Fischer-Tropsch Reactor: Particle Size & Tube Diameter Influence

Anuncio

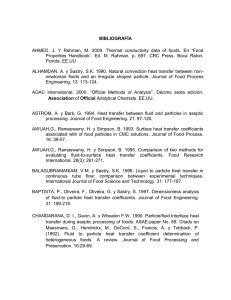

Fischer-Tropsch synthesis Andreas Jess Christoph Kern University Bayreuth, Department of Chemical Engineering, Bayreuth, Germany. 369 Research Article Influence of Particle Size and Single-Tube Diameter on Thermal Behavior of Fischer-Tropsch Reactors Part I: Particle Size Variation for Constant Tube Size and Vice Versa Simulation of a single tube of a wall-cooled multitubular Fischer-Tropsch (FT) reactor with a cobalt catalyst indicates that the reactor performance is improved by enlarging the catalyst particle diameter. This aspect is studied for variation of the particle size for a fixed tube diameter and vice versa. For a syngas conversion per pass of about 30 % as target and a typical industrially used single-tube diameter of 40 mm, a particle size of > 3 mm is appropriate with regard to a high production rate of higher hydrocarbons. For a particle diameter of < 3 mm, a temperature runaway can only be avoided by rather low cooling temperatures, and the target conversion cannot be reached. In addition, the pressure drop then gets rather high. The reasons for this behavior are: (i) the heat transfer to the cooled tube wall for a given tube size is considerably enhanced by increasing the particle size; (ii) the influence of pore diffusion on the effective rate gets stronger with rising particle size which decreases the danger of temperature runaway. Keywords: Cobalt catalyst, Fischer-Tropsch synthesis, Fixed-bed reactor, Reactor modeling Received: August 18, 2011; revised: November 04, 2011; accepted: November 18, 2011 DOI: 10.1002/ceat.201100615 1 CO + 3 H2 → CH4 + H2O Introduction The Fischer-Tropsch synthesis (FTS) has the potential to produce fuels like gasoline and diesel oil as well as petrochemicals from fossil and renewable sources. In recent years, the availability of cheap natural gas and raw materials like coal and biomass has given momentum to FTS. The capacities will increase in the near future with natural gas favored as feedstock, and around 2015 the global annual production rate of fuels via FT will be about 30 million tons, mostly produced in countries like South Africa, Malaysia, and Qatar. FTS is described by: CO + 2 H2 → (–CH2–) + H2O 0 = –152 kJ mol–1 (1) DR H298 where the term (–CH2–) represents a methylene group of a normal paraffin. For kinetic synthesis description, methane formation is often considered as a separate reaction: – Correspondence: Prof. Dr.-Ing. A. Jess ([email protected]), University Bayreuth, Department of Chemical Engineering, Universitätsstraße 12, 95440 Bayreuth, Germany. Chem. Eng. Technol. 2012, 35, No. 2, 369–378 0 = –206 kJ mol–1 DR H298 (2) The third reaction that plays an important role, at least if iron-based catalysts are used, is the mostly unwanted formation of carbon dioxide by the water gas shift reaction: CO + H2O → CO2 + H2 0 = –41 kJ mol–1 DR H298 (3) Today, cobalt and iron are considered to be the most attractive FT catalysts. Iron is cheaper, but has a considerable water gas shift activity (Eq. (3)). This is a drawback compared to cobalt, as CO2 is an unwanted byproduct and less valuable hydrocarbons are formed. Two reactor types are currently favored for low-temperature FT synthesis (< 250 °C): the multitubular fixed-bed and the slurry bubble column. Here, only the multitubular reactor with cobalt as catalyst is considered, although the analysis of the reactor behavior done in this work is also valid for other catalysts. Details on FT reactors and general aspects of the synthesis are found elsewhere [1–16]. One advantage of the multitubular reactor is that a modular scale-up is possible from data of one representative single tube. Nevertheless, reactor modeling is still needed to optimize the © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.cet-journal.com 370 A. Jess, C. Kern reactor with regard to productivity and safety aspects (temperature runaway). Such a modeling has to take into account the intrinsic kinetics, pore diffusion limitations, and the radial heat transfer from the fixed bed to the wall and finally to the cooling medium, usually boiling water. The most difficult problem to solve in the design of FT reactors is the high exothermicity combined with temperature sensitivity of the product selectivity. Hence, an efficient heat removal is needed. For the common tube length of about 10 m, the syngas conversion per pass is typically 30 %, but a gas recycle, usually with a recycle ratio of 2, enables a high overall