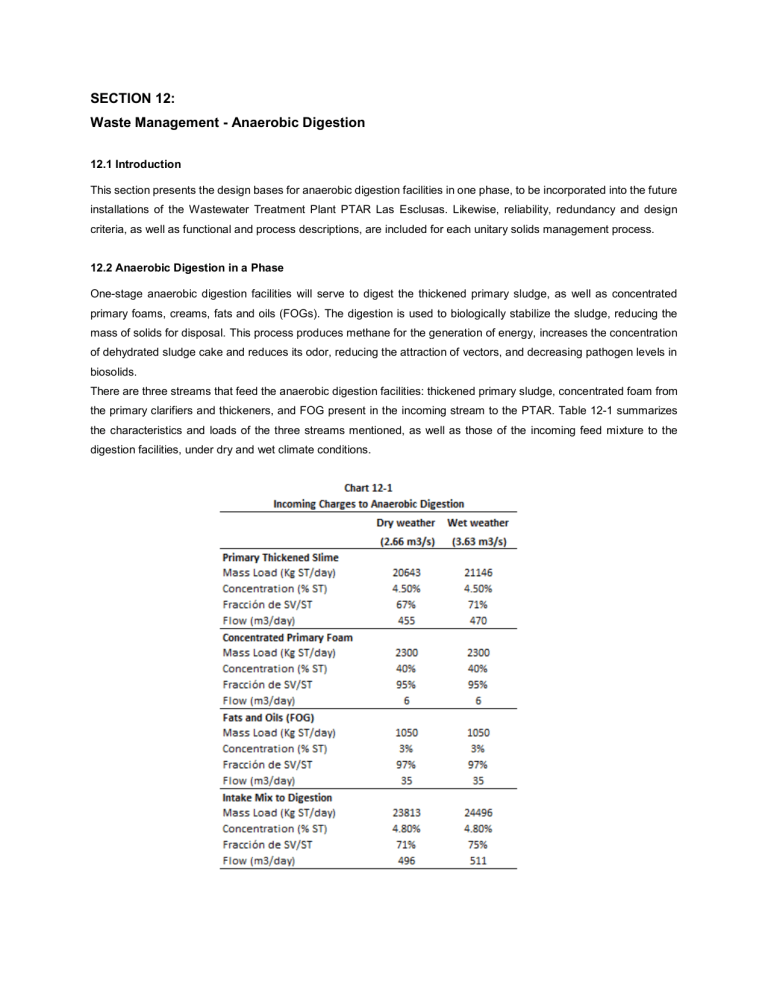

SECTION 12: Waste Management - Anaerobic Digestion 12.1 Introduction This section presents the design bases for anaerobic digestion facilities in one phase, to be incorporated into the future installations of the Wastewater Treatment Plant PTAR Las Esclusas. Likewise, reliability, redundancy and design criteria, as well as functional and process descriptions, are included for each unitary solids management process. 12.2 Anaerobic Digestion in a Phase One-stage anaerobic digestion facilities will serve to digest the thickened primary sludge, as well as concentrated primary foams, creams, fats and oils (FOGs). The digestion is used to biologically stabilize the sludge, reducing the mass of solids for disposal. This process produces methane for the generation of energy, increases the concentration of dehydrated sludge cake and reduces its odor, reducing the attraction of vectors, and decreasing pathogen levels in biosolids. There are three streams that feed the anaerobic digestion facilities: thickened primary sludge, concentrated foam from the primary clarifiers and thickeners, and FOG present in the incoming stream to the PTAR. Table 12-1 summarizes the characteristics and loads of the three streams mentioned, as well as those of the incoming feed mixture to the digestion facilities, under dry and wet climate conditions. 12.2.1 General description Three new digesters will be built for the handling of solids, with the necessary provisions for the construction of a fourth digester in the future. Three new digesters will be built for the handling of solids, with the necessary provisions for the construction of a fourth digester in the future. The four digesters will be designed with the same dimensions and hydraulic characteristics. These digesters will have an operating temperature of 35oC, and under wet weather conditions they will provide a 20-day Solid Retention Time (SRT), with one of them out of service. Likewise, the digesters will comprise a mixing system, to promote the digestion process. The fully digested mesophilic sludge will be transferred to the digested sludge storage tank for its further dehydration. 12.2.2 Reliability and Redundancy Criteria • The SRT of the digestion process is about 20 days in wet weather conditions, with a digester out of service. Likewise, said SRT is approximately 30 days in humid climate conditions, with all digesters in service. In this way, a stable operation of the digesters and a greater degradation of volatile solids (VS) will be ensured, maximizing gas and energy production. • All pump systems will have a stand-by pump. 12.2.3 Design Criteria By means of the anaerobic digestion process the SVs are destroyed, resulting in a reduction in the total mass of the sludge solids. Table 12-2 summarizes design and performance criteria as well as loads. Each digester will be equipped with a system for the complete mixing of its contents, in order to standardize the temperature and eliminate short circuits. Likewise, the digesters system will have pumps for the transfer of the digested mesophilic sludge to the digested sludge storage tank, for its subsequent dehydration. The design criteria for the mixing system and the pumps are presented in Table 12-3. Chart 12-3 Mixing Design Criteria for Digesters and Sludge Transfer Parameter Value Digester Mixing System Number Type 3 (1 for each digester) Pumping Mix Mixing Assembly Type - Floor Mounted Mixing Mouthpieces - Foam spray nozzles mounted on the wall Total number of nozzles per tank 8 mounted on the floor 8 mounted on the wall Mixing pumps Number of units per digester 2 (1 operating, 1 in stand-by) Type of pump Horizontal Centrifuge Crusher Solids concentration (%ST) 2.5% - 3% Design capacity (m3/hr) 1135 Total dynamic head - TDH (m) 12.2 Maximum Pumping Speed (rpm) 1200 Maximum Motor Power (kW) Motor Drive Type 57 Constant speed Digestion Mesophilic Sludge Transfer Pumps Number of units Type of pump Solids concentration (%ST) 3 (2 operating, 1 in stand-by) Progressive Cavity 0% - 6% Design capacity (m3/hr) 91 Total dynamic head - TDH (m) 15 Maximum Pumping Speed (rpm) 350 Maximum Motor Power (kW) 15 Motor Drive Type Constant speed Transfer Pump Crushers Number of units 3 Type of pump 100 Design capacity (m3/hr) 91 Maximum Motor Power (kW) 3.7 Motor Drive Type Change of direction of rotation 12.2.4 Description of the Anaerobic Digestion Process The thickened sludge pumps located in the primary sludge thickener building will transfer the thickened primary sludge to the digesters. The concentrated primary foams will be pumped into the thickened primary slurry piping at a point prior to the digestion facilities. The FOGs will have a feed line to the independent digesters, due to their pre-heating. The feed slurry mixture will be evenly distributed to the 3 diggers of 5,000 m3 each. These digesters will have a pumping mixing system comprising horizontal crusher pumps, suction and discharge piping as well as a high speed nozzle arrangement designed to provide a complete mixture of the contents as well as entrainment of any foam. For each digester a crusher pump will be provided in operation and another in stand by. On the other hand, 3 progressive cavity pumps (2 in operation and 1 in stand-by) will be provided for the transfer of digested mesophilic sludge from the digesters to the digested sludge storage tank. 12.2.5 Description of Operation The sludge feed pumps will start or stop based on the conditions of the primary sludge thickening facilities. Concentrated foam pumps will start only when thickened primary sludge flows into the digesters. The incoming flow to the digestion facilities will be monitored by means of a magnetic flow meter; And each of the digesters will have a motorized valve in charge of distributing the thickened mixture of primary sludge, as well as concentrated primary foams, in an equitable way among the digesters in operation. Because the FOGs will be pre-heated prior to entering the digesters, to assist in handling and pumping, they will have a magnetic flowmeter and independent motorized valves for equitable distribution among the digesters in operation. On the other hand, the mixing system of the three digesters can operate continuously, or in time intervals. Sufficient mixing will maximize Volatile Solids Reduction (VSR) and gas production. The digested mesophilic sludge will overflow into a moist well to maintain a constant level within the digesters. Once the wet pit level reaches the high level set point, a motorized valve will open and a digested mesophilic slurry transfer pump will start to pump slurries into the digested sludge storage tank. Also, once the level of the wet pit reaches its low set point, the transfer pump will stop and the motorized valve will close. 