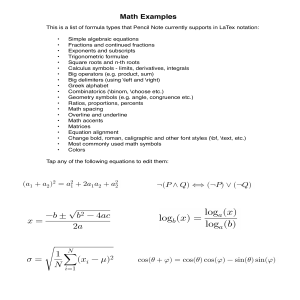

Pergamon Chemical Engineering Science, Vol. 50, No. 24, pp. 4045—4059, 1995 Copyright C 1995 Elsevier Science Ltd Printed in Great Britain. All rights reserved 0009-2509/95 $9.50 + 0.00 PROCESS SYSTEMS ENGINEERING: HALFWAY THROUGH THE FIRST CENTURY JACK PONTON Department of Chemical Engineering, The University of Edinburgh, King's Buildings, Mayfield Road, Edinburgh EH93JL, Scotland (Received 1 July 1995) The area of chemical engineering which has become known as Process Systems Engineering developed initially out of the availability of a tool, the high-speed digital computer. Coincidentally, 50 years ago, computers appeared for the first time, and as they became more generally available and useful, chemical engineers were amongst the first to recognise and exploit their potential for large scale calculations. Most of the efforts of early process systems engineers were focused on circumventing the limitations of early computers, particularly their lack of speed and of storage capacity to handle the very large problems whose solution was an ultimate aim. Over the last few years these constraints have practically vanished. However, some of the discipline's most important long-term achievements have come in the form of a better understanding of large-scale concepts; these have resulted from the need to analyse and decompose problems and procedures so that they might be accessible to computing machines of limited capacity. This has also made them more accessible to we human computing machines of likewise limited capability. The first half century of process systems engineering was dominated by mathematics. Over the next half century, mathematics will be taken for granted, and emphasis will shift to information and understanding: how it can be represented, captured, accessed, transferred and exploited. The ability to perform very large numerical calculations in a simple and routine manner will encapsulate the mathematical achievements of the last 50 years and make them accessible to all chemical engineers. Future research can thus concentrate on new areas. The current ready availability of computers is already having a major effect on the way in which all chemical engineers and scientists work. In the future, computers will become not just available, but ubiquitous, providing instantaneous access to the sophisticated mathematical and informatic tools which have been and will be developed. It is diffcult to predict the impact of this ubiquity, and any prediction is likely to be an underestimate. Still harder to assess are the consequences of not just the power and ubiquity of computer tools, but their connectivity. This will provide fast, worldwide connection between computer software and computer users on an unprecedented scale, and seems likely to create a qualitative change in the way in which engineers will use creatively their expanding range of powerful tools 1. SETTING THE SCENE The term "process systems engineering" (PSE) seems to have been coined by Takamatsu [60] at the first PSE conference in 1982. (There have since been five such meetings throughout the world.) To paraphrase his definition: "PSE is the discipline of systematic planning, design, operation and control of chemical processes," We may seek further clarification in the definitions of the elementary terms from e.g. the OED [46]. Process: "Course of action, proceeding, esp. series of operations in manufacture etc.; natural or involuntary operation, series of changes." System: "Complex whole, set of connected things or parts, organized body of material or immaterial things. For the readership of this journal, a definition of engineering should be superfluous.1 t Keywords identifying PSE are thus: actions, operations, manufacturing, natural, material, immaterial, complex, connected parts, organized body. Compare all of the above with Danckwerts' [18] 1966 definition of chemical engineering science (CES) as: the aspects of science developed by chemical engineers for their own purposes in fields not covered by other branches of technology." That is, anything that interests us which no one else has claimed! Finally, in the context of chemic engineering science, it may be well to note the essential difference in attitude and aims of scientists and engineers. This was admirably encapsulated in the 19th century by Von Kårmån: "Scientists study what is. Engineers create what never was." Process systems engineering is thus, like CES, so wide in scope as to, at least in principle, embrace practically any and every activity. Certain eminent PSE practitioners have indeed been heard to claim that all the "rest" of chemical engineering is really PSE . 1 The author had in fact planned to quote a definition, but the Oxford dictionary, typically, gave an idiosyncratic and unsatisfactory one, while Chambers [15], published in Edinburgh, cannily defines engineering recursively as "the art or profession of an engineer". Table 1. Some PSE topics Optimisation of process design or operation Process design Process control Plant data reduction Mathematical modelling of process plant Design and simulation of complex unit operations Computational fluid dynamics (CFD) Modelling of thermodynamic properties using equations of state, group contribution methods, etc. Molecular modelling and prediction of molecular properties Statistical thermodynamics Equation solving and optimization algorithms Computer representation of engineering information Computer representation of process knowledge The true key elements of PSE are however complexity and connectivity applied either on the macroscopic scale of traditional manufacture, the subject's usual domain, or indeed to the smaller or even microscale, where CES is more commonly seen to be relevant. Table 1 shows some topics which have been proposed as part of process systems engineering. Not everyone, and certainly not the author, would agree with all of the list. In particular, areas where problem size dominates subtlety, such as CFD and molecular modelling, all dependent for their current importance on the same developments in computer technology which have underpinned PSE, see below, have involved little of the "systems" approach which characterises PSE. They will therefore be excluded from this discussion, although their increasing importance for the future is not disputed. More controversially perhaps, the author intends to exclude process control from this discussion, although occasional reference may be made to papers in that subject. The major strand of control engineering, certainly in terms of published papers, is really a branch of applied mathematics. It is to be hoped that the subject, or that part of it which relates to process engineering, will some day be firmly reclaimed by the process engineering community and developed in the language of process engineers. Although there have been some hopeful signs [45], this day has yet to dawn. 1.1. Computers and PSE Fig. 1. Development of computer power since 1945 Most PSE practitioners have been interested in the exploitation of computer technology. The main international process systems journal is Computers and Chemical Engineering. Most PSE research certainly involves the use of computers, but then there is now very little scientific activity which does not. Historically, PSE turned to computers as these provided a means of handling large-scale problems, which in the early days meant the solution of "large" sets of equations. Note that the definition of "large" is a relative one; it can be taken to mean "just bigger than can conveniently and economically be handled by present technology". In the context of the development of computers over the last half century, this definition is elastic indeed. Computers in 1945 had been constructed, for wartime decrypting activities, see e.g. [29], out of telephone switching equipment with typical switch times of about 0.1 s. The use of more than a few hundred switches was ruled out by physical size and power consumption. However one seeks to display progress in speed, miniaturisation or cheapness of computer systems, one encounters improvements of many orders of magnitude. A typical presentation of the Process systems engineering: halfway through the first century 4046 development of cost and performance of computer systems, after [33], is shown in Fig. 1. This is even more striking when quantified and converted to a logarithmic scale, as is also shown. The cost—performance ratio has improved by at least six orders of magnitude. 