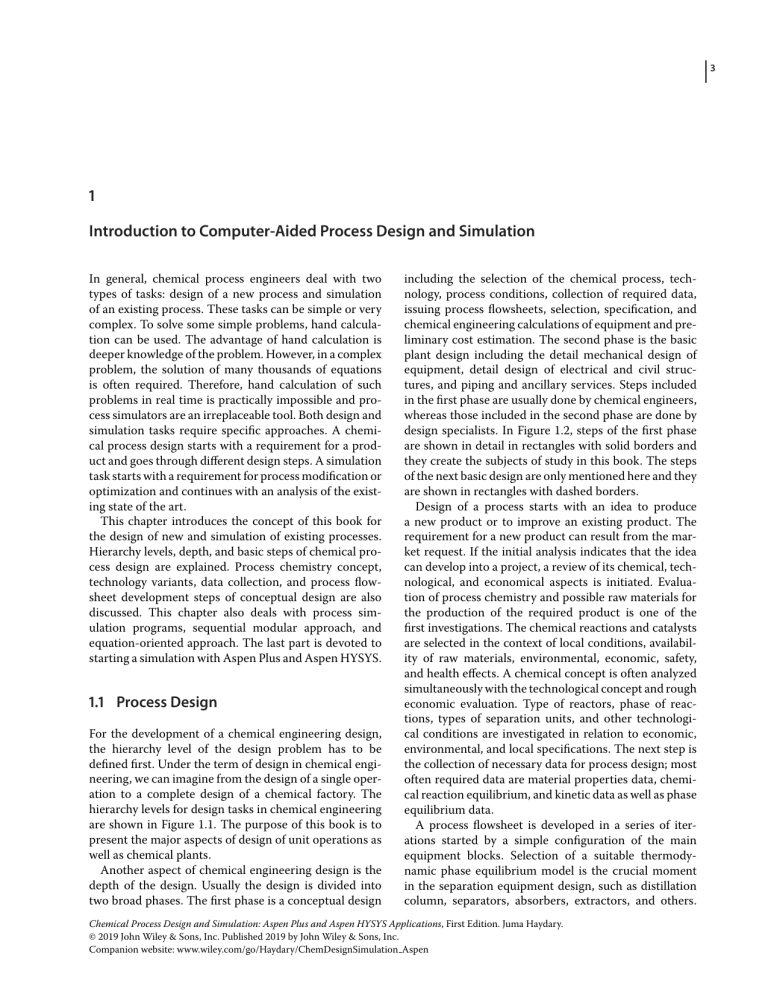

3 1 Introduction to Computer-Aided Process Design and Simulation In general, chemical process engineers deal with two types of tasks: design of a new process and simulation of an existing process. These tasks can be simple or very complex. To solve some simple problems, hand calculation can be used. The advantage of hand calculation is deeper knowledge of the problem. However, in a complex problem, the solution of many thousands of equations is often required. Therefore, hand calculation of such problems in real time is practically impossible and process simulators are an irreplaceable tool. Both design and simulation tasks require specific approaches. A chemical process design starts with a requirement for a product and goes through different design steps. A simulation task starts with a requirement for process modification or optimization and continues with an analysis of the existing state of the art. This chapter introduces the concept of this book for the design of new and simulation of existing processes. Hierarchy levels, depth, and basic steps of chemical process design are explained. Process chemistry concept, technology variants, data collection, and process flowsheet development steps of conceptual design are also discussed. This chapter also deals with process simulation programs, sequential modular approach, and equation-oriented approach. The last part is devoted to starting a simulation with Aspen Plus and Aspen HYSYS. 1.1 Process Design For the development of a chemical engineering design, the hierarchy level of the design problem has to be defined first. Under the term of design in chemical engineering, we can imagine from the design of a single operation to a complete design of a chemical factory. The hierarchy levels for design tasks in chemical engineering are shown in Figure 1.1. The purpose of this book is to present the major aspects of design of unit operations as well as chemical plants. Another aspect of chemical engineering design is the depth of the design. Usually the design is divided into two broad phases. The first phase is a conceptual design including the selection of the chemical process, technology, process conditions, collection of required data, issuing process flowsheets, selection, specification, and chemical engineering calculations of equipment and preliminary cost estimation. The second phase is the basic plant design including the detail mechanical design of equipment, detail design of electrical and civil structures, and piping and ancillary services. Steps included in the first phase are usually done by chemical engineers, whereas those included in the second phase are done by design specialists. In Figure 1.2, steps of the first phase are shown in detail in rectangles with solid borders and they create the subjects of study in this book. The steps of the next basic design are only mentioned here and they are shown in rectangles with dashed borders. Design of a process starts with an idea to produce a new product or to improve an existing product. The requirement for a new product can result from the market request. If the initial analysis indicates that the idea can develop into a project, a review of its chemical, technological, and economical aspects is initiated. Evaluation of process chemistry and possible raw materials for the production of the required product is one of the first investigations. The chemical reactions and catalysts are selected in the context of local conditions, availability of raw materials, environmental, economic, safety, and health effects. A chemical concept is often analyzed simultaneously with the technological concept and rough economic evaluation. Type of reactors, phase of reactions, types of separation units, and other technological conditions are investigated in relation to economic, environmental, and local specifications. The next step is the collection of necessary data for process design; most often required data are material properties data, chemical reaction equilibrium, and kinetic data as well as phase equilibrium data. A process flowsheet is developed in a series of iterations started by a simple configuration of the main equipment blocks. Selection of a suitable thermodynamic phase equilibrium model is the crucial moment in the separation equipment design, such as distillation column, separators, absorbers, extractors, and others. Chemical Process Design and Simulation: Aspen Plus and Aspen HYSYS Applications, First Edition. Juma Haydary. © 2019 John Wiley & Sons, Inc. Published 2019 by John Wiley & Sons, Inc. Companion website: www.wiley.com/go/Haydary/ChemDesignSimulation Aspen 4 Chemical Process Design and Simulation Chemical industry Chemical factory Chemical plant Unit operation Chemical or physical process Figure 1.1 Hierarchy levels for chemical engineering design Step-by-step or simultaneous solution of mathematical models of individual nodes in the flowsheet provides material and energy balance information and also, in some cases, information on the main equipment size. In