Crathco® Beverage Dispensers

Anuncio

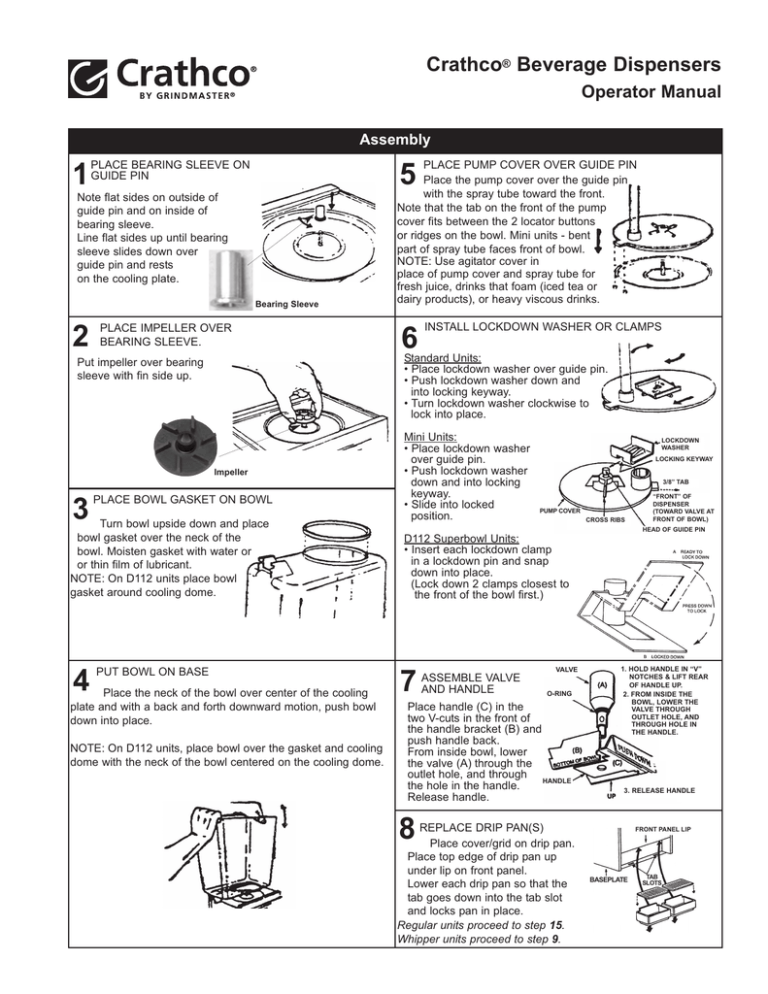

Crathco® Beverage Dispensers Operator Manual Assembly 1 PLACE BEARING SLEEVE ON GUIDE PIN Note flat sides on outside of guide pin and on inside of bearing sleeve. Line flat sides up until bearing sleeve slides down over guide pin and rests on the cooling plate. Bearing Sleeve 2 PLACE IMPELLER OVER BEARING SLEEVE. Impeller PLACE BOWL GASKET ON BOWL Turn bowl upside down and place bowl gasket over the neck of the bowl. Moisten gasket with water or or thin film of lubricant. NOTE: On D112 units place bowl gasket around cooling dome. 4 6 INSTALL LOCKDOWN WASHER OR CLAMPS Standard Units: • Place lockdown washer over guide pin. • Push lockdown washer down and into locking keyway. • Turn lockdown washer clockwise to lock into place. Put impeller over bearing sleeve with fin side up. 3 PLACE PUMP COVER OVER GUIDE PIN Place the pump cover over the guide pin with the spray tube toward the front. Note that the tab on the front of the pump cover fits between the 2 locator buttons or ridges on the bowl. Mini units - bent part of spray tube faces front of bowl. NOTE: Use agitator cover in place of pump cover and spray tube for fresh juice, drinks that foam (iced tea or dairy products), or heavy viscous drinks. 5 PUT BOWL ON BASE Place the neck of the bowl over center of the cooling plate and with a back and forth downward motion, push bowl down into place. NOTE: On D112 units, place bowl over the gasket and cooling dome with the neck of the bowl centered on the cooling dome. Mini Units: • Place lockdown washer over guide pin. • Push lockdown washer down and into locking keyway. • Slide into locked position. LOCKDOWN WASHER LOCKING KEYWAY 3/8” TAB PUMP COVER CROSS RIBS “FRONT” OF DISPENSER (TOWARD VALVE AT FRONT OF BOWL) HEAD OF GUIDE PIN D112 Superbowl Units: • Insert each lockdown clamp in a lockdown pin and snap down into place. (Lock down 2 clamps closest to the front of the bowl first.) 7 ASSEMBLE VALVE AND HANDLE VALVE O-RING Place handle (C) in the two V-cuts in the front of the handle bracket (B) and push handle back. From inside bowl, lower the valve (A) through the outlet hole, and through HANDLE the hole in the handle. Release handle. 1. HOLD HANDLE IN “V” NOTCHES & LIFT REAR OF HANDLE UP. 2. FROM INSIDE THE BOWL, LOWER THE VALVE THROUGH OUTLET HOLE, AND THROUGH HOLE IN THE HANDLE. 3. RELEASE HANDLE 8 REPLACE DRIP PAN(S) Place cover/grid on drip pan. Place top edge of drip pan up under lip on front panel. Lower each drip pan so that the tab goes down into the tab slot and locks pan in place. Regular units proceed to step 15. Whipper units proceed to step 9. FRONT PANEL LIP BASEPLATE TAB SLOTS Assembly (cont.) 9 VALVE HOLE (WHIPPER UNITS ONLY) PRESS SPRING UP INTO PLACE AGAINST THE BOTTOM OF THE BOWL. RUBBER INLET ADAPTER SPRING 10 (WHIPPER UNITS ONLY) INSERT HANDLE INTO “V” NOTCHES IN BOWL AND PLACE VALVE INTO HOLE (INSIDE BOWL). “W” IS WHIPPER VALVE (WHIPPER UNITS ONLY) 14 ASSEMBLE THE Assemble white rubber inlet adapter by stretching one end over the large tubular inlet on top of the whipper housing. Attach the other end over the ring sleeve on the underside of the handle. 15 TOP Ring sleeve on bottom of handle Rubber inlet adapter Plastic whipper housing FILL BOWL(S) WITH PRODUCT and place lid(s) on bowl(s). Turn spray switch on first then refrigeration. HANDLE SHOULDERS GO INTO “V’ NOTCHES I/ON SPRAY O/OFF I/ON REFRIG. O/OFF VALVE HOLE RINGSLEEVE DOWN SPRING 11 (WHIPPER UNITS ONLY) TURN VALVE 90° TO LOCK. Cross slot (located on top of valve) should run left to right across the bowl when locked. 12 (WHIPPER UNITS ONLY) 13 (WHIPPER UNITS ONLY) IMPORTANT: NEVER RUN REFRIGERATION UNLESS SPRAY OR AGITATE IS ON. (LOOKING DOWN INTO BOWLS) CROSS-SLOT VALVE DOWN IN HOLE READY TO LOCK AFTER 90° TURN, VALVE IS LOCKED PUSH WHIPPER BLADE INTO PLACE. Replace the whipper blade by lining up the flat inside the blade with the flat side of the motor shaft. Push blade firmly into place. REPLACE WHIPPER CHAMBER Replace whipper chamber by positioning the medium-sized opening up and tilting 1/8 turn to the right. Put whipper chamber over whipper blade and turn to the left until it locks into place. Page 2 Crathco® Beverage Dispensers DISASSEMBLY 1 DRAIN ALL BEVERAGE FROM BOWLS 4 REMOVE PUMP COVER Remove pump cover by lifting up on spray tube. 5 REMOVE BOWL AND BOWL GASKET Twist bowl back and forth while lifting up. Bowl gasket will be around bottom of bowl. A. Remove bowl lid(s) and drip tray(s) B. Drain through valve then C. Tip unit forward, gently press spray tube back a short distance to lift the edge of the pump cover to allow remaining beverage in well to be drained through valve. 2a. STANDARD & MINI UNITS: REMOVE VALVE AND HANDLE Lift valve. Handle drops into operator’s other hand. NOTE: On D112 units, bowl gasket will be around cooling dome. 2b. WHIPPER UNITS: • DISASSEMBLE THE RUBBER INLET ADAPTER Remove one end from the large tubular inlet on top of the whipper housing and the other end from the ring sleeve on the underside of the handle. Ring sleeve on bottom of handle Rubber inlet adapter Plastic whipper housing • REMOVE WHIPPER CHAMBER Turn whipper chamber to the right until it releases and you can pull it off of the whipper blade. REMOVE IMPELLER AND BEARING SLEEVE Remove impeller and bearing sleeve by lifting them straight up. NOTE: Check impeller and bearing sleeves for wear. See page 5. 6 Impeller 7 • REMOVE WHIPPER BLADE Pull whipper blade off of the motor shaft. VALVE • TURN VALVE 90° TO UNLOCK. REMOVE HANDLE AND VALVE. VALVE HOLE • REMOVE SPRING FROM BOTTOM OF BOWL. 3 Bearing Sleeve THOROUGHLY CLEAN ALL PARTS IN WARM WATER USING A MILD NON-ABRASIVE DETERGENT AND RINSE THOROUGHLY. CAUTION: ABRASIVES WILL SCRATCH PLASTIC PARTS. WASH BOWL LIDS IN COOL OR LUKEWARM WATER TO AVOID LEAKS DUE TO SEALED SURFACE BEING DAMAGED. HANDLE SPRING REMOVE LOCKDOWN WASHER(S) Standard Unit: Twist lockdown washer counterclockwise, slide to release keyway. Then lift out. Mini Unit: Slide to release keyway, then lift out. D112 Unit: Release each clamp. Crathco® Beverage Dispensers SANITIZE Immerse parts in sanitizing solution for 1-2 minutes. Remove parts from sanitizing solution and drain. DO NOT RINSE. Place parts on a clean surface to air dry. Wipe the machine, condensate tray and cooling plate depression with a cloth wetted with sanitizer solution. IMPORTANT: Never pour dry powder, crystals, or concentrate into a dry bowl. Premixing beverage in separate container is recommended. If mixing in bowl, always add water first. Page 3 ROUTINE MAINTENANCE: For all Models Cleaning Your Dispenser To optimize performance or when using dairy products, clean unit daily. Regular cleaning of bowl components will result in maximum pumping efficiency, proper seating and sealing, and prevention of leaks at the valve O-Ring and bowl gasket by removing dried-on beverage solids and pulp from moving sealed parts. 1. Wash all bowl components regularly. Follow all local health codes. * Refer to Disassembly, Cleaning, and Assembly instructions on pages 1-3. Sanitizing Your Dispenser * Refer to Disassembly and Assembly instructions on pages 1-3. 1. In the bowl, mix one gallon of Oxford Chemical’s Disinfectant/Sanitizer Formula C or its equivalent. 2. Turn on spray motor(s) and allow sanitizer to spray around inside of bowl for a period of time as recommended by the sanitizer manufacturer. Formula C is satisfactory for this purpose when mixed in a solution of 1 liquid ounce of cleaner to 4 gallons of water. Run spray motor(s) for 60 seconds. In areas with extreme hard water, consult the local health authority. 3. Drain sanitizer completely and thoroughly during each step of the cleaning process (wash, rinse, and sanitize). Refer to tips on draining in Disassembly Guide on page 3. HELPFUL HINTS 1. Noisy Impeller: Do not run impeller dry. The impeller will make a chattering sound in an empty bowl. Remove the impeller and run a small amount of water in the bowl. 2. Valve and O-Ring: On the first installation, if there is an after-drip, place your hand on the valve and with a slight downward pressure turn it slightly. This will help seat the o-ring so that it is properly aligned with the valve seat. If an o-ring becomes cut or worn it should be replaced. If you are pumping VALVE CAP a product which has excessive pulp, a separate valve weight may be purchased to add extra weight so the o-ring will press down against the pulp and guarantee a positive shut-off. 3. Valve Cap Use: The Valve Cap (Part # 2039) insures that a tight valve seal will occur with products containing heavy pulp. The Valve Cap can be installed by placing it on top of the VALVE Valve after the Valve has been assembled into the bowl. See Figure A. 4. High Water Marks on Bowl: When you agitate, you may get “high water marks” as the beverage level drops. Keep the bowl as full as possible. Frosted bowls are available which are helpful in reducing the appearance of water marks. 5. To Spray or Not to Spray: Most beverages can be sprayed. It is best not to spray iced tea, iced coffee, natural juices, or beverages that foam (whipped drinks). A special agitator plate is Figure A used in place of a pump cover and spray tube to promote circulation. 6. Proper Cooling: Always keep spray switch on when refrigeration switch is on. A unit must spray or agitate to cool. Failure to do this will cause impeller to lock-up. The dispenser is designed to run 24 hours a day. Keep both spray and agitate on when beverage is in the bowls. 7. Condensation: Condensation on the bowls and lids is natural, cool, and refreshing. The amount of condensation is affected by humidity. Condensation will run down the front panel into the drip tray. Remember to occasionally empty the drip trays. 