12.2.6 Acquisition Process The Employer has classified the Anaerobic Digester Mixing System as one of the seven (7) Main Teams of the project. Accordingly, each Bidder must submit in its bid, the respective documents that demonstrate the mixing system proposed for the digesters, meets both the criteria described in the Technical Specification, and the criteria of performance and experience required for the proposed equipment. The Contractor shall assume responsibility for the complete mixing system of the anaerobic digesters. This system must be supplied and coordinated through the Contractor, by a single manufacturer. The Contractor must install the three (3) new anaerobic digestion units with all necessary ancillary equipment. The nominal volume of each digester will be 5,000 m3. The anaerobic digesters will operate in the mesophilic mode with operating temperatures between 35 °C and 38 °C to treat sedimented primary solids with addition of ferric chloride (20 mg / L at 40 mg / L) and polymer. The mixing system will be hydraulic with external pumping units and auxiliary piping with nozzles. The pumped mixing system must deliver at least 7.0 kW / 1000 m3 in the discharge of the nozzles. Likewise, the manufacturer supplying the mixing system of the anaerobic digesters, through the Contractor, shall document the mixing operation experience with the same or equivalent equipment in five (5) sites for a period of at least five (5) years in each. The Contractor shall review and approve the documents and referrals corresponding to the mixing system of the anaerobic digesters before awarding the construction contract for the PTAR Las Esclusas. 12.3 Heating System of Digesters 12.3.1 General description In order to optimize the process of anaerobic digestion, the temperature of the digesters will be maintained at 35 ˚C by means of a heating system. Accordingly, the sludge contained in the digesters will be circulated through concentric tube heat exchangers. In this way, the heat of the hot water circulating inside the heat exchanger will be transferred to the sludge through the wall of the tube containing said sludge, before it is returned to the digester. The water will be heated by the heat recovered from the routing of the generator motors as well as by means of pyrotubular boilers. To see the sizing of generators and boilers, refer to Section 13 - Cogeneration, of the Design Bases. 12.3.2 Reliability and Redundancy Criteria • The digesters will have recirculation pumps for stand-by sludge. • A hot water pump will be supplied from the standby primary circuit. 12.3.3 Design Criteria Table 12-4 summarizes the design criteria for the heating system of the digesters. 12.3.4 Description of Warming Processes of Digesters The temperature of the digesters should be maintained at 35 ° C to provide optimum conditions to the mesophilic bacteria. As mentioned above, maintaining this temperature in the digesters is achieved by feeding and recirculating the slurry through concentric tube heat exchangers. Each digester will have its own independent heat exchanger. The recirculation slurry piping shall be configured in such a way as to enable Digesters No. 1 and 2 to use the heat exchanger of the other digester if necessary. Digester No. 3 and Future Digester No. 4 will have the same functionality Horizontal centrifugal impeller pumps will be supplied to recirculate the sludge through the heat exchangers. Each digester will have a separate recirculation pump. Digesters No. 1 and 2 will share a pump in stand-by. Digester No. 3 will have a stand-by pump that will be shared with digester No. 4 in the future. Hot water will be produced by means of the generator motors and the boiler system, to heat the digesters. The hot water will be circulated through the digesters by means of the hot water pumps of the primary circuit. The water temperature will vary between 70 ° C and 90 ° C. Said water will be transported using insulated pipe to minimize heat loss. Each heat exchanger will have a separate hot water pump from the secondary circuit, and a three-way temperature control valve. The hot water pump of the secondary circuit will circulate hot water continuously through the heat exchanger. A three-way temperature control valve allows mixing of hot water from the primary circuit with water from the secondary circuit to maintain the temperature of the latter. As hot water enters the primary to secondary circuit, a same amount of water with lower temperature exits the secondary circuit to the primary circuit, to be reheated by the generator motors or the boiler. 12.3.5 Description of the Operation of the Digester Heating System Heating of the digesters will start with one of the following conditions: • The temperature of the digester sludge is lower than the temperature of the lowest set point. • The magnetic flow meter installed in the feed line to the digesters indicates presence of flow. Any of these conditions will initiate the respective recirculation sludge pump for heating, and the hot water recirculation pumps for the secondary circuit feeding the heat exchanger. Once it is started, the heating system of each digester will be controlled by the modulation of a three-way valve for temperature control, in order to maintain a temperature set point in the sludge exiting the heat exchanger. The maximum temperature of the sludge leaving the heat exchanger should not exceed 40.5 ° C to prevent backflow of sludge into the heat exchanger tubes. The hot water pump for the primary circuit will operate continuously and the temperature of the primary circuit will be controlled by the generator motors and the boiler system. 12.4 Digestion Gas Collection and Management System 12.4.1 Abstract The gas produced through the anaerobic digestion process will be collected from all the digesters in service and stored in a double membrane gas meter. The stored gas will be processed by a treatment system before being used by the generator engines and the pyrotubular boiler. Excess gas from digestion will be sent to a tea to be incinerated. 