2 In the early days of PSE, much ingenuity was expended in trimming large problems down to match the available computer power. Because of the exponential growth of computer power and availability, this has, almost suddenly, ceased to be necessary for a wide range of activities. A further significance of the use of computers, be-yond their power as calculating machines, lies in the nature of the problem formulation which must be performed when a computer is to be used. This point is discussed below. 2. THE PAST The first decades of PSE were undoubtedly dominated by mathematics, largely, but not always, numerical mathematics. Process systems engineers were mainly concerned with the construction and solution of mathematical models. A microcosm of PSE's development may be seen in the development of techniques for modelling multicomponent distillation. 2.1. Equations and equation solving: multicomponent distillation Chemical engineers, perhaps uniquely amongst designers, have as one of their basic operations a device whose mathematics is so intractable that it was probably never solved rigorously until the advent of the computer. The multicomponent distillation column is described by a large set of non-linear algebraic equations which must be solved iteratively. While it would have been possible to perform these calculations with a team carrying out hand calculations as was done for the simpler, linear, frame calculations for airships in the 1930s [56], there is no evidence that this was in fact done. Designers relied on a variety of shortcut analytical procedures, which are still used for initial design [22, 61]. Occasionally a "rigorous" method was used, in fact a poorly formulated repeated substitution procedure, first proposed in 1932 [38] but still described, with variations, in standard texts well into the 1960s, see e.g. [57]. Interestingly, it also seems that many practitioners of chemical process design did not understand how to formulate the distillation problem properly. A systematic method of counting the number of equations and unknowns in multicomponent problems was not described fully until the late 1950s [37]. While workers in the forefront of the development of mathematical methods, e.g. [3], understood very clearly what they were doing, the nature of the problem appears to have been widely misunderstood until quite some time later. Although the proper mathematical formulation had been presented in several places, e.g. [40, 24], many respectable engineering scientists did not appreciate fully the difference between firm specifications, e.g. on a product composition from a column, and estimated values which change as an iterative solution proceeds. Similarly, a process referred to as "iteration" was not always understood to be formally the solution of a set of non-linear algebraic equations. Much nonsense was talked about the need for "intuition" in the use and solution of distillation problems, including the following superb piece of technophobia. "It is questionable whether the multicomponent [distillation] problem is susceptible of a statistically acceptable solution. The similarity of individual program printouts to "solutions" is perhaps only a "matter of taste" . . . "[30] Rigour in problem formulation represents an important aspect of the significance of the use of computers, and the "systems" approach in general, to process engineering. In performing approximate hand calculations it is possible to obtain some sort of answer without having fully or correctly formulated the problem. Computers are not capable of ad libbing on behalf of their users; the problem must be correctly posed, and in order to do this it must be fully understood. Computers have thus not only enabled us to solve larger problems faster, they have forced us to understand more precisely what problem we are trying to solve. 2.2. Modelling complete chemical plants A hint of a new vision of the scope and scale of PSE began to emerge in the early 1960s with the first attempts to provide mathematical and computer solvable models of whole chemical processes [32, 55, 17]. This was a truly revolutionary concept, since no one had previously considered using a computer to model the whole of any complex engineering artefact. By contrast, at about this time a leading U.K. aircraft manufacturer was still using the 1930s techniques alluded to above. The "computer" used to design much of Britain's last single-seater fighter was a roomful of calculating machine operators filling out the numbers in a sort of spreadsheet table [2] ! Early attempts to model whole processes stretched the limits of the computers then available. Ingenuity had to be exercised to squeeze the data sets for even moderately sized problems into then-available memory. It was not unusual 2 The ultimate index would account for size, which has itself fallen by six or seven orders of magnitude, as well, and could be something like "megaflops per dollar per m 3 ". This will have increased by at least 12 orders of magnitude in 50 years, a development probably unmatched in the history of any technology. growth of computer power and availability, this has, almost suddenly, ceased to be necessary for a wide range of activities. A further significance of the use of computers, beyond their power as calculating machines, lies in the nature of the problem formulation which must be performed when a computer is to be used. This point is discussed below. Process systems engineering: halfway through the first century 4047 for the complete mass balance to exist only on mass storage, with relevant sections pulled into "working memory" as required. When dynamic simulation of complete process was attempted [13] this stretched the ability of computers to handle the stiff differential equations which describe most process problems. There was insumcient memory capacity to use the recently developed implicit methods [27] on a large scale, and explicit techniques could take tens of minutes to simulate seconds of operation of even moderately sized plants. 2.3. Optimization: generating and exploring alternatives The use of a systematic or "systems" approach to large problems dates from the very beginning of the period. During WW2 the discipline of operations research (OR) developed as a means of organising and managing large projects. As well as insights into the management of complexity, OR became closely linked to optimisation, particularly in the area of linear programming, the optimisation of linear systems. Chemical engineers found formal common ground with the OR community in U.K. during the brief period of existence of the Lancaster University Systems Engineering Department, in which the late David Rippin played an important role. More generally, the chemical engineering community eagerly took over, and indeed contributed to, developments in non-linear optimisation, for use in a very wide range of applications. Both "process" and "engineering science" areas of the discipline frequently require a systematic means of choosing numerical values in a model to ensure that some quantity (error, cost, size, mean square deviation, free energy, profit, etc.) should take either a maximum or minimum value. Publications in both fundamental and applied aspects of optimisation over the years have reflected links between the mathematics and process engineering communities in this field, e.g. [31, 43, 25]. 2.4. Summary To summarise: at the start of our period we could not solve more than a few equations of any type. By "the present", let us say 1990, we hardly need to consider the solution of any reasonably large system of equations as a problem. We also know more, although not everything, about how we should formulate or pose engineering problems. 3. THE PRESENT PSE is now well established and in regular use. The principal application is large-scale equation solving. Skill is still sometimes needed in correctly formulating problems. Significantly, the discipline is being seen as a means of "alternative generation". This is coming to involve information handling as much as numerical computation. 