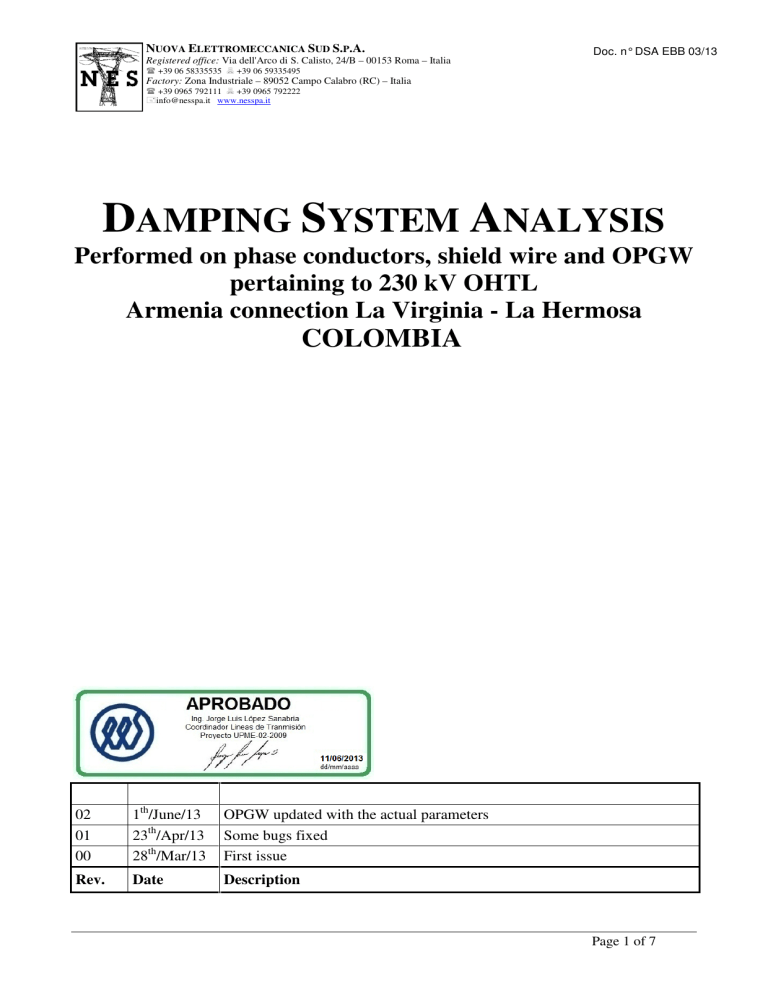

NUOVA ELETTROMECCANICA SUD S.P.A. Doc. n° DSA EBB 03/13 Registered office: Via dell'Arco di S. Calisto, 24/B – 00153 Roma – Italia +39 06 58335535 +39 06 59335495 Factory: Zona Industriale – 89052 Campo Calabro (RC) – Italia +39 0965 792111 +39 0965 792222 [email protected] www.nesspa.it DAMPING SYSTEM ANALYSIS Performed on phase conductors, shield wire and OPGW pertaining to 230 kV OHTL Armenia connection La Virginia - La Hermosa COLOMBIA 02 01 00 1th/June/13 23th/Apr/13 28th/Mar/13 OPGW updated with the actual parameters Some bugs fixed First issue Rev. Date Description Page 1 of 7 Nuova Elettromeccanica Sud S.p.A. Doc. n° DSA EBB 03/13 rev.2 of 1th/June/13 1. Foreword On request of EBB, damping studies have been performed on the following cables of the above captioned project: • ACAR 600 12/7 (Φ 22.58mm) for twin bundle phase conductors, • GW AWG 7#9 (Φ 8.71mm) for shield wire • OPGW AFL DNO-9663 (Φ 10.8mm) The studies have been performed by mean of a specific computer program, called Tecnosoft III, designed for vibration analysis of overhead cables exposed to natural wind. By using this program, it is possible to calculate aeolian vibration amplitudes and the relevant alternating bending strains on the conductor, establishing the balance between the energy introduced by the wind and the energy dissipated by the conductor, with and without the application of vibration dampers and/or spacers. In this report, the results of the studies are reported together with the recommendations for the quantity and the positioning of the spacers and the vibration dampers. These recommendations are valid for spacers and vibration dampers produced by the company NES only. 2. Line parameters The parameters of the lines under examination have been derived from the input data files for damping study provided by EBB. The nature of terrain is Mountainous. The tensile loads are available at the EDS after creep at 15 °C. The values are: • ACAR 600 12/7 = 12.52 kN • GW AWG 7#9 = 6.74 kN • OPGW AFL DNO-9663 = 5.95 kN (12 % UTS) Minimum Span = 90 m Average Span = 473m Maximum Span = 1101 m. The average temperature of the coldest month of the year is 5 °C. 3. Damping Systems The damping system proposed for the twin bundle of ACAR 600 12/7 consists of NES twin spacerdamper type 8.40.02.861. The damping system proposed for the GW AWG 7#9 consists of NES vibration damper type 8.50.01.401. The damping system proposed for the OPGW AFL DNO-9663 consists of NES vibration damper type 8.50.01.470. In case to install the damper outward the suspension clamp or tension clamp, the additional rods set 8.45.37.833 is needed. 4. Calculation parameters The tensile load of the ACAR 600 12/7 conductor has been taken equal to 12.9 kN corresponding to the load condition of the average span at the average temperature of the coldest month of the year. The tensile load of the GW AWG 7#9 shield wire has been taken equal to 7 kN corresponding to the load condition of the average spans at the average temperature of the coldest month of the year. The tensile load of the OPGW AFL DNO-9663 has been taken equal to 6.06 kN corresponding to the load condition of the average spans at the average temperature of the coldest month of the year. Armor rods at the suspension clamp for the conductors and shield wire have been considered. Armor Page 2 of 7 Nuova Elettromeccanica Sud S.p.A. Doc. n° DSA EBB 03/13 rev.2 of 1th/June/13 Grip Suspension clamps and preformed tension clamps have been considered for the OPGW. The spacers are distributed along the spans in accordance with the in-span positioning tables NES INST EBB 02/13. The assumed wind functions Single (Var2) and Bundle (Var2), have been considered at a turbulence level of 8% which is typical of the above mentioned areas. 