Grounding & Lightning Calculation for Distillation Units

Anuncio

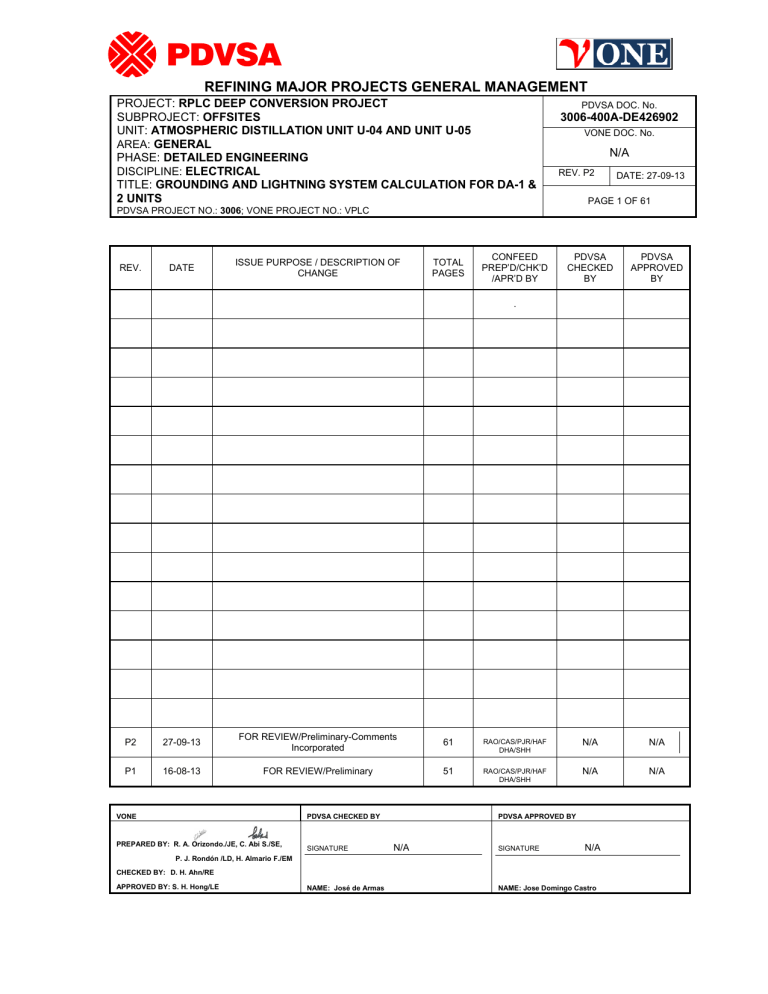

REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT U-04 AND UNIT U-05 AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & 2 UNITS PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PAGE 1 OF 61 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC REV. DATE ISSUE PURPOSE / DESCRIPTION OF CHANGE TOTAL PAGES CONFEED PREP’D/CHK’D /APR’D BY DATE: 27-09-13 PDVSA CHECKED BY PDVSA APPROVED BY . P2 27-09-13 FOR REVIEW/Preliminary-Comments Incorporated 61 RAO/CAS/PJR/HAF DHA/SHH N/A N/A P1 16-08-13 FOR REVIEW/Preliminary 51 RAO/CAS/PJR/HAF DHA/SHH N/A N/A VONE PDVSA CHECKED BY PREPARED BY: R. A. Orizondo./JE, C. Abi S./SE, _ SIGNATURE PDVSA APPROVED BY N/A SIGNATURE N/A P. J. Rondón /LD, H. Almario F./EM CHECKED BY: D. H. Ahn/RE APPROVED BY: S. H. Hong/LE NAME: José de Armas NAME: Jose Domingo Castro REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT U-04 AND UNIT U-05 AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & 2 UNITS PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC DATE: 27-09-13 PAGE 2 OF 61 RPLC DEEP CONVERSION PROJECT GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & DA-2 UNITS REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT U-04 AND UNIT U-05 AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & 2 UNITS PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 3 OF 61 Contents 1 SCOPE ................................................................................................................................................ 4 2 OBJECTIVE ........................................................................................................................................ 4 3 REFERENCE ...................................................................................................................................... 4 4 DEFINITIONS ...................................................................................................................................... 5 5 TERMS ................................................................................................................................................ 6 5.1 IEEE 80 ............................................................................................................................................... 6 5.2 PIP PCCEL001 .................................................................................................................................... 7 6 SPECIFICATIONS FOR GROUNDING DESIGN ................................................................................. 7 6.1 Grounding Electrodes ....................................................................................................................... 7 6.2 Maximum Fault Current ..................................................................................................................... 8 6.3 Soil Resistivity ................................................................................................................................... 9 6.4 Electrical Protection Operation Time ............................................................................................... 9 6.5 Conductor Sizing Calculation ........................................................................................................... 9 6.6 Rod Resistance to Ground and Maximum Density Current Calculations ................................... 10 6.7 Grounding Bus Bar.......................................................................................................................... 12 7 SIMULATIONS .................................................................................................................................. 12 8 SUMMARY ........................................................................................................................................ 15 9 RESULTS AND RECOMMENDATIONS ........................................................................................... 16 10 LIGHTNING PROTECTION CALCULATION .................................................................................... 16 10.1 Terms, NFPA 780 .............................................................................................................................. 16 10.2 References ....................................................................................................................................... 