Informe Final del Proyecto Interno HC-1304.1

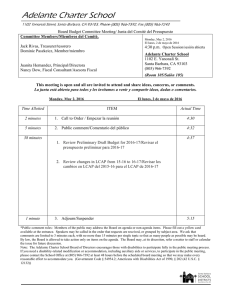

Anuncio