5. Evaluation criterion To evaluate the damping system performance, the criterion of the maximum allowable bending strain, based on IEEE paper 31TP65-156 [1], has been applied. For the ACAR 600 12/7, containing aluminum elementary wires in outer layer, a bending strain of 150 microstrains is internationally accepted as the limit below which no fatigue failure o conductor strands can occur. For the OPGW and shield wire, containing aluminum clad steel elementary wires in outer layer, a bending strain of 225 microstrains is internationally accepted as the limit below which no fatigue failure o conductor strands can occur. The criterion of the maximum allowable bending strain is the most severe evaluation criterion compared with the CIGRE evaluation procedure [2]. This procedure is based on the calculation of the conductor lifetime by means of the Miner's theory. However, the CIGRE method can be adopted only when the statistical distribution of the wind speed is available. 6. Calculation results 6.1 ACAR 600 12/7 The calculation has been performed first on the conductor alone (see Annex 1) and then on the same conductor equipped with the damping system composed by vibration dampers and flexible spacers. The bending strains on the conductor alone resulted to be above the safety limit of 150 microstrains in the lower frequency range of vibrations. These vibrations are excited by low speed winds that, in a normal wind speed distribution, have the higher percentage of presence. Thus, the application of damping system is justified. The calculation of the optimum quantity and positioning of the damping system shows that the spacer-damper 8.40.02.861 (distributed in accordance with the in-span positioning tables NES INST EBB 02/13) can control the vibration levels within safety limit when installed according to the following criteria (see Annex 2 about the average span and Annex 3 about the longest span) 6.2 GW AWG 7#9 The calculation has been performed first on the cable alone (see Annex 4) and then on the same equipped with vibration dampers. The bending strains on the shield wire alone resulted to be above the safety limit of 225 microstrains in the lower frequency range of vibrations. These vibrations are excited by low speed winds that, in a normal wind speed distribution, have the higher percentage of presence. Thus, the application of damping system is justified. The calculation of the optimum quantity and positioning of the vibration dampers shows that the vibration damper type 8.50.01.401 can control the vibration levels within safety limit when installed according to the following criteria: • For span lengths up to 600 m, one vibration damper per span, positioned at 0.8 m from the suspension (or tension) clamp edge (see Annex 5). Page 3 of 7 Nuova Elettromeccanica Sud S.p.A. of 1th/June/13 Doc. n° DSA EBB 03/13 rev.2 • For longer spans, two vibration dampers per span (one at a span extremity), positioned at 0.8 m from the suspension (or tension) clamp edge (see Annex 6). 