8. Single Bowl Operation: If you find it necessary to run your dispenser with only one bowl containing beverage, put one half (1/2) cup of water in the unused cooling plate depression(s) for best one-bowl operation and efficiency. Page 4 Crathco® Beverage Dispensers PREVENTATIVE MAINTENANCE Top of Impeller Bottom of Unused Impeller Inner center section should be flush with exterior part of impeller. Figure B 1) Wash all bowl components regularly. 2) Wash impeller and bearing sleeve individually and check for wear. a) Check for wear on bearing sleeve (flange should be 1.77mm thick - thickness of penny or quarter). (Figure C) b) Check for wear on impeller (inner white center section should be flush with colored part of impeller). (Figure B) c) If bearing sleeve or impeller do not spin freely or are worn - replace them. (Figure F) d) Worn parts can cause personal injury, impair cooling and can damage machine. (Figure D & E) 3) Check valve o-rings and bowl gaskets for wear or damage replace every 6 months or as needed. 4) Every 6 months or more often if needed: unplug unit, remove panels, clean condenser and interior. (Remove dust and lint from fins with a soft brush and vacuum.) 5) For further information, visit www.grindmaster.com or call (800) 695-4500. New bearing sleeve Figure C 3220 Large Blue Impeller (D & WD model) 1161 Small Red Impeller (E model) Universal Impeller (all models) 1008 Valve O-ring 1012 Bowl Gasket - for D, WD models 5 gallon (or 3 gallon) bowl 1013 Bowl Gasket for E model and/or 9 liter bowl 2010 Bowl Gasket for 12 gallon SuperBowls (D112) 1150 Bearing Sleeve for 12 gallon Super Bowl (D112) 1983 Crathco® Beverage Dispensers flange (approx. 1.77mm - thickness of penny or quarter) Worn bearing sleeve (replace when worn to approx. 1mm or 1/2 thickness of penny or quarter). Figure D Figure E Part #s for Preventative Maintenance Description Part # Bearing Sleeve (all units except D112) Bottom of Worn Impeller Replace when worn. Yellow or white area no longer flush but indented. Figure F worn flange Bearing sleeve with flange missing is extremely worn. Discard immediately. CAUTION: Handle with care. Sharp edges may cause personal injury or damage to machine. Bearing sleeve and impeller should spin freely when held like this. If parts do not spin freely or are worn, unit will not cool properly and worn parts may damage machine. 3587 Universal Impeller (Part # 3587) Page 5 TROUBLESHOOTING GUIDE PROBLEM No or partial Refrigeration: Compressor Runs POSSIBLE CAUSE • Condenser clogged with dust or lint NOTE: Unit must spray or agitate properly to obtain cooling • Unit not properly spraying or agitating • Faulty fan motor • Loss of refrigerant No Refrigeration: Compressor Does Not Run SOLUTION • Unplug unit, remove panels and clean out all lint and dust from condenser and inside machine. Use vacuum cleaner or bottle brush. • See “Problem” - “No Spray or Agitation” • Replace motor (call for service) • Call for service • Call for service No Spray or Agitation: Spray Motor Runs • Replace sleeve and/or impeller if worn. • Impeller does not spin; check for worn bearing sleeve and/or impeller (see page 5) • If using a dairy based product, make sure you are using the correct impeller (blue or red with “M” on bottom or a black Universal Impeller) • If not worn, clean impeller and bearing sleeve. Impeller must spin freely on bearing sleeve to spray and refrigerate properly. Chattering Impeller • Impeller chatters and/or does not spin properly No Spray: Spray Motor Does Not Run Leaky Bowl • Call for service • Gasket improperly installed • Worn or nicked bowl gasket Leaky Valve Noisy Unit • Raise drive magnet higher on motor shaft, but not high enough to rub. (Call for service or see service manual) • Reinstall gasket. Check directions for bowl assembly. • Replace gasket • Foreign particles on valve, o-ring or valve stem • Nicked or cut o-ring • O-ring twisted so will not seat uniformly • Clean valve and o-ring • Worn bearings in either fan motor or spray motor(s) • Bent fan blade • Replace motor(s) (call for service) • Replace o-ring • Remove and remount • Unplug unit and re-bend fan blade to correct alignment If you still need help, call an authorized service center in your area or call Grindmaster Corporation’s Technical Service Department. You can reach Technical Service at (800) 695-4500 (USA & Canada only) or 1-502-425-4776 Monday-Friday, 8:00 AM-6:00 PM Eastern Standard Time. Please have the model and serial number ready so that accurate information can be given. Prior authorization must be obtained from Grindmaster Corporation’s Technical Service Department for all warranty claims. Page 6 Crathco® Beverage Dispensers STANDARD BOWL ASSEMBLY PARTS 1010A 2266 2484 1013 1161/3587 1288 1090 1261 1092 1734 1012 3220 1742 1740 1741 1735 Part # Description Models Used On 1010A Dispense Valve w/ O-ring All standard (non-whipper) 1012 O-ring for Dispense Valve All 1013 1090 1092 1161 Standard Bowl Gasket 3 Gal. Bowl 3 Gal. Bowl Spray Tube Standard Bowl Impeller (blue) All D15, D25, D35, HD and WD models (for 5 & 3 gallon bowls) All D15, D25, D35, HD and WD models All D15, D25, D35, HD and WD models w/ 3 gal. bowls All D, HD and WD models 3587 1261 1288 1734 Universal Impeller (black) 5 Gal. Bowl Spray Tube 5 Gal. Bowl Washer, Lockdown Standard Bowl Pump Cover for Red (p/n 1008) or Black (p/n 3587) Impeller (use with spray tube) Agitator for use with Red (p/n 1008) or Black (p/n 3587) Impeller Standard Bowl Pump Cover for Blue Impeller (use with spray tube) Standard Bowl Agitator for Blue Impeller (for iced tea, viscous products, or orange juice) All models All D15, D25, D35, HD and WD models w/ 5 gal. bowls All D15, D25, D35, HD and WD models All D15, D25, D35, HD and WD models 2231 Plastic Drip Tray D15-4, D25-4, D35-4, E27-4, D112-4, HD & WD models 2232 Plastic Drip Tray Grid D15-4, D25-4, D35-4, E27-4, D112-4, HD & WD models 2240 Standard Bowl Lid All D15, D25, D35 and WD models (Do not use on HD models) 1735 1740 1741 1742 All D15, D25, D35, HD and WD models All D15, D25, D35, HD and WD models All D15, D25, D35, HD and WD models All D15, D25, D35, HD and WD models 1116 Bowl Lid for Heated Units HD (heated models) 2243 Stainless Steel Drip Tray D15-3, D25-3, D35-3, D112-3 and HD-3 models 2266 Dispense Valve Handle All standard (non-whipper) 2484 Non-Contact Handle All standard (non-whipper) 2305 Stainless Steel Drip Tray Grid D15-3, D25-3, D35-3, D112-3 and HD-3 models 3220 Bearing Sleeve All Crathco® Beverage Dispensers Page 7 Mini Bowl (E27 & E47) Bowl Assembly Parts 3335 1010A 2911 2914 1012 2802 1994 3220 1008 or 3587 2910 or 3629 2012 2999 2010 2660 3330 2232 2231 2682 Part # 1008 1010A 1012 1994 2010 2012 2231 2232 2266 2484 2660 2682 2802 2910 2911 2914 2999 3220 3330 3335 3587 3629 Page 8 Description Mini Bowl Impeller (red) Dispense Valve w/ O-ring Dispense Valve O-ring 7 Liter Bowl Mini Bowl Gasket Mini Bowl Lock Washer Mini Twin Plastic Drip Tray Mini Twin Plastic Drip Tray Grid Dispense Valve Handle (pictured w/ std bowl assembly photo) Non-Contact Handle (pictured w/ std bowl assembly photo) Mini Quad Drip Tray (Plastic) Mini Quad Drip Tray Grid Standard 9 Liter Bowl Mini Bowl Pump Cover (use w/ spray tube) use w/ red impeller (p/n 1008) Mini Bowl Agitator (use with iced tea, orange juice, and viscous products) 9 Ltr. Mini Bowl Spray Tube Cover for 9L Bowl Bearing Sleeve Stainless Steel Drip Tray, E27, E47 Stainless Steel Drip Tray Grid, E27, E47 Universal Impeller (black) Mini Bowl Pump Cover - use with black impeller (p/n 3587) Crathco® Beverage Dispensers Super Bowl (D112) Bowl Assembly Parts 1165 1257 1162 3225 1010A 2023 1012 1161/ 3587 2266 1175 2305 2243 1150 2231 2232 2484 Part # Description Models Used On 1010A 1012 1150 1155 1161 1162 1165 1175 All Standard (non-whip) All D112 D112 All D, HD, and WD models D112 D112 D112 2023 Dispense Valve w/ O-ring O-ring for Dispense Valve Bowl Gasket Super Bowl Lid Impeller (blue) Super Bowl (12 gal) w/ hardware Super Bowl Pump Cover (use with spray tube) Super Bowl Spray Tube Agitator (use in place of pump cover and spray tube for iced tea, orange juice, and viscous products) Lockdown Cam 2231 Plastic Drip Tray D15, D25, D35, E27, D112, HD15, and all WD models 2232 Plastic Drip Tray Grid “ 2243 Stainless Steel Drip Tray All D, HD, and WD models 2266 2484 Dispense Valve Handle Non-Contact Handle All Standard (non-whipper) All Standard (non-whipper) 2305 Stainless Steel Drip Tray Grid D15, D25, D35, D112, HD15, and all WD models 3225 3587 Bearing Sleeve Universal Impeller (black) D112 All models 1257 Crathco® Beverage Dispensers D112 D112 Page 9 Whipper Unit Parts (Different from Standard) 1298 2955 1980 1936A 1416 2979 2982A 2977A 1012 1931 2497 1929 Part # 1012 1298 1416 1929 1931 1936A 1980 2497 2955 2977A 2979 2982A Page 10 Description Dispense Valve O-ring Whipper Housing Chamber Whipper Assy Restrictor Valve Whipper Assembly Spring Whipper Activation Switch Whipper Motor w/ Harness Whipper Blade Inlet Whipper Adapter Whipper Dispense Valve Handle Whipper Dispense Valve w/ O-ring Slinger Washer Whipper Base Crathco® Beverage Dispensers MCX Mag-Drive™ Impeller by Crathco® Purely the Best Features: Proprietary one-piece design using advanced, magnetic compound material... • Smooth surfaces assure complete sanitizing • High performance nylon bearing - harder material for longer life • More powerful and efficient action • One size fits all - use in all types of beverages and all models • Common parts for lower inventory • Crathco Bubblers™ * Built simple * Built stronger * Built to last Specifications and Use: • Part #: 3587 • Recommended for use in all models (standard, mini, and super) Bowl size 9L 2.4 gal. Recommended Recommended Pump Cover Agitator (when spraying) (when not spraying) part # 2910 part # 2911 part # 1735 part # 1740 (or 7L) 18L 5 gal. (or 3 gal.) (1741 may also be (1742 may also be used on 60 Hz units) used on 60 Hz units) Crathco® Beverage Dispensers Page 11 SET-UP UNPACKING Your dispenser is packed in 2 cartons: base pack and bowl pack. Unpack base by opening bottom flaps. See Figure G. IMPORTANT NOTES: 1. Do not leave base upside down as this can damage refrigeration system. 