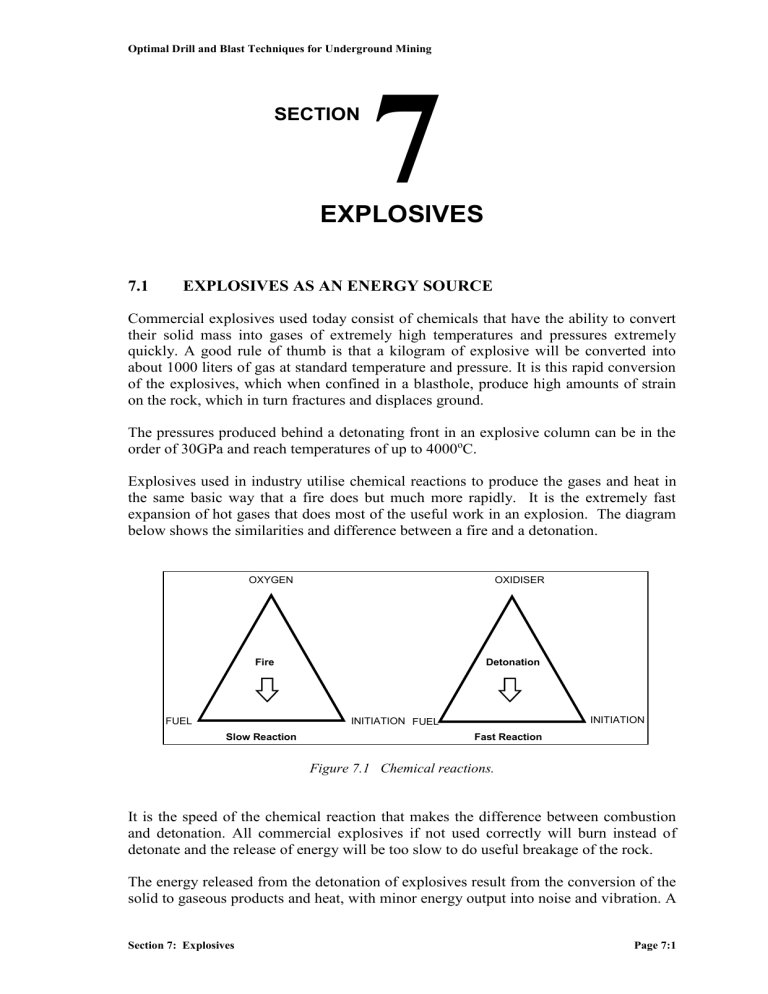

Optimal Drill and Blast Techniques for Underground Mining SECTION 7 EXPLOSIVES 7.1 EXPLOSIVES AS AN ENERGY SOURCE Commercial explosives used today consist of chemicals that have the ability to convert their solid mass into gases of extremely high temperatures and pressures extremely quickly. A good rule of thumb is that a kilogram of explosive will be converted into about 1000 liters of gas at standard temperature and pressure. It is this rapid conversion of the explosives, which when confined in a blasthole, produce high amounts of strain on the rock, which in turn fractures and displaces ground. The pressures produced behind a detonating front in an explosive column can be in the order of 30GPa and reach temperatures of up to 4000oC. Explosives used in industry utilise chemical reactions to produce the gases and heat in the same basic way that a fire does but much more rapidly. It is the extremely fast expansion of hot gases that does most of the useful work in an explosion. The diagram below shows the similarities and difference between a fire and a detonation. OXYGEN OXIDISER Fire FUEL Detonation INITIATION INITIATION FUEL Slow Reaction Fast Reaction Figure 7.1 Chemical reactions. It is the speed of the chemical reaction that makes the difference between combustion and detonation. All commercial explosives if not used correctly will burn instead of detonate and the release of energy will be too slow to do useful breakage of the rock. The energy released from the detonation of explosives result from the conversion of the solid to gaseous products and heat, with minor energy output into noise and vibration. A Section 7: Explosives Page 7:1 Optimal Drill and Blast Techniques for Underground Mining shock wave is created during the conversion that is highly compressed and superheated. This detonation wave travels through the unreacted explosives, driving the detonation further, at a speed greater than the speed of sound in that material. The detonation wave travels at different speeds for different explosive compositions and also at different speeds for the same explosive depending on the conditions in which it is used. Generally the detonation wave travels in the range of 2000m/s to 7500m/s for commonly available commercial explosives. The way in which the detonation wave travels through the explosive is important to the total energy output. If the detonation wave travels slower than the speed of sound in the explosive then the explosive is said to deflagrate, which is basically a rapid burning. The deflagration will generate larger volumes of gas and provide less shock energy from the explosive product. Expanding Gases Shock/Stress Wave in the Surrounding Media Chapman-Jouquet Plane Shock Front in the Explosive EXPLOSIVE Direction of Detonation Undisturbed Explosive Primary Reaction Zone Stable By-products Mainly Gases Figure 7.2 Schematic of detonation process. The useful energy given out by an explosive detonating is divided into the two segments: - Shock or Brisance energy - Gas or heave energy Section 7: Explosives Page 7:2 Optimal Drill and Blast Techniques for Underground Mining Historical Theories Chapman and Jouguet developed the classical hydrodynamic theory of steady-state detonation very early this century. In its simplest form the theory states: PCJ = K * * (VODCJ)2 PCJ VODCJ K = = = = CJ detonation pressure explosive density CJ velocity of detonation constant The theory was based on a one dimensional, discontinuous model. The detonation front propagated through the explosive at a single characteristic velocity (VODCJ ) which is dependent only on the density of the explosive. Explosives, which exhibit such behaviour, are known as ideal explosives. Only molecular explosives i.e. nitroglycerin, react in this way; it is found that commercial explosives are not described by the model. The one dimensional model assumes the entire detonation front is flat and perpendicular to the axis of movement. The discontinuous model assumes that the reaction zone is two-dimensional and acts only as a boundary between reacted and unreacted products. The theory assumes all chemical reactions have gone to 100% completion after passing through this ‘boundary’. discontinuous reaction boundary detonation direction fully reacted product unreacted product Figure 7.3 Principles of the C-J Theory. Zeldovich, von Neumann and Doring (1940’s - ZND Theory) extended the CJ theory to the case where chemical reaction occurs at a finite rate. The detonation wave was considered to be discontinuous and the system one-dimensional. As all commercial explosives work in a non-ideal manner, which can be seen by the explosive’s velocity being dependent on the charge diameter, a theory based on ideal explosives cannot be used. The reaction zone cannot be discontinuous as the chemical reaction during transformation of the solid to a gas is not instantaneous. The detonation takes place in three-dimensions and the theory only assumes one dimension. Taking these three points into consideration this theory and the equation (1) shown above cannot be used to estimate commercial explosive performance. Section 7: Explosives Page 7:3 Optimal Drill and Blast Techniques for Underground Mining After the introduction of non-ideal explosives such as ANFO, watergels and emulsions in the 1950’s there was a need for new theories. Wood & Kirkwood (1954) and Bdzil, Stewart and Fickett (1980’s - DSD Theory) attempted to formulate reactive hydrodynamic equations that better predicted reaction rate parameters. Present Theories A great deal of work has been carried in the last ten years on new theories to predict explosive performance. The basis behind these theories is combining both the explosive and rock properties i.e. Lownds’ Rock Model. Experimental work measuring performance parameters such as diameter effects and shock front curvature are fitted to reactive hydrodynamic equations. Different explosive formulations will have different equation parameters. The same explosive formulation will have different parameters based on the level of confinement and diameter. To determine the explosive’s performance parameters, the following need to be taken into account: - the explosive’s available total energy - the explosive’s effective fragmentation and heave energy i.e. at what pressure or volume expansion does effective fragmentation start and finish. - the expansion work at the maximum detonation velocity - the expansion work at the actual (lower) detonation velocity - the rock mass properties 7.1.1 Shock Energy The influence of the shock energy is greatest in the direction of travel of the shock front and is mostly used up initiating cracks through the rock mass. Generally the shock is used to shatter, not displace rock. Care must be taken not to assume that hard rock must therefore always require a high shock energy explosive to break. Geological conditions play a major role in the use of energy and this will be discussed later. (See Section 6 Fracture Mechanisms). 7.1.2 Gas Energy Gas energy is sometimes referred to as bubble energy, as one of the quantitative tests to measure the energy is carried out underwater to measure the size of the bubble of gas produced upon detonation. Gasses produced in the reaction zone following the detonation wave, account for 8590% of the energy released by the explosive detonating. The gas energy release is the cause of the majority of rock breakage and movement. The gas pressure is exerted on the blasthole wall by the expanding gasses after the reaction has completed. The volume and pressure of the gas is dependent on the temperature at detonation and the formulation of the explosive. Section 7: Explosives Page 7:4 Optimal Drill and Blast Techniques for Underground Mining The gas pressure works by exceeding the rock’s compressive strength in the area immediately around the blasthole, then enlarging cracks inherent in the rock structure and those created by the shock wave. Confinement of the gas energy is therefore essential to achieving good efficiency from the gas pressure. 7.2 EXPLOSIVE TRAIN 7.2.1 Stimulus - Detonator - Primer - Main Charge Upon initiation of an explosive, a detonation or shock front passes through the explosive. Immediately behind the front a primary reaction zone contains an area of chemical reactions - this is where solid ingredients are converted to high pressure gasses. Fundamentally, the detonation front compresses, and therefore heats, the sensitiser agents, usually bubbles. This assists the reaction occurring between the oxidiser and fuel, producing the large amounts of gas. Emulsions need other source of sensitising such as glass balloons or gassing. Sensitisers in emulsion explosives may be in the form of glass/solid spheres (microballoons) or in the form of chemically generated gas bubbles. Damage to these sensitisers through poor handling, effects of detonating cord, or dead pressing will lead to a reduction in sensitivity of the product. Should the loss of sensitivity be of a large order, the product may misfire or not detonate at all. The inherent physical character of AN provides its sensitivity. The prills themselves are porous, and air voids are present between the prills. The detonation process continues along the column, provided the critical density and diameter are not exceeded, and that the sensitisers are not impaired. Behind the detonation front, the chemical reaction produces high temperature and pressure gases, referred to as detonation pressure. These gasses work on the borehole wall and lead largely to the formation of cracks in the rock mass. Behind the reaction plane, the gasses expand further, opening up the cracks and heaving fractured rock. Fragmentation is extended at the same time. This pressure is the borehole pressure. Typically it is of the order of 30 - 70% of the detonation pressure. Finally, rock mass movement occurs. Further fragmentation occurs through rocks colliding with each other and through impact on the stope floor. Muckpile shape will be influenced by shot timing, layout and powder factor, amongst other things. The way in which the explosives are initiated is important to their overall effectiveness. If the stimulus from the detonator and primer is not sufficient then either deflagration or a misfire will occur. If the sensitivity is too high then adjacent blastholes may sympathetically detonate from the shock wave generated from the first hole detonating. Section 7: Explosives Page 7:5 Optimal Drill and Blast Techniques for Underground Mining 7.3 CHEMICAL EXPLOSIVES All explosives used by the mining industry are chemical type explosive that can be broken down into two sub groups: - Molecular explosives - Composite explosives. The components which go into making an explosive can be regarded as either: - A fuel source or - An oxidiser source. Explosives also contain other categories of ingredients to improve their performance or handling capabilities. Some examples are: - Emulsifiers, which allow the oxidizer and fuel sources to be blended together - Sensitisers, which are plastic or glass balloons, or chemicals that react to form gas bubbles - Pressure enhancers, such as powdered metals that increase the heat of reaction - Stabilisers, which include chalk and zinc oxide, that work as an antacid to enhance storage 7.3.1 Classes of Explosives All dangerous goods in Australia are classified by Statutory Authorities as to the main risk the good present. These classification define how goods can be transported, used, and stored. Explosives are divided into the following groups Class 1.1 Substances and articles which have a mass explosive hazard. (i.e. entire article explodes) Examples, ANFO, packaged emulsions detonating cord, boosters and detonators Class 1.2 Substances which have a projection hazard but non a mass hazard Example: bullets Class 1.3 Substances which have a fire hazard or minor blast hazard or minor projection hazard Class 1.4 Substances which present no significant blast hazard Class 1.5 Very insensitive substances which have a mass blast hazard Class 1.6 Extremely insensitive substances which do not have a mass blast hazard. Section 7: Explosives Page 7:6 Optimal Drill and Blast Techniques for Underground Mining These groups are further broken down by a compatibility criteria or group designated by a letter. These lettering groups can then be used to separate the items which can and cannot be stored together. For example detonators are Class 1.1 group B, which must not be stored with ANFO, which is Class 1.1 Group D Other examples: Primer sensitive explosives are assigned to Group D. AN prill is classified as a Class 5.1 Oxidising Agent. Emulsions can be Class 1.5 or 1.1 Group D, depending on their density and sensitivity. Unsensitised emulsion matrix is transported as a 5.1 Oxidising agent. 