1. Diámetro interior liso y constante para permitir un flujo sin

Anuncio

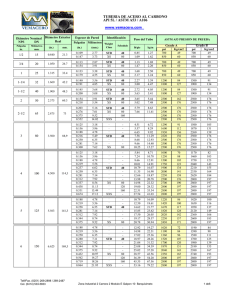

VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] 1. Diámetro interior liso y constante para permitir un flujo sin restricciones. 2. Extremos de corte cuadrado 3. Bisel, maquinado con precisión para una buena unión soldada. 4. .Identificación clara del diámetro, schedule o espesor de pared y material o código de colada. 5. Espesor uniforme para máxima resistencia. 1 de 17 VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] Conexiones de Acero al Carbono Soldables Según ASTM A234 90˚ Codos Radio Largo Tee reductoras y reducciones, Concentricas y Excentricas 90˚ Reducing Elbows Long Radius Caps 90˚ Elbows Long Radius, Long Tangent Lap Joint Stub Ends ................................... 90˚ codos Radio corto Saddles Laterals 45˚ codo Radio largo Seamless and Welded Pipe, Dimensions Dimensional Tolerances of Fittings 180˚ Returns Long Radius Short Radius Material and Manufacturing Standards Butt Welding Ends, Design and Dimensions Straight Tees and Crosses 2 de 17 VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] ASTM STANDARDS CCTF carbon steel welding fittings are manufactured from seamless steel tubing and furnished in accordance with ASTM Standard A-234, with material specifications in accordance with ASTM A-106, Grade B, for fittings made from pipe; ASTM A-515, Grade 65 or 70, for fittings made from plate. CCTF alloy steel welding fittings are furnished in accordance with ASTM standard A-234, with materials specification including A-335, Grade P1, carbon-molybdenum, and Grade P12, P11, P22, P5, P7; P9 chrome molybdenum, for fittings made from pipe. ASTM A-204 Grade B, carbon molybdenum, and ASTM A-387 Grades 12, 11, 22, 5, 7, 9 chrome molybdenum for fittings made from plate. CCTF welding fittings are also available in accordance with ASTM specification A-420 covering low-temperature service, down to -150˚F (-101˚C). CCTF stainless steel welding fittings are manufactured and available in the following types: 304, 304L, 316, 316L and 347. They are furnished in accordance with ASTM Standard A-403, with material specifications to ASTM A-312 covering fittings made from pipe, and A-240 for fittings made from plate. Refer to CCTF catalogue “Stainless Steel Welding Fittings. ANSI, MSS, ASME and CSA Standards ASME/ANSI and MSS standards govern fitting dimensions and tolerances, ASME/ANSI B16.9 “Wrought Steel Buttwelding Fittings”, si the basic standard. It covers steel butt-welding fittings sizes NPS 1/2 through NPS 48 (DN 15 through DN 1200). Other ASME/ANSI and MSS standards, written to supplement B16.9, are as follows: ASME/ANSI B16.25: Butt-welding Ends ASME/ANSI B16.28: Butt-welding short radius elbows and returns MSS SP-43: Light-wall stainless steel fittings, NPS 3/4 through NPS 24 (DN 20 through DN 600) MSS SP-75: High Test Wrought Welding Fittings The following codes and ASME/ANSI B31.1: ASME/ANSI B31.3: ASME/ANSI B31.4: ASME/ANSI B31.5: ASME/ANSI B31.8: ANSI/ASME B36.10M: ANSI/ASME B36.19M: CSA Z183: CSA Z184: CAN3-Z245.11-M91: ASME: standards influence the manufacture of welding fittings, where applicable. Power piping Petroleum refinery piping Liquid petroleum transportation piping system Refrigeration piping Gas transmission and distribution piping systems Welded and seamless wrought steel pipe Stainless steel pipe Oil pipe line transportation systems Gas pipe line systems Requirements for wrought steel butt welding fittings Boiler and pressure vessel code SPECIAL METALS High Test Steel. High test pipe line welding fittings, conforming to CSA Standard CAN3-Z245.11 or MSS SP-75, are available with physical properties to match pipe with *42,000, 46,000, 52,000, 60,000, 65,000, and over p.s.i. minimum yield strengths. Other Ferrous Alloys. Fittings are available manufactured from ASTM alloy specifications other than those listed in the “ASTM Standards” above. Non-Ferrous Metals. Fittings of relatively common metals, such as aluminum, nickel, copper, etc., can be readily furnished; production is limited only be availability of raw materials. The same is true of less common metals, such as the various grades of Hastelloy, Inconel, Incoloy, Monel, Alloy-20, rare types of stainless steel and other unusual analyses. *Equals 290, 317, 359, 414, 448 Mpa, respectively. METRIC EQUIVALENTS The International System (SI) metric equivalent of British units are shown throughout this catalogue. NPS (Nominal Pipe Size) = DN, ▲ (Nominal Diameter) Operating Pressure Class = PN, ▲ (Pressure Number) 1 inch = 25.4 millimetres 1 pound, weight = 0.4536 kilograms 1 psi = 0.06895 bars 1 psi, stress = 0.006895 megapascals (MPa) ▲ From the SI designations, Diamètre Nominal and Pression Nominale. 3 de 17 VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] 90˚ ELBOW LONG RADIUS Standard, Extra Strong, Schedule 160, Double Extra Strong Carbon and ferritic alloy steel, ASTM A-234 ASME/ANSI B16.9 STANDARD WEIGHT NPS DN 1/2 15 3/4 20 1 25 1 1/4 32 1 1/2 40 2 50 2 1/2 65 3 80 (2) 3 1/2 90 4 100 5 125 6 150 8 200 10 250 12 300 14 350 16 400 18 450 20 500 22 550 24 600 26 650 30 750 36 900 42▲ 1100 Outside Diameter at Bevel O.D. .840 21 1.050 27 1.315 33 1.660 42 1.900 48 2.375 60 2.875 73 3.500 89 4.000 102 4.500 114 5.563 141 6.625 168 8.625 219 10.750 273 12.750 324 14.000 356 16.000 406 18.000 457 20.000 508 22.000 559 24.000 616 26.000 660 30.000 762 36.000 914 42.000 1067 Centre Wall to Inside End Diameter Thickness Approx. I.D. T Weight A 1.50 .622 0.109 0.2 38 15.80 2.77 0.09 (1) 1.12 .824 0.113 0.3 29 20.93 2.87 0.14 1.50 1.049 0.133 0.4 .38 26.64 3.38 0.18 1.88 1.380 0.140 0.5 48 35.05 3.56 0.23 2.25 1.610 