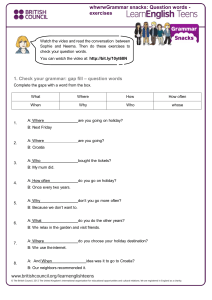

Heat Transfer Exercises: Conduction, Convection, Radiation

Anuncio

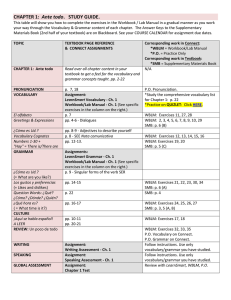

Chris Long & Naser Sayma Heat Transfer: Exercises 2 Download free eBooks at bookboon.com Heat Transfer: Exercises © 2010 Chris Long, Naser Sayma & Ventus Publishing ApS ISBN 978-87-7681-433-5 3 Download free eBooks at bookboon.com Heat Transfer: Exercises Contents Contents Preface 5 1. Introduction 6 2. Conduction 11 3. Convection 35 4. Radiation 60 5. Heat Exchangers 79 4 Download free eBooks at bookboon.com Click on the ad to read more Preface Heat Transfer: Exercises Preface Worked examples are a necessary element to any textbook in the sciences, because they reinforce the theory (i.e. the principles, concepts and methods). Once the theory has been understood, well chosen examples can be used, with modification, as a template to solve more complex, or similar problems. This work book contains examples and full solutions to go with the text of our e-book (Heat Transfer, by Long and Sayma). The subject matter corresponds to the five chapters of our book: Introduction to Heat Transfer, Conduction, Convection, Heat Exchangers and Radiation. They have been carefully chosen with the above statement in mind. Whilst compiling these examples we were very much aware of the need to make them relevant to mechanical engineering students. Consequently many of the problems are taken from questions that have or may arise in a typical design process. The level of difficulty ranges from the very simple to challenging. Where appropriate, comments have been added which will hopefully allow the reader to occasionally learn something extra. We hope you benefit from following the solutions and would welcome your comments. Christopher Long Naser Sayma Brighton, UK, February 2010 5 Download free eBooks at bookboon.com Introduction Heat Transfer: Exercises 1. Introduction Example 1.1 The wall of a house, 7 m wide and 6 m high is made from 0.3 m thick brick with k 0.6 W / m K . The surface temperature on the inside of the wall is 16oC and that on the outside is 6oC. Find the heat flux through the wall and the total heat loss through it. Solution: For one-dimensional steady state conduction: q k q dT k Ti To dx L 0 .6 16 6 20 W / m 2 0 .3 Q qA 20 6 7 840 W The minus sign indicates heat flux from inside to outside. 6 Download free eBooks at bookboon.com Introduction Heat Transfer: Exercises Example 1.2 A 20 mm diameter copper pipe is used to carry heated water, the external surface of the pipe is subjected to a convective heat transfer coefficient of h 6 W / m 2 K , find the heat loss by convection per metre length of the pipe when the external surface temperature is 80oC and the surroundings are at 20oC. Assuming black body radiation what is the heat loss by radiation? Solution qconv h Ts T f 680 20 360 W / m 2 For 1 metre length of the pipe: Qconv q conv A qconv 2 r 360 2 0.01 22.6 W / m For radiation, assuming black body behaviour: q rad Ts4 T f4 q rad 5.67 10 8 353 4 293 4 q rad 462 W / m 2 For 1 metre length of the pipe Qrad q rad A 462 2 0.01 29.1 W / m 2 A value of h = 6 W/m2 K is representative of free convection from a tube of this diameter. The heat loss by (black-body) radiation is seen to be comparable to that by convection. 7 Download free eBooks at bookboon.com Introduction Heat Transfer: Exercises Example 1.3 A plate 0.3 m long and 0.1 m wide, with a thickness of 12 mm is made from stainless steel ( k 16 W / m K ), the top surface is exposed to an airstream of temperature 20oC. In an experiment, the plate is heated by an electrical heater (also 0.3 m by 0.1 m) positioned on the underside of the plate and the temperature of the plate adjacent to the heater is maintained at 100oC. A voltmeter and ammeter are connected to the heater and these read 200 V and 0.25 A, respectively. Assuming that the plate is perfectly insulated on all sides except the top surface, what is the convective heat transfer coefficient? Solution Heat flux equals power supplied to electric heater divided by the exposed surface area: q V I V I 200 0.25 1666.7 W / m 2 A W L 0 .1 0 .3 This will equal the conducted heat through the plate: k T2 T1 t 1666.7 0.012 98.75C qt T1 T2 100 16 k q (371.75 K) The conducted heat will be transferred by convection and radiation at the surface: q hT1 T f T14 T f4 h q T14 T f4 T 1 Tf 1666.7 5.67 10 371.75 8 371.75 293 4 293 4 12.7 W / m 8 Download free eBooks at bookboon.com 2 K Introduction Heat Transfer: Exercises Example 1.4 An electronic component dissipates 0.38 Watts through a heat sink by convection and radiation (black body) into surrounds at 20oC. What is the surface temperature of the heat sink if the convective heat transfer coefficient is 6 W/m2 K, and the heat sink has an effective area of 0.001 m2 ? Solution q Q hTs T Ts4 T4 A 0.38 6Ts 293 5.67 10 3 Ts4 293 4 0.001 5.67 10 8 Ts4 6Ts 2555.9 0 This equation needs to be solved numerically. Newton-Raphson’s method will be used here: f 5.67 10 8 Ts4 6Ts 2555.9 df 22.68 10 8 Ts3 6 dTs T n 1 s 5.67 10 8 Ts4 6Ts 2555.9 T T 22.68Ts3 6 df dTs n s f n s Start iterations with Ts0 300 K Ts1 300 5.67 10 8 300 4 6 300 2555.9 324.46 K 22.68 300 3 6 5.67 10 8 324.46 4 6 324.46 2555.9 T 324.46 323 K 22.68 324.46 3 6 2 s 9 Download free eBooks at bookboon.com Introduction Heat Transfer: Exercises The difference between the last two iterations is small, so: Ts0 323 K 50C The value of 300 K as a temperature to begin the iteration has no particular significance other than being above the ambient temperature. In the past 5 years we have drilled around 95,000 km —that’s more than twice around the world. Who are we? We are the world’s leading provider of reservoir characterization, drilling, production, and processing technologies to the oil and gas industry. Who are we looking for? We offer countless opportunities in the following domains: n Operations n Research, Engineering, and Manufacturing n Geoscience and Petrotechnical n Commercial and Business We’re looking for high-energy, self-motivated graduates with vision and integrity to join our team. What will you be? careers.slb.com 10 Download free eBooks at bookboon.com Click on the ad to read more Conduction Heat Transfer: Exercises 2. Conduction Example 2.1 Using an appropriate control volume show that the time dependent conduction equation in cylindrical coordinates for a material with constant thermal conductivity, density and specific heat is given by: 2T 1 T 2T 1 T r 2 r r z 2 t Were k is the thermal diffusivity. c Solution Consider a heat balance on an annular control volume as shown the figure above. The heat balance in the control volume is given by: Heat in + Heat out = rate of change of internal energy Q r Q z Q r r Q z z Q r r Q r Q r r Q z z Q z Q z z u t (2.1) 11 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises u mcT Substituting in equation 2.1: Q Q (mcT ) r z r z t (2.2) Fourier’s law in the normal direction of the outward normal n: Q T k A n Qr kA T T k 2 r z r r ( A 2 r z ) Q z kA T T k 2 r r z z ( A 2 r r ) Equation 2.1 becomes T T T k 2 r z r k 2 r r z mc r r z z t (2.3) Noting that the mass of the control volume is given by: m 2 r r z Equation 2.3 becomes T T T k r r k r z cr r r z z t Dividing by r, noting that r can be taken outside the brackets in the second term because it is not a function of z. Also dividing by k since the thermal conductivity is constant: 1 T 2T c T r r r r z 2 k t Using the definition of the thermal diffusivity: 1 2T T r 2T 1 T r r r r 2 r r z 2 t k and expanding the first term using the product rule: c which gives the required outcome: 12 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises 2T 1 T 2T 1 T r 2 r r z 2 t Example 2.2 An industrial freezer is designed to operate with an internal air temperature of -20oC when the external air temperature is 25oC and the internal and external heat transfer coefficients are 12 W/m2 K and 8 W/m2 K, respectively. The walls of the freezer are composite construction, comprising of an inner layer of plastic (k = 1 W/m K, and thickness of 3 mm), and an outer layer of stainless steel (k = 16 W/m K, and thickness of 1 mm). Sandwiched between these two layers is a layer of insulation material with k = 0.07 W/m K. Find the width of the insulation that is required to reduce the convective heat loss to 15 W/m2. WORK AT THE FOREFRONT OF AUTOMOTIVE INNOVATION WITH ZF, ONE OF THE WORLD’S LEADING AUTOMOTIVE SUPPLIERS. ZF.COM/CAREERS 13 Download free eBooks at bookboon.com Click on the ad to read more Conduction Heat Transfer: Exercises Solution q UT U where U is the overall heat transfer coefficient given by: q 15 0.333W / m 2 K T 25 (20) 1 L p Li Ls 1 U hi k p k i k s ho 1 0.333 1 L p Li Ls 1 1 hi k p k i k s ho 0.333 1 1 L p Ls 1 1 1 0.003 0.001 1 Li k i 0.07 1 16 8 0.333 hi k p k s ho 0.333 12 Li 0.195m (195 mm) Example 2.3 Water flows through a cast steel pipe (k = 50 W/m K) with an outer diameter of 104 mm and 2 mm wall thickness. 