three-phase reclosers Effective July 2014 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-30 280-30-24 Eaton and Cooper Power Systems are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. For Eaton's Cooper Power Systems three-phase recloser product information call 1-877-277-4636 or visit: www.cooperpower.com. Technical Data 280-40 Effective July 2014 Supersedes May 2005 Types VWE, VWVE37, VWVE38X, WE, WVE27, and WVE38X, three-phase electronically controlled reclosers Type VWVE27 Type WE General The W-group electronically controlled, three-phase automatic circuit reclosers from Eaton's Cooper Power Systems provide reliable, economical overcurrent protection for distribution circuits rated through 38 kV. Compact in design, these reclosers can be easily installed on poles or in substations. The six reclosers in this group provide serviceproven dependability and long operating life. Commanded by an Eaton's Cooper Power Systems electronic recloser control, these automatic circuit reclosers offer superior coordination and application capability unmatched by other system protection apparatus. Their broad application capabilities permit the user to select exactly the right recloser for the protection required. Recloser settings are configured by the electronic control with accurate, preset tripping characteristics and reclosing times. Trip times are precise and unvaried, enabling close coordination with other protective devices on the system. When system requirements change, program settings are easily altered with no sacrifice of accuracy or consistency. When needed, application expertise backed by world-wide recloser application experience is available. Knowledgeable design capability – based on more than fifty years of recloser manufacturing experience – has made Eaton's Cooper Power Systems the industry leader. Progressive product development programs, using the latest technologies, have resulted in the production of modern, efficient Eaton's Cooper Power Systems reclosers. W-group reclosers, like all reclosers from Eaton's Cooper Power Systems, are designed and manufactured in accordance with ANSI® C37.60. The six distinct reclosers in the W-group – Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X – offer a broad selection of ratings to fit varied system needs. Recloser and control accessories enable further tailoring of the protective program to achieve maximum system operating flexibility. Mounting equipment, available for pole or substation, eases installation of the recloser wherever system requirements demand. 280-40-1 Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 Ratings and characteristic features Ordering information Three-phase protection on systems rated 2.4 through 14.4 kV is provided by Types WE or VWE reclosers. Types WVE27 or VWVE27 can be applied on systems rated through 24.9 kV. Higher-voltage system protection (24.9 through 34.5 kV) is provided by Types WVE38X and VWVE38X reclosers. A ratings summary for this recloser group is shown in Table 1. For ratings and basic application information for other reclosers, refer to Catalog Section 280-05. A complete electronically controlled recloser installation includes these items: Operation The recloser, control, and interconnecting cables are ordered and priced separately. Accessories for the recloser and the control are ordered and priced separately. Sensing current transformers, mounted in the recloser, supply faultsensing information to the electronic control. Tripping and closing signals from the control energize the operating circuits in the recloser. Due to a single CT ratio for all ratings, minimum-trip values of the electronic control are independent of the continuous-current and interrupting ratings of the recloser. Flexibility in coordination with other protective devices is provided by dual time-current characteristics from a choice of available curves, minimum trip values, reclosing and resetting time settings, and a selection of accessories. Closing solenoid Contact-closing energy is provided by a closing solenoid that also stores energy in the trip mechanism. High-voltage closing solenoids are connected to the system on the source-side of the recloser. Selection of solenoid voltage rating is based on the system phase-tophase operating voltage. Low-voltage closing solenoids can be employed. Auxiliary voltage must then be supplied to the recloser. Oil or vacuum interruption A choice of interrupting medium is available. Types WE, WVE27, and WVE38X reclosers use oil as the arc interrupting medium. Movable bridge-type contacts provide two breaks in series on each phase. Separate self-generating interrupter chambers at each of the two breaks provide for effective interruption of all currents, from minimum load to rated maximum fault. Vacuum interruption, used in Types VWE, VWVE27, and VWVE38X, offers considerably longer duty cycles and long contact life. A single break on each phase is accomplished by separating contacts inside the vacuum interrupter. All arcing is contained within the vacuum envelope. Low-energy arc interruption in a vacuum results in far less shock and contact wear, extending the recloser mechanism life. Because interruption within the vacuum envelope does not add contaminants to the insulating oil, recloser maintenance is minimized and intervals between oil changes can generally be extended. Surge protection Best operating results are achieved if reclosers are protected with surge arresters. On line applications, arrester protection is recommended on both sides of the recloser. (If protection is on one side only, it should be on the source-side.) In substations, arresters should be on the load-side. Eaton's Cooper Power Systems distribution-class arresters provide excellent protection and are available with mounting brackets to fit our reclosers. Refer to Catalog Sections 235-35 and 235-99. 280-40-2 www.cooperpower.com • Recloser and accessories • Electronic control and accessories • Interconnecting control cable • Recloser mounting equipment (if required) To order a recloser, electronic control, and control cable: 1. Use Tables 2 and 3 to construct a catalog number that describes the required recloser. 2. From Tables 4-15, specify the catalog numbers that describe the required recloser accessories, mounting equipment, and factory assemblies. 3. Order the required electronic recloser control (control is ordered separately from recloser). Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 Table 1. Summary of Ratings Nominal Voltage (kV) Maximum Continuous Current (amps) Maximum Interrupting Rating at Nominal Interrupting Medium Recloser Type 14.4 560* 10000 oil WE 14.4 560* 12000 vacuum VWE 24.9 560* 8000 Oil WVE27 24.9 560* 12000 vacuum VWVE27 34.5 560* 8000 oil WVE38X 34.5 560* 12000 vacuum VWVE38X * Can be increased to 800 amps, continuous, with an 800-amp continuous current accessory. Table 2. Basic Recloser Catalog Numbers Recloser Type Catalog Number Table 4. Multi-Ratio Bushing Current-Sensing Transformers Factory-Installed on Load-Side Bushings 2,4, and 6* WE KWE* Description Catalog Number VWE KVWE* WVE27 KWVE27* WVE38X KWVEP* Types WE and VWE Three 600:5 BCTs on 13 in. creepage bhushings Three 600:5 BCTs on 17 in. creepage bushings Three 1200:5 BCTs on 13 in. creepage bushings KA804W3 KA110W3** KA827W3 VWVE27 KVWVE27* VWVE38X KVWVEP* Types WVE27 and VWVE27 Three 600:5 BCTs on 26-1/2 in. creepage bushings Three 1200:5 BCTs on 26-1/2 in. creepage bushings KA14WV3 KA24WVE Types WVE38X and VWVE38X Three 600:5 BCTs on 26-1/2 in creepage bushings Three 1200:5 BCTs on 26-1/2 in. creepage bushings KA82WV3 KA83WV3 * Replace asterisk in catalog number with closing coil code number from Table 3. Table 3. Closing Solenoid Coil Voltage Code Numbers NNote: When ordering, specify load- or source-side mounting of BCTs. * To specify accessory BCTs on source-side bushings, include the digit 9 after the A in the catalog number and specify source-side bushings in the order description. Phase-to-Phase Closing Coil Operating Voltages ±15% (kV) Code No. 2.4 1 3.3 10 4.16-4.8 2 Table 5. 600:5 Multi-Ratio Bushing Current Transformers for Field Installation 6.0 6 Description Catalog Number 7.2-8.32 3 Slip-on bushing current transformer kit: one BCT per kit KA712L2 11.0 9 Set of 3 BCTs KA712L2-3 12.0-13.2 4 5 Wiring kit for KA712L2-3 (one wiring kit required per recloser) KA895R7* 14.4 17.0 12 20.0 11 23.0-24.9 13 Table 6. Hardware (Service-Related) 34.5 14 Description Catalog Number KA476R KA66WV Low-Voltage Closing Coils Operating Voltage (Vdc) ** Catalog number includes the extra creepage bushing. * Includes 7 ft. cable. If longer cable is required, specify length on order. 48 16* 125 7* Manual closing tool: de-energized recloser; factory installed WE, VWE, WVE27, and VWVE27 WVE38X and VWVE38X 250 8* T-handle manual closing tool; de-energized recloser KA90R2 Oil-level sight gauge; factory-installed KA161W * Requires either low-voltage dc closing accessory (KA631R) or low-voltage ac closing accessory (KA742R). Otder separately. www.cooperpower.com 280-40-3 Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 Table 7. Low-Voltage Closing and Transfer Switch; Factory-Installed Description Catalog Number Three-state auxiliary switch with six independent contacts KA369R3 Low-voltage dc closing, requires that recloser be ordered with dc closing coil 48 Vdc Types WE, WVE27, WVE38X Types VWE, VWVE27, VWVE38X 125 Vdc Types WE, WVE27, VWVE38X Types VWE, VWVE27, VWVE38X 250 Vdc Types WE, WVE27, WVE38X Types VWE, VWVE27, VWVE38X Low-voltage ac closing, requires that recloser be ordered with dc closing coil 120 Vac Types WE, WVE27, WVE38X Types VWE, VWVE27, VWVE38X 240 Vac Types WE, WVE27, WVE38X Types VWE, VWVE27, VWVE38X KA631R12 KA631R14 KA631R3 KA631R7 KA631R4 KA631R8 KA742R3 KA742R7 KA742R4 KA742R8 Table 8. Bushings and Terminals; Factory-Installed (set of six) Description Catalog Number 17 in. creepage standard-length bushings Types WE and VWE KA25W Flat-pad terminals, two-hole Types WE and VWE with 13 in. or 17 in. creepage, standard or CT-length bushings Types WVE27, WVE38X, VWVE27, VWVE38X with 26-1/2 in. creepage, standard-length bushings Types WVE27, WVE38X, VWVE27, VWVE38X with 26-1/2 in. creepage, CT-length bushings KA82W1 KA62RV3 KA62RV4 Flat-pad terminals, four-hole Types WE and VWE with 13 in. or 17 in. creepage, standard or CT-lenth bushings Types WVE27 and VWVE27 with 26-1/2 creepage, standard-length bushings Types WVE27 and VWVE27 with 26-1/2 in. creepage CT-length bushings KA156W1 KA61RV3 KA61RV4 Stud terminals, 1-1/8-12 UNF-2A Types WE, VWE with 13 in. or 17 in. creepage, standard or CT-length bushings Types WVE27, WVE38X, VWVE27, VWVE38X with 26-1/2 in. creepage, standard-length bushings Types WVE27, WVE38X, VWVe27, VWVE38X with 26-1/2 in. creepage, CT-length bushings KA800W1 KA59RV3 KA59RV4 280-40-4 www.cooperpower.com Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Technical Data 280-40 Effective July 2014 Table 9. Mounting Equipment Catalog Number Shipping Weight (lb) KA89WV1 326 Single-size control and/or meter trough on KA89WV1 frame KA89WV4 11 Double-size control and/or meter trough on KA89WV1 frame KA89WV5 22 Single- or double-size control on load-side of KA89WV1 frame KA89WV9 17 KA89WV2 34 Frame with load- and source-side arrester brackets KA146W6 162 Single-pole mounting hanger KA146W5* 122 End-mounted pole hanger KA706R3 126 Inboard (source) KA126H3 20 Outboard (load) KA847W 20 KA146W2 50 Description Substation mounting equipment Basic mounting frame Mounting brackets Removable tank-lifting windlass for KA89WV1 frame Pole-mounting equipment Surge arrester mounting brackets Tank-lifting windlass for single-pole hanger * Requires KA883R BCT conduit assembly when recloser has source-side BCTs. Table 10. Continuous Current Accessory; Factory-Installed Description Catalog Number 800 amp continuous current capability on recloser without accessory BCTs Type WE, eyebolt terminals, 4/0-1000 MCM KA59WE2 Type WE, stud terminals, 1 1/8-12 UNF-2A KA59WE1 Type VWE, eyebolt terminals, 4/0-1000 MCM KRW63V2 Type VWE, stud terminals, 1 1/8-12 UNF-2A KRW63V1 Types WVE27, WVE38X, eyebolt terminals, 1/0-750 MCM KA74WE2 Types WVE27, WVE38X, stud terminals, 1 1/8-12 UNF-2A KA74WE1 Type VWVE27, eyebolt terminals KRW64V2 Type VWVE27, stud terminals, 1 1/8-12 UNF-2A KRW64V1 Type VWVE38X, eyebolt terminals, 1/0-750 MCM KRW59V2 Type VWVE38X, stud terminals, 1 1/8-12 UNF-2A KRW59V1 800 amp continuous current capability on recloser equipped with accessory BCTs Type WE, eyebolt terminals, 4/0-1000 MCM KA59WE2 Type WE, stud terminals, 1 1/8-12 UNF-2A KA59WE1 Type VWE, eyebolt terminals, 4/0-1000 MCM KRW63V2 Type VWE, stud terminals, 1 1/8-12 UNF-2A KRW63V1 Types WVE27 and WVE38X, eyebolt terminals, 1/0-750 MCM KA74WE4 Types WVE27 and WVE38X, stud terminals 1 1/8-12 UNF-2A KA74WE3 Type VWVE27, eyebolt terminals, 1/0-750 MCM KRW64V4 Type VWVE27, stud terminals, 1 1/8-12 UNF-2A KRW64V3 Type VWVE38X, eyebolt terminals, 1/0-750 MCM KRW59V4 Type VWVE38X, stud terminals, 1 1/8-12 UNF-2A KRW59V3 www.cooperpower.com 280-40-5 Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 Factory assemblies and kits • Reclosers can be factory-assembled in mounting frames. • External meters can be factory-wired. • Wiring kits are available for field installation of inter-accessory wiring. Table 11. Factory Assembly of Recloser and Accessories in KA89WV1 Substation Mounting Frame* Description Catalog Number Recloser and electronic control on frame; no accessories KA800WE * Factory assembly only. Recloser, control, accessories, and mounting frame must be ordered separately. Table 12. Factory Assembly of Recloser in Mounting Frames* Description Catalog Number Recloser in KA146W5 only; with or without BCTs KA881R2 Recloser in KA706R3; with or without BCTs KA881R1 * Covers factory assembly only. Recloser and mounting must be specified separately. Table 13. Factory Assembly of Conduit and Wiring* Description Catalog Number Factory installed BCT conduit for use with KA146W5 frame when BCTs are mounted on the pole-side KA883R2 * Covers factory assembly only; recloser, accessories, and mounting must be specified separately. Table 14. Conduit and Wiring Kits for Field Installation* Description Catalog Number Recloser in KA146W5 single-pole mounting frame Conduit kit for BCTs when recloser is to be mounted with BCTs on pole-side KA883R1 * A kit includes all conduit and wire necessary to connect recloser and accessories specified. Kits are shipped disassembled. Table 15. Training-Related; Equipment Maintenance and Operation DVDs Description Catalog Number General Maintenance and Inspection Procedures for Kyle Reclosers DVD (28 min.) KSPV1A Mechanical Operation, Service and Testing of Kyle Three-Phase Electronic Reclosers DVD (27 min.) KSPV4A Type MET Electronic Recloser Control Tester Operating Instructions and Testing Procedures DVD (25 min.) KSPV7A 280-40-6 www.cooperpower.com Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Technical Data 280-40 Effective July 2014 Features and detailed description W-group electronically controlled, three-phase oil reclosers protect systems operating through 34.5 kV. Refer to Ratings and Specifications section. These ratings, and the wide range of programmable settings provided by the electronic control, permit meeting a variety of application requirements. Basically the same in operation as three-phase hydraulically controlled reclosers (Catalog Section 280-30), these reclosers possess the added operating flexibility of electronic control. A choice of oil or vacuum as the arc interrupting medium is available: • Types WE, WVE27, and WVE38X reclosers use oil (Figure 1). Bridge-type contacts provide two current breaks in series for each phase. Each current break employs a separate, vented, selfgenerating, arc-interrupting chamber for effective interruption of the recloser’s full current range. • Vacuum interruption is utilized by Types VWE, VWVE27, and VWVE38X reclosers (Figure 2). A single break on each phase is accomplished by separating a set of contacts within the vacuum chamber. Low-energy arc interruption in a vacuum extends the duty cycle and results in less shock and demonstration, extending recloser mechanism life. OIL DIP STICK Aids in checking oil level. Closing force is supplied by a closing solenoid, which is energized by line-to-line connections inside the recloser. This solenoid closes the main contacts of all phases while simultaneously charging the opening springs in preparation for a tripping operation. The control signals tripping and closing. Fault currents are sensed by three 1000:1 ratio sensing current transformers, located in the recloser. These CTs provide a continuous measurement of line current, monitored by the electronic control. When current level exceeds the programmed minimum trip level, the magnitude of the overcurrent is integrated with time, using a programmed time-current curve characteristic. The control then energizes the trip coil in the recloser. This releases the tripping springs, opening the main contacts of all three phases. If reclosing is programmed, the control then activates the closing mechanism. The reclosers are self-contained; they require no external power source (except as required by certain accessories). The electronic recloser control provides simple determination of phase- and ground-trip sequences and operations-to-lockout. Minimum phase-and ground-trip values, timing of tripping, and reclosing and resetting timing are adjustable at the control, without de-energizing the recloser. Application flexibility is enhanced by dual-timing characteristics from a choice of time-current curves for phase and ground tripping levels. LIFTING LUGS Used for hoisting recloser or lifting mechanism out of tank. CLAMP-TYPE TERMINALS Accept No. 1/0-500 MCM cable in horizontal or vertical position. RECEPTACLE Provides connection for control cable. BUSHINGS Wet-process porcelain, glaze color is light gray, Munsell 5BG 7.0/0.4. MANUAL OPERATING HANDLE Provides manual opening and lockout. O-RING GASKET Of Buna-N is confined, and provides positive weatherproof seal between head casting and tank under all operating conditions. CONTACT POSITION INDICATOR MOVING CONTACTS Have copper-tungsten alloy tips for long life. NAMEPLATES Supply complete recloser data. INTERRUPTERS Self-generating; vented for fast arc-extinction. CLOSING SOLENOIT Closes contacts and charges opening springs. Figure 1. Untanked Type WE recloser illustrates simplified mechanism resulting from electronic control. Construction of Types WVE27, WVE38X, VWE, VWVE27, and VWVE38X is similar except for the vacuum interrupters on VWE, VWVE27, and VWVE38X. www.cooperpower.com 280-40-7 Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 Construction Recloser Like other Eaton's Cooper Power Systems reclosers, these are designed for long service life and minimum maintenance. Heads are aluminum castings. Tanks are heavy-gauge steel, finished with polyester powder paint (Munsell 5BG 7.0/0.4; light gray is the standard color). An “O”-ring gasket confined in a groove provides an oil-tight and weatherproof seal between the head and tank. A 1/2 in. brass oilsampling-and-drain valve, located near the bottom of the tank, is standard. Bolts through the head casting support the recloser, securing it to the mounting. The complete internal mechanism is suspended from the head casting, allowing tank removal without disturbing the mechanism and head assembly. Lowering the tank with a wire rope winch (available as an accessory) permits easy access to the mechanism. Insulating supports, from which the three interrupters are suspended, are made of filament-wound glass epoxy for high electrical and mechanical strength, and moisture resistance. CLOSING TOOL PORT For manually closing deenergized recloser. CLOSING SOLENOID CONTACTOR Momentarily energizes closing solenoid on signal from electronic control. FUSES Protect system in event of closing solenoid failure. SLEET HOOD Houses manual operating handle and contact position indicator. CURRENT EXCHANGE Through beryllium-copper garter springs for low resistance and high reliability. INSULATING SUPPORTS Fiberglass construction. VACUUM INTERRUPTERS Have extended duty cycle, require no maintenance, and are easily replaced. Figure 2. Untanked Type VWVE27 vacuum recloser (shown from closing contractor side). 280-40-8 www.cooperpower.com Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Technical Data 280-40 Effective July 2014 Oil interrupters Types WE, WVE27, and WVE38X use oil as the arc-interrupting medium. Fast arc interruption (down to 2 1/2 cycles clearing) is furnished by bridge-type contacts (Figure 3), providing two current breaks in series per phase. The bayonet-type, silver-plated, tungsten-alloy moving contacts resist erosion and provide good conductance. The stationary-contact assemblies are tulip-type clusters of silver-plated contact fingers held by garter springs. The contacts are self-cleaning due to the wiping action of opening and closing. Each current break has a self-generating-type arc interrupter structure including a series of vented chambers. As the contacts open, the arc generates gas pressure in the upper chamber, which blasts oil across the arc and out through the vents. As a result, arc extinction is fast, and arc energy levels do not increase as quickly at higher fault-current levels. Vacuum interrupters Enclosed in the interrupter is a stationary and a moving contact assembly. The moving contact has a travel of approximately onehalf inch, its shaft passing through a flexible bellows that maintains vacuum integrity. Contacts consist of a special non-welding alloy. Because the smallest amount of internal contamination can significantly shorten the life of a vacuum interrupter, a clean-room facility is used for interrupter production. Special care is taken to avoid even minute contamination from any source, including dust particles, machining oils, or human body salts. Recloser operation Tripping When current flow exceeds the minimum-trip value needed to satisfy the programmed timing characteristics, the control energizes a trip solenoid in the recloser. This solenoid releases a latch, and a spring-loaded toggle assembly opens the recloser contacts. Types VWE, VWVE27, and VWVE38X use vacuum as the interrupting medium. Vacuum interrupters (Figure 4) provide fast, low-energy arc interruption with long contact and interrupter life, low mechanical stress, and maximum operating safety. With arc interruption taking place in a vacuum, contact and interrupter life are several times greater than with interruption in oil, virtually eliminating interrupter maintenance. Because of the shorter contact stroke, mechanical stress and wear on the mechanism is substantially reduced. Eaton's Cooper Power Systems vacuum interrupters are designed with a metal and ceramic housing for maximum strength and longterm vacuum integrity. The high-alumina ceramic has more than five times the strength of glass, permits a higher processing temperature to develop maximum purity of the assembly, and is impervious to helium penetration to sustain the vacuum level. Metal endclosures and the arcing chambers are of high-purity alloy to minimize contamination. Figure 4. Cross section of a typical vacuum interrupter used in vacuum interrupting reclosers. Figure 3. Cross-section of a typical self-generating interrupter used in oil interrupting reclosers. www.cooperpower.com 280-40-9 Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 Closing Closing force – and the force to charge the opening springs – is supplied by a high-voltage closing solenoid connected phaseto-phase (Figure 5). When the recloser contacts are closed, the solenoid plunger is latched in the down position. This latch is tripped simultaneously with the release of the recloser opening springs, and the solenoid plunger moves upward for a closing operation. At the programmed reclosing time, the electronic control energizes a rotary solenoid in the recloser. Movement of the rotary solenoid allows a high-voltage contactor to close momentarily, connecting the closing solenoid to the line. The plunger is pulled into the solenoid closing the recloser contacts and charging the opening springs. Plunger movement also opens the high-voltage contactor (Figure 6), de-energizing the closing solenoid. Closing operation of the recloser mechanism activates a switch (b contact) in the recloser, disconnecting the rotary solenoid from the electronic control. The closing solenoid is designed for repeated-momentary rather than continuous operation. If a malfunction of the solenoid plunger or the closing-coil contactor results in the closing solenoid energizing for an extended period, a closing-solenoid fuse within the recloser opens the high-voltage circuit, protecting the closing solenoid from the thermal damage. CLOSING SOLENOID FUSE MAIN CONTACTS SENSING CTs ØC The recloser can be manually tripped at any time by lowering the yellow manual operating handle under the sleet hood. With the handle down, the control cannot close the recloser. CLOSING SOLENOID Raising the yellow handle on a recloser may or may not close the recloser pending the control type. CLOSING SOLENOID CONTACTOR SOURCE LOAD ØB 4 3 ROTARY SOLENOID SWITCH ØA 1 Manual operation TRIP SOLENOID 6 5 Figure 6. KA1143R double break contactor - applicable to reclosers with potential coils rated above 30 kV. 2 TERMINAL BUSHING CONTROL RECEPTACLE PIN Figure 5. Diagram showing phase-to-phase connection of highvoltage closing solenoid.. Raising the yellow handle on a recloser controlled with a Form 4C, FXB, Form 5, or Form 6 control will not close the recloser. Manual closing is accomplished by raising the yellow handle and then moving the manual control switch to the close position. The recloser will close if the recloser closing coil has the proper voltage applied to it. Raising the yellow handle on a recloser controlled with a Form 3A control will close the recloser unless the control is in the lockout position. If the control is in the lockout position when the yellow handle is raised, manual closing is accomplished by moving the manual control switch to the close position. The recloser will close if the recloser closing coil has the proper voltage applied to it. Similarly, the recloser can be operated from the manual control switch on the electronic control panel, provided the manual operating handle is up. A red contact position indicator flag, adjacent to the manual operating handle, shows recloser contact position. Current sensing Three 1000:1-ratio current sensing transformers are provided with the recloser, supplying both phase and ground (zero-sequence) currents. They are connected to the control cabinet by means of a plug-in cable, which can be up to 125 ft. in length, thus permitting remote mounting of the control away from the recloser. 