2006 Shi - Analysis of the moment–rotation behaviour of stiffened end plate

Anuncio

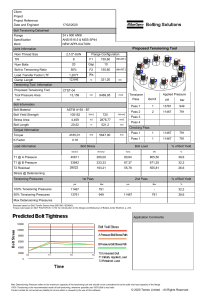

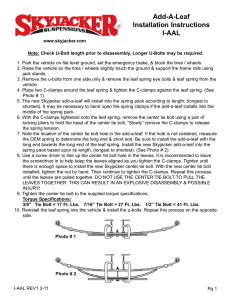

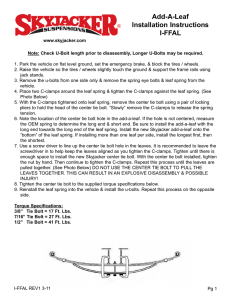

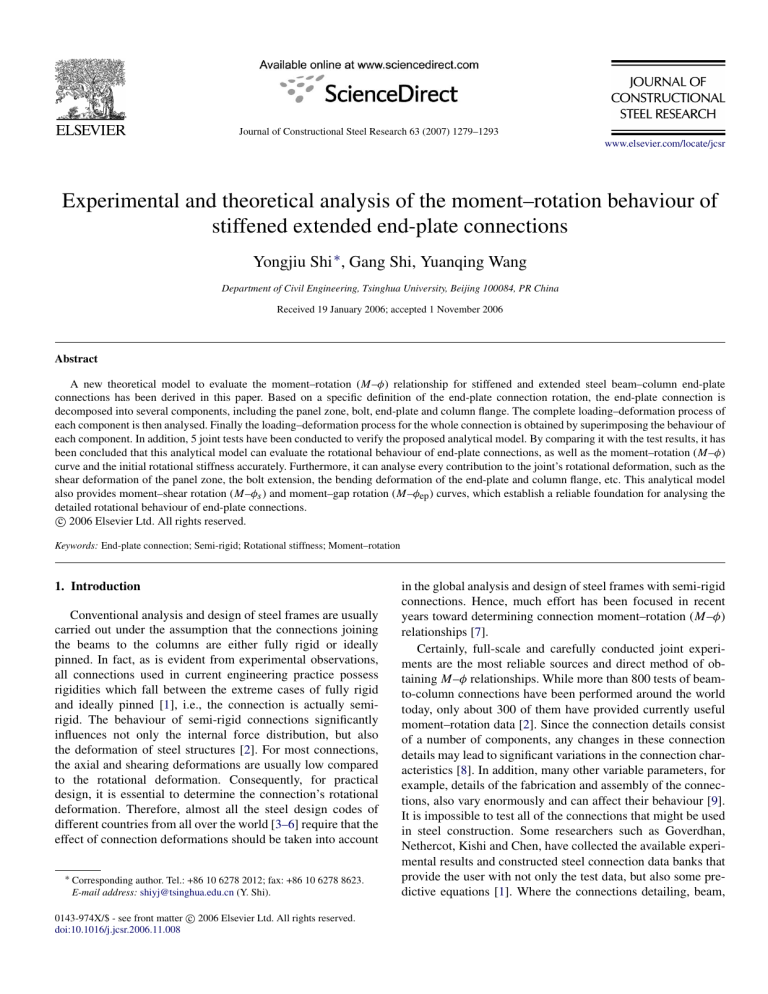

Journal of Constructional Steel Research 63 (2007) 1279–1293 www.elsevier.com/locate/jcsr Experimental and theoretical analysis of the moment–rotation behaviour of stiffened extended end-plate connections Yongjiu Shi ∗ , Gang Shi, Yuanqing Wang Department of Civil Engineering, Tsinghua University, Beijing 100084, PR China Received 19 January 2006; accepted 1 November 2006 Abstract A new theoretical model to evaluate the moment–rotation (M–φ) relationship for stiffened and extended steel beam–column end-plate connections has been derived in this paper. Based on a specific definition of the end-plate connection rotation, the end-plate connection is decomposed into several components, including the panel zone, bolt, end-plate and column flange. The complete loading–deformation process of each component is then analysed. Finally the loading–deformation process for the whole connection is obtained by superimposing the behaviour of each component. In addition, 5 joint tests have been conducted to verify the proposed analytical model. By comparing it with the test results, it has been concluded that this analytical model can evaluate the rotational behaviour of end-plate connections, as well as the moment–rotation (M–φ) curve and the initial rotational stiffness accurately. Furthermore, it can analyse every contribution to the joint’s rotational deformation, such as the shear deformation of the panel zone, the bolt extension, the bending deformation of the end-plate and column flange, etc. This analytical model also provides moment–shear rotation (M–φs ) and moment–gap rotation (M–φep ) curves, which establish a reliable foundation for analysing the detailed rotational behaviour of end-plate connections. c 2006 Elsevier Ltd. All rights reserved. Keywords: End-plate connection; Semi-rigid; Rotational stiffness; Moment–rotation 1. Introduction Conventional analysis and design of steel frames are usually carried out under the assumption that the connections joining the beams to the columns are either fully rigid or ideally pinned. In fact, as is evident from experimental observations, all connections used in current engineering practice possess rigidities which fall between the extreme cases of fully rigid and ideally pinned [1], i.e., the connection is actually semirigid. The behaviour of semi-rigid connections significantly influences not only the internal force distribution, but also the deformation of steel structures [2]. For most connections, the axial and shearing deformations are usually low compared to the rotational deformation. Consequently, for practical design, it is essential to determine the connection’s rotational deformation. Therefore, almost all the steel design codes of different countries from all over the world [3–6] require that the effect of connection deformations should be taken into account ∗ Corresponding author. Tel.: +86 10 6278 2012; fax: +86 10 6278 8623. E-mail address: [email protected] (Y. Shi). 0143-974X/$ - see front matter c 2006 Elsevier Ltd. All rights reserved. doi:10.1016/j.jcsr.2006.11.008 in the global analysis and design of steel frames with semi-rigid connections. Hence, much effort has been focused in recent years toward determining connection moment–rotation (M–φ) relationships [7]. Certainly, full-scale and carefully conducted joint experiments are the most reliable sources and direct method of obtaining M–φ relationships. While more than 800 tests of beamto-column connections have been performed around the world today, only about 300 of them have provided currently useful moment–rotation data [2]. Since the connection details consist of a number of components, any changes in these connection details may lead to significant variations in the connection characteristics [8]. In addition, many other variable parameters, for example, details of the fabrication and assembly of the connections, also vary enormously and can affect their behaviour [9]. It is impossible to test all of the connections that might be used in steel construction. Some researchers such as Goverdhan, Nethercot, Kishi and Chen, have collected the available experimental results and constructed steel connection data banks that provide the user with not only the test data, but also some predictive equations [1]. Where the connections detailing, beam, 1280 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 Notation Ae E Eb Eh E bh G Ic f,l Ic f,r M M Rd,s N1 Ni 1Ni Vp bep ef ew fv fy f by f bu h bw h cw ht 1l 1l1 1l2 lb tc f,l tc f,r tcw tep yi y1 y2 α εi effective area of bolt shank threaded section; elastic modulus of steel; elastic modulus of bolt; hardening modulus of steel; hardening modulus of bolt; shear modulus; moment of inertia of the column panel zone left flange; moment of inertia of the column panel zone right flange; the joint moment; the design moment resistance of the panel zone; the transferred tension force of a single bolt in the first bolt-row; the transferred tension force of a single bolt in the ith bolt-row; the actual increase of the bolt tension force in the ith bolt-row; volume of the panel zone; end-plate width; distance from the bolt centre to the beam flange surface; distance from the bolt centre to the beam web surface; the steel shear strength; the steel yield strength; the bolt yield strength; the bolt ultimate tension strength; beam web height; column web height; the distance between the centre lines of the beam top and bottom flanges; deformation at the beam tension flange centreline caused by the bolt extension; the extension of a single bolt in the first bolt-row; the extension of a single bolt in the second boltrow; bolt shank length, equal to the thickness of plates which the bolt clamped plus the washers thickness; thickness of the column panel zone left flange; thickness of the column panel zone right flange; column web thickness; end-plate thickness; distance from the ith bolt-row centreline to the neutral axis; distance from the first bolt-row centreline to the neutral axis; distance from the second bolt-row centreline to the neutral axis; the ratio of the compression distribution area between the contacted surfaces around a bolt on the bolt shank area; the bolt tension strain of the ith bolt-row. and column sizes used in frame analysis are significantly different from the available experiments, however, the connection behaviour retrieved