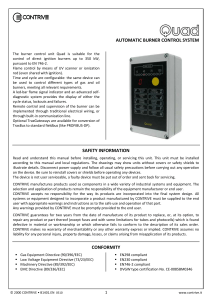

X6-03 X6-03 X4-02 X4-02 X7-02 X9-04 X5-01 X5-02 X92 FUEL X54 AIR 1 X7-01 X53 BC X56 X7-01 X3-0 X3-03 X3-04 1 X3-05 P CO X8-02 X8-02 L X3-03 X7-02 1 L X9-04 S Geräte-Nr.: 0503020021 X8-0 1 X8-04 L N SV X5-01 P PE Best.-Nr.: 600402 W-FM5 IGNITION X5-02 SIEMENS FM VDE X5-03 X5-03 N X3-0 PE FLANGE L FUSE 1 T6.3 IEC 60127-2/V N LINE L VOLTAGE PE PE L L MOTOR ALARM MOTO SAFETY LOOP L PE 230 VAC 50 or 60 Hz -20C to + 60C 1P - 4 F to +140 F 1 L PE CE-xxxxxxxxxxxxx DIN Rg.xxxxxxxxxxxxxx Refer to data sheet 7543 X3-02 1 L N V3/PV V1 • N PE V2 PE N PE P LT L LT 2 L min P min ON/OFF 3 L N OPERATION L L RESET L + P air L X10-06 X3-02 1 X10-06 QRB/CL X10-05 ION QRB/ X10-05 QRA P max/POC PE LMV27.210A2WH X75 1 QRA L max FLAME Siemens Building Technologies HVAC Products GmbH Made in Germany X75 FUEL P 1 PE 83250302 1/2018-08 Combustion Manager W-FM 50 COUNTER U + – A F esc VSD info h min s % V P Installation and operating instruction P i S X64 VSD X74 Installation and operating instruction Combustion Manager W-FM 50 1 User instructions .............................................................................................................. 5 1.1 Target group .................................................................................................................. 5 1.2 Symbols .......................................................................................................................... 5 1.3 Guarantee and Liability ............................................................................................... 6 2 Safety ..................................................................................................................................... 7 2.1 Designated application ............................................................................................... 2.2 When gas can be smelled ......................................................................................... 2.3 Safety measures ........................................................................................................... 2.3.1 Normal operation ................................................................................................... 2.3.2 Electrical connection ............................................................................................ 2.3.3 Gas supply .............................................................................................................. 2.4 Alterations to the construction of the equipment ................................................. 2.5 Noise emission ............................................................................................................. 2.6 Disposal ......................................................................................................................... 3 7 7 7 7 7 8 8 8 8 Product description ........................................................................................................ 9 3.1 Function .......................................................................................................................... 9 3.1.1 Burner Control ....................................................................................................... 9 3.1.2 Low gas programme ............................................................................................. 9 3.1.3 Valve proving ....................................................................................................... 10 3.1.4 Variable speed drive .......................................................................................... 10 3.1.5 Calculation ........................................................................................................... 11 3.1.6 Data backup ........................................................................................................ 11 3.1.7 Referencing the actuator .................................................................................. 12 3.1.8 Program sequence ............................................................................................. 13 3.1.8.1 Operating phase .......................................................................................... 13 3.1.8.2 Gas direct ignition ....................................................................................... 14 3.1.8.3 Gas with ignition pilot valve ...................................................................... 15 3.1.8.4 Fuel oil EL modulating and multi-stage, heavy oil multi-stage .......... 16 3.1.8.5 Medium and heavy oil modulating ........................................................... 17 3.2 Inputs ............................................................................................................................ 18 3.2.1 Voltage supply .................................................................................................... 18 3.2.2 Safety circuit ........................................................................................................ 18 3.2.3 Reset ..................................................................................................................... 18 3.2.4 Air pressure switch ............................................................................................ 18 3.2.5 Minimum pressure switch ................................................................................. 19 3.2.6 Max. pressure switch ......................................................................................... 19 3.2.7 Valve proving gas pressure switch ................................................................ 20 3.2.8 Heavy oil immediate start ................................................................................. 20 3.2.9 Flame sensor ....................................................................................................... 21 3.2.10 Load controller analogue input ..................................................................... 22 3.2.11 Load controller building management ........................................................ 22 3.2.12 Load controller via contacts .......................................................................... 23 3.2.13 Fuel Meter ......................................................................................................... 23 3.3 Outputs ........................................................................................................................ 24 3.3.1 Alarm ..................................................................................................................... 24 3.3.2 Motor ..................................................................................................................... 24 3.3.3 Ignition .................................................................................................................. 24 3.3.4 Frequency converter .......................................................................................... 24 83250302 1/2018-08 La 2-112 Installation and operating instruction Combustion Manager W-FM 50 3.3.5 Analogue output ................................................................................................. 3.4 Technical data ............................................................................................................. 3.4.1 Electrical data ..................................................................................................... 3.4.2 Ambient conditions ............................................................................................ 3.4.3 Dimensions .......................................................................................................... 4 25 26 26 26 27 Installation ........................................................................................................................ 28 4.1 Electrical connection ................................................................................................. 28 5 Operation .......................................................................................................................... 30 5.1 Operating interface .................................................................................................... 5.1.1 Operating panel .................................................................................................. 5.1.2 Display .................................................................................................................. 5.2 Displaying and adjusting parameters .................................................................... 5.2.1 Password ............................................................................................................. 5.2.2 Manual load ......................................................................................................... 5.3 Parameters .................................................................................................................. 5.3.1 Password level .................................................................................................... 5.3.2 Info level ............................................................................................................... 5.3.3 Service level ........................................................................................................ 6 Commissioning .............................................................................................................. 46 6.1 Prerequisite ................................................................................................................. 6.2 Adjusting the burner .................................................................................................. 6.2.1 Adjusting gas side ............................................................................................. 6.2.2 Adjust modulation oil side ................................................................................ 6.2.3 Adjust multi-stage oil side ................................................................................ 6.3 Check combustion ..................................................................................................... 6.4 Calculate gas throughput ......................................................................................... 7 30 30 31 33 34 35 36 36 44 45 46 46 47 61 75 86 87 Servicing ............................................................................................................................ 88 7.1 Notes on servicing ..................................................................................................... 88 7.2 Service plan ................................................................................................................. 89 8 Troubleshooting ............................................................................................................ 90 8.1 Procedures for fault conditions ............................................................................... 8.1.1 Display OFF ......................................................................................................... 8.1.2 Display OFF S ..................................................................................................... 8.1.3 Fault ....................................................................................................................... 8.1.4 Lockout ................................................................................................................. 8.2 Fault history ................................................................................................................. 8.3 Rectifying faults .......................................................................................................... 9 90 90 90 91 91 92 94 Technical documentation ....................................................................................... 102 9.1 Frequency converter ............................................................................................... 102 9.1.1 Frequency converter Nord size I … III ......................................................... 102 9.1.2 Frequency converter Nord size IV ................................................................ 104 83250302 1/2018-08 La 3-112 Installation and operating instruction Combustion Manager W-FM 50 83250302 1/2018-08 La 10 Spares ............................................................................................................................... 106 11 Notes ................................................................................................................................. 108 12 Key word index ............................................................................................................ 109 4-112 Installation and operating instruction Combustion Manager W-FM 50 1 User instructions 1 User instructions Translation of original operating instructions This manual forms part of the equipment and must be kept on site. Carefully read the manual prior to working on the unit. 1.1 Target group The manual is intended for the operator and qualified personnel. They should be observed by all personnel working with the unit. Work on the unit must only be carried out by personnel who have the relevant training and instruction. Persons with limited physical, sensory or mental capabilities may only work on the unit if they are supervised or have been trained by an authorised person. Children must not play with the unit. 1.2 Symbols Immediate danger with high risk. Non observance can lead to serious injury or death. DANGER Danger with medium risk. Non observance can lead to environmental damage, serious injury or death. WARNING Danger with low risk. Non observance can cause damage to the equipment and injury to personnel. CAUTION Important information Requires direct action Result after an action Itemisation Range of values … 83250302 1/2018-08 La 5-112 Installation and operating instruction Combustion Manager W-FM 50 1 User instructions 1.3 Guarantee and Liability Guarantee and liability claims for personal and equipment damage are excluded, if they can be attributed to one or more of the following causes: non approved application, non-observance of the manual, operation with faulty safety equipment, continual operation despite a fault, improper installation, commissioning, operation and service, repairs, which have been carried out incorrectly, the use of non original Weishaupt parts, force majeure, unauthorised modifications made to the unit, the installation of additional components, which have not been tested with the unit, the installation of combustion chamber inserts, which impede full flame formation, unsuitable fuels, defects in the inlet lines. 83250302 1/2018-08 La 6-112 Installation and operating instruction Combustion Manager W-FM 50 2 Safety 2 Safety 2.1 Designated application The combustion manager W-FM 50 is suitable for use with single fuel burners. Improper use could: endanger the health and safety of the user or third parties, cause damage to the unit or other material assets. 2.2 When gas can be smelled Avoid open flames and spark generation, for example: do not operate light switches, do not operate electronic equipment, do not use mobile telephones. Open doors and windows. Close gas isolating valve. Warn the inhabitants, do not ring door bells. Leave the building. Inform the heating contractor or gas supplier from outside of the building. 2.3 Safety measures Safety relevant fault conditions must be eliminated immediately. Components, which show increased wear and tear or whose design lifespan is or will be exceeded prior to the next service should be replaced as a precaution. The design lifespan of the components is listed in the service plan [ch. 7.2]. 2.3.1 Normal operation All labels on the unit must be kept in a legible condition. Stipulated settings, service and inspection work should be carried out at regular intervals. Only operate the unit with its cover closed. Do not touch moving parts during operation. Do not touch the oil carrying parts of medium and heavy oil burners during operation. 2.3.2 Electrical connection For work carried out on live components: Observe the accident prevention instructions DGUV Regulation 3 and adhere to local directives, tools in accordance with EN 60900 should be used. 83250302 1/2018-08 La 7-112 Installation and operating instruction Combustion Manager W-FM 50 2 Safety 2.3.3 Gas supply Only the gas supply company or an approved agent may carry out installation, alteration and maintenance work on gas appliances in buildings and properties. Pipework must be subject to a combined load and valve proving test and/or usability testing relative to the pressure range intended, e. g. DVGW-TRGI, worksheet G 600. Inform the gas supply company about the type and size of plant prior to installation. Local regulations and guidelines must be observed during installation, e. g. DVGW-TRGI, worksheet G 600; TRF Band 1 and Band 2. The gas supply pipework should be suitable for the type and quality of gas and should be designed in such a way that it is not possible for liquids to form, e. g. condensate. Observe vaporisation pressure and vaporisation temperature of liquid petroleum gas. Use only tested and approved sealing materials, whilst observing all process information. Re-commission the appliance when changing to a different type of gas. Carry out soundness test after each service and fault rectification. 2.4 Alterations to the construction of the equipment All conversions require written approval from Max Weishaupt GmbH. No additional components may be fitted, which have not been tested for use with the equipment. Do not use combustion chamber inserts, which hinder flame burnout. Use only original Weishaupt replacement parts. 2.5 Noise emission The noise emissions are determined by the acoustic behaviour of all components fitted to the combustion system. Prolonged exposure to high noise levels can lead to loss of hearing. Provide operating personnel with protective equipment. Noise emissions can further be reduced with a sound attenuator. 2.6 Disposal Dispose of all materials and components in a safe and environmentally friendly way at an authorised location. Observe local regulations. 83250302 1/2018-08 La 8-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3 Product description 3.1 Function 3.1.1 Burner Control A burner control for oil and gas burners is integrated in the combustion manager. It controls the sequence of operation, monitors the flame and communicates with all components. 3.1.2 Low gas programme The low gas pressure switch monitors the gas connection pressure from operating phase Ph22. If the gas pressure set at the low gas pressure switch is not achieved, the combustion manager initiates a safety shutdown and starts the low gas programme. In the low gas programme the combustion manager carries out a safety shutdown and initiates a restart after the low gas waiting time (10 seconds). This low gas waiting time doubles after every unsuccessful start attempt. If the start attempts exceed the repetition limit value (parameter 223) the combustion manager goes to lockout. The repetition counter and the low gas waiting time are automatically reset when the burner starts. 83250302 1/2018-08 La 9-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.1.3 Valve proving The valve proving gas pressure switch checks if the valves are tight. It signals the combustion manager if the pressure increases or decreases to an impermissible level during valve proving. Valve proving is carried out automatically by the combustion manager: after every controlled shutdown, prior to burner start following lockout or power outage. 1. Test phase (function sequence for valve proving valve 1): Valve 1 remains closed, valve 2 opens, the gas escapes and the pressure between valve 1 and valve 2 reduces, valve 2 closes again, both valves remain closed for 10 seconds. If the pressure increases to above the value set during these 10 seconds, valve 1 is leaking. The combustion manager initiates a controlled shutdown. 