12.4.2 Reliability and Redundancy Criteria There will be a tea (burner) in stand-by to burn the excess gas in case the operating tea fails or a second tea is required to burn the excess gas. 12.4.3 Design criteria The design criteria for the digester gas collection and management system are summarized below in Table 12-5. 12.4.4 Description of Processes of the Digesters Gas Collection System The dual membrane gas meter has a membrane that increases or decreases the available volume based on the incoming gas flow of the digesters. The space between the inner and outer membrane is pressurized to 20 mbar using atmospheric air from a fan in operation and one in stand-by. The pressurized air acts on the inner membrane to maintain the pressure of 20 mbar for the gas system of the digesters. From storage, the gas is treated and used in the generator engines. Excess gas is incinerated by means of the teas. 12.4.5 Description of Processes of the Digesters Gas Collection System All the digested gas will be led first to the membrane gasometer. A level sensor will be installed on the top of the outer membrane to monitor. The level of the inner membrane, this determines the amount of gas stored. The gas can freely leave the storage membrane for use in generators and the boiler. When the storage of the digested gas reaches the capacity limit, a motorized valve opens towards the tea to incinerate the excess gas. Once the storage levels are lowered to a predetermined level, the motorized valve will close thereby stopping the burning of excess gas. In the event that a bypass operation is required on the gasometer, in the event that it is necessary to remove it from service for maintenance operations, the motorized valves in the plugs will open, and the pressure regulating valves in the plugs will maintain The pressure in the gas digestion system. The teas have an autopilot control to turn on every time gas from the digesters enters. 12.5 Reception and Storage of Fats and Oils (FOGs) The proposed FOG reception station will receive, store, heat and equalize the FOG delivered in tank trucks. In this way, the hot FOGs will be pumped to each of the digesters in operation, and will enter these through the hot sludge return pipes. It is estimated that the facility will receive about 10 FOG trucks a day. With an average capacity of 3,800 liters in each truck, it is estimated that approximately 38,000 liters will be received per day. 12.5.2 Reliability and Redundancy Criteria • A recirculating crusher pump will be supplied in stand-by for the FOG pumping station. • A stand-by power supply pump will be supplied. 12.5.3 Design criteria Chart 12-6 Design Criteria for the FOG Reception System Parameter Value Truck Unloading Discharge flow (L/s) Pretreatment 40-65 Rock Trap Online Crusher FOG Elevation Station Number of units 2 (1 operating, 1 in stand-by) Type of pumps Recirculation Crushers pumps Design capacity (m3/hr) 235 Total dynamic head - TDH (m) 13 Maximum Pumping Speed (rpm) 1200 Maximum Motor Power (kW) 18.8 Motor Drive Type Constant velocity Storage Tanks FOG Capacity (m3) 140 Operating pressure (mbar) 20 Mixing pumps FOG tank Number of units Solid concentration (%ST) Type of pumps 2 (1 operating, 1 in stand-by) Centrifuges Horizontal Crushers 2.5% - 3% Design capacity (m3/hr) 235 Total dynamic head - TDH (m) 12 Maximum Pumping Speed (rpm) Maximum Motor Power (kW) Motor Drive Type 1200 15 Constant velocity FOG heat exchangers Number of units Type 1 Concentric tubes Nominal Heat Transfer (kW) 74 Surface Area of Heating (m2) 2.4 Number of Tubes 6 Sludge Flow (m3/h) 34 Hot water flow (m3/h) 34 Recirculation Pumps Number of units 2 (1 operating, 1 in stand-by) Type of pumps Progressive Cavity Solid concentration (%ST) 2% - 5% Design capacity (m3/hr) 34 Total dynamic head - TDH (m) 6 Maximum Pumping Speed (rpm) 350 Maximum Motor Power (kW) 5.6 Motor Drive Type Constant velocity Secondary Circuit Hot Water Pumps Number of units 1 Type of pumps Centrifuge in line Design capacity (m3/hr) 34 Total dynamic head - TDH (m) 5.5 Maximum Pumping Speed (rpm) 1750 Maximum Motor Power (kW) 0.75 Motor Drive Type Constant velocity FOG Feed Pumps Number of units 2 (1 operating, 1 in stand-by) Type of pumps Progressive Cavity Solid concentration (%ST) 2.5% - 3% Design capacity (m3/hr) 6.8 Total dynamic head - TDH (m) 15 Maximum Pumping Speed (rpm) 300 Maximum Motor Power (kW) 3.7 Motor Drive Type Variable 12.5.4 Description of Processes The station shall be designed to discharge FOG from the tankers in the discharge area by means of air compressors mounted on the truck or by means of the force of gravity. The discharge area will be melted at the site, particularly nonslip slope to a drainage channel that will collect spills, wash water, and flow by gravity into the FOG sump. The discharge area will be designed to facilitate the washing of this as well as to contain the spills. The following is a detailed description of the FOG receiving station process: • The inlet pipe of the receiving station shall be equipped with a quick-connect coupling to allow discharge of the FOG tanks. • The FOGs will go through a large-capacity rock trap designed to catch stones. Said operation will be controlled by a motorized valve located downstream of said rock trap. The FOGs will then pass through a crusher to the lift station. • The FOG lift station consists of two recirculating crushing pumps which will transfer the FOGs to the storage tank located near the digestion facility. The FOG storage / equalization tank will be heated and mixed. To heat the FOGs, hot water from the primary circuit will be pumped through a concentric tube heat exchanger. A progressive cavity independent heat pump and a shredder will circulate the FOGs in the storage bin by means of the FOG heat exchanger. The setting temperature is 43 ° C. The storage tank will also be provided with a mixing system with recirculation crushers and nozzles. There will be two progressive cavity FOG transfer pumps. The pumps will be provided with automatic controls and will be equipped with frequency inverters, flow meters and pressure transducers. The tank will be provided with a level transducer that will start and stop the pumps, and announce alarms. 