conversion of about 90 %. Both the recycle and the limited conversion per pass help to remove reaction heat and avoid a runaway. According to a recent review from Steynberg et al. [17], the number of serious modeling studies on fixed-bed FT reactors reported in the open literature is limited [1, 18–22]. Since the publication of Steynberg‘s review, to our knowledge only two more studies on the simulation of fixed-bed FT reactors have been published: Guettel and Turek [2] compared different reactors by a 1D approach (fixed bed, monolithic reactor, and microreactor) demonstrating the potential of new concepts to decrease mass transfer resistances. In an own work [16], results of the simulation of multitubular reactors were presented for iron and cobalt catalysts. Comparison of the 2D with a simpler 1D model indicated that the calculated syngas conversion is similar, but the runaway behavior predicted by the 1D model leads to a critical, too high cooling temperature. Hence, if all heat transfer data is available, the more accurate 2D model should be preferred. During modeling of a wall-cooled FT reactor we realized by chance that the particle size has a strong impact on the thermal behavior of a multitubular reactor. Surprisingly, at least at first sight, the increase of the particle size showed a positive effect and motivated to have a closer look. For example, a higher conversion can be obtained for larger particles without temperature runaway, although the FT reaction is strongly influenced by pore diffusion and the effective rate for a given temperature decreases with increasing particle size. One reason is the influence of the particle size on heat transfer. As already stated by Steynberg et al., the heat transfer to the tube wall can be considerably enhanced by increasing the catalyst particle diameter [17]. Unfortunately, no details have been given. The objective of this paper is, therefore, the detailed simulation of the influence of the catalyst particle size on the behavior of a multitubular FT reactor with regard to syngas conversion and production rate of hydrocarbons per tube which has, to the best of our knowledge, not been performed until now. The kinetic data of a commercial cobalt catalyst were taken as example, and the attempt was made to cover all main aspects, including particularly intrinsic kinetics, mass transfer limitations, all heat transfer parameters (involving the influence of particle size), and runaway behavior. Finally, general conclusions beyond FT were derived to determine the general influence of the particle size on the behavior of wall-cooled fixedbed reactors. www.cet-journal.com 2 Intrinsic and Effective Reaction Rate of FTS on Cobalt Since the discovery of the synthesis in 1923 by Franz Fischer and Hans Tropsch, the kinetics have been studied extensively. The reaction rate is mostly described by using power law or Langmuir-Hinshelwood equations. An overview of rate equations for cobalt is given in [23]. In the initial phase of the synthesis, the catalyst pores are filled with liquid higher hydrocarbons (wax), which leads to a decrease of the effective reaction rate by pore diffusion for particle diameters of more than ∼1 mm (see below). Although numerous publications on FTS kinetics exist, the number of reports with quantitative kinetic equations for commercial catalysts is very limited. The intrinsic rate constant of H2 consumption on a commercial cobalt catalyst was determined by Yates and Satterfield [23] and Maretto and Krishna [24]. According to [17], the intrinsic activities of new-generation industrial cobalt catalysts are threefold higher than those reported by these authors. Based on the data given in the above-mentioned literature, the equation of the rate of H2 consumption was estimated (using the threefold values) by: rm;H2 cCO;g dn_ H2 km;H2 ;LH cH2 ;g 2 dmcat 1 KCO cCO;g (4) The rate constant of this Langmuir-Hinshelwood equation and the adsorption coefficient are: 37 400 J mol 1 km;H2 ;LH 0:8 m6 mol 1 kg 1 s 1 e RT (5) 68 500 J mol 1 KCO 5 10 9 m3 mol 1 e RT (6) Based on these equations, a pseudo-first-order rate constant can be determined: cCO;g rm;H2 km;H2 cH2 ;g with km;H2 km;H2 ;LH 2 (7) 1 KCO cCO;g The influence of pore diffusion is considered by the effectiveness factor gpore: gpore rm;H2 ;eff tanh f 1 ≈ (for f ≥ 2) f f km;H2 cH2 ;g and in the case of FTS the Thiele modulus is given by: s km;H2 qp cH2 ;g Vp f Ap;ext Deff;H2 ;l cH2 ;l (8) (9) Vp/Ap,ex is the ratio of particle volume to external surface area, and cH2,l is the hydrogen concentration in liquid wax, calculated by the Henry coefficient (HH2,c ≈ 20 000 Pa m3mol–1): cH2 ;l pH2 ;g RT c HH2 ;c HH2 ;c H2 ;g © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (10) Chem. Eng. Technol. 