14 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises i. ii. Calculate the heat loss by convection and conduction per metre length of uninsulated pipe when the water temperature is 15oC, the outside air temperature is -10oC, the water side heat transfer coefficient is 30 kW/m2 K and the outside heat transfer coefficient is 20 W/m2 K. Calculate the corresponding heat loss when the pipe is lagged with insulation having an outer diameter of 300 mm, and thermal conductivity of k = 0.05 W/m K. Solution Plain pipe Q 2 r1 Lhi Ti T1 Q 2Lk T1 T2 lnr2 / r1 Q 2 r2 Lho T2 To Ti T1 Q 2 r1 Lhi T2 T1 Q 2 Lk / ln(r2 / r1 ) T2 To Q 2 r2 Lho Adding the three equations on the right column which eliminates the wall temperatures gives: Q Q L 2LTi To ln r2 / r1 1 1 hi r1 k ho r2 2 15 (10) 163.3W / m 1 ln0.052 / 0.05 1 30000 0.05 50 20 0.052 15 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises Insulated pipe 2 Ti To Q lnr2 / r1 ln(r3 / r2 ) 1 1 L hi r1 k k ins ho r3 16 Download free eBooks at bookboon.com Click on the ad to read more Conduction Heat Transfer: Exercises Q L 2 15 (10) 7.3W / m 1 ln0.052 / 0.05 ln(0.15 / 0.052) 1 30000 0.05 50 0.05 20 0.15 For the plain pipe, the heat loss is governed by the convective heat transfer coefficient on the outside, which provides the highest thermal resistance. For the insulated pipe, the insulation provides the higher thermal resistance and this layer governs the overall heat loss. Example 2.4 Water at 80oC is pumped through 100 m of stainless steel pipe, k = 16 W/m K of inner and outer radii 47 mm and 50 mm respectively. The heat transfer coefficient due to water is 2000 W/m2 K. The outer surface of the pipe loses heat by convection to air at 20oC and the heat transfer coefficient is 200 W/m2 K. Calculate the heat flow through the pipe. Also calculate the heat flow through the pipe when a layer of insulation, k = 0.1 W/m K and 50 mm radial thickness is wrapped around the pipe. Solution The equation for heat flow through a pipe per unit length was developed in Example 2.3: Q 2LTi To ln r2 / r1 1 1 hi r1 k ho r2 Hence substituting into this equation: Q 2 10080 20 0.329 10 6 W 1 ln50 / 47 1 0.047 2000 16 0.05 200 For the case with insulation, we also use the equation from Example 2.3 Q Q 2LTi To lnr2 / r1 ln(r3 / r2 ) 1 1 hi r1 k k ins ho r3 2 10080 20 5.39 10 3 W 1 ln50 / 47 ln(100 / 50) 1 0.047 2000 16 0.1 0.1 200 Notice that with insulation, the thermal resistance of the insulator dominates the heat flow, so in the equation above, if we retain the thermal resistance for the insulation and ignore all the other terms, we obtain: 17 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises Q 2LTi To 2 10080 20 5.44 10 3 W ln(100 / 50) ln(r3 / r2 ) 0.1 k ins This has less than 1% error compared with the full thermal resistance. Example 2.5 A diagram of a heat sink to be used in an electronic application is shown below. There are a total of 9 aluminium fins (k = 175 W/m K, C = 900 J/kg K, 2700kg / m 3 ) of rectangular cross-section, each 60 mm long, 40 mm wide and 1 mm thick. The spacing between adjacent fins, s, is 3 mm. The temperature of the base of the heat sink has a maximum design value of Tb 60C , when the external air temperature T f is 20oC. Under these conditions, the external heat transfer coefficient h is 12 W/m2 K. The fin may be assumed to be sufficiently thin so that the heat transfer from the tip can be neglected. The surface temperature T, at a distance, x, from the base of the fin is given by: T Tf T b T f cosh m( L x) sinh mL where m 2 hP and Ac is the cross sectional area. kAc Determine the total convective heat transfer from the heat sink, the fin effectiveness and the fin efficiency. 18 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises Solution Total heat fluxed is that from the un-finned surface plus the heat flux from the fins. Q Qu Q f Qu Au h (Tb T f ) w s N 1) h Tb T f Qu 0.04 0.0039 1) 12 60 20 0.461 W For a single fin: dT Q f kAc dx x 0 Where Ac is the cross sectional area of each fin Since T Tf T b T f cosh m( L x) sinh mL Linköping University – Innovative, well ranked, European Interested in Engineering and its various branches? Kick-start your career with an English-taught master’s degree. liu.se/master Click here! 19 Download free eBooks at bookboon.com Click on the ad to read more Conduction Heat Transfer: Exercises Then dT sinh m( L x) m Tb T f cosh mL dx Thus dT sinh mL Q f kAc kAc m Tb T f dx x 0 cosh mL Q f kAc m Tb T f tanh(mL) hpkAc 1/ 2 T b T f tanh mL Since hP m kAc 1 2 P 2( w t ) 2(0.04 0.001) 0.082 m Ac w t 0.04 0.0001 40 10 6 m 2 1 12 0.082 2 11.856 m 1 m 6 175 40 10 mL 11.856 0.06 0.7113 tanhmL tanh0.7113 0.6115 Q f 12 0.082 175 40 10 6 1/ 2 60 20 0.6115 2.03 W / fin So total heat flow: Q Qu Q f 0.461 9 2.03 18.7 W Finn effectiveness fin Qf Fin heat transfer rate Heat transfer rate that would occur in the absence of the fin hAc Tb T f fin 2.03 106 12 40 10 6 60 20 20 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises Fin efficiency: Actual heat transfer through the fin Heat that would be transferred if all the fin area were at the base temperature fin Qf fin hAs Tb T f As wL wL Lt Lt 2 L( w t ) As 2 0.06(0.04 0.001) 4.92 10 3 m 2 fin 2.03 0.86 12 4.92 10 3 60 20 Example 2.6 For the fin of example 4.5, a fan was used to improve the thermal performance, and as a result, the heat transfer coefficient is increased to 40 W/m2 K. Justify the use of the lumped mass approximation to predict the rate of change of temperature with time. Using the lumped mass approximation given below, calculate the time taken, , for the heat sink to cool from 60oC to 30oC. T T T f i hA T f exp s mC Solution Consider a single fin (the length scale L for the Biot number is half the thickness t/2) Bi hL h t / 2 40 0.0005 10 4 k k 175 Since Bi 1 , we can use he “lumped mass” model approximation. T T hA exp T T mC f i s f mC T T f ln hAs Ti T f 21 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises m As t / 2 T Tf ln 2h Ti T f Ct 2700 900 0.001 ln 30 20 42 seconds 2 40 60 20 Example 2.7 The figure below shows part of a set of radial aluminium fins (k = 180 W/m K) that are to be fitted to a small air compressor. The device dissipates 1 kW by convecting to the surrounding air which is at 20oC. Each fin is 100 mm long, 30 mm high and 5 mm thick. The tip of each fin may be assumed to be adiabatic and a heat transfer coefficient of h = 15 W/m2 K acts over the remaining surfaces. Estimate the number of fins required to ensure the base temperature does not exceed 120oC Find and follow us: http://twitter.com/bioradlscareers www.linkedin.com/groupsDirectory, search for Bio-Rad Life Sciences Careers http://bio-radlifesciencescareersblog.blogspot.com John Randall, PhD Senior Marketing Manager, Bio-Plex Business Unit Bio-Rad is a longtime leader in the life science research industry and has been voted one of the Best Places to Work by our employees in the San Francisco Bay Area. Bring out your best in one of our many positions in research and development, sales, marketing, operations, and software development. Opportunities await — share your passion at Bio-Rad! www.bio-rad.com/careers 22 Download free eBooks at bookboon.com Click on the ad to read more Conduction Heat Transfer: Exercises Solution Consider a single fin: P 2( w t ) 2(0..005 0.03) 0.07 m Ac w t 0.005 0.03 150 10 6 m 2 hP m kAc 1 1 2 15 0.07 2 6.2361 m 1 6 180 150 10 mL 6.2361 0.1 0.62361 tanhmL 0.5536 Q f hPkAc 1/ 2 T b T f tanh(mL) Q f 15 0.07 180 150 10 6 1/ 2 (From example 2.5) 120 20 0.5536 9.32 W So for 1 kW, the total number of fins required: N 1000 108 9.32 23 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises Example 2.8 An air temperature probe may be analysed as a fin. Calculate the temperature recorded by a probe of length L = 20 mm, k = 19 W/m K, D = 3 mm, when there is an external heat transfer coefficient of h = 50 W/m2K, an actual air temperature of 50oC and the surface temperature at the base of the probe is 60oC. Solution The error should be zero when Ttip T . The temperature distribution along the length of the probe (from the full fin equation) is given by: cosh m( L x) Tx T Tb T hP m kA cosh mL 1/ 2 htip mk htip mk sinh m( L x) sinh mL A D 2 / 4, P D At the tip, x L , the temperature is given by ( cosh( 0) 1 , sinh( 0) 0 ): Ttip T Tb T cosh mL 1 htip mk sinh mL Where is the dimensionless error:, 0, Ttip T (no error) 24 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises 1, TL Tb For L 20mm, T 50C , A D 2 / 4, hP m kA 1/ 2 (large error) k 19W / m K , D 3mm, h htip 50 W / m 2 K Tb 60C P D h D 4 2 k D 1/ 2 4h kD 1/ 2 4 50 19 0.003 1/ 2 59.235 m 1 mL 59.235 0.02 1.185 50 h 0.0444 mk 59.235 19 Tx T 1 0.539 Tb T cosh 1.185 0.0444 sinh 1.185 QUALIFY FOR A GLOBAL CAREER in engineering, architecture or technology management