- Ninguna Categoria

Heavy Lift Installation of Offshore Structures Thesis

Anuncio

HEAVY LIFT INSTALLATION STUDY

OF

OFFSHORE STRUCTURES

LI LIANG

(MS. Eng, NUS)

A THESIS SUBMITTED

FOR THE DEGREE OF MASTER OF ENGINEERING

DEPARTMENT OF CIVIL ENGINEERING

NATIOANL UNIVERSITY OF SINGAPORE

2004

HEAVY LIFT INSTALLATION STUDY

OF

OFFSHORE STRUCTURES

LI LIANG

(MS. Eng, NUS)

A THESIS SUBMITTED

FOR THE DEGREE OF MASTER OF ENGINEERING

DEPARTMENT OF CIVIL ENGINEERING

NATIOANL UNIVERSITY OF SINGAPORE

ii

ACKNOWLEDGMENTS

The author would like to express his sincere appreciation to his supervisor Associate

Professor Choo Yoo Sang. The author is deeply indebted to his most valuable guidance,

constructive criticism and kind understanding. Appreciation is extended to Associate

Professor Richard Liew and Dr. Ju Feng for their assistance and encouragement.

In addition, the author would like to thank the National University of Singapore for

offering the opportunity for this research project.

Finally, the author is grateful to his family, the one he loves, and all his friends, whose

encouragement, love and friendship have always been the major motivation for his study.

TABLE OF CONTENTS

CHAPTER 1

1.1

1.2

1.3

INTRODUCTION ...................................................................................... 1

Background

Objectives and Scope of Present Study

Organisation of Thesis

CHAPTER 2

2.1

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.3

REVIEW OF LIFTING DESIGN CRITERIA .......................................... 10

Review of Various Lifting Criteria

Practical Considerations for Standard Rigging Design

Sling Design Loads (SDL)

Shackle Design Loads

Lift Point Design Loads

Shackle Sizing

Tilt during Lifting

COG Shift Factor

Summary

CHAPTER 3

3.1

3.2

3.2.1

3.2.2

3.3

3.4

3.4.1

3.4.2

3.4.3

3.5

3.6

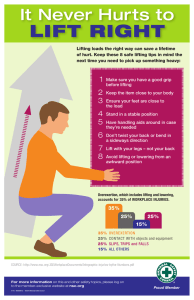

HEAVY LIFTING EQUIPMENT AND COMPONENTS....................... 24

Introduction

Heavy Lift Cranes

Crane Vessel Types

Frequently Used Crane Vessels

Heavy Lift Shackles

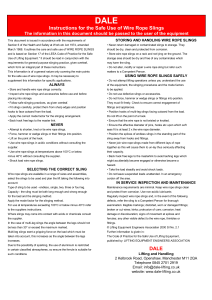

Heavy Lift Slings

Sling properties

Grommets versus Slings

Sling and Grommet Properties

Lift Points

Summary

CHAPTER 4

4.1

4.2

4.2.1

4.2.2

4.2.3

4.3

4.3.1

4.3.2

4.4

4.4.1

4.4.2

4.5

RIGGING THEORY AND FORMULATION ......................................... 57

Introduction

Rigging Sling System with Four Lift Points

Using Main or Jib Hook without Spreader Structure

Using Main or Jib Hook with Spreader Structure

Using Main and Jib Hooks at the Same Time

Rigging Sling System with Six Lift Points

Using Main or Jib Hook with Spreader Frame

Using Main and Jib Hooks without Spreader Structure

Rigging Sling System with Eight Lift Points

Using Main or Jib Hook with/without Spreader Structure

Using Main and Jib Hooks without Spreader Structure

Summary

i

CHAPTER 5

5.1

5.2

5.3

5.4

JACKET LIFTING.................................................................................... 78

Introduction

Vertical Lift of Jackets

Horizontal Lift of Jackets

Summary

CHAPTER 6

6.1

6.2

6.3

6.4

MODULE LIFTING.................................................................................. 88

Introduction

Vertical Module Lift and Installation

Deck Panel Flip-Over

Summary

CHAPTER 7

7.1

7.2

7.3

7.4

7.5

7.6

7.7

FPSO STRUCTURE LIFTING............................................................... 102

Introduction

Lift Procedures and Considerations for FPSO Modules

Rigging Systems with Multiple Spreader Bars

Lifting of Lower Turret

Lifting of Gas Recompression Module

Lifting of Flare Tower

Summary

CHAPTER 8

8.1

8.2

8.3

8.4

8.5

8.6

SPECIAL LIFTING FRAME DESIGN .................................................. 121

General Discussion

Effect of the Shift of the Centre of Gravity

Lift Point Forces

Padeye Checking

Trunnion Checking

Summary

CHAPTER 9 FINITE ELEMET ANALYSIS FOR LIFTING DESIGN ....................... 139

9.1

Introduction

9.2

Finite Element Analysis for Module Lifts

9.2.1 Structural and Material Details

9.2.2 Finite Element Modelling and Analysis

9.2.3 Discussions

9.3

Finite Element Analysis for Lifting Padeye Connection

9.3.1 Structural Details

9.3.2 Loading Cases

9.3.3 Finite Element Modelling

9.3.4 Result Analysis

9.4

Summary

CHAPTER 10 CONCLUSIONS AND FUTURE WORKS.......................................... 170

10.1

Conclusions

10.2

Recommendation for Future Work

BIOBLIOGRAPHY ....................................................................................................... 174

APPENDIX A FEM ANALYSIS FOR JACKET UPENDING PADEYE .................... 181

ii

Summary

Successful lift installations of heavy offshore structures require comprehensive and

detailed studies involving many engineering and geometrical constraints including

geometric configuration of the structure, its weight and centre of gravity, member

strength, rigging details, lifting crane vessel and other construction constraints. These

constraints need to be resolved efficiently in order to arrive at a cost-effective solution.

This thesis summarises the results of detailed investigations by the author involving

actual offshore engineering projects. The thesis first reviews the lift criteria adopted in

the offshore industry. The key practical considerations for selection of appropriate

crane barges, rigging components are discussed. The algorithms and formulations for

rigging systems with various number of lift points are then presented.

Practical considerations for module and jacket lifts are investigated. For deck panel

flip-over operation, the force distribution between two hooks which varies with

changing module inclined angle, is calculated consistently. Lifting procedures and

rigging systems with multiple spreader bars for Floating Production Storage &

Offloading (FPSO) modules are also studied. Emphasis is given to the design and

analysis of lifting unique components to meet the stringent installation requirements.

The thesis is reports on a versatile spreader frame design which incorporates a

combination of padeye and lifting trunnions.

Detailed finite element modelling and

analysis are conducted to analyze the lifting module and padeye connection. It is found

that finite element analysis can provide important detailed stress distributions and

limits for safety verification of lift components.

iii

Nomenclature/Abbreviation

A

-

Cross Sectional Area

AISC -

American Institute Steel Construction

API

-

American Petroleum Institute

CoG

-

Centre of Gravity

CRBL -

Calculated Rope Breaking Load

CGBL -

Calculated Grommet Breaking Load

D

-

Pin Hole Diameter of Padeye

DAF

-

Dynamic Amplification Factors

DB

-

Derrick crane Barge

Dh

-

Pin Diameter of Shackle

DNV -

Det Norske Veritas

E

-

Modulus of elasticity of Steel

Eb

-

the sling bend efficiency (reduction) factor

Et

-

Efficiency of termination method

FEM -

Finite Element Method

FEA

Finite Element Analysis

-

FPSO -

Floating Production Storage and Offloading

Fb

-

Allowable bending stress

Ft

-

Allowable Tensile stress

Fy

-

Material Yield stress

Fu

-

Steel Tensile strength

Fv

-

Allowable shear Stress

G

-

Shear Modulus of elasticity of Steel

iv

H4

-

height of hook block above module (without spreader structure), or

height of spreader above module (with spreader)

H5

-

height of hook block above spreader (with spreader), or,

=0 (without spreader)

