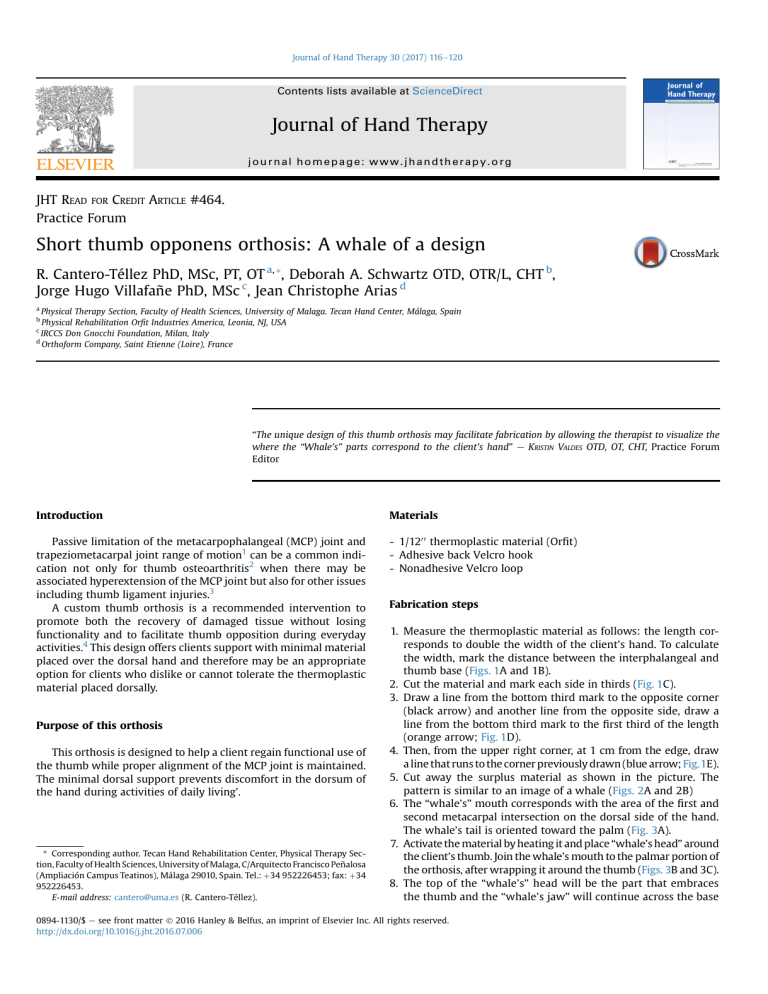

Journal of Hand Therapy 30 (2017) 116e120 Contents lists available at ScienceDirect Journal of Hand Therapy journal homepage: www.jhandtherapy.org JHT READ FOR CREDIT ARTICLE #464. Practice Forum Short thumb opponens orthosis: A whale of a design R. Cantero-Téllez PhD, MSc, PT, OT a, *, Deborah A. Schwartz OTD, OTR/L, CHT b, Jorge Hugo Villafañe PhD, MSc c, Jean Christophe Arias d a Physical Therapy Section, Faculty of Health Sciences, University of Malaga. Tecan Hand Center, Málaga, Spain Physical Rehabilitation Orfit Industries America, Leonia, NJ, USA IRCCS Don Gnocchi Foundation, Milan, Italy d Orthoform Company, Saint Etienne (Loire), France b c “The unique design of this thumb orthosis may facilitate fabrication by allowing the therapist to visualize the where the “Whale’s” parts correspond to the client’s hand” e KRISTIN VALDES OTD, OT, CHT, Practice Forum Editor Introduction Materials Passive limitation of the metacarpophalangeal (MCP) joint and trapeziometacarpal joint range of motion1 can be a common indication not only for thumb osteoarthritis2 when there may be associated hyperextension of the MCP joint but also for other issues including thumb ligament injuries.3 A custom thumb orthosis is a recommended intervention to promote both the recovery of damaged tissue without losing functionality and to facilitate thumb opposition during everyday activities.4 This design offers clients support with minimal material placed over the dorsal hand and therefore may be an appropriate option for clients who dislike or cannot tolerate the thermoplastic material placed dorsally. - 1/1200 thermoplastic material (Orfit) - Adhesive back Velcro hook - Nonadhesive Velcro loop Purpose of this orthosis This orthosis is designed to help a client regain functional use of the thumb while proper alignment of the MCP joint is maintained. The minimal dorsal support prevents discomfort in the dorsum of the hand during activities of daily living’. * Corresponding author. Tecan Hand Rehabilitation Center, Physical Therapy Section, Faculty of Health Sciences, University of Malaga, C/Arquitecto Francisco Peñalosa (Ampliación Campus Teatinos), Málaga 29010, Spain. Tel.: þ34 952226453; fax: þ34 952226453. E-mail address: [email protected] (R. Cantero-Téllez). Fabrication steps 1. Measure the thermoplastic material as follows: the length corresponds to double the width of the client’s hand. To calculate the width, mark the distance between the interphalangeal and thumb base (Figs. 1A and 1B). 2. Cut the material and mark each side in thirds (Fig. 1C). 3. Draw a line from the bottom third mark to the opposite corner (black arrow) and another line from the opposite side, draw a line from the bottom third mark to the first third of the length (orange arrow; Fig. 1D). 4. Then, from the upper right corner, at 1 cm from the edge, draw a line that runs to the corner previously drawn (blue arrow; Fig.1E). 5. Cut away the surplus material as shown in the picture. The pattern is similar to an image of a whale (Figs. 2A and 2B) 6. The “whale’s” mouth corresponds with the area of the first and second metacarpal intersection on the dorsal side of the hand. The whale’s tail is oriented toward the palm (Fig. 3A). 7. Activate the material by heating it and place “whale’s head” around the client’s thumb. Join the whale’s mouth to the palmar portion of the orthosis, after wrapping it around the thumb (Figs. 3B and 3C). 