from a database may not correctly represent the actual connections. Furthermore, not every structural engineer has access to the database of experimental results. The most widely used semi-rigid connections are the angle cleat and end-plate connections. For end-plate connections, the common approaches for predicting the M–φ relationship, besides experiments, are the T-stub analogy, the yield line theory and the finite element analysis [10]. Early attempts to develop a design methodology for endplate connections were based on the T-stub analogy developed by Douty and McGuire [11], Nair et al. [12], Kato and McGuire [13], Agerskov [14] and others. More recently, methods based on refined yield line analysis have been suggested, in which the widely accepted design procedures of end-plate connections are derived from [15–19]. Eurocode 3 [3] has formally recommended an M–φ curve for end-plate connections based on the T-stub yield line theory. The finite element analysis of end-plate connections was first developed by Krishnamurthy [20–22]. An exhaustive analytical study of four-bolt, unstiffened, extended end-plates, along with a series of experimental investigations, leads to the development of the design procedure found in Ref. [23]. Tarpy and Cardinal carried out an elastic finite element study and experimental verification for unstiffened end-plate connections and also proposed a design methodology [24]. Maxwell et al. [25] developed a prediction equation for the ultimate moment of the connection and the M–φ relationships based on the finite element method and experimental as well. Sherbourne and Bahaari used 3-D finite elements to analyze end-plate connections. In addition to the overall behaviour, the contribution of the bolt, end-plate and column flange flexibility to the connection rotation was singled out [26]. With the finite element method, they also studied the structural properties of an extended end-plate connected to an unstiffened column flange [27]. Based on 34 stiffened, extended end-plate connections and 19 end-plate connections without stiffeners in the tension region, they produced a single standardized M–φ function for each of these two connection types by curve fitting [28,29]. Shi et al. used many new functions of the finite element method and simulated the mechanical behaviour of end-plate connections and each component more accurately [9, 30,31]. Currently the widely accepted nonlinear M–φ relationship formulae are the polynomial model, the power model and the exponential model. From a survey of these existing models, it was found that the coefficient and parameters involved in these modeling formulae, by and large, were calibrated from the relevant test results or finite element analysis results. But curve fitting will not give any indications as to how connection components deform or fail, and provides less help to designers for improving connection design. In the design M–φ curve recommended by Eurocode 3, the nonlinear part is also determined by curve fitting, and the corresponding research is mostly based on the end-plate connections with 1281 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 unstiffened columns, which may not be suitable for all the endplate connection types. Furthermore, the last part of this curve is the horizontal line and this cannot consider the hardening effect, which leads to great discrepancies with the actual behaviour of the connection [32]. Finite element analysis is precise and reliable, and can analyze complicated connection profiles that may be difficult to investigate by experiment. However, such finite element analysis generally requires a large commercial package and is not therefore feasible for many practical applications. Most importantly, the effects of torque, lack of fit, construction imperfections and defects, etc., may be difficult to include in a finite element model. A well-defined theoretical method that can be easily carried out and is only based on the connection’s details is needed indeed for the analysis of the end-plate connection M–φ relationship. Fig. 1. Test specimen and loading arrangement. 2. End-plate connection standard details Many experiments have been performed to investigate the influences of the connection details on the connection’s behaviour. Ghobarah et al. [33–35] concluded that connections with unstiffened columns showed very poor behaviour as compared with those that were stiffened. Tsai and Popov [36] pointed out that an end-plate rib stiffener and stronger bolts can significantly improve the behaviour of end-plate connections under large cyclic loading, and the extended end-plate moment connections can be designed to develop the full plastic moment capacity of the beam under cyclic loading, and the effect of the prying force was reduced by the use of the end-plate rib stiffener. Adey et al. [37] proposed that the application of extension stiffeners increases the connection flexural strength, yield rotation as well as energy dissipation capacity. Summarising the available test results and other relevant research results, standard details of end-plate moment connections for multistorey steel frames, especially in seismic regions, can be proposed as follows: The end-plate extends on both sides; the column flange and end-plate are stiffened; the thickness of the column flange stiffener and the end-plate extension stiffener should be no less than the thickness of the beam flange and web respectively; the thickness of the column flange is equal to the end-plate within the range of 100 mm above and below the extension edge of the end-plate. In this paper, an analytical model for the M–φ relationship of this type of end-plate connection has been proposed and the corresponding joint tests have been conducted to verify the analytical results. 