0.145 0.75 57 40.89 3.68 0.34 3.0 2.067 0.154 1.5 76 52.50 3.91 0.68 3.75 2.469 0.203 3.0 95 62.71 5.16 1.35 4.50 3.068 0.216 4.5 114 77.93 5.49 2.03 5.25 3.548 0.226 6.2 133 90.12 5.74 2.8 6.00 4.026 0.237 8.5 152 102.26 6.02 3.8 7.50 5.047 0.258 14.2 190 128.19 6.55 6.4 9.00 6.065 0.280 23 229 154.05 7.11 10.4 12.00 7.981 0.322 45 305 202.72 8.18 20 15.00 10.02 0.365 78 381 254.5 9.27 35 18.00 12.00 0.375 118 457 304.8 9.53 53 21.0 13.25 0.375 147 533 336.6 9.53 66 24.0 15.25 0.375 202 610 386.1 9.53 91 27.0 17.25 0.375 256 686 438.2 9.53 115 30.0 19.25 0.375 310 62 489.0 9.53 139 33.0 21.25 0.375 394 838 539.8 9.53 177 36.0 23.25 0.375 446 914 590.6 9.53 201 39.0 25.25 0.375 550 991 641.4 9.53 247 45.0 29.25 0.375 736 1143 743.0 9.53 331 54.0 35.25 0.375 1062 1372 895.4 9.53 478 63.0 41.25 0.375 1370 1600 1047.8 9.53 616 EXTRA STRONG SCHEDULE 160 DOUBLE EXTRA STRONG Inside Wall Diameter Thickness Approx. I.D. T Weight .546 .147 0.2 13.87 3.73 .09 .742 .154 0.2 18.85 3.91 .09 .957 .179 0.5 24.31 4.55 0.23 1.278 .191 0.7 32.46 4.85 0.32 1.500 .200 1.0 38.10 5.08 0.45 1.939 .218 2.0 49.25 5.54 0.9 2.323 .276 4.0 59.00 7.01 1.8 2.900 .300 6.0 73.66 7.62 2.7 3.364 .318 8.5 85.45 8.08 3.83 3.826 .337 12 97.18 8.56 5.4 4.813 .375 20 122.25 9.53 9.0 5.761 .432 32 146.33 10.97 14 7.625 .500 68 193.68 12.70 31 9.750 .500 112 247.65 12.70 50 11.750 .500 150 298.45 12.70 68 13.00 .500 192 330.2 12.70 86 15.00 .500 258 381.0 12.70 116 17.00 .500 326 431.8 12.70 147 19.00 .500 420 482.6 12.70 189 21.00 .500 520 533.4 12.70 234 23.00 .500 606 584.2 12.70 273 25.00 .500 729 635.0 12.70 328 29.00 .500 953 736.6 12.70 429 35.00 .500 1412 889.0 12.70 635 41.00 .500 1890 1041.1 12.70 820 Inside Wall Diameter Thickness Approx. I.D. T Weight 0.815 .250 0.6 20.7 6.35 0.27 1.160 .250 1.0 29.5 6.35 0.45 1.338 .281 1.8 34.0 7.14 0.81 1.687 .344 3.2 42.9 8.74 1.44 2.125 .375 6.0 54.0 9.53 2.70 2.624 .438 9.0 66.7 11.13 4.05 3.438 .531 19 87.3 13.49 8.5 4.313 .625 33 109.6 15.88 15 5.187 .719 59 131.8 18.26 27 6.813 .906 127 173.05 23.01 57 8.500 1.125 270 215.90 28.58 122 10.126 1.312 460 257.20 33.53 207 11.188 1.406 563 284.18 35.71 253 12.812 1.594 825 325.42 40.49 371 Inside Wall Diameter Thickness Approx. I.D. T Weight .599 .358 0.8 15.21 9.09 0.36 .896 .382 1.4 22.76 9.70 0.63 1.100 .400 2.0 27.94 10.16 0.90 1.503 .436 3.8 38.18 11.07 1.71 1.771 .552 7.1 44.98 14.02 3.20 2.300 .600 11.2 58.42 15.24 5.04 (2) (2) 2.728 .636 16.2 69.29 16.15 7.3 3.152 .674 21.2 80.06 17.12 9.5 4.063 .750 38 103.20 19.05 17 4.897 .864 63 124.38 21.95 28 6.875 .875 120 174.63 22.23 54 4 de 17 (1) May be furnished as 1.5 in (38mm) at the manufacturer’s option. (2) 3-1/2XXS is not specified in ASME/ANSI B36.10M. ▲) Produced from X-rayed, stress-relieved welded pipe. (▲ Welds are 100% radiographed in accordance with the requirements of ASME Boiler & Pressure Vessel Code. These fittings are also available in other sizes and/or wall thicknesses. INCHES POUNDS MILLIMETRES KILOGRAMS VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] 90˚ ELBOWS SHORT RADIUS Standard Weight, Extra Strong, and Double Extra Strong Carbon and ferritic alloy steel, ASME/ANSI B16.28, ASTM A-234 STANDARD WEIGHT NPS DN 1 25 1 1/4 32 1 1/2 40 2 50 2 1/2 65 3 80 3 1/2 90 4 100 5 125 6 150 8 200 10 250 12 300 14 350 16 400 18 450 20 500 24 600 (2) 30 (2) 36 (2) 750 (2) 900 Outside Diameter at Bevel O.D. 1.315 33 1.660 42 1.900 48 2.375 60 2.875 73 3.500 89 4.000 102 4.500 114 5.563 141 6.625 168 8.625 219 10.750 273 12.750 324 14.000 356 16.000 406 18.000 457 20.000 508 24.000 610 30.000 762 36.000 914 Centre to End Nominal A 1.0 25 1.25 32 1.5 38 2.0 51 2.5 64 3.0 76 3.5 89 4.0 102 5.0 127 6.0 152 8.0 203 10.0 254 12.0 305 14.0 356 16.0 406 18.0 457 20.0 508 24.0 610 30.0 762 36.0 914 Inside Diameter I.D. 1.049 26.64 1.380 35.05 1.610 40.89 2.067 52.50 2.469 62.71 3.068 77.93 3.548 90.12 4.026 102.26 5.047 128.19 6.065 154.05 7.981 202.72 10.02 254.5 12.00 304.8 13.25 336.6 15.25 387.4 17.25 438.2 19.25 489.0 23.25 590.6 29.25 743.0 35.25 895.4 Wall Thickness T .133 3.38 .140 3.56 .145 3.68 .154 3.91 .203 5.16 .216 5.49 .226 5.74 .237 6.02 .258 6.55 .280 7.11 .322 8.18 .365 9.27 .375 9.53 .375 9.53 .375 9.53 .375 9.53 .375 9.53 .375 9.53 .375 9.53 .375 9.53 Approx. Weight .25 .11 .38 .17 .50 .23 .88 .40 1.75 .79 3.00 1.35 4.00 1.80 6.00 2.70 9.5 4.28 15.5 7 31 14 55 25 78 35 104 47 118 53 148 67 210 95 288 130 480 216 695 313 (1) NPS 3-1/2 (DN 90) XXS is not specified in ASME/ANSI B36.10. (2) These sizes not covered in ASME/ANSI B16.28. These fittings are also available in other sizes and/or wall thicknesses. INCHES POUNDS MILLIMETRES KILOGRAMS 5 de 17 EXTRA STRONG Inside Diameter I.D. 1.500 38.10 1.939 49.25 2.323 59.00 2.900 73.66 3.364 85.45 3.826 97.18 4.813 122.25 5.761 146.33 7.625 193.68 9.750 147.65 11.750 298.45 13.00 330.02 15.00 381.0 17.00 431.8 19.00 482.6 23.00 584.2 29.00 736.6 35.00 889.0 Wall Thickness T .200 5.08 .218 5.54 .276 7.01 .300 7.62 .318 8.08 .337 8.56 .375 9.53 .432 10.97 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 Approx. Weight .75 .34 1.50 .68 2.25 1.01 3.75 1.69 5.50 2.48 7.75 3.5 13.5 6.1 22.5 10.1 46 21 71 32 100 45 132 59 160 72 160 87 280 126 370 167 634 285 940 423 DOUBLE EXTRA STRONG Inside Diameter I.D. 1.100 27.94 1.503 38.13 1.771 44.98 2.300 58.42 (1) 2.728 69.29 3.152 80.06 4.063 103.20 4.897 124.38 6.875 174.63 Wall Thickness T .400 10.16 .436 11.07 .552 14.02 .600 15.24 (1) .636 16.15 .674 17.12 .750 19.05 .864 21.95 .875 22.23 Approx. Weight 1.5 .68 2.8 1.26 4.9 2.21 7.0 3.15 10.5 4.73 14.1 6.35 26 12 43 19.4 80 36 VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] 45˚ ELBOWS LONG RADIUS Standard Weight, Extra Strong, Schedule 