17 10.3 Keraunic Level and Lightning Flash Density................................................................................. 17 10.4 Protection Philosophy ..................................................................................................................... 17 11 CONCLUSIONS AND RECOMMENDATIONS ................................................................................. 19 12 ATTACHMENTS ............................................................................................................................... 19 REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT U-04 AND UNIT U-05 AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & 2 UNITS PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC 1 DATE: 27-09-13 PAGE 4 OF 61 SCOPE The scope of this document is limited to the grounding and lightning system calculation design of Atmospheric Distillation Unit 04 and Unit 05. 2 OBJECTIVE The objective of this document is to present the criteria, methodology and calculation use to design the grounding and lightning systems in Atmospheric Distillation Unit 04 and Unit 05, required at permanent facilities for the RPLC Deep Conversion Project in Puerto La Cruz Refinery of PDVSA, Venezuela. 3 Grounding and lightning systems will be designed to achieve the following objectives: To assure that a person in vicinity of grounded facilities will not be exposed to a critical electrical shock, by keeping touch and step voltages under tolerable levels as per IEEE 80. To provide means to carry electric currents into the earth under fault conditions without exceeding any operating limits or adversely affecting continuity of service without creating a fire or explosive hazards. To assure that a person, equipment, or structures in DA-1 and DA-2 areas will be protected against lightning discharges. REFERENCE (1) Codes and Regulations • National Electrical Code NFPA 70 2011. • IEEE Std 80 - 2000 IEEE Guide For Safety in AC Substation Grounding. • IEEE 142 IEEE Recommended Practice for Grounding of Industrial and Commercial Power Systems. • PIP PCCEL001 Instrumentation Electrical Design Criteria • NFPA 70 (2011) National Electrical Code. • PDVSA N 201 (1993) Obras Eléctricas. (2) Project Documents • GENERAL SPECIFICATION FOR ELECTRICAL SYSTEM AND INSTALLATION N° 3006-5000-DE115001. • SHORT-CIRCUIT STUDY FOR DA-1 & 2 UNITS N° 3006-400A-DE322901 • CABLE LIST DA-1 UNIT N° 3006-404A-DE707001 • CABLE LIST DA-2 UNIT N° 3006-405A-DE707001 • ELECTRICAL PROTECTION COORDINATION STUDIES FOR DA-1 & 2 UNITS N° 3006-400A-DE321902 REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT U-04 AND UNIT U-05 AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & 2 UNITS PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PAGE 5 OF 61 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC 4 DATE: 27-09-13 • ELECTRICAL PROTECTION COORDINATION STUDIES DA-2 UNIT N° 3006-405A-DE321001 (3) Project Drawings • PLOT PLAN UNIT 04 N° 3006-404A-DM206001 • PLOT PLAN UNIT 05 N° 3006-405A-DM206001 • KEY LINE DIAGRAM N° 3006-404A-DE216001 • KEY LINE DIAGRAM N° 3006-405A-DE216001 • INSTALLATIONS DETAILS -GROUNDING & LIGHTNING FOR DA-1 & DA-2 UNITS N° 3006-400A-DE272901 • HAZARDOUS AREA CLASSIFICATION DISTILLATION UNIT 1 (DA-1) REVAMP N° 3006-404A-DE217001 DRAWING UNIT 04 ATMOSPHERIC • HAZARDOUS AREA CLASSIFICATION DISTILLATION UNIT 2 (DA-2) REVAMP N° 3006-405A-DE217001 DRAWING UNIT 05 ATMOSPHERIC (4) Others supplied by Hyundai • AIG-2012-531-CT-02_Resistivity Test Results. See Annex A. • 02. Borehole Location Plan_Rev.1. See Annex A. • Short Circuit Calculation N° 3006-500A-DE322001 • Electrical Grounding Philosophy N° 3006-500A-DE272401 • Instrument Grounding Philosophy N° 3006-500A-DI2C6011 • Earthing & Lightning Protection Calculation N° 3006-500A-DE426002 DEFINITIONS 1) COMPANY: PDVSA, Petróleos, S.A. 2) MAIN PROJECT: Engineering, Procurement, Construction and Start Up Assistance of the Environmental Units, Auxiliary Units and Revamp of the Atmospheric Distillation Units of the Deep Conversion Project, Puerto La Cruz Refinery 3) PROJECT: 4) CONTRACTOR: A consortium formed by HYUNDAI ENGINEERING & CONSTRUCTION CO., LTD., HYUNDAI ENGINEERING CO., LTD., and WISON ENGINEERING LTD. who is the EPC Contractor for the MAIN PROJECT. Detail engineering service for DA-1 & DA-2 Units REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT U-04 AND UNIT U-05 AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & 2 UNITS PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 