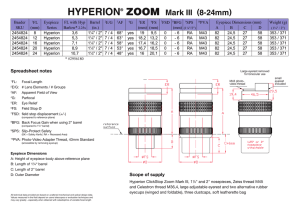

The instruction of JHY food and pharmaceuticals double movement mixer Location:Zhengzhou JINHE Machinery Manufacture Co.,LTD. Tel:86-371-55982206 Fax:86-371-65613933 JHY food and pharmaceuticals double movement mixer Welcome clients to choose the advanced, high efficiency and energy saving mixer produced by our company. Please read the instruction before you use the machine so that you can use the equipment better . I.Overview Currently, Industry using mixers, the prevalence of low mixing efficiency, mixing time, barrel corner, high energy consumption, feeding high intensity, using security issues, this process well arranged, raw materials and working capital cycle increased. In order to overcome these defects, My company after more than ten years of unremitting efforts, we have researched cross rotating shaft double movement mixer,mixing with high efficiency, short mixing time, small energy consumption, feeding, convenient, use safety,etc. Widely used in pharmaceutical, chemical, food, fodder, ceramics, metallurgy and other in dustries, is a kind of ideal and efficient mixing equipment.And my company has indepen dent research and development of intellectual property rights,and obtained the national patents. Patent No.: ZL200920089568.X. JHY food and pharmaceuticals double movement mixer is 2014 company grand launch of the outstanding products. it's main advantages are:the double movement, excellent mixing technology based on realize special in food and pharmaceuticals industry mixed, the equipment adopts 304 or 316L stainless steel, the appearance of the equipment adopts stainless steel skin,appearance more beautiful and generous, in line with the national GMP certification requirements. II.Feature 1.Composition structure JHY food and pharmaceuticals double movement mixer, Is made up of double-cone rotary barrel and inside the barrel shaft and screw blade assembly kit form. When the equipment is working, container axis and blade inner axis rotate at the same time, different axis and different speed, the barrel and the inner rotating shaft are sealed by a special sealing component. 2. The characteristics of the equipment 1, High mixing efficiency, compared with traditional mixer, mixing time can be shortened by more than 60%, Lower power consumption than traditional mixer 20%-30%. 2,As mixer small turning radius, material on the lower located directly above, It is more convenient than v-type mixer, low labor intensity. Outlet using stainless steel sanitary butterfly valve, more convenient and flexible. 3,The equipment is more compact and reasonable, more stable and reliable operation, more flexible, convenient maintenance, is the representative of the domestic advanced mixer. 4,The operation of the mixing machine due to the rotating radius of the barrel is relatively small, so the space is very small, the relative V type mixer with better security. 5, On the operator panel equipped with timing, start, move the key. 6, In order to safe operation and safe operation of this device ad hoc bond operation mode. That only press ready key and run two button keys to make them work. This would eliminate the man-made accidents caused by unintentional touch. III.Structure Perspective 1.Outside shell 1.Internal power 3.Control panel 4.Feeding port 5.Discharge port 6.Spiral blade 7.Container(barrel) IV. Technical parameter Barrel Model capacity (L) Max loading capacity MAX Loading weight (L) (kg) speed Motor Barrel Blade speed speed (r/min) (r/min) power (kw) Size Weight Length * width * (kg) height(mm) JHY100 100 75 150 21 47 1.1 1370x660x1200 JHY200 200 170 200 16 37 2.2 1550x865x1420 JHY400 400 340 400 14 33 4.0 1450x830x1220 JHY600 600 510 600 12 28 5.5 1720x950x1460 JHY1000 1000 850 1000 10 23 7.5 2073x1020x1685 JHY1500 1500 1280 1500 8 18 11 2365x1100x1850 V.Operating procedures 1,Cleaning barrel inside, after cleaning up the discharge port valve, the feed inlet to the level, in order to prevent the feed barrel rotation, the fixed pin can be inserted on the right side of the device (JHY100 no fixed pin). 2, Open the inlet cover, mixing the materials into a barrel, the barrel material accounted for volume 70% is the best. 3, Finished charging, close the feed cover, adjust the mixing time, the equipment right barrel fixed pin out of all. 4, Close the power switch while pressing the "prepare" button and the "run" button, the barrel and screw the blades rotating at the same time, you could mix. 5, When finished material mix, please turn outlet valve to a position just below. 6, Open the outlet valve, material after removing the barrel, should clean up residues materials, then close the outlet valve. 7, If a material inlet and a material accumulation, one can not be all finished, then close the outlet valve, rotating barrel laps or while pressing the "prepare" button and "positive shake" ( "get ready" and "negative shake" ), then open the outlet valve, remove the material. 8, If you need to clean inside the barrel. first, you must turn off the power, open the barrel clasp, then open the barrel left half, you can clean inside the barrel or you can take off barrel internal blades and then cleaned inside the barrel and leaves, after cleaning, you need to install blade and close the barrel. VII. Security operational considerations 1, Equipment installation and adjustment parallel to the barrel rotation and flexible, and fixing bolts. 2, Mixing machine are rotating parts, avoiding bruising or scratch when equipment working the staff not to near. 3, In the operation "work" and "shake" button, for security reasons, in order to prevent wrong operation, set the "preparation key" add "operation button" double bond operations. Specific operations are: first press the "preparation key", then press "work" or "shake" ; 4, Timer can control the mixing time according to different materials, can be appropriately preset mixing time; 5, In the process of charging and discharging, you need to close the key switch to prevent accidental touch keys causing personal injury. VIII.Equipment maintenance 1, Reducer maintenance: the specific maintenance method must be according to attached reducer introduction content. 2, Gear, chain wheel maintenance: maintenance on a monthly basis, maintain open the equipment when the back door, even apply grease on the gears and chain wheel. 3, Bearing maintenance: maintenance on a monthly basis, open the door at the back of the equipment, from the bearing sleeve seat will grease into bearing spindle, the end surface of the flange sleeve with an oiling mouth, grease from the hole into the blade shaft bearing. 4, Sealing components maintenance: A. Equipment sealing parts are vulnerable parts, often in the equipment during the work to check whether the leakage of powder, powder leakage observation hole is located at the end of the material barrel flange side wall. B. After the leakage of powder, immediately stop using, promptly notify the manufacture, under the guidance of the manufacturers to check. (1) .Replace the sealing ring (inner package frame rotation shaft lip type skeleton rubber oil seal GB/T13871-1992). (2). Manual polishing and the sealing ring is stainless steel sealing sleeve. After each removal, it should be filled with grease in the bearing. C. Attention:seal components should not be removed at will, so as to avoid damage to equipment parts and components.