This is an open access article published under an ACS AuthorChoice License, which permits copying and redistribution of the article or any adaptations for non-commercial purposes. Article pubs.acs.org/JPCC Study of the Iron Catalyst for Ammonia Synthesis by Chemical Potential Programmed Reaction Method Bartłomiej Wilk, Rafał Pelka,* and Walerian Arabczyk Downloaded via 190.186.97.13 on September 2, 2020 at 18:26:53 (UTC). See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles. West Pomeranian University of Technology, Szczecin, Institute of Chemical and Environment Engineering, 10 Pułaskiego Str, 70-322 Szczecin, Poland ABSTRACT: A new method, entitled chemical potential programmed reaction, for determining the physicochemical properties of iron ammonia synthesis catalyst has been proposed. Two model reactions were applied: nitriding of the iron catalyst and reduction of the obtained nitrides. Measurements of the rates of those reactions were carried out at 350 °C in a differential tubular reactor. The reactor is equipped with a system that allows us to perform simultaneous thermogravimetric measurements and a catharometric system to determine hydrogen concentration in the gas phase. The reactor was fed with a mixture of ammonia and hydrogen of varying composition, which was changing in a controlled way. Different accelerations of the nitriding potential change were applied. During the processes of nitriding of nanocrystalline iron and reduction of the obtained nanocrystalline iron nitrides rates of these processes were measured. The minimum nitriding potential, at which the phase transformation of nanocrystallites of a certain size took place, was determined. As a result, the relative nanocrystallite size distribution related to the active surface of nanocrystallites was calculated. Then, making use of the mean size of nanocrystallites the absolute size distribution was obtained. Bimodal size distribution of nanocrystallites in test samples was observed. The dependence of the minimum nitriding potential on the mass of crystallites was determined. During the reduction of iron nitrides, similarly as in the iron nitriding process, nanocrystallites underwent a phase transition in their entire volume in the order of the largest to the smallest in size. ■ INTRODUCTION Iron catalyst for ammonia synthesis was the object of research performed in order to verify the effectiveness of a new method for determining the physical and chemical properties of nanomaterials. The fused iron catalyst for ammonia synthesis is industrially prepared by melting iron oxides with structural promoters (Al2O3, CaO) and an activating promoter (K2O). By reduction with hydrogen of the resultant alloy, an active form of the catalyst having nanocrystalline structure is obtained.1,2 Metal oxide (mainly Al2O3, CaO) bridges connecting the individual crystallites of iron form the 3-dimensional (3D) structures.3 Promoters placed on the surface of the crystallites form the 2-dimensional (2D) structures.4 In the active iron catalyst, there is a thermodynamic equilibrium between iron nanocrystallites and promoters located in the 2D and 3D structures.4,5 Therefore, the structure of the active iron catalyst, due to the presence of structural promoters, is stable at high temperatures. The structure of the catalyst after fixing at a given temperature did not change at lower temperatures.6 The surface of iron nanocrystallites is wetted by a layer of K +O, and iron atoms are combined with potassium atoms by oxygen bridges. The presence of activating promoter (K2O) after the reduction process increases the number of active sites on the catalyst surface, which is dependent on the chemical composition of the surface of the catalysts and temperature.7−9 Oxygen atoms prevent the extraction of potassium from the surface during the processes.3−12 © 2017 American Chemical Society A model of interactions between iron nanocrystallites and promoters and the explanation of the resulting nanometric structure is presented elsewhere.4,5 By studying the kinetics of the nitriding of nanocrystalline iron, it was found that the reaction rate was limited by the rate of dissociative adsorption of ammonia on the surface of iron. A reaction model of nanocrystalline materials with a gas phase was elaborated, wherein the chemical process rate is limited by a surface reaction rate.13 According to this model, in the nitriding process with ammonia, each nanocrystallite forming a solid solution of nitrogen in α-iron, α-Fe(N), after reaching the critical concentration of nitrogen undergoes a phase transition in its whole volume to a phase γ′-Fe4N. The phase transition of nanocrystallites occurs in the order from the smallest to the largest in size.14 Based on studies of nitriding of nanocrystalline iron and reduction of obtained nanocrystalline nitrides of iron at a constant temperature and at different nitriding potentials, it was found15−18 that for each composition of the mixture of ammonia and hydrogen steady states were fixed. In these states, the reaction rate in the solid was zero (constant content of nitrogen in the solid sample), and the rate of catalytic ammonia decomposition reaction was constant. Additionally, in Received: September 22, 2016 Revised: April 4, 2017 Published: April 5, 2017 8548 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556 Article The Journal of Physical Chemistry C the single-phase areas chemical equilibrium states occurred between the ammonia−hydrogen mixture, the catalyst surface, and the solid-phase volume (chemical potentials of nitrogen present in the gas phase, on the surface and in the volume of iron nanocrystallites were equal to each other, μg = μs = μb). In turn, in the multiphase areas chemical equilibrium states occurred between the gas phase and catalyst surface, and the nonequilibrium state held between the gas-phase and solidphase volume. It was also observed that specific nitriding degrees are a function of the nitriding potential and the nanocrystallite size distribution.15−18 In the steady-state conditions, hysteresis was observed for a dependence of the iron nitriding degree on nitriding potential for processes carried out at temperatures of 300,19 350,16−18 and 400, 450, 500, and 550 °C.15 It has been shown that phase transformations occurring in a nanocrystalline iron−ammonia−hydrogen system at a given temperature are observed in a range of potential, and not as in a coarse-grained system, at the specific value of nitriding potential.15−22 It has been shown that for the nanocrystalline iron, apart from the single component areas, there are areas of the coexistence of two phases, and furthermore, in the reduction process there is the area of coexistence of the three solid phases.15−19,23−25 In the nitriding processes of nanocrystalline iron α-Fe(N) to iron nitride γ′-Fe4N which were conducted in conditions of stationary states, there were simultaneously nanocrystallites that formed a solid solution of nitrogen in iron and those, which were converted into iron nitride phase,17,21,26 according to the extended phase rule of Gibbs due to the presence of an additional degree of freedom associated with the size of the nanocrystallites.27 On the basis of X-ray diffraction (XRD) studies, it was found17,21,26 that the minimum nitriding potential at which the phase transition of each nanocrystallite of a certain size begins is a function of the nanocrystallite mass distribution. It was observed that the smaller the crystallite the greater the value must be for the gas-phase nitriding potential to begin the phase transition of the crystallite from α-Fe(N) phase to nitride γ′Fe4N. Theoretical studies proved that the active surface area of nanocrystallite which undergoes phase transition depends proportionally (linear dependence) on the nitriding potential at which the phase transition takes place for both nitriding18 reaction and reduction.27 Consequently, a model of the transformation of nanocrystallites for the nanocrystalline iron nitriding and reduction process has been proposed where nanocrystallites undergo phase transition throughout their volume in the order from the largest to the smallest.17,27 Therefore, it has been concluded14−22,27−29 that the phenomena occurring in a nanocrystalline iron−ammonia− hydrogen system cannot be described on the basis of the wellknown Lehrer’s diagram30−34 for bulk materials. Because of the long time it might take for some processes to approach the equilibrium state, conducting measurements in these conditions might not be experimentally feasible. There may also arise a question whether the observed states are actually equilibrium ones or only very close to equilibrium. Therefore, the chemical potential programmed reaction (CPPR) method has been elaborated and is presented in this paper to perform studies on close-to-equilibrium states. As mentioned above, properties of nanomaterials, with changing chemical potential of a gas phase, μ, depend both on nanocrystallite sizes (crystallite size distribution, CSD) and chemical composition of their surface d(physicochemical property) dμ = physicochemical property (CSD, ∑ θi) i where θi is the surface coverage degree of the ith chemical species. Commonly used temperature-programmed methods are based on the dependencies of physical and/or chemical properties of the test substances on temperature. These methods, however, work in conditions far from equilibrium. In analogy, one can use the dependencies of physical and/or chemical properties of nanomaterials on chemical potential of the gas phase, with which they react. This is possibly due to the fact that one of the properties of nanomaterials is that nanocrystallites of a certain mass undergo a phase transition at the specific chemical potential of a gas phase.18,27 Additionally, the new method operates at close-to-equilibrium states which leads to a significant extension of research opportunities. Thus, the idea of this method is (analogically to other programmed techniques) to continuously change the chemical potential of a gas phase and observe the reaction of the solid sample. Change in concentration of the gas reactant occurs in such a way that close-to-equilibrium states can be established. Then, conversion degree in the solid phase is measured. On the basis of dependence of the measured values of parameters characteristic for a given method to measure the conversion degree on change in the concentration of the gas reactant it is possible to define physicochemical properties of a nanomaterial. The conversion degree can be measured, for example, by means of thermogravimetry, X-ray diffraction (XRD), mass spectrometry, infrared (FTIR), Raman, Mössbauer spectroscopy, and electron paramagnetic resonance (EPR). The physicochemical properties to be determined may include: phase composition, average crystallite size, crystallite size distribution, lattice constants changes, and so on. When dealing with nanomaterials, crystallite size distribution determination has become the fundamental measurement because their physical (e.g., melting temperature, absorption of electromagnetic wave, magnetic characteristics) and chemical (e.g., catalytic activity, selectivity, creation of new materials) properties depend on the nanoparticle size.35−42 Adsorption depends on the morphological characteristics of the nanoparticles (their size and