Ohio State University South Campus Chiller Plant

Anuncio

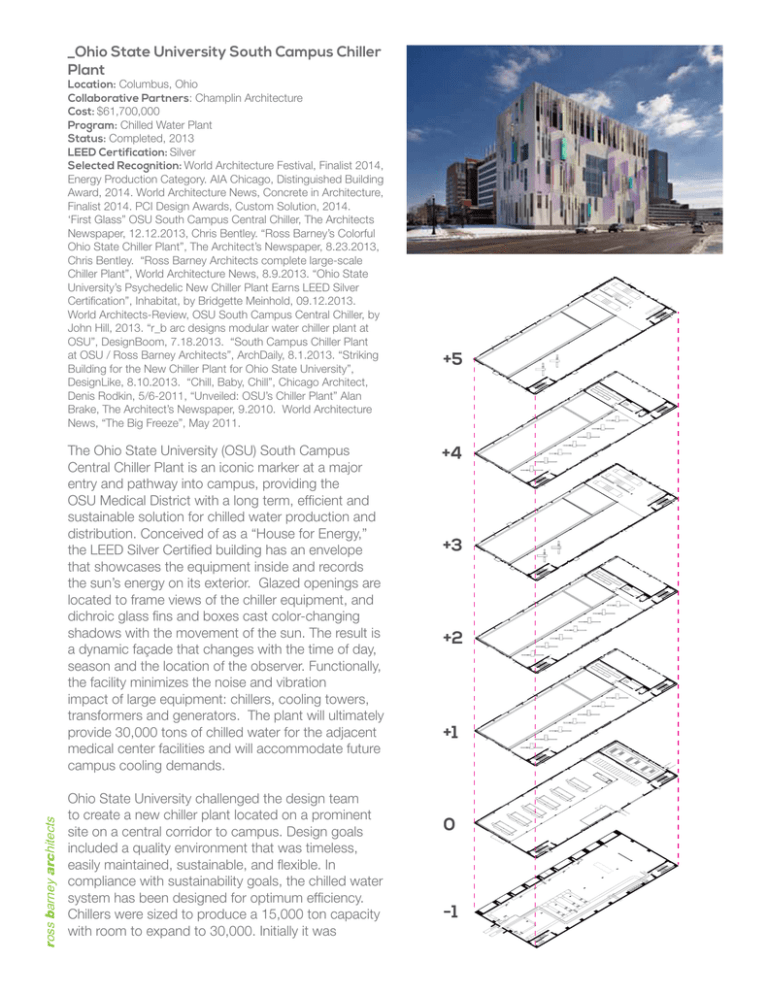

_Ohio State University South Campus Chiller Plant Location: Columbus, Ohio Collaborative Partners: Champlin Architecture Cost: $61,700,000 Program: Chilled Water Plant Status: Completed, 2013 LEED Certification: Silver Selected Recognition: World Architecture Festival, Finalist 2014, Energy Production Category. AIA Chicago, Distinguished Building Award, 2014. World Architecture News, Concrete in Architecture, Finalist 2014. PCI Design Awards, Custom Solution, 2014. ‘First Glass” OSU South Campus Central Chiller, The Architects Newspaper, 12.12.2013, Chris Bentley. “Ross Barney’s Colorful Ohio State Chiller Plant”, The Architect’s Newspaper, 8.23.2013, Chris Bentley. “Ross Barney Architects complete large-scale Chiller Plant”, World Architecture News, 8.9.2013. “Ohio State University’s Psychedelic New Chiller Plant Earns LEED Silver Certification”, Inhabitat, by Bridgette Meinhold, 09.12.2013. World Architects-Review, OSU South Campus Central Chiller, by John Hill, 2013. “r_b arc designs modular water chiller plant at OSU”, DesignBoom, 7.18.2013. “South Campus Chiller Plant at OSU / Ross Barney Architects”, ArchDaily, 8.1.2013. “Striking Building for the New Chiller Plant for Ohio State University”, DesignLike, 8.10.2013. “Chill, Baby, Chill”, Chicago Architect, Denis Rodkin, 5/6-2011, “Unveiled: OSU’s Chiller Plant” Alan Brake, The Architect’s Newspaper, 9.2010. World Architecture News, “The Big Freeze”, May 2011. ross barney architects The Ohio State University (OSU) South Campus Central Chiller Plant is an iconic marker at a major entry and pathway into campus, providing the OSU Medical District with a long term, efficient and sustainable solution for chilled water production and distribution. Conceived of as a “House for Energy,” the LEED Silver Certified building has an envelope that showcases the equipment inside and records the sun’s energy on its exterior. Glazed openings are located to frame views of the chiller equipment, and dichroic glass fins and boxes cast color-changing shadows with the movement of the sun. The result is a dynamic façade that changes with the time of day, season and the location of the observer. Functionally, the facility minimizes the noise and vibration impact of large equipment: chillers, cooling towers, transformers and generators. The plant will ultimately provide 30,000 tons of chilled water for the adjacent medical center facilities and will accommodate future campus cooling demands. Ohio State University challenged the design team to create a new chiller plant located on a prominent site on a central corridor to campus. Design goals included a quality environment that was timeless, easily maintained, sustainable, and flexible. In compliance with sustainability goals, the chilled water system has been designed for optimum efficiency. Chillers were sized to produce a 15,000 ton capacity with room to expand to 30,000. Initially it was +5 +4 +3 +2 +1 0 -1 anticipated equipment expansion would take place in the future but upon completion the University was able to expand equipment immediately to satisfy demand, due to the design team’s ability to bring the project in under budget. The result is a striking new gateway to campus, housing a functional chiller plant. ross barney architects Over 200 precast panels were created using 11 different panel types. The number of panel types significantly reduced costs. To create variation, panels were flipped or rotated, multiplying the visual variety without adding to production costs. Final transportation sizes of 9’ -0” x 30’-0” dictated feasibility of final panel dimensions, allowing accelerated installation with fewer parts and pieces. To enhance casted color from the dichroic fins, the precast concrete panels received a high-gloss polish. The polishing process is the same used for concrete floor slabs, in which diamond pads are used to grind and smooth. Upon completion, the project became the first in the United