HSE

-

Health and Safety Executive

Ix, Iy -

Moment of Inertia

Lh

-

Inside Length of Shackle

Li

-

length of ith sling

MBL -

Minimum Breaking Load

MWS -

Marine Warranty Surveyor

Rai

-

ith Cheek plate Radius of Padeye

Rm

-

Main plate Radius of Padeye

SACS -

Structural Analysis Computer System

SDL

Sling Design Load

-

SSCVs -

Semi-Submersible Crane Vessels

Sx, Sy -

Sectional Modulars

SWL -

Safe Working Load

T

-

Static Sling Load

Tci

-

ith Cheek plate thichness of Padeye

Th

-

Crane Hook Load

Tm

-

Main plate thichness of Padeye

Wh

-

Jaw width of shackle

Wh, Lh -

the width and length of hook block

Wm, Lm, Hm - the width, length and height of module, respectively

Wsp, Lsp -

width and length of spreader

v

WLL -

Shackle Working Load Limit

d

-

Sling rope diameter

fb

-

Actual bending stress

fc

-

Actual Combined stress

fcog

-

COG shift factor

ft

-

Actual Tensile stress

fv

-

Actual shear Stress

xc, yc -

location of the centre of gravity of module in local coordinate system

θi

-

angle of sling with respect to the horizontal plane

τg

-

Punching strength

vi

List of Tables

Table 2.1

Lifting Criteria comparison - Single Crane Lift

Table 2.2

Lifting Criteria comparison - Double hook Lift

Table 2.3

Dynamic Amplification Factors

Table 3.1

Some of Heavy Lifting Crane Vessels in the World

Table 3.2

Shackle Side Loading Reduction

For Screw Pin and Safety Shackles Only

Table 4.1

Formulations for rigging configurations with four lift points

(using main or jib hook block without spreader)

Table 4.2

Formulations for rigging configurations with four lift points

(using main or jib hook block with spreader structure)

Table 4.3

Formulations for rigging configurations with four lift points

(using main and jib hook blocks at the same time )

Table 4.4

Formulations for rigging configurations with six lift points

(using main or jib hook block )

Table 4.5

Formulations for rigging configurations with six lift points

(using main and jib hook blocks at the same time)

Table 4.6

Formulations for the rigging configurations with eight lift points

(using main or jib hook block at a time )

Table 4.7

Formulations for rigging configurations with eight lift points

(using main and jib hook blocks at the same time )

Table 7.1

Lifting Operation Summary for Laminaria FPSO

Table 7.2

Contingency Actions Plan / Procedure

Table 7.3

Preparation Check List

Table 7.4

Loadout Check List

Table 7.5

Installation Check List

Table 8.1

Weight and COG data

Table 8.2

Total Weight and COG

vii

Table 8.3

Member Analysis Result Summary

Table 9.1

Load factor used for lifting analysis

Table 9.2

Design value of material parameter

Table 9.3

Sample of Member Group Properties

Table 9.4

Sample of SACS Section Properties

Table 9.5

Sample of SACS Plate Group Properties

Table 9.6

Sample of SACS Plate Stiffener Properties

Table 9.7

SACS Loading Summary

Table 9.8

Sample of SACS Loading ID and Description

Table 9.9

Type of Support Constraints and Member Releases

Table 9.10

SACS Load Combinations

Table 9.11

Sample of 75% Lifting Weight Factor

Table 9.12

SACS Combined Load Summation

Table 9.13

Support Reactions

Table 9.14

Spring Reaction

Table 9.15

Sample of SACS Member Stress Listing

Table 9.16

Joint Stress Ratio Listing

Table 9.17

Sling Force Summary

Table 9.18

Dimensions and length of each tubular member

Table 9.19

Maximum stress (MPa) of each case

Table 9.20

Maximum stress (MPa) for braces

Table A.1

Member forces coming out from SACS analysis

viii

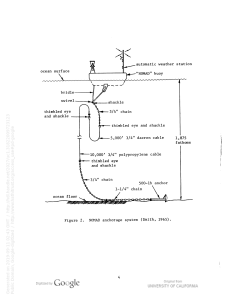

List of Figures

Figure 1.1

Thesis Organizations Vs Contents of Study

Figure 2.1

Centre of gravity (COG) shift

Figure 3.1

Lifting Equipment and Components

Figure 3.2

Saipem S7000 SSCV 14000 ton Capacity

Figure 3.3

Sheerleg Crane Vessel – Asian Hercules II : 3200 ton Capacity

Figure 3.4

Derrick Barge Crane – Thialf : 14200 ton Capacity

Figure 3.5

Derrick Lifting Barge DB101: 3150 ton Capacity

Figure 3.6

Samples of Some Shackles (Green Pin and Crosby)

Figure 3.7

Sling Forming & Cross Section

Figure 3.8

Sling Configuration

Figure 3.9

Actual usage of Slings

Figure 3.10

Lift point connections- Padeye and Trunnion

Figure 3.11

Fabricated Lifting Padeye

Figure 3.12

Actual fabricated Lifting Trunnion

Figure 3.13

Details of a Typical Padeye

Figure 4.1

Determination of rigging configuration: tasks, inputs and outputs

Figure 4.2

Rigging configuration for four-lift-point sling systems using main or jib hook block without spreader

Figure 4.3

Rigging configurations for four-lift-point sling systems using main or jib hook block and spreaders

Figure 4.4a

Rigging configuration for four-lift-point sling systems using main and jib hook blocks and spreader bars

Figure 4.4b

Hook load distribution for four-lift-point sling systems using both main and jib hook blocks

Figure 4.5a

Rigging configuration for six-lift-point sling system using main or jib hook block with spreader frame

ix

Figure 4.5b

Sling tensions for six-lift-point sling system using main or jib hook block with spreader frame

Figure 4.6a

Rigging configuration for six-lift-point sling system using both main and jib hook blocks

Figure 4.6b

Hook load distribution for six-lift-point sling systems using both main and jib hook blocks

Figure 4.7a

Rigging configuration for eight-lift-point sling system using main or jib hook block without spreader frame

Figure 4.7b

Rigging configuration for eight-lift-point sling system using main or jib hook block with two parallel spreader bars

Figure 4.7c

Rigging configuration for eight-lift-point sling system using main or jib hook block with spreader frame

Figure 4.8a

Rigging configuration for eight-lift-point sling system using both main and jib hook blocks

Figure 4.8b

Hook load distribution for eight-lift-point sling systems using both main and jib hook blocks

Figure 5.1

Vertical Lifting of Jacket

Figure 5.2a

Horizontal Lifting of Jacket

Loadout operation at Fabrication Yard (2800ton)

Figure 5.2b

Horizontal Lifting of Jacket

Dual Crane Lifting a Tripod Jacket (6200 ton)

Figure 5.2c

Horizontal Lifting of Jacket

Dual lift of a Jacket from transportation barge

Figure 5.3

ISO View of lifting horizontal Jacket (3150ton)

Figure 6.1

Deck Panel Stacking in progress

Figure 6.2

Computer Model for Deck Panel Flip-over

Figure 6.3

Deck Panel – 180 Degree Flip Over

Figure 6.4

Module Lifting – Four Sling Arrangement

Figure 6.5

Module Installation – One Lifting Bar Arrangement

Figure 6.6

Module Lifting – Two Bars System

Figure 6.7

Module Lifting – Three Bars System

x

Figure 6.8

Lifting with a spreader frame

Figure 6.9

Multi-Tier Rigging System

Figure 6.10

Tendem Lift of a Module

Figure 7.1

Rigging arrangement for lifting FPSO modules with spreader bars

Figure 7.2

Lifting of Lower Turret (680 ton)

Figure 7.3

Lifting of Upper Turret Manifold Deck Structure with Three Spreader Bars

Figure 7.4

Lifting of Upper Turret – Gantry Structure

Figure 7.5

Lifting of Swivel Stack – Bottom Assembly

Figure 7.6

Lifting of Gas Recompression Module

Figure 7.7

Upending and Lifting of 92-metre Flare Tower

Figure 8.1

Lifting Frame Details

Figure 9.1

Computer Lifting Model Plot

Figure 9.2

COG Shift of Module during Lifting

Figure 9.3

Jacket Loadout arrangement

Figure 9.4

Upending process of Jacket

Figure 9.5

Jacket positions for the four load cases

Figure 9.6

Configuration of Joint 164

Figure 9.7

Boundary conditions for the FE model

Figure 9.8

Finite element mesh

Figure 9.9

1st-principal stress contour of load case D

Figure 9.10

Local view of Von Mises stress contour of load case D

xi

Figure A.1

Load conditions

Figure A.2

Stress distribution for the braces of load case A

Figure A.3

Stress distribution for the braces of load case B

Figure A.4

Stress distribution for the braces of load case C

Figure A.5

Stress distribution for the braces of load case D

xii

CHAPTER 1

1.1

INTRODUCTION

Background

Heavy lifts are frequently carried out during the fabrication and/or installation of major

offshore components and structures, such as welded girder beams, tubular columns,

deck panels, sub-assemblies, flares, bridges and completed jackets / modules. Without

heavy lifting equipment, offshore steel platforms cannot be built effectively.

