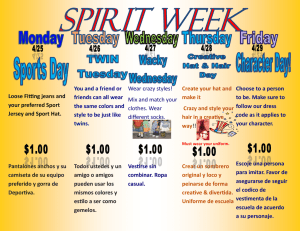

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/308702420 Improvement of Wear Resistance of UHMWPE by Adding Solid Lubricating Fillers Article in Key Engineering Materials · September 2016 DOI: 10.4028/www.scientific.net/KEM.712.155 CITATIONS READS 3 199 4 authors, including: Sergey Panin Institute of Strength Physics and Materials Sciences, SB RAS, Tomsk, Russia V. O. Alexenko 22 PUBLICATIONS 9 CITATIONS 386 PUBLICATIONS 737 CITATIONS SEE PROFILE SEE PROFILE Some of the authors of this publication are also working on these related projects: Development of fundamental approach to creating wear-resistance extrudable biocompatible polymer nanocomposites for 3D printing of implants with complex geometry View project Foundations of diagnostics of prefracture and prediction of lifetime of multilevel structurally inhomogeneous media View project All content following this page was uploaded by Sergey Panin on 15 January 2019. The user has requested enhancement of the downloaded file. Key Engineering Materials ISSN: 1662-9795, Vol. 712, pp 155-160 doi:10.4028/www.scientific.net/KEM.712.155 © 2016 Trans Tech Publications, Switzerland Submitted: 2016-05-01 Revised: 2016-05-31 Accepted: 2016-05-31 Online: 2016-09-27 Improvement of Wear Resistance of UHMWPE by Adding Solid Lubricating Fillers S.V. Panin1,2,a, L.A. Kornienko1,b, V.O. Alexenko1,2,c, L.R. Ivanova1,d 1 Institute of Strength Physics and Materials Sciences SB RAS, 34021, Tomsk, Russia 2 National Research Tomsk Polytechnic University, 634050, Tomsk, Russia a [email protected], [email protected], [email protected], [email protected] Keywords: ultra-high molecular weight polyethylene, filler, graphite, molybdenum disulfide, polytetrafluoroethylene, wear resistance, permolecular structure. Abstract. For estimating effectiveness of adding solid fillers for composites with ultra-high molecular weight polyethylene matrix tribotechnical characteristics of UHMWPE mixture with graphite, molybdenum disulfide and polytetrafluoroethylene were investigated under dry friction, boundary lubrication and abrasion. The optimum filler weight fraction was determined in terms of increasing wear resistance. Permolecular structure and surface topography of wear tracks for UHMWPE composites with different weight fraction of the fillers was studied. The mechanisms of wear of polymeric composites “UHMWPE-graphite”, “UHMWPE-PTFE” and “UHMWPE-MoS2” under dry sliding friction and abrasive wear are discussed. Introduction Ultra-high molecular weight polyethylene (UHMWPE) possesses performance characteristics quite appropriate for polymers, while low friction coefficient, high wear and chemical resistance in corrosive environments, high impact strength, low temperature of embrittlement provide its stability and possibility for wide applications in various fields of engineering and operating conditions. The use of composite materials with UHMWPE matrix ensures multiple increasing of wear resistance of metal-polymer friction units. Recently, micro- and nanocomposites with UHMWPE matrix are actively developed. Type and size of fillers are determined by the scope of application fields and the environment where the composites are operated (vacuum, reactive and inert environment, cryogenic or elevated temperatures) [1-4]. The solid lubricating filler (graphite, molybdenum disulfide, PTFE) are widely used in lubricants (oil additive) and manufacturing of antifriction coatings (in case of PTFE) to be applied in a wide temperature range (-45 to +400˚C). The choice of lubrication method depends on the structure (design) and operating conditions of a friction pair. In the current paper a solid lubricant is added into UHMWPE as a filler, as it can effectively operate at very low temperatures (e.g., cryogenic ones), when the liquid or paste-type lubricants cannot withstand extreme conditions. Under development of UHMWPE composite materials designers usually are guided towards the preferential conditions of their operation: abrasion, dry sliding friction, friction in the boundary lubrication, etc. In doing so, the minimum wear is characteristic for the case with the presence of lubricating medium in the tribocontact area. The aim of the study is a comparative analysis of the mechanical properties and tribotechnical characteristics of UHMWPE composites with the