by Honeywell

Installation instructions

EN54 Vigilon 4/6 loop control panel based

Fire detection and alarm system

1

Zones 17

Fault

Power Fault

System Fault

Delay

2

18

3

19

4

20

5

21

6

22

7

23

8

24

9

25

10

26

15 16

11 12 13 14

30 32

27 28 29 30

Fire

15:45

Healthy

Verify

Sounder

Vigilon Fire System

GENT 2010

Pt 2 & 4

Designed to EN54

CB253

CB254

Power

Test

Disablement

4188-875 issue 5_07/10_Vigilon 4-6L EN54_Install

Previous

Next

Installation instructions

Repeat Indicator panel - - - - - - - - - - - - - 28

Contents

Technical data- - - - - - - - - - - - - - - - - - - - 28

Cable - - - - - - - - - - - - - - - - - - - - - - - - 28

Installation - - - - - - - - - - - - - - - - - - - - - 28

Notes on system installation - - - - - - - - - - 4

Installation requirements Second fix installation - Fixture and fittings - - As fitted drawings - - - Cable type and routing - Fire sensor covers - - - Earth continuity - - - - Mains supply - - - - - Local Manual Call Point -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

4

4

4

4

4

4

4

4

4

S-Quad Sensors - - - - - - - - - - - - - - - - 29

General specification - - - - Base - - - - - - - - - - - - Base Gasket - - - - - - - - - Base labels - - - - - - - - - Indicators - - - - - - - - - - Dust Cover - - - - - - - - - Do's and Don't - - - - - - - Siting - - - - - - - - - - - - Metal back box - - - - - - - In - Out wiring to S-Quad bases

Programmable input/output - -

EN54 information - - - - - - - - - - - - - - - 5

Optional functions with requirements of this

European standard - - - - - - - - - - - - - - - - - - 5

System wiring- - - - - - - - - - - - - - - - - 5

Requirements of cables Loop cable - - - - - - Mains Supply cable - - Typical Vigilon system Devices per Device loop -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

6

6

6

7

8

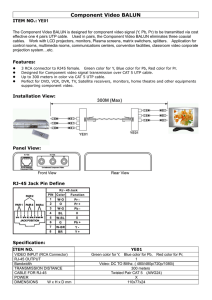

Vigilon panels- - - - - - - - - - - - - - - - - 10

Technical data- - - - - - - - - - - Installation checks - - - - - - - - - Back box installation - - - - - - - Semi-Flush fixing the control panel- Battery box for VIG1-72 panel - - - 19 inch Rack mounting frames - - - Wiring the battery box - - - - - - - Cable termination and markings - - Mains and battery supply connections

Mains supply - - - - - - - - - - - Terminals for external circuits - - - Loop circuits - - - - - - - - - - - Master alarm circuits - - - - - - - Auxiliary relay circuits - - - - - - Clean contacts- - - - - - - - - - - RS232 / RS485 Communication - - Connecting a Remote printer - - - - On completion of wiring installation -

-

-

-

-

-

-

-

-

10

12

13

14

14

15

15

16

16

16

17

18

19

19

19

20

20

20

Mimic panel - - - - - - - - - - - - - - - - - 21

Technical Data - - - - - - - - - Typical Mimic illuminations - - - Compatibility - - - - - - - - - - Installation - - - - - - - - - - - Mounting the backbox - - - - - - External wiring - - - - - - - - - How to fit the inner door assembly Where to connect the internal cables

How to fit the outer cover - - - - -

-

-

-

-

-

-

-

-

-

21

21

22

22

22

23

23

24

24

Repeat Panel (loop connectable) - - - - - - - - 25

Compatibility - - - - - - Technical Data - - - - - Installation - - - - - - - Back box mounting - - - Doors, Cables and Power up

2

-

-

-

-

-

-

-

-

-

-

-

-

-

25

25

26

26

26

-

-

-

-

-

-

-

-

-

-

-

29

29

29

29

29

29

29

30

30

30

30

Tools for S-Quad - - - - - - - - - - - - - - - 31

To remove an S-Quad To fit an S-Quad - - To fit a dust cover - - To remove a dust cover

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

31

31

31

31

S-Quad Semi-flush fixing kit (S4-FLUSH) - - - 32

Technical data- - - - - - - - - - - - - - - - - - - - 32

Beam Sensor - - - - - - - - - - - - - - - - - 33

Technical Data - - - - - - - - - - - - - - - - - - Do's and Dont's - - - - - - - - - - - - - - - - - - Test Keyswitch - - - - - - - - - - - - - - - - - - How to install an Angle bracket and fit a Beam sensor How to pre-assemble the parallel bracket - - - - - - How to install a Parallel Bracket and fit a Beam sensor

33

34

35

35

36

36

Duct kit - - - - - - - - - - - - - - - - - - - - 37

Technical date- - - - - - - - - - - - - - - - - - - - 37

3

S Speech, Sounder Strobe mark II - - - - - - - 38

Technical data- - - - - - - - - - - - - - - - - - - - 38

Installation - - - - - - - - - - - - - - - - - - - - - 39

Environmentally protected Heat Sensor - - - - - 40

General data - - - - - - - - - - - - - - - - - - - - 40

Manual Call Points - - - - - - - - - - - - - - 41

Technical data- - - - - - - - - - - - - - - - - - - - 41

Installation - - - - - - - - - - - - - - - - - - - - - 41

Keyswitch Interface / MCP - - - - - - - - - - 43

Keyswitch assembly Technical data- - - Installation - - - - Operation - - - - - Label - - - - - - - Features- - - - - - Cables - - - - - - Installation - - - - -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

43

43

44

44

44

45

45

45

Interface Modules for Vigilon Low voltage (LV) Input/Output - - - - - - - - 45

Wiring diagrams - - - - - - - - - - - - - - - - - - 46

Technical data- - - - - - - - - - - - - - - - - - - - 47

Vigilon EN54 System

Interface Module for Vigilon Medium Voltage (MV) Output - - - - - - - - - 48

Features- - - Cables - - - Installation - Wiring - - - Technical data-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

48

48

48

48

49

Mains Powered Interface (from Qtr 3 2010)- - - 50

Technical Data

Features- - - Installation - Mains supply External wiring

Options - - - -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

50

51

51

52

53

53

Vigilon Network Node - - - - - - - - - - - - 54

Technical data- - - - - - - - - - - Power supply - - - - - - - - - - - Installation - - - - - - - - - - - - Semi-Flush fixing the Network node Terminate and mark cable - - - - - Mains supply - - - - - - - - - - - Mains and battery supply connections

Terminals for external circuits - - - Network connections - - - - - - - Master alarm circuits - - - - - - - Auxiliary relay circuits - - - - - - Clean contacts- - - - - - - - - - - Remote printer - - - - - - - - - - RS232 / RS485 Communication - - On completion of wiring installation -

-

-

-

-

-

-

-

-

54

55

56

57

57

57

57

57

58

58

58

59

59

59

59

Network of systems - - - - - - - - - - - - - - 60

Copper network connections - Fibre network connections - - Network wiring - - - - - - - Network cable screen continuity

How to minimise cross talk - -

-

-

-

-

-

-

-

-

-

-

-

60

60

61

61

61

Network cables - - - - - - - - - - - - - - - - 62

Domain Bridge across Networks - - - - - - - - 63

Vigilon system parts - - - - - - - - - - - - - - 67

Preface

This is the fifth issue of the Installation instructions for the EN54 Vigilon

system based on the 4/6 loop panels. These instructions must be read in

conjunction with the recommendations in BS5839:Part 1 code of practice

for Fire detection and alarm system for buildings.

Associated Documents

Operating instructions

Log book

Conventions

"

This is a note to highlight important text that is

normally hidden in the main text.

&

This is either a caution to prevent damage to the

equipment or a warning to inform of dangerous conditions

that may result in injury or death.