3.1. Equation solving and modelling It is now hardly ever diffcult to solve a large-scale process engineering steady-state modelling problem. To refer back to the example mentioned above, multicomponent distillation calculations are now routine; a designer will often run dozens of cases for a design using full tray-to-tray calculations with the most rigorous thermodynamic models available. The calculation will seldom fail. Even large unsteady-state models are relatively tractable, to the extent that a significant limitation is now problem formulation, or model construction, and the interpretation of large volumes of numerical results. Although there have been some new developments in the theory of large sets of differential—algebraic equations (DAEs) the groundwork for most of the techniques now in use was laid in the 1960s and early 1970s. One interesting point is the "discovery" [49] of the existence of DAEs as a class of equations. Many chemical engineers had been happily solving mixtures of differential and algebraic equations, having observed, but not felt it to be matter of note, that real chemical engineering problems in practice always consisted of a mixture of such equations. The formalisation of special properties of DAEs is another interesting illustration of interaction between process systems engineers and mainstream mathematics [471 PSE has also driven our understanding of the processes which we have tried to model, This understand* ing in turn, should help us to develop better processes. Once again distillation provides a good example. The need to simulate nonideal, azeotropic separations has produced an enhanced understanding of exactly what these involve, see e.g. [64]. This can lead not only to better azeotropic separations, but potentially, by in• cluding reactive distillation, which has features in common with the distillation of azeotropes, to innovative processes which may suggest leaps in technology, such as using a single combined reactor-separator in place of a reactor and seven columns [65]. 3.2. Alternative generation and exploration Optimisation of large systems with continuous decision variables (e.g. sizes and costs) is in almost as good shape, although practical diffculties still occur. In fact, the three topics of steady-state modelling, unsteady-state modelling, and continuous optimisation now depend on the same underlying technologies, the ability to solve emciently and reliably very large sets of "sparse" linear equations, e.g. [11, 24], and the provision of reliable values of partial derivatives, e.g. [50]. Chemical engineers and their collaborators have contributed to both these developments. The most striking feature of the present is the growth of the use of the computer, mathematical and informatics techniques to generate and analyse alternatives. Process systems engineering: halfway through the first century 4048 There are many aspects to this wide spectrum of activities and approaches. At one end the problem is formalised as one in optimisation or mathematical programming. At the other, ideas from the domain of artificial intelligence are employed. Sitting alongside these primarily computer-based techniques are a range of "methodologies" and "insights" devised to augment, supplement or replace computer methods. Since activity in this field tends to focus on the design of process flowsheets, this area of PSE is usually referred to as "process synthesis." The problem is characterised by the existence of many discrete alternatives. Is there a heat exchanger or is there not? Does the reactor operate in the gas or liquid phase? Mathematically these belong to the class of integer programming problems. These have been investigated since the early days of OR, see e.g. [28]. In practice, these discrete or integer decisions are combined with continuous quantities whose values have to be chosen optimally. When all continuous relationships are linear, the resulting mixed integer linear program (MILP) can be solved relatively effectively. A particular diffculty which arises in chemical engineering is that the continuous relationships are generally non-linear. The resultant MINLP, mixed integer non-linear program is much harder to deal with, and chemical engineers have consequently made significant contributions to this area [21]. The alternative veiwpoint, which some have seen as being diametrically opposed to the mathematical formulation and solution of such problems, is to consider how a human designer would approach this type of problem, and attempt to encapsulate his or her knowledge in a set of rules or "heuristics" programmed into the computer. Such programs became fashionable in the 1980s as "expert systems." However, the chemical engineering community was writing them in the 1960s [41]. It was seen rather quickly that this heuristic approach seldom worked very well This focused attention on the rules used, and encouraged the analysis of fundamental problems and activities in design. For example, the observation that the application of a single simple rule [51] would usually produce a good process for heat recovery helped in the development [39] of "thermodynamic insights" which have been valuable in the understanding and design of such processes. In the context of the design of complete processes, a model hierarchical approach has been presented [20] and widely described to both industry and academia. The approach represents a formalisation of what many practitioners already did, but nonetheless provides a valuable insight into the nature of design activity. Interestingly, it relies a great deal on shortcut methods and approximate estimates. The author's objective was not to provide a computerbased technique, but to identify rules. The lasting value of the work lies in its paradigrn for carrying out a complex task in a structured, top-down manner, which can be applied to activities other than conceptual chemical process design. 3.3. Artificial intelligence and process systems engineering The late 1980s saw an upsurge in activity in the informatics discipline called artificial intelligence (Al). The longterm aim of the Al community is the understanding, and replication by artificial means, of human intelligence. In the world of science, and most Al practitioners are scientists rather than engineers, it is perfectly respectable to have aims which are neither achievable nor particularly useful or desirable if they were in fact achieved. A great deal of nonsense was however talked about how Al would immediately affect engineering and industry. The Japanese Ministry of Technology, MITI, was reportedly sponsoring a "fifth-generation computer" project to produce an "intelligent" computer. This caused a great flurry in parts of the West, particularly amongst government planners in the U.K. who poured most of the civilian research budget for several years into "information technology". Nothing much was later heard of the fifth-generation computer, and a cynic or conspiracy theorist might suggest that it was a red herring to distract Western industry's policy-makers while Japanese industry got on with more useful activities such as perfecting the videorecorder and inventing the camcorder. Useful techniques did emerge from the Al community as a result of this activity, and these were applied, with varying success, in many areas of process engineering, e.g. [19, 8, 44, 36]. Where they failed, it was largely because the tools were inappropriate to the problems. The chemical industry is faced with many intractable problems, and within the hardest-headed engineer or manager lurks the desire for an instant, magic solution to these problems. New and poorly understood techniques were eagerly seized upon in the hope that they will provide such solutions. This happened successively with expert systems, neural networks and fuzzy logic, all of which are useful techniques in appropriate domains, but none of which can in any sense be a universal tool. This will happen again, and so scepticism should be applied to claims made for a new technique. We should always beware of snake oil sales persons. Despite the "overselling" of Al in this period, two legacies do have lasting value. Firstly, Al techniques have now taken their place as part of integrated systems in which they are applied to appropriate parts of a larger problem, often alongside conventional numerical computing techniques. None of these tools is "intelligent", but the complete system may, in a sense, be regarded as possessing this property in some measure [35]. Secondly, attempts to provide "intelligent" computer-based tools for process design using Al techniques have also led to paradigrns for the activity they aimed to support [58, 7]. These, rather than the tools themselves, arguably constitute the greatest lasting value of this area of research to the chemical engineer. ing community. 