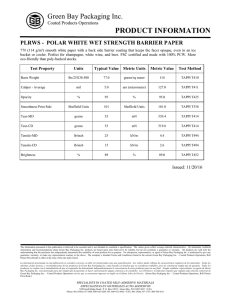

TEARING RESISTANCE OF PAPER Introduction Tearing resistance is primarily a property of the inner structure of the sheet, but surface treatment sometimes affects the values to a marked degree. Moisture content of the paper has a large effect on its tearing resistance so test specimens must be carefully conditioned. Higher moisture content and higher relative humidity of the test environment actually increase the tearing resistance. The tearing resistance is the force necessary to propagate a tear through a paper sheet; this force is measured in units of gram-force. The principal method used for evaluating the tearing resistance is the Elmendorf tear test (named after the inventor of the standard instrument). The instrument operates on the principle of determining the work done in tearing the paper for a predetermined distance by measuring the loss of potential energy from a pendulum. The desired tearing resistance (force) is obtained by dividing the tearing work by the distance over which the tearing force acts (work = force distance). The tearing resistance of paper and paperboard grades varies over a very wide range, from fairly small values in tissue grades to very great values in paperboard. To deal with the problem of having to cover this wide range with one instrument, two different testing procedures have been developed and codified in TAPPI Test Method T 414 and International Standard ISO 1974. TAPPI Test Method T 414 is based largely on the standard instrument of capacity 1600 gf. Of the two tear testers (Lorentzen & Wettre) available and standing side by side in our paper testing laboratory, it is the one on the right-hand side that should be used with T 414. The main disadvantage of method T 414 is that the number of plies to be torn at a time varies from one grade to another and becomes unreasonably large with tissue paper. By contrast, International Standard ISO 1974 prescribes that always four plies be torn at a time. (ISO stands for “International Organization for Standardization”.) This requirement necessitates the use of several tear testers of different capacity. Accordingly, both tear testers will be used in this procedure. 25 Significance The tear test has great significance in the requirements of paper and paperboard that are to be subjected to tearing forces in conversion or in actual use. This would include utility papers such as bags, wrapping stock, building papers, map paper, paper used in children's books, and others. 0ften, onverters rely more heavily on tearing resistance than any other single property. Tearing resistance is an empirical property often used as a control test in manufacturing. It is sometimes interpreted to reflect the general nature of the fiber present in the paper as well as the beating or refining treatment to which it has been subjected. This is because the test is somewhat dependent upon fiber length and the bonding strength between the fibers. Generally speaking, a dense sheet gives a lower tear than a bulky one of the same material and weight; and long fibers offer greater resistance to tear than short ones. Occasionally, the tearing resistance is misused by people who wrongly assume it to be a measure of runnability of the paper sheet either on the paper machine or in a web-fed printing operation. Tearing resistance has nothing whatever to do with runnability. To obtain a measure of runnability, an entirely different test must be made, and this has been termed the "in-plane tearing test" (see Van den Akker, Wink, and Van Eperen, TAPPI 50 (9), 466-470 IMPORTANT: NEVER FORCE THE INSTRUMENT. IF IT DOES NOT REACT TO A COMMAND AS EXPECTED, YOU ARE USING AN INAPPROPRIATE PROCEDURE. YOU CAN ALWAYS RETURN TO THE BEGINNING BY PRESSING THE RESET BUTTON, WHICH IS THE RED PUSH BUTTON ON THE REAR PANEL. (1967)). Test Specimens A test specimen is cut to rectangular shape, 63 mm by at least 53 mm. The 63 mm dimension is critical since it determines the length of the tear. Use the special paper cutter designed to give a precise 63 mm length with parallel edges. The other dimension (53 mm or greater) is not critical. Cut specimens for tearing tests in MD (the 63 mm dimension is parallel 26 to MD) and in CD (the 63 mm dimension is parallel to CD). TAPPI Test Method T 414: Operating Instructions The two tearing testers (manufacturer: Lorentzen and Wettre, Sweden) standing side by side in the paper testing laboratory each possess an on-board computer and display the test results digitally. For method T 414, use the one on the right-hand side. 1. Turn on the power of the tear tester on the by flipping the large black toggle switch on the rear panel from its downward off-position to the upward on-position. 2. On the rear panel, locate the small metal toggle switch directly underneath the red reset button. This switch is capable of three positions labeled 1, 2, and 3. With the B-pendulum in place, the switch must be in position 2; otherwise, all test results will be wrong. 