7.3.2 Molecular Explosives These substances contain both the fuel and oxidisers in the molecular structure of the explosive, and nothing has to be added to make them sensitive to detonation. Explosives such as Trinitrotoluene (TNT), Nitroglycerin (NG), Pentaerythritoltetranitrate (PETN), Lead Azide and Diazol (diazadinitrophenol) are commonly used molecular explosives. This type of explosives is usually fairly sensitive to shock, friction and heat, detonate at extremely high velocities and provide the most energy per kilogram. They are mostly used in initiating devices such as detonators, boosters and detonating cord. 7.3.3 Composite Explosives These types of explosives are composed of mixtures of fuel sources, oxidisers and other ingredients, which when brought together form an explosive. ANFO, watergel, and emulsion explosives are of this category, and comprise most common commercial mining explosives. Other ingredients may be added to change the physical properties, ie viscosity, density. These explosives make up the bulk of an explosive load and are not usually sensitive to detonator stimulation, therefore require a strong initiation source (primer) to detonate. 7.4 PROPERTIES OF EXPLOSIVES There are two broad categories of explosive properties. These properties define how a commercial explosive will perform under field conditions. Physical properties - Density Sensitivity Water resistance Chemical stability Fume characteristics Oxygen balance - Temperature Section 7: Explosives Page 7:7 Optimal Drill and Blast Techniques for Underground Mining Detonation properties - Velocity of detonation Energy / Strength Effective energy Critical diameter The physical characteristics are used to define the loading parameters and methods, whereas the detonation characteristics define how the explosive works internally and releases energy. These characteristics usually are related, hence it is important not to look at each in isolation. 7.4.1 Physical Properties Density An explosive's density is defined as the weight per unit volume of the explosive, and the units generally used are grams per cubic centimeter. This factor is important in determining the suitability of a particular explosive for a particular blasting operation. A high density explosive is normally suited for hard massive type rock as a higher charge of explosives may be placed into a given hole size, while low density explosives are most suitable for soft and/or jointed type rock formations. In general, higher density bulk explosives require bigger hole diameters to detonate, where the lower density explosives have more voids and therefore are usually more sensitive to initiation. A variation in density allows the energy distribution of the explosive that is placed in a given hole to be varied so that optimal performance may be obtained. All explosives have a critical density at which the explosive will not detonate. For ANFO, the critical density is around 1.2g/cc. Loading application and pressures are important considerations in the determination of the effective density of the explosive. Sensitivity Sensitivity is the measure of ease of initiation or the ease with which the explosive can be detonated by heat, friction, impact or shock. An explosive with high sensitivity is easily initiated while explosives having low sensitivity are more difficult to initiate. Section 7: Explosives Page 7:8 Optimal Drill and Blast Techniques for Underground Mining Touch Heat No 2 Det No 6 Det No 8 Det Primer Lead Azide NG Dynamite Cap sens Emulsion Bulk Emulsion Figure 7.4 Sensitivity. This property should not be confused with 'sensitiveness', that is a measure of the propagating ability of an explosive (for cartridged explosives). The sensitivity of an explosive may be determined by numerous different types of tests, including the gap sensitivity test, the drop test and the minimum primer test. In the explosive train, detonators are the most sensitive component and must therefore be handled with utmost care. Explosive manufacturers can change the ease of initiation by changing the formulation of the explosive. The trend has been to make the bulk explosives (ANFO, Emulsions) less sensitive, and make the initiating components (detonators, primers) stronger. Modern explosives can be categorised as either: - Primer sensitive, which require the input of relatively large amounts of energy ; or - Detonator sensitive, which require a No 8 detonator to initiate. Desensitisation may occur in explosives which are sensitised by gas balloons or gassing, through the compressive destruction of the air voids (which is known as dead pressing), which provide hot spots for the continuation of the detonation wave. Gassed explosives are less susceptible to dead pressing than those sensitised with GMBs, as the gas bubble can recover from the compression, whereas the GMBs are likely to bust. This dead pressing can occur from hydrostatic pressures induced due to loading method and dynamic pressures from other blastholes detonating. Water Resistance The water resistance of an explosive refers to its ability to detonate after its exposure to water. Explosives differ widely in their resistance to water and moisture penetration. When blasting is to be conducted under wet conditions, an explosive with good water resistance (i.e. an emulsion or watergel explosive) should be selected. Explosives penetrated by water have their efficiency impaired and, upon prolonged exposure or in severe water conditions, they may be desensitised to a point where they no longer detonate. Section 7: Explosives Page 7:9 Optimal Drill and Blast Techniques for Underground Mining The water resistance of a product depends not only on the type of packaging of the explosive, but also its inherent ability to withstand water and the water conditions. Static water at low pressures will not affect the explosive as quickly as dynamic water, especially at high pressure. The quality of the water is also an important characteristic to the effect on an explosive. The pH of the water can affect the sleep time of explosives, as the emulsifiers used in the emulsion are sensitive to gross changes in pH. There is no standard test for an explosive’s water resistance, and the rating given is generally qualitative in nature. Chemical Stability The chemical stability of an explosive is defined as its ability to remain chemically unchanged when kept under specified storage conditions. Less stable explosives have shorter shelf lives than more stable explosives when stored under the same conditions. The shelf life of explosives can vary from hours to years depending on the formulation and the conditions of use and storage. Chemical decomposition can occur due to temperature and humidity. Decomposition can make the explosive more sensitive or less sensitive depending on the explosive formulation. For example, nitroglycerin based explosives become less stable and deteriorate more quickly than cast primers. ANFO has good stability over long periods of time if correctly stored, and most emulsion explosives have a 12 -18 month shelf life. The explosive manufactures provide storage condition and shelf life recommendations for all explosives. Fume Characteristics Upon detonation of commercial explosives, the gasses produced are principally carbon dioxide, nitrogen and steam. These are non-toxic in nature. Poisonous gases including carbon monoxide and nitrogen oxides are also produced as a result from any detonation. In the explosives industry, the production of visible toxic gases, in particular nitrogen oxides, is called fume. It is produced by non-ideal detonations resulting from oxygen imbalance, improper priming, and the presence of excess water, inadequate confinement or other factor. Toxic detonation gas characteristics Carbon monoxide Colourless, odourless, tasteless. It is lighter than air so rises. Once inhaled it inhibits oxygen being absorbed into the blood stream. Oxides of Nitrogen Usually nitrogen dioxide, which is a reddish brown gas that is easily recognised. It affects mucus membranes in throat and lungs, and stops the intake of oxygen. Section 7: Explosives Page 7:10 Optimal Drill and Blast Techniques for Underground Mining 60 Fume (l/kg) CO NOx 50 40 30 20 10 0 0 1 2 3 4 5 6 7 8 Fuel Oil (wt%) Figure 7.5 Amount of toxic gas produce if ANFO is incorrectly made. Oxygen Balance In a detonation, when there is exactly enough fuel to react with the oxidizer, the explosive is said to be oxygen balanced. FUEL OXYGEN Figure 7.6 Oxygen Balance. Oxygen balance is essential to the correct functioning of the explosive. Fume characteristics, sensitivity and energy output are all affected by improper balance. An excess of oxygen in the explosive will result in the formation of nitrogen oxides (NO and NOx), and a deficit of oxygen will cause carbon monoxide (CO) to form. If the fuel to oxidiser ratio is not balanced the reactions cannot be fully completed. The energy released from the explosive is reduced and fumes will result. Section 7: Explosives Page 7:11 Energy (%) Optimal Drill and Blast Techniques for Underground Mining 100 80 60 40 20 0 0 5 10 15 Fuel oil (%) Figure 7.7 Energy verses fuel oil content for ANFO. Temperature Sensitivity Explosives are formulated to work in certain temperature ranges consistent with the place of use. Explosives manufactured for use in hot conditions will be less sensitive if used in colder areas. The same applies for explosives imported from countries where the climate differs from Australia. It is important that the working temperature range is known for each type of explosive. Explosives become more sensitive with heat and can burn or explode if exposed to high temperatures. The physical properties will also change, for example emulsions may become less firm and less viscous. It is possible that the explosive’s chemical structure may change with temperature, making some explosives inert and others very sensitive. ANFO prills will break down the non-caking coating if the temperature cycles around 38oC (the actual temperature depends on the crystal habit modifier used). Some water based emulsions may recrystallise and become inert when frozen. Most emulsions will begin to decompose at around 80oC or higher. The temperature of the rock around the borehole is a major factor to consider. Some rock reacts once exposed to air, and if the rock has this characteristic, special explosive formulations are required to ensure safety and stability of the explosive. 