6 OF 61 5) SUBCONTRACTOR: INELECTRA S.A.C.A. 6) CONFEED: A consortium formed by JGC, INELECTRA and CHIYODA, who is the contractor for the RPLC Deep Conversion Project Phase II. 7) RPLC: Refinery Puerto La Cruz 8) SOC: Seoul Operation Center 9) PMT: Project Management Team 10) PMC: Project Management Consultant as a member of COMPANY and Toyo Engineers 11) DHT: Document Handling Team 12) Project Space: CONTRACTOR’s EDMS 13) SIMDE: COMPANY’s EDMS 14) PM: Project Manager 15) EM: Engineering Manager 16) SE: Senior Engineer 17) JE: Junior Engineer 18) LD: Lead Discipline Engineer 19) DC: Document Controller 20) DRN: Design Review Notice 5 TERMS 5.1 IEEE 80 Auxiliary ground electrode: A ground electrode with certain design or operating constraints. Its primary function may be other than conducting the ground fault current into the earth. Fault current division factor (Sf): A factor representing the inverse of a ratio of the symmetrical fault current to that portion of the current that flows between the grounding grid and surrounding earth. Ground: A conducting connection, whether intentional or accidental, by which an electric circuit or equipment is connected to the earth or to some conducting body of relatively large extent that serves in place of earth. Grounded: A system, circuit, or apparatus provided with ground for the purposes of establishing a ground return circuit and for maintaining its potential at approximately the potential of earth. Ground Current: A current flowing into or out of the earth or its equivalent serving as a ground. Ground Electrode: A conductor imbedded in the earth and used for collecting ground current from or dissipating ground current into the earth. Ground Potential Rise (GPR): The maximum electrical potential that a substation grounding grid may attain relative to a distant grounding point assumed to be at the potential of remote earth. Ground Return Circuit: A circuit in which the earth or an equivalent conducting body is utilized to complete the circuit and allow current circulation from or to its current source. REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT U-04 AND UNIT U-05 AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & 2 UNITS PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 7 OF 61 Grounding Grid: A system of horizontal ground electrodes that consists of a number of interconnected, bare conductors buried in the earth, providing a common ground for electrical devices or metallic structures, usually in one specific location. Grounding System: Comprises all interconnected grounding facilities in a specific area. Step Voltage: The difference in surface potential experienced by a person bridging a distance of 1 m with the feet without contacting any grounded object. Surface Material: A material that covers the soil with the purpose to reduce the step and touch voltages. Generally this material has a high resistivity. Symmetrical Grid Current (Ig): That portion of the symmetrical ground fault current that flows between the grounding grid and surrounding earth. Symmetrical Ground Fault Current (If): The maximum rms value of symmetrical fault current after the instant of a ground fault initiation. As such, it represents the rms value of the symmetrical component in the first half-cycle of a current wave that develops after the instant of fault at time zero. Touch Voltage: The potential difference between the ground potential rise (GPR) and the surface potential at the point where a person is standing while at the same time having a hand in contact with a grounded structure. Transferred Voltage: A special case of the touch voltage where a voltage is transferred into or out of the substation from or to a remote point external to the substation site. 5.2 PIP PCCEL001 AC Safety Ground: The grounding system required by NEC Article 250 to provide protection for personnel and electrical equipment. The instrument ground bus is connected to the safety ground in accordance with NEC requirements. Field Instrument Enclosure: The term used in the generic sense to indicate a cabinet or building that houses instruments and/or wiring termination external to instrument rooms or control buildings. Instrument Ground System (IGS): Instrumentation ground system connected to a high-quality earth ground and isolated from all other grounds. Instrument Rooms: The term used in the generic sense for a walk-in-type structure, including rack rooms, remote instrument enclosures, or any completely enclosed structure that houses control equipment. Junction Box: A protective enclosure around connections between electric wires or cables. The junction box may be a field junction box (JB) or it may be within a control building or instrument enclosure, where it is referred to as an interface box (IB) or marshalling cabinet. 