solid lubricating fillers MoS 2, C and PTFE under dry friction, boundary lubrication and abrasive wear. Experimental UHMWPE powder (GUR-2122 by Ticona, Germany) with a molecular weight of 4.0 million carbon units and particle size of 5-15 microns, colloidal graphite, C-1 ( 1-4 µm), molybdenum disulfide MVCh-1 ( 1-7 µm), F-4PN20 polytetrafluoroethylene ( 14 and 180 µm) were used. Specimens of polymeric composites were prepared by hot pressing at specific pressure of 10 MPa All rights reserved. No part of contents of this paper may be reproduced or transmitted in any form or by any means without the written permission of Trans Tech Publications, www.ttp.net. (#70911477, University of Tennessee, Knoxville, USA-30/10/16,14:48:31) 156 Advanced Materials for Technical and Medical Purpose and sintering temperature of 200 ºC with subsequent cooling rate of 5°C/min. Mixing of polymeric blends of the UHMWPE and fillers (C, MoS2, PTFE) was carried out in a planetary ball mill MR/0.5*4 with preliminary dispersing components in an ultrasonic bath. Wear resistance of materials under dry friction was measured by "block-on-ring" scheme under the load of 68.8 N and rotation speed of 100 rev/min (according to ASTM G99) with the use of SMT-1 wear testing machine (sliding rate was 0.32 m/sec). The specimen size was equal to 7×7×10 mm. Diameter of 100Cr6 steel counterface was 62 mm. The friction surfaces of the specimens were examined by optical profilometer Zygo New View 6200. Friction track area was automatically calculated with its manual selection with the help of «Rhino Ceros 3.0» software. Abrasion tests were performed with the use of MI-2 machine for rubber abrasion testing. Wear resistance was estimated under loading of 0.15 MPa and sliding speed of 17.0 m/min relative to the pair of specimens. Abrasive paper R 240 with a grain size of 58.5 µm was fixed on the counterface (Russian Federation State Standard 426). Volume abrasion was determined by weighing the specimens and further recalculation of weight loss in every 5 minutes. Method of testing meets the requirements of ASTM G99 and DIN 50324. Tribotechnical characteristics were calculated by averaging data over four specimens of each type. Structural investigations were carried out with the use of scanning electron microscope LEO EVO 50 under accelerating voltage of 20 kV onto cleavage surfaces of notched specimens mechanically fractured after exposure into liquid nitrogen. Mechanical characteristics were determined by tensile tests performed with the use of electromechanical testing machine Instron 5582 for dog-bone shaped specimens with the data averaging over five samples of each type (GOST 11262-80). Results and discussion Tribomechanical characteristics of UHMWPE as well as composites “UHMWPE + n wt. % C”, “UHMWPE + n wt. % MoS2”, and “UHMWPE + n wt. % PTFE” are shown in Tables 1-3. It is seen that mechanical properties (tensile strength, elongation at failure) change slightly, and the friction coefficient of all tested composites is decreased. Tribotechnical characteristics of these composites substantially depend on the filler weight fraction and type of wear testing (dry friction, boundary lubrication, abrasive wear). Table 1. Mechanical properties and friction coefficient of the composites “UHMWPE-С” Content of filler, C, wt.% Density, , g/cm3 0 3 5 10 0.936 0.953 0.967 0.989 Shore Hardness, D 56.7±0.6 57.5±0.5 57.5±0.4 57.6±0.6 Yield point σ0,2, МPа 19.2±0.9 19.5±1.0 19.6±1.2 20.1±1.3 Ultimate strength σU, МPа 34.3±1.7 30.3±1.5 29.7±1.5 28.5±1.8 Elongation at failure, ε, % Friction factor, ƒ 470±23.6 471±23.8 513±25.1 538±25.3 0.16 0.1 0.11 0.12 Table 2. Mechanical properties and friction coefficient of the composites “UHMWPE-MoS2” Content of filler, MoS2, wt.% 0 3 5 10 Density, , g/cm3 0.936 0.954 0.975 1.010 Shore Hardness, D 56.7±0.6 56.2±0.6 56.9±0.5 56.9±0.5 Yield point σ0,2, МPа 19.2±0.9 18.4±0.8 18.6±0.7 18.7±0.9 Ultimate strength σU, МPа 34.3±1.7 26.2±1.9 26.9±1.6 26.7±1.9 Elongation at failure, ε, % Friction factor, ƒ 470±23.6 494±24.6 515±25.3 535±24.1 0.16 0.095 0.1 0.11 Key Engineering Materials Vol. 712 157 Dry sliding friction Diagrams of wear intensities at the steady-state wearing stage (I, mm2/min) of the above mentioned composites are given in Fig. 1 (a, b). It seen that the lowest wear rate is observed in the composites “UHMWPE + (3-5) wt. % C”, and “UHMWPE + 10 wt. % MoS2” (wear rate decreases almost by 2 times as compared to pure UHMWPE). The data on wear track surface roughness in the composites fully correlate with the data on wear intensity. Table 3. Mechanical properties and friction coefficient of the composites “UHMWPE-PTFE” Content of filler, PTFE, wt.