280-40-10 www.cooperpower.com Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Technical Data 280-40 Effective July 2014 Electronic controls Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X reclosers are controlled by Eaton's Cooper Power Systems electronic recloser control. Eaton's Cooper Power Systems offers a choice of electronic controls to use in conjunction with these reclosers. Figure 7. Form 6 recloser control. Figure 8. Form 5 micorprocessor-based recloser control. The Form 6 control, shown in Figure 7, provides maximum protective hardware design and simple interactive graphical interfaces for complete user customization. All standard control operating parameters including minimum trip levels, time-current curve selection, and sequences of recloser operation are keyboard programmable. This control utilizes a powerful PC-based interface software to configure control settings, record metering information, and establish communication parameters. It also provides analysis tools that include fault locating, event recording, and oscillography functions. For complete descriptive and ordering information on the Form 6 control, refer to Bulletin 03010. The Form 5 control, shown in Figure 8, performs outstanding protection, metering, and communication functions. The control includes three serial ports, one designated for the PC based configuration software, to meet expanded SCADA and automation applications. The Form 5 control includes extensive per-bushing metering to monitor up to six voltages for open tie applications, a customizable data profiler, sequence of event recorder, and system alarms, all available through serial communications. Numerous application problems are solved with loop scheme availability, switch mode, and triple-single applications. For complete descriptive and ordering information on the Form 5 control, refer to Bulletin 99012. www.cooperpower.com 280-40-11 Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 Ratings and specifications Table 16. Electrical Ratings Description Types WE and VWE Types WVE27 and VWVE27 Type VWVE38X Type WV38X Nominal system voltage (kV) 2.4-14.4 24.9 24.9-34.5 24.9-34.5 Maximum rated voltage (kV) 15.5 27 38 38 Rated impulse withstand voltage (BIL) (kV crest) 110 VWVE27: 125** WVE27: 150 150 170 60 Hz withstand voltage (kV rms) Dry, one minute Wet, ten seconds 50 45 60 50 70 60 70 60 Rated maximum continuous current (A) 560* 560* 560* 560* Bushing creepage distance (in.) 13 26-1/2 26-1/2 26-1/2 * Extendible to 800 amps with accessory. ** Extendible to 150 kV BIL with accessory on VWVE27 recloser only. Table 17. Interrupting Ratings - Phase and Ground Trip Nominal Voltage (kV) Interrupting Rating (rms sym Amps) 4.8 12000 8.32 10000 14.4 10000 VWE 14.4 12000 WVE27 24.9 8000 VWVE27 24.9 12000 WVE38X 34.5 8000 VWVE38X 34.5 12000 Recloser Type WE Table 18. Duty Cycle Type WE Number of Unit Operations Maximum Circuit X/R Value 15-20 45-55 90-100 28 20 10 Total 58 28 20 10 Total 58 28 20 10 Total 58 88 112 32 Total 232 88 112 32 Total 232 88 112 32 Total 232 3 7 14 15-20 45-55 90-100 WVE27 15-20 45-55 90-100 WVE38X 15-20 45-55 90-100 VWE 15-20 45-55 90-100 VWVE27 15-20 45-55 90-100 VWVE38X 280-40-12 % of Interrupting Rating www.cooperpower.com 4 8 15 4 8 15 4 8 15 4 8 15 4 8 15 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Technical Data 280-40 Effective July 2014 Dimensions and weights Table 19. Dimensions of Recloser Without BCT Accessory* Type Bushing Type WE VWE 13 in. standard creepage or 17 in. extra creepage WVE27 VWVE27 26 1/2 in. creepage A (In.) B (In.) C (In.) D (In.) 41 5/8 11 1/8 26 5/8 15 43 7/8 11 1/8 28 7/8 15 47 3/4 11 3/4 26 5/8 21 1/8 50 11 3/4 28 7/8 21 1/8 A (In.) B (In.) C (In.) D (In.) 46 3/8 11 7/8 26 5/8 19 3/4 48 5/8 11 7/8 28 7/8 19 3/4 52 1/2 12 5/8 26 5/8 25 7/8 54 3/4 12 5/8 28 7/8 25 7/8 * Dimensions configured to the nearest 1/8 in. Table 20. Dimensions of Recloser With BCT Accessory* Type Bushing Type WE VWE 13 in. standard creepage or 17 in. extra creepage WVE27 VWVE27 26 1/2 in. creepage * Dimensions configured to the nearest 1/8 in. 46 3/8" 11 3/8" 17 1/8" 1 MAXIMUM 16 /4" WIDTH Source 11 3/8" 13 1/2" VWE, WE: 3 1/8" VWVE27, WVE27: 4 1/8" Side B Terminal Connectors 1/0 - 500 MCM D Tapped Holes for 1/2-13 Bolts 1 1/2" Ground Connector 8 SOL-2/0 STR A Ground C Connector 1/ -13 2 36 3/4" 42 3/8" 13 1/8" Figure 9. Dimensions of W-group 15 kV and 27 kV three-phase electronically controlled reclosers. www.cooperpower.com 280-40-13 Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 46 3/8" F F 21 1/4" 20 3/8" MAXIMUM WIDTH Source E Side Terminal Connectors WVE38X, VWVE38X 1/0 - 500 MCM B 4" Tapped holes (12) for 1/2-13 bolts D Ground Connector 1/ -13 2 1 1/2" A C 37" 42 5/8" 17 1/4" Figure 10. Dimensions of W-group 38 kV three-phase electronically controlled reclosers. Table 21. Weights and Oil Capacity Recloser Type Weight with Oil*(lb) Oil Capacity (gal) WE 790 38 WVE27 840 38 WVE38X 990 52 VWE 790 45 VWVE27 830 45 VWVE38X 990 61 * Add 25 lbs. for each bushing current transformer. 280-40-14 www.cooperpower.com Table 22. Dimensions of W-group 38 kV Recloser With and Without BCT Accessory* Type Bushing Type A (In.) B (In.) C (In.) D (In.) E (In.) F (In.) WVE38X VWVE38X 26 1/2 in. creepage 47 1/8 49 3/8 15 15 26 5/8 28 7/8 20 1/2 20 1/2 10 10 15 1/8 15 1/8 WVE38X VWVE38X 26 1/2 in. w/ BCT 51 3/4 54 15 7/8 15 7/8 26 5/8 28 7/8 25 1/8 25 1/8 9 1/2 9 1/2 15 5/8 15 5/8 * Dimensions configured to the nearest 1/8 in. Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Technical Data 280-40 Effective July 2014 This page is intentionally left blank. www.cooperpower.com 280-40-15 Technical Data 280-40 Types VWE, VWVE27, VWVE38X, WE, WVE27, and WVE38X three-phase reclosers Effective July 2014 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-40 280-40-16 Eaton and Cooper Power Systems are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. ANSI® is a registered trademark of the American National Standards Institute. For Eaton's Cooper Power Systems three-phase recloser product information call 1-877-277-4636 or visit: www.cooperpower.com. Technical Data 280-42 Effective May 2014 Supersedes December 2009 NOVA15, NOVA27, and NOVA38 three-phase, microprocessorcontrolled recloser Description The NOVA™ three-phase, electronically controlled, vacuum-interrupting automatic circuit reclosers from Eaton’s Cooper Power Systems provide reliable, economical overcurrent protection, advanced metering, and automation systems for distribution circuits rated through 34.5 kV. The NOVA recloser combines solid cycloaliphatic-epoxy polymerencapsulated vacuum interrupters with a reliable, lightweight operating mechanism that utilizes a magnetic actuator to provide a lifetime of trouble-free operation. The solid polymer system does not rely on a gaseous, liquid, or foam dielectric. The NOVA recloser is highly resistant to ozone, oxygen, moisture, contamination, and ultraviolet light. The NOVA recloser is available with two configuration options: controlpowered interface and auxiliary-powered interface. Designed and tested to be compatible with Eaton’s Cooper Power Systems three-phase controls, these automatic circuit reclosers offer superior coordination, protection, and application capabilities. Recloser operations are programmed in an electronic control with accurate characteristics and a host of advanced features. Precise operating tolerances enable close coordination with other protective devices on the system. When system requirements change, program settings are easily altered with no sacrifice of accuracy or consistency. Compact and lightweight, NOVA reclosers are easily installed on poles or in substations. Mounting equipment is available for both pole and substation applications. Recloser and control accessories enable further tailoring of the protective program to achieve maximum system operating flexibility. Eaton’s Cooper Power Systems is strongly committed to improving the reliability of the electric power industry. Technological advances, including the newest microprocessor-based controls and solid insulation NOVA distribution switchgear products, represent our investment in the future. The NOVA recloser is not only a technological breakthrough, but a valuable component that brings significant operational savings to the utility business unit, lowering the installation, operation, training, and maintenance costs on your power distribution system. When needed, application expertise, backed by world-wide systems engineering knowledge and experience, is available. Customer-focused design capability, based on more than 65 years of recloser experience, has made Eaton’s Cooper Power Systems the industry leader. NOVA reclosers, like all reclosers from Eaton’s Cooper Power Systems, are designed and manufactured in accordance with IEEE Std C37.60™2003 standard. 280-42-1 Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Ratings and characteristic features Surge protection Three-phase protection on systems rated 2.4 through 14.4 kV is provided by NOVA15 reclosers. NOVA27 reclosers can be applied on systems rated through 27.6 kV. Higher-voltage system protection at 34.5 kV is provided by NOVA38 reclosers. A ratings summary for NOVA reclosers is shown in Tables 1–3. For ratings and basic application information of other reclosers from Eaton’s Cooper Power Systems, see Catalog Section 280-05. Best operating results are achieved if reclosers are protected with surge arresters. On line applications, arrester protection is recommended on both sides of the recloser. (If protection is on one side only, it should be on the source side. In substations, arresters should be on the load side.) Eaton’s Cooper Power Systems distribution-class arresters provide excellent protection and are available with mounting brackets to fit our reclosers (see Catalog Sections 235-35 and 235-99). Operation Sensing current transformers, embedded in the recloser, supply fault-sensing information to the electronic control. Tripping and closing signals from the control energize the operating circuits in the recloser. Due to a single CT ratio for all ratings, minimum-trip values of the electronic control are independent of the continuous-current and interrupting ratings of the recloser. Ordering information Flexibility in coordination with other protective devices is provided by varied time–current characteristics from a choice of standard or customized curves, minimum trip values, reclosing and resetting time settings, and a selection of accessories. 1. See the Constructing a Catalog Number section to construct a catalog number that describes the required recloser. Vacuum interruption 3. Order the required electronic recloser control (Base catalog number of the control must be included when ordering a NOVA recloser). A single break on each phase is accomplished by separating contacts inside the vacuum interrupter. All arcing is contained within the vacuum envelope. The patented axial-magnetic vacuum interrupters, used in NOVA reclosers, offers extended and increased duty cycles compared with oil or radial-magnetic interrupters. The axial-magnetic field keeps the arc in a diffused mode, resulting in less arc power to be dissipated, resulting in low thermal stress, suitable for encapsulation. Data plate Figure 1. NOVA recloser. 280-42-2 www.cooperpower.com Manual OPEN handle All NOVA reclosers include a Form 6 microprocessor-based recloser control. The Form 6 control includes full protection, TCC Editor, metering, and diagnostics for your application needs. To order a NOVA recloser, electronic control, and control cable: 2. From Tables 6–13, specify the catalog numbers that describe the required recloser accessories. Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Features and detailed description Surface tracking NOVA microprocessor-controlled, three-phase reclosers protect systems operating through 34.5 kV (see Ratings and Specifications section of this catalog). These ratings and the wide range of programmable settings provided by Eaton’s Cooper Power Systems electronic controls permit meeting a variety of application requirements. The cycloaliphatic epoxy is highly resistant to contaminants and resists tracking and flashovers under extreme pollution levels to reduce both flashovers and the associated cost of repairs. Recloser operation Fault currents are sensed by three 1000:1 ratio sensing current transformers embedded in the recloser. These CTs provide a continuous measurement of line current, monitored by the electronic control. When current level exceeds the programmed minimum trip level, the magnitude of the overcurrent is integrated with time, using a programmed time–current curve characteristic. The control then signals the trip in the recloser, opening the main contacts of all three phases. Hydrophobicity The module maintains excellent hydrophobicity, a property characterized by water beading into isolated drops, and is highly resistant to moisture absorption. Hydrophobicity prevents continuous sheets of water from forming leakage current paths that deteriorate the creepage withstand level. Ultraviolet resistance The cycloaliphatic epoxy resists ultraviolet radiation damage even in harsh climates, maintaining a smooth, unblemished, self-cleansing surface with low-adhesion to contaminants. Tensile strength The control signals tripping and closing. The recloser always maintains energy for a tripping operation following a closing operation. Outstanding tensile and flexural strength characteristics mean the NOVA recloser modules are tough and non-fragmenting, reducing shipment and handling charges. The electronic recloser control provides determination of phase- and ground-trip sequences and operations to lockout and reclosing and resetting timing, adjustable with the control without de-energizing the recloser. Shed design Construction Recloser Designed for long service life and no maintenance, the NOVA recloser has three solid-polymer interrupter modules with embedded current transformers and a standard aluminum mechanism housing; light gray is the standard color. Cycloaliphatic-epoxy polymer encapsulation provides solid insulation and maintenance-free, environmentally safe operation. There is no monitoring or maintaining of gas pressure or oil levels; there are no toxic or environmentally unfriendly materials. There are no foam fillers or insulation seals, eliminating potential moisture ingress areas. The NOVA recloser module exhibits good absorption of elastic energy and resistance to cracking and crack propagation. Additionally, durable environmental properties make the solid polymer suitable for outdoor applications, including seacoasts, deserts, and areas of high pollution. Heater Magnetic Actuator Aluminum Mechanism Trip-and-Close Housing (Standard) Capacitors OPEN/CLOSE Contact Position Indicator The shed design utilizes alternate-sized skirts. The major sheds shield and protect the minor sheds to enhance the hydrophobicity and ultraviolet resistance of the module, eliminate formation of microcracks, and ensure extra-protected creepage. Additionally, sharp edges direct water away from the unit. Water paths and ice formations are effectively eliminated. Flashover recovery Flashovers occur when an object, usually wildlife, contacts energized parts of the equipment. The NOVA recloser minimizes the effect of flashovers with remarkable physical resilience, arc-quenching properties, and a self-healing ability. NOVA recloser can withstand the enormous forces experienced during faults without wholesale damage and allows re-energizing after external flashover without cleaning. Manual OPEN Handle Actuator Board Auxiliary Input Power Receptacle Mechanical Operations Counter Control Cable Receptacle Heater Ground Connector #10 - #2 Stranded Figure 2. NOVA recloser Type B mechanism with auxiliary-powered interface (view from bottom of recloser with bottom cover and actuator board safety shield removed). www.cooperpower.com 280-42-3 Technical Data 280-42 Effective May 2014 Vacuum interrupters NOVA reclosers use vacuum as the interrupting medium. Vacuum interrupters (Figure 3) provide fast, low-energy arc interruption with long contact and interrupter life, low mechanical stress, and maximum operating safety. With arc interruption taking place in a vacuum, contact and interrupter life are several times greater than with interruption in oil, virtually eliminating interrupter maintenance. Eaton’s Cooper Power Systems vacuum interrupters are designed with a metal and ceramic housing for maximum strength and long-term vacuum integrity. Oxygen-free, high-conductivity copper, stainless steel, and a nickel-copper alloy are used in the vacuum interrupters. The high-alumina ceramic has more than five times the strength of glass, which permits a higher processing temperature to develop maximum purity of the assembly, and is impervious to helium penetration, maintaining the vacuum level. Additionally, it provides wear resistance, chemical resistance, and a high dielectric strength. Enclosed in the interrupter are a stationary and a moving contact assembly. The moving contact has a travel of approximately onehalf inch, its shaft passing through a flexible bellows that maintains vacuum integrity. Contacts consist of a high purity copper sintered with aluminathermic chromium. NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Because the smallest amount of internal contamination can significantly shorten the life of a vacuum interrupter, special care is taken to avoid even minute contamination from any source, including dust particles, machining oils, or human body salts. No paraffinic oils are used in the machining process, all machined parts are put through a cleaning/degreasing process, and then all components are electro-polished in a positive-pressure, air-filtered area. A Class 100 clean room facility is used for the final interrupter production. The furnaces employ a custom-designed, three-stage pumping system to yield high levels of vacuum. Every vacuum interrupter is then tested and tracked with individual serial numbers. Electronic control NOVA15, NOVA27, and NOVA38 reclosers are controlled by an Eaton’s Cooper Power Systems three-phase electronic recloser control. A choice of microprocessor-based controls are available to use in conjunction with these reclosers. Control-powered interface The Type D NOVA recloser mechanism (see Figure 4) with the control-powered interface is fully operational with Form 5 and Form 6 VTC-ready, microprocessor-based controls equipped with the required dc-to-dc converter, interface circuit, and a fully shielded 19-pin cable. It is not compatible with the Types F3A nor FXB controls. The control-powered interface includes a 19-pin receptacle on the recloser and an internal heater (for humidity control) powered from the control input power supply (ac or dc). The dc-to-dc converter board converts the control’s 24 Vdc battery supply to 53 Vdc to charge the trip/close capacitors in the NOVA recloser mechanism. The dc-to-dc converter board also houses voltage monitoring and conditioning circuits that protect the battery from failure and provide trip/close operations without ac power. In the absence of ac power to the electronic control, the control battery will provide the trip and close operations. A complete fourtrip sequence with minimal reclose intervals as configurated for each control is obtainable without ac power. The recloser and control system is capable of exceeding over one thousand operations on battery power only. Figure 3. Cross section of a vacuum interrupter used in NOVA reclosers. O P E N Potential Transformer (120/240 Vac) C L O S E D Electronic Control 19-Pin Control Cable 120/240 Vac Power Cable (optional) Figure 4. Control-powered NOVA recloser configuration with potential transformer input power. 280-42-4 www.cooperpower.com Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 AC auxiliary input Potential Transformer (120/240 Vac) O P E N Electronic Control 14-Pin Control Cable 120/240 Vac Power Cable (optional) 2-Pin Auxiliary-Powered Output Cable* *Note: Control receptacle ordered separately. The trip-and-close capacitors are charged through both the ac auxiliary input power and the recloser control. Upon loss of ac power, the capacitors will be continuously charged from the control battery to allow tripping and will also be trickle-charged to allow for back-up closing. The charge on the capacitors will be maintained for the duration of the control battery power. Allow one minute between back-up close operations to recharge the capacitors. However, the NOVA recloser is ready to trip immediately after performing a backup closing. Should the battery power discharge to the disconnect level, back-up closing is disabled until ac auxiliary power is resumed. Apply ac auxiliary input power to the NOVA recloser to recharge the capacitors. Manual operation The recloser can be opened manually with a hotstick to pull down the yellow manual OPEN handle under the sleet hood. With the handle in the OPEN position, the control cannot close the recloser. The recloser is closed, following a manual open, by pushing the yellow handle back under the sleet hood and then using the microprocessor control to close the recloser. Figure 5. Auxiliary-powered NOVA recloser mechanism configuration with potential transformer input power. Similarly, the recloser can be operated from the manual control switch on the electronic control panel, provided the manual operating handle is up. A red contact position indicator flag, adjacent to the manual operating handle, shows recloser contact position. Auxiliary-powered interface Internal voltage sensor option The Type B NOVA recloser mechanism (see Figure 5) with the auxiliary-powered interface is fully operational with standard Form 6 microprocessor-based controls and standard 14-pin control cables. The auxiliary-powered interface includes a 14-pin receptacle on the recloser and an internal heater (for humidity control) powered from the auxiliary input power supply. The NOVA recloser is available with internal voltage sensors at time of order. Using a high-voltage resistor within each interrupter module with source-side connections, the sensing option, cable, and control support a magnitude accuracy of 2% or better and a phase degree accuracy of ±1.5°. The internal voltage sensing option is compatible with a Form 5 or Form 6 Pole-Mount controls. The Type B NOVA recloser mechanism, with the auxiliary-powered interface, requires a voltage source of 48 Vdc, 125 Vdc, 250 Vdc, 120 Vac, or 240 Vac, which must be specified at the time of order. The auxiliary-powered interface is connected to a 2-pin male receptacle located next to the 14-pin female control receptacle. The voltage source is used to maintain power to the trip-and-close capacitors in the recloser and to power the heaters. Accessories DC auxiliary input The trip-and-close capacitors are maintained from the dc source. Upon loss of the dc power, the trip-and-close capacitors will maintain trip and close power for several minutes. If the trip-and-close capacitors are discharged, the recloser is inoperative until dc power is resumed. Auxiliary switch A three-stage auxiliary switch can be provided as an accessory. Each stage has two independent contacts that permit any desired combination of “a” (follow state of recloser contacts) and “b” (opposite recloser contacts) positions. The switch contacts are insulated for 600 V and have a continuous current rating of 10 A. Their interrupting ratings are shown in Table 5. Terminals The standard terminal is an eyebolt, 1/0–500 mcm (630 A). Eyebolt 4/0–1000 mcm (800 A), 2-hole and 4-hole, flat-pad terminals, and stud-type terminals are available as an accessory. Pole-mounting hanger A pole-mounting hanger, which bolts directly to the recloser frame, is available for pole-mounting installation. Arrestor-mounting brackets The arrestor-mounting bracket accessory can be bolted to the recloser frame and pole-mounting hanger for the addition of inboard and outboard arresters. The arresters are not included with the brackets. Substation-mounting frame A substation-mounting frame accessory is available for substationmounting applications. www.cooperpower.com 280-42-5 Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Ratings and specifications Table 1. Voltage Ratings (kV) Description 15 kV 15 kV 27 kV 27 kV 38 kV Maximum Voltage 15.5 kV 15.5 kV 29.2 kV 29.2 kV 38.0 kV Rated Basic Impulse Level 110.0 kV 125.0 kV 125.0 kV 150.0 kV 170.0 kV Radio Noise Limit (µV) 100 @ 9.4 kV 100 @ 9.4 kV 100 @ 16.4 kV 100 @ 16.4 kV 100 @ 23.0 kV Power Frequency Withstand, Dry 50 kV 50 kV 60 kV 60 kV 70 kV Power Frequency Withstand, Wet 45 kV 45 kV 50 kV 50 kV 60 kV Description 15 kV 15 kV 27 kV 27 kV 38 kV Rated Continuous Current 630 A* 630 A* 630 A* 630 A* 630 A* Short Circuit Current, Symmetrical 12.5 kA** 12.5 kA** 12.5 kA** 12.5 kA** 12.5 kA Making Current, Asymmetrical Peak 31.0 kA 31.0 kA 31.0 kA 31.0 kA 31.0 kA Cable Charging Current 10 A 10 A 25 A 25 A 40 A Table 2. Current Ratings (Amperes) * 800 amp accessory is also available. ** 16.0 kA option is also available. (Making Current is 40.0 kA Asymmetrical Peak.) Table 3. Mechanical Ratings Description 15 kV 15 kV 27 kV 27 kV 38 kV Min. Mechanical/Electrical Operations Without Maintenance (C-O) 10,000 10,000 10,000 10,000 10,000 Mass (Weight) - kg (lbs) 86 (190) 91 (200) 91 (200) 101 (223) 101 (223) Table 4. Duty Cycle Type Percentage of Interrupting Rating Number of Unit Operations Minimum Circuit X/R Value NOVA 15-20 88 4 45-55 112 8 90-100 32 15 Total 232 Table 5. Auxiliary Switch Interrupting Ratings Volts Inductive AC (amps) NonInductive AC (amps) Inductive DC (amps) NonInductive DC (amps) 24 – – 15.0 20.0 48 – – 7.5 10.0 120 60 80 – – 125 – – 1.5 2.0 240 30 60 – – 250 – – 0.45 0.5 280-42-6 www.cooperpower.com Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Dimensions 271 (10.75) Terminal Connectors 1/0 - 500 MCM (Standard) A 388 (15.5) A 388 (15.5) A Terminal Connectors 1/0 - 500 MCM (Standard) B C O P E N 285 (11.25) C L O S E D 285 (11.25) 1000 (39.50) 413 (16.25) Note: mm NOTE:AllAlldimensions dimensionsare are mm(inches). (inches). Dimensions are approximate. Dimensions shownshown are approximate. Terminal Options A B C Eyebolt, 1/0 - 500 mcm Cable Range (630 A maximum) 80 (3.25) NOVA15 110 kV BIL 791 (31.25) 508 (20) Eyebolt, 4/0 - 1000 mcm Cable Range (800 A maximum) 108 (4.25) NOVA15 125 kV BIL 847 (33.25) 564 (22.25) Flat Pad, 2-hole (630 A maximum) 114 (4.5) NOVA27 125 kV BIL 847 (33.25) 564 (22.25) Flat Pad, 4-hole (800 A maximum) 121 (4.75) NOVA27 150 kV BIL 946 (37.25) 663 (26.0) Stud Type, 1.125 - 12 threads (800 A maximum) 82 (3.25) NOVA38 170 kV BIL 946 (37.25) 663 (26.0) Creepage Distances 15 kV 110 kV BIL 15 kV 125 kV BIL 27 kV 125 kV BIL 27 kV 150 kV BIL 38 kV 170 kV BIL Terminal to terminal 1052 (41.5) 1052 (41.5) 1052 (41.5) 1052 (41.5) 1052 (41.5) Lower terminal to ground/earth 673 (26.5) 772 (30.5) 772 (30.5) 950 (37.5) 950 (37.5) Description Figure 6. NOVA recloser dimensions, NOVA27 shown. www.cooperpower.com 280-42-7 Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Note: All dimensions are mm (inches). Dimensions shown are approximate. Pole 1089 (43.0) 637 (25.0) 592 Min. (23.25) A B Mounting Holes for 0.75 Bolts 290 (11.5) O P E N 686 mm (27 in) 779 (30.75) Pole Pole Terminal Options A Eyebolt, 1/0 - 500 mcm Cable Range (630 A maximum) 80 (3.25) NOVA15 110 kV BIL Dimension B 791 (31.25) Eyebolt, 4/0 - 1000 mcm Cable Range (800 A maximum) 108 (4.25) NOVA15 125 kV BIL 847 (33.25) Flat Pad, 2-hole (630 A maximum) 114 (4.5) NOVA27 125 kV BIL 847 (33.25) Flat Pad, 4-hole (800 A maximum) 121 (4.75) NOVA27 150 kV BIL 946 (37.25) Stud Type, 1.125 - 12 threads (800 A maximum) 82 (3.25) NOVA38 170 kV BIL 946 (37.25) Figure 7. Dimensions of NOVA recloser with pole-mounting hanger and arrester-mounting bracket accessories. 