For an offshore platform, the issue of final installation of the completed jacket /

topside is considered as early as the conceptual study stage. The major determining

factor is availability of heavy lift crane vessel around the region. Heavier structures

can be fabricated if a lager crane vessel is selected for the project. Many topside

structures are split into several modules instead of an integrated deck structure due to

non-availability of sufficient lifting capacity of heavy offshore crane barge in the

region or at required time window schedule.

Offshore hook-up and commissioning costs are very high as compared to those for the

same work performed onshore. This has led to the fabrication of very large modules,

where the intention is to minimize hook-up associated with connecting modules

together offshore.

The great advancement of offshore technology during the last 30 years was largely due

to the development of very heavy lift equipment. Thirty years ago, a 1000 ton module

would be considered a very heavy lift, while the biggest crane barge in the world at

that time could hardly lift 2000 tons at the required lifting radius. In South East Asia,

the biggest crane barge available in the region at the time was only around 600 tons.

1

Nowadays, a semi-submersible derrick barge can lift a structure up to 12,000 tons.

In the recent past, a 10,000 ton jacket in the North Sea would have to be launched.

Using present day equipment, the same jacket can now be lift-installed by a semisubmersible crane barge which has two cranes. In most cases, lift-installed jacket is

more cost-effective. In South East Asia, jackets and decks are getting larger and

heavier, with the largest jacket to-date around 10,000 tons and the largest deck around

11,500 tons. Single lift installation can be a very attractive cost alternative. For

platform decommissioning or removal, it may be possible to use a crane barge to pick

up the old deck and old jacket. It may be appropriate to mention that the Offshore

Industry would not have developed to what it is today without all the heavy lift

equipment developed over the last 30 years.

For fabrication of offshore structures, the method which was first developed in the

United States more than 40 year ago is quite different from other industries. Offshore

structures are usually first fabricated in small units. After fabrication, these will be

moved to an open area for assembly. Offshore contractors tend to do as much work as

possible on the ground to minimize work in the air. This method is productivity driven.

In fabrication, one can do a much better and faster job on the ground and in a weather

protected workshop. This fabrication technique means that there are a lot of heavy

lifting operations in the yard as compared to typical onshore building construction.

Before all the sub-units are assembled, these may need to go through many lifting

operations, such as, roll up, stacking, flipping, etc. Each lift by itself could be more

than one thousand tons. In this type of fabrication technique, there are a lot of

2

opportunities for errors. Safety and accident prevention should thus be considered in

the design stage.

For offshore installation, major cost savings can be achieved if the structure can be

installed in one piece. For integration of topside modules, it can save significant

offshore hook-up time. For jacket, the cost of fabricating launch trusses can be

eliminated. A heavier lift requires a larger crane barge. It is a very high premium to

pay for the rental of a big derrick barge, especially if none is available in the area and it

has to be mobilized from elsewhere. A large capacity crane is an expensive equipment

and crane usage is normally considered as part of the overhead cost for fabrication

yards. Usually the cost is included in the fabrication tonnage rate. It will normally

involve fewer people to operate a crane onshore. For offshore installation, a crane

barge usually has only one big crane, except for larger semi-submersible derrick

barges which can accommodate two cranes side-by-side. When a derrick crane barge is

mobilized for an offshore installation project which includes hook-up and

commissioning, it will have 200 to 300 workers/engineers on board. The cost is

extremely high. Some of the semi-submersible derrick barges have accommodation

capacity for more than 700 men. In addition, the client will also need to pay for

mobilization and demobilization costs. Depending on location, these costs could be

millions of dollars. To design a structure to suit the installation contractor is certainly

an excellent way to minimise cost.

For a typical project, the offshore portion accounts for around 30% of the total project

cost. The question that comes to everyone's mind is how to reduce this number and be

more competitive. One of the solutions is to reduce offshore hook-up time. This means

3

that one should make the lift of a structure as heavy as possible and with few lifts as

necessary. However, one should be extremely careful in interpreting this statement.

The project may not be cheap if one has to mobilize a big derrick barge from far away

supply base. It could also be expensive if it requires two barges to do the lift and the

other barge has to be mobilized from elsewhere. Making a single heavy lift to

minimize hook up time or to eliminate the launch trusses is an excellent idea provided

we have the right equipment at a reasonable price and at the right time.

For FPSO module installation, there are normally 20 to 30 heavy lifts. The need to

design a common rigging system to suit different configurations, weights and centres

of gravity is a challenge to all designers. Since it is usually impossible to have a

common rigging system for all lifts, the designer needs to minimize the number of

rigging changes to reduce the schedule associated with heavy lifts for the planned

installation sequence.

4

1.2

Objectives and Scope of Present Study

As indicated in Section 1.1, heavy lifts in major offshore projects are required to be

conducted safely and cost-effectively. It is always a challenge for a structural design

engineer to produce an optimized design for both the lifted structure and lifting rigging

system for use with the selected crane barge that will lead to cost savings. The author

has been involved in some major offshore projects which required considerations for

alternative designs and detailed analysis for different structural schemes for heavy lift.

The author is thus motivated to investigate the inter-related engineering and fabrication

issues and to document the findings in this thesis.

The two key objectives of the research study are:

•

Investigate lifting schemes which can provide cost-effective solutions and safe

operations for heavy lift installation of structures, and

•

Evaluate selected rigging systems with different spreader and lift point

arrangements to provide guidelines for heavy lift design.

The scope of the present study can be summarized as follows:

•

To study the current design codes for lift design and highlight key

considerations for heavy lift;

•

To evaluate heavy lift rigging systems which involve different crane barges and

lifted structures with associated spreader arrangement and consistent lift point

combinations. Practical issues involved in actual projects, especially for lift

installation of jackets, offshore decks and modules for FPSO (Floating

Production Storage and Offloading) vessel will be investigated.

•

To investigate global structural responses of lifted structures and detailed stress

5

conditions of the lift point through finite element analyses.

•

To document the findings on heavy lift in the thesis for future reference by

designers and engineers.

6

1.3

Organisation of Thesis

Figure 1.1 summarises the organisation and contents of the thesis.

Following the introduction, Chapter 1 and Chapter 2 provide a thorough review and

discussion of current design codes and standards used in heavy lift. The discussion

covers the codes and recommendations from API - RP2A (2000), DNV Marine

Operations Part 2 - Recommended Practice RP5 Lifting (1996), Phillips Petroleum

(1989), Heerema (1991), Noble Denton & Associates (NDA) (1996), Health and

Safety Executive (HSE) (1992) and Shell (1990).

Lifting equipment and components, including details on crane vessel/barge, slings,

shackles and lift points are discussed in Chapter 3. Lift points are the locations where

large sling tensions are transmitted to the lifted module structure. Lift points should be

properly selected to allow sling tensions to smoothly transfer to strong structural

members. Two common types of lift points which connect rigging systems to module

structures are padeyes and trunnions. With appropriate factored sling tensions, slings

and shackles can be selected from available sling and shackle lists (inventories) or

ordered from suppliers. It has always been the focus of the design codes to provide

consistent safety factors for the lift components within a rigging system for heavy lift.