2. Check that all 4 rubber feet are attached to legs after removing from base pad. Check base pad or carton for missing feet and replace on legs. 3. Never lift from louvres/ventilation slots. Instead, place fingers under base plate. 1. Roll chassis up-side down 2. Open bottom flaps. Fold back. CHASSIS 3. Hold flaps out of way. Roll the carton over. BOTTOM PAD 4. Lift off carton. Remove bottom pad. Figure G INSTALLATION 1. Place base on counter. 2. For heated units (HD15/WHD15) units only: Install Safety Arms Tools required: Phillips Head Screwdriver a) Place unit on its side so you have access to the bottom of the unit. b) Line up arm holes so they line up to the holes on the bottom of the unit; arms will extend forward as shown in illustration. See Figure H. c) Attach arms with screws provided. 3. Leave sufficient air space (6”(15cm)) on sides (also rear of D35 triple) for proper airflow and efficient operation. See Figure I. IMPORTANT: Failure to provide required airspace can damage unit. 4. Plug into properly grounded, 3 prong outlet. 5. Assemble bowl parts and drain trays. See Assembly instructions (pgs 1-2). See Figure J. Figure H LOCKDOWN WASHER SPRAY TUBE 3/8” TAB PUMP COVER BOWL GASKET 6” (15 cm) (D35 only) IMPELLER BOWL BEARING SLEEVE COOLING PLATE GUIDE PIN CHASSIS 6” (15 cm) (all units) FR ON T Figure I Figure J Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500 • www.grindmaster.com • email: [email protected] © Grindmaster Corporation, 2004 PRINTED IN USA 0607 Form # CC-377-06 Part # 3682 DESEMPAQUE Su dispensador está empacado en dos cajas: una para la base y una para los tanques. Desempaque la base abriendo las alas de debajo de la caja. Vea la figura G. NOTAS IMPORTANTES: 1. No deje la base boca abajo porque puede dañar el sistema de refrigeración. 2. Revise que las 4 gomas estén adjuntas a las patas después de remover de la base. Revise la caja si no los encuentra. 3. Nunca levante la base de las rendijas de ventilación. En lugar de eso, coloque sus dedos debajo de la base para levantar. 1. Dele la vuelta al chasis 3. Sostenga las solapas fuera. Dele vuelta al cartón. 2. Abra las solapas de abajo. Dóblelas hacia atrás. CHASIS Almohadilla protectora de abajo 4. Levante el cartón. Remueva la almohadilla protectora de abajo. Figura G INSTALACIÓN 1. Coloque la base en la mesa. 2. Para unidades de calentado (HD15/WHD15) únicamente: Instale los Brazos de Seguridad Herramientas requeridas: desarmador Phillips a) Coloque la unidad de lado para que tenga acceso a la parte de debajo de la unidad. b) Alinee los agujeros de los Brazos de Seguridad para que se alineen con los agujeros de la parte de debajo de la unidad; los brazos se extenderán hacia delante como se muestra en la ilustración. Vea la Figura H. c) Adjunte los Brazos con los tornillos proveídos. 3. Deje suficiente aire (6" (15cm)) de cada lado (también en la parte de atrás de la D35 unidad triple) para que el aire fluya adecuadamente y haya una operación eficiente. Vea la Figura I. IMPORTANTE: Si no se deja el espacio apropiado la unidad se puede dañar. 4. Conecte la unidad en un enchufe de tres entradas y con tierra. 5. Arme las piezas del Tanque y las charolas de drenaje. Vea instrucciones (paginas 1-2). Vea la Figura J. Figura H Placa de sujeción Tubo rociador 3/8" tab Cubierta de la bomba Empaque del tanque Propulsor 6" (15 cm) (D35 solamente) Tanque Casquillo Plato de enfriamiento Guía central Chasis 6" (15 cm) (todas las unidades) Fr en te Figura I Figura J Tel.: +1.502.425.4776 • Fax +1.502.425.4664 • www.grindmaster.com • e-mail: [email protected] © Grindmaster Corporation, 2004 IMPRESO EN USA 0607 Formulario # CC-377-06 Pieza # 3682 Propulsor MCX Mag-Drive™ Hecho por Crathco® Lo mejor Características: Diseño de una pieza usando un material magnético avanzado... • Superficie plana que asegura una limpieza completa • Cojinete de nylon de alto desempeño material mas duro para una vida más larga • Acción mas fuerte y eficiente • Una medida para todos - se usa en todos los modelos de dispensadores de bebidas • Partes comunes, menor inventario • Dispensadores de bebidas Crathco: * Construidos simples * Construidos más fuertes * Construidos para durar Especificaciones y Uso: • Pieza # 3587 • Es recomendable su uso en todos los modelos (estándar, mini, y súper) Tamaño del Tanque Cubierta de la bomba recomendada (cuando usa tubo rociador) Agitador recomendado (cuando no usa rociador) 9 L - 2.4 Pieza # 2910 Gal. (o 7 L) Pieza # 2911 18 L- 5 Gal. (ó 3 Gal.) Pieza 1735 Pieza 1740 (1741 puede también ser usada en unidades de 60hz) (1742 puede también ser usada en unidades de 60hz) Dispensadores de Bebida Crathco Página 11 PIEZAS DE UNIDADES WHIPPER (DIFERENTES DE LAS ESTANDAR) 1298 2955 1980 1936A 1416 2979 2982A 2977A 1012 1931 2497 1929 Pieza # 1012 1298 1416 1929 1931 1936A 1980 2497 2955 2977A 2979 2982A Página 10 Descripción O-ring de válvula de dispensado Adaptador del whipper Válvula del whipper Resorte del whipper Switch activador del whipper Motor del whipper con cableado Aspas del whipper Adaptador de goma Asa de la válvula de dispensado del whipper Asa de la válvula de dispensado del whipper con o-ring limpiador Base del whipper Dispensadores de Bebida Crathco PIEZAS DEL SUPER TANQUE D112 1165 1257 1162 3225 1010A 2023 1012 1161/ 3587 2266 1175 2305 2243 1150 2231 2232 Part # 1010A 1012 1150 1155 1161 1162 1165 1175 1257 2023 Description 2484 Models Used On Válvula dispensadora con o-ring Todos los modelos estándar (no whipper) O-ring de la válvula dispensadora Todos Empaque del Tanque D112 Tapadera del Súper Tanque D112 Propulsor (azul) Todos los modelos D, HD y WD Súper Tanque de 12 galones con accesorios D112 Cubierta de la bomba del súper tanque (use con tubo rociador) D112 Tubo rociador del súper tanque D112 Agitador (use en lugar de la cubierta de la bomba y el tubo rociD112 ador para té frío, jugo de naranja y productos viscosos) Placa de sujeción D112 2231 Charola de drenaje de plástico Modelos D15, D25, D35, E27, D112, HD15 y todos los WD 2232 Tapadera de la charola de drenaje de plástico “ 2243 Charola de drenaje de acero Todos los modelos D, HD y WD 2266 2484 Asa de válvula de dispensado Asa de no contacto Todos los modelos estándar (no whipper) 2305 Tapadera de la charola de drenaje de acero Modelos D15, D25, D35, D112, HD15 y todos los WD 3225 3587 Casquillo de acero Propulsor Universal (negro) D112 Todos Dispensadores de Bebida Crathco Todos los modelos estándar (no whipper) Página 9 PIEZAS DEL TANQUE DE LOS MODELOS E27 & E47 3335 1010A 2911 2914 1012 2802 1994 3220 1008 or 3587 2910 or 3629 2012 2999 2010 2660 3330 2232 2231 2682 Part # 1008 1010A 1012 1994 2010 2012 2231 2232 2266 2484 2660 2682 2802 2910 2911 2914 2999 3220 3330 3335 3587 3629 Página 8 Description Mini Propulsor (rojo) Válvula de dispensado con o-ring O-ring de la válvula Tanque de 7 litros Mini Empaque del tanque Mini placa de sujeción Charola de drenaje mini doble (plástico) Tapadera de charola de drenaje mini doble (plástico) Asa de válvula de dispensado (fotografiada con el tanque estándar) Asa de no contacto (fotografiada con el tanque estándar) Charola de drenaje mini cuádruple (plástico) Tapadera de charola de drenaje mini cuádruple (plástico) Tanque estándar de 9 litros Cubierta de la bomba para el Mini Tanque (use con tubo rociador) use con propulsor rojo (1008) Agitador para el Mini Tanque (use con té frío, jugo de naranja y productos viscosos) Tubo rociador del mini tanque de 9 litros Tapadera del tanque de 9 litros Casquillo de acero Charola de drenaje de acero, E27, E47 Tapadera de charola de drenaje de acero E27, E47 Propulsor Universal (negro) Cubierta de la bomba Mini tanque - use con el propulsor negro (p/n 3587) Dispensadores de Bebida Crathco PIEZAS DEL TANQUE ESTANDAR 1010A 2266 2484 1013 1161/3587 1288 1090 1261 1092 1734 1012 3220 1742 1740 1741 1735 Pieza # Descripción Modelos en los que se usa 1010A Válvula y O-ring Todos los modelos estándar ( no whipper) 1012 O-ring para válvula Todos los modelos 1013 1090 1092 1161 Empaque para el tanque estándar Tanque de 3 galones Tubo rociador para tanque de 3 galones Propulsor (azul) Todos los modelos D15, D25, D35, HD y WD (de 5 y 3 galones) Todos los modelos D15, D25, D35, HD y WD Todos los modelos D15, D25, D35, HD y WD con tanques de 3 galones Todos los modelos D, HD y WD 3587 1261 1288 1734 Propulsor Universal (negro) Tubo rociador para tanque de 5 galones Tanque de 5 galones Placa de sujeción Cubierta de la bomba para los propulsores rojo (1008), negro (3587) (use con tubo rociador) Agitador para uso con propulsores rojo (1008) y negro (3587) Cubierta de la bomba estándar para propulsor azul (use con tubo rociador) Agitador estándar para propulsor azul (para té frío, producto viscoso o jugo de naranja) Todos los modelos Todos los modelos D15, D25, D35, HD y WD con tanques de 5 galones Todos los modelos D15, D25, D35, HD y WD Todos los modelos D15, D25, D35, HD y WD 2231 Charola de drenaje plástico Modelos D15-4, D25-4, D35-4, E27-4, D112-4, HD & WD 2232 Tapadera de charola de drenaje plástico Modelos D15-4, D25-4, D35-4, E27-4, D112-4, HD & WD 2240 Tapadera de tanque estándar Todos los modelos D15, D25, D35 y WD (no use en unidades HD) 1116 Tapadera para unidades para bebidas calientes HD (Modelos para bebidas calientes) 2243 Charola de drenaje de acero Modelos D15-3, D25-3, D35-3, D112-3 y HD-3 2266 2484 Asa de la válvula de dispensado Asa de no contacto Todos los modelos estándar ( no whipper) 2305 Tapadera de charola de drenaje de acero Modelos D15-3, D25-3, D35-3, D112-3 y HD-3 3220 Casquillo Todos los modelos 1735 1740 1741 1742 Dispensadores de Bebida Crathco Todos los modelos D15, D25, D35, HD y WD Todos los modelos D15, D25, D35, HD y WD Todos los modelos D15, D25, D35, HD y WD Todos los modelos D15, D25, D35, HD