160, Double Extra Strong Carbon and ferritic alloy steel, ASTM A-234, ASME/ANSI B16.9 STANDARD WEIGHT NPS DN 1/2 15 3/4 20 1 25 1 1/4 32 1 1/2 40 2 50 2 1/2 65 3 80 3 1/2 90 4 100 5 125 6 150 8 200 10 250 12 300 14 350 16 400 18 450 20 500 22 550 24 600 26 650 30 750 36 900 42▲ 1100 Outside Centre to Diameter End at Bevel Nominal O.D. A .840 .62 21 16 1.050 .44 27 11 1.315 .88 33 22 1.660 1.00 42 25 1.900 1.12 48 29 2.375 1.38 60 35 2.875 1.75 73 44 3.500 2.00 89 51 4.000 2.25 102 57 4.500 2.50 114 64 5.563 3.12 141 79 6.625 3.75 168 95 8.625 5.00 219 127 10.750 6.25 273 150 12.750 7.50 324 190 14.000 8.75 356 222 16.000 10.00 406 254 18.000 11.25 457 286 20.000 12.50 508 318 22.000 13.50 559 343 24.000 15.00 610 381 26.000 16.00 660 406 30.000 18.50 762 470 36.000 22.25 914 565 42.000 26.00 1067 860 EXTRA STRONG Wall Inside Wall Inside Diameter Thickness Approx. Diameter Thickness Approx. Weight Weight T I.D. T I.D. .622 .109 .08 15.80 2.77 .04 .824 .113 .08 .742 .154 .16 20.93 2.87 .04 18.85 3.91 .07 1.049 .133 .25 .957 .179 .28 26.24 3.38 .11 24.31 4.55 .13 1.380 .140 .33 1.278 .191 .44 35.05 3.56 .15 32.46 4.85 .20 1.610 .145 .47 1.500 .200 .60 40.89 3.68 .21 38.10 5.08 .27 2.067 .154 .78 1.939 .218 1.05 52.50 3.91 .35 49.25 5.54 .47 2.469 .203 1.66 2.323 .276 1.91 62.71 5.16 .75 59.00 7.01 .86 3.068 .216 2.25 2.900 .300 3.08 77.93 5.49 1.01 73.66 7.62 1.39 3.548 .226 3.16 3.364 .318 4.75 90.12 5.74 1.42 85.45 8.08 2.14 4.026 .237 4.25 3.826 .337 5.88 102.26 6.02 1.91 97.18 8.56 2.65 5.047 .258 7.25 4.813 .375 10.0 128.19 6.55 3.26 122.25 9.53 4.65 6.065 .280 11.5 5.761 .432 16.7 154.05 7.11 5.18 146.33 10.97 7.5 7.981 .322 22.5 7.625 .500 34 202.72 8.18 10 193.68 12.70 15 10.02 .365 39 9.750 .500 53 254.5 9.27 18 247.65 12.70 24 12.00 .375 59 11.750 .500 74 304.8 9.53 27 298.45 12.70 33 13.25 .375 74 13.00 .500 95 336.6 9.53 33 330.2 12.70 43 15.25 .375 101 15.00 .500 131 387.4 9.53 46 381.0 12.70 59 17.25 .375 128 17.00 .500 170 438.2 9.53 5 431.8 12.70 77 19.25 .375 155 19.00 .500 205 489.0 9.53 70 482.6 12.70 92 21.25 .375 197 21.00 .500 260 539.8 9.53 89 533.4 12.70 117 23.25 .375 223 23.00 .500 295 590.6 9.53 100 584.2 12.70 133 25.25 .375 275 25.00 .500 365 641.4 9.53 124 635.0 12.70 164 29.25 .375 367 29.00 .500 475 743.0 9.53 165 736.6 12.70 214 35.25 .375 531 35.00 .500 706 895.4 9.53 239 889.0 12.70 318 41.25 .375 710 41.00 .500 950 1047.8 9.53 320 1041.4 12.70 428 SCHEDULE 160 DOUBLE EXTRA STRONG Inside Wall Inside Wall Diameter Thickness Approx. Diameter Thickness Approx. Weight Weight I.D. T I.D. T .434 .308 0.17 11.02 7.82 .08 .815 .250 .38 .599 .358 .40 20.70 6.35 .17 15.21 9.09 .18 1.160 .250 .50 .896 .382 .55 29.46 6.35 .23 22.76 9.70 .25 1.338 .281 1.00 1.100 .400 1.15 34.0 7.14 .45 27.94 10.16 .52 1.687 .344 1.75 1.503 .436 2.13 42.85 8.74 .79 38.18 11.07 .96 2.125 .375 3.00 1.771 .552 3.75 53.98 9.53 1.35 44.98 14.02 1.7 2.624 .438 4.5 2.300 .600 5.75 66.65 11.13 2.0 58.42 15.24 2.6 *2.728 *.636 8.65 69.29 16.15 3.9 3.428 .531 9.5 3.152 .674 10.7 87.33 13.49 4.3 80.06 17.12 4.8 4.313 .625 4.3 4.063 .750 19 109.55 15.88 7.65 103.20 19.05 8.6 5.187 .719 30 4.897 .864 32 131.8 18.26 13.5 124.38 21.95 14.4 6.813 .906 64 6.875 .875 60 173.05 23.01 29 174.63 22.23 27 8.500 1.125 135 215.9 28.58 61 10.126 1.312 230 257.2 33.32 104 11.188 1.406 278 284.2 35.71 125 12.812 1.594 415 325.4 40.49 187 - • NPS 3-1/2 (DN 90) XXS is not specified in ASME/ANSI B36.10M. ▲ Produced from x-rayed, stress relieved welded pipe. Welds are 100% radiographed in accordance with the requirements of ASME Boiler & Pressure Vessel Code. These fittings are also available in other sizes and/or wall thicknesses. 6 de 17 INCHES POUNDS MILLIMETRES KILOGRAMS VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] 180˚ RETURNS LONG RADIUS SHORT RADIUS Standard Weight & Extra Strong Carbon and ferritic alloy steel, ASTM A-234, ASME/ANSI B16.9 ASME/ANSI B16.28 LONG RADIUS NPS 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 3 1/2 4 5 6 8 10 12 14 16 18 20 22 24 (3) 26 (3) 30 Outside Diameter DN O.D. .840 15 21 1.050 20 27 1.315 25 33 1.660 32 42 1.900 40 48 2.375 50 60 2.875 65 73 3.500 80 89 4.000 90 102 4.500 100 114 5.563 125 141 6.625 150 168 8.625 200 219 10.750 250 273 12.750 300 324 14.000 350 356 16.000 400 406 18.000 450 457 20.000 500 508 22.000 550 559 24.000 600 610 26.000 (3) 650 660 30.000 (3) 750 762 Center to Center Nominal H .300 76 2.25 57 3.00 76 3.75 95 4.50 114 6.00 152 7.50 191 9.00 229 10.50 267 12.0 305 15.0 381 18.0 457 24.0 610 30.0 762 36.0 914 42.0 1067 48.0 1219 54.0 1372 60.0 1524 66.0 1676 72.0 1829 78.0 1981 90.0 2286 Back to Face Nominal J 1.88 48 1.69 43 2.19 56 2.75 70 3.25 83 4.19 106 5.19 132 6.25 159 7.25 184 8.25 210 10.31 262 12.31 313 16.31 414 20.38 518 24.38 619 28.0 711 32.0 813 36.0 914 40.0 1018 44.0 1118 48.0 1219 52.0 1321 60.0 1524 SHORT RADIUS Center to Center Nominal K (1) (1) (1) (1) 2.0 51 2.5 64 3.0 76 4.0 102 5.0 127 6.0 152 7.0 178 8.0 203 10.0 254 12.0 305 16.0 406 20.0 508 24.0 610 28.0 711 32.0 813 36.0 914 40.0 1016 (2) (2) 48.0 1219 (2) (2) 60.0 1524 Back to Face Nominal L 1.62 41 2.06 52 2.44 62 3.19 81 3.94 100 4.75 121 5.5 140 6.25 159 7.75 197 9.31 237 12.31 313 15.38 391 18.38 467 21.0 533 24.0 610 27.0 686 30.0 762 36.0 914.4 45.0 1143 STANDARD WEIGHT Long Radius Inside Wall Diameter Thickness Approx. Weight I.D. T .622 .109 .25 15.80 2.77 .11 .824 .113 .33 20.93 2.87 .15 1.049 .133 .75 26.64 3.38 .34 1.380 .140 1.0 35.05 3.56 .45 1.610 .145 1.5 40.89 3.68 .68 2.067 .154 3.0 52.50 3.91 1.35 2.469 .203 6.0 62.71 5.16 2.70 3.068 .216 9.0 77.93 5.49 4.05 3.548 .226 12.5 90.12 5.74 5.63 4.026 .237 17.0 102.26 6.02 7.65 5.047 .258 28.5 128.19 6.55 12.83 6.065 .280 46 