read more MASTER’S STUDIES >>> 25 Download free eBooks at bookboon.com Click on the ad to read more Conduction Heat Transfer: Exercises Ttip 0.539Tb T T Ttip 0.53960 50 50 55.39C Hence error 5.39C Example 2.9 A design of an apartment block at a ski resort requires a balcony projecting from each of the 350 separate apartments. The walls of the building are 0.3 m wide and made from a material with k = 1 W/m K. Use the fin approximation to examine the implications on the heat transfer for two separate suggestions for this design. In each case, the balcony projects 2 m from the building and has a length (parallel to the wall) of 4 m. Assume an inside temperature of 20oC and an outside temperature of 5oC; the overall (convective + radiative) heat transfer coefficient on the inside of the building is 8 W/m2 K and on that on the outside of the building is 20 W/m2 K a) A balcony constructed from solid concrete and built into the wall, 0.2 m thick, k = 2 W/m K. b) A balcony suspended from 3 steel beams, k = 40 W/m K, built into the wall and projecting out by 2 m each of effective cross sectional area Ae 0.01 m 2 , perimetre P 0.6 m (The actual floor of the balcony in this case may be considered to be insulated from the wall c) No balcony. Solution a) For the concrete balcony Treat the solid balcony as a fin Bi ho t / 2 kb 26 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises Bi 20 0.1 1 2 Not that Bi is not << 1, thus 2D analysis would be more accurate. However, treating it as a fin will give an acceptable result for the purpose of a quick calculation. P 2 ( H t ) 2 ( 4 0 .2) 8 .4 m Ac H t 4 0.2 0.8 m 2 To decide if the fin is infinite, we need to evaluate mL (which is in fact in the notation used here is mW) hP mW kA 1/ 2 20 8.4 W 2 0 .8 1/ 2 2 20.5 This is large enough to justify the use of the fin infinite equation. Qb ho Pk b Ac 1/ 2 T2 To 1 ho Pk b Ac 1 / 2 T2 To ho Pk b qb Ac Ac 1/ 2 T2 To (1) Also assuming 1-D conduction through the wall: qb hi (Ti T1 ) qb (2) kb (T1 T2 ) L (3) Adding equations 1, 2 and 3 and rearranging: qb (To Ti ) 1 L Ac hi k b ho Pk b (4) 1/ 2 This assumes 1D heat flow through the wall, the concrete balcony having a larger k than the wall may introduce some 2-D effects. 27 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises From (4) qb 20 (5) 1 0 .3 0 .8 8 2 20 8.4 2 1/ 2 77.2 W / m 2 Compared with no balcony: qb (To Ti ) 20 (5) 52.6 W / m 2 1 L 1 1 0.3 1 hi k w ho 8 1 20 The difference for one balcony is Ac (77.2 52.6) 0.8 24.6 19.7 W For 350 apartments, the difference is 6891 W. For the steel supported balcony where Ac 0.01 m 2 and P 0.6 m INDEPENDENT DEDNIM LIKE YOU We believe in equality, sustainability and a modern approach to learning. How about you? Apply for a Master’s Programme in Gothenburg, Sweden. www.gu.se/education 28 Download free eBooks at bookboon.com Click on the ad to read more Conduction Heat Transfer: Exercises As before, however, in this case Bi << 1 because k s k b hP mW kA 1/ 2 20 6 w 40 0.1 1/ 2 2 11 mW 2 , so we can use the infinite fin approximation as before qb (To Ti ) 1 L Ac hi k s ho Pk s 1/ 2 20 ( 5) 1 0.3 0.01 8 40 20 6 40 1/ 2 182 W / m 2 Qb Ac qb 0.01 182 1.82 W / beam For 350 apartments, Qb 1915 W Example 2.10 In free convection, the heat transfer coefficient varies with the surface to fluid temperature difference T s T f . Using the low Biot number approximation and assuming this variation to be of the form h G Ts T f Where G and n are constants, show that the variation of the dimensionless n temperature ratio with time will be given by n 1 nhinit t Where T s Tf Tinit T f , Area Mass Specific Heat Capacity and hinit = the heat transfer coefficient at t = 0. Use this expression to determine the time taken for an aluminium motorcycle fin ( 2750 kg / m 3 , C 870 J / kgK ) of effective area 0.04 m2 and thickness 2mm to cool from 120oC to 40oC in surrounding air at 20oC when the initial external heat transfer coefficient due to laminar free convection is 16 W/m2 K. Compare this with the time estimated from the equation ( e ht ) which assumes a constant value of heat transfer coefficient. Solution Low Biot number approximation for free convection for Bi 1 Heat transfer by convection = rate of change of internal energy 29 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises hA(Ts T f ) mC d (Ts T f ) (1) dt n We know that h G (Ts T f ) Where G is a constant. (Note that this relation arises from the usual Nusselt/Grashof relationship in free convection; for example: Nu 0.1Gr Pr 1/ 3 in turbulent flow or Nu 0.54Gr Pr 1/ 4 for laminar flow) Equation 1 then becomes: G Ts T f (T n Tf ) s mC d (Ts T f ) A dt t d (Ts T f ) GA dt t 0 mC t 0 (Ts T f ) n1 t GnAt Ts T f mC At t 0, T s n Ts T f n (2) t 0 T f Ts ,i T f If we divide equation 2 by Ts ,i T f And use the definition T T s s ,i n T Tf f We obtain GnAt mC Ts ,i T f n n 1 GnAt Ts ,i T f mC n Since G Ts ,i T f h i , the heat transfer coefficient at time t = 0, then n hi At 1 mC 30 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises Or n nhi t 1 For aluminium 2750 kg / m 3 , C 870 J / kg K For laminar free convection, n = ¼ m A X 2750 0.04 0.002 0.22 kg n 0.04 A 2.1 10 4 m 2 K / J mC 0.22 870 nhi t 1 which gives 31 Download free eBooks at bookboon.com Click on the ad to read more Conduction Heat Transfer: Exercises t n 1 nhi When T 40C 40 20 0 .2 120 20 Then t 0.2 1 590 s 1 / 4 16 2.1 10 4 1 / 4 For the equation e h t which assumes that the heat transfer coefficient is independent of surface-to-fluid temperature difference. t ln ln 0.2 479 s h 16 2.1 10 4 Percentage error = 590 479 100 19% 590 Example 2.11 A 1 mm diameter spherical thermocouple bead (C = 400 J/kg K, � � ���������� ) is required to respond to 99.5% change of the surrounding air � � ��������� � � � ��� � ���� ����������� , � � ������� � ⁄��� and Pr = 0.77) temperature in 10 ms. What is the minimum air speed at which this will occur? 32 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises Solution Spherical bead: ���� � ��� � ������� � � �� � ⁄6 Assume this behaves as a lumped mass, then �� � �� � ����� �� � �� (given) For lumped mass on cooling from temperature Ti �� � �� � ��������� � ����� �� � �� �� �� ������������ � ������� �� ��� � ����� �� � ��� Which gives the required value of heat transfer coefficient �� � ��� ��� So 33 Download free eBooks at bookboon.com Conduction Heat Transfer: Exercises � � 0.� �� �� � �� 0.� � � � � � 6 6 �� 0.� � 10�� � 400 � 7800 � 260 � ⁄�� � 6 ��� � �� 260 � 10�� � � �.� � 0.0262 For a sphere ��� ��� � 2 � �0.4��� ��� � 0.06��� � �� �.� From which with Pr = 0.707 ��� ��� � � 0.4��� � 0.06��� � �.4 � 0 ���� ���� �� � 0.2��� � 0.04��� Using Newton iteration � ����� � � � � ���� � ���� Starting with ReD = 300 ��� ��� � 300 � �0.4√300 � 0.06�300���� � �.4� 0.222 � 300 � 0.2 0.04 0.01782 � � � √300 300��� Which is close enough to 300 From which �� � ��� � 4.� ��� �� 34 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises 3. Convection Example 3.1 Calculate the Prandtl number (Pr = Cp/k) for the following a) b) c) Water at 20C: = 1.002 x 103 kg/m s, Cp = 4.183 kJ/kg K and k = 0.603 W/m K Water at 90C: = 965 kg/m3, = 3.22 x 107 m2/s, Cp = 4208 J/kg K and k = 0.676 W/m K Air at 20C and 1 bar: R = 287 J/kg K, = 1.563 x 105 m2/s, Cp = 1005 J/kg K and k = 0.02624 W/m K d) Air at 100C: 1.46 10 6 T 3 2 kg/m s 110 T C p 0.917 2.58 10 4 T 3.98 10 8 T 2 kJ / kg K (Where T is the absolute temperature in e) f) g) K) and k = 0.03186 W/m K. Mercury at 20C: = 1520 x 106 kg/m s, Cp = 0.139 kJ/kg K and k = 0.0081 kW/m K Liquid Sodium at 400 K: = 420 x 106 kg/m s, Cp = 1369 J/kg K and k = 86 W/m K Engine Oil at 60C: = 8.36 x 102 kg/m s, Cp = 2035 J/kg K and k = 0.141 W/m K HUNGRY FOR SOMETHING NEW? GET GROWING WITH LIDL We’re one of Europe’s largest retailers coming to the U.S. Apply today at careers.lidl.com 35 Download free eBooks at bookboon.com Click on the ad to read more Convection Heat Transfer: Exercises Solution a) Solution Solution Cp 1.002 10 3 4183 6.95 0.603 k CCp 1.002 10 33 4183 1.002 10 4183 6.95 p Pr b) Pr k 6.95 00.603 .603 k a) a) Pr Cp C p 965 3.22 10 7 4208 1.93 0.676 k k C p 965 3.22 10 77 4208 CCp 4208 1.93 p C p 965 3.22 10 Pr c) Pr k k 1.93 0 . 676 0.676 k k b) b) Pr c) c) Pr C p k CCpp Pr Pr Pk 100000 1.19 kg / m 3 k RT 287 293 100000 P kg P 100000 511.19 //mm33 kg . 19 1 . 19 1 . 563 10 1005 RT 287 293 Pr RT 287 293 0.712 0.02624 5 11.19 .1911.563 .56310 10 51005 1005 0.712 Pr d) Pr 0.712 00.02624 .02624 d) d) 1.46 10 6 T 3 2 1.46 10 6 3733 / 2 2.18 10 5 kg / m s 110 T 110 373 6 3 2 6 3/ 2 11.46 10 11.46 10 6T 3 2 6 373 3 / 2 . 46 10 . 