y WD Todos los modelos estándar ( no whipper) Página 7 GUIA DE RESOLUCIÓN DE PROBLEMAS PROBLEMA Refrigeración nula o parcial: El Compresor trabaja CAUSA PROBABLE • El condensador está atascado con polvo NOTA: La unidad debe rociar o agitar apropiadamente para • La unidad no está rociando o agitando obtener enfriamiento • El motor del ventilador no sirve • Perdida de refrigerante No refrigera: El compresor no trabaja SOLUCION • Desenchufe la unidad, remueva los paneles y limpie el polvo del condensador y del interior de la máquina. Use una aspiradora o un cepillo suave. • Vea "Problema" - "La maquina no rocía o no agita" • Reemplace el motor (llame para servicio • Llame al servicio • Llame al servicio La máquina no rocía o no agita: El motor de rociado si trabaja • El propulsor no da vuelta: revise si está desgasta- • Reemplace el casquillo y/o el propulsor. • Si está usando un producto lácteo, asegúrese de do el casquillo y/o el propulsor (ver pagina 5) estar usando el propulsor adecuado (azul o rojo con una "M" en la parte de abajo o el propulsor negro Universal) • Si no está desgastado, limpie el propulsor y el casquillo. El propulsor debe dar vuelta libremente en el casquillo para que rocíe y que refrigere adecuadamente. Propulsor ruidoso • El propulsor hace ruido o no da vuelta apropiadamente No rocía: El motor rociador no trabaja Tanque con fugas • Suba el magneto a una posición mas alta sobre la flecha del motor, pero no tan alto que tope. (llame al servicio o vea el manual de servicio) • Llame al servicio • El empaque está instalado incorrectamente • Empaque desgastado o picado • Reinstale el empaque. Revise las direcciones para su instalación • Reemplace el empaque Válvula con fugas • Partículas extrañas en la válvula, el o-ring. • O-ring desgastado o cortado • O-ring enrollado y no colocado uniformemente • Limpie la válvula y el o-ring • Reemplace el o-ring • Remueva y vuelva a instalar Unidad ruidosa • Casquillos desgastados en el motor del ventilador • Reemplace el/los motor(es) o en el motor rociador • Aspas del ventilador dobladas • Desenchufe la unidad y enderece las aspas dobladas Si aún necesita ayuda, llame a un centro autorizado de servicio en su área o llame al Servicio Técnico de Grindmaster Corporation. Puede llamar al Servicio Técnico al +1-502-425-4776 de lunes a Viernes de 8:00 AM-6:00 PM EST. Por favor tenga listo el modelo y el número de serie de la máquina para que se le pueda dar la información adecuada. Todas los reclamos bajo garantía deben ser previamente autorizados por el departamento de Servicio Técnico de Grindmaster Coporation. Página 6 Dispensadores de Bebida Crathco MANTENIMIENTO PREVENTIVO Parte de debajo de un propulsor desgastado Parte de debajo de un propulsor no usado Parte de arriba del propulsor Reemplácelo cuando esté desgastado. El área amarilla o blanca no está al mismo nivel del área de color El área amarilla o blanca debe estar al mismo nivel del área de color Figura B 1) Lave todos los componentes del tanque regularmente. 2) Lave el propulsor y casquillo individualmente y revise que no haya desgaste. a) Revise que no haya desgaste en el casquillo ( la parte de abajo debe tener por lo menos 1.77 mm de grosor) (Figura C) b) Revise que no haya desgaste en el propulsor (la parte blanca o amarilla del centro debe estar sólida y por arriba de la parte de color (Figura B) c) Si el casquillo o el propulsor no dan vuelta libremente o si están desgastados - reemplácelos (Figura F) d) Piezas gastadas pueden causar daños a personas, refrigerado inconsistente y puede dañar la máquina (Figura D&E) 3) Revise los o-rings de la válvula y el empaque del tanque por si hay desgaste o daño - reemplace cada 6 meses o cuando sea necesario. 4) Cada 6 meses o más seguido si es necesario: Desenchufe la unidad, remueva los paneles, limpie el condensador y el interior. (Remueva el polvo de las rendijas con un cepillo suave y una aspiradora.) 5) Para más información, visite www.grindmaster.com o llame al +1.502.425.4776, si está fuera de los Estados Unidos llame a su distribuidor local. Casquillo nuevo Borde (aprox. 1.77 mm) Figura C Casquillo desgastado (reemplace cuando ha llegado a un grosor de aprox. 1mm) Figura D Figura E Números de Pieza para el Mantenimiento Preventivo Descripción Pieza # Casquillo (todas las unidades excepto D112) 3220 Propulsor azul grande (modelos D y WD) 1161 Propulsor rojo pequeño (modelo E) 1008 Propulsor universal (todos los modelos) 3587 O-ring de la válvula 1012 Empaque del tanque - para modelos D y WD Tanque de 5 galones (o de 3) 1013 Empaque del tanque - para modelos E y/o de 9 litros 2010 Empaque para el tanque de 12 galones modelo D112 1150 Propulsor para el modelo D112 1983 Dispensadores de Bebida Crathco Figura F Borde desgastado Un casquillo sin borde quiere decir que está extremadamente desgastado PRECAUCION: Maneje con cuidado. Los bordes afilados pueden causar daños a personas o a la máquina. El Casquillo y el propulsor debería moverse libremente cuando se sostiene de esta manera. Si las piezas no se mueven libremente, la máquina no refrigerará apropiadamente y las piezas desgastadas pueden dañar la máquina. Propulsor Universal (pieza # 3587) Página 5 MANTENIMIENTO RUTINARIO: Para todos los modelos Limpie el dispensador Para optimizar el funcionamiento o si usa productos lácteos, lave la unidad diariamente. La limpieza regular de los componentes del tanque resultará en un bombeo más eficiente y en la prevención de fugas en el o-ring de la válvula y empaque del tanque ya que se remueven los sólidos secos y pulpa de las piezas. 1. Limpie todos los componentes del tanque regularmente. Siga los códigos de salud locales. * Refiérase a las instrucciones de Desarmado, Limpieza y Armado en las páginas 1-3. Desinfecte su dispensador * Refiérase a las instrucciones de Desarmado y Armado en las páginas 1-3. 1. En el tanque, mezcle un galón de Desinfectante Oxford Chemical Formula C o su equivalente. 2. Encienda el motor de rociado y deje que el desinfectante se rocíe dentro del tanque por un período de tiempo que sea el recomendado por el fabricador del desinfectante. La formula C es buena para este propósito cuando se mezcla en una solución de 1 onza líquida en 4 galones de agua. Deje que el motor rociador opere por 60 segundos. En las áreas con agua muy dura, consulte a las autoridades de salud. 3. Drene el desinfectante completamente en cada uno de los pasos de limpieza (lave, desagüe y desinfecte) Refiérase a las sugerencias de drenado en la guía de desarmado en la página 3. SUGERENCIAS DE AYUDA 1. Propulsor ruidoso: No permita el funcionamiento del propulsor en seco. El propulsor hará ruido si el tanque está vacío. Remueva el propulsor y corra un poco de agua en el tanque. 2. Válvula y O-ring: En la instalación, si hay fuga de producto, coloque su mano en la válvula y con un movimiento suave hacia abajo presione y gire. Esto ayudará a alinear el o-ring en la válvula. Si un o-ring TAPADERA DE se corta o se desgasta, debe ser reemplazado. Si usted está dispensando producto con LA VÁLVULA mucha pulpa, puede comprar un peso para la válvula para agregar peso extra y que el o-ring presione la pulpa y se garantice el cerrado completo. 3. Uso de la tapadera de la válvula: La tapadera de la válvula (pieza # 2039) asegura el cerrado de la válvula cuando hay producto que contiene mucha pulpa. La tapadera de la VÁLVULA válvula puede ser instalada colocándola sobre la válvula después de que se ha colocado en el tanque. Vea la figura A. 4. Marcas de agua en el tanque: Cuando usted agita, puede obtener "marcas de agua" cuando el nivel de la bebida baja. Mantenga el tanque tan lleno como sea posible. Puede comprar tanques opacos si no desea que dichas marcas sean vistas. 5. Rociar o no rociar?: La mayoría de las bebidas pueden ser rociadas. Es mejor NO rociar el Figura A té frío, café frío, jugos naturales, o bebidas que generen espuma. Un agitador especial es usado en lugar de la cubierta de la bomba y el tubo rociador. 6. Enfriado apropiado: Siempre mantenga el rociado en encendido cuando la refrigeración esté encendida. Una unidad debe agitar o rociar para refrigerar. Si no se siguen estas instrucciones el propulsor se trabará. El dispensador está diseñado para trabajar las 24 horas del día. Mantenga en encendido el rociador y el refrigerado mientras haya producto en los tanques. 7. Condensación: La condensación en los tanques y tapaderas es natural y refrescante. La cantidad de condensación está relacionada con la humedad. La condensación se dará en el frente hacia las charolas. Recuerde ocasionalmente vaciar las charolas. 8. Operación de un solo tanque: Si necesita operar solamente un tanque, ponga la mitad de una taza de agua en el plato de refrigerado que no esta usando para mayor eficiencia. Página 4 Dispensadores de Bebida Crathco Desarmado 1 4 DRENE TODA LA BEBIDA DE LOS TANQUES A. Remueva la(s) tapa(s) y la(s) charola(s). B. Drene por la válvula y luego, C. Incline la unidad hacia delante, suavemente presione el tubo rociador hacia atrás una distancia corta para levantar la punta de la cubierta de la bomba y dejar que lo que queda de bebida salga por la válvula. REMUEVA LA CUBIERTA DE LA BOMBA Remueva la cubierta de la bomba levantando el tubo rociador. 5 2a. UNIDADES ESTANDAR & MINI: REMUEVA LA VÁLVULA Y EL ASA REMUEVA EL TANQUE Y EL EMPAQUE DEL TANQUE Gire el tanque hacia atrás y hacia delante mientras que lo levanta. El empaque estará en la parte de abajo del tanque. Levante la válvula. El asa y sostenga el asa con la otra mano. NOTA: En las unidades D112, el empaque estará alrededor de la rueda de enfriado. 