3.4. Summary: what we can do now Before moving on to the future, it is useful to summarise just what we now can and cannot do. We can: large systems of equations solve very large system of equations (10000 -100000) Process systems engineering: halfway through the first century 4049 solve quite large continuous optimisation problems (1000s of constraints, 100s of decision variables) understand that there are "good" and "bad" ways of formulating these problems solve some very large special discrete problems solve medium-sized non-linear discrete/continuous problems, adopt a systematic approach to some "creative" problems. We cannot yet, easily: formulate complex problems in a natural way, visualise or "understand" the solutions to large problems, reuse parts of problems, models or solutions out of, sometimes even within, their original context, construct generalised discrete problems ("superstructures") model procedures and activities, especially creative activities. In general, we are now well placed to solve problems of arbitrary size and complexity, provided we can pose them correctly. We have learned a great deal about the correct formulation of problems, so that in principle we know how to do this. For very large-scale problems, there are simply practical diffculties in assembling all the information correctly and consistently. 4. THE FUTURE Organising a view into the future is obviously harder than organising one of the past, not just because it is the future and thus unknown in detail, but because a small number of critical elements are so extremely uncertain. It is possible to be wrong qualitatively in what might seem to be quite minor aspects, and to find that these change so much that the entire shape of the future is different. Inter alia, the prognosticator can end up looking very silly even a year or two later. Examples abound, from the famous late 19th century remark that "All that remains for physics is the next decimal place" (just before relativity, quantum theory, etc.) to predictions about the development and impact of technology. The latter include two personal reminiscences. The first in the 1970s from a distinguished professor of computer science: "Some remarkable developments will take place if computer memory ever costs less than one U.S. cent per bit. But of course this will never happen." [42]. The first sentence has certainly been fully justified. But memory now costs about 10 -4 cents per bit and is still getting cheaper. The second, to the author's embarrassment, was his own in 1979 to the effect that ready availability of cheap microprocessors would in the end have little impact on manufacturing because the cost of sensors and transducers, particularly electromechanical elements, would remain high [52]. While the latter is true, the effect of electronics becoming so very much cheaper was totally misjudged, showing that a quantitative change, if large enough, will have significant qualitative effects. With these caveats we will look at the future under four headings. computing technology and its impact the drive to solve larger and larger problems managing discrete choice in design and modele the workplace of the future. 4.1. Computer technology The only thing that seems certain about computer technology is that it will become even more all-pervasive. There are some developments of which we can be certain by simple extrapolation of the current trend. We can thus expect to see: lots and lots of computing power wide ranging, fast, high bandwidth communications sophisticated graphical displays elegant interactive facilities some major breakthrough in software engineering. The challenge for us, as process systems engineers, is to extract the maximum benefit from new technology, while working closely with the informatics community, but without losing our skills as process engineers. Although it is necessary to appreciate the way in which problems get larger in computational terms, see below, there will be enough computing power available, either on the user's own desk or at the end of a high-speed, high bandwidth line, to solve nearly all the problems which most engineers want to tackle, and present the results in interesting and creative ways. It is, however, fair to say that much more thought has to go into the last step, which until recently has been largely ignored by engineers and process software developers. It seems likely that some major conceptual breakthrough will occur in our ability to create complex software. It has been widely observed that software engineering is still essentially a "craft industry" and that its equivalent of the industrial revolution has still to occur. The incentives for such a development are absolutely compelling, and while need alone is not a sumcient condition for progress, as witness the billions which have been poured into fusion Process systems engineering: halfway through the first century 4050 research, there would seem to be more cause for optimism here. This is because there are some good indications of possible, practical, directions for this breakthrough, e.g. although it is not yet clear exactly what form it will take. Certain developments would imply changes of a qualitative nature which are not just extrapolations of current technology. Here prediction is much more dangerous, but it is likely that few, if any, of the following developments will occur: "intelligent" computers (but we will find ways to solve more loosely posed problems) direct two-way speech and vision communication (but computers will generate sound and pictures), ultrafast "supercomputers" (but there will be many, many fast "small" computers). Anything resembling an "artificial brain" is unlikely to be developed. The reason is simply one of scale. Although the average memory available to a computer has increased by about four orders of magnitude to say about 10 8 bits, the human brain contains about 10 14 neurons, and these are now known to be complex computing elements rather than simple storage units or "gates". Thus, even if the current rate of size increase could be maintained, several decades would be required for us to reach "brain-sized" computers. Because of the complexity of neurons, the equivalent of at least another two orders of magnitude might be needed to provide equivalent functionality. However, artificial intelligence research will continue to provide programming techniques which are of value even if the wider aims of that community are never realised. True two-way speech and vision communication may well require computational power comparable with the brain, and, unless realised by some quite different approach (which is of course possible), is equally unlikely to occur. Generation of sound and sophisticated animated vision is however already possible, and will become easier to combine with conventional "calculation" programs. The above are important observations, because, if correct, they imply that while computers may be cheaper, smaller and more powerful, they will not be fundamentally different from those in use today. Computers with which one could hold an intelligent conversation would change the ground rules for PSE (and much else!) so radically that all predictions in this section would be invalid. Finally, economies of scale suggest that the most cost-effective computing should be obtained by buying the type of computer with the largest market share. It was suggested, several years ago, that if computing power could be made additive, then connecting many small, cheap, mass market