154.05 7.11 20.70 7.981 .322 90 202.72 8.18 40.50 10.02 .365 156 254.5 9.27 70.20 12.00 .375 236 304.8 9.53 106.20 13.25 .395 294 336.6 9.53 132.30 15.25 .375 404 387.4 9.53 181.80 17.25 .375 512 438.2 9.53 230.4 19.25 .375 617 489.0 9.53 277.7 21.25 .375 787 539.8 9.53 354.2 23.25 .375 890 590.6 9.53 400.5 25.25 .375 1100 641.4 9.53 495.0 29.25 .375 1441 743.0 9.53 648.5 (1) These sizes of Short Radius Returns are not available. (2) Available by special order only. (3) These sizes not covered by ASME/ANSI B16.9 or ASME/ANSI B16.28. Particulars and specifications of Long Radius, Sch. 160 and XXS, and Short Radius XXS available on request. These fittings are also available in other sizes and/or wall thicknesses. INCHES POUNDS MILLIMETRES KILOGRAMS 7 de 17 EXTRA STRONG Short Radius Approx. Weight (1) (1) (1) (1) .50 .23 .75 .34 1.0 .45 1.8 .81 3.5 1.58 6.0 2.70 8.0 3.60 12.0 5.40 19.0 8.55 31.0 14 62 28 110 49.5 156 70 208 94 236 106 296 133 420 189 (2) (2) 576 259 (2) (2) 960 432 Long Radius Inside Wall Diameter Thickness Approx. Weight I.D. T .546 .147 .45 13.87 3.73 .20 .742 .154 .45 18.85 3.91 .20 .957 .179 1.0 24.31 4.55 .45 1.278 191 1.5 32.46 4.85 .68 1.500 .200 2.0 38.10 5.08 .90 1.939 .213 4.4 49.25 5.54 2.0 2.323 .276 7.5 59.00 7.01 3.38 2.900 .300 12.0 73.66 7.62 5.40 3.364 .318 17.0 85.45 8.08 7.65 3.826 .337 23.5 97.18 8.56 10.6 4.813 .375 40.0 122.25 9.53 18 5.761 .432 67 146.33 10.97 30 7.625 .500 138 193.68 12.70 62 9.750 .500 215 247.65 12.70 62 11.750 .500 300 298.45 12.70 135 13.00 .500 376 330.2 12.70 236 15.00 .500 524 381.0 12.70 236 17.00 .500 676 431.8 12.70 304 19.00 .500 824 482.6 12.70 371 21.00 .500 1040 533.4 12.70 468 23.00 .500 1183 584.2 12.70 468 25.00 .500 1458 635.0 12.70 656 29.00 .500 1910 736.6 12.70 860 Short Radius Approx. Weight (1) (1) (1) (1) (1) (1) (1) (1) 1.5 .68 3.0 1.35 4.5 2.03 7.5 3.38 11.0 5 15.5 7 27.0 12 45.0 20 92 41 142 41 200 90 264 144 320 144 388 175 560 252 (2) (2) 740 (2) (2) (2) 1272 572 VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] STRAIGHT TEES & CROSSES* Standard Weight and Extra Strong Carbon and ferritic alloy steel, ASTM A-234, ASME/ANSI B16.9 STANDARD WEIGHT NPS DN 1/2 15 3/4 20 1 25 1 1/4 32 1 1/2 40 2 50 2 1/2 65 3 80 3 1/2 90 4 100 5 125 6 150 8 200 10 250 12 300 14 350 16 400 18 450 20 500 22 550 24 600 26 650 30 750 36 900 42 1100 Outside Diameter O.D. .840 21 1.050 27 1.315 33 1.660 42 1.900 48 2.375 60 2.875 73 3.500 89 4.000 102 4.500 114 5.563 141 6.625 188 8.625 218 10.750 273 12.750 324 14.000 356 16.000 406 18.000 457 20.000 508 22.000 559 24.000 10 26.000 860 30.000 762 36.000 914 42.000 1067 Centre to End, Run. C 1.00 25 1.12 29 1.50 38 1.88 48 2.25 57 2.50 64 3.00 76 3.38 86 3.75 95 4.12 105 4.88 125 5.62 143 7.00 178 8.50 216 10.0 254 11.0 279 12.0 305 13.5 343 15.0 381 16.5 419 17.0 432 19.5 495 22.0 559 26.5 673 30.0 762 Center to End, Outlet M 1.00 25 1.12 29 1.50 38 1.88 48 2.25 57 2.50 64 3.00 76 3.38 86 3.75 95 4.12 105 4.88 125 5.62 143 7.00 178 8.50 216 10.0 254 11.0 279 12.0 305 13.5 343 15.0 381 16.5 419 17.0 590.6 19.5 495 22.0 559 26.5 673 28.0 711 Inside Diameter I.D. .622 15.80 .824 20.93 1.049 26.64 1.380 35.05 1.610 40.89 2.067 52.50 2.469 62.71 3.068 77.93 3.548 90.12 4.026 102.3 5.047 128.2 6.065 154.0 7.981 202.7 10.02 254.5 12.00 304.8 13.25 336.6 15.25 387.4 17.25 438.2 19.25 489.0 21.25 539.8 23.25 9.53 25.25 641.4 29.25 743.0 35.25 895.4 41.25 1048 Wall Thickness T .109 2.77 .113 2.87 .133 3.38 .140 3.56 .145 3.68 .154 3.91 .203 5.16 .216 5.49 .226 5.74 .237 6.02 .258 6.55 .280 7.11 .322 8.18 .365 9.27 .375 9.53 .375 9.53 .375 9.53 .375 9.53 .375 9.53 .375 9.53 .375 259 .375 9.53 .375 9.53 .375 9.53 .375 9.53 Tees size 20 NPS (DN 500) and smaller, and Crosses size 16 NPS (DN 400) and smaller, are normally furnished as seamless. Larger size non-seamless Tees and Crosses are produced from X-rayed, stress relieved welded pipe. Welds are 100% radiographed in accordance with the requirements of ASME Boiler & Pressure Vessel Code. Approx. Weight Tee .25 .11 .37 .17 .63 .28 1.25 .57 1.5 .68 2.0 .9 4.0 1.8 6.0 2.7 7.5 3.4 10.2 4.6 16 7.3 23.5 10.7 44.8 20 74.2 34 126 56.70 159 71.55 220 99.0 295 132.8 363 163.4 449 202 515 103 655 295 1010 455 1450 653 1730 779 EXTRA STRONG Approx. Weight Cross 1.60 .72 2.10 .95 2.55 1.15 3.40 1.53 4.10 1.85 5.65 2.54 9.25 4.16 11.20 5.04 25.0 11 41.5 19 72 32 96 43 121 54 145 65 170 77 195 88 230 584.2 - Inside Diameter I.D. .546 187 .742 18.85 .957 24.31 1.278 32.46 1.500 38.10 1.939 49.25 2.323 59.00 2.900 73.66 3.364 85.45 3.826 97.18 4.813 122.2 5.761 146.3 7.625 193.7 9.750 247.6 11.750 298.4 13.00 330.2 15.00 381.0 17.00 431.8 19.00 482.6 21.00 533.4 23.00 12.70 25.00 635.0 29.00 736.6 35.00 889.0 41.00 1041 Wall Thickness T .147 3.73 .154 3.91 .179 4.55 .191 4.85 .200 5.08 .218 5.54 .276 7.01 .300 7.62 .318 8.08 .337 8.56 .375 9.53 .432 10.97 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 12.70 .500 281 .500 12.70 .500 12.70 .500 12.70 .500 12.70 Approx. Weight Tee .34 .15 .44 .2 .8 .36 1.6 .73 2.0 .9 3.0 1.3 5.7 2.6 7.7 3.5 10.0 .45 14 6.3 23 10.4 38.2 17 67 30 110 50 165 74 225 101 265 119 358 161 358 161 540 243 625 135 840 378 1175 529 1650 743 1970 887 Approx. Weight Cross 2.20 .99 2.60 1.17 3.25 1.46 4.15 1.87 6.20 2.79 9.50 4.28 12.7 5.72 18.0 9.1 31.5 14 52.0 24 85.0 38 130 59 145 65 180 81 210 95 210 95 300 - *Reduced outlet crosses available on request. These fittings are also available in other sizes and/or wall thicknesses. 