2. Test phase (function sequence for valve proving valve 2): Valve 1 opens, valve 2 remains closed, pressure between valve 1 and valve 2 increases, valve 1 closes again, both valves remain closed for 10 seconds. If the pressure decreases to below the value set during these 10 seconds, valve 2 is leaking. The combustion manager initiates a controlled shutdown. 3s 1 2 3 4 5 80 10 s 3s 10 s 1 2 V1 81 82 1 2 3 4 5 P 83 V2 P 4 Valve 1 Valve 2 Pressure between valve 1 and valve 2 Valve proving gas pressure switch Operating phases 3.1.4 Variable speed drive Via an analogue output, the W-FM controls the frequency converter of the fan motor and matches the speed to the burner capacity. This reduces electrical consumption. The speed and the rotation direction are monitored by an inductive proximity switch and an asymmetrical transmitter disc. 83250302 1/2018-08 La 10-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.1.5 Calculation A calculation can be triggered in modulating commissioning, if P1 and P9 are programmed. During a calculation, a straight line is generated from the operating point displayed to P1 or P9. The values on the straight are adopted as the new operating points. Initiate a calculation after P9: Press and hold [+] key for 3 … 5 seconds. Initiate a calculation after P1: Press and hold [–] key for 3 … 5 seconds. If during commissioning only P1 and P9 are programmed, the combustion manager initiates an automatic calculation when exiting P1 and calculates P2 to P8. 1 2 P1 P2 P3 P4 P5 P6 P7 P8 P9 P1 P2 P3 P4 P5 P6 P7 P8 P9 1 Automatic calculation 2 Calculation from P5 to P9 3.1.6 Data backup In the ABE, the settings of the combustion manager can be saved via parameter 050 (Backup). If the unit needs to be replaced, or if the parameters have unintentionally been altered, the data can be transferred back to the combustion manager. Data transfer (Restore) from ABE to the combustion manager is only possible if the burner data is identical [ch. 5.3]. WARNING Soot and CO formation because no combustion analysis has been carried out. At heat demand, the burner starts automatically approx. 30 seconds after the data transfer (Restore). Directly following the data transfer (Restore): Check sequence of operation. Carry out a combustion analysis at all load point. Only in conjunction with frequency converter Following data transfer (Restore) a speed standardisation with subsequent adjustment must be carried out. 83250302 1/2018-08 La 11-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.1.7 Referencing the actuator In operating phase Ph10 (Home Run) the combustion manager references the actuators, whereby the actuator drives over a reference marker. The actuator then drives back and determines the inner edge of the reference marker. All settings are referenced to this position. The combustion manager references the fuel actuators to the reference marker OPEN and the air actuator to the reference marker CLOSED. The setting range of the air damper shaft is limited mechanically, therefore the air actuator cannot drive to reference marker OPEN. If the actuators have been mixed up, a reference fault is identified (fault code 85). 0° 1 2 90° 112° 108° 4 3 1 2 3 4 83250302 1/2018-08 La Reference range CLOSED Reference marker CLOSED (air actuator) Reference range OPEN Reference marker OPEN (fuel actuator) 12-112 -8° -6° Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.1.8 Program sequence 3.1.8.1 Operating phase Ph00 Ph02 Ph10 Ph12 Ph22 Ph24 Ph30 Ph36 Ph38 Ph39 Ph40 Ph42 Ph44 Ph50 Ph52 Ph60 Ph62 Ph70 Ph72 Ph74 Ph78 Ph80 Ph81 Ph82 Ph83 Ph90 83250302 1/2018-08 La Lockout phase Safety phase Home run Standby Fan / safety valve ON Pre-purge position Pre-purge Ignition position Pre-ignition Test low gas pressure switch (fuel valve 1 opens, only with Gas) Fuel release Ignition OFF Flame Signal Flame stabilisation (only with Gas with pilot ignition) Ignition pilot valve OFF (only with Gas with pilot ignition) Operating setting 1 Operating setting 2 Post burn time Post-purge position Post-purge Post-purge Venting valve train (only during valve proving) Test without pressure (only during valve proving) Fill valve train (only during valve proving) Test with operating pressure (only during valve proving) Low gas waiting time 13-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.1.8.2 Gas direct ignition 1 00 02 10 12 22 24 30 36 38 39 40 42 44 60 62 70 72 74 78 2 X3-03:1, X3-04:1 3 X5-03:1 4 X10-05:2 5 X3-02:1 6 X5-01:2 7 X5-02:2 8 X9-04:2 9 0 q w e X3-05:1 X4-02:3 X6-03:3 X8-02:1 X7-01:3 1 2 3 4 5 6 7 8 9 0 q w e 83250302 1/2018-08 La Signal at input / output actuated No signal on input Input without influence Operating phases Safety circuit Heat demand controller Flame Signal Air pressure switch Minimum pressure switch Max. pressure switch Valve proving pressure switch Fan motor Ignition unit Safety valve Fuel valve 1 Fuel valve 2 14-112 80 81 82 83 90 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.1.8.3 Gas with ignition pilot valve 1 00 02 10 12 22 24 30 36 38 40 42 44 50 52 60 62 70 72 74 78 2 X3-03:1, X3-04:1 3 X5-03:1 4 X10-05:2 5 X3-02:1 6 X5-01:2 7 X5-02:2 8 X9-04:2 9 0 q w e r X3-05:1 X4-02:3 X6-03:3 X8-02:1 X7-01:3 X7-02:3 1 2 3 4 5 6 7 8 9 0 q w e r 83250302 1/2018-08 La Signal at input / output actuated No signal on input Input without influence Operating phases Safety circuit Heat demand controller Flame Signal Air pressure switch Minimum pressure switch Max. pressure switch Valve proving pressure switch Fan motor Ignition unit Safety valve Fuel valve 1 Fuel valve 2 Ignition pilot valve 15-112 80 81 82 83 90 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.1.8.4 Fuel oil EL modulating and multi-stage, heavy oil multistage 1 00 02 10 12 22 24 30 36 38 40 42 44 60 62 70 72 74 78 2 X3-03:1, X3-04:1 3 X5-03:1 4 X10-05 5 X3-02:1 6 X5-01:2 7 X5-02:2 8 9 0 q w e X3-05:1 X4-02:3 X8-02:1 X7-01:3 (2 X7-02:3 (1 (2 1 2 3 4 5 6 7 8 9 0 q w e 83250302 1/2018-08 La (1 X6-03:3 Only with heavy oil and long pre-ignition phase (parameter 281). Only with operating mode 12 (oil modulating). Signal on input / output activated No signal on input Input without influence Operating phases Safety circuit Heat demand controller Flame Signal Air pressure switch Minimum pressure switch Max. pressure switch Fan motor Ignition unit Safety valve Fuel valve 1 Fuel valve 2 Fuel valve 3 16-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.1.8.5 Medium and heavy oil modulating 1 00 02 10 12 22 24 30 36 38 40 42 44 60 62 70 72 74 78 2 3 4 5 6 7 8 X3-04:1 9 0 q w e r X3-05:1 X5-03:1 X10-05 X3-02:1 X5-01:2 X5-02:2 X9-04:2 X4-02:2 X6-03:2 X8-02:1 X7-01:2 X7-02:2 (1 1 2 3 4 5 6 7 8 9 0 q w e r 83250302 1/2018-08 La (1 Only for evaluation in operating phase PH38 … PH62 (parameter 286). Signal on input / output activated No signal on input Input without influence Operating phases Safety circuit Heat demand controller Flame Signal Air pressure switch Minimum pressure switch Max. pressure switch Heavy oil immediate start Fan motor Ignition unit Safety valve Fuel valve 1 Fuel valve 2 Fuel valve 3 17-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.2 Inputs L PE N X3-04 3.2.1 Voltage supply L The voltage supply is connected to inputs X3-04:3-5. 1 2 3 4 5 PE N L The mains frequency is set in parameter 125. L PE N X3-04 3.2.2 Safety circuit L X3-03 L In the diagnostic code, the inputs X3-03:1/2 and X3-04:1/2 are combined as safety circuit. If one of the inputs is open the W-FM carries out at least one safety shutdown. If the repetition value is exceeded an open input leads to lockout. 1 2 3 4 5 The repetition value can be set in parameter 215. At input X3-04:1/2 all external components of the safety circuit are switched in sequence, these include: Emergency-Off switch Safety time limiter (STL) Low water safety interlock, etc. 1 2 The burner flange limit switch is connected to input X3-03:1/2. PE N X8-04 L 1 2 X3-04 RESET OPERATION 1 2 3 4 5 X3-05 3.2.3 Reset 1 2 3 L MOTOR ALARM MOTOR CONT (1 (2 A reset button can be connected to input X8-04:1. Pressing this button in lockout for 1 … 6 seconds will reset the combustion manager. Pressing the button for a longer or shorter period will be ignored by the combustion manager and therefore has no effect. PE N L With lockout function(1 If the push button is also required for manual lockout, it must be connected to mains input X3-04:5 (L). If the combustion manager is in an operating phase, pressing the push button for 1 to 6 seconds will initiate a manual lockout. Without lockout function(2 If the push button is not required to carry out manual lockout it must be connected to alarm output X3-05:2. L X3-02 3.2.4 Air pressure switch 1 2 83250302 1/2018-08 La P The closing contact of the air pressure switch is connected input X3-02. If the signal is missing once the fan has started, the combustion manager initiates a lockout. The air pressure switch must have been deactivated, contact open, prior to the fan starting. 18-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description PE min L X5-01 3.2.5 Minimum pressure switch 1 2 3 P The closing contact of the min. pressure switch is connected to input X5-01. For burners without min. oil pressure switch, a bridge has to be connected to terminal 2 and terminal 3. Low gas pressure switch In gas operation, the combustion manager expects a signal at input X5-01:2 from operating phase Ph22 . If the pressure drops below the value set, the pressure switch contact opens and the combustion manager starts the low gas programme [ch. 3.1.2]. Minimum oil pressure switch In oil operation, the combustion manager expects a signal at input X5-01:2 from operating phase Ph38 or operating phase Ph40 (depending on parameter 276). If the pressure drops below the value set, the pressure switch contact opens and the combustion manager initiates a lockout. Lockout occurs in operating phase Ph38 (pre-ignition) after a delay of 30 seconds. In all subsequent phases, lockout occurs immediately. PE min L X5-02 3.2.6 Max. pressure switch 1 2 3 P The opening contact of the max. pressure switch is connected to input X5-02. For burners without max. oil pressure switch, a bridge has to be connected to terminal 2 and terminal 3. High gas pressure switch The combustion manager expects a signal at input X5-02:2 from operating phase Ph40. If the value set at the pressure switch is exceeded, the pressure switch contact opens and the combustion manager initiates a lockout. Maximum oil pressure switch The combustion manager expects a signal at input X5-02:2 from operating phase Ph22 . If the value set at the pressure switch is exceeded, the pressure switch contact opens and the combustion manager initiates a lockout. Lockout occurs in operating phase Ph22 (fan ON) after a delay of 30 seconds. In all subsequent phases, lockout occurs immediately. 83250302 1/2018-08 La 19-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description PE min L X9-04 3.2.7 Valve proving gas pressure switch 1 2 3 P The opening contact of the valve proving gas pressure switch is connected to input X9-04. Input X9-04 is only activated during valve proving [ch. 3.1.3]. The time of valve proving can be set in parameter 241 . If the pressure set is not achieved in operating phase Ph81 (test without pressure), the contact closes. If the pressure set is exceeded in operating phase Ph83 (test with operating pressure), the contact opens. PE min L X9-04 3.2.8 Heavy oil immediate start 1 2 3 The input is only activates for the return flow temperature sensor on heavy oil burners. The release contact of the return flow temperature sensor is connected to input X9-04. In modulating heavy oil operation, the combustion manager carries out a nozzle circulation for maximum 45 seconds. If the signal is present at X9-04 before this time has elapsed, the nozzle circulation is shortened accordingly. If the signal is missing after this time has elapsed, the combustion manager initiates a home run with subsequent repetition. During operation, the signal is monitored according to the setting of parameter 286. 83250302 1/2018-08 La 20-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.2.9 Flame sensor If the flame signal in operating phase Ph44 does not correspond to the value required, the combustion manager initiates safety shutdown with restart. If the flame signal during operation does not maintain the required value, the combustion manager initiates a controlled shutdown with restart. Two controlled shutdowns in sequence lead to lockout. A flame signal at heat demand (operating phase Ph12) leads to start prevention. A flame signal during pre-purge (operating phase Ph30 … Ph36) or post-purge (operating phase Ph78) leads to lockout after one repetition and repeated occurrence. Parameter 954 shows the current flame signal as a percentage value. QRA QRA X10-06 QRA… BR 1 2 + The flame sensor QRA… (UV cell) is connected to input X10-06. BU Response limit extraneous light Operation Flame signal Parameter 954 greater than 18 % min 24 % Ionisation electrode QRB/C QRB/C-N X10-05 PE ION L 1 2 3 4 5 The ionisation electrode is connected to input X10-05:2. Sensor current min.: 4 μA Sensor current max.: 16 … 40 μA Flame signal Parameter 954 approx. 30 % 100 % QRB… QRB/C QRB/C-N L X10-05 PE ION 1 2 3 4 5 83250302 1/2018-08 La The flame sensor QRB… (photo resistor) is connected to input X10-05:3/4. Flame signal Parameter 954 Response limit extraneous light (resistance less than approx. 10 % 400 kΩ) Operation (resistance less than 230 kΩ) approx. 16 % Short circuit identification (resistance less than – 0.5 kΩ) 21-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description X5-03 L 4...20 GND The contact for heat demand is connected to input X5-03:1 (burner ON/OFF). °C - 1 2 3 4 5 ON/OFF + 1 2 3 4 X64 3.2.10 Load controller analogue input The analogue load signal is connected to terminals X64:1 (4 … 20 mA) and X64:2 (GND). A signal of less than 3 mA deactivates the analogue input and the load pre-setting at input X5-03:2/3 has priority (parameter 942). If no load controller is connected to input X5-03:2/3, the combustion manager remains at the current rating until heat demand is interrupted. Modulating operation with load controller In modulating operation, parameter 123 determines the minimum correcting element step. Signal on X64:1/2 3 … 4 mA 20 mA Load W-FM 20 % 100 % Multi-stage operation (fuel oil only) In multi-stage operation a hysteresis of 1 mA exists between the operating points, which eliminates unnecessary load changes. Two stage: Signal on X64:1/2 3 … 5 … 12 mA 13 … 15 … 20 mA Load W-FM Stage 1 Stage 2 Three stage: Signal on X64:1/2 3 … 5 … 7 mA 8 … 10 … 12 mA 13 … 15 … 20 mA Load W-FM Stage 1 Stage 2 Stage 3 3.2.11 Load controller building management X5-03 ON/OFF COM X92 L A BUS interface for building management can be connected to input COM X92: Modbus: Bus-Interface Modbus OCI412.10 (Order No.: 660 285), eBUS: Adapter MPA eBUS (Order No.: 743 090). 1 2 3 4 Interface To ensure that load pre-setting is carried out by the building management system, input X5-03:1 (burner ON/OFF) must be connected to voltage output X5-03:4 for burner start. The settings required for Bus communication are set in parameters 141 to 148. 83250302 1/2018-08 La 22-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.2.12 Load controller via contacts The contact for heat demand is connected to input X5-03:1 (burner ON/OFF). The load control distinguishes between multi-stage and modulating operation. The operating mode is set in parameter 201 . Modulating operation with load controller X5-03 ON/OFF L 1 2 3 4 °C If input X5-03:2 (CLOSED) is activated, the burner capacity reduces. If input X5-03:3 (OPEN) is activated, the burner capacity increases. If none of the two inputs is activated, the burner capacity remains unchanged. X5-03 1 2 3 4 X5-03 Operating mode sliding two stage with thermostat 1 2 3 4 ON/OFF L ON/OFF L If thermostats or pressure regulators are connected to inputs X5-03, the modulating fuel can only be operated in sliding two stage operation. At heat demand input X5-03:2 (CLOSED) is activated and the burner drives to partial load. If the temperature drops below the value set, input X5-03:3 (OPEN) is activated and the burner drives to full load. If a signal is applied to input X5-03:3, input X5-03:2 is ignored. P P P P P P P Multi-stage operation (fuel oil only) X5-03 ON/OFF L Two and three stage: 1 2 3 4 °C Input two stage Stage 1 Stage 1 Stage 2 X5-03:1 X5-03:2 X5-03:3 Operating mode three stage Stage 1 Stage 2 Stage 3 X5-03 1 2 3 4 X5-03 If input X5-03:3 is activated during three stage operation, the burner drives to stage 3, the signal from stage 2 is no longer relevant. 1 2 3 4 ON/OFF L ON/OFF L P P Low impact start: At heat demand and with the bridge between terminal 1 and 2 the burner ignites in stage 1 and then automatically drives to stage 2. If input X5-03:3 is also activated the burner drives to stage 3. Change-over release: P P A bridge connects terminals 2 and 3. At heat demand the burner drives to stage 1. If inputs X5-03:2/3 are then activated simultaneously the burner drives via stage 2 to stage 3. X75 3.2.13 Fuel Meter 1 2 83250302 1/2018-08 La It is possible to connect a fuel meter with Reed contact to input X75. A prerequisite for this is that no frequency inverter is connected and activated. The meter pulses per unit volume must be set in parameter 128 . The impulse frequency must not exceed 300 Hz. 23-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.3 Outputs MOTOR ALARM MOTOR CONT X3-05 3.3.1 Alarm A mains voltage signal is given at alarm output X3-05:2 in lockout (operating phase Ph00). 1 2 3 In addition, start prevention can also be signaled. To do this, parameter 210 should be set to 1. ALARM MOTOR CONT MOTOR ALARM MOTOR CONT X3-05 MOTOR X3-05 3.3.2 Motor 1 2 3 Normal operation M L The fan motor is connected to output X3-05:1 via contactor or star delta switching. N The fan motor is connected to output X3-05:3 via contactor or star delta switching. If an air pressure switch is fitted, continuous running fan is only possible via pressure switch relief. To do this, a vent valve has to be fitted to the air pressure switch and connected to output X3-05:1. 1 2 3 M L Continuous operation N PE N L X4-02 3.3.3 Ignition The ignition unit is connected to output X4-02. 1 2 3 Ignition behaviour Gas Pre-ignition in operating phase Ph38 can be adjusted in parameter 226 . Ignition behaviour Oil In parameter 281 ,the switch-on point of ignition (operating phase Ph22 or Ph38) is determined. Pre-ignition in operating phase Ph38 can be adjusted in parameter 266 . 3.3.4 Frequency converter 0...10 V 10 V X74 24 V 1 2 3 4 5 The frequency converter and the speed sensor are connected at output X74. Frequency converter Terminal X74:1 X74:2 X74:3 Function 24 V input; supply from frequency converter Signal acquisition Speed setpoint signal (parameter 645) Speed measurement Terminal X74:4 X74:5 83250302 1/2018-08 La Function Speed return signal (input actual speed) 10 V; supplied by combustion manager 24-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.3.5 Analogue output 0...10 V 10 V X74 24 V 1 2 3 4 5 Instead of the frequency converter, a load dependent analogue signal can be emitted at output X74:3. Prerequisite is an external 24 V DC voltage source at input X74:1/2. The values given relate to an analogue signal of 0 … 10 V, if a signal of 2 … 10 V or 0/2 … 10 V is set in parameter 645 the voltages listed will change. Conversion: (original value x 0.8) + 2 =new value Modulating operation Rating Off Ignition load Partial load (20 %) Full load (100 %) Curve point – P0 P1 P9 Analogue signal 0V 1V 2V 10 V Curve point – P1 P2 Analogue signal 0V 5V 10 V Curve point – P1 P2 P3 Analogue signal 0V 3V 5V 10 V Two stage operation Rating Off Stage 1 Stage 2 Three stage operation Rating Off Stage 1 Stage 2 Stage 3 83250302 1/2018-08 La 25-112 Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.4 Technical data 3.4.1 Electrical data Combustion Manager Mains voltage / Mains frequency Consumption Internal unit fuse External fuse Type of protection 230 V / 50 … 60 Hz max 30 W T6.3H, IEC 127-2/5 max 16 AB IP 00 Display and operating unit (ABE) Mains voltage Consumption Type of protection (front) DC 5 V max 50 mW IP54 to IEC 529 Type of protection (rear) Protection class IP00 to IEC 529 II to DIN EN 60 730-1 Actuator STE 50 1.2 Nm DC/AC 24 V / 50 … 60 HZ max 7.5 W 1.2 Nm 5 s / 90° IP 54 II Mains voltage Consumption Torque Setting time Type of protection Protection class STE 50 3 Nm DC/AC 24 V / 50 … 60 HZ max 10 W 3 Nm 4 s / 90° IP 54 II 3.4.2 Ambient conditions Temperature in operation Temperature during transport / storage relative humidity 83250302 1/2018-08 La 26-112 –20 … +60 °C –20 … +60 °C max 95 %, no dew point Installation and operating instruction Combustion Manager W-FM 50 3 Product description 3.4.3 Dimensions Combustion manager 230 mm 217 mm 122 mm 135 mm 60 mm Display and operating unit (ABE) Recess dimension: 127 x 91 mm ± 0.5 mm 17 mm 96 mm 18 mm 83250302 1/2018-08 La 27-112 126,4 mm 132 mm 90,6 mm S P i V VSD F A info h min s % esc - + Installation and operating instruction Combustion Manager W-FM 50 4 Installation 4 Installation 4.1 Electrical connection DANGER WARNING Risk of electric shock Working on the device when voltage is applied can lead to electric shock. Isolate the device from the power supply prior to starting any work. Safeguard against accidental restart. Electric shock despite disconnection from the voltage supply It is possible that electrical components on burners with frequency converters continue to carry voltage and cause electric shock even after the voltage supply has been disconnected. Wait approx. 