- Ninguna Categoria

GDI Engine Spray Impingement Characterization

Anuncio

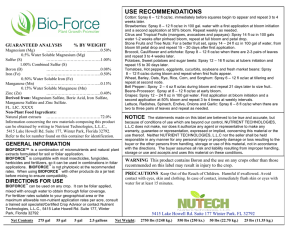

SPRAY IMPINGEMENT CHARACTERIZATION OF A SWIRL TYPE INJECTOR FOR GASOLINE DIRECT INJECTION ENGINES LI Bo, LI Yunqing, WANG Defu. School of Transportation Science and Engineering BUAA, Beijing, 100083, Peoples R China Keywords: Gasoline Direct Injection engine, swirl type injector, spray impingement characterization. Abstract Engine efficiency and emissions depend on the initial fuel spray, evaporation, mixture preparation and distribution inside the chamber. This phenomenon is based on the interaction of the in-cylinder air motion, tumble or swirl. One drawback of the gasoline direct injection (GDI) engine is that the spray impingement on the piston and cylinder wall often leads to high emissions of unburned hydrocarbons and soot [1]. To further understand the spray impingement characteristics that are related to the GDI engine performance of economy, emission and the combustion, the sprays into constant volume chamber within a flat wall installed under different back pressure value from a swirl type GDI injector were visualized. The spray impinging development, spray penetration at normal and radius direction of wall, spray tip velocity and droplet characteristics were measured at various injection pressure, ambient back pressure, wall distance from the injector tip to the impinging wall, and wall inclination angle. Experimental results showed that the spray structure exhibited a large hollow cone angle and wide spreading at low back pressure, therefore the fuel film adhered on wall after being impinged is thin and it is favourable for fuel evaporation and diffusion, however, it is unfavourable for fuel evaporation and diffusion under high back pressure. The spray growth velocity is sharply decreased, also the spray height and spray radius growth rate decreased after impingement of the spray. Impinging sprays exhibit longer spray penetration behaviour at normal and radius direction of the wall under higher injection pressure, shorter wall distances and larger angles of wall inclination. The spray height and spray radius decreased with the increase of ambient pressure. Higher injection and lower ambient pressure promote an increase of the spray area, and causes more rapid movement of the spray. Higher ambient pressure slows down the spray movement. The formed vortexes under high back pressure become one of factors that increase the spray height and decrease the spray radius and spray tip velocity growth rate. 1 Introduction Gasoline Direct Injection (GDI) has been an emerging and successful technology in cutting down emissions, saving fuel consumption and improving the thermal efficiency of engines. GDI engines have potential to achieve greater fuel economy compared with a diesel engine at partial loads and burst forth favourable performance than port fuel injection engines at high loads. In particular, under partial load operation when the fuel is injected late during the compression stroke, the goal is to quickly transport the fuel-air mixture towards the spark plug with no fuel impingement on surfaces, and to achieve complete droplets evaporation in the short time available between the end of injection and the start of ignition [2]. At present, GDI engines with the function of fuel stratified injection are in mass production, and it offers lower fuel consumption up to 15% in the case of overall-lean partial load operation. The spray characteristics from the high pressure swirl injector which are generally employed for these engines. Hence, the relative location of the injector and spark plug, piston geometry, cylinder geometry and injection timing are important criteria in the design of GDI engines, air motion and fuel spray delivery characteristics become important factors for investigation. It is necessary to obtain a detailed understanding of the spray wall impingement process and its effects on the engine emissions. Therefore, experimental techniques and numerical methods should be consolidated to investigate the fuel spray atomization, the vaporization and the wall impingement processes of the hollow-cone fuel spray. To maintain stable, stratified combustion and acquire the thermodynamic potential for reducing specific fuel consumption, coupling with the advantages of quicker starting, improving transient response and formation of the fuel-air mixture in the cylinder must be more precisely controlled [3]. In this paper, the effects of the fuel injection pressure, ambient back pressure, impinging distance from injector nozzle to impinging wall and impinging wall inclination on the impinging spray development were investigated. The impinging spray growth velocity and spray penetration from normal and radius directions along the wall for various wall conditions were analyzed through the experiment. 