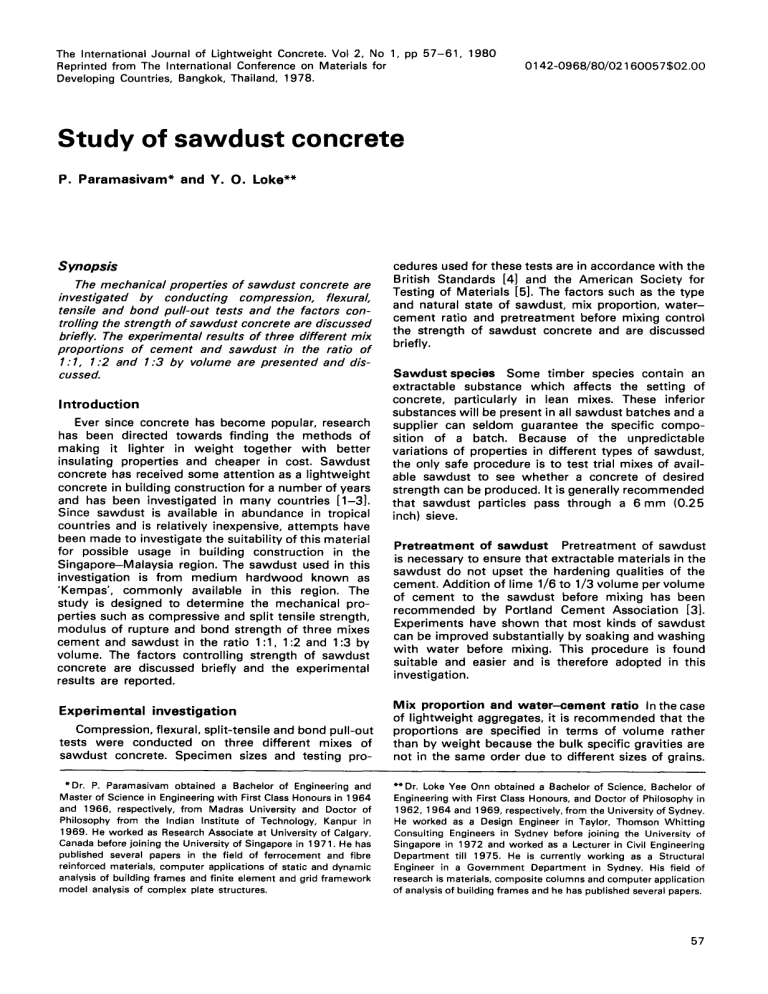

The International Journal of Lightweight Concrete. Vol 2, No 1, pp 57-61, 1980 Reprinted from The International Conference on Materials for Developing Countries, Bangkok, Thailand, 1978. 0142-096~80/02160057502.00 Study of sawdust concrete P. Paramasivam* and Y. O. Loke** Synopsis The mechanical properties of sawdust concrete are investigated by conducting compression, flexural, tensile and bond pull-out tests and the factors controlling the strength of sawdust concrete are discussed briefly. The experimental results of three different mix proportions of cement and sawdust in the ratio of 1 : 1, 1:2 and 1:3 by' volume are presented and discussed. I ntroduction Ever since concrete has become popular, research has been directed towards finding the methods of making it lighter in weight together with better insulating properties and cheaper in cost. Sawdust concrete has received some attention as a lightweight concrete in building construction for a number of years and has been investigated in many countries [1-3]. Since sawdust is available in abundance in tropical countries and is relatively inexpensive, attempts have been made to investigate the suitability of this material for possible usage in building construction in the Singapore-Malaysia region. The sawdust used in this investigation is from medium hardwood known as 'Kempas', commonly available in this region. The study is designed to determine the mechanical properties such as compressive and split tensile strength, modulus of rupture and bond strength of three mixes cement and sawdust in the ratio 1:1, 1:2 and 1:3 by volume. The factors controlling strength of sawdust concrete are discussed briefly and the experimental results are reported. cedures used for these tests are in accordance with the British Standards [4] and the American Society for Testing of Materials [5]. The factors such as the type and natural state of sawdust, mix proportion, w a t e r cement ratio and pretreatment before mixing control the strength of sawdust concrete and are discussed briefly. Sawdust species Some timber species contain an extractable substance which affects the setting of concrete, particularly in lean mixes. These inferior substances will be present in all sawdust batches and a supplier can seldom guarantee the specific composition of a batch. Because of the unpredictable variations of properties in different types of sawdust, the only safe procedure is to test trial mixes of available sawdust to see whether a concrete of desired strength can be produced. It is generally recommended that sawdust particles pass through a 6 mm (0.25 inch) sieve. Pretreatment of sawdust Pretreatment of sawdust is necessary to ensure that extractable materials in the sawdust do not upset the hardening qualities of the cement. Addition of lime 1/6 to 1/3 volume per volume of cement to the sawdust before mixing has been recommended by Portland Cement Association [3]. Experiments have shown that most kinds of sawdust can be improved substantially by soaking and washing with water before mixing. This procedure is found suitable and easier and is therefore adopted in this investigation. Compression, flexural, split-tensile and bond pull-out tests were conducted on three different mixes of sawdust concrete. Specimen sizes and testing pro- Mix proportion and water-cement ratio In the case of lightweight aggregates, it is recommended that the proportions are specified in terms of volume rather than by weight because the bulk specific gravities are not in the same order due to different sizes of grains. *Dr. P. Paramasivam obtained a Bachelor of Engineering and Master of Science in Engineering with First Class Honours in 1964 and 1966, respectively, from Madras University and Doctor of Philosophy from the Indian Institute of Technology, Kanpur in 1969. He worked as Research Associate at University of Calgary, Canada before joining the University of Singapore in 1971. He has published several papers in the field of ferrocement and fibre reinforced materials, computer applications of static and dynamic analysis of building frames and finite element and grid framework model analysis of complex plate structures. ** Dr. Loke Yee Onn obtained a Bachelor of Science, Bachelor of Engineering with First Class Honours, and Doctor of