7.4.2 Detonation Properties Velocity of Detonation The velocity of detonation (VOD) is the rate at which the detonation wave travels through the explosive column. The VOD is an important property to consider in determining explosive functioning and performance. The detonation wave commences at the point of initiation in the explosive column and travels at supersonic speeds throughout the explosive charge. Typical detonation velocities of commercial explosives range from 2000 - 7500m/s. Section 7: Explosives Page 7:12 Optimal Drill and Blast Techniques for Underground Mining The following have an influence on VOD: - Hole diameter (VOD increases up to steady state with increasing diameter) - Primer (diameter, type, length) - Confinement (increases reaction rate, ie VOD) - Particle size (smaller size, higher VOD) - Explosive density (higher density, higher VOD, up to critical density) - Temperature (minimal) - Water content, particularly of ANFO (increased water content lowers VOD) VODs are measured for explosive products by manufacturers and are quoted on technical specification sheets. Users of explosives also measure VODs of explosives. In doing so, an idea of the quality of the supplied explosive is obtained. This, after time, indicates consistency, the effects of ageing, and allows a record of performance to be built up. There are many models on how the explosive and VOD interact with the rock but no definitive theory. VOD should only be used as a quality indicator of the same explosive used under the same conditions in a standard test setup. In hole VOD results are prone to other factors influencing the final VOD and should not be used to determine explosive performance. VOD testing should not be used as a definitive test to compare the performance of two different products. The most popular method currently used to measure the VOD of an explosive is aontinuous recorder. Continuous recorders, although being more complicated, expose great detail with respect to run-up velocities and time taken to obtain steady state velocity. Examples of VOD's: ANFO Detonating Cord Titan 4000G Emulite® 100 HDP Booster EXPLOSIVE TYPE Composite High Explosive Bulk Emulsion Packaged Emulsion Cast Booster VOD 3500 - 4500m/s 7200m/s 4000 - 5200m/s 5400m/s 7200m/s Energy / Strength The energy or strength of an explosive is a measure of its ability to do work on its surroundings, i.e. mullock or ore. The energy of the initial explosive is stored as chemical energy and upon detonation is released and used. The utilisation of explosive energy is governed by the laws of conservation of energy and mass. Section 7: Explosives Page 7:13 Optimal Drill and Blast Techniques for Underground Mining The energy can be expressed in terms of either the weight or the volume of explosive. These are known as: - the Absolute Weight Strength (AWS) - the Absolute Bulk Strength (ABS) The AWS is the measure of the absolute amount of energy (J) available in each gram of explosive. The ABS is the measure of the absolute amount of energy (J) available in each cubic centimetre of explosive. The ABS is obtained by multiplying the AWS by the density of the explosive. Energy can also be expressed in relative terms. These are known as: - the Relative Weight Strength (RWS) - the Relative Bulk Strength (RBS) of an explosive. The Relative Weight Strength (RWS) of an explosive is a measure of the energy available per weight of explosive as compared to an equal weight of ANFO (100%). RWSE = AWSE x 100 where AWSA RWSE = relative weight strength of explosive AWSE = absolute weight strength of explosive AWSA = absolute weight strength of ANFO The relative bulk strength of an explosive is a measure of the energy available per volume of explosive as compared to an equal volume of bulk ANFO at a density of 0.80g/cc. It is calculated by RBS = RWSE x Explosive density ANFO density It is important to note that the calculations and measurements all assume a theoretical detonation under ideal condition. This ideal detonation assumes all ingredients react fully. There is no program currently available to exactly predict the way in which commercial explosives release energy. Any measurement has inherent faults as rock masses responds differently to explosive energy and also affect the way in which the detonation proceeds. Effective Energy The effective energy of an explosive is considered as the energy used to effectively fragment and heave the rock volume. This energy is a percentage of the total energy available from the detonation reaction. As described earlier the initial detonation energy deforms and crushes a zone surrounding the explosive. This deformation process is considered as an energy loss as the proportion of effected rock is small when compared to the overall blast volume. Section 7: Explosives Page 7:14 Optimal Drill and Blast Techniques for Underground Mining This is often explained as the area under the Pressure-Volume (VP) curve from V0 to Vcutoff. Where V0 is the initial blasthole volume and Vcutoff is the volume at cut-off, which is approximately 100 Mpa. Vcutoff is usually 10-20 times V0. Po Pressure Pcutoff V0 Vcutoff Volume Figure 7.8 Pressure - volume curve diagram. The effective expansion work may only be 50 - 70% of the total energy, with the biggest losses involved with heat retained in the reaction products. To divide the total effective energy into fragmentation, crush and heave energy there is a need for an explosive rock model such as Lownds’ Rock Model. Such models introduce rock and blast design parameters such as rock strength, Young’s Modulus, Poisson’s Ratio, burden, bench height and hole diameter. Critical Diameter This term is a measured quantity that indicates the diameter at which a stable detonation no longer occurs in the explosive. This is an important factor in defining the hole sizes in which the explosive can be used. Explosives with high sensitivity usually have a- small critical diameter, so can be used in small boreholes. The explosive’s formulation defines how small the diameter will be. Explosive PETN TNT Dynamite ANFO Emulite 150 Bulk Emulsion Reaction Zone (mm) 0.2 0.3 5 20 - 25 - Dcrit (mm) 1-5 5 15 - 20 30 - 60 15 - 20 40 - 75 The reaction zone on the detonation wave is one of the overriding factors in the critical diameter determination, with a smaller reaction zone allowing a smaller critical diameter. Particle size of the explosive ingredients is also an important factor, with most molecular explosives having very small critical diameters. Section 7: Explosives Page 7:15 Optimal Drill and Blast Techniques for Underground Mining The minimum diameter for explosive use is not always larger than the critical diameter, as confinement will influence the detonation. It is important to know the minimum recommended diameter as not all explosives will detonate in all hole sizes. 7.5 EXPLOSIVE PRODUCTS 7.5.1 ANFO During the 1960's, ANFO started to replace dynamite in dry holes because of its cost savings, safer handling characteristics and quicker loading. Since their introduction ANFO products have found extensive use in a variety of blasting applications such as surface mining of coal, metal mining, quarrying and underground mining. ANFO has a high weight strength and low bulk strength compared to other bulk explosive types e.g. emulsions. It excels in gas (heave energy) production and provides a moderately high velocity of detonation. Fuel Content ANFO consists of Ammonium Nitrate (AN) and fuel oil (FO). The most widely used ANFO product is an oxygen-balanced, free flowing mixture of 94 percent AN prills and 6 percent diesel fuel oil. For optimum results (e.g. in terms of energy release and fume generation) this mixing ratio by weight is desirable. The energy decreases with too little or too much oil. Various types of fuels can be used in the manufacture of ANFO. Legislation requires fuels with high flash points to be used as a safety precaution to reduce the flammability of the product. The commercial manufacture of ANFO utilises distillate. The distillate provides a cost effective fuel source which is readily absorbed by the AN to produce an evenly mixed product. Experimentation with the use of waste oil as a fuel source for ANFO has been carried out over the last several years. With appropriate refining and dilution, waste oil can be used as a fuel source for large diameter applications (311mm). The use of waste oil potentially increases the generation of noxious fumes and reduces the effective energy generated. Limited, if any, testing has been carried out in underground small hole diameter applications. Properties of ANFO Density The bulk density of ANFO depends on the density and the fine distribution of the AN prill used in the mix. The majority of ANFO has a poured density of 0.8 - 0.85g/cc. Pneumatically loaded ANFO has a loaded density of 0.85 - 0.95g/cc. Higher densities can be achieved although care must be taken with regard to the critical diameter. Section 7: Explosives Page 7:16 Optimal Drill and Blast Techniques for Underground Mining By increasing the density of ANFO the detonation properties change. The velocity of detonation (VOD) will increase with increasing density due to the smaller particle size. Hole Diameter The hole diameter in which the ANFO is loaded will affect the detonation properties. The critical diameter of ANFO is the smallest diameter in which ANFO will detonate. Hole diameters near the critical diameter will reduce its VOD. As the hole diameter increases, the VOD of ANFO will increase. This relationship will continue to a point where maximum VOD for ANFO is achieved. Under normal conditions this occurs at approx 127 to 151mm ANFO (density = 0.85g/cc) 6000 5000 Confined 4000 VOD (m/s) 3000 Unconfined 2000 1000 0 0 100 200 300 400 500 Charge Diameter (mm) . Figure 7.9 Effect of confinement on VOD for ANFO. Provided that full order detonation is achieved (above 75mm for ANFO) the total energy yielded will not dramatically change, however the application of the energy into the rock mass will. As a general rule, as the hole diameter decreases (below approx 151mm), the detonation becomes less ideal and a higher proportion of heave energy will be produced. Sensitivity The sensitivity of ANFO is dependent on: Particle size - sensitivity increases with decreasing size Density - sensitivity increases with increasing density (dead-pressing will occur at high densities) Fuel content - sensitivity decreases with over fuelling Confinement - sensitivity increases with increasing confinement Section 7: Explosives Page 7:17 Optimal Drill and Blast Techniques for Underground Mining In the majority of blasting applications ANFO is booster sensitive and requires adequate priming. In small diameter tunneling applications ANFO can be made cap/detonator sensitive by