12.5.5 Description of the Operation of the FOGs Reception Station The FOG reception station is designed to be operated automatically, with little attention from the operator and the FOG carrier. This station will accept FOG from the transporters, equalize and heat the FOGs, and transfer the FOGs from the storage tanks to the anaerobic digesters automatically. The detailed functional description of the receiving station of the FOGs is summarized below: • The transport system of the FOGs will be connected to the quick connection piping of the receiving station and will discharge, through the rock trap and the crusher. • The FOG lift station will collect the FOGs and two recirculation crusher pumps will be transferred to the FOG storage tanks by a level transmitter located at the lift station. • The storage tank / equalization heating and recirculation systems will operate continuously. These pumps will be stopped automatically based on a low set point in the tank. • The FOG transfer pumps, from the storage tank / equalization tank to the digesters, will be variable speed. The speed and flow rate of the pumps will initially be selected by the operator, based on the amount of grease stored in the tank and the anticipated discharges of the next day. The pump speed will automatically increase if the FOG level reaches a high level set point. The pump speed will increase even further if the FOG level reaches a high-high set point. The speed of the pump will also increase to the maximum speed if the level of the FOG reaches a point where the available storage volume is below 3,800 L (the capacity of the FOG tankers). • The sludge / FOG piping will be designed to circulate the fluid between the digesters in service, with a continuous pumping 24 hours a day, 7 days a week. • When a high pressure set point is reached in the transfer line, or a low water set point in the storage and mixing tank, the transfer pumps will be stopped automatically. The pumps will shut down automatically if the discharge pressure within the line reaches a certain set point, which may indicate an obstruction in the line, or that all valves to the digesters are closed. • The pumps will be exchanged for equitable wear after each use or a set operating time interval. The lead pump / secondary pump sequence can also be set manually. SECTION 12 CALCULATION MEMORY – A BALANCE OF MASS FOR SOLIDS PTAR LAS ESCLUSAS BALANCE OF MASS FOR SOLIDS The calculation of the mass balance calculation for the solids of the PTAR Las Esclusas has been developed for the following load conditions: • Dry Weather • Weather Wet • Average Annual Payload (CPA) • Monthly Maximum Load (CMM) • Maximum weekly load (CMS) The mass balance for the solids produced under the conditions mentioned above is part of the estimation of primary sludge production in the primary clarifiers. This estimation contemplates a calculation procedure for the determination of the solids loads under the conditions of Dry Time and Wet Time, followed by a slightly different procedure for the calculation under the conditions of CPA, CMM and CMS. Once the mud loads produced under these five conditions were determined in the primary clarification process, the mass balance was carried out for the other sludge treatment processes. In another calculation report corresponding to the heating calculations of the digesters, the use of the methane gas generated in the digesters when used as fuel in the cogeneration of electric energy will be analyzed for the heating of the sludge present in the digesters. For simplicity in the analysis carried out in the heating calculation memory of the digesters of the data recorded in the present mass balance of solids, only values corresponding to the CPA, CMM and CMS conditions were used. For the estimation of the loads in Dry Time and in Wet Time, the following input parameters were used: Chart 1 Parameters of the Inflow to the PTAR Las Esclusas for Conditions of Dry Weather and Wet Weather (Year 2,030) Parameter Dry weather Wet weather Flow (m3/s) 2.66 3.63 DBO5 156 126 130 105 (mg/L) SST (mg/L) Also, to estimate the production of solids in Dry Time and Wet Time, the recirculation flow rates of the plant corresponding to the supernatant of the thickening by gravity and the filtration of the dehydration process were taken into account. The calculation of recirculation flows can be found in the mass balance of the particular processes that produce them. Also, to estimate the production of solids in Dry Time and Wet Time, the recirculation flow rates of the plant corresponding to the supernatant of the thickening by gravity and the filtration of the dehydration process were taken into account. The calculation of recirculation flows can be found in the mass balance of the particular processes that produces them. In accordance with the above, the estimation of the solids production for the primary clarification process under Dry Weather and Wet Weather conditions is shown below. Chart 2 Mass Balance for Primary Clarification Under Dry Weather and Wet Weather Conditions Parameter Dry weather Wet weather Flow (m3/s) 2.66 3.63 DBO, mg/L 156 126 SST, mg/L 130 105 35853 39518 35.9 39.5 29877 32931 29.9 32.9 Flow (m3/s) 0.012 0.013 DBO, mg/L 0.1 0.1 DBO load, kg/day 906 999 SST, % 0.1 0.1 1.077 1.113 Flow (m3/s) 0.01 0.01 DBO, % 0.1 0.1 DBO load, kg/day 512 548 SST, % 0.1 0.1 SST load, kg/day 618 613 Flow (m3/s) 2.68 3.65 DBO, mg/L 156 126 SST, mg/L 130 105 37271 41066 37.3 41.1 31572 34657 31.6 34.6 Influent flow DBO load, kg/day DBO load, TON/day SST load, kg/day STT load, TON/day Recirculation flow Gravity Thickening Supernatant SST load, kg/day Dehydration Filtration Affluent to Primary Clarification DBO load, kg/day DBO load, TON/day SST load, kg/day STT load, TON/day Primary Clarification Removals (with contribution of recirculation flows) DBO remotion, % 42% 42% SST remotion, % 62% 62% Primary Clarification Effluent DBO load, kg/day 21617 23818 DBO load, TON/day 21.6 23.8 DBO, mg/L 93.6 75.6 12012 13237 STT load, TON/day 12 13.2 SST, mg/L 52 42 18018 19856 80% 80% 14414 15885 3604 3971 40 20 SST load, kg/day Raw Primary Sludge (LP) Solid Load, kg ST/d Fraction of Volatile Solids, SV/ST Volatile Solids Load, kg SV/d Load of NonVolatiles, kg SNV/d Chemical