3. Open the large valve in the air line located on the wall behind the tearing tester to admit air pressure to the instrument. On the meter located at the left side of the instrument column, adjust the air pressure reading (clamping pressure) to 0.55 MPa on the black scale. This is done by means of the black knob on the left side of the instrument: pull out the red locking ring, rotate the black knob clockwise to obtain the required pressure reading, then push the locking ring home. 4. The display window will show "Calibr. zero reading," indicating that the instrument is ready for ZERO CALIBRATION, a simple procedure that must be carried out before a test series on a new sample. As a part of zero calibration, the number of plies to be torn simultaneously in the tear test must be stored. With a new sample, however, we don't know at first what that number n of plies should be. Therefore, we carry out a preliminary test with the objective to determine the optimum number n of plies to be torn at one time. 5. For this preliminary test, an arbitrary number of plies is chosen. With tissue paper of relatively low basis weight, choose 10 or even 20 plies; with board of much greater basis 27 weight, choose one or two plies. On the selector switch located at the upper left corner of the display window, set the number of plies to be torn simultaneously in the preliminary test. This number is then automatically stored in computer memory. In principle, any number from 1 to 64 can be used. Of these numbers, only 1, 2, 3, 4, 6, 8, 10, 12, and 16 can be set directly with the selector switch. If the number of plies you have chosen for the preliminary test is directly accessible with the selector switch, carry out ZERO CALIBRATION according to Subroutine 1; then continue with step 7. 6. The numbers 5, 7, 9, 11, 13, 14, 15, and 17 to 64 are not accessible with the selector switch. If the number of plies chosen for the preliminary test is one of these numbers, carry out ZERO CALIBRATION according to Subroutine 2; then continue with step 7. 7. Next, carry out the preliminary test according to Subroutine 3. The number of plies torn simultaneously in this test must agree with the number stored in memory during zero calibration. Make a note of the value displayed under "Str:" in units of gf , because this is the desired tearing strength per single ply. In general, this is only an approximate value but it permits us to estimate the optimum number of plies, n, according to Ошибка! 8. After these preliminary operations, the actual tear test will now be carried out on specimens comprising n plies, where n is the number determined in step 7 according to equation (1). Make only one test per specimen, each specimen consisting of the same number n of plies. Tear five specimens in MD and five in CD. (Tappi Standard T 414 requires that 10 specimens be torn in each direction. To conserve sample, only five specimens are torn in this course.) Make tests alternately with the wire sides of all plies of a specimen facing the pendulum, then away from the pendulum. Carry out these tests as described in steps 9 to 14. 9. To begin the actual tear test, press the RESET button. This is the red push button on the rear panel. The instrument returns to the beginning, with the window displaying "Calibr. zero 28 reading." 10. Do ZERO CALIBRATION and enter the number n, determined in step 7, by following the steps described in Subroutine 1 or Subroutine 2. Upon completion of these steps, we have n plies in the clamps, the initial cut has been made, and the window displays "n 11. B Test no: 1,0" Press the PEND key to set the pendulum in motion. Catch the pendulum on its return swing. Press the PEND key to reset the pendulum stop. The window displays "Str: xx.x gf D: + x.x OK!" 12. The operator either ACCEPTS or DOES NOT ACCEPT this value. He ACCEPTS by simply clamping a new specimen and making the initial cut. The last (i.e., the fifth) specimen is accepted by pressing YES. A test is NOT ACCEPTED by pressing NO. It will then not be used by the computer in the final calculation of the mean and standard deviation. 13. Make five acceptcable tests. Then, to conclude, press YES, then NO. The display will be, for example: "Mean: 38.0 gf S: 3.5 gf" where S is the standard deviation. Press YES to obtain the display "M: 40.5 gf m: 35.5 g," where M is the greatest and m is the smallest value measured. 14. Press YES to terminate this series, the window displaying "n B Test no: 1;0" 29 SUBROUTINE 1 ZERO CALIBRATION. THE NUMBER OF PLIES CAN BE SET BY SELECTOR SWITCH • The display window should show "Calibr. zero reading." • Set the number of plies to be torn at one time with the selector switch. With nothing in the clamps, release the pendulum by pressing, then releasing the PEND key. The pendulum stop pulls back, and the pendulum starts to swing to the right. Catch the pendulum in your left hand when it comes swinging back. Hold it to the left of the pendulum stop. • Press, then release the PEND key once more to raise the pendulum stop. Slowly and gently bring the pendulum up against the stop. • At this point, the display window will show the following type of information: "1451 248 mm 131 deg" Repeat this procedure at least three times. • Press the CAL key. The window displays something like "1455 calibrated!" and the clamps open automatically. This completes the zero calibration. None of the numbers displayed during this procedure are worth noting. They are automatically stored in computer memory and used internally in subsequent data manipulation. • To