2b. UNIDADES CON WHIPPER: • DESARME EL ADAPTADOR DE GOMA Anillo localizado en la parte de abajo del asa Adaptador de goma blanco Remueva el lado sobrepuesto en la entrada tubular grande arriba del adaptador del whipper y luego el otro lado del anillo localizado en la parte de abajo del asa. Adaptador del whipper 6 REMUEVA EL PROPULSOR Y EL CASQUILLO Remueva el propulsor y el casquillo halándolos hacia arriba. • REMUEVA EL ADAPTADOR DEL WHIPPER NOTA: Observe si hay desgaste en estas piezas. Vea la página 5 Voltee el adaptador del whipper hacia la derecha hasta que se libere y pueda sacarla de las aspas. Propulsor • REMUEVA LAS ASPAS DEL WHIPPER Hale las aspas del whipper 7 • VOLTEE LA VÁLVULA 90º PARA LIBERAR. REMUEVA EL ASA Y LA VÁLVULA Válvula Agujero de la válvula • REMUEVA EL RESORTE DE LA PARTE DE ABAJO DEL TANQUE. Casquillo LIMPIE TODAS LAS PIEZAS CON AGUA TIBIA USANDO UN DETERGENTE SUAVE NO ABRASIVO Y DESAGÜE. PRECAUCION: LOS ABRASIVOS PUEDEN RAYAR LAS PIEZAS PLASTICAS. LAVE LAS TAPADERAS DE LOS TANQUES CON AGUA FRIA O TIBIA PARA EVITAR FUGAS Y DAÑO EN LAS AREAS SELLADAS. Asa Resorte 3 REMUEVA LA(S) PLACA(S) DE SUJECIÓN DESINFECTE Unidades Estándar: Gire la placa de sujeción en el sentido contrario a las manecillas del reloj, y deslice para liberar, luego sáquela. Sumerja las piezas en una solución desinfectante por 1-2 minutos. Remueva las piezas de la solución desinfectante y drene. NO DESAGÜE. Coloque las piezas en una superficie plana y deje que se sequen al aire. Limpie la máquina, el plato de condensador y el plato de refrigerado con un trapo mojado con la solución desinfec tante. Unidad Mini: Deslice para liberar y luego sáquela. Unidad D112: Libere cada abrazadera. Dispensadores de Bebida Crathco IMPORTANTE: Nunca eche polvo seco, cristales o líquidos concentrados en un tanque seco. Se recomienda que se mezcle la bebida en otro tazón primero. Si mezcla en el tanque mismo, siempre añada agua primero. Página 3 Armado (Cont.) 9 Agujero para la válvula (PARA UNIDADES CON WHIPPER SOLAMENTE) (PARA UNIDADES CON WHIPPER SOLAMENTE) 14 ARME EL ADAPTADOR DE GOMA PRESIONE EL RESORTE CONTRA LA PARTE DE ABAJO DEL TANQUE. Arme el adaptador de goma blanco estirando uno de los lados sobre la Resorte 10 (PARA UNIDADES CON WHIPPER SOLAMENTE) INSERTE EL ASA EN LAS HENDIDURAS EN FORMA DE "V" DEL TANQUE Y COLOQUE LA VÁLVULA EN EL ORIFICIO (ADENTRO DEL TANQUE). "W" es Válvula de Whipper entrada tubular grande arriba del adaptador del whipper. El otro lado Los lados del asa entran en las hendiduras "V" Adaptador de goma blanco colóquelo alrededor del anillo localizado en la parte de abajo del Adaptador del whipper asa. 15 Parte de Arriba Anillo localizado en la parte de abajo del asa LLENE EL/LOS TANQUE(S) CON PRODUCTO Y coloque la(s) tapa(s) en el/los tanque(s). Primero encienda el switch de "spray" (rociado) y luego el de refrigerado. I/ON SPRAY O/OFF I/ON REFRIG. O/OFF Agujero para la válvula Anillo de abajo Resorte 11 IMPORTANTE: NUNCA ENCIENDA EL REFRIGERADO A MENOS QUE EL ROCIADO O AGITADO ESTE ENCENDIDO. (PARA UNIDADES CON WHIPPER SOLAMENTE) (vista hacia abajo en los tanques) Marca - cruzada VOLTEE LA VÁLVULA A 90º PARA ASEGURAR. La marca (localizada arriba de la válvula) debe estar en dirección de izquierda a derecha en el tanque cuando está en su lugar. 12 Válvula en el agujero lista para cerrar Después de la vuelta de 90° la válvula esta en su lugar (PARA UNIDADES CON WHIPPER SOLAMENTE) PRESIONE LAS ASPAS DEL WHIPPER EN SU LUGAR. Reemplace las aspas del whipper alineando la parte plana interior de las aspas con la parte plana de la flecha del motor. Presione las aspas firmemente en su lugar. 13 (PARA UNIDADES CON WHIPPER SOLAMENTE) REEMPLACE EL ADAPTADOR DEL WHIPPER Reemplace el adaptador del whipper posicionando la abertura mediana hacia arriba y rotando 1/8 vueltas hacia la derecha. Ponga el adaptador del whipper sobre las aspas del whipper y mueva hacia la izquierda hasta que se quede fijo en su lugar. Página 2 Dispensadores de Bebida Crathco Dispensadores de Bebidas Crathco Manual para Operadores Armado 1 COLOQUE EL CASQUILLO METALICO EN LA GUIA CENTRAL DE LA BASE Note los lados planos en la parte exterior de la guía y en la parte interior del casquillo. Deslice el casquillo en la guía de la base alineando las partes planas hasta que el casquillo esté sobre la base de enfriado. Casquillo metálico 2 COLOQUE EL PROPULSOR SOBRE EL CASQUILLO 5 COLOQUE LA CUBIERTA DE LA BOMBA SOBRE LA GUIA CENTRAL DE LA BASE 6 INSTALE LA PLACA DE SUJECIÓN Coloque la cubierta de la bomba sobre la guía con el tubo rociador hacia el frente. Note que la punta sobresaliente en la parte delantera de la tapa cabe entre los dos marcadores dentro del tanque. En las unidades E27 y E47 la parte doblada del tubo rociador está de frente a la parte frontal del tanque. NOTA: Use la cubierta de la bomba tipo "agitador" en lugar de la cubierta de la bomba con tubo rociador para jugos frescos, bebidas que sacan espuma (té frío o productos lácteos), o bebidas viscosas Unidades Estándar: Coloque el propulsor sobre el casquillo, la parte plana hacia abajo. • Coloque la placa de sujeción sobre la guía central. • Empuje la placa hacia abajo y en posición de cerrado. • Gire la placa en el sentido de las manecillas del reloj para que encaje en su lugar. Placa de sujeción Unidades Mini: Propulsor 3 COLOQUE EL EMPAQUE EN EL TANQUE Voltee el tanque hacia abajo y coloque el empaque en el cuello del mismo. Lubrique el empaque con agua o con una capa fina de lubricante. NOTA: En las unidades D112 coloque el empaque alrededor de la rueda de enfriado. • Coloque la placa de sujeción sobre la guía central. • Empuje la placa hacia abajo y en posición de Cubierta de la bomba cerrado. • Deslice a la posición de cerrado Camino de cierre 3/8" tab " Frente" del dispensador (hacia la válvula del frente del tanque) Aspas Cabeza de la guía central Unidades modelo D112: A. Listo para cerrar • Inserte cada una de las abrazaderas en la guía y presione hasta que queden en su lugar. (Primero cierre las abrazaderas más cercanas al frente del tanque) Presione hacia abajo para que cierre B. Cerrado 4 COLOQUE EL TANQUE SOBRE LA BASE Coloque el cuello del tanque en el centro de la base de enfriado y con un movimiento continuo hacia abajo, de adelante hacia atrás, fije el tanque en su lugar. NOTA: En las unidades D112, coloque el tanque sobre el empaque y la rueda de enfriado con el cuello del tanque centrado en la rueda de enfriado. 7 ARME LA VÁLVULA Y EL ASA Coloque el asa (C) entre las dos hendiduras en forma de "V" en la parte delantera del tanque (B) y empuje el asa hacia atrás. Desde adentro del tanque, baje la válvula (A) a través del orificio de salida y a través del hueco en el asa. Suelte el asa. 8 REEMPLACE LA(S) CHAROLA(S) 1. Sostenga el asa en las hendiduras "V" y levante la parte de atrás del asa. 2. Desde adentro del tanque, baje la válvula a través del agujero de afuera y a través del agujero del asa. Válvula O-ring de parte del abajo tanque Asa 3. Suelte el asa. LABIO DEL PANEL FONTAL Coloque las cubiertas en las charolas. Coloque la orilla de arriba de la charola BASE abajo del labio del panel frontal. Baje cada charola para que las orillas entren en los orificios y queden aseguradas. En unidades regulares proceda con el paso 15. En unidades con whipper proceda con el paso 9. ORIFICIOS Beverage Dispensers Mini, Standard, Heated, Whipper and Super Bowl Models Service Manual Table of Contents Unpacking ................................................. 2 Installation ................................................. 2 Assembly .................................................. 3-4 Disassembly .............................................. 5 Routine Maintenance .............................. 6 Helpful Hints ............................................. 6 Preventative Maintenance ....................... 7 Security Kit Installation ............................ 8-9 Service Base Assembly Components ............. 10 Installing Pump & Fan Motors ............ 10 Replacement of Compressor Overload and Relay ............................. 10 Replacement of Temperature Control .. 11 Magnetic Lock ...................................... 12 Evaporator Assembly .......................... 12 Refrigeration Test ................................ 12 Trouble Shooting Guide ........................... 13 Exploded Views ......................................... 14-19 Wiring Diagrams ........................................ 20-24 Refrigeration Schematic ............................................ 25 Cap Tube Specs .................................. 25 Refrigerant Charges ........................... 25 Prior authorization must be obtained from Grindmaster Corporation for all warranty claims. Grindmaster Corporation™ 4003 Collins Lane Louisville, KY 40245 USA (502) 425-4776 (800) 695-4500 (800) 568-5715 (Technical Service Only) FAX (502) 425-4776 www.grindmaster.com Grindmaster Corporation, 1996 PRINTED IN USA Patents Pending 0404 Form #CC-375-05 Part #3275 SET-UP UNPACKING Your dispenser is packed in 2 cartons: base pack and bowl pack. Unpack base by opening bottom flaps. See Figure A. IMPORTANT NOTES: 1. Do not leave base upside down as this can damage refrigeration system. 2. Check that all 4 rubber feet are attached to legs after removing from base pad. Check base pad or carton for missing feet and replace on legs. 3. Never lift from louvres/ventilation slots. Instead, place fingers under base plate. 1. Roll chassis up-side down 2. Open bottom flaps. Fold back. CHASSIS 3. Hold flaps out of way. Roll the carton over. BOTTOM PAD 4. Lift off carton. Remove bottom pad. Figure A INSTALLATION 1. Place base on counter. 2. For heated units (HD15/WHD15) units only: Install Safety Arms Tools required: Phillips Head Screwdriver a) Place unit on its side so you have access to the bottom of the unit. b) Line up arm holes so they line up to the holes on the bottom of the unit; arms will extend forward as shown in illustration. See Figure B. c) Attach arms with screws provided. 3. Leave sufficient air space (6”(15cm)) on sides (also rear of D35 triple) for proper airflow and efficient operation. See Figure C. IMPORTANT: Failure to provide required airspace can damage unit. 4. Plug into properly grounded, 3 prong outlet. 