8. The top of the “whale’s” head will be the part that embraces the thumb and the “whale’s jaw” will continue across the base 0894-1130/$ e see front matter Ó 2016 Hanley & Belfus, an imprint of Elsevier Inc. All rights reserved. http://dx.doi.org/10.1016/j.jht.2016.07.006 R. Cantero-Téllez et al. / Journal of Hand Therapy 30 (2017) 116e120 117 Fig. 1. Measuring the material. (A) Mark the base of the thumb. (B) Measure the distance to the interphalangeal joint of the thumb and trim. (C) Divide the material into thirds. (D) Draw a line from the bottom third mark to the opposite corner; draw a second line from the bottom third inward, about 1/3 of the length of the material (see orange arrow). (E) Trim away about a ½” of material from the top two thirds (see blue arrow). (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.) of the dorsum of the hand to approach the “whale’s tail” (Fig. 3D). 9. Orient the thumb correctly according to the specific clinical condition of the client. Once the material has molded and hardened, it can be cut on the ulnar side, the edges, rounded, and Velcro strapping applied (Figs. 3E and 3F). Clinical implications This “whale” design thumb orthosis with its minimal dorsally placed thermoplastic material may offer clients greater comfort and more freedom to perform daily activities. References 1. Bani MA, Arazpour M, Curran S. Design and construction of custom-made neoprene thumb carpo-metacarpal orthosis with thermoplastic stabilization for first carpo-metacarpal joint osteoarthritis. J Hand Ther. 2013;26(3): 279e281. 2. Bertozzi L, Valdes K, Vanti C, Negrini S, Pillastrini P, Villafane JH. Investigation of the effect of conservative interventions in thumb carpometacarpal osteoarthritis: systematic review and meta-analysis. Disabil Rehabil. 2015;37(22):2025e 2043. 3. Michaud EJ, Flinn S, Seitz Jr WH. Treatment of grade III thumb metacarpophalangeal ulnar collateral ligament injuries with early controlled motion using a hinged splint. J Hand Ther. 2010;23(1):77e82. 4. O’Brien VH, McGaha JL. Current practice patterns in conservative thumb CMC joint care: survey results. J Hand Ther. 2014;27(1):14e22. 118 R. Cantero-Téllez et al. / Journal of Hand Therapy 30 (2017) 116e120 Fig. 2. Cutting the material. (A) Cut away highlighted material. (B) Round corners. R. Cantero-Téllez et al. / Journal of Hand Therapy 30 (2017) 116e120 119 Fig. 3. The molding process. (A) Place the material around the radial border of the hand with the “whale” face over the 2nd metacarpal. (B) Stretch the proximal strip around to the ulnar side and secure to the palmar piece. (C) Mold the “whale” face through the first web space. (D) Cut apart on the dorsal hand. (E) Attach Velcro hook adhesive to the thermoplastic material. (F) The completed orthosis with the thumb in proper position. 120 R. Cantero-Téllez et al. / Journal of Hand Therapy 30 (2017) 116e120 JHT Read for Credit Quiz: #464 Record your answers on the Return Answer Form found on the tear-out coupon at the back of this issue or to complete online and use a credit card, go to JHTReadforCredit.com. There is only one best answer for each question. #1. A key feature of the device is its a. approval by most insurance companies b. esthetic qualities c. minimal dorsal piece d. minimal palmar piece #2. The thumb IP joint is a. free to move through a significant ROM b. restricted to a limited ROM c. not a consideration d. the most important consideration #3. A primary goal is to provide the patient with a. bragging rights at the corporate water fountain b. a totally pain free hand c. maximal pulp-to-pulp pinch d. comfort and freedom to function #4. The authors recommend a. padding between the dorsal metacarpals and the dorsal thermoplastic piece b. wearing the orthosis primarily during sleep c. wearing the protective orthosis during tissue healing d. having a sophisticated knowledge of whale anatomy before attempting to design the template #5. A disadvantage to the orthotic device is its construction cost a. true b. false When submitting to the HTCC for re-certification, please batch your JHT RFC certificates in groups of 3 or more to get full credit.