Renewable Resources - Sust

Anuncio

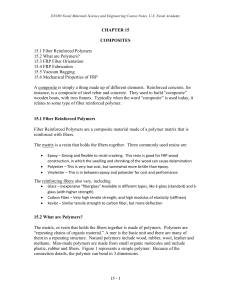

Use of pine resin derivatives as plastic components” Juan López Martínez. UPVa “Use of pine resin derivatives as plastic components” Proyecto Investigador RESEARCH GROUP Plastics processing and characterization Responsible Juan López Martínez Polytechnic University of Valencia Campus of Alcoy [email protected] Sustainable Materials -Recycled Materials -Biodegradable Materials -Natural Materials Transformation Processes -Product Development -Injection Process -Rapid Prototyping MATERIAL SCIENCE EXTRACTION SYNTHESIS CHEMISTRY MODIFICATION: FORMULATION, ADITIVATION CHARACTERIZATION APLICATION REUTILIZATION, RECYCLED Field of Research Finantial support 80% is from Companies Manufacturing Companies: From small size to transnational. Special relationship with Technological Institutes: -AIJU (Toy) -AITEX (Textil) --AIMPLAS (Plastic) Group: • 8 Proffesors • 8 Researchers Contributors: • Rafael Balart (Biocomposites) • Santiago Ferrándiz (Product Development) • Marina Patricia Arrieta (Natural Aditives) Sustainable “Materials” Biodegradable Plastics Plastics comming Hydrodegradable, Photo. from natural resources Plastics Plastics Recycling Examples of materials polimeric Non renewable resources Renewable Resources Synthetics Naturals Traditional plastics: Polyethilene, Polypropylene Ivory Cellulose Acetate Natural Rubber Table I. Polimeric materials clasification Plastics coming from renewables resources. The raw material is a product with vegetal or animal origin “cultivated” Adventages-Disadvantages Promoting the philosofy of waste Life cycle Food consumption Versatility in production Plastics coming from natural renewable resources Its apear because of: Oil one day will run out Less ambient impact Versatility Production Environmental problems: Plastic’s Island INVESTMENT IN NATURAL AND RECYCLED POLYMERS PRESENCE IN PLASTICS MATERIALS BASE POLYMER TERMOPLASTHICS: Poly(Lactic acid) (PLA) THERMOSETS: Bio-resin ADDITIVES MAJORITY ADDITIVES: 5-20% MINORITY ADITIVES: <5% THERMOPLASTICS Most common: PLA, PHB, Thermoplastic starch. Historically: Celullose and its derivatives: Nitrate, Acetate and Butirate. LIGNINE BASED POLYMERS Liquid wood Pine resin’s derivatives There are published studies at theoretical level Bicu, I., & Mustaţă, F. (1999). Diels-Alder polymerization of some derivatives of abietic acid. Die Angewandte Makromolekulare Chemie, 264(1), 21-29. Pine resin’s Thermoplastics derivatives Kim, W. S., Byun, K. R., Lee, D. H., Min, K. E., Park, L. S., Seo, K. H., ... & Park, S. Y. (2003). Synthesis of photocrosslinkable polymers using abietic acid and their characterization. Polymer journal, 35(5), 450-454. Thermoplastics derivatives from pine resin Viability Big companies are necesary. Greats efforts in research. Profitability in the medium to the long therm. Relapse in some clasics: cellulosics Strong competiton with industrial agriculture Termosheets: “Bioresinas” Li, C., Liu, X., Zhu, J., Zhang, C., & Guo, J. (2013). Synthesis, Characterization of a Rosin-based Epoxy Monomer and its Comparison with a Petroleum-based Counterpart. Journal of Macromolecular Science, Part A, 50(3), 321-329. FUKAGAWA, Kiyotaka, et al. POLYMER DERIVED FROM DEHYDROABIETIC ACID AND USES THEREOF. U.S. Patent No 20,130,022,907, 24 Ene. 2013. TANGUAY, Christopher M., et al. BIORESIN COMPOSITION FOR USE IN FORMING A RIGID POLYURETHANE FOAM ARTICLE. U.S. Patent Application 12/796,737, 9 Jun. 2010. TransFurans Chemicals bvba Industriepark Leukaard 2 B-2440 Geel T: +32-14/57.87.47 F: +32-14/57.87.67 E: [email protected] Furfural Furfural is the base chemical of today’s furan chemistry. It can be produced from virtually any agricultural waste material by acid catalysed digestion of hemicelluloses. This process can be considered as one of the oldest forms of chemical biorefinery. About 70% of the world production of FF is converted to furfuryl alcohol. Furfural is also used as an extractant, solvent and chemical feedstock for other furan chemicals. Furfuryl alcohol (FA) Furfuryl alcohol is the main derivative of furfural produced by a catalytic hydrogenation. This bio-alcohol finds a large application base in the formulation of foundry and refractory thermoset resins. R. CHECA USA COMPARATIVE PRICES: APPLICATION: SURFBOARDS Thermosets derivatives from pinoe resin Viability No big instalation Can start with simples uses Requires research resources, but some of it exists. Profitability in the short-medium term. Growing market. Great versatility and advantages as active products: Pine resins Any drawbacks… MAJORITY ADITIVES IN PLASTICS One of the mainly uses Catalogo LURESA Other Aditives: Plasticizers s l Toy Industry experience Resistencia Maxima 14 12 10 8 6 4 2 CIT BEN EFA2 EFA1 ELO DOTP PGA DINCH DOA DINP DEHP 0 Comparison of the Tensile Strength of PVC plastisols, plasticizers derived from o-phthalates, substitutes and synthetic plasticizers coming from natural sources. EDIBLE FILMS Functional properties of Sodium and Calcium Caseinate antimicrobial active films Aditives derived from pine resin Viability Is the star product that have to be maintained. Facilities and Experiency ara available. Can start with small applications Non big resources in research (availables) Short term profitability Growing market Great versatility and advantages as active products: Pine resins Another aditives FUENTES-AUDÉN, Cristina, et al. Formulation of new synthetic binders: Thermomechanical properties of resin/recycled polymer blends. Polymer Engineering & Science, 2011, vol. 52, no 2, p. 242-249. Gonzalez, Miguel A., et al. Synthesis and biological evaluation of abietic acid derivatives. European journal of medicinal chemistry, 2009, vol. 44, no 6, p. 2468-2472. Minority derivatives of pine resine Viability High grade value-added products. Can lead to alternative products: Insecticides, parapharmacy… Can start with small applications and customized distribution Requires high research resources (available) Profitability at medium-long term Growing market Great versatility and advantages as active products : Pine resins Strategies Thermoplastic Polymers: Knowing the long-term posibilities and the existence of interesting products: waxes and dyes Thermosets polymers: Research efforts in an emerging field Additives majority: Keep positioning and reinforce it with new uses Additives minority: derived from pine resin: Leverage external research. TOYS AND PLEISURE SUBSTITUCION FORMALDEHIDOS EN COCHES ALTA GAMA EL “EQUIPO NASAL” DE AUDI ESTUDIA LOS OLORES EN EL AUTOMÓVIL TEXTILES ANTIBACTERIANOS TINTAS ECOLOGICAS (ECOLOGICAL INKS) LAST SECTOR Reason to fight for the production Is a basic resours and also our resource. Is a wealth of less favored areas Is a natural renewable resource Reason to fight for the production Is a resource that generates knowledge and new possibilities HIELO HELADOS JUGUETES PLASTICO ¿? GRACIAS POR ESCUCHARME THANKS FOR YOUR ATTENTION Gracias Grâce Obrigado Thanks