An appropriate rigging system includes available lift points (strong points in the

module structure), available slings in inventory, spreader structure (bar or frame) and

hook block(s) of the crane barge. In actual rigging arrangement, the sling system can

involve four, six, eight or more lift points, and spreader bar or frame may be used to

7

protect the module from significant compressive forces or possible damage. Chapter 4

summarises the investigation into the algorithms and formulations to determine the

configurations of rigging sling systems, which are affected by the location of lift

points, length of slings and geometry of spreader and hook block. The hook block(s)

involved in a particular rigging system can be one (main or jib hook) or two (both

main and jib) at a time. Emphasis is placed on the determination of the critical

geometrical quantities of the rigging system including the sling angles with respect to

the horizontal plane and the distances between the module, spreader structure and hook

blocks. This chapter also serves as a theoretical basis of the following three chapters

which focus on practical issues in lift design of real projects, of which author was

involved as project manager or engineer.

Chapters 5, 6, and 7 discuss the practical considerations in lift design and operations

for jacket, modules and modules for FPSO (Floating Production Storage and

Offloading). A special design for a lifting frame is proposed and analyzed in Chapter

8.

Finite Element Analysis (FEA) is widely accepted in almost all engineering

disciplines. A finite element model can represent and analyse a detailed structural

component with greater precision than conventional simplified hand calculations. This

is because the actual shape, load and constraints, as well as material property can be

specified with much greater accuracy than that used in hand calculations. Chapter 9

discusses finite element approaches in heavy lift design and analysis. Two important

lift applications, for living quarter module lifting and padeye connection for heavy lift,

are investigated and reported in this chapter.

8

Finally, conclusions and general discussions are given in Chapter 10.

Evaluation of Design

Criteria

Equipment Selection and

Component Design

Rigging Theory and

Formulations

(Chapter 2)

(Chapter 3)

(Chapter 4)

Theory and Knowledge

Structures

to Be Lifted

Rigging System

Lift Points

Lift Operation

Scopes for Design and Analysis

Jacket Lifting

Lifting Frame Design

(Chapter 5)

(Chapter 8)

Module Lifting

(Chapter 6)

FEM Analysis for Lifting System

(Chapter 9)

FPSO Structure Lifting

(Chapter 7)

Applications

Figure 1.1

Special Case

Considerations

Thesis organization and contents of the thesis

9

CHAPTER 2

2.1

LIFTING CRITERIA

Review of Various Lifting Criteria

There are several lifting criteria and specifications written specifically for offshore

heavy lift, including API-RP2A (2000), DNV Marine Operation Part 2 Recommended

Practice RP5 (1996), Phillips Petroleum (1989), Heerema (1991), Noble Denton &

Associates (NDA) (1996), Health and Safety Executive UK (HSE) (1992) and Shell

(1990). Amongst these criteria, some of these are either not updated or strictly for inhouse use. Only the API, DNV and HSE codes are easily available to the general

public. The API codes are the oldest and the most well established in the Offshore

Industry. The HSE recommendation deals with cable laid slings and grommets in

detail, but it does not address other lifting system or factors such as dynamic

amplification, weight growth, etc. This recommendation should be used in conjunction

with other codes. The DNV code is the most comprehensive and is widely used in the

North Sea.

For South-East Asia, the most commonly accepted criterion is still the API-RP2A

(2000) with a number of modifications to cater for weight inaccuracy etc. The original

lifting criterion in the API RP2A (2000) was written mostly by engineers working in

the Gulf of Mexico. The document was intended for those lifts performed in the area.

Over the years, the code expanded and received acceptance as a worldwide standard.

Although these criteria are written primarily for offshore lift, they can also be adopted

for onshore lift with minor modifications. In fact, this has been done for many years.

10

During the performance of the lift, there will be dynamic loads induced by the action

of the waves on the crane vessel and the cargo barge. These loads are conventionally

allowed for by the application of Dynamic Amplification Factors (DAF) to the static

load in the hooks and slings. Typical value of DAF, as used at present in relation to

Semi-Submersible Crane Vessels (SSCVs), is about 1.10 for slings in offshore

operations. This will be in addition to any quasi-static changes in the hook and sling

loads associated with the load transfer.

A second category of dynamic loads exists. This is associated with the action of

slewing the crane or of starting or stopping the hook as it is being raised or lowered.

These loads are normally allowed for in the specification of the safe working load

(SWL) of the crane. It should be recognized that the skill of the crane operator can

have a significant effect in reducing these forces. Also, but to a lesser extent, his

expertise will help to prevent the build-up of dynamic oscillations induced by the

waves.

Some extensive analyses of the dynamics of the lift have been carried out by using

SSCVs. In most cases, actual SSCV /module/ cargo barge combinations and rigging

geometries with predicted COG (Centre of Gravity) positions have been used. The

dynamic analyses drew attention to a number of interesting results as follows:

•

It was found that increasing the barge draught tended to decrease the DAF in

short period sea states.

11

•

When the module was on the barge with the slings tensioned, there was a

spread of natural periods from 3-8 s. Hence, there were both significant

dynamic effects and considerable scatter in the results.

•

The DAFs were generally worse in beam seas (i.e., beam onto the barge).

•

The DAFs were less for the heavier modules.

•

The sling load DAFs were in general larger than the hook load DAFs.

•

The DAFs were quite low, while the module was freely suspended. There

would be some advantage in picking a module off the crane vessel's own deck

rather than off a cargo barge.

The distinction between beam and head sea DAF was sufficiently marked to allow

recommended DAFs for head seas to be significantly less than for beam seas.

12

2.2

Practical Considerations for Standard Rigging Design

This section discusses the design requirements for the selection and design of heavy

lift rigging as given by Shell.

2.2.1. Sling Design Loads (SDL)

Standard 4 point Lifts for the Jacket or Deck

The sling design load (SDL) is based on the factored lift weight, with the individual

sling loads being determined from DNV Marine Operation, Part 2 Recommended

Practice RP5 Lifting. The procedure to be used is summarized below:

a)

Distribute the lift weight to the lifting points, adopting the factored lift weight

based on the factors presented in the weight control engineering.

b)

Increase each individual lifting point load by 10% to account for inaccuracy in

the calculation of the centre of gravity.

c)

Further increase each individual lifting point load to account for the Dynamic

Amplification Factors given in “Cable Laid and grommets” Guidance Note PM

20, Health and Safety Executive - see Table 2.3.

d)

Further increase each individual lifting point load by the skew load distribution

factor of 1.25 as recommended in DNV RP5, which primarily accounts for

different sling stiffness and lengths than theoretically assumed.

13

e)

Calculate the sling load accounting for the angle the sling makes with the

horizontal, including allowance for component tilt. This sling angle should not

be below 55° at any point for level lifts.

As an example, the SDL for a 500 tonne (factored) lift, evenly distributed to 4 points,

offshore, with a 60° sling angle would be:

SDL =

500 × 1.1 × 1.2 × 1.25

= 238.2 tonnes

4 × sin 60°

(2.1)

2.2.2 Shackle Design Loads

These loads may be calculated as for the slings, but can be decreased by the sling

factored weight above the shackle point.

2.2.3 Lift Point Design Loads

This is primarily to determine adequate rigging sizes. For the design of the structure

and lift points (padeyes), design loads should be based on the structural analysis

requirements.

SDL is used to determine the sling, or grommet size. The governing design criteria is

given in HSE, which sets out the basis for the design criteria listed below and has been

developed for heavy lift slings of diameter 100mm and above, where the rope is not

usually tested to destruction, and which would normally be required for deck, module

and jacket lifts.

14

Individual Slings (Single Slings)

a)

At the sling eye,

Minimum Calculated Rope Breaking Load,

SDL × 2 .25 × 0 .55

Eb

CRBL =

(2.2)

Note: the 0.55 factor allows for uneven distribution of the sling load to each leg of the sling

eye due to friction.

CRBL = the sum of the individual minimum breaking loads of the core and outer unit

ropes of the sling multiplied by a 0.85 spinning loss factor (HSE).