reducing the particle size of the AN prills. Note a No 12 strength detonator will initiate ANFO in small diameter pressure loaded holes. Water Resistance Due to the hygroscopic nature of AN, ANFO has no water resistance. The addition of fuel oil does not provide any water resistance. Lack of water resistance is the major limitation and disadvantage of ANFO. The sensitivity, VOD and strength of ANFO are all reduced by the absorption of moisture. Orange fumes after detonation are a good indication of the presence water when using ANFO. VOD (m/s) 4000 3500 3000 2500 2000 1500 0 2 4 6 8 10 Wt % water Figure 7.10 Effect of water on VOD of ANFO. Shelf Life The ideal storage conditions for ANFO are cool, dry conditions. For AN, temperature cycling about 32C and increasing humidity will promote deterioration of the prill. As a result ANFO suffers the same deterioration problems as AN. The ANFO will eventually deteriorate to a solid mass. The rate of degradation depends on the storage conditions. ANFO is classified as a 1.1D dangerous good and must be stored in appropriately licensed magazines. Manufacture Legislation requires that a license must be obtained from the appropriate authorities to manufacture explosives. The manufacturing process involves the blending of prilled AN and fuel oil. The most effective method is injecting fuel oil at the base of an auger carrying AN. The rotation of the auger provides even and consistent mixing. ANFO can be purchased premixed or manufactured on demand by site based manufacturing units. For larger operations bulk delivery trucks manufacture ANFO and deliver a down the hole service. Section 7: Explosives Page 7:18 Optimal Drill and Blast Techniques for Underground Mining In most cases legislation requires the addition of a dye to enable easy identification of ANFO as compared to AN. Provided the quantity of dye is kept consistent, coloration is a good indicator of whether a good mix is being achieved. Change in ANFO colouring may not be an indication of poor mixing but due to the mix or type of dye being used. All manufacturing units are specifically designed to meet safety requirements. All manufacturing units should be inspected and authorised prior to commissioning by the relevant authorities. Any manufacturing unit should be well maintained and serviced on a regular basis. 7.5.2 ANFO-PS Derivatives A number of ANFO based explosives are finding widespread application. include: These ALANFO A small percentage of aluminium (a fuel) is added to increase performance. ANFO PS Polystyrene beads are added in various proportions to density of the ANFO. SANFOLD This is essentially the same as ANFO PS, but an emulsion is also added. This improves product up hole loading characteristics. reduce the The reduction in the bulk density in ANFO-PS is an effective method of reducing the bulk strength. Common blend ratios range from 70% ANFO - 30% PS through to 30% ANFO 70% PS. The manufacturing process generally involves premixing the ANFO using a mineral or vegetable oil as the fuel source. The polystyrene is added to the ANFO and blended. Due to large differences in particle densities of prill and polystyrene segregation is a common problem. The use of light grade oils to replace distillate as the fuel source in the manufacture of ANFO PS products is necessary to prevent the separation of AN prills and polystyrene beads. The higher viscosity of the oils, as compared to distillate, leads to the oil remaining on the surface of the ANFO prill and assists in the cohesion of the AN and polystyrene beads. Distillate will also dissolve the PS beads and lead to their collapse. Parameters that affect the performance of ANFO are the same for ANFO PS. The main benefit in using ANFO PS is that it has a high weight strength (90 - 99) and low bulk strength (35 - 85) as compared to ANFO. It excels in gas or heave energy production and provides a low velocity of detonation. The main drawback is the occurrence of segregation during the loading process. This can result in inconsistent loading densities causing potential performance and reliability problems. When used in controlled blasting applications the inconsistency may also result in poor performance Section 7: Explosives Page 7:19 Optimal Drill and Blast Techniques for Underground Mining Density The bulk density of ANFO PS depends on the volume of polystyrene in the mix. ANFO PS has a poured density of 0.3 - 0.7g/cc. Pneumatically loaded ANFO PS has a loaded density of 0.4 - 0.8g/cc. Segregation may occur during the loading operation and could result in higher loading densities. By increasing the density of ANFO PS the detonation properties change. The speed of detonation (VOD) will increase with increasing density. Hole Diameter The hole diameter in which the ANFO PS loaded will affect the detonation properties. The recommended minimum hole diameter for ANFO PS products is 32 to 45mm, dependant on the PS quantity in the blend. Hole diameters near the critical diameter will reduce the VOD. As the hole diameter increases the VOD will increase. This relationship will continue to a point where maximum VOD for ANFO PS is achieved. Water Resistance Due to the hygroscopic nature of AN, ANFO-PS has no water resistance. The addition of oil does not provide any water resistance. The sensitivity, VOD and strength of ANFO are all reduced by the absorption of moisture. Orange fumes are a good indication of the presence of water when using ANFO PS. ANFO-PS Emulsion Blends This is essentially the same as ANFO-PS, but an emulsion is added as a tackifying agent. This reduces product segregation and improves hole-loading characteristics. The two main application are in uphole large diameter stoping and development rounds. The emulsion helps prevent segregation of the polystyrene beads. The main benefit in using ANFO PS - Emulsion blends is that it has a high weight strength and low bulk strength as compared to ANFO. The small quantity of emulsion maintains a consistent mix during hole loading. It excels in gas or heave energy production and provides a low velocity of detonation. The current blends available range from 5 - 10% emulsion with 30 - 80% PS. 7.5.3 Emulsions Emulsion explosives are liquids consisting of a continuous oil fuel phase containing dispersed droplets of oxidiser solution. The oxidiser droplets, which comprise around 90% of the volume, may range in size from around 0.2m up to 10 m. The continuous oil phase resists the ingress of water that would otherwise dilute the oxidiser phase. The oxidiser solution consists of a super-saturated solution of ammonium nitrate (sometimes with calcium or sodium nitrates) in water. The oil phase contains the fuels and emulsifiers, and consists primarily of hydrocarbon compounds, which include oils, diesel fuel and waxes. Emulsifiers are used to stabilise the mixture so that the components do Section 7: Explosives Page 7:20 Optimal Drill and Blast Techniques for Underground Mining not separate and the nitrates in solution do not crystallise. It is necessary to sensitise emulsion explosives through a reduction in density to below the critical value, which is achieved by mixing in air, use of a chemical gassing agent or through the addition of glass or plastic micro-spheres. High-energy fuels can also be used to improve the sensitivity and performance of the explosive but these tend to be expensive. Emulsion explosives are inherently unstable, ie with time the supersaturated oxidiser droplets will crystallise and the fuel and oxidiser phases separate. As the level of crystallisation increases the viscosity, pumpability, water resistance and explosive performance of the emulsion decreases. Various factors including the presence of gassing chemicals, particulate material, and excessively high or low temperatures enhance the ageing process. The choice of emulsifying system is critical, as the shelf life, gassed blend stability, water resistance and stress resistance is determined by the type of emulsifier and its concentration. For those applications that are manufactured close to the site of use, and require a relatively short sleep time, the traditional emulsifier used is sorbitan monooleate (SMO). As the requirements of mines have become more demanding in terms of longer available sleep times and water resistance, emulsifiers based on polyisobutylene-succinic anhydride (PIBSA) have become the emulsifier of choice for repumpable emulsions. A photomicrograph of a repumpable downhole is shown in Figure 7.12. The physical properties of emulsion explosives can be varied to suit the application. This is achieved by varying the fuel phase components. Packaged product requires a putty-like consistency, which is imparted by the use of waxes. Repumpable down hole emulsions use lower viscosity fuels such as diesel or mineral oil, and have a relatively low viscosity. Up hole emulsions, as they need to be repumpable, also use lower viscosity fuels, however the emulsifier system is selected to enable a very high viscosity to be achieved upon introduction into the blast hole by the delivery system. Figure 7.11. Photomicrograph of a repumpable downhole explosive emulsion. The photomicrograph has been computer enhanced to increase the differentiation between the dark continuous fuel phase and light disperse oxidiser phase. The particle size range is from around 1m to 10m. Section 7: Explosives Page 7:21 Optimal Drill and Blast Techniques for Underground Mining Figure 7.12. Photomicrograph of a repumpable emulsion showing the onset of crystallisation. The scale is the same as for Figure 7.12. Underground emulsions are specifically designed to be retained uphole against the force of gravity. An explanation of how this is achieved is detailed in Section 7.4.7. The major physical difference between up hole and down hole emulsions is the particle size distribution. This is achieved by subjecting the emulsion to a high shear field either by forming a spray, or forcing the emulsion through a small orifice under high pressure. The decrease in particle size leads to the increase in solid-like behaviour, which contributes significantly to the up hole retention. Figure 7.13. Diluted Underground Emulsion. Section 7: Explosives Page 7:22 Optimal Drill and Blast Techniques for Underground Mining The scale is the same as for Figure 7.11. The oxidiser droplets are the darker drops, which show a particle size range of around 300nm to 2m, which is much smaller than for the down hole emulsions shown in Figures 7.11 and 7.12. The density range of sensitised emulsions normally varies from 1.10g/cc to 1.3g/cc. Emulsion products can contain up to 40 per cent ANFO and have a very good water resistance because of the inherent nature of their compositions. Care should be taken when using emulsions if dynamic water is present. The stability of emulsions is extremely good with compositions remaining consistent for long periods of time. Sensitisation The emulsion matrix is sensitised with the use of either micro balloons or chemical gassing. Micro balloons are hollow glass or plastic balloons which entrap micro bubbles of air. Micro balloons are rated by their ability to resist crushing. The addition of micro balloons sensitises and reduces the density of the emulsion. The final sensitivity and density of the emulsion are determined by the volume of micro balloons added. If, during any part of the