this step, some case studies at the level of equipment simulation are done. To set optimal process conditions and cost minimization, a number of case studies employing flowsheet configuration, external conditions, and requirements have to be done. Process integration aimed at the maximization of energy efficiency is another impotent step of process flowsheet development. Finally, the optimal process configuration is selected and its cost is estimated. Often, cost estimation is required for more than one alternative of the process. It can also serve as an objective function for optimization. Note that sometimes the design steps become woven together or their order may be altered and sometimes not all steps may be necessary. Experience from already existing plants pays a very important role in this process. The majority of designs are based on previously existing experience. 1.2 Process Chemistry Concept Usually, new products are produced as a result of one or more chemical reactions; however, in some cases only Defining the required product Evaluation of possible chemical concepts and selection of suitable method Evaluation of possible technologies and local conditions, reviewing environmental, safety and health effects, selection of suitable technology Collection of data required for design (material properties data, chemical equilibrium and kinetic data, phase equilibrium data, etc.) Process flowsheet development, material and energy balances, equipment selection and design, process simulation of the base case Case studies, energy analysis, optimization of parameters Preliminary cost estimation Detailed mechanical equipment design, piping and instrument design, civil and electrical structures design, detailed flwsheets Project cost estimation Construction of the plant Figure 1.2 Main steps of a chemical plant design 1 Introduction to Computer-Aided Process Design and Simulation physical processes are the subject of the design, for example, separation of a component or a group of components from a natural mixture. Crude oil primary separation is a good example of such processes. If the new product is a result of chemical reactions, the designing process begins with the search for chemical reactions leading to this new product. Initial local conditions play an important role in the process chemistry selection. Use of an existing plant, modification of an existing plant, and design of a completely new plant are three different initial situations that affect the selection of an appropriate chemistry for the new product. The search for a potential chemistry begins with books, textbooks, and encyclopedias. More detailed information can be found in journals, patents, and other publications. The first result of an initial search is the answer to the question, if exact chemistry of the required product production is known. The following answers to this question are possible: 1. Yes, our required product is a pure chemical and the stoichiometry of chemical reactions for its production is known. 2. Our product is the result of a number of different chemical reactions, where the stoichiometry of only some reactions is known and balance at the molecular level is impossible. 3. Our product is the result of many chemical reactions with unknown stoichiometry; technologies are developed based on empirical observations. In many cases, more than one choice for raw materials for a new product is available. The appropriate raw material and also the catalyst type are selected considering the best economic indicators satisfying environmental and safety conditions. An initial economic and environmental overview helps to exclude most inconvenient methods from further investigation. Chemistry with the best economic indicators may not be always the same; it is strongly affected by local conditions such as availability of raw materials, possibility of using existing technologies and infrastructure, environmental regulations, availability of energy sources, and so on. 1.3 Technology Concept When chemistry is selected, analysis of its various technology variants follows. The technology variations are studied for chemistries that were not excluded by the process chemistry analysis. In conceptual design, the subject of technology concept is to search for different technology alternatives for the selected chemistry including r reactor variations, r separation alternatives, r alternatives for material stream recycling, r concept of energy integration, and r environmental, health, and safety effects. In the reactor selection step, a very important decision to be made is the choice between continuous and batch processes, which is mostly influenced by the character of the process and production capacity. For many processes with considerable capacities, continuous processes are preferred. The reaction phase is another important issue. The conversion and process efficiency can be strongly affected by the reaction phase. Reaction conditions such as temperature, pressure, and heat transfer between the reactor and surrounding environment (isothermal or