5 minutes before commencing work. Electric voltage has dissipated. The electrical connection must only be carried out by qualified electricians. Observe local regulations. Connect combustion manager Use cable entry grommets on the housing. Connect wiring to wiring diagram enclosed. Control circuits, which are taken directly via a 16 AB fuse from a 3 phase or single phase alternating current supply, must only be connected between a phase conductor and earth potential neutral conductor. On mains supply, which does not have a neutral, the control voltage must be supplied via an isolating transformer. The pole of the transformer, which is to be used as the neutral conductor, must be earthed. Phase L must not be mixed up with the neutral conductor N. Contact protection will otherwise no longer be given. Malfunctions, which endanger operational safety could occur. The cable cross section of the voltage supply must be suitable for the nominal current of the external fuse (maximum 16 AB). All other cable connections must be suitable for the relevant internal unit fuse (T6.3H). Earthing and neutral conductor must conform to local regulations. The following applies for cable length: Display and operating unit, load controller, safety interlock circuit, burner flange, reset key - maximum 20 m (100 pF/m). BCI interface maximum 20 m (100 pF/m). Connecting the burner motor The motor must be protected against thermal overload and short circuit. Weishaupt recommend the use of a motor protection switch. Open terminal box on motor. Connect voltage supply to wiring diagram enclosed, observe motor rotation. 83250302 1/2018-08 La 28-112 Installation and operating instruction Combustion Manager W-FM 50 4 Installation Variable speed drive (optional) If the frequency converter is located on the motor, the cable to the frequency converter is not screened. If the frequency converter is separate the control line and the motor connection must be screened. Apply screen to the screen clamp on frequency converter. Use screen cable glands (metal) on the burner. Connect gas valve train Observe wiring diagram supplied. Connect double gas valve (plug K32). Solenoid coil on W-MF or DMV Actuator on VGD. Connect limit switch for valve lift monitoring (plug S33 / S35), only with VGD. Connect ignition gas valve (plug K31). Connect low gas pressure switch (plug B31). Connect valve proving gas pressure switch (plug B32). If required, connect high gas pressure switch (plug B33). 83250302 1/2018-08 La 29-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation 5 Operation 5.1 Operating interface 5.1.1 Operating panel Display and operating unit (ABE) 1 S P i V h min esc VSD F 1 A - + 5 2 4 3 [Enter] [info] 2 3 2 and 3 4 5 4 and 5 info s % [+] [–] [+] and [–] [A] Air [F] Fuel [F] and [A] back-up of value changes; entry to parameter and values call up information press for approx. 3 seconds: Info level press for approx. 5 seconds: Service level navigation through parameter structure; changing values press simultaneously: return/cancel selects the damper position selects the fuel supply press simultaneously: selects the frequency converter (optional) OFF function Press [ENTER] and any other key simultaneously. Immediate lockout. 83250302 1/2018-08 La 30-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation 5.1.2 Display The black cursor in the display shows the status of the inputs and outputs, the unit of values and the active level. 1 2 3 4 5 6 S u z t P i V h min s % r e w q 0 9 8 7 1 2 3 4 5 6 7 8 9 0 q w e r t z u 83250302 1/2018-08 La Heat demand by the boiler control (start) Burner motor Ignition Fuel valves Flame signal on Flame failure or lockout Degree of angle setting Percentage value Second Minute Hour (together with volume = V/h) Volume (m3, l, ft3, gal) Actuator OPEN Actuator CLOSED Service level Info level Parameter level (engineer level) 31-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Display OFF The parameter setting is missing, incomplete or has been deleted. No heat demand from controller (input X5-03:1). Safety circuit not closed at heat demand (input X3-03:1/2 and X3-04:1/2). Display Ph The combustion manager is in an operating phase and waits for signals or activates outputs depending on the program sequence. The combustion manager is in an operating phase and shows the remaining run time programmed (example: pre-purge). Display Op The combustion manager is in modulating operation and shows the current load in percent. The combustion manager is in multi-stage operation and shows the current fuel stage. When the fuel stage is changed, the additional display on or of indicates the switching of the relevant fuel valve. Display flashes Manual load is activated. The combustion manager is in manual load default. Deactivate manual load: Press and hold [esc] key for 5 seconds. Fault display During a fault condition, the display alternately shows the error code C and diagnostic code D [ch. 8.3]. The combustion manager is in lockout. Once the fault has been rectified, the combustion manager has to be reset [ch. 8.1.4]. The combustion manager initiates a safety shutdown. The burner restarts automatically once the fault condition has been rectified. The combustion manager shows an occurrence, which does not lead to a shutdown. 83250302 1/2018-08 La 32-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation 5.2 Displaying and adjusting parameters Password level (engineer level) call up level Press [F] and [A] keys simultaneously and then enter the password [ch. 5.2.1]. Info-/Service level The Info or Service level can only be called up from the standard display. Press [Enter]. For Info level 1 … 3 s For Service level 3 … 5 s Next parameter Press [+] key. Press [+] key. – or – Briefly press [Enter]. Previous parameter Press [–] key. Press [–] key. Press [Enter]. Press [Enter] 1 … 3 s. Press [esc]. Press [Enter] 3 … 5 s. One level lower One level higher – or – Briefly press [esc] key. Change value Press [+] or [–] key. not possible Press [Enter]. not possible Save value 83250302 1/2018-08 La 33-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation 5.2.1 Password Enter password Press [F] and [A] simultaneously for approx. 2 seconds. The display shows CodE. Enter the first digit using [+] or [–] and confirm with [ENTER]. Repeat procedure until the password has been entered. Exit password entry using [ENTER]. The display shows PArA (parameter level) for a short time and then changes over to 400: SEt (setup). S P i V h min s S %P i S P i S V h min s % V h min s %P i V h min s % Deactivating password If no key is activated for 30 minutes, the combustion manager automatically deactivates the password and blocks the level. In the password level, the password can be aborted early: Press [esc] key until the display shows CLr CodE. Let go of the [esc] key. The combustion manager blocks the password level and changes to the operating display. S P i V S S P i 83250302 1/2018-08 La h min s % 34-112 s % 3s P i V h min V h min s % Installation and operating instruction Combustion Manager W-FM 50 5 Operation 5.2.2 Manual load If a signal is applied to input X5-03:1 (burner ON), each load setting within the load limit can be selected manually. If manual load is activated, the current load flashing in the operating display. Manual load can be activated using a key combination or parameter 121 . If manual load is set via parameter 121 additional functions are available. Load default ---0.0 … 19.9 P0 20.0 … 100.0 P1 … P3 Function Parameter 121 Manual load deactivated Manual OFF, remains active even after fuel changeover. Initiate ignition position (multi stage operation only) Initiate load setting within the load limits. Key combination not possible not possible not possible Initiate load setting within the load limits. Values outside of the load limits can be Only values within the load limits can be adjusted, but not initiated. If the load lim- adjusted. its are extended during active manual load, the burner reacts accordingly. For the duration of commissioning (400 Set), manual load is ignored. With the exception of Manual OFF, manual load is deactivated during fuel changeover. Manual load via key combination Activate manual load: Press and hold [F] key. The display shows LoAd. Set manual load using [+] or [-] key. The manual load set flashes. Manual load burner OFF: Drive to minimum load position and release [F] and [-] keys. Press [F] and [-] keys again. Deactivate manual load: Press and hold [esc] key for approx. 5 seconds. S S P i P i V h min s % V S S P i V h min s % 5s Manual load via parameter 121 Enter password [ch. 5.2.1]. Select parameter 121 . Press [Enter]. Set manual load using [+] or [-] key. Press [Enter]. Manual load is initiated. 83250302 1/2018-08 La 35-112 P i V h min s % h min s % Installation and operating instruction Combustion Manager W-FM 50 5 Operation 5.3 Parameters 5.3.1 Password level Internal parameter (000: Int) Parameter Function 050 Data backup [ch. 3.1.6] Transfer of data sets between W-FM and ABE with identical burner identification (parameter 113). If the backup or restore is incorrect, a negative value is displayed. The cause of the error is described in error code 137 see. Save from W-FM to ABE (Backup): Press [Enter]. The display shows bAC_up. Press [Enter]. Set 1 using [+] key and confirm with [Enter]. Following successful execution the display is reset to 0. 055 056 057 Save from ABE to W-FM (Restore): Press [Enter]. The display shows bAC_up. Press [+] key. The display shows rEStorE. Set 1 using [+] key and confirm with [Enter]. Following successful execution the display is reset to 0. Burner identification of data backup (read only). ASN excerpts of data backup (read only). Software version when creating backup (read only). General parameters (100: PArA) Parameter 102 103 104 105 107 108 111 113 121 123 Function Date of manufacture DD.MM.YY Production number Parameter default setting: Customer code Parameter default setting: Version Software version Software variation ASN excerpt for comparison with data backup (parameter 056) Burner identification: Identical to the burner serial number (name plate). The burner identification has to be reset if the combustion manager has been replaced. Manual load Minimum setting step in percent Only load changes, which exceed the value set are initiated, this avoids unnecessary setting movements in modulating operation. 123.00: Load default from building management 123.01: Analogue load controller on X64 123.02: Load controller contact on X5-03 83250302 1/2018-08 La 36-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Parameter Function 124 Flame failure test (TÜV test) The flame failure test can only be carried out in operating setting 1 (operating phase Ph60). The flame failure test closes the fuel valves and calculates the time up to flame failure. The calculated time is displayed in the diagnostic code in multiples of 0.2 seconds (example Loc.D: 8 = 1.6 seconds). For the flame failure test the burner drives to the load defined under parameter 133 . If no load is defined in parameter 133 , the flame failure test is carried out at the current load. 125 126 128 130 133 141 142 Press [Enter]. Set value 1 using [+] key and confirm with [Enter]. Following successful execution, the display alternately shows the error code Loc.c: 7 and diagnostic code Loc.d: x. Mains frequency 0: 50 Hz 1: 60 Hz Display illumination Fuel meter The value must correspond to the number of impulses per unit of volume (l, m³) of the fuel meter. If the value is set to 0 , the fuel meter stops. Delete error history [ch. 8.1] Load for flame failure test Operating mode building management 0: OFF 1: Modbus, the combustion manager operates as Slave, the RTU transfer mode is used (Remote Terminal Unit) 2: eBUS Recurrence time if communication is interrupted (setting range: 0 … 7200 s) If communication to the building management system fails, the next load controller according to priority will be activated once this time has elapsed. If no other load controller is connected, the burner remains at the current load or it drives to the load defined in parameter 148. 143 Priority 1: Load controller building management Priority 2: Load controller on analogue input X64 Priority 3: Load controller on input X5-03 Unit address of combustion manager as eBUS participant 144 145 146 1: Address 03 2: Address 13 3: Address 33 4: Address 73 5: Address F3 6: Address 1F 7: Address 3F 8: Address 7F Send cycle in seconds for the eBUS 05 and 09 Unit address of combustion manager as Modbus participant Baud rate Modbus The Baud rate of the combustion manager and the building management system must be identical. 147 0: 9600 1: 19200 Parity Modbus The parity of the combustion manager and the building management system must be identical. 0: no Parity bit 1: odd Parity bit 2: even Parity bit 83250302 1/2018-08 La 37-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Parameter Function 148 Replacement load (setting range: 0 … 100 %) Load default for communication failure with building management system. 161 162 –––: no replacement load 0 … 19.9: burner OFF Number of lockouts Operating hours since last reset 163 164 Reset: Press [Enter]. Press [–] key. The display shows 0, operating hours have been reset. Total operating hours (voltage applied to combustion manager) Start-ups since last reset 166 167 Reset: Press [Enter]. Press [–] key. The display shows 0, start-ups have been reset. Total start-ups Fuel volume since last reset 190 Reset: Press [Enter]. Press [–] key. The display shows 0, the fuel volume has been reset. Position of actuators at lockout 0: Standby position 1: Post-purge position 191 … 193 not used 195 Repetition counter for heavy oil immediate start Number of heavy oil start attempts with missing signal at input X9-04 until lockout. 83250302 1/2018-08 La 38-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Burner control (200: PAr0) Parameter Function 201 Operating mode ––: not defined (delete curves) 1: Gas direct ignition 2: Gas pilot ignition 5: fuel oil EL, MS and S two stage Z 6: fuel oil EL, MS and S three stage T 12: fuel oil EL modulating 23: fuel oil MS and S modulating 204 208 Other settings without function (3, 4, 7 … 11, 13 … 22 und 24 … 27). not used Program stop 210 0: deactivated 1: Pre-purge position (operating phase Ph24) 2: ignition position (operating phase Ph36) 3: interval time 1 (operating phase Ph44) 4: interval time 2 (operating phase Ph52) Alarm at start prevention Determines whether a signal is given at output X3-05:2 during start prevention. 211 0: no alarm (no signal at output X3-05:2) 1: Alarm (signal at output X3-05:2) Fan run-up time (setting range: 2.0 … 60 s) 212 Time from fan start to start of actuators. Switch off behaviour / max. time to partial load (setting range: 0.2 … 45 s.) If heat demand is no longer present, the burner drives as far as possible to partial load in a predetermined time and then switches off. 215 The burner takes approx. 32 seconds to drive from 100% load to 20% (partial load). Repetition counter safety circuit (setting range: 1 … 16) 221 Number of safety shutdowns by the safety circuit before lockout occurs [ch. 3.2.2]. Flame sensor Gas 222 0: QRC 1: ionisation electrode/QRA Pre-purge Gas When using a valve proving system and two Class A fuel valves pre-purge following a controlled shutdown can be omitted (to EN 676). 223 0: OFF 1: ON (pre-purge phase parameter 225) Repetition counter low gas pressure switch (setting range: 1 … 16) 225 Number of safety shutdowns by the low gas pressure switch before lockout occurs [ch. 3.1.2]. Pre-purge time Gas in operating phase Ph30 (setting range: 20 … 3600 s) 226 Once the pre-purge positions have been reached, the combustion manager remains in Ph30 for the duration of the time set. Pre-ignition Gas (setting range: 0.2 … 3600 s) 230 Duration of pre-ignition time in operating phase Ph38. Interval time 1 Gas 232 The interval time 1 in operating phase Ph44 acts as stabilisation time following flame formation. Interval time 2 Gas The interval time 2 in operating phase Ph52 acts as stabilisation time following flame formation. 83250302 1/2018-08 La 39-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Parameter Function 233 Post burn time Gas (setting range: 0.2 … 60 s) 236 The combustion manager remains in operating phase Ph70 for the duration of the time set, the flame sensor is ignored during this time. Post-purge time Gas (setting range: 0.2 … 6480 s) Once the post-purge position has been reached, the combustion manager remains in operating phase Ph74 for the duration of the time set, the flame sensor is ignored during this time. Low gas pressure switch input / installation position 237 0: OFF 1: Low gas pressure switch fitted upstream of valve 1 (factory setting) 2: Low gas pressure switch fitted between valve 1 and valve 2, valve proving via low gas pressure switch High gas pressure switch 234 If a high gas pressure switch is fitted, set parameter to 1. 239 241 0: OFF 1: high gas pressure switch 2: valve closing contact With forced intermittent activated, a controlled shutdown with subsequent restart is initiated after 23 hours and 45 minutes uninterrupted burner operation. 0: OFF 1: forced intermittent activated Valve proving In accordance with DIN EN 676 valve proving is not necessary if pre-purge is activated and the burner rating is less than 1200 kW. 248 0: valve proving OFF (only with capacity < 1200 kW, parameter 222 must be set to 1: ON) 1: valve proving at stat-up 2: valve proving at shutdown (factory setting) 3: valve proving at stat-up and shutdown Post-purge time 3 Gas (setting range: 0.2 … 6480 s) 261 The combustion manager remains in operating phase Ph78 for the duration of the time set except if a new heat demand interrupts the post-purge time 3 in operating phase Ph78. Flame sensor Oil 265 0: QRB 1: QRA Pre-purge time Oil in operating phase Ph30 (setting range: 15 … 3600 s) 266 Once the pre-purge positions have been reached, the combustion manager remains in operating phase Ph30 for the duration of the time set. Pre-ignition time Oil (setting range: 0.6 … 3600 s) 270 Once the ignition positions have been reached, the combustion manager remains in operating phase Ph38 for the duration of the time set. Interval time 1 Oil 272 273 The interval time 1 in operating phase Ph44 acts as stabilisation time following flame formation. not used Post-burn time Oil (setting range: 0.2 … 60 s) 274 The combustion manager remains in operating phase Ph70 for the duration of the time set, the flame sensor is ignored during this time. Post-purge time Oil (setting range: 0.2 … 6480 s) Once the post-purge position has been reached, the combustion manager remains in operating phasePh74 for the duration of the time set, the flame sensor is ignored during this time. 83250302 1/2018-08 La 40-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Parameter Function 276 Minimum oil pressure switch 277 0: OFF 1: active from operating phase Ph38 2: active from operating phase Ph40 with solenoid valve upstream of pressure switch (e.g. pump with valve) Max. oil pressure switch If a max. oil pressure switch is fitted set parameter to 1. 