3. Test specimens Five specimens of stiffened and extended beam-to-column end-plate connections with various details are tested under monotonic loads. A sketch of a typical connection specimen is shown in Figs. 1 and 2. The out-of-plane deformation of specimens was restrained during tests. The details of these 5 specimens are shown in Table 1 and Fig. 3. The beam and column sizes with welded I-shaped cross-sections used for all these 5 specimens were identical. The section depths, Fig. 2. Testing set. Table 1 Types and details of specimens Specimen number End-plate thickness (mm) Bolt diameter (mm) EPC-1 EPC-2 EPC-3 EPC-4 EPC-5 20 25 20 25 16 20 20 24 24 20 web thicknesses and flange thicknesses of the columns and beams are 300 mm, 8 mm and 12 mm, and the flange widths are 250 mm and 200 mm, respectively. The thickness of the column flange is equal to that of the end-plate within the range of 100 mm above and below the extension edge of the endplate. The thicknesses of the column stiffener and end-plate rib stiffeners are 12 mm and 10 mm respectively. Full penetration welds are applied between the end-plate and beam flanges as well as the column flange splices, and the other welds, including the welds between the flanges and webs of beams and columns, end-plates and beam webs, are fillet welds with 8 mm leg size. 1282 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 Table 2 Material properties Material Measured yield strength (MPa) Measured tensile strength (MPa) Measured elastic modulus (MPa) Design value of bolt pre-tension force (kN) Measured bolt average pre-tension force (kN) Steel (thickness ≤ 16 mm) Steel (thickness > 16 mm) Bolts (M20) Bolts (M24) 391 363 995 975 559 537 1160 1188 190 707 204 228 – – – – 155 225 – – 185 251 Table 3 Test results Specimen number Loading capacity (kN) Moment resistance (kN m) Moment resistance change compared with EPC-1 (%) Initial rotational stiffness S j,ini (kN m/rad) Initial rotational stiffness change compared with EPC-1 (%) Failure mode EPC-1 EPC-2 EPC-3 286.4 268.4 325.3 343.7 322.1 390.3 0.0 −6.3 13.6 52 276 46 094 46 066 – −11.8 −11.9 EPC-4 342.3 410.8 19.5 47 469 −9.2 EPC-5 296.1 355.4 3.4 41 634 −20.4 Bolt fracture Bolt fracture Buckling of beam flange and web in compression Buckling of beam flange and web in compression Bolt fracture and buckling of end-plate rib stiffener in compression Fig. 4. A gauged bolt. Fig. 3. Details of connections. The steel is grade Q345 (nominal yielding stress f y = 345 MPa), and the bolts are high strength friction-grip bolts (Grade 10.9). The material properties of the steel and bolts are obtained from tensile tests on coupons and from the bolts’ certificate of quality, as shown in Table 2. The proof elastic modulus of the bolts is taken as 206 000 N/mm2 . One line of bolts on each connection was instrumented using strain gauges, and these bolts are numbered in Fig. 3. Two shallow slots were grooved symmetrically on the unthreaded portion of the bolt shank, and in each slot a strain gauge was fixed and covered with resin for protection (Fig. 4). The alignment of the two strain gauges was secured to be perpendicular to the beam flange during the tightening of the bolts, so that the maximum and minimum strain of the bolt in the connection moment plane could be measured. The bolt axial force can be calculated by taking the average of the two strain gauges’ measured values. All bolts were tightened by the calibrated wrench method. The design values of bolt pre-tension forces and the actually applied bolt pre-tension forces are listed in Table 2. The contact surface between the end-plate and column flange was prepared by blasting, with a slip coefficient 0.44. Fig. 1 displays all the displacement transducers installed to measure the joint deformation. No. 1 was used to monitor the displacement at the loading point. Nos. 2–10 measure the relative deformation between the end-plate and column flange. Nos. 11 and 12 measure the inner shearing deformation of the panel zone. Nos. 13 and 14 were arranged next to the column stiffeners to measure the shearing deformation of the panel zone. No. 15 measures the slippage between the end-plate and column flange. 4. Test results and discussion 4.1. Rotational stiffness and M–φ, M–φep , M–φs curves The test results of the specimens are summarised in Table 3. The failure modes of specimens are shown in Fig. 5. In these tests, the fracture and necking positions of all the failed bolts appear on the threaded portion and not at the strain gauge slots, as shown in Fig. 5, which indicates that these grooved slots do not damage the bolt capacity. With regard to the joint rotation φ, the conventional definition is suggested as the angle change between the beam Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 1283 Fig. 5. Failure modes of the specimens. Fig. 6. Definition of joint rotation. and the column from its original configuration [1]. In this paper, the joint rotation φ of the beam-to-column end-plate connection is defined as the relative rotation between the centre lines of the beam top and bottom flanges at the beam end, and it usually includes two parts: the shearing rotation φs , contributed by the panel zone of the column, and the gap rotation φep , caused by the relative deformation between the end-plate and the column flange, including the bending deformation of the end-plate and column flange as well as the extension of the bolts (Fig. 6). The shearing rotation φs is calculated by ∆/ h t , and the gap rotation φep is calculated by δ/ h t , giving φ = φs + φep , where ∆ is the displacement difference of the panel zone at the centre lines of the top and bottom beam flanges at the beam end which can be measured by displacement transducer Nos. 13 and 14; δ is the gap between the end-plate and the column flange at the beam tension flange centre line, which can be measured by displacement transducer No. 4; and h t is the distance between the centre lines of the top and bottom beam flanges, and is 288 mm. M–φ curves of all the specimens are shown in Fig. 7. M–φs and M–φep curves of each specimen are also measured to verify the analytical model, and the comparison results are shown in Figs. 12 and 13. The loading capacity presented in Table 3 is the maximum pushing load applied. The moment resistance is calculated by multiplying the load with the arm of the loading(1.2 m). It can be seen from Fig. 7 that the M–φ curves of all the end-plate connection specimens are almost linear when the moment is less than 60 kN m; therefore the initial rotational stiffnesses, Fig. 7. M–φ curves of the specimens. S j,ini , of the connections are defined as the secant rotational stiffnesses up to this bending moment. According to Eurocode 3 [3], S j,ini is compared to the flexural stiffness of the connected beam EIb /L b . The connection is rigid when S j,ini is larger than 25EIb /L b for unbraced frames, nominally pinned when S j,ini is less than 0.5EIb /L b , and semi-rigid when S j,ini is between these two values. If we assume that the natural beam length of specimens is 1.2 m × 2 = 2.4 m, then EIb /L b is 9751 kN m, and S j,ini for all the specimens are about 4.3–5.4 times EIb /L b , so all the tested connections are semi-rigid. If the tested beam section sizes are applied in 4–5 m span frames and EIb /L b is 4681–5851 kN m, the Sj,ini of all the connections are about 7.1– 11.2 times EIb /L b , and therefore all the connections