280-42-8 www.cooperpower.com Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Note: All dimensions are mm (inches). NOTE: All dimensions (inches). Dimensions shownare are mm approximate. Dimensions shown are approximate. A B C O P E N 870 (34.25) 2216 (87.25) adjustable to 2826 (111.25) in 76 (3) increments 965 (38) Terminal Options A Eyebolt, 1/0 - 500 mcm Cable Range (630 A maximum) 80 (3.25) Eyebolt, 4/0 - 1000 mcm Cable Range (800 A maximum) 457 (18) 552 (21.75) 19 (0.75) Mounting Hole (4) 1060 (41.75) B C NOVA15 110 kV BIL 791 (31.25) 508 (20) 108 (4.25) NOVA15 125 kV BIL 847 (33.25) 564 (22.25) Flat Pad, 2-hole (630 A maximum) 114 (4.5) NOVA27 125 kV BIL 847 (33.25) 564 (22.25) Flat Pad, 4-hole (800 A maximum) 121 (4.75) NOVA27 150 kV BIL 946 (37.25) 663 (26.0) Stud Type, 1.125 - 12 threads (800 A maximum) 82 (3.25) NOVA38 170 kV BIL 946 (37.25) 663 (26.0) Figure 8. Dimensions of NOVA recloser with substation-mounting frame accessory. www.cooperpower.com 280-42-9 Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Constructing a catalog number To order a basic NOVA recloser with eyebolt terminals, for use with 120 Vac closing and a 14-pin control cable, the catalog number would be constructed like this: KNOVA Basic letters for a NOVA recloser with base Form 6 recloser control* 15A Recloser Type: 15A for 15 kV, 630 A continuous, 12.5 kA interrupting 27A for 27 kV, 630 A continuous, 12.5 kA interrupting 38A for 38 kV, 630 A continuous, 12.5 kA interrupting 1 Bushing Terminals: 1 for eyebolt terminal, 1/0 to 500 MCM, 630 A max.† 3 for 2-hole flat pad terminal, 630 A max. 4 for 4-hole flat pad terminal, 800 A max. 5 for stud-type terminal, 800 A max. 1 Interface: 1 for NOVA AP, with auxiliary-powered interface 120 Vac closing (14-pin & 2-pin receptacles) 2 for NOVA AP, with auxiliary-powered interface 240 Vac closing (14-pin & 2-pin receptacles) 3 for NOVA CP, with control-powered interface (19-pin receptacle), 120 Vac Heater 4 for NOVA CP, with control-powered interface (19-pin receptacle), 240 Vac Heater 5 for NOVA AP, with auxiliary-powered interface 125 Vdc closing (14-pin & 2-pin receptacles) 6 for NOVA AP, with auxiliary-powered interface 250 Vdc closing (14-pin & 2-pin receptacles) 7 for NOVA AP, with auxiliary-powered interface 48 Vdc closing (14-pin & 2-pin receptacles) KNOVA 15A 1 1 KNOVA15A11 is the catalog number for the required basic NOVA recloser. * Include the base catalog number of the selected control when ordering a NOVA recloser. † Standard terminal, included when ordering a NOVA recloser. Table 8. Continuous Current Options* Table 6. BIL Options Description Catalog Number Description Catalog Number 15 kV 125 kV BIL KNOVA28-1 15 kV 800 A option KNOVA22-1 27 kV 150 kV BIL KNOVA25-1 27 kV 800 A option KNOVA24-1 38 kV 800 A option KNOVA27-1 * When ordering the standard eyebolt terminal in conjunction with the 800 A option, eyebolt terminals suitable for 4/0 – 1000 mcm conductors will be provided. Table 7. Interrupting Rating* Description Catalog Number 16 kA Maximum Interrupting 16 kA * Applicable to KNOVA15A/27A only Table 9. Internal Voltage Sensing Option* Description Catalog Number Internal Voltage Sensing option, 15.5-38 kV KNOVA-848 Internal Voltage Sensing Cable (basic cable, no length) KA97ME Internal Voltage Sensing Cable, maximum 50 feet Replace X with number of feet. KA97ME-X * Available with Form 5 and Form 6 Controls only. 280-42-10 www.cooperpower.com Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Table 10. Mounting Equipment Description Catalog Number Single pole-mounting hanger with stainless steel hardware KNOVA54-3 Single concrete-pole-mounting hanger with stainless steel hardware KNOVA54-4 Surge-arrester-mounting brackets with stainless steel hardware Inboard KNOVA61-2 Outboard KNOVA61-1 Alley-pole-mounting hanger with stainless steel hardware KNOVA352-1 Arrester brackets (set of 3) KNOVA353-1 Arrester brackets (set of 6) KNOVA353-2 Substation-mounting frame with stainless steel hardware includes control-mounting bracket for FXA, FXB (single- and double-size cabinet), Form 5, and Form 6 Yard and Pole Mount KNOVA59-1 Field kit for NOVA recloser on substation-mounting frame KA89WV1 KNOVA457-1 Field kit for NOVA recloser on substation-mounting frame KA584R1 KNOVA457-4 Table 11. Factory Assembly Description Catalog Number Recloser in single pole-mounting hanger KNOVA54-3 KNOVA354-1 Recloser in single pole-mounting hanger KNOVA54-3 with arrester brackets KNOVA354-2 Recloser on alley-pole-mounting hanger KNOVA352-1 KNOVA456-1 Recloser on alley-pole-mounting hanger KNOVA352-1 with arrester brackets KNOVA456-2 * Covers factory assembly only; recloser, control, and mounting equipment must be ordered separately. Table 12. Auxiliary Switch Description Catalog Number Three-stage auxiliary switch with six independent contacts and receptacle for KNOVA82 cable KNOVA66-2 Auxiliary switch cable for KNOVA66-2, auxiliary switch to control, (basic cable, no length) KNOVA82 Auxiliary switch cable, maximum 100 feet. Replace X with number of feet. KNOVA82-X Table 13. Miscellaneous Accessories Description Catalog Number Low-voltage AC input cable (auxiliary-powered Type B interface only, basic cable, no length) KA11ME1 Replace X with number of feet. KA11ME1-X Source and load wildlife guards, 630 A recloser (set of 6) KNOVA56-6 Source and load wildlife guards, 800 A recloser (set of 6) KGS560-6 www.cooperpower.com 280-42-11 Technical Data 280-42 NOVA15, NOVA27, and NOVA38 three-phase, microprocessor-controlled reclosers Effective May 2014 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-42 May 2014 280-42-12 Eaton, Cooper Power Systems, and NOVA are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. IEEE Std C37.60™-2003 standard is a trademark of the Institute of Electrical and Electronics Engineers, Inc., (IEEE). This publication is not endorsed or approved by the IEEE. For Eaton’s Cooper Power Systems NOVA recloser product information call 1-877-277-4636 or visit: www. cooperpower.com. Technical Data 280-45 Effective July 2014 Supersedes March 2003 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A; three-phase; air-insulated; electronically controlled recloser General VSA-group electronically controlled, threephase, automatic circuit reclosers with vacuum interrupters from Eaton's Cooper Power Systems, provide reliable and economical overcurrent protection for 15 kV distribution systems. VSA-group reclosers are available with ratings up to 1200 amps continuous and 20,000 amps interrupting current, for line and substation applications. A choice of electronic recloser controls enables the user to meet a wide variety of application requirements. VSA16 recloser The use of vacuum as the interrupting medium and air as the insulating medium, improves safety and substantially reduces long term maintenance costs. The reclosers in this group provide serviceproven dependability and long operating life. Commanded by an Eaton's Cooper Power Systems electronic recloser control, these automatic circuit reclosers offer superior coordination and application capability, unmatched by other system protection apparatus. The variety of available VSAgroup ratings permits the user to select precisely the right recloser for the protection required. Recloser operations are programmed on the electronic control panel with accurate, preset tripping characteristics and reclosing times, enabling close coordination with other protective devices on the system. When system requirements change, program settings are easily altered with no sacrifice of accuracy or consistency. Recloser and control accessories enable further tailoring of the protective program to achieve maximum system operating flexibility. VSA20A recloser When needed, application expertise, backed by world wide recloser application experience, is readily available. Knowledgeable design capability – based on over 50 years of recloser manufacturing experience – has made Eaton's Cooper Power Systems the industry leader. Progressive product development programs, using the latest technologies, have resulted in the production of modern, efficient Eaton's Cooper Power Systems reclosers. Since the majority of faults are temporary in nature, they can be cleared with only a momentary circuit interruption. Therefore, permanent outages are usually prevented. With outage time kept to a minimum, customer service and system reliability is improved and utility income is maintained. VSA-group reclosers, like all reclosers from Eaton's Cooper Power Systems, are designed and built in accordance with ANSI® C37.60. 280-45-1 Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Effective July 2014 Ratings Table 1. Summary of Ratings VSA-group reclosers can be applied in a wide variety of protective schemes on distributions systems ranging from 2.4 through 14.4 kV. Basic ratings are shown in Table 1. Nominal Voltage (kV) Maximum Continuous Current (amps) Maximum Interrupting Rating at Nominal Voltage (sym amps) Interrupting Medium Recloser Type 14.4 600 12000 vacuum VSA12B 14.4 800 12000 vacuum VSA12 14.4 800 16000 vacuum VSA16 14.4 800 20000 vacuum VSA20 14.4 1200 20000 vacuum VSA20A Characteristic features Fault-sensing information for VSA-group reclosers is supplied to the electronic control by bushing-type current transformers mounted in the recloser. Tripping and closing signals from the control energize operating circuits in the recloser. Minimum-trip values of the control are independent of the continuous current and interrupting ratings of the recloser. Flexibility in coordination with other protective devices is provided by dual time-current characteristics available from a broad choice of timecurrent curves, a wide range of minimum-trip values, and a variety of programmable reclosing times. Energy to operate the vacuum interrupters is provided by a motordriven operator supplied from a 240 Vac source. The motor operator closes the recloser by charging the closing springs, which in turn provides the force to close the vacuum interrupters and charge the opening springs. Since their introduction in 1966, Eaton's Cooper Power Systems vacuum interrupters have had an excellent reliability record and have grown to be the most complete line of vacuum switchgear available in the industry. Mounting equipment VSA-group reclosers are furnished in standard frames with corner lifting eyes. Mounting equipment is available for either pole or substation installation of the recloser (See Table 6 for mounting accessories). Surge protection Best operating results are achieved when reclosers are protected with surge arresters. On line applications, arrester protection is recommended on both sides of a recloser. If protection is to be provided on one side only, it should be on the source side. In substations, arresters should be located on the load side. Eaton's Cooper Power Systems distribution-class surge arresters provide excellent protection. See Catalog Section 235-35 for information about the UltraSIL™ Polymer-Housed VariSTAR™ surge arrester and Catalog Section 235-99 for the UltraSIL Polymer-Housed Evolution™ surge arrester. 280-45-2 www.cooperpower.com Ordering information A complete electronically controlled VSA-group recloser installation includes: • Recloser and its accessories. • Electronic control and its accessories. • Control cable. • Mounting equipment. To order a recloser, electronic control, and control cable: 1. Use Table 2 to specify the catalog number that describes the required recloser. 2. From Tables 3 - 8, specify the catalog numbers that describe the required recloser accessories and mounting equipment. 3. Order the required electronic recloser control. (The control is priced separately from the recloser.) Table 2. Basic Recloser Catalog Numbers Recloser Type Catalog Number VSA12B KVS-15-12-600 VSA12 KVS-15-12-800 VSA16 KVS-15-16-800 VSA20 KVS-15-20-800 VSA20A KVS-15-20-1200 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Technical Data 280-45 Effective July 2014 Table 3. Multi-Ratio Bushing Current-Sensing Transformers; Factory-Installed Description Catalog Number Three 600:5 BCTs (accuracy class C100) on bushings 1, 3, and 5 KA65VS1 Three 600:5 BCTs (accuracy class C100) on bushings 2, 4, and 6 KA65VS2 Three 1200:5 BCTs (accuracy class C200) on bushings 1, 3, and 5 KA65VS3 Three 1200:5 BCTs (accuracy class C200) on bushings 2, 4, and 6 KA65VS4 Table 4. Bushings, Terminals; Factory-Installed Description Catalog Number 17-in.-creepage bushings, VSA12B, VSA12, VSA16, VSA20 KA59VS Stud-type terminals, 11¼8-12 UNF-2A, VSA12, VSA16, VSA20 KA79VS1 4 hole flat-pad terminals, VSA12, VSA16, VSA20 KA79VS2 Stud-type terminals, 11¼8-12 UNF-2A, VSA12B KA79VS3 4 hole flat-pad terminals, VSA12B KA79VS4 Table 5. Service-Related; Factory-Installed Description Catalog Number 120 Vac motor operator KA60VSM2 External spring-charging accessory* KA59VSM2 External contact-position-indicating accessory KA61VSM4 * Cannot be used with 2 sets of multi-ratio BCTs. Table 6. Mounting Equipment Description Catalog Number VSA12B, VSA12, VSA16, VSA20 Substation mounting frame extension KA55VS1 Electronic control mounting bracket Double-size cabinet KA55VS4 Single-pole mounting hanger KA56VS VSA20A Substation mounting frame extension KA55VS8 Electronic control mounting bracket Double-size cabinet KA55VS9 Single-pole mounting hanger KA52VSM Table 7. Remote Operation and Indication; Factory-Installed Description Catalog Number Three -stage auxiliary switch KA55VSM3 Table 8. Form 6 Rack Mount Substation Interface; Factory-Installed Description Catalog Number DC Station Supply Interface* KVS-SS-XXX** * Requires a dc source from a substation battery. ** Specify station supply voltage. Replace XXX with 24, 48, or 125 to indicate dc voltage. www.cooperpower.com 280-45-3 Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Effective July 2014 Features and detailed description BUSHINGS wet-process porcelain; can be field replaced. LIFTING EYES all four corners enable balanced lifting for easy installation. WEATHERPROOF OPERATOR CABINET provision for padlocking; window to view contact position indicator. BUSHING LEAD silverplated copper for ample current carrying capacity. VACUUM INTERRUPTER ASSEMBLY permits convenient interrupter inspection and replacement. INTERRUPTER SUPPORTS epoxy-fiberglass; provide mechanical and electrical strength. STANDARD FRAME can be pole-mounted without crossarms; leg extensions are available for substation use. Figure 1. VSA20A three-phase, air-insulated vacuum recloser with inspection cover removed. Recloser Construction VSA-group three-phase reclosers from Eaton's Cooper Power Systems feature vacuum interruption with air insulation and lowvoltage motor operation. These reclosers are designed for circuit protection on systems operating through 14.4 kV. Eaton's Cooper Power Systems air-insulated vacuum reclosers offer extra-long service life and require minimal maintenance. Duty cycles are four times those of comparably rated oil-interrupting reclosers. Vacuum interrupter contacts, as well as the entire recloser, require no service other than periodic maintenance inspection. Because of the large selection of continuous and interrupting current ratings and the flexibility provided by Eaton's Cooper Power Systems electronic recloser controls; VSA-group reclosers can be applied to meet a wide variety of requirements. Housings are fabricated of hot-rolled steel which is phosphatized to resist corrosion, then finished with polyester powder paint. Finish color is light gray, Munsell 5BG 7.0/0.4 The vacuum interrupters in VSA reclosers provide reliable, shock free fault-current interruption with long interrupter life. The combination of vacuum interruption and air insulation provides longer maintenance intervals and lower maintenance costs than comparable oil-insulated reclosers. Vacuum interruption also provides greater safety for indoor applications than arc interruption in oil. Nonferrous alloys are used for mechanism linkages; stainless steel is used for shafts and hardware. Other steel parts are plated. Needle bearing or hard brass bushings are swaged into mechanism plates and linkages to provide long, trouble-free life for moving parts. Closing and tripping operations of the recloser are both powered by springs. The motor-operator loads the closing springs, which charge the opening springs during closing. For ease of inspection, all internal parts are readily accessible by removing an inspection panel on either side of the recloser. An external 240 Vac source supplies power for the motor operator and the cabinet heaters. The 240 Vac supply is not required to trip the recloser. Fault currents are sensed by 1000:1-ratio bushing current transformers mounted in the recloser (2000:1 current transformers are used in VSA20 and VSA20A reclosers), which provide sensing of both phase and ground (zero sequence) currents. They provide a continuous measurement of line current that is monitored by the recloser control. When the control’s programmed minimum trip level is exceeded, the control energizes the trip solenoid in the recloser operating mechanism, opening the recloser. 280-45-4 www.cooperpower.com All gears and latches are permanently lubricated; sealed ball bearings are used in the motor. Vacuum interrupters are mounted independently of the bushings. The bushing rods clamp to a current transfer member of the interrupter mounting assembly. Therefore, the bushings can be replaced quickly and easily without disturbing the interrupter or requiring any interrupter adjustment. Insulating supports for the three interrupters are made of filamentwound glass epoxy for high electrical and mechanical strength and moisture resistance. Cabinet heaters are provided in both the operator mechanism cabinet and the interrupter mechanism cabinet. The heaters are supplied from the 240-Vac auxiliary power source and are connected through a DPST on-off toggle switch and one amp fuses. The mechanism cabinet heater operates at 57 watts. The enclosure heaters operate at 115 watts total. Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Technical Data 280-45 Effective July 2014 Closing Closing energy, as well as the force to charge the opening springs, is supplied by the motor operating mechanism, through motor-loaded closing springs. A 240 Vac motor charges the closing springs through a multi-stage gear drive. When 240 Vac is present, the motor is automatically operated to keep the closing springs in a charged state. To close the recloser, the control initiates a signal which energizes a solenoid in the recloser operating mechanism. Once actuated, the solenoid releases the closing springs, which close the vacuum interrupters and charge the opening springs. Stored energy provides multiple operations Figure 2. Vacuum interrupter assembly. Should the recloser’s 240 Vac motor supply voltage be lost while the closing spring is charged and contacts are closed, an OpenClose-Open sequence remains stored in the recloser operating mechanism. If the recloser trips under these conditions, the stored closing operation allows an immediate reclosing, if required. After such a closing, one additional trip operation then remains stored. Once closed, the recloser always contains energy for at least one trip operation. Motor operation Manual operation VSA-group air-insulated, vacuum reclosers employ a 240 Vac, motordriven operating mechanism to charge closing and opening springs. A closed recloser can be manually tripped from inside the operator cabinet, using the RESET-TRIP knob, or from outside the cabinet by pulling down the Manual Trip pull-ring. When the recloser is manually tripped, the closing circuit is opened to prevent reclosing. The recloser can be manually restored to service by placing the RESET-TRIP knob at RESET and moving the manual control switch on the recloser control to CLOSE. The manual control switch on the recloser control panel can also be used for tripping. Tripping Recloser tripping employs stored spring energy. When line current exceeds the programmed minimum-trip value, in one or more phases, the control energizes a trip solenoid in the operating mechanism. The solenoid trips a latch which releases a spring-loaded toggle assembly, opening the recloser contacts and a switch which interrupts the 24-volt signal from the control. Maximum clearing time is 2-1/2 cycles. Tripping, because it employs stored spring energy released by a 24-volt signal from the control, will occur even if the 240-volt supply is lost. CONTACT POSITION INDICATOR linked to main operating shaft; visible through window in operator cabinet. DRIVE MOTOR 240 Vac operates closing mechanism; needs no lubrication. SPRING CHARGE INDICATOR linked to closing springs; for indication of stored energy operation in event of loss of low voltage motor supply. MANUAL CLOSE LEVER permits manual closing of the recloser. MANUAL CLOSE PULLRING permits manual closing of the recloser. The recloser can be manually closed by pulling down the Manual Close Pullring located under the operator cabinet. An emergency means is provided to manually close VSA-group reclosers on a de-energized line in the absence of the 240 Vac power supply. AUXILIARY SWITCH (accessory) is available to provide remote indication of recloser contact position. MANUAL RESET-TRIP KNOB provides means for manual tripping; must be in RESET position to permit closing. OPERATOR CABINET HEATER control switch and fuse. MULTI-RATIO CT TERMINAL BOARD (accessory) provides convenient customer connection to the desired current transformer ratio. MANUAL TRIP PULLRING provides means for manual tripping. Figure 3. VSA-group recloser operating mechanism components. www.cooperpower.com 280-45-5 Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Effective July 2014 A hand crank can be applied to the motor to charge the closing springs. Once charged, the closing springs can be released either from inside or from below the operator mechanism cabinet. As with electrical operations, the opening springs are charged by release of the closing springs, so even a manually closed unit has sufficient stored energy for a trip operation. Vacuum interrupters The high quality vacuum interrupters used in VSA-group reclosers are manufactured exclusively at the Distribution Switchgear plant. Eaton's Cooper Power Systems vacuum interrupters are used worldwide in the industry’s broadest line of fault protection and switching apparatus, where they have established a proven record of long term reliability. Vacuum interrupters provide fast, low energy arc interruption with long contact and interrupter life and low mechanical stress. With arc interruption taking place in a vacuum, contact and interrupter life are four times greater than with interruption in oil. At the same time, mechanical stress and wear on the mechanism is substantially reduced. Combined, these factors result in greatly reduced maintenance costs over the life of the recloser. Vacuum interrupters from Eaton's Cooper Power Systems are designed with a metal-and-ceramic housing for maximum strength. The high-alumina ceramic used in Eaton's Cooper Power Systems vacuum interrupters permits a high processing temperature to develop maximum purity of the assembly and is impervious to helium penetration. Metal end closures and the arcing chambers are of high-purity alloys to minimize contamination. Enclosed in the interrupter is a stationary and a moving contact assembly. The moving contact has a travel of 7/16 in., its shaft passing through a flexible bellows which maintains vacuum integrity. Contacts are made of a special non-welding alloy. Because even the smallest amount of internal contamination can significantly shorten a vacuum interrupter’s life, a state-ofthe-art clean-room manufacturing facility is used for vacuum interrupter production. Special care is taken to avoid even minute contamination; whether it be from dust particles, machining oils, or human body salts. Figure 5. Form 6 microprocessor-based recloser control. Microprocessor-based control for maximum flexibility The operation of a VSA-group recloser is commanded by an Eaton's Cooper Power Systems electronic recloser control. The Form 6 control, shown in Figure 4, provides maximum protective hardware design and simple interactive graphical interfaces for complete user customization. All standard control operating parameters including minimum trip levels, time-current curve selection, and sequences of recloser operation are keyboard programmable. This control utilizes a powerful PC based interface software to configure control settings, record metering information, and establish communication parameters. It also provides analysis tools that include fault locating, event recording, and oscillography functions. The Form 6 rack mount substation interface accessory enables application of Form 6 rack mount controls and VSA reclosers to substation installations. Located in the motor operator cabinet, the substation interface accessory allows the Form 6 rack mount control to be located up to 500 ft. from a VSA recloser. (Table 9). The factory-installed interface accessory may be powered by a either a 24, 48, or 125 Vdc substation battery, as specified at time or order. The quiescent battery drain upon the substation is only 40 milliamperes. All VSA reclosers include a 14 pin control cable receptacle to provide convenient connection of the Form 6 rack mount recloser control to either the KA85ME control cable or KME6-1859/ KME6-1811 junction boxes. For complete descriptive information on the Form 6 control, refer to Bulletins B280-00031 and B280-00032. Figure 4. Vacuum interrupters are used in VSA-group reclosers. 