STD-API/PETRO STD

54b-ENGL

L777

m

0732270 05b743L bTO

m

Brushless Synchronous

Machines-500 kVA and Larger

API STANDARD 546

SECOND EDITION, JUNE1997

American

Petroleum

Institute

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

S T D - A P I / P E T R OS T DS q b - E N G L

1797 W O732290 0 5 b 7 4 3 2 537 W

Brushless Synchronous Machines500 kVA and Larger

Manufacturing, Distribution and Marketing Department

API STANDARD 546

SECOND EDITION, JUNE 1997

American

Petroleum

Institute

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

STD.API/PETRO STD

5Yb-ENGL

1777

m 0732270

05b71.133 Y73

m

SPECIAL NOTES

All rights reserved No p a n of this work may be reproduced, storedin a retrievalsystem, or

transmitted by any means, electronic, mechanical, photocopying, recording,or otherwise,

without prior written permission

from the pubLisheK Contact the Publishec

MI Publishing Services, 1220 L Street, N. W ,Washington, D.C. 20005.

Copyright Q 1997 American Petroleum Institute

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

API publications necessarily address problems

of a general nature. With respect to particular circumstances, local,state, and federal laws and regulations should be reviewed.

A P I is not undertaking to meet the duties of employers, manufacturers, or suppliers to

warn and properly train andequip their employees, andothers exposed, concerning health

and safety risks and precautions, nor undertaking their obligations under local, state, or

federal laws.

Information concerning safety and health risks and proper precautions with respect

to particular materials and conditions should

be obtained from the employer, the manufacturer or

or the material safety data sheet.

supplier of that material,

Nothing contained in any A P I publication is to be construed as granting any right, by

implication or otherwise, for the manufacture, sale, or useany

of method, apparatus, or product covered by letters patent. Neither should anything contained in the publication be construed as insuring anyone against liability for infringement of letters patent.

Generally,API standards are reviewed and revised, reaffirmed,

or withdrawn at least every

five years. Sometimes a one-time extension of up to two years will be added to this review

cycle. This publication will no longer bein effect five years after its publication dateas an

operative API standard or, where an extension has been granted, upon republication. Status

API Authoring Department [telephone (202)

of the publication can be ascertained from the

682-8000]. A catalog of API publications and materials is published annually and updated

quarterly by API, 1220 L Street, N.W., Washington, D.C.20005.

This document was produced underM I standardization proceduresthat ensure appropriate notification and participation in the developmental process and is designated as an API

standard. Questions Concerning the interpretation of the content of this standard or comments and questions concerning the procedures under which this standard was developed

should be directed in writing to the directorof the Authoring Department (shown

on the title

page of this document), American Petroleum Institute, 1220 L Street, N.W., Washington,

D.C.20005. Requestsfor permission to reproduce or translate all

or any part of the material

published herein shouldalso be addressed to the director.

API standards are publishedto facilitate the broad availability of proven, sound engineering and operating practices. These standards are not intended

to obviate theneed for applyingsoundengineeringjudgmentregardingwhenandwherethesestandardsshouldbe

utilized. The formulation and publication of API standards is not intended in any way to

inhibit anyone from using any other practices.

Any manufacturer marking equipment or materials in conformance with the marking

requirements of an A P I standard is solely responsible for complying with all the applicable

requirements of that standard. APIdoes not represent, warrant, or guarantee that

such prodA P I standard.

ucts do in fact conform to the applicable

S T D = A P I / P E T R O STD 54b-ENLL L997 m 0732270 0 5 b 7 4 3 43 0 T

W

FOREWORD

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

M I publications may be used

by anyone desiring to doso. Every effort has been made

by

the Instituteto assure the accuracy and reliability of data

the contained in them; however, the

Institute makes no representation, warranty, or guarantee

in connection with this publication

and hereby expressly disclaims any liability or responsibility for loss or damage resulting

from its use or for the violation of any federal, state, or municipal regulation with which this

publication may conflict.

be submitted to the directorof the ManufacturSuggested revisions are invited and should

ing, Distribution and Marketing Department, American Petroleum Institute, 1220 L Street,

N.W.,Washington, D.C. 20005.

iii

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

STD.API/PETRO

S T D 5qb-ENGL L777 I0732290 05b743524b

m

CONTENTS

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Page

1 GENERAL ..........................................................

1.1 Scope ...........................................................

1.2

1.3

1.4

1.5

1.6

AlternativeDesigns ................................................

Corresponding and ConflictingRequirements ...........................

CoordinationResponsibility ......................................... 1

DefinitionofTerms ................................................

2

ReferencedPublications ............................................

3

2 BASICDESIGN ....................................................

2.1

2.2

2.3

2.4

General..........................................................

Electrical Design ..................................................

Insulation Systems.................................................

MechanicalDesign ................................................

3 ACCESSORIES ....................................................

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

1

1

1

1

TerminalBoxes ..................................................

WindingTemperatureDetectors .....................................

BearingTemperatureDetectors ......................................

SpaceHeaters ...................................................

ScreensandFilters ................................................

Alarms and Control Devices for Machine Protection ....................

GroundConnectors ...............................................

VibrationDetectors ...............................................

4 INSPECTION.=STING.ANDPREPARATION

FORSHIPMENT ...................................................

5

5

6

8

8

24

24

25

25

25

26

26

26

26

General .........................................................

Inspection.......................................................

FinalTesting ....................................................

Preparation for Shipment ..........................................

27

27

27

29

35

5 GUARANTEEANDWARRANTY .................................

36

6 VENDOR’SDATA .................................................

6.1 Proposals .......................................................

6.2 ContractData ....................................................

36

36

38

4.1

4.2

4.3

4.4

SYNCHRONOUS MOTOR DATA SHEETS

. . . . . . . . . . 41

SYNCHRONOUS GENERATOR DATA SHEETS. . . 53

PROCEDURE FOR DETERMINATIONOF

RESIDUAL UNBALANCE........................... 65

APPENDIXDVENDORDRAWINGANDDATA

REQUIREMENTS ................................... 73

APPENDIX A

APPENDIX B

APPENDIX C

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

~~

~

S T D * A P I / P E T R O S T D 5Vb-ENGL L777 S 0732270 05b7V3b L82 W

page

APPENDIX ESYNCHRONOUSMOTORDATASHEET

GUIDE ...............................................

APPENDIX F SYNCHRONOUSGENERATORDATA

SHEET GUIDE.......................................

79

95

Figures

Shaft Vibration Limits(Relative to Bearing Housing Using Noncontact

Vibration Probes): For all Hydrodynamic Sleeve Bearing Machines;

With the Machine Securely Fastenedto a Massive Foundation............. 30

2 Bearing Housing Radial and Axial Vibration Limits: For Sleeve

and Antifriction Bearing Machines; With

the Machine Securely

Fastened to a Massive Foundation

.................................... 31

C- 1 Sensitivity Check Work Sheet .......................................

66

C-2 Sensitivity Check Work Sheet .......................................

67

68

C-3 Residual Unbalance Work Sheet .....................................

69

C-3 Residual Unbalance Work Sheet (Continued) ...........................

C 4 Sample Calculations for Residual Unbalance ...........................

70

C-4 Sample Calculationsfor Residual Unbalance (Continued) ................. 71

1

Tables

1

2

3

4

5

dex

Voltage

Ratings ...................................................

6

Starting Capabilities ................................................

7

Machine Enclosures andCorresponding NEMA or E C Specifications ....... 9

MaximumSeventy of Defects in Castings .............................

28

DC Test Voltages for Insulation Resistance and Determination of

.................................................