46 10 373 T 4 2.18 10 55 kg mmss4 8 2 2.18 10 kg//10 373 C p 0.110 110 3.98 10 T 0.917 2.58 373 3.98 10 8 3732 917 110T2T.58 10 T 110 373 1007.7 J / kg K 4 8 2 4 8 2 CCp 00.917 .91722.58 .5810 10 4TT 33.98 .9810 10 8TT 2 00.917 .91722.58 .5810 10 4373 37333.98 .9810 10 8373 3732 p 1007 J /5kg 1007 K .7 2.18.710 Pr 1007.7 J / kg K 0.689 0.03186 5 22.18 .1810 10 51007 1007.7.7 0.689 Pr e) Pr 0.689 00.03186 .03186 e) e) Cp 1520 10 6 139 0.0261 k 0.0081 10 3 CCp 1520 10 66 139 1520 10 139 p Pr Pr k 0.0081 10 33 00.0261 .0261 k 0.0081 10 Pr 36 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises f) f) Pr g) Pr g) Pr Cp k Cp k Cp k Cp Pr Comments: k 420 10 6 1369 0.0067 86 420 10 6 1369 0.0067 86 8.36 10 2 2035 1207 0.141 8.36 10 2 2035 1207 0.141 Large temperature dependence for water as in a) and b); Comments: small temperature dependence for air as in c) and d); use of Sutherland’s law for viscosity as in part d); Large temperature dependence for water as in a) and b); difference between liquid metal and oil as in e), f) and g); small temperature dependence for air as in c) and d); units of kW/m K for thermal conductivity; use of Sutherland’s law for viscosity as in part d); use of temperature dependence of cp as in part a). difference between liquid metal and oil as in e), f) and g); units of kW/m K for thermal conductivity; Example 3.2 use of temperature dependence of cp as in part a). Calculate the appropriate Reynolds numbers and state if the flow is laminar or turbulent for Example 3.2 the following: Calculate the appropriate Reynolds numbers and state if the flow is laminar or turbulent for a) A 10 m (water line length) long yacht sailing at 13 km/h in seawater = 1000 kg/m3 and the following: 3 = 1.3 x 10 kg/m s, b) A compressor disc of radius 0.3 m rotating at 15000 rev/min in air at 5 bar and 400C and a) A 10 m (water line length) long yacht sailing at 13 km/h in seawater = 1000 kg/m3 and 6 3 2 3 1.46 10 T s, =1.3 x 10 kg/m kg/m s 110 disc T of radius 0.3 m rotating at 15000 rev/min in air at 5 bar and 400C and b) A compressor 6 3 2dioxide gas at 400 K flowing in a 20 mm diameter pipe. For the viscosity c) 0.05 1kg/s of10 carbon .46 T 6 kg/m 32 s 1 . 56 110 T10 T kg/m s take 233 dioxide T c) 0.05 kg/s of carbon gas at 400 K flowing in a 20 mm diameter pipe. For the viscosity 3 5 d) The roof of a coach 1.56 10 66Tm3 2long, travelling at 100 km/hr in air ( = 1.2 kg/m and = 1.8 x 10 take kg/m s kg/ms) 233 T over e) The flow of exhaust gas (p = 1.1 bar, T = 500ºC, R = 287 J/kg K and = 33.56 x 105 kg/m s) d) The roof of a coach 6 m long, travelling at 100 km/hr in air ( = 1.2 kg/m and = 1.8 x 105 a valve guide of diameter 10 mm in a 1.6 litre, four cylinder four stroke engine running at kg/m s) an exhaust 3000 rev/min (assume 100% volumetric efficiency an inlet density of 1.2 kg/m3 and e) The flow of exhaust gas (p = 1.1 bar, T = 500ºC, R = 287 J/kg K and = 3.56 x 105 kg/m s) over port diameter of 25 mm) a valve guide of diameter 10 mm in a 1.6 litre, four cylinder four stroke engine running at 3000 rev/min (assume 100% volumetric efficiency an inlet density of 1.2 kg/m3 and an exhaust port diameter of 25 mm) 37 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Solution uL 13 10 3 10 3600 2.78 10 7 1.3 10 3 10 3 a) Re b) T 400 273 673 K 1.46 10 6 6733 2 3.26 10 5 110 673 (turbulent) kg / m s 15000 2 1571 rad / s 60 u r 1571 0.3 471 .3 m / s 100000 P 2.59 kg / m 3 RT 287 673 GET A MASTER’S DEGREE IN UMEÅ! • modern campus • world class research • 32 000 students • top class teachers • ranked nr 1 in Sweden by international students Master’s programmes: • Architecture • Industrial Design • Science • Engineering APPLY NOW! 38 Download free eBooks at bookboon.com Click on the ad to read more Convection Heat Transfer: Exercises Characteristic length is r not D Re c) uD 2.59 471.3 3 1.12 10 7 5 3.26 10 m uA u u D 2 4 4m D 2 Re uD 4m D 4m D 2 D 1.56 10 6 400 3 2 1.97 10 5 233 400 Re d) u kg / m s 4 0.05 1.6 10 5 5 0.02 1.97 10 (turbulent) 100 10 3 27.8 m / s 3600 Re e) (turbulent) uL 1.2 27.8 6 11.1 10 7 1.8 10 5 (turbulent) be the mass flow through the exhaust port Let m m = inlet density X volume of air used in each cylinder per second m 1.2 u 1.6 10 3 3600 1 0.012 kg / s 4 60 2 4m D2 Re d ud 39 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Re 4 0.01 0.012 6869 3.56 10 5 0.025 (laminar) Comments: Note the use of D to obtain the mass flow rate from continuity, but the use of d for the characteristic length Note the different criteria for transition from laminar flow (e.g. for a pipe Re 2300 plate Re 3 10 5 ) Example 3.3 Calculate the appropriate Grashof numbers and state if the flow is laminar or turbulent for the following: a) A central heating radiator, 0.6 m high with a surface temperature of 75C in a room at 18C ( = 1.2 kg/m3 , Pr = 0.72 and = 1.8 x 105 kg/m s)] b) A horizontal oil sump, with a surface temperature of 40C, 0.4 m long and 0.2 m wide containing oil at 75C ( = 854 kg/m3 , Pr = 546, = 0.7 x 103 K1 and = 3.56 x 102 kg/m s) c) The external surface of a heating coil, 30 mm diameter, having a surface temperature of 80C in water at 20C ( = 1000 kg/m3, Pr = 6.95, = 0.227 x 103K1 and = 1.00 x 10-3kg/m s) d) Air at 20ºC ( = 1.2 kg/m3 , Pr = 0.72 and = 1.8 x 105 kg/m s) adjacent to a 60 mm diameter vertical, light bulb with a surface temperature of 90C Solution a) Gr 2 g T L3 2 T 75 18 57 K 1 1 1 K 1 T 18 273 291 Gr 1.2 2 9.81 57 0.6 3 291 1.8 10 3 2 1.84 10 9 Gr Pr 1.84 10 9 0.72 1.3 10 9 b) L (mostly laminar) Area 0.4 0.2 0.0667 m Perimeter 2 0.4 0.2 40 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises T 75 40 35 K 2 g T L3 854 2 9.81 0.7 10 3 35 0.0667 3 4.1 10 4 Gr 2 2 2 3.56 10 Gr Pr 4.1 10 4 546 2.24 10 7 Heated surface facing downward results in stable laminar flow for all Gr Pr c) 41 Download free eBooks at bookboon.com Click on the ad to read more Convection Heat Transfer: Exercises T 80 20 60 K 2 g T L3 1000 2 9.81 0.227 10 3 60 0.033 3.6 10 6 Gr 2 2 3 1 10 Gr Pr 3.6 10 6 6.95 25 10 6 L d) (laminar) Area D 2 D Perimeter 4D 4 T 90 20 70 K 1 1 1 K 1 T 20 273 293 2 g T L3 1.2 2 9.8 70 0.0153 3.5 10 4 Gr 2 2 5 293 1.8 10 Gr Pr 3.5 10 4 0.72 2.5 10 4 (laminar) Comments: Note evaluation of for a gas is given by 1 / T For a horizontal surface L A / p Example 3.4 Calculate the Nusselt numbers for the following: a) A flow of gas (Pr = 0.71, = 4.63 x 105 kg/m s and Cp = 1175 J/kg K) over a turbine blade of chord length 20 mm, where the average heat transfer coefficient is 1000 W/m2 K. b) A horizontal electronics component with a surface temperature of 35C, 5 mm wide and 10 mm long, dissipating 0.1 W by free convection from one side into air where the temperature is 20C and k = 0.026 W/m K. c) A 1 kW central heating radiator 1.5 m long and 0.6 m high with a surface temperature of 80ºC dissipating heat by radiation and convection into a room at 20C (k = 0.026 W/m K assume black body radiation and = 56.7 x 109 W/m K4) d) Air at 4C (k = 0.024 W/m K) adjacent to a wall 3 m high and 0.15 m thick made of brick with k = 0.3 W/m K, the inside temperature of the wall is 18C, the outside wall temperature 12C 42 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Solution a) Cp Pr Solutionk C p C4p.63 10 5 1175 ka) Pr k 0.0766 W / m K Pr 0.71 C p 4.63 10 5 1175 0.02 0.0766 W / m K 1000 261 Nu Pr 0.71 0.0766 k k h L b) Nu h L Nu k h L 1000 0.02 q L0.0766 261 k T k hL q L b) Nu k 0 .1 T k Q q A 0.01 0.005 2000 W / m 2 0 .1 Q q 2000 W / m 2 A 0.01 0.005 T 35 20 15 C T 35 20 15 C L 50 5 Area mm 0.001667 m Perimeter Area 30 50 3 5 L Perimeter 30 3 mm 0.001667 m h L 2000 0.001667 8 .5 2000 0.001667 h L 15 .026 0 k 8 .5 Nu Nu k c) 15 0.026 qc L q L Nu T k c Nu c) T k In thisIncase, q must be the convective heat flux – radiative heat flux this case, q must be the convective heat flux – radiative heat flux Ts T80 273 353 K s 80 273 353 K 273 293 T T20 273 293 KK 20 4 4 9 4 9 .56 10 35344 Q R QRATs4ATsT4 T 56 7 .710 1.15.500.6.6353 293 293 4416 416WW T 80 20 60 K T 80 20 60 K Qc Q QR 1000 416 584 W Qc Q QR 1000 416 584 W 43 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Qc 584 649 W / m 2 A 1.5 0.6 q L 649 0.6 Nu c 249 T k 60 0.026 qc T 12 4 8 K d) q k b T1 T2 60 C W (assuming 1-D conduction) 0.318 12 12 W / m 2 0.18 q L 12 3 Nu c 188 T k 8 0.024 q Comments: Nu is based on convective heat flux; sometimes the contribution of radiation can be significant and must be allowed for. The value of k is the definition of Nu is the fluid (not solid surface property). Use of appropriate boundary layer growth that characterises length scale. 