280-45-6 www.cooperpower.com Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Effective July 2014 Table 12. Cable lengths for Form 6 rack mount substation interface accessory Cable Lengths for 24 Vdc Substation Form 6 Interface Accessory Wire Gauge Meters Feet 18 AWG 16 AWG 14 AWG 12 AWG* 12 18 30 50 40 60 100 175 Cable Lengths for 48 Vdc Substation Form 6 Interface Accessory Wire Gauge Meters Feet 18 AWG 16 AWG 14 AWG 12 AWG* 24 36 60 100 80 120 200 350 Cable Lengths for 48 Vdc Substation Form 6 Interface Accessory Wire Gauge Meters Feet 18 AWG 16 AWG 14 AWG 12 AWG* 48 54 90 150 120 180 300 500 * 12 gauge cable to be used with junction box accessory KME6-1859 or KME6-1181. Ratings and specifications Table 9. Voltage Ratings Maximum Design Voltage (kV) 15.5 Nominal Operating Voltage (kV) 2.4-14.4 Basic Insulation Level (BIL) (kV) 110 60 Hertz Withstand Voltage (kV) Dry, one minute Wet, ten seconds 50 45 Max RIV at 1.0 MHz/9.41 kV (micro-volts) 100 Table 10. Current Ratings Continuous Current Rating (amps) VAS12B VSA12, VSA16, VSA20 VSA20A 600 800 1,200 Symmetric Interrupting Current (amps) VSA12, VSA12B VSA16 VSA20, VSA20A 12,000 16,000 20,000 Cable Charging Current (amps) 2 Magnetizing Current (amps) VSA12,VSA12B VSA16, VSA20 VSA20A 28 42 Three-Second Current, Symmetric (amps) VSA12, VSA12B VSA16 VSA20, VSA20A 12,000 16,000 20,000 Momentary Current, Asymmetric (amps) VSA12, VSA12B VSA16 VSA20, VSA20A 20,000 25,600 32,000 Capacitive Switching, General Purpose, Isolated Bank (amps). 250 Table 11. Electrical Specifications Trip Solenoid: Operating voltage (Vdc) 24 Peak current (A) 12.2 Actuation time (cycles) 1.25 Close Solenoid: Operating voltage (Vdc) 24 Peak current (A) 15.5 Actuation time (cycles) 1.5 Spring Charging Motor: Standard Accessory Operating Voltage (Vac) 240 120 Voltage Range (Vac) 160-257 90-127 Maximum Current, RMS (A) 14 18 Steady State Current (A) 4.1 9 Motor Running Time (cycles) 40 40 Sensing Current Transformers VSA12, VSA12B, VSA16 1000:1 VSA20, VSA20A 2000:1 Maximum Arcing Time (cycles) 1.0 Interrupting Time (cycles) 2.5 www.cooperpower.com 280-45-7 Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Effective July 2014 Table 13. Mechanical Life Open-Close, no load, operations 2500 Table 14. Bushing Specifications Bushing creepage distance (in.) VSA12, VSA12B, VSA16, VSA20 VSA20A 12* 17 Arcing distance (in.) - phase to ground VSA12, VSA12B, VSA16, VSA20 VSA20A 7 1¼2 7 3¼4 Arcing distance (in.) - phase to phase VSA12, VSA12B, VSA16, VSA20 VSA20A 9 5¼8 11 * 17 in. creepage distance available as an accessory. Table 15. Duty Cycle Percent of Maximum Circuit Interrupting Rating Maximum X/R Ratio Number of Unit Operations 15-20 4 88 45-55 8 112 90-100 15 32 Total 232 Table 16. Mechanical Specifications Operating Temperature (°C) Minimum Maximum VSA12,VSA12B, VSA16, VSA20 VSA20A -30 +50 +40 Closing Mechanism Spring Operated Opening Mechanism Spring Operated Contact Gap (inches) 7/16 Close Contact Travel Time (cycles) 0.5 Open Contact Travel Time (cycles) 0.5 Allowable Contact Erosion (inches) 0.125 Opening Time (24 Vdc solenoid), signal to Contact Part (msec.) 25 Closing Time (24 Vdc solenoid), signal to Contact Make (msec.) 32 Table 17. Auxiliary Switch Interrupting Ratings Volts Inductive as (amps) Non-Inductive as (amps) Inductive dc (amps) Non-Inductive dc (amps) 24 – – 15.0 20.0 48 – – 7.5 10.0 120 60 80 – – 125 – – 1.5 2.0 240 30 60 – – 250 – – 0.45 0.5 280-45-8 www.cooperpower.com Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Effective July 2014 Dimensions and weights UNIVERSAL CLAMP TYPE TERMINAL VSA12, VSA16, VSA20 ACCEPTS 4/0 TO 1000 MCM CABLE VSA12B ACCEPTS 1/0 TO 500 MCM CABLE 55-3/4 24-1/2 26" CLEARANCE REQUIRED FOR BUSHING REMOVAL 12 10-1/4 12 11-1/4 3-1/8 44-1/2 12 13-1/8 48 61-1/8 14-3/4 DOOR OPEN 42 22 KNOCKOUTS (3) FOR 1" CONDUIT FITTING IN BOTTOM OF OPERATING CABINET Recloser Type Weight* (lbs) VSA12/12B/16/20 525 SOURCE 16-1/4 6-1/4 4 4-1/4 * Add 25 lbs. for each bushing current transformer. Figure 6. Outline dimensions for Types VSA12, VSA12B, VSA16 and VSA20 reclosers. www.cooperpower.com 280-45-9 Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Effective July 2014 VSA20A 1-1/4 - 12 UNF THREADED STUD TERMINALS 62-3/4 32-1/2 26" CLEARANCE REQUIRED FOR BUSHING REMOVAL 11-1/4 3-7/16 14 11-3/4 14 51-1/2 14 13 50 62-3/4 14-3/4 DOOR OPEN 49 30 Recloser Type Weight* (lbs) VSA20A 740 KNOCKOUTS (3) FOR 1" CONDUIT FITTING IN BOTTOM OF OPERATING CABINET SOURCE 20-1/4 4 * Add 25 lbs. for each bushing current transformer. 10-1/4 Figure 7. Outline dimensions for Type VSA20A recloser. 280-45-10 www.cooperpower.com 8-1/4 Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A three-phase reclosers Effective July 2014 STANDARD ELECTRONIC RECLOSER CONTROL CABINET MOUNTING BRACKETS: FRONT KA55VS2 KA55VS4 (DOUBLE-SIZE CONTROL CABINET) BACK KA55VS3 KA55VS5 (DOUBLE-SIZE CONTROL CABINET) VSA12/12B/16/20 VSA20A A 22-1/2 30-1/2 B 82-15/16 84-7/8 C 37-1/4 39-1/4 D 20 22 E 36-3/4 38-3/4 F 42-1/2 49-1/2 FRONT OPTIONAL ARRANGEMENTS FOR MOUNTING ELECTRONIC RECLOSER CONTROL (FOR CLARITY, OPERATOR ON FRONT OF RECLOSER IS NOT SHOWN) OPER. CAB. D DOUBLE-SIZE CAB. B (AT MINIMUM HEIGHT) C ADJUSTABLE VSA12/12B/16/20 96-1/16 TO 114-1/16 VSA20A 97-7/8 TO 115-7/8 IN 3" INCREMENTS ELEC. CNTRL. CAB. E STANDARD CABINET 13-1/2 18 STD. SIZE CAB. 34-3/4 DBL. SIZE CAB. ALTERNATE MOUNTING ELECTRONIC CONTROL (SEE DETAIL) SUBSTATION MOUNTING FRAMES: VSA12, VSA12B, VSA16, VSA20 — KA55VS1 VSA20A — KA55VS8 A 1-1/4 1-1/4 1-1/4 GROUNDING CONNECTOR 2/0-250 MCM F 1-1/4 3/4 DIA. HOLES FOR 5/8 ANCHOR BOLTS (4), NOT FURNISHED Recloser Type Weight* (lbs) VSA12/12B/16/20 VSA20A 675 890 *Add 25 lbs. for each bushing current transformer. Figure 8. Outline dimensions and weights for VSA-group reclosers with substation mounting frame accessory (weights shown are for recloser and mounting frame only). www.cooperpower.com 280-45-11 Technical Data 280-45 Types VSA12, VSA12B, VSA16, VSA20, and VSA20A threephase reclosers Effective July 2014 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-45 280-45-12 Eaton, Cooper Power Systems, UltraSIL, Evolution, and VariSTAR are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. ANSI® is a registered trademark of American National Standards Institute. For Eaton’s Cooper Power Systems VSA-group reclosers product information call 1-877-277-4636 or visit: www. cooperpower.com. Electrical Apparatus 280-57 Effective July 2014 Supersedes December 1997 Type VSO three-phase electronically controlled recloser Introduction Operating The benefits of automatic-reclosing overcurrent protection can be realized on higher voltage distribution systems with Eaton’s Cooper Power Systems Type VSO electronically controlled, oilinsulated vacuum recloser. A high continuous current rating and a high fault-current-clearing capability make the Type VSO recloser an ideal selection for substation or main feeder protection applications. Your system benefits from: Reclosers clear most faults with only momentary current interruption since the majority of faults are temporary in nature; thus, extended outages are usually prevented. With outage time kept to a minimum, customer service is improved and utility income is maintained. The Type VSO recloser includes an integral box frame fabricated of welded angle and channel steel that facilitates handling and mounting. The frame can be quickly assembled into an Eaton’s Cooper Power Systems substation mounting extension or single-pole hanger. • High reliability resulting from the application of time-tested vacuum interruption and control technologies to this higher-rated recloser • Extended maintenance intervals with longlife maintenance-free vacuum interrupters that eliminate oil contamination from arcing by-products • Simplified coordination with a familiar Form 3A electronic recloser control, or enhanced coordination flexibility with the Form 4C microprocessor-based recloser control Basic Ratings The VSO recloser has a rating of 560 amps maximum continuous current (extendable to 800 amps with an accessory) and 12000 or 16000 symmetrical amps maximum interrupting current at a maximum voltage of 38 kV. The recloser controls available provide the Type VSO recloser with a wide range of operating parameters to simplify coordination with other protective devices on a system. Sensing-current transformers mounted inside the recloser provide line-current information to the recloser control. Tripping and closing commands from the control energize operating circuits in the recloser. Operation of the recloser contacts is accomplished through the release of charged opening and closing springs. A motor-and-gear-train mechanism charges the closing springs; release of the closing springs closes the main contacts and charges the opening springs. Energy to operate the motor must be supplied to the recloser from an external 240 Vac source. 280-57-1 Electrical Apparatus 280-57 Type VSO three-phase electronically controlled recloser Effective July 2014 Current interruption takes place within vacuum interrupters that are suspended in oil from a mechanism frame under the head of the recloser. The head mechanism transfers forces from the operator mechanism to the moving contact in each of the three vacuum interrupters, causing them to move simultaneously through a oneinch stroke. Table 3. Mounting Equipment Description Catalog No. Single-pole hanger KVSO52V Substation-mounting-frame extension KVSO51V Tank-lifting mechanism KVSO56V Surge protection Best operating results are achieved when reclosers are protected with surge arresters. On line applications, arrester protection is recommended on both sides of a recloser. If protection is to be provided on one side only, then it should be on the source-side. In substations, arresters should be located on the load-side. Eaton’s Cooper Power Systems, distribution-class surge arresters provide excellent protection for the Type VSO recloser. See Technical Data 235-99, UltraSIL™ Polymer-Housed Evolution™ Surge Arrester or Technical Data 235-35, UltraSIL Polymer-Housed VariSTAR™ Surge Arrester for information. Table 1. Basic Recloser Recloser Type Catalog No. VSO 12,000 amp interrupting KVSO38-12-560 Table 2. Recloser Accessories Accessory Description Catalog No. VSO 16,000 amp interrupting KVSO38-16-560 Bushing current transformers 600:5 multi-ratio BCTs mounted on bushings 1,3,5 KVSO53VD 600:5 multi-ratio BCTs mounted on bushings 2,4,6 KVSO53VE 1200:5 multi-ratio BCTs mounted on bushings 1,3,5 KVSO53VK 1200:5 multi-ratio BCTs mounted on bushings 2,4,6 KVSO53VL Three thermal-amp demand meters; five-amp movement/five-amp scale* Without instantaneous elements KRW324V20-3 With instantaneous elements KRW324V1-3 Vertical rain-tight meter trough; three sockets with circuit KA335R903 closing contacts** Meter trough mounting-and-wiring kit for use on KVSO54V substation extension 800-amp continuous current accessory on recloser equipped with accessory BCTs (with eyebolt terminals) KVSO55VD (with 1-1/8-inch-12 stud terminals) 120-Vac motor operator KVSO55VC KVSO57V Potential-type battery charger in operator cabinet*** 120-Vac 240-Vac KA58VSM1 KA58VSM2 External spring-charging accessory KA59VSM External contact-position-indicating accessory Flat-pad terminals KA61VSM2 On recloser without accessory BCTs KA62RV3 On recloser with accessory BCTs KA62RV4 * Metering accessories are also available installed in the upper portion of a double-size ME control cabinet. ** KVSO54V meter trough mounting required if meters are to be mounted on substation frame. *** For use with Form 3A electronic controls only, requires addition of KA1144ME control accessory. 280-57-2 www.cooperpower.com Ordering information A complete electronically controlled recloser installation includes: • recloser and its accessories • recloser control and its accessories • interconnecting control cable • recloser mounting equipment Accessories for the recloser are priced separately and must be ordered separately. Orders must include: 1. Catalog number and type designation of the basic recloser (Table 1). 2. Catalog number and description of recloser accessories (if required). See Table 2. 3. Catalog number and description of recloser mounting equipment (if required). See Table 3. Type VSO three-phase electronically controlled recloser Electrical Apparatus 280-57 Effective July 2014 BUSHINGS Made of wet-process porcelain; glaze color is light gray, Munsell 5BG 7.2/0.4. CLAMP-TYPE TERMINALS Terminals are tin-plated; accept horizontal or vertical 1/0 to 500 MCM copper or aluminum conductor. OPERATING MECHANISM Spring-operated stored-energy close mechanism; 240 Vac charging motor; contact position and spring charge state indicators visible from outside of cabinet. OIL DIPSTICK (not visible) Permits accurate oil level determination. AUXILIARY SWITCH Four-state switch permits remote contact status indication and control of other devices coincidentally with contact opening and closing. WINDLASS (accessory) Allows easy access to interior of pole-mounted recloser. Permits one person to raise or lower oil-filled tank. TRIP AND CLOSE PULL RINGS Initiate trip and close operations from outside mechanism cabinet with hand or hookstick. METERING (accessory) Three socket-type thermal amperedemand meters. Rain-tight through that can be conveniently mounted on frame. Accessories sold separately. RECLOSER CONTROL Type ME Form 3A and Form 4C controls provide convenient, programmable control for Type VSO electronically controlled reclosers. The recloser control can be remotely located to a distance of 35 feet. OIL DRAIN VALVE (not visible) Makes oil draining or sampling a cleaner, easier procedure. SUBSTATION EXTENSION Simple and compact; with recloser box frame forms strong rigid support for recloser, control, and accessories. Adjustable for terminal top height of 9’7” to 10’ 10” in 3-inch increments. OIL SIGHT GAUGE (back side of tank) Permits quick visual “hands-off” check for adequate oil level. Figure 1. Type VSO recloser in substation extension, untanked, with some accessories The electronically controlled, oil-insulated, three-phase Type VSO vacuum recloser from Eaton’s Cooper Power Systems can be used in substations or in close-in feeder applications where it would be subject to high fault current levels. Line current is sensed by three 1000:1 ratio current transformers mounted on bushings 1, 3, and 5 under the recloser head. They provide the recloser control with a continuous measurement of line current. Vacuum interrupters provide a single break on each phase through separation of contacts within each vacuum envelope. All arcing is contained within the interrupters. Low energy arc interruption in a vacuum results in far less shock and demonstration, extending the recloser mechanism life. Vacuum interruption offers longer duty cycles and long contact life. When the programmed minimum-trip is exceeded, and after the programmed time delay, the control energizes a trip solenoid in the recloser to release the charged opening springs. The force required to trip and close the recloser contacts is provided by the release of charged opening and closing springs in the operator cabinet. A motor-operated mechanism, powered from an external 240 Vac supply, charges the closing springs. Release of the closing springs closes the recloser contacts and also charges the opening springs. The Type VSO recloser is designed and built in accordance with ANSI® C37.60. Each recloser is thoroughly tested before shipment. When the recloser contacts open, the recloser control activates the closing mechanism. Energy to operate the trip solenoid and activate the closing mechanism is provided by the control. www.cooperpower.com 280-57-3 Electrical Apparatus 280-57 Type VSO three-phase electronically controlled recloser Effective July 2014 Construction Operation In common with other reclosers from Eaton’s Cooper Power Systems, Type VSO reclosers are designed for long service life with minimum maintenance. The recloser head is an aluminum casting. The tank is fabricated of heavy-gauge steel and is finished with a corrosion-inhibiting-epoxy prime coat, followed by a finish coat of thermosetting acrylic paint. Finish color is light gray, Munsell 5BG 7.0/0.4. Tripping The oil-filled tank can be lowered and raised easily by one person with a windlass accessory, usable whether the recloser is mounted in a substation frame or on a pole. An oil sampling-and-drain valve, oil level sight gauge, and oil dipstick are provided as standard features. An oil-tight, weather-resistant seal between the head and the tank is assured by a Buna-N synthetic rubber gasket confined in a groove in the head to provide controlled compression. The recloser head is attached to a welded angle- and channel-steel box frame which facilitates handling and mounting. The tank is suspended within the box frame from the head. Each interrupter is independently suspended from the internal mechanism under the recloser head in a way which eliminates mechanical stress on the bushings as well as any need for adjustment between the bushing and interrupter. Wet-process porcelain bushings are oil-filled, capacitively graded type. Two targets, visible through windows in the operator cabinet door, provide continuous (easily readable) indications of contact position and closing spring charge state. Contact position indication is either CLOSED (white letters on red background) or OPEN (white letters on green background). Spring charge state indication is either SPRING CHARGED (black letters on yellow background) or SPRING DISCHARGED (black letters on white background). A four-stage auxiliary switch is provided as standard. Normally set for four “a” and four “b” contacts, the switch can be programmed for other “a” and “b” combinations totaling eight. It is operated by the recloser mechanism and is wired to a terminal block in the operator cabinet. The switch can be used to provide a remote indication of contact position or to switch other devices, such as alarm circuits, coincidentally with recloser contact opening and closing. Line current in all three phases is sensed by 1000:1 ratio current transformers on bushings 1, 3, and 5 under the recloser head. Continuous signals from the CTs, proportional to line currents, are routed to the recloser control, where they are monitored. When the line current flows in excess of the programmed minimum trip level, in one or more phases, and after a time delay based on the programmed time-current characteristic, a trip solenoid in the operating mechanism is energized by the control. The solenoid trips a latch that releases the charged trip springs and mechanism. A linkage simultaneously operates all three phases, opening the recloser contacts and a switch which interrupts the trip signal from the control. Closing As with contact opening, contact closing force is provided through the release of stored spring energy. The closing springs are charged by operation of a 240 Vac motor and gear train. Upon receiving a closing signal from the control, a solenoid energizes, tripping a latch which releases the closing springs. When released, the closing springs cause the operating mechanism to close the vacuum interrupter contacts and simultaneously charge the opening springs. Immediately following the release of the closing springs, the 240 Vac motor runs to recharge the springs in preparation for the next closing operation. Limit switches interrupt the supply to the motor and the signal from the control when the closing springs are fully charged. Spring charging time is less than one second. An external 240 Vac source supplies power for the motor operator. An undervoltage relay opens a contact in the motor circuit if the 240-volt motor supply voltage falls below 165 volts. This prevents the motor from operating on inadequate voltage, which could result in motor stalling and burnout. If the 240-volt supply voltage is lost, the recloser can still perform a limited number of trip and close operations, operating from the stored spring energy. If power loss occurs while the main contacts are closed (and the motor has run to recharge the closing springs), the capability exists to trip, close, and trip again. If power loss occurs while the main contacts are open, the capability exists to close once and trip once. Manual A closed recloser can be tripped manually from inside the operator cabinet by moving the Trip-Reset knob to TRIP or from outside the cabinet by pulling down on the yellow trip ring under the cabinet. When the recloser is manually tripped, the closing circuit is opened to prevent reclosing. The recloser can be manually restored to service either by moving the Trip-Reset knob to RESET and pressing the Manual Close lever down or by pushing up on the yellow trip ring and pulling down on the close ring. The manual operation described in the preceding paragraph involves levers that are mechanically linked to the operating mechanism. The recloser can also be tripped and closed with the Manual Control switch on the recloser control panel. An emergency means is provided to manually close the recloser (on an energized line if necessary and with the closing springs discharged) in the absence of 240 Vac auxiliary power. A crank stored inside the operator cabinet door is engaged with the motor shaft and cranked through approximately 150 turns to charge the closing springs; a closing operation can then be initiated. 