Polarization

31

vi

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

STD.API/PETRO

S T D 5Vb-ENGL

L777 I0732270 05b7437 019 I

Brushless Synchronous Machines-500 kVA and Larger

SECTION 1-GENERAL

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Scope

1.1

1.1.1 Thisstandardcoverstheminimumrequirementsfor

specified

1.1.2

machine

is theWhen

aspurpose

special

on

the Purchaser’s Synchronous Machine Data Sheets (Appendix A), theparagraphsthat are markedwith squarebullets).(

form-wound and bar-wound

paragraph

apply.

also

shall

Where

a

includes both a round

and

in Petroleum

standard includes

square

bullet,

that

pxagraph apply

shall

when

h e machine

is

purpose, or when indicated on thedata

synchronousmotorsandgeneratorswithtwodifferent

rotor

specified as

sheets

designs:

machinethe

if

specified

been

has not

puras special

a.Theconventional salient-polerotorwithsolid or laminated

poles.

b. Thecylindrical rotor withsolid or laminatedconstruction.

Pose in the Purchase Order.

Note 1: A round bullet (@) at the beginning of a paraamph indicates that

either a decision is required or further information is to be provided by the

purchaser. This informationshould be indicatedonthe data sheets (see

Appendix A); otherwise it shouldbe stated in the quotation requestor in the

order.

ingful as an aid to procurement, the purchaser must complete

the data sheets in Appendix or

A B. [ESP]

1.1.3 Thisstandardrequiresthepurchaser

to specifycertain detailsand

In order for this standard to be mean-

1.2 AlternativeDesigns

Note 2: A square bullet (W) at the beginning of the paragraph indicates additional requirementsfor special-purpose machines. Special-purpose machines

are: motors that drivehigh-inema loads, vertical machines that support highthrust loads, part of o complete vain requiring vibration sensitivity criteria,

operate in abnormally hostile environments, or are critical unspared equip

ment.

The vendor may offer alternative designs (see 6.1.10 for

proposal requirements). Equivalents such as metric dimensions, fasteners, and flanges may be substituted as mutually

[ESP]

agreed upon by the purchaser and the vendor.

Note 3: This standard may be applied

to adjustable speed motors with apprcpriate attention to the specific requirements of such applications.For adjustable speed applications, proper selection the

of motor and drive is required

to

avoid the following conditions:

1.3 CorrespondingandConflicting

Requirements

1.3.1 ms documentrecognizes two different systems of

a. Motor rms current exceeding the continuous sinusoidal nameplate rat-

ing due to excessive voltageharmonics or improper voltshertz levels.

standards for themanufacturingandtestingofelectrical

b. Excessive winding temperature due toinsufficient cooling, excessive

torque levels, improper

voltslhem

levels

and

increased

losses

due

harto

machines: the North American

IEEE, and NEMA

~standards; and the International IEC and IS0 standards. The

monics.

c. Insufficientmotor accelerating torque atreduced speeds due to insuffiNorthAmericanStandardsarethebasedocuments.When

cient voh/hertz levels or limitations in the drive’smomentary current

specified by the purchaser,thecorresponding International

capacity and excitation system.

Standards are acceptable for useas alternatives; however, this

d. Increasedsoundlevels

due to increased fan speed, excitation of

mustnot be construed that they are identical

to the North

mechanicalresonances,and/or magnetic noisecaused by supplysource

harmonics.

systemAmerican

which of

Standards.

selectionThe

of stane. Mechanicalfailureof the motor or coupling due to toque pulsations,

dards to be utilized shall depend upon the machine’s applicaoperation at or near mechanical resonances, or excess speed.

tion

and site location.

f. Winding failures due to repetitive high amplitude voltage spikes created

by the drive system.

purchaser

should

TheNote:

requirements

specific

contained

be

thataware

g. Motorground insulation overstress due to increasedcommonmodewithincorresponding

standards may differ.

voltage.

In

Of conflict between the

Order, this

Damage

h.motor

the

to

and

drive

due

to improper application of system

capacitance.

the

information

in

the

standards,

referenced

any

andstandard,

i. Higher motor temperatures whichmay limit application in Division 2

inquiry or order shallgovernoverthisstandard,while

this

classified locations.

standards.

referenced

any overgovernshall

standard

[ESP]

j. Shaft voltages/currents due to harmonics whichmay cause bearing

failure.

k. Possible

resonance with, and overheating of, surge capacitors (surge

1.4 CoordinationResponsibility

capacitors are not recommended).

1. Rotor heating due to drive-created space harmonicmmf(e.g.

6th. 12th.

Thevendorshall

be responsible for providingthepuretc. harmonic rotor currents).

installation

details

necessary

the

all

chaser

with

for

and

oper-

ation as an

Pm Of the

6.2 for the

information

required).

[ESP]

Note 4: [ESP] designates

use

of an electrical standard

paragraph.

[MSP]

designates

of

use

the

a mechanical

standard

paragraph.

1

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

(see

~~

S T D * A P I / P E T R O S T D S q b - E N G L L777 M 0732270 05b7438 T 5 5 M

2

API STANDARD

546

1.5 Definition of Terms

with unit responsibility, considers excitations

of torsional natural frequencies includingbut not limited to the following:

1.5.1 pull-in torque: The pull-in torque of a synchronous

a. Gear problems suchas unbalance and pitch line runout.

motor is themaximumconstanttorqueunderwhichthe

or circuits.

motor will pull the connected inertia load into synchronism at b. Torsional transients suchas motor start-ups short

the rated voltage and frequency when the field excitation is

c. Torsional excitation resulting from drivers such as motors

applied.

and reciprocating engines.

d.Torsionalexcitationsresultingfromadjustable

speed

1.5.2 pullsut torque: The pull-out torque of a synchrodrives. [ESP]

nous motor is the maximum sustained torque that the motor

will developat synchronous speed with the rated voltage, fre- Note:Thefirsttorsionalnaturalfrequencyof

synchronous-motoddrivenequipment combinations nonnallylies between twice the line frequency and

quency and excitation applied.

1.5.3

locked-rotor

toque: The

minimum

average

torque that the motor will produce with

a locked rotor at any

angular position of the rotor with its rated voltage and frequency applied. [ESP]

1.5.4 accelerating torque: Thedifferencebetweenthe

shaft torque and allload torques, i.e., the net torque available

for accelerating the rotating parts. [ESP]

1.5.5 pulsating toque: Thepulsatingtorque of a synchronous motor is the single amplitudethe

of exciting pulsating torque that is superimposedon the mean uniform starting

torque. The frequency of this torque oscillation is twice the

rotor-slip frequency and thus decreases linearly (at the usual

rated frequenciesof 50 or 60 hertz) from100 or 120 hertz toO

hertz as the speed increases from zeroto synchronous speed.

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

1S.6synchronousmachinecharacteristicdata:

For definitionof synchronous machine characteristic data see

ANSVIEEE 100 or IEC 34-10.

1.5.7 cold start:,A motor start that occurs when the rotor

and stator are initially at ambient temperature. [ESP]

1.5.8 hot start: Any restart of the motor that occurs when

the motor is at a temperature above ambient temperature.

[ESPI

1.5.9 lateralcritical speed: Corresponds to resonant

frequencies of the rotor, bearings, and bearing support system. [ESP]

Note: The basic identificationof critical speeds is made from the natural frequencies of the system and of the forcing phenomena.If the frequencyof any

is equalto or

harmoniccomponent of aperiodicforcingphenomenon

approximates the frequency of any mode of rotor vibration, a condition of

resonance may exist. If resonance exists at a finite speed, thatspeed is called

a criticalspeed. This standardis concerned with actual resonant

speeds rather

than various calculatedvalues. Actual criticalspeeds are notcalculated

undamped values butare critical speeds confirmed by test-standdata. Critical

speeds above the maximum test speed shall be calculated damped values or

shall be determined by externally applied rotor excitations.

[ESP]

1.5.10torsionalcriticalspeed:

Corresponds to resonant frequencies of the complete mass-elastic system in the

drive train including couplings and driven equipment. The

torsional analysis, whichis normally providedby the supplier

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

zero frequency and is excited from the motor during start-up. Thismeans that

at least the first torsional critical speed is traversed each time such a drive

train is started.Dependingon the mechanicalcharacteristics of the drive

train, at the resonant speed defined by the intersection of the natural torsional

frequency and the frequency of the torque oscillations, the electrical torque

oscillation may be-escalated to a point at which unacceptably high torsional

stress occurs in the shaft system if there is not sufficient damping within the

system. [ESP]

1.5.1 1 forcing phenomena for vibration excitation:

Defined as follows: The exciting frequency

may be less than,

equal to, or greater than the synchronous frequency of the

rotor. Potential excitations to be considered in the design of

the system shall include but are not limited to the following

sources:

a. Mechanical unbalancein the rotor system.

b. Oil-film instabilities (whirl

or whip).