44 Download free eBooks at bookboon.com Click on the ad to read more Convection Heat Transfer: Exercises Example 3.5 In forced convection for flow over a flat plate, the local Nusselt number can be represented by the general expression Nu x C1 Re nx . In free convection from a vertical surface the local Nusselt number is represented by Nu x C 2 Grxm , where C1, C2, n and m are constants a) Show that the local heat transfer coefficient is independent of the surface to air temperature difference in forced convection, whereas in free convection, h, depends upon (Ts T)m b) In turbulent free convection, it is generally recognised that m = 1/3. Show that the local heat transfer coefficient does not vary with coordinate x. Solution a) Nu x hx k Re x ux For forced convection: Nu x C1 Re nx Hence k ux h C1 x n This shows that the heat transfer coefficient for forced does not depend on temperature difference. For free convection Grx Hence Nu x C 2 Grxm 2 g T x 3 2 k 2 g T x 3 h C 2 x 2 m (1) So for free convection, heat transfer coefficient depends on T m b) From (1), with m = 1/3 for turbulent free convection: 45 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises k 2 g T x 3 h C 2 x 2 k 2 g T h C 2 x 2 2 g T h kC 2 2 1/ 3 1/ 3 x 1/ 3 Hence the convective heat transfer coefficient does not depend on x Example 3.6 An electrically heated thin foil of length L = 25 mm and width W = 8 mm is to be used as a wind speed metre. Wind with a temperature T and velocity U blows parallel to the longest side. The foil is internally heated by an electric heater dissipating Q (Watts) from both sides and is to be operated in 5 2 air with T 20C , C p 1.005 kJ / kg K , 1.522 10 m / s 1.19 kg / m 3 and Pr 0.72 . The surface temperature, T of the foil is to be measured at the trailing edge – but can be assumed to be constant. Estimate the wind speed when T 32C and Q 0.5 W . Solution Firstly, we need to estimate if the flow laminar or turbulent. is Assuming a critical (transition) Reynolds number of Re 3 10 5 the velocity required would be: u turb 3 10 5 3 10 3 3 10 5 1.522 10 5 304 m / s L L 25 10 3 Wind speed is very unlikely to reach this critical velocity, so the flow can be assumed to be laminar. Nu x 0.331 Re 1x/ 2 Pr 1 / 3 Nu av 0.662 Re1L/ 2 Pr 1 / 3 q av L Ts T k 46 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Re1L/ 2 q av q av L Ts T k 0.662 Pr 1 / 3 0 .5 / 2 1250 W / m 2 0.025 0.008 Re1L/ 2 1250 0.025 32 20 0.0253 0.662 0.721 / 3 173.5 Re L 3 10 4 u Re L 3 10 4 1.522 10 5 18.3 m / s L 25 10 3 . 47 Download free eBooks at bookboon.com Click on the ad to read more Convection Heat Transfer: Exercises Example 3.7 The side of a building of height H = 7 m and length W = 30 m is made entirely of glass. Estimate the heat loss through this glass (ignore the thermal resistance of the glass) when the temperature of the air inside the building is 20C, the outside air temperature is -15C and a wind of 15 m/s blows parallel to the side of the building. Select the appropriate correlations from those listed below of local Nusselt numbers to estimate the average heat transfer coefficients. For air take: ρ= 1.2 kg / m3, μ = 1.8 x 10-5 kg / m s, Cp = 1 kJ / kg K and Pr = 0.7. Free convection in air, laminar (Grx < 109): Nux = 0.3 Grx1/4 Free convection in air, turbulent (Grx > 109): Nux = 0.09 Grx1/3 Forced convection, laminar (Rex < 105): Nux = 0.33 Rex0.5 Pr1/3 Forced convection, turbulent (Rex > 105): Nux = 0.029 Rex0.8 Pr1/3 Solution Pr Cp k gives: k Cp Pr 1.8 10 5 1000 0.026 W / m K 0.7 First we need to determine if these flows are laminar or turbulent. For the inside (Free convection): 1 1 1 T 20 273 293 K 1 48 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Gr 2 g T L3 1.2 2 9.81 T 7 3 2 1.8 10 5 2 293 Gr 5.1 1010 T (Flow will be turbulent over most of the surface for all reasonable values of T ) For the outside (Forced convection) Re L u L 1.2 15 30 3 10 7 5 1.8 10 (Flow will be turbulent for most of the surface apart from the first 0.3 m) Hence we use the following correlations: On the inside surface: Nu x 0.09Gr 1 / 3 On the outside surface: Nu x 0.029 Re 0x.8 Pr 1 / 3 For the inside: 2 g Ti Ts x 3 hx 0.09 Nu x 2 k x h constant 3 1/ 3 x 1/ 3 constant Hence heat transfer coefficient is not a function of x hav hx L (1) For the outside: ux hx Nu x 0.029 k h constant x 0.8 x 0.8 Pr 1 / 3 C x 0.2 49 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises xL C 1 hav h dx L L x 0 xL x 0.2 dx x 0 hx L 0.8 (2) Write a heat balance: Assuming one-dimensional heat flow and neglecting the thermal resistance of the glass q hi Ti Ts q ho Ts To hi Ti Ts ho Ts To (3) From equation 1 2 g Ti Ts H 3 hi H 0.09 k 2 Ti 1/ 3 How could you take your studies to new heights? By thinking about things that nobody has ever thought about before By writing a dissertation about the highest building on earth With an internship about natural hazards at popular tourist destinations By discussing with doctors, engineers and seismologists By all of the above From climate change to space travel – as one of the leading reinsurers, we examine risks of all kinds and insure against them. Learn with us how you can drive projects of global significance forwards. Profit from the know-how and network of our staff. Lay the foundation stone for your professional career, while still at university. Find out how you can get involved at Munich Re as a student at munichre.com/career. 50 Download free eBooks at bookboon.com Click on the ad to read more Convection Heat Transfer: Exercises 1.2 2 9.81 T1 Ts 0.026 hi 0.09 1.8 10 5 2 293 hi 1.24 Ti Ts 1/ 3 (4) From equation 2: ho W 0.029 u W k 0.8 ho 0.8 Pr 1 / 3 0.026 0.029 1.2 15 30 30 0.8 1.8 10 5 0. 8 0 .7 1 / 3 ho 26.7 W / m 2 K (5) From (3) with (4) and (5) 1.24 Ti Ts 4/3 1.24 20 Ts 4/3 26.7 Ts To 26.7 Ts 15 Ts 0.0464 20 Ts 4/3 15 (6) To solve this equation for Ts an iterative approach can be used First guess: Ts 10C Substitute this on the right hand side of equation 6: Ts 0.0464 20 10 4/3 15 10.7C For the second iteration we use the result of the first iteration: Ts 0.0464 20 10.7 4/3 15 10.6C The difference between the last two iterations is 0.1C , so we can consider this converged. Ts 10.6C 51 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises From which: q ho Ts To 26.7 10.6 15 117 W / m 2 Q qA 117 30 7 24600 W 24.6 kW Example 3.8 The figure below shows part of a heat exchanger tube. Hot water flows through the 20 mm diameter tube and is cooled by fins which are positioned with their longest side vertical. The fins exchange heat by convection to the surrounds that are at 27C. Estimate the convective heat loss per fin for the following conditions. You may ignore the contribution and effect of the cut-out for the tube on the flow and heat transfer. a) natural convection, with an average fin surface temperature of 47C; b) forced convection with an air flow of 15 m / s blowing parallel to the shortest side of the fin and with an average fin surface temperature of 37C. GET GROWING WITH LIDL US JOIN OUR TEAM TODAY We’re one of Europe’s largest retailers coming to the U.S. Apply today at careers.lidl.com 52 Download free eBooks at bookboon.com Click on the ad to read more Convection Heat Transfer: Exercises The following correlations may be used without proof, although you must give reasons in support of your choice in the answer. Nux = 0.3 Rex1/2 Pr1/3 Nux = 0.02 Rex0.8 Pr1/3 Nux = 0.5 Grx1/4 Pr1/4 Nux = 0.1 Grx1/3 Pr1/3 Rex < 3 x 105 Rex 3 x 105 Grx < 109 Grx 109 For air at these conditions, take: Pr = 0.7, k = 0.02 W / m K, μ = 1.8 x 10-5 kg /m s and ρ = 1.0 kg / m3 Solution On the outside of the water tube, natural convections means that we need to evaluate Gr number to see if flow is laminar ot turbulent Gr 2 g T L3 2 T 47 27 20 K 1 1 27 273 300 Gr K 1 12 9.81 20 0.13 1.8 10 5 2 300 2 10 6 (Laminar) (L here is height because it is in the direction of the free convection boundary layer) 53 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises So we use: Nu x 0.5 Grx Pr 1/ 4 hav hav L L 1 h dx constant x 1 / 4 dx L 0 0 hx L 3/ 4 Nu av 2 GrL Pr 1 / 4 3 Nu av 1/ 4 2 2 10 6 0.7 23 3 hav Nu av k 23 0.02 4.6 W / m 2 K 0.1 L q av hav T Q q av A hav TA 4.6 20 0.1 0.05 2 (Last factor of 2 is for both sides) Q 0.92 W For forced convection, we need to evaluate Re to see if flow is laminar or turbulent 54 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Re u L 1 15 0.05 4.17 10 4 5 1.8 10 (Laminar) (L here is the width because flow is along that direction) Nu x 0.3 Re1x/ 2 Pr 1 / 3 L h 1 hav hdx x L L0 1/ 2 Nu av 0.6 Re1L/ 2 Pr 1 / 3 0.6 4.17 10 4 hav 1 / 2 0.71 / 3 109 Nu av k 109 0.02 43.5 W / m 2 K 0.05 L T 10C Q q av A hav TA 43.5 10 0.1 0.05 2 Q 4.35 W Example 3.9 Consider the case of a laminar boundary layer in external forced convection undergoing transition to a turbulent boundary layer. For a constant fluid to wall temperature difference, the local Nusselt numbers are given by: Nux = 0.3 Rex1/2 Pr1/3 (Rex < 105) Nux = 0.04 Rex0.8 Pr1/3 (Rex ≥ 105) Show that for a plate of length, L, the average Nusselt number is: Nuav = (0.05 ReL0.8 - 310) Pr1/3 55 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Solution Nu av hav k L Where for a constant surface-to-fluid temperature: hav x L 1 L h dx hturbulent dx laminar L 0 xL 56 Download free eBooks at bookboon.com Click on the ad to read more Convection Heat Transfer: Exercises Since for laminar flow ( Re x 10 5 ): Nu x 0.3 Re1x/ 2 Pr 1 / 3 hlam k u 0.3 x hlam u 0.3 k 1/ 2 x1 / 2 Pr 1 / 3 1/ 2 Pr 1 / 3 x 1 / 2 C lam x 1 / 2 Where C lam does not depend on x Similarly: hturb C turb x 0.2 Where Cturb u 0.04 k 0.8 Pr 1 / 3 Hence x L 1 L 1 / 2 hav Clam x dx C turb x 0.2 dx L 0 xL xL L x1 / 2 x 0.8 1 hav Clam Cturb L 1/ 2 0 0.8 xL Nu av hav k L Nu av Clam 1 / 2 C turb 0.8 L x L0.8 2xL k 0.8k Nu av u 0.6 1/ 2 x 1/ 2 L Pr 1/ 3 u L 0.8 u x L 0.05 57 Download free eBooks at bookboon.com 0.8 1/ 3 Pr Convection Heat Transfer: Exercises But u xL 10 5 (The transition Reynolds number) So Nu av Pr 1 / 3 0.6 10 5 1/ 2 0.05 Re 0L.8 0.05 10 5 0. 