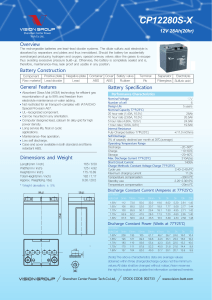

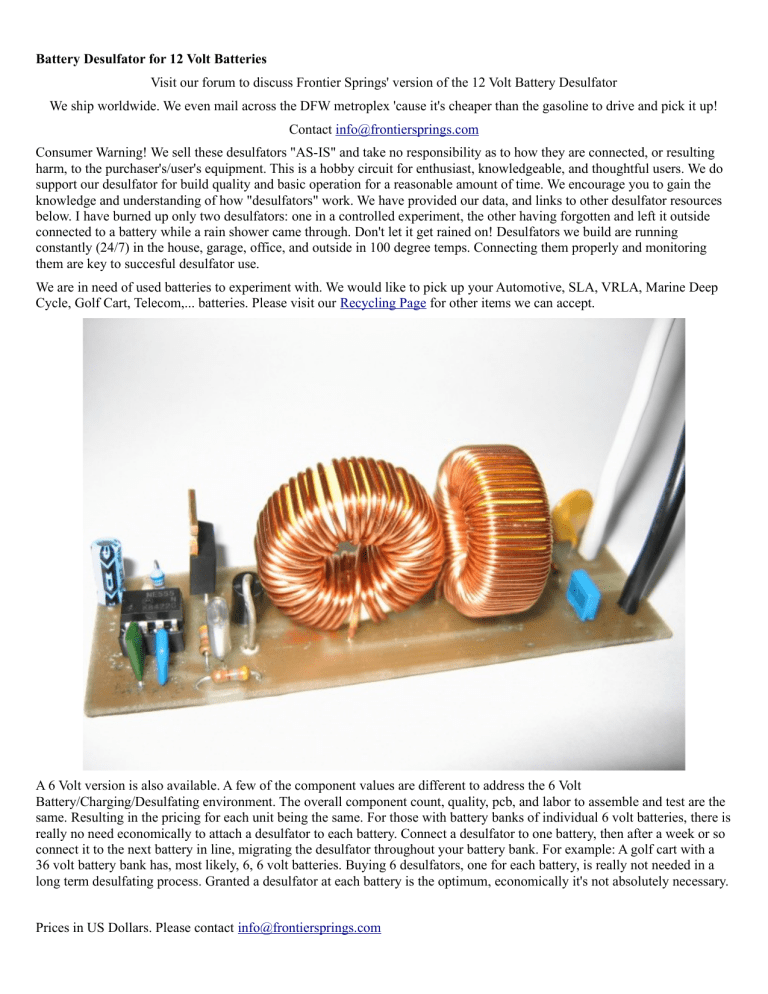

Battery Desulfator for 12 Volt Batteries Visit our forum to discuss Frontier Springs' version of the 12 Volt Battery Desulfator We ship worldwide. We even mail across the DFW metroplex 'cause it's cheaper than the gasoline to drive and pick it up! Contact [email protected] Consumer Warning! We sell these desulfators "AS-IS" and take no responsibility as to how they are connected, or resulting harm, to the purchaser's/user's equipment. This is a hobby circuit for enthusiast, knowledgeable, and thoughtful users. We do support our desulfator for build quality and basic operation for a reasonable amount of time. We encourage you to gain the knowledge and understanding of how "desulfators" work. We have provided our data, and links to other desulfator resources below. I have burned up only two desulfators: one in a controlled experiment, the other having forgotten and left it outside connected to a battery while a rain shower came through. Don't let it get rained on! Desulfators we build are running constantly (24/7) in the house, garage, office, and outside in 100 degree temps. Connecting them properly and monitoring them are key to succesful desulfator use. We are in need of used batteries to experiment with. We would like to pick up your Automotive, SLA, VRLA, Marine Deep Cycle, Golf Cart, Telecom,... batteries. Please visit our Recycling Page for other items we can accept. A 6 Volt version is also available. A few of the component values are different to address the 6 Volt Battery/Charging/Desulfating environment. The overall component count, quality, pcb, and labor to assemble and test are the same. Resulting in the pricing for each unit being the same. For those with battery banks of individual 6 volt batteries, there is really no need economically to attach a desulfator to each battery. Connect a desulfator to one battery, then after a week or so connect it to the next battery in line, migrating the desulfator throughout your battery bank. For example: A golf cart with a 36 volt battery bank has, most likely, 6, 6 volt batteries. Buying 6 desulfators, one for each battery, is really not needed in a long term desulfating process. Granted a desulfator at each battery is the optimum, economically it's not absolutely necessary. Prices in US Dollars. Please contact [email protected] Measurement Data and Test Conditions: Configuration #1 - Pre-Production Desulfator #2, pcb version #4, D1=MR852, R3=3.3k, R4=1.1k, C1=47uF16V, R1=1meg, R2=68K, C2=.001uF This is the version we sell as an assembled and tested unit. Battery: full charge, 12.9 volts measured with VOM, SLA battery type (power wheels), 12 volt nominal, 9.5 amp-hour nominal, stable for test duration, no charger used. Battery Lead Wires: 14 gauge, 5 inch length positive lead, 5 inch length negative lead Frequency: 0.86 msec measured with oscilloscope = calculated 1163 Hz (1 / 0.86msec) Negative Pulse Width: 50usec measured with oscilloscope; calculated 5.8% duty cycle (50usec / 860usec) Current Draw: 65 milliamps, measured with VOM "Peak Voltage": 45.2 volts, measured with VOM across C6 Voltage Spike - oscilloscope pos and neg test leads on battery: 51 volts Voltage Spike - oscilloscope pos and neg test leads on Desulfator: 56 volts Voltage Spike - oscilloscope pos test lead on battery, neg test lead on Desulfator: 52 volts Voltage Spike - oscilloscope pos test lead on Desulfator, neg test lead on Battery: 52 volts Q1 and L1 slightly warm to the touch Configuration #2 - Pre-Production Desulfator #1, pcb version #4, D1=MR852, R3&R4=390ohms, C1=47uF16V, R1=1meg, R2=68K, C2=.001uF Battery: full charge, 12.9 volts measured with VOM, SLA battery type, 12 volt nominal, 7.5 amp-hour nominal, stable for test duration, no charger used. Battery Lead Wires: 14 gauge, 6 inch length positive lead, 4.5 inch length negative lead Frequency: 0.83 msec measured with oscilloscope = calculated 1205 Hz (1 / 0.83msec) Negative Pulse Width: 49usec measured with oscilloscope; calculated 6% duty cycle (49usec / 830usec) Current Draw: 80 milliamps, measured with VOM "Peak Voltage": 31 volts, measured with VOM across C6 Voltage