are still classified as semi-rigid. The influence of connection details on the behaviour of endplate connections can be analyzed from Table 3 and Fig. 7. EPC-1 is a reference specimen, and the other connection specimens alter only one or two parameters from EPC-1. EPC2 has increased the end-plate thickness compared with EPC1, but its moment resistance decreases remarkably and its initial rotational stiffness changes less; its rotational stiffness 1284 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 Fig. 8. Bolt tension force generated by applied moment. is much larger than EPC-1 when nonlinearity of the M–φ curve occurs. EPC-3 has increased the bolt diameter, which also means a larger bolt pre-tension force; its moment resistance is much higher than EPC-1, which fails by bolt fracture. EPC-4 has increased both the end-plate thickness and bolt diameter; its moment resistance is the largest among all the specimens; higher rotational stiffness is observed during its loading process. EPC-5 has reduced the end-plate thickness, but its moment resistance increases on the contrary, because the end-plate is thin and its bending stiffness is smaller, leading to the bolt tension force distribution among the four bolts in tension being more uniform. Meanwhile, its initial rotational stiffness decreases significantly, with excellent ductility and rotation capacity. 4.2. Bolt force and distribution The bolt tension forces generated by the applied moments are shown in Fig. 8. In this paper, the bolt tension force 1285 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 Table 4 Moment values of curve of Specimens 1, 2 and 3 (kN m) Specimen number Curve 1 Curve 2 Curve 3 EPC-1 EPC-2 EPC-3 EPC-4 EPC-5 80 80 100 100 70 199 210 224 226 209 248 248 300 289 230 indicates the tension force increment caused by the joint moment, excluding the pre-tension force. The loading stages corresponding to curve 1, 2 and 3 in Fig. 8 are listed in Table 4. The applied moment at curve 1 is around the design moment resistance of the connection from the Chinese codes [6, 38,39], where the connection is in the elastic stage. The applied moment at curve 2 is around the knee point of the M–φ curves of each specimen, where the nonlinearity and partial plasticity occur. Curve 3 corresponds to the moment where the nonlinearity is obvious and plasticity has developed significantly. From Fig. 8, it can be noted that, for all these connections, generally the neutral axis of the connection is around the centre line of the bolts group, which is on the centre line of the connection when the bolts are arranged symmetrically about the beam section centre line, and the bolt force generated by the bending moment is approximately distributed linearly. The negative values in the compression zone means that the bending moment will reduce the resultant bolt force to levels below the pre-tension level. For EPC-1, EPC-2, EPC-4 and EPC-5, the maximal tension force appears on the first bolt-row, and the tension force of the second bolt-row develops gradually. For EPC-3, the tension force of the second bolt-row is maximal at the initial loading stage. With the moment increasing, the tension force of the first bolt-row exceeds the second bolt-row and remains maximal up to failure. 5. Analytical model As specified above, the end-plate joint rotation φ consists of the shearing rotation φs and the gap rotation φep . The gap rotation φep is contributed by the flexural deformation of the end-plate and column flange as well as the extension of the bolts. This analytical model will evaluate the M–φs and M–φep curve respectively, and then superpose these two curves to get the final M–φ curve. 5.1. Analytical model for M–φs curve From the relevant research findings [32,40], the M–φs curve adopting a trilinear model is recommended as shown in Fig. 9. Some research [40] has indicated that the restraints around the column panel zone, especially the column flange, will increase the panel zone loading capacity and its stiffness. The Chinese steel structural design code [6] simplifies this contribution and presents the calculation equation for the design moment resistance of the panel zone as: M Rd,s = 4 4 4 fy f v V p = f v h bw h cw tcw = · √ · h bw h cw tcw .(1) 3 3 3 3 Fig. 9. M–φs model. When the joint applied moment M is equal to M Rd,s , the panel zone yields, and the panel zone shear strain reaches γ = γ y = f v /G. The shear rotation actually is the shear strain, and is also the shearing rotation φsy = γ y . When M ≤ M Rd , the joint shearing rotation initial stiffness K s,ini is given by: K s,ini = = M Rd,s M Rd,s = φsy γy 4 3 f v h bw h cw tcw f v /G = 4 · G · h bw h cw tcw . 3 (2) From Eqs. (1) and (2), it is noted that the restraints around the panel zone increase its resistance and stiffness by 1/3. According to Krawinkler et al. [40], after yielding, the panel zone rotational stiffness can be attributed to the bending of the column flanges, and it can be computed as: Kp = 12 EIc f,r 12 EIc f,l + 5 tc f,l β 5 tc f,r β (3) where β is a factor intended to account for the beneficial effect of column shear above and below the joint, whose calculation method can be obtained from Ref. [40]. This post-yielding stiffness is developed up to the yielding of the column flanges occurring for a shear deformation of the panel zone, which can be approximately assumed to be equal to 4 γ y . Therefore, the corresponding moment is given by: M p = K s, ini · γ y + K p · 3γ y . (4) After the development of this moment, i.e., the column flange yielding, the panel zone rotational stiffness attributed to the strain hardening can be computed as: Ks = Eh K s,ini . E (5) 5.2. Analytical model for M–φep curve (i) Analysis assumptions From the test results obtained by this paper, and the typical end-plate connections meeting the abovementioned standard details and requirements, we can simplify and assume that the bolt tension strain generated by the applied moment is 1286 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 Substituting Eq. (9) into Eqs. (6)–(8), it can be obtained that at this moment, the bolt tension strain is given by ε0 = 1Ni P = . E b Ae α E b Ae (10) The total bolt force is Fig. 10. Bolt tension strain and force generated by the applied moment. approximately a linear distribution, and the neutral axis of the connection is located approximately at the beam mid-height, and the bolt tension strains in each of the two rows of bolts are considered as equal. Here the specified bolt tension strain is the increment caused by the applied joint moment, excluding the pretension strain. Until the end-plate