8 Nu av 0.05 Re 0L.8 310 Pr 1 / 3 Example 3.10 A printed circuit board dissipates 100 W from one side over an area 0.3m by 0.2m. A fan is used to cool this board with a flow speed of 12 m / s parallel to the longest dimension of the board. Using the average Nusselt number relationship given in Example 3.9 to this question, calculate the surface temperature of the board for an air temperature of 30 ºC. Take an ambient pressure of 1 bar, R = 287 J / kg K, Cp = 1 kJ / kg K, k = 0.03 W / m K and μ = 2 x 10-5 kg/m s Solution q av Q 100 1666.7 W / m 2 A 0.2 0.3 58 Download free eBooks at bookboon.com Convection Heat Transfer: Exercises Pr C P k 2 10 5 10 3 0.667 0.03 u L Re L P 10 5 1.15 kg / m 3 RT 287 303 Re L 1.15 12 0.3 2.07 10 5 5 2 10 Using the formula for Nusselt Number obtained in Example 3.9: Nu av 0.05 Re 0L.8 310 Pr 1 / 3 Nu av 0.05 2.07 10 5 Nu av T 0 .8 310 0.667 1/ 3 511 hav k q av L L Tk q av L 1666.7 0.3 32.6C Nu av k 511 0.03 Ts T T Ts 30 32.6 62.6C 59 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises 4. Radiation Example 4.1 In a boiler, heat is radiated from the burning fuel bed to the side walls and the boiler tubes at the top. The temperatures of the fuel and the tubes are T1 and T2 respectively and their areas are A1 and A2. a) Assuming that the side walls (denoted by the subscript 3) are perfectly insulated show that the temperature of the side walls is given by: A1 F13T14 A2 F23T24 T3 A2 F23 A1 F13 14 where F13 and F23 are the appropriate view factors. b) Show that the total radiative heat transfer to the tubes, Q2, is given by: AF A F Q 2 A1 F12 1 13 2 23 T14 T24 A2 F23 A1 F13 If it really matters, make it happen – with a career at Siemens. siemens.com/careers 60 Download free eBooks at bookboon.com Click on the ad to read more Radiation Heat Transfer: Exercises c) Calculate the radiative heat transfer to the tubes if T1 = 1700C, T2 = 300C, A1 = A2 = 12m2 and the view factors are each 0.5? Solution a) Q 2 Q 1 2 Q 3 2 (1) Since the walls are adiabatic Q 3 2 Q 13 (2) From (2) A3 F32 T34 T24 A1 F13 T14 T34 A1 F13 T14 A3 F32 T24 T A3 F32 A1 F13 4 3 A F T 4 A2 F23 T24 T3 1 13 1 A2 F23 A1 F13 b) 1/ 4 since Ai Fij A j F ji From (1) Q 2 A1 F12 T14 T24 A3 F32 T34 T24 Q 2 A1 F12 T14 T24 A2 F23 T34 T24 61 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises A1 F13 T14 A3 F32 T24 4 4 Q2 A1 F12 T1 T2 A2 F23 T24 A3 F32 A1 F13 A1 F13 T14 A3 F32 T24 A3 F32T24 A1 F13T24 4 4 Q2 A1 F12 T1 T2 A2 F23 A3 F32 A1 F13 A1 F13 T14 A1 F13T24 4 4 Q2 A1 F12 T1 T2 A2 F23 A3 F32 A1 F13 A1 F13 Q 2 A1 F12 T14 T24 A2 F23 T14 T24 A3 F32 A1 F13 A F A F Q 2 A1 F12 T14 T24 T14 T24 2 23 1 13 A3 F32 A1 F13 A F A F Q 2 T14 T24 A1 F12 2 23 1 13 A2 F23 A1 F13 c) T34 A1 F13 T14 A3 F32 T24 A1 F13 T14 A2 F23 T24 A3 F32 A1 F13 A2 F23 A1 F13 T34 12 0.5 1973 4 12 0.5 573 4 1662 K 12 0.5 12 0.5 66 6 Q 2 56.7 10 9 1973 4 573 4 6 7.68 10 W 66 Example 4.2 Two adjacent compressor discs (Surfaces 1 and 2) each of 0.4 m diameter are bounded at the periphery by a 0.1 wide shroud (Surface 3). a) Given that F12 = 0.6, calculate all the other view factors for this configuration. b) The emissivity and temperature of Surfaces 1 and 2 are 1 = 0.4, T1 = 800 K, 2 = 0.3, T2 = 700K and Surface 3 can be treated as radiatively black with a temperature of T3 = 900 K. Apply a grey body radiation analysis to Surface 1 and to Surface 2 and show that: 2.5 J1 – 0.9 J2 = 45545 W/m2 62 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises and W/m2. 3.333 J2 – 1.4 J1 = 48334 The following equation may be used without proof: E B ,i J i N Fi , j ( J i J j ) 1 i j 1 i c) Determine the radiative heat flux to Surface 2 Solution a) r1 r2 r 0.2 m a 0 .1 m r2 0.2 2 a 0.1 a 0 .1 0 .5 r1 0.2 F12 0.6 (Although this is given in the question, it can be obtained from appropriate tables with the above parameters) 63 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises F11 0 (As surface 1 is flat, it cannot see itself) F13 1 0.6 0.4 (From the relation F ij 1 in an enclosure) F21 0.6 (Symmetry) F22 0 F23 0.4 F31 A1 0.2 2 F13 0.4 0.4 A3 2 0.2 0.1 F32 0.4 (Symmetry) F33 1 0.4 0.4 0.2 Scholarships Open your mind to new opportunities With 31,000 students, Linnaeus University is one of the larger universities in Sweden. We are a modern university, known for our strong international profile. Every year more than 1,600 international students from all over the world choose to enjoy the friendly atmosphere and active student life at Linnaeus University. Welcome to join us! Bachelor programmes in Business & Economics | Computer Science/IT | Design | Mathematics Master programmes in Business & Economics | Behavioural Sciences | Computer Science/IT | Cultural Studies & Social Sciences | Design | Mathematics | Natural Sciences | Technology & Engineering Summer Academy courses 64 Download free eBooks at bookboon.com Click on the ad to read more Radiation Heat Transfer: Exercises b) n E b ,i J i J i J j Fij 1 i j 1 i Apply to surface 1, (i = 1) Let E b ,1 1 1 1 1 J 1 1 F12 J 1 J 2 F13 J 1 J 3 E b ,1 J 1 1 1 F12 1 F13 1 F12 J 2 1 F13 J 3 Eb,1 T14 J 3 T34 (Radiatively black surface) 1 1 1 1 1 0.4 1.5 0.4 T14 2.5 J 1 0.9 J 2 0.6 T34 56.7 10 9 800 4 2.5 J 1 0.9 J 2 0.6 56.7 10 9 900 4 2.5 J 1 0.9 J 2 45545 W / m 2 Applying to surface 2 (1) (i = 2) E b , 2 J 2 1 2 F21 2 F23 2 F21 J 1 2 F23 J 3 Eb, 2 T24 2 1 2 2 1 0.3 2.333 0.3 T24 3.333 J 2 1.4 J 1 0.9333 T34 3.333 J 2 1.4 J 1 48334 W / m 2 (2) 65 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises c) From (2): J1 3.333 J 2 48334 1.4 Substituting in (1) 2.5 3.333 J 2 48334 0.9 J 2 45545 W / m 2 1.4 J 2 26099 W / m 2 The net radiative flux to surface 2 is given by q2 E b , 2 J 2 56.7 10 9 700 4 26099 5.351 10 3 W / m 2 1 2 1 0 .3 0 .3 2 The minus sign indicates a net influx of radiative transfer as would be expected from consideration of surface temperatures. www.sylvania.com We do not reinvent the wheel we reinvent light. Fascinating lighting offers an infinite spectrum of possibilities: Innovative technologies and new markets provide both opportunities and challenges. An environment in which your expertise is in high demand. Enjoy the supportive working atmosphere within our global group and benefit from international career paths. Implement sustainable ideas in close cooperation with other specialists and contribute to influencing our future. Come and join us in reinventing light every day. Light is OSRAM 66 Download free eBooks at bookboon.com Click on the ad to read more Radiation Heat Transfer: Exercises Example 4.3 The figure below shows a simplified representation of gas flame inside a burner unit. The gas flame is modelled as a cylinder of radius r1 = 10 mm (Surface 1). The burner comprises Surface 2 (a cylinder of radius r2 = 40 mm and height h = 40 mm), concentric with Surface 1 and a concentric base (Surface 3), of radius r3 = 40 mm. The end of the cylinder, Surface 4, opposite to the base is open to the surrounding environment. a) Given that F21 = 0.143 and F22 = 0.445 use the dimensions indicated on the diagram to calculate all the other relevant view factors. b) The flame, base and surroundings can be represented as black bodies at constant temperatures T1, T3 and T4, respectively. The emissivity of the inside of Surface 2 is ε2 = 0.5. Apply a grey body radiation analysis to Surface 2 and show that the radiosity is given by: J2 (T24 F21T14 F23T34 F24T44 ) 1 F21 F23 F24 The following equation may be used without proof: E b ,i J i 1 i i c) N Fij J i J j j 1 The temperatures T1 and T3 are found to be: T1 = 1800K and T3 = 1200K, and the surrounds are at 500 K. Estimate the temperature T2, using a radiative heat balance on the outer surface of Surface 2, where the emissivity is ε0 = 0.8 Solution a) A1 2 r1 h 67 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises A2 2 r2 h A3 A4 r22 r12 F11 0 F13 F14 F11 F12 F13 F14 1 but A1 F12 A2 F21 F12 A2 r 40 F21 2 F21 0.14338 0.57352 A1 r1 10 Thus F13 F14 1 0.57352 0.21324 2 F21 F22 F23 F24 1 F23 F24 1 F21 F22 1 0.14338 0.44515 0.20574 2 2 F31 F32 F33 F34 1 F33 0 A1 F13 A3 F31 F31 A1 2 r1 h 2 0.01 0.04 F13 F13 0.21324 0.11373 2 2 A3 r2 r1 0.04 2 0.012 A2 F23 A3 F32 68 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises F32 A2 2 r2 h 2 0.04 0.04 F23 F23 0.20574 0.43891 2 2 A3 r2 r1 0.04 2 0.012 F34 1 0.11373 0.43891 0.44736 Similarly (using symmetry) F41 F31 0.11373 F42 F32 0.43891 F43 F34 0.44736 F44 0 b) n E b ,i J i J i J j Fij 1 i j 1 i At Navigant, there is no limit to the impact you can have. As you envision your future and all the wonderful rewards your exceptional talents will bring, we offer this simple guiding principle: It’s not what we do. It’s how we do it. Impact matters. navigant.com ©2013 Navigant Consulting, Inc. All rights reserved. Navigant Consulting is not a certified public accounting firm and does not provide audit, attest, or public accounting services. See navigant.com/licensing for a complete listing of private investigator licenses. 