prepare the instrument for a tear test, place the appropriate number of plies in the clamps. Assume, for example, that we had selected 8. • Press the CLAMP key. The clamps close shut, gripping the specimen. • Depress the knife lever as far down as it will go. The display will now show: "8 B Test no: 1; 0" This indicates that 8 plies are to he torn simultaneously; that the B pendulum is being used; that the instrument is ready for test 1; and that no previous tests have been accepted. • Return to “Test Method and Operating Instructions” and continue with step 7 if you are doing 30 the preliminary test or with step 11 if you are doing the actual test. SUBROUTINE 2 ZERO CALIBRATION. THE NUMBER OF PLIES CANNOT BE SET BY SELECTOR SWITCH • The window displays "Calibr. zero reading." Suppose you wish to use 20 plies. First, set the selector switch to N. • With nothing in the clamps, release the pendulum by pressing, then releasing the PEND key. The pendulum swings to the right. On the return swing to the left, grasp the pendulum with your 1eft hand. Hold it to the left of the pendulum stop. Press and release the PEND key again to raise the pendulum stop. Slowly and gently bring the pendulum up against the stop. • At this point, the window displays information of this type: "1451 248mm 131 deg" Repeat this procedure at least three times. • Press the CAL key. The window displays "Number of Plies: 1." Further dialog with the instrument proceeds as follows: PRESS WINDOW DISPLAY KEY COMMENT Number of plies: 1 YES Number of plies: 2 YES Number of plies: 4 YES Number of plies: 8 NO Number of plies: 7 NO Number of plies: 6 NO Number of plies: 5 YES Number of plies: 10 YES YES has the effect of doubling the number. NO diminishes the number by 1. 31 PRESS WINDOW DISPLAY KEY COMMENT Number of plies: 20 We obtain the desired number, 20. CAL Pressing CAL stores 20 in memory, and the clamps open automatically. 20 plies fixed Operator: put 20 plies in clamp. CLAMP Clamps close. KNIFE Depress knife lever down to the stop . 20 B Test no:1;0 The stored number 20 is displayed ; B refers to the pendulum used; the instrument is ready for test 1; zero tests have so far been accepted. • Zero calibration has been achieved, the number 20 stored in computer memory, and the instrument is ready for the first tear test. • Return to “Test Method and Operating Instructions”; continue with step 7 if you are doing the preliminary test and with step 11 if you are doing the actual test. SUBROUTINE 3 PRELIMINARY TEAR TEST • Recall that the purpose of this preliminary test is to obtain an estimate of the optimal number n of plies to use in testing our sample for tear. Suppose a specimen is in the clamps, the initial cut has been made, and the window displays, for example: "20 B Test no: 1;0" telling us the specimen consists of 20 plies, the B pendulum is being used, and the instrument 32 is ready for the first tearing test. • Press PEND to release the pendulum. Catch the pendulum on its return swing and press PEND to reset the pendulum stop. The window displays, for example: "Str: 25.3 gf D: +0 OK!" This means that in this case the tearing strength per ply is 25.3 gf ; the difference D between this value and the mean value at this juncture is zero; and as far as the instrument is able to detect, the test is a valid one. • One preliminary tearing test suffices to obtain the desired estimate of n, and we therefore wish to terminate the preliminary test. Terminate by following these three steps: Press the YES key. The window displays: "20 B Test no. 2;1" Press the NO key. The window displays: "Mean: 25.3 gf Press the YES key. The window displays: "M: 25.3 gf S:**.* gf" m: 25.3 gf". • Make a note of this tearing strength per ply, in our example 25.3 gf , and use it in equation (1) to calculate n. • Press the YES key one more time to conclude this preliminary measurement and to initiate a new series. The window displays "20 B Test no: 1;0." • Return to “Test Method and Operating Instructions”, complete step 7, and continue with the testing procedure. 33 International Standard ISO 1974 34 Tear Factor The instrument determines the average tearing force per ply in units of gf from the five measurements made in a given direction. Divide this average value by the grammage (basis weight in units of gf/m2) to obtain the tear factor. TAPPI standards require that the tear factor be expressed in units of dm2. Suppose, for example, that the tearing strength = a gf and that the grammage = b gf/m2. The tear factor is then Tear Factor = (tearing strength)/(basis weight) a gf = = m2 100 dm2 b gf 1 m2 100 a/b dm2 Tear Index The tear index, like tear factor, is defined as tearing strength divided by basis weight. The tear index, however, must be expressed in units of mN/(gf/m2). As before, suppose that tearing strength = a gf and basis weight = b gf/m2. The tear index is then given by Tear Index = (tearing strength)/(basis weight) a gf = = m2 9.81 mN b gf 1 gf 9.81 a/b mN/(gf/m2) Report For machine direction (MD) and cross direction (CD), report the mean values of tearing strength in units of gf , of tear factor in units of dm2, and of tear index in units of mN/(gf / m2). 35 Also determine and report a 95% confidence interval for each mean. References ASTM D 689 TAPPI T 411 ISO 1974 36