and the column flange separate, the bolt force contributed by the bending moment can be assumed to be linearly distributed as shown in Fig. 10. The tension force indicates an increment in the bolt force and compression force indicates a decrement in the bolt force. (ii) Joint rotation contributed by bolt extension Before the moment is applied to the connection, the bolts are tightened to the bolt pre-tension force P. From the static equilibrium, the contact force C between the end-plate and the column flange around this bolt is also equal to P. With the joint moment developing, the bolts in tension can experience the following three stages: Stage 1: The first stage lasts until the end-plate and the column flange separate around bolt location, i.e., εi ≤ ε0 . During this stage, with the joint moment developing, the contact force between the end-plate and the column flange decreases while the bolt tension force increases. Assuming the applied moment is M, and the contact force becomes C 0 = C − 1C, and the total bolt tension force is increased to Ni = P + 1Ni , where C is the initial contact force between the end-plate and column flange under pre-tension P; 1C, 1N are the contact force decrement and bolt tension increment caused by applied moment. From the static equilibrium, it can be obtained that 1C = α1Ni , and α is the ratio of the contact area around a bolt to the bolt shank area, according to the analysis results [31], the value of α can be taken as 10 conservatively. The actual increment in bolt tension force can be expressed as 1Ni = E b Ae εi (6) and the tension force on this bolt is given by Ni = (α + 1)1Ni (7) (8) Whenever the contact force between the end-plate and the column flange around this bolt is reduced to zero, i.e., the endplate and the column flange separate around bolt, the decrement of this contact force is given by 1C = α1Ni = P, so that 1Ni = P . α (11) 1li = ε0 · lb . (12) Stage 2: The second stage starts from the separation of the end-plate and the column flange around the bolt and lasts until bolt yielding in tension, i.e., ε0 < εi ≤ εby − ε p . During this stage, the actual increase of the bolt tension force can still be calculated by Eq. (6), and the total tension force on this bolt is Ni = P + E b Ae εi (13) and when yielding, the total bolt strain is equal to the yielding f strain εby = Ebyb , and the actual bolt tension strain increment is given by εi = εby − ε p = f by Ae − P f by P − = . Eb E b Ae E b Ae (14) The total tension force of this bolt is given by Ni = f by Ae (15) where ε p is the bolt pre-tension strain taken as ε p = E bPAe ; f by is the bolt yield strength. Stage 3: The third stage starts from the bolt yielding in tension until the bolt reaches its ultimate tension strength, i.e., εby − ε p < εi ≤ εbu − ε p . During this stage, the actual increment of the bolt tension force is given by 1Ni = f by Ae + E bh Ae (εi − εby ) − P. (16) The total tension force of this bolt is evaluated as Ni = f by Ae + E bh Ae (εi − εby ). (17) When the bolt reaches its ultimate tension strength, its total f −f f strain is equal to the ultimate tension strain εbu = Ebyb + buE bh by , and this bolt tension strain increment is εi = εbu − ε p . (18) The total tension force of this bolt is given by and the extension deformation of this bolt is given by 1li = εi · lb . α+1 P α and the extension deformation of this bolt is Ni = (9) Ni = f bu Ae . (19) The joint rotation contributed by bolt extension deformation, which is also called bolt extension rotation in the following text, can be obtained by the following pivotal points of procedure (a)–(e). Linking these points with straight lines, the moment–bolt extension rotation curve will be obtained: (a) The contact force between the end-plate and the column flange at the first bolt-row is reduced to zero, i.e., at the stage where the end-plate separates from the column flange by applying moment at the first bolt-row. Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 1287 Fig. 11. End-plate stiffness. Here the actual increments on the bolt tension force, the bolt tension strain, the total tension force and the extension of the bolt in the first bolt-row can be calculated by Eqs. (9)–(12) respectively. From the linear distribution assumption, the bolt tension strain in tension zone εi can be calculated from εi = ε1 · yi . y1 (20) The tension force of this bolt can be calculated from Eqs. (6) and (7), and can also be calculated as Ni = N1 · yi . y1 (21) (b) The contact force between the end-plate and the column flange at the second bolt-row is reduced to zero, i.e., at the moment the end-plate is separated from the column flange by applying moment at the second bolt-row. Here the actual increment on the bolt tension force, the bolt tension strain, the total tension force and the extension of the bolt in the second bolt-row can be calculated by Eqs. (9)–(12) respectively. Similarly, bolt tension strain in tension zone εi can be calculated as ε2 (22) εi = · yi . y2 (c) The first bolt-row yields. Here the bolt tension strain and the total tension force of the bolt in the first bolt-row can be calculated by Eqs. (14) and (15) respectively. The bolt tension strain in tension zone εi can be calculated by Eq. (20). (d) The second bolt-row yields. Here the bolt tension strain and the total tension force of the bolt in the second bolt-row can be calculated by Eqs. (14) and (15) respectively. The bolt tension strain in tension zone εi can be calculated by Eq. (22). (e) The bolt of the first bolt-row reaching ultimate tension strength. Here the bolt tension strain and the total tension force of the bolt in the first bolt-row can be calculated by Eqs. (18) and (19) respectively. The bolt tension strain in tension zone εi can be calculated by Eq. (20). After the tension strain of the bolts(Fig. 10) in the tension zone has been obtained, the actual increment on the bolt tension force, the total tension force and the extension deformation of this bolt can be calculated. The corresponding joint moment and the bolt extension rotation can be calculated as: X M =2 (Ni · yi ) (23) 1l1 1l2 1li 1l = = = (24) ht 2y1 2y2 2yi P where, is summation for all the bolts in the tension zone. From the above calculation procedure (a)–(e), we can get some pivotal points for the joint moment and the corresponding bolt extension rotation. Linking these pivotal points by the sequence of the magnitudes of the corresponding bolt extension rotation, the moment–bolt extension rotation curve can be obtained, extending the straight line segment by its own slope beyond the point (e). (iii) Joint rotation