69 Download free eBooks at bookboon.com Click on the ad to read more Radiation Heat Transfer: Exercises For surface 2, i = 2, j = 1, 3, 4 Eb, 2 J 2 F12 J 2 J 1 F23 J 2 J 3 F24 J 2 J 4 1 2 2 2 0.5 , 1 0.5 1 0.5 J 1 E b ,1 , J 3 E b ,3 , J 4 E b , 4 (1, 3, 4 are black) E b , 2 J 2 F12 J 2 E b ,1 F23 J 2 E b ,3 F24 J 2 E b , 4 J 2 F21 F23 F24 1 T24 T14 F21 T34 F23 T44 F24 J2 c) J2 T24 T14 F21 T34 F23 T44 F24 F21 F23 F24 1 56.7 10 9 T24 1800 4 0.57352 1200 4 0.20574 500 4 0.20574 0.57352 20574 0.20574 1 J 2 36.47 10 9 T24 70913 On the outside of surface 2: q 2 2,0 T24 T44 Also q2 Eb, 2 J 2 T24 36.47 10 9 T24 70913 1 2 2 20.23 10 9 T24 70913 56.7 10 9 0.8 T24 500 4 T2 1029 K 70 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises Example 4.4 The figure below shows a schematic diagram, at a particular instant of the engine cycle, of a cylinder head (Surface 1), piston crown (Surface 2) and cylinder liner (Surface 3). a) Using the dimensions indicated on the diagram, and given that F12 = 0.6, calculate all the other relevant view factors. b) The cylinder head can be represented as a black body at a temperature T1 = 1700 K and the emissivity of the piston crown is 2 0.75 . Apply a grey body radiation analysis to the piston crown (Surface 2) and show that the radiosity is given by: J2 = 42.5 x 10-9 T24 + 71035 + 0.1 J3 The following equation may be used without proof: Eb,i J i 1 i i c) N Fij J i J j j 1 Similar analysis applied to the cylinder liner gives: J3 = 107210 + 0.222 J2 If the surface temperature of the piston crown is, T2 = 600 K, calculate the radiative heat flux into the piston crown. d) Briefly explain how this analysis could be extended to make it more realistic Solution a) A1 A2 r 2 50 2 2500 mm 2 71 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises A3 DL 100 25 2500 mm 2 F11 0 (Flat surface) F12 0.6 (Given) F13 1.0 F12 1.0 0.6 0.4 By Symmetry: F21 F12 0.6 F23 F32 0.4 F22 0 F31 A1 F13 0.4 Since A1 A3 A3 Do you have to be a banker to work in investment banking? Deutsche Bank db.com/careers Agile minds value ideas as well as experience Global Graduate Programs Ours is a complex, fast-moving, global business. There’s no time for traditional thinking, and no space for complacency. Instead, we believe that success comes from many perspectives — and that an inclusive workforce goes hand in hand with delivering innovative solutions for our clients. It’s why we employ 135 different nationalities. It’s why we’ve taken proactive steps to increase female representation at the highest levels. And it’s just one of the reasons why you’ll find the working culture here so refreshing. Discover something different at db.com/careers 72 Download free eBooks at bookboon.com Click on the ad to read more Radiation Heat Transfer: Exercises F32 0.4 (By symmetry) F33 1.0 F31 F32 1.0 0.4 0.4 0.2 b) For surface 2, i = 2 Eb,2 J 2 F21 J 2 J 1 F23 J 2 J 3 1 2 2 J 1 T14 (Black body) 1 0.75 1 0.75 3 2 0.75 , Eb, 2 T24 T24 J 2 1/ 3 J2 J2 F21 J 2 T14 F23 J 2 J 3 1 F21 T14 F23 J 3 3 1 1 F21 F23 3 T24 56.7 10 9 T24 1 0.6 56.7 10 9 1700 4 0.4 J 3 3 1 1 0.6 0.4 3 J 2 42.5 10 9 T24 71035 0.1 J 3 We are also given that J 3 107210 0.222 J 2 0.1 J 3 10721 0.0222 J 2 Hence 73 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises J 2 42.5 10 9 600 4 71035 10721 0.0222 J 2 0.97778 J 2 5508 81756 J 2 89247 W / m 2 Also q2 E b , 2 J 2 56.7 10 9 600 4 89247 246 10 3 W / m 2 1 2 1/ 3 2 Negative sign indicates J 2 E b , 2 E 2 , so net flux is into the piston crown. c) To make the analysis more realistic, it needs to be extended by including convection from the piston crown, and cylinder liner. Radiation from the piston underside also needs to be included. We then carry out analysis over a complete engine cycle. Example 4.5 The figure below shows the variation of view factor Fi,j with geometric parametres h / L and W / L for the case of two rectangular surfaces at right angles to each other. This plot is to be used to model the radiative heat transfer between a turbocharger housing and the casing of an engine management system. The horizontal rectangle, W = 0.12 m and L = 0.2 m, is the engine management system and is denoted Surface 1. The vertical rectangle, h = 0.2 m and L = 0.2 m, is the turbocharger casing and denoted by Surface 2. The surrounds, which may be approximated as a black body, have a temperature of 60C. a) Using the graph and also view factor algebra, evaluate the view factors: F 1,2, F2,1, F1,3 and F2,3 b) By applying a grey-body radiation analysis to Surface 1 with ε1 = 0.5, show that the radiosity J1 is: J1 = 28.35 x 10-9 T14 + 0.135 J2 + 254 (W/m2) The following equation may be used without proof: Eb,i J i 1 i i N Fij J i J j j 1 74 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises c) A similar analysis is applied to Surface 2 with ε2 = 0.4 obtained the result: J2 = 22.7 x 10-9 T24 + 0.097 J1 + 350 (W/m2). Use this to estimate the surface temperature of the engine management system when the turbocharger housing has a surface temperature of T2 = 700K. Solution h 0. 2 1, L 0. 2 W 0.12 0 .6 L 0. 2 From the figure: F12 0.27 A1 F12 A2 F21 F21 A1 w 0.12 F12 F12 0.27 0.162 A2 h 0.2 F11 F12 F13 1 F11 0 75 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises F13 1 F12 1 0.27 0.73 F21 F22 F23 1 F22 0 F23 1 F21 1 0.162 0.838 For a grey body radiative heat transfer in an enclosure (n surfaces) n E b ,i J i J i J j Fij 1 i j 1 i Applying for surface 1, i = 1 (the casing) Real drive. Unreal destination. As an intern, you’re eager to put what you’ve learned to the test. At Ernst & Young, you’ll have the perfect testing ground. There are plenty of real work challenges. Along with real-time feedback from mentors and leaders. You’ll also get to test what you learn. Even better, you’ll get experience to learn where your career may lead. Visit ey.com/internships. © 2012 Ernst & Young LLP. All Rights Reserved. See More | Opportunities 76 Download free eBooks at bookboon.com Click on the ad to read more Radiation Heat Transfer: Exercises E b ,1 J 1 F12 J 1 J 2 F13 J 1 J 3 1 1 1 Eb,1 T14 J 3 T34 1 1 1 1 0.5 1.0 0.5 So J1 J1 T14 F12 J 2 F13 T34 1 F12 F13 56.7 10 9 T14 0.27 J 2 0.73 56.7 10 9 3334 1 0.27 0.73 J 1 28.35 10 9 T14 0.135 J 2 254 W / m2 (1) c) Given: J 2 22.68 10 9 T24 0.0972 J 1 350 J 2 22.68 10 9 700 4 0.0972 J 1 350 W / m2 W / m2 J 2 5796 0.0972 J 1 (2) Substituting from equation 2 into equation 1: J 1 28.35 10 9 T14 0.135 5796 0.0972 J 1 254 W / m2 Which gives: J 1 28.7 10 9 T14 1050 W / m2 Applying a heat balance to surface 1 qin qout 77 Download free eBooks at bookboon.com Radiation Heat Transfer: Exercises E J b ,1 1 57.9 10 9 T14 28.7 10 9 T14 1050 qin 1 1 1 q in 28. 10 9 T14 1050 q out 1 T14 T4 0.5 56 .7 10 9 T14 333 4 Combining and solving for T1, gives: T1 396 K Note that qin = - q since q is out of the surface when q > 0 . STUDY. PLAY. The stuff you'll need to make a good living The stuff that makes life worth living NORWAY. YOUR IDEAL STUDY DESTINATION. WWW.STUDYINNORWAY.NO FACEBOOK.COM/STUDYINNORWAY 78 Download free eBooks at bookboon.com Click on the ad to read more Heat Exchangers Heat Transfer: Exercises 5. Heat Exchangers 5. Heat Exchangers Example 5.1 Example 5.1 A heat exchanger consists of numerous rectangular channels, each 18 mm wide and 2.25 mm high. In anheat adjacent pair ofconsists channels, are two streams: channels, water k = each 0.62518W/m and and air k2.25 = 0.0371 W/mIn A exchanger of there numerous rectangular mmKwide mm high. K, separated by a 18 mm wide and 0.5 mm thick stainless steel plate of k = 16 W/m K. The fouling an adjacent pair of channels, there are two streams: water k = 0.625 W/m K and air k = 0.0371 W/m 4 2 m2thick K/W stainless and 5 x 10 K/W, and thefouling Nusselt resistances andmm water areand 2 x0.5 104mm K, separatedfor byair a 18 wide steelmplate of krespectively, = 16 W/m K. The 2 hydraulic diameter. = 5.95are where the4 subscript 'Dh' 5refers to m the number given m2 K/W and x 104 K/W, respectively, and the Nusselt resistances forby airNu andDhwater 2 x 10 number given by NuDh = 5.95 where the subscript 'Dh' refers to the hydraulic diameter. a) Calculate the overall heat transfer coefficient ignoring both the thermal resistance of the separatingthe wall and the two foulingcoefficient resistances. a) Calculate overall heat transfer ignoring both the thermal resistance of the b) Calculate the overall heat transfer coefficient with separating wall and the two fouling resistances. these resistances. c) is the transfer coefficient? b) Which Calculate the controlling overall heatheat transfer coefficient with these resistances. c) Which is the controlling heat transfer coefficient? Solution: Solution: Hydraulic Diameter = 4 x Area / Wetted perimetre Hydraulic Diameter = 4 x Area / Wetted perimetre 2.25 10 3 18 10 3 Dh 4 4 10 3 3 3 3 (2.2510 18)18 10 2.25 10 Dh 4 4 10 3 (2.25 18) 10 3 Nu D k h DDh k Nu h Dh 5.95 0.625 (a) hwater 930W / m 2 K 3 4 10 5.95 0.625 (a) hwater 930W / m 2 K 3 4 10 5.95 0.0371 hair 55.186W / m 2 K 3 4 10 5.95 0.0371 hair 55.186W / m 2 K 3 4 10 1 1 1 U W / m2 K 1 52.1 930 55 . 