Abbreviations

ac - Alternating current

AS - Anti surge

C - Common

CH -Channel

dc - Direct current

DKC - Display keyboard card

EMC - Electromagnetic Compatibility

EOL - End of line

ESD - Electrostatic discharge

GND - Ground

I/F - Interface

IO or I/O - Input output

IOC - Input output card (Card15)

IP - Ingress protection

LCD - Liquid crystal display

LED - Light emitting diode

LPC - Loop processor card

LPCB - Loss prevention council certification board

LVD - Low voltage directive

MCC - Main controller card (CARD 0)

MCP - Manual call point

MICC - Mineral insulated copper cable

NC - Normally closed

N/O - Normally open

NVM - Non Volatile Memory (NVM on backplane CARD 14)

OC - Open circuit

OS - Outstation (Loop device)

PCB - Printed circuit board

PSU - Power supply unit

QB - Quick blow

Rx - Receiver

SC - Short circuit

S3 - Speech sounder strobe

S4 - Speech sounder strobe sensor

T - Anti-surge (fuse)

TBA - To be advised

3

Installation instructions

Notes on system

installation

The power-up of the control panel and

commissioning of the system is done by the

Servicing organisation.

Installation requirements

Cable type and routing

Appropriate attention must be given to ensure correct cable type is

installed in accordance with as fitted drawings, site specific information

and recommendations of BS5839 Part 1 : 2002. The cables must be

installed using cable manufacturers recommended fixings and

accessories.

Fire sensor covers

Each fire sensor may be supplied with a plastic dust cover and can be

ordered separately. If supplied, the cover must be fitted to prevent dust

and dirt from the building work contaminating the fire sensor.

It is recommended that the installer follow the general requirements of

BS5839:Part 1, which is the code of practice relating to fire detection and

Earth continuity

alarm systems for buildings. The installer must follow the relevant parts

of BS7671 : 1992 Requirements for Electrical installations, IEE wiring

All earth connection points should be clean to provide a good

regulations 16th edition if installation is in the United Kingdom, UK.

electrical conductivity path. To maintain the earth continuity all

earth leads and fittings provided should be installed. The loop cable

screen must be continued through each system device on the loop

Second fix installation

circuit, whether the earth is connected to the device or not.

To prevent the possibility of damage or dirt degrading the performance or

appearance of the products, the installed products must be suitably

protected until all major building work in the area is complete.

"

The installation of all outstanding parts is usually

carried out during commissioning of the system.

Fixture and fittings

"

Do not rely on any part of building structure for earthing.

Some of the system products having metal enclosures have a zinc

coating around the cable termination points, the coating provide a good

electrical conductivity path for cable earth termination.

The zinc coating on the metal enclosures should not be damaged. Any

damage will expose bare metal, which can corrode and make a poor

earth connection.

It is the installer's responsibility to provide adequate fixtures and fittings

for the type of construction surface onto which a product is to be

installed, whilst utilising the fixing points on the respective product. As an

aid to this decision, the weight and overall size of each full assembly

Mains supply

together with implications on cable entries and routing should be taken

Mains supply to any fire alarm control and indicating equipment must be

into consideration.

via an unswitched 5A fused spur unit. A 'disconnect device' must be

provided to disconnect both poles and must have a minimum gap of

3mm. The 'disconnect device' should be available as part of the building

installation and must be easily accessible after installation is complete.

All these procedures assume that the cable, gland,

steel box (BESA box) and other related accessories are provided

by the installer.

"

As fitted drawings

The installer should acquire site specific information from the interested

parties, for details on the location of products for installation. The

acquired information together with this guide and the relevant standards

should be used to assist the work.

Each product assembly can be identified from its package label. The

contents of all packages should be checked for any discrepancies.

&

All mains powered equipment must be earthed.

Local Manual Call Point

To comply with the requirements of EN54 : Part 2 : 1997 a conventional

manual call point must be installed near the main control panel. The call

point must be wired to an input line of an interface unit on the loop circuit.

During commissioning call point input must be set up to evacuate all

sectors without delay.

"

Failure to install and configure a local manual call

point in the manner described above when delays are set up on

the system will result in the panel not complying to

EN54 : Part 2 : 1997.

4

Vigilon EN54 system

EN54 information

Optional functions with requirements of this European standard

The Control panel complies with the requirements of EN54 : Part 2 : 1997. In addition to the basic requirements of the standard the panel conforms

to the following optional clauses:

Clause

Description

7.8

Output to fire alarm devices

7.11

Delays to action outputs

8.3

Fault signals from point

9.5

Disablement of each addressable point

10

Test condition

System wiring

"

If instructed by the project, the installer may need to terminate as well as connect the cables to the appropriate terminal

blocks.

Cable separation

Where the outgoing and return cables of a loop which covers more than the equivalent of one zone they must not run together, for example, either

close to the Control Panel or in a service duct. There should be as much physical separation as possible between the cables and the mechanical

protection of the cable should be to a particularly high standard. This is to minimise the risk of accidental damage to both cables. There should be

separation from the mains supply cable.

Lightning protection

Where a loop cable or network cable is to be mounted to an external wall or between two buildings then consideration should be given to the use of

lightning protection devices.

Other loop devices

1

There must be a good earth

connection to the voltage surge

protection device.

1

1

Zones 17

2

18

3

19

4

20

6

22

7

23

8

24

9

25

10

26

15 16

11 12 13 14

30 32

27 28 29 30

Fire

Verify

Healthy

Sounder

Vigilon Fire System

GENT 2010

Pt 2 & 4

Designed to EN54

System Fault

230V ac

5

21

15:45

Fault

Power Fault

Delay

CB253

CB254

Power

Test

Next

Previous

Disablement

3

Vigilon

Control

Panel

Loop

powered

interface

1

Loop voltage

surge protection

2

2

Input Output line

voltage surge

protection

2

Zone circuit

Sounder circuit

4

Secure

Network

4

Other loop devices

1

4

1

Zones 17

Fault

230V ac

3

Power Fault

System Fault

Delay

2

18

3

19

4

20

5

21

3

Mains 230Vac

voltage surge

protection

Network

voltage surge

protection

1

6

22

7

23

8

24

9

25

10

26

Mains

powered

interface

15 16

11 12 13 14

30 32

27 28 29 30

Fire

15:45

Verify

Healthy

Sounder

Vigilon Fire System

GENT 2010

Pt 2 & 4

Designed to EN54

CB253

CB254

Power

Test

Previous

Next

Disablement

Vigilon

Control

Panel

2

230V ac

3

2

Zone circuit

Sounder circuit

5

Installation instructions

Requirements of cables

Loop cable

The British Standard BS5839 Part 1 : 2002 Code of practice for system

design, installation, commissioning and maintenance states the

requirements for standard and fire-resisting cables in Clause 26.2 section

d and e.

d) Standard fire-resisting cables should meet PH 30 classification

when tested in accordance with EN50200 and maintain circuit integrity if

exposed to the following test:

- a sample of the cable is simultaneously exposed to flame at a

temperature of 830ºC - 0+40ºC and mechanical shock for 15min,

followed by simultaneous exposure to water spray and mechanical shock

for a further 15min.

e) Enhanced fire-resisting cables should meet the PH120 classification

when tested in accordance with EN 50200 and maintain circuit integrity if

exposed to the following test:

- a single sample of the cable is simultaneously exposed to flame at a

temperature of 930ºC - 0+40ºC and mechanical shock for a period of

60min, followed by simultaneous exposure to water spray and

mechanical shock for a further 60min."

Vigilon loop cable carries both data and power supply, therefore its

selection is important. Note the following:

¨ In countries where the European EMC directive is in

force, only EMC Compliant cables are to be used.

¨ The loop cable usage must not exceed 1Km. This

includes the cable usage on main loop, spur circuits

and interface lines.

¨ Single pair cable must be used. It is NOT permissible to

run mixed loops or outgoing and return pairs in a multi

core cable, due to inadequate separation and possible

electrical interference problems.

¨ Each core of the loop cable must be 1.5mm2 cross

section area.

¨ the cable screens must be capable of being earthed at

each system device (outstation).

¨ Red is the preferred cover sheath for fire applications.

¨ The specified loop circuit cables are also suitable for

wiring master alarm, auxiliary relay, input/output lines

and mains supply.

"

The cables listed in this manual are those that have

been tested for EMC compliance with the system products.

Loop Cable usage

"

There is a maximum limit of 1Km loop cable usage

allowed per loop circuit. This maximum limit is the sum of the

cable used to wire the main loop circuit, the spurs off main loop

circuit, plus cables that run to all input / output lines off the loop

powered interface units installed on the same loop.