Precipitation Ferric Chloride Dosage, mg/L Ferric Sludge Production (kg/m3 treated / mg/L dosed) 0.000383 Production of Chemical Sludge, kg/d 3522 2403 Production of Chemical Sludge, TON/d 3.52 2.4 Solid Load, kg ST/d 21540 22259 Solid concentration, %ST 1.50% 1.50% Fraction of Volatile Solids, SV/ST 66.90% 71.40% 1.436 1484 14414 15885 7126 6374 Raw Primary Sludge + Chemical Sludge (LP + Q) Flow (m3/day) Volatile Solids Load, kg SV/d Load of NonVolatiles, kg SNV/d Note: As can be seen in the Table, the contribution of the recirculation flow rates (supernatant of thickening by gravity and filtering of the band press filters) is very low, so that the associated loads were not taken into account in the sludge Resulting from the process (raw primary sludge + chemical sludge). On the other hand, for the calculation of the solids production in primary clarification under CPA, CMM and CMS conditions, the following input parameters were assumed: In accordance with the above, the estimation of solids production for the primary clarification process under the conditions of CPA, CMM and CMS is shown below. Chart N.4 Balance of Mass for Primary Clarification Under CPA, CMM and CMS Conditions Parameter Average Annual Load (CPA) Monthly Maximum Load (CMM) Weekly Maximum Load (CMS) Raw Primary Sludge (LP) Solid Load, kg ST/d 19500 24375 29520 80% 80% 80% Volatile Solids Load, kg SV/d 15600 19500 23400 Load of Non-Volatile Solids, kg SNV/d 3900 4875 5850 2 3.7 7.4 40 30 20 3674 4899 Fraction of Volatile Solids, SV/ST Chemical Precipitation Flow rate, m3/s Ferric Chloride Dosage, mg / L Ferric Sludge Production (kg/m3 treated / mg/L dosed) Production of Chemical Sludge, kg/d 0.000383 2648 Raw Primary Sludge + Chemical Sludge (LP + Q) Solid Load, kg ST/d 22148 28049 34149 Solid concentration, %ST 1.50% 1.50% 1.50% Fraction of Volatile Solids, SV/ST 70.40% 69.50% 68.50% Flow (m3/day) 1477 1870 2277 Volatile Solids Load, kg SV/d 15600 19500 23400 Load of Non- Volatiles, kg SNV/d 6548 8549 10749 Solid Load, kg ST/d 2300 2300 2300 Solid concentration, %ST Fraction of Volatile Solids, SV/ST Flow (m3/day) Volatile Solids Load, kg SV/d Load of Non- Volatiles, kg SNV/d Fats and Oils Retained (G & A) Solid Load, kg ST/d 40% 40% 40% 95% 95% 95% 5.75 5.75 5.75 2185 2185 2185 115 115 115 1050 1050 1050 3% 3% 3% 97% 97% 97% 35 35 35 1019 1019 1019 32 32 32 Concentrated Primary Foam (EP) Solid concentration, %ST Fraction of Volatile Solids, SV/ST Flow (m3/day) Volatile Solids Load, kg SV/d Load of Non- Volatiles, kg SNV/d As mentioned above, once the solids loads produced in the primary clarification were determined for each of the conditions studied, the mass balance was performed for the subsequent processes. The assumed input parameters for below. gravity thickening are shown In accordance with the above, the mass balance performed for the thickening by gravity is shown below. Chart N. 6 Mass Balance for Gravity Thickness Average Monthly Weekly Parameter Annual Load Maximum Maximum (CPA) Load (CMM) Load (CMS) Raw Primary Sludge + Chemical Sludge (LP + Q) Dry weather Wet weather Solid Load, kg ST/d 22148 28049 34149 21540 22259 Solid concentration, %ST 1.5% 1.5% 1.5% 1.5% 1.5% Fraction of Volatile Solids, SV/ST 70.4% 69.5% 68.5% 66.9% 71.4% 1477 1870 2277 1436 1484 15600 19500 23400 14414 15885 6548 8549 10749 7126 6374 Solid Surface Load, kg ST / d / m2 83.4 105.7 128.6 81.1 83.8 Surface Hydraulic Load, m3 / m2-d 5.6 7 8.6 5.4 5.6 Hydraulic Retention Time (SSV-based), hrs 17.3 13.6 11.2 17.7 17.2 Flow (m3/day) Volatile Solids Load, kg SV/d Load of Non- Volatiles, kg SNV/d Gravity Thickness Design Bases Thickened Primary Sludge (TPS) Solid Load, kg ST/d 21041 26647 32442 20463 21146 Solid concentration, %ST 4.5% 4.5% 4.5% 4.5% 4.5% Fraction of Volatile Solids, SV/ST 70.4% 69.5% 68.5% 66.9% 71.4% 468 592 721 455 470 14820 18525 22230 13693 15091 6221 8122 10212 6770 6055 Flow (m3/day) Volatile Solids Load, kg SV/d Load of Non- Volatiles, kg SNV/d Gravity Thickening Supernatant Solid Load, kg ST/d 1107.41 1402 1707 1077 1113 Solid concentration, %ST 0.1% 0.1% 0.1% 0.1% 0,11% Fraction of Volatile Solids, SV/ST 70.4% 69.5% 68.5% 66.9% 71.4% 1009 1278 1556 981 1014 780 975 1170 721 794 327 427 537 356 319 Flow (m3/day) Volatile Solids Load, kg SV/d Load of Non- Volatiles, kg SNV/d The assumed input parameters for the mass balance of anaerobic digestion are shown below. Chart N. 7 Design Parameters for Anaerobic Digestion Parameter Number of digesters Value Volume of each digester, m3 5000 3 Diameter, m 27 Area, m2 573 Depth at Wall Level, m 8.7 For the anaerobic digestion, it is necessary to estimate the Destruction of Volatile Solids (SV) based on the Solid Retention Time, for which curves were developed from data reported in the literature1. Using the equation of this curve, the corresponding percentages of SV destruction were calculated according to each solid loading condition. The exercise performed is shown below. Chart N. 8 Reduction of Volatile Solids based on WEF MOP 8 % Destruction of Volatile Solids TRS (days) 100% Activated Waste Sludge 100% Primary Sludge Calculated for Primary Sludge 10 8 50 50 11.3 11 52 52 12.5 13 54 54 13.8 16 56 56 15 18 58 57 16.3 19 59 58 17.5 21 60 59 18.8 22 61 60 20 23 62 61 21.3 24 62 61 22.5 24 62 62 23.8 25 62 62 25 26 63 63 26.3 26 63 63 27.5 27 63 63 28.8 27 63 63 30 28 63 63 31.3 28 63 63 32.5 29 63 64 33.8 29 63 64 35 30 64 63 37.5 30 64 63 40 31 64 63 42.5 32 64 64 45 32 65 64 47.5 32 65 65 50 33 65 66 In accordance with the above, the mass balance performed for anaerobic digestión. Chart N. 10 Mass Balance for Anaerobic Digestion Monthly Average Annual Weekly Maximum Parameter Maximum Load Load (CPA) Load (CMS) (CMM) Thickened Primary Sludge (TPS) Solid Load, kg ST/d Solid concentration, %ST Fraction of Volatile Solids, SV/ST Flow (m3/day) Volatile Solids Load, kg SV/d Load of NonVolatiles, kg SNV/d Dry Wet weather weather 21041 26647 32442 20463 21246 4.5% 4.5% 4.5% 4.5% 4.5% 70.4% 69.5% 68.5% 66.9% 71.4% 468 592 721 455 470 14820 18525 22230 13693 15091 6221 8122 10212 6770 6055 2300 2300 2300 2300 2300 40% 40% 40% 40% 40% 95% 95% 95% 95% 95% 5.75 5.75 5.75 5.75 5.75 2185 2185 2185 2185 2185 115 115 115 115 115 1050 1050 1050 1050 1050 3% 3% 3% 3% 3% 97% 97% 97% 97% 97% 35 35 35 35 35 Concentrated Primary Foam (EP) Solid Load, kg ST/d Solid