C. Internal rubs.

d. Misalignment.

e. Loose rotor-system components.

f. Hysteresis and friction.

g. Start-up condition frequencies.

h. Twice the line frequencies.

1. Electrical unbalance.

J. Mechanical pulsations producedby the motor load.

k. Electrical exciting pulsating torque with double slip frequency. [ESP]

1. Short circuits (faults)on the electrical system.

1.5.12servicefactor:

Themultiplier to thenameplate

power rating defining the maximum continuous power capability of the machine.A Service Factor(S.F.) greater than 1.O

can be specified when required. For example,a machine with

a Service Factor of 1.15 is able to run at 115 percent of its

2.2.1.3.

rated load witha temperature rise in accordance with

[ESPI

1.5.13 trip speed (in revolutions per minute): The speed

to

at which the independent emergency speed device operates

shut down the machine. [ESP]

1.5.14 power factor: The ratio of kilowatt input to kilovolt-ampere input for a motor or the ratio of kilowatt output

to kilovolt-ampere output fora generator. [ESP]

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

STD.API/PETRO

S T D 54b-ENGL

L977

m

0732290 0 5 b 7 V 3 7 991

KVA AND LARGER

BRUSHLESS

SYNCHRONOUS

MACHINE+500

(30.1O

The editions of the following standards,codes, and specifications that arein effect at the time of publication of this standard shall, to the extent specified herein, form a part of this

standard.Theapplicability of changesinstandards,codes,

and specifications that occur after the inquiry shall be mutually agreedupon by the purchaser and the vendor.

Std 670

Std 671

RP 684

RP 686

ABMA’

Std 7

Std 8.2

Std 9

Std I l

Std 20

B1.l

Synchronous

UnifìedInchScrewThreads(UN

Thread Form)

and UNR

B 1.20.1 Pipe Threads, GeneralPurpose (Inch)

Cast Iron Pipe Flanges and Flanged Fittings,

B16.1

Class 25,125,250, and 800

Recommended Practice for Classification of

Locationsfor Electrical Installations at PetroB 16.2

leum Facilities

Lubrication,Shaft-Sealing, andControl-Oil

B16.5

Systemsfor Special-Purpose Applications

ReciprocatingCompressors for Petroleum,

Chemical and Gas Industry Services

vibration,Axial-Position,andBearing-Temperature Monitoring Systems

Special-Purpose Couplingsfor Refinery SerB16.11

vice

TutorialontheAPIStandardParagraphs

B3 1.3

Covering Rotor Dynamics and Balance

and Installation

Machinery

Installation

Design

ASTM6

A 278

Shaft and Housing Fitsfor Metric Radial Ball

and Roller Bearings

MountingAccessories,Inch

Design-Locknuts, Washers, and Adapters

Load Ratings and Fatigue Lifefor Ball Bearings

Load RatingsandFatigueLife

for Roller

Bearings

Radial Bearings of Ball,CylindricalRoller

and Spherical Roller Types, Metric Design:

Basic Plan for Boundary Dimensions, Tolerances and Identification Code

A 345

A 395

A 515

A 536

E 94

E 125

E 142

AGMA?

9002

for

BoresandKeyways

(Inch Series)

for Flexible Couplings

E 709

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Std 618

General

Requirements

Machines

ASMES

API

Std 614

3

ms14

1.6 ReferencedPublications

RP 500

m

Ring Joint Gasketsand Groovesfor Steel Pipe

Flanges

Pipe Flanges and

Flanged Fittings Boiler and

PressureVesselCode,

SectionV,“Nondestructive Examination;” Section VIU, “Rules

for Construction of PressureVessels;”and

Section IX, “Welding and Brazing Qualifications’’

ForgedSteelFittings,Socket-Weldingand

Threaded

Chemical Plant and Petroleum Refinery Piping

Gray Iron Castings for Pressure-Containing

Partsfor Temperatures Upto 650’F

Flat-RolledElectricalSteels

for Magnetic

Applications

Ferritic

Ductile

Iron

Pressure-Retaining

Castingsfor Use at Elevated Temperatures

Carbon Steel Pressure Vessel Plates

for Intermediate- and Higher-Temperature Service

Ductile Iron Castings

Guidefor Radiographic Testing

Reference Photographsfor Magnetic Panicle

Indications on Ferrous Castings

Method for ControllingQuality of Radiographic Testing

Practice for Magnetic Pam‘cle Examination

AWS7

AI SI^

American Iron and Steel Institute-Material

Properties of Stainless Steel

’American BearingManufacturersAssociation, 1101 ConnecticutAvenue,

N.W., Suite700, Washington, D.C.20036.

2AmericanGear Manufacturers Association,1500 King Street, Suite20 f . Alexandria, Virginia223 14.

’American Iron and Steel Institute, 1101 17th StreetN.W., Washington, D.C.

20005.

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

D1.l

Structural Welding Code-Steel

JAmericanNationalStandardsInstitute,

1 1 West42ndStreet, New York,

New York 10036.

sAmericanSociety of MechanicalEngineers, 345 East 47thStreet,New

York, New York 10017.

bAmeri~anSociety for Testing and Materials, 1 0 0 Bar Harbor Drive, West

Conshohocken, Pennsylvania 19428.

’AmericanWelding Society, 550 N.W. Le JeuneRoad,Miami,Florida

33135.

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

S T D - A P I / P E T R O S T D 5Yb-ENGL L797

0732290 05b744O b03

API STANDARD

546

CENELEC*

EN 10126 Cold RolledNon-orientedElectricalSteel

Sheet on Strip Delivered in the Fully Processed State

EN 10165 Cold Rolled Electrical Alloyed Steel Sheet on

Strip Delivered in the Semi-processed State

IEP

34

38

72

79

894

Rotating Electrical Machines

Standard Voltages

Dimensions and Ourput Ratings for Rotating

Electrical Machines

Electrical Apparatus

for Explosive Gas Amtospheres

Guide for a Test Procedure for the Measurement of Loss Tangent of Coils and Bars for

Machine Windings

IEEE’”

43

85

95

100

115

286

303

429

522

841

Recommended Practicefor Testing Insulation

Resistance of Rotating Machinery

Test Procedurefor Airborne Sound Measurements on Rotating Electric Machinery

Recommended Practicefor Insulation Testing

of Large AC Rotating Machinery with High

Direct Voltage

Stana!ard Dictionary of Electrical and Electronic Tenns

Test Proceduresfor Synchronous Machines

Recommended Practice for Measurement of

Power-Factor lip-Up of Rotating Machinery

Smor Coil Insulation

Recommended Practicefor Auxiliary Devices

for Motors in Class I-Groups A, B, C, and D,

Division 2 Locations

Standard Test Procedure

for the Evaluationof

Sealed Insulation Systems for AC Electrical

MachineryEmployingForm-WoundStator

Coils

Guide for Testing Turn-to-Turn Insulation on

Form-Wound Stator Coils for AC Rotating

Electric Machines

Standard for Petroleum and Chemical Industry-Severe Duty

Totally

Enclosed

FanCooled (TEFC) Squirrel

Cage

Induction

Motors-Up to and Including 500 HP

ISO”

7

Pipe Threads (Pressure Type)

-C,

rue de Stassart: 35 B1050, Bruxelles, Belgium.

91ntemational Uectrotechnical Commission, 1, rue de Varembe, Geneva,

Switzerland.

loInstitute of Electrical and ElectronicsEngineen, 345 East 47th Street, New

York,New York 10017.