computers together would give much better value for money than the then conventional mainframe computer [53]. Mainframes have since practically disappeared, with the exception of so-called "supercomputers", which have a tiny market share, largely in high-cost research and military circles. The networking technology required to support effective connectivity now exists and is becoming widespread. Along with spectacular performance increases in the power of low-cost machines, this will probably seal the fate of the high-cost special-purpose supercomputer. Computing power is clearly headed to become a true commodity product, like gasoline or soap. 4.2. The drive to solve still larger problems The opportunity here is that the size of a problem should no longer be a factor in our consideration of whether or not we should pose or solve the problem. The definition of "large" in the context of problem size is an elastic one. The need to attempt: "Just larger than the biggest problem I can presently solve", has been a powerful driving force for developments in PSE, numerical mathematics and computers over the last 50 years. However, there are signs that some of the customers are at last satisfied with their ability to solve problems, such as steady state, and even dynamic process simulations, of a size sumcient to meet most of their needs. This has come about largely through the increased power and accessibility of computers. Future developments in computer and network technology will thus increase their satisfaction regardless of input from the PSE community. Table 2. Scaleability Scaleability for an order of magnitude increase in problem size: Linear (10 x) Polynomial (100—1000 x ) Exponential (100-1,000,000 x ) Factorial ( 3,628,800 x ) Scaleability for typical classes of problem: Equation solving is linear or mildly polynomial Continuous optimisation is polynomial Discrete optimisation is exponential or factorial Many practising engineers are now finding the construction of a large, complex model a tighter constraint than the actual model solution. This undoubtedly represents an appropriate and important area of endeavour for future process systems engineers. It is not a problem in conventional mathematics, but is essentially one of information management associated with alternative generation. For this reason it is discussed below along with this topic. We might conclude that improvements in numerical techniques are likely to be less of a priority for the future than they have been hitherto. This is probably correct, but nonetheless we should be aware of the nature of "scaleability", i.e. how the computational demands of a solution procedure grow with the size of the problem. Four categories of scaleability can be identified: linear, polynomial, exponential and factorial. The growth of computational load for a factor of ten increase in problem size for these categories is shown in Table 2. Process systems engineering: halfway through the first century 4051 Scaleability, however, is linked primarily to the class of problem and to its formulation, also shown in the table. Thus, the classes of problem with which we are now reasonably happy, i.e. equation solving and continuous optimisation, are those which scale least aggressively. Discrete optimisation is fundamentally harder, and there are still probably mathematical developments to be explored in this area. The indications are that mathematics alone will not serve, but that an understanding of the structure of a given problem can lead to the development of special-purpose algorithms which transform it into an easier category [48]. At present, such understanding comes only by human analysis and generally requires also a degree of special insight or serendipity. A challenge for the future is clearly to develop a systematic approach to the invention of such algorithms. One approach to this may lie through the conjunction of mathematical programming and mathematical logic [54]. Another view is that since formalising the understanding of the problem is the key, this can be regarded as an area for the use of computers to manipulate knowledge in the wider sense. 4.3. Managing choice There is a common theme that underlies three superficially different problem areas: the invention and design of chemical processes, the construction of mathematical models and the development of algorithms to solve certain classes of optimisation problem. These activities all involve choice between alternatives. While our ability to solve larger problems has been largely achieved by improvements in the speed, capacity and price of computer hardware, our ability to manage choice will depend on developments in software technology. As process systems engineers, we have had little or nothing to contribute to the hardware revolution. However, we have been in the software business almost since its inception, and can look forward to participating, along with informatics specialists, in the coming "software revolution", in the same way as we have contributed to numerical mathematics over the last few decades. Recent developments in software engineering have provided techniques to represent and manipulate complex information on computers, especially the paradign of "object-oriented" programming. This is one of the key tools to develop the kind of software which will implement all the ideas discussed below. The new programming techniques are important because they enable the developer of process engineering software to formulate his or her ideas at a higher level of abstraction, more divorced from the mechanics of how the computer will actually carry out the tasks required. This is the logical extension of the process which began when programs started to be written in Fortran rather than in machine code. Like that innovation, the result will be qualitative change in what we are able to do. Other trends in software engineering will continue to make computers more "user friendly" and thus extend the range and complexity of task which can conveniently be tackled. One important development will be the provision of computer "desktop" software environments tailored to the needs and thought patterns of the user, rather than operating systems designed around the convenience of the computer itself. Another development will be the advent of "usertolerant" software, where errors or ambiguities in the presentation of a problem are resolved automatically, rather than causing the program to fail. Ideas originating in safety critical software, for the control of aircraft, nuclear reactors and chemical plants, are likely to play a part in this area. While all of these are primarily software engineering developments, they cannot be provided to the process engineering community by the efforts of software technologists alone. Process engineers will be required to define the appropriate higher-level abstractions from an engineering viewpoint, see "Future Modelling", appropriate models for a process engineer's desktop, see "Workplace of the Future", or the appropriate degree of "fuzziness" and default actions for user-tolerant software. 4.3.1. Future process design and synthesis. The key opportunity is to use improved human—computer synergy to invent new, better processes. To achieve this it will be necessary first to consolidate existing techniques and ideas. In particular, to bring together the mathematical programming techniques which provide the best approach to the optimisation of well-defined problems with a single, numerical, objective, and the "knowledge-based" techniques which have helped to provide insights into the process of design and invention. To improve the creativity of the synthesis process, it is desirable to learn how to formulate the problem statement in terms of goals rather than in terms of a choice amongst given technologies which might achieve a given goal. If this can be achieved, then process synthesis will be able to invent new technologies as well as processes using existing technologies. The "networked supercomputer" made out of communicating high-performance workstations need not be located in a single building, city or even country, but can be a global entity. It will thus have access to data and knowledge sources throughout the world. The entire body, not only of process engineering knowledge, but of chemical and biological knowledge, will be available to a program carrying out process synthesis, along with the computer power to carry out simulations at the molecular level. Allied to the ability to perform goal-directed synthesis, this offers the possibility of essentially unlimited creativity in process invention. A better understanding of processes and engineering activities will be crucial to these developments in PSE, as it was for the earliest activities. Correspondingly, the analysis of engineering problems needed to apply PSE techniques and, increasingly, new insights developed by the use of new PSE tools, will act as positive feedback in advancing out knowledge of how to invent and design chemical processes. 