279 0: OFF 1: oil pressure switch 2: valve closing contact With forced intermittent activated, a controlled shutdown with subsequent restart is initiated after 23 hours and 45 minutes uninterrupted burner operation. 281 0: OFF 1: forced intermittent activated Point of ignition Oil 284 0: ignition on in operating phase Ph38 (short pre-ignition) 1: ignition on in operating phase Ph22 (long pre-ignition at fan start) Post-purge time 3 Oil (setting range: 0.2 … 6480 s) 286 The combustion manager remains in operating phase Ph78 for the duration of the time set except if a new heat demand interrupts the post-purge time 3 in operating phase Ph78. Evaluation of heavy oil immediate start If the signal is missing during the operating phase set, the W-FM initiates a shutdown with a subsequent restart (repetition). The number of repetitions can be set in parameter 195 . 287 0: signal only required in operating phase Ph38 1: signal required in operating phases PH38 … PH62 Maximum waiting time for signal for heavy oil immediate start in operating phase PH38 (setting range: 1 … 45 s) Commissioning parameter (400: SEt) Parameter set 400 is used to adjust the fuel air compound regulation (see Ch. 6). Compound (500: PArA) Parameter Function 501 Special positions fuel actuator 502 501.00: standby position (is activated in operating phases Ph10, Ph12 and Ph00 ) 501.01: Pre-purge position (is only activated in operating phase Ph24 ) 501.02: Post-purge position (is activated in operating phase Ph72 ) Special position air actuator 503 502.00: standby position (is activated in operating phases Ph10, Ph12 and Ph00 ) 502.01: Pre-purge position (is activated in operating phase Ph24 ) 502.02: Post-purge position (is activated in operating phase Ph72 ) Special positions frequency converter 522 503.00: standby position (is activated in operating phases Ph10, Ph12 and Ph00 ) 503.01: pre-purge position (is activated in operating phase Ph24 ) 503.02: Post-purge position (is activated in operating phase Ph72 ) Drive up ramp (setting range: 5 … 20 s) 523 The ramp should be at least 20% slower than that of the frequency converter. Drive up ramp (setting range: 5 … 20 s) The ramp should be at least 20% slower than that of the frequency converter. 83250302 1/2018-08 La 41-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Parameter Function 542 Activation of frequency converter 544 0: not activated 1: activated Operating ramp modulating Time for the actuators to drive from low load to high load. 545 Recommended factory setting: 32 s Lower load limit (setting range: 20 … 100 %) Defines the lower modulating limit (partial load). If no limit has been defined, the lower load limit in operation is automatically set to 20 %. 546 – – – –: no load limit defined (20 %) Upper load limit (setting limit: 20 … 100 %) Defines the upper modulating limit (full load). If no limit has been defined, the upper load limit in operation is automatically set to 100 %. – – – –: no load limit defined (100 %) Actuators (600: ACtr) Parameter Function 601 … 613 Configuration of actuators 641 606.00: fuel actuator 606.01: air actuator Speed standardisation During speed standardisation, a setpoint signal of 95 % (9.5 V) is sent to the frequency converter. The speed achieved is saved as 100% value, which means that a reserve of 5% is available during operation. The maximum frequency at the frequency converter must therefore be 52.6 Hz. If the frequency converter is fitted to the burner, the maximum frequency has been factory preset. If the frequency converter is external, the maximum frequency has to be set to this value. Starting standardisation: Press [Enter]. Set value 1 using [+] key and confirm with [Enter]. The fan motor starts with the air damper open. Following successful execution the display is reset to 0. If a negative value appears (-X), the normalisation has failed. 642 The combustion values must be checked after every speed standardisation. Standardised speed During speed standardisation a 95% signal is signalled to the frequency converter and the speed achieved is saved as the standard speed. 642.00: Standard speed saved from micro controller 1. 642.01: Standard speed saved from micro controller 2. 645 The speeds of the two micro controllers may vary by up to 1.5 %. Analogue output X74 This output can be used to signal a load dependent analogue signal [ch. 3.3.5] or to activate a frequency converter [ch. 3.3.4]. In conjunction with a frequency converter the voltage at output X74 and and at setpoint input of the frequency converter must be set identically. 0: DC 0 … 10 V 1: DC 2 … 10 V 2: DC 0/2 … 10 V 83250302 1/2018-08 La 42-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Parameter Function 652 Activation of the frequency converter with safety circuit open 653 0: no activation 1: frequency converter is activated with 0 Speed monitoring in standby, standby speed 0 % 0: no speed monitoring 1: speed monitoring activated Fault history (700: HISt) Parameter set 700 is used to localise and correct faults [ch. 8.2]. Process data (900: dAtA) Parameter Function 903 Current capacity 922 903.00: Fuel 903.01: Air Actuator step position 935 922.00: fuel actuator 922.01: air actuator Absolute speed 936 Current actual speed (recorded by transmitter disc on motor) Standardised speed 942 Current speed signal in percent. Active load source (load controller) The parameter shows the load source currently active. If more than one load source is available, the combustion manager prioritises to the sequence listed below. The priority cannot be altered. 947 1: load by curve setting 2: manual load 3: load controller via building management 4: external load controller via analogue input X64 terminal 1 / terminal 2 5: external load controller via contacts X5-03 terminal 2 / terminal 3 Contact interrogation W-FM (bit coded output) 947.00: inputs 1: min. pressure switch 2: max. pressure switch 4: internal fuel selection 8: air pressure switch 16: load controller OPEN 32: load controller ON 64: load controller CLOSED 128: safety circuit 947.01: outputs 948 1: safety valve 2: ignition 4: fuel valve 1 8: fuel valve 2 16: fuel valve 3 / pilot valve 32: internal fuel selection 1 Contact return signal network meter 83250302 1/2018-08 La 43-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation Parameter Function 950 Relay nominal condition (Bit coded output) 951 1: alarm 2: safety valve 4: ignition 8: fuel valve 1 16: fuel valve 2 32: fuel valve 3 / pilot valve Mains voltage (standardised) Value displayed x factor = current voltage 954 960 961 981 982 992 Factor 230 V: 1.683 Factor 120 V: 0.843 Current flame signal in percent [ch. 3.2.9] Current fuel throughput Current operating phase [ch. 3.1.8] Fault history: fault codes Fault history: diagnostic codes Fault flags 5.3.2 Info level In the Info level, parameter values can be displayed but not altered. Select parameter using [+] or [-] key. Press [Enter] 1 … 3 s. Parameter value appears. Parameters 167 162 164 163 166 113 107 108 102 103 104 105 143 Function Fuel volume since last reset Operating hours since last reset Start-ups since last reset Total operating hours (voltage applied to combustion manager) Total start-ups Burner identification: identical to the burner serial number (name plate) Software version Software variation Date of manufacture DD.MM.YY Production number Parameter default setting: Customer code Parameter default setting: Version Unit address of combustion manager as eBUS participant 83250302 1/2018-08 La 44-112 Installation and operating instruction Combustion Manager W-FM 50 5 Operation 5.3.3 Service level In the service level, parameter values can be displayed but not altered. Select parameter using [+] or [-] key. Press [Enter] 1 … 3 s. Parameter value appears. Parameters 954 960 121 922 Function Current flame signal in percent [ch. 3.2.9] Current fuel throughput Manual load Actuator step position 936 922.00: fuel actuator 922.01: air actuator Standardised speed 161 701 … 725 Current speed signal in percent Number of lockouts FaultHistory [ch. 8.1.3] 83250302 1/2018-08 La 45-112 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 6 Commissioning 6.1 Prerequisite Commissioning must only be carried out by qualified personnel. Only correctly carried out commissioning ensures the operational safety. Observe the prerequisites for commissioning in the installation and operating manual of the burner. This manual contains detailed information about: general installation regulations, nozzle selection, connecting measuring devices, replacing filter inserts, checking the gas connection pressure, carrying out soundness test, venting the gas valve train, setting the gas pressure regulator, pre-setting the pressure switch. 6.2 Adjusting the burner In addition to this chapter, the information about adjustment in installation and operating manual of the burner should be observed. This manual contains detailed information about: speeds (in in conjunction with frequency converter), pump pressure, flow and return pressure, default settings, mixing pressure. 83250302 1/2018-08 La 46-112 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 6.2.1 Adjusting gas side Prerequisite Open gas isolating valve. Pressure in gas valve train increases. Close isolating valve. Switch on voltage supply. The display shows either OFF UPr or OFF. S S P i P i V h min s % V h min s % burner off and not programmed burner off OFF UPr OFF 1. Enter password Press [F] and [A] simultaneously for approx. 2 seconds. The display shows CodE. Enter the first digit using [+] or [–] and confirm with [ENTER]. Repeat procedure until the password has been entered. Exit password entry using [ENTER]. The display shows PArA (parameter level) for a short time and then changes over to 400: SEt (setup). S P i V h min s %P i S S P i S V h min s % V h min s %P i V h min s % 2. Switch on burner Ensure there is a demand for heat. A black dash appears below the S symbol (start). A heat demand from the boiler controller is required for the duration of commissioning, that means signal on input X5-03:1. S P i V 83250302 1/2018-08 La 47-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 3. Start setup Press [ENTER]. If the combustion manager has been pre-programmed, the display shows run 1. Select type of setting (from step 9). If the combustion manager has not been programmed, the display shows parameter 201 2. Define parameters 201, 542 and 641 and set P0 (from step 4). 201: Operating mode 542: Activation of frequency converter 641: Speed standardisation S P i 1 S V h min s % V h min s % P i V h min s S % P i 2 4. Set operating mode The following steps must only be carried out if the combustion manager is not programmed. If the combustion manager has been pre-programmed, proceed with step 9. Press [ENTER]. The display shows only the parameter value. Set operating mode using [+] or [–] keys and confirm with [Enter]. 1: direct ignition 2: pilot ignition Exit entry using [esc]. The display shows parameter 201 with the current operating mode. S S P i P i V h min s % S % P i V S P i V 83250302 1/2018-08 La h min s % 48-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 5. Activate/deactivate frequency converter Press [+] key. The display shows parameter 542. Press [Enter]. The display shows only the parameter value. Activate or deactivate the frequency converter using [+] or [–] and confirm with [ENTER]. 0: without frequency converter 1: with frequency converter Exit entry using [esc]. The display shows parameter 542 with the current setting. S S P i P i V h min s S % % P i V h min s % S P i V h min s % 6. Carry out speed standardisation Speed standardisation must only be carried out in conjunction with a frequency converter. If no frequency converter is fitted, skip speed standardisation 641 using the [+] key. Press [+] key. The display shows parameter 641. Press [ENTER]. Set value to 1 using the [+] and start speed standardisation by pressing [ENTER]. Check rotation direction of burner motor The fan motor starts with open air damper setting. Once standardisation is complete, the display changes form 1 to 0. Exit speed standardisation using [esc]. The standardised speed can be read in parameter 642. S S S P i P i P i V h min s S % V S P i V 83250302 1/2018-08 La h min s % 49-112 S % P i h min % m 3 m 3/h l P i s % V h min s % l/h Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 7. Preset ignition load point Press [+] key. The display shows the ignition load point P0. press and hold [A] and using [+]/[–] set air damper setting 4.0 … 9.0. Press and hold [F] and set gas butterfly valve setting 8.0 … 13.0° using [+]/[–]. Only in conjunction with frequency converter The ignition speed must not be less than 70 %. Press and hold [A] and [F] (VSD) simultaneously and set speed using [+]/[–]. S P i S V h min s % P i S V h min s % P i S V h min s % P i h min s % S P i V h min s % 8. Preset full load point Press [+] key. The display shows the full load point P9. Press and hold [A] and using [+]/[–] set air damper setting from setting diagram. Press and hold [F] and set gas butterfly valve setting 45.0 … 50.0° using [+]/[–]. Only in conjunction with frequency converter Press and hold [A] and [F] (VSD) simultaneously and set speed to 100 % using [+]/[–]. Press [+] key. Exit pre-setting. The display changes to run. S P i S V h min s % P i S V h min s % P i S V h min s % P i V S P i V h min s % V h min s % S P i 83250302 1/2018-08 La 50-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 9. Select type of setting The following can be selected as type of setting: Adjustment with flame Pre-setting without flame Pre-setting without flame is only used, if the operating points are known, for example if the combustion manager is exchanged. Adjustment with flame 1 Press [Enter]. Check rotation direction of burner motor The burner starts pre-purge Ph12 and stops in ignition position Ph36 without flame formation. The display shows the ignition load point P0. Set mixing pressure in ignition position (from step 11). Pre-setting without flame 2 Briefly press [esc] key. The display shows the ignition load point P0. The black dash below the S symbol disappears. Pre-set operating points without flame (from step 10). S S 1 P i P i S V h min s % P i V h min s S % 2 V P i V 83250302 1/2018-08 La S % P i 51-112 h min s % h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 10. Pre-set points without flame This step must only be carried out, if the type of setting without flame has been selected previously. The adjustment with flame (from step 11) is not replaced by this process. Press [+] key. The display shows the operating point P1. Press and hold [A] and pre-set air damper setting using [+]/[–]. Press and hold [F] and pre-set gas butterfly valve setting using [+]/[–]. Only in conjunction with frequency converter Press and hold [A] and [F] (VSD) simultaneously and pre-set speed using [+]/ [–]. S P i S V h min s % P i S V h min s P i % S V h min s % P i V h min s % S P i V h min s % Press [+] key. The display shows CALC. The combustion manager starts the calculation. The display then shows the operating point P2. Set position air damper setting [A] and gas butterfly valve [F], with optional frequency converter also set speed [A] and [F] (VSD). Using the [+] key select and pre-set points P3 to P9 in sequence. S P i S P i S V h min s % P i S V h min s P i % S V h min s % P i V S P i V h min s % S S P i P i V 83250302 1/2018-08 La h min s % V 52-112 h min s % h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning Exit pre-setting using [esc]. The display shows 400 SEt. Press [ENTER]. The display shows run. Press [ENTER]. Check rotation direction of burner motor The burner starts pre-purge and stops in ignition position without flame formation. The display shows the ignition load point P0. S P i V h min s % S P i V h min s % S P i V h min s % 11. Check mixing pressure in ignition position The mixing pressure in ignition position must be 0.5 … 2 mbar above the combustion chamber pressure. If necessary, adjust mixing pressure via air damper setting: Only in conjunction with frequency converter The ignition speed must not be less than 70 %. Press and hold [A] and [F] (VSD) simultaneously and set speed using [+]/[–]. S P i S V h min s % P i S V h min s % P i V S P i V 83250302 1/2018-08 La h min s % 53-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 12. Check gas valves Press [+] key and ensure that the valves open and close correctly. The burner attempts to ignite. The low gas pressure switch reacts. After the interruption, the display shows OFF UPr. Open gas isolating valve. Press [ENTER], until the burner starts again. The display shows P0 again with the values set for mixing pressure in ignition position. 13. Igniting the burner Press [+] key. The burner starts and stops in ignition position. The display shows the following operating phases: PH 38: Ignition ON PH 40: Fuel valve Ph 42: Ignition OFF PH 44: Flame in ignition position S P i S P i V S P i % h V h S % V h P i S % V h min P i l % V h min s % 14. Adjust setting pressure on pressure regulator Check the setting pressure at the pressure regulator and if necessary adjust. 15. Check combustion Determine combustion values at ignition position. Set O2 content approx. 4 … 5 % above gas butterfly valve setting. 83250302 1/2018-08 La 54-112 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 16. Pre-set operating point P1 Press [+] key. The display shows the operating point P1. Pre-set gas throughput [F] and air quantity [A] whilst observing combustion values. Operating point P1 must lie below the partial load required and within the capacity graph. Only in conjunction with frequency converter Select speed in operating point P1 as low as possible, but not less than 50 %. Observe flame stability. Slowly reduce speed using [F] and [A] (VSD), whilst opening air damper setting alternately using the [A] key. Press [+] key. The display shows operating point P2. If no other points have been defined, the combustion manager carries out a calculation and calculates all missing points up to P9, the display briefly shows CALC. S P i S V h min s P i % S V h min s % P i S V h min s % P i V S m P i V h min s % S P i S V h min s % P i m V 83250302 1/2018-08 La 55-112 l h min l/h s % h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 17. Drive to full load Using the [+] key, drive to the points in sequence up to P9. Check combustion values at each point and if necessary correct via the gas butterfly valve setting [F]. S P i S V h min s P i % V h min % s S P i V h min s % S S P i P i V h min s % V h min s % 18. Adjust full load When adjusting, the ratings data given by the boiler manufacturer and the capacity graph of the burner should be observed. Only in conjunction with frequency converter Select speed at full load as low as possible, but not less than 80 %. Observe flame stability. Calculate gas throughput (operating volume VB) required [ch. 6.4]. Set gas butterfly setting [F] in full load point to approx. 60 … 70°. Adjust setting pressure at the pressure regulator until gas throughput (VB) is achieved. Check combustion values Determine combustion limit and set excess air [ch. 6.3]. Determine gas throughput again. If necessary adjust setting pressure at pressure regulator and reset excess air. The setting pressure must not be altered once this work has been completed. S P i S V h min s % P i S V h min s % P i S V h min s % P i V S P i V 83250302 1/2018-08 La h min s % 56-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 19. Re-define point 1 (only for ZMI) This step should only be carried out on burners in version ZMI. On burners of different version, skip this step and proceed with step 20. Drive to P1 using the [–] key. Reduce gas butterfly valve setting [F] until minimum burner rating has been achieved. Check combustion values and if necessary adjust whilst observing the minimum air damper setting [A]. Minimum air damper setting [A] Combustion head Combustion head CLOSED OPEN Natural Gas Without variable speed drive with VSD Liquid Petroleum Gas Without variable speed drive with VSD 0° 5° 3° 8° 0° 5° 8° 13° S P i S V h min s % P i S V h min s P i % V h min s % S P i V h min s % To achieve a constant operating behaviour, it is necessary to initiate a calculation from P9 to P1. Drive to P9 using the [+] key. Press [–] for approx. 