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

15

25

68

76

228

26 1

28 1

286

773

774

775

1027

1680.1

19404

3448

3452

3453

3506

5579

7005

7483

8501

9013

9328

(ISOLDIS 15) Rolling Beanngfladial Bearings

GeneralRequirements for Competence of

Calibrationand TestLabs

(ISOLDIS 68) I S 0 General Puvose Screw

Threads

Rolling Bearings-Static Load Ratings

Pipe Threads (Non-PressureType)

I S 0 General Purpose Metric Screw Threaa3

Rolling Bearings-Dynamic Load Ratings and

Rating Life, Part 1, “Calculation Methods”

I S 0 System of Limits and Fits, Part 1, “Bases

of Tolerances, Deviations and Fits”; and Part

2, “Tables of Standard Tolerance Grades and

Limit Deviationsfor Holes and Shafts”

(ISOR 773) Rectangular or Square Parallel

Keys and Keyways

(ISOR 774)Taper Keys and Keyways

(ISOR 775) Cylindricaland 1/10 Conical

Shaft Ends

Radiographic I m g e QualityIndicators for

Non-Destructive Testing

Acoustics-TestCode

for Measurement of

Airborne Noise Rotating Electrical Machinery (2 P m )

Mechanical

Vibration-Balance

Quality

Requirements of Rigid

Rotor

Standard Industrial Liquid Lubricants-IS0

viscosity Classijkation

Non-Destructive Testing PenetrantInspection-General Principles

Non-Destructive Testing Liquid

Penetrant

Inspection-Verijìcation

CorrosionResistantStainlessSteelFasteners-Specifications

Non-Destructive Testing RadiographicPhenomenon-Basic Rules

Metallic Flanges(3 Parts)

Dimensionsfor Gaskets

Preparation of Steel Substrates(2 parts)

Welding and Allied Processes

Steel Plates and Strips for Pressure Purposes

(5 P

9691

10721

228

m)

Rubber-Recommendations for Workmanship of Pipe Joint Rings

Steel Structures: Materials and Design

Pipe Threads Part I , Dimensions, Tolerances

and Designdon

ternat national Organization for Standardization, IS0 publications are available from American National Standards Institute, i 1 West 42nd Street, New

York,New York 10036.

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

4

BRUSHLESS

SYNCHRONOUS MACHINES-500

NEMA"

MG 1

NFPAi3

70

496

497M

Motors

and

SSPc'4

SP 6

Generators

Electrical

National

Code

Pressurized

Purged

andEnclosures

for Electrical Equipment

Classifcation of Gases, VaporsandDusts for

ElectricalEquipmentinHazardous

(Classified) Locations

Commercial

Blast

Cleaning

Standards

Exchanger

ManuTubular

of the

facturen Association

W e e l Structures Painting Council, 4400 Fifth Avenue, Pittsburgh, knnsylvania 15213-2683.

L5TubularExchange Manufacturers Association, 25 North Broadway, Tarrytown, New York I0591.

SECTION 2-BASIC

General

2.1.1 The equipment (includingauxiliaries)covered by this

standard shall be suitable for the specified operating conditions and shall be designed and constructed for a minimum

service life of 20 years and at least 3 years of uninterrupted

continuous operation.It is recognized that this is a design criterion and that unintenupted operationfor this period of time

involves factors beyond the vendor's

control. [ESP]

O

5

TEMAIS

l2NationalElectrical Manufacturers Association,1300 North 17thStreet,

Suite 1847, Rosslyn, Virginia22209.

'3Nationf Fire Protection Association,I Batterymarch F'ark, Quincy, Massachusetts 02269.

2.1

KVA AND LARGER

2.1.2 Machines shall be designed for continuous operation

and long periods of inactivity in an atmosphere that is made

corrosive by traces of chemicals normally present in apetroleumprocessingfacilityandinanenvironmentthat

may

include highhumidity,storms,salt-ladenair,insects,plant

life, fungus, and rodents. Machines shall besuitable for operation, periods of idleness, storage, and handling at the ambient temperatures listed under Site Data on data

the sheets (see

Appendix A orB). If additional considerations are necessary

in the proposal, the purchaser shall specify them. [ESP]

DESIGN

The arrangement shall provide adequate clearance areas and

safeaccess for installation,operation,andmaintenance.

[ESPI

2.1.6 The design of piping systems shall achieve the

lowing:

fol-

a.Propersupportandprotection

to preventdamagefrom

vibration or from shipment, operation, and maintenance.

b. Properstiffnessandnormalaccessibility

for operation,

maintenance, and thoroughcleaning.

c. Installation in a neat and orderly arrangement adapted

to

the contour of the machine without obstructing access openings.

d. Elimination of air pockets.

e. Complete drainage through low points without disassembly of piping.

f. Provision for easy removal of covers for maintenance and

inspection. [ESP]

2.1.3 Control of the sound pressure level of all equipment

O 2.1.7 Electrical components and installations shall be suitfurnished shall be ajoint effort of the purchaser and the venable for the area classification specified by the purchaser on

dor. The equipment furnishedby the vendor shall conform to

the data sheets and shall meet the requirements ofNFF'A 70,

the maximum allowable sound pressure level specifiedby the

Articles 500, 501, 502 and 505 (Class, Group, Division or

purchaser. The measuring and reporting of sound pressure

Zone,andTemperatureCode),

or IEC79-1 (Zone, Class,

level data shall be in accordance with4.3.5.l .1 g.ESP]

Group, and Temperature Code) as well as local codes. The

purchaser will furnish with his inquiry any applicable local

0 2.1.4 All equipment shall be designed to run safely at the

codes or regulations.[ESP]

overspeeds specified in NEMA MG 1-21.45, 22.47, IEC 341, or to the specified trip speed (including overshoot) of the

2.1.8 Oil reservoirs and housings that enclose parts such as

connected equipment, whicheveris ,mater.

bearings, shaft seals, instmments, control elements, and terminals shall be designedto minimize contaminationby mois2.1.5 The arrangement of the equipment, including number

ture,dust,andotherforeignmatterduringperiodsof

of bearings, terminal housings, conduit, piping, and auxiliaoperation or idleness. To avoid condensation, the minimum

ries, (including the rotating elements of the exciter, the field

inlet

temperature of the bearing cooling water shallbe above

discharge resistor,

and

synchronizing

controls as applicable)

the ambientair temperature. [ESP]

shall be developed jointly by the purchaser and the vendor.

I

l

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

0

S T D * A P I / P E T R O S T D 54b-ENGL 1977 I0732270 0 5 b 7 4 4 2 48b I

API STANDARD

546

2.1.9 Equipment shall be designed to permit rapid andeconomical maintenance. Majorparts such as frame components

and bearing housings shall be designed (shouldered or doweled) and manufactured to ensure

accurate alignment on reassembly.Easilyremovablecovers

shall beprovided

for

maintenance and inspection of coil end turns, the exciter, synchronizing controls and rotor windings

as applicable. [ESP]

Table 1-Voltage

or Horsepower

kVA

5004,000

500-7,000

1,000-12,000

3,500-Above

m .

Phases

3

3

3

3

(hertz)

60

60

60

60

Ratings

Motor

Voltage

2,300

4,000

6.600

13,200

Bus

Voltage

2400

4,160

6,900

13,800

2.1 .I O Every effort shallbe made to avoid requirementsfor

FW.

special tools. However, when tools and fixtures not commerkW

Phases

(hertz)

Voltage

(a)

(b)

ciallyavailablearerequiredto

disassemble, assemble, or

5

0

0

4

,

0

0

0

3

50

3,000

3,300

maintain the unit, they shall be included in the quotation and

500- 1 2,000

3

50

6.000

6,600

furnished as part of the initial supply. For multiple-unit instal3

50

10,000

4,000-Above

11,Ooo

lations, the requirements for quantities of special tools and

fixtures shall be mutually agreed upon by the purchaser and

Note 1 : Either oneof the voltage seriesa or b is used in certain countries

vendor. [ESP]

(EC38 Ed. 1983).