8 de 17 INCHES POUNDS MILLIMETRES KILOGRAMS VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] STRAIGHT TEES Schedule 160 & Double Extra Strong Carbon and ferritic alloy steel, ASTM A-234, ASME/ANSI B16.9 SCHEDULE 160 NPS DN 3/4 20 1 25 1 1/4 32 1 1/2 40 2 50 2 1/2 65 3 80 3 1/2 90 4 100 5 125 6 150 8 200 10 250 12 300 14 350 16 400 Outside Diameter at Bevel O.D. 1.050 27 1.315 33 1.660 42 1.900 48 2.375 60 2.875 73 3.500 89 4.000 102 4.500 114 5.563 141 6.625 188 8.625 219 10.750 273 12.750 324 14.000 356 16.000 406 Centre to End, Center to End, Run. Outlet. Nominal Nominal C M 1.12 1.12 29 29 1.50 1.50 38 38 1.88 1.88 48 48 2.25 2.25 57 57 2.50 2.50 64 64 3.00 3.00 76 76 3.38 3.38 86 86 3.75 3.75 95 95 4.12 4.12 105 105 4.88 4.88 124 124 5.62 5.62 143 143 7.00 7.00 178 178 8.50 8.50 216 216 10.00 10.00 254 254 11.00 11.00 279 279 12.00 12.00 305 305 INCHES POUNDS MILLIMETRES KILOGRAMS Inside Diameter I.D. .612 15.54 .815 20.70 1.160 29.46 1.338 33.99 1.687 42.85 2.125 53.98 2.624 66.65 3.438 87.33 4.313 109.6 5.187 131.8 6.813 173.1 8.500 215.9 10.126 257.2 11.188 284.2 12.812 325.4 9 de 17 Wall Thickness T .219 5.6 .250 6.35 .250 6.35 .281 7.14 .344 8.74 .375 9.53 .438 11.13 .531 13.49 .625 15.88 .719 18.26 .906 23.01 1.125 28.58 1.312 33.32 1.406 35.71 1.594 40.49 DOUBLE EXTRA STRONG Approx. Weight .65 .29 1.10 .50 2.10 .95 3.00 1.35 4.5 2.03 7.0 3.15 11.5 5.18 21.5 9.7 37 17 63 28 114 51 265 119 389 175 525 236 820 369 Inside Diameter I.D. .434 11.02 .599 15.21 .896 22.76 1.100 27.94 1.503 38.18 1.771 44.98 2.300 58.42 2.728 69.29 3.152 80.06 4.063 103.2 4.897 124.4 6.875 174.6 - Wall Thickness T .308 7.82 .358 9.09 .382 9.70 .400 10.16 .436 11.07 .552 14.02 .600 15.24 .636 16.15 .674 17.12 .750 19.05 .864 21.95 .875 22.23 - Approx. Weight 1.16 .52 1.25 .56 2.32 1.04 3.38 1.52 5.20 2.34 9.63 4.33 13.5 6.08 23 10.35 25 11 40 18 66 30 120 54 - VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] *REDUCING TEES & REDUCERS Concentric and Eccentric Standard Weight, Extra Strong, Schedule 160, Double Extra Strong Carbon and ferritic alloy steel, ASTM A-234, ASME/ANSI B16.9 Outlet or Reduced End Run NPS NPS DN 1/2 DN ▲ 1/4 ▲ 3/8 15 6 10 #▲3/8 3/4 20 10 1/2 15 1 3/8 25 10 1/2 15 3/4 20 1 1/4 1/2 32 15 3/4 20 1 25 1 1/2 1/2 40 15 3/4 20 1 25 1 1/4 32 2 3/4 50 20 1 25 1 1/4 32 1 1/2 40 2 1/2 1 65 25 1 1/4 32 1 1/2 40 2 50 #▲ 1 3 80 25 1 1/4 32 1 1/2 40 2 50 Nominal Center-to-End Tees Run Outlet C 1.00 25 1.00 25 1.12 29 1.12 29 1.50 38 1.50 38 1.50 38 1.88 48 1.88 48 1.88 48 2.25 57 2.25 57 2.25 57 2.25 57 2.50 64 2.50 64 2.50 64 2.50 64 3.00 76 3.00 76 3.00 76 3.00 76 3.38 86 3.38 86 3.38 86 3.38 86 M 1.00 25 1.00 25 1.12 29 1.12 29 1.50 38 1.50 38 1.50 38 1.88 48 1.88 48 1.88 48 2.25 57 2.25 57 2.25 57 2.25 57 1.75 44 2.00 51 2.25 57 2.38 60 2.25 57 2.50 64 2.62 67 2.75 70 2.62 67 2.75 70 2.88 73 3.00 76 Nominal Length of Reducers L 1.5 ■ 38 1.5 38 2.0 51 2.0 51 2.0 51 2.0 51 2.0 51 2.0 51 2.5 64 2.5 64 2.5 64 2.5 64 3.0 76 3.0 76 3.0 76 3.0 76 3.5 89 3.5 89 3.5 89 3.5 89 3.5 ■ 89 3.5 89 3.5 89 3.50 89 APPROXIMATE WEIGHTS STANDARD WEIGHT Tee .25 .11 .25 .11 .37 .17 .37 .17 .60 .25 .65 .27 .69 .31 1.3 .59 1.2 .54 1.2 .54 2.1 .95 1.8 .82 1.7 .77 1.7 .77 2.0 .91 2.0 .91 2.1 .95 2.2 1.00 3.0 1.36 3.2 1.45 3.5 1.60 3.5 1.60 5.0 2.27 5.1 2.31 5.1 2.31 5.2 2.36 Reducer .22 0.1 .25 0.1 .27 0.1 .30 0.14 .32 0.15 .34 0.15 .37 0.17 .39 0.18 .44 0.2 .47 0.21 .50 0.23 .58 0.26 .82 .37 .89 .40 .94 .43 1.03 .47 1.42 .64 1.59 .72 1.71 .78 1.84 2.5 2.10 1.0 2.28 1.0 2.42 1.1 2.56 1.16 10 de 17 EXTRA STRONG SCHEDULE 160 Tee .27 .12 .28 .13 .43 .20 .44 .20 .75 .34 .75 .34 .80 .40 1.65 .75 1.66 .75 1.90 .86 2.2 1.00 2.3 1.04 .4 1.10 2.6 1.18 2.7 1.22 2.7 1.22 2.8 1.27 2.8 1.27 4.2 1.91 4.3 1.95 4.5 2.04 4.5 2.04 6.0 2.72 6.0 2.72 6.12 2.81 6.4 2.95 Tee .63 .29 .63 .29 .90 .41 .90 .41 1.00 .45 1.67 .76 1.68 .76 2.00 .91 2.41 1.09 2.49 1.13 2.60 1.18 2.90 1.32 3.35 1.52 3.60 1.63 3.75 1.70 3.90 1.77 5.90 2.68 6.00 2.72 6.20 2.81 6.60 3.00 9.20 4.17 9.35 4.24 9.68 4.4 Reducer .24 .11 .25 .11 .31 .14 .33 .15 .36 .16 .42 .19 .46 .21 .49 .22 .52 .24 .55 .25 .61 .28 .66 .30 .89 .40 .90 .41 1.02 .46 1.20 .54 1.55 .70 1.75 .79 2.02 .92 2.25 1.02 2.45 1.11 2.60 1.18 2.70 1.22 2.75 1.25 Reducer .27 .12 .29 .13 .31 .14 .6 .16 .41 .19 .46 .21 .51 .23 .59 .27 .66 .30 .74 .34 .81 .37 .90 .41 1.30 .59 1.52 .69 1.78 .81 1.84 .83 2.10 .95 2.31 1.05 2.43 1.10 2.59 1.17 2.91 1.32 3.10 1.41 3.43 1.6 DOUBLE EXTRA STRONG Tee 1.12 .51 1.14 .52 1.19 .54 1.95 .88 2.02 .92 2.14 .97 2.84 1.29 2.93 1.33 3.08 1.40 3.26 1.48 4.26 1.93 4.41 2.00 4.65 2.11 5.18 2.35 8.00 3.63 8.40 3.81 9.13 4.14 9.18 4.16 12.0 5.4 12.2 5.5 12.5 5.7 Reducer 2.50 1.13 2.50 1.13 2.60 1.18 2.61 1.18 2.72 1.23 2.894 1.94 2.90 1.32 2.96 1.34 2.99 1.36 3.02 1.37 3.06 1.39 3.12 1.42 3.20 1.45 3.31 1.50 3.40 1.54 3.46 1.57 3.52 1.60 3.64 1.65 3.75 1.70 3.9 1.77 4.00 1.8 INCHES POUNDS MILLIMETRES KILOGRAMS VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] *REDUCING TEES & REDUCERS CONCENTRIC AND ECCENTRIC continued Outlet or Reduced End Run NPS NPS DN DN 2 1/2 65 3 1/2 #1 14 90 32 1 1/2 40 2 50 2 1/2 65 3 80 #▲ 1 4 100 25 1 1/2 40 2 50 2 1/2 65 3 80 3 1/2 90 5 2 125 50 2 1/2 65 3 80 3 1/2 90 4 100 #▲ 2 6 150 50 2 1/2 65 3 80 3 1/2 90 4 100 5 125 #▲ 3 8 200 80 3 1/2 90 4 100 5 125 6 150 #▲ 3 10 250 80 4 100 5 125 6 150 8 200 Nominal Center-to-End Tees Run Outlet C 3.38 86 3.75 95 3.75 95 3.75 95 3.75 95 4.12 105 4.12 105 4.12 105 4.12 105 4.12 105 4.88 124 4.88 124 4.88 124 488 124 4.88 124 5.62 143 5.62 143 5.62 143 5.62 143 5.62 143 5.62 143 7.00 178 7.00 178 7.00 178 7.0 178 7.0 178 8.5 216 8.5 216 8.5 216 8.5 216 8.5 216 M 3.25 83 3.12 79 3.25 83 3.50 89 3.62 92 3.38 86 3.50 89 3.75 95 3.88 98 4.00 102 4.12 105 4.25 108 4.38 111 4.50 114 4.62 117 4.75 121 4.75 121 4.88 124 5.00 127 5.12 130 5.38 137 6.00 152 67.00 152 6.12 156 6.38 162 6.62 168 7.25 184 7.25 184 7.50 191 7.62 194 8.00 203 Nominal Length of Reducers L 