5. Assemble bowl parts and drain trays. See Assembly instructions that follow. See Figure D. NOTE: See pages 8 - 9 for Installing Security Kit Instructions. Figure B LOCKDOWN WASHER SPRAY TUBE 3/8” TAB PUMP COVER BOWL GASKET IMPELLER BOWL BEARING SLEEVE COOLING PLATE GUIDE PIN 6” (15 cm) CHASSIS (D35 only) 6” (15 cm) (all units) FR ON T Figure D Figure C Crathco® Beverage Dispensers Page 2 Assembly 1 PLACE BEARING SLEEVE ON GUIDE PIN Note flat sides on outside of guide pin and on inside of bearing sleeve. Line flat sides up until bearing sleeve slides down over guide pin and rests on the cooling plate. 2 PLACE IMPELLER OVER BEARING SLEEVE. Put impeller over bearing sleeve with fin side up. 3 PLACE BOWL GASKET ON BOWL Turn bowl upside down and place bowl gasket over the neck of the bowl. Moisten gasket with water. NOTE: On D112 units place bowl gasket around cooling dome. 4 PUT BOWL ON BASE Place the neck of the bowl over center of the cooling plate and with a back and forth downward motion, push bowl down into place. NOTE: On D112 units, place bowl over the gasket and cooling dome with the neck of the bowl centered on the cooling dome. PLACE PUMP COVER OVER GUIDE PIN Place the pump cover over the guide pin with the spray tube toward the front. Note that the tab on the front of the pump cover fits between the 2 locator buttons on the bowl. Mini units - bent part of spray tube faces front of bowl. NOTE: Use agitator cover in place of pump cover and spray tube for fresh juice, drinks that foam (iced tea or dairy products), or heavy viscous drinks. 5 6 INSTALL LOCKDOWN WASHER OR CLAMPS Standard Units: • Place lockdown washer over guide pin. • Push lockdown washer down and into locking keyway. • Turn lockdown washer clockwise to lock into place. Mini Units: • Place lockdown washer over guide pin. • Push lockdown washer down and into locking keyway. • Slide into locked position. LOCKDOWN WASHER LOCKING KEYWAY 3/8” TAB PUMP COVER CROSS RIBS “FRONT” OF DISPENSER (TOWARD VALVE AT FRONT OF BOWL) HEAD OF GUIDE PIN D112 Superbowl Units: • Insert each lockdown clamp in a lockdown pin and snap down into place. (Lock down 2 clamps closest to the front of the bowl first.) 7 ASSEMBLE VALVE AND HANDLE Place handle (C) in the two V-cuts in the front of the handle bracket (B) and push handle back. From inside bowl, lower the valve (A) through the outlet hole, and through the hole in the handle. Release handle. VALVE O-RING 1. HOLD HANDLE IN “V” NOTCHES & LIFT REAR OF HANDLE UP. 2. FROM INSIDE THE BOWL, LOWER THE VALVE THROUGH OUTLET HOLE, AND THROUGH HOLE IN THE HANDLE. HANDLE 3. RELEASE HANDLE 8 FRONT PANEL LIP REPLACE DRIP PAN(S) Lower pan cover into the top of the drip pan. Place top edge of drip pan up under lip on front panel. TAB Lower each drip pan so that the BASEPLATE SLOTS tab goes down into the tab slot and locks pan in place. Regular units proceed to step 15. Whipper units proceed to step 9. Page 3 Crathco® Beverage Dispensers Assembly (cont.) 9 VALVE HOLE PRESS SPRING UP INTO PLACE AGAINST THE BOTTOM OF THE BOWL. 10 THE RUBBER INLET ADAPTER 14 ASSEMBLE Assemble white rubber inlet adapter by stretching one end over the large tubular inlet on top of the whipper housing. SPRING Attach the other end over the ring sleeve on the underside of INSERT HANDLE INTO “V” NOTCHES AND PLACE the handle. VALVE INTO HOLE. Ring sleeve on bottom of handle Rubber inlet adapter Plastic whipper housing “W” IS WHIPPER VALVE 15 TOP FILL BOWLS WITH PRODUCT and replace lids on bowls. Turn spray switch on first then refrigeration. HANDLE SHOULDERS GO INTO “V’ NOTCHES I/ON SPRAY O/OFF I/ON REFRIG. O/OFF VALVE HOLE RINGSLEEVE DOWN SPRING 11 TURN VALVE 90° TO LOCK. Cross slot (located on top of valve) should run left to right across the bowl when locked. (LOOKING DOWN INTO BOWLS) CROSS-SLOT VALVE DOWN IN HOLE READY TO LOCK AFTER 90° TURN, VALVE IS LOCKED PUSH WHIPPER BLADE INTO PLACE. Replace the whipper blade by lining up the flat inside the blade with the flat side of the motor shaft. Push blade firmly into place. 12 13 REPLACE WHIPPER CHAMBER. VALVE Replace whipper chamber by HOLE positioning the medium-sized opening up and tilting 1/8 turn to the right. Put whipper SPRING chamber over whipper blade and turn to the left until it locks into place. Crathco® Beverage Dispensers Page 4 DISASSEMBLY 1 4 DRAIN ALL BEVERAGE FROM BOWLS B A. Remove bowl lid(s) and drip tray(s) B. Drain through valve then C. Tip unit forward, gently press spray tube back a short distance to lift the edge of the pump cover to allow remaining beverage in well to be drained through valve. A REMOVE PUMP COVER Remove pump cover by lifting up on spray tube. 5 REMOVE BOWL AND BOWL GASKET Twist bowl back and forth while lifting up. Bowl gasket will be around bottom of bowl. NOTE: On D112 units, bowl gasket will be around cooling dome. 2a. STANDARD & MINI UNITS: REMOVE VALVE AND HANDLE Lift valve. Handle drops into operator’s other hand. 2b. WHIPPER UNITS: • DISASSEMBLE THE RUBBER INLET ADAPTER Remove one end from the large tubular inlet on top of the whipper housing and the other end from the ring sleeve on the underside of the handle. Ring sleeve on bottom of handle Rubber inlet adapter Plastic whipper housing NOTE: Check impeller and bearing sleeves for wear. See page 7. • REMOVE WHIPPER CHAMBER Turn whipper chamber to the right until it releases and you can pull it off of the whipper blade. 7 • REMOVE WHIPPER BLADE Pull whipper blade off of the motor shaft. VALVE • TURN VALVE 90° TO UNLOCK. REMOVE HANDLE AND VALVE. VALVE HOLE • REMOVE SPRING FROM BOTTOM OF BOWL. 3 Mini Unit: Slide to release keyway, then lift out. THOROUGHLY CLEAN ALL PARTS IN WARM WATER USING A MILD NON-ABRASIVE DETERGENT AND RINSE THOROUGHLY. CAUTION: ABRASIVES WILL SCRATCH PLASTIC PARTS. WASH BOWL LIDS IN COOL OR LUKEWARM WATER TO AVOID LEAKS DUE TO SEALED SURFACE BEING DAMAGED. HANDLE SPRING REMOVE LOCKDOWN WASHER(S) Standard Unit: Twist lockdown washer counterclockwise, slide to release keyway. Then lift out. 6 REMOVE IMPELLER AND BEARING SLEEVE Remove impeller and bearing sleeve by lifting them straight up. SANITIZE Immerse parts in sanitizing solution for 1-2 minutes. Remove parts from sanitizing solution and drain. DO NOT RINSE. Place parts on a clean surface to air dry. Wipe the machine, condensate tray and cooling plate depression with a cloth wetted with sanitizer solution. IMPORTANT: Never pour dry powder, crystals, or concentrate into a dry bowl. Premixing beverage in separate container is recommended. If mixing in bowl, always add water first. D112 Unit: Release each clamp. Page 5 Crathco® Beverage Dispensers ROUTINE MAINTENANCE: For all Models Cleaning Your Dispenser To optimize performance or when using dairy products, clean unit daily. Regular cleaning of bowl components will result in maximum pumping efficiency, proper seating and sealing, and prevention of leaks at the valve O-Ring and bowl gasket by removing dried-on beverage solids and pulp from moving sealed parts. 1. Wash all bowl components regularly. Follow all local health codes. * Refer to Disassembly, Cleaning, and Assembly instructions on pages 3-4. Sanitizing Your Dispenser * Refer to Disassembly and Assembly instructions on pages 3-4. 1. In the bowl, mix one gallon of Oxford Chemical’s Disinfectant/Sanitizer Formula C or its equivalent. 2. Turn on spray motor(s) and allow sanitizer to spray around inside of bowl for a period of time as recommended by the sanitizer manufacturer. Formula C is satisfactory for this purpose when mixed in a solution of 1 liquid ounce of cleaner to 4 gallons of water. Run spray motor(s) for 60 seconds. In areas with extreme hard water, consult the local health authority. 3. Drain sanitizer completely and thoroughly during each step of the cleaning process (wash, rinse, and sanitize). Refer to tips on draining in Disassembly Guide on page 3. HELPFUL HINTS 1. Noisy Impeller: Do not run impeller dry. The impeller will make a chattering sound in an empty bowl. Remove the impeller and run a small amount of water in the bowl. 2. Valve and O-Ring: On the first installation, if there is an after-drip, place your hand on the valve and with a slight downward pressure turn it slightly. This will help seat the o-ring so that it is properly aligned with the valve seat. If an o-ring becomes cut or worn it should be replaced. If you are pumping a product which has excessive pulp, a separate valve weight may be purchased to add extra VALVE CAP weight so the o-ring will press down against the pulp and guarantee a positive shut-off. 3. Valve Cap Use: The Valve Cap (Part # 2039) insures that a tight valve seal will occur with products containing heavy pulp. The Valve Cap can be installed by placing it on top of the Valve after the Valve has been assembled into the bowl. See Figure E. 4. High Water Marks on Bowl: When you agitate, you may get “high water marks” as the VALVE beverage level drops. Keep the bowl as full as possible. Frosted bowls are available which are helpful in reducing the appearance of water marks. 5. To Spray or Not to Spray: Most beverages can be sprayed. It is best not to spray iced tea, iced coffee, natural juices, or beverages that foam (whipped drinks). A special agitator plate is used in place of a pump cover and spray tube to promote circulation. 6. Proper Cooling: Always keep spray switch on when refrigeration switch is on. A unit must Figure E spray or agitate to cool. Failure to do this will cause impeller to lock-up. The dispenser is designed to run 24 hours a day. Keep both spray and agitate on when beverage is in the bowls. 7. Condensation: Condensation on the bowls and lids is natural, cool, and refreshing. The amount of condensation is affected by humidity. Condensation will run down the front panel into the drip tray. Remember to occasionally empty the drip trays. 