concentration, %ST Fraction of Volatile Solids, SV/ST Flow (m3/day) Volatile Solids Load, kg SV/d Load of NonVolatiles, kg SNV/d Fats and Oils Retained (G & A) Solid Load, kg ST/d Solid concentration, %ST Fraction of Volatile Solids, SV/ST Flow (m3/day) Volatile Solids Load, kg SV/d 1018.5 1018.5 1018.5 1018.5 1018.5 Load of NonVolatiles, kg SNV/d 31.5 31.5 31.5 31.5 31.5 24391 29997 35792 23813 24496 4.8% 4.7% 4.7% 4.8% 4.8% 74% 72% 71% 71% 75% 508 633 762 495 511 18024 21729 25434 16897 18294 6367 8268 10358 6916 6202 Mixing Feeding to Digesters Solid Load, kg ST/d Solid concentration, %ST Fraction of Volatile Solids, SV/ST Flow (m3/day) Volatile Solids Load, kg SV/d Load of NonVolatiles, kg SNV/d Loading Digesters Number of digesters operating Total volume of digesters, m3 2 10000 Solid Retention Time (SRT) in Digesters, d 19.7 15.8 13.1 20.2 19.6 Loading SV to Digesters, kg SV/d / 1,000 m3 1802 2173 2543 1690 1829 Design for minimum 15 days of SRT under Max Monthly condition with a digester out of service Number of digesters operating Total volume of digesters, m3 Solid Retention Time (SRT) in Digesters, d 3 15000 29.5 23.7 19.7 30.3 29.4 Loading SV to Digesters, kg SV/d / 1202 1449 1,000 m3 Digestion Performance - With Digester Out of Service 1696 1126 1220 Destruction of Volatile Solids from Primary Sludge,% 63% 62% 61% 63% 63% Destruction of Volatile Solids from G & A and EP,% 97% 97% 97% 97% 97% Total Destruction of Volatile Solids, kg Sv / d 12090 13793 15294 11447 12246 Digesters Performance - All in Service Destruction of Volatile Solids from Primary Sludge,% 63% 62% 61% 63% 63% Destruction of Volatile Solids from G & A and EP,% 97% 97% 97% 97% 97% Total Destruction of Volatile Solids, kg Sv / d 12507 14669 16584 11798 12678 Anaerobic Digested Sludge - With the Principal Digester Out of Service Solid Load, kg ST/d 12301 16204 20498 12366 12250 Solid concentration, %ST 2.4% 2.6% 2.7% 2.5% 2.4% Fraction of Volatile Solids, SV/ST 48% 49% 49% 44% 49% Flow (m3/day) 508 633 762 495 511 Volatile Solids Load, kg SV/d 5934 7936 10140 5450 6048 Load of NonVolatiles, kg SNV/d 6367 8268 10358 6916 6202 General Anaerobic Digestion Performance - With the Principal Digester Out of Service General Volatile Solids Reduction,% 69% Gas Production by SV Destroyed, m3 / kg SV Removed 0.94 Production of Gas from Digesters, m3/d 11364.48 68% 65% 70% 69% 12965 14376 10760 11511 The following table shows the design parameters for the digested solids storage tank. The mass balance for the digested solids storage tank is shown below. Note: Design for 4 days of storage under Max Monthly Conditions to allow Dehydration Systems maintenance during weekends and holidays. The last process contemplated in the mass balance for the solids corresponds to the dehydration with band press filters. The design parameters are shown below. To finalize the present document, the mass balance for the dehydration process is shown. Chart N. 14 Parameter Mass Balance for Dehydration Monthly Average Annual Weekly Maximum Maximum Load Load (CPA) Load (CMS) (CMM) Dry weather Wet weather Anaerobic Digested Sludge Solid Load, kg ST/d 12301 16204 20498 12366 12250 Solid concentration, %ST 2.4% 2.6% 2.7% 2.5% 2.4% Fraction of Volatile Solids, SV/ST 48.2% 49.0% 49.5% 44.1% 49.4% 508 633 762 495 511 508323 632903 761677 495483 510665 5934 7936 10140 5450 6048 6367 8268 10358 6916 6202 16.9 26 25.3 Flow (m3/day) Flow (L/day) Volatile Solids Load, kg SV/d Load of Non- Volatiles, kg SNV/d Daily Storage Tanks for Dehydration Number of tanks Tank width, m Depth of the tank, m 2 7.33 5 Length of each tank, m 7.33 Volume for each tank, m3 269 537 Total volume, m3 25.4 20.4 Storage hours Design for 24 hours storage under the condition Average Annual Operational Requirements of Filters Band Press - 7 days a week Hr/Day of Operation Limited by the Load of Solids 3.9 5.1 6.5 3.9 3.9 Hr/Day of Operation Limited by Hydraulic Load 4.1 5.1 6.1 4 4.1 Hr/Day of Operation Critical Value 4.1 5.1 6.5 4 4.1 Hydraulics Solid Solid Hydraulics Hydraulics 17% 21% 27% 17% 17% 5.5 5.4 5.6 5.8 Limiting Load % Used of Available Capacity (24 hr of Operation) Operational Requirements of Filters Band Press - 5 days a week Hr/Day of Operation Limited by the Load of Solids 5.5 7.2 9.1 Hr/Day of Operation Limited by Hydraulic Load 5.7 7.1 8.6 Hr/Day of Operation Critical Value 5.7 7.2 9.1 5.6 5.8 Hydraulics Solid Solid Hydraulics Hydraulics 24% 30% 38% 23% 24% 11686 15394 19473 11747.79 11637.79 Solid concentration, %ST 27% 27% 27% 27% 27% Fraction of Volatile Solids, SV/ST 48.2% 49% 49.5% 44.1% 49.4% 43 57 72 44 43 5637 7539 9633 5177 5746 6049 7855 9840 6570 5891.83 615 810 1025 618 613 Solid concentration, %ST 0.08% 0.090% 0.090% 0.09% 0.08% Fraction of Volatile Solids, SV/ST 48.2% 49.0% 49.5% 44.1% 49.4% Flow rate of solids, m3/d 465 576 690 452 468 Spraying Water Flow, m3/d 7 days/no Operation 276 347 439 269 278 741 923 1129 721 745 297 397 507 272 302 318 413 518 346 310 Limiting Load % Used of Available Capacity (24 hr of Operation) Dehydrated cake Solid Load, kg ST/d Flow (m3/day) Volatile Solids Load, kg SV/d Load of Non- Volatiles, kg SNV/d Filtered out Solid Load, kg ST/d Total flow, m3/d Volatile Solids Load, kg SV/d Load of Non- Volatiles, kg SNV/d Note: The installation of 4 units is recommended in order to be able to handle the variability in the quantity of solids, and to lower the cost of polymers. The normal operation will comprise 3 available units and 1 reserve, working 5 days per week and 6 hours per day, to allow both the start and the washing of the units within an 8-hour workshift. SECTION 12 CALCULATION MEMORY – B EQUIPMENT ASSOCIATED TO WASTE MANAGEMENT - ANAEROBIC DIGESTION • Mixing Pump: Equipment labeling: 701 – 706 Total capacity installed (kW): 57 each Pump Capacity (gpm): 5,000 The sizing of the pumps and motors for the digester mixing system was provided by Vaughan, a mixing system manufacturer. They used the digester tank size, configuration and percent solids content of the sludge to determine the required pump/motor capacity for mixing. Two (2) pump/motors will be provided for each digester. They will be configured one (1) Duty and one (1) Standby. • Heating pump: Equipment labeling: 707 – 711 Total capacity installed (kW): 7.5 each Pump Capacity (gpm): 360 The sizing of the pumps and motors for digester heating