Spike - oscilloscope pos and neg test leads on battery: 24 volts Voltage Spike - oscilloscope pos and neg test leads on Desulfator: 49 volts Voltage Spike - oscilloscope pos test lead on battery, neg test lead on Desulfator: 34 volts Voltage Spike - oscilloscope pos test lead on Desulfator, neg test lead on Battery: 40 volts Notes: the battery was recycled/reused from a UPS and was only 7 volts when received. A desulfator and either a trickle charger or 2 amp solar panel has been on this battery for a few weeks. Although the battery is charged to full voltage, I have not done a energy capacity test to verify it's current amp-hour capacity. Q1 and L1 slightly warm to the touch Configuration #3 - Prototype #7, D1=FR308, R3&R4=390ohms, C1=47uF16V, R1=1meg, R2=68K, C2=.001uF Battery: at rest starting battery voltage 12.5 volts, 13.3 volts during test and after charging a few hours, SLA type (Power Wheels), 12 volt nominal, 9.5 amp-hours Charger connected (15 volt, 400 milliamp, non-regulating) Battery Lead wires: 14 gauge, 10 inches each battery lead Frequency: 0.84msec, 1190 Hz Negative Pulse Width: 49 usec, 4.1% duty cycle Current Draw: 48 milliamps "Peak Voltage": 40.3 Volts, VOM across capacitor midway between desulfator and battery (lead length reference) Voltage Spike - oscilloscope pos and neg test leads on battery: 45 volts Voltage Spike - oscilloscope pos and neg test leads on Desulfator: 56 volts Voltage Spike - oscilloscope pos test lead on battery, neg test lead on Desulfator: 52 volts Voltage Spike - oscilloscope pos test lead on Desulfator, neg test lead on Battery: 50 volts Test performed after a 20 hour burn in period All components cool to the touch Configuration #4 - Prototype #3, "Classic" component values, D1=NTE597, R3&R4=330ohms, C1=47uF16V, R1=470k, R2=22K, C2=.0022uF Battery: full charge, 12.9 volts measured with VOM, SLA battery type (power wheels), 12 volt nominal, 9.5 amp-hour nominal, stable for test duration, no charger used. Battery Lead Wires: 18 gauge, 5 inch length positive lead, 5 inch length negative lead Frequency: 0.76 msec measured with oscilloscope = calculated 1316 Hz (1 / 0.76msec) Negative Pulse Width: 33usec measured with oscilloscope; calculated 4.3% duty cycle (33usec / 760usec) Current Draw: 31.5 milliamps, measured with VOM "Peak Voltage": 17.1 volts, measured with VOM across separate diode/cap "peak meter" circuit Voltage Spike - oscilloscope pos and neg test leads on battery: 32 volts Voltage Spike - oscilloscope pos and neg test leads on Desulfator: 38 volts Voltage Spike - oscilloscope pos test lead on battery, neg test lead on Desulfator: 35 volts Voltage Spike - oscilloscope pos test lead on Desulfator, neg test lead on Battery: 34 volts All components cool to the touch I built a few prototypes as a project in wet cell lead acid battery preventive maintenance and rejuvenation for renewable energy systems and was curious as to how well they worked. Frontier Springs offers our version of the classic 12 Volt Battery Desulfator. We design, print, drill, etch, assemble, and test the pcb board in house using standard "Laser Printer PCB Making" techniques. It's Home Brew! The pcb board we offer is perfectly suited to AC's classic design using original component values or other values for experimentation and final build. The pcb board provides a nice chassis for your project. To build your own from Frontier Spring's interpreted schematic and PCB these are some of the parts and their specs that are used. The PCB is generally drilled with a .026 inch (#71) bit, which I break after about three or four boards... The L1, 220uH, coil leads are drilled with a .0315 inch (0.80mm) bit. The L2, 1000uH, coil leads are drilled with a .0472 inch (1.20mm) bit. Q1 and the fuse are drilled with a .040 inch bit. I drill the pcb before etching. I go over the pcb where I drilled and using a permanent marker dab around to cover copper that does not need to be etched off around the drilled holes. This really makes for a nicer board for when you go to solder the components. You will have complete copper around the holes to solder to. Resistors are 1/4 watt L1 - Inductor, Toroid, Vertical Mount, 220.0 uH, 5.8 IDC, 0.054 