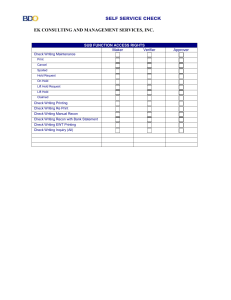

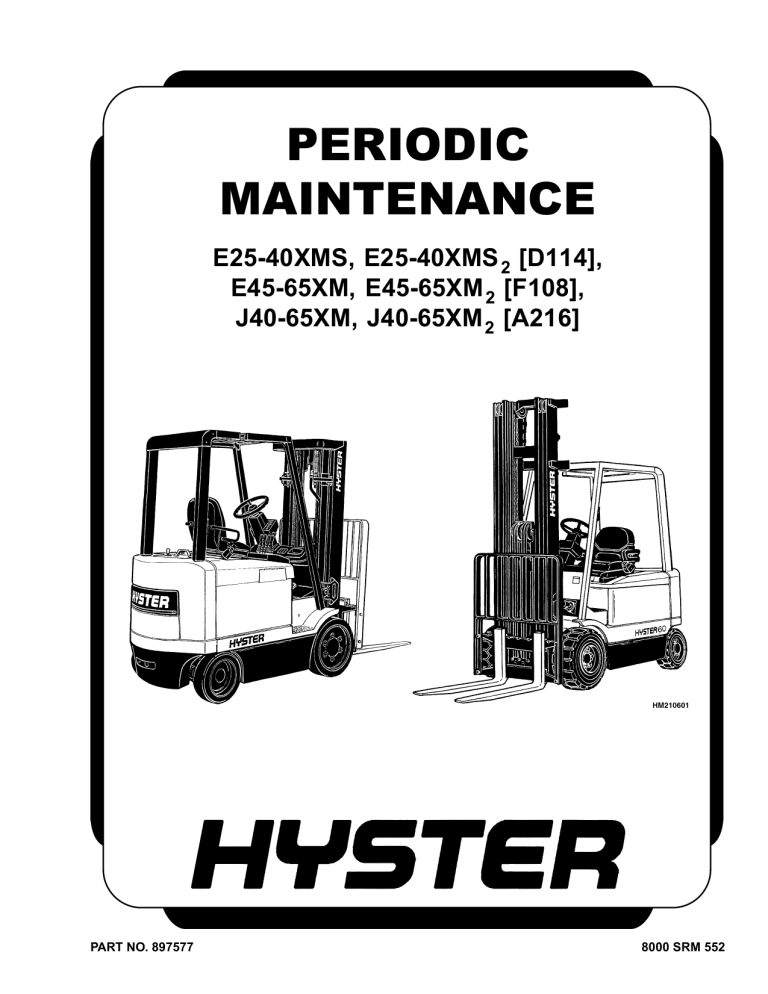

3(5,2',& 0$,17(1$1&( E25-40XMS, E25-40XMS 2 [D114], E45-65XM, E45-65XM 2 [F108], J40-65XM, J40-65XM 2 [A216] PART NO. 897577 8000 SRM 552 SAFETY PRECAUTIONS MAINTENANCE AND REPAIR • When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load. • Do not lift heavy parts by hand, use a lifting mechanism. • Wear safety glasses. • DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. • Disconnect the battery ground cable on internal combustion lift trucks. • Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section. • Keep the unit clean and the working area clean and orderly. • Use the correct tools for the job. • Keep the tools clean and in good condition. • Always use HYSTER APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer. • Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts. • Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs. • Be sure to follow the WARNING and CAUTION notes in the instructions. • Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems. • Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated. NOTE: The following symbols and words indicate safety information in this manual: WARNING Indicates a condition that can cause immediate death or injury! CAUTION Indicates a condition that can cause property damage! Periodic Maintenance Table of Contents TABLE OF CONTENTS General ................................................................................................................................................................. Serial Number Data ........................................................................................................................................ How to Move Disabled Lift Truck ................................................................................................................... How to Tow Lift Truck................................................................................................................................. How to Put Lift Truck on Blocks..................................................................................................................... How to Raise Drive Tires ............................................................................................................................ How to Raise Steering Tires ....................................................................................................................... Maintenance Schedule......................................................................................................................................... Maintenance Procedures Every 8 Hours or Daily.............................................................................................. How to Make Checks with Key OFF .............................................................................................................. Tires and Wheels ......................................................................................................................................... Forks ............................................................................................................................................................ Adjust....................................................................................................................................................... Remove .................................................................................................................................................... Install..................................................................................................................................................... Forks, Mast, and Lift Chains, Inspect ..................................................................................................... Safety Labels ............................................................................................................................................. Steering Column Latch ............................................................................................................................. Operator Restraint System....................................................................................................................... Battery Restraint System E25-65XM and E25-65XM 2 ........................................................................... Battery Restraint System J40-65XM and J40-65XM 2 ............................................................................ Battery ....................................................................................................................................................... Hydraulic System ...................................................................................................................................... How to Make Checks with Key ON .............................................................................................................. Gauges, Horn, and Fuses .......................................................................................................................... Steering System ........................................................................................................................................ Service Brakes ........................................................................................................................................... Parking Brake ........................................................................................................................................... Control Levers and Pedals........................................................................................................................ Direction and Speed Control Pedals......................................................................................................... Lift System Operation............................................................................................................................... Maintenance Procedures Every 250 Hours or Six Weeks................................................................................ Steering Tie Rods........................................................................................................................................... Maintenance Procedures Every 500 Hours or Three Months ......................................................................... Hydraulic Tank Breather .............................................................................................................................. Differential and Speed Reducer .................................................................................................................... Wheel Nut Torques ........................................................................................................................................ Steering Axle Spindles .................................................................................................................................. Steering Tie Rods........................................................................................................................................... Mast................................................................................................................................................................ Lift Chains ..................................................................................................................................................... Wear Check................................................................................................................................................ Forks............................................................................................................................................................... Brake Fluid .................................................................................................................................................... Other Lubrication .......................................................................................................................................... Seat Brake (E25-65XM and E25-65XM 2 Only)............................................................................................ Electrical Inspection...................................................................................................................................... Contactors.................................................................................................................................................. Motor Brushes ........................................................................................................................................... Motor Brushes, General............................................................................................................................ Maintenance Procedures Every 1000 Hours or Six Months............................................................................ Copyright © HYSTER COMPANY 2001 1 1 1 1 2 2 3 3 8 8 8 9 9 9 10 10 11 11 11 11 12 13 14 14 15 15 15 15 15 16 16 16 16 17 17 17 18 18 18 18 19 19 19 20 20 20 21 21 21 22 35 i Table of Contents Periodic Maintenance TABLE OF CONTENTS (Continued) Lift Chains ..................................................................................................................................................... Forks............................................................................................................................................................... Check Upper and Lower Bearings, Integral Sideshift Carriage................................................................. Maintenance Procedures Every 2000 Hours or Yearly .................................................................................... Hydraulic System .......................................................................................................................................... Change