contributed by the bending deformation of the end-plate and column flange The joint rotations contributed by the bending deformation of the end-plate and column flange are called the end-plate rotation and the column flange rotation respectively. The bending deformation of the end-plate and column flange can be calculated according to the bolt tension force obtained by the above calculation procedure (a)–(e), taking into account only the deformation of the end-plate and column flange around one bolt-row on both sides of the beam tension flange. Since the calculation procedure of the column flange deformation is the same for the end-plate, the end-plate rotation is given to introduce the calculation method. For the end-plate connection meeting the above standard details requirements, the beam flange, the beam web and the end-plate extension rib stiffener can be considered as the fixed restraints of the end-plate segment. The end-plate segment around the bolt in tension can be separated and simplified into a two-edge fixed plate [41] as shown in Fig. 11. The arrow is the bolt clamp force. As the pre-tension bolt clamps the plates effectively, it can be assumed that the end-plate segment is fixed at the bolt centre line. Furthermore, this end-plate segment can be decomposed into two plates with opposite ends fixed. The stiffness of this end-plate segment k I or kII is equal to the φb = 1288 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 Fig. 12. Comparison of the M–φs curve from the analytical models and tests. summation of stiffness of these two plates: kI or kII = k1 + k2 (25) where k I or kII is the stiffness of the end-plate segment around one bolt of the first and second bolt-rows respectively. If b1 or b2 is larger than ew + e f , b1 or b2 is set equal to ew + e f , as shown in Fig. 11. In particular, when the plate bending spans are of the same order of magnitude as the plate thickness itself [42], the plate’s shear deformation cannot be neglected. From material Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 Fig. 13. Comparison of the M–φep curve from analytical model and tests. 1289 1290 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 mechanics, the k1 and k2 can be expressed as k1 = β1 k 2 = β2 1 3 ew 12EI + α s ew GA 1 e3f 12EI + αs e f GA = β1 1 3 ew 3 Eb1 tep + α s ew Gb1 tep 1 = β2 e3f 3 Eb2 tep + αs e f Gb2 tep (26) (27) where αs = 1.5, is a parameter taking into account the shear deformation; β1 = 1 − A2 /(b1 ew ) and β2 = 1 − A1 /(b2 e f ) are the reduction coefficients, because the stiffness of the areas A1 and A2 in Fig. 11 have been calculated repeatedly. After yielding occurs at the section edge of the endplate segment and it reaches its bending resistance, according to references [3,32], the end-plate segment stiffness is approximate to 1/7 of its initial stiffness, i.e., k I /7 or kII /7. After the total cross-section of the end-plate segment yields, it reaches its ultimate bending resistance. Taking into account the strain hardening, the end-plate segment stiffness is taken as Eh Eh E k I or E kII . From Ref. [41], the bolt tension force corresponding to the bending resistance of a two-edge fixed end-plate segment is given by Ny = 2 f bep tep y 6e f + 2 f (e f + ew )tep y 3ew . (28) When this segment reaches its ultimate bending resistance, the bolt tension force is taken as Nu = 1.5N y . (29) Based on the bolt tension force calculated from the above calculation procedure (a)–(e), the end-plate deformation at the first bolt-row ∆ep1 and second bolt-row ∆ep2 can be calculated. The deformation at the centre line of the beam tension flange ∆ep , is taken as the average of ∆ep1 and ∆ep2 , i.e., ∆ep = (∆ep1 + ∆ep2 )/2. The corresponding end-plate rotation is given by φep = ∆ep . ht (30) From the above calculation procedure (a)–(e), the joint moment and the corresponding end-plate rotation can be calculated. The moment–end-plate rotation curve can be obtained. After point (e), the line slope is taken as EEh K i , where K i is the initial stiffness of this curve, i.e. the slope of the first straight line segment of this curve. For the actual behaviour of all the end-plate connection moment–rotation (M–φ) curves, its tangent stiffness is always decreasing. Accordingly, it is required to revise the moment–end plate rotation curve obtained above. Whenever the slope of any straight line segment is larger than its preceding straight line segment, its slope is taken equal to its preceding straight line segment, and the moments of the pivotal points do not change. For the calculation procedure (e), if the edge of the end-plate segment does not yield, i.e. the bolt tension force corresponding to the bending resistance of the end-plate segment is larger than the bolt’s ultimate tension resistance, this indicates that the end-plate is rather thick and it does not yield. Here, the slope of the last straight line segment, i.e. the straight line segment after point (e), is taken to be equal to the slope of its preceding straight line segment. This circumstance should be avoided during the design. According to the relevant tests and investigation results [3,32,43], the failure of the end-plate in bending can provide the joint with higher deformation capacity, while the failure of bolts in tension is much less dissipative and less deformable. The seismic design rule of “strong connection, weak plate” should be adopted. It also suggested applying the end-plate with moderate thickness and adequately stiffening. The bolt diameter should be adequate so that the bolt ultimate tension resistance is higher than the end-plate segment ultimate bending resistance, in order to assure the joint ductility and energy dissipation capacity. For the end-plate connection with a strong bolt and weak end-plate, it may happen that the bending resistance of the endplate segment at the first bolt-row is below the bolt tension force of the first bolt-row when the end-plate and column flange separate at this position, i.e. the end-plate segment yields prior to the separation of the end-plate and column flange. Here a pivotal point should be added to the moment–end-plate rotation curve, which is the bolt tension force of the first boltrow corresponding to the yielding resistance of the end-plate segment at this position. The relevant bolt transferred tension force, the bolt extension, the bending deformation of the endplate and the corresponding end-plate rotation can then be calculated. (iii) Moment–gap rotation (M–φep ) curve The moment–gap rotation (M–φep ) curve can be obtained by superposing the moment–bolt extension rotation curve, the moment–end plate rotation curve and the moment–column flange rotation curve. The calculation method for the moment–column flange rotation curve is the same as that for the moment–end plate rotation curve. If the column flange is wider than the end-plate, the values of b1 and b2 for the column flange should be taken as the values of the end-plate. 