% 0 5 10 20 40 Density, , g/cm3 Shore Hardness, D 0.926 0.97 1.00 1.06 1.22 59.5±0.6 59.8±0.5 59.6±0.6 59.7±0.6 59.8±0.6 Ultimate strength σU, МPа 32.3±0.9 29.2±1.0 27.0±1.2 24.7±1.3 20.2±1.0 Elongation at failure, ε, % 485±23.6 465±23.6 428±25.1 406±24.3 217±23.2 Crystalli nity χ, % 44.8 39.5 35.8 35.0 26.0 Friction factor, ƒ 0.12 0.067 0.067 0.068 0.075 a b Fig. 1. Wear intensity (I) and roughness of wear track surface (Ra) (b) for UHMWPE and composites: а) pure UHMWPE (1), UHMWPE + 3 wt. % C (2), UHMWPE + 5 wt. % C (3), UHMWPE + 10 wt. % C (4); b) pure UHMWPE (1), UHMWPE + 3 wt. % MoS2 (2), UHMWPE + 5 wt. % MoS2 (3), UHMWPE +10 wt.% MoS2 (4) at the steady-state wearing stage under dry friction For “UHMWPE-PTFE” composites the optimum filler weight fraction also makes 10 wt. % PTFE (Fig. 2, a, b). Moreover, the finer powder of the filler the more the effect is pronounced (14 vs 180 µm). Thus, the optimum content of the solid lubricating fillers, providing double increase in wear resistance under dry sliding friction was determined. Further increase in the weight fraction of these fillers is not effective in terms of improving wear resistance of UHMWPE composites under dry sliding friction. Wear track surfaces (at the steady-state wearing stage) as well as permolecular structure of the all above composites were investigated to clarify the relationship between the nature of the wear at dry sliding friction, pattern of the formed structure and the type and weight fraction of fillers in UHMWPE composites. It is shown that filling UHMWPE by particles of carbon and molybdenum disulfide as well as polytetrafluoroethylene gives rise to a gradual change in permolecular structure: the formation of spherulitic structure is suppressed, while permolecular structure of UHMWPE becomes less uniform due to the fact that the filler particles prevent the spherulite growth during the crystallization. 158 Advanced Materials for Technical and Medical Purpose The difference in the tribotechnical characteristics of UHMWPE with the three solid lubricating fillers is related to their lubricity (adhesion to the metal counterface). As a matter of fact it is determined by the specific lattice structure of graphite, molybdenum disulfide and polytetrafluoroethylene [11]. Friction under boundary lubrication conditions. Results of wear tests of all composites in the lubricating medium (distilled water) indicate that the investigated fillers in the distilled water environment act as a solid lubricant, too. Firstly, under the boundary lubrication wear rate decreases both for the pure (unfilled) UHMWPE, as well as for composites “UHMWPE + n wt. % MoS2”, “UHMWPE + n wt. % C” and “UHMWPE + n wt. % PTFE”. Secondly, the wear rate of the composites in the distilled water is lower than that for the pure UHMWPE in the same environment. Wear track surface roughness (Ra) of the composites in the lubricating medium is lower than that of pure UHMWPE. a b Fig. 2. Wear intensity (I) and roughness of the wear track surface (Ra) of UHMWPE and composites “UHMWPE-PTFE”: pure UHMWPE (1), UHMWPE + 5 wt. % PTFE (2), UHMWPE+10 wt.% PTFE (3), UHMWPE+20 wt.% PTFE (4) and UHMWPE+40 wt.% PTFE (5) at the steady-state wearing stage Fig. 3. Wear intensity (I) and roughness of wear track surface (Ra) of UHMWPE and composites “UHMWPE-С”, “UHMWPE-MoS2”: pure UHMWPE (1), UHMWPE + 3 wt. % С (2), UHMWPE +5 wt.%С(3), UHMWPE + 10 wt.% С (4), UHMWPE+3 wt. % MoS2 (5), UHMWPE+5 wt. % MoS2 (6), UHMWPE+10 wt.