Philosophy in 1962, 1964 and 1969, respectively, from the University of Sydney. He worked as a Design Engineer in Taylor, Thomson Whitting Consulting Engineers in Sydney before joining the University of Singapore in 1972 and worked as a Lecturer in Civil Engineering Department till 1975. He is currently working as a Structural Engineer in a Government Department in Sydney. His field of research is materials, composite columns and computer application of analysis of building frames and he has published several papers. Experimental investigation 57 Therefore, mix proportions of sawdust concrete are specified by volume in this investigation. The watercement ratio has been found to be very important in affecting the strength of sawdust concrete. The sawdust particles absorb most of the water leaving insufficient water for setting of the cement. The water-cement ratio varies from 0.4 to 1.2 depending on the mix proportions. The lean mixes fail to set between 5 and 12 hours and therefore admixture of 4 to 5% is required for lean mix sawdust concrete to accelerate the setting time. Preparation of specimens Extensive research was carried out at University of Singapore [6,7] by trial mixes on pretreatment of sawdust before mixing, water-cement ratio and the admixtures required for mixing. The optimum soaking time for Kempas sawdust was found to be one hour prior to mixing. The sawdust, to be used was first weighed in its natural dry state and then soaked in water for one hour. tt was allowed to drain for about 15 minutes and then again weighed in order to obtain the weight of water in the sawdust. The water-cement ratios for three different mixes 1:1, 1:2 and 1:3 were found to be 0.48, 0.90 and 1.20 respectively. An admixture 'Rapidard' was required for the lean mix 1:3 to accelerate the setting time and the amount required was 4% by weight of cement. The sawdust and cement were mixed thoroughly because of the difference in unit weights. The mixing needed a little longer period than the ordinary concrete. The specimens are compacted by vibration. The specimens were stripped after 24 hours and cured in water. testing machine platens as shown in Figure 2. The bending specimens measured 102 x 102 x 508 mm ( 4 x 4 x 2 0 inch) were tested on a span of 4 6 0 m m (18 inch) with the third point loading arrangement illustrated in Figure 3. These tests were carried out according to British Standards Specifications [4] and bond pull-out tests were conducted according to American Society of Testing Materials [5]. Two types of specimens were considered for the bond pull-out tests. The deformed steel bars of 20 mm (0.75 inch) diameter were embedded vertically in a 152 mm (6 inch) cube specimen as shown in Figure 4. In the other type of specimen, two bars are embedded horizontally in a 152 × 152 x 3 0 4 m m (6 × 6 × 12 inch) prism as shown in Figure 5. The bars were placed at 76 mm and 228 mm height from the bottom and then this was split into two halves before testing as shown in Figure 6. Pull-out tests were conducted with the universal testing machine as shown in Figure 7. Testing procedure An Avery Compression machine was used to determine the compressive and tensile strengths. Compressive strength was determined on a 152 mm (6 inch) cube by direct compressive loading as shown in Figure 1. Tensile strength determinations were done by split cylinder test and bending test. Split cylinder tests were conducted on a 152 mm (6 inch) diameter and 304 mm (12 inch) high cylinder with plywood packing between the specimen and the Figure 1 Compression test Figure 2 Figure 3 Split cylinder test Bending test Figure 6 Figure 4 Figure 5 Splitting of prism into two cubes Vertically embedded bar Horizontally embedded bars Figure 7 Bond pull-out test Results a n d discussion The important parameter which affects the mechanical properties of the sawdust concrete is the mix proportion. Three mix proportions of cement and sawdust in the ratio 1:1, 1:2 and 1:3 by volume are considered and the results are presented. Compressive and tensile strength The compressive strength of three mix proportions is plotted against the number of days of curing in water in Figures 8 and 9. The 28-days compressive strength of 1:3, 1:2 and 1:1 mix proportions are 5 N/mm = (725 psi) 8.7 N/mm = (1250 psi) and 29.8 N/ram 2 (4300 psi) respectively and in the ratio of 1:3.5:6. Their dry densities are 850 kg/cm 3 (53 pcf), 930 kg/cm 3 (58 pcf) and 1490 kg/cm 3 (93 pcf) respectively. Figures 10 and 11 show the variation of modulus of rupture and split tensile strength of mix proportions with number of curing days. The ratio of modulus of rupture at 28-days is in the range of 1:1.9 and 2.7 for 1:3, 1:2 and 1:1 mix proportions respectively and the split tensile strength is also in the ratio of 1:1.25:1.7 respectively. The strength for 1:1 mix proportions is comparable to that of ordinary concrete. However, the cost of production will be higher than of the other two mixes. 