There is a further maximum limit of 100m cable run allowed per

input / output line off loop powered interface unit.

Enhanced cables

¨ Mineral insulated cable (MICC) to BS6207:Part 1

¨ Approved Enhanced cable:

Draka Firetuf Plus Enhanced FTPLUS2EH1.5RD

¨ Prysmian (formally Pirelli) FP PLUS *

Standard cables

Approved EMC cables for loop wiring

¨ Draka Firetuf EMC Standard 1.5mm2

FTEMC2EH1.5RDR

¨ Draka Firetuf FTZ2E1.5 FIRETUF OHLS *

fire resistant data cable

¨ Raydex CDT FG950 *

¨ Cavicel SpA FIRECEL SR 114H *

distributed by Cables Britain

¨ AEI Cables FIRETEC *

¨ BICC Pyrotenax FLAMESIL FRC *

¨ Datwyler LIFELINE *

¨ Alcatel cable PYROLON E * distributed by Winstonlead

¨ Huber & Suhner RADOX FR *

¨ Prysmian (formally Pirelli) FP200 FLEX *

¨ Prysmian (formally Pirelli) FP200 GOLD *

"

The cables marked * utilise laminated aluminium tape

with a tinned drain wire for electrostatic screening. Under certain

environmental conditions galvanic action may take place

between the aluminium and the drain wire. This will severely

degrade EMC performance as the foil to drain wire impedance

will increase.

Armoured variants of the cables marked * can also be used on

loop circuit.

Mains Supply cable

The mains supply cable must be a standard fire-resisting type and should

meet PH30 classification, like the standard and enhanced cables listed

above.

6

Vigilon EN54 system

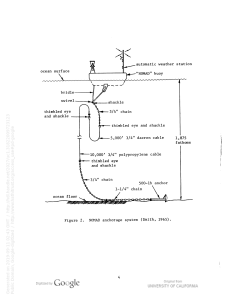

Typical Vigilon system

The loops allow wiring of addressable devices like fire sensors, alarm sounders, call points, interface units, mimic and repeat panels. A

combined maximum of up to 200 devices is allowed per loop circuit, a further limit on a loop circuit is determined by the load factor.

Conventional

Sounders on

(Two master

alarm circuits)

250mA per circuit

Clean

contacts rated

1A @ 24Vdc

Fire /Fault

Two auxiliary relays

contacts rated 1A @ 24Vdc

Port 1 (RS485)

1

Zones 17

3

19

2

18

Fault

4

20

5

21

6

22

7

23

8

24

9

25

10

26

15 16

11 12 13 14

30 32

27 28 29 30

Fire

15:45

Verify

Healthy

Power Fault

System Fault

Delay

Sounder

Vigilon Fire System

GENT 2010

Pt 2 & 4

Designed to EN54

CB253

CB254

Optional Loop circuits 2 to 4/6

Power

Port 0 (RS232)

Test

Previous

Next

Disablement

EN Vigilon

Control Panel

Loop circuit 1

S4

i/o

230V ac

Mimic Panel

230V ac

230V ac

S

Spur

Magnetic door

release

S

S4

T

4

230V ac

Tx

T

4

S

4

S

S4

o~

Rx

Addressable System Devices

S

S

3

230V ac / 24V dc

Conventional 2-wire

system equipment

S4

i

Repeat Panel

S

Conventional 2-wire

system equipment

(eg 7800 detectors)

S4

MP

3

4

4

4

S

3

S

Battery box

(needed for

VIG1-72 only)

S4

Input output signals

may be used to control

and monitor:

Plant equipment

Building management system

Output to control plant

3

S

Conventional Products off

interface inputs

- S-Quad

Sensor Speech Sounder & Strobe

S4

i/o

- S4 4-Input/Output

loop powered interface

- Magnetic door release

- S-Cubed

Voice enhanced Speech,

Sounder, Strobe Unit

S4

i

- S4 1-Input

loop powered interface

- Conventional Fire Detector

S4

o

- S4 1-Output + Confirmation

input loop powered interface

- End of Line Unit

- Manual Call Point

- T Breaker

S4

o~

- S4 Mains switching output

loop powered interface

- Alarm sounder

- Manual Call Point

4

T

Tx

Rx

- Beam sensor

Transmitter and receiver

S4

MP

LED off S sensor

L

- Remote LED

- S4 - Input/Output

mains powered interface unit

7

Installation instructions

Devices per Device loop

"

It is important that redundancy is built into the system to accommodate future expansions.

The number of devices on one loop circuit can be limited by the total number of addresses available, the electrical load on the circuit, the maximum

cable length and other geographical considerations.

¨ A loop circuit must not cover more than 10,000m2 of floor area of a protected site.

¨ In total a maximum of 200 devices are allowed per loop circuit..

¨ As a general rule allow 1000 load factor per loop circuit.

¨ A maximum of 512 loop devices is allowed per panel.

The following table can be used as a rough guide only to determine the loop load.

"

For a precise battery standby value use the Battery Standby Calculator. The Battery Standby Calculator tool should be used

during system design stage to determine the loop loading. The tool can be downloaded from the Gent Expert forum

(www.gentexpert.co.uk), which is accessible to registered users.

Load

factor per

device

Maximum

devices

per loop

VIG-RPT-72 Repeat panel (loop powered)

3

4

VIG-MIM-A3 A3 Zonal and Mimic Panel

3

4

S4-720 Heat Sensor

0.5

200

S4-780 Heat Sensor & Sounder

7 - 13*

140 - 60*

S4-720-ST-VO Heat Sensor, Speech & Strobe

17 - 25*

60 - 40*

S4-710 Optical Heat Sensor

0.5

200

S4-770 Optical Heat Sensor & Sounder

6 - 12*

150 - 60*

8 - 15*

120 - 65*

0.5

200

10

100

S4-771 Dual Optical Heat Sensor & Sounder

7-12*

150 - 15*

S4-711-ST-VO Dual Optical Heat Sensor, Speech & Strobe

16-24*

55 - 40*

0.5

200

16-24*

55 - 40*

0.5

200

1 - 24

5 - 28

1

24 - 32

28 - 32

170

1

2

26

5

170

170

32

100

5

200

S4-34440 Mains powered interface

4

8~

S4-34418 Keyswitch interface

4

170

S4-34800 Manual call point

4

200

Device code number

Description

S4-711-VO Dual Optical + Heat Sensor & Speech

S4-711 Dual Optical Heat Sensor

S4-711-ST Dual Optical Heat Sensor & Strobe

S4-911 Dual Optical Heat Sensor & CO

S4-911-ST-VO Dual Optical Heat Sensor CO, Speech & Strobe

34729 EP heat sensor

S4-34410 1 - LV Input interface (IZ - EZ)

S4-34450 4 - LV Input/Output interface (IZ - EZ)

S4-34420 1 - LV Output Interface

IZ = Value Including Zone

EZ = Value Excluding Zone

Switch Input

Relay Output

Zone Input

Every LED Output

S4-3441 or S4-34415 1 - MV Output Interface module

8

Vigilon EN54 system

Load

factor per

device

Maximum

devices

per loop

S4-34760 Venturi-Air Duct Kit

0.5

200

S4-34740 Beam sensor pair

3 -per pair

16 (ie 8

pair)

0.4

127

9

22

100

40

5

200

5 - 17

200 - 55

S3-VP-ST-XR Sounder (standard tone) with red strobe

S3IP-VP-ST-XR - Speech complex tone with red strobe

13 - 25

80 - 40

S3-VP-ST-XW Sounder/speech with white strobe

S3IP-VP-ST-XW

37

25

S3IP-SN-ST-XR Sounder standard tone with red strobe

13

80

10

100 ~

4

30~

Device code number

Description

34701 Tee breaker

S2IP-ST-XR Strobe Red

S2IP-ST-XW Strobe White

S3-SN-X Sounder (standard tone)

S3IP-SN-X

S2IP-SN-X/XX

S3-VP-X Sounder (standard tone) - with speech

S3IP-VP-X

Supported products

34415 or Single Channel Interface or

34410 Loop powered zone module

34450 Loop powered interface

The load factors and maximum devices stated in the table above are revised due to changes in product specification

~ - A maximum of up to 100 input channels are allowed per loop.