280-57-4 www.cooperpower.com Type VSO three-phase electronically controlled recloser Electrical Apparatus 280-57 Effective July 2014 LIMIT SWITCH De-energizes trip-coil circuit to minimize battery drain when recloser opens. CONTACT POSITION INDICATOR Linked to main operating shaft; visible through window in cabinet door. TRIP SOLENOID Operates on 24 Vdc signal from electronic control; trips latch releasing opening springs. UNDERVOLTAGE RELAY Prevents motor from operating if 240 Vac supply voltage fails below 165 volts; safeguards motor from stalling and burnout. SERIES UNIVERSAL MOTOR, 240 VAC Charges closing springs in less than one second; low power requirement; needs no lubrication. CLOSE SOLENOID Operates on 24 Vdc signal from electronic control; trips latch releasing closing springs. FUSED PULLOUT SWITCH Provides a safe visible means of disconnecting motor power source. MANUAL CLOSE LEVER Permits manual release of closing springs from operating mechanism cabinet. CLOSING SPRING CHARGE STATE INDICATOR Indicates whether springs are charged or discharged; visible through window in cabinet door. EXTERNAL CLOSE PULL RING Permits manual release of closing springs from beneath cabinet with hand or hookstick. FOUR-STAGE AUXILIARY SWITCH Used for remote contact position indication or switching of other devices coincidentally with recloser operations; with terminal strip for convenient connection. MANUAL TRIP AND RESET KNOB Permits manual release of trip springs from operating mechanism cabinet. OPERATIONS COUNTER Indicates accumulated total of tripping operations performed by recloser. HEATER CONTROL Switch and fuses for operator cabinet heater. CLOSING SPRINGS Charged by drive motor; provide energy to close main contacts; simultaneously charge opening springs. (Opening springs are located in recloser head mechanism.) CURRENT TRANSFORMER TERMINAL BLOCKS Used for connection to multiratio bushing current transformer accessory. EXTERNAL TRIP PULL RING Permits manual release of trip springs from beneath cabinet by hand or with hookstick. Figure 2. Operating mechanism used on Type VSO recloser. www.cooperpower.com 280-57-5 Electrical Apparatus 280-57 Type VSO three-phase electronically controlled recloser Effective July 2014 Vacuum interrupters Recloser control Vacuum interrupters provide a single break on each phase. Vacuum interrupters provide fast, low-energy arc interruption with long contact and interrupter life, low mechanical stress, and maximum operating safety. With arc interruption taking place in a vacuum, isolated from the insulating oil, contact and interrupter life is greatly extended, and oil contamination and maintenance are virtually eliminated. At the same time, mechanical stress and wear on the mechanism is minimal. Type VSO recloser is electronically controlled by an Eaton’s Cooper Power Systems recloser control. A choice of two controls can be used in conjunction with this recloser. The Form 3A control, shown in Figure 4, is a solid-state electronic control system, using conventional, discrete, electronic components. Control operating parameters are programmed via plug-in modules. These programming components provide precise values for operating parameters, which include: time-current characteristics, reclosing delay intervals, and minimum trip levels. The control provides simple selector switch determination of phase- andground-trip sequences and operations to lockout. Operating characteristics can be quickly and easily changed to meet new application requirements by simply changing the dial settings or plugin component(s), without removing the recloser from service. The Form 3A control can be equipped with a variety of accessories to provide remote operation and monitoring for SCADA applications. Some of the available accessories include: remote fault indication, remote modification of operating characteristics, and remote operation. Figure 3. Vacuum interrupter used in Type VSO recloser (cutaway to show contacts). Eaton’s Cooper Power Systems vacuum interrupters are designed with a metal and ceramic housing for maximum strength. The highalumina ceramic has more than five times the strength of glass, permits a higher processing temperature to develop maximum purity of the assembly, and is impervious to helium penetration to sustain the vacuum level. Metal end closures and the arcing chambers are of high-purity alloy to minimize contamination. Enclosed in the interrupter is a stationary and a moving contact assembly. The moving contact has a travel of one inch, its shaft passing through a flexible bellows which maintains vacuum integrity. Contacts are made of a special non-welding alloy. Figure 5. Form 4C microprocessor-based recloser control. The Form 4C Type ME microprocessor-based recloser control, shown in Figure 5, incorporates computer technology to provide enhanced application versatility and ease of operation. All standard control operating parameters including; phase- and ground-fault minimum trip levels, time-current curve selection, and sequences of recloser operation, are keyboard programmable. Simple keyboard sequences, and dedicated function keys, provide convenient programming and interrogation of the control’s various operating parameters. A large LCD display provides control feedback during programming and integration, and either front panel LCD indicators provide control and recloser status, at a glance. The control is equipped with 38, keyboard-selectable, time-current curves, which are interchangeable for use as either phase or ground. Each of the curves can be custom modified to provide an almost unlimited coordination flexibility. The control provides a wide range of standard features, which include: supervisory operation, remote status indication, fault indication via LCD targets and counters, Fault Footprint™ event recorder, recloser duty monitor, demand metering, and load profile monitor. Figure 4. Form 3A Type ME electronic recloser control. 280-57-6 www.cooperpower.com The microprocessor-based control can also be equipped with an accessory supervisory input/output board to extend the supervisory operation capabilities of the control. Electrical Apparatus 280-57 Type VSO three-phase electronically controlled recloser Effective July 2014 Accessories Accessories available for the Type VSO recloser are described in the following paragraphs. Bushing-type, multiratio current transformers Multiratio current transformers for operating relays or load meters can be mounted on the source-side bushings (Figure 6), the loadside bushings, or both the source- and load-side bushings. Whether three or six current transformers are ordered, the accessory includes six extra-length bushings to accommodate the current transformers and maintain an equal terminal-top height. (When the accessory is ordered for one side only, extender sleeves are included on the opposite side). Addition of the transformers increases terminal top height by five inches. These current transformers have only one primary turn – the bushing rod. They are offered with secondary windings that provide primary/secondary current ratios of either 600:5 or 1200:5. Different ratios can be obtained by connection to appropriate taps on their secondary windings. The ratios obtainable from 600:5 and 1200:5 transformers, and the corresponding accuracy classes, are shown in Table 4. For ease of connection and ratio selection, secondary taps are factory-wired to terminal blocks (one corresponding to each transformer) in the mechanism cabinet (Figure 7). Wiring from meters or relays is routed into the cabinet by the customer and joined to two of the five terminals on each block to obtain the ratio desired. Two thumbscrews in each of the blocks, positioned to short and ground the current transformers for shipping, are then removed and repositioned to complete electrical connection of the device. To order bushing-type multiratio current transformers see the Recloser Accessories listing under ORDERING INFORMATlON. Figure 6. Multiratio current transformers. Table 4. Bushing-Type Current Transformer Ratios, Terminal Connections, and Accuracies Ratio Terminal Connection Relay Accuracy Class Metering Accuracy Class 600:5 X1-X5 C100 .3B-0.5 .6B-1.0 1.2B-2.0 500:5 450:5 400:5 X2-X5 X3-X5 X1-X4 – – – .3B-0.5 .3B-0.5 .3B-0.2 .6B-1.0 .6B-1.0 .6B-0.5 1.2B-2.0 1.2B-2.0 1.2B-2.0 300:5 250:5 200:5 X2-X4 X3-X4 X4-X5 – – – .3B-0.2 – – .6B-0.5 .6B-0.2 .6B-0.2 1.2B-1.0 1.2B-0.5 1.2B-0.5 150:5 X1-X3 – – – 1.2B-0.2 100:5 X1-X2 – – – – 50:5 X2-X3 – – – – Ratio Terminal Connection Relay Accuracy Class Metering Accuracy Class 1200:5 1000:5 900:5 800:5 X1-X5 X2-X5 X3-X5 X1-X4 C200 – – – .3B-2.0 .3B-2.0 .3B-1.0 .3B-1.0 .6B-4.0 .6B-4.0 .6B-4.0 .6B-2.0 1.2B-8.0 1.2B-8.0 1.2B-8.0 1.2B-4.0 600:5 500:5 400:5 X2-X4 X3-X4 X4-X5 – – – .3B-0.5 .3B-0.5 .3B-0.2 .6B-1.0 .6B-1.0 .6B-0.5 1.2B-2.0 1.2B-2.0 1.2B-1.0 300:5 X1-X3 – .3B-0.2 .6B-0.5 1.2B-1.0 200:5 X1-X2 – – .6B-0.2 1.2B-0.5 100:5 X2-X3 – – – 1.2B-0.1 www.cooperpower.com 280-57-7 Electrical Apparatus 280-57 Type VSO three-phase electronically controlled recloser Effective July 2014 800-Amp continuous current The continuous current carrying capability of the Type VSO recloser can be increased, extending its rating from 560 amps to 800 amps, with this accessory. It consists of larger bushing terminals stainless steel bushing clamps, and associated small hardware. Two types of bushing terminals are offered: a 1-1/8 inch-12 stud type terminal and an eyebolt terminal that accepts 2/0-1000 MCM copper or aluminum conductor. 120-Volt AC motor operator Figure 7. Current transformer terminal blocks. Current metering Useful in load balance studies, current metering is offered for the Type VSO recloser in the form of three 3-1/2-inch socket-mounting thermal ampere-demand meters. The five-amp movement/five-amp scale meters are available with or without instantaneous indicators in addition to the average indicators. A meter trough mounting-and wiring kit contains the parts required to conveniently mount the trough to the substation extension alongside the control and make electrical connections to the current transformer terminal blocks inside the mechanism cabinet. Current metering can also be ordered in the upper portion of a double-size Form 3A electronic control cabinet. Figure 8. Current metering accessory. 280-57-8 www.cooperpower.com For installations where 240 Vac auxiliary power is not accessible, the Type VSO recloser can be ordered with an accessory which permits operation on 120 Vac. All of the standard recloser capabilities are retained. Potential-type battery charger Form 3A electronic recloser controls contain battery charging circuits that require a 120 Vac supply voltage. For those installations where 120 Vac is not available at the control, or when a prior model Form 3 control (which may not have a battery charger) is to be used, the recloser must be equipped with a battery charger. Installed in the operator cabinet, chargers are provided in either of two versions: 240 Vac for the standard Type VSO recloser, or 120 Vac for the Type VSO recloser equipped with the 120 Vac motor operator accessory. Type VSO three-phase electronically controlled recloser Electrical Apparatus 280-57 Effective July 2014 External spring charging Enhanced operator safety is provided by this accessory, which relocates the receptacle for the hand spring charging crank from the side of the operator cabinet to its underside (Figure 9). When recharging springs in a recloser on a live circuit, a lineman need not have any part of his body closer to exposed live parts than the underside of the cabinet to effectively operate the crank. External contact position indicator Spotting a tripped recloser in a row of substation-mounted reclosers, or spotting a tripped pole-mounted recloser from a moving vehicle is easy with this indicator accessory (Figure 10). A green cylinder (1-1/4-inch diameter x 2 inches long), mechanically linked to the mechanism is enclosed in a sleeve extending from the bottom of the mechanism cabinet. When the recloser contacts are open, the cylinder extends from the sleeve (green visible); when the contacts are closed, the cylinder retracts into the sleeve (green hidden). The cylindrical indicator design provides a definite indication easily seen from various positions around the cabinet end of the recloser, eliminating possible difficulty in viewing and interpreting a flag-type indicator from some positions. Figure 9. External spring-charging accessory. Figure 10. External contact position indicating accessory (shown with green cylinder extended from sleeve, indicating open recloser contacts). www.cooperpower.com 280-57-9 Electrical Apparatus 280-57 Type VSO three-phase electronically controlled recloser Effective July 2014 Flat-pad terminals Two-hole or four-hole flat-pad type bushing terminals (Figure 11) of silver-plated, red brass alloy are offered for the Type VSO recloser. Figure 11. Flat-pad terminals. Mounting Equipment Single-pole hanger Consisting of two horseshoe-shaped, galvanized channel-steel brackets, the Type VSO recloser single-pole hanger (Figure 12) forms a strong rigid supporting frame when joined to the recloser’s welded box frame. The hanger brackets are conveniently bolted to the box frame with four 1/2-inch bolts while the recloser is on the ground. The recloser/hanger assembly is then hoisted into position and secured to the pole with two 3/4-inch through-bolts (customerfurnished). Two reinforcing washers are included with the accessory. Substation Extension Compact and adjustable, the Type VSO recloser substation extension (Figure 13) provides a structure of ample strength to support the recloser and a complement of accessories. Consisting of four galvanized angle-steel legs, galvanized strap-steel braces, and associated hardware, the extension is easily assembled to the recloser frame. A mounting strap is provided for the recloser control, located to allow space for mounting the metering accessory alongside. The extension is adjustable in three-inch increments to provide a terminal-top height of nine feet, nine inches to eleven feet. 280-57-10 www.cooperpower.com Figure 12. Type VSO recloser mounted in single-pole hanger, with windlass accessory. Type VSO three-phase electronically controlled recloser Electrical Apparatus 280-57 Effective July 2014 Tank Lifting Windlass One person can easily lower and raise the oil-filled tank with this accessory, which is usable with pole-mounted or substationmounted Type VSO reclosers. The windlass, (Figure 14) features a 30-to-1 ratio worm-and-pinion gear box that minimizes cranking effort and holds the tank stationary any time cranking is stopped and the operator’s hand is removed from the crank. A shear pin connects the crank to the gear box shaft to guard against overstressing the mechanism when the tank is fully raised. Supplied partly assembled to newly ordered Type VSO reclosers, the windlass accessory can also be ordered separately for addition to reclosers in the field. Figure 14. Tank lifting windlass accessory Figure 13. Type VSO recloser mounted in substation extension, with control and some accessories. www.cooperpower.com 280-57-11 Electrical Apparatus 280-57 Type VSO three-phase electronically controlled recloser Effective July 2014 Ratings and specifications Table 5. Voltage Nominal system voltage (kV rms) Rated maximum voltage (kV rms) 34.5 38 Rated impulse withstand voltage BIL) (kV crest) 150 60 Hz withstand voltage (kV rms) dry, one minute 70 wet, 10 seconds 60 Maximum Radio influence @ 23 kV (uV) 100 Table 6. Continuous Current Maximum continuous current (amps) 560* * Can be increased to 800 amps by adding an 800-amp accessory. Table 7. Interrupting Current Interrupting current (rms sym. amps) VSO 12 VSO 16 12000 16000 Table 8. Duty Cycle Percent of interrupting rating X/R ratio No. of operations 15-20 4 88 45-55 8 112 90-100 15 32 Total: 232 Table 9. Spring-Charging Motor Nominal operating voltage (Vac) Voltage range (Vac) 240 160-257 Inrush current (rms amps) 13 Steady-state current (amps) 8 Motor running time (cycles) 40 Table 10. Auxiliary Switch Interrupting ratings (amps) Volts Inductive (ac) Noninductive (ac) Inductive (dc) Noninductive (dc) 24 – – 15.0 20.0 48 – – 7.5 10.0 120 60 80 – – 125 – – 1.5 2.0 240 30 60 – – 250 – – 0.45 0.5 Table 11. Trip Solenoid Nominal operating voltage (Vdc) 24 Approx. peak current, 1-1/2 cycles (amps) 5.65 Table 12. Specifications Contact closing time* (cycles) 0.75 Contact opening time** (cycles) 0.5 Bushing creepage distance (inches) 26-1/2 Mechanical life (no-load operations) 2500 * Time from initial contact motion to contact make. ** Time from contact break to end of contact motion. 280-57-12 www.cooperpower.com Type VSO three-phase electronically controlled recloser Electrical Apparatus 280-57 Effective July 2014 Dimensions and weights Figure 15. Type VSO recloser outline dimensions Table 13. Weight without control (lb) 1130 Weight with pole-top frame (lb) 1193 Weight with substation frame (lb) 1271 Oil capacity (gal) 65 www.cooperpower.com 280-57-13 Electrical Apparatus 280-57 Effective July 2014 280-57-14 www.cooperpower.com Type VSO three-phase electronically controlled recloser Type VSO three-phase electronically controlled recloser Electrical Apparatus 280-57 Effective July 2014 www.cooperpower.com 280-57-15 Electrical Apparatus 280-57 Type VSO three-phase electronically controlled recloser Effective July 2014 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-57 280-57-16 Eaton, Cooper Power Systems, UltraSIL, VariSTAR, and Fault Footprint are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. ANSI® is a registered trademark of the American National Standards Institute. For Eaton's Cooper Power Systems Type VSO three-phase recloser product information call 1-877-277-4636 or visit: www.cooperpower.com. Technical Data 280-76 Effective July 2014 Supersedes August 1996 MET electronic recloser control tester Description The MET electronic recloser control tester from Eaton's Cooper Power Systems is designed specifically for testing Type ME Form 2, Form 3, Form 3A, Form 4A, Form 4C, Form 5, Types FX, FXA, and FXB controls. The tester has the capability to check the following: • Battery voltage (load and no load) • Battery charge and discharge rates • Minimum-trip current (phase- and ground-trip) • Operating sequence • Control response time (phase- and ground trip) • Reclosing time • Reset time • Electrical operation of recloser • Functioning of various accessories through simulation of the conditions under which they operate The self-contained unit, compactly packaged in a handy carrying case with a detachable front cover, includes the following: • Multi-scale dc meter with associated switches for checking the battery and battery-charging circuits • Multi-scale ac meter and adjustable current source to duplicate the output of the sensing bushing current transformers of the recloser • Solid-state digital clock to measure time of the test • Simulator circuit to simulate recloser operation and duplicate recloser mechanism response times to trip and close signals • Switches and associated circuitry for performing the various tests • Cables for connecting the control, recloser, and control battery to the tester • Internal buzzer sounds if a mis-match between grounds on the ME control and MET tester exists 280-76-1 Technical Data 280-76 MET electronic recloser control tester Effective July 2014 Ordering information Table 1. Specifications Input 120 Vac; 60 Hz; single-phase (fused for 2 amps) Output 0–3000 mA continuously adjustable from front panel of tester Instrumentation The tester is supplied as a complete unit and includes all necessary interconnecting cables. To order, specify tester by description and catalog number. MET electronic recloser control tester: Catalog No. KMET DC meter Edgewise panel meter with 2-in. horizontal scale; accuracy ± 5% of full scale Recloser simulator Panelswitched ranges 0–4/40 mA; 0–40 volts AC meter* Edgewise panel meter with 2-in. horizontal scale; accuracy ± 5% of full scale Panel-switched ranges 0–30/100/300/1000/3000 mA Timer Digital clock timer 0–999.999 seconds in 0.001-second increments; with manual reset No external equipment or accessories are required when using this tester. The tester can check the operation of the electronic control and the recloser (provided reclosing power is available at the recloser). However, the control cannot operate the recloser through the tester. Recloser operation is simulated with red and green indicating lights on the tester panel. A built-in time delay is also provided to simulate the response time of the solenoid-closing recloser mechanisms to a trip signal (2-½ cycles) and a closing signal (30 cycles) from the control. * Jacks are provided on the panel for connecting external ammeter if different ranges, greater accuracy, or calibration of panel meter is required. Table 2. Interconnecting Cables* 15-ft. cable for connecting electronic control to tester. 15-ft. extender cable for connecting end of recloser cable to tester. 15-ft. cable for directly connecting control battery terminals to tester. * Connector terminations on all cables are polarized to assure proper interconnection. Carrying case The unit is packaged in a sturdy Formica®-covered carrying case with removable front cover and provision for storing interconnecting cables, spare fuses, and bulbs. Dimensions (overall) 9-½ in. high; 21 in. wide; 13-¼ in. deep. Weight (approximate) Net: 33 lbs; shipping: 37 lbs. Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-76 280-76-2 Eaton and Cooper Power Systems are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. Formica® is a registered trademark of The Diller Corporation. For Eaton's Cooper Power Systems MET recloser control tester product information call 1-877-277-4636 or visit: www. cooperpower.com. Technical Data 280-101 Effective January 2014 Supersedes August 2013 SPEAR™ single-phase recloser system Contents Description Page Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Ordering Information. . . . . . . . . . . . . . . . . . . . . . . 2 Constructing a Recloser Catalog Number. . . . . . . 3 Recloser Accessories and Mounting Equipment . 3 Constructing a Control Catalog Number. . . . . . . . 5 Control Accessories. . . . . . . . . . . . . . . . . . . . . . . . 6 Recloser Features . . . . . . . . . . . . . . . . . . . . . . . . . 8 Ratings and Characteristic Features . . . . . . . . 8 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Vacuum Interruption . . . . . . . . . . . . . . . . . . . . 8 Surge Protection . . . . . . . . . . . . . . . . . . . . . . . 8 Recloser Operation . . . . . . . . . . . . . . . . . . . . . 8 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Vacuum Interrupters . . . . . . . . . . . . . . . . . . . . 9 Manual Operation . . . . . . . . . . . . . . . . . . . . . . 9 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Ratings and Specifications . . . . . . . . . . . . . . . . . 10 Description Page Control Features.. . . . . . . . . . . . . . . . . . . . . . . . . Control Security. . . . . . . . . . . . . . . . . . . . . . . . Protection Profiles. . . . . . . . . . . . . . . . . . . . . . Reclosing and Overcurrent Protection/TCCs. . High Current Lockout. . . . . . . . . . . . . . . . . . . . Cold Load Pickup. . . . . . . . . . . . . . . . . . . . . . . Hot Line Tag. . . . . . . . . . . . . . . . . . . . . . . . . . . Fast Trips Disabled. . . . . . . . . . . . . . . . . . . . . . Sequence Coordination . . . . . . . . . . . . . . . . . . Manual Close Time Delay. . . . . . . . . . . . . . . . . Metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagnostic Tools. . . . . . . . . . . . . . . . . . . . . . . . Recloser Wear Monitor . . . . . . . . . . . . . . . . . . Sequence of Events Recorder. . . . . . . . . . . . . Data Profiler. . . . . . . . . . . . . . . . . . . . . . . . . . . Contact Input/Output (I/O) Module Option . . . Communications . . . . . . . . . . . . . . . . . . . . . . . Font Panel Human Machine Interface (HMI). . Display LCD Module . . . . . . . . . . . . . . . . . . . . User Interface and LED Indicators. . . . . . . . . . Operating Panel. . . . . . . . . . . . . . . . . . . . . . . . One-Touch Function Keys. . . . . . . . . . . . . . . . . Operation Upon Loss of AC Power.. . . . . . . . . Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 13 13 13 13 13 13 13 13 13 13 13 14 14 14 14 14 15 15 15 16 17 17 17 280-101-1 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Description Ordering information The SPEAR™ single-phase recloser and control is the latest addition to Eaton’s Cooper Power Systems product offering for single-phase electronically controlled reclosers. This solution provides reliable, economical overcurrent protection, advanced metering, and SCADA communications for distribution circuits rated through 34.5 kV. To order a basic SPEAR recloser: Specifically with the SPEAR recloser, it uses a solid cycloaliphaticepoxy polymer with an encapsulated vacuum interrupter. The SPEAR recloser’s mechanism is reliable, lightweight, and utilizes a magnetic actuator to provide a lifetime of trouble free operation. The solid polymer system does not rely on a gaseous, liquid, or foam dielectric insulating material. The SPEAR recloser is highly resistant to ozone, oxygen, moisture, contamination, and ultraviolet light. Designed and tested with the SPEAR control, the SPEAR recloser offers superior coordination, protection, and application capabilities. Recloser operations are programmed using the SPEAR control with accurate characteristics and a host of advanced features. Precise operating tolerances enable close coordination with other protective devices on the system. When system requirements change, program settings are easily altered with no sacrifice of accuracy or consistency. Compact and lightweight, SPEAR reclosers are easily installed on poles or in substations. Mounting equipment is available for both pole and substation mounting applications. Recloser and control accessories enable further tailoring of the protective program to achieve maximum system operating flexibility. The SPEAR control is the next in a line of fully integrated controls developed by Eaton’s Cooper Power Systems. This means one standard operating system and front panel to train technicians on. This translates to fewer training expenses, reduced inventory, and a distribution system that is much easier to maintain. In addition to the flexible and user-friendly platform, the new SPEAR control has the communications technology to take your system into the future. With fully modular communication compatibilities, the SPEAR control supports cellular and radio communications utilizing Serial DNP3 protocol. A side panel RS-232 communications port is available for connection to SCADA or other devices. The communication port is accessed by swing the control panel forward. The SPEAR control can compute power, energy, power factor, and power flow direction based upon the recloser’s CT current output, and the customer supplied voltage input. The standardized front panel of the SPEAR control can be used to program and interrogate the control, as well as to display metering and alarm information. Control parameters can also be programmed via personal computer using ProView™ NXG interface software. Temporary connection to the control can be made through the front panel USB port allowing programming and data downloads to a laptop or PC. The ProView NXG interface software includes the functionality modify time-current curves (TCCs), and provide diagnostic information. The SPEAR control analysis tools include event recording, data profiling, and various metering capabilities. 280-101-2 www.cooperpower.com • See the Constructing a recloser catalog number section to construct a catalog number that describes the required recloser. • From Tables 1 through 5, specify the catalog numbers that describe the required accessories. To order a basic SPEAR control: • On page 5, see the Constructing a control catalog number section that describes the required control. • From Table 6, specify the catalog number that describes the required control cable. • From Tables 7 through 12, specify the catalog numbers that describe the required accessories. Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Constructing a recloser catalog number To order a basic SPEAR recloser, 15 kV, with 8 kA fault interrupting and 400 amp continuous current, the catalog number would be constructed in this manner: KSPEAR Basic letters for a SPEAR recloser 15 Recloser Maximum Operating Voltage 15 for 15 kV, 110 kV BIL 27 for 27 kV, 125 kV BIL 38 for 38 kV, 170 kV BIL 8 Fault Interrupting Current 8 for 8 kA 12 for 12.5 kA 400 Continuous Current Rating 400 for 400 amp (8 kA use only) 630 for 630 amp (12.5 kA use only) 800 for 800 amp (12.5 kA use only) KSPEAR 15 8 400 KSPEAR15-8-400 is the catalog number for the required basic SPEAR recloser. Recloser options and mounting equipment Table 1. Rating Impulse Voltage (BIL) Options Description Catalog Number 125 kV BIL for KSPEAR15 150 kV BIL for KSPEAR27 KSPR-255-60 KSPR-255-61 Table 2. Tank and Heater Options Description 120 Vac Heater Mild steel tank Stainless steel tank 240 Vac heater Mild steel tank Stainless steel tank Catalog Number KSPR-MS-120 KSPR-SS-120 KSPR-MS-240 KSPR-SS-240 Table 3. Bushing Terminals Description Catalog Number Standard eyebolt terminals, 1/0-500 MCM † Eyebolt terminals, 4/0-1000 MCM ‡ 2-hole flat pad terminals † 4-hole flat pad terminals Stud-style terminals, 1.125 dia. threaded KSPR-201-21 KSPR-201-22 KSPR-201-23 KSPR-204-24 KSPR-201-25 † For use with 400 and 630 amp continuous current only ‡ For use with 800 amp continuous current only www.cooperpower.com 280-101-3 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Table 4. Miscellaneous Accessory Options Description Catalog Number Wildlife restraints, set of 2 Terminal shields for enhanced environmental protection, set of 2 for 400 or 630 amp eyebolt, 2-hole flat pad or stud terminals for 800 amp eyebolt or 4-hole flat pad terminals KSPR-56-7 KSPR-245-1 KSPR-245-2 Table 5. Mounting Equipment Options Description Catalog Number Pole mounting extension † Crossarm mounting bracket, set of 2 Arrester mounting brackets Standard, galvanized steel Set of 1 Set of 2 Stainless steel Set of 1 Set of 2 KSPR-364 KA39H2 KSPR-932-2 KSPR-932-1 KSPR-932-4 KSPR-932-3 † Pole mounting extension bracket is required for any recloser application greater than 125 kV BIL. 280-101-4 www.cooperpower.com Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Constructing a control catalog number To order a basic SPEAR control for use with the SPEAR recloser, for 120 Vac primary power, with a standard 8 amp-hour battery, mild steel cabinet, standard 2 input/output auxiliary contacts, standard DNP protocol, no communication interface and English language, the catalog number would be constructed in this manner: KSPEARC Basic letters for a SPEAR control A Recloser Maximum Operating Voltage A for use with: SPEAR recloser 0 Primary Power Code 0 = 120 Vac primary power 1 = 240 Vac primary power 0 Battery option: 0 = 8 Amp-hour battery 1 = Mounting provisions only for 8 amp-hour battery (No battery) 0 Cabinet option: 0 = Mild steel cabinet 1 = Stainless steel cabinet 1 Front panel option: 1 = Standard inserts 0 I/O option: 0 = Standard, 2 input/2 output contacts 0 Communication protocol 0 = Standard, DNP 0 Communication interface 0 = standard, none 1 = RS-232 Communications card E Language E = English KSPEARC A 0 0 0 1 0 0 0 E KSPEARCA0001000E is the catalog number for the control in the example above. www.cooperpower.com 280-101-5 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Control accessories Table 6. Control Cables Description Catalog Number Control cable: (basic cable, no length) Replace “X” with desired length. Select from 5 to 50 feet. Armored (10 ft.) control cable: (basic cable, no length) Replace “X” with desired length. Select from 11 to 50 feet. KA148ME KA148ME-X KA149ME KA149ME-X Table 7. Receptacles and Wiring Description Catalog Number AC input receptacles 120 Vac or 240 Vac input receptacle, 2-pin 120 Vac input receptacle, 3-pin No input receptacle; for hard-wiring input KSPRC-1775-H KSPRC-1775-J KSPRC-1775-0 Table 8. Input Cables Description Catalog Number AC input cables Input cable, 120 or 240 Vac, two-wire for 2-pin input, for use with KSPRC-1775-H receptacle. (Basic cable, no length) Replace “X” with desired length. Select from 0-50 feet.* Armored (10 ft) input cable: (Basic cable, no length) Replace “X” with desired length. Select from 10-50 feet. Input cable, 120 Vac, three-wire for 3-pin input, for use with KSPRC-1775-J receptacle. (Basic cable, no length) Replace “X” with desired length. Select from 0-50 feet.* * To order a mating plug body only (no cable, for customer supplied cable), enter length as “0”. 280-101-6 www.cooperpower.com KA11ME1 KA11ME1-X KA124ME KA124ME-X KME4-67-3 KME4-67-3-X Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Table 9. Automation Packages† Description Wireless communication provisions package Includes 13.5 Vdc interface board and radio mounting tray (Radio and communications interface card not included) Cellular communications connection and protection package: 32” SMA(m)-N(m) coax pigtail, 700 MHz-2 GHz Polyphaser and mounting hardware, N(f)-type external termination WiFi/Max communications connection and protection package 32” SMA(m)-N(m) coax pigtail, 2 GHz-6 GHz Polyphaser and mounting hardware, N(f)-type external termination, TNC(m)-SMA(f) inline coaxial adapter 125 MHz-1 GHz N-terminated radio connection and protection package 25” N(m)-N(m) coax pigtail, 125 MHz-1 GHz Polyphaser and mounting hardware, N(f)-type external termination 700 MHz-2 GHz TNC-terminated radio connection and protection package 32” TNC(m)-N(m) coax pigtail, 700 MHz-2 GHz Polyphaser and mounting hardware N(f)-type external termination Polyphaser and mounting hardware - 125 MHz-1 GHz Polyphaser and mounting hardware - 700 MHz-2 GHz Polyphaser and mounting hardware - 2 GHz-6 GHz Catalog Number KSPRC-1774-29 KSPRC-1774-22* KSPRC-1774-23* KSPRC-1774-24* KSPRC-1774-25* KSPRC-1775-A* KSPRC-1775-B* KSPRC-1775-C* † Required Communication Interface Option: (1) RS-232 Interface * Requires that the KSPRC-1774-29 Wireless Communication Provisions Package also be ordered Table 10. Communication Support Equipment Description Catalog Number USB Cable: Type A male to Type B male connectors 2.0 meters (6.5 feet) length KSPRC-66 Table 11. Cable Locking Sleeves Description Catalog Number Cable locking sleeve, quantity 1 Cable locking sleeve, quantity 2 Cable locking sleeve, quantity 3 KSPRC-1772-1 KSPRC-1772-2 KSPRC-1772-3 Table 12. Miscellaneous Accessories Description Catalog Number 120 Vac Battery charger for spare batteries Adapter cable, 15 ft., for use with KMET Tester KME5-60-1 KSPRC-145-15 www.cooperpower.com 280-101-7 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Recloser features Recloser operation Ratings and characteristic features Fault currents are sensed by one 1000:1 ratio sensing current transformer embedded in the recloser. This CT provides a continuous measurement of line current, monitored by the electronic control. When current level exceeds the programmed minimum trip level, the magnitude of the overcurrent is integrated with time, using a programmed time–current curve characteristic. The control then signals the trip in the recloser, opening the main contact of the encapsulated vacuum bottle. Single-phase protection on systems rated 2.4 through 14.4 kV is provided by SPEAR15 reclosers. SPEAR27 reclosers can be applied on systems rated through 27.0 kV. Higher-voltage system protection at 34.5 kV is provided by Type SPEAR38 reclosers. A ratings summary for SPEAR reclosers is shown in Tables 13. Operation Sensing current transformers, embedded in the recloser, supply fault-sensing information to the electronic control. Tripping and closing signals from the control energize the operating circuits in the recloser. Due to a single CT ratio for all ratings, minimum-trip values of the electronic control are independent of the continuous-current and interrupting ratings of the recloser. Flexibility in coordination with other protective devices is provided by varied time–current characteristics from a choice of standard or customized curves, minimum trip values, reclosing and resetting time settings, and a selection of accessories. Vacuum interruption A single break on each phase is accomplished by separating contacts inside the vacuum interrupter. All arcing is contained within the vacuum envelope. The patented axial-magnetic vacuum interrupters, used in SPEAR reclosers, offers extended and increased duty cycles compared with oil or radial-magnetic interrupters. The axial-magnetic field keeps the arc in a diffused mode, resulting in less arc power to be dissipated, resulting in low thermal stress, suitable for encapsulation. Surge protection Best operating results are achieved if reclosers are protected with surge arresters. On line applications, arrester protection is recommended on both sides of the recloser. (If protection is on one side only, it should be on the source side. In substations, arresters should be on the load side.) Eaton’s Cooper Power Systems distribution class arresters provide excellent protection and are available with mounting brackets to fit SPEAR reclosers. The control signals tripping and closing. The recloser always maintains energy for a tripping operation following a closing operation. The electronic recloser control provides determination of phase trip sequences and operations to lockout and reclosing and resetting timing, adjustable with the control without de-energizing the recloser. Construction Recloser Designed for long service life and no maintenance, the SPEAR recloser has a solid-polymer interrupter module with an embedded current transformer and a standard mild steel mechanism housing; light gray is the standard color. Cycloaliphatic-epoxy polymer encapsulation provides solid insulation and maintenance-free, environmentally safe operation. There is no monitoring or maintaining of gas pressure or oil levels; there are no toxic or environmentally unfriendly materials. There are no foam fillers or insulation seals, eliminating potential moisture ingress areas. The SPEAR recloser module exhibits good absorption of elastic energy and resistance to cracking and crack propagation. Additionally, durable environmental properties make the solid polymer suitable for outdoor applications, including seacoasts, deserts, and areas of high pollution. Surface tracking The cycloaliphatic epoxy is highly resistant to contaminants and resists tracking and flashovers under extreme pollution levels to reduce both flashovers and the associated cost of repairs. Hydrophobicity The module maintains excellent hydrophobicity, a property characterized by water beading into isolated drops, and is highly resistant to moisture absorption. Hydrophobicity prevents continuous sheets of water from forming leakage current paths that deteriorate the creepage withstand level. Ultraviolet resistance The cycloaliphatic epoxy resists ultraviolet radiation damage even in harsh climates, maintaining a smooth, unblemished, self-cleansing surface with low-adhesion to contaminants. Tensile strength Outstanding tensile and flexural strength characteristics mean the SPEAR recloser module is tough and non-fragmenting, reducing shipment and handling charges. Manual OPEN Shed design The shed design utilizes alternate sized skirts. The major sheds shield and protect the minor sheds to enhance the hydrophobicity and ultraviolet resistance of the module, eliminate formation of microcracks, and ensure extra-protected creepage. Additionally, sharp edges direct water away from the unit. Water paths and ice formations are effectively eliminated. Flashover recovery Figure 1. SPEAR recloser 280-101-8 www.cooperpower.com Flashovers occur when an object, usually wildlife, contacts energized parts of the equipment. The SPEAR recloser minimizes the effect of flashovers with remarkable physical resilience, arc-quenching properties, and a self-healing ability. SPEAR reclosers can withstand Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 the enormous forces experienced during faults without wholesale damage and allows reenergizing after external flashover without cleaning. Vacuum interrupters SPEAR reclosers use vacuum as the interrupting medium. Vacuum interrupters (Figure 2) provide fast, low-energy arc interruption with long contact and interrupter life, low mechanical stress, and maximum operating safety. With arc interruption taking place in a vacuum, contact and interrupter life are several times greater than with interruption in oil, virtually eliminating interrupter maintenance. Because the smallest amount of internal contamination can significantly shorten the life of a vacuum interrupter, special care is taken to avoid even minute contamination from any source, including dust particles, machining oils, or human body salts. No paraffinic oils are used in the machining process, all machined parts are put through a cleaning/ degreasing process, and then all components are electro-polished in a positive-pressure, air-filtered area. A Class 100 clean room facility is used for the final interrupter production. The furnaces employ a custom-designed, three-stage pumping system to yield high levels of vacuum. Every vacuum interrupter is then tested and tracked with individual serial numbers. Manual operation The recloser can be opened manually with a hotstick to pull down the yellow manual OPEN handle under the sleet hood. With the handle in the OPEN position, the control cannot close the recloser. The recloser is closed, following a manual open, by pushing the yellow handle back under the sleet hood and then using the electronic control to close the recloser. Similarly, the recloser can be operated from the manual control switch on the electronic control panel, provided the manual operating handle is up. A red contact position indicator flag, adjacent to the manual operating handle, shows recloser contact position. Accessories Figure 2. Cross section of a vacuum interrupter used in SPEAR reclosers. Eaton’s Cooper Power System vacuum interrupters are designed with a metal and ceramic housing for maximum strength and long-term vacuum integrity. Oxygen-free, high conductivity copper, stainless steel, and a nickel-copper alloy are used in the vacuum interrupters. The high alumina ceramic has more than five times the strength of glass, which permits a higher processing temperature to develop maximum purity of the assembly, and is impervious to helium penetration, maintaining the vacuum level. Additionally, it provides wear resistance, chemical resistance, and a high dielectric strength. Terminals The standard terminal is an eyebolt, 1/0–500 mcm (630 A). Eyebolt 4/0– 1000 mcm (800 A), 2-hole and 4-hole, flat-pad terminals, and stud-type terminals are available as an accessory. Pole-mounting hanger A pole-mounting hanger, which bolts directly to the recloser tank, is available for pole-mounting installation. Arrester-mounting brackets The arrester-mounting bracket accessory can be bolted to the recloser tank. The arresters are not included with the brackets. Enclosed in the interrupter is a stationary and a moving contact assembly. The moving contact has a travel of approximately onehalf inch, its shaft passing through a flexible bellows that maintains vacuum integrity. Contacts consist of a high purity copper sintered with aluminathermic chromium. www.cooperpower.com 280-101-9 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Table 13. Ratings and specifications Rating 15-8-400 15-12-630 15-12-800 27-8-400 27-12-630 27-12-800 38-8-400 38-12-630 38-12-800 Maximum Design Voltage (kV) Nominal Operating Voltage (kV) Basic Insulation Level (BIL*) (kV) 60 Hertz Withstand Voltage (kV) Dry, one minute Wet, ten seconds Max RIV at 1.0 MHz 9.4 kV (µV) 16.4 kV (µV) 23.0 kV (µV) Continuous Current Ratings (A) Sym. Interrupting Current (A) Overload Capability 125% - 8 Hours (A) 150% - 4 Hours (A) Cable Charging Current (A) Line Charging Current (A) Three-Second Current, Sym. (A) 15.5 14.4 110 15.5 14.4 110 15.5 14.4 110 27.0 24.9 125 27.0 24.9 125 27.0 24.9 125 38.0 34.5 170 38.0 34.5 170 38.0 34.5 170 50 45 50 45 50 45 60 50 60 50 60 50 70 60 70 60 70 60 100 100 100 100 100 100 400 8,000 630 12,500 800 12,500 400 8,000 630 12,500 800 12,500 100 400 8,000 100 630 12,500 100 800 12,500 500 600 10 2 8,000 788 945 10 2 12,500 None – 10 2 12,500 500 600 25 5 8,000 788 945 25 5 12,500 None – 25 5 12,500 500 600 40 5 8,000 788 945 40 5 12,500 None – 40 5 12,500 *Extended BIL option available on 15.5 kV and 27 kV products. Table 14. Mechanical Life 2,500 Minimum Operations Table 15. Duty Cycle Percent of Maximum Circuit Interrupting Rating Minimum X/R Ratio Number of Unit Operations at 12.5 kA 15-20 4 88 45-55 8 112 90-100 17 32 Total 232 Table 16. Mass (Weight) per Single-Phase Recloser Recloser SPEAR15 SPEAR27 SPEAR38 lbs (kg) 105 (48) 110 (50) 120 (55) 280-101-10 www.cooperpower.com Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Receptacle - Control Cable Creepage Distances Description SPEAR15 SPEAR27 SPEAR38 Terminal to Terminal 40.9 in 1040 mm 26.5 in 673 mm 40.9 in 1040 mm 30.5 in 772 mm 40.9 in 1040 mm 37.5 in 950 mm Lower Terminal to Ground 15.75 in (401 mm) 10.5 in (267 mm) 9.75 in (248 mm) A A Ground Connector #6 Solid to 250 MCM Stranded Cable Range C D B 12 in (305 mm) Mounting Holes for 5/8 in (15 mm) Bolts 16.25 in (159 mm) 11.25 in (283 mm) SPEAR Recloser Dimensions SPEAR15 SPEAR27 SPEAR38 B C D 34.5 in 878 mm 36.75 in 933 mm 40.5 in 1033 mm 27.5 in 693 mm 29.5 in 749 mm 33.5 in 848 mm 45.55 in 1157 mm 47.75 in 1213 mm 51.5 in 1312 mm Terminal Option Type Dimension A Eyebolt - (630 A) 1/0 to 500 MCM Cable Range Eyebolt - (800 A) 4/0 to 1000 MCM Cable Range Flat Pad - 2 Hole (630 A max) Flat Pad - 4 Hole (800 A max) Stud Type - (800 A max) 1.125 - 12 threads 3.25 in/80 mm 4.25 in/108 mm 4.5 in/114 mm 4.75 in/121 mm 3.25 in/82 mm Figure 3. Recloser dimensions. www.cooperpower.com 280-101-11 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 6 .6 in (167.6 mm) SPEAR Recloser Top View Ø .8 1 in (20.6 mm) 6 .6 in (167.6 mm) 1 8 .0 in (457.2 mm) 6 .6 in (167.6 mm) Ø .8 1 in (20.6 mm) 1 8 .0 in (457.2 mm) SPEAR Recloser Side View NNote: Dimensions for recloser are shown on page 11. Figure 4. Recloser dimensions with pole-mounting accessory. 280-101-12 www.cooperpower.com SPEAR Recloser Mounting Channel Dimensions. Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Control features Sequence coordination Control security The SPEAR control Sequence Coordination feature will allow the control to step through selected operations in the operating sequence without tripping when a down-line recloser is proceeding through its reclose sequence. The number of advances is programmable from one to three operations to provide trip coordination with the down-line recloser. The SPEAR single-phase recloser control has multiple customerprogrammable security codes to limit control programming and viewing function access to authorized personnel. The SPEAR control is capable of supporting numeric passwords. The front panel HumanMachine Interface (HMI) includes a user-selected security code to access the settings. Plus, the ProView NXG interface software has its own security levels for multiple-user access. Protection profiles Manual close time delay The SPEAR control includes a Manual Close Delay which provides a delay from the time the manual CLOSE button is pushed to the time the manual close operation is performed. The SPEAR control provides two protection profiles, each capable of fully specifying the operation of the control. The protection profiles are selectable through the front-panel push button interface or through the interface software and USB communication port. Each protection profile contains overcurrent protection and operation settings. The SPEAR control comes equipped with a full complement of metering capabilities, which include instantaneous, demand, demand peak, and energy metering. The control will be capable of the following metering values: Reclosing and overcurrent protection/TCCs • Real and reactive power, including direction of power flow • Demand currents • Instantaneous currents • Instantaneous voltage • Instantaneous frequency • Energy • Instantaneous power factor • Metering Settings which include demand interval, and alarm thresholds for current, voltage, frequency, power factor, frequency, kVA, kVAR, and kW The SPEAR control offers flexible phase overcurrent protection which can be programmed with up to four operations-to-lockout. Each time-current curve (TCC) can be individually programmed from up to fifty-four standard curves which can be further customized. Timecurrent curves are available for fast and delayed operations. Reclose intervals and reset time can also be programmed by the user. High current lockout The High Current Lockout (HCL) feature will automatically lockout the control when the current exceeds a programmed threshold. The active number of selectable operations to lockout is independently selectable for each protection profile. Metering Cold load pickup Diagnostic tools The SPEAR control provides a Cold Load Pickup (CLPU) feature that will prevent the control from tripping due to short-term increases in current caused by loss of normal load diversity or feeder inrush. This feature has an independently programmable minimum trip value, time-current curve, reclose interval, and number of operations to lockout for each protection profile. The CLPU feature will also inhibit ‘normal’ overcurrent protection during the CLPU active time. The SPEAR control comes complete with a suite of diagnostic tools to help troubleshoot problems, analyze system events and conditions, and monitor the life of your recloser. All diagnostic information is stored in non-volatile memory so even if the control loses power, all system and event information will remain intact. Hot line tag The SPEAR control includes a Hot Line Tag (HLT) membrane push button that will block all Close operations, local or remote, for liveline work. The control will trip on one operation-to-lockout on the composite curve of the HLT definite time and the TCC1 curve, whichever is faster, when HLT is active. Hot Line Tag takes precedence over Cold Load Pickup, Non-Reclosing, and Fast Trips Disabled. The Hot Line Tag time delay is independently selectable for each protection profile. Fast trips disabled The Fast Trips Disabled feature will ignore the normal TCCs and number of trips and instead use the Fast Trips Disabled settings when Fast Trips Disabled is active. Fast Trips Disabled is independently selectable for each protection profile. www.cooperpower.com 280-101-13 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Recloser wear monitor Contact input/output (I/O) module option The Recloser Wear Monitor will observe the life of the recloser apparatus by recording how many times the recloser has been opened as well as keep track of the current interrupted in percentage compared to preset total Duty Cycle Factor. The monitor allows for programmable entries to preset the duty of an existing recloser. The SPEAR control comes pre-configured with two sets of Input and Output contacts. This feature permits connection of contact type input devices (switches, relays) and discrete indicating devices (relays, LEDs, lamps) to the SPEAR control to affect local discrete input/output. The SPEAR control is designed to only have a maximum of 2 Inputs and Output contacts. Additional I/O is not required. Sequence of events recorder The Sequence of Events (SOE) Recorder is capable of capturing discrete events such as Open/Close status changes, faults, mechanism failures, etc. The SOE places an accurate time stamp and analog information on the events and stores them in non-volatile memory so they won’t be lost in the event that the control loses power. The SOE recorder is capable of maintaining up to 1000 events and can record up to 48 different event types, including overcurrent trip, control trip, non-reclose ON/OFF, external alarm, and control lockout. Data profiler A fully configurable data profiler is available which allows the user to collect information by sampling data at selectable intervals. These time-stamped values can then be viewed to determine weekly load profiles, hourly voltage and/or current fluctuations, battery voltage and current, and frequency. The number of days of information the data profiler can provide depends upon configuration parameters. Communications The SPEAR control is equipped with one communication accessory expansion bay offering versatile support for modern communication media. One distinct communication option is available, providing two-way, real time SCADA communications with a remote terminal unit (RTU), short or long-range radio, or other communication devices with DNP3 support. The following option is available: • RS-232 (isolated) Serial communication card The expansion bay communication accessory concept offers high versatility with respect to communication medium and protocol support. Additional accessories are being continuously developed. Contact your Eaton’s Cooper Power Systems representative for the latest information regarding particular media and communication protocol support Figure 5. Serial RS-232. Figure 6. SPEAR single-phase recloser control-side panel communication port. 280-101-14 www.cooperpower.com Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Front panel human-machine interface (HMI) Display LCD module (Figure 7) The SPEAR control has a newly designed, intuitive Human-Machine Interface (HMI) (Figure 8) that is designed to minimize training costs. • 4 lines-by-16 characters with backlighting option • Designed with simple to use arrow keypad look and operation • Automatic backlight shut off after 15 minutes of inactivity User interface and LED indicators The status indicator LEDs (Figures 9 and 10) provide instant notification on the recloser and control status. Figure 7. Display LCD module. • PHASE