6 6.1 SPECIFICATIONS FOR GROUNDING DESIGN Grounding Electrodes According to document N° 3006-5000-DE115001 “General Specification for Electrical System and Installation”, a grounding grid shall be provided as the general grounding electrode. This grounding grid shall be of bare copper conductors, buried at minimum of 0.45 meters below grade level. According to document N° 3006-5000-DE115001 “General Specification for Electrical System and Installation” and drawing N° 3006-500A-DE272401 “Electrical Grounding Philosophy” the REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT U-04 AND UNIT U-05 AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION FOR DA-1 & 2 UNITS PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC DATE: 27-09-13 PAGE 8 OF 61 cable size of the main grounding grid shall be a minimum of 2/0 AWG (70 mm2), and a minimum cable size of 2 AWG (35 mm2) for derivations. The cable size of the main grounding grid for building substation shall be 250 MCM. Size of cable intended for grounding grid for packaged substation is to be confirmed. Nevertheless 250 MCM also is to be assumed. Grounding rods shall be a minimum of 5/8 inch of diameter and 8 feet length. The underground connections between the main ground grid and the derivations shall be exothermic type. Compression and mechanical connectors shall be used for aboveground connections. It is recommended exothermic connections for download conductors intended for lightning systems. Exothermic connections shall not be done in areas where flammable liquids or explosive vapors are present or thought to be present. In the latter case, a combustible gas indicator test shall be made to assure that the area is safe i.e. the explosimeter reading shall be zero. The constructive characteristics are shown in the document N° 3006-400A-DE272001 “Grounding and Lightning Installation Details”. The conductors will have current capacity and mechanical strength to be able to connect to: 6.2 All non-energized metallic structures that accidentally might be, such as: transformers cases, motor frames and skids, cable trays, ducts, vessels, fences, tanks and any other miscellaneous supporting structures. Lightning rods, surge suppressors, control and lighting circuits, neutral of transformers, etc. Maximum Fault Current Maximum one-phase short circuit level is at SS98-2C-SWG-501 (34.5 kV) and equals 0.8 kA (bus-tie breaker closed) according to information indicated in PDVSA Doc. No. 3006-500A-DE322001 Rev. A supplied by Hyundai. One-phase short circuit level at 4.16 kV is 0.4 kA for all study cases according to information indicated in PDVSA Doc. No. 3006-400A-DE322901 Rev. A. Maximum one-phase short circuit level is at SS04-MCC-202A (0.48 kV) and equals 46.86 kA for case 5 (worst operating condition), also according to information indicated in PDVSA Doc. No. 3006-400A-DE322901 Rev. A. All these one phase short circuit currents will return via its equipment grounding conductor or through the grounding mesh, according to information shown in CABLE LIST DA-1 UNIT 3006-404A-DE707001 and CABLE LIST DA-2 UNIT 3006-405A-DE707001. There are no expected ground currents to flow into the soil, neither from any near overhead distribution line nor from any other source. So fault current division factor is assumed to be zero. REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC 6.3 DATE: 27-09-13 PAGE 9 OF 61 Soil Resistivity According to document AIG-2012-531-CT-02_Resistivity Test Results, there are four two-layer soil resistivity models, calculated for process and buildings of interest: two (2) models for DA-1 & two others for DA-2. Table 1. Electrical Resistivity Models for DA-1. Point ERT 01 PROCESS AREA DA‐1 322,643 E; 1,129,635 N Depth (m) Resistivity (Ω*m) 0 ‐ 3.6 11.5 > 3.6 2.4 Point ERT 03 SS04 & SRG04 322,605 E; 1,129,711 N Depth (m) Resistivity (Ω*m) 0 – 2.1 25.2 > 2.1 22.3 Study points coordinates are UTM Table 2. Electrical Resistivity Models for DA-2. Point ERT 05 PROCESS AREA DA‐2 & SRG05 322,882 E; 1,129,322 N Depth (m) Resistivity (Ω*m) 0 – 0.5 9.5 > 0.5 8.03 Point ERT 06 SS05 322,869 E; 1,129,326 N Depth (m) Resistivity (Ω*m) 0 ‐ 1.04 45.2 > 1.04 8.1 Study points coordinates are UTM Complete resistivity results are shown in Annex A. 6.4 Electrical Protection Operation Time The fault duration shall correspond to maximum fault clearing time of backup protections, which comprises the moment of fault occurrence until the fault clearance. For this period of time it was assumed 0.25 s at all voltage levels (IEEE Std. 80-2000 Sec 16.2.2). Nevertheless, the assumption of this period of time corresponds to the expected value. When the electrical protection coordination studies are issued, further examination of fault clearance times is needed to confirm actual cross sectional area of transformers neutral groundings, actually rated at 2/0 AWG in the Electrical Grounding Philosophy, and neutral groundings of diesel generators, also rated at 2/0 AWG in the Electrical Grounding Philosophy N° 3006-500A-DE272401. 6.5 Conductor Sizing Calculation Considering the short time temperature rise in a ground conductor, its minimum sizing is determined by the formula (see IEEE Std 80 – 2000, sec. 11.3.1.1, Equation 41): A 197.4 =I ∗ Where: Akcmil = conductor cross section, (kcmil) ∗ ∗ ln 0 0 REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC Tm = maximum allowable temperature, (°C) Ta= ambient temperature, (°C) PAGE 10 OF 61 1083 °C 40 °C αr = thermal coefficient of resistivity at reference temperature Tr, (1/°C) Tr = reference constants, (°C) DATE: 27-09-13 temperature for 0.00393 °C-1 material 20°C ρr = resistivity of the ground conductor at reference temperature Tr, (µΩ-cm) 1.72 µΩ-cm K0= (1/ αr)-Tr, (°C) 234°C tc = duration of the current, (s) 0.25s TCAP = thermal capacity per unit volume from Table 1, (J/cm3°C) 3.42 J/cm3°C Note that αr and ρr are both defined at the same reference temperature of Tr. Table 1 (see IEEE Std 80 – 2000, sec. 11.3.1.1) provides data for αr and ρr at 20°C. Akcmil = 164.1 kcmil Result indicates that the grounding conductor must have a minimum size of 164.1 kcmil (4/0 AWG), equivalent to 83.13 mm2. This size does not take into account the decrement factor. This value is greater than the one indicated in the Electrical Grounding Philosophy for LV transformers where actual cross sectional area of transformers neutral grounding is rated at 2/0 AWG. Further examination of fault clearance times is needed to validate this area. 6.6 Rod Resistance to Ground and Maximum Density Current Calculations Grounding systems usually consist of local electrodes placed from the grid into the soil in order to reach deeper layers. For any given 5/8” diameter and 2.4 m length rod, its resistance is: Rrod 4* L * Ln 1 2 * L R Where: Rrod = Resistance of any given rod (W) r = Average resistivity, (Ω*m) Given in Table 3 L = Length of rod, (m) 2.4 m R= Radius of rod, (m) 0.0079375 m As stated in 6.3 resistivity values are expressed in a two-layer model of soil. But the resistance equation is given as a function of a resistivity. To account for this, IEEE 80 suggests using an average value of resistivity in order to compute with this equation. Average values are given below for all cases. REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC DATE: 27-09-13 PAGE 11 OF 61 Table 3. Average Electrical Resistivity for DA-1/DA-2. Point ERT 01 PROCESS AREA DA‐1 322,643 E; 1,129,635 N Point ERT 03 SS04 & SRG04 322,605 E; 1,129,711 N Average Resistivity (Ω*m) =(11.5+2.4)/2=6.95 Average Resistivity (Ω*m) =(25.2+22.3)/2=23.75 Point ERT 05 PROCESS AREA DA‐2 & SRG05 322,882 E; 1,129,322 N Point ERT 06 SS05 322,869 E; 1,129,326 N Average Resistivity (Ω*m) =(9.5+8.03)/2=8.675 Average Resistivity (Ω*m) =(45.2+8.1)/2=26.65 Resistance for any individual rod follows: Table 4. Resistance of one rod as a function of its location in DA-1/DA-2. Point ERT 01 PROCESS AREA DA‐1 322,643 E; 1,129,635 N Point ERT 03 SS04 & SRG04 322,605 E; 1,129,711 N Rod Resistance (Ω) = 2.81 Rod Resistance (Ω) = 9.60 Point ERT 05 PROCESS AREA DA‐2 & SRG05 322,882 E; 1,129,322 N Point ERT 06 SS05 322,869 E; 1,129,326 N Rod Resistance (Ω) = 3.51 Rod Resistance (Ω) =10.78 All values of grounding rods are lower than maximum NEC limit of 25 Ω per one electrode. All multiple rods shall meet restrictions given in “Electrical Grounding Philosophy” N° 3006-500A-DE272401 Notes 6 & 7 and in GENERAL SPECIFICATION FOR ELECTRICAL SYSTEM AND INSTALLATION N° 3006-5000-DE115001 Sec. 13.3.9. Another condition to be met is the maximum current density around any rod. This is compute using equation 4.2 of IEEE 142, as follows: I max Where: dImax = Maximum density current (A/m) 1140 * d *t REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 12 OF 61 t = duration of the current, (s) d= rod diameter (mm) 0.25 s 15.875 mm Worst case for any of the above points is the one with less resistivity e.g. ERT 01. For this case Imax = 1.37 kA/m which shall be use as the maximum density current in order to keep the current density in the earth to a low value. 