59 illustrate the variation of bond stresses of vertically and horizontally embedded bars with the number of days of curing for three different mixes 1:1 1:2 and 1:3 respectively. The bond strength of horizontally embedded bars is about 8 0 % of the vertically embedded bars. This may be due to the fact that horizontally placed bars were subjected to an accumulation of air and water trapped underneath the bars during casting. In the case of the horizontally embedded bars, the bond strength of the top bars is in the range of 50% of the bottom bars. This is because the bottom bars with a greater cover underneath are subjected to a greater sedimentation of concrete. The mix 1:1 has good bond strength and is comparable to the other lightweight concretes. Bond strength Figures 12-14 psi 800 N/mm 2 w 5 ~" 700 600 ~ 4 c~ u_ o 3 Lo J 2 o 500 400 200 :E 1 100 0 0 Conclusions This !nvestigation presents the compressive, tensile and bond strengths of sawdust concrete of three different mix proportions 1:1, 1:2 and 1:3. The controlling factors such as water-cement ratio, admixture and pretreatment before mixing for the 'Kempas' sawdust available in Singapore and Malaysia N/mrn 2 MIX PROPORTION 300 ~ Mix 1:3 ?' 4'2 ' 2'1 a ' 14 28 35 NUMBER OF DAYS Figure 10 Modulus of rupture ] N/m m 2 psi 1:1 0 o'o 300 5000 -r B30 4000 Z UJ rr Iu3 3000 w 20 " 10o 100 > d3 u3 W rr 2000 ~ 10 • 0 i 0 7 I I 14 21 218 315 NUMBER OF DAYS Figure 8 i 0 1000 0 U 7 14 NUMBER Figure 1 1 42 Compressive strength t psi 1400 bZ 1200 F-t~ 1000 w 8 c~ ~ w6 cO d3 W4 n 2~ 0 ~ 2 0 ? rtion i: 3 600 400 N/turn 2 6 I I I I 14 21 28 35 NUMBER OF DAYS Compressive strength I &2 0 /0 Split tensile strength psi bar I000 / 800 600 // // o ~o ~ topl bar 400 2 200 200 Figure 9 60 i 42 800 I 0 OF i 3s DAYS ~ 8 N/ram 2 i 28 0 0 I 7 NUMBER Figure 12 0 I 1~ 21 OF 2|~, DAYS Bond strength of mix #:1 psi N/mm z N/mm 2 psi 400 Ln2 300 500 3 bar /y ,J3 ',,D ILl n," I.-bq a z o rn r 4.00 W n~ 300 y / 1:3 L_Horizontal bottom bar 200 200 r-[3 1 // " _ ~ 00 / top bar I 0 7 Figure 13 I 14 NUMBER I 100 I 21 28 OF DAYS Bond strength of mix 1:2 region are discussed. From the results obtained so far, sawdust concrete shows some promise for use in building construction. At present, sawdust is available at a low price in most of the tropical countries. In view of this, sawdust should be considered seriously for partition walls, false ceiling roofing boards, etc. It should, however, be recognised that further research needs to be done before it can be used as a building material. References 1. Baver, L. W., 'Sawdust concrete investigation', Division of Agricultural Engineering Journal of American Society of Agriculture Engineers, Vol. 21, No. 9, 1940. 2. Portland Cement Association Britain, Concrete Information No. CP48, 'Sawdust concrete used experimentally in farm construction'. 0 - 0 / 7 Figure 14 I 14 NUMBER I I 21 28 OF DAYS Bond strength of mix 1:3 3. Portland Cement and Concrete Association of Australia, Concrete Information, No. C1-2 'Sawdust concrete'. 4. British Standards Institution B.S. 1881, Part 4, 'Method of testing concrete for strength, London 1967. 5. American Society for Testing of Materials, Designation C496-71 and C234-71, 'Splitting tensile strength of cylindrical concrete specimens; Standard method of test for bond developed with reinforcing steel', Part 14, Philadelphia 1976. 6. Tan, S. T., Tan, B. L. and Soh, W. M., 'Properties of sawdust concrete', BoEng. Project, Department of Civil Engineering, University of Singapore, Singapore, 1974. 7. Lim, C. K., Lim, E. Y. and Liu, H. Y., 'Further studies on the behaviour of sawdust concrete', B.Eng. Project, Department of Civil Engineering, University of Singapore, 1975. 61