FAULT: This LED illuminates when the control issues an overcurrent trip signal while the phase current exceeds the programmed minimum trip value. • ABOVE MIN TRIP: This LED illuminates when the control detects that current is above the programmed minimum trip value • LOCKOUT: This LED illuminates to indicate the control is in a locked out state, i.e. a reclosing sequence is not in progress. This LED does not indicate that the recloser is open. • OPEN: This LED illuminates to indicate the recloser is in the open position • CLOSED: This LED illuminates to indicate the recloser is in the closed position. The LED will blink when a delayed CLOSE is active. A Close will occur when the manual close delay timer expires. Common look and feel similar to other ProView NXG Based controls simplifies HMI understanding and operation Indicators for phase fault and above minimum trip at a glance Indicators show control diagnostics LED indicates the status of the recloser (Open, Closed, or Locked out) Front panel USB port allow for easy connection to laptop Trip and Close membrane push buttons are easily operated in any condition Soft-keys allow for single push activation of commonly used control functions Hot Line Tag membrane push button for easy activation of HLT. A ring of three (3) LEDs indicates when HLT is active. Figure 8. Front panel Human-Machine Interface (HMI). www.cooperpower.com 280-101-15 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 • ALARM: This LED illuminates to indicate an alarm condition exists. The LED will flash for unacknowledged alarms, and will continuously illuminate for acknowledged alarms. • CONTROL OK: This indicator illuminates to indicate that the control passed self-diagnostics and is capable of normal operation • AC POWER: This indicator is illuminated when the presence of ac input power to the control is sensed • BATTERY: This LED illuminates to indicate battery voltage is low or the battery failed an operator-initiated manual test The DATA PORT section (Figure 11) on the front operating panel allows for direct connection to a personal computer. • The USB data port is a client port used to communicate with the control from a personal computer. This port is used for accessing the control with ProView NXG application software. All settings, metering, alarms, and events are available from this port. Operating panel (Figure 12) Figure 9. Status Indicator LEDs. • TRIP (Lockout) Membrane Push Button: The TRIP push button provides front-panel access to trip (lockout) the recloser. When pressed, the TRIP push button opens the recloser and locks out the control. • CLOSE Membrane Push Button: When pressed, the CLOSE push button returns the control to the initial or home sequence position, closing the recloser. The control is ready for the start of a new trip/close sequence. • HOT LINE TAG ON/OFF: Hot Line Tag is provided for live-line work applications. All closing operations are disabled when the Hot Line Tag feature is activated. Hot Line Tag prevents all closing attempts from the control and shifts protection to one trip-to-lockout on the composite curve of the Hot Line Tag definite time and the TCC1 curve (whichever is faster). Hot Line Tag takes precedence over Cold Load Pickup, Non-Reclosing, and Fast Trips Disabled. Hot Line Tag is activated from either the operator panel membrane push button, local, or remote communications. All sources must be off to de-activate Hot Line Tag. The Hot Line Tag function may only be reset by the source which initiates it. • Figure 10. Status Indicator LEDs. Figure 12. Operating Panel. Figure 11. Data Port. 280-101-16 www.cooperpower.com Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 One-touch function keys (Figure 13) Operation upon loss of ac power SUPERVISORY OFF The control is equipped with an 8 Amp-Hour 24 Vdc lead acid battery for operation upon loss of ac power. The control maintains full operation from the battery for a period of time dependent upon the battery size: When the SUPERVISORY OFF red indicator is illuminated, supervisory commands are blocked. Supervisory functions through the USB data port is not blocked. Communications through the front panel USB port remain active independent of the status of the SUPERVISORY OFF switch. Activation of this function key is restricted to the operator panel. Operational data and metering information are available while the control is in the SUPERVISORY OFF position. NON RECLOSE The control is operating in a non-reclosing mode when the NON RECLOSE indicator is illuminated. Non-reclosing mode disables any automatic reclosing operations. Non-reclosing does not alter the active TCC. Activation is possible from the SCADA port, the interface software, or locally (via the front panel). BATTERY TEST A direct shortcut to run the battery test feature. The LCD screen will show the battery voltage and current. After the battery test is run, the battery test results are shown (battery voltage and current). ALT PROFILE 1 The SPEAR control has two protection profiles; a normal profile, and Alternate Profile. When the operator panel display lights are active and the ALT PROFILE indicator is not illuminated, the Normal profile is active. Only one profile can be active. To select the alternate profile, press the ALT PROFILE button. • 8 Amp-Hour – 48 hour (approximate) maximum (20 °C) Control programming settings and parameters – including event recorder – are stored in non-volatile memory and retained upon loss of control power. The time/date clock will continue to operate for approximately 30 days after loss of control power. Accessories Incoming power receptacles The Incoming Power Receptacle allows the user to conveniently plug the power cable into the control, eliminating the need for hardwiring to the control. Table 8 includes the part number for the ac input cable of varying lengths. Cable locking sleeves To prevent detachment of the control cable from the control cabinet by unauthorized personnel, a cable-locking sleeve is available to enclose the cable plug. The plug is passed through the sleeve and the sleeve is then fastened from inside the control cabinet. There is no access to the cable receptacle without opening the locked cabinet door and detaching the sleeve. The cable locking sleeves can be ordered up to a quantity of three (3). Refer to Table 11 for the correct catalog number based on quantity. To return to the Normal profile, press the ALT PROFILE button to deselect it. These functions can also be completed remotely via communications interfaces. Figure 13. One-touch function keys. www.cooperpower.com 280-101-17 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 6.00 (152.4) 13.15 (334.01) 12.01 (305.05) 1.13 (28.70) LIFTING LUG 11.75 (298.45) 10.63 (270.00) 1.69 (42.93) LATCHES WITH PADLOCK PROVISIONS 22.60 (574.04) MOUNTING CHANNELS 20.87 (530.1) 17.72 (450.09) 1.46 (37.08) 9.84 (249.94) Front View (Door Removed) .87 (22.1) Right Side View PROVISIONS FOR UP TO 5/8 in (15 mm) MOUNTING HARDWARE POWER SUPPLY BATTERY Back View Figure 14. SPEAR control dimensions. 280-101-18 www.cooperpower.com GROUND LUG FOR #4 TO #14 SOLID OR STRANDED WIRE Front View With Control and Door Removed for Clarity 1.12 (28.45) Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 VENT OPENINGS INPUT RECEPTACLE FEMALE RECEPTACLE FOR RECLOSER CONTROL CABLE Bottom View FOR RADIO ANTENNA RECEPTACLES CONTROL MODULE OPTIONAL RS-232 COMMUNICATION PORT CONTACT I/O MODULE Module Side View Figure 14. SPEAR control dimensions (continued). www.cooperpower.com 280-101-19 Technical Data 280-101 SPEAR single-phase recloser system Effective January 2014 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-101 January 2014 280-101-20 Eaton, Cooper Power Systems, ProView, and SPEAR are valuable trademarks of Eaton, in the U.S. and other countries. You are not permitted to use these trademarks without the prior written consent of Eaton. For Eaton’s Cooper Power Systems SPEAR recloser system product information call 1-877-277-4636 or visit: www.cooperpower.com. Technical Data 280-104 Effective April 2014 Supersedes May 2011 Form 4D microprocessor-based recloser control and accessories Description The Form 4D recloser control is the first in a line of fully integrated controls developed by Eaton’s Cooper Power Systems. These controls will feature a standard look and feel, and a universal platform that can be programmed for almost any protective application. This means one standard operating system and front panel to train field technicians on. That translates to fewer training expenses, reduced inventory, and a distribution system that is much easier to maintain. In addition to the flexible and user-friendly platform, the new Eaton’s Cooper Power Systems controls will have the communications technology to take your system into the future. With fully modular communication compatibility, these controls will support cellular and radio communications utilizing the DNP3 and other serial and network protocols. Side panel RS-232, fiber-optic, Ethernet, and RS-485 ports are available for connection to SCADA or other devices. These ports are accessed by swinging the control panel forward. The Form 4D recloser control provides phase and ground current sensing, and three-phase voltage sensing. The Form 4D control can compute power, energy, power factor, and power flow direction from these current and voltage inputs. The standardized front panel of the Form 4D control can be used to program and interrogate the control, as well as to display metering and alarm information. Control parameters can also be programmed via personal computer using ProView NXG™ interface software. Temporary connection to the control can be made through the front panel USB port. The ProView NXG interface software includes the functionality to create and modify time-current curves (TCCs), and provides diagnostic information. The Form 4D control analysis tools include event recording, data profiling, and various metering capabilities. 280-104-1 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Ordering information To order a basic Form 4D microprocessor-based recloser control: • From Table 1, construct a catalog number that describes the required control. • From Table 2, specify the catalog number that describes the required control cable. • From Tables 3 through 11, specify the catalog numbers that describe the required accessories. Table 1. Base Form 4D Pole-Mounted Microprocessor-Based Recloser Control Description Catalog Number Base letters for a Form 4D control, pole-mount control Specify control usage option (Replace “X”) A = For use with Eaton’s Cooper Power Systems auxiliary and line-powered reclosers with 14-pin connection (WE, WVE27, WVE38X, VWE, VWVE27, VWVE38X, VSA12, VSA12B, VSA16, VSA20, VSA20A, VSO12,VSO16, NOVA15, NOVA27, NOVA38) B = For use with Eaton’s Cooper Power Systems control-powered NOVA reclosers with 19-pin connection (NOVA15A, NOVA27A, or NOVA38A) Specify battery option (Replace “X”) 0 = 8 Amp-Hour battery 1 = 13 Amp-Hour battery A = Mounting provisions only for the 8 Amp-Hour battery (batteries not included) B = Mounting provisions only for the 13 Amp-Hour battery (batteries not included) Specify current sensing option (Replace “X”) 0 = Standard, 1 Amp CT Specify voltage connection scheme (Replace “X”) 0 = Universal voltage inputs Specify control cabinet code (Replace “X”) 0 = Mild-steel cabinet 1 = Stainless-steel cabinet Specify front-panel code (Replace “X”) 0 = Inserts, Domestic 1 = Inserts, International [Includes SEF inserts as standard.] Specify I/O options (Replace “X”) 0 = No universal contacts required 1 = One set of universal contacts, 4in/4out, 12-250 Vac, maximum 12-gauge wire 2 = Two sets of universal contacts, 8in/8out complete, 12-250 Vac, maximum 12-gauge wire 3 = Three sets of universal contacts, 12in/12out complete, 12-250 Vac, maximum 12-gauge wire 4 = Four sets of universal contacts, 16in/16out complete, 12-250 Vac, maximum 12-gauge wire Specify communication protocols, Port 1* (Replace “X”) 0 = DNP, IEC 60870-5 (for use with any interface option) 2 = 2179, MODBUS, DNP, and IEC 60870-5 (for use with serial interfaces only) Specify communication interfaces, Port 1* (Replace “X”) 0 = Standard; None 1 = RS232 DB9 2 = Serial Fiber ST 3 = RS485 TB, Isolated 4 = Ethernet 100 BASE FX Single-Mode (Fiber-Optic) LC 5 = Ethernet 100 BASE FX Multi-Mode (Fiber-Optic) MTRJ 6 = Ethernet 100 BASE FX Multi-Mode (Fiber-Optic) ST 7 = Ethernet 100 BASE FX Multi-Mode (Fiber-Optic) SC 8 = Ethernet 10/100 BASE T/TX (Copper) RJ45 Specify communication protocols, Port 2* (Replace “X”) 0 = DNP, IEC 60870-5 (for use with any interface option) 1 = IEC 61850, DNP, and IEC 60870-5 (for use with Ethernet interfaces only) 2 = 2179, MODBUS, DNP, and IEC 60870-5 (for use with serial interfaces only) Specify communication interfaces, Port 2* (Replace “X”) 0 = Standard; None 1 = RS232 DB9 2 = Serial Fiber ST 3 = RS485 TB, Isolated 4 = Ethernet 100 BASE FX Single-Mode (Fiber-Optic) LC 5 = Ethernet 100 BASE FX Multi-Mode (Fiber-Optic) MTRJ 6 = Ethernet 100 BASE FX Multi-Mode (Fiber-Optic) ST 7 = Ethernet 100 BASE FX Multi-Mode (Fiber-Optic) SC 8 = Ethernet 10/100 BASE T/TX (Copper) RJ45 Specify language option (Replace “X”) E = English S = Spanish, Latin-America X = Other Language (contact factory) KME4DP KME4DPX * Refer to the following for communication protocol and communication interface compatibility rules: • DNP Serial is compatible with Communication Interface options 1-3. • DNP TCP/IP is compatible with Communication Interface options 4-8. • IEC 60870-5-101 is compatible with Communication Interface options 1-3. • IEC 60870-5-104 is compatible with Communication Interface options 4-8. • IEC 61850 is compatible with Communication Interface options 4-8. • Cooper 2179 and Modbus are compatible with Communication Interface options 1-3. 280-104-2 www.cooperpower.com KME4DPXX KME4DPXXX KME4DPXXXX KME4DPXXXXX KME4DPXXXXXX KME4DPXXXXXXX KME4DPXXXXXXXX KME4DPXXXXXXXXX KME4DPXXXXXXXXXX KME4DPXXXXXXXXXXX KME4DPXXXXXXXXXXXX Form 4D microprocessor-based recloser control and accessories Technical Data 280-104 Effective April 2014 Table 2. Control Cable Description Catalog Number For Types WE, WVE27, WVE38X, VWE, VWVE27, VWVE38X, AC-NOVA15, AC-NOVA27A, AC-NOVA38A Control cable, 18 gauge, Select from up to 79 feet. (Replace “X” with desired cable length.) Control cable, 16 gauge, Select from 80 to 125 feet. (Replace “X” with desired cable length.) Control cable, 14 gauge, Select from 126 to 200 feet. (Replace “X” with desired cable length.) KA1ME-X KA18ME-X KA35ME-X For Types VSA12, VSA12B, VSA16, VSA20, VSA20A, VSO12, VSO16 Control cable, 18 gauge, Select from 11 to 20 feet. (Replace “X” with desired cable length.) Control cable, 16 gauge, Select from 21 to 35 feet. (Replace “X” with desired cable length.) Control cable, 14 gauge, Select from 36 to 50 feet. (Replace “X” with desired cable length.) KA1ME-X KA18ME-X KA35ME-X For Types DC-NOVA15A, DC-NOVA27A, DC-NOVA38A (control-powered NOVA reclosers) Control cable, 16 gauge, Select from 11 to 125 feet. (Replace “X” with desired cable length.) KA1119R6-X Table 3. Communication Support Equipment Description Catalog Number USB cable, Type A male-to-Type B male connectors, 2 meters (6.5-ft.) KME4D-66 Table 4. Receptacles and Wiring Description Catalog Number AC input receptacles 120 Vac or 240 Vac input receptacle, 2-pin 120 Vac input receptacle, 3-pin 240 Vac input receptacle, 3-pin KME4D-1775-H KME4D-1775-J KME4D-1775-K Low-voltage closing receptacles* 120 Vac low-voltage closing 2-pin input and 2-pin output receptacles 120 Vac low-voltage closing with 3-pin input and 2-pin output receptacles 120 Vac low-voltage closing with inlet hole and 2-pin output receptacle 240 Vac low-voltage closing with 2-pin input and 2-pin output receptacles 240 Vac low-voltage closing with 3-pin input and 2-pin output receptacles 240 Vac low-voltage closing, for 2 wire with inlet hole and 2-pin output receptacle 240 Vac low-voltage closing, for 3 wire with inlet hole and 2-pin output receptacle KME4D-1775-A KME4D-1775-B KME4D-1775-C KME4D-1775-D KME4D-1775-E KME4D-1775-F KME4D-1775-G *Low-voltage closing receptacles are only applicable to control usage “A”. Refer to Table 1. www.cooperpower.com 280-104-3 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Table 5. Input and Low Voltage Closing Cables Description Catalog Number AC input cables Input cable, 120 or 240 Vac, two-wire for 2-pin input, for use with KME4D-1775-H, A or D receptacles. Replace “X” with desired length. Select from 10 to 80 feet. Input cable, 240 Vac, three-wire for 3-pin input, for use with KME4D-1775-K or E receptacles. Replace “X” with desired length. Select from 10 to 80 feet. Input cable, 120 Vac, three-wire for 3-pin input, for use with KME4D-1775-J or B receptacles. Replace “X” with desired length. Select from 10 to 80 feet. Low-voltage closing cables Low-voltage closing cable, 2-wire, for use with KME4D-1775-A, B, C, D, E, F, or G receptacles. Replace “X” with desired length. Select from 10 to 80 feet . KA11ME1-X KME4-67-2-X KME4-67-3-X KA13ME1-X Table 6. Internal Voltage Sensing Description Catalog Number Internal Voltage Sensing input receptacle, 4-pin KME4D-3799-A NNote: Internal voltage sensing receptacle is only compatible with reclosers equipped with internal voltage sensors. NNote: The internal voltage sensing cable (KA97ME) is ordered with the recloser. If a replacement cable is required, contact your Eaton’s Cooper Power Systems representative. Table 7. Cable Locking Sleeves Description Catalog Number Cable locking sleeve, (quantity of 1) KME4D-1772-1 Cable locking sleeve, (quantity of 2) KME4D-1772-2 Cable locking sleeve, (quantity of 3) KME4D-1772-3 Cable locking sleeve, (quantity of 4) KME4D-1772-4 Cable locking sleeve, (quantity of 5) KME4D-1772-5 Table 8. Terminal Blocks (maximum 12-gauge wire) Description Catalog Number BCT shorting-type terminal block for (LOAD) bushings 2, 4, 6 KME4D-1773-A BCT shorting-type terminal block for (SOURCE) bushings 1, 3, 5 KME4D-1773-B Terminal block and receptacle for wiring of three-stage auxiliary switch, KA542R3 . KME4D-1801-11 NNote: For every one terminal block accessory ordered, the maximum additional I/O allowed quantity is reduced by one. Table 9. Convenience Outlet Description Catalog Number Fused 120 Vac, 3-wire polarized GFI convenience outlet KME4D-1776 Table 10. Miscellaneous Accessories Description Catalog Number 120 Vac Battery Charger for spare batteries KME5-60-1 “Made in USA” decal K89-407-1 280-104-4 www.cooperpower.com Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Table 11. Automation Accessory Packages (A maximum of two accessories can be ordered. KME4D-1774-21 is not included in this maximum.) Description Catalog Number Wireless communication provisions package 13.5 Vdc interface board, radio mounting tray (Radio and communications interface cards not included) KME4D-1774-21 Cellular communications connection and protection package 32” SMA(m)-N(m) coax pigtail, 700MHz - 2GHz PolyPhaser and mounting hardware, N(f)-type external termination KME4D-1774-14* WiFi/WiMax communications connection and protection package 32” SMA(m)-N(m) coax pigtail, 2GHz-6GHz Polyphaser and mounting hardware, N(f)-type external termination, TNC(m)-SMA(m) in-line coaxial adapter KME4D-1774-15* 125MHz to 1GHz N-terminated radio connection and protection package 25” N(m)-N(m) coax pigtail, 125MHz to 1GHz PolyPhaser and mounting hardware N(f)-type external termination KME4D-1774-16* 700MHz to 2GHz TNC-terminated radio connection and protection package 32” TNC(m)-N(m) coax pigtail, 700MHz to 2GHz PolyPhaser and mounting hardware, N(f)-type external termination KME4D-1774-17* PolyPhaser and mounting hardware - 125MHz-1GHz N(f)-type external termination KME4D-1774-A* PolyPhaser and mounting hardware - 700MHz-2GHz N(f)-type external termination KME4D-1774-B* PolyPhaser and mounting hardware - 2GHz-6GHz N(f)-type external termination KME4D-1774-C* * Requires that the KME4D-1774-21 wireless communication provisions package also be ordered. Note: Corresponding communication interfaces from Port 1 and/or Port 2 must be ordered in conjunction with automation accessories. PROVISIONS FOR UP TO 5/8" MOUNTING HARDWARE. 1.13 LIFTING LUG 15.07 1.45 20.19 GROUND LUG FOR #6 to #14 SOLID OR STRANDED WIRE FOR RADIO ANTENNA RECEPTACLE RECEPTACLE FOR RECLOSER CONTROL CABLE QUARTER TURN LATCH WITH 18.00 PADLOCK PROVISIONS (.295-.394” SHACKLE DIAMETER) QUARTER TURN LATCH 21.94 13.40 1.25 LASER CUT VENT OPENINGS OPENINGS FOR OPTIONAL RECEPTACLES UNDER STAINLESS COVERS, ACCESSABLE ONLY FROM INSIDE OF CABINET CONTROL POWER INPUT CONTROL WEIGHT: 29 kg (63 lbs.) [without battery] 8 AH BATTERY WEIGHT: 6 kg (13 lbs.) 13 AH BATTERY WEIGHT: 10 kg (24 lbs.) (All weights are approximate.) Figure 1. Form 4D pole mount recloser control weight and dimensions. www.cooperpower.com 280-104-5 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Control features Hot line tag Control security The Form 4D includes a Hot Line Tag (HLT) switch that will block all Close operations, local or remote, for live-line work. The control will trip on one operation-to-lockout on the composite curve of the HLT definite time and the TCC1 curve, whichever is faster, when HLT is active. Hot Line Tag takes precedence over Cold Load Pickup, NonReclosing, and Fast Trips Disabled. The Hot Line Tag time delay is independently selectable for each protection profile. The Form 4D recloser control has multiple customer-programmable security codes to limit control programming and viewing function access to authorized personnel. The Form 4D control is capable of supporting strong passwords containing letters (upper and lower case), numbers, and symbols. The front panel Human-Machine Interface (HMI) includes a user-selected security code to access the settings. Plus, the ProView NXG interface software has its own security levels for multiple-user access. Protection profiles The Form 4D control provides two protection profiles, each capable of fully specifying the operation of the control. The protection profiles are selectable through the front-panel push-button interface or through the interface software and USB communication ports. Each protection profile contains overcurrent protection, voltage protection, frequency protection, sync check, sensitive earth fault protection, and operation settings. Reclosing and overcurrent protection/TCCs Fast trips disabled The Fast Trips Disabled feature will ignore the normal TCCs and number of trips and instead use the Fast Trips Disabled settings when Fast Trips Disabled is active. Fast Trips Disabled will have separate phase and ground settings and is independently selectable for each protection profile. Ground trip precedence The Form 4D control comes equipped with an option for Ground Trip Precedence. When ground trip precedence is selected to be active, the sequence uses the ground operations to lockout for fault current above both phase and ground minimum trip values. The Form 4D control offers flexible phase and ground overcurrent protection which can be programmed with up to four operationsto-lockout. Each time-current curve (TCC) can be individually programmed from up to fifty standard curves which can be further customized. Time-current curves are available for fast and delayed operations. The time-current curves are also selectable from a graphical TCC editor to visualize any modifications prior to configuring the control. Reclose intervals and reset time can also be programmed by the user. Voltage protection TCC editor II Six levels of frequency protection are included with the control, with each level configurable as either overfrequency or underfrequency. A frequency restoration function, which can be enabled or disabled, will allow the recloser to automatically close should the frequency return to within configured settings for a user-settable time. Coordination and actual time current modifications are available with a graphic, interactive TCC editor. The TCC Editor II includes a complete database of standard recloser industry time current curves, both ANSI® and IEC types, along with the ability to customize the TCCs with multipliers, constant time adders, or minimum response time adders. The user is also able to derive their own specific TCC through data point entry. Sensitive earth fault The Form 4D control includes Sensitive Earth Fault (SEF) protection, which will provide tripping of the recloser for ground currents below normal ground minimum trip elements. The SEF feature has programmable operations-to-lockout and reclose intervals independent of the ground settings and is independently selectable for each protection profile. High current lockout The High Current Lockout (HCL) feature will automatically lockout the control when the current exceeds a programmed threshold. The active number of operations-to-lockout is selectable for both phase and ground and is independently selectable for each protection profile. Cold load pickup The Form 4D control provides a Cold Load Pickup (CLPU) feature that will prevent the control from tripping due to short-term increases in current caused by loss of normal load diversity or feeder inrush. This feature has an independently programmable minimum trip value, time-current curve, reclose interval, and number of operations to lockout for each protection profile as well as for both phase and ground. The CLPU feature will also inhibit ‘normal’ overcurrent protection during the CLPU active time. 280-104-6 www.cooperpower.com The Form 4D control includes three levels each of over- and undervoltage protection and includes single-phase and threephase protection for both over- and undervoltage conditions. Both functions include a phase pickup, a phase time delay, a three-phase pickup, and three-phase time delay. One overvoltage and one undervoltage alarm is also provided. Frequency protection Sync check The Form 4D control includes sync check functionality, which is used to qualify any close