shape). On the other hand, chemical environment (presence of adsorbates) determines the morphology of nanoparticles.39 As mentioned above, the equilibrium states were considered in previous studies (with step-wisely changed chemical potential of a gas mixture); however, continuous change in chemical potential of a gas phase was not applied yet. Summing up, not only were the above-mentioned phenomena experimentally observed and reported but also thermodynamic basic principles of them were published. In particular equilibrium state in nanoscale structures was described in previous works.5,18 The hysteresis for a dependence of the iron nitriding degree on nitriding potential was explained in terms of the energy demand of individual components of the studied nanoscale system.18,27 These three works are the theoretical basis of the proposed method. Using the proposed new method, in this paper, research of the nanocrystalline iron−ammonia−hydrogen system has been presented on the basis of measuring the rate of nanocrystalline 8549 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556 Article The Journal of Physical Chemistry C out in hydrogen flow of 9 dm3/h at atmospheric pressure, poly thermally, increasing the process temperature to 500 °C at 10 °C/min and then the sample was annealed for 0.5 h in order to stabilize the nanocrystalline structure of the catalyst. The change in mass of the sample in the thermogravimetric measurements was expressed by nitriding degree, α, defined as the mass ratio of nitrogen attached at a given moment of time during the chemical process with respect to the initial weight of iron contained in the solid sample (XN/XFe [mol/mol]). Nitriding process of iron and reduction of the obtained iron nitrides were carried out at varying nitriding potentials. Nitriding potential values of the gas mixture at a given moment of the process were calculated from the equation pNH P = 3/23 [Pa−0.5] pH (1) iron nitriding and reduction of the obtained iron nitrides in a controlled way in states close to chemical equilibrium. During the studies, the CPPR method was applied using thermogravimetry and XRD. ■ EXPERIMENTAL SECTION Industrial prereduced triply promoted nanocrystalline iron catalyst for ammonia synthesis in the form of irregular particles with a diameter of 1.0−1.2 mm was studied.43 By atomic emission spectrometry with inductively coupled plasma using the spectrometer PerkinElmer Optime 5300DV, the chemical composition of the catalyst was determined. The catalyst in addition to the metallic iron contained (wt %) 3.3 Al2O3, 2.8 CaO, and 0.65 K2O. By X-ray diffraction using a Philips X-ray diffractometer X’Pert X-ray with a copper lamp and using the Rietveld method, the average crystallite size of iron (45 nm) was determined. Apart from that, using X-ray diffraction, nanoCSD was determined by means of the method proposed by Pielaszek.44 Fityk software45 as well as an online calculator by Pielaszek46 were used to analyze the diffraction patterns. The surface area of the catalyst determined by the BET method using a Quadrasorb SI apparatus (Quantachrome Instruments, Automated Surface Area & Pore Size Analyzer) was 12 m2/g.47 Nanocrystalline iron nitriding process and reduction of the resulting nanocrystalline nitrides of iron were conducted using gases supplied by Air Liquide: ammonia having a purity of 99.998% and hydrogen of 99.999%. Nanocrystalline iron nitriding process and reduction of the resulting nanocrystalline nitrides of iron were carried out in a differential tubular reactor35 connected to a system for regulating gas flows (Figure 1). Processes were carried out at 2 where pNH3 and pH2 represent partial pressures of ammonia and hydrogen, respectively, in the gas phase. Chemical processes were performed at a constant ammonia flow rate, V̇ NH3 = const, and hydrogen flow changing constantly according to the following expression ⎡ 3⎤ ̇ ± β t ⎢ cm ⎥ VḢ 2 = V0H H2 2 ⎣ min ⎦ (2) where βH2 is the hydrogen flow acceleration and V̇ 0H2 is the initial hydrogen flow at t = 0. The change of the nitriding potential of ammonia−hydrogen mixture during the conducted processes can be expressed as follows: P(t ) = ̇ (VNH ̇ + V0H ̇ ± β t )0.5 VNH H 3 3 2 2 ̇ ± β t )1.5 pat0.5 (V0H H 2 2 [Pa−0.5] (3) Hydrogen concentration changes in time in the gas phase can be described by the following nonlinear equation: X H 2 (t ) = ̇ +β t V0H H 2 2 ̇ + V0H ̇ +β t VNH H 3 2 2 (4) The change in hydrogen flow at the inlet to the reactor and the calculated (eq 4) participation of hydrogen in a nitriding mixture for one of the processes carried out at a constantly changing flow rate of hydrogen (βH2 = ± 0.4 cm3/min2) and the flow of ammonia (V̇ NH3 = 35 cm3/min) are shown in Figure 2. Nitriding processes of nanocrystalline iron were initiated from fixing the initial nitriding potential in the system, which was lower than the minimum nitriding potential necessary for the development of phase γ′-Fe4N. The minimum nitriding potential of the gas mixture was determined based on data obtained for nanocrystalline iron nitriding process performed in the stationary states at 350 °C, which was described in previous papers.22,24 A gas mixture of the determined initial nitriding potential was fed to the reactor to establish the steady state. After the composition of the reaction mixture was fixed in the reactor, the flow of hydrogen was reduced constantly in the nitriding process. The processes of nitriding were carried out up to the moment when the nitriding potential corresponding with the obtaining of saturated with nitrogen γ′-Fe4N phase in the nitriding process conducted in stationary states was achieved. Figure 1. Experimental setup used in the CPPR method: 1, sample holder; 2, single layer of grains; 3, reactor furnace; 4, reactor wall; 5, thermocouple; 6, electronic flowmeters. 