adiabatic conditions) are other important parameters of reactors. Most preferable temperatures and pressures for chemical reactors are those near the ambient temperature and atmospheric pressure; many processes require different conditions. However, for selecting high or low temperatures and pressures there has to be a proper reason. Although the catalyst selection is a part of the chemistry concept, its methods of application and regeneration are usually studied as technology variations. Often, the method of catalyst introduction determines the reactor type, for example, fixed bed reactors and fluidized bed reactors. A chemical reactor usually requires very good mass and heat transfer conditions. Therefore, reaction phase, reaction conditions, and catalyst type determine the type and structure of the reactor used. Most often used continuous reactors are CSTR (continuous stirred tank reactor) and tubular reactor. To model CSTR reactors, the theory of ideal mixing is often applied; whereas in tubular reactors modeling, the theory of plug flow is employed. For each reactor variant for a given technology, environmental, safety, and health aspects have to be also evaluated. The reaction products are usually in form of homogeneous or heterogeneous mixtures, and the required product has to be separated, which usually requires a series of operations. For heterogeneous mixtures, separation processes such as filtration, cyclone separation, precipitation, sedimentation, and so on. are employed. For the separation of homogeneous mixtures, separation methods such as distillation, absorption, extraction, partial condensation, and so on. can be used. Different concepts for the separation of reaction products have to be evaluated. Before starting the flowsheet synthesis by process simulation, the designer may prepare a short list of material stream integration alternatives that have to be considered for further studies. Even for simple problems, the number of alternatives is very high. The 5 6 Chemical Process Design and Simulation goal is to select suitable alternatives without detailed simulation of all possible alternatives. The technology has to be designed at the optimum recycling rate of raw material considering also environmental, safety, and health issues. Note that recycling of material streams in the whole range may not always be the most effective method. Variations of process energy integration have to be also evaluated as a part of the technology concept. In this step, the basic alternatives of the process energy integration are studied; detailed design of energy integration and heat exchanger networks are the subject of the process integration accompanied by simulation of different alternatives. After the technology variations evaluation including environmental, safety, and health aspects, the designer has a short list of cases that need to be simulated using a process simulator to make further decisions. 1.4.2 1.4 Data Collection 1.4.3 The quality of a simulation strongly depends on the quality of data and parameters of the model used. Data quality and availability are two of the most challenging issues in many simulations. Simulation software used in chemical process design contains many databases of material properties data and phase equilibrium data, particularly for conventional components. However, in many cases, independent experimental data are very helpful in the results verification. In addition, for all nonconventional substances, the material properties data and phase equilibrium data are missing. Also, phase equilibrium data are not available for all possible binary pairs of conventional components. Another type of required data is the chemical equilibrium data and kinetic parameters of chemical reactions. Simulation software usually contains a property analysis tool. These tools are used for detail property analysis of pure components and binary and ternary interactions. Modeling of chemical reactors requires information on reaction stoichiometry, equilibrium constant, and kinetic parameters of chemical reactions. In some cases, the reaction conversion is known, for example, in very fast reactions, where full conversion is achieved immediately. Equilibrium constants can be calculated by minimization of the Gibbs free energy. Simulation software provides these calculations; however, experimental values of the equilibrium constant and its temperature dependence provide better results, and they can be used for the verification of data calculated by Gibbs free energy minimization. Rate equation and kinetic parameters of the used chemical reactions enable to calculate reaction conversion and reactor sizes when using a kinetic reactor model. 