OHM - J.W. Miller Series 2300 - Jameco part #387268 L2 - Inductor, Toroid, Vertical Mount, 1000.0 uH, 2.4 IDC, 0.3 OHM - J.W. Miller Series 2300 - Jameco part#388041 Q1 - MOSFET, IRF9Z34N, TO-220AB - Jameco part# 670581 Fuse - PPTC Resettable, 1.10A-Hold, 2.20A-Trip, 40A-Max - Jameco part# 199912 C1 & C4 - Radial Lead Electrolytic with o.1 inch lead spacing Notes on Inductors: Delevan Inductors have been an original part choice for the classic "AC" Desulfator. Here are the Delevan "Series DC780 High Current Power Line Chokes" specification to compare with the J.W.Miller parts listed in the previous paragraph: 220 uH - 2.8 IDC, 0.150 ohms 1000 uH - 1.0 IDC, 0.818 ohms The Miller Series 2300 Inductors have a higher current capacity and lower resistance. The Delevan's are over three times more expensive versus the Millers. For my thoughts the Miller Inductors are the better choice. Using big toroid coils will build a large magnetic field. When that large magnetic field collapses, it generates the large voltage pressure toward the battery. Big Coils - Big Mag Field - Big Voltage! Thick and short multistrand wire to transport that big voltage spike to the battery. Doubling up 14 gauge multistrand wire has seen 60 volt spikes to the battery. Small gauge or long wire lengths will choke the high voltage spike. Don't Choke the Spike! For a lead acid (wet cell) battery they do remarkably well - Knocking off sulfate crystals from the battery plates. The picture shows one attached to my lawn mower SLA battery. I know this is subjective but the last couple times I mowed, the battery felt slightly stronger at the end. The mower's battery was in very good condition to start with anyway (tho it is a 4 year old battery now). The battery desulfator will help keep it that way. I have one working on a 12volt 7amp-hour UPS battery that is not helping the battery so much. The UPS battery started at only 7 volts and it's only up to 10.5 volts. There is a lot of internet anecdotes that these small UPS batteries don't respond to well because of the nature of their environment in the UPS. Update! After a couple months on the desulfator and charger this UPS battery is showing some signs of life. I have done some slight "over volt" charging to kick the battery. DO NOT connect the desulfator to the battery while you are doing any kind of over volt experiments in rejuvenating batteries. Typical max charging voltage is 14.4 volts to the battery which the desulfator is fine with. You can prototype your own for about 15 dollars and a couple hours of time. Or, buy mine with the etched pc board so I can fund my next project. You can find information and a great discussion forum on building your own here: Lead Acid Battery Desulfation Pulse Generator. I stand on their shoulders with gratitude. The version I build is the original low power version with the P-Channel Mosfet. I started off the prototypes with simple point to point wiring. I used some honkin' big coils for the extra umph I think they provide to the circuit. The 60.3 volt "peak voltage" is measured across the capacitor of the "peak voltage" measurement test point of the circuit and is solely generated by the desulfator. That is what is hitting the plates of the battery of only a few microsecond duration and 1250 times per second - As this voltage decreases it is an indicator of lowering sulfation of the battery. Some of my better batteries show 30 volt peaks and very good batteries are showing 15-20 volt peaks. Please read Alastair Couper's original article in PDF format from Home Power magazine issue HP77. Go to the Car and Deep Cycle Battery FAQ to get educated on battery issues. Read their Section 16 on battery sulfation. Highly recommended! Battery desulfators are perfect for golf cart and motorcycle batteries to help maintain and extend the life. Car batteries and Marine deepcycle batteries will also benefit. Certainly any lead acid wet cell. I've owned a couple motorcycles and keeping the battery maintained in excellent condition is a skill we should all have. Use this battery desulfator on all your 12volt batteries and it will pay for itself by at least extending the life of all those vehicle batteries.