350 °C, which was measured with a thermocouple placed in the vicinity of the sample. The measurement setup was equipped with a system to stabilize and control the temperature during the processes. The reactor was equipped with a magnetic sensor system to measure sample mass. A sample of the catalyst of approximately 1 g was placed in a platinum basket in a form of a single layer of grains. The reactor was fed by the reaction gas mixture of varying composition. The change in the composition of the nitriding mixture was carried out by a system of electronic mass flowmeters (by Brooks) connected to a computer. The computer was equipped with software that allows simultaneous control of flows on all flowmeters according to predefined programs. The hydrogen content in the outlet gas of the reaction space was determined by means of katharometric method. A test sample was preprepared by the reduction of the passive layer of the catalyst. The reduction process was carried 8550 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556 Article The Journal of Physical Chemistry C In order to better present experimental data, nitriding potential values were expressed by the natural logarithm of the nitriding potential. Figure 2. Dependences of the hydrogen flow and of its content in a nitriding mixture on time of the nitriding process and reduction of the obtained nanocrystalline iron nitrides at 350 °C; V̇ NH3 = 35 cm3/min, βH2 = ± 0.4 cm3/min2. Figure 4. Dependence of the nitriding degree of sample on the nitriding potential for nitriding of nanocrystalline iron and reduction of nanocrystalline iron nitrides conducted at different hydrogen flow accelerations. In the process of reducing of obtained nitride, hydrogen flow was increased constantly up to a final nitriding potential at which total reduction of the nanocrystalline nitrides to nanocrystalline iron, α-Fe(H), took place. ■ For the performed cycles of processes with different hydrogen flow acceleration, as in the case of processes carried out in stationary conditions, one can observe the phenomenon of hysteresis for each cycle. Along with an increase in acceleration βH2, a shift in isotherms for nitriding process to higher nitriding potentials and a shift in isotherms for reduction process toward lower nitriding potentials were observed. Nanocrystalline iron nitriding process and reduction of iron nitrides can be described by the general equation of chemical reactions: nitriding 3 α ‐Fe + NH3 XooooooooY γ ′‐Fe4N1 − x + H 2 reduction 2 Rates of the nitriding process can be described by the following equation:19 RESULTS AND DISCUSSION Four cycles of nitriding of nanocrystalline iron to nanocrystalline iron nitride γ′-Fe4N were performed and its reduction for different hydrogen flow accelerations, βH2, amounting to ±0.1 cm3/min2, ±0.2 cm3/min2, ±0.3 cm3/min2, and ±0.4 cm3/ min2. Nitriding processes were conducted at a constant flow of ammonia V̇ NH3= 35 cm3/min. Hydrogen flow was changed from the initial value V̇ 0aH2 = 58 cm3/min (corresponding with the minimum nitriding potential, P0a = 0.24 × 10−2 Pa−0.5) up to V̇ H2= 7 cm3/min (corresponding with the maximum nitriding potential P = 3.85 × 10−2 Pa−0.5). Reduction processes of the obtained nanocrystalline nitrides of iron were performed starting from the hydrogen flow, at which their preceding nanocrystalline iron nitriding processes were completed, i.e., from V̇ 0rH2 = 7 cm3/min to a value of V̇ H2 = 136 cm3/min, for which the nitriding potential was P = 0.06 × 10−2 Pa−0.5. For these processes, Figure 3 shows the relationship between the nitriding potential of a gas mixture and the nitriding degree of sample versus time of the process at different βH2. For the performed cycles of nitriding processes of nanocrystalline iron and reduction of the obtained nanocrystalline iron nitrides the dependence of the nitriding degree on the nitriding potential was developed, which is shown in Figure 4. ra = kaα(t , CMD)[P(t ) − P0a(α)] (5) In an analogous manner, one can describe rates of the reduction process rr = k rα(t , CMD)[P(t ) − P0r(α)] (6) where a and r refer to the nitriding and reduction process, respectively; k is the reaction rate constant; P(t) is the nitriding potential changing according to predefined dependence; P0a and P0r are the nitriding potential in equilibrium states; and P0 = f(α) where α = f(CSD). For a single crystallite, Sact, i mi = const and P0 = const where Sact,i is the active surface area of the ith nanocrystallite and mi is the ith nanocrystallite’s mass. In previously conducted processes of nanocrystalline iron nitriding and reduction of nanocrystalline iron nitrides in the states of equilibrium, in which P(t) = P0(α), the rates of nitriding of nanocrystalline iron or reduction of the obtained nanocrystalline iron nitrides were zero. Based on the dependence of the nitriding degree on the process time, the rates of reduction and nitriding process were determined. Nitriding rates are presented as functions of the nitriding degree in Figure 5a and those of the natural logarithm of the nitriding potential in Figure 6a. Figures 5b and 6b, respectively, present dependences of the reduction process rates on the nitriding degree and on the natural logarithm of the nitriding potential. By arrows the directions of the processes were marked. Figure 3. Dependence of the nitriding potential of gas mixture (dashed line) and of the nitriding degree of sample (solid line) versus time for nitriding of nanocrystalline iron and reduction of the obtained nanocrystalline iron nitrides at 350 °C. 8551 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556 Article The Journal of Physical Chemistry C Figure 5. Dependence of (a) the nitriding process rate and (b) the reduction process rate on the nitriding degree for the processes conducted at different hydrogen flow accelerations Figure 6. Dependence of (a) the nitriding process rate and (b) the reduction process rate on the natural logarithm of the nitriding potential for the processes carried out at different hydrogen flow accelerations. Figure 7. Dependence of hydrogen flow accelerations, βH2, on the nitriding potential for two maximum values of nitriding degree observed during (a) nitriding process and (b) reduction process. higher value, the greater step βH2 is applied, so the chemical reaction will be faster as well. For the process carried out in stationary states (βH2 = 0), the rates of nitriding and reduction are zero because the value of P in eqs 5 and 6 are equal to P0. Based on the determined dependences of the process rate on the βH2 parameter value one can evaluate how far the process conducted with a specific change in nitriding potential differs at a given moment from the process carried out in stationary conditions. For maxima of the dependence of the nitriding and reduction process rate for processes carried out with different hydrogen flow acceleration on the nitriding degree the dependence of the hydrogen flow acceleration on the nitriding potential is shown in Figure 7. The minimum nitriding potential, required to complete the conversion of iron nanocrystallites saturated with For the conducted processes of nitriding of nanocrystalline iron and reduction of the obtained nitride γ′-Fe4N a similar, bimodal pattern of changes in the rate of chemical reactions as a function of the nitriding degree was observed (the same number of peaks occurring and similar values of the nitriding degree corresponding to the maximum rate). The observed maxima of the reaction rate correspond to the phase transition of a fraction of nanocrystallites most abundant in the sample. Nitriding and reduction rate depend on βH2 with which the process was conducted. The higher the βH2 parameter value, the higher reaction rates corresponding to different nitriding degrees. At a constant process temperature (k = const) and at a given nitriding degree ( Sac, i mi = const), the expression (P − P0) has the 8552 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556 Article The Journal of Physical Chemistry C Figure 8. Crystallite mass distribution determined using reaction rate data for (a) nitriding and (b) reduction processes carried out at different hydrogen flow accelerations Figure 9. Crystallite size distributions determined using reaction rate data for (a) nitriding and (b) reduction processes carried out at different hydrogen flow acceleration rates. For comparison, the results obtained using Pielaszek’s method44 were added. nitrogen, α-Fe(N), having a size corresponding to a specific nitriding degree (in this case there are crystallites of sizes prevailing in the test samples) to the phase of iron nitride γ′Fe4N, was extrapolated. The maxima for the dependence of the nitriding and reduction process rate for processes carried out with different hydrogen flow acceleration shown in Figure 5 are present at a specific nitriding degree. A similar dependence as shown in Figure 7 can be determined for any value of the nitriding degree. On the basis of the presented dependences of the rates of nitriding and reduction processes carried out in conditions close to the stationary ones, nanocrystallite mass distributions (CMD) for single-stage phase transition α-Fe(N) → γ′-Fe4N and γ′-Fe4N → α-Fe(N) were determined using a method described elsewhere28 (Figure 8). The nitriding degree, XN/XFe [mol/mol], as the conversion degree, α [mol/mol], of the phase α-Fe(N) to γ′-Fe4N was presented on the x-axis. The conversion degree is defined as a ratio of mass of nitrogen in iron at a given moment of reaction to the nitrogen mass in γ′Fe4N. The symmetry of the above plots leads to a very interesting conclusion. During reduction of iron nitrides under conditions close to equilibrium nanocrystalllites undergo a phase transition in the order of their size from the biggest to the smallest. The same order was previously observed during the nitriding reaction. However, as far as reduction is considered, that was the first time such a phenomenon was observed. Using CMD plots for transitions taking place in both directions the CSD for each of the processes carried out with different hydrogen flow acceleration was determined. Ratios of individual fractions were chosen so that the area under the CMD = f(α) curve was equal to unity. On the basis of previous studies on nitriding of nanocrystalline iron catalyst by means of XRD, it was assumed that nanocrystallite size range was 20− 100 nm and a shape factor, Sact,i/(mi ρ−1), as for the sphere. With the selected range of diameters of crystallites the mean crystallite size calculated based on the obtained CSD is equal to the average diameter obtained by XRD. The obtained CSDs are shown in Figure 9 together with CSDs obtained using Pielaszek’s method.44 For all the processes carried out with continuously variable nitriding potential by constant variation of the hydrogen flow with varying acceleration βH2 bimodal distributions of crystallites were observed. These distributions were observed regardless of the phase transformation direction in a region of α-Fe(N) and γ′-Fe4N. Increasing the hydrogen flow acceleration in the nitriding mixture during the conducted process resulted in reduced accuracy of the resulting size distribution of crystallites present