6.7 Grounding Bus Bar 6.7.1 Plant/Safety Grounding Bar PG bus bar shall be used to ground equipment cases, instrument enclosures, panel boards and rack rooms placed inside process-instrument buildings, analyzer house or other buildings and for process-field instruments. Other grounding bars shall be allocated each 30 meters minimum in process areas. 6.7.2 Instrument Grounding bar (IG) IG bus bar shall be used to connect the instrument ground system (IGS) isolated from all other grounds. It shall be connected at one point to a high-quality earth ground (a ground rod arrangement placed for instance in a triangular configuration); each rod will have a grounding test well, and shall also be connected at one point to the main grounding grid. 6.7.3 Intrinsically Safe Grounding bar (ISG) Similarly, ISG bus bar shall be used to ground intrinsically safe instrument equipment. It also shall be connected at one point to a high-quality earth ground (a ground rod arrangement placed for instance in a triangular configuration); each rod will have a grounding test well, and shall also be connected at one point to the main grounding grid. These criteria meet the “Electrical Grounding Philosophy” N° 3006-500A-DE272401. 7 SIMULATIONS The simulations were made using the commercial software ETAP 7.5.0. The software uses a two layer soil model, the faulted current along with the expected clearing time to calculate the grounding grid resistance according to a given electrode arrangement, calculates GPR and evaluates the dangerous points where surface voltage profiles are greater than maximum tolerable voltages. The DA-1 and DA-2 grounding grids have an irregular pattern. For that reason calculations were made using the Finite Element option available in ETAP, recommended for non regular grids configurations. Figures 1 to 7 show the arrangement of conductors and grounding rods for all substations. REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC Figure 1. ETAP Graphical Interface for SS04. Figure 2. ETAP Graphical Interface for SRG04. PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 13 OF 61 REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC Figure 3. ETAP Graphical Interface for SS05. Figure 4. ETAP Graphical Interface for SRG05. PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 14 OF 61 REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 15 OF 61 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC Figure 5. ETAP Graphical Interface for CCM DA-2. 8 SUMMARY Below are two tables that summarize the physical characteristics of the grounding system for each substation and area. Table 5. Summary of the Grounding System for SS04, SS05 & CCM. UNIT SS04 SS05 CCM DA‐2 Etouch (Tolerable) Estep (tolerable) Short Area (m2) (Horizontal Conductor of Mesh Total Ground Ground Circuit (kA) x Vertical) Size (MCM) Interval (m) Wire Lenght (m) Resistivity (ohm) Em (Calculated) Es (Calculated) 0 0 0 40m x 24m 18m x 30m 12m x 10m 500 250 500 4m x 4m 6m x 6m 2m x 2m 544m 228m 142m 0.31 0.22 0.28 240.8 267.1 0 0 247.7 294.9 0 0 235.3 245.2 0 0 REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 16 OF 61 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC Table 6. Summary of the Grounding System for DA-1/DA-2, SRG04 & SRG05. 9 UNIT Total Ground Ground Area (m2) Conductor Size (AWG) Wire Lenght Resistivity (m) (ohm) DA‐1 21594.39 #2/0 1105m 0.31 36 DA‐2 689249.5 #2/0 793m 0.31 44 SRG04 1338.85 #2/0 150m 0.37 9 SRG05 112.77 #2/0 109m 0.17 6 # of Rods RESULTS AND RECOMMENDATIONS No currents will be flowing from the designed grounding grid into the earth so the rise of the grid potential with respect to remote earth is zero and consequently there are no expected values of step and touch voltages inside the area. Though, it is recommended to validate this information with design data from the main substation at 230 kV to analyze if there may exist transferred potentials either from the main substation grid or interconnected substations grids inside the refinery to the