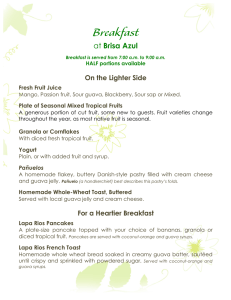

Fruit Juice Standardization Report: Codex Alimentarius, 1982

Anuncio