Filter for Hydraulic Oil ............................................................................................................... Change Hydraulic Oil ............................................................................................................................... Differential and Speed Reducer .................................................................................................................... Service Brakes ............................................................................................................................................... Contactors ...................................................................................................................................................... Wheel Bearings.............................................................................................................................................. Steer Wheels, Lubrication ........................................................................................................................ Drive Wheels, Lubrication ........................................................................................................................ Lift Chains ..................................................................................................................................................... Replace Upper and Lower Bearings, Integral Sideshift Carriage .............................................................. Steering Axle.................................................................................................................................................. King Pins and Rod Ends (Steering Cylinders)......................................................................................... Other Lubrication .......................................................................................................................................... Battery Maintenance ......................................................................................................................................... How to Charge Battery.................................................................................................................................. How to Change Battery ................................................................................................................................. General....................................................................................................................................................... Change E25-65XM and E25-65XM 2 Battery ........................................................................................... Change J40-65XM and J40-65XM 2 Battery ............................................................................................ Lift and Tilt System Leak Check ...................................................................................................................... Lift Cylinders Leak Check ............................................................................................................................ Tilt Cylinders Leak Check ............................................................................................................................ Safety Procedures When Working Near Mast.................................................................................................. Lift Chain Adjustments ..................................................................................................................................... PMT Circuit Check ............................................................................................................................................ Welding Repairs ................................................................................................................................................. Overhead Guard Changes ................................................................................................................................. Wheels and Tire Maintenance........................................................................................................................... Tires and Wheels E25-65XM and E25-65XM 2 ............................................................................................. Remove Wheels from Lift Truck ............................................................................................................... Remove and Install Tire on Wheel ........................................................................................................... Pneumatic Tires and Wheels J40-65XM and J40-65XM 2 ........................................................................... Remove Wheels from Lift Truck ............................................................................................................... Remove Wheel from Pneumatic Tire........................................................................................................ Install