signal to the recloser when enabled via the sync check settings. Sync check allows for closing for any combination of dead/live bus/line, and to perform anticipatory closing for a live bus/ live line condition by calculating slip and anticipating the mechanism closing delay. In addition to the anticipatory close calculation, the sync check system performs verification of line and bus voltage magnitudes and frequencies to determine that they are within predetermined ranges, and that the angular differences between the two systems is also within the pre-determined range. Sequence coordination The Form 4D control Sequence Coordination feature will allow the control to step through selected operations in the operating sequence without tripping when a down-line recloser is proceeding through its reclose sequence. The number of advances is programmable from one to three operations to provide trip coordination with the down-line recloser. Form 4D microprocessor-based recloser control and accessories Technical Data 280-104 Effective April 2014 Manual close time delay Data profiler The Form 4D control includes a Manual Close Delay which provides a delay from the time the manual CLOSE button is pushed to the time the manual close operation is performed. A fully configurable data profiler is available which allows the user to collect information by sampling data at selectable intervals. These time-stamped values can then be viewed to determine weekly load profiles, daily harmonic disturbances, or hourly voltage fluctuations. The number of days of information the data profiler can provide depends upon configuration parameters. Metering The Form 4D control comes equipped with a full complement of metering capabilities, which include instantaneous, demand, demand peak, and energy metering. The control will be capable of the following metering values: • Real and reactive power for single- and three-phase, including direction of power flow. • Demand currents on a per-phase basis. • Instantaneous currents, including ground current. • Instantaneous voltage on a per-phase basis. • Instantaneous frequency. • Energy on a per-phase basis. • Positive, negative, and zero sequence voltages. • Harmonics on a per-phase basis for voltage and current. • Instantaneous power factor on a per-phase basis. • Metering settings which include demand interval, and alarm thresholds for current, single-phase kW, three-phase kW, singlephase kVAR, and three-phase kVAR. Diagnostic tools Internal voltage sensing A four-wire cable and input receptacle accessory is required for Type NOVATM three-phase reclosers with the internal voltage sensing (IVS) option. Internal voltage sensors, located on the source side, indicate voltage magnitude within an accuracy 2% or better and a phase degree accuracy within 1.5 degrees (includes sensor, cable, and control). The 4-pin receptacle accessory is prewired to the voltage inputs on the control. Contact input/output (I/O) module option The Contact I/O Module option (Figure 2) permits connection of contact-type input devices (switches, relays) and discrete indicating devices (relays, LEDs, lamps) to the Form 4D control to effect local discrete input/output. The I/O module accessory is used for supplementing normal local controls and status indicators for Contact I/O functions. The initial Contact I/O Module option contains four factory-set inputs and four outputs for Contact I/O functions. Each Form 4D control can accommodate four Contact I/O modules. Additional modules require user programming via the software. The Form 4D control comes complete with a suite of diagnostic tools to help troubleshoot problems, analyze system events and conditions, and monitor the life of your recloser. All diagnostic information is stored in non-volatile memory so even if the control loses power, all system and event information will remain intact. Recloser wear monitor The Recloser Wear Monitor will observe the life of the recloser apparatus by recording how many times the recloser has been opened as well as keep track of the current interrupted in percentage compared to preset total Duty Cycle Factor. The monitor allows for programmable entries to preset the duty of an existing recloser. Sequence of events recorder The Sequence of Events (SOE) Recorder is capable of capturing discrete events such as Open/Close status changes, faults, mechanism failures, etc. The SOE places an accurate time stamp and analog information on the events and stores them in non-volatile memory so they won’t be lost in the event that the control loses power. The SOE recorder is capable of maintaining up to 1000 events and can record up to 116 different event types, including overcurrent trip, control trip, non-reclose ON/OFF, external alarm, and control lockout. Figure 2. Contact I/O module option. www.cooperpower.com 280-104-7 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Communications The Form 4D pole mount control is equipped with two communication board accessory expansion bays offering versatile support for modern communication media. Five distinct communication options are available, providing two-way, real time digital communications with a remote terminal unit (RTU), wireless, telephone modem, Ethernet network, or other communication devices. Any combination of two communication boards can be installed. The following options are available: • RS-232 (isolated) Serial communication card • RS-485 (isolated) Serial communication card • Fiber-optic-based Serial communication card with ST Connectors • 10/100 Base-T/TX Ethernet communication card with RJ-45 connector • 100 Base-FX Ethernet communication card with Ethernet Fiber, ST Connector (multi-mode) • 100 Base-FX Ethernet communication card with Ethernet Fiber, MTRJ connector (multi-mode) • 100 Base-FX Ethernet communication card with Ethernet Fiber, SC connector (multi-mode) • 100 Base-FX Ethernet communication card with Ethernet Fiber, LC connector (single-mode) The expansion bay based Communication Board Accessory concept offers high versatility with respect to communication medium and protocol support. Additional accessories are being continuously developed. Contact your Eaton’s Cooper Power Systems representative for the latest information regarding particular media and communication protocol support. Ethernet Fiber, ST Ethernet Copper, RJ-45 Ethernet Fiber, MTRJ Serial, RS-232 Ethernet Fiber, SC Serial, RS-485 Ethernet Fiber, LC (single-mode) Serial Fiber, ST Figure 4. Side panel communication options. Figure 3. Form 4D pole mount recloser control side panel communication ports. 280-104-8 www.cooperpower.com Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Front panel human-machine interface (HMI) The Form 4D recloser control has a newly designed, intuitive Human-Machine Interface (HMI) (Figure 5) that is designed to minimize training costs. PHASE FAULT A Display LCD module (Figure 6) B ALARM C CONTROL OK • 4 lines-by-20 characters with backlighting option GROUND FAULT AC POWER • LCD display panel contrast is field-adjustable to allow for various mounting heights and applications. SENSITIVE GND BATTERY • Designed with a new ‘cell phone’ look and operation • Automatic backlight shut off after 15 minutes of inactivity FREQUENCY TRIP User interface and LED indicators PHASE VOLTAGE ENTER VOLTAGE TRIP A B C ABOVE MIN TRIP X Y Z EDIT ESC The status indicator LEDs (Figures 7 and 8) provide instant notification on the control and recloser status. • A PHASE FAULT • B PHASE FAULT LOCKOUT • C PHASE FAULT OPEN • GROUND FAULT CLOSED • SENSITIVE GND FAULT These LED indicators illuminate when the control issues an overcurrent trip signal while the respective phase current or ground current exceeds the minimum pickup value. DATA PORTS Figure 6. Display LCD module. • FREQUENCY TRIP: This LED illuminates to indicate the recloser tripped due to an under or overfrequency condition. • VOLTAGE TRIP: This LED illuminates to indicate the recloser tripped due to an under or overvoltage condition. TRIP CLOSE OFF New cellphone look and feel is easy(LOCKOUT) to understand and operate PHASE FAULT A Indicators show location and type of fault at a glance B Large, mechanical Trip and Close buttons are easily operable in any condition NON RECLOSE SUPERVISORY OFF ALT PROFILE 1 CONTROL OK GROUND FAULT AC POWER SENSITIVE GND BATTERY PHASE VOLTAGE ENTER VOLTAGE TRIP A B C ABOVE MIN TRIP X Y Z EDIT ESC LOCKOUT OPEN DATA PORTS CLOSED TRIP GND TRIP BLOCKED ALARM C FREQUENCY TRIP LED indicates the status of the recloser (Open, Closed, or Locked out) HOT LINE TAG CLOSE HOT LINE TAG OFF (LOCKOUT) GND TRIP BLOCKED NON RECLOSE ALT PROFILE 1 SUPERVISORY OFF Indicators show control diagnostics and status of source and load line voltages Front panel USB ports allow for easy connection to laptop or data dump to USB harddrive Soft-keys allow for single push activation of commonly used control schemes Hot Line Tag switch for easy activation of HLT. A ring of LEDs indicates when HLT is active. Figure 5. Front panel Human-Machine Interface (HMI) www.cooperpower.com 280-104-9 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 • ABOVE MIN TRIP: This LED illuminates when the control detects that current is above the programmed minimum trip value for Bushings 1-2, Bushings 3-4, Bushings 5-6, Ground or Sensitive Ground. These LED indicators illuminate when the control detects the presence of voltage greater than the “V present” setting on the System Configuration dialog. The LED will go out if the voltage on that phase is less than 95% of the “V present” setting. PHASE FAULT • LOCKOUT: This LED illuminates to indicate the control is in a locked out state, i.e. a reclosing sequence is not in progress. This LED does not indicate that the recloser is open. • OPEN: This LED illuminates to indicate the recloser is in the open position. A B C • A B ALARM C CONTROL OK PHASE FAULT ACALARM POWER GROUND FAULT CONTROL OK BATTERY CLOSED: This LED illuminates to indicate the recloser is in the closed position. The LED will blink when aFAULT delayed CLOSE is GROUND active. A Close will occur when the manual close delay timer expires. SENSITIVE GND SENSITIVE GND FREQUENCY TRIP BATTERY PHASE VOLTAGE ENTER FREQUENCY TRIP PHASE FAULT VOLTAGE TRIP A AC POWER ENTER TRIP B VOLTAGE C ABOVE MIN TRIP ESC GROUND ABOVE FAULT MIN TRIP SENSITIVE GND A Y Z B DATA C PORTS FREQUENCY TRIP TRIP Figure 7. Status indicator LEDs. CLOSE Figure 9. Data ports. CLOSE HOT LINE TAG AC POWER BATTERY (LOCKOUT) CLOSE HOT LINE TAG ALARM: This LED illuminates to indicate an alarm condition exists. The LED will flash for unacknowledged alarms, and will continuously illuminate for acknowledged alarms. SUPERTRIP DATAVOLTAGE PORTS GND TRIP NON VISORY BLOCKED RECLOSE MIN TRIP The left port is aABOVE host port used forOFF connecting to a USB flash EDIT ESC memory device to upload or download SUPER-data and settings files GND TRIP or to upgrade theNON firmware. All settings, metering, alarms, and VISORY events are available from this port. BLOCKED RECLOSE ALT • The Data Port LED is illuminated when the USB memory stick is CLOSED PROFILE 1 and properly inserted detected. ALT CONTROL OK: This indicator illuminates to indicate that OFF the conOperating panel trol passed(LOCKOUT) self-diagnostics and is capable of normal operation. PROFILE 1 OFF (LOCKOUT) AC POWER: This indicator is illuminated when the presence of ac input power to the control is sensed. • BATTERY: This LED illuminates to indicate battery voltage is low or the battery failed an operator-initiated manual test. • PHASE VOLTAGE A • PHASE VOLTAGE B • PHASE VOLTAGE C • PHASE VOLTAGE X • PHASE VOLTAGE Y • PHASE VOLTAGE Z www.cooperpower.com TRIP (LOCKOUT) CLOSE HOT LINE TAG OFF GND TRIP BLOCKED ALT PROFILE 1 Figure 10. Operating panel. • A B X Y ALT The right port1is a client port usedOFF to communicate with the PROFILE control from a personal computer. This port is used for accessing SUPEROFF GND TRIP NONwithLOCKOUT the control ProView VISORY NXG application software. All settings, BLOCKED RECLOSE metering, alarms, and events are available from this port. OFF OPEN • TRIP PHASE VOLTA ENTER HOT LINE TAG • ALARM CONTROL SENSITIVE GND CLOSED TRIP 280-104-10 Z DATA GROUND FAULTPORTS CLOSED OPEN • Y C Z PHASE FAULT X EDIT ESC LOCKOUT • X B BATTERY CLOSED • Y The DATA PORTS section (Figure 9) on the front operating panel A B C allows for direct connection to a personal computer. LOCKOUT OPEN EDIT X AC POWER PHASE VOLTAGE ENTER VOLTAGE TRIP OPEN CONTROL OK A Figure 8. Status indicator LEDs. FREQUENCY TRIP LOCKOUT ABOVE MIN TRIP EDIT ESC APHASEBVOLTAGE C ALARM TRIP (Lockout) Pushbutton: The TRIP pushbutton provides frontpanel access to trip (lockout) the recloser. When pressed, the TRIP pushbutton opens the recloser and locks out the control. DATA PORT NON RECLOSE SUP VIS O Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 • • CLOSE Pushbutton: When pressed, the CLOSE pushbutton returns the control to the initial or home sequence position, closing the recloser. The control is ready for the start of a new trip/ close sequence. HOT LINE TAG ON/OFF: Hot Line Tag is provided for live-line work applications. All closing operations are disabled when the Hot Line Tag feature is activated. Hot Line Tag prevents all closing attempts from the control and shifts protection to one trip-to-lockout on the composite curve of the Hot Line Tag definite time and the TCC1 curve (whichever is faster). Hot Line Tag takes precedence over Cold Load Pickup, Non-Reclosing, and Fast Trips Disabled. Hot Line Tag is activated from either the operator panel toggle switch, local or remote communications, or configurable logic. All sources must be off to de-activate Hot Line Tag. The Hot Line Tag function may only be reset by the source which initiates it. One-touch function keys (Figure 11) GND TRIP BLOCKED T D RIP The Ground Trip Blocked function blocks all ground sensing in the control for the active profile. This ALARM indicator is illuminated when Ground Trip Block is activated from the SCADA port, the interface software, or locally (via the front panel) causing CONTROL OK the control to block all ground sensing. NON RECLOSE BATTERY mode when the NON The control is operating in a non-reclosing RECLOSE indicator is illuminated. Non-reclosing mode disables any automatic reclosing operations. Non-reclosing does not alter the activeENTER TCC. Activation is possible fromVOLTAGE the SCADA port, the interface PHASE software, or locally (via the front panel). SUPERVISORY OFF IP CLOSE AC POWER A B C X Y Z EDIT ESC supervisory commands are blocked. Supervisory functions through When the SUPERVISORY OFF red indicator is illuminated, the USB data ports are not blocked. Communications through the front panel USB port remain active independent of the status of the SUPERVISORY OFF switch. Activation of this function key is restricted to the operator panel. Operational data and metering information are available while the control is in the SUPERVISORY OFF position. ALT PROFILE 1 DATA PORTS The Form 4D control has two protection profiles; a normal profile, and Alternate Profile 1. When the operator panel display lights are active and the ALT PROFILE 1 indicator is not illuminated, the Normal profile is active. Only one profile can be active. Operation upon loss of ac power The control is equipped with either an 8 Amp-Hour or 13 Amp-Hour 24 Vdc lead acid battery for operation upon loss of ac power. The control maintains full operation from the battery for a period of time dependent upon the battery size: • 8 Amp-Hour – 24 hour (approximate) maximum (20°C) • 13 Amp-Hour – 36 hour maximum (20°C) Control programming settings and parameters – including event recorder – are stored in non-volatile memory and retained upon loss of control power. The time/date clock will continue to operate for approximately 30 days after loss of control power. Accessories Low-voltage closing The Low-Voltage Closing Accessory utilizes 120 or 240 Vac for closing power. Multiple low-voltage closing accessories are available for reclosers equipped with low voltage closing. The low-voltage closing accessories available for the Form 4D recloser control include the appropriate receptacles and wiring based upon the input supply voltage. Tables 4 and 5 list the available low voltage closing input/output receptacles and cables for the Form 4D control. Incoming power receptacles The Incoming Power Receptacle allows the user to conveniently plug the power cable into the control, eliminating the need for hardwiring to the control. Various options are available based upon the input power voltage and phase sensing requirements. Tables 4 and 5 include the available input receptacles and cables. Cable locking sleeves To prevent detachment of the control cable from the control cabinet by unauthorized personnel, a cable-locking sleeve is available to enclose the cable plug. The plug is passed through the sleeve and the sleeve is then fastened from inside the control cabinet. There is no access to the cable receptacle without opening the locked cabinet door and detaching the sleeve. The cable locking sleeves can be ordered up to a quantity of five. Refer to Table 7 for the correct catalog number based on quantity. 120 Vac GFI duplex outlet The GFI Duplex Outlet is available for controls powered by 120 Vac or 240 Vac three-wire supply power. This convenience outlet is rated for 3 Amperes and is accessible through the front door in the control cabinet. The 120 Vac GFI Duplex Outlet can be used for many applications, such as power for the MET Tester, auxiliary measurement equipment, and supplemental lighting. Refer to Table 9 for the catalog number. BCT terminal block accessory HOT LINE TAG OFF GND TRIP BLOCKED NON RECLOSE SUPERVISORY OFF ALT PROFILE 1 Separate BCT terminal blocks provide a connection point for external 600:5 or 1200:5 multi-ratio bushing current transformers. BCT terminal blocks are available for both the load or source sides and include wire for all ratios of the BCT. Refer to Table 8. Auxiliary terminal block accessory An auxiliary terminal block and receptacle is available for three-stage auxiliary switch wiring. Refer to Table 8. Figure 11. One-touch function keys. To select the alternate profile, press the ALT PROFILE 1 button. To return to the Normal profile, press the ALT PROFILE 1 button to deselect it. These functions can also be completed remotely via communications interfaces. www.cooperpower.com 280-104-11 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Table 12. Eaton’s Cooper Power Systems Controls-Accessory Cross-Reference Guide Accessory Description Form 3A* Form 4C Form FXA Form FXB Form 5 (swing-panel, below s/n 3000) Form 5 (fixed-panel, above s/n 3000 or beginning with CP57) Form 6 (below s/n 10,000) Form 6 (above s/n 10,000 or beginning with CP57) Form 4D Control Cables For WE, WVE27, WVE38X, VWE, VWVE27, VWVE38X, AC NOVA 18 gauge cable, 10-79 ft length KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X 16 gauge cable, 80-125 ft length KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X 14 gauge cable, 126-200 ft length KA35ME-X KA35ME-X KA35MX-X KA35ME-X KA35ME-X KA35ME-X KA35ME-X KA35ME-X KA35ME-X For VSA12, VSA12B, VSA16, VSA20, VSA20A, VSO12, VSO16 18 gauge cable, 11-20 ft length KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X KA1ME-X 16 gauge cable, 21-35 ft length KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X KA18ME-X 14 gauge cable, 36-50 ft length KA35ME-X KA35ME-X KA35ME-X KA35ME-X KA35ME-X KA35ME-X KA35ME-X KA35ME-X KA35ME-X KA1119R6-X KA1119R6-X KA1119R6-X KA1119R6-X KA1119R6-X KA1119R6-X KA1119R6-X KA1119R6-X For DC-NOVA15A, DC-NOVA27A 16 gauge cable, 11-125 ft length Communication Support Equipment USB Cable, 6 ft KME4D-66 Receptacles and Wiring AC Input Receptacles 120 Vac power input accessory KA840ME1, 2, 4, 6, & 7 w/ 2-pin receptacle KME4-55-11 KFXA-23-1 KFXA-23-1 w/ 3-pin receptacle KME4-55-5 KFXA-23-2 KFXA-23-2 w/ 2-pin receptacle KFXA-23-1 KFXA-23-1 w/ 3-pin receptacle KFXA-23-1 KFXA-23-2 KFXA-22-1 KFXA-22-1 KME5-53-1 KME5-53-6 KME6-1775-H KME6-1775-H KME4D-1775-H KME5-53-7 KME6-1775-J KME6-1775-J KME4D-1775-J KME5-53-6 KME6-1775-H KME6-1775-H KME4D-1775-H KME5-53-8 KME6-1775-K KME6-1775-K KME4D-1775-K KME5-52-15 KME6-1775-A KME6-1775-A KME4D-1775-A 240 Vac power input accessory KME5-53-1 Low Voltage Closing Receptacles 120 Vac lowvoltage closing KA840ME3 w/ 2-pin input, 2-pin outlet receptacles KME4-57-6 w/ 3-pin input, 2-pin outlet receptacles KME4-57-3 KME5-52-16 KME6-1775-B KME6-1775-B KME4D-1775-B w/ inlet hole for hard wiring, 2-pin outlet receptacle KME4-57-2 KME5-52-17 KME6-1775-C KME6-1775-C KME4D-1775-C KME5-52-18 KME6-1775-D KME6-1775-D KME4D-1775-D w/ 3-pin input, 2-pin outlet receptacles KME5-52-20 KME6-1775-E KME6-1775-E KME4D-1775-E for 2 wire w/ inlet hole, 2-pin outlet receptacle KME5-52-19 KME6-1775-F KME6-1775-F KME4D-1775-F for 3 wire w/ inlet hole, 2-pin outlet receptacle KME5-52-21 KME6-1775-G KME6-1775-G KME4D-1775-G 240 Vac lowvoltage closing KA840ME5 w/ 2-pin input, 2-pin outlet receptacles 280-104-12 KME5-52-3 www.cooperpower.com KME5-52-5 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Table 12. Eaton’s Cooper Power Systems Controls-Accessory Cross-Reference Guide (continued) Accessory Description Form 3A* Form 4C Form FXA Form FXB Form 5 (swing-panel, below s/n 3000) Form 5 (fixed-panel, above s/n 3000 or beginning with CP57) Form 6 (below s/n 10,000) Form 6 (above s/n 10,000 or beginning with CP57) Form 4D Input and Low Voltage Cables AC Input Cables 120 Vac input cable accessory X ft cable, plug for 2-pin receptacle (10 to 80 ft) KA11ME1-X KA11ME1-X KA11ME1-X KA11ME1-X KME4-67-1-X KME4-67-1-X KA13ME1-X X ft cable, plug for 2-pin receptacle (10 to 80 ft) KA11ME1-X KA11ME1-X X ft cable, plug for 3-pin receptacle (10 to 80 ft) KME4-67-1-X KA13ME1-X KA13ME1-X KA13ME1-X X ft cable, plug for 3-pin receptacle (10 to 80 ft) KA11ME1-X KA11ME1-X KA11ME1-X KA11ME1-X KA11ME1-X KME4-67-3-X KME4-67-3-X KME4-67-3-X KA11ME1-X KA11ME1-X KA11ME1-X KME4-67-2-X KME4-67-2-X KME4-67-2-X KA13ME1-X KA13ME1-X KA13ME1-X KA97ME-X KA97ME-X 240 Vac input cable accessory KA11ME1-X KA11ME1-X Low Voltage Closing Cables Low-voltage closing cable, 120/240 Vac, 2 wire, X ft (10 to 80 ft) KA13ME1-X KA13ME1-X KA13ME1-X KA13ME1-X Internal Voltage Sensing Internal voltage sensing cable, 4-wire, for use with front panel with internal voltage sensing, X ft (5 to 35 ft) IVS Input Receptacle, 4-pin KME4D-3799-A Cable-locking sleeves For control cable, qty # (max 5) KA614ME1 KME4-56-A BCT shorting-type for bushing 2, 4, 6 KA1170ME1 BCT shorting-type for bushing 1, 3, 5 KA1170ME2 KFXA-24-# KFXA-24-# KME5-54-A KME5-54-A KME6-1772-# KME6-1772-# KME4D-1772-# KME4-83-1 KME5-61-1 KME5-61-4 KME6-1773-A KME6-1773-A KME4D-1773-A KME4-83-2 KME5-61-2 KME5-61-5 KME6-1773-B KME6-1773-B KME4D-1773-B KME4-81-1 KME5-62-1 KME5-62-2 KME6-1801-1 KME6-1801-1 KME4D-1801-11 KME5-51-1 KME5-51-4 KME6-1776-A KME6-1776 KME4D-1776 Terminal Blocks Terminal block and receptacle for wiring 3-stage aux switch KA542R3 Convenience Outlet Fused 120 Vac, 3-wire polarized GFI convenience outlet www.cooperpower.com 280-104-13 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Table 12. Eaton’s Cooper Power Systems Controls-Accessory Cross-Reference Guide (continued) Accessory Description Form 3A* Form 4C Form FXA Form FXB Form 5 (swing-panel, below s/n 3000) Form 5 (fixed-panel, above s/n 3000 or beginning with CP57) Form 6 (below s/n 10,000) Form 6 (above s/n 10,000 or beginning with CP57) Form 4D Automation Packages* Full Automation Accessory Package - Cellular KME4D-1774-14 Full Automation Accessory Package - WiFi/WiMAX KME4D-1774-15 Full Automation Accessory Package - 125MHz -1GHz N-terminated radio KME4D-1774-16 Full Automation Accessory Package - TNC-terminated radio, 700MHz 2GHz KME4D-1774-17 Wireless communication package KME4D-1774-21 Polyphaser and mounting hardware - 125MHz - 1GHz KME4D-1774-A Polyphaser and mounting hardware - 700MHz - 2GHz KME4D-1774-B Polyphaser and mounting hardware - 2GHz - 6GHz KME4D-1774-C Miscellaneous Accessories 120 Vac battery charger for spare batteries KME4-85-1 KME4-85-1 KME5-60-1 KME5-60-1 KME5-60-1 KME5-60-1 *Form 3A is an analog control, and as such has a myriad accessories that perform functions made standard in the newer digital controls. These accessories are not listed here. For further clarification, consult an Eaton’s Cooper Power Systems representative. 280-104-14 www.cooperpower.com Form 4D microprocessor-based recloser control and accessories Technical Data 280-104 Effective April 2014 www.cooperpower.com 280-104-15 Technical Data 280-104 Form 4D microprocessor-based recloser control and accessories Effective April 2014 Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53188 United States Cooperpower.com © 2014 Eaton All Rights Reserved Printed in USA Publication No. 280-104 April 2014 280-104-16 Eaton, Cooper Power Systems, NOVA, and ProView NXG are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use the these trademarks without the prior written consent of Eaton. IEEE Std C57.12.28™-2005 and Std C57.12.29™-2005 standards are trademarks of the Institute of Electrical and Electronics Engineers, Inc., (IEEE). This publication is not endorsed or approved by the IEEE. IEEE® is a registered trademark of the Institute of Electrical and Electronics Engineers, Inc. ANSI® is a registered trademark of American National Standards Institute. For Eaton’s Cooper Power Systems Form 4D recloser product information call 1-877-277-4636 or visit: www. cooperpower.com. Eaton 1000 Eaton Boulevard Cleveland, OH 44122 United States Eaton.com Eaton’s Cooper Power Systems Business 2300 Badger Drive Waukesha, WI 53186 United States CooperPower.com © 2014 Eaton All Rights Reserved Printed in USA Eaton and Cooper Power Systems are valuable trademarks of Eaton in the U.S. and other countries. You are not permitted to use these trademarks without the prior written consent of Eaton. All other trademarks are property of their respective owners.