2012, 35, No. 2, 369–378 Fischer-Tropsch synthesis Combination of Eqs. (9) and (10) yields the following equation for the Thiele modulus: v Vp u u km;H2 qp f (11) t Ap;ex Deff;H ;l RT 2 HH2 ;c The effective diffusion of dissolved hydrogen in the liquidfilled porous catalyst is described by an effective diffusion coefficient Deff,H2,l, which considers that only a portion of the particle is permeable and that the path through the particle is random and tortuous. Both aspects are taken into account by porosity eP and tortuosity sP: Deff;H2 ;l ep D sP mol;H2 ;l (12) The molecular diffusivity of H2 in liquid FT products is calculated by the Wilke-Chang equation [25]. For temperatures of 200–260 °C, Dmol,H2,l is 4 · 10–8 m2s–1 [26], and eP/sP is 0.3 [26, 27]. Fig. 1 presents the effective (formally first-order) rate constant of H2 consumption (gporekm,H2) for spherical particles with diameters ranging from 0.5 to 6 mm. Pore diffusion strongly affects the effective rate constant within the typical temperature regime of FT synthesis of 200–250 °C for particle diameters above 0.5 mm. The reason is the slow diffusion of dissolved H2 in the liquid-filled pores of the catalyst. External diffusion limitations are negligible for temperatures below 400 °C, which is an unrealistically high temperature for FT synthesis. The apparent (effective) activation energy at a certain temperature is an important parameter characterizing the thermal sensitivity of a catalyst and a reactor and is given by: EA;eff d ln km;H2 ;eff 1 ≈R R T2 d 1=T 1 T1 1 km;H2 ;eff T1 for DT→0 ln km;H2 ;eff T2 (13) If a reaction is limited by pore diffusion (like FTS), EA,eff may vary from the maximum intrinsic value to about half of this value, if the range of relevant particle sizes and reaction temperatures induces a transition of the effective rate constant from the intrinsic kinetic regime to the regime of strong pore diffusion limitation. Then Eq. (13) has to be used to calculate EA,eff. For FT on cobalt, Eq. (13) is also needed even in the intrinsic regime, because both the rate constant km,H2,LH (Eq. (5)) and the adsorption coefficient KCO (Eq. (6)) are functions of the temperature, and the apparent activation energy is the result of the interplay of both terms (Eq. (7)). 3 Pressure Drop of an FT Fixed-Bed Reactor For technical fixed-bed reactors, the particle size is limited by the pressure loss: Dpb fb LR qmol Mg u2s dp 2 (14) where us is the superficial velocity (empty tube) and fb is the friction factor of a packed bed which is given by the following equation based on the particle Reynolds number, Rep = usdp/m [28]: 1 e 300 (15) 3:5 1 e fb e3 Rep For a packed bed of spheres (equal diameter, porosity e = 0.4), Eq. (15) simplifies to: fb ≈ 33 1700 Rep (16) Fig. 2 indicates that for typical conditions of the FTS (see Tab. 1) the particle size should be higher than 1 mm to avoid an excessively high pressure drop. The dotted lines in Fig. 2 represent the extrapolation to pressure drops > 5 bar, where Eq. (14) leads to inaccurate values, because then the change of the gas density has to be considered and the pressure drop gets very high compared to the assumed total pressure of 24 bar. 4 Figure 1. Intrinsic and effective rate constant of H2 consumption (Eq. (7)) for a cobalt catalyst for different particle diameters (spheres) ranging from 0.5 to 6 mm (reactor entrance, i.e., cCO = cCO,in; other reaction conditions in Tab. 1). Chem. Eng. Technol. 2012, 35, No. 2, 369–378 371 FT Fixed-Bed Reactor Model (Multitubular Reactor) For simulation of a multitubular FT reactor, typical reaction conditions as listed in Tab. 1 were used. One aspect was neglected for simplifying: The syngas entering the reactor may not only consist of CO and H2, but may contain methane and also CO2, which are either already present in the fresh syngas or in the recycle gas. If mass dispersion is neglected (which is reasonable as proved by respective calculations), the mass balance for hydrogen yields: us dcH2 rm;H2 qb dz © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (17) www.cet-journal.com 372 A. Jess, C. Kern If axial dispersion of heat is neglected, the heat balance of the 2D model is: 2 dT d T dT qmol cp us krad rm;H2 ;eff qb DR HH2 dz dr 2 r dr (18) Boundary conditions are: T = Tin (for z = 0) (19) dT 0 dr (for r = 0 and all z) (20) krad Figure 2. Pressure drop of fixed bed with a