Wheel in Pneumatic Tire .............................................................................................................. Install Three- or Four-Piece Wheel in Pneumatic Tire ........................................................................... Add Air to Tires ......................................................................................................................................... Wheels, Install........................................................................................................................................... Solid Rubber Tires on Pneumatic Wheels .................................................................................................... Remove Wheels from Lift Truck ............................................................................................................... Remove Solid Rubber Tire from Pneumatic Wheel ................................................................................. Install Solid Rubber Tire on Pneumatic Wheel ....................................................................................... Wheels, Install........................................................................................................................................... Adhesives and Sealants ..................................................................................................................................... ii 35 35 35 36 36 36 37 37 37 38 38 38 38 38 38 38 38 38 39 39 40 40 40 43 45 45 45 46 48 49 51 51 51 51 51 52 52 52 53 54 55 56 56 57 57 57 59 60 61 HYSTER COMPANY 2001 Periodic Maintenance Table of Contents TABLE OF CONTENTS (Continued) This section is for the following models: E25-40XMS, E25-40XMS 2 [D114], E45-65XM, E45-65XM 2 [F108], J40-65XM, J40-65XM 2 [A216] Copyright © HYSTER COMPANY 2001 iii 8000 SRM 552 General General On lift trucks before XM 2 when turning the key switch to the ON position the Brush Wear Indicator and Motor Temperature Indicator will illuminate. On XM 2 lift trucks, there is no brush wear indicator, but the LCD screen will show a status code indicating that the brushes need replacing as described in the Operating Manual. Contact your dealer if any LED Indicators do not illuminate during the "check" part of initial lift truck operation. This section contains a Maintenance Schedule and the instructions for maintenance and inspection. The Maintenance Schedule has time intervals for inspection, lubrication and maintenance. The time intervals are based on a normal operation. A normal operation is considered to be one eight hour shift per day in a relatively clean environment on an improved surface. Multiple shifts, dirty operating conditions, etc., will require a reduction in the recommended time periods in the Maintenance Schedule. Your dealer for Hyster lift trucks has the equipment and trained service personnel to do a complete program of inspection, lubrication and maintenance. A regular program of inspection, lubrication and maintenance will help your lift truck give more efficient performance and operate for a longer period of time. WARNING Do not make repairs or adjustments unless you have both authorization and training. Repairs and adjustments that are not correct can make a dangerous operating condition. Do not operate a lift truck that needs repairs. Report the need for repairs immediately. If repair is necessary, put a "DO NOT OPERATE" tag in the operator’s area. Remove the key from the key switch. Disconnect the battery connector. CAUTION Disposal of lubricants and fluids must meet local environmental regulations. Disposal of batteries must meet local environmental regulations. Some users have service personnel and equipment to do the inspection, lubrication and maintenance shown in the Maintenance Schedule. Service Manuals are available from your dealer for Hyster lift trucks to help users who do their own maintenance. SERIAL NUMBER DATA The serial number code for the lift truck is on the nameplate. The code is also stamped on top of the rear bulkhead of the frame. It is on the bulkhead inside the right rear leg of the overhead guard. HOW TO MOVE DISABLED LIFT TRUCK How to Tow Lift Truck WARNING Use extra caution when towing a lift truck if any of the following conditions exist: • Brakes do not operate correctly. • Steering does not operate correctly. • Tires are damaged. • Traction conditions are bad. • The lift truck must be moved on a steep grade. If the steering pump motor does not operate, steering control of the lift truck can be slow and difficult. Do NOT tow the lift truck if there is no power. Poor traction can cause the disabled lift truck or towing vehicle to slide. Steep grades will require additional brake force to stop the lift truck. Never carry a disabled lift truck unless the lift truck MUST be moved and cannot be towed. The lift truck used to carry the disabled lift truck MUST have a rated capacity equal to or greater than the weight of the disabled lift truck. The capacity must be for a load center equal to half the width of the disabled lift truck. See the nameplate of the disabled lift truck for the approximate total weight. The forks must extend the full width of the disabled lift truck. Put the weight center of the disabled lift truck on the load center of the forks. Do not damage the under side of the lift truck. 