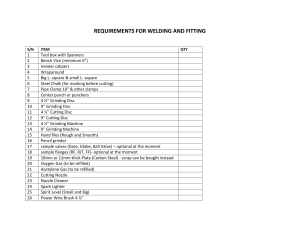

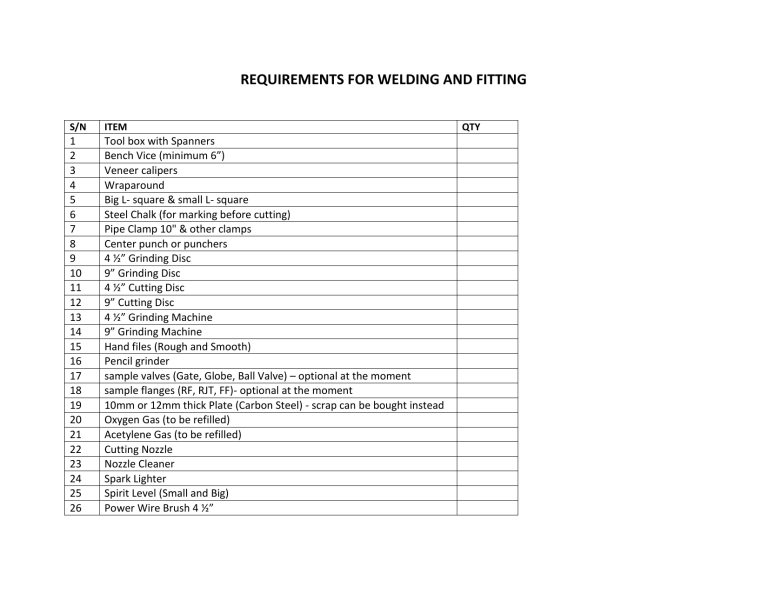

REQUIREMENTS FOR WELDING AND FITTING S/N ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 Tool box with Spanners Bench Vice (minimum 6”) Veneer calipers Wraparound Big L- square & small L- square Steel Chalk (for marking before cutting) Pipe Clamp 10" & other clamps Center punch or punchers 4 ½” Grinding Disc 9” Grinding Disc 4 ½” Cutting Disc 9” Cutting Disc 4 ½” Grinding Machine 9” Grinding Machine Hand files (Rough and Smooth) Pencil grinder sample valves (Gate, Globe, Ball Valve) – optional at the moment sample flanges (RF, RJT, FF)- optional at the moment 10mm or 12mm thick Plate (Carbon Steel) - scrap can be bought instead Oxygen Gas (to be refilled) Acetylene Gas (to be refilled) Cutting Nozzle Nozzle Cleaner Spark Lighter Spirit Level (Small and Big) Power Wire Brush 4 ½” QTY 27 28 29 30 Hand Wire brush Chipping Hammer (for removing slag from weld) E7018 Electrode for Hot Pass, Filling and Capping Safety boot size 44