EXECUTIVE SUMMARY

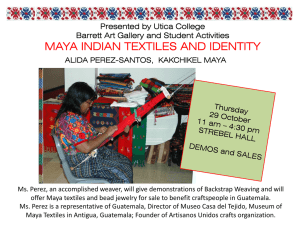

Anuncio