1.4.1 Material Properties Data As the easiest and a very good source of material properties data of conventional components, the database of the simulation software is used. (See Example 2.6 in the next chapter for ethyl acetate material properties data analysis.) If components that are not qualified as conventional such as pseudocomponents, assays, blends, nonconventional solids, and so on. are present, some information on their properties are required for their characterization. The more properties are known, the better characterization of a nonconventional component can be achieved. Phase Equilibrium Data For a satisfactory design of separation and reaction equipment, the quality of the model for phase equilibrium calculations has a crucial effect. The quality of the model is given by its ability to describe the real process. Phase equilibrium experimental data enable the verification of the used thermodynamic model (see Example 2.7). Vapor–liquid and liquid–liquid experimental data have been published for thousands of binary systems in databases such as DECHEMA and National Institute of Standards and Technology (NIST). However, for thousands of other binary systems, these data are not available. Parameters of phase equilibrium models based on activity coefficients can be calculated by contribution methods such as UNIQUAC Functional-group Activity Coefficients (UNIFAC); in a real project design, experimental verification of the phase equilibrium model is necessary. Reaction Equilibrium and Reaction Kinetic Data 1.5 Simulation of an Existing Process Process modeling is not used only in the design of new processes. It is considered as a very useful tool in existing processes intensification and optimization. Increasing the unit operation efficiency, minimization of material and energy losses, and removal of different operational malfunctions are usual reasons for existing processes modeling. A simulation task starts with the definition of the goal (goals) based on the requirement for an existing process improvement. The next step is to study the process technological schemes and documentation to extract the information required for the simulation. Process technological schemes are usually very detailed and contain 1 Introduction to Computer-Aided Process Design and Simulation different types of information. Only some information can be used for process simulation. A process engineer has to extract the necessary information and to create the process flow diagram (PFD) based on simulation goals and the technological scheme of the process. In the next step, data from the plant operation have to be collected. Some plant data can be used as the input data to the simulator and some for the comparison of model and real plant data. In addition, data described in Section 1.4 have also to be collected for proper process simulation. After the preparation of a simplified PFD and the collection of all necessary data, process simulation with different scenarios can be realized. Based on the simulation results and their comparison with operational data and analysis of different scenarios, the process modification can be suggested. 1.6 Development of Process Flow Diagrams Development of a PFD for a design task usually starts with very simple diagrams with no heat exchanger networks, reactor kinetic models, material, or heat integration. Figure 1.3 shows an example of a simplified flow diagram created for the design of vinyl acetate production from acetic acid and acetylene. After calculating these simplified schemes and gaining the knowledge on the process background, the schemes can be improved by including two side heat exchangers, reactor kinetic models, and material and energy recycling streams. An example of a more complex PFD for the same process (production of vinyl acetate) is shown in Figure 1.4. In case of a simulation task, the starting point is the process technological scheme to be analyzed and simplified for the simulation goals definition. The PFD required for the process simulation is derived from the technological scheme by selecting equipment and streams that can affect the simulation goal. Simulation programs use block modules to model different types of equipment. Sometimes the simulation flow diagram differs from the real PFD because real equipment in a simulation program can be modeled by one, two, or even more unit operation blocks; or, vice versa, one operation block in the simulation software can represent more than one real piece of equipment. Two different modes of a PFD for process simulation can be developed using a simulator: active mode and onhold mode. When the active mode is used, calculation of the units is performed simultaneously with PFD creation (after installing each unit operation block, its calculation is done). In the on-hold mode, first the PFD is completed and then the calculation is started. 