process prior to detonation a high percentage of the micro balloons are crushed, the emulsion will partially or fully desensitise. This may result in low order detonation or a misfire. This problem can be partially overcome by using stronger micro balloons. Chemical gassing relies upon the formation of micro gas bubbles to sensitise the emulsion. In principle the sensitisation process is the same as adding micro balloons. The quantity of trace chemicals added will determine the volume of gas bubbles produced thus determining the density of the emulsion. Since the gassing is generated by a chemical reaction, a period of time is required for the reaction to occur, ie the gas is not generated instantaneously. By controlling certain chemical and physical variables, the rate of gas generation can be adjusted for different applications. Due to the compressible nature of gas a density profile is produced for vertical columns of gassed emulsions. Due to the weight of emulsion above a gas bubble it is compressed, thus reducing the density of the surrounding emulsion. Therefore the density of the explosive progressively increases towards the bottom of the blasthole due to the hydrostatic head of pressure created by the weight of explosive above it. Thus the bulk strength is higher in the toe of a downhole where a higher energy is generally desirable. As an effectively loaded up hole emulsion is solid-like in flow behaviour, a density profile with height does not occur. Current gassing technology limits the height of a gas sensitised explosive column to approx 80m. Depths exceeding this can result in desensitisation of the emulsion. Explosive column of solid sensitised emulsions do not have a density profile due to the incompressible nature of micro balloons. The compressive strength of the micro balloons is generally greater than the hydrostatic pressure of explosive columns under normal blasting applications. Section 7: Explosives Page 7:23 Optimal Drill and Blast Techniques for Underground Mining Manufacture Emulsions are specifically formulated for different applications which require the use of many different raw ingredients. These ingredients can be categorised into two main areas - oxidisers and fuels. The oxidiser solution generally consists of either solely Ammonium Nitrate (AN) or a mixture of AN, Calcium Nitrate (CN) and/or Sodium Nitrate (SN). The primary oxidiser used is AN with CN and SN added to modify the performance for the intended application. The fuel phase generally consists of emulsifiers, oils, waxes and distillate. Combinations of each of these ingredients will produce a specific product for a specific application. Considerations taken into account include water resistance, viscosity and energy. The manufacturing process of bulk emulsions involved blending a supersaturated oxidiser solution with a fuel phase. The blending process disperses the oxidiser phase into micro fine droplets throughout the fuel phase forming an emulsion. This process also act to increase the viscosity producing an emulsion with a thick consistency. Oxidiser AN,SN,CN, Water Fuel Oil, Emulsifier Bulk Emulsion Storage Blender Transfer Pump Figure 7.14 To Delivery Tankers or Bulk Trucks Bulk emulsion manufacture process. Emulsions can be blended with different ratios of ANFO for a wide variety of applications. Typically, blends with greater than 60% emulsion are pumped and blends with less than 60% are augured. Different blends are used based on a number of different criteria including hole diameter, geology and required energy. Bulk Emulsions - Up-Holes 7.5.4 Up Hole Emulsion and Delivery System Up hole emulsions are specifically designed to be retained up hole, upon introduction into the blast hole by the associated delivery system. This is achieved by altering the flow characteristics of the emulsion from being viscous and pumpable, to solid-like in character when under the influence of gravity. The up hole delivery system is mounted on a truck chassis (see Figure 7.15), and consists of the following systems: Section 7: Explosives Page 7:24 Optimal Drill and Blast Techniques for Underground Mining Emulsion delivery system. This consists of an emulsion storage tank, which is connected via a progressive cavity pump and homogeniser to the delivery hose fitted with a spray nozzle at the end of the hose. A hose pusher/retractor apparatus introduces the hose into the blast hole, and withdraws it at an appropriate rate for the design density to be achieved. Chemical sensitising system, which includes storage tanks, pumps, flow meters and injection ports. The gassing trace chemicals are introduced via injection into the centre of the emulsion stream and are mixed in at the end of the hose using the shear nozzle A water ring lubrication system, which is used to lubricate emulsion flow through the hose. The water used is incorporated into the loaded product. PLC control system to control emulsion flow, pumping pressure, chemical sensitisation injection rates, hose retract rate, pumping over pressure cut off, homogeniser pressure and other key parameters. Different emulsion densities are available, through changing the delivery parameters of gassing chemical input rate and hose retraction rate. The latest technology trucks are able to change these parameters during the loading phase, allowing (so-called) differential loading. For best performance, the blast holes need to be clean, dry and constant diameter. The system can cope with wet holes, however holes with dynamic water will be very difficult to load. It is necessary to clean holes after drilling, as residual particulate matter will inhibit retention. Figure 7.15: Underground Emulsion Truck Under ideal hole conditions the sleep time emulsions in the hole is approx 30 days. Factors including ground temperature and ground water will affect the sleep time. Section 7: Explosives Page 7:25 Optimal Drill and Blast Techniques for Underground Mining Cartridged Emulsions The emulsions used in cartridged products are similar to those used in bulk applications. A wax is added to the fuel phase to stiffen the emulsion into a putty like consistency. The formulations are modified according to the application, to either a cap sensitive or non cap sensitive product. The critical diameter of most cap sensitive cartridged products is approx 20mm. Oxidiser Fuel AN,SN,CN, Water Oil, Wax, Emulsifier Sensitiser Packing Machine Transfer Pump Cooling Bath Blender Transfer Pump Boxing, storage and delivery Figure 7.15 Packaged emulsion manufacture process. Formulation modifications that are introduced to cartridged products include the addition of Aluminium (Al) and a reduction in water content. The addition of Al into an emulsion will increase the heat of detonation thus increasing the energy available. Aluminised emulsions are identifiable by the grey colour produced by the aluminium. Specialised manufacturing processes are required to achieve a reduction in water content which will increase the available energy. The inherent water resistance combined with the plastic wrapping provides a water proof product - provided the wrapping is unbroken. Exposed emulsion only provides excellent water resistance, the emulsion will eventually deteriorate in water over an extended period of time. The major applications for cartridged products is in development rounds and stoping applications. In development rounds a 25mm or 32mm product is used depending on the hole diameter. Stoping applications involve larger diameter products either manually or pneumatically loaded into the blast hole. Most cartridged emulsions are manufactured in 25kg boxes. The normal recommended shelf life is 12 months if stored in cool conditions. Section 7: Explosives Page 7:26 Optimal Drill and Blast Techniques for Underground Mining 7.5.5 Watergels These explosives were originally developed to eliminate the need for nitroglycerin in explosives. They consist of oxidising salts, fuels, and sensitises dissolved or dispersed in a continuous liquid phase. Gels and cross-linkers thicken the product and provide it with water resistance. Water + + - - + + + - + + + + + + + + - Oil - + - + - - - - - + + + + + - - Oil - - - - + - - + + + Oil in Water Figure 7.16 Simplified explosive watergel. Oxidising salts may be Ammonium Nitrate, Sodium Nitrate or Calcium Nitrate. Fuels such as Hexamine, Monomethylamine Nitrate, Trinitrotoluene, Aluminium or Ammonium Perchlorate provide both sensitivity and oxygen balance. Physical sensitisation is provided by entrapped air bubbles, either alone or with chemical sensitises. Physical Properties of Watergels The liquid phase is thickened by gums or long chain organic molecules. The thickeners or cross linkers determine the consistency of the product, and also the water resistance of it. Water resistance is, in general, very good. Densities of watergels range between 0.80g/cm and 1.60g/cm; the most common ones lying between 1.10g/cm and 1.35g/cm. Excellent tamping characteristics mean that watergels can be loaded at higher borehole densities than cartridged explosives. Watergels are safer to handle than NG based explosives. They are sensitive to normal priming methods, and relatively less sensitive to accidental initiation when compared to NG based explosives. Detonation Properties of Watergels Velocity of detonation varies with hole diameter and confinement. Typically it lies between 3400m/s and 6000m/s. High shock energies make watergels suitable for blasting of hard materials in wet ground. However, long run up times can lead to poor performance where difficult toe conditions exist. Section 7: Explosives Page 7:27 Optimal Drill and Blast Techniques for Underground Mining 7.5.6 Detonators Electric detonator An instantaneous electric detonator is a detonator that does not contain a delay element; the detonator fires instantaneously. Delay electric detonators are similar to instantaneous electric detonators in make-up except for a delay element in the detonator. Electrical energy is delivered into the detonator by two plastic insulated metal wires called leg or lead wires that enter the detonator through a rubber/plastic/neoprene plug. This plug, crimped tightly in the open end of the detonator shell (normally aluminium) forms a water resistant seal and firmly positions the leg wires inside the detonator shell. The ends of the leg wires are joined inside the detonator by a short length of high resistant wire called the 'bridge wire', which is embedded in the detonator's ignition mixture or fuse head. When sufficient electrical current passes through the system, the bridge wire heats and fires the fuse head. The fuse head ignites the priming charge which detonates the high explosive base charge. Plastic covered lead wires Neoprene plug Detonator tube Neoprene sleeve Fusehead Priming charge Base charge Figure 7.18 Instantaneous electric detonator. Section 7: Explosives Page 7:28 Optimal Drill and Blast Techniques for Underground Mining Dyno Nobel NONEL® detonators The components of a NONEL® detonator can be best described by referring to the figure below. 7. The aluminium shell 6. The isolation cup is made of a semi-conductive material preventing any static electricity in the NONEL tube from affecting the pyrotechnics in the detonator. 