5.3. Moment–rotation (M–φ) curve The moment–rotation (M–φ) curve can be obtained by superposing the moment-shearing rotation (M–φs ) curve and the moment–gap rotation (M–φep ) curve. During the process of superposing, for the moment value of each pivotal point of the M–φs curve and M–φep curve, adding the corresponding shearing rotation φs and gap rotation φep , the joint rotation φ is equal to φs + φep . Linking these pairs of M and φ, the M–φ curve of the end-plate connection can be obtained. 6. Comparison of analytical and test results and discussion The M–φ curves for test specimens EPC-1–EPC-5 have been calculated using the above analytical model, and the comparison between the M–φs curves, the M–φep curves and Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 1291 Fig. 14. Comparison of the M–φ curves from the analytical model and tests. the M–φ curves of the analytical models and test results are shown in Figs. 12–14. The comparison between the joint initial rotational stiffness, S j,ini , of the analytical models and test results are listed in Table 5. The value of S j,ini from the analytical model is taken as the slope of the first straight line segment of its M–φ curve. In Figs. 12–14 and Table 5, Model 1 denotes that the analytical results are calculated according to the material property values specified in the current Chinese 1292 Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 Table 5 Comparison of S j,ini of specimens from analytical and test results Specimen number Model 1 (kN m/rad) Model 2 (kN m/rad) Test (kN m/rad) Model 1/ Test Model 2/ Test EPC-1 EPC-2 EPC-3 EPC-4 EPC-5 49 690 53 911 49 845 54 136 43 441 46 811 50 577 39 712 50 775 40 331 52 276 46 093 46 066 47 469 41 634 0.95 1.17 1.08 1.14 1.04 0.90 1.10 0.86 1.07 0.97 1.08 0.98 Average steel design code; the yield strength of Q345 steel is f y = 345 MPa; the ultimate strength is f u = 470 MPa; the yield strength of grade 10.9 bolt is f by = 940 MPa and its ultimate tension strength is f bu = 1040 MPa; the elastic modulus of steel is E = 2.06 × 105 N/mm2 and its shear modulus G = 79 × 103 MPa. Model 2 denotes that the analytical results are calculated according to the material actual properties obtained from coupon tests which are listed in Table 2. The steel’s hardening modulus is assumed to be E h = 0.04E; the bolt’s hardening modulus is assumed to be E bh = 0.1E b ; Poisson’s ratio is taken as µ = 0.3; and the elastic modulus of bolt is taken as E b = 2.06 × 105 N/mm2 . The other connection parameters are taken as h bw = 276 mm, h cw = 276 mm, tcw = 8 mm, Ae = 244.8 mm2 (M20) or 352.5 mm2 (M24); lb = 48 mm (EPC-1), or 58 mm (EPC-2), or 50 mm (EPC-3), or 60 mm (EPC-4), or 40 mm (EPC-5); α = 10, d f = 288 mm, y1 = 200 mm, y2 = 88 mm, ew = 49 mm, e f = 50 mm, b1 = 100 mm, b2 = 95 mm, β = 0.856. From the comparison of the results in Figs. 12–14 and Table 5, it can be concluded that: (1) The M–φ curves, the M–φs curves and the joint initial rotational stiffnesses obtained from the analytical model coincide well with the test results if the actual material properties are applied. The comparison verifies the accuracy of this analytical model. In practical structural design, where the nominal material property specified in current code is applied, the analytical models also give satisfactory solutions with adequate accuracy. (2) The M–φep curves obtained from the analytical results coincide well with the tests results at the initial loading stage. After nonlinearity occurs in the loading curves, there are some discrepancies between the analytical results and the test results. The possible reasons behind these discrepancies may be explained as follows: The end-plate and column flange deformation is evaluated under the assumption that the endplate segment is fixed at the bolt centre line. The endplate and column flange contact closely due to the bolt pretension force at the initial loading stage, and this assumption is reasonable. With the joint moment increasing, the contact force between the end-plate and column flange is significantly reduced and even if they separate, this assumption will lead to some discrepancies, but the discrepancies do not considerably influence the evaluation of joint total rotation (Fig. 14). The final results of the M–φ curve are in accordance with the tests generally. 7. Conclusions (1) In this paper, the stiffened and extended beam–column end-plate connection has been recommended for end-plate moment connections in multistory steel frames, and its standards details have been proposed. Five full-scale joint tests of this type of end-plate connection have been conducted to investigate the influences of bolt size and end-plate thickness on the joint behaviour. The rotational stiffness, moment resistance and moment–rotation (M–φ) curves are obtained. A clear definition for the end-plate connection rotation has been proposed. With a special method to measure the bolt strain, the distribution and the development of bolt tension force have been obtained during the tests. (2) A new analytical model to evaluate the moment–rotation (M–φ) relationship of this type of end-plate connection has been proposed. The end-plate connection is decomposed into several components, including the panel zone, bolt, endplate and column flange. The complete loading process of each component is analysed. The moment–rotation curve of the whole connection is obtained by superimposing each component. Comparing with the test results, it has been verified that this analytical model can sufficiently predict the rotational behaviour of end-plate connections, such as the initial rotational stiffness and the moment–rotation (M–φ) curve. Furthermore, the contributions to the joint rotational deformation of each component, such as shear deformation of the panel zone, the bolt extension, bending deformation of the end-plate and column flange etc. are provided. This analytical model can also provide the moment–shear rotation (M–φs ) and moment–gap rotation (M–φep ) curves, thus provide a reliable foundation for analysing the detailed rotational behaviour of end-plate connections. Acknowledgements The writers gratefully acknowledge the support for this work, which was funded by the Tsinghua Basic Research Foundation (Grant No. JCqn2005006) and the Natural Science Foundation of China (No. 50578083). References [1] Chen WF, Lui FM. Stability design of steel frames. Boca Raton (FL): CRC Press; 1991. Y. Shi et al. / Journal of Constructional Steel Research 63 (2007) 1279–1293 [2] Attiogbe E, Morris G. Moment–rotation functions for steel connections. Journal of Structural Engineering 1991;117(6):1703–18. [3] CEN: prEN1993-1-8. Eurocode 3: Design of steel structures: Part 1.8 Design of joints. 