* - These values are applicable when sounder is operating in turbo mode or with bell tone.

LV - Low voltage

MV - Medium voltage

9

Installation instructions

Vigilon panels

Technical data

The Vigilon panels (VIG1-24 or VIG1-72) are analogue addressable fire

alarm panel designed to the requirements of EN54 Parts 2 and 4. The

panels can accommodate up to 4 or 6 loop circuits for the connection of

Vigilon range of analogue and addressable devices. The panels have

integral mains derived power supply. The VIG1-24 panel has integral

batteries and the VIG1-72 panel have batteries fitted in a separate

enclosure for extended standby supply. The batteries supply standby

power in the event of mains power failure. A lockable front door prevents

unauthorised access to fire alarm controls but allows all of the indicators

to be seen. The panels have integral zonal indicators to provide zone fire

or fault indications. Two push button controls are located on the front

door below the display that enable Fire messages to be scrolled in the

event of multiple fires. The panels are designed for surface or semi-flush

mounting with rear and top cable entry points.

Standard

Designed to EN54 Part 2:1997 +

AMD 1:2006 (and include optional

clauses 7.8, 7.10, 7.11, 8.3, 9.5

and 10)

Approval

LPCB approved

Panel dimensions in

mm with outer door

height 543 x width 406 x depth 172

1

Zones 17

Fault

Power Fault

System Fault

Delay

2

18

3

19

4

20

5

21

6

22

7

23

8

24

9

25

10

26

Control panel

15 16

11 12 13 14

30 32

27 28 29 30

Panel weight

VIG1-24 10.2Kg approximately + 2 batteries

12V 21Ah battery - weight 6Kg

each

VIG1-72

Battery box#

# with 4 batteries

# with 8 batteries

10.2Kg

7.2Kg

31.2Kg

55.2Kg

Fire

15:45

Verify

Healthy

Sounder

Vigilon Fire System

GENT 2010

Pt 2 & 4

Designed to EN54

CB253

CB254

Storage temperature

-10 to 55ºC

Operating

temperature

-5 to 40ºC

Relative Humidity

(Non condensing)

Temperature

-5 to 40°C

up to 90%

Emission

BS EN61000-6-3:2001 Part 1

Residential, Commercial & Light

Industry Class B limits.

Immunity

BS EN50130-4: 1996: Part 4

Alarm systems: Electromagnetic

compatibility. Product family

standard: Immunity requirements

for components of fire, intruder and

social alarm systems.

Ingress Protection

IP30

Colour

Door: Grey (Pantone 422)

Back box: Graphite Grey

(RAL 7024)

Loops

The panel is supplied with a loop

card for 1 loop circuit. It can

support up to 4/6 Loop circuits,

using optional loop cards.

Network

Two types of network cards are

available for secure network

connection:

Fibre Optics - 2Km maximum

Copper (RS485) - 1.2Km maximum

RS232 and RS485

connections

The panel will require an optional

standard IO Card to facilitate

RS232 for connections for domain

bridging and remote printer. The

maximum cable length allowed for

RS232 is 15m.

Power

Test

Previous

Next

Disablement

042bc

Features

¨ Analogue addressable fire alarm control panel

¨ Supports up to four or six loop circuits per panel

¨ Up to 200 addressable devices can be connected to a

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

10

loop circuit. Devices like sensors, MCPs and interface

units etc.

Two master alarm circuits

Optional RS485 to connect to a Repeat Indicator panel

Optional RS232 to connect to another control panel

(domain bridge) or external printer

USB for commissioning tool connection

Two sets of auxiliary relay change over contacts

configurable to operate with fire, fault or disablement

One set of clean voltage-free change over contacts that

operates with fire events

Standby supply to power the system during mains failure

LCD alphanumeric display with back light to show event

information

Integral 32 zone LED indicators (with First fire steady /

flashing or disable integral zone indication's options)

LED lights for event indication

Local buzzer gives audible sound to announce events

Push button for essential controls and menu options

Four programmable control buttons (U1 to U4)

A remote battery box (for VIG1-72 panel only)

The panel has an RS485 port to

accept the Repeat Indicator panels.

The Commissioning tool can be

connected to the panel via the

USB port on the Master Control

Card.

Vigilon EN54 System

Devices per loop

A maximum of 200 addressable

devices per loop circuit.

Device label

Each device can be given a

32 character label for identification.

Each MCP is restricted to

28 character label.

Plug in Card slots

MCC / LCC -P1

IOC / N/W -P2

Loop 1 - P3

Loop 2 - P4

Loop 3 - P5

Loop 4 - P6

Loop 5#, IOC or

N/W-P7

Loop 6#, IOC or

N/W -P8

Master Control card - supplied

Input Output card / Network card

Loop card - supplied

Loop card option

Loop card option

Loop card option

Loop card#, Input Output card or

Network card

Loop card#, Input Output card or

Network card

Controls

(with door open)

Access level 2a

Sound Alarms, Silence Alarms,

Reset, Cancel Buzzer, Verify,

F1-F4 keys, Menu On/Off key,

QWERTY key board, U1-U4 keys

User having door key available if configured to perform

site specific actions by triggering of

command builds 251, 252, 253 and

254.

Access level 2b

Access as level 2a plus access to

User having an outer complete level 2 menu commands.

door key and

customer password

Access level 3

Engineer having an

outer door key and

engineer password

Access as level 2b plus access to

all level-3 menu commands.

Indicators

Fire (red)

32 - Zones (red) hidden until lit

Power (green)

Power Fault (amber)

Delay (amber)

Test (amber)

Verify (amber)

CB253 CB254 (amber)

Fault (amber)

Disablement (amber)

System fault (amber)

Sounder (amber)

Logs

Active Logs: Fire, Fault and

Disablement

Historic log: All events

Event logs: Fault, Disablement,

Warning, Supervisory, Exceptions

and Historic fires.

Printer

The integral printer if fitted

operates when the outer door is

open. The 'printer menu' include:

ON, OFF, Line feed and Test print

controls.

# - for VIG1-72 only

Clean contacts

1 set of voltage free change over

contacts rated 1A @ 24Vdc, active

with a fire event.

Master alarm circuits 2 - (24 volts nominal)

400 mA max per circuit

MA1 - fuse 1A FS1

MA2 - fuse 1A FS2

(20 x 5mm) on Terminal card.

Voltage-free contacts rated

1A @ 24Vdc

Aux relay 1 2 sets of change over contacts

configured to operate immediately

with Fire event. The relay is

normally de-energised.

Auxiliary relays

Aux relay 2 2 sets of change over contacts

configured to operate immediately

with Fault event. The relay is

normally energised.

The relays can be re-configured to

operate with Fire, Fault or

Disablement event, with a

maximum delay of up to

10 minutes and can operate in a

normally energised or de-energised

state.

Internal sounder

To announce Fire and Fault

events, plus give a key press

confirmation beep.

Display

Alpha-numeric display - 8 lines by

40 characters per line, back-lit,

(Black characters on green

background, liquid crystal display)

Menus

Controls

(with door closed)

Access level 1

[Control], [Setup], [Information] and

[Test Engineering] menus

accessed via Menu On/Off, F1, F2,

F3 and F4 buttons.

Next and Previous buttons

operable during Fire condition only.

An optional remote printer can be

connected to the panel.

Batteries and Battery Box

The batteries provide 24/72 hour standby supply plus power to alarm

load for 30 minutes. The Battery Loop Loading calculator can be used to

determine the load on the loop to achieve the standby power in the event

of mains failure. The battery box is only used with the VIG1-72 panel and

can be installed in a remote location up to 10m cable distance away from

the control panel when using 1.5mm2 MICC. When using 2.5mm2 MICC

then the cable then this distance can be increased to 15m.

Battery box

dimensions in mm

height 437 x width 421 x depth 174

Terminals

Accept cable size of up to 2.5mm2

Battery box weight 31.2Kg with 4 batteries

(including

55.2Kg with 8 batteries

batteries)

1 x 12V 21Ah battery weight is 6Kg

11

Installation instructions

Battery

VIG1-24 Batteries installed in the panel

2 x Powersonic 12V 21Ahr (supplied)

Model number PG12V21 B

VIG1-72 Batteries installed in a battery box

4 x Powersonic 12V 21Ahr (supplied).