3.5 89 4.00 ■ 102 4.00 102 4.00 102 4.00 102 4.00 102 4.00 ■ 102 4.00 102 4.00 102 4.00 102 4.00 102 4.00 102 5.00 127 5.00 127 5.00 127 5.00 127 5.00 127 ■ 5.50 140 5.50 140 5.50 140 5.50 140 5.50 140 5.50 140 ■ 6.00 152 6.00 152 6.00 152 6.0 152 6.0 152 7.0 ■ 178 7.0 178 7.0 178 7.0 178 7.0 178 APPROXIMATE WEIGHTS STANDARD WEIGHT Tee 6.0 2.72 7.5 3.40 7.5 3.40 8.2 3.72 8.3 3.76 9.5 4.31 12.0 5.44 12.0 5.44 9.4 4.26 9.4 4.26 9.5 4.31 10.0 4.35 14.5 6.6 14.5 6.6 14.5 6.6 15.0 6.8 15.1 6.9 19.5 8.9 20.0 9.1 21.0 9.5 21.5 9.8 21.5 9.8 23 10.4 38 17.2 39 17.7 40.5 18.4 41.0 18.6 44.0 20 72.0 32 75.0 34 75.0 34 79.0 36 79.2 36 Reducer 2.64 1.20 2.68 68.1 2.72 1.23 2.77 1.26 2.82 1.28 2.88 1.31 2.91 73.9 2.94 1.33 2.97 1.35 3.02 1.37 3.08 1.40 3.12 1.42 3.28 1.49 3.36 1.52 3.55 1.61 3.69 1.67 3.81 1.74 4.28 1.94 4.40 2.00 4.64 2.10 4.81 21.8 5.06 2.30 5.32 2.41 7.29 3.31 7.65 3.47 8.12 3.68 8.53 3.8 9.02 4.1 11.0 5.0 12.5 5.6 15.0 6.8 17.0 7.7 21.0 9.5 EXTRA STRONG Tee 7.5 3.40 11.0 5.0 11.2 5.1 12.0 5.4 12.6 5.7 13.0 5.9 13.0 5.9 13.6 6.2 14.2 6.4 14.9 6.8 18.0 8.1 18.2 8.3 18.8 8.5 20.0 9.1 22.5 10.2 30 13.6 31 14.1 31.5 14.3 32.0 14.5 32.5 14.7 33.0 15 63 29 63 29 64 29 65 30 65 30 90 41 92 41 96 43 98 44 100 45 Reducer 2.90 1.32 3.10 78.7 3.20 1.45 3.35 1.52 3.50 1.59 4.00 1.81 4.10 104.1 4.30 1.95 4.50 2.04 4.60 2.1 4.75 2.2 4.90 2.2 5.30 2.4 5.50 2.5 5.75 2.6 6.10 2.8 6.50 3.0 7.75 3.5 8.25 3.7 8.75 4.0 9.50 4.3 11.00 5.0 12.00 5.4 14.50 6.6 16.0 7.3 16.5 7.5 17.0 7.7 18.5 8.4 21.0 9.5 23.0 10.4 25.0 11.3 28.0 12.7 29.5 13.4 SCHEDULE 160 Tee 10.20 4.6 16.8 7.6 17.2 7.8 17.7 8.0 18.5 8.4 30.5 13.8 31.0 14.1 31.7 14.4 33.2 15.1 45.5 20.6 48.2 21.9 48.9 22.2 50.5 22.9 52.6 23.9 98.7 44.8 101 46 104 47 181 82 183 83 190 86 193 88 208 94 DOUBLE EXTRA STRONG Reducer 3.75 1.7 5.40 2.5 5.59 2.5 5.64 2.6 5.81 2.6 7.95 3.6 9.00 4.1 10.5 4.8 11.7 5.3 13.0 5.9 15.0 6 17.5 7.9 19.1 7 28.5 12.9 33.0 15.0 37.0 17 41.0 19 45.0 20.5 49.0 22 53.0 24 59.0 27 *Wall thickness and other pipe size data are in accordance with ASME/ANSI B36.10M. INCHES POUNDS MILLIMETRES KILOGRAMS 11 de 17 Tee 13.5 6.1 16.3 7.4 16.7 7.6 17.5 7.9 18.5 8.4 21.5 9.8 22.0 10.0 22.7 10.3 23.3 10.6 24.5 11 35.6 16.2 36.2 16.4 37.2 17 38.0 17 39.0 18 53.0 24 56.6 26 57.5 26 58.5 27 59.3 27 62.1 28 96.5 44 97.5 44 100 45.5 104 47 - Reducer 4.25 1.9 4.72 119.9 5.30 2.4 5.64 2.6 5.92 2.7 6.20 2.8 6.53 3.0 6.72 3.1 6.89 3.1 7.10 3.2 7.40 3.4 10.5 4.8 12.2 5.5 13.7 6.2 14.9 6.8 15.5 7.0 17.5 7.9 18.2 8.3 19.0 8.6 19.7 89 21.0 9.5 25.7 11.7 27.1 12.3 28.5 13 29.7 13.5 33.0 15 41.0 19 44.0 20 48.0 22 52.0 24 VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] REDUCING TEES & REDUCERS CONCENTRIC AND ECCENTRIC continued Outlet or Reduced End NPS NPS DN DN #▲4 12 300 100 5 125 6 150 8 200 10 250 ▲ 14 6 350 150 8 200 10 250 12 300 ▲ 16 6 400 150 8 200 10 250 12 300 14 350 ▲ 18 8 450 200 10 250 12 300 14 350 16 400 20 ▲ 8 ▲ 10 500 200 250 12 300 14 350 16 400 18 450 22 ▲ 10 ▲ 12 550 250 300 14 350 16 400 18 450 20 500 24 ▲ 10 ▲ 12 ▲ 14 600 250 300 350 16 400 Nominal Center-to-End Tees Run Outlet C 10.0 254 10.0 254 10.0 254 10.0 254 10.0 254 11.0 279 11.0 279 11.0 29 11.0 279 12.0 305 12.0 305 12.0 305 12.0 305 12.0 305 13.5 343 13.5 343 13.5 343 13.5 343 13.5 343 15.0 381 15.0 381 15.0 381 15.0 381 15.0 381 15.0 381 16.5 419 16.5 419 16.5 419 16.5 419 16.5 419 16.5 419 17.0 43 17.0 432 17.0 432 17.0 432 M 8.50 216 8.50 216 8.63 219 9.00 229 9.50 241 9.38 238 9.75 248 10.13 257 10.63 270 1038 264 10.75 273 11.13 283 11.63 295 12.00 305 11.75 298 12.13 308 12.63 321 13.00 330 13.00 330 12.75 324 13.13 333 13.63 346 14.00 356 14.00 356 14.50 368 14.13 359 14.63 371 15.00 381 15.00 381 15.50 394 16.00 406 15.13 384 15.63 397 16.00 406 16.00 406 Nominal Length of Reducers L 8.0 ■ 203 8.0 203 8.0 203 8.0 203 8.0 203 13.0 330 13.0 330 13.0 330 13.0 330 14.0 356 14.0 356 14.0 356 14.0 356 14.0 356 15.0 381 15.0 381 15.0 381 15.0 381 15.0 381 ■ 20.0 508 20.0 508 20.0 508 20.0 508 20.0 508 20.0 508 20.0 ■ 508 20.0 508 20.0 508 20.0 508 20.0 508 20.0 508 ■ 20.0 508 20.0 508 20.0 508 20.0 508 APPROXIMATE WEIGHTS STANDARD WEIGHT Tee 101 46 105 47 105 47 105 47 130 59 146 66 147 66 149 67 152 68 179 81 186 84 196 88 211 95 219 99 236 106 249 112 261 117 270 122 282 127 294 133 307 139 316 143 329 149 341 155 355 161 366 166 382 173 395 179 412 187 429 195 443 201 451 25 455 206 268 12 479 217 Reducer 23.0 10.4 25.0 11.3 28.0 12.6 30.0 13.5 32.0 14.4 58.0 26 59.5 27 61.0 27 64.0 29 69.0 31 72.0 32 75.0 34 80 36 81 36 82 37 84 38 85 38 110 50 117 53 123 56 126 57 128 58 133 60 140 64 143 65 149 68 152 69 154 70 156 7117 12 de EXTRA STRONG SCHEDULE 160 Tee 132 59 134 60 136 61 140 63 148 67 184 83 187 84 190 86 196 88 231 104 236 106 248 111 259 117 261 117 302 136 311 140 332 149 340 153 352 158 379 172 385 175 401 182 418 190 432 196 449 204 471 214 479 217 487 221 499 226 522 237 540 245 556 252 562 255 571 259 585 285 Tee 301 137 305 139 308 140 315 143 332 151 410 186 435 197 470 213 495 225 540 245 565 256 610 277 675 340 750 340 - Reducer 32 14.5 33 15 34 15.5 36 16 39 18 59 27 61 28 62 28 75 34 89 40 95 43 101 48 106 48 112 51 115 52 117 53 119 54 149 68 153 69 158 72 165 75 168 76 171 78 175 79 181 82 183 83 187 85 191 87 194 88 INCHES Reducer 72.0 32.5 75.0 34 83.0 38 94.0 43 110 50 125 57 137 62 153 69 168 76 190 86 220 120 265 120 - DOUBLE EXTRA STRONG Tee - Reducer 67.0 30 69.0 31 72.0 33 75.0 34 - POUNDS MILLIMETRES KILOGRAMS VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] REDUCING TEES & REDUCERS CONCENTRIC AND ECCENTRIC continued Nominal APPROXIMATE WEIGHTS Length of Run Outlet STANDARD WEIGHT EXTRA STRONG SCHEDULE 160 Reducers NPS NPS C M L Tee Reducer Tee Reducer