5. The Delay Ignition Buffer (DIB). This is a very fine mesh disk that is pressed onto the top element. The 7 DIB controls the signal transmission of the tube 6 providing a reliable signal pick-up and contributes to detonator accuracy. It also prevents any timing or 5 functionality problems that are associated with depressurization of the NONEL assembly. NONEL assemblies are normally a closed system that becomes 4 highly pressurized during functioning. If a rupture occurs in the shock tube, without the DIB the rapid depressurization could cause separation of the 3 reacting pyrotechnic, thereby resulting in poor timing 2 or functionality problems. 4. The delay train. A stack of drawn lead pyrotechnic 1 elements, the burning characteristics of which determine the timing of the detonator. Figure 7.19 Construction of 3. The Cushion disk (CD). This is a “wiper ring” the NONEL® Detonator used that ensures that all traces of the explosives charges in the LP series. are cleaned from the shell wall. The CD was developed to prevent instantaneous detonation that could occur if the shell walls were not cleaned of residual traces of explosives during the loading process. In addition, it aids in resisting “reverse propagation,” and increases impact resistance. 2. A lead azide primary charge. 1. The high strength PETN base charge. Section 7: Explosives Page 7:29 Optimal Drill and Blast Techniques for Underground Mining NONEL® tube The NONEL tube is the unique component in the NONEL system. It is made of a high quality plastic tube (OD = 3mm), the inside of which is coated with an explosive dust. When initiated NONEL tube has a propagation velocity (VOD) of 2100m/s. A close contact detonation is necessary to reliably initiate the tube that transmits an explosive shock wave to initiate the detonator. External layer for abrasion resistance and UV protection Middle layer for tensile strength, elongation and chemical resistance Inner Layer reliably holds the explosive dust in place Figure 7.20 NONEL® tube. The NONEL® system is highly resistant to initiation by static, stray electric energy or high frequency radio transmissions. It can also resist mechanical interference and rough handling better than other initiation systems. NPED detonator A recent development in detonator technology is the Non Primary Explosives Detonator (NPED), a detonator that contains no primary explosives. Most detonators in the industry today contain a combination of primary and secondary explosives. The two main active parts in a detonator are: Delay Element - a pyrotechnic composition that gives the detonator its time delay from initiation to firing. Base Charge - a secondary explosive that gives the detonator its initiation force. In the contact surface between the delay element and the base charge in a conventional detonator there is a small quantity of a primary explosive. Its purpose is to quickly transfer the relatively slow deflagration in the delay element to a detonation in the base charge. A characteristic of primary explosives is that they are easily initiated through heat, friction or impact, features which are desirable for the initiation of the base charge in a Section 7: Explosives Page 7:30 Optimal Drill and Blast Techniques for Underground Mining detonator. At the same time they make the detonator more sensitive to accidental initiation. Secondary explosives are less sensitive to heat, friction and impact, and are consequently more difficult to initiate. In the NPED detonator, the sensitive primary explosive has been replaced with an Initiation Element that is filled with a secondary explosive. This explosive has been specially treated to obtain what is known as DDT, Deflagration to Detonation Transition. This means that deflagration is accelerated up to detonation in a controlled manner. The delay element in the NPED detonator contains entirely new types of pyrotechnic compositions. This is the first time in the industry that delay time compositions with high time accuracy and excellent moisture resistance have been produced without using lead compounds, toxic or carcinogenic substances. A NONEL NPED detonator is made up of following components: 6. Detonator Shell The detonator shell is made of aluminium. 5. Delay Element The delay element consists of an aluminium tube filled with a pyrotechnic composition. Using pyrotechnic compositions with different deflagration speeds and varying lengths of the delay element, different delay times are obtained. 4. Delay Compound 3. Initiation Element The initiation element consists of a steel tube filled with PETN, which is a secondary explosive. 2. PETN 1. Base Charge The base charge is Hexogen (RDX) a secondary explosive pressed directly into the aluminium detonator shell. The detonator is #12 strength. Electronic detonators Electronic detonators differ from other detonators in the means by which they provide delay times. An electronic detonator relies on an electronic timer to provide the delay from the time that the initial impulse is received to the time that the bas charge fires. This difference is the reason that electronic detonators are extremely accurate, typical scatter would be in the region of 0.02% shift from nominal firing time, irrespective of total delay. There are a number of types of electronic system available, ranging from Section 7: Explosives Page 7:31 Optimal Drill and Blast Techniques for Underground Mining the pre programmed (in the factory) to fully programmable (in the field) systems. In between these two extremes are the auto programmable systems, a less flexible but still accurate system. Electronic systems, through their very nature, provide features and benefits that are not possible with other systems. Apart from being extremely accurate, every detonator can be given an individual delay, making the system very flexible. They can be tracked individually from point of manufacture to point of consumption in the blast They require complex coded signals issues by dedicated firing boxes before they will fire, all control equipment can be password protected, and checks on the integrity of the detonator. All system connections can be done at any point during the loading of the blast, allowing defective units to be identified and corrected prior to firing the shot. Other benefits are realized through stock rationalization and streamlined manufacture processes – no longer do we need specific detonators to provide specific delays. Whilst the level of use currently is low, electronic detonators are definitely a safer, more secure, accurate and flexible means of initiation, and will become the initiation system of choice in the future. The HotShot detonator The detonator consists of an electronic delay module in combination with an instantaneous detonator. The shell is made from copper, this giving greater protection to the electromnics than an aluminium shell An integrated circuit constitutes the heart of the detonator. This contains a capacitor for energy storage, and separate safety circuits to protect against electrical overload. The chip itself also has internal safety circuits on the inputs. Typical characteristics for the Dyno Nobel electronic detonator include:- The detonator initially has no initiation energy of its own. - The detonator cannot be detonated without a unique activation code. - The detonator is equipped with over-voltage protection - The initiation system operates with low voltages on bench operations are carried out at 9 volts, arming and firing (carried out from the safe firing point) are done at 26 volts The Tagger and Blast Cradle The HotShot tagger is the key component of the system. It is used for all on bench testing, and once in a position of safety, the tagger is used to design the blast and program the detonators. Whilst not fully programmable, the HotShot system offers a fair degree of flexibility, such that it closely replicates current shocktube systems. Arming and firing can only be done when the blast key and tagger are installed in the cradle. The system requires the use of passwords and sends coded signals to the Section 7: Explosives Page 7:32 Optimal Drill and Blast Techniques for Underground Mining detonators when the firing instruction is received, thus preventing unauthorized use of the system. Typical system characteristics are:- Shortest time between two adjacent period numbers (the interval time) is 1ms. Longest delay time is 20.0 secs. They system will fire 600 detonators, and will allow for 1000m of lead in line. Max hole depth is 35m, and inter hole pitch is 10m. DigiDet: This is a hybrid shock tube/electronic system. The transmission of signals is carried out by conventional shock tube, however the delay in the detonators is achieved through the use of electronic timing devices. It is therefore non programmable, but offers a very accurate detonator with virtually no training required for shot crews. 7.5.7 Detonating Cord Detonating cord is a round, flexible cord containing a center core of high explosive. The explosive core, usually pentaerythritol tetranitrate (PETN) is covered with various combinations of materials, including textiles, waterproofing materials, and plastics which protect it from damage caused by physical abuses or exposure to extreme temperature, water, oil, or other elements and provide such essential features as tensile strength, flexibility and desirable handling characteristics. Detonating cord is a safe and reliable non-electric detonating device. Detonating cord requires an explosive input for reliable initiation, commonly a detonator, minimum #8 strength, or another detonating cord. PETN detonates at a velocity of about 6,700 metres per second. Plastic Covering PETN Explosive Nylon Fibres Cotton Figure 7.22 Detonating cord. The ability of detonating cord to initiate other explosives depends on the size of the PETN coreload, usually expressed as grams of PETN per linear metre of cord, and the Section 7: Explosives Page 7:33 Optimal Drill and Blast Techniques for Underground Mining initiation sensitivity of the receptor. The most widely used cords are 3.6 to 10 grams of PETN per metre. Detonating cords commonly used in commercial blasting are “self-to-self” propagating which provides a high degree of versatility in use. Detonating cords are high explosives, and must be stored, transported and handled in a safe manner. Only approved tools are to be used when cutting detonating cord. The PETN coreload of detonating cords is sensitive to initiation by impact and friction; approved tools avoid ‘by-pass’ and impact cutting methods. Likewise, joins are to be made using approved methods. Sensitivity The sensitivity of all bulk and pumped explosives to detonating cord is variable and tends to be greater for good confinement, small diameters, high temperatures and low densities. For example tests have indicated that ANFO is unlikely to side initiate in hole diameters exceeding 65mm for detonating cord of 7g/m or less, but will for a 10g/m detonating cord if warm and at a low density but not at a lower temperature and higher density. ANFO/Emulsion mixtures (ie Heavy ANFO) tend to be less sensitive but have also been seen to be cord sensitive under certain conditions. As a general rule there is a high probability of all bulk explosives being initiated by 8 to 10g/m cords but minimal likelihood of initiation with core-loads of 4g/m or less. NB: If a low core load downline is knotted in any way the knot may provide sufficient added energy to initiate the