2002. [4] American Institute of Steel Construction (AISC). Allowable stress design specification for structural steel buildings. Chicago (IL); 1989. [5] American Institute of Steel Construction (AISC). Load and resistance factor design specification for structural steel buildings. Chicago (IL); 1999. [6] GB50017-2003. Code for design of steel structures. 2003 [in Chinese]. [7] Chen WF. Practical analysis for semi-rigid frame design. Singapore: World Scientific; 2000. [8] Shi YJ, Chan SL, Wong YL. Modeling for moment–rotation characteristics for end-plate connections. Journal of Structural Engineering 1996; 122(11):1300–6. [9] Shi G, Shi YJ, Wang YQ, Chen H. Numerical simulation and experimental study on bolted end-plate connections. In: The eighth international symposium on structural engineering for young experts, vol. 1. 2004. p. 137–42. [10] Kukreti AR, Murray TM, Abolmaali A. End-plate connection moment–rotation relationship. Journal of Constructional Steel Research 1987;8:137–57. [11] Douty RT, McGuire W. High strength bolted moment connections. Journal of the Structural Division 1965;91(ST2):101–28. [12] Nair RS, Birkemoe PC, Munse WH. High strength bolts subject to tension and prying. Journal of the Structural Division 1974;100(ST2):351–72. [13] Kato B, McGuire W. Analysis of T-stub flange-to-column connections. Journal of the Structural Division 1973;99(ST5):865–88. [14] Agerskov H. High-strength bolted connections subject to prying. Journal of the Structural Division 1976;102(ST1):161–75. [15] Zoetemeijer P. Semi-rigid bolted beam-to-column connections with stiffened column flanges and flush-end plates. In: Howlett JH, Jenkins WM, Stainsby R, editors. Joints in structural steelworks. London: Pentech Press; 1981. p. 2.99–2.118. [16] Packer JA, Morris L. A limit state design method for the tension region of bolted beam–column connections. The Structural Engineer 1977;55(10): 446–58. [17] Mann AP, Morris LJ. Limit design of extended end-plate connections. Journal of the Structural Division 1979;105(ST3):511–26. [18] Witteveen J, Stark JWB, Bijlaard FSK, Zoetemeijer P. Welded and bolted beam-to-column connections. Journal of the Structural Division 1982; 108(ST2):433–55. [19] Stark JWB, Bijlaard FSK. Design rules for beam-to-column connections in Europe. Journal of Constructional Steel Research 1988;10:415–62. [20] Krishnamurthy N. Correlation between 2- and 3-dimensional finite element analyses of steel bolted end-plate connections. Computers & Structures 1976;6:381–9. [21] Krishnamurty N, Huang HT, Jefferey PK, Avery LK. Analytical M-θ curves for end-plate connections. Journal of the Structural Division 1979; 105(ST1):133–45. [22] Krishnamurthy N. Modeling and prediction of steel bolted connection behavior. Computers & Structures 1980;11:75–82. [23] American Institute of Steel Construction. Manual of steel construction: Load and resistance factor design. 3rd ed. Chicago (IL); 2001. 1293 [24] Tarpy TS, Cardinal JW. Behavior of semi-rigid beam-to-column end plate connections. In: Howlett JH, Jenkins WM, Stainsby R, editors. Joints in structural steelworks. London: Pentech Press; 1981. p. 2.3–2.25. [25] Maxwell SM, Jeckins WM, Howlett JH. Theoretical approach to the analysis of connection behavior. In: Howlett JH, Jenkins WM, Stainsby R, editors. Joints in structural steelworks. London: Pentech Press; 1981. p. 2.49–2.70. [26] Sherbourne AN, Bahaari MR. 3D simulation of end-plate bolted connections. Journal of Structural Engineering 1994;120(11):3122–36. [27] Bahaari MR, Sherbourne AN. 3D simulation of bolted connections to unstiffened columns-II. Extended endplate connections. Journal of Constructional Steel Research 1996;40(3):189–223. [28] Sherbourne AN, Bahaari MR. Finite element prediction of end plate bolted connection behavior I: Parametric study. Journal of Structural Engineering 1997;123(2):157–64. [29] Bahaari MR, Sherbourne AN. Finite element prediction of end plate bolted connection behavior II: Analytic formulation. Journal of Structural Engineering 1997;123(2):165–75. [30] Shi G, Shi YJ, Wang YQ, Li S, Chen H. Finite element analysis and tests on bolted end-plate connections in steel portal frames. Advances in Structural Engineering 2004;7(3):245–56. [31] Shi G, Shi YJ, Chen H. Finite element analysis of beam–column bolted end-plate connections in steel frames. In: Seventh pacific structural steel conference. 2004. [32] Faella C, Piluso V, Rizzano G. Structural steel semirigid connections. Boca Raton (FL): CRC Press LLC; 2000. [33] Ghobarah A, Osman A, Korol RM. Behaviour of extended end-plate connections under cyclic loading. Engineering Structures 1990;12(1): 15–27. [34] Korol RM, Ghobarah A, Osman A. Extended end-plate connections under cyclic loading: Behaviour and design. Journal of Constructional Steel Research 1990;16:253–80. [35] Ghobarah A, Korol RM, Osman A. Cyclic behaviour of extended endplate joints. Journal of Structural Engineering 1992;118(5):1333–53. [36] Tsai KC, Popov EP. Cyclic behavior of end-plate moment connections. Journal of Structural Engineering 1990;116(11):2917–30. [37] Adey BT, Grondin GY, Cheng JJR. Cyclic loading of end plate moment connections. Canadian Journal of Civil Engineering 2000;27(4):683–701. [38] JGJ82-91. Specification for design, construction and acceptance of high strength bolt connections in steel structures. 1991 [in Chinese]. [39] CECS102:2002. Technical specification for steel structure of light-weight buildings with gabled frames. 2003 [in Chinese]. [40] Krawinkler H, Bertero VV, Popov EP. Shear behavior of steel frame joints. Journal of the Structural Division 1975;101(ST11):2317–36. [41] Li S, Shi G, Shi YJ, Wang YQ, Chen H. Research on end-plate bearing capacities under action of single bolt in the bolted end-plate connection of steel structures. In: Second international symposium on steel structures. 2002. p. 433–9. [42] Krishnamurthy N. A fresh look at bolted end-plate behavior and design. Engineering Journal 1978;15(2):39–49. [43] Shi G, Shi YJ, Li S, Wang YQ. Cyclic tests of semirigid end-plate connections in multi-story steel frames. Journal of Building Structures 2005;26(2):74–80 [in Chinese].