is from manufacturer’s standard sizes of tube-intube heat exchangers that meet the heating demand of the digester. For the digester heating pumps this flow rate was determined to be 360 GPM. From this system curve at a flow of 360 gpm (0.52 MGD) the TDH for the pump is 32’. A Wemco 4x11 CE Torque Flow Pump was selected to meet the flow and head conditions. This pumps would require a 10 HP motor (7.5 kW). • Rotary pump Equipment labeling:712 – 714 Total capacity installed (kW): 15 each Pump Capacity (gpm): 400 The sizing of the pumps and motors for digested sludge transfer are dependent on the feeding rate of the digesters from the thickened sludge pumps. The thickened sludge pumps (4 duty pumps) are designed to send a maximum total feed flow of 800 gpm to the digesters. If all four (4) thickened sludge duty pumps and the two (2) standby pumps are running the “All” on flow is 1,200 gpm. There are three (3) digested sludge transfer pumps. They are designed in a two (2) duty and one (1) standby arrangement. Each pump will be designed for a capacity of 400 gpm each. The two (2) duty pumps be able to match the maximum digester feed flow and all three (3) pumps will be able to match the all on flow from the thickened sludge pumps. A system curve was developed by Hazen for the transfer of sludge from the digesters to the digested sludge holding tank. At the typical digested sludge concentration of 2.5% total solids, determined the pumps would need to be able to handle a TDH of 76’ when two (2) pumps were running at 400 gpm each and when three (3) pumps were running at 400 gpm each. The system curve can be found in the file: 030 – Digested Sludge Transfer Pumps Design. To account for variability of solids concentration and digester performance, the design point of 400 gpm @ 115’ TDH parameters a Moyno progressive cavity pump was selected to allow pumping up to 4.5% solids. A single stage 2000 series pump with a 20 HP (15kW) motor will be able to handle the conditions. • Crusher for Rotative Pump: Equipment Labeling: 715 – 717 Total capacity installed (kW): 3.7 each Capacity (gpm): 800 The inline grinders and motors are sized at a minimum to meet the transfer pump capacities and then upsized to match the pipe suction size of 8”. The transfer pumps are designed for maximum flow of 400 gpm. The transfer grinders are also sized to match the suction line size of 8”. The 8” Muffin Monster grinder can handle a flow of 800 gpm. There is a dedicated grinder to each transfer pump. The motor sizing for the grinders will be 5 HP (3.7 kW). • Primary hot water pump: Equipment labeling: 718 – 719 Total capacity installed (kW): 5.6 each Pump Capacity (gpm): 600 The sizing of the primary hot water loop pumps is dependent on the heating requirements of the digesters, fine screen spray wash, FOGs tank and FOGs washdown water. The maximum hot water flow required to provide heat transfer to all facilities was determined to be 600 gpm (see Excel file: Hot Water Heat Balance). There will be one (1) duty and one (1) standby hot water pump. A system curve was developed by Hazen to determine the headloss in the primary hot water loop at maximum flow (see File : 051 – Primary Hot Water Loop Pump Design). The TDH @ 600 gpm for the system was 32’. A Bell and Gossett series 1510 pump with a 7.5 HP (5.6 kW) will meet the requirements. • Secondary hot water pump: Equipment labeling: 720 – 723 Total capacity installed (kW): 3.7 each Pump Capacity (gpm): 200 The sizing of the pumps and motors for the secondary loop hot water pumps is dependent on digester heat exchanger design. (filename: Las Esclusas Digester Heating Calculations – tab Maintenance Heating). For the secondary loop pumps this flow rate was determined to be 200 GPM. Hazen then created a secondary heating loop system curve (filename: 060 – Secondary Hot Water Loop Pumps Design). The TDH @ 200 gpm for the system was 40’. A Bell and Gossett series 80 standard inline pump with a 5.0 HP (3.7 kW) motor will meet the requirements, Secondary Hot Water Loop Pump Selection. There will be four (4) pumps of this capacity provided. There will be one (1) pump installed and dedicated to each digester heat exchanger for a total of three (3). The fourth pump will be an uninstalled spare. • Hot water pump FOG: Equipment labeling: 724 Total capacity installed (kW): 0.75 each Pump Capacity (gpm): 80 File 070 – FOG System Design Calculations outlines the heating requirements for the FOGS storage tank. A Walker HEX (see file 071 – FOG HEX) was selected. From the HEX it was determined 80 gpm of hot water was required. Hazen created a system design for the secondary hot water loop and determined a pump capable of 80 gpm @ 22’ TDH was required, see file 072 – FOG HEX Hot Water Pump Design. A Bell and Gossett pump was selected with a 1 HP motor. • Washdown hot water pump: Equipment labeling: 726 Total capacity installed (kW): 0.38 each Pump Capacity (gpm): 20 Both the digester and FOGS facilities will benefit from hot washdown/flushing water when needing to clean piping, thanks etc. The FOGs facility will benefit most. A plate and frame heat exchanger will be utilized to heat the plant washdown water using the primary hot water loop. The secondary inline pump that will push hot water through this heat exchanger is called the FOGs Washdown Hot Water Pump. The design for this pump can be found in file 081 – FOG Washdown Hot Water Pump Design. This pump is designed to flow 20 gpm @ 12’TDH utilizing a ½ HPpump. • Boiler: Equipment labeling: 727 Total capacity installed (kW): 1.5 each Capacity (BTU/hr): 2,678,000 The boiler was designed for a rated output of 2,678,000 BTU/hr (80 Boiler HP). This boiler will require a 2 HP (1.5 kW) motor blower motor based on the Clever Brooks Model of this size. • Boiler - pump: Equipment labeling: 728 – 729 Total capacity installed (kW): 1.1 each Pump Capacity (gpm): 100 There will be two (2) boiler feed pumps. They will be one (1) duty and one (1) standby. Each pump is sized based on the maximum circulation rate for an 80 HP boiler from Clever Brooks. A system design for the boiler feed pumps was created by Hazen, see file 100 – Boiler Feed Pump Design. The pump is designed for 100 gpm @ 27’ TDH. The Bell and Gossett Model 2.5 AB pump with a 1.5 HP (1.1 kW) motor was selected to fit the demands. • FOG discharge pump: Equipment