6.3 OPGW AFL DNO-9663 The calculation has been performed first on the cable alone (see Annex 7) and then on the same equipped with vibration dampers. The bending strains on the shield wire alone resulted to be well above the safety limit of 225 microstrains in a wide frequency range, thus the application of vibration dampers is justified. The calculation of the optimum quantity and positioning of the vibration dampers shows that the vibration damper type 8.50.01.470 can control the vibration levels within safety limit when installed according to the following criteria: • For span lengths up to 400 m, one vibration damper per span, positioned at .52 m from the suspension clamp edge (see Annex 8). • For span lengths up to 800 m, two vibration dampers per span (one at a span extremity), positioned at .52 m from the suspension clamp edge (see Annex 9). • For longer spans, three vibration dampers per span (one at a span extremity, two at the other one), the first one positioned at 0.52 m from the suspension clamp edge, the second one at 0.5 m from the first one (see Annex 10). For tension clamps, it is recommended to install the same number of dampers recommended for suspensions clamps, installed on the free length of the reinforcing rods set and on reinforcing rod set. 7. Conclusions According to the calculations described above, the damping systems proposed for the lines in subject can provide an excellent performance in controlling the levels of aeolian vibrations within the safety limits referred in par. 5. 8. Installation criteria ACAR 600 12/7 SPACER-DAMPER NES 8.40.02.861 SPAN LENGTH (m) from to 0 109 110 155 156 229 230 303 304 376 377 447 448 517 518 585 586 635 636 709 710 784 785 843 844 916 917 968 969 1043 1044 1115 NUMBER PER EACH SPAN PER PHASE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Page 4 of 7 Nuova Elettromeccanica Sud S.p.A. of 1th/June/13 Doc. n° DSA EBB 03/13 rev.2 SPAN LENGTH (m) from to 1116 1179 NUMBER PER EACH SPAN PER PHASE 17 See in-span positioning tables NES INST EBB 02/13 for details. GW AWG 7#9 - DAMPER NES 8.50.01.401 SPAN LENGTH (m) L≤600 L>600 NUMBER PER EACH SPAN 11 2 DISTANCE OF INSTALLATION FROM CLAMP EDGE (m) X1=0.77 X1=0.77 OPGW AFL DNO-9663- DAMPER NES 8.50.01.470 SPAN LENGTH (m) L≤400 400<L≤800 L>800 NUMBER OF DAMPERS PER EACH SPAN 12 2 33 DISTANCES OF INSTALLATION (XI= 0.23 m) ON TENSION CLAMP ON AGS CLAMP (m) X1=0.51, (X2=null) See below See below X1=0.51, (X2=null) X1=0.51, X2= 0.44 See below For tension clamps, it is recommended to install the vibration dampers on the free length of the reinforcing rods set. The performances of the dampers are independent of the installation side. 1 In case of span between suspension and tension sets, it’s recommended to install the damper at suspension side. In case of span between suspension and tension sets, it’s recommended to install the damper at suspension side. 3 In case of span between suspension and tension sets, it’s recommended to install two dampers at suspension side. 2 Page 5 of 7 Nuova Elettromeccanica Sud S.p.A. of 1th/June/13 Doc. n° DSA EBB 03/13 rev.2 References [1] IEEE Standardization of conductor vibration measurements IEEE 31 TP 65-156 Vol. Pas 85 N1, 1966 [2] CIGRE Recommendation for the evaluation of the lifetime of transmission line conductors Electra N° 63, 1979 [3] Diana, Gasparetto, Tavano, Cosmai Field measurement and field data processing on conductor vibration (comparison between experimental and analytical results). CIGRE 22-11 September 1982 APPENDIX THE COMPUTER PROGRAM The TECNOSOFT III computer program has been developed for the simulation of the dynamic response of single and bundled conductors subjected to the wind induced vibrations. The program require the following input data: • Conductor characteristics (stranding, overall diameter, weight, UTS, tensile load). • Span length. The value to be considered is the actual length of the conductors. However, for normal spans with the towers at the same altitude, the distance between the towers can be also used. • Type of suspension clamp. The "Clamp strain factor” is set to 1 