Eb

= the sling bend efficiency (reduction) factor

= 1- 0 . 5

(2.2a)

( D/d ) 0 . 5

D = minimum diameter around which the sling is bent

d = cable laid rope diameter

Note: D should preferably always exceed d to avoid sling load de-rating.

b) At the sling termination,

Minimum CRBL =

SDL ×2 . 25

Et

(2.3)

Where, Et = Efficiency of termination method = 0.75 for hand splices, 0.95 for

mechanical, or swaged splices and 1.0 for resin poured sockets.

Doubled slings

Where slings are doubled around the shackle and/or the lifting hook of the crane,

effectively halving the sling length, the equations given in a), b), are modified as

follows:

15

c) At the sling eye,

Minimum CRBL =

SDL × 2 . 25 × 0 . 55

Eb

(2.4)

SDL × 2 . 25 × 0 . 55

Et

(2.5)

SDL × 2 . 25 × 0 . 55

Et

(2.6)

d) At the sling termination,

Minimum CRBL =

e) At the sling bend,

Minimum CRBL =

Individual Grommets

Grommets sling may be sized as follows:

f) Minimum Calculated Grommet Breaking Load,

Minimum CGBL =

SDL × 2 . 25 × 1 . 1

Eb

(2.7)

Doubled Grommets

g) Minimum Calculated Grommet Breaking Load,

Minimum CGBL =

SDL × 2 . 25 × 1 . 1

2 xE b

(2.8)

16

2.2.4 Shackle Sizing

The sizing of shackles is much simpler than slings and can be based on the following:

Minimum Shackle Working Load Limit, WLL = Sling Design Load, SDL

Note: The WLL is usually quoted by the major shackle Manufacturers, e.g. Crosby

Group, and should be taken as analogous to the safe working load. The WLL is usually

based on a ratio of ultimate strength to WLL of not less than 4 for shackles above 200

tonnes WLL. Should any Manufacturer quote WLL's based on a lower factor, the WLL

should be derated accordingly. Higher ratios between ultimate strength and WLL are

normally adopted for shackles below 200 tonnes capacity, however in these cases the

WLL must not be increased above the Manufacturer's quoted values.

Shackle to Shackle Connection

It is often necessary to make up long sling lengths using 2 slings joined together with a

shackle/shackle connection, usually by joining pin/pin. This is acceptable and no

derating of the shackle is required.

Side Loads on Shackles

Shackle WLL's are quoted for sling loads in line with the shackle i.e. at right angles to

the pin. Should the lift configuration result in side loading, not perpendicular to the pin

shackle, de-rating as recommended by the Manufacturer is necessary. To avoid side

17

loading during the lifting, it is necessary to ensure a close fit-up between the inside of

the shackle jaws and the padeye main, or cheek plates. The width of the main/cheek

plate combination should preferably exceed 0.8 times of the jaw width.

In certain circumstances, the shackle available far exceeds the design requirement for

the width of the main/cheek plate combination. In such cases, this width can be

reduced to one half of the jaw width by adopting non-load bearing centralisers between

the padeye and shackle jaw to ensure an in-line lift.

2.2.5 Tilt during Lifting

Decks and modules

Matched sling pairs should be used to limit the tilt of the module, or deck, to less than

2° in either the transverse or longitudinal direction, or less than 3° in diagonal

direction, whichever is less. Where, due to excessive eccentricity of the package

centroid, the tilt exceeds this value, the lengths of the sling pairs should be altered

accordingly.

Lifting of the jacket off the barge

Sling lengths for side lifting of the jacket off the barge deck, at the offshore location,

should preferably be selected so that the barge deck and the jacket framing interface

remain parallel during the lift off. This avoids possible damage due to the jacket being

18

impacted as it is raised off the barge sea-fastenings and it also provides more clearance

between the hook and the boom sheave.

FPSO Module Lifts

For installation of fabricated modules onto FPSO, in most cases, there will be a

specific requirement in which one of the support legs is required to be settled down

first. This will require the detailed sling calculation to ensure module tilt to the touchdown corner.

Other Lifts

For certain operations, specific tilt angles may be required to allow safe

lifting/installation as would apply when installing a bridge between two platforms.

2.2.6 COG Shift Factor

Possible Centre of Gravity (COG) shift shall be accounted for by applying a COG shift

factor (fcog) to all assigned weights in the load combinations. fcog is calculated for the

support point most sensitive to shift in COG, and applied equally for the whole

structure.

The COG from the analyses shall be used in the calculations of the COG shift.

19

fcog factor shall be calculated as follows:

f cog =

dx + a dy + b

×

≥ 1 . 05

b

b

(2.9)

where, as shown in Figure 2.1, a and b are the distances between analysis COG and

nearest footing in x and y directions and dx and dy are the distances between the

position of maximum shifted COG and analysis COG

in x and y direction,

respectively.

20

2.3

Summary

Lifting criteria and sling specifications in practice are first reviewed in this chapter.

These codes include API-RP2A (2000), Det Norske Veritas (DNV) RP-5, Phillips

Petroleum, Heerema, Noble Denton & Associates (NDA), HSE and Shell. API, DNV

and HSE codes are easily available to the general public. The API codes are the oldest

and the most well established in the offshore industry.

Practical considerations for standard rigging design are discussed in detail. The

practical and important considerations in rigging design are

• Sling Design Loads (SDL),

• Shackle Design Loads,

• Lift Point Design Loads,

• Shackle Sizing,

• Tilt during Lifting and

• COG Shift Factor.

21

Table 2.1 Lifting Criteria comparison - Single Crane Lift

Range of Module Weight

1

2

3

4

5

6

Noble

Denton

DnV

Heerama

Shell

BP

Oxy

Amoco

Chevron

>2500

>2500

>2500

>1000

>2500

>2500

>2500

>2500

A. Weight Factor (Pre-AFC)

B. DAF (Slings)

C. Skew load factor

D. CG Shift factor

E. Tilt factor

F=AxBxCxDxE

1.125

1.10

1.25

1.05

1.00

1.62

1.10

1.10

1.25

1.00

1.00

1.51

1.15

1.10

1.50

1.00

1.00

1.90

1.15

1.10

1.50

1.05

1.00

1.99

1.15

1.10

1.50

1.00

1.00

1.90

1.15

1.10

1.50

1.00

1.00

1.90

1.15

1.10

1.25

1.05

1.00

1.66

1.15

1.10

1.50

1.00

1.05

1.99

7 G. Rigging weight factor

8 H. Lift point design factor

9 I. Load member design factor

1.03

1.35

1.15

1.03

1.35

1.15

1.03

1.00

1.00

1.03

1.00

1.00

1.03

1.25

1.10

1.03

1.30

1.15

1.03

1.30

1.15

1.03

1.30

1.15

10 J. Sling Design = (F x G)

11 K. Lift point Design = (F x H)

12 L. Load member design = (F x I)

1.67

2.19

1.87

1.56

2.04

1.74

1.95

1.90

1.90

2.05

1.99

1.99

1.95

2.37

2.09

1.95

2.47

2.18

1.71

2.16

1.91

2.05

2.59

2.29

The overall lift point design factor (K) from API RP 2A (2000) is 2.00.

Table 2.2 Lifting Criteria comparison - Double hook Lift

Range of Module Weight

1

2

3

4

5

6

7

8

Noble

Denton

LOC

>2500

>1000

A. Weight Factor (Pre-AFC)

B. DAF (Slings)

C. CG Shift factor

D. Tilt factor

E. Yaw factor

F. Torsion factor

G. Skew factor

H=AxBxCxDxExFxG

Heerema Chevron

>2500

>2500

BP

Amoco

>8000

>2500

1.125

1.10

1.03

1.03

1.05

1.00

1.00

1.38

1.15

1.10

1.05

1.03

1.05

1.00

1.10

1.58

1.15

1.10

1.05

1.03

1.05

1.00

1.00

1.44

1.25

1.10

1.05

1.03

1.00

1.00

1.10

1.64

1.15

1.10

1.08

1.03

1.00

1.00

1.10

1.55

1.15

1.10

1.05

1.03

1.05

1.10

1.00

1.58

9 I. Rigging weight factor

10 J. Lift point design factor

11 K. Load member design factor

1.03

1.35

1.15

1.03

1.00

1.00

1.03

1.10

1.10

1.03

1.30

1.15

1.03

1.25

1.10

1.00

1.35

1.15

12 L. Sling Design = (H x I)

13 M. Lift point Design = (H x J)

14 N. Load member design = (H x K)

1.42

1.86

1.59

1.63

1.58

1.58

1.48

1.58

1.58

1.68

2.13

1.88

1.59

1.93

1.70

1.58

2.13

1.82

The overall lift point design factor (K) from API RP 2A (2000) is 2.00.