1.7 Process Simulation Programs Simulation is defined in (1) as imitation of the operation of a real-world process or system over time. A more detailed definition of process simulation is provided in (2): Simulation is a process of designing an operational model of a system and conducting experiments with this model for the purpose either of understanding the behavior of the system or of evaluating alternative strategies for the development or operation of the system. It has to be able to reproduce selected aspects of the behavior of the system modeled to an accepted degree of accuracy. C2H2-REC REACTOR HEATER MIX COOLER SEP AA S1 S3 S4 C2H2 PRODUCT S6 WASTE DC2 DC1 S7 S11 S12 S13 Figure 1.3 Simplified PFD for the vinyl acetate production process design 7 W10 R1 VT5 S14 W11 F2 PUMP MIX S13 PRODUCT S1 C2H20 R2 Figure 1.4 More complex PFD for vinyl acetate production W7 AA0 MIX3 F1 MIX4 W6 O1 DC2 S2-1 WASTE W5 O2 S12 S11 MIX5 S2-2 W4 SPLIT W3 S3 DC1 VT1 S10 WASTE1 W2 S4 W9 VTPARA Q REACTOR S5 VT2 MIX2 W1 VT3 C2H2-REC S7 W8 S6 S9 SEP1 ODP1 CACL2W CACL2W1 VT4 S8 SEP2 8 Chemical Process Design and Simulation 1 Introduction to Computer-Aided Process Design and Simulation r calculation Flowsheet topology Unit operation models r Physical property models Figure 1.5 Structure of a process simulator The term “simulation” in this book is used in two different meanings. The first meaning indicates the calculation type (design and simulation) as explained in the introduction of this chapter. The second meaning is modeling of a process by a simulator. Process simulation (modeling) plays a crucial role in all process engineering activities including research and development, process design, and process operation. Larger extend of process simulation includes different computer-based activities such as computer fluid dynamics, but the subject of simulation in this book is flowsheeting of chemical processes by software called process simulators. Basically, process simulators can work in two modes: sequential modular mode and equation-oriented mode (see Section 1.7.1); however, they predominantly work in sequential modular mode, where the output streams of a unit model are evaluated from input streams and the desired design parameters. Individual unit models are solved in a sequence parallel to the material flow. Simulators are generally constructed in a three-level hierarchy as shown in Figure 1.5. Tasks of the flowsheet topology level are r sequencing of unit modules, r initialization of the flowsheet, r identification of the recycle loops and tear streams, and r convergence of the overall mass and energy balance of the flowsheet. Tasks of the unit operation model level are r solving of each unit (such as heat exchangers, reactors, r separators, and so on) using input from the flowsheet topology level with a specialized calculation procedure for each unit type and feedback of outputs from the unit calculation to the flowsheet topology level. Physical property mode level deals with r calculation of thermodynamic models for phase equilibrium, of enthalpy, entropy, and other temperature-dependent properties of components and streams, and it has to be accessed by the unit operation mode as well as the flowsheet topology level. At each level, sets of nonlinear equations are solved using the number of iteration loops and the interactive solution procedure. More details of modular simulators are presented in (3). Table 1.1 shows a list of the most commonly used process simulation programs. Each of them has its own advantages and limitations. Aspen Plus enables steadystate simulation of a wide range of processes including production of chemicals, hydrocarbons, pharmaceuticals, solids, polymers, petroleum assays and blends, and other applications. Aspen HYSYS is a very powerful simulation tool for hydrocarbon, chemical, and petroleum applications. Aspen Plus and Aspen HYSYS are parts of the program package AspenOne released by Aspentech, Inc. Both software are applied in this book in the simulation of different types of processes. Released in December 2012 AspenOne V8.0, in 2016 AspenOne V9 and in 2017 AspenOne V10 represented a significant jump compared to older versions, not only in graphics but also in functionality. Previous books on Aspen Plus or Aspen HYSYS application used the older AspenOne V7 version, which had quite different graphics than the currently available versions. In this book, mainly AspenOne V9 was used; however, in some examples also Versions 8.6 and 8.8 were applied. Note that every process simulation software has been developed based on the same chemical engineering principles. If one manages the work with one of them, it is easy to learn to work with the others. Both Aspen HYSYS and Aspen Plus via Aspen Dynamics enable also dynamic simulation of processes. This book, however, deals only with processes in steady state. 1.7.1 Sequential Modular versus Equation-Oriented Approach Basically, two different approaches can be applied for the simulation of a system of unit operations interconnected by material and energy streams. The first method widely used by process simulators is the sequential modular mode that divides the mathematical model of the whole system consisting of thousands of equations into smaller submodels (models of modules). The unit models are then calculated independently of other modules, and the output streams are evaluated based on the input streams and design parameters. The solution sequence is generally parallel to material flow in the process. By recycling the streams, the module input is changed, and therefore the module has to be reevaluated. More complex 9