4.3.2. Future modelling. The opportunity here is to model anything and everything, easily and reliably, and in any detail required. Solving models will get still easier, and the size of problem which can be handled, once a model is constructed, will get larger as computers get larger and faster, this being a class of problem which scales nearly linearly. However, as models get larger, constructing, testing, verifying, maintaining and adapting them, etc. will get harder. This modelling process is a discrete choice situation, like discrete optimisation and process synthesis, which scales badly. Process systems engineering: halfway through the first century 4052 There are two aspects of the overall problem. One is that of the modelling process, and the other is that of model representation. At present, our techniques for the latter are limited and primitive, and our understanding of the former almost non-existent. In practice, these are related, since our ability to understand any process is, to a greater or lesser extent, affected by our ability to represent the artefact created by that process. The modelling process: The thinking of most model builders has been dominated by the mathematics of the solution procedure, which until recently appeared to be the more diffcult step. Early writers on the subject of modelling, e.g. [5], implied that modelling was largely about the transformation of largely selfevident equations into a form suitable for analysis. Despite work on the representation of models described below, little attention has given to structured aids to model building or to the nature of modelling as a human activity. Several workers have noted similarities between the "creative" activity of process design or synthesis, including the statement: "Design is modeling" [63]. This paper also described a computer environment for preliminary design which has subsequently evolved into a generic environment for design and modelling in the broadest sense [16]. Although the corollary to the above statement follows logically, i.e. at least some aspects of modelling must be design, and one major work on a modelling environment [59] has led to an environment for process design, the links between the two activities remain to be pursued more fully. In particular, there have been no insights into the nature of modelling comparable to those which we have now obtained into design [20, 7]. Nonetheless, the analogy exists, and tools which are now under development to support design and synthesis of chemical processes should lend themselves to designing models for chemical processes. Thus, understanding the nature of the modelling process, and developing a meta-model of that process, and perhaps a meta-language to describe it, are important future goals for process systems engineers. The provision of an environment for managing the whole modelling process on a computer, once a satisfactory model of that process is developed, then becomes closely analogous to managing the design of a chemical plant [10]. Tools developed for both tasks should be closely related, or even interchangeable, whether the process is driven by a human modeller, or by some automatic model synthesis algorithm. The representation of models: It is now generally agreed that the solution of a model should be separated from its construction. There is no diffculty in turning a set of equations automatically into a solution procedure, normally numerical, but occasionally analytical. This focuses attention on equations as the means of constructing a model, and it is now clear that, for most engineers, writing down equations is not a particularly natural means of constructing a model. Nor are equations alone sumcient to encapsulate all the information which the modeller may wish to include in a model. An alternative, higher-level, approach to model representation is to develop one based on physical phenomena. A number of workers [62, 14] have recently described this approach. Modern software techniques, especially objectoriented programming and graphical user interfaces, are helpful in developing these representations and tools for their implementation. Now that these techniques are available, process engineers can apply them to develop representations of process engineering entities. Experience with early representations will help to identify possibilities for further and better developments. A feature of the object-oriented approach is the ability to create hierarchies of objects. This is particularly appropriate for the representation of multifaceted models, e.g. for different purposes and at different levels of detail. This is a common, and diffcult, task for the model builder. The maintenance of con e sistency between such different models is one of the major problems of large-scale model development. It will be aided both by higher-level representations, and by a better understanding of the modelling process and tools for managing it. 4.3.3. Automatic algorithm generation. Process systems engineers have historically spent much of their time inventing algorithms: for numerical solution of equations, for optimisation and for process synthesis. Is there in fact any fundamental difference between the task of inventing a process and that of inventing an algorithm? This problem has never been explicitly addressed by process systems engineers, and is still a novel one for computer scientists. A recent attempt at automatic algorithm generation from the latter discipline [34] uses techniques which would be regarded as rather simpleminded in the context of process synthesis. It is also possible that developments in the combination of mathematical programming and logic already referred to [54] could lead to techniques for generating for special purposes the type of algorithms for MINLP which have proved highly effective for particular problems. The opportunity here is one where PSE may contribute to informatics, rather than vice versa, in the transformation of software development from a craft to a systematised technology. 4.3.4. Summarising the future of managing choice. An attempt has been made to draw together three rather different subject areas which the author believes share common features, and whose future development will benefit from advances in the same general areas, namely techniques to understand and represent complex entities and complex activities. These advances may be made by process engineers, by computer scientists, or by groups involving specialists from both disciplines. We will also need certain developments for which only process system engineers can ultimately be responsible: A better understanding of the nature of process design, especially of the creative elements of design, and their relation to underlying science. A proper understanding of the nature of modelling, both model construction and the wider activity of developing and managing models in different contexts, e.g. throughout the course of a process design. Process systems engineering: halfway through the first century 4053 A new high-level abstraction for physical entities, to replace and augment the use of equations, to represent phenomena, equipment, processes and activities. Finally, a unification of all the above, e.g. a universal language to express and distribute models of everything relevant to process engineering. Figure 2: A process engineer is desktop 4.4. The workplace of the future To conclude, we will attempt to illustrate how current and future