explosive. Desensitization of Explosives By Detonating Cord If the coreload of the downline is too low to initiate the explosives then it potentially damages the structure of the explosive immediately around it and desensitizes it. The extent of energy loss depends on the explosive, its density, the power of the downline, the blasthole diameter, the strength of the confining rock and the period between the downline firing and the returning initiation wave from the primer. Evidence of this desensitization or "dead pressing" is sometimes seen in quarries using ANFO in holes with diameters between 50 - 76mm. Packed ANFO prills can occasionally be seen in the half barrels on the back wall of a blast. This is indicative of low order explosive detonation, as a fully charged hole should cause the rock to be shattered for some distance beyond the borehole wall. Barrels should only be seen where smooth blasting techniques have been used. It is now widely accepted that, due to the resultant concentration of energy released in the detonation wave, point initiation of explosives results in higher shock impulse on the side of the blasthole than does side initiation. This gives finer fragmentation, especially in the stronger rock types, but not necessarily more heave. Section 7: Explosives Page 7:34 Optimal Drill and Blast Techniques for Underground Mining 7.5.8 Cast Boosters High velocity, high energy boosters have been developed to initiate less sensitive explosives such as bulk ANFO and emulsion. Cast boosters are less susceptible to accidental detonation from impact, shock or friction than dynamite based products, but must be handled in the same safe manner as with all explosive types and systems. Cast boosters are high explosives that detonate at varying velocities depending on explosive composition, producing large volumes of gases at very high pressures. Cast boosters are most commonly made of Pentolite, a mixture of PETN (pentaerythritol tetranitrate) and TNT (trinitro toluene). These are high explosives that accept initiation from a No 8 strength detonator or suitable detonating cord. PETN / TNT mixture Cardboard or plastic shell Detonation wells Figure 7.23 General make-up of a cast booster. Density The density of cast boosters made of a Pentolite mixture is approximately 1.60g/cc. Initiation Sensitivity This is dependent on particle size of ingredients, density, diameter, temperature and static water pressure encountered. Cast boosters require a No 8 strength detonator or detonating cord, as specified for the booster construction, for optimum initiation. Manufacturers may include a sensitiser mechanism for application with low strength detonating cords. Water Resistance The selection of a booster must include its ability to perform well under both high hydrostatic pressures and long sleeping times. Cast boosters have a very good water resistance and perform well under high water pressures and long sleeping times. Physical Strength The physical strength (the ability to remain intact during handling and use) of a booster must be so that the detonator or detonating cord remains well embedded in the booster Section 7: Explosives Page 7:35 Optimal Drill and Blast Techniques for Underground Mining until the charge is initiated. Cast boosters have very good physical properties due to their solid ingredients. Energy A cast booster should have sufficient energy to initiate the detonation reaction in the main charge and sustain it until the primed explosive produces enough energy to support the detonation reaction by itself. 7.6 TEST WORK UNDERTAKEN ON EXPLOSIVES Explosives require vast amounts of testing before becoming available as commercial explosives. Below is a list of the most common tests carried out by explosive manufacturers. 7.6.1 Sensitivity The explosive’s sensitivity is the ease that an explosive can be initiated. Explosive products are graded as to their sensitivity, e.g. Class 1.5 is non cap sensitive and Class 1.1 is cap sensitive, thus bulk products will usually be classified as Class 1.5 (can only be initiated with a booster) and cartridged products as Class 1.1. Minimum Initiation Requirements This test is performed to determine the minimum booster or cap size necessary to initiate the explosive. Gap Sensitivity A small diameter unconfined cap sensitive cartridged emulsion must be able to initiate another cartridge through a 12mm air gap. This test is only performed on cartridged products. Critical Diameter All explosives have a diameter under which they will not detonate which is known as the critical diameter. Explosive companies conduct tests to determine this diameter and the product Technical Data Sheets have recommended minimum diameters for each explosive formulation. These minimum diameters are larger than the critical diameters. This also becomes relevant when tying detonating cord around emulsion cartridges as in a pre-split charging operation; if the cord is pulled too tight around the explosive then it is possible that, upon initiation of the cord, the explosive can be cut instead of detonating as the explosive charge is now below its critical diameter. Drop Impact Weights of up to 5kg are dropped onto a sample of explosive from heights up to 1 metre. Emulsions, watergels and ANFO products will not detonate from this impact. Section 7: Explosives Page 7:36 Optimal Drill and Blast Techniques for Underground Mining Side Impact This tests the products ability to withstand a glancing blow from an object without sign of detonation or burning. Bullet Tests Samples of explosive are placed on a steel backing plate and then shot with high powered bullets or similar projectiles. Emulsions, watergels and ANFO should not detonate. Friction Samples of explosive are placed on a steel rod and another rod is slid across the sample to analyse the effect of friction on samples. Thermal Analysis Samples have heat applied and the temperature monitored. If the temperature does not rise at a constant rate it indicates a form of internal combustion or self sustaining reaction. Burning Tests Various sizes of confined and unconfined samples, up to 200kg, are burnt in wood or diesel generated fires. Samples must not detonate. A UN classification test also uses heat to determine what class the explosive should be either a 5.1 Oxidiser or a 1.1 Explosive Static Electricity Samples of explosives are subjected to electrical discharges of up to 20,000 volts to observe reaction. 7.6.2 Explosives Performance Assessment This type of monitoring has a primary application to modeling, providing the basic information on explosive performance and explosive/rock interaction which is required to calibrate and verify model predictions. To a large extent, performance monitoring can be used whenever the explosive user feels that the explosive product, initiation system, or blast design can be optimised. Blasthole VOD Two main techniques exist for measurement of blasthole velocity of detonation (VOD), though many variations in instrumentation may be observed within the two main groups: i. Point contact methods which measure time of propagation of the shock front between known distance intervals, providing a relatively small number of readings over the full length of the blasthole; ii. Continuous methods which provide a continuous signal which can be interrogated to determine VOD, either over the full length of the blasthole or specific sections (e.g. around the primer). Section 7: Explosives Page 7:37 Optimal Drill and Blast Techniques for Underground Mining The measurement of blasthole VOD is not a simple task, and the success rate, irrespective of the technique used, may be as low as 70%. Despite claims by some workers, no technique currently in use today will give perfect results every time a blasthole is monitored. To a greater or lesser extent, all methods rely on linear regression to determine velocities over an interval, and the main differences between the techniques is the minimum size of interval over which an accurate measurement can be made. Point to Point Methods The common techniques used include fibre optic based, and plasma continuity based measurement systems. With the fibre optic technique, electronic timing circuitry records the moment at which the plasma strikes an optic fibre. The optic fibre transmits an intense pulse of light, and continues to do so from the moment it is "hit", to the completion of the detonation reaction in that blasthole. At locations further along the column, additional targets transmit pulses and time intervals between transmissions are recorded using a high speed counter/timer. This technique can measure VOD to acceptable levels of accuracy over intervals as small as approximately 0.1 metres. The fibre optic method has been found to give unsatisfactory results in blastholes where the column height of explosive is large (e.g. 30 metres or more). It is proposed that at the hydrostatic pressures which are present at the base of long charges, the nature of the plasma undergoes dramatic change, emitting much less light than for short columns. The result is that only weak signals are recorded, and VOD measurements are frequently not obtained. The fibre optic method has the main advantages that it does not require the insertion of current carrying, or electronic probes into the explosive, and should be less influenced by extraneous electronic "noise". The second common point contact method is the plasma continuity technique, and is capable of the same levels of measurement accuracy as the fibre optic method. With this method electrodes are placed in the explosive during charging at known intervals (e.g. ½ metre or 1 metre intervals). A small voltage is applied across the electrodes, but no current flows through them because the ends of the electrodes are open-circuit. Section 7: Explosives Page 7:38 Optimal Drill and Blast Techniques for Underground Mining 2 m ANFO column (100 mm dia.) 1.0 0 -1.0 0.032 0.033 0.034 0.035 TIME (sec) Explosive CJ Plane Direct ion of Det onat ion Blast hole Wall Det onat ion Front Figure 7.24 Schematic showing pin contactor method for VOD measurement and signal record. When the detonation front strikes the electrode pair, the ionisation within the plasma permits a small current to flow between the electrodes. The commencement of this flow is used to trigger timing circuitry for a direct read out of time interval, or the entire signal may be recorded in full for operator interpretation. Section 7: Explosives Page 7:39 Optimal Drill and Blast Techniques for Underground Mining INSTANTANEOUS VOD ANFO (100 mm dia.) 4500 4300 Ve lo city (m /s) Avg. VOD = 3840 m/s 4100 3900 3700 3500 0 1 2 3 4 5 6 7 8 9 10 Distance (m) Figure 7.25 Analysis of VOD over discrete intervals gives instantaneous VOD. Data collected in this manner can be analysed in a number of ways. Velocities over each discrete interval can be calculated to consider variations in VOD along the column length in these cases the error associated with each discrete measurement is a maximum. Alternatively, all data may be analysed by regression to obtain an estimate of much higher accuracy which applies to the entire charge length, as shown in the following figure. VOD REGRESSION ANFO (100 mm dia.) 12 Dista nce (m ) 10 VOD = 3849 m/s 8 6 2 r 2 = 0.99998 4 2 0 0 500 1000 1500 2000 2500 3000 Time (us) Raw Data Regression Figure 7.26 Regression