1. The towed lift truck must have an operator. 2. Raise the carriage and forks approximately 300 mm (12 in.) from the surface. Install a chain 1 General 8000 SRM 552 to prevent the carriage and mast channels from moving. 3. Tow with another lift truck of equal or greater capacity than the disabled lift truck. Install a load of approximately half-capacity on the forks of the lift truck that is being used to tow the disabled lift truck. The half-capacity load will increase the traction of the lift truck. Keep the load as low as possible. 4. Use a towing link made of steel that fastens to the tow pins in the counterweights of both lift trucks. 5. Release the parking brake. 6. Tow the lift truck slowly. HOW TO PUT LIFT TRUCK ON BLOCKS a. Before removing the mast and drive axle, put blocks under the counterweight so that the lift truck cannot fall backward. b. Before removing the counterweight, put blocks under the mast assembly so that the lift truck cannot fall forward. The surface must be solid, even and level when the lift truck is put on blocks. Make sure that any blocks used to support the lift truck are solid, one piece units. NOTE: Some lift trucks have lifting eyes. These lift points can be used to raise the lift truck so that blocks can be installed. 1. Put blocks on each side (front and back) of the steering tires to prevent movement of the lift truck. See Figure 1. 2. Put the mast in a vertical position. Put a block under each outer mast channel. How to Raise Drive Tires WARNING The lift truck must be put on blocks for some types of maintenance and repair. The removal of the following assemblies will cause large changes in the center of gravity: mast, drive axle, battery or counterweight. When the lift truck is put on blocks, put additional blocks in the following positions to maintain stability: 3. Tilt the mast fully forward until the drive tires are raised from the surface. 4. Put additional blocks under the frame behind the drive tires. NOTE: E45-65XM, E45-65XM 2 SHOWN. OTHERS SIMILAR. 1. DRIVE TIRES 2. STEERING TIRES Figure 1. Put Lift Trucks on Blocks 2 8000 SRM 552 Maintenance Schedule 5. If the hydraulic system will not operate, use a hydraulic jack under the side of the frame near the front. Make sure that the jack has a capacity equal to at least half the weight of the lift truck. See the nameplate. How to Raise Steering Tires 2. Use a hydraulic jack to raise the steering tires. Make sure that the jack has a capacity of at least 2/3 of the total weight of the lift truck as shown on the nameplate. 3. Put the jack under the steering axle or frame to raise the lift truck. Put blocks under the frame to support the lift truck. 1. Apply the parking brake. Put blocks on both sides (front and back) of the drive tires to prevent movement of the lift truck. See Figure 1. Maintenance Schedule The MAINTENANCE SCHEDULE has two time periods. If the lift truck is operated less than eight hours each day, do maintenance at the 1 DAY, 6 WEEKS, 3 MONTHS, 6 MONTHS, and 1 YEAR periods. If the lift truck is operated more than eight hours each day, do maintenance at the periods shown in hours (8, 250, 500, 1000, 2000). The approximate locations of the items indicated in the MAINTENANCE SCHEDULE are shown in Figure 2, Figure 3, and Figure 4. The MAINTENANCE SCHEDULE has the maximum service intervals for average conditions. Inspect and lubricate more frequently if the lift truck operates in dirty or difficult conditions. Figure 2. E25-40XM, E25-40XM 2 Maintenance Points 3 Maintenance Schedule 8000 SRM 552 Figure 3. E45-65XM, E45-65XM 2 Maintenance Points NOTE: *TOP OF COUNTERWEIGHT. Figure 4. J40-60XM, J40-60XM 2 Maintenance Points 4 8000 SRM 552 Maintenance Schedule Table 1. Maintenance Schedule Item No. Item Oil Leaks 8 hr/ 250 hr/ 500 hr/ 1000 hr/ 2000 hr/ Procedure or 1 day 6 wks. 3 mo. 6 mo. 1 yr. Quantity X Check for leaks Specification 1 Tires 13 Forks 12 Mast and Carriage X X Check operation Safety Labels X Replace as See Parts Manual necessary Check operation Multipurpose Lubricate as Grease necessary See NOTE 2 Check operation 17 Direction and Speed Control Steering 4 7 X Check condition X Check condition X X Gauges, Horn, Lights, X Reverse Alarm and Fuses Battery X Hood Latch or Battery X Restraint Seat Belt and Seat X Rails CIL Hydraulic Oil ("FULL" mark) X E25-40XM, E25-40XM 2 X E45-65XM, E45-65XM 2 X J40-60XM, J40-60XM 2 Parking Brake X CIL Check operation Check condition Check operation Check condition C 19 liter (20 qt) C 23 liter (24 qt) C 27 liter (29 qt) Check operation L 11 Lift Chains X L X 15 