186 1 1 U 52.1 W / m 2 K 930 55.186 1 0.5 10 3 1 1 U 2 10 4 5 10 4 1 50.2 3 930 55.1186 0.5 16 1 10 b) U 2 10 4 5 10 4 50.2 930 55.186 16 W / m2 K W / m2 K b) c) The controlling heat transfer coefficient is the air heat transfer coefficient. c) The controlling heat transfer coefficient is the air heat transfer coefficient. 79 Download free eBooks at bookboon.com Heat Exchangers Heat Transfer: Exercises Example 5.2 A heat exchanger tube of D = 20 mm diameter conveys 0.0983 kg/s of water (Pr = 4.3, k = 0.632 W/m K, = 1000 kg/m3, = 0.651 x 103 kg/ms) on the inside which is used to cool a stream of air on the outside where the external heat transfer coefficient has a value of ho = 100 W/m2 K. Ignoring the thermal resistance of the tube walls, evaluate the overall heat transfer coefficient, U, assuming that the internal heat transfer coefficient is given by the Dittus-Boelter relation for fully developed turbulent pipe flow: . Nu D 0.023 Re 0D.8 Pr 0.4 Solution: m VA V m A Re D 4 0.0983 VD 4m 9613 D 0.02 0.651 10 3 Nu D 0.023 9613 0.8 4.3 0.4 63 Nu D h hD k Nu D k 63.3 0.632 2000W / m 2 K D 0.02 1 1 U 2000 100 1 95.2W / m 2 K Example 5.3 a) Show that the overall heat transfer coefficient for a concentric tube heat exchanger is given by the relation: r r r 1 U o o ln o o k ri hi ri ho -1 80 Download free eBooks at bookboon.com Heat Exchangers Heat Transfer: Exercises With the terminology given by the figure below b) A heat exchanger made of two concentric tubes is used to cool engine oil for a diesel engine. The inner tube is made of 3mm wall thickness of stainless steel with conductivity k = 16 W/m K . The inner tube radius is 25mm and has a water flow rate of 0.25 kg/s. The outer tube has a diameter of 90mm and has an oil flow rate of 0.12 kg/s. Given the following properties for oil and water: oil: C p 2131 J/kg K, 3.25 10 2 kg/m s, k 0.138 W/m K Water: C p 4178 J/kg K, 725 10 6 kg/m s, k 0.625 W/m K Using the relations: Nu D 5.6 Nu D 0.023 Re 0D.8 Pr 0.4 Re D 2300 Re D 2300 I joined MITAS because I wanted real responsibili� I joined MITAS because I wanted real responsibili� Real work International Internationa al opportunities �ree wo work or placements �e Graduate Programme for Engineers and Geoscientists Maersk.com/Mitas www.discovermitas.com � for Engin M Month 16 I was a construction M supervisor ina cons I was the North Sea supe advising and the N he helping foremen advis ssolve problems Real work he helping International Internationa al opportunities �ree wo work or placements ssolve p 81 Download free eBooks at bookboon.com Click on the ad to read more Heat Exchangers Heat Transfer: Exercises Calculate the overall heat transfer coefficient. Which is the controlling heat transfer coefficient? If the heat exchanger is used to cool oil from 90oC to 55oC, using water at 10oC calculate the length of the tube for a parallel flow heat exchanger Solution: a) For the convection inside Q Ai hi (Ti T1 ) Q 2 ri Lhi (Ti T1 ) (1) For the convection outside Q Ao ho (To T1 ) Q 2 ro Lho (To T1 ) (2) For conduction through the pipe material Q 2 r k dT dr 82 Download free eBooks at bookboon.com Heat Exchangers Heat Transfer: Exercises Q dr dT 2 r L r (3) Integrating between 1 and 2: Q ro ln T2 T1 2 r L ri (4) From 1 and 2 Q Ti T1 2 ri Lhi (5) Q T2 To 2 ro Lho (6) Adding 4, 5 and 6 Ti To Q lnro / ri 1 1 2L k hi ri ho ro Rearranging Q Ti To U o Ti To 2Lro ro ro ro 1 ln k r hr h i i i o Therefore, overall heat transfer coefficient is r r r 1 U o o ln o o k ri hi ri ho 1 b) i) To calculate the overall heat transfer coefficient, we need to evaluate the convection heat transfer coefficient both inside and outside. 83 Download free eBooks at bookboon.com Heat Exchangers Heat Transfer: Exercises Re Vm Dh For water: D 2 Vm m , A Re 4m 4 0.25 8781 D 0.05 725 106 Pr Cp k Re > 2300 A 4 725 10 6 4178 4.85 0.625 (turbulent flow) Therefore: Nu D 0.023 Re 0D.8 Pr 0.4 0.023 87810.8 4.850.4 62 Need help with your dissertation? Get in-depth feedback & advice from experts in your topic area. Find out what you can do to improve the quality of your dissertation! Get Help Now Go to www.helpmyassignment.co.uk for more info 84 Download free eBooks at bookboon.com Click on the ad to read more Heat Exchangers Heat Transfer: Exercises From which: hi Nu D k 62 0.625 775 W / m 2 K D 0.05 For oil: Dh 4 (rb2 ra2 ) 4 Area 2(rb ra ) 2(0.045 0.025) 0.034 m Perimeter 2 (rb ra ) Re 2m 2 0.12 Vm Dh 2m ( rb ra ) 33 2 2 ( rb ra ) (rb ra ) 0.045 0.028 3.25 10 2 Re < 2300 (Laminar flow) Therefore: Nu D 5.6 ho Nu D k 5.6 0.138 22.7 Dh 0.034 W/m2 K 1 0.028 28 0.028 1 U o ln 21.84 25 725 0.025 22.7 16 W/m2 K ii) The controlling heat transfer coefficient is that for oil, ho because it is the lower one. Changes in ho will cause similar changes in the overall heat transfer coefficient while changes in hi will cause little changes. You can check that by doubling one of them at a time and keep the other fixed and check the effect on the overall heat transfer coefficient. iii) Thi 90C , Tci 10C , Tho 55C Tco is unknown. This can be computed from an energy balance For the oil side: Q m hC ph (Thi Tho ) 0.12 2131(90 35) 8950 W Q m cC pc (Tco Tci ) 0.25 4178(Tco 10) 8950 W Therefore Tco 18.56C Evaluate LMTD 85 Download free eBooks at bookboon.com Heat Exchangers Heat Transfer: Exercises T1 90 10 80C T2 55 18.56 36.44C Tlm T2 T1 36.44 80 56.1C ln(T2 / T1 ) ln(36.44 / 80) Q UATlm U o 2 ro LTlm L Q U o 2 ro Tlm 8950 41.5m 21.84 2 0.028 56.1 Example 5.4 Figure (a) below shows a cross-sectional view through part of a heat exchanger where cold air is heated by hot exhaust gases. Figure (b) shows a schematic view of the complete heat exchanger which has a total of 50 channels for the hot exhaust gas and 50 channels for the cold air. The width of the heat exchanger is 0.3m Using the information tabulated below, together with the appropriate heat transfer correlations, determine: i. ii. iii. iv. v. the hydraulic diameter for each passage; the appropriate Reynolds number; the overall heat transfer coefficient; the outlet temperature of the cold air; and the length L Use the following relations: Using the relations: Nu D 4.6 Nu D 0.023 Re 0D.8 Pr 1 / 3 Re D 2300 Re D 2300 86 Download free eBooks at bookboon.com Heat Exchangers Heat Transfer: Exercises Data for example 4.4 Hot exhaust inlet temperature Hot exhaust outlet temperature Cold air inlet temperature Hot exhaust total mass flow Cold air total mass flow Density for exhaust and cold air Dynamic viscosity, exhaust and cold air Thermal conductivity, exhaust and cold air Specific heat capacity, exhaust and cold air Heat exchanger wall thickness Heat Exchanger wall thermal conductivity Hot exhaust side fouling resistance Cold air side fouling resistance 100oC 70oC 30oC 0.1 kg/s 0.1 kg/s 1 kg/m3 1.8x10-5 kg/m s 0.02 W/m K 1 kJ/kg K 0.5 mm 180 W/m K 0.01 K m2/W 0.002 K m2/W Solution: Re VL L Dh Dh (Hydraulic diameter) 4 cross sectional area 4 w H 4 0.003 0.3 5.94 mm perimenter 2w H 20.003 0.3 87 Download free eBooks at bookboon.com Heat Exchangers Heat Transfer: Exercises For a single passage: V m / 50 0.1 / 50 2.22 H w 0.003 0.3 1 Re m/s 1 2.22 5.94 10 3 733 1.8 10 5 Re 2300 (laminar flow) Nu D 4.6 h Nu D k 4.6 0.02 15.5 W / m 2 K 3 Dh 5.98 10 88 Download free eBooks at bookboon.com Click on the ad to read more Heat Exchangers Heat Transfer: Exercises Since the thermal properties are the same and the mass flow rate is the same then the hot stream and cold stream heat transfer coefficients are also the same. 1 t 1 U R f , h R f ,c k hc hh 1 1 0.5 10 3 1 0.01 0.002 180 15.5 15.5 1 7.1 W / m 2 K Note that if the third term in the brackets that includes the resistance through the metal is neglected, it will not affect the overall heat transfer coefficient because of the relatively very small thermal resistance. Q m C p (Th ,i Th ,o ) m C p (Tc ,i Tc ,o ) Tc ,o Tc ,i (Th,i Th ,o ) 30 (100 70) 60 o C Also Q UATlm Tlm is constant in a balanced flow heat exchanger Tlm 100 60 70 30 40C Q m C p Th ,i Th ,o 0 .1 1000100 70 60 w / passage 50 Area of passage: A Q 60 0.211 m 2 UTlm 7.1 40 And since: A w L L 0.211 0.704 m 0 .3 89 Download free eBooks at bookboon.com