Note 2: For synchronousmotos with a leading power factor (overexcited)

2.1.ll When special tools are provided, theyshall be packthe recommended ratedvoltage is the nominal bus voltage. W P ]

aged in separate, rugged boxes and marked as special tools

Note 3: Motorsfor adjustable speed drive applications may have non-stanbe tagged to indicate its

for (taghtem number). Each tool shall

dard voltage ratings.

intended use. [ESP]

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

6

when operated, both mechanically and

elecmcally, at rated

power, voltage, and frequency. In applications that require an

be used to avoid

overload capacity, a higher rating should

exceeding the temperature rises for the class of insulation

used and to provide adequate torque capacity. If a Service

Factor of 1.15 is specified, the motor may have a temperature

0 2.1.13 Many factors (suchas oil- or purge-piping and ductrise ofan additional 10°C (18’F) over that specified in2.3.1.1

work loads, alignment at operating conditions, supporting

when continuously operated at the service-factor power outstructure, handling during shipment, and handling and assem- put and the rated voltage and frequency.[ESP]

bly at the site) may adversely affect site performance. When

Maximum momentary overload capability

for synchronous

specified, to minimize the influence ofthese factors, the venbe

per

NEMA

MG

1-22.41

or

IEC 34-1.

generators

shall

dor shall review and comment on the purchaser’s piping and

foundationdrawing,andthevendor’srepresentative

shall

2.2.2 STATORWINDINGS

observe a check of the piping and ductwork performed by

parting the ductwork and flanges.The vendor’s representative

shall check alignment at the operating temperature

and, when O 2.2.2.1 Wheredifferentialprotection is specified or when

specifiedbythepurchaser,bothendsofeachstator-phase

specified, shall be present duringthe initial alignment check.

windingshall be brought out to the terminal housing that

[ESPI

encloses the currenttransformers (see 3.1.8 for additional

2.1 .I4

Spare partsfor the machines and all furnishedauxilrequirements). [ESP]

iaries shall meet all the criteria ofthis standard. [ESP]

2.2.2.2 Coil ends shall be braced to preventinsulation

2.2 Electrical Design

cracking and fatigue as a result of motion during operation

and starting. Thestator windings shallbe braced to withstand

2.2.1 RATINGANDVOLTAGE

an external line-line-ground shortcircuit at full load and 110

percent of rated voltage. Motor windingsshall withstand the

O 2.2.1.1 Standardratingsshall be selected. Iftherequired

starting duties specified in 2.2.6 with a life of at least SOO0

rating falls between two listed ratings, the larger listed rating

full-voltage starts. [ESP]

shall be selected. For generators, standard kilovolt-ampere

and kilowatt ratings shallbe selected. [ESP]

2.2.3 LOADREQUIREMENTS

2.2.1.2 Ingeneral,motors

are ratedinaccordancewith

2.1.12 Themachineshallperformwithin

the specified

acceptance criteria on the test stand and on its permanent

foundation. After installation, the performance of the combined units shall be the joint responsibility of the purchaser

and the vendor whohas responsibility for the train. [ESP]

Table l . Generators shall have thebus voltage rating shown.

O

2.2.1.3

Machines shall be capable of continuous operation

at rated load and temperature rise in accordance with2.3.1.1

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

2.2.3.1 Unless otherwise specified, the load torque characteristics and totalload inertia referred to the motor shaft shall

be in accordance with NEMAMG 1, Part 21 or IEC 34-1.

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

STD.API/PETRO STD 5Llb-ENGL 1777 I0732290 05b7Ll43 312 E

BRUSHLESS

SYNCHRONOUS MACHINES-500 KVA AND LARGER

2.2.6STARTINGCAPABILITIES

2.2.3.2 Shouldtheloadshaveothercharacteristicsthan

those listedin NEMA MG 1, Part 2 1, the purchaser shall fully

2.2.6.1 Fixed-speed motors shall have the starting capabilispecifytheloadcharacteristicsofthedrivenequipment.

These shall include:

ties in Table2. [ESP]

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

0

7

a. The speed torque characteristics of the load under the most

stringent starting conditions.

b. When required, the speedtorque characteristics of the load

duringreacceleratingconditions,

the lengthofmaximum

voltage interruptions or fault related collapse, the expected

voltage at motor terminals during re-acceleration.

c. The total load inertia (Wkz) referred to themotorshaft

O

speed, where W is the rotating weight and k is the radius of

gyration. This total load inertia shall include all loads connected to themotorshaft,such as couplings, gearbox and

driven equipment. [ESP]

Note: Wk2[lb-fi’] = 23.731 Fg-m’]

1 =0.25GDz

D=2R

2.2.4VOLTAGEANDFREQUENCYVARIATIONS

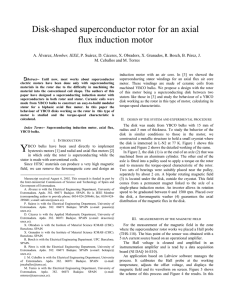

Number of Starts at a

of 1.O

3

2

3

3

Note 1: The first startis a cold start.

Note 2: The starting capabilitiesfor synchronous motorsm normally a result

of an individual design for the specific load characteristics

of the driven

equipment and the electrical power system

for the most stringent conditions.

by one for

Therefore, itmay be necessary to reduce the number of starts

large, high inertia drives like gear-type

turbocompressors., and so forth. For

pumps and otherlow inertia applications, the number

of s m may be

increased to allow maximum starting flexibility

for the operation.

2.2.5STARTINGCONDITIONS

start

2.2.5.1 Unlessotherwisespecified,themotorshall

and accelerate the connected load to running speed in accordance with NEMA MG 1, Part 21 or E C 34-1. [ESP]

2.2.6.3 The minimum safe stall (locked rotor) time shall be

the greater of150 percent of, or5 seconds more than, the time

required to accelerate the actual driven load with the voltage

values specified under Paragraph 2.2.1.2. If these conditions

cannot be met, the vendor shall notifythe purchaser so that a

workable solution can be jointly developed. The method of

safe stall time calculation and the limits shall be described

with the proposal. [ESP]

2.2.5.2 Therequirements for startingcapability,speedtorque, and acceleration time shall be determined withfolthe

lowing information,as applicable, furnishedby the purchaser:

a. The minimum expected voltage at motor terminals under

specified inrush currents or,

b. The minimum available system short circuit inkVA,the

X / R ratio, and the minimum motor terminal voltage during

starting, withallvaluesreferenced

at themotorterminals.

[ESPI

2.2.7

PERFORMANCE

2.2.5.3 Whenthemotorspeed-torquecume

at the conditions specified in 2.2.5.2 aor b. is plotted over the load speed

torque curve, the motor developed torque shall exceed the

load torque by a minimum of 10 percent (motor rated torque

as base) at all locations throughout the speed range up to the

motor pull-in torque point. [ESP]

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Table 2-Starting Capabilities

Consecutive

2-second

jogging applications 10

seconds apart.

Consecutive stmsmotor

with

the

coasting

to

rest betweenstarts.

Consecutive startsmotor

with

the

coasting

to

rest and remainingidle for20 minutes.

Evenly

spaced

starts

firstin

hour before

continuous running.

2.2.4.1 Unless otherwise specified, the machine shall operate with a maximum voltage variation of +lo percent and a

maximum frequency variation of+5 percent and a total combined variation not to exceedf10 percent, per NEMA MG 1,

Part 21, Part 22, or IEC-34. [ESP]

O

2.2.6.2 Starting capabilities for motors different from those

shown in Table 2shall be jointly developed between the pur2).

chaser and the vendor (see note following Table

Factor Service

Capability

Where:

J = polar mass moment of inertia (kg-m’).

G = rotating(kg).

R = radiusofinertia(m).

O

Note: Typical petroleum process plant operationsare such that a motor will

have a period of initialuse of about 2 months for pump and compressor runin and initial plant operations, during which time the maximum starting

capability may be used. A need for maximum capability may also occur during

are usually longer

subsequent start-ups. Between these start-up periods, there

periods of continuous cunning.[ESP]

2.2.7.1 With their ratedvoltageandfrequency

applied,

machines shall, as a minimum, operate with the characteristics listed below. This does not apply to units started by, or

operated on adjustable speed drives. Where these limits will

have an adverse effect on other characteristics, particularly

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

STDmAPIIPETRO STD 54b-ENGL

8

API STANDARD

546

efficiency,the vendor shall state the effect and recommend

preferred values.