SS-98 2B ground grid, that can affect the SS-04 and/or SS-05 step and touch potentials. Simulation results indicates that the grounding grid resistance of DA-1 equals Rg=0.03 W and for DA-2 is Rg=0.05 W. Grounding grid resistance of SS04 is Rg=0.31 W and for SS05 is Rg=0.22 W. Similar results for grounding grid resistance of SRG04 which is Rg=0.37 W, that of SRG05 which is Rg=0.17 W and that of CCM which is Rg=0.28 W Complete simulation results are shown in Attachment B. The grounding grids resistances values are low compare to known values of industrial ground grids, due to low soil resistivity. In all cases the addition of grounding rods will reduce even more the total resistance of the grids. This can be seen from tables 1 & 2, where resistivity values in deeper layers are even lower than near surface. The interconnection with other grids inside the refinery will improve the grounding system. 10 10.1 LIGHTNING PROTECTION CALCULATION Terms, NFPA 780 Lightning flash density (Ng): The yearly number of flashes to ground per square kilometer (flashes/ Km2/ year). Rolling sphere method: This is a model based on the simple electrogeometric method. To apply the method, an imaginary sphere is rolled over the structure. All surface contact points are deemed to require protection, while the unaffected surfaces and volumes are deemed to be protected. This method is explained in NFPA 780 2011. Air Terminal or Strike termination device: A component of a lightning protection system that intercepts lightning flashes and connects them to a path to ground. Strike termination devices include air terminals, metal masts, permanent metal parts of structures, and overhead ground wires installed in catenary lightning protection systems. REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC 10.2 10.3 DATE: 27-09-13 PAGE 17 OF 61 References (1) Codes and regulations • National Electrical Code NFPA 70 2011. • PDVSA N 201 1993 Obras Eléctricas. • NFPA 780 2011 Standard for the Installation of Lightning Protection Systems. (2) Project Documents • General Specification for Electrical System and Installation Doc. N° 3006-5000-DE115001. (3) Project Drawings • Plot Plan Unit 04 N° 3006-404A-DM206001 • Plot Plan Unit 05 N° 3006-405A-DM206001 • Grounding and Lightning Installation Details N° 3006-400A-DE272001 (4) Others • Actualización de la actividad de rayos en Venezuela, empleando la información del proyecto satelital de la Nasa. Junio 2009. L. Díaz, M. Martínez, J. Ramírez, J. Rodríguez. Keraunic Level and Lightning Flash Density Keraunic level value according to document “Actualización de la actividad de rayos en Venezuela, empleando la información del proyecto satelital de la Nasa” is considered to be 13 (thirteen) thunderstorm days per year. To compute the lightning flash density, the following equation given by IEEE Std. 998-1996 is used. 0.12 1.56 / / Where: NG = lightning flash density TD = thunderstorm days per year 10.4 Protection Philosophy Lightning protection shall be designed according to NFPA standard 780, which applies the rolling sphere method to compute its distances. Facilities located inside protected areas will be considered adequately protected against lightning strokes. These protected areas are buildings, pipe racks, air cooler bays and platforms, if they meet grounding requirements. Above platforms equipment operating under pressure if meet their grounding requirements and its metal thickness greater than 4.8 mm need no lightning design. Packaged substations lightning system shall be design and installed by package vendor. 10.4.1 Substations Package substations lightning systems design are beyond the scope of this document. Vendor shall protect their transformers yards using air terminals. SRG buildings also shall be protected using Franklin rods installed on the top of them. REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 PAGE 18 OF 61 PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC 10.4.2 DATE: 27-09-13 SRG04, SRG05 and CCM DA-2 Lightning Protection System Lightning protection of these buildings consists of air terminals, spaced at a distance no greater than 7.6 m since its rod length is 24 in (0.6 m). Limiting distances found in Sec. 4.6.2.1, 4.8.1, 4.8.1.2, 4.8.3 and in Figure 4.8.3(a) are accomplished in SRG04 and SRG05 lightning design. Corresponding drawings are shown in Attachment D. 10.4.3 Pipe Rack Structures The metal framework of a pipe rack structure shall be permitted to be utilized as the main conductor of a lightning protection system if it is thicker than 4.8 mm and electrically continuous (NFPA 780 2011 Sec 4.16.1). Also pipe racks shall be connected to ground at each 40 meters minimum according to document “General Specification for Electrical System and Installation”. 