Table 2.3 Dynamic Amplification Factors (DAF)

Design (factored)

Lift Weight (tonne)

DAF Offshore

DAF Inshore

<100

100 to 1000

>1000

1.30

1.15

1.20

1.10

1.10

1.05

22

Y

Support location

Analysis COG

dy

Max. COG shift

X

b

Design envelope

a

dx

Figure 2.1 : Centre of Gravity (COG) Shift

23

CHAPTER 3

3.1

HEAVY LIFTING EQUIPMENT AND

COMPONENTS

Introduction

As shown in Figure 3.1, crane vessel, rigging components including shackles, slings

and grommets and lift point connections (including padeyes and trunnions) are basic

considerations in heavy lift design.

The crane barge is the most expensive piece of equipment and the most important

member in lift operation as well. The safety of the crane barge during lift operations is

the first consideration for both crane barge owner and client. The characteristics of the

crane barge also constrain the rigging arrangement and necessary reinforcement of the

module structure.

To safely pick up and install the module is the ultimate objective of carrying out a lift

operation. The module cannot be damaged or overstressed or distorted during lift.

Reinforcement is needed when the module is too flexible to withstand the load during

lift.

The rigging system is the only connection of module to crane vessel. The rigging

components include slings, spreader structure, shackles, padeyes (or trunnions) and

their arrangement. The selection or design of a rigging arrangement is dependent on

the barge characteristics, module structural pattern and behaviour during lift, and the

site parameters.

24

3.2

Heavy Lift Cranes

In the mid 1980s, the available lifting capacity was increased dramatically with the

introduction of the latest generation of Semi Submersible Crane Vessels (SSCVs):

S7000 (with up to 14000 ton capacity) in Figure 3.2 and DB102 (with up to 12000 ton

capacity). Coupled with the upgrading of the Heerema SSCVs, Balder and Hermod,

the availability of these vessels has led to development of lifted jacket concepts for

medium and deeper water and modules over 10000 ton in weight. Table 3.1 lists some

of heavy lifting crane vessels in the world.

Nowadays it is generally recognized that the application of large SSCVs, such as

McDermott's DB102 (12000 ton capacity) and Saipem’s S7000 (14000 ton capacity),

may reduce the costs of offshore installation work significantly, especially for large

integrated topsides and liftable jacket structures. The dynamic aspects of heavy lift

installations are to some extent yet unknown. However, the knowledge of these aspects

is essential to properly assess the feasibility and safety of heavy lift operations.

Both the lifting capacity and the installed lift weights have increased dramatically

during the past two decades. For a long time the available offshore crane capacity used

to be well ahead of the demand and did not impose any significant restrictions on the

weight and dimensions of lift-installed offshore platforms. In recent years, however,

the maximum available crane capacity of large SSCV's has become a limiting factor in

the design of integrated topsides and liftable jackets.

For example, the maximum dimensions of liftable jackets are effectively constrained

by the crane capacity and outreach of large SSCV's, as well as by minimum clearance

25

requirements between the jacket legs and the crane booms. In addition it has become

apparent that the dynamic aspects of large offshore installations should not be ignored

as these may seriously impact the feasibility, safety and schedule of lift operations.

In recognition of these tendencies, many experts has been active from an early stage

onwards in promoting the theoretical and practical development of offshore heavy lift

analyses as an integral consideration in the design of large liftable offshore structures.

The objectives of such analyses are three folds: firstly, given the large weights and

sizes of present day integrated topsides and liftable jackets, the extrapolation on the

basis of past experience is often not possible and unreliable, and therefore one wants to

be reassured beforehand that a proposed lift installation is technically feasible.

Secondly, it should be verified that a lift operation can be performed in a safe manner

without unacceptable risk to personnel involved or to the structure or the crane vessel.

Thirdly, an assessment of the workability (or weather downtime) of a lift operation is

required by project management when deciding on the installation time in relation to

the fabrication schedule. Moreover it may be of interest to establish whether the

workability is determined by factors under the control of the engineering design

project team or of the installation contractor.

In an actual project, the choice between an integrated deck or split modules can be

difficult.

The split module concept is to separate the integrated deck into smaller

pieces called modules, by splitting the integrated deck in vertical or horizontal

directions, which can be easily lifted by smaller crane vessel (with lower cost), but

result in higher offshore hook-up cost.

Besides using a larger crane vessel to install

the integrated deck, “Float-over” method is also used for installation of heavy deck

without weight limitation. The float-over method will not be discussed in this thesis.

26

3.2.1 Crane Vessel Types

In general, the floating crane lift vessel can be classified into two main groups:

A) Sheer Leg Crane, like Asian Hercules II in Figure 3.3.

Advantages

- Less draft for access in-shore shallow water area

- Smaller in barge size, easy maneuvers

- Economic saving

Disadvantages

- Non swivel of crane boom

- Offshore lifting limitation

B) Derrick Crane Barge (or SSCVs)

This group can be further classified into two types:

Type I – Facilitated with dual crane booms, such as S7000 in Figure 3.2 & Thialf

in Figure 3.4.

Type II – Single crane boom, like DB30, DB50 & DB101 as shown in Figure 3.5

Advantages of Derrick Barge

- Swivel of crane boom, more lifting flexibility

- More suitable to offshore lifting operation

- Bigger barge size, more stability

Disadvantages

- Deep draft for not able to access in-shore shallow water area

- Big barge size, not easy maneuvers

27

3.2.2 Frequently Used Crane Vessels

Sheer Leg Floating Crane – Asian Hercules II

Asian Hercules II, as shown in Figure 3.3, is a self-propelled lifting vessel that

has a maximum hoisting capacity of 3200 ton. The crane structure comprises

mainly an A-frame and jib.

The A-Frame can be skidded along fixed tracks on deck into three different

working positions:

Position 1

:

Located at 5.2 m from forward of vessel

Position 2

:

Located at 33.0 m from forward of vessel

Position 3

:

Located at 59.0 m from forward of vessel

The general specifications are as below:

Length (overall)

:

91.00 m

Breadth moulded

:

43.00 m

Depth moulded

:

8.50 m

Max. /Min draft

:

5.00/2.40 m

Gross tonnage

:

10560 tons

Net tonnage

:

3168 tons

Displacement

:

16500 tons (even keel)

Speed

:

7 knots (12.97 km/hr)

Deck loading

:

15 ton/m²

The crane structure has been designed based on the following criteria:

Harbour condition:

•

Wind speed

:

20 m/s

•

Current

:

3 Knots

Offshore condition:

•

Wind speed

:

20 m/s

•

Current

:

5 Knots

•

Max. sig. wave height

:

Hs = 1m

28

Derrick Barge – Thialf

Thialf, as shown in Figure 3.4, is the largest Deepwater Construction Vessel

(DCV) operated by Heerema Marine Contractors and is capable of a tandem lift

of 14,200 ton. The dual cranes provide for depth reach lowering capability as

well as heavy lift capacity to set topsides. This multi-functional dynamic

positioned DCV is tailored for the installation of foundations, moorings,

SPAR's, Tension Leg Platforms (TLPs) and integrated topsides, as well as

pipelines and flowlines.

Main dimensions as below,

Length overall

201.6m

Length of vessel

165.3m

Breadth

88.4m

Depth to work deck

49.5m

Draught

11.8-31.6m

GRT

136,709 ton

NRT

41,012 ton

Deck load capacity

15 mT/square metre

Total deck load capacity

12,000 mT

Transit speed with 12,000 tons deck load 6 knots at 12.5 metres (43.6 ft) draft.