0

a. The maximum locked-rotor current shall not exceed 500

percent of the full-load current.

b. The minimum locked-rotor, pull-in, and pull-out torques

shall not be less than the values listed in NEMA MG 1 Part

21 or IEC 34-1. [ESP]

c. Current pulsations under the actual operating conditions

shall be within the limits stated within API 618 or NEMA

MG 1-2 1.84,as specified.

2.3

0732270 05b7444 2 5 7

L777

InsulationSystems

2.3.1GENERALREQUIREMENTS

Class B temperature-rise limits apply tothe armature, field,

and exciter windings.

2.3.1.1 Allwindingsshallhave

an epoxybase,vacuum

pressureimpregnated,nonhygroscopic

insulation system,

including the stator lead connections to the windings. When

bus bars are used, they shallbe insulated. As a minimum, the

insulation system shall meet the criteria for Class F insulation: however, the allowable temperature rise above ambient,

40°C (104"F), shall not exceed that listedfor Class B insulation in NEMA MG 1, Part 21, MG 1, Part 22, ANSI (250.13,

or IEC 34-1 limits as applicable. For ambient temperatures

above 40°C (104°F) the allowable temperature rise shall be

reduced accordingly. Strand insulationshall adhere tightly to

the strand. Turn and ground wall insulation shall be resistant

to the effects of corona.The integrity ofstrand and turn insulation shall be maintained during forming, winding and VPI

treatment. [ESP]

2.3.1 2 For multiturn stator windings, additional turn insulation shall be used as required to maintain the integrity of

turn insulation in the noses

or other areas of coil deformation.

The insulation system shall be capable of withstanding the

surgetestspecified in4.3.4.2. Special provisions shall be

made to seal the leads where theyexit the coil. Coils shall be

tightly secured in their slots and securely braced outside the

slots to withstand electromagnetic and mechanical stresses

duringstart-upandundernormal

operating conditions, as

well as mechanical forces associated with out-of-phase synchronization and short-circuit conditions.[ESP]

2.3.1.3 Field-coilturninsulationshall be maintainedduringforming,winding,andcuring.Rotor

coils madefrom

rectangular wire or edge-wound strips shall be adequately

insulated and securely braced. Additional ground insulation

and blocking shall be used as required to maintain the integrity of insulation. To improve the cooling effect, individual

turns of the windings may project on particular sides or all

around the pole to formcoolingfins.Adequatecreepage

paths, distances and clearances shall be provided on all current-carrying conductors. The complete

rotor winding system

shallwithstandthemechanicalandelectrical

stresses that

occurduring start-up andundernormaloperating,surge,

as well as during

overspeed,andshort-circuitconditions,

shutdown and all tests Specified. The rotor insulation system

for motors shall be protected

by shorting out the rotor through

the exciter converter and by-pass thyristorsor by a field discharge resistor.

The insulation on field windings shall maintain

its integrity

while withstandingthe centrifugal forces and thermalstresses

at ClassFtemperaturewithoutdamage.Specialattention

shall be given to adequate supportof both coil-to-coil connections and coil-to-main-field-lead connections.

2.3.1.4 The exciter m a t u r e and exciter fieldinsulation

shall be Class F, highly

using

amoisture-and

chemical-resistant,curedmaterial.Theconductor

strands

shall be individually insulated by an enamel coating, a glass

weave, or a combination of these that is saturated with varnish to provide turn-to-turn insulation.

2.3.1.5 The total insulation system shall be impervious to

the operating conditions specified in 2.1.2. Sheared exposed

edges of insulationpartsshallbesealed.Allinsulation,

including lead insulation, shallbe impervious to attack by the

lubricating oil specified. Leads shall be braced and protected

from chafingagainstthemotorframeand

teminal box.

[=pl

2.3.1.6 All stator insulation

systems

shall

be service

proven and shall have been subjected

to thermal evaluation in

accordance with IEEE 429 or IEC 34-[ESP]

18.

2.3.2SEALEDINSULATIONSYSTEMS

2.3.2.1

StatorWindings

Stators shall have a sealed insulation system isthat

capable

of withstanding a sealed winding conformance test in accordance with NEMAMG 1-20.49. [ESP]

2.3.2.2ExciterWindings

When specified, the exciter armature and field windings

shall have a sealed insulation system, as defined by NEMA

MG 1-1.27.2.

2.4MechanicalDesign

2.4.1

ENCLOSURES

2.4.1.1

GeneralRequirements

The following general requirements apply

to enclosures:

a. Enclosure parts shall be made of cast or nodular iron, cast

steel, orsteelplate.Purchaser-approvedfiber-reinforced

materials may be usedfor parts suchas covers or nonsupportive enclosure sections. All enclosure parts shall have a mini--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

- S T D - A P I / P E T R O STD 5Yh"ENGL L777 E '0732270 05b74V5 175 E

BRUSHLESS

SYNCHRONOUS MACHINES-500 KVAAND LARGER

mum rigidity equivalent to that of sheet steel with a nominal

thickness of 3.0 millimeters( V g inch).

Table 3"achine

e. The impact of potential risks due to possible circulating

currentsintheenclosureshall

be considered for machines

usingmulti-sectionenclosuresinstalledinclassifiedlocato possible circulatingcurtions. Overheating or sparking due

rents shall be avoided, where necessary,by bonding together

the

conducting

components

in

a

secure electrical and

mechanical manner, or by the provision of adequate bonding

straps between the motor housing components.

f. When specified, machines to be installed in classified Div.

2 or Zone 2areas shall be provided with provisionsfor effective pre-start purging. [ESP]

IPCode

34-6

IEC

Drip-proof

Guarded

DPG

1.25.5 IC01 IP22

Weather protected

Type I

Type II

WP-I

WP-II

1.25.8.1

1.25.8.2

IF23

IPW24

IC0 I

IC01

Totally enclosed

Fan cooled

pipe ventilated

Waterlair cooled

Aidair cooled

TEFC

TEPV

TEWAC

TEAAC

1.26.2

1.26.6

lP44/54

IP44

IP44/54

IP44/54

IC41 I

IC3 1137

IC81W

IC61 1'

1C6164

1.26.8

1.26.9

2.4.12.3 Totally

enclosed

machines

shall

meet

the

following criteria:

Table 3 lists types of machine enclosures and the

NEMA or IEC specifications to which they shall conform.

The purchaser shall specifythe type of enclosure on the data

sheets. Enclosures shall also conformto the requirements of

2.4.1.2.2,2.4.1.2.3 and 2.4.1.2.4. [ESP]

2.4.1.2.2 Drip-proof,

weather-protected

Type

I and

weather-protected TypeII enclosures shall meet the following

criteria:

a. Ventilation and other openings shall be limited in size by

design or by metal screens in accordance with 2.4.10.5 and

3.5.1.

b. Weather-protected enclosures shall be constructed so that

any accumulation of water will drain from the motor before

reaching the levelof the windingsor other live parts.

c. When abrasive-dust conditions have been specified on the

data sheets under Site Data, electrical insulation shall be protected fromthe abrasive actionof airborne particles. This probe inadditiontothe

VPI resinandthe

tectionshall

manufacturer's standard coating.[ESP]

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

MG 1

Method of

Note: The designation used for degree

of protection consists of the lettersIP

followed by two characteristic numeralssignifying conformity withthe conditions indicated in the tables. When itis required to indicate a degree of protection by only onechamteristic numeral, the omitted numeralshall be

replaced bythe letter X. For example 1PX5 or1P2X

0 2.4.1.2.1

Note: Dripproof enclosures m not recommended for the operating conditions specified in 2. I .2 (that is outdoor operation without a protective shelter).Purchasersapplyingthisdegree

of protectionshould expect reduced

reliability (see 2.1.I 1.