labeling: 730 – 731 Total capacity installed (kW): 15 each Pump Capacity (gpm): 100 There will be two (2) FOGs unloading pumps located at the FOGs receiving facility to pump FOG from the receiving facility wetwell to the FOG storage tank. They will be configured one (1) duty and one (1) standby. File FOG System Design Calculations determined each pump is required to be able to pump 1,000 gpm, which is a typical maximum off-loading rate from a grease trap vacuum truck. A system design for the unloading pumps was developed by Hazen and can be found in file 110 – FOGs Unloading Pump Design. The system design determined the 1,000 gpm pumps need to be able to handle approximately 50’ TDH. A Vaughan E series Vertical Chopper Pump was picked for this application. A 25 HP (18.8 kW) motor will be used for each pump. File 111 – FOGs Unloading Pumps is the manufacturers pump curve. • Mixing pump of FOG: Equipment labeling: 732 – 733 Total capacity installed (kW): 15 each Pump Capacity (gpm): 1,000 The sizing of the pumps and motors for the FOG mixing system was provided by Vaughan, a mixing system manufacturer. They used the FOG tank size, configuration and percent solids content of the FOG to determine the required pump/motor capacity for mixing. Two (2) pump/motors will be provided. They will be configured one (1) Duty and one (1) Standby. • Heating pump of FOG: Equipment labeling: 734 Total capacity installed (kW): 3.7 each Pump Capacity (gpm): 150 The sizing of the pump and motor for FOG heating is from manufacturer’s standard sizes of tube-in-tube heat exchangers that meet the heating demand of the FOG storage tank. (filename: FOG System Design Calculations). For a 74 kW heat exchanger requires a FOG flow of 150 GPM. Hazen then created a heating loop system curve (filename: 140 – FOGs Heating Pump Design). From this system curve at a flow of 150 gpm (0.22 MGD) the TDH for the pump is 19’. The pump was designed for 150 gpm @ 37’ to account for clogging. A Moyno progressive cavity pump was selected. The Moyno pump will require a 5.0 HP (3.7 kW) motor. • FOG transfer pump: Equipment labeling: 736 – 737 Total capacity installed (kW): 3.7 each Pump Capacity (gpm): 30 The FOGs feed pumps will transfer stored FOGs from the FOGs storage tanks to the digesters. The pumps are designed to constantly feed FOGs rotating through the digesters in service to evenly distribute the flow. Calculations performed in file FOG System Design Calculations indicate a maximum average rate of FOG received of 12.8 gpm (2.9 m3/hr). To accommodate for unbalanced FOG delivery throughout the day the FOG feed pumps will be designed for 30 gpm (7 m3/hr). The system design indicates a TDH of 49’ at 30 GPM. The pump to be used for this application was selected to operate at 30 gpm @ 138’ to account for clogging. A Moyno 2000 series progressive cavity pump was selected for this application. This pump will require a 5 HP (3.7 kW) motor. • FOG grinder: Equipment labeling: 738 Total capacity installed (kW): 3.7 each Pump Capacity (gpm): 400 This grinder is located at the FOGs receiving station and will process FOGs as it is unloaded from the trucks after it passes through the rock trap and before it enters the unloading pump wet well. It is anticipated the truck will be able to unload at 635 gpm (40 L/s). To accommodate max flows with minimum headloss through the grinder an 8” grinder with a 5 HP (3.7 kW) motor was selected. • FOG Crusher Heating: Equipment labeling: 739 Total capacity installed (kW): 3.7 each Pump Capacity (gpm): 150 This grinder is located upstream of the FOGs heating pumps and will process the same flow as the heating pump capacity. The grinder will require a 5 HP (3.7 kW) motor was selected. • FOG Crusher Transfer: Equipment labeling: 740 - 741 Total capacity installed (kW): 3.7 each Pump Capacity (gpm): 30 These grinders are located upstream of the FOGs transfer pumps and will process the same flow as the transfer pump capacity. The grinder will require a 5 HP (3.7 kW) motor. • Fine Screens Spray Hot Water Pump Equipment labeling: 742 Total capacity installed (kW): 1.2 each Pump Capacity (gpm): 80 The Fine Screens will need heated spray water. The primary hot water loop will be used to heat the spray water by utilizing a plate and frame heat exchanger. The design flows for the hot water through the heat exchanger will be 80 gpm. The system was modeled and it was determined the pumps would need to be able to handle a TDH of 28’. A Bell and Gossett series 1510 Model 2x2x5.25 pump with a 1.5 HP (1.2 kW) motor was selected. • Air blowers for gasometers: Equipment labeling: 801 - 802 Total capacity installed (kW): 1.5 each Capacity (cfm): N.A. The double membrane digested gas holder will need to have the outer membrane inflated by a blower. The blower will be supplied by the membrane manufacturer. There will be two (2) blowers provided, one (1) duty and one (1) standby. The size of the blowers has been estimated based on information from manufacturer of Gasholder. • Multi-Stage Centrifugal Blowers for Biogas: Equipment labeling: 803 – 804 Total capacity installed (kW): 30 each Capacity (cfm): 600 The Maximum flow of digester gas that would be needed by 3 engine generators and 1 boiler would be 592 cfm (1,005 m3/hr) as shown in file Las Esclusas Digester Heating Calculations. Each blower (which is part of the digester gas cleaning and drying system) will be capable of processing this flow. From a blower curve specific to digester gas, the design point of 600 CFM at 7.5 psi results in 35 BHP, see file 160 – Gas drying Blowers. The blowers will be sized for 40 HP (30 kW) to handle the proposed loading. • Biogas cooler: Equipment labeling: 805 Total capacity installed (kW): 45 each Capacity (BTU/Hr): 150,000 The glycol chiller for the digester gas compressor/dryer will be supplied by the manufacturer. Using estimates from previous projects similar in size and scope the chiller would draw approximately 60 amps. At 3 phase 460 V power the chiller would use approximately 60 HP (45 kW) of power. • Fan for cooling of biogas: Equipment labeling: 806 Total capacity installed (kW): 0.8 each Capacity (gpm): N.A. This fan cools the biogas before entering the heat exchanger as part of the digester gas cooling and drying. It is estimated to be 1 hp (0.8 kW) based on previous projects of similar scope and size.