4 seconds. The display shows CALC. Release [–] key. The combustion manager starts the calculation. The display then shows the operating point P8. S S P i P i V h min s % V h min P i S s % V Continue with Adjusting operating points (step 21). 83250302 1/2018-08 La 57-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 20. Initiate a calculation To achieve a constant operating behaviour, it is necessary to initiate a calculation from P9 to P1. Press [–] for approx. 4 seconds. The display shows CALC. Release [–] key. The combustion manager starts the calculation. The display then shows the operating point P8. S S P i P i V h min s % V h min P i S s % V h min s % 21. Adjusting the operating points If the [–] key is pressed again for more than 4 seconds, a calculation is started from the point shown to P1. Briefly press [–] key, to ensure points calculated or set are not overwritten. The operating points should only be adjusted via the fuel supply [F]. Changes to the air quantity influence the linearity, which has a negative effect on the load control and VSD. Check combustion values Press and hold [F] key and using [+]/[–] optimise combustion values. Optimise combustion values at each operating point, until P1 has been reached. S P i S V h min s % P i V h min s % S P i V h min s % S S P i P i V 83250302 1/2018-08 La 58-112 h min s % V h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 22. Define upper load limit (full load) Full load can be limited via parameter 546 . Exit setting mode using [esc]. The display shows 546 – – – –. Full load has not been defined, that means full load ≙ P9 (100 % load assignment). If full load is to be limited: Press [Enter]. The display shows only the parameter value. Set load limit using [+] or [–] and confirm with [ENTER]. Burner drives to value set. Exit entry using [esc]. The display shows 546 with the current upper load limit. S S P i P i S V h min s % % P i V h min s % S P i V h min s % 23. Define lower load limit (partial load) Partial load can be limited via parameter 545. When adjusting, the ratings data given by the boiler manufacturer and the capacity graph of the burner should be observed. Press [+] key. The display shows 545 – – – –. Partial load has not been defined, that means partial load ≙ P1. Press [Enter]. The display shows only the parameter value. Set load limit using [+] or [–] and confirm with [ENTER]. Burner drives to value set. Determine fuel throughput and if necessary adjust load limit. Exit entry using [esc]. The display shows 545 with the current lower load limit. S S P i P i S V h min s % % P i V S P i V 83250302 1/2018-08 La h min s % 59-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 24. Save points Exit level using [esc]. The display shows 400 SEt. Exit entry using [esc]. The display shows oP (Operate) with the current rating. S S P i S P i V h min s % P i V h min s % V h min s % 25. Check start behaviour Switch off and restart burner. Check start behaviour and if necessary correct ignition position. If the ignition position has been altered: Re-check start behaviour. 26. Carry out data backup Press keys [F] and [A] simultaneously. Select 000: Int using [-] key and confirm with [ENTER]. The display shows parameter 050.00: 0 Press [Enter]. The display shows bAC_up. Press [Enter]. Set 1 using [+] key and confirm with [ENTER]. Following successful data backup the display is reset to 0 . The values have been backed up from the combustion manager to the ABE. Exit levels using [esc]. 27. Set pressure switch and carry out concluding work For further details see burner installation and operating manual. 83250302 1/2018-08 La 60-112 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 6.2.2 Adjust modulation oil side Prerequisite Open oil shut off devices. Switch on voltage supply. The display shows either OFF UPr or OFF. S S P i P i V h min s % V h min s % burner off and not programmed burner off OFF UPr OFF 1. Enter password Press [F] and [A] simultaneously for approx. 2 seconds. The display shows CodE. Enter the first digit using [+] or [–] and confirm with [ENTER]. Repeat procedure until the password has been entered. Exit password entry using [ENTER]. The display shows PArA (parameter level) for a short time and then changes over to 400: SEt (setup). S P i V h min s %P i S S P i S V h min s % V h min s %P i V h min s % 2. Switch on burner Ensure there is a demand for heat. A black dash appears below the S symbol (start). A heat demand from the boiler controller is required for the duration of commissioning, that means signal on input X5-03:1. S P i V 83250302 1/2018-08 La 61-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 3. Start setup Press [ENTER]. If the combustion manager has been pre-programmed, the display shows run 1. Select type of setting (from step 9). If the combustion manager has not been programmed, the display shows parameter 201 2. Define parameters 201, 542 and 641 and set P0 (from step 4). 201: Operating mode 542: Activation of frequency converter 641: Speed standardisation S P i 1 S V h min s % V h min s % P i V h min s S % P i 2 4. Set operating mode The following steps must only be carried out if the combustion manager is not programmed. If the combustion manager has been pre-programmed, proceed with step 9. Press [ENTER]. The display shows only the parameter value. Set operating mode using [+] or [–] keys and confirm with [Enter]. 12: fuel oil EL modulating 23: medium and heavy oil modulating Exit entry using [esc]. The display shows parameter 201 with the current operating mode. S S P i P i V h min s % S % P i V S P i V 83250302 1/2018-08 La h min s % 62-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 5. Activate/deactivate frequency converter Press [+] key. The display shows parameter 542. Press [Enter]. The display shows only the parameter value. Activate or deactivate the frequency converter using [+] or [–] and confirm with [ENTER]. 0: without frequency converter 1: with frequency converter Exit entry using [esc]. The display shows parameter 542 with the current setting. S S P i P i V h min s S % % P i V h min s % S P i V h min s % 6. Carry out speed standardisation Speed standardisation must only be carried out in conjunction with a frequency converter. If no frequency converter is fitted, skip speed standardisation 641 using the [+] key. Press [+] key. The display shows parameter 641. Press [ENTER]. Set value to 1 using the [+] and start speed standardisation by pressing [ENTER]. Check rotation direction of burner motor The fan motor starts with open air damper setting. Once standardisation is complete, the display changes form 1 to 0. Exit speed standardisation using [esc]. The standardised speed can be read in parameter 642. S S S P i P i P i V h min s S % V S P i V 83250302 1/2018-08 La h min s % 63-112 S % P i h min % m 3 m 3/h l P i s % V h min s % l/h Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 7. Preset ignition load point Press [+] key. The display shows the ignition load point P0. The ignition load point P0 is factory preset, see burner data sheet. If values are available proceed with step 8. If the combustion manager is not programmed (e. g.. if it has been replaced) the air damper position and the position of the oil quantity regulator must be enter Press and hold [A] and using [+]/[–] set air damper setting. Press and hold [F] and using [+]/[–] set position of oil quantity regulator. Only in conjunction with frequency converter The ignition speed should be 100 %. Press and hold [A] and [F] (VSD) simultaneously and set speed to 100 % using [+]/[–] key. S P i S V h min s % P i S V h min s % P i S V h min s % P i h min S P i V 83250302 1/2018-08 La h min s % 64-112 s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 8. Preset full load point Press [+] key. The display shows the full load point P9. Press and hold [A] and using [+]/[–] set air damper setting from setting diagram, see burner installation and operating manual. Determine the position of the oil quantity regulator from the burner data sheet. Press and hold [F] and set value using [+]/[–] key. Only in conjunction with frequency converter Press and hold [A] and [F] (VSD) simultaneously and set speed to 100 % using [+]/[–]. Press [+] key. Exit pre-setting. The display changes to run. S P i S V h min s % P i S V h min s % P i S V h min s % P i V S P i V h min s % V h min s % S P i 83250302 1/2018-08 La 65-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 9. Select type of setting The following can be selected as type of setting: Adjustment with flame Pre-setting without flame Pre-setting without flame is only used, if the operating points are known, for example if the combustion manager is exchanged. Adjustment with flame 1 Press [Enter]. Check rotation direction of burner motor The burner starts pre-purge Ph12 and stops in ignition position Ph36 without flame formation. The display shows the ignition load point P0. Set mixing pressure in ignition position (from step 11). Pre-setting without flame 2 Briefly press [esc] key. The display shows the ignition load point P0. The black dash below the S symbol disappears. Pre-set operating points without flame (from step 10). S S 1 P i P i S V h min s % P i V h min s S % 2 V P i V 83250302 1/2018-08 La S % P i 66-112 h min s % h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 10. Pre-set points without flame This step must only be carried out, if the type of setting without flame has been selected previously. The adjustment with flame (from step 11) is not replaced by this process. Press [+] key. The display shows the operating point P1. Press and hold [A] and pre-set air damper setting using [+]/[–]. Press and hold [F] key and using [+]/[–] key preset position of oil quantity regulator. Only in conjunction with frequency converter Press and hold [A] and [F] (VSD) simultaneously and pre-set speed using [+]/ [–]. S P i S V h min s % P i S V h min s P i % S V h min s % P i V h min s % S P i V h min s % Press [+] key. The display shows CALC. The combustion manager starts the calculation. The display then shows the operating point P2. Set position air damper setting [A] and oil quantity regulator [F], with optional frequency converter also set speed [A] and [F] (VSD). Using the [+] key select and pre-set points P3 to P9 in sequence. S P i S P i S V h min s % P i S V h min s P i % S V h min s % P i V S P i V h min s % S S P i P i V 83250302 1/2018-08 La h min s % V 67-112 h min s % h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning Exit pre-setting using [esc]. The display shows 400 SEt. Press [ENTER]. The display shows run. Press [ENTER]. Check rotation direction of burner motor The burner starts pre-purge and stops in ignition position without flame formation. The display shows the ignition load point P0. S P i V h min s % S P i V h min s % S P i V h min s % 11. Check mixing pressure in ignition position The mixing pressure in ignition position must be 2 … 5 mbar above the combustion chamber pressure. If necessary, adjust mixing pressure via air damper setting: Only in conjunction with frequency converter The ignition speed should be 100 %. Press and hold [A] and [F] (VSD) simultaneously and set speed to 100 % using [+]/[–] key. S P i S V h min s % P i S V h min s % P i V S P i V 83250302 1/2018-08 La h min s % 68-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 12. Check pump pressure The pump pressure in ignition position must be approx. 1 … 2 bar less than that of the full load pressure, see burner data sheet. Check pump pressure at pressure gauge. Remove closing cap 1 (types T and TA only). Undo locknut 2 (types T and TA only). Set pump pressure using pressure regulating screw 3. increase pressure: clockwise rotation, decrease pressure: anticlockwise rotation. 3 3 1 + 1 3 2 2 3 13. Igniting the burner Press [+] key. The burner starts and stops in ignition position. The display shows the following operating phases: PH 38: Ignition ON PH 40: Fuel valve Ph 42: Ignition OFF PH 44: Flame in ignition position S P i S P i V S P i % h V h S % V h P i S % V h min P i l % V h min s % 14. Check combustion Determine combustion values at ignition position. Set O2 content of approx. 4 … 5 % by positioning the oil quantity regulator [F] whilst observing the return pressure. Fuel oil EL: min 6 … 8 bar Heavy oil: min 12 bar 83250302 1/2018-08 La 69-112 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 15. Pre-set operating point P1 Only in conjunction with frequency converter In oil operation, the speed should only be reduced so far, that the pump pressure set at full load does not fall by more than 15 %. Press [+] key. The display shows the operating point P1. Check combustion values and correct if necessary. Press [+] key. The display shows operating point P2. If no other points have been defined, the combustion manager carries out a calculation and calculates all missing points up to P9, the display briefly shows CALC. S P i S V h min s P i % S V h min P i s % S V h min s P i % V S h min s % m P i V h min s % S P i S V h min s m P i % V l h min l/h s % 16. Drive to full load Using the [+] key, drive to the points in sequence up to P9. Check combustion values at each point and correct via the position of the oil quantity regulator [F]. S P i S V h min s % P i V h min s % S P i V h min s % S S P i P i V 83250302 1/2018-08 La 70-112 h min s % V h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 17. Adjust full load When adjusting, the ratings data given by the boiler manufacturer and the capacity graph of the burner should be observed. Only in conjunction with frequency converter Select speed at full load as low as possible, but not less than 80 %. Observe flame stability. The burner has been factory pre-sized for a specific oil throughput, see burner data sheet. Set pump pressure and oil quantity regulator position to the data given on the burner data sheet. Determine oil throughput, if necessary adjust position of oil quantity regulator [F] until the oil throughput required is achieved. Check combustion values Determine combustion limit and set excess air [ch. 6.3]. S P i S V h min s % P i S V h min s P i % V S h min s % P i V h min s % The pump pressure must not be altered once this work has been completed. 18. Initiate a calculation To achieve a constant operating behaviour, it is necessary to initiate a calculation from P9 to P1. Press [–] for approx. 4 seconds. The display shows CALC. Release [–] key. The combustion manager starts the calculation. The display then shows the operating point P8. S S P i P i V h min s % V h min P i S s % V 83250302 1/2018-08 La 71-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 19. Adjusting the operating points If the [–] key is pressed again for more than 4 seconds, a calculation is started from the point shown to P1. Briefly press [–] key, to ensure points calculated or set are not overwritten. The operating points should only be adjusted via the fuel supply [F]. Changes to the air quantity influence the linearity, which has a negative effect on the load control and VSD. Check combustion values Press and hold [F] key and using [+]/[–] optimise combustion values. Optimise combustion values at each operating point, until P1 has been reached. S P i S V h min s P i % V h min s % S P i V h min % s S S P i P i V h min % s V h min s % 20. Define upper load limit (full load) Full load can be limited via parameter 546 . Exit setting mode using [esc]. The display shows 546 – – – –. Full load has not been defined, that means full load ≙ P9 (100 % load assignment). If full load is to be limited: Press [Enter]. The display shows only the parameter value. Set load limit using [+] or [–] and confirm with [ENTER]. Burner drives to value set. Exit entry using [esc]. The display shows 546 with the current upper load limit. S S P i P i S V h min s % % P i V S P i V 83250302 1/2018-08 La h min s % 72-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 21. Define lower load limit (partial load) Partial load can be limited via parameter 545. When adjusting, the ratings data given by the boiler manufacturer and the capacity graph of the burner should be observed. Press [+] key. The display shows 545 – – – –. Partial load has not been defined, that means partial load ≙ P1. Press [Enter]. The display shows only the parameter value. Set load limit using [+] or [–] and confirm with [ENTER]. Burner drives to value set. Determine fuel throughput and if necessary adjust load limit. Exit entry using [esc]. The display shows 545 with the current lower load limit. S S P i P i S V h min s % % P i V h min s % S P i V h min s % 22. Save points Exit level using [esc]. The display shows 400 SEt. Exit entry using [esc]. The display shows oP (Operate) with the current rating. S S P i S P i V h min s % P i V h min s % 23. Check start behaviour Switch off and restart burner. Check start behaviour and if necessary: correct ignition position, increase oil temperature at oil preheater. If the ignition position has been altered: Re-check start behaviour. If the oil temperature has been altered: Re-check start behaviour. Restart each point and check combustion values. 83250302 1/2018-08 La 73-112 V h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 24. Carry out data backup Press keys [F] and [A] simultaneously. Select 000: Int using [-] key and confirm with [ENTER]. The display shows parameter 050.00: 0 Press [Enter]. The display shows bAC_up. Press [Enter]. Set 1 using [+] key and confirm with [ENTER]. Following successful data backup the display is reset to 0 . The values have been backed up from the combustion manager to the ABE. Exit levels using [esc]. 25. Set pressure switch and carry out concluding work For further details see burner installation and operating manual. 83250302 1/2018-08 La 74-112 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 6.2.3 Adjust multi-stage oil side Only in conjunction with frequency converter When using a frequency converter please note: Ignition speed and speed in full load should be 100 %. It is recommended that the speed at the on and off switch points is 100 %. Speed at the operating points below full load must only be reduced so far as to ensure safe operating behaviour whilst: maintaining speed at 60 %, maintaining minimum pump pressure, see installation and operating manual of burner. Prerequisite Open oil shut off devices. Switch on voltage supply. The display shows either OFF UPr or OFF. S S P i P i V h min s % V h min s % burner off and not programmed burner off OFF UPr OFF 1. Enter password Press [F] and [A] simultaneously for approx. 2 seconds. The display shows CodE. Enter the first digit using [+] or [–] and confirm with [ENTER]. Repeat procedure until the password has been entered. Exit password entry using [ENTER]. The display shows PArA (parameter level) for a short time and then changes over to 400: SEt (setup). S P i V h min s %P i S S P i S V h min s % V h min s %P i V h min s % 2. Switch on burner Ensure there is a demand for heat. A black dash appears below the S symbol (start). A heat demand from the boiler controller is required for the duration of commissioning, that means signal on input X5-03:1. S P i V 83250302 1/2018-08 La 75-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 3. Start setup Press [ENTER]. If the combustion manager has been pre-programmed, the display shows run 1. Select type of setting (from step 9). If the combustion manager has not been programmed, the display shows parameter 201 2. Define parameters 201, 542 and 641 and set P0 (from step 4). 201: Operating mode 542: Activation of frequency converter 641: Speed standardisation S P i 1 S V h min s % V h min s % P i V h min s S % P i 2 4. Set operating mode The following steps must only be carried out if the combustion manager is not programmed. If the combustion manager has been pre-programmed, proceed with step 9. Press [ENTER]. The display shows only the parameter value. Set operating mode using [+] or [–] keys and confirm with [Enter]. 