Tee Reducer DN DN 24 18 17.0 16.50 20.0 490 160 597 198 600 450 432 419 508 222 73 271 90 20 17.0 17.00 20.0 506 165 614 205 500 432 432 508 230 75 279 93 19.5 16.63 534 665 26 #▲ 12 ■ 24.0 650 300 495 422 610 242 302 ▲ 14 19.5 17.00 547 679 ■ 24.0 350 495 432 610 248 308 ▲ 16 19.5 17.00 24.0 561 691 400 495 432 610 254 313 18 19.5 17.50 24.0 575 170 714 215 450 495 444 610 261 77 324 98 20 19.5 18.00 24.0 592 172 733 221 500 495 457 610 268 78 332 100 22 19.5 18.50 24.0 623 174 756 229 550 495 470 610 283 79 343 104 24 19.5 19.00 24.0 643 177 780 235 600 495 483 610 292 80 354 107 ▲ 14 22.0 19.0 675 865 30 ■ 24.0 750 350 559 483 610 305 392 ▲ 16 22.0 19.0 690 895 ■ 24.0 400 559 483 610 313 406 ▲ 18 22.0 19.5 721 932 ■ 24.0 450 559 495 610 327 423 20 22.0 20.0 744 180 978 264 ■ 24.0 500 559 508 610 337 82 444 120 22 22.0 20.5 24.0 768 200 1031 270 550 559 521 610 348 91 468 122 24 22.0 21.0 24.0 792 215 1050 275 600 559 533 610 359 98 476 125 26 22.0 21.5 24.0 845 235 1085 282 650 559 546 610 383 107 492 128 ▲ 16 26.5 22.0 1280 1220 36 ■ 24.0 900 400 673 559 610 581 553 ▲ 18 26.5 22.5 1305 1310 ■ 24.0 450 673 572 610 592 594 ▲ 20 26.5 23.0 1360 319 1395 320 ■ 24.0 500 673 584 610 617 141 633 145 ▲ 22 26.5 23.5 1390 146 ■ 24.0 550 673 597 610 631 665 24 26.5 24.0 24.0 1410 340 1510 360 600 673 610 610 640 154 685 163 26 26.5 24.5 24.0 1425 1555 650 673 622 610 646 705 30 26.5 25.0 24.0 1432 375 1595 385 750 673 635 610 650 170 723 175 ▲ 18 30.0 25.5 24.0 1550 1770 42 1100 450 762 648 610 703 803 ▲ 20 30.0 26.0 24.0 1590 1810 500 762 660 610 721 821 ▲ 22 30.0 26.0 24.0 1630 1850 550 762 660 610 739 839 ▲ 24 30.0 26.0 24.0 1645 390 1865 405 600 762 660 610 745 177 846 184 ▲ 26 30.0 27.5 24.0 1665 425 1890 440 650 762 698 610 755 193 857 200 30 30.0 28.0 1690 445 1910 465 ■ 24.0 750 762 711 610 767 202 866 211 36 30.0 28.0 1710 470 1935 495 ■ 24.0 900 762 711 610 776 213 878 225 When ordering Reducing Tees, specify the run pipe size first, followed by the outlet size. Example 2 x 2 x 1. When ordering Reducers, specify the Large End first, followed by the Small End size and the type. Example: 2 x 1 eccentric. These fittings are also available in other sizes and/or wall thicknesses. Wall thickness and other pipe size data are in accordance with ASME/ANSI B36.10M. Refer to page 6. Outlet or Reduced End Nominal Center-to-End Tees #This size of Reducing Outlet Tee is not covered in ANSI B16.9 ▲ This size of Reducer is not covered in ANSI B16.9 ■ This size of Reducer supplied concentric, only. INCHES POUNDS MILLIMETRES KILOGRAMS DOUBLE EXTRA STRONG Tee - Reducer - Tees size 20 NPS (DN 500) and smaller, and Reducers size 24 NPS (DN 600) and smaller, are normally furnished as seamless. Larger size non-seamless Tees and Reducers are produced from X-rayed, stress relieved welded pipe. Welds are 100% radiographed in accordance with the requirements of the ASME Boiler & Pressure Vessel Code. 13 de 17 VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] CAPS Standard, Extra Strong, Schedule 160, Double Extra Strong Carbon and ferritic alloy steel, ASTM A-234 ASME/ANSI B16.9 STANDARD WEIGHT NPS 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 3 1/2 4 5 6 8 10 12 14 16 18 20 22 24 26 30 36 42 Outside Diameter Wall Nominal at Bevel Thickness Length (1) DN E O.D. T .840 .109 1.0 15 21 2.77 25 1.050 .113 1.0 20 27 2.87 25 1.315 .133 1.5 25 33 3.38 38 1.660 .140 1.5 32 42 3.56 38 1.900 .145 1.5 40 48 3.68 38 2.375 .154 1.5 50 60 3.91 38 2.875 .203 1.5 65 73 5.16 38 3.500 .216 2.0 80 89 5.49 51 4.000 .226 2.5 90 102 5.74 64 4.500 .237 2.5 100 114 6.02 64 5.563 .258 3.0 125 141 6.55 78 6.625 .280 3.5 150 168 7.11 89 8.625 .322 4.0 200 219 8.18 102 10.750 .365 5.0 250 273 9.27 127 12.750 .375 6.0 300 324 9.53 152 14.000 .375 6.5 350 356 9.53 165 16.000 .375 7.0 400 405 9.53 178 18.000 .375 8.0 450 457 9.53 203 20.000 .375 9.0 500 508 9.53 229 22.000 .375 10.0 550 559 9.53 254 24.000 .375 10.5 600 610 9.53 267 26.000 .375 10.5 650 680 9.53 267 30.000 .375 10.5 750 762 9.53 267 36.000 .375 10.5 900 914 9.53 267 42.000 .375 12.0 1100 1067 9.53 305 EXTRA STRONG Wall Nominal Approx. Thickness Length (1) Weight T E .1 .147 1.0 .05 3.73 25 .1 .154 1.0 .05 3.91 25 .2 .179 1.5 .09 4.55 38 .3 .191 1.5 .14 4.85 .38 .4 .200 1.5 .18 5.08 38 .6 .218 1.5 .27 5.54 38 .9 .276 1.5 .41 7.01 38 1.4 .300 2.0 .64 7.62 51 2.2 .318 2.5 1.0 8.08 64 3.0 .337 2.5 1.4 8.56 64 4.5 .375 3.0 2.0 9.53 76 7.2 .432 3.5 3.3 10.97 89 12.0 .500 4.0 5.4 12.70 102 18 .500 5.0 8.2 12.70 127 27 .500 6.0 12 12.70 152 33 .500 6.5 15 12.70 185 42 .500 7.0 19 12.70 178 55 .500 8.0 25 12.70 203 68 .500 9.0 31 12.70 229 86 .500 10.0 39 12.70 254 96 .500 10.5 44 12.70 267 110 .500 10.5 50 12.70 267 132 .500 10.5 60 12.70 267 192 .500 10.5 87 12.70 267 225 .500 12.0 102 12.70 305 SCHEDULE 160 DOUBLE EXTRA STRONG Wall Nominal Wall Nominal Approx. Thickness Length Approx. Thickness Length Approx. (1) (1) Weight T E Weight T E Weight .09 .04 .1 .05 .2 .250 1.5 .4 .38 1.5 1.0 .09 6.35 38 .2 9.09 38 .45 .4 .250 1.5 .5 .382 1.5 1.5 .18 6.35 38 .2 9.70 38 .68 .5 .281 1.5 .6 .400 1.5 2.5 .23 7.14 38 .3 10.16 38 1.1 .8 .344 1.75 1.25 .436 1.75 3.0 .36 8.74 44 .6 11.07 44 1.4 1.0 .375 2.0 1.75 .552 2.0 4.0 .45 9.53 51 .8 14.02 51 1.8 2.0 .438 2.5 2.9 .600 2.5 6.0 .91 11.13 64 1.3 15.24 64 2.7 (2) .636 3.0 7.5 2.8 (2) 16.15 76 3.4 1.3 3.5 .531 3.0 5.9 .674 3.0 9.0 1.6 13.49 76 2.7 17.12 76 4.1 5.8 .625 3.5 10 .750 3.5 13.5 2.6 15.88 89 4.5 19.05 89 5.1 9.2 .719 4.0 15 .864 4.0 18 4.2 18.26 102 6.8 21.95 102 8.2 15 .906 5.0 31 .875 5.0 26 6.8 23.01 127 14 22.23 127 12 25 1.125 6.0 57 11.3 28.58 152 26 35 1.312 7.0 95 16 33.32 178 43 43 1.406 7.5 130 20 35.71 191 59 54 1.594 8.0 165 25 40.49 203 75 73 33 (1) Dimensional tolerances. 