MG 1

of

IIEC 34, Part 5, NEMA MG 1. Part 5

*IEC34, Part 6, NEMA MG 1, Part 6

3Shaft Driven SecondaryFan

4Auxiliary SecondaryFan

2.4.1.2 Machine Enclosures and Corresponding

NEMA orIEC Specifications

O

Desi,mtionSpecificationsDegree

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Enclosure Type

c. All theenclosure'sbolts,studs,and

other fastening

devices shall be made of corrosion-resistant materials. When

specified, AIS1300 series or IS0 3506 stainless steel shall be

used. Internal fastening devices shall use

locknuts, lock washers, locking plates, or tie wires.

d. The enclosure shall be designed to facilitate cleaning and

painting of the interior.

0

Enclosures and Corresponding

NEMA or IEC Specifications

b. Air deflectors shall be made of corrosion-resistant material

Cooling?

Protection1

NEMA

NEMA

Common

or shall have corrosion-resistant plating or treatment.

O

9

a. Designs in which the stator laminations form a partof the

enclosure or in which the stator laminations are

otherwise

exposed to external cooling

air are not acceptable.

b. Fan covers shall be made of castor nodular iron, cast steel,

cast aluminum, steel plate, or aluminum plate. Covers shall

have a minimum rigidity equivalent to that of steel plate with

a nominal thickness of 3.0 millimeters ( V g inch). Purchaserapprovedfiber-reinforcedmaterials may beused.Theair

intake opening shall be guarded by a gill or a metal screen

fastened on the outside of the

fan cover. Requirements for

grills or metal screensare covered in 2.4.10.5.

c. Sheet metal covers or wrappers used to form air passages

over the enclosure shall have a minimum rigidity equivalent

to that of steel plate with a nominal thickness of3.0 millimeters ( V 8 inch).

d.Totallyenclosedmachinesshallbeequippedwitha

plugged,threadeddrainconnectionlocatedatthelowest

point of the frame. This connection shall be shown on the outline drawing.

e.Requirementsforair-to-airheatexchangertubesarein

2.4.10.8.

f. Where an enclosure make-upair intake is requiredfor sup

plying pressurized air to the bearing seals, the intake shallbe

provided with filters suitable for the site data given on the

Data Sheets.

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

API STANDARD

546

10

for drain holes. A level alarm towarn of cooler leakage shall

be provided.

0 g. A flow-sensing device shall be provided for mounting in

the water supply piping to each cooler. When specified, this

device shall have a local indicator calibrated in gallons per

minute, as well as switches activated by low and high flow.

The high-flow switch shall be used to activate an alarm. The

2.4.1 2.4 Totally enclosed water-air-cooled machines shall

low-flow switch shallbe supplied with the machine manufacmeet the following criteria:

turer’s recommended setting, below which the machine will

a. Cooling water systems shall be designed for the following

overheat and winding damage will result within 15 minutes

conditions unless the vendor notifiesthe purchaser that conof the low-flow occuirence.

flict will arise affecting performance, sizelcost and integrity

0 h. When specified, air temperature sensors shall be provided

of the cooler. The purchaser shall approve the final selection. to sense air temperature into and ofout

the coolers.

i.

Requirements

for

heat

exchanger

tubes

are in 2.4.10.8.

Velocity

over heat exchange

surfaces

1S-2.5 mk

(5-8

[ESPI

Maximum

allowable

working

pressure

5 bar (ga)

(275 psig)

g. Machines for Div. 1 or Zone 1 locations shall be certified

for that location, or arranged for purging and pressurizing

with clean, dry air or inert gas as per the requirements of

NFPA 496 or IEC 79- 13. Alternatively, totally enclosed pipe

ventilated (TEPV) construction suitable for the installation

shall be used. [ESP]

O

Test pressure (minimumof 1.5 times t h e

maximumallowableworkingpressure)

7.9 bar (ga)

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

Maximum pressure drop

Maximum inlet temperature

Maximum outlet temperature

Maximum temperaturerise

Minimum temperature rise

Fouling factor on water

side

2.4.2FRAMEANDMOUNTINGPLATES

(2115 psig)

I bar

I5 psig

90°F

32T

1

49°C

20°F

17OC

30°F

11°C

20OF

0.35mz-KkW 0.002hr-ftLOF/Btu

2.4.2.1 Theframeshall beof castornodulariron,cast

steel, or welded steel plate construction with removable end

bells or end plates to permit removal

of the rotor and facilitate

replacementofstatorcoils.Theframeofthecompletely

assembledmachineonitspermanentfoundation,withthe

rotor installed and rotatingon its oil film, shall be free from

smctural resonance within55 percent of the electric line frequency and the following frequency ranges:

Note: The criterion for velocity over the exchange surfaces is intended to

minimize water-side fouling; the criterion for minimum temperature rise is

intended to minimize the use of cooling water.

b. When specified, machines shall be provided with multiple

coolers to allow one coolerto be removed from service without reducing the continuous operating capability.

0 c. The location of the cooler, orientation of the water box

inletandoutlet,materialsandconstruction

of thecooler,

cleaning requirements, and means of leak detection shall be

Leak

developedjointly by thepurchaserandthevendor.

detectors shall be provided to sense tube leakage. For double

tube coolers, these detectors shall sense inner tube leakage

and when specified, outer tube leakage.

d. Cooler designs shallbe of the water-tube type (water in the

tubes). U-tube constructionis not permitted. The construction

of the water box and header shall be such that leaking tubes O

can be readily plugged and all tubesare accessible for cleaning.

O e. The machine’s interior shall be baffled or otherwise constructed to prevent cooler-tubeleakagefromstrikingthe

windingsdirectly.Whenspecified,coolersmountedabove

the windings shall be of double-tube construction, requiring

no further baffling.Alternatively,single-tube,top-mounted

coolers with proper baffling approved by the purchaser may

be used where experience has proved this construction to be

adequate.Pedestal-mountedcoolersorcoolersmounted

underneath the winding may be of single-tube construction.

Cooler materials shallbe compatible with the water supply.

f. The machine shall be constructed so that cooler leakage

will collect and drain before reaching the level of the windings. In pressurized enclosures,a liquid seal shallbe provided

O

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

N =n

N

,k 0.20N0,

Where:

N = frequency range, in hertz.

No,,= operating speed frequency,in hertz.

n = 1,2, and 3. [ESP]

Note: Transfer of vibration from surrounding equipment

is avoided by proper

layout of the foundation, which is the responsibility of the purchaser. After

the machine is erected, the n a t d frequency of the foundation must differ by

at least S O percent fromone and two times the running-speed fiequency and

by at least &20 percent from one and two times the electric line frequency.

[ESPI

2.4.22 The stress values used in the design of

the frame

shall not exceed the maximum allowable stress criteria specified in Section VIII, Division I, of the ASME Code or IS0

10721 for the material used. The conditions evaluated shall

haninclude short circuits, out-of-phase synchronism, thrusts,

dling, and specified seismic loading. [ESP]

2.4.2.3 The h e includingtransitionbase,

if supplied

with the machine, and the bearing supports shallbe designed

to have sufficient strength and rigidity

to limit changes of

alignment caused by the worst combination of torque reaction, conduit and pipingstress, magnetic imbalance, and thermal distortion to 0.05 millimeter (0.002 inch) at the coupling

flange. (Thisis not to be confused with the normal repeatable

thermalgrowthbetweenambientandoperatingtemperatures.) [ESP]

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

S T D - A P I / P E T R O STD Sqb-ENGL L997:a

BRUSHLESSSYNCHRONOUS

MACHINES-500

0732290 OSb74Y7 TbA

KVA AND LARGER

11

2.4.2.4 Frames on

horizontal

machines

shall

be

rigid

enough to permit the machine to be moved by the use of the

[ESP]

lateral, axial, and vertical jackscrews.

The epoxy primer shall be compatible with epoxy grout.