Model number PG12V21 B

The battery box can optionally

accommodate up to 8 x Powersonic

12V 21Ah

Temperature

monitoring

Inside the VIG1-24 panel and in the

battery box for VIG1-72 panel - for

automatic adjustment of battery

charge voltage with change in

temperature.

&

Always use the recommended replacement

battery, as there is a risk of an explosion if incorrect

battery is used.

Power supply

Standard

Designed to EN54 Part 4:1997 +

AMD 1:2002 and AMD 2:2006

Mains operating

voltage

230V 50Hz +10% -6% is

protected by a 3.15A (T) 250V

Ceramic (20 x 5mm) on PSU.

Input current - 1.4A

Nominal supply voltage 24V +1V, -4V

for master alarm

circuits

Battery circuit(s)

Terminals to connect to internally

or externally housed batteries.

Batteries reach fully charged

state in 72Hr for VIG1-24 and

VIG1-72.

Battery current with

mains disconnected

VIG1-24 - 4.5A max.

VIG1-72 - 6.2A max.

Light indications

To show the status of PSU

Mains FS6 T3.15A Ceramic

44V supply FS2 F3.15A Glass

Battery charge circuit 1 FS1 F10A Ceramic for VIG1-72

only

Battery charge circuit 2 FS7 F5A Ceramic for VIG1-24 only

FS3 F10A Ceramic for VIG1-72 only

All fuses 20mm x 5mm size

EN54 Part 4 data

VIG1-24

I min -> 780uA

I max a -> 162mA @ 43.5V

I max b -> 2.4A @ 43.5V and

2 x 0.5V @ 24V

Ri max -> 1.25R

UVLO -> 20.7V ± 0.4V

VIG1-72

&

Hazardous voltages may still be present even if

this indication is extinguished.

Installation checks

A VIG1-24 and VIG1-72 panels include the following parts:

¨ Back box assembly with PSU to power the Control panel

¨ Inner door for Control panel

¨ Moulded outer door

¨ Loop Card (1- loop card supplied), can accommodate

up to 4 maximum in VIG1-24 and up to 6 in VIG-72

panel

¨ Main Controller Card for VIG-24 or VIG-72 panel

¨ VIG1-24 is supplied with 2x12V 21Ah batteries

VIG1-72 is supplied with 4x12V 21AH batteries for

installation inside a battery box (the battery box can hold

up to 8 x 12V 21Ah batteries)

¨ A Battery box is supplied with VIG1-72 panel only

Parts supplied in spares packs

Part

Cable tie

-10 to +55ºC

Operating temperature -5 to 40ºC

Relative Humidity

(Non condensing)

Qty

Battery

VIG1-72 box

3

3

1

1

2

2

22K 0.5W Resistor

1

Battery lead

Spade tag

2

1

4

Link lead

4

up to 90%

Temperature -5 to 40°C

Maximum current from 5.8A

battery without mains

connected

12

Qty

VIG1-24

Ferrite core

PSU Fuses

Storage temperature

I min -> 780uA

I max a -> 108mA @ 43.5V

I max b -> 1.6A @ 43.5V and

2 x 0.5V @ 24V

Ri max -> 1.25R

UVLO -> 20.7V ± 0.4V

Battery lead fused

i

1

Instructions

1

1

Vigilon EN54 System

20 x 5mm

Fuse 5A QB Ceramic

1

20 x 5mm

Fuse 3.15A AS Ceramic

1

20x 5mm

Fuse 3.15A QB glass

1

a.

Identify the package VIG1-24 / VIg1-72 and check that

it contains all the parts.

b.

Remove the temporary cover from the Back box.

c.

Knock out/in the required cable entry points from the

Control panel back box and from the Battery box.

d.

Use the fixing points provided to mount the Back box

and Battery box to the wall using suitable fixings.

1

1

2

20x 5mm

Fuse 10A QB Ceramic

4

&

1

The fixings must support a fully assembled

Control panel and Battery box.

The VIG1-24 panel with batteries weigh 22.2Kg and the

VIG1-72 panel weigh 10.2Kg. The batteries for a VIG1-72

panel are mounted in an external battery box weighing

either 31.2Kg (4 batteries) or 55.2Kg (8 batteries).

Terminal block

1

1

Adhesive backed foam

pad

Each battery pair of 2 x 12V 21Ah is supplied with:

4 x bolts

4 x washers

e.

Stick the adhesive backed foam pad supplied to cover

gaps around the centre key-hole fixing point in the back

box. This is done to seal any gaps to prevent ingress.

f.

Terminate each cable at the entry point leaving 400mm

tail wire length and mark each core to identify its final

connecting point.

4 x spring washers

Back box installation

These instructions cover installation of the panel and battery box. The

cards and batteries are installed during the commissioning of the system

by the servicing organisation.

"

The control panel can be surface or flush mounted.

The only time it should not be flush mounted is when the battery

box is close fitted beneath the control panel.

Earth to

Inner door

&

If the mains cable is not connected to the

respective terminals then ensure the tail ends are insulated

to guard against accidental switching ON of the mains

supply.

Cable entry points

18 - Back

18 - Top

2 - Bottom side

(on the right)

9-off Earth points

(1-0ff bottom side

on the right hand)

Mains supply

cable

Knock outs

502mm

1.7m

Backplane

Dust

cover

over

backplane

Adhesive backed foam pad

to seal up gap to prevent

ingress

PSU

0V

to printer

Back box

for VIG-72 shown

5-off Backbox

fixing points

(includes

1 keyhole)

Fitted on VIG1-72 only

390mm

Floor level

13

Installation instructions

Semi-Flush fixing the control panel

The control panel may be semi-flush mounted using a semi-flush surround VIG-24-FLUSH. A stainless steel variant of the

semi-flush surround (VIG-FLUSH-SS) will require a stainless steel door VIG_DOOR_SS.

a.

Check the contents of the semi-flush surround package.

b.

Cut out an aperture in the wall to allow the semi-flush surround to be fitted, see the diagram below for dimensions of

the aperture in the wall.

c.

Using the fixing holes on the semi-flush surround secure it into the aperture side walls.

d.

Knock out the appropriate top or rear cable points on the control panel back box.

e.

Route the cables through the cable entry points into the back box and at the same time insert the back box into the

semi-flush surround.

f.

Fit the back box to the semi-flush surround using the 5 - 5mm fixing-screws supplied in the spares pack.

Control panel

semi-flush surround

Aperture depth

- 132mm

Cross section of

the wall to which

the panel is to be

semi-flush mounted

Aperture Height:

510mm - Control panel

Flush

Surround

Control Panel

5mm diameter

fixing holes

Aperture Width:

390mm - Control panel

Battery box for VIG1-72 panel

The connecting battery cables from the control panel to the battery box can be either 1.5mm2 or 2.5mm2.

The battery box can be mounted beneath the control panel or in a remote location. The battery box can be up to 10m cable distance away using

1.5mm2 cable or 15m cable distance using 2.5mm2 cable.

Earth lead

Locakable Door

Backbox

Cable entry points

3 - Back

5 - Top

Earth points

2-off on the top side

of the case

Terminal

card

5-off Backbox

fixing points

Upper Shelf

Hole for battery cables

from terminal card

to batteries on lower shelf

Lower Shelf

14

Vigilon EN54 system

19 inch Rack mounting frames

4 holes with

threaded

bushes for

securing

control panel

Panel

Battery box

4 holes with

threaded

bushes for

securing

battery box

9U

14U

6 off holes for securing

to 19" Rack

10 off holes for securing

to 19" Rack

Wiring the battery box

Panel

P3

P2

P1

Where the wiring is terminated

at the top of the panel ensure

the cables run neatly

down the side of the

enclosure to the terminals

Wiring options

Cable distance

1.5mm sq - 10m maximum

2.5mm sq - 15m maximum

Control panel

B1B2B1+

B2+

TH+TH-

Battery box

in a remote

location

Control

panel

TH+ B1+ B2+

TH- B1- B2-

P6

P4

P3

P1

P2

Here the battery box is

shown mounted beneath

the control panel

TH1

Battery

box

Battery Box

15

Installation instructions

"

Mains supply

To maintain earth continuity, an earth lead (not

supplied), is required to be fitted to an earth point in the control

panel with the other end to an earth point in the battery box.