10.4.4 Heater B-0501 The heater located in unit 05 is classified as heavy duty, according to NFPA 780 2011 Sec 6.1, due to the fact that the cross-sectional area of the flue is greater than 0.3 m2 and its height is greater than 23 m. The materials shall be class II as shown in Table 7. Table 7 Minimum class II material requirements (NFPA 780 2011 Sec 4.1.1.1.2). Type of conductor Air terminal, solid Parameter Diameter Cooper SI US SI US 12.7 mm 1/2 in 15.9 mm 5/8 in Size each strand Main conductor, cable 15 AWG 13AWG Weight per length 558 g/m 0.375 lb/ft 283 g/m 0.190 lb/ft Cross-section area 58 mm2 2/0 AWG 97 mm2 4/0 AWG Size each strand Bonding conductor, cable Cross-section area (solid or stranded) Bonding Thickness 1.30 mm conductor, solid strip Width 12.7 mm Main conductor, solid strip Aluminum 17 AWG 14 AWG 6 AWG 4 AWG 0.051 in 1/2 in 1.63 mm 0.064 in 12.7 mm 1/2 in Thickness 1.63 mm 0.064 in 2.61 mm 0.1026 in Cross-section area 58 mm2 2/0 AWG 97 mm2 4/0 AWG If metal structures as metal platforms, ladders, and other metal bodies are inherently bonded through construction shall not require further bonding. Metal bodies located in the heater system without an inherently connection shall be bonded to the structure using materials of the aforementioned table. REFINING MAJOR PROJECTS GENERAL MANAGEMENT PROJECT: RPLC DEEP CONVERSION PROJECT SUBPROJECT: OFFSITES UNIT: ATMOSPHERIC DISTILLATION UNIT 1 (U-04) AND UNIT 2 (U-05) AREA: GENERAL PHASE: DETAILED ENGINEERING DISCIPLINE: ELECTRICAL TITLE: GROUNDING AND LIGHTNING SYSTEM CALCULATION PDVSA PROJECT NO.: 3006; VONE PROJECT NO.: VPLC PDVSA DOC. No. 3006-400A-DE426902 VONE DOC. No. N/A REV. P2 DATE: 27-09-13 PAGE 19 OF 61 If these heavy-duty metal stacks have a metal thickness higher of 4.8 mm they neither require air terminals nor down conductors (NFPA 780 2011 Sec 6.10.1). Metal stacks shall be grounded by at least two grounding electrodes as equally spaced as practicable around the stack. If metal guy wires and cables are used to support stacks, these last shall be grounded at their lower ends. B-0501 vendor shall confirm if these conditions are met for the heater in order to be considered self protected. The sufficient condition that shall meet the equipment since it is classified as a hazardous area class I, division 2 (N° 3006-405A-DE217001) is that any openings where flammable concentrations of vapor or gas escape to the atmosphere shall be closed or protected against the entrance of flame. Otherwise, the vendor shall design and install a lightning system according to NFPA 780 Sec. 6 requirements. 11 CONCLUSIONS AND RECOMMENDATIONS According to the results obtained from grounding calculations, there are no expected values of step and touch voltages. Also, the grounding grids resistance values are low, which brings an alternative low resistance path to fault currents. These results correspond to design values indicated in the Electrical Grounding Philosophy and the General Specification for Electrical System and Installation. Results also indicates that the grounding conductor must have a minimum size of 164.1 kcmil (4/0 AWG), equivalent to 83.13 mm2 (not taken into account the decrement factor) for maximum one-phase short circuit level at SS04-MCC-202A (0.48 kV) which equals 46.86 kA. This value is greater than indicated in the Electrical Grounding Philosophy and the General Specification for Electrical System and Installation for LV transformers, where actual cross sectional area of transformers neutral grounding is rated at 2/0 AWG. Further examination of fault clearance times is needed to confirm actual cross sectional area for transformers neutral groundings and neutral groundings of diesel generators. It is recommended to validate this design with design data from the main substation at 230 kV to analyze if there may exist transferred potentials either from the main substation grid or interconnected substations grids inside the refinery to the SS-98 2B ground grid, that can affect substations step and touch potentials. 12 ATTACHMENTS ATTACHMENT A. RESISTIVITY RESULTS ATTACHMENT B. ETAP SIMULATION RESULTS ATTACHMENT C. GROUNDING DRAWINGS ATTACHMENT D. LIGHTNING DRAWINGS