Fork Pins And Guides 18 Hydraulic Filter See NOTE 1 L L C −180 to 38 C (0 to 100 F) SAE 10W API SC/CC Silicone Spray Hyster P/N 328388 Lubricate linkage Check condition 30W Motor oil and lubrication or Hyster Chain Check and Cable adjustment and Lubricant (P/N length 171350) As necessary Motor oil 1 See Parts Manual X=Check C=Change L=Lubricate CIL=Check Indicator Light during operation NOTE 1: Equalization charge is required approximately each month. NOTE 2: Multipurpose grease with 2 to 4% Molybdenum Disulfide. NOTE 3: Lubricate lower spindle bearings at 250 hours and upper bearings during assembly. NOTE 4: Replace the contacts in the hydraulic pump contactor every 1000 hours of operation. Replace the other contacts in the contactors when the thickness is 30% of a new contact. See the Service Manual for detailed information. NOTE: Never use steam to clean electrical parts. 5 Maintenance Schedule 8000 SRM 552 Table 1. Maintenance Schedule (Continued) Item Item No. 3 Motor Brushes 6 Service Brakes 8 Brake Fluid Seat Brake and Parking Brake Adjustment 16 Wheel Nut Torque E25-40XM, E25-40XM 2 Drive Wheels (Wheel Bolts) Steer Wheels (Whl. Nuts Pneu.) Steer Wheel Castle Nuts (Cushion) E45-65XM, E4565XM 2 J40-60XM, J40-60XM 2 Drive Wheels (Wheel Nuts) Steer Wheels (J40-60XM 2) 19 Steering Axle Rod Ends (Steering Cyl.) King Pins 8 hr/ 250 hr/ 500 hr/ 1000 hr/ 2000 hr/ Procedure or Specification 1 day 6 wks. 3 mo. 6 mo. 1 yr. Quantity CIL X Check condition See Parts Manual X CIL CIL X X Check operation See Parts Manual Check condition 0.24 liter (0.5 pt) SAE J-1703 X Adjust as necessary X Check torque Must hold a load on a 15% grade 332 N•m (245 lbf ft) Check torque 156 N•m (115 lbf ft) Check grease Multipurpose and tighten to Grease correct torque See NOTE 2 68 N•m (50 lbf ft) Initial 3 N•m (2 lbf ft) Final X X X 237 to 305 N•m (175 to 225 lbf ft) 237 to 305 N•m Check torque (175 to 225 lbf ft) Check operation Lubricate as 2 Fittings required 2 Fittings Multipurpose See NOTE 3 grease See NOTE 2 Check torque X L L Tie Rods L E25-40XMS 6 Fittings L J40-65XM 6 Fittings X=Check C=Change L=Lubricate CIL=Check Indicator Light during operation NOTE 1: Equalization charge is required approximately each month. NOTE 2: Multipurpose grease with 2 to 4% Molybdenum Disulfide. NOTE 3: Lubricate lower spindle bearings at 250 hours and upper bearings during assembly. NOTE 4: Replace the contacts in the hydraulic pump contactor every 1000 hours of operation. Replace the other contacts in the contactors when the thickness is 30% of a new contact. See the Service Manual for detailed information. NOTE: Never use steam to clean electrical parts. 6 8000 SRM 552 Maintenance Schedule Table 1. Maintenance Schedule (Continued) Item Item 8 hr/ 250 hr/ 500 hr/ 1000 hr/ 2000 hr/ Procedure or Specification No. 1 day 6 wks. 3 mo. 6 mo. 1 yr. Quantity 10 Mast Check condition See NOTE 2 9 L Pivots 2 Fittings Multipurpose 10 L Sliding Surfaces As required grease 12 L Sideshift Carriage 4 Fittings 12 X C Integral Sideshift Check wear 2.5 mm (3/32 in.) Carriage or less (Upper/Lower 4 Bearings Bearings) 20 Contactors X C Check condition See Parts Manual See NOTE 4 Hinges, Levers, L L As required Multipurpose Linkage, Pedals Seat grease Rails See NOTE 2 or Silicone Spray Hyster P/N 328388 14 Differential/Speed Ultr Gear Lube Reducer SAE 80W or Gear X C 2.9 liter (3.1 qt) Oil SAE 80W-90 E25-40XM, E25-40XM 2 (Chevron) or X C 4.2 liter (4.4 qt) equivalent E45-65XM, E45-65XM 2 X C 3.7 liter (3.9 qt) J40-60XM, J40-60XM 2 5 Hydraulic Tank X C Clean or replace See Parts Manual Breather 2 Wheel Bearings L As necessary Multipurpose grease See NOTE 2 Seat Plate And Seat L Use Silicon Spray Brake Pivots Hyster P/N 328388 Brake Linkage And L Multipurpose Shaft grease See NOTE 2 Hoist And Tilt X Lubricate as Use Silicon Spray Controls necessary Hyster P/N 328388 Steering Column Tilt X Lubricate as Use Silicon Spray Mechanism necessary Hyster P/N 328388 X=Check C=Change L=Lubricate CIL=Check Indicator Light during operation NOTE 1: Equalization charge is required approximately each month. NOTE 2: Multipurpose grease with 2 to 4% Molybdenum Disulfide. NOTE 3: Lubricate lower spindle bearings at 250 hours and upper bearings during assembly. NOTE 4: Replace the contacts in the hydraulic pump contactor every 1000 hours of operation. Replace the other contacts in the contactors when the thickness is 30% of a new contact. See the Service Manual for detailed information. NOTE: Never use steam to clean electrical parts. 