MICC

CABLE TERMINATION

Softskin (Fire Tuf)

CABLE TERMINATION

MICC CABLE

GLAND

ZINC PLATED

LOCK WASHER

BRASS

LOCKNUT

EARTH

DRAIN

WIRE

Should not

be more than

50mm long

and must be

sleeved

Softskin Cable

GLAND

PANEL

enclosure

&

Ensure that the mains supply cable enters the

panel through a dedicated cable entry point.

"

These fire alarm system products are NOT designed

to be powered from IT Power systems.

All mains powered equipment must be earthed.

Mains supply to any fire alarm control and indicating equipment must be

via an unswitched 5A fused spur unit. A disconnect device must be

provided to disconnect both poles and must have a minimum gap of

3mm. The Disconnect device should be available as part of the building

installation and must be easily accessible after installation is complete.

Dedicated mains supply

from consumer unit

BOARD

TERMINALS

5A Unswitched

fused spur unit

&

Terminate each cable at the dedicated entry point on the enclosure,

using the cable manufacturer recommended techniques.

Where the cable is not required to be connected, leave 400mm tail wire

length (unless otherwise instructed) and mark each core identifying its

final point of connection.

Where the cable is required to be connected, ensure it is secured to the

respective terminal.

Wiring tests

&

Don't undertake high voltage insulation tests

WITH THE CABLES CONNECTED to the panel and system

device terminals. Such a test may damage the electronics

circuitry in loop devices and at the panel.

Mains and battery supply connections

The mains and battery supply cables must be installed to the stage to

facilitate the power up for commissioning, which is carried out by the

Servicing organisation.

&

Where mains cable is to remain disconnected, its

tail ends must be insulated to prevent dangerous

conditions arising in the event of accidental switching On

of the mains supply.

16

must be sleeved

50mm

Use cable ties

(supplied)

ferrite

core

(supplied)

L

270mm

The wires between the termination point and terminals should be as

short and straight as possible.

Where a cable has an earth drain wire, the wire must be fitted to the

earth point nearest to the cable entry point. Ensure the drain wire length

does not exceeding 50mm.

Gland

35mm

Cable termination and markings

Panel

45mm

Unused knockouts that have been removed must NOT

be left open.

mains

cable

mains cable

N

P2

PSU PCB

The mains cable must be stripped

back to the length shown to allow

live and neutral wires to be wound

twice through the ferrite core.

5mm

The fused spur isolator cover should be marked:

FIRE ALARM - DO NOT SWITCH OFF

The fire alarm equipment’s fused spur unit must be fed from a

dedicated switch or protective device at the local mains supply

distribution board.

Vigilon EN54 system

Terminals for external circuits

The Terminal card holds all the terminals for the connection of external circuits. The exceptions are:

¨ terminals for CARDS in slots P7 and P8, these are located on the Backplane

¨ terminals for mains supply, these are located on the mains terminal block

¨ terminals for batteries, these are also optionally located on the PSU.

Backplane

Terminal card

NETWORK CARD IN SLOT P8

0V1 +VE1 -VE1 0V2 N/C +VE2 -VE2 N/C

LOOP CARD IN SLOT P8 (Loop 6)

L1 0V L2 0V

A

5V

CARD 4

LOOP 4

CARD 3

LOOP 3

L1 0V L2 0V

CARD 2

LOOP 2

L1 0V L2 0V

CARD 1

LOOP 1

L1 0V L2 0V

L1 0V L2 0V

IO CARD IN SLOT P8

B 0V CTS Rx RTS TX

P2

Clean C

NC C NO

Master alarm

PB1

P3

MA1+ MA1- MA2+ MA2-

IO (RS232) CARD IN SLOT P7

N/C

0V CTS RX RTS TX

P5

LOOP CARD IN SLOT P7 (Loop 5)

L1 0V L2 0V

P6

0V1 +VE1 -VE1 0V2 N/C N/C +VE2 -VE2 (WITH NETWORK CARD IN SLOT P2 OF BACKPLANE)

PB2

A

RS485

5V B 0V

RS232

Tx CTS Rx RTS

(WITH IO CARD IN SLOT P2 OF BACKPLANE)

P4

Auxiliary Relay 1

NC C NO NC C NO

Auxiliary Relay 2

NC C NO NC C NO

P8

P7

RS232 0V

0V 0V 0V 0V

P12

Quick release terminals

PSU board (located behind the cardboard cover)

L

N

P2

17

Installation instructions

Loop circuits

The loop circuits can each accept connection of addressable devices a

maximum of 200 devices is allowed per loop. To maintain earth

continuity on a loop it is important for the loop cable screen to be

continued through each system device, whether the earth is connected to

a device or not.

"

A loop circuit must not cover more than 10,000m2 of floor area of

a protected site.

A spur circuit must always be taken from the line common

terminals of a 3-way loop device.

"

As every loop device has an isolator fitted, it is not

necessary to apply special attention where there are more than

32 devices. However no more than a maximum of 512 devices

shall be installed on one control panel.

A spur should not cover more than the equivalent of one zone as

defined in BS5839 : Part 1.

3

S device

(2-way)

L2

02

L1

01

2 - way device

L1

+

+

+

L2

0V

+

10

1L

20

2L

L2

0V

L1

0V

Earth to

metal box

Note: The 0V terminals

in the terminal plate

are electrically

connected together.

C3

IN4

OUT5

Manual call point

S-Quad

L2

02

L1

01

C3

LOOP CIRCUIT 1

IN4

OUT5

S3 device

(2-way)

S-Quad

L1 0V L2 0V

LOOP n

Terminal Card

PANEL

18

Vigilon EN54 System

Master alarm circuits

Clean contacts

The control panel operates the master alarm circuits in the event of a fire

in the system. The two master alarm circuits accept the connection of

conventional alarm sounders including the conventional

Speech-Sounder-Strobe S3 products.

The control panel will operate the clean contacts when a fire event is

received from the system. The clean contacts can be used to switch

plant equipment, such as lift control system. The relay operates in the

event of a fire. The contacts should be powered from an independent

power supply.

22K Ohms - End-of-line resistor

fitted in the last alarm sounder

Change over contacts

rated 1A @ 24Vdc, to

control external equipment

The clean contact relay is

normally de-energised

and operates with a fire

event without delay.

Conventional

alarm sounders

NC C NO

P6

MA1+ MA1- MA2+ MA2-

P5

PANEL

MASTER ALARMS

Terminal Card

CLEAN

CONTACTS

MA1 - FS2 1A

Terminal card

MA2 - FS1 1A

PANEL

Auxiliary relay circuits

The control panel operates the auxiliary contacts when the configured

event is received from the system. The auxiliary relay 1 and 2 contacts

can be used to control external equipment, such as an automatic dialler

that makes the call for fire fighting action. The relays can be individually

re-configured to operate with either fire, fault or disablement event in the

system. The relay operation can also be delayed by up to 10 minutes

and can be set up to operate in a normally energised or de-energised

state. The contacts should be powered from an independent power

supply.

Change over contacts rated 1A @ 24Vdc,

to control external equipment

NC C NO NC C NO NC C NO NC C NO

P7

AUXILIARY

RELAY 1 Terminal Card

P8

AUXILIARY

RELAY 2

PANEL

Factory default:

Aux relay 1 is normally de-energised and operates with a

fire event without delay.

Aux relay 2 is normally energised and de-energises with a

fault event without delay.

Note: Aux relay 2 has been shown in the above diagram in

its de-energised state, which is the state when there is

no power to the panel.

19

Installation instructions

RS232 / RS485 Communication

Connecting a Remote printer

The control panel offers RS232 and RS485 communication via the IO

card.

When a remote printer is connected to a standalone Vigilon control

panel, it will print local system events.

Terminals for IO card

in slot P2 of the backplane

RS232

Tx CTS Rx RTS

(Serial printer)

25-way D-type connector

P4

Rx

RS485

A 5V B 0V

Remote Printer

Rx

PORT 0

An IO card (not supplied) must be inserted in slot 2 of

the backplane of the panel, which will facilate remote printer

functionality.