analysis gives VOD over full charge length. Section 7: Explosives Page 7:40 Optimal Drill and Blast Techniques for Underground Mining Using regression techniques in conjunction with the point contact method, multiple measurements of VOD per blasthole can easily be obtained, and an average velocity of detonation can be calculated with a precision of ± 1% or better. Simultaneous monitoring in up to 16 holes per blast has also been conducted for production blasting. Blasthole VOD calculations, however, must be conducted with considerable care. It has been clearly demonstrated that significant run-up zones can exist around the primer. Blasthole VOD within approximately 4 blasthole diameters may be significantly less than the steady state velocity. This itself may be an important aspect of performance monitoring, since it will influence the fragmentation potential of the explosive in the vicinity of the primer. Since primers are generally located at the base of the explosive column, improved performance during the early period of detonation may improve conditions. Further complications may be introduced around the interfaces between different explosives in the one blasthole where combination loading is practised. Experience in measurement of blasthole VOD indicates that the variability between blastholes is significantly greater than the variability within a blasthole, generally attributable to blasthole loading practices or ground conditions (i.e. In-flow of water). Therefore, more meaningful information can be obtained by conducting measurements on many blastholes, than by increasing the number of measurements, and measurement accuracy, in a single blasthole. Continuous Methods Several methods are available for the continuous measurement of blasthole VOD, the better known ones being the SLIFER method, the CORRTEX method, and the resistance wire method. The SLIFER technique for blasthole VOD measurement is a method of continuous measurement of detonation velocity, permitting identification of small inconsistencies in behaviour. This method of continuous measurement is considerably more complex than the point contact method, and in this case utilises the resonance effect of a shorted coaxial cable to allow the position of the plasma front (which provides the short circuiting of the cable) to be calculated at any instant. The length of coaxial cable is lowered into the blasthole at the time of charging. The cable probe forms part of an oscillator circuit, the frequency of which varies with the length of the cable. As the cable is progressively consumed by the detonating shock front, the circuit resonance changes continuously, and a frequency to voltage converter outputs a voltage signal which is recorded on high speed recorders. The technique is capable of detecting quite small anomalies in the detonation velocity in the blasthole, and can provide valuable information concerning the effect of primer size on run-up velocities, the effect of additional priming, and the behaviour at explosive/explosive interfaces in combination loading. Since the SLIFER technique also relies on the plasma at the detonation front to effect cable shorting, the success of this technique is also dependent on the quality of the plasma. Experimentally, plasma characteristics vary quite considerably depending on explosive formulations, blasthole condition, and blasthole depth. The SLIFER has the main Section 7: Explosives Page 7:41 Optimal Drill and Blast Techniques for Underground Mining disadvantage of requiring quite complex analysis to calculate VOD from the recorded signal, since there is no simple proportionality between signal amplitude or signal gradient and VOD. The CORRTEX method is the most complex method for measurement of VOD, requiring very expensive instrumentation. The method uses time domain reflectometry to interrogate the two-way transit time of an electric pulse reflected off the end of a coaxial cable. The method is not dissimilar from radar. As a shock wave advances along the cable length, the cable is either shortened or compressed, causing the two-way transit time to shorten. Even relatively slight compression of the cable is sufficient to produce a reflection, enabling the precise location of the point of application of the pressure to be calculated. The CORRTEX method has been commercialised in the form of the VODR system. Despite the claims of extreme precision, this device samples relatively slowly (10 µs per point, 10kHz sample rate), and therefore effectively takes samples every 5cm or so. Recognising that several samples are required before a reasonable estimate of velocity can be made, this technique is able to provide VOD measurements over intervals of approximately 0.1 to 0.2m. Int erference from st emming Hole init iat ion VOD % Slope 6 4 2 0 0.192 0.193 0.194 0.195 Time (seconds) Figure 7.27 VOD measurement using the resistance wire method. The resistance wire method relies on a linear relationship between the length of wire in the blasthole and the resistance of the wire. A constant current is applied to a length of resistance wire which is inserted into the blasthole at the time of charging. As the wire is consumed by the advancing detonation front, the resistance varies linearly. The variation in resistance is reflected in the voltage drop along the wire. An example of a continuous VOD signal obtained from resistance wire in a bulk watergel explosive is shown in the waveform previous. The method also relies on the conductivity of the plasma, in the same manner as the SLIFER and point contact methods, and is therefore subject to the same limitations with respect to reliability. 7.6.3 Accessory Performance Assessment The performance of explosive accessories relates primarily to the accuracy of delay detonators, and the matching of initiating systems to explosive products. Section 7: Explosives Page 7:42 Optimal Drill and Blast Techniques for Underground Mining The degree of scatter in initiation times from a delay detonator can be measured using a range of electronic timing equipment. Such testing is generally limited to one detonator per measurement. High speed photography permits measurement of many detonators in a single firing, but is limited in accuracy by the framing rate of the camera. Some workers have claimed to be able to measure the initiation times of in-hole delay elements using high speed photography, relying on detonating cord "tell-tales" to provide the surface expression of in-hole detonation. This method is disruptive, influencing the performance of the blast, and should be avoided. Perhaps the simplest way to test delay accuracy on multiple samples is to use a microphone and some form of full waveform recorder. This technique is capable of measuring the firing times of at least 10 detonators per firing, with an accuracy of ± 1ms or better. This level of precision is more than adequate for most detonators, including the newer electronic detonators which claim to have a precision of ± 1ms for any period of delay. A simple arrangement for measurement with a microphone is shown in next diagram, with the microphone placed as shown. #9 #13 #7 #15 Microphone Monit or #5 #17 #3 #19 #1 #21 Lead in #1 400 #3 #5 #7 #9 #11 #13 #15 #17 #19 #21 200 0 -200 -400 0 0.1 Time (seconds) 0.2 0.3 6 9 ms Figure 7.28 Arrangement for determining the timing of delay elements using a microphone. The fundamental data obtained from delay testing are the mean and standard deviation, from which all applicable statistics can be calculated. These two parameters introduce the concepts of accuracy and precision. Accuracy, in relation to delay variability, can be defined as the proximity of the mean initiation time for a single group of delays to a nominal or quoted firing time. Hence, an accurate batch of delay elements would have a mean firing time approximating the nominal initiation time. The standard deviation, on the other hand, is an indicator of precision. Precision is a measure of the scatter of a group of firing times. Section 7: Explosives Page 7:43 Optimal Drill and Blast Techniques for Underground Mining Delay Accuracy If a small sample of initiation times is sampled, the mean of the sample will not necessarily coincide with the nominal initiation time. This may be due to random variation, or the true mean being offset from the nominal initiation time. This offset may be due to the manufacturing process and/or the subsequent storage conditions prior to testing. To enable all results, irrespective of nominal delay time or delay type, to be grouped together to calculate the "accuracy", the normalised mean firing time (), is calculated according to the equation: n n 100 % where µ is the mean firing time for a single group of delays, and n is the nominal initiation time for the group. Accuracy therefore represents the offset between the nominal initiation time for a group of delay detonators, and the actual mean firing time for those delays. Delay Precision The nature of pyrotechnic compounds is such that delay elements do not react with a constant reaction rate, irrespective of the degree of quality control over manufacturing conditions, but rather within specified tolerances. Detonation times will be distributed around the batch mean firing time. This scattering effect can be attributed to variations in the chemical kinetics of the delay compound and the absolute volume of the product in the delay itself. Unlike the offset with the sample mean which was assumed to be due to factors affecting the manufacturing process and subsequent use, the variance is attributable to variation in the compound itself. Grain size, purity, and moisture content will all affect the reaction rate. Absolute control over all these parameters is not feasible, and as such, the variation is an inherent property of pyrotechnic delay elements. Precision of delay elements is therefore defined in terms of the standard deviation of a group of delays and the mean initiation time, and in statistical terms is referred to as the coefficient of variation, , expressed as a percentage. 100% where is the calculated standard deviation, and µ is the calculated mean firing time (usually approximately equal to the nominal initiation time). Section 7: Explosives Page 7:44 Optimal Drill and Blast Techniques for Underground Mining F-Factor The "F-Factor" presents a single number capable of representing both the accuracy and precision of a group of delays, defined by: F X where X is the midpoint between the nominal delay time and the nominal delay time of the next delay in the series. Hence, the F-Factor represents the number of standard deviations between the mean time and the halfway point to the next delay in the series. For high precision delays, with very low probability of overlap with the next element in the series, the F-Factor will be high. A low F-Factor means that scatter is likely to exceed half the interval to the next element in the series, and overlap between detonators is likely. Any sample of delays may be classified according to their F-Factors, and the probability of overlap (assuming adjacent delays have the same F-Factor) may be calculated. F-Factor Range 0.0 – 0.5 0.5 – 1.0 1.0 – 1.5 1.5 – 2.0 2.0 – 2.5 Overlap Probability 50.0 – 24.0% 24.0 – 7.9% 7.9 – 1.7% 1.7 – 0.23% 0.23 – 0.02% Figure 7.29 Overlap probabilities for various F-Factors. Section 7: Explosives Page 7:45