% MoS2 (7) at the steady-state stage of wear. Abrasive paper R 240. Key Engineering Materials Vol. 712 159 These results testify for the fact that the fillers (molybdenum disulfide, graphite and polytetrafluoroethylene) act as a solid lubricant under the wear of UHMWPE composites at dry sliding friction (this is a similarity between liquid boundary lubrication and introducing solid lubricant in the polymer). Abrasive wear. The influence of fillers (C, MoS2 and PTFE) on the abrasion resistance of UHMWPE microcomposites was also analyzed. The diagram of the abrasive wear intensity of the composites “UHMWPE + n wt. % C” and “UHMWPE + n wt. % MoS2” with the abrasive grain size of 240 (58.5 µm) is shown in Fig. 3. It might be seen that the abrasion resistance is increased by 1.3-1.5 times when UHMWPE is filled with molybdenum disulfide and graphite. Moreover, composites with molybdenum disulfide have somewhat higher wear resistance as compared to composites “UHMWPE + n wt. % C”. Abrasion resistance depends on the graphite content in the composite weakly (columns 2-4), and molybdenum disulfide is more effective when its content of 3-5 wt. %, even when the abrasive wear (columns 5-7) using P 240. These above described results show that the molybdenum disulfide and graphite similar to the case of dry sliding friction, facilitate the sliding of abrasive paper along specimen surface. However the latter cannot "protect" the matrix from cutting because of incommensurable the sizes of the filler and abrasive grains (1-4 µm vs. 58 µm). Abrasive wear intensity of UHMWPE filled with PTFE is close to that of pure UHMWPE. The same dependence was revealed between the wear track surface roughness (Ra) and the size of the filler. In this case fixed abrasive particles cut the matrix and soft polytetrafluoroethylene cannot "protect" the matrix (grooves widths are comparable with that of pure UHMWPE specimens). Apparently, soft polytetrafluoroethylene under abrasive wear only facilitates sliding of abrasive paper along the specimen surface [5]. Summary The content of graphite micropowder (3 wt. %), molybdenum disulfide (10 wt. %) and PTFE (10 wt. %) to provide the higher wear resistance under the dry sliding friction (up to two times in contrast with pure UHMWPE) was determined. This effect is accompanied by a decrease in the friction coefficient down to 1.5 times. Molybdenum disulfide, graphite and polytetrafluoroethylene play the role of a solid lubricant in the wear of UHMWPE composites, as well as under friction in a lubricating environment. In the case of abrasive wear the C and MoS2 do not perform effectively as a solid lubricant to improve the wear resistance of polymer composites on UHMWPE because of the incommensurable sizes of the filler and abrasive grains. In doing so molybdenum disulfide is more efficient filler from the view point of abrasive wear resistance. During abrasive wear the soft polytetrafluoroethylene filler is not able to "protect" the matrix from cutting of the fixed abrasive particle. That is why “UHMWPE-PTFE” composites cannot be effectively used under abrasive wear. Contrary, “UHMWPE-PTFE” composites with 10 wt. % of the filler can be effectively used for friction units (particularly, in medicine) in the absence of the lubricant. Filling UHMWPE by the solid lubricating microparticles C and MoS 2 is effective for all three kinds of wear. Therefore, the UHMWPE composites (UHMWPE + 10 wt. % MoS2 and UHMWPE + 3 wt. % C) can be effectively used for the friction units to be used without a lubricant under extreme operating conditions. Acknowledgments The study was performed under support of fundamental Research Program of the State Academies of Sciences for 2013–2020, RFBR project No. 14-01-00789 as well as grant of the President of the Russian Federation for support of leading scientific schools No. NSh-2817.2014.1. 160 Advanced Materials for Technical and Medical Purpose References [1] Harley L. Stein. Ultra high molecular weight polyethylene (UHMWPE), Engineered Materials Handbook, vol. 2: Engineering Plastics, 1999. [2] P.R. Buseck, V.V. Kovalevski and J.M. Cowley. Comparison of carbon in shungite rocks to other natural carbons: an X-ray and TEM study, Carbon. 39, 2 (2001) 243-256. [3] N.K. Myshkin, M.I. Petrokovets, A.V. Kovalev, Tribology of polymers: Adhesion, friction, wear and mass transfer, Tribology International. 38 (2005) 910-921. [4] S.V. Panin, L.A. Kornienko, V.P. Sergeev, N. Sonjaitham, M.V. Tchaikina. Wear-resistant ultrahigh-molecular-weight polyethylene-based nano- and microcomposites for implants, Journal of Nanotechnology. 2012 (2012), 729756. [5] S.V. Panin, L.A. Kornienko, N. Sonjaitham, L.R. Ivanova, S.V. Shilko. Abrasive wear of micro- and nanocomposites based on ultra-high molecular weight polyethylene (UHMWPE). Part 1. Composites based on UHMWPE filled with microparticles AlO(OH) and Al2O3, Friction and wear. 33, 4 (2012) 233-239. View publication stats