GND

Tx

PORT 1

IO card

"

GND

Tx

A standard IO card (not supplied) must be inserted in slot P2 of the

backplane of the panel, which facilate RS232 and RS485 communication

via terminal block P4 onTerminal card. Note the RS232 is PORT 0 and

RS485 is PORT 1. The domain address and communication baud rate

are configured by setting the DIL switch located on the left edge of the

Display Keyboard card.

Terminal card

PANEL

IO, Network or

Loop card option

IO or Loop card option

NETWORK CARD IN SLOT P8

0V1 +VE1 -VE1 0V2 N/C +VE2 -VE2 N/C

IO (RS232) CARD IN SLOT P7

N/C

0V CTS RX RTS TX

LOOP CARD IN SLOT P8 (Loop 6)

L1 0V L2 0V

LOOP CARD IN SLOT P7 (Loop 5)

L1 0V L2 0V

A

5V

IO CARD IN SLOT P8

B

0V CTS Rx RTS TX

Terminals for

IO card configured for

Remote printer

in slot P2 of the backplane

RS485

RS232

A 5V B 0V Tx CTS RxRTS

P4

If the IO card to which a

remote printer is connected

is installed in a spare slot

Terminal card

on the backplane then use

the corresponding terminals PANEL / NODE

On completion of wiring installation

PB1

MCC / LCC

- P1

I/O or N/W

- P2

LOOP or RS232

- P3

LOOP or RS232

- P4

LOOP or RS232

- P5

LOOP or RS232

- P6

LOOP or RS232

- P7

LOOP, N/W or I/O

- P8

Backplane

PANEL

20

PB2

On completion of all wiring refit the temporary cover onto

the back box. All outstanding work is done by the servicing

organisation during commissioning.

Vigilon EN54 System

Mimic panel

Customised Mimic

Technical Data

Panel dimensions height 403mm, width 338mm,

depth 101mm

Weight

7.9Kg without batteries

10.5Kg with batteries

Storage

temperature

-10 to 55ºC

Operating

temperature

0 to 45ºC

Relative humidity Up to 90% temperature

(Non condensing) 5 - 45°C

Battery

2 x 6V 7Ah sealed lead acid

(weight 1.3Kg each)

The integral battery provides

power for 72 hours in standby

condition and a further

30 minutes in alarm.

Mains operating

voltage

230V 50Hz +10% -6%

Emission

BS EN61000-6-3 : 2001

Immunity

BS EN50130-4 : 1996 : Part 4

LVD

BS EN 60950-2006

Zonal Mimic

Ingress protection IP30 (estimated)

An A3 Mimic or Zonal panel must be connected to a loop circuit of the

fire detection and alarm system. It is used to provide indication of fire

events in the system. However it can also be used to provide indication

of fault and supervisory events in the system. The panel can be mounted

in landscape or portrait orientation.

A Customised Mimic holds a pictorial overlay that represents the

protected building or an area within. A fire event is indicated by the

illumination of appropriate red LEDs behind the overlay to show the

location of the fire.

Colour

Door - Pantone 422

Back box - Graphite Grey

(RAL 7024)

Control

Cancel fault buzzer / lamp test

button

Indicators

1536 high intensity RED

LEDs.

Loop connection

3-way connection to a loop

circuit

Typical Mimic illuminations

Customised Mimic

A Zonal Mimic provides a traditional zone by zone indication of a fire.

Each zone is given a location label to identify the area within a building.

Zonal Mimic

ZONE n

The panel illumination defaults to a Zonal Mimic but can be

reprogrammed during commissioning to be a Customised Mimic. An

array of red lights illuminates individually or in groups. Illuminations may

be applied to include custom shapes, text and digital clock in small or

large size. A site specific 'welcome message' may be configured for

display during quiescent conditions that can scroll if it is too long to fit the

display area. First or last fire flashing option, with in phase or anti phase

flash.

Zone in fire

- steady indication

Latest zone in fire

- flashing indication

The panel has its own mains derived power supply with battery for

standby power in the event of mains supply failure.

Flashing in phase

or anti phase

21

Installation instructions

Compatibility

1 Set

As a Zonal Mimic panel the system control panel must have the

following card software:

Control panel CARD

EN54

Control Panel software

LPC

Shorter Card ONLY

³ V4.19

³ means equal to or greater than

As a Customised Mimic panel the system control panel must have the

latest card software.

~

Overlay pack for A3 Mimic

panel

1 x pre-printed Zonal sheet

2 x blank A3 sheets for printing

a Mimic or Zonal overlay

1 x LED spacing sheet

The overlays in the pack are high

quality UV protected A3 paper.

A magnetic strip used to hold an overlay

in place is fitted to the top side of the inner

door.

Installation

Mounting the backbox

Fuses on Master Repeat Card

Fuses Rating

FS4

3.15A AB Ceramic 20mm x 5mm

FS2

3.15A AB Ceramic 20mm x 5mm

FS3

2AQB

20mm x 5mm

The Mimic Panel set consists of:

Component

The A3 Customised Mimic panel can be mounted either landscape or

portrait, while an A3 Zonal mimic panel must only be mounted landscape

when using the overlay supplied.

a. Locate the package Back box assembly u.

Landscape orientation

Earth points

4-off

Quantity

Top cable entry points

5-off Back

5-off Top

1

by Honeywell

VIGILON FIRE SYSTEM

NOT YET IN SERVICE

AWAITING COMMISSIONING

u

Backbox assembly

by Honeywell

1

240mm

v

VIGILON FIRE SYSTEM

NOT YET IN SERVICE

AWAITING COMMISSIONING

Inner door assembly

Back box

1

w

x

Outer cover assembly

Key for Outer cover

y

3.15A 20mm x 5mm AB Ceramic

z

2A 20mm x 5mm Quick Blow Fuse

380mm

1

Portrait orientation

Cable entry points

5 - Back and 5 - Top

2

1

1

2

}

380mm

Back box

Earth points

4-off

AWAITING COMMISSIONING

1

by Honeywell

Link lead

NOT YET IN SERVICE

|

Battery lead

VIGILON FIRE SYSTEM

{

6V 7Ah Battery

240mm

22

b.

Knock out the required cable entry points from the back

box.

c.

Mark out the 4-back box fixing positions on the wall to

which the panel is to be mounted and secure it with

suitable fixings.

Vigilon EN54 system

&

Ensure the mains power is isolated to from the panel.

d.

Terminate the loop and mains cables at the entry points and if required connect the cables to the appropriate

terminals.

e.

All the other parts are installed during commissioning.

External wiring

Loop OUT

Loop COM

From

Loop IN

Mains fused spur

Master Repeat Card

L

0C LC 01 L1 02 L2

N P9

P17

P16

RESET

3.15A(T)

mains fuse L

N

FS4

P9

0C LC 01 L1 02 L2

FS4

WRITE PROTECT

DANGER

P4

L

N

P16

The external cables are routed into the back box using the cable entry points on the back box. The left 4 entry points are for the loop cables that

connects to terminal block P16. The right cable entry point is for the mains cable which is connects to the terminal block P9.

"

All the other parts supplied with the A3 mimic panel are fitted during the commissioning stage, however the procedures are

described here for completeness.

How to fit the inner door assembly

The following procedures describe how to fit the inner door assembly to the backbox.

Hinge pin

Align the inner door assembly v to the two hinge pin positions j on the back

box u and slide the door down until it is seated correctly. Insert the top

(removable) hinge pin k and secure it by rotating the pin into the back box.

Close the inner door assembly l and lock it using the fastners at position m.

For minor adjustment of the inner door, open the fixing screw and adjust the

hinge plate to a required position and then secure the plate to the backbox

by tightening the screw .

Magnetic strip

Inner door assembly

Back box

assembly

Adjustable Hinge Plates

23

Installation instructions

Where to connect the internal cables

Fit earth lead

from back box

to inner door

Connect the flat

flexible cable from

inner door to MRC

Back box

Inner door

Master Repeat Card (MRC)

Remove the protective cardboard cover from the Master Repeat Card. Connect the earth lead j from the back box to the inner door assembly.

Connect the flat flexible cable k to socket P13 on the Master Repeat Card , see details on fitting and remove of flat flexible cable.