The

purchaser shall submitto the vendor the specificationsfor the

epoxy primer. [ESP]

2.4.2.5 Horizontalmachinesshallbeequippedwithvertito facilitate alignment. If

cal jackscrews appropriately located

size and weight prohibit the use of jackscrews, other provisions shall be made for vertical

jacking. [ESP]

2.4.2.7.5 Anchorboltsshallnotbeused

machine to the mounting plates.[ESP]

O

2.4.2.6 Whenspecified,themachine

with soleplatesor a baseplate.[ESP]

2.4.2.7 The term mounting plate refers

and soleplates. [ESP]

2.4.2.7.6 Mounting plates that are to be grouted shall have

50-millimeter-radiused (Zinch radiused) outside comers (in

the plan view). Mounting surfaces that are not to be grouted

[ESP]

shall be coated with a rust preventative.

shall befurnished

to both baseplates

2.4.2.7.7 Mounting plates shall be designed to extend at

least 25 millimeters (1 inch) beyond the outer sides of the

machine feet. [ESP]

2.4.2.7.1 Mountingplatesshallbeequippedwithvertical

jackbolts to permit leveling of the mounting plates.

[ESP]

a. For baseplates, a minimum 16 millimeter( V 8 inch) diameter jackbolt hole shall be located 100 millimeters (4 inches)

from each anchor bolt hole along the same centerline as the

anchor bolt holes.

b. For soleplates, a minimumof 4 jackbolt holes shall be supbe designed for a minimum of 16 milplied. These holes shall

limeter ( V 8 inch) jackbolt and shall be located in each comer

of the soleplate. In addition, for soleplates longer than 0.9

meters (3 feet) two additional jackbolt holes shall be instalied

in the soleplateat midspan with theircenterlines similar to the

comer jackbolt holes.Soleplates1.8meters

(6 feet)and

0.9 meters (3 feet)

longer shallhaveamaximumspanof

between jackbolt holes on each side of the

soleplate.All jackbolt holes shall be located a minimum of 100 millimeters (4

inches) from the anchor bolt holes.

c. Jackbolt holes shall be drilled and tapped a length equal

to

the diameter of the jackbolt. The soleplate shall be counterboredatthe

jackbolt holelocations to adiameterlarge

enough to allow the use of a socket drive over the head of the

jackbolt. The depth of the counterbore shall be equal to the

thickness of the soleplate minus the diameter of the jackbolt.

2.4.2.7.3 When centerline supports are provided, they shall

be designed and manufactured to permit the machine to be

moved by using the horizontal jackscrews.[ESP]

0

2.4.2.7.4 When epoxy grout is specified on the data sheets,

the vendor shall commercially sandblast, in accordance with

SSPC SP 6 or IS0 8501,allthe grouting surfaces ofthe

mountingplatesandshallprecoatthesesurfaceswitha

catalyzedepoxyprimerappliedtodegreasedwhitemetal.

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

2.4.2.7.8 The vendor of the mounting plates shall

furnish

AIS1 300 or IS0 3506 series stainless steel shim packs at

least 3.0 millimeters (I/* inch) thick between the machinefeet

andthemountingplates.Allshimpacksshall

straddle the

hold-down bolts. [ESP]

2.4.2.7.9

[ESPI

Anchor bolts will be furnished by the purchaser.

2.4.2.7.10 Fasteners for attaching thecomponents to the

mounting plates and jackbolts for leveling thesoleplatesshall

be supplied by the vendor. [ESP]

2.4.2.7.11 The horizontal and vertical jack bolts shall be

16 millimeter M16 I S 0 68 (Vs inch minimum diameter with

UNC threads). [ESP]

2.4.2.8 Frame mounting surfaces on a horizontal machine

shall be machined on a common plane parallel to a horizontal

plane through the theoretical centerline. The mounting surfaces shall be machined within 0.13 millimeter (0.005 inch)

of a plane through the lowest foot, and each foot shall be parallel to that plane, in the transverse or longitudinal direction,

within 0.17 millimeter per meter (0.002 inch per foot). The

upper and lower surfaces of bearing pedestals and mounting

plates shall be machined parallel. [ESP]

2.4.2.9 The mounting surface on a vertical motor shall be

machined perpendicular to themotor’s centerline, and this

surface shall not deviate from that perpendicular plane

by

more than 0.17 millimeter per meter (0.002 inch per foot).

[ESPI

2.4.2.1 O The machined finish of the mounting surface

shall

notexceed 6.4 micrometers (250 microinches)arithmetic

Hold-down or foundation bolt holes

average roughness (R).

shall be drilled perpendicular to the mounting surfaceor surfaces and, when the machinedsurface is a castor other unmachined, uneven surface, spot-faced to a diameter three times

that of the hole diameter. [ESP]

--`,,,`,``,```,,,,,```,`,,,```,`-`-`,,`,,`,`,,`---

2.4.2.7.2 To assist in machinepositioning,themounting

plates shallbefurnishedwithhorizontal

jackbolts (for

machine movement in the horizontal plane) the same size as

or larger than the vertical jackbolts. The lugs holding these

jackscrews shall be attached to the mounting plates so that

they do not interfere with the installation or removal of the

drive element and the installation or removal of shims used

for alignment. [ESP]

to fasten the

2.4.2.11 Theframesupport or supportsshallbeprovided

with two pilot holesfor dowels. The holes shall be

as near the

Licensee=ExxonMobil/1890500101

Not for Resale, 08/01/2008 03:59:01 MDT

vertical as is possible and shallbe located to provide adequate

space for field drilling, reaming, and placement of dowels.

Unlessotherwisespecified,onlythesupportsormounting

feet onthe drive end of horizontal machines shall

be doweled.

Vertical machines shall havea rabbeted fit to the base and two

dowels. [ESP]

2.4.2.12 Alignmentdowelsorrabbeted fits shall be provided to facilitate disassembly and reassemblyof end bells or

plates, bearing-housing mounting plates, and bearing housings. When jackscrews are used as a means of parting contactingfaces,one

of thefacesshall

be counterbored or

recessed to prevent a leaking joint or an improper fit caused

by marring of the face. [ESP]

2.4.3.3.1 The details of threading shall conform to ASME

B1.l or IS0 68 and IS0 261. [MSP]

2.4.3.3.2 Cap screws

shall

be supplied

on

all

frame

connections except oil piping, unless studs

are specifically

approved by the purchaser. [MSP]

2.4.3.3.3 Adequate clearance shall be provided at bolting

locations to permit the use of socket box

or wrenches. [MSP]

2.4.3.4 Openings for pipingconnections,exceptbearing

oil inlet lines, shallbe at least 20 millimeters (3/4 inch) nominal pipesize. All pipeconnectionsshall

be flangedor

machined and studded. Where flanged

or machined and studin sizes

dedopeningsareimpractical,threadedopenings

through

40

millimeters

(1

inches)

nominal

pipe

size,

shall

2.4.2.13 Whentapereddowelpinsareprovidedbythe

vendor, the top end

of the dowel shall have an undercut shank be fitted in accordance with 2.4.3.4.1 through 2.4.3.4.3 unless

otherwise specified. [MSP]

threaded to the nominal diameter nearest the dowel’s outside

diameter. Thefirst two threads shallbe machined off, and the

2.4.3.4.1 A pipenipple,preferablynotmorethan

150

shank shall be beveled to prevent damage when the pin

is

millimeters

(6

inches)

long,

shall

be screwedintothe

driven. A hex nut shall be provided with each pin. [ESP]

threaded opening.

O 2.4.2.14 Liftinglugs,throughholes,

or eyeboltsshall be

2.4.3.4.2 Pipe nipples shallbe a minimum of Schedule 80.

providedforliftingmajorcomponentsandtheassembled

machine. Any special mechanisms for lifting major compo2.4.3.4.3 Tappedopeflingsandbosses

for pipethreads

nentsand the assembledmachineshall be supplied in the

ASME B 16.5 or IS0 7005.

shall conform to

quantities shown on thedata sheets. [ESP]

2.4.3.5 Pipingflangesshallconform

to ASME B16.2 or

2.4.2.15 Allfabricatedweldedstructuralsteelshallbe

IS0 7483 or IS0 9691 or B16.5 as applicable, exceptas specpost-weld stress relieved. This does not apply to sheet metal

ified in 2.4.3.5.1 and 2.4.3.5.2.

components. [ESP]