for metal to metal clamps, while a values less than one can be considered when AGS clamps or other clamp improving the slippage of the conductor outer strand are used. These clamps can reduce the outer wires dynamic bending strains. • Armor rods characteristics, if any (length, rod diameter, number of rods) • Wind characteristics. The program contains several Wind Power Functions. The most appropriate wind function and the level of wind turbulence are input choices based on an evaluation of the terrain roughness. The variations of wind turbulence at low wind speed can also be considered. Wind power functions for single and bundled conductors are available. The wind power functions for bundled conductors take into account that the leeward sub-conductors take less energy form the wind [3]. • Analytical model of the vibration dampers. It is represented by the dynamic response curve of the damper. A "Safety factor on dampers" is applied to the calculation to take into account the normal variation of the damper characteristics during production. This value is normally taken equal to 1.5, which means a reduction of the damper power of 33.3%. This allows considering, in the calculation, the worse damper response. The computer program calculates the bending stiffness and the damping coefficient of the conductor. The conductor bending stiffness, EJ, is derived from the conductor stranding data. The conductor self-damping H is derived from the conductor stranding data and from the tensile load. Page 6 of 7 Nuova Elettromeccanica Sud S.p.A. Doc. n° DSA EBB 03/13 rev.2 of 1th/June/13 The "Exp wavelength" and the "Exp amplitude" are exponents used in the formula for the calculation of the energy dissipated by the vibrating conductor and for the calculation of the conductor self-damping parameter H. The above exponents have been determined by laboratory tests performed by various researchers. The optimum position and the quantity of the vibration dampers per span are calculated by means of a TECNOSOFT III sub-program called "Optimization". The input data for this sub-program are the analytical model of the vibration damper, the wind power function adopted, the conductor parameters and the characteristics of the armor rods, if any. After the set up of the input data, the program is ready to perform the required calculations. The following span configurations can be analyzed in term of vibration behavior. The results are generally presented in graphical form, but are also available in tabulation form. Vibration behavior of a single conductor without dampers. The variations of the maximum bending strain at the suspension clamps and the variations of the antinode vibration amplitude are shown in the vibration frequency range. Vibration behavior of a single conductor with dampers. The variations of the maximum bending strain at the suspension clamps and at the damper clamp, together with the variations of the antinode vibration amplitude and of the vibration amplitude at the damper clamp are shown in the vibration frequency range. Vibration behavior of a conductor bundle without dampers. The variations of the maximum bending strain at the suspension clamps and the variations of the maximum antinode vibration amplitude are shown in the vibration frequency range. Vibration behavior of a conductor bundle with dampers and spacers or spacers dampers. The variations of the maximum bending strain at the suspension clamps and at the damper/spacer damper clamps, together with the variations of the antinode vibration amplitude and the vibration amplitude at the damper clamp are shown in the frequency range. Page 7 of 7