Wind Turbine Capacity Factor Computation: A Modular Approach

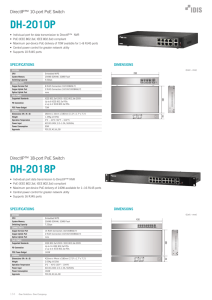

Anuncio

IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 26, NO. 3, SEPTEMBER 2011 987 Power Engineering Letters A Modular Approach to Enhance Capacity Factor Computation of Wind Turbine Generators Shyh-Jier Huang and Hsing-Ho Wan Abstract—In this letter, a modular approach is proposed to compute the capacity factor of wind turbine generators, with which the systematic calculation under manufacturing data can be performed with a higher flexibility. This proposed approach has been compared with existing methods through site wind speed data. Test results help confirm the feasibility of the method for wind source assessment applications. Index Terms—Capacity factor, computing module, wind turbine generator (WTG). sistent. Although the CF computation based on either quadratic function [3], [7] or cubic model [2] has been proposed, however, because the wind energy assessment may move away from assumption in favor of direct experimental fits to actual data, a modular CF computation method is proposed in this letter that is mainly based on manufacturer’s power curves. The new method is flexible and data driven. By using CF computations for WTGs under real wind conditions collected in Taiwan, the method is being considered an effective alternative in addition to several existing methods. I. INTRODUCTION O EVALUATE the performance of wind energy conversion system at sites, power curve modeling of wind turbine generators (WTGs) is often deemed one of important tasks. However, it requires an arduous effort to formulate an appropriate model between power output and wind speed at nonrated operation region of WTGs. Some previously published literature have reported their study in this direction of research. A cubic function model was suggested for the site matching with WTG in [1], by which it was also applied to find optimum speed parameters in [2]. Then, a quadratic function model containing second-degree and constant terms was developed as well for energy estimation and turbine-site pairing performance [3]. Besides, a quadratic function model along with second-degree, one-degree, and constant terms was utilized to reliability evaluation [4] and cost-effective assessment [5]. Through aforementioned literature review, it is found that the modeling of nonrated region on power curve of a WTG can be made based on cubic, quadratic, or linear functions. Apart from mathematic functions, a nonparameter model of wind turbine based on a neural network was meanwhile suggested [6], yet its effectiveness was highly hinged on a large number of data set as well as an appropriate training strategy. Recently, the concept of capacity factor (CF) of a WTG has become more important to assess the amount of energy delivered than ever since the wind resource is known to be seldom con- T Manuscript received March 11, 2010; revised September 8, 2010; accepted May 12, 2011. Date of publication August 2, 2011; date of current version August 19, 2011. Paper no. TEC-0028-2010. The authors are with the Department of Electrical Engineering, National Cheng Kung University, Tainan 70101, Taiwan (e-mail: clhuang@mail. ncku.edu.tw; [email protected]). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TEC.2011.2158022 II. PARADIGM In this section, a modular approach for computing CF of WTGs is derived. The power curve of a WTG is characterized by cut-in vc , rated vr , and cut-out vf speeds. Based on the manufacturing data of WTGs, the nonrated operation region of the power curve can be modeled by an n-degree polynomial, through which the CF can be expressed as n 1 αi ψi + ψR (1) CF = PR i=0 where PR is the rated output, αn , . . . α0 are the curve-fitting coefficients, and Ψn and ΨR are computing modules for nonrated and rated regions which are derived as n n k k ψn = cn pn e−p − q n e−q + Γ k k n n × γ qk , − γ pk , k k ψ0 = e−p − e−q k ψR = e−q − e−s k k k (2) where p = vc /c; q = vr /c; s = vf /c; k and c are Weibull shape and scale factors, respectively, and γ is the incomplete gamma function. From the aforementioned derivations, the CF computation is seen to perform with the product of various coefficients based on the models concerned. As an example, when the machine output power P is characterized by the wind speed v with a polynomial expression of P(v) = α3 v 3 + α2 v 2 + α1 v + α0 , the CF can be accordingly presented along with the modules of Ψ3 , Ψ2 , Ψ1 , and Ψ0 to construct a generalized form of CF = (α3 Ψ3 +α2 Ψ2 +α1 Ψ1 +α0 Ψ0 )/PR +ΨR , thereby realizing the 0885-8969/$26.00 © 2011 IEEE 988 IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 26, NO. 3, SEPTEMBER 2011 Table III CF COMPUTATION OF GE-1.5SE AT MAILIAO WIND FARM Table IV CF COMPUTATION