in the system. Determination of the crystallite size distribution with maximum accuracy is possible in the case of processes performed in the equilibrium states. Processes carried out at low βH2 values make it possible to obtain approximate information on the shape of distribution in a shorter time compared to the processes in stationary states. As presented in Figure 9, results obtained by XRD Pielaszek’s method do not show the real structure of the studied iron catalyst, since the maximum no. 2 is not detected. Nowadays, a better understanding of the structure and properties of catalysts containing nanoparticles as active species is a key factor in many industries. Size distribution of nanoparticles can be measured by, e.g., electron microscopies 8553 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556 Article The Journal of Physical Chemistry C (SEM, TEM, STM)48 and atomic force microscopy. The measurement is performed directly by measuring the length of nanoparticle. It is also possible to determine the shape of the observed objects. However, these techniques require a lot of grains to be observed and analyzed due to inhomogeneity of nanomaterials.17 Apart from that, it can be difficult to distinguish borders inside the agglomerates of nanoparticles and, therefore, the analysis by means of microscopies may be sometimes sort of subjective. Using techniques based on gas sorption measurements49 we obtain information related to the surface area of the whole solid sample. However, agglomerates and single particles are not distinguished which may lead to incorrect information about the solid structure. Methods based on X-ray diffraction can be applied to characterize the whole sample of nanocrystalline substances. Generally, XRD-based methods are related to the volume of a crystallite. One of these methods uses the Scherrer’s equation for determining the average size of nanocrystallites. The Rietveld method,50 originating from Hall method, enables us to determine the average crystallite size together with lattice strains. To determine size distributions of nanocrystallites, the whole diffraction line profile has to be analyzed.44,51−54 As an example, Pielaszek44 presented a method for determining the nanocrystallite size distribution which is a modification of classical methods for determining the mean size of crystallites. Other XRD-based techniques for determination the crystallite size distribution are the Warren−Averbach method or the method proposed by Vogel.55 The most important feature of the proposed in this paper method is that it is a chemical method in which the whole solid sample can be analyzed. In this method, a response of a chemical system to changes in chemical potential of a gas phase is studied. The phenomenon that nanocrystallites of a certain Sact/V ratio undergo a phase transition at the specific chemical potential of a gas phase is used, assuming that the chemical composition of the surface of each nanocrystallite is the same. This means that the obtained CSD is related to active surface area. Active surface is a very important parameter when dealing with processes occurring on the surface of catalytic nanomaterials. However, this method also has some limitations. One of them is the requirement to operate in the close-to-equilibrium state. To show how far we can be from equilibrium let us consider the following examples. In the region of classical kinetics where P(t) ≫ P0(α), every nanocrystallite may react and undergo the phase transition. We can, of course, assess the shape of GSD under kinetics conditions,56 but the obtained result might not be accurate. On this end, we are maximally far away from equilibrium. At the opposite end, where P(t) = P0(α) we deal with real equilibrium. This state, however, can be difficult to achieve. But the results obtained in equilibrium states are the most accurate. Therefore, we propose the CPPR method which operates in an intermediate region, viz. where P(t) changes in some vicinity of P0(α). The closer the equilibrium we operate the better. When the distance between P(t) and P0(α) is increased the accuracy of the method decreases because we approach the kinetic region (Figure 9). The second limitation is connected with β parameter. Namely, the proposed method requires a phase transition to occur. It means that value of β must change in such a way to allow the phase transition. If there are several phase transition then mass increments (reaction rate in the solid phase: Figure 5, the nitriding reaction rate changes from 0 at the beginning to 0 at the end of the chemical reaction) should be zero between one and another crystallographic phase. Each technique uses different assumptions which results in differences between e.g. “volumetric” and “surface” methods. Agglomerates of small crystallites in the “surface” method can be treated as one large “crystallite”. In turn, XRD-based methods use a sometimes very complicated mathematical apparatus and assume a rather unimodal distribution of particles. This is, however, correct only for some cases, because many times one deals with substances that are characterized by bi- or trimodal distributions.17,35,56,57 An example of such a substance is iron ammonia synthesis catalyst (Figure 9). Therefore, results obtained by means of different methods should not be strictly compared with each other, because this can lead to different conclusions. ■ CONCLUSIONS By using the CPPR method it was possible to conduct kinetic studies in states close to chemical equilibrium. Several accelerations of nitriding potential change have been applied during investigations of the nitriding process of nanocrystalline iron α-Fe(N) to iron