90 (2) This size not covered in ASME/ANSI B36.10M. 41 dimensions of wrought steel pipe. 110 These fittings are also available in other sizes and/or wall 50 thicknesses. 127 58 145 66 175 79 235 107 295 134 14 de 17 INCHES POUNDS MILLIMETRES KILOGRAMS VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] SADDLES Carbon and ferritic alloy steel, ASTM A-234 A-515 Gr. 70 A-106 Gr. B Nominal Size of Nozzle NPS STANDARD WEIGHT Nominal Header Size Approx. Weight NPS DN 1/4 DN 1/4 - 48 6 1/2 6 - 1200 1/2 - 48 15 3/4 15 - 1200 3/4 - 48 20 1 20 - 1200 1 - 48 25 1 1/4 25 - 1200 1 1/4 - 48 32 1 1/2 32 - 1200 1 1/2 - 48 40 2 40 - 1200 2 - 48 50 2 1/2 50 - 1200 2 1/2 - 48 65 3 65 - 1200 3 - 48 80 3 1/2 80 - 1200 3 1/2 - 48 90 4 90 - 1200 4 - 48 100 5 100 - 1200 5 - 48 125 6 125 - 1200 6 - 48 150 8 150 - 1200 8 - 48 200 10 200 - 1200 10 - 48 250 12 250 - 1200 12 - 48 300 14 300 - 1200 14 - 48 350 16 350 - 1200 16 - 48 400 18 400 - 1200 18 - 48 450 20 450 - 1200 20 - 48 500 24 500 - 1200 24 - 48 600 600 - 1200 A .63 16 .81 21 .81 21 .88 22 1.25 32 1.50 38 1.50 38 1.63 41 1.50 38 1.75 44 1.75 44 2.00 51 2.50 64 2.75 70 3.00 76 3.50 89 4.00 102 4.00 102 4.25 108 5.25 133 6.00 152 B .75 19 .88 22 1.25 32 1.31 33 1.38 35 1.75 44 2.00 51 2.13 54 2.25 57 2.25 57 2.50 64 3.00 76 3.75 95 4.25 108 5.00 127 5.50 140 6.00 152 7.50 191 8.00 203 8.00 203 9.50 241 Saddles are used to reinforce intersecting welded junctions and are not intended to be used as pressure containing fittings. A vent hole prevents pressure build-up of welding gasses between saddle and header. Saddles are made from welding grade seamless steel, and are fully normalized. 15 de 17 C .19 4.8 .19 4.8 .19 4.8 .19 4.8 .19 4.8 .25 6.4 .25 6.4 .28 7.1 .31 7.9 .31 7.9 .38 7.9 .38 9.7 .44 11.2 .44 11.2 .44 11.2 .44 11.2 .44 11.2 .44 11.2 .50 12.7 .50 12.7 .50 12.7 D .22 5.6 .22 5.6 .22 5.6 .22 5.6 .22 5.6 .31 7.9 .31 7.9 .31 7.9 .41 10.4 .41 10.4 .38 9.7 .44 11.2 .50 12.7 .50 12.7 .50 12.7 .50 12.7 .50 12.7 .56 14.2 .63 16.0 .63 16.0 .63 16.0 .5 .23 .5 .23 .75 .34 1.0 .45 1.0 .45 2.0 .90 3.0 1.35 4.0 1.80 5.0 2.25 6.0 2.70 7.0 3.15 12.0 5.40 22.0 10 33.0 15 45.0 20 57.0 26 76 34 107 48 152 69 163 73 248 112 INCHES POUNDS MILLIMETRES KILOGRAMS VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] WELDING *LATERALS Standard Weight and Extra Strong Carbon and ferritic alloy steel, STANDARD WEIGHT NPS DN 1 25 1 1/4 32 1 1/2 40 2 50 2 1/2 65 3 80 3 1/2 90 4 100 5 125 6 150 8 200 10 250 12 300 14 350 16 400 18 450 20 500 24 600 A 5.75 146 6.25 159 7.00 178 8.00 203 9.50 241 10.00 245 11.50 292 12.00 305 13.50 343 14.50 368 17.50 445 20.50 521 24.50 622 27.00 686 30.00 762 32.00 813 35.00 889 40.50 1029 B 1.75 45 1.75 45 2.00 51 2.50 64 2.50 64 3.00 76 3.00 76 3.00 76 3.50 89 3.50 89 4.50 114 5.00 127 5.50 140 6.00 152 6.50 165 7.00 178 8.00 203 9.00 229 EXTRA STRONG Approx. Weight 1.85 .83 2.60 1.17 3.45 1.55 4.95 2.23 9.5 4.28 12.0 5.40 17.7 8 19.5 9 29.2 13 41.7 19 77.5 35 13 59 190 86 225 101 290 131 340 153 412 185 554 249 A 6.50 165 7.25 184 8.50 216 9.00 229 10.50 267 11.00 279 12.50 318 13.50 343 15.00 381 17.50 445 20.50 521 24.00 610 27.50 699 31.00 787 34.50 876 37.50 953 40.50 1029 47.50 1207 B 2.00 51 2.25 57 2.50 64 2.50 64 2.50 64 3.00 76 3.00 76 3.00 76 3.50 89 4.00 102 5.00 127 5.50 140 6.00 152 6.50 165 7.50 191 8.00 203 8.50 216 10.00 254 Approx. Weight 2.75 1.24 4.10 1.85 5.35 2.41 7.80 3.51 13.7 6.17 19.2 8.6 26. 12 34.6 16 51.4 23 82.3 37 135 61 199 90 279 126 344 155 432 194 551 248 637 287 903 406 Laterals are fabricated from Grade B standard and extra strong seamless pipe. The working pressure of any fabricated Lateral must be rated at only 40% of the allowable working pressure established for the pipe from which the lateral is made. Dimensions and price of 100% strength laterals will be furnished on request. Laterals are also available in other materials, sizes and/or wall thicknesses. *Reducing laterals can be supplied withthe same centre-to-end dimensions as shown above. INCHES POUNDS MILLIMETRES KILOGRAMS 16 de 17 VEMACERO, C.A. TELF (251) 269-2898 / 2487 [email protected] BUTT WELDING ENDS ASME/ANSI B16.9 For fittings with wall thickness equal to that of the pipe to which they are to be welded. Nominal Wall Thickness (T) End Preparation Less than x* Cut square or slightly camfer, at mfr’s option x* to .88 incl. (22) Plain bevel as in sketch (a). More than .88 (22) Compound bevel as in sketch (b). x* = 0.19 (5) for carbon steel or ferritic alloy steel and 0.12 (4) for austenitic alloy steel. Millimetres in brackets. SIZE RANGES ASME/ANSI B16.9 The following size ranges of Welding Fittings are covered by ANSI B16.9. “Steel Butt-Welding Fittings.” 90˚ Long Radius Elbows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2" to 48" incl. 45˚ Long Radius Elbows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2" to 48" incl. 90˚ Long Radius Reducing Elbows . . . . . . . . . . . . . . . . . . . . . 2" to 24" incl. Tees, Straight and Reducing Outlets . . . . . . . . . . . . . . . . . . . 1/2" to 48" incl. Crosses, Straight and Reducing Outlets . . . . . . . . . . . . . . . . 1/2" to 48" incl. Welding Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2" to 48" incl. Lap-Joint Stub Ends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2" to 24" incl. Welding Reducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4" to 48" incl. Long Radius Return Bends . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2" to 24" incl. INFORMATION contained in this catalogue, we do not accept responsibility for the consequences of any errors, nor for the effects of any subsequent changes made by the various sources of data. 17 de 17 SWF