Ballast pump capacity 20,800 cubic metre/hour

PORTSIDE or STARBOARD CRANE

Main hoist revolving

7,043 ton up to 31.2 m (102 ft)

Auxiliary hoist

900 ton at 36.0 - 79.2 m (120 - 260 ft)

Whip hoist

198 ton at 41.0 - 129.5 m (134 - 425 ft)

29

Derrick Barge – DB101

DB101, as shown in Figure 3.5, has the following details:

Main Dimensions:

LOA

146.3 m (480 ft)

Beam

51.9 m (170.3 ft)

Depth

36.6 m (120 ft)

Working Draft

Min. 7.5m (24.6 ft), 23.5m (Max. 77 ft)

Clear Deck:

43,000 sq. ft.

Tonnage:

Gross 52,313, Net 15,693

Cranes

Main Crane: IHC E-3500

Boom Length:

Main

67.0m (219.75 ft)

Aux.

97.33m (319.33 ft)

Whip

104.2m (341.75 ft)

Hook Capacity:

Main 2,430 ton (2,700 stons) @ 66 - 78 ft. (Revolving),

3,150 ton (3,500 stons)

@ 66 - 78 ft. (Tied Back),

540 ton (600 stons)

@ 115 - 279 ft. (Aux.) &

135 ton (150 stons)

@ 350.0 ft. (Whip)

Deck Cranes: 83 ton (92 stons)

@ 25 ft.

30

3.3

Heavy Lift Shackles

Shackles are used in lifting and static systems as removable links to connect wire rope,

chain and other fittings. The shackles used most commonly in industry are

manufactured by two groups, namely Green Pin and Crosby as shown in Figure 3.6.

The wide range of shackle sizes provides choices to designer, with the working load

limit from 0.5 ton to 1200 ton. The shackles are mostly used to connect sling to padeye

on the lifting components. However, the shackles can also be utilized to adjust

(increase) a particular sling length in a set of slings.

Design

The theoretical reserve capability of carbon / alloy shackles should be as a minimum 5

to 1. Known as the DESIGN FACTOR, it is usually computed by dividing the catalog

ultimate load by the working load limit. The ultimate load is the average load or force

at which the product fails or no longer supports the load. The working load limit is the

maximum force which the product is authorized to support in general service. The

design factor is generally expressed as a ratio such as 5 to 1. Also important to the

design of shackles is the selection of proper steel to support fatigue, ductility and

impact properties.

Type & Applications

-

Screw pin shackles are mainly used for non-permanent applications.

-

Bolt-type shackles are preferably used for long term or permanent

applications and in circumstances where the pin of the shackle may

rotate during loading.

31

-

Chain shackles are used mainly on one-leg systems.

-

Anchor shackles on multi-leg systems.

Shackle Material

The following are the common materials used for shackle manufacturing:

Mild steel, untreated, which is comparable to ISO Grade 3;

High tensile steel, untreated or normalized, which is comparable to ISO Grade 4;

High tensile steel, quenched and tempered, which is comparable to ISO Grade 6;

Alloy steel, quenched and tempered, which is comparable to ISO Grade 8;

All shackles are upset-forged, on special requirement drop-forged shackles can be

obtained.

The proper performance of premium shackles depends on good manufacturing

techniques that include proper forging and accurate machining. Closed die forging of

shackles assures clear lettering, superior grain flow, and consistent dimensional

accuracy. A closed die forged bow allows for an increased cross section that, when

coupled with quench and tempering, enhances strength and ductility. Closed forging

combined with close tolerance pin hole assures good fatigue life, particularly with

screw pin shackle.

Quench and tempering assures the uniformity of performance and maximizes the

properties of the steel. This means that each shackle meets its rated strength and has

required ductility, toughness, impact and fatigue properties. The job requirements

demand this reliability and consistency.

32

The quench and tempering process develops a tough material that reduces the risk of

brittle, catastrophic failure. The shackle bow will deform if overloading occurs, giving

warning before ultimate failure.

The proper application of shackles requires that the correct type and size of shackle be

used. The shackle's working load limit, its size, a traceability code and the

manufacturer’s name should be clearly and boldly marked in the bow. Traceability of

the material chemistry and properties is essential for confidence in the product.

Material chemistry should be independently verified prior to manufacturing.

For example, a Green Pin standard shackle has following technical indications:

WLL 125 T - Working Load Limit 125 tons

Bs

- the manufacturer's symbol

H

- Traceability code

6

- Grade

CE

- Conformity European.

Documentation

Shackles can be supplied from vendors with the following documents:

•

a work certificate;

•

a certificate of basic raw material;

•

an inspection certificate DIN 50049 - 3.1.B or 3.1.C.;

•

a proof-load test certificate;

•

a certificate with the actual breaking load found on the tested samples;

•

a test report of Magnetic Particle Examination and

•

a test report of Ultrasonic Examination.

33

Usage

The correct type of shackle should be selected for a particular application. The

Working Load Limit (WLL) should be applied in a straight pull and overloads must

not be made. Side-loads should be avoided as the products are not designed for this

purpose.

If side-loads are required, as shown in Table 3.2, shackles should be fitted to the load

in a manner that allows the shackle body to take the load in a true line along its centreline; and not in such a way that bending loads are induced, other than those for which

the shackle is designed.

When using shackles in conjunction with multi-leg slings, due consideration should be

given to the effect of the angle between the legs of the sling. As the angle increases so

does the load in the sling leg and consequently in any shackle attached to that leg.

To avoid eccentric loading of the shackle, a loose spacer may be used on either end of

the shackle pin or a shackle with a smaller jaw width should be used. Welding

washers or spacers to the inside faces of shackles or closing shackle jaws shall not be

used to reduce the width between the shackle jaws, as this will have adverse effects on

the mechanical properties of shackles. Extreme circumstances or shock loadings must

be well taken into account on selecting the products.

The applications, where the shackle pin can rotate and possibly be unscrewed due to

movement (e.g. of the load or rope), must be avoided.

34

Finished shackles may not be heat-treated because this may affect the Working Load

Limit and the material structure.

Shackles in use should be subject to thorough examination by a competent person at

least every 6 months. In practice, re-certificate is carried out by mechanical

Professional Engineer. This is necessary because the product in use may be affected by

wear, misuse, overloading with consequent deformation of the steel structure.

Shackles should be inspected before use to ensure that:

•

the body of the shackle and pin are both identifiable as being of the same

quality grade;

•

all markings are readable;

•

the pin is of the correct type;

•

the threads of the pin and the body are undamaged;

•

the body and pin are not distorted and unduly worn;

•

the body and pin are free from nicks, gouges and cracks.

Also, the pin should be correctly screwed into the shackle eye, i.e. tighten finger tight,

then lock using a small tommy bar or suitable tool so that the collar of the pin is fully

seated on the shackle eye. The pin needs to be the correct length so that it penetrates

the full depth of the screwed eye and allows the collar of the pin to bed on the surface

of the shackle eye. Incorrect seating of the pin may be due to a bent pin, too tight

fitting thread or misalignment of pin holes.

35

It is important not to replace a shackle pin with a bolt, other than one designed for the

purpose, as it may not be suitable for the loads imposed.

It is important in the case of shackles fitted with a bolt, nut and split cotter pin that the

length of the plain portion of the bolt is such that the nut will jam on the inner end of

the thread or on the eyes of the shackle, and that the rivet on the bolt is cross drilled for

a split cotter pin. A bolt type shackle in operation without using a split cotter pin

should not be used.

36

3.4

Heavy Lift Slings

As an important lifting component, the sling is limited in design not only by the lifted

weight and also by the factors listed below:

•

Being pre-rigged on the structure;

•

Diameter - the largest slings to date have been about 400 mm, though currently

available machinery can build slings 475 mm in diameter;

•

Weight of the slings - the sling making machinery has an upper weight limit,

about 80 ton, for any individual sling. Thus large diameter slings are restricted

by the length in which they can be manufactured;

•

An installation contractor may wish to lay the slings down on the module after

lifting so that they can be removed individually. This is to avoid the slings

moving towards each other, hence limiting possible damage on the module.