nitride γ′-Fe4N and reduction of the obtained iron nitride. Critical nitriding potentials, at which phase transformations of nanocrystallites of a certain size occur in the above-mentioned reactions, have been determined. Furthermore, hysteresis phenomenon for a dependence of the iron nitriding degree on nitriding potential has been confirmed. Iron nanocrystallite size distribution in the iron ammonia synthesis catalyst has been determined and it occurred to be bimodal. Accuracy of size distribution measurement depended on nitriding potential change accelerations. In comparison to other known methods of determining size distributions, the proposed method is based on the relation of the active surface to the mass (volume) of a nanocrystallite. It is advantageous since it enables studying elementary processes due to connection of measured values with surface phenomena. It was also discovered that during both the nitriding and reduction of iron nitrides nanocrystallites underwent phase transition in their entire volume in the order of their sizes from the largest to the smallest. All of the results were obtained in a significantly shorter period of time in comparison to the case when processes would be carried out under conditions of equilibrium state. ■ AUTHOR INFORMATION Corresponding Author *Tel: +48 91 449 47 30. Fax: +48 91 449 46 86. E-mail: [email protected]. ORCID Rafał Pelka: 0000-0002-0896-8839 Author Contributions The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript. Notes The authors declare no competing financial interest. ■ ACKNOWLEDGMENTS The scientific work was financed by The National Centre for Research and Development, program ‘Lider’, Project No. LIDER/025/489/L-5/13/NCBR/2014. 8554 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556 Article The Journal of Physical Chemistry C ■ (24) Kiełbasa, K.; Arabczyk, W. Studies of the Ammonia Decomposition over a Mixture of α-Fe(N) and γ′-Fe4N. Pol. J. Chem. Technol. 2013, 15, 97−101. (25) Kiełbasa, K.; Pelka, R.; Arabczyk, W. Studies of the Kinetics of Ammonia Decomposition on Promoted Nanocrystalline Iron Using Gas Phases of Different Nitriding Degree. J. Phys. Chem. A 2010, 114, 4531−4534. (26) Moszyński, D.; Moszyńska, I.; Arabczyk, W. Iron Nitriding and Reduction of Iron Nitrides in Nanocrystalline Fe-N System. Mater. Lett. 2012, 78, 32−34. (27) Arabczyk, W.; Ekiert, E.; Pelka, R. Hysteresis Phenomenon an a Reaction System of Nanocrystalline Iron and a Mixture of Ammonia and Hydrogen. Phys. Chem. Chem. Phys. 2016, 18, 25796−25800. (28) Pelka, R.; Arabczyk, W. Studies of the Kinetics of Reaction Between Iron Catalysts and Ammonia − Nitriding of Nanocrystalline Iron with Parallel Catalytic Ammonia Decomposition. Top. Catal. 2009, 52, 1506−1516. (29) Pelka, R.; Arabczyk, W. Modelling of Nanocrystalline Iron Nitriding Process − Influence of Specific Surface Area. Chem. Papers 2011, 65, 198−202. (30) Lehrer, E. The Equlibrium Iron-Hydrogen-Ammonia. Z. Electrochem. 1930, 36, 383−392. (31) Kunze, J. Nitrogen and carbon in iron and steel thermodynamics; Akademie-Verlag: Berlin, 1990. (32) Du Marchie van Voorthuysen, E. H.; Feddes, B.; Chechenin, N. G.; Inia, D. K.; Vredenberg, A. M.; Boerma, D. O. Low-Temperature Nitridation of Iron Layers in NH3−H2 Mixtures. Phys. Stat. Sol. (A) 2000, 177, 127−133. (33) Du Marchie van Voorthuysen, E. H.; Chechenin, N. C.; Boerma, D. O. Low-Temperature Extension of the Lehrer Diagram and the Iron-Nitrogen Phase Diagram. Metall. Mater. Trans. A 2002, 33, 2593−2598. (34) Sokołowska, A.; Rudnicki, J.; Beer, P.; Maldzinski, L.; Tacikowski, J.; Baszkiewicz, J. Nitrogen Transport Mechanisms in Low Temperature Ion Nitriding. Surf. Coat. Technol. 2001, 142−144, 1040−1045. (35) Pelka, R.; Kiełbasa, K.; Arabczyk, W. Catalytic Ammonia Decomposition during Nanocrystalline Iron Nitriding at 475 degrees C with NH3/H2 Mixtures of Different Nitriding Potentials. J. Phys. Chem. C 2014, 118, 6178−6185. (36) Karch, J.; Birringer, R.; Gleiter, H. Ceramics Ductile at Low Temperature. Nature 1987, 330, 556−558. (37) Lojkowski, W.; Fecht, H. J. Structure of Intercrystalline Interfaces. Prog. Mater. Sci. 2000, 45, 339−568. (38) Poliakoff, M.; King, P. Phenomenal Fluids. Nature 2001, 412, 125. (39) Gleiter, H. Nanostructured Materials: Basic Concepts and Microstructure. Acta Mater. 2000, 48, 1−29. (40) Beck, I. E.; Bukhtiyarov, V. I.; Pakharukov, I. Y.; Zaikovsky, V. I.; Kriventsov, V. V.; Parmon, V. N. Platinum Nanoparticles on Al2O3: Correlation Between the Particle Size and Activity in Total Methane Oxidation. J. Catal. 2009, 268, 60−67. (41) Pelka, R.; Kielbasa, K.; Arabczyk, W. The Effect of Iron Nanocrystallites’ Size in Catalysts for Ammonia Synthesis on Nitriding Reaction and Catalytic Ammonia Decomposition. Cent. Eur. J. Chem. 2011, 9, 240−244. (42) Pelka, R.; Glinka, P.; Arabczyk, W. The Influence of Iron Nanocrystallite Size on a Nitriding Process Rate. Mater. Sci.-Poland 2008, 26, 349−356. (43) Arabczyk, W.; Jasińska, I. The Current State of Knowledge of Iron Catalysts Used in Ammonia Synthesis. Przem. Chem. 2006, 85, 130−137. (44) Pielaszek, R. FW1/5/1/4 Method for Determination of the Grain Size Distribution from Powder Diffraction Line Profile. J. Alloys Compd. 2004, 382, 128−132. (45) Wojdyr, M. Fityk: a General-Purpose Peak Fitting Program. J. Appl. Crystallogr. 2010, 43, 1126−1128. REFERENCES (1) Liu, H. Z. Ammonia Synthesis Catalysts: Innovation and Practice; World Science Publishing Co. Ltd.: Singapore, 2013. (2) Schlögl, R. In Catalytic Ammonia Synthesis, Fundamental and Practice; Jennings, J. R., Ed.; Plenum Press: New York, 1991. (3) Altenburg, K.; Bosch, H.; van Ommen, J. G.; Gellings, P. J. The Role of Potassium as a Promoter in Iron Catalysts for Ammonia Synthesis. J. Catal. 