5: two stage 6: three stage Exit entry using [esc]. The display shows parameter 201 with the current operating mode. S S P i P i V h min s % S % P i V S P i V 83250302 1/2018-08 La h min s % 76-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 5. Activate/deactivate frequency converter Press [+] key. The display shows parameter 542. Press [Enter]. The display shows only the parameter value. Activate or deactivate the frequency converter using [+] or [–] and confirm with [ENTER]. 0: without frequency converter 1: with frequency converter Exit entry using [esc]. The display shows parameter 542 with the current setting. S S P i P i V h min s S % % P i V h min s % S P i V h min s % 6. Carry out speed standardisation Speed standardisation must only be carried out in conjunction with a frequency converter. If no frequency converter is fitted, skip speed standardisation 641 using the [+] key. Press [+] key. The display shows parameter 641. Press [ENTER]. Set value to 1 using the [+] and start speed standardisation by pressing [ENTER]. Check rotation direction of burner motor The fan motor starts with open air damper setting. Once standardisation is complete, the display changes form 1 to 0. Exit speed standardisation using [esc]. The standardised speed can be read in parameter 642. S S S P i P i P i V h min s S % V S P i V 83250302 1/2018-08 La h min s % 77-112 S % P i h min % m 3 m 3/h l P i s % V h min s % l/h Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 7. Preset ignition load point Only in conjunction with frequency converter The ignition speed should be 100 %. Press and hold [A] and [F] (VSD) simultaneously and set speed to 100 % using [+]/[–] key. Press [+] key. The display shows the ignition load point P0. Press and hold [A] and using [+]/[–] set air damper setting, see burner installation and operating manual. Press [+] key. Exit ignition load point pre-setting. The display changes to run. S P i S V h min s % P i S V h min s % P i V S P i V h min s % V h min s % S P i 83250302 1/2018-08 La 78-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 8. Select type of setting The following can be selected as type of setting: Adjustment with flame Pre-setting without flame Pre-setting without flame is only used, if the operating points are known, for example if the combustion manager is exchanged. Adjustment with flame 1 Press [Enter]. Check rotation direction of burner motor The burner starts pre-purge Ph12 and stops in ignition position Ph36 without flame formation. The display shows the ignition load point P0. Set mixing pressure in ignition position (from step 10). Pre-setting without flame 2 Briefly press [esc] key. The display shows the ignition load point P0. The black dash below the S symbol disappears. Pre-set operating points without flame (from step 9). S S 1 P i P i S V h min s % P i V h min s S % 2 V P i V 83250302 1/2018-08 La S % P i 79-112 h min s % h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 9. Pre-set points without flame This step must only be carried out, if the type of setting without flame has been selected previously. The adjustment with flame (from step 10) is not replaced by this process. Using [+] key select and pre-set the following points in sequence: Point 1 (ignition stage) Switch point from P1 to P2 Operating point 2 Switch point from P2 to P3 (only with three stage operation) Operating point 3 (only with three stage operation) P1 P2on P2 P3on P3 Press and hold [A] and pre-set air damper setting using [+]/[–]. S P i S V h min s % P i V h min s % S P i V h min s % V h min s % S P i Using [–] key select and pre-set the following points: Switch point from P3 to P2 Switch point from P2 to P1 P3oF P2oF Press and hold [A] and pre-set air damper setting using [+]/[–]. Exit pre-setting using [esc]. The display shows 400 SEt. Press [Enter]. The display shows run. Press [Enter]. The burner starts pre-purge and stops in ignition position without flame formation. The display shows the ignition load point P0. S P i V S P i V S P i V S P i V 83250302 1/2018-08 La h min s % 80-112 h min s % h min s % h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 10. Check mixing pressure in ignition position The mixing pressure in ignition position must be 2 … 5 mbar above the combustion chamber pressure. If necessary, adjust mixing pressure via air damper setting: S P i S V h min s % P i S V h min s % P i V h min s % S P i V h min s % 11. Check pump pressure The pump pressure must be set according to the nozzle selected. Check pump pressure at pressure gauge. Remove closing cap 1 (types T and TA only). Undo locknut 2 (types T and TA only). Set pump pressure using pressure regulating screw 3. increase pressure: clockwise rotation, decrease pressure: anticlockwise rotation. 3 3 1 + 1 3 83250302 1/2018-08 La 81-112 2 2 3 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 12. Igniting the burner Press [+] key. The burner starts and stops in ignition position. The display shows the following operating phases: PH 38: Ignition ON PH 40: Fuel valve Ph 42: Ignition OFF PH 44: Flame in ignition position Check pump pressure. Check combustion values Standard: approx. 5 % O2 content 3LN (multiflam): approx. 4 … 4.5 % O2 content If necessary adjust air damper setting whilst observing the mixing pressure. S P i S P i V h S P i % V S P i % h V h S % V h min P i l % V h min s % 13. Adjusting operating point P1 Press [+] key. The display shows point P1. If P1 has not been pre-set, the values from P0 are adopted for P1 . Pre-set air damper setting [A] whilst observing the combustion values. S P i V h Pl i S l/h % S m 3 m h min P i V s % s % h min 14. Determine switch point P2on Press [+] key. The display shows P2on. Valve operating point 2 remains closed. If P2on has not been pre-set, the values from P1 are adopted for P2on . Set excess air (O2 content approx. 7 %) via air damper setting [A] whilst observing flame stability. S P i V h Pl i S l/h % S m 3 m h min P i V 83250302 1/2018-08 La 82-112 h min s % s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 15. Set pre-set point P2_d Press [+] key. The display shows the pre-set point P2_d. Valve operating point 2 remains closed. Pre-set air damper setting [A] expected for the operating point P2 . The value is not activated yet. The pre-set point reduces insufficient air during the activation of operating point P2. S P i V h S l/h % Pl i S m 3 m h min P i V h min s % % s 16. Activate operating point P2 Press [+] key. The display shows P2. Valve operating point 2 opens. The preset air damper setting from P2_d is activated. Pre-set air damper setting [A] whilst observing the combustion values. S P i V h Pl i S l/h % S m 3 m h min P i V h min s s % % 17. Adjust full load When adjusting, the ratings data given by the boiler manufacturer and the capacity graph of the burner should be observed. Repeat procedure for three stage operation: switch point P3on (step 14), pre-set point P3_d (step 15), operating point P3 (step 16). S S S P i P i V h min s % P i V h min s % V h min s % Determine fuel throughput and if necessary adjust pump pressure. Check combustion values Determine combustion limit and set excess air [ch. 6.3]. The pump pressure must not be altered once this work has been completed. 83250302 1/2018-08 La 83-112 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 18. Initiate partial load Press [–] key. The display shows switch point P3oF. The switch point determines, at which air damper setting the valve of the stage above closes. The point itself can not be activated. Adapt air damper setting [A]. The switch point must lie minimum 5° above the switch point of the respective stage. Press [–] key and observe switch off behaviour. Check combustion values in operating point P2 . Set excess air via air damper setting [A], do not alter fuel pressure in the process. Repeat procedure for operating point P1. S P i V h Pl i S l/h % S m 3 m h min P i V h min s s % % S S P i P i V h min s % V h min % s 19. Check operating behaviour Activate operating points several times using the [+] and [–] keys and observe the switch-over behaviour. If the flame is unstable or a pressure surge occurs: Decrease air damper setting [A] in the change-over point. If soot or CO is formed: Increase air damper setting [A] in the change-over point. 20. Save points The operating point P1 must be activated once, otherwise the display shows OFF UPr when exiting commissioning and the combustion manager remains unprogrammed. Activate operating point P1 . Press [esc] twice. The display shows oP (Operate) and an operating point. S S P i V 83250302 1/2018-08 La S P i h min s % P i V 84-112 h min s % V h min s % Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 21. Check start behaviour Switch off and restart burner. Check start behaviour and if necessary: correct ignition position, increase oil temperature at oil preheater. If the ignition position has been altered: Re-check start behaviour. If the oil temperature has been altered: Re-check start behaviour. Restart each point and check combustion values. 22. Carry out data backup Press keys [F] and [A] simultaneously. Select 000: Int using [-] key and confirm with [ENTER]. The display shows parameter 050.00: 0 Press [Enter]. The display shows bAC_up. Press [Enter]. Set 1 using [+] key and confirm with [ENTER]. Following successful data backup the display is reset to 0 . The values have been backed up from the combustion manager to the ABE. Exit levels using [esc]. 23. Set pressure switch and carry out concluding work For further details see burner installation and operating manual. 83250302 1/2018-08 La 85-112 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 6.3 Check combustion Determine excess air Slowly close air damper(s) in the relevant operating point, until the combustion limit is reached (CO content approx. 100 ppm or smoke number approx. 1). Measure and document O2 content. Read air number (λ). Increase air number to ensure sufficient excess air: by 0.15 … 0.2 (equates to 15 … 20 % excess air), by more than 0.2 for more difficult conditions, such as: dirty combustion air, fluctuating intake temperature, fluctuating chimney draught. Example λ + 0.15 = λ* Set air number (λ*), do not exceed CO content of 50 ppm. Measure and document O2 content. Check flue gas temperature Check flue gas temperature. Ensure that the flue gas temperature complies with the data provided by the boiler manufacturer. If necessary adjust flue gas temperature, e g.: Increase burner capacity in partial load to avoid condensation in the flue gas ducts, except on condensing units. Reduce burner capacity in full load to improve efficiency. Adjust heat exchanger to the data provided by the manufacturer. Determine flue gas losses Drive to full load. Measure combustion air temperature (tL) near the air damper(s). Measure oxygen content (O2) and flue gas temperature (tA) at the same time at one point. Determine flue gas losses using the following formula: qA = qA tA tL O2 83250302 1/2018-08 La (tA - tL ) ( A2 )+B 21- O2 Flue gas losses [%] Flue gas temperature [°C] Combustion air temperature [°C] Volumetric content of oxygen in dry flue gas [%] Fuel factors Natural Gas A2 B 0.66 0.009 86-112 Liquid Petroleum Fuel oil Gas 0.63 0.68 0.008 0.007 Installation and operating instruction Combustion Manager W-FM 50 6 Commissioning 6.4 Calculate gas throughput Formula symbol VB f QN η Hi Explanation Operating volume [m3/h] Volume measured at gas meter at current pressure and temperature (gas throughput). Standard volume [m3/h] Volume gained by gas at 1013 mbar and 0 °C. Conversion factor Heat rating [kW] Boiler efficiency (e. g. 92 % ≙ 0.92) Calorific value [kWh/m3] at 0 °C and 1013 mbar tGas PGas PBaro VG TM Gas temperature at gas meter [°C] Pressure at gas meter [mbar] Barometric air pressure [mbar], see table Gas throughput determined at gas meter Measuring time [seconds] VN Example values – – – 6000 kW 0.92 10.35 kW/m3 (Natural Gas E) 10 °C 250 mbar 500 m ≙ 955 mbar 18.2 m³ 120 seconds Calculate normal volume Calculate the normal volume (VN) using the following formula. QN VN = η VN = Hi 6000 kW = 630.1 m³/h 0.92 10.35 kW/m³ Calculate conversion factor Determine gas temperature (tGas) and pressure (PGas) at gas meter. Determine barometric air pressure (PBaro) from table. Height 0 100 200 above sea level [m] PBaro 1013 1001 990 [mbar] 300 400 500 600 700 800 900 1000 1100 1200 1300 978 966 955 943 932 921 910 899 888 877 866 Calculate conversion factor (f) using the following formula. f= PBaro + PGas 1013 273 273 + tGas f= 955 + 250 273 = 1.148 1013 273 + 10 Calculate operating volume (gas throughput) required VB = VN f VB = 630.1 m³/h = 548.9 m³/h 1.148 Determine current operating volume (gas throughput) Measure gas throughput (VG) at gas meter, measuring time (TM) should be a minimum of 60 seconds. Calculate operating volume (VB) using the following formula. VB = 83250302 1/2018-08 La 3600 VG TM 87-112 VB = 3600 18.2 m³ = 546.0 m³/h 120 s Installation and operating instruction Combustion Manager W-FM 50 7 Servicing 7 Servicing 7.1 Notes on servicing DANGER DANGER Risk of explosion due to leaking gas Improper service work can lead to escaping gas and explosion. Close fuel shut off devices prior to starting work. Care should be taken when dismantling and assembling gas carrying components. Close the screws on the test points ensuring the tests points are sealed. Risk of electric shock Working on the device when voltage is applied can lead to electric shock. Isolate the device from the power supply prior to starting any work. Safeguard against accidental restart. Danger of getting burned on hot components Hot components can lead to burns. Allow components to cool. WARNING Servicing must only be carried out by qualified personnel. The combustion plant should be serviced annually. Depending on site conditions more frequent checks may be required. Components, which show increased wear and tear or whose design lifespan is or will be exceeded prior to the next service should be replaced as a precaution. The design lifespan of the components is listed in the service plan [ch. 7.2]. Weishaupt recommends a service contract is entered into to ensure regular inspections. The following components must only be replaced and must not be repaired: combustion manager flame sensor actuator gas valve oil solenoid valve nozzle head (shut off needle), pressure regulator pressure switch Prior to every servicing Inform the operator about the extent of service work to be carried out. Switch off mains switch of installation and safeguard against accidental reactivation. Close fuel shut off devices. 83250302 1/2018-08 La 88-112 Installation and operating instruction Combustion Manager W-FM 50 7 Servicing Following servicing Check tightness of oil and gas carrying components. Check function of: adjustable mixing head, ignition, flame monitoring, gas carrying components (gas connection pressure and setting pressure), oil pump (pump pressure and suction resistance), pressure switch Check control and safety devices. Check combustion values, if necessary re-adjust the burner. Enter combustion values and settings in the commissioning record and/or test sheet. 7.2 Service plan For detailed information see installation and operating manual of burner. 83250302 1/2018-08 La 89-112 Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting 8 Troubleshooting 8.1 Procedures for fault conditions Check prerequisites for operation: Voltage supply available. Heating switch is set to On. The combustion manager recognises irregularities of the burner and displays these on the display and operating unit (ABE). The following conditions can occur: Display OFF [ch. 8.1.1] Display OFF S [ch. 8.1.2] Fault [ch. 8.1.3] Lockout [ch. 8.1.4] 8.1.1 Display OFF The following faults may be corrected by the operator: Fault Cause Rectification Burner not operating Temperature regulator or pressure reguAdjust temperature regulator or preslator on heat exchanger has been set insure regulator on heat exchanger. correctly Boiler or heating circuit control is not Check function and setting of boiler functioning or has not been set correctly or heating circuit control. 8.1.2 Display OFF S The following faults may be corrected by the operator: Fault Cause Safety circuit open Temperature limiter or pressure limiter on heat exchanger has triggered(1 Low water safety interlock on heat exchanger has triggered(1 Rectification Reset temperature limiter or pressure limiter on heat exchanger. Top up water. Reset low water safety interlock on heat exchanger. (1 Notify your heating contractor or Weishaupt Customer Service if the problem occurs repeatedly. 83250302 1/2018-08 La 90-112 Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting 8.1.3 Fault If a fault occurs, the combustion manager initiates a controlled shutdown. The display and operating unit alternates between Err.c: (error code) and Err.d: (diagnostic code). The burner restarts automatically as soon as the fault condition has been rectified. Example Faults must only be rectified by qualified personnel. Read the fault code and proceed according to the fault message [ch. 8.3]. 8.1.4 Lockout If a lockout condition occurs, the combustion manager initiates a fault shutdown and burner lockout. The display and operating unit alternates between Loc.c: (error code) and Loc.d: (diagnostic code). Once the fault has been rectified, the combustion manager has to be reset for restart. Example Lockouts must only be rectified by qualified personnel. Read the fault code and proceed according to the fault message [ch. 8.3]. Resetting WARNING Damage resulting from incorrect fault repair Incorrect fault repair can cause damage to the equipment and injure personnel. Do not carry out more than 2 lockout resets successively. Faults must be rectified by qualified personnel. If the ABE displays a fault: Press [Enter] for approx. 2 seconds. rESEt is displayed. Release key. The burner has been reset. Exchanging the unit If the combustion manager or the ABE are replaced: Select and check fault history and lockout history and include a copy when returning the unit for exchange. 83250302 1/2018-08 La 91-112 Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting 8.2 Fault history The combustion manager stores the last 25 faults and lockouts in the fault history (parameter 700), 701 is the fault, which occurred last. The fault history can be called up in the service level or password level. Display faults Select service level or password level [ch. 5.2] Select parameter 700 using the [+] key and confirm with [Enter] (password level only). Select faults in sequence using [+] or [–] key. press [Enter] (press service level 1 … 3 s). Fault level flashes. Select fault level in sequence using [+] or [–] key. If fault levels 05 and 06 show ·-·- in the display: press [Enter] (press service level 1 … 3 s). Value is displayed. S P i V h min s % S S P i P i V h min s V % h min s % S S P i P i V Parameters Level 701 01 02 … 03 725 04 05 06 83250302 1/2018-08 La h min s % V h min s % Definition Fault codes Diagnostic code Fault class (arranges faults by priority) Operating phase Start-up counter 0: Lockout, highest priority 1: Safety shut down with software reset 2: Low voltage 3: Safety shut down in safety phase 4: Safety shutdown start prevention 5: Safety shutdown shutdown 6: Signal without switch off reaction Operating phase at time of fault [ch. 3.1.8]. Number of start-ups at time of fault. Rating Press [Enter] to display. Load at time of fault. Press [Enter] to display. 