2 Experiment arrangement and instrument 2.1 Spray impingement visualization system The high pressure fuel supply system used in this study is shown schematically in Figure 1 with the swirl type injector installed inside a constant volume chamber. The high pressurized nitrogen gas is responsible for delivering highpressure fuel up to 15Mpa to the injector. The chamber is equipped with two quartz windows and connected to a pressurized bottle of mixture gas composed of nitrogen and carbon dioxide (N2:93.75%, CO2:6.25%) that the molecular weight of mixture is equal to the molecular weight of air. The maximum pressure value inside the chamber is 1.2Mpa. A flat wall plate was installed into the chamber. The distance between the injector nozzle tip and the flat wall and the inclined angle of the flat wall can be adjusted conveniently. The injection signal is controlled by ST Microelectronics L9707 module which also generates 5V TTL pulse with provided time delay, and the pulse will be transmitted to high speed camera synchronously. The spray images were recorded by high speed camera from Phantom Company with 512×512 resolution, frame rate of 10,000 frames per second. The black thick line indicates the fuel or air, whereas the solid line represents the signal. The macroscopic structure of the fuel spray impingement, such as spray penetration and spray development can be acquired directly from the images captured by the high speed camera. The schematic of inwardly opening, single fluid and swirl type direct injection injector applied is shown in Figure 2. Figure 2 Schematic of Swirl type injector 2.2 Spray impingement experimental conditions In this paper the injection fuel mass of each time is set to 26.66mg for lean burn destination and the pulse width of injection was set according to different injection pressure. The spray development of impingement was conducted in terms of the following conditions as Table 1. Injection system Injector Injection pressure(Mpa) Ambient pressure(Mpa) Fuel mass injected each time(mg) Wall distance(mm) Wall inclination angle(degree) Description Swirl-type 2, 3, 4, 5, 6 0.05-1.2 26.66 30, 40, 50, 60 0, 30, 45, 60 Table 1: Experimental conditions for impinging spray 2.3 Spray impingement penetration definition Figure 1 Constant volume chamber and fuel injection system for spray impingement investigation In order to describe the spray development behaviour after impingement, here the spray height and spray radius parameter are introduced from Figure 3 for vertical spray impingement and figure 4 for inclined impingement. Spray radius R represents the spray penetration development along wall surface after impingement, while spray height H represents the spray penetration development along vertical wall surface direction after impingement. L represents impinging distance between injector nozzle and wall and ș means wall inclination angle. Line 1: Pinj=6.0Mpa, Pback=0.1Mpa; Line 2: Pinj=5.0Mpa, Pback=0.1Mpa; Line 3: Pinj=4.0Mpa, Pback=0.1Mpa; Line 4: Pinj=6.0Mpa, Pback=1.0Mpa; Line 5: Pinj=5.0Mpa, Pback=1.0Mpa; Line 6: Pinj=4.0Mpa, Pback=1.0Mpa; Figure 3 Vertical spray impingement definitions Figure 5 Vertical spray impingement development Figure 4 Inclination spray impingement definitions 3 Results and discussion 3.1 Spray impingement at 0 degree wall inclination angle Figure 5 shows the effects of injection pressure, ambient back pressure, and at wall distance L=50mm on the macroscopic behaviour of the fuel spray impingement. 0ms 1ms 2ms 3sm 4ms Once the spray tip touch the wall, some of droplets wet the surface of the wall and others especially from outside of the hollow cone spray sharply splash and rapidly move toward two sides. At the same time, there are vortexes formed at the front of spray development. With the increase of injection pressure, the spray impingement height, spray radius, sprays tip speed and vortexes intensity increased. The higher velocity at the point of impingement due to the high injection pressure causes a higher radial velocity near the wall and results in a sharper tip of spray. The smooth wall surface with less friction is also a reason for this phenomenon. Under low ambient back pressure, the spray structure showed a hollow cone type formation which impinged on the wall with thin droplets fuel film adhering and covering comparatively large area. It is favourable for droplets evaporation and diffusion. With the increase of ambient back pressure, the spray is compact and with a solid cone and decreased spray angle, and fuel just distributes in a small range which resulted the formation of thick droplets fuel film adhering on the impingement wall, and it is hard for droplets evaporation during quite short time. After it impinges the wall, the spray momentum is reduced and the spray tip velocity of moving two sides is slowed down obviously due to the resistance induced by high ambient pressure. The spray height and spray radius are smaller than at lower ambient pressure. There are vortexes formed during spray development and the vortexes are stronger under high ambient back pressure than under low ambient back pressure. These also become the factors which slow down the spray tip velocity. Figure 6 Influence of wall distance on spray height Figure 6 shows that the spray height decreased with the increase of wall distance. The spray height increased in the beginning of impingement until to the maximum and then starts to decrease due to droplets evaporation, spread and the decreased spray tip momentum. Figure 9 Influence of wall distance on spray radius Figure 7 Influence of wall distance on spray radius Figure 7 indicates that the spray radius increased with the increase of wall distance but the spray tip velocity of moving toward two sides is decreased which is the result of spray momentum is slow down with the increase of wall distance and most of the droplets evaporating and spreading during spray development. The spray radius under high ambient back pressure from figure 9 showed the same development tendency as under low back pressure but the spray radius values are smaller than under low back pressure which also can be found the reason that higher back pressure with higher resistance on spray development. 