7 Maintenance Procedures Every 8 Hours or Daily 8000 SRM 552 Maintenance Procedures Every 8 Hours or Daily HOW TO MAKE CHECKS WITH KEY OFF Tires and Wheels WARNING Air pressure in pneumatic tires can cause tire and wheel parts to explode. The explosion of wheel parts can cause serious injury or death. Remove all of the air from the tires before the tires are removed from the lift truck. If the air pressure is less than 80% of the correct air pressure, the tire must be removed before air is added. Put the tire in a safety cage when adding air pressure to the tire. Follow the procedures described in Add Air to Tires. When air is added to the tires, use a remote air chuck. The person adding air must stand to the side of the safety cage and not in front of it. Inspect the tires for wire, rocks, glass, pieces of metal, holes, cuts and other damage. See Figure 5. Remove any object that will cause damage. Check for loose or missing hardware. Remove any wire strapping or other material that is wrapped around the axle. Make sure the wheel bolts or nuts are tight. Tighten the wheel bolts or nuts in a cross pattern to the correct torque value shown in the Maintenance Schedule table. If the lift truck has pneumatic tire, keep the tires at the correct air pressure. See the Nameplate. Check the air pressure with a gauge when the tires are cold. If it is necessary to add air to a tire that is warm, check one of the other tires on the same axle and add air to the tire that has low pressure so that the air pressures are equal. The air pressure of the warm tires must always be equal to or greater than the specification for air pressure for cold tires. Check pneumatic wheels for bent or damaged rims. Check for loose or missing parts. 1. CHECK FOR DAMAGE (REMOVE NAILS, GLASS, AND OTHER OBJECTS FROM TREAD) 2. MAKE SMOOTH EDGES 3. CHECK TIRE PRESSURE (PNEUMATIC TIRES) Figure 5. Tires Check CAUTION Check all wheel bolts or nuts after 2 to 5 hours of operation: when new lift trucks begin operation and on all lift trucks when the wheels have been removed and installed. Tighten the bolts or nuts in a cross pattern to the correct 8 torque value shown in the Maintenance Schedule. When the bolts or nuts stay tight for eight hours, the interval for checking the torque can be extended to 500hours. Tighten the castle nuts of the steer wheel spindles of these units to 68 N•m (50 lbf ft) while rotating the wheel in each direction at EACH installation. Loosen the nuts 1/4 turn. Pull and push at top of wheel to 8000 SRM 552 Maintenance Procedures Every 8 Hours or Daily check for movement (end play). If there is movement, tighten the castle nuts to 3 N•m (2 lbf ft). Install the cotter pins at the nearest alignment positions. Install the hub cap. Additional torque checks are not required. Forks The identification of a fork is determined by how it is connected to the carriage. These lift trucks have hook forks. Adjust Hook forks are connected to the carriage by hooks and lock pins. See Figure 6. These lock pins are installed through the top fork hooks and fit into slots in the top carriage bar. Adjust the forks as far apart as possible for maximum support of the load. Raise the lock pin in each fork to slide the fork on the carriage bar. Make sure the lock pin is engaged in the carriage bar to lock the fork in position after making adjustments. 4. LOCK PIN ASSEMBLY 5. CARRIAGE 1. FORK REMOVAL NOTCH 2. FORK 3. HOOK Figure 6. Hook Fork Remove WARNING Do not try to lift a fork without a lifting device. The forks can weigh up to 400 lb each. Slide a hook fork to the fork removal notch on the carriage. See Figure 6 and Figure 7. Lower the fork onto blocks so that the bottom hook of the fork moves through the fork removal notch. Lower the carriage further so that the top hook of the fork is disengaged from the top carriage bar. Move the carriage away from the fork, or use a lifting device to move the fork away from the carriage. 1. CARRIAGE BARS 2. HOOK FORK 3. BLOCKS Figure 7. Hook Fork Removal 9 Maintenance Procedures Every 8 Hours or Daily 8000 SRM 552 Install Move the fork and carriage so that the top hook on the fork can engage the top carriage bar. Raise the carriage to move the lower hook through the fork removal notch. Slide the fork on the carriage so that both upper and lower hooks engage the carriage. Engage the lock pin with a notch in the top carriage bar. Forks, Mast, and Lift Chains, Inspect WARNING NEVER work under a raised carriage or forks. Lower the carriage or use chains on the mast weldments and carriage so that they cannot move. Make sure the moving parts are attached to a part that does not move. Do not try to correct fork tip alignment by bending the forks or adding shims. Replace bent forks. Never repair damaged forks by heating or welding. Forks are made of special steel using special procedures. Replace damaged forks. 1. Inspect the welds on the mast and carriage for cracks. Make sure that the nuts and bolts are tight. 2. Inspect the channel for excessive wear in the areas of roller contact. Check the rollers for wear or damage. 3. Inspect the load backrest extension for cracks and damage. 4. Inspect the forks for cracks and wear. Check that the fork tips are aligned as shown in Figure 8. Check that the bottom of the fork is not worn. Fork Tip Alignment Length of Forks 3% Dimension 915 mm (36 in.) 1220 mm (48 in.) 1830 mm (72 in.) 27 mm (1.10 in.) 37 mm (1.45 in.) 55 mm (2.15 in.) 1. TIP ALIGNMENT (MUST