92-112 Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting Delete faults Only the fault history in the service level can be deleted. The fault history in the password level is not affected by the deleting process. Enter password [ch. 5.2.1]. Select parameter 130. Press [Enter]. The display shows value 0. Set value to 1 within 3 seconds using [+] key, confirm with [Enter] key, then set value to 2 and confirm again with [Enter] key. When the display changes to 0 the delete process has been completed. If the display shows -1 the duration of 3 seconds was exceeded and the delete process was aborted. S S P i P i S V h min s % P i V h min s % V h min s % V h min s % S P i 3s S P i V 83250302 1/2018-08 La 93-112 h min s % Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting 8.3 Rectifying faults Fault code Diagnostic codes 1 2 Cause 0 No air pressure switch signal from operating phase PH24 1 4 0 1 2 0 Air pressure switch signal prior to operating phase Ph22 Air pressure switch signal prior to start-up Flame signal during pre-purge Flame signal during shutdown Flame signal during start-up Loss of flame 3 … 255 Flame failure due to TÜV test 12 81 83 Valve proving V1 leaking Valve proving V2 leaking 14 20 0 1 64 0 POC open POC closed POC open prior to start-up Low pressure switch has reacted 21 1 0 Low gas programme [ch. 3.1.2] High pressure switch has reacted 22 0 1 50 … 67 # Safety circuit / burner flange open Safety circuit / burner flange open during start-up Internal fault 70 23 26 0 1 2 3 # Load invalid Modulating curve point undefined Standby position undefined Pre-purge position undefined Post-purge position undefined Ignition position undefined Internal fault – 23 26 Load invalid Multi-stage curve points undefined – 2 3 4 7 71 72 73 83250302 1/2018-08 La Rectification No flame signal in operating phase Ph44 No flame signal in operating phase Ph52 94-112 Check flame sensor (soiled, defective, signal strength…) Correct ignition load point Check air pressure switch (setting, connection) Clean fan wheel and air guide Check pressure and negative pressure hoses Check air pressure switch Check flame sensor Check flame sensor (soiled, defective, signal strength…) Check fuel supply Check combustion Duration of fuel values closed to flame failure. Solution: 0.2 s (value 5 = 1 s) Check valve proving pressure switch [ch. 3.1.3] Check solenoid valve Check valve closing contact (function, connection) Check low pressure switch Check fuel supply Check gas supply Check high pressure switch Check fuel supply Check safety devices Replace combustion manager if fault reoccurs Set curve points for all actuators Set special positions for all actuators Replace combustion manager if fault reoccurs Set curve points for all actuators Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting Fault code 76 Diagnostic codes 1 2 4 16 # 80 1 75 2 Cause Rectification Current load incorrect Target load incorrect Target position incorrect Different positions reached Internal fault – – – Repeat standardisation Replace combustion manager if fault reoccurs Combustion manager was unable to cor- Combustion manager has not been standrect speed deviations and has reached the ardised for this motor lower regulating limit. Frequency converter Repeat standardisation speed to high. The ramp times of the frequency converter Combustion manager was unable to cor- are longer than those of the combustion rect speed deviations and has reached the manager. upper regulating limit. Frequency conCheck ramp times (parameter 522, verter speed too low. 523). The reference line of the frequency converter is not linear: Adjust combustion manager/frequency converter control signal (parameter 645). 81 1 83250302 1/2018-08 La Interference impulses on sensor line speed input 95-112 Frequency converter reacts too slowly: Check frequency converter settings (inlet filter, slip compensation, fade-out of different speeds). Optimise EMC measures. Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting Fault code 82 Diagnostic codes 1 Cause 2 3 Repeat standardisation Check the connection Check distance speed sensor / transmitter disc. Motor did not reach stable speed during The ramp times of the frequency converter start. are longer than those of the combustion Frequency converter run-up time too long. manager. Check ramp times (parameter 522, Speed below minimum limit for standard523). isation. The reference line of the frequency converter is not linear: Adjust combustion manager/frequency converter control signal (parameter 645). 4 Rectification Ramp time during run down during standardisation too short Standardised speed not saved No speed signal Increase ramp time (parameter 523). Frequency converter reacts too slowly: Check frequency converter settings (inlet filter, slip compensation, fade-out of different speeds). 5 6 7 15 20 21 22 23 24 128 255 83250302 1/2018-08 La Speed of frequency converter is below the minimum standardised speed (650 rpm) Increase speed of frequency converter. Incorrect rotation direction Check rotation direction. Check installation of transmitter disc. Impulse pattern (60°, 120°, 180°) incorCheck the connection rect, interference impulses on the sensor Check distance speed sensor / transmitter disc. line Optimise EMC measures. Standardised speed is not within the per- – mitted range Speed deviation between micro controlRepeat standardisation ler 1 und micro controller 2 Standardisation in incorrect operating Switch off heat demand and repeat phase standardisation. Safety circuit / burner flange open during Repeat standardisation standardisation. Air actuator not referenced Check actuator. Frequency converter deactivated Activate frequency converter and repeat standardisation. Standardisation started without valid operCheck operating mode (parameter ating mode 201, 301) and repeat standardisation. Frequency converter is activated, but is Carry out standardisation. not standardised. Motor is rotating, but is not standardised Carry out standardisation. 96-112 Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting Fault code 83 Diagnostic codes 1 2 … 3 4… 7 8 … 15 Cause Rectification Speed not achieved, lower control limit Rectification see error code 80. was activated Speed not achieved, upper control limit Rectification see error code 80. was activated Aborted due to interference impulses on Optimise EMC measures. sensor line Modulating operation: Curve gradient freCheck ramp times (parameter 522, quency converter too steep (speed not 523). achieved) Depending on the ramp time (parameter 522, 523), the speed alteration between two operating points must not exceed a specific percentage. 84 16 … 31 10 % at 20 s 20 % at 10 s 40 % at 5 s No speed signal 32 … 63 Speed deviation too high 1 Modulating operation: Curve gradient frequency converter too steep Check the connection Check distance speed sensor / transmitter disc. Check ramp times (parameter 522, 523). Check ramp times (parameter 522, 523). Depending on the ramp time (parameter 522, 523), the speed alteration between two operating points must not exceed a specific percentage. 10 % at 20 s 20 % at 10 s 40 % at 5 s 2 … 3 85 86 Modulating operation: Curve gradient fuel actuator too steep 4 … 7 Modulating operation: Curve gradient air actuator too steep 0 Fuel actuator referencing error 1 Air actuator referencing error 128 … 255 Parameter settings of one actuator have been changed. 0 Position error fuel actuator 1 Fuel actuator line break 8 16 … 255 83250302 1/2018-08 La The position change between two operating points must not exceed maximum 31°: Adjust operating points. Check, if actuators have been mixed up. Check, if actuator is blocked. – Check, if actuator is blocked. min 0.5 V between Pin 5 and 2 or 6 and 2: Check wiring Modulating operation: Curve gradient fuel The position change between two operatactuator too steep ing points must not exceed maximum 31°: Adjust operating points. Fuel actuator overloaded or mechanically Check, if actuator is blocked. twisted 97-112 Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting Fault code 87 Diagnostic codes 0 1 Cause Rectification Position error air actuator Air actuator line break 8 Modulating operation: Curve gradient air actuator too steep 16 … 255 Check, if actuator is blocked. min 0.5 V between Pin 5 and 2 or 6 and 2: Check wiring The position change between two operating points must not exceed maximum 31°: Adjust operating points. Check, if actuator is blocked. 90 … 91 # Air actuator overloaded or mechanically twisted Internal fault 93 3 Flame sensor short circuit 95 # 3 4 5 6 # 3 4 5 6 External voltage relay contact (internal) Ignition unit Fuel valve 1 Fuel valve 2 Fuel valve 3 Relay contact fused (internal) Ignition unit Fuel valve 1 Fuel valve 2 Fuel valve 3 96 97 0 98 # 2 3 4 5 6 # 99 … 100 83250302 1/2018-08 La Safety relay fused (internal) or external voltage applied to safety relay Relay does not activate (internal) Safety valve Ignition unit Fuel valve 1 Fuel valve 2 Fuel valve 3 Internal fault relay activation 98-112 Replace combustion manager if fault reoccurs Check flame sensor Check wiring Check flame sensor Check wiring Check relay contact: Apply voltage. Output X3-05:1 must be de-energised. Switch off voltage and unplug plug X3-05. No ohmic connection must exist between output X3-05:1 and input X3-04:4 (N). If a criteria is not met: Replace combustion manager Rectification see error code 96. Replace combustion manager if fault reoccurs Replace combustion manager if fault reoccurs Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting Fault code Diagnostic codes 105 # 0 1 2 3 4 5 6 7 8 9 10 11 12 13 106 … 110 # Cause Rectification Internal fault contact interrogation Minimum pressure switch Max. pressure switch Valve proving pressure switch Air pressure switch Load controller OPEN Load controller ON / OFF Load controller CLOSED Safety circuit / burner flange Safety valve Ignition unit Fuel valve 1 Fuel valve 2 Fuel valve 3 Reset Internal fault Can be caused by capacitive loads or direct current feed at the inputs. The input, at which the fault occurred is displayed with diagnostic code. 111 # 112 # 113 … 115 # Mains frequency too low Voltage return Internal fault 116 117 120 121 … 124 Operating cycle lifespan exceeded Lifespan exceeded Interference impulses on fuel meter input Internal fault – No fault Replace combustion manager if fault reoccurs Replace combustion manager Replace combustion manager Optimise EMC measures. Reset parameters or reset data using Restore. Replace combustion manager if fault reoccurs Reset parameters. Replace combustion manager if fault reoccurs Reset parameters or reset data using Restore. Replace combustion manager if fault reoccurs Replace combustion manager if fault reoccurs Reset parameters. Replace combustion manager if fault reoccurs Replace combustion manager if fault reoccurs Reset parameters. Replace combustion manager if fault reoccurs No fault # # 0 # 125 … 126 # Internal fault 127 # Internal fault 128 0 Internal fault 129 … 131 # Internal fault 132 # Internal fault 133 … 135 # Internal fault 136 Restore started 1 83250302 1/2018-08 La 99-112 Replace combustion manager if fault reoccurs Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting Fault code 137 Diagnostic codes 255 (-1) 254 253 252 251 (-2) (-3) (-4) (-5) 250 (-6) 249 (-7) 248 (-8) 247 (-9) 246 (-10) 245 (-11) 244 (-12) 243 (-13) 242 (-14) 241 (-15) 240 (-16) 239 (-17) 157 (-99) 146 150 1 2 1 (-1) 2 (-2) 3 (-3) 4 (-4) 5 (-5) 165 … 166 # 83250302 1/2018-08 La Cause Rectification Aborted due to Time-out during Backup / Restore or ABE does not have this function. Aborted due to transfers error Restore cannot be carried out at present Restore incomplete No burner identification Backup data set invalid, Restore not possible Backup has unsuitable burner identification and must not be uploaded. Restore cannot be carried out at present Backup data set invalid, Restore not possible Aborted due to Time-out during Restore Access error Restore Software version and Backup data set not compatible, Restore not possible Backup data comparison between the micro controllers incorrect Backup is incorrect and cannot not reloaded Backup contains unsuitable ASN and must not be uploaded No Backup in ABE Backup memory in ABE faulty Restore successful, however Backup data less than in current system Modbus Time-out eBUS Time-out TÜV test in invalid operating phase Check the connection Repeat Backup / Restore. Replace ABE. Repeat Backup / Restore. Define burner identification (parameter 113). – – Repeat Backup / Restore. – Repeat Backup / Restore. – Repeat Backup / Restore. – – – Repeat Backup / Restore. – – – Start TÜV test in operating phase Ph60 Adjust load and repeat TÜV Test. Load during TÜV test less than lower load limit (parameter 545) Load during TÜV test higher then upper load limit (parameter 546) Manual abort TÜV test No fault No flame failure after fuel valves have shut Check for extraneous light. down Check wiring Check soundness of valves. Internal fault – 100-112 Installation and operating instruction Combustion Manager W-FM 50 8 Troubleshooting Fault code Cause Rectification Manual lockout by contact Manual lockout by ABE Manual lockout by PC-Tool Communication between W-FM and ABE was interrupted during curve setting Communication between W-FM and PCTool was interrupted during curve setting Reset attempt by PC-Tool Internal fault No fault – System fault free No operating mode selected No fuel supply defined No curves defined Standardised speed undefined Backup / Restore was not possible Internal fault operating mode setting – – – – – – 202 # 1 2 … 3 4 … 7 8 … 15 16 … 31 # 203 # Internal fault operating mode setting 204 24 … 52 Program stop is activated. Operating phase is shown in diagnostic code. 205 # Internal fault 206 0 Impermissible unit combination (combus- – tion manager - ABE) Combustion manager version too old – ABE version too old – Internal fault Replace combustion manager if fault reoccurs Impermissible operating mode Redefine operating mode (parameter 201). Internal fault Replace combustion manager if fault reoccurs 167 Diagnostic codes 1 2 3 8 9 33 168 … 171 # 200 201 207 0 1 208 … 209 # 210 0 240 … 250 # 83250302 1/2018-08 La 101-112 – – – Replace combustion manager if fault reoccurs Redefine operating mode (parameter 201). Redefine operating mode (parameter 201). Replace combustion manager if fault reoccurs Deactivate program stop (parameter 208). Replace combustion manager if fault reoccurs Installation and operating instruction Combustion Manager W-FM 50 9 Technical documentation 9 Technical documentation 9.1 Frequency converter Detailed information see Frequency converter CD. The construction and arrangement of diagnostic LEDs is dependent on the size of the frequency converter. 9.1.1 Frequency converter Nord size I … III 1 2 3 1 2 3 1 2 ON 1 Interfaces 2 DIP switches 3 Diagnostic LED's Interface The interface is used to access the frequency converter via a PC. The Software required can be found on the Frequency Converter CD. A connection cable RJ12 to SUB-D9 is required for the connection (Order No. 743 361). A readily available USB interfaces converter USB to RS232 is also required for the connection to the USB port. DIP switches The analogue inputs AIN1 and AIN2 are configured via setting of the DIP switches. Factory setting (2 … 10 V): Switch 1: OFF Switch 2: OFF 83250302 1/2018-08 La 102-112 Installation and operating instruction Combustion Manager W-FM 50 9 Technical documentation Diagnostic LED's LED 1 (BUS-S) 2 (BUS-E) 3 (DS) Signal – – OFF Green Flashing green 0.5 Hz(1 4 Hz(1 Flashing red/green 4 Hz(1 1 … 25 Hz(1 Flashing red Number ≙ flashing codes (1 1 Hz ≙ once per second 83250302 1/2018-08 La 103-112 Description System bus status (not used) System bus fault (not used) No mains voltage and no control voltage Operation, FC operating Ready for operation Start blocked Warning Intensity overload Fault, flashing codes see Frequency converter CD Installation and operating instruction Combustion Manager W-FM 50 9 Technical documentation 9.1.2 Frequency converter Nord size IV 1 2 3 2 3 4 1 9 0 8 5 7 6 B A 1 Interfaces 2 Diagnostic LED's 3 Status LED's Interface The interface is used to access the frequency converter via a PC. The Software required can be found on the Frequency Converter CD. A connection cable RJ12 to SUB-D9 is required for the connection (Order No. 743 361). A readily available USB interfaces converter USB to RS232 is also required for the connection to the USB port. Diagnostic LED's LED 1 (DOUT1 ) Signal yellow 2 (DOUT2) 3 (BRAKE) 4 (TEMP) 5 (DIN4) 6 (DIN3) 7 (DIN2) 8 (DIN1) yellow yellow yellow yellow yellow yellow yellow 9 (BUS-S) OFF Green Flashing green OFF Flashing red red 0 (BUS-E) 83250302 1/2018-08 La Description Alarm from frequency converter (digital output 1) Signal at digital output 2 Mechanical brake Excess temperature at motor Signal at digital input 4 Signal at digital input 3 Signal at digital input 3 Frequency converter start release (digital input 1) No Bus communication (system bus) Bus communication Bus warning System bus is operating correctly Monitoring fault No system bus 104-112 Installation and operating instruction Combustion Manager W-FM 50 9 Technical documentation Status LED's LED A (AS-i) B (DS) Signal – OFF Green Green ON + red flashing 0.5 Hz(1 4 Hz(1 Flashing red/green 4 Hz(1 1 … 25 Hz(1 Flashing red Number ≙ flashing codes Flashing green (1 1 Hz ≙ once per second 83250302 1/2018-08 La 105-112 Description Status AS interface (not used) No mains voltage and no control voltage Operation, FC operating Frequency converter not ready for operation, control voltage applied but no mains voltage Ready for operation Start blocked Warning Intensity overload Fault, flashing codes see Frequency converter CD Installation and operating instruction Combustion Manager W-FM 50 10 Spares 10 Spares 1.01 1.03 1.04 1.02 83250302 1/2018-08 La 106-112 Installation and operating instruction Combustion Manager W-FM 50 10 Spares Pos. 1.01 1.02 1.03 1.04 83250302 1/2018-08 La Description ABE for W-FM 50/54 Plug cable ABE-W-FM 50 –2m – 10 m Combustion manager W-FM50 230 V 50/60 Hz W-FM plug – X3-02 Air pressure switch – X3-03 Limit switch burner flange – X3-04 Mains and safety circuit – X3-05 Fan, alarm – X4-02 Ignition unit – X5-01 Min. oil pressure switch – X5-02 Max. oil pressure switch – X5-03 Control circuit – X6-03 Safety valve – X7-01 Oil valve stage 2 – X7-02 Oil valve stage 3 – X8-02 Oil valve stage 1 – X8-04 Operation Reset 50 – X9-04 Valve proving pressure switch – X10-05 Flame sensor QRB, QRD, ionisation – X10-06 Flame sensor QRA – X64 Reserve 4-20mA – X74 Frequency converter connection – X75 Fuel meter 107-112 Order No. 600 408 400 406 600 407 600 402 716 301 716 302 716 303 716 410 716 305 716 307 716 308 716 309 716 312 716 313 716 314 716 317 716 411 716 418 716 413 716 414 716 416 716 417 716 415 Installation and operating instruction Combustion Manager W-FM 50 11 Notes 11 Notes 83250302 1/2018-08 La 108-112 Installation and operating instruction Combustion Manager W-FM 50 12 Key word index 12 Key word index Extraneous light ................................................................... 21 A ABE ........................................................................................ 26 Actuator................................................................................. 43 Air actuator ........................................................................... 41 Air number ............................................................................ 86 Air pressure .......................................................................... 87 Air pressure switch............................................................. 18 Alarm.............................................................................. 24, 39 Ambient conditions............................................................. 26 Analogue input..................................................................... 22 Analogue signal........................................................... 22, 25 Atomising pressure..................................................... 69, 81 B Backup .................................................... 11, 36, 60, 74, 85 Baud rate .............................................................................. 37 Building management ................................................ 22, 37 Burner control (200: PAr0)............................................... 39 Burner flange limit switch.................................................. 18 Burner identification ........................................................... 36 Burner motor ........................................................................ 24 Burner ON .................................................................... 