In actual lift projects, sling retention devices (keepers plates) must be fitted to the

trunnions to keep the slings in place during transportation and sling connection. Slings

need to be tied down to the lay-down platform using soft ropes, to prevent movement

during transportation. For a module, sling slashing may be required to prevent

damage to module equipment.

3.4.1 Sling properties

The cable laid slings and grommets are most commonly used in heavy lift operation.

The term "cable laid" indicates wire rope constructed from six smaller diameter ropes

laid up in a helical manner about a single core rope. A hand-spliced soft eye is placed

at each end of the rope section to form a "cable laid sling". The term "grommet" refers

37

to a continuous sling made up in the form of a rubber band. Eyes are formed by

securing the two parts of the grommet together with seizing to produce a loop at each

end.

A common trait of these systems is that they require an element with high tensile

stiffness and relatively low bending stiffness. Selection rules for wire ropes are rooted

in history, of which the purpose or derivation is not easily traced. Most

implementations are the result of the design engineers' biases and experiences, based

on many years of practical use of cables and wire ropes.

The task of designing a wire-rope-based system follows the basic description of the

design process. In addition, each step may be decomposed into several inter-related

subtasks. For instance, system definition subtasks include the selection of a drum,

selection of the appropriate number and sizes of sheaves, selection of wire rope end

fittings, and design of the wire rope itself.

The design of a typical wire rope involves the selection of the following geometrical

and material parameters as shown in Figure 3.7.

•

Numbers of wire lays in each strand, wires in each wire lay, and strand lays in

the rope

•

Diameters of the individual wires and strands as well as the total rope diameter

•

Lay lengths (pitches) of the wire lays within the strands and the strands within

the rope

•

Configuration of the strands and total rope (i.e., lay directions, etc.)

•

Individual wire cross sections

38

•

Core type

•

Wire and core materials (including treatment, etc.).

Conventional wire rope slings are limited to diameters of about 4 inches. Braided

slings and several other types of multipart slings have also been used for heavy lifts,

but cable laid slings have proven their superiority and are presently the standard for the

industry. The generally recognized authority for the design and construction of cable

laid slings and grommets is Guidance Note PM 20, “Cable Laid Slings and Grommets”

issued by U.K. Health and Safety Executive. The guidance note was prepared by a

working group of experts primarily from the offshore construction and wire rope

manufacturing industries. The note covers construction procedures and prescribes how

safe working loads are to be established.

One of the problems encountered in the construction of cable laid or any large

diameter slings is the maintenance of an acceptable tolerance on differential length.

Three factors involved in the minimization of the tolerances are:

•

Control of the production of the unit ropes from which the slings are

constructed.

•

Accurate measurement and marking of rope during construction.

•

Mechanical control of splicing tensions to achieve a balanced termination.

Some measurable length differential will be present at the end of construction and the

magnitude can be expected to increase due to differential permanent elongation under

load. A reasonable tolerance on length for the life of the slings is ±0.25 percent of the

length. The length differential for a matched set of 100 foot slings constructed under

ideal conditions may be as much as 6 inches.

39

Heavy lift slings are made of machine spun cable laid rope and usually terminated by

hand made eyes and splices. The eye and splice sections are softer than the cable

section. These are up to 40 rope diameters in length and significantly affect the overall

sling characteristics. Sling splices can slip during load take up and some allowance

should be made in the sling load calculations for this effect. The characteristics

become stiffer and more linear with repeated use.

Grommets are made out of a single length of wire rope which is spun into a continuous

multi-strand loop of wire. They generally have softer characteristics than slings of

similar minimum breaking load (MBL). The single grommet is softer than the

equivalent double sling with two spliced eyes. No slippage allowance is necessary in

grommet design.

3.4.2. Grommets versus Slings

In one major offshore lift project, dual crane lifts with doubled grommets were used to

provide four parts per lifting point. These proved to be lighter as a percentage of the

module weight than doubled slings and resulted in rigging weights approximating to

2% of the lift weight. For the single crane lifts doubled slings were used and resulted in

rigging weights between 3 and 3.5% of the lifted weight.

The grommet lengths were adjusted to permit the centre of lift to be matched to the

centre of gravity. This was achieved by means of intentionally scheduled late

manufacture of a pair of grommets. However, this resulted in potential for late delivery

40

of rigging and therefore careful integration of grommet and module fabrication

scheduling was required. In spite of the rigging being a low percentage of overall

module weight, the individual rigging components still weighed approximately 50 ton

each and rigging installation in the module fabrication yard, at the lift height required,

presented some difficulty and necessitated the preparation of detailed handling

procedures.

An allowance should be made in the design for differential tension across the hook or

padeye. This is due to friction preventing the full load equalization in the rope or

spliced eyes. The tension ratio between the two parts is usually taken as 45:55. This

corresponds to a coefficient of friction of 6.4% around a 180 degree bend.

Slings apply a torque to the crane hook and lifting padeyes. This causes a 2% increase

in sling loads for single hook lifts, increasing to 4% in long and slender modules. Sling

torque has a negligibly small effect on sling loads in double hook lifts.

3.4.3. Sling and Grommet Properties

A.

Properties of rope and splice

A1.

New rope (1st load cycle)

T =

Cr × Lo

d mr

nr

(3.1)

Where,

T = Load in % MBL

Lo = Extension in % of original length

d = Sling rope diameter (mm)

Cr = 132.8 ± 25%

nr = 1.75

mr = 0.3807

41

Used rope (2nd cycle onwards)

Elastic modulus E = 2533 ± 25% kg/mm²

A2.

New eye/splice (1st load cycle)

T=

Ce × Lo ne

d me

(3.2)

Where,

Ce = 16.48 ± 30%

ne = 3.5

me = 0.6286

Used eye/splice (2nd load cycle onwards)

Elastic modulus E = 1357 ± 25% kg/mm²

B.

Grommet properties

These properties are for a simple continuous two-part grommet, i.e. having two ropes

connecting the padeye to the hook.

B1.

New grommet (1st load cycle)

T=

C g × Lo ng

d mg

(3.3)

Where,

T = Load in % MBL of tow ropes

Lo = Extension in % of original length between hook and padeye

d = grommet rope diameter (mm)

Cg = 69.0 ± 25%

ng = 1.80

mg = 0.4618

42

3.5

Lift Points

Lift points are the locations where intensive sling tensions meet with module structure.

Lift points should be properly designed to allow sling tensions smoothly transfer to

other strong structural members. Depending on the factored lift loads, slings and

shackles can be selected from available sling and shackle lists (inventories) or ordered

from suppliers. How to get safe enough and yet reasonably factored lift point loads has

been the focus of all industry design codes.

There are basically two types of lift points which connect rigging systems to module

structures: Padeye and trunnion, as shown in Figure 3.10.

Padeyes are important lift components, which link module structure and shackles. In

lift arrangement, a shackle locks up a padeye by inserting shackle pin through padeye

hole, while the shackle bow connects to a sling.

The design of padeye requires special attention and detailing. It is recommended that

padeyes to be designed with the main connections in shear rather than in tension. High

tension loads in the thickness direction of steel material should be avoided. Padeyes

should be also dimensioned to properly fit up with shackles and avoid uneven contact

areas, which is usually resolved by using cheek plate and spacer plates.

Although the padeyes themselves are usually adequately designed for vertical and

horizontal loads, the structure to which the padeyes connect must be able to accept and

transmit the total vertical and horizontal forces back into structure.

Trunnions are normally used to lift very heavy modules. The advantages of trunnions

43

are their simplicity in rigging connections where slings or grommets are looped over

the braces without the use of shackles, and the freedom for a sling or a grommet to

rotate around the trunnion brace. The latter may be beneficial for module upending,

overturning or rotating.

Trunnions can be either cast or fabricated. Ideally the diameter of the trunnion should

be four times the sling diameter. The use of cast trunnions means that early design is

required because castings have a long lead time. The fabricated trunnions are

frequently used in the offshore industry.

44

3.6

Summary