developments might actually look to practitioners of chemical, process and process systems engineering working with their computers. The examples are taken from current work by the author and his colleagues. It should be emphasised that there is other work in this direction being carried out elsewhere, and so this is only our view of one possible future. The opportunities for the creative use of computer technology are extensive and exciting because: All calculations will be done on a computer. We can carry out all our activities either on the computer or with the aid of the computer. Computers will store information of all sorts: text, sound, pictures ... All the information needed to describe anything will be available on a computer somewhere in the world. All computers in the world will be able to talk to each other rapidly. The last of these raises many exciting possibilities for a new style of cooperative working by groups and individuals throughout the world. Already, academics, and some parts of industry, make extensive use of the Internet [4] for electronic mail and discussion groups. The World Wide Web (WWW) [12] uses the Internet to provide literally worldwide access to a vast range of information in what may ultimately become a highly structured way. Developments in this area are currently extremely rapid and extensive. It may even be that these are the sort of innovations which will lead to qualitative step change in our ways of working. While not of a magnitude equivalent to, say, the development of a truly intelligent computer, the results of the new global communications network are equally hard to predict3.} Most computer users are now familiar with the computer screen "desktop". Process engineers, designing plants, analysing data or building models, can expect to have their own desktop tailored to the needs of chemical engineers and to their thought patterns. 3 "Having earlier reflected on the overselling of "fifth-generation computers" in the 1980s, the author is somewhat concerned by similarities in the way in which the "information superhighway" is being promoted in the 1990s. However, a critical difference is that the information highway already exists and is being used, so that the scope for damage by corporatist planners is more limited. Process systems engineering: halfway through the first century 4054 Figure 2 shows how a process engineer's desktop (worktop, planttop?) might appear [6]. The icons shown on the central window are process engineering "objects". They are computer representations of things that process engineers wish to work with, such as processes, streams of material or chemical species. The objects are linked together by lines which show their history; the engineer did something to an object at the top of the tree to create those shown linked to it further down. Pointing to a link with the mouse (or finger?) will display (or speak?) a message reminding the user what was done. The icons can be manipulated, e.g. by dragging them into others representing application programs, to perform various operations. In the figure two objects, one a process and the other a single unit, have been opened up in the right-hand windows to display or to edit their contents. In the background a text window shows the output from design calculations performed on a process object by the AspenPlus package. While providing more sophisticated data management than current computer operating systems, this is still a system for managing data. For managing the activity for which the data are required, e.g. designing a process, developing a suite of models, conducting a series of experiments through a computer link, a higher-level system is needed. Figure 3 shows windows illustrating part of such a system for managing design and model building [10]. The trees, which here run from left to right, in the two upper windows, show two views into a model of the design activity. The one on the right shows how the "artifact" itself, here a process design, has evolved. Each node is a complete design; when "opened" it might display a flowsheet as shown below it, together with descriptive documents and icons representing executable models and simulation results, see below. The tree on the left records the development of the reasoning behind the process design or model. This will include documents and, in a computer-compatible form, a representation of the discussions arguments, etc. which underpin the reasoning [9]. One view of this is shown in the form of a network in the fourth window. The models themselves, although represented by a single icon, will be compound objects containing text, pictures, mathematical equations, high-level modelling language representations, computer code and perhaps results of typical runs of the model. Finally, the engineer will want to organise information and objects in the form of reports for his or her own use, and, most importantly, to share with colleagues, perhaps throughout the world. Figure 4 shows a simple example of an active document which might represent such a report [26]. The underlined words represent hypertext links to points in this or other documents. The reader can move to these by pointing and clicking. This particular example has been published on the World Wide Web and is thus available to anyone in the world with a computer and Internet connection. It is not just the text which is available however. The published document shown here also contains the process engineering objects used or referred to by the author. The icons in the text are active and give access to the objects which they represent in whatever form is required or appropriate. Here one of the processes has been brought into the same object viewer shown in the desktop in Fig. 2. The reader can copy this and work with it as one of her own objects, e.g. run a program which uses it. It is also possible to run programs across the WWW at the site where the original document was stored, or indeed anywhere. 5. CLOSING THOUGHTS The first half century of process systems engineering has left the chemical and process engineering community with a powerful range of tools and techniques. These are now in daily use, improving the effectiveness of the wide range of the community's activities. The task of developing these techniques has also contributed to our understanding of the complex and interconnected systems that form the heart of chemical engineering. The period has coincided almost exactly with that in which effective digital computer hardware has become available. Developments in computer hardware and numerical mathematics have gone hand in hand, and a point has now been reached where neither of these will be the main constraint to future advances in PSE. The next half century will thus be different. Rather than by hardware, it will be dominated by developments in software. Rather than classical numerical mathematics, we should expect to see advances in the understanding, representation and manipulation of complex systems, achieved by information scientists, mathematicians and engineers. This will be an exciting period for PSE. We will be able to work with more complex systems in a manner which is more natural to us. The potential consequences of worldwide communication and cooperation are so dramatic that it is really impossible to predict their impact. The goals of PSE however remain the same. While we practitioners tend to be fascinated by our own and others' technology, it is well to remember that it is outcomes which are important, and in closing to summarise these: improved understanding of process engineering, better, easier, faster communication between people, enhanced group and individual creativity. Process systems engineering: halfway through the first century 4046 REFERENCES Adler, R.M., 1995, Emerging standards for component software. IEEE Comput. 