8. Single Bowl Operation: If you find it necessary to run your dispenser with only one bowl containing beverage, put one half (1/2) cup of water in the unused cooling plate depression(s) for best one-bowl operation and efficiency. Crathco® Beverage Dispensers Page 6 PREVENTATIVE MAINTENANCE Top of Impeller Bottom of Unused Impeller Yellow or white area should be flush with colored area. Figure A 1) Wash all bowl components regularly. 2) Wash impeller and bearing sleeve individually and check for wear. a) Check for wear on bearing sleeve (flange should be 1.77mm thick - thickness of penny or quarter). (Figure B) b) Check for wear on impeller (inner white center section should be flush with colored part of impeller). (Figure A) c) If bearing sleeve or impeller do not spin freely or are worn - replace them. (Figure E) d) Worn parts can cause personal injury, impair cooling and can damage machine. (Figure C & D) 3) Check valve o-rings and bowl gaskets for wear or damage replace every 6 months or as needed. 4) Every 6 months or more often if needed: unplug unit, remove panels, clean condenser and interior. (Remove dust and lint from fins with a soft brush and vacuum.) 5) For further information, visit www.grindmaster.com or call (800) 695-4500. New bearing sleeve Figure B 3220 Large Blue Impeller (D & WD model) 1161 Small Red Impeller (E model) Universal Impeller (all models) 1008 Figure C Figure D Figure E worn flange Bearing sleeve with flange missing is extremely worn. Discard immediately. CAUTION: Handle with care. Sharp edges may cause personal injury or damage to machine. Bearing sleeve and impeller should spin freely when held like this. If parts do not spin freely or are worn, unit will not cool properly and worn parts may damage machine. 3587 Valve O-ring 1012 Bowl Gasket - for D, WD models 5 gallon (or 3 gallon) bowl 1013 Bowl Gasket for E model and/or 9 liter bowl 2010 Bowl Gasket for 12 gallon SuperBowls (D112) 1150 Bearing Sleeve for 12 gallon Super Bowl (D112) 1983 Page 7 flange (approx. 1.77mm - thickness of penny or quarter) Worn bearing sleeve (replace when worn to approx. 1mm or 1/2 thickness of penny or quarter). Part #s for Preventative Maintenance Description Part # Bearing Sleeve (all units except D112) Bottom of Worn Impeller Replace when worn. Yellow or white area no longer flush but indented. Universal Impeller (Part # 3587) Crathco® Beverage Dispensers SECURITY KIT INSTALLATION - STANDARD UNITS The valve security kit locks dispense valve to prevent use when store is closed. The bowl security kit locks the lid on the bowl to prevent unauthorized access. Standard Security Kit Includes ITEM KIT (contents listed below) PAD LOCK COVER LOCK STRAP VALVE LOCKING BOX KEY VALVE LOCKING BOX CHANNEL TOP D15 PART # / QTY 2509 1503 / (2) 2450 / (2) 2502 / (1) 2503 / (1) N/A D25 PART # / QTY 2510 1503 / (3) 2451 / (2) 2502 / (2) 2503 / (2) N/A D35 PART # / QTY 2511 1503 / (4) 2450 / (2) 2502 / (3) 2503 / (3) 2554 / (1) How to Assemble Bowl Locking Strap FRONT ROW - TOP No tools are needed to assemble kit. One pair of Cover Lock Straps are needed per dispenser. They are designed to work on 5 gallon bowls only with the double wall bowl cover #2240. Each pair of cover straps uses one Padlock. The Model D35 triple bowl unit also requires a top channel bar. UNPLUG MACHINE BEFORE INSTALLING KIT 1) For - 3 Models (with stainless side panels), hook the bottom end of the strap into the louvre in the top row nearest the dispenser’s front on both sides of the dispenser. (See Figure 1) For - 4 Models (with plastic side panels), hook the bottom end of the strap under the second section* of the top louvre on both sides of the dispenser. (*note the sections under the louvres)(See Figure 1) 2) Bring both tops of the cover straps together (above the bowl cover). 3) Place padlock into the holes of the cover straps and lock together. RD NDA STA - 3’S NT FRO SECOND SECTION* FROM THE FRONT TOP ROW RD NDA STA - 4’S NT FRO Figure 1 Note: D35 only - The top channel is interlocked into place on top of the bowls in the same manner as described above. Interlock the side without the padlock first. (See Figure 2) PADLOCK HERE Valve Box Locking Installation Instructions for Standard Units The extended side of the box with the turned-up edge is the top. Figure 2 1) Place the turned up edge (#1) over the top edge of the handle. 2) Place #2 behind the “Push” part of the handle. 3) Next, raise the box while keeping it pressed against the front panel of the dispenser. Hook the turned-up edge (#1) over the top of the handle. 4) Slide the locking bar (#3), through the slots (#4). 5) Add the padlock through the hole and lock. NOTE: Kit designed for “cup activated” handle (pictured). Kit will not work with “non-contact” handle. Crathco® Beverage Dispensers Page 8 SECURITY KIT INSTALLATION - MINI MODELS The valve security kit locks dispense valve to prevent use when store is closed. The bowl security kit locks the lid on the bowl to prevent unauthorized access. Mini Security Kit Includes ITEM KIT (contents listed below) SECURITY BRACKET SECURITY UPRIGHT LOCKDOWN CHANNEL SCREW, 10-24 X 3/4 PADLOCK VALVE LOCKING BOX LOCKING BAR CAP NUT 5/16 SS SCREW SECURITY CLAMP E27 E29 E47 E49 PART # / QTY 5350 2755 / (1) 2756 / (1) 2760 / (1) 0077 / (1) 1503 / (2) 3203 / (2) 3202 / (1) 0053 / (2) 0061 / (2) 2754 / (1) PART # / QTY 5351 2755 / (1) 2943 / (1) 2760 / (1) 0077 / (1) 1503 / (2) 3203 / (2) 3202 / (1) 0053 / (2) 0061 / (2) 2754 / (1) PART # / QTY 5352 2755 / (1) 2756 / (1) 2761 / (1) 0077 / (1) 1503 / (3) 3203 / (4) 3202 / (2) 0053 / (2) 0061 / (2) 2754 / (1) PART # / QTY 5353 2755 / (1) 2943 / (1) 2761 / (1) 0077 / (1) 1503 / (3) 3203 / (4) 3202 / (2) 0053 / (2) 0061 / (2) 2754 / (1) Tools required: 1 regular blade screwdriver, 1 Phillips screwdriver Lockdown Channel Padlock Security Upright Instructions: UNPLUG MACHINE BEFORE INSTALLATION 1) Remove all bowls from unit. 2) Remove the left side panel and back panel. 3) Clip security bracket over the back lip of top tray between the bowl indentations. (see drawing) 4) Reassemble back and side panel. The back panel fits over the security bracket. 5) Situate the security clamp over the drip lip and tighten the screw (#0077), so the tab, located on the back of the security clamp, slides into the security bracket’s slot. (see drawing) 6) Bolt the security upright onto the security clamp using 2 cap nuts and 5/16 SS screws provided. (see drawing) 7) Reassemble the bowls on the unit. 8) Place the lockdown channel on top of bowls, making sure the lockdown channel’s opening slips into the security upright’s notch. Screw 10-24 x 3/4 Security Bracket 5/16 Screw Top Tray Cap Nut Back of Unit Security Clamp Drip Lip Front of Unit Mini Model Valve Locking Device Exploded View Valve Valve Locking Device Installation Steps 1) Place locking box underneath bowl where valve protrudes. 2) Insert locking bar through the slits on each side of the locking box. • For Models E27 and E29 put the locking bar through both boxes. • For Models E47 and E49 put the locking bar through two of the locking boxes from the center with the lock on the outside. Next, install the two other boxes from the outside to the center. 3) Place the padlocks into the hole on each locking bar and lock. NOTE: Kit designed for “cup activated” handle (pictured). Kit will not work with “non-contact” handle. Page 9 Handle Step 3 Step 1 Step 2 Crathco® Beverage Dispensers SERVICE BASE ASSEMBLY COMPONENTS (Refrigerated Unit) Pump Motor (one for each bowl) Evaporator Assembly Thermostat and Power Switches Condenser Compressor Condenser fan and motor Refrigeration Tubing (Model D35 shown here) INSTALLING PUMP AND FAN MOTORS: For All Models Tools Required: Phillips screwdriver 1. Disconnect from power. 2. Remove cabinet panels. 3. Disconnect wires leading from motor to terminal board and/or switch. 4. Loosen bolts holding motor in place and replace with new motor. NOTE: Loosen bolts that hold top tray to frames for easier pump motor installation. Retighten bolts after reassembly. 5. Connect wires from new motor to terminal board and switch. 6. Replace cabinet panels. NOTE: When installing or repairing the pump it is important to adjust the magnetic lock. On page 5 are the instructions that should be followed for adjusting the magnetic lock (See Figure N). REPLACEMENT OF COMPRESSOR OVERLOAD AND RELAY: (Figure Q) For Standard, Whipper and Mini Models 1. Disconnect from power and remove front panel. 2. Remove plastic cover (A) and lock wire (E27s have a nut to unscrew) (B) from compressor housing and note positions of overload (C), relay (D) and wiring. E 3. Disconnect overload (C) from housing and wires, put overload spring clip (E) on new overload, then rewire and replace in proper position on compressor. C F 4. Pull off relay (D) and disconnect wires, then rewire and push new relay onto the compressor terminals (F). 5. Replace plastic cover (A) and lock wire (B), front panel of dispenser and service cord to power supply. Crathco® Beverage Dispensers F A B D Figure Q Page 10 REPLACEMENT OF TEMPERATURE CONTROL (PART # 1059) Tools Required: Phillips Screwdriver; Grease or Petroleum Jelly; Putty or similar substance 1. Unplug unit. 2. Remove front panel and side panel, located on the switch side, to access the temperature control mounting screws, located on the front right corner of the frame. 3. Remove the two (2) terminals to the control. Remove the two (2) screws holding the control to the frame. 4. Pull the control tube out of the evaporator, noting its direction and length it was inserted into the evaporator. 5. Straighten the new tube out and lubricate it with grease or petroleum jelly if possible. 6. Slide the control into the copper tube inside the evaporator. 7. Make sure the control slides into the tube the same distance as the old one. Reseal the opening with putty or a similar substance. 8. Bend excess tubing away from the fan blade. 9. Reassemble the terminals, screws and panels. 