1980, 66, 326−334. (4) Arabczyk, W.; Narkiewicz, U.; Moszyński, D. Double-Layer Model of the Fused Iron Catalyst for Ammonia Synthesis. Langmuir 1999, 15, 5785−5789. (5) Arabczyk, W.; Pelka, R.; Jasińska, I. Extended Surface of Materials as a Result of Chemical Equilibrium. J. Nanomater. 2014, 2014, No. 473919. (6) Jasińska, I.; Lubkowski, K.; Arabczyk, W. Wpływ Temperatury Redukcji na Powierzchnię Właściwą i Aktywną Preredukowanego Katalizatora Ż elazowego do Syntezy Amoniaku. Przem. Chem. 2003, 82, 230−233. ́ (7) Kowalczyk, Z.; Jodzis, S.; Sroda, J.; Diduszko, R.; Kowalczyk, E. Influence of Aluminium and Potassium on Activity and Texture of Fused Iron Catalysts for Ammonia Synthesis. Appl. Catal., A 1992, 87, 1−14. (8) Arabczyk, W.; Narkiewicz, U.; Kałucki, K. Model of Active Surface of Iron Catalyst for Ammonia Synthesis. Vacuum 1994, 45, 267−269. (9) Paál, Z.; Ertl, G.; Lee, S. B. Interactions of Potassium, Oxygen and Nitrogen with Polycrystalline Iron Surfaces. Appl. Surf. Sci. 1981, 8, 231−249. (10) Strongin, D. R.; Somorjai, G. A. In Catalytic Ammonia Synthesis, Fundamental and Practice; Jennings, J. R., Ed.; Plenum Press: New York, 1991. (11) Ertl, G.; Prigge, D.; Schlögl, R.; Weiss, M. Surface Characterization of Ammonia Synthesis Catalysts. J. Catal. 1983, 79, 359−377. (12) Somorjai, G. A.; Materer, N. Surface Structures in Ammonia Synthesis. Top. Catal. 1994, 1, 215−231. (13) Wróbel, R.; Arabczyk, W. Solid−Gas Reaction with Adsorption as the Rate Limiting Step. J. Phys. Chem. A 2006, 110, 9219−9224. (14) Arabczyk, W.; Wróbel, R. Study of the Kinetics of Nitriding of Nanocrystalline Iron Using TG and XRD Methods. Solid State Phenom. 2003, 94, 185−188. (15) Moszyńska, I.; Moszyński, D.; Arabczyk, W. Hysteresis in Nitriding and Reduction in the Nanocrystalline Iron-AmmoniaHydrogen System. Przem. Chem. 2009, 88, 526−529. (16) Wilk, B.; Arabczyk, W. Studies on the Nitriding and Reduction in the Nanocrystalline Iron-Ammonia-Hydrogen System. Przem. Chem. 2014, 93, 1036−1040. (17) Wilk, B.; Arabczyk, W. Investigation of Nitriding and Reduction Processes in a Nanocrystalline Iron−Ammonia−Hydrogen System at 350°C. Phys. Chem. Chem. Phys. 2015, 17, 20185−20193. (18) Arabczyk, W.; Ekiert, E.; Pelka, R. Size-Dependent Transformation of α-Fe into γ′-Fe4N in Nanocrystalline the Fe−NH3−H2 System. J. Phys. Chem. C 2016, 120, 17989−17995. (19) Wilk, B.; Kiełbasa, K.; Arabczyk, W. Nitriding of Nanocrystalline Iron with Ammonia−Hydrogen Mixture at 300°C. Przem. Chem. 2015, 94, 1816−1820. (20) Moszyński, D.; Moszyńska, I. Phase Transformations During Nitriding of Nanocrystalline Iron. Przem. Chem. 2013, 92, 1332−1335. (21) Moszyński, D.; Moszyńska, I.; Arabczyk, W. The Transformation of Alpha-Fe into Gamma′-Fe4N in Nanocrystalline Fe-N System. Appl. Phys. Lett. 2013, 103, 253108. (22) Moszyński, D. Nitriding of Nanocrystalline Iron in the Atmoshperes with Variable Nitriding Potential. J. Phys. Chem. C 2014, 118, 15440−15447. (23) Moszyński, D.; Kiełbasa, K.; Arabczyk, W. Influence of Crystallites′ Size on Iron Nitriding and Reduction of Iron Nitrides in Nanocrystalline Fe-N System. Mater. Chem. Phys. 2013, 141, 674− 679. 8555 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556 Article The Journal of Physical Chemistry C (46) Pielaszek, R. Method FW1/4/5M of full Grain Size Distribution Determination. http://science24.com/fw145m/ (accessed April 14, 2016). (47) Arabczyk, W.; Jasińska, I.; Lubkowski, K. The Surface Properties of Iron Catalyst for Ammonia Synthesis. React. React. Kinet. Catal. Lett. 2004, 83, 385−392. (48) Pingel, T.; Skoglundh, M.; Grönbeck, H.; Olsson, E. Revealing Local Variations in Nanoparticle Size Distributions in Supported Catalysts: A Generic TEM Specimen Preparation Method. J. Microsc. 2015, 260, 125−132. (49) Brunauer, S.; Emmett, P. H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309−319. (50) Rietveld, H. M. A Profile Refinement Method for Nuclear and Magnetic Structures. J. Appl. Crystallogr. 1969, 2, 65−71. (51) Ganesan, P.; Kuo, H. K.; Saavedra, A.; De Angelis, R. J. Particle Size Distribution Function of Supported Metal Catalysts by X-Ray Diffraction. J. Catal. 1978, 52, 310−320. (52) Ungár, T.; Gubicza, J.; Ribárik, G.; Borbély, A. Crystallite Size Distribution and Dislocation Structure Determined by Diffraction Profile Analysis: Principles and Practical Application to Cubic and Hexagonal Crystals. J. Appl. Crystallogr. 2001, 34, 298−310. (53) Ungár, T. Characterization of Nanocrystalline Materials by XRay Line Profile Analysis. J. Mater. Sci. 2007, 42, 1584−1593. (54) Ida, T.; Goto, T.; Hibino, H. Particle Statistics in Synchrotron Powder Diffractometry. Z. Kristallogr. Proc. 2011, 1, 69−74. (55) Vogel, W. Size Distributions of Supported Metal Catalysts: An Analytical X-Ray Line Profile Fitting Routine. J. Catal. 1990, 121, 356−363. (56) Pelka, R.; Arabczyk, W. A New Method for Determining the Nanocrystallite Size Distribution in Systems where Chemical Reaction Between Solid and a Gas phase Occurs. J. Nanomater. 2013, 2013, No. 645050. (57) Pelka, R.; Kiełbasa, K.; Arabczyk, W. The Temperature Effect on Iron Nanocrystallites Size Distribution. Curr. Nanosci. 2013, 9, 711− 716. 8556 DOI: 10.1021/acs.jpcc.6b09607 J. Phys. Chem. C 2017, 121, 8548−8556

Anuncio

Documentos relacionados

Descargar

Anuncio

Añadir este documento a la recogida (s)

Puede agregar este documento a su colección de estudio (s)

Iniciar sesión Disponible sólo para usuarios autorizadosAñadir a este documento guardado

Puede agregar este documento a su lista guardada

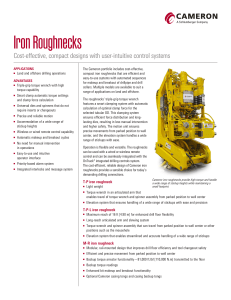

Iniciar sesión Disponible sólo para usuarios autorizados