28(3), 68-77. Alder, G.M., 1995, personal communication. Amundsen, N.R. and Pontinen, A.J., 1958, Multicomponent distillation calculations on a large digital comAris, R., 1978, Mathematical Modelling Techniques. Pitman, London. Ballinger, G.H., Baiares-Alcåntara, R., Costello, D., Fraga, E.s., Krabbe, J., King, J.M.P., Laing, D.M., McKinnel, C., Ponton, J.W., Skilling, N. and Spenceley, M.W., 1994, Developing an environment for creative process design. Chem. Engng Res. Des. 72A, 316-324. [7] Baöares-Alcåntara, R., 1991, Representing the engineering design process: two hypotheses. Computer Aided Design 23, 595+3. Baöares-Alcåntara, R., Ko, E.I., Westerberg, A.W. and Rychener, M.D., 1988, DECADE: a hybrid expert system for catalyst selection. Comput. Chem. Engng 12, 923-938. [9] Baiares-Alcåntara, R. and King, J.M.P., 1995, Egide: a design support system for conceptual design support, in Al System Support for Conceptual Design (Edited by J.E.E. Sharpe). Springer, Berlin. R. and Lababdidi, H.M.S., 1995, Design support systems for process engineering, Il: KBDS, an experimental prototype. Comput. Chem. Engng 19, 279-301. Bending, M.J. and Hutchison, H.P., 1973, The calculation of steady state incompressible flow in large networks of pipes. Chem. Engng Sci. 28, 1857—1864. Berners Lee, T., Cailliau, R., Luotonen, A., Nielsen, H.F. and secret, A., 1994, The World Wide web. Commun. ACM 37(8), 7æ82. [13] Bobrow, S., Ponton, J.W. and Johnson, A.I., 1971, Simulation of the transient behaviour of complex chemical plants using a modular approach. Can. J. Chem. Engng 49, 391-397. [14] Bogusch, R. and Marquardt, W., 1995, A formal representation of process model equations. Comput. Chem. Engng 19S, 211-216. [15] Chambers 20th Century Dictionary, 1983, New Edition. Edinburgh. [16] Coyne, R., Ehrenberger, M. and the n-dim group, 1994, Information modeling for software engineering: an illustrative project history. EDRC Technical Report 0588-94. [17] Crowe, c.M., Hamielec, A.E., Hoffman, T.w., Johnson, A.l., Woods, D.R. and Shannon, P.T., 1971, Chemical Plant Simulation. Prentice-Hall, Englewood Cliffs, NJ. [18] Danckwerts, P.V., 1966, Science and chemical engineering, Chem. Engr July/August, 155—159. [19] Dhurjati, P.s., Lamb, D.E. and Chester, D.L., 1987, Experience in the development of an expert system for fault diagnosis in a commercial scale plant. In Foundations of Computer Aided Process Operations (edited by Reklaits and Spriggs), pp. 589—526. CACHE/Elsevier. Douglas, J.M., 1988, Conceptual Design of Chemical Processes. McGraw-Hill, New York. [21] Duran, M.A. and Grossmann, I.E., 1986, An outer approximation algorithm for a class of mixed integer nonlinear programs. Math. Prog. 36, 307—339. [22] Fenske, M.R., 1932, Fractionation of straight run Pennsylvania gasoline. Ind. Engng Chem. 24, 482. [23] Fletcher, R., personal communication regarding work performed for ICI around 1965, reported in Moré, J.J., 1990, A collection of nonlinear model problems. Lectures in Applied Mathematics, Vol. 26, p. 723. [24] Fletcher, R., 1992, An optimal positive definite update for sparse Hessian matrices. Mathematics Report NA145. University of Dundee. [25] Fletcher, R., Hall, J.A.J. and Johns, W.R., 1991, Flexible retrofit design of multiproduct batch plants. Comput. Chem. Engng 15, 843-852. [26] Fraga, E.S., An example of separation sequence synthesis. http: //www. chemeng.ed.ac.uk/ecosse/webreports/wr01.html. Process systems engineering: halfway through the first century 4047 puter. Ind. Engng Chem. 50, 73()—736. [27] [4] Anonymous, 1995, The Internet. Economist 336 (Suppl. 1-26), 7921. Gear, C.W., 1968, The automatic integration of stiff ordinary differential equations. Proceedings of the IFIP Conference, pp. A81—85, Edinburgh. [28] Gomory, R.E., 1958, Outline of an algorithm for integer solutions to linear programs. Bull. Am. Math. Soc. 64, 275278. [29] Hinsley, F.H. and Stripp, A., 1993, The Codebreakers. Oxford University Press, Oxford. [30] Hoffman, E.J., 1964, Azeotropic and Extractive Distillation, pp. 208—209. Wiley—lnterscience, New York. [31] Jackson, R., 1964, A generalized variational treatment of optimization problems in complex chemical plant. Chem. Engng Sci. 19, 253-260. [32] Johns, W.R., 1970, Mathematical considerations in preparing general purpose programs for design or simulation of chemical processes. Proceedings ofEFCE Conference, Florence, 1970 (Network '67, the original ICI flowsheeting program, predates this paper by three years, but is not described earlier in the open literature). [33] Johns, W.R., 1995, Process systems integration. Keynote paper at Instn Chem. Engrs Research Event, Edinburgh. [34] Kozo, J.R., 1994, Genetic programming as a means of programming computers by natural selection. Statist. Comput. 4(2), 87-112. [35] Kramer, M.A., 1995, What happened to Al? Acta Chim. Slovenica 42, 101—113. [36] Kramer, M.A. and Leonard, J.A., 1990, Diagnosis using backpropagation neural networks—analysis and criticism. Comput. Chem. Engng 14, 1323—1338. [37] Kwauk, M., 1956, A method for counting variables in separation processes. A.I.Ch.E. J. 2, 24()—248. [38] Lewis, W.K., et al., 1932, Studies in distillation. Ind. Engng Chem. 24, 494. [39] Linnhoff, B. and Flower, J.R., 1978, Synthesis of heat exchanger networks I: systematic generation of optimal networks. A.I.Ch.E. J. 24, 633—642. [40] Mah, R.S.H., Michaelson, S. and Sargent, R.W.H., 1962, Dynamic behaviour of multicomponent, multistage systems. Numerical methods for the solution. Chem. Engng Sci. 17, 619. [41] Masso, A.H. and Rudd, D.F., 1969, The synthesis of system designs. A.I.Ch.E. J. IS, 10—17. [42] Michaelson, S., 1970, personal communication. [43] Murtagh, B.A. and Sargent, R.W.H., 1969, A constrained minimisation method with quadratic convergence. In Optimization (edited by R. Fletcher), pp. 215—346. Academic Press, New York. [44] Myers, D.R., Davis, J.F. and Herman, D.J., 1988, A task oriented approach to knowledge based systems for process engineering design. Comput. Chem. Engng 12, 959-972. [45] Narraway, L.T., Perkins, J.D. and Barton, G.W., 1991, Interaction between process design and process control: economic analysis of process dynamics. J. Process Control 1, 243-250. [46] The Concise Oxford Dictionary, 1987, 7th Edition. Oxford University Press, Oxford. [47] Pantelides, C.C., Gritsis, D., Morison, K.R. and Sargent, R.W.H., 1988, The mathematical modelling of transient systems using differential-algebraic equations. Comput. Chem. Engng 12, 449—454. [48] Pekny, J.F., Miller, D.L. and Kudva, G.K., 1993, An exact algorithm for resource constrained sequencing with application to production scheduling under an aggregate deadline. Comput. Chem. Engng 17, 671482. [49] Petzold, L.R., 1982, Differential-algebraic equations are not ODEs. SIAM J. Sci. Statist. Comput. 3, 367-384. Ponton, J.W., 1979, The microchip revolution is only about TV games. Rafinate (the journal of the Edinburgh University Chemical Engineering Society) 1, 2. Ponton, J.W., 1982, The numerical evaluation of analytical derivatives. Comput. Chem. Engng 6, 331—333. [52] Ponton, J.W. and Donaldson, R.A.B., 1974, A fast method for the synthesis of optimal heat exchange networks. Chem. Engng Sci. 29, 2375—2377. Ponton, J.W., Johnston, E.M., Forsyth, J.M., Matheson, A. and Rutherford, F.M., 1989, Real time dynamic simulation using networked computers. Comput. Chem. Engng 13, 1245—1254. Raman, R. and Grossmann, I.E., 1991, Relation between MILP modeling and logical inference for chemical process synthesis. Comput. Chem. Engng IS, 73—84. Sargent, R.W.H. and Westerberg, A.W., 1966, SPEEDUP in chemical engineering design. Trans. Instn Chem. Engrs 42, 314. Shute, N., 1954, Slide Rule. Heinemann, London. Smith, B.D., 1963, Design of Equilibrium Stage Processes. McGraw-Hill, New York. Stephanopoulos, G. et al., 1987, Design kit: an object oriented environment for process engineering. Comput. Chem. Engng 11, 655—674. [59] Stephanopoulos, G., Henning, G. and Leone, H., 1990, ModelLA: a modeling language for process engineering— Il: multifaceted modeling of processing systems. Comput. Chem. Engng 14, 847—869. [60] Takamatsu, T., 1983, The nature and role of process systems engineering. Comput. Chem. Engng 7, 203—218. Underwood, A.J.V., 1946, Fractional distillation of multicomponent mixtures. J. Inst. Petroleum 32, 614. Våzquez-Romån, R., 1992, Computer aids for process model building. Ph.D. thesis, ICSTM, University of London. Westerberg, A.W., Subramainian, E. and Ponder, G.W., 1990, A future computer environment for preliminary design. In Foundations of Computer-Aided Process Design (edited by J.J. Siirola et al.), pp. 507-528. CACHE/Elsevier.