10. The control is in approximate calibration and the bowl temperature should be between 35 and 40 degrees. Minor adjustments can be made by turning the cut in/cut out adjustments screws on the control side. EVAPORATOR TRAY TEMPERATURE CONTROLLER Condensate Tray Remote bulb inserted into evaporator Evaporator Tubing Temperature Controller Remote bulb inserted into evaporator Page 11 Thermostat Well Crathco® Beverage Dispensers MAGNETIC LOCK THIS IS A TRIAL AND ERROR ADJUSTMENT Magnetic Lock Problems BEARING SLEEVE GUIDE PIN If a unit is not spraying, check the following: IMPELLER STAINLESS TOP a) The impeller must spin freely when the bearing sleeve is held between TRAY the thumb and the forefinger, 3/32” ALLEN SET b) The impeller should turn when assembled and the motor switch is SCREW turned “ON”. c) The pump motor runs without the impeller in place. PUMP MOTOR d) The air-gap between the drive magnet and the impeller is too great, NUT causing a loss of “magnetic lock”. NOTE: When adjusting the drive magnet on the pump motor shaft, place Figure N the drive magnet assembly as high as possible and still leave 1/16” clearance between the magnet and the underside of the top tray. The spacers on the motor bracket may be removed first for easier access. Magnetic Lock Adjustment 1. Remove the pump motor assembly from the unit by loosening the (2) pump motor bolts with a 7/16 wrench. (To remove the left pump motor assembly on a D25, you will have to remove the (2) bolts that connect the frame to the top tray on the left side and raise the frame slightly to slide the motor out.) 2. With a 3/32 Allen Wrench, loosen the (2) set-screws on the drive magnet and raise the magnet. The magnet should be as close as possible to the evaporator cover without rubbing. Tighten the set-screws and replace the pump motor assembly. TOP TRAY ASSEMBLY STEPS (EVAPORATOR ASSEMBLY) 1. Unplug the unit. 2. Remove all panels. 3. Remove 4 tray mounting bolts in upper corners. 4. Evacuate refrigerant. 5. Disconnect pump motor wires. 6. Unsolder suction line and capillary tube. 7. Replace filter drier. 8. Swap pump motor assemblies to new evaporator assembly. 9. Reassemble. 10. Evacuate and charge system. REFRIGERATION TEST 1. Add water to well. 2. Turn unit ON - if refrigeration is OK a frost pattern will form in less than 5 minutes. Crathco® Beverage Dispensers Page 12 Trouble Shooting Guide PROBLEM POSSIBLE CAUSE No or partial Refrigeration: Compressor Runs Note: Unit must spray or agitate properly to obtain cooling • Not clear air flow • Condenser clogged with dust or lint No Refrigeration: Compressor Does Not Run Note: Unit must spray or agitate properly to obtain cooling • Defective compressor overload protector • Compressor cycles on overload protector No Spray or Agitation: Spray Motor Runs • Faulty fan motor • Loss of refrigerant • Fan blade hitting wires or tubing SOLUTION • Provide 6” clearance on sides and back • Remove front panel and clean out all lint and dust . Use vacuum cleaner or bottle brush. • Replace motor • Return to factory - call for RMA. • Bend wires or tubing to clear. • Replace. • Check for low line voltage. Then check relay and overload and replace if necessary. • Replace switch. • Replace temperature control. • Locate and correct. • Return to factory - call for RMA. • Faulty refrigeration switch • Temperature control open • Faulty electrical connection • After checking all of above, if compressor doesn’t run • Pump impeller does not spin; check for worn • Replace sleeve and/or impeller. bearing sleeve and/or impeller (impeller rubbing on stainless steel evaporator) • Pump impeller does not spin freely on • Clean impeller bearing. Ream out impeller bearing sleeve. bearing if necessary. Impeller must spin freely on bearing sleeve. • Impeller chatters but does not spin properly • Raise drive magnet higher on motor shaft, but not high enough to rub. No Spray: Spray Motor Doesn’t Run • • • • Loose electrical connection to motor Faulty spray switch Faulty motor Drive magnet binds on plastic evaporator cover Leaky Bowl • Gasket improperly installed • Worn or nicked bowl gasket • Ordinary condensation build-up • • • • Locate and correct Replace spray switch Replace motor Relocate magnet (NOTE: Magnet should be about 1/16” from plastic to prevent binding or rubbing.) • Reinstall gasket. Check directions for bowl assembly. • Replace gasket • Keep drip pan attached to catch condensation. Noisy Unit • Worn bearings in either fan or pump motor • Bent fan blade • Pump impeller and/or sleeve chattering • Replace motor(s) • Re-bend fan blade to correct alignment • Replace impeller and/or sleeve Unit Does Not Heat • Loose electrical connection to heating element • Locate and correct Unit Overheats • Faulty thermostat • Replace thermostat If you still need help, call an authorized dealer in your area or Grindmaser Corporation’s Technical Service Department. You can reach Technical Service at (800) 425-4776 Monday-Friday, 8:00 AM-6:00 PM Eastern Standard Time. Please have the model and serial number ready so that accurate information can be given. Prior authorization must be obtained from Grindmaster Corporation’s Technical Service Department for all warranty claims. Page 13 Crathco® Beverage Dispensers Exploded View Standard and Whipper Models (D15, D25, D35, & WD) Crathco® Beverage Dispensers Page 14 Parts List Standard and Whipper Models Page 15 Crathco® Beverage Dispensers Standard Whipper Components Crathco® Beverage Dispensers Page 16 Exploded View Mini Models (E27/9 or E47/9) Page 17 Crathco® Beverage Dispensers Parts List Mini Models (E27/9 or E47/9) Crathco® Beverage Dispensers Page 18 Exploded View and Parts List HD15 - Heated Models Page 19 Crathco® Beverage Dispensers Super Bowl (D112) Bowl Assembly Parts 1165 1257 1162 3225 1010 2023 1012 3587 2266 2484 (not shown) 2305 1175 2243 2231 1150 2232 Part # 1010 1012 1150 1155 1162 1165 1175 Description Dispense Valve O-ring for Dispense Valve Bowl Gasket Super Bowl Lid Super Bowl (12 gal) Super Bowl Pump Cover (use with spray tube) Super Bowl Spray Tube Models Used On All Standard (non-whip) All D112 D112 D112 D112 D112 1257 Agitator (use in place of pump cover and spray tube for iced tea, orange juice, and viscous products) D112 2023 Lock Washer D112 2231 Plastic Drip Tray D15, D25, D35, E27, E47, D112, HD15, and all WD models 2232 Plastic Drip Tray Grid D15, D25, D35, E27, E47, D112, HD15, and all WD models 2243 Stainless Steel Drip Tray D15, D25, D35, E27, E47, D112, HD15, and all WD models 2266 Dispense Valve Handle All Standard (non-whip) 2305 Stainless Steel Drip Tray Grid D15, D25, D35, E27, E47, D112, HD15, and all WD models 2484 3225 3587 Handle, Non Cup Contact Bearing Sleeve Impeller (black) All Standard (non-whip) All All D, HD, and WD models Crathco® Beverage Dispensers Page 20 Wiring Diagrams Standard Models 115V & 220V Single Bowl D15/D155/D156 Double Bowl D25/D255/D256 Triple Bowl D35/D355/D356 Page 21 Crathco® Beverage Dispensers Wiring Diagrams for Mini Models (115V & 220V) Models E27, E275, and E276 or E29, E295, and E296 Models E47, E475, and E476 or E49, E495, and E496 Crathco® Beverage Dispensers Page 22 Wiring Diagrams Whipper Models Single Bowl WD15 Double Bowl 2WD25 1WD25-4 Triple Bowl 3WD35 2WD35-4 1WD35-4 Page 23 Crathco® Beverage Dispensers Wiring Diagram for Heated Models (HD15 & WHD15) 115V/60Hz and 230V/50Hz Crathco® Beverage Dispensers Page 24 Refrigeration Schematic CAP TUBE SPECIFICATIONS Model OD ID Length GCS Part # D15 .073 .031 76” 2308 D25 .087 .036 60” 1324 D25 .088 .036 52” 2968 D35 .093 .042 66” 3361 D112 .097 .042 97” 1199 WD35 .093 .042 66” 3361 Page 25 REFRIGERANT CHARGE FOR CRATHCO DISPENSERS 1 oz = 28.34952 grams grams D15 89 D155/6 97 D25 190 D255/6 190 D35/D355 197 E17 50 E27 120 E275/6 89 E47 161 E475/6 161 D112 196 D1125 196 ounces 3.1 3.4 6.7 6.7 6.9 1.8 4.2 3.1 5.7 5.7 6.9 6.9 1/6 hp 1/5 hp 1/3 hp 1/6 hp 1/5 hp 1/4 hp Crathco® Beverage Dispensers Grindmaster® Coffee Grinders and Brewers • Espressimo® Espresso Machines • Crathco® Hot Beverage Dispensers Crathco® Cold and Frozen Beverage Dispensers • American MetalWare® Coffee and Tea Systems Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500 P.O. Box 35020 • Louisville, KY 40232 • USA www.grindmaster.com • email: [email protected] Crathco® The Bubbler™ Parts Reference Guide 1288 5 Gallon bowl Notches cut into side no spray tube 2911 Agitator For Mini Bowl Units 1994 7 liter Bowl no notches but hole for spray tube 11 1/5” 2802 9 liter Bowl 9 1/4 12.130 7 3/4 1090 3 Gallon Bowl 1156 Bowl w/o Hardware No notches but hole for spray tube 1741 Pump Cover For large Impeller 2910 Pump Cover For Mini Bowl units Notches cut into side no spray tube 1740 Agitator For Small Impeller 1165 Pump Cover For 12 Gallon Unit 3220 Bearing Sleeve -3,-4 1004 Bearing Sleeve -1,-2 V cut notch in top only used on D-112 5.58” 3225 Bearing Sleeve D112 11 1/2” 1150 Bowl Gasket D-112 1013 Bowl Gasket D Series 1” 1011 O-ring For D112 Dispense Hardware 3.188” 2010 Bowl Gasket E Series 1/2” 1012 Dispense Valve O-ring 4.313” 8 1/8 4 3/ 12 1092 Spray Tube For 3-Gallon bowl 4.313” 6.906” 1261 Spray Tube For 5-Gallon Bowl 2914 Spray Tube For 9 Liter Bowl 4.875” /4 83 2011 Spay Tube For 7 Liter Bowl 1175 Spray Tube For 12-Gallon Bowl 2012 Lockdown Washer E Series 1734 Lockdown Washer D Series 2023 Lockdown Cam D112 2484 Non Contact Handle 2266 Cup activated Handle 2955 Handle For Whipper Unit 2977A Valve With O-Ring for Whipper unit 1010A Valve With O-Ring 2039 Valve Cap 1929 Whipper Valve spring 1155 Bowl Cover 2240 Bowl Cover D Series 1733 Magnet For Pump Motor Standard units 2.1” 2049 Magnet For Pump Mini units 2497 Inlet Adapter 1.8” ” 1.8 1161M Large Milk Fat Impeller 1.8” 1008M Small Milk Fat Impeller 3709 Low Foam Impeller 3587 Standard Impeller 3333 Anti-cycle Timer 1986 Valve Bushing For 12 Gallon unit 1987 Valve Bushing Nut For 12 Gallon unit 1022 Hinge Bracket For 12 Gallon unit 1931 Whipper Switch