22, 23 Bus interface........................................................................ 22 C Calculation............................................................................ 11 Change-over release.......................................................... 23 CO content .......................................................................... 86 Combustion control............................................................ 86 Combustion limit ................................................................. 86 Combustion Manager ........................................................ 26 Commissioning..................................................... 46, 47, 61 Compound............................................................................ 41 Condensate............................................................................ 8 Connection pressure ........................................................... 9 Consumption........................................................................ 26 Contact interrogation ......................................................... 43 Continuous ventilation ....................................................... 24 Conversion factor ............................................................... 87 D Data backup ........................................... 11, 36, 60, 74, 85 Data set ................................................................................. 36 Design lifespan ............................................................... 7, 88 Diagnostic code ............................................................... 101 Dimensions........................................................................... 27 Direct ignition....................................................................... 39 Display ............................................................. 30, 31, 33, 37 Display and operating unit ................................. 26, 30, 90 Display illumination ............................................................. 37 Disposal .................................................................................. 8 E eBUS ..................................................................................... 37 Electrical connection.......................................................... 28 Emergency-Off .................................................................... 18 Engineer level....................................................................... 33 Excess air.............................................................................. 86 Exchanging the unit ............................................................ 91 83250302 1/2018-08 La F Fan motor.............................................................................. 24 Fan run-up time ................................................................... 39 Fault ....................................................................................... 90 Fault code.......................................................................... 101 Fault history .......................................................................... 43 Flame failure test ................................................................. 37 Flame sensor......................................................... 21, 39, 40 Flame signal ......................................................................... 21 Flame stabilisation time ..................................................... 39 Flashing ......................................................................... 32, 35 Flue gas losses.................................................................... 86 Flue gas measurement....................................................... 86 Flue gas temperature ......................................................... 86 Frequency ............................................................................. 37 Frequency converter ........... 24, 41, 42, 49, 63, 77, 102 Fuel meter..................................................................... 23, 37 Fuel stage ............................................................................. 32 Fuel valve ........................................................ 14, 15, 16, 17 Fuel volume .......................................................................... 38 Full load ............................................ 42, 56, 59, 71, 72, 83 Fuse ....................................................................................... 26 G Gas connection pressure.................................................... 9 Gas temperature ................................................................. 87 Gas throughput ................................................................... 87 Guarantee............................................................................... 6 H Heat demand ............................................................... 22, 23 Heavy oil intermediate start .............................................. 20 High gas pressure switch ................................................. 40 Humidity ................................................................................ 26 I Ignition load point ................................................ 50, 64, 78 Ignition pilot valve................................................................ 15 Ignition position ................................................................... 50 Ignition speed .............................................................. 50, 53 Ignition unit ............................................. 14, 15, 16, 17, 24 Illumination............................................................................ 37 Impulse frequency............................................................... 23 Info level ................................................................................ 33 Input COM X92................................................................... 22 Input X10-05.......................................... 14, 15, 16, 17, 21 Input X10-06........................................................................ 21 Input X3-02 ............................................ 14, 15, 16, 17, 18 Input X3-03 .................................................... 14, 15, 16, 18 Input X3-04 ............................................ 14, 15, 16, 17, 18 Input X5-01 ............................................ 14, 15, 16, 17, 19 Input X5-02 .......................................................................... 19 Input X5-03 ............................................ 14, 15, 16, 17, 23 Input X9-04 ............................................ 14, 15, 16, 17, 20 Input X75 .............................................................................. 23 Input X8-04 .......................................................................... 18 Interface ................................................................... 102, 104 109-112 Installation and operating instruction Combustion Manager W-FM 50 12 Key word index Ionisation electrode ............................................................ 21 L Liability..................................................................................... 6 Lifespan............................................................................ 7, 88 Limit switch........................................................................... 18 Load change ........................................................................ 36 Load controller............................................................. 22, 23 Load limit............................................................................... 42 Load signal ........................................................................... 22 Lockout.......................................................................... 18, 90 Low gas pressure switch ...................................... 9, 19, 40 Low gas programme ............................................................ 9 Low impact start.................................................................. 23 M Mains frequency .......................................................... 26, 37 Mains voltage ............................................................... 18, 26 Manual load .................................................................. 35, 36 Manual OFF.......................................................................... 35 Max. oil pressure switch .................................................... 19 Max. pressure switch ......................................................... 19 Min. oil pressure switch..................................................... 19 Min. pressure switch .......................................................... 19 Modbus ................................................................................. 37 Modulating.................................................................... 22, 39 Modulation limit ................................................................... 42 Motor.............................................................................. 24, 28 Multi-stage.................................................................... 22, 23 Point of ignition.................................................................... 41 Post burn time ..................................................................... 40 Post-purge position............................................................ 41 Post-purge time................................................................... 40 Pre-ignition phase................................................ 16, 17, 24 Pre-purge.............................................................................. 39 Pre-purge position...................................................... 39, 41 Pre-purge position ............................................................. 41 Pre-purge time..................................................................... 39 Pressure regulating screw ........................................ 69, 81 Pressure regulator .............................................................. 23 Pressure switch relief......................................................... 24 Program stop ....................................................................... 39 Programme sequence......................................... 14, 15, 16 Pump pressure ............................................................ 69, 81 R Ramp time............................................................................. 41 Referencing .......................................................................... 12 Repetition counter ............................................................. 39 Reset.............................................................................. 18, 91 Restore.................................................................................. 36 S OFF function ........................................................................ 30 Oil throughput...................................................................... 71 Operating mode .......................................................... 22, 23 Operating phase ................................... 13, 14, 15, 16, 17 Operating point ................................................................... 11 Operating setting ................................................................ 13 Operating stage 1............................................................... 84 Operating unit...................................................................... 30 Operating volume ............................................................... 87 Output X3-05 ........................................ 14, 15, 16, 17, 24 Output X4-02 ........................................ 14, 15, 16, 17, 24 Output X6-03 ................................................ 14, 15, 16, 17 Output X7-01 ................................................ 14, 15, 16, 17 Output X7-02 ................................................ 14, 15, 16, 17 Output X3-05 ...................................................................... 24 Output X74 .................................................................. 24, 25 Safety circuit ................................... 14, 15, 16, 17, 18, 39 Safety measures.................................................................... 7 Safety shutdown ................................................................. 32 Safety time limiter................................................................ 18 Safety valve .................................................... 14, 15, 16, 17 Save ........................................................................ 11, 33, 36 Service................................................................................... 88 Service contract .................................................................. 88 Service interval .................................................................... 88 Service level ......................................................................... 33 Setting step.......................................................................... 36 Setting time .......................................................................... 26 Smell of gas ........................................................................... 7 Software version ......................................................... 36, 44 Spares ................................................................................ 107 Special positions................................................................. 41 Speed alteration.................................................................. 97 Speed measurement.......................................................... 24 Speed standardisation................................. 42, 49, 63, 77 Stabilisation time................................................................. 39 Standard volume ................................................................. 87 Standby position ................................................................. 41 Start prevention........................................................... 24, 39 Start-up ................................................................................. 38 STL ......................................................................................... 18 Storage.................................................................................. 26 Switch off behaviour........................................................... 39 P T Parameter ........................................ 36, 38, 41, 42, 43, 44 Parity ...................................................................................... 37 Partial load...................................................... 42, 59, 73, 84 Password ........................................................ 34, 47, 61, 75 Password level..................................................................... 33 Photo resistor....................................................................... 21 Pilot ignition.......................................................................... 39 Temperature ......................................................................... 26 Thermostat............................................................................ 23 Three stage .......................................................................... 39 Throughput ........................................................................... 71 Torque ................................................................................... 26 Transport............................................................................... 26 Tree stage............................................................................. 22 N Nozzle circulation ................................................................ 20 O 83250302 1/2018-08 La 110-112 Installation and operating instruction Combustion Manager W-FM 50 12 Key word index Two stage ..................................................................... 22, 39 Type of operation ................................................................ 39 Type of protection............................................................... 26 U Unit address......................................................................... 37 UV cell ................................................................................... 21 V Valve proving................................................................ 10, 20 Valve proving gas pressure switch ................................. 20 Valve proving pressure switch ......................................... 20 Voltage supply ..................................................................... 18 VSD........................................................................................ 43 X X5-02..................................................................................... 17 83250302 1/2018-08 La 111-112 Max Weishaupt GmbH · 88475 Schwendi Weishaupt close by? Addresses, telephone numbers etc. can be found at www.weishaupt.de We reserve the right to make changes. All rights reserved. The complete program: Reliable technology and prompt, professional service W Burners up to 570 kW The compact burners, proven millions of times over, are economical and reliable. Available as gas, oil and dual fuel burners for domestic and commercial applications. The purflam® burner version with special mixing head gives almost soot-free combustion of oil with greatly reduced NOx emissions. The wall-hung condensing boilers WTC-GW have been developed to meet the highest demands in ease of operation and efficiency. Modulating operation means these units operate quietly and economically. monarch® WM Burners and Industrial Burners Floor-standing condensing boilers for oil and gas up to 1,200 kW up to 11,700 kW These legendary industrial burners are durable and versatile. Numerous variations of oil, gas and dual fuel burners meet a wide range of applications and capacity requirements. The floor-standing condensing boilers WTC-GB (up to 300 kW) and WTC-OB (up to 45 kW) are efficient, low in pollutants and versatile in use. Even the largest capacities can be covered by cascading up to four gas condensing boilers. WKmono 80 Brenner Solar systems up to 17,000 kW The WKmono 80 burners are the most powerful monoblock burners from Weishaupt. They are available as oil, gas or dual fuel burners and are designed for tough industrial application. The stylish flat-plate collectors are the ideal complement for any Weishaupt heating system. They are suitable for solar water heating and for combined heating support. With versions for on-roof, in-roof and flat roof installations, solar energy can be utilised on almost any roof. WK Burners Water heaters/Energy storage up to 32,000 kW These industrial burners of modular construction are adaptable, robust and powerful. Even on the toughest industrial applications these oil, gas and dual fuel burners operate reliably. The diverse program of potable water and energy storage for various heat sources includes storage volumes of 70 to 3,000 litres. In order to minimize storage losses, potable water cylinders from 140 to 500 litres are available with highly efficient insulation using vacuum insulation panels. MCR Technology / Building Automation from Neuberger Heat pumps From control panels to complete building management systems - at Weishaupt you can find the entire spectrum of modern control technology. Future orientated, economical and flexible. 83250302 1/2018-08 La Wall-hung condensing boilers for gas up to 240 kW up to 180 kW The heat pump range offers solutions for the utilisation of heat from the air, the soil or ground water. Some systems are also suitable for cooling buildings. Service Geothermal probe drilling Weishaupt customers can be assured that specialist knowledge and tools are available whenever they are needed. Our service engineers are fully qualified and have extensive product knowledge, be it for burners, heat pumps, condensing boilers or solar collectors. With its daughter company, BauGrund Süd, Weishaupt also offers geothermal probe and well drilling. With the experience of more than 10,000 systems and more than 2 million meters of drilling, BauGrund Süd offers a comprehensive service program.