length of 12 m for different particle diameters and two gas velocities (related to empty reactor; other conditions in Tab. 1). dT aw;int Tw;int;1 Tw;int;2 dr (for r = 0.5dR,int at the wall) (21) Eq. (18) considers the bed and the fluid as a pseudohomogeneous medium, i.e., the heat transfer in the bed up For cobalt, the water gas shift reaction (Eq. (3)) does not to the wall is represented by the effective radial thermal conplay a role. In this work, methane formation was also not conductivity krad. By Eq. (21), the model assumes a jump in temsidered as a parallel reaction to the formation of higher hydroperature at the wall from Tw,int,1 to Tw,int,2, which considers carbons (C2+). Thus, Eq. (4) representing the overall H2 conthat krad decreases strongly in the vicinity of the wall, and the sumption rate was applied. introduction of aw,int accounts for the heat transfer near the wall. The fourth boundary condition is Table 1. Data on chemical media and reaction conditions of Fischer-Tropsch synthesis related to the heat transfer from the exterused to model a multitubular fixed-bed reactor. All values at 24 bar and 240 °C, assumed nal tube side to the heat transfer medium standard internal tube diameter of 4 cm, and standard particle diameter of 3 mm (here boiling water): Parameter Value Superficial gas velocity us (empty reactor)a 0.55 m s–1 Total molar gas concentration (feed) qmol 563 mol m–3 Hydrogen concentration (feed) cH2,in 375 mol m–3 Total pressure p 24 bar Diameter of spherical cobalt-catalyst particle dp 3 mm Length of tubes LR 12 m (Internal) diameter of single tube dR 4 cm Bulk density of catalyst bed qb 700 kg m–3 Inlet concentration of hydrogen 66.6 vol.-% (rest CO) Adiabatic rise in temperature DTad 1690 K Kinematic viscosity m of gas mixture (feed) 4 · 10–6 m2s–1 Thermal conductivity of gas mixture (feed) kg 0.16 Wm–1K–1 Effective radial thermal conductivity krad 3.6 Wm–1K–1 Heat capacity of gas mixture (feed) cp 30 J mol–1K–1 Heat transfer coefficient (bed to internal tube wall) aw,int 1040 Wm–2K–1 Heat transfer coefficient (external tube wall to boiling water, 25 bar) aw,ex 1600 Wm–2K–1 Overall thermal transmittance Uoverall 336 Wm–2K–1 a) For a CO conversion of 27 % per pass and an assumed recycle rate of 2.5, the conversion related to the fresh syngas would be 95 %. For a selectivity of 90 % to C5+-hydrocarbons, which is given in the literature for modern cobalt catalysts [29], the production rate would be 38 kg C5+ per day and tube. www.cet-journal.com © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim q_ aw;int Tw;int;1 Tw;int;2 1 dw 1 Tw;int;2 Tcool kwall aW;ex (22) The term (dw/kwall + 1/aw,ex)–1 summarizes the thermal resistance of heat conduction in the wall with thickness dw and of the heat transfer from the tube to the cooling medium (here boiling water). The resistance of heat conduction through the wall (dw/kwall) is negligible: For 0.5 cm wall thickness and a thermal conductivity (steel) of 50 W m–1K–1, dw/kwall is only 0.0001 K W–1 compared to the (also rather low) external heat transfer resistance (1/aw,ex) to the boiling water of 0.0006 K W–1. The coefficient aw,int for the heat transfer from the bed to the internal wall was calculated by the following correlation for the Nusselt number Nu [30, 31]: aw;int dp 5 dp kbed Nu 1:3 kg dR kg (23) 1=3 0:19 Re3=4 p Pr The coefficient aw,ex for the external heat transfer from the tube to the boiling water Chem. Eng. Technol. 2012, 35, No. 2, 369–378 Fischer-Tropsch synthesis 373 with Rep = usdp/m and Pr = m/a = mcpqmol/kg. Eqs. (23) and (24) are not valid (or only to a limited extent) for low values of dR/ dp < 5. kbed is the effective thermal conductivity of the bed without flow, and kbed/kg is in the range of 2–10, if the thermal conductivity of the particles is high compared to the fluid (kp/kg >10). In general, the values of the static contribution kbed/kg given in the literature vary. Hofmann and Chao found that under reaction conditions kbed/kg is smaller than without reaction [34, 35]. Apparently, there is an interaction between this static thermal conductivity and the kinetics [36]. According to Westerterp, a value for kbed/kg of 4 should be used (as done in this work) for modeling of wall-cooled reactors [36]. All heat transfer parameters for typical reaction conditions are listed in Tab. 1. It is important to note that the particle size has a strong influence both on aw,int and krad, and thus, on the overall thermal resistance (1/Uoverall): conditions in Tab. 1; resistance of wall (dw/kwall) was neglected). With increasing