How to fit the outer cover

Back box

Outer Cover

A

A

Hook the Outer Cover over the top edge of the Back Box . Close the bottom of the Outer Cover onto the Back box and secure the

Outer Cover by the two captive screws on the cover using the key supplied.

Ensure the zonal mimic or customised mimic plan is located centrally within the anti glare window of the outer cover.

For full information see leaflet supplied with the product.

24

Vigilon EN54 System

Technical Data

Repeat Panel

(loop connectable)

Panel healthy

15:45

Panel dimensions

height 403mm, width 338mm,

depth 101mm

Weight

9Kg with batteries (approximate)

Storage

temperature

-10 to 55ºC

Operating

temperature

0 to 45ºC

Relative humidity

(Non condensing)

Up to 90% temperature

5 to 45°C

Battery

12V 7Ah sealed lead acid

Mains operating

voltage

230V +10% -6% 50Hz

Emission

BS EN61000-6-3 : 2001

Immunity

BS EN50130-4 : 1996 : Part 4

LVD

BS EN 60950-2006

Ingress protection

IP31 (estimated)

Colour

Door - Pantone 422

Back box - Graphite Grey

(RAL 7024)

Controls

(with door closed)

Access level 1

Next and Previous buttons

operable during fire condition

only.

Control buttons

(with door open)

Access level 2

Sound Alarms, Silence Alarms,

Reset Fire, Cancel Fault Buzzer,

Verify, F1-F4, Menu On/Off and

U1-U4.

Indicators

Fire, Verify, Power, Fault, Power

Fault, System Fault, Delay and

CB253/254.

EN panel only: Sounder,

Sounder, Delay, Disablement

Test and 32-Fire Zone LEDs.

BS panel only: Commission and

Warning.

Display: 8 lines 40 characters

per line, back-lit LCD.

Loop connection

3-way connection to a loop circuit

EN54-17 data

Fire detection and

fire alarm system

short circuit isolators

Vmax 42V

24V

Vmin

VSO min 8V

IS max 1A

ZC max 0.1W

Vigilon Fire System

GENT 2007

The repeat panel duplicates all of the control panel indications and the

essential controls.

The repeat panel has its own mains derived power supply with battery for

standby power in the event of mains supply failure. A lockable front door

prevents unauthorised access to fire alarm controls but allows all of the

indicators to be seen. The panel is designed for semi-flush or surface

mounting and facilitates both rear and top cable entry points.

This repeat panel can be installed on a loop circuit of the Gent Vigilon fire

detection and alarm system. It can be sited near an entry or exit point of

a building and fit in with the loop cable routing.

Compatibility

The repeat panel is compatible with system control panel having card

and software listed below:

Control panel

CARD

LPC

Shorter Card

ONLY

Control Panel Software

EN54

BS5839

³ V4.19

³ 3.90

³ means equal to or greater than

Vnom

40V

VSO max 16V

IC max

0.4A

IL max

20mA

25

Installation instructions

Aperture depth should not be

less than: 59mm

Repeat panel

semi-flush surround

Installation

The Repeat Panel Set consists of:

Parts

Quantity

À

Backbox assembly

1

Á

Outer door assembly

1

Â

Inner door assembly

1

Ã

20 Way ribbon cable

1

Ä

40 Way ribbon cable

1

Spares pack (includes battery leads and

membrane labels for BS panel )

1

Battery 12V 7Ahr

1

Aperture Height:380mm

Repeat Panel

5mm diameter

fixing holes

Fuses on the Master Repeat Card

Fuse

Rating

FS4

3.15A AS 20mm x 5mm

FS2

3.15A AS 20mm x 5mm

FS3

2A QB 20mm x 5mm

Cable entry points

4-off - Back and 4-off - Top

310mm

45mm

Secure the back box to the wall with suitable fixings. If

the backbox is to be semi-flushed then use the optional

semi-flush surround.

c.

Terminate the cable at the entry point leaving 400mm

tail wire length.

If mains supply cable ends are not required to be

connected then ensure the ends are insulated for safety.

3-off

Earth points

d.

Doors, Cables and Power up

1.65m

cL

L

0C LC 01 L1 02 L2

Refit the temporary cover to protect the panel until all

building work is complete.

The doors and cables are installed after building work is finished.

a. Remove the protective cover from the backbox.

115mm

115mm

N P9

b.

Fit the inner door to the panel enclosure

remembering to connect the earth lead from the

backbox to the inner door. Fit the outer moulded door

to the backbox.

c.

Wiring the panel:

P17

P16

RESET

DANGER

P4

285mm

370mm

&

FS4

WRITE PROTECT

L

N

Ensure the mains supply is completely powered

down before wiring the mains cable ends.

P8

P2

DANGER

DO NOT

REMOVE

SW3

• connect the mains cable to terminal block P9 on the

WARNING

BUZZER

DISABLE

P7

USB

FS3

2A(QB)

Removal of

cover exposes

live parts.

FS2

P5

+ -

RS485

Floor level

DANGER

WD1

P14

0V 24V

Master Repeat Card.

BT+ BT-

P1

• fit battery lead supplied in the spares to connector P5

PB2

Backbox

on Master Repeat Card.

• connect the loop cables to terminal block P16 on the

Master Repeat Card.

• connect the 40 way ribbon cable to the Master Repeat

Card connector P2 and the other end to Display Key Card

on the top right edge connector - P1.

• connect the 20 way ribbon cable to the Master Repeat

Card connector P1 and the other end to Display Key Card

on the top right edge connector - P6.

Fixing centres

4-off

Find the Repeat panel Back box package and

remove the temporary cover.

d.

26

Aperture Width: 320mm

b.

&

Back box mounting

a.

Cross section of

the wall to which

the panel is to be

semi-flush mounted

Power-up is done during commissioning by the service

organisation and it involves switching ON the mains

supply and connection of battery leads. The Power up

indications are:

• all the LEDs on the panel are lit for a short duration and a

power up message displayed.

• the local buzzer sounds

• the display reads: Main panel is off Line

• the Fault and System Fault LEDs are lit.

Vigilon EN54 system

Spur Connection

mains electrical

supply

Loop OUT

Loop IN

Zones

1

17

2

18

3

19

4

20

5

21

6

22

7

23

8

24

9

25

10

26

11

27

12

28

13

29

14

30

Fault

System Fault

Delay

15

30

16

32

Fire

Panel healthy

15:45

Verify

Power Fault

XXXXX --- Fire Alarm System

GENT 2009

Designed to EN54 Pt 2 & 4

Test

Sounder

CB1

0C LC 01 L1 02 L2

CB2

Disablement

Power

Previous

Next

3.15A(T)

mains fuse L

N

FS4

P9

P16

Repeat panel

Loop COM

Loop IN

From Mains fused spur

Loop OUT

Inner and outer

doors not shown

40-way

ribbon

to DKC

3.15A(T)

mains fuse

Master Repeat Card

L

0C LC 01 L1 02 L2

20-way

ribbon

to DKC

N P9

P17

P16

RESET

FS4

WRITE PROTECT

DANGER

P4

L

N

P8

P2

DANGER

DO NOT

REMOVE

SW3

BUZZER

DISABLE

P7

USB

FS3

2A(QB)

DANGER

Removal of

cover exposes

live parts.

FS2

WD1

P14

P5

+ -

RS485

0V 24V

BT+ BT-

WARNING

P1

PB2

Black

Earth to

Inner door

Red

12V 7Ah battery

Battery Fuse

FS2

3.15A(T)

Ceramic

(Anti Surge)

27

Installation instructions

Installation

a.

Open the outer cover.

The repeat indicator panel provides messages and indications of system

events and it connects directly to the Vigilon fire panel.

J5

J7

b

a

+

-

RS485

REL

J6

24V

Repeat Indicator panel

ON

1 2 3 4 5 6 7 8

1

2

3

4

5

6

7

8

9

0

Back cable entry point

Thinned sections

on sides of enclosure for

cable entry

4 enclosure fixing points

Technical data

Dimensions in mm

height 177 x width 206 x

depth 48.5

Full assembly weight 750g

b.

Insert the external cable into the backbox assembly at

the required entry point.

c.

Mark the fixing points and secure the backbox to the

wall.

d.

Connect the cable to terminals.

Storage temperature 0 to 60ºC