OF GE-1.5SE AT SIHHU WIND FARM Fig. 1. Power curves of the WTG under manufacturing data and different models. Table I PARAMETERS OF MAILIAO AND SIHHU WIND FARMS IN TAIWAN Table V CF COMPUTATION OF NEG-MICON2000 AT MAILIAO FARM Table II SPECIFICATIONS OF THE CONSIDERED WIND TURBINE GENERATORS systematic and modular approach for wind source assessment applications considered. Table VI CF COMPUTATION OF NEG-MICON2000 AT SIHHU FARM III. METHOD COMPARISONS In preliminary wind energy evaluation, power curves of WTGs are often characterized by different models [1], [3], [4], [8]. Fig. 1 presents manufacturing data [9] and four existing models of the power curve on the same graph for WTGs. To validate the effectiveness of the method, it is employed to investigate the CF for the WTG of wind farms located at Mailiao and Sihhu Township located near central Taiwan. Table I lists Weibull parameters of these two wind farms, which are obtained by the long-term wind data recorded in the Central Weather Bureau, Taiwan. The total number of hours recording the mean wind speed of Mailiao and Sihhu wind farms are 32 443 and 35 013, respectively, which was collected from the monitoring lasting over 4 years. Table II lists the specifications of two WTGs considered in this letter. Efforts on CF computations using existing models have been made and proposed in [2], [3], and [7]. Among these methods, the method in [2] was derived from the model in [1], while the methods in [3] and [7] were developed from the model in [3]. Each existing method is applicable for a specific model only. In this letter, the proposed approach is compared with existing methods through real wind farm data, where the CF using different models [1], [3], [4], [8] as well as [9] (manufacture data) is individually shown in Tables III–VI. As the table lists, the proposed methods and several existing methods are applied to compute the CF under different models, where the symbol “” means not applicable. As an example, when the model of a WTG in [1] is considered for CF estimation, only the method proposed in [2] would present a closed form for CF computation. Then, as for the model in [3] is employed, only methods proposed in [3] and [7] are applicable, while others are not. Note that the acronym “Manu.” used in the cell stands for the manufacturer. Now, from the tabulations of these tables, it is found that for all these five cases, the proposed method is applicable and reaches good agreement with previously published techniques whenever the test outcome is available for the comparison. It is also observed that the model using manufacturing data would yield a highest CF, implying that the model per se seems to own a higher potential to provide larger energy than several existing models, which may be a useful reminder in the evaluation of wind projects. IV. CONCLUSION This letter presents a modular approach to estimate the CF of WTGs, offering a quick grasp of scenarios considered and benefiting the engineers for wind resource assessment in wind power projects. Currently, with the technical support IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 26, NO. 3, SEPTEMBER 2011 of utility engineers, the method is being extended to evaluate more wind sites in Taiwan. The estimation reliability has become the major concern that will be reported in the near future. REFERENCES [1] S. H. Jangamshetti and V. G. Rau, “Site matching of wind turbine generators: A case study,” IEEE Trans. Energy Convers., vol. 14, no. 4, pp. 1537–1543, Dec. 1999. [2] S. H. Jangamshetti and V. G. Rau, “Normalized power curves as a tool for identification of optimum wind turbine generator parameters,” IEEE Trans. Energy Convers., vol. 16, no. 3, pp. 283–288, Sep. 2001. [3] S. Y. Hu and J. H. Cheng, “Performance evaluation of pairing between sites and wind turbines,” Renewable Energy, vol. 32, pp. 1934–1947, 2007. 989 [4] P. Giorsetto and K. F. Utsurogi, “Development of a new procedure for reliability modeling of wind turbine generators,” IEEE Trans. Power App. Syst., vol. 102, no. 1, pp. 134–143, Jan. 1983. [5] R. Karki and R. Billinton, “Cost-effective wind energy utilization for reliable power supply,” IEEE Trans. Energy Convers., vol. 19, no. 2, pp. 435–440, Jun. 2004. [6] S. Kelouwani and K. Agbossou, “Nonlinear model identification of wind turbine with a neural network,” IEEE Trans. Energy Convers., vol. 19, no. 3, pp. 607–612, Sep. 2004. [7] M. H. Albadi and E. F. El-Saadany, “Wind turbine capacity factor modeling—A novel approach,” IEEE Trans. Power Syst., vol. 24, no. 3, pp. 1637–1638, Aug. 2009. [8] S. Mathew, Wind Energy: Fundamentals, Resource Analysis and Economics. Berlin, Germany: Springer-Verlag, 2006. [9] Dartan Power Station Operation and Maintenance Manual. Taiwan Power Company, Taipei, Taiwan, 2010.