particle diameter, the heat transfer resistance of the bed (Rheat,bed = dR/(8kbed) decreases, whereas the thermal resistance at the internal reactor wall (Rheat,wall,int = 1/aw,int) increases. The external resistance to the boiling water (Rheat,wall,ex = 1/aw,ex) is in general small and has a very low influence on the overall heat transfer. In total, the overall heat transfer resistance decreases until a particle diameter of about 4 mm is reached (Fig. 3). The influence of the particle size on the overall thermal transmittance (Uoverall) of a cooled tubular reactor is more pronounced for a large tube diameter (Fig. 4). For example, an increase of the particle diameter from 1 to 6 mm leads to an increase of Uoverall by about 14 % and 80 % for a single tube of 2 and 7 cm diameter, respectively. For particle Reynolds numbers above 100, which in this case is already reached at a small particle size of 1 mm, kbed is proportional to dp, whereas aw,int is almost independent of dp (∼dp–0.25). The influence of dp on Uoverall vanishes for high values of dp and Rep (Fig. 4 for dp > 6 mm), as the heat transfer resistance at the internal wall gets high and determines the overall heat transfer. For dR/dp values < 5, the applicability of Eqs. (22) and (23) is also limited, as undesirable wall effects (bypassing, slippage) may occur (dashed line in Fig. 4). 1 d 1 d 1 R w Uoverall 8 krad aw;int kwall aw;ex 5 Simulation of a Multitubular FT Reactor 5.1 Reactor Behavior for Constant Tube Diameter and Particle Size was determined by well-known correlations [32]. The coefficient krad for the radial effective heat conduction in the bed is given by [30, 33]: krad kbed h kg kg 7 2 Rep Pr 1 2 i with 2dp dR kbed ≈4 kg (24) (25) The overall thermal transmittance Uoverall is not needed in this work for reactor modeling (in contrast to a 1D model where only axial temperature gradients are considered), but nevertheless Eq. (25) is useful to illustrate the effect of the particle size on the overall heat transfer. Fig. 3 depicts for a typical tube diameter of 4 cm that the particle size has a strong influence on the overall heat transfer resistance (Rheat,overall = 1/Uoverall) as well as on the respective individual contributions of the heat transport within the bed (Rheat,bed = dR/8kbed), at the internal reactor wall (Rheat,wall,int = 1/aw,int), and of the external heat transfer to the boiling water (Rheat,wall,ex = 1/aw,ex; For simulation of reactor behavior, the differential equations (Eqs. (17)–(22)) were solved numerically by the commercial program Presto Kinetics. The reactor behavior with regard to the axial temperature profile and syngas conversion is illustrated in Fig. 5 for an assumed standard tube diameter of 4 cm and a particle diameter of 3 mm. Obviously, cooling temperatures of more than 206 °C should be avoided to exclude a temperature runaway. Here, the following definitions are used: – The ignition temperature (Tig) characterizes the cooling temperature, where a clear temperature runaway occurs (e.g., 211 °C in Fig. 5). – The appropriate cooling temperature (Tcool = Tin = 206 °C in Fig. 5) characterizes Tcool for a safe operation of the reactor. Thereby, it is assumed that Tcool should be 5 K below Tig. In some cases discussed here, Tcool may be even lower than 5 K below Tig, if a certain syngas conversion as target is already reached. A syngas conversion of preferably 27 % (per pass) was supposed, because the total syngas conversion would then be 90 % for the assumed typical recycle ratio of 2.5 used in FT reactors. In this case, the cooling temperatures listed in the tables are marked with a star as superscript. Figure 3. Influence of the particle diameter on the thermal resistances of a cooled tubular reactor for a constant tube diameter of 4 cm. Chem. Eng. Technol. 2012, 35, No. 2, 369–378 © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.cet-journal.com 374 A. Jess, C. Kern short-chain hydrocarbons are formed more and more, and the catalyst may also deactivate. – To characterize the reaction temperature, Tmean = (Tcool + Tmax)/2 is used. 5.2 Figure 4. Influence of the particle diameter on the overall thermal transmittance Uoverall of a cooled tubular reactor. Dashed line: limitation of the applicability of Eqs. (22) and (23) for dR/dp < 5 (other conditions in Tab. 1). Influence of Single-Tube Diameter for Constant Particle Size The influence of the tube diameter (dR) on the H2 conversion per pass and on the corresponding production rate of C5+-hydrocarbons for a particle diameter of 3 mm is depicted in Fig. 