States to deploy a polished finish on an exposed exterior surface of a precast panel. Additionally, polishing alleviated the owner’s concerns with maintenance and durability. The process provides resilience against staining and streaking typically seen on unfinished precast panels. The slope of the panel was designed to assist in preventing stains from developing on the surface, ultimately proving to be a successful approach that has allowed the building to age well. Dichroic Glass Fins: The dichroic fins activate the exterior using sunlight as a means of recording the time of day and season. The dynamic expression changes as the observer’s perspective shifts. The desired affect created a technical challenge. The design team worked closely with Goldray Industries of Canada to perfect and experiment with what had been a first time application of dichroic film laminations at this scale. Dichroic film is created by adding micro thin layers of metal to a translucent material. The metallic layer alters the wave length and therefore the color of light passing through. The finished product can have as many as 30 to 50 layers of material, yet the thickness of the total coating is 30 to 35 millionths of an inch (about .000760 to .000890 mm). Since the metal is reflective, the film transmits a variety of colors. There are a total of 177 fins and 8 glass boxes. The majority of the fins measure 3’-0” wide x 5’-0” high, easing the fabrication and installation process. A bracket system holds the glass in place and prevents rotation. The Chiller is unusual in that it is not designed for human occupants, but houses inanimate equipment. Because of this, conventional sustainable strategies needed to be rethought. Opportunities for environmentally conscious design were in the siting, water efficiency, and use of sustainable materials rather than the typical emphasis on the energy efficiency of the envelope, lighting, or HVAC systems. Based on the project’s location on the campus of a major university within a medium sized city, the project received five LEED points for Development Density and Community Connectivity and six points for access to Public Transportation, due to its adjacency to multiple campus and Medical Center bus routes. Additionally, the project is sited on a former surface parking lot and no new parking spaces were added. The Walk Score rating for the site is 83. Without a conventional HVAC system, the building is very energy efficient. The design team’s energy reduction strategies focused on the use of locally sourced materials with low embodied energy. Regional materials consisted of over 30% of the total materials cost for the project. Additionally, there is a commitment to purchase 244,000 kWh of Green Power over a two-year period. This strategy resulted in two LEED points for both Recycled Content and Regional Materials, in addition to all available points for low-emitting materials. ross barney architects The project consisted of mostly shop fabricated components: precast concrete panels, structural steel and glass, which helped to minimize waste on the job site. Over 75% of construction waste was recycled on the project. The project also used all low-emitting materials, achieving all four possible LEED points for these items. Water conservation strategies for the project concentrated on the use of high-efficiency plumbing fixtures and the installation of native and droughtresistant landscaping. All plant seed sourcing was nearby and the project has zero use of potable water for irrigation. The project has an anticipated potable water usage of 1.53 kGal per year, which is a 50% reduction from the baseline design. Additionally, the project sought to maintain as much open area on the site as possible. The project was granted a point for exemplary performance for providing vegetation for 71% of the open site area. This high amount of pervious site area greatly reduces the amount of precipitation directed to the storm sewers. T/O PRECAST PANEL LEVEL 04 LEVEL 03 LEVEL 2M LEVEL 02 LEVEL 1M LEVEL 01