3.2 Spray impingement at 30 degree wall inclination angle In this following Figure 10, only the downward spray penetration after impingement was measured because the upward penetration is very small in comparison to the downward penetration. Spray penetration increases with an increase of the wall inclination angle. This tendency indicates that the effect of wall impingement on spray is reduced owing to the reduction in radial droplets momentum when increasing the inclination angle of the wall. 0ms Figure 8 Influence of wall distance on spray height Figure 8 describes the same development as low back pressure that the spray height decreased with the increase of wall distance, but the spray height is obviously lower than under low ambient back pressure conditions which can be explained by that higher ambient back pressure with higher resistance on spray itself. The thicker droplets film adhering on the wall is unfavourable for fuel evaporation. 1ms 2ms 3sm 4ms Line 1: Pinj=6.0Mpa, Pback=0.1Mpa; Line 2: Pinj=5.0Mpa, Pback=0.1Mpa; Line 3: Pinj=4.0Mpa, Pback=0.1Mpa; Line 4: Pinj=6.0Mpa, Pback=1.0Mpa; Line 5: Pinj=5.0Mpa, Pback=1.0Mpa; Line 6: Pinj=4.0Mpa, Pback=1.0Mpa; Figure 10 Vertical spray impingement development Figure 11 Influence of wall distance on spray height Figure 14 Influence of wall distance on spray radius In the case of the inclined wall from Figure 11-14, the downward penetration of the spray is very large. It may indicate that the increased angle of wall inclination reduces the effect of impingement on the macroscopic spray characteristics. As the injection pressure increases, so does spray velocity. With the increase of wall inclined angle, the spray path behaviour is enhanced. The reason for this is that it was affected by the droplets gravitation, drag and friction forces. The spray pattern under high ambient back pressure is compact and the spray height, spray radius and spray tip velocity are smaller than low back pressure. When the impingement angle is 0 deg, it has effects on the drag and friction force as well as the ambient gas density. 4 Conclusions Figure 12 Influence of wall distance on spray radius Figure 13 Influence of wall distance on spray height This experimental study was performed investigating the effects of injection pressure, ambient back pressure, wall distance from the injector tip to impinging wall, and wall inclination angle on the macroscopic behaviour of fuel sprays impingement. The conclusions of this study can be summarized as follows: (1) Providing physical understanding and experimental data for validating CFD simulations. (2) Providing support for designing the relative position of injector and spark plug, piston and cylinder geometry. (3) Impinging sprays exhibit longer spray penetration behaviour at normal and radius direction of the wall under higher injection pressure, shorter wall distances and larger angles of wall inclination. However, the spray height and spray radius decreased with the increase of ambient pressure. (4) The spray growth velocity is sharply decreased after impingement of the spray. The spray height and spray radius growth rate decreased due to ambient mixture gas resistance and decreased droplets momentum. (5) Higher injection and lower ambient pressure promote an increase of the spray area, and causes more rapid movement of the spray. Higher ambient pressure slows down the spray movement. (6) The spray structure showed a large hollow cone angle and wide spreading at low back pressure, therefore the fuel film adhered on wall is thin and it is favourable for fuel evaporation and diffusion, but it is converse under high back pressure and it is unfavourable for fuel evaporation and diffusion. (7) The formed vortexes under high back pressure are stronger than under low back pressure. This became one of factors that increase the spray height and decrease the spray radius and spray tip velocity growth rate. Acknowledgements Financial support from Engine Department of R&D Centre, China FAW Group Corporation is gratefully acknowledged. The authors would like to thank the students from BUAA for their valuable technical support during the course of this work. References [1] Sang Yong Lee, Sung Uk Ryu. Recent Progress of SprayWall Interaction Research, Journal of Mechanical Science and Technology (KSME Int.J.), Vol.20, No.8, PP. 11011117, 2006. [2] N ABANI, SBAKSHI and RVRAVIKRISHNA. Multidimensional modelling of spray, in-cylinder air motion and fuel-air mixing in a direct-injection engine, Sadhana Vol.32,Part 5, October 2007, pp.597-617. [3] S.KIM, J.M.NOURI, Y.YAN and C. ARCOUMANIS. EFFECTS OF INTAKE FLOW ON THE SPRAY STRUCTURE OF A MULTI-HOLE INJECTOR IN A DISI ENGINE, International Journal of Automotive Technology, Vol. 10, No.3, pp. 277-284(2009).

Anuncio

Descargar

Anuncio

Añadir este documento a la recogida (s)

Puede agregar este documento a su colección de estudio (s)

Iniciar sesión Disponible sólo para usuarios autorizadosAñadir a este documento guardado

Puede agregar este documento a su lista guardada

Iniciar sesión Disponible sólo para usuarios autorizados