6 (additional data in Tab. 2; NC,crit, Nad, and km,H2,eff at Tig are explained in Part II of this paper). For the cooling temperature, a safety distance of 5 K to the critical cooling temperature, where a temperature runaway occurs, was chosen (Tcool = Tcool,crit – 5 K). Values of Tcool, Tmax, and of Uoverall etc. are listed in Tab. 2. Other parameters and assumptions are summarized in Tab. 1. A conversion per pass of preferably 27 % was assumed as target, i.e., for a typical recycle ratio of 2.5 the total conversion related to fresh feed would then be 90 %. For the given conditions, this target is missed for a tube diameter of more than 39 mm, because a temperature runaway is then only avoided by a rather low cooling temperature, which in turn leads to a low reaction temperature and rate (Tab. 2). This tube diameter can be regarded as optimal for a particle size of 3 mm, as it is the largest possible diameter to reach the target of 27 % conversion. For slightly higher tube diameters of up to 45 mm, the production rate of C5+hydrocarbons per tube would be higher, but the target of 27 % conversion is then more and more missed, e.g., only 20 % conversion at the maximum of the production rate of 37 kg per day, which is almost the same value as for dR = 39 mm (35 kg per day). 5.3 Influence of Particle Size for Constant Tube Diameter The impact of the particle size (dp) on the performance of a cooled single-tube FT reactor for a tube diameter of 40 mm and a conversion of preferably 27 % is illustrated in Fig. 7 and Tab. 3. For Tcool, a safety distance of 5 K to the critical cooling temperature, where a runaway occurs, was chosen (Tcool = Tig – 5 K). The respective values of Tcool and of Tmax are listed in Tab. 3. Figure 5. Influence of cooling temperature on the behavior of a wall-cooled FT reactor (single tube with 4 cm diameter; spherical particles with 3 mm diameter; For dp < 3.5 mm, the target of 27 % conversion Tcool = Tin; other conditions in Tab. 1). cannot be reached with regard to Tig. The thermal transmittance Uoverall is low (201 Wm–2K–1 for 0.5 mm compared to 355 Wm–2K–1 for 3 mm, Fig. 6). In addi– The temperature in the tube center at the position of the tion, the influence of pore diffusion increases with increasing axial temperature maximum is denoted as Tmax. The value is particle size and hence the effective activation energy drops, limited to 250 °C. At higher temperatures, methane and www.cet-journal.com © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim Chem. Eng. Technol. 2012, 35, No. 2, 369–378 Fischer-Tropsch synthesis Figure 6. Influence of single-tube diameter (dR) on H2 conversion (XH2 = XCO) per pass and production rate of C5+-hydrocarbons of a cooled single-tube FT reactor for 3 mm particle diameter and a syngas conversion of preferably 27 %. 375 which helps to avoid a thermal runaway (details in Section 6). The decrease of gpore (Fig. 7, right) and with that of the effective rate is actually considered as a drawback, but this is compensated by a higher cooling temperature as long as the reaction temperature remains below the limit of 250 °C. This is needed to avoid excessive formation of methane as well as of short-chain hydrocarbons. For the given tube size of 40 mm, a particle size of 4 mm is optimal. For higher dp values, the ratio dR/dp gets too low and with that undesirable wall effects (bypassing) may occur (dR/dp < 5 for dp > 8 mm). Fig. 8 depicts radial temperature profiles for small and large particles (1 and 6 mm) at the position, where the axial temperature maximum is just reached. For dp = 6 mm, the effective radial thermal conductivity (krad) is threefold higher compared to 1 mm, whereas the heat transfer coefficient at the internal wall side (aw,int) is lower for Table 2. Influence of tube size dR on Uoverall, Tcool = Tin, Tmax, Tig, gpore at Tmean = (Tcool + Tmax)/2, km,H2,eff at Tig, NC,crit at Tig, Nad, and EA,eff at Tig; Tcool should be 5 K below Tig; if Tcool < Tig – 5 K to reach a conversion of 27 % per pass, the values are marked with a star. dR [mm] dp [mm] 15 20 60 70 Tig [°C] gpore at Tmean [%] km,H2,eff at Tig [m3kg–1s–1] NC,crit Nad EA,eff at Tig [kJ mol–1] 477 215* 219 > 250 45 – 360 40 55 Tmax [°C] 381 35 50 Tcool [°C] 437 30 45 Uoverall [W m–2K–1] 3 214* 211* 209* 221 224 225 242 223 217 44 44 45 – – – 4.91 · 10 –5 150 75 84 2.27 · 10 –5 189 80 90 1.72 · 10 –5 202 86 97 –5 341 206 225 211 48 1.26 · 10 229 96 107 324 202 220 207 56 1.00 · 10–5 243 104 116 310 198 214 203 65 0.77 · 10–5 272 112 126 75 0.58 · 10 –5 314 121 136 0.46 · 10 –5 348 128 143 0.33 · 10 –5 385 135 151 296 284 263 194 191 187 206 201 196 199 196 192 81 87 Figure 7. Influence of particle diameter (dp) on H2 conversion per pass, production rate of C5+-hydrocarbons, and pore effectiveness factor (gpore at Tmean = (Tcool + Tmax)/2, 40 mm tube diameter, conversion per pass of preferably 27 %). Chem. Eng. Technol. 2012, 35, No. 2, 369–378 © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.cet-journal.com 376 A. Jess, C. Kern Table 3. Influence of particle diameter dp on Uoverall, Tcool = Tin, Tmax, Tig, km,H2,eff, TC,crit at Tig, Nad, and EA,eff. Other data is shown in Fig. 7; Tcool should be 5 K below Tig; if Tcool < Tig –5 K to reach the target conversion of 27 % per pass, the values are marked with a star as superscript. dp [mm] dR [mm] 0.5 1 Tcool [°C] Tmax [°C] Tig [°C] km,H2,eff at Tig [m3kg–1s–1] NC,crit Nad EA,eff at Tig [kJ mol–1] 201 184 189 189 0.29 · 10–5 586 156 175 193 –5 513 153 172 –5 367 136 152 –5 229 96 109 –5 191 80 88 –5 255 2 313 3 4 Uoverall [W m–2K–1] 341 40 355 188 195 206 214* 194 204 225 232 200 211 221 0.42 · 10 0.72 · 10 1.26 · 10 1.57 · 10 5 362 220* 237 229 1.76 · 10 174 79 86 6 365 225* 241 236 1.95 · 10–5 158 78 85 7 367 229* 245 242 2.11 · 10–5 147 76 84 248 –5 135 75 82 8 367 232* 247 6-mm particles (201 Wm–2K–1) compared to 1811 Wm–2K–1 for 1-mm particles. This diminishes the positive effect of dp on krad. The overall thermal transmittance (Eq. (25)) is 365 Wm–2K–1 for dp = 6 mm, which is 30 % higher compared to 1-mm particles (255 Wm–2K–1). This underlines the advantage of large particles for the overall radial heat transport. Fig. 8 indicates that the overall heat transfer resistances in the bed (8 K) and at the internal wall side (7 K) are almost equal for dp = 6 mm, whereas for dp of 1 mm, the heat transfer resistance of the bed is dominant (DTbed >> DTwall). 6 Conclusions and Outlook Simulation of a wall-cooled single tube of a multitubular FT reactor with cobalt as catalyst demonstrates that the reactor performance is improved by increasing the catalyst particle 2.30 · 10 size. The reasons for this at first sight unexpected behavior are: (i) The radial heat transfer for a given tube diameter is considerably enhanced by increasing the particle size. (ii) The influence of pore diffusion on the effective reaction rate of syngas gets stronger with rising particle diameter, which lowers the temperature sensitivity of the reactor and decreases the danger of a temperature runaway. Three questions are still open: Is it possible to improve the reactor performance by means of an eggshell catalyst, where the influence of pore diffusion is negligible? Which is the optimal combination of particle size and tube diameter? Is it possible to derive general guidelines for the appropiate choice of particle and tube size for wall-cooled fixed-bed reactors beyond the case of FTS? These questions will be addressed in Part II of this series of two papers. The authors have declared no conflict of interest. Figure 8. Radial temperature profiles in a 40-mm single tube for two different particle sizes (in both cases, Rheat,wall,ex = 1/aW,ex = 1/1600 m2K W–1; axial positions at Tmax: z = 4.2 m for dp = 1 mm and 2.1 m for dp = 6 mm; other conditions in Fig. 6). www.cet-journal.com © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim Chem. Eng. Technol. 2012, 35, No. 2, 369–378 Fischer-Tropsch synthesis Symbols used a Ap,ex c cp dp dR dw Deff Dmol EA fb HH2,c km km,H2,LH km,eff KCO LR mcat Mg Nad NC Ntubes Nu p pi Pr q_ r rm rm,eff R Rheat Rep T us Uoverall Vp X z [m2s–1] [m2] thermal diffusivity external surface area of a catalyst particle [mol m–3] concentration [J mol–1K–1] heat capacity of gas phase [m] particle diameter [m] diameter of a single tube [m] wall thickness of a single tube [m2s–1] effective diffusion coefficient [m2s–1] molecular diffusion coefficient [J mol–1] activation energy [–] friction factor of packed bed [Pa m3mol–1] Henry coefficient of hydrogen in liquid wax [m3kg–1s–1] rate constant for (pseudo) first-order equation [m6mol–1kg–1s–1] rate constant for LangmuirHinshelwood equation for FT on Co [m3kg–1s–1] effective reaction rate constant [m3mol–1] adsorption coefficient for CO [m] reactor length (single tubes) [kg] mass of catalyst [kg mol–1] molar mass of gas phase [–] dimensionless parameter of heat generation [–] dimensionless parameter of cooling capacity [–] number of single tubes [–] Nusselt number [Pa] total pressure [Pa] partial pressure of component i [–] Prandtl number [W m–2] heat flux [m] radial direction [mol kg–1s–1] reaction rate per unit of mass of catalyst [mol kg–1s–1] effective rate per mass of catalyst [J mol–1K–1] ideal gas law constant (8.314) [m2K W–1] heat transfer resistance [–] Reynolds number related to particle [ °C, K] temperature [m s–1] superficial gas velocity [W m–2K–1] overall thermal transmittance [m3] particle volume [–] conversion [m] axial coordinate Greek symbols aW,int [W m–2K–1] aW,ex [W m–2K–1] DRHH2 [J mol–1] heat transfer coefficient from bed to internal wall heat transfer coefficient from outer shell tube to boiling water enthalpy of FT reaction related to 1 mol H2 (76 kJ mol–1) Chem. Eng. Technol. 2012, 35, No. 2, 369–378 DTad e eP f gpore kg [K, °C] [–] [–] [–] [–] [W m–1K–1] kbed [W m–1K–1] krad [W m–1K–1] kwall [W m–1K–1] m qp qb qmol sP [m2s–1] [kg m–3] [kg m–3] [mol m–3] [–] 377 adiabatic rise in temperature porosity of fixed bed particle porosity Thiele modulus pore effectiveness factor thermal conductivity of gas phase thermal conductivity of the fixed bed without flow effective radial thermal conductivity in the fixed bed thermal conductivity of reactor wall material kinematic viscosity density of catalyst bulk density of catalyst bed molar density of gas phase particle tortuosity Subscripts cool crit eff ex g ig in int l max w cooling critical effective external gas phase ignition reactor inlet internal liquid maximum value wall References [1] A. Jess, R. Popp, K. Hedden, Appl. Catal., A 1999, 186, 321. [2] R. Güttel, T. Turek, Chem. Eng. Sci. 2009, 64, 955. [3] R. B. Anderson, The Fischer-Tropsch Synthesis, Academic Press, Orlando, FL 1984. [4] M. E. Dry, in Catalysis Science and Technology (Eds: J. R. Anderson, M. Boudart), Springer Verlag, New York 1981, 159– 255. [5] M. E. Dry, Catal. Today 2002, 71, 227. [6] J. Eilers, S. A. Posthuma, S. T. Sie, Catal. Lett. 1990, 7, 253. [7] J. Falbe, Chemierohstoffe aus Kohle, Georg Thieme Verlag, Stuttgart 1977. [8] M. W. Haenel, Erdoel Erdgas Kohle 2006, 122, 78. [9] H. Schulz, Appl. Catal., A 1999, 186, 3. [10] R. Zennaro, F. Hugues, E. Caprani, DGMK/SCI-Conference Synthesis Gas Chemistry, Dresden, October 2006. [11] G. Schaub, R. Rohde, A. M. Subiranas, DGMK/SCI-Conference Synthesis Gas Chemistry, Dresden, October 2006. [12] S. T. Sie, R. Krishna, Fuel Process. Technol. 2000, 64, 73. [13] S. T. Sie, R. Krishna, Appl. Catal., A 1999, 186, 55. [14] S. T. Sie, M. M. G. Senden, H. M. H. Van Wechem, Catal. Today 1991, 8, 371. [15] R. Güttel, U. Kunz, T. Turek, Chem. Eng. Technol. 2008, 31, 746. © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.cet-journal.com 378 A. Jess, C. Kern [16] C. Kern, A. Jess, Chem. Eng. Technol. 2009, 32, 1164. [17] A. Steynberg, M. Dry, M. E. Davis, B. B. Breman, in FischerTropsch Technology, Studies in Surface Science and Catalysis 152 (Eds: A. Steynberg, M. Dry), Elsevier, Amsterdam 2004. [18] H. E. Atwood, C. O. Bennett, Ind. Eng. Chem. Proc. Des. Dev. 1979, 18, 163. [19] G. Bub, M. Baerns, Chem. Eng. Sci. 1980, 33, 348. [20] Y. N. Wang, Y. Y. Xu, Y. W. Li, Y. L. Zhao, B. J. Zhang, Chem. Eng. Sci. 2003, 58, 867. [21] J. W. A. De Swart, Ph. D. Thesis, University of Amsterdam 1996. [22] J. W. A. De Swart, R. Krishna, S. T. Sie, in Natural Gas Conversion IV, Studies in Surface Science and Catalysis 107 (Eds: M. de Pontes, R. L. Espinoza, C. P. Nicolaides, J. H. Scholz, M. S. Scurrell), Elsevier, Amsterdam 1997. [23] I. C. Yates, C. N. Satterfield, Energy Fuels 1991, 5, 158. [24] C. Maretto, R. Krishna, Catal. Today 1999, 52, 279. [25] C. R. Wilke, P. Chang, AIChE J. 1955, 1, 264. [26] H. Raak, Ph. D. Thesis, University Karlsruhe 1995. www.cet-journal.com [27] T. Kuntze, Ph. D. Thesis, University Karlsruhe 1991. [28] S. Ergun, Chem. Eng. Prog. 1952, 48, 89. [29] J. R. Farrauto, C. H. Bartholomew, Fundamentals of Industrial Catalytic Processes, 2nd ed., Wiley, New York 2006. [30] VDI-Wärmeatlas: Berechnungsblätter für den Wärmeübergang, 9th ed., Springer-Verlag, Berlin 2002. [31] M. Nilles, Ph. D. Thesis, University Karlsruhe 1991. [32] E. U. Schlünder, Einführung in die Wärmeübertragung, Vieweg & Sohn, Braunschweig 1986. [33] E. U. Schlünder, E. Tsotsas, Wärmeübertragung in Festbetten, durchmischten Schüttgütern und Wirbelschichten, Georg Thieme Verlag, Stuttgart 1988. [34] H. Hofmann, VDI-Bericht 349, 1979. [35] R. E. Chao, R. A. Caban, M. M. Irizarry, Can. J. Chem. Eng. 1973, 51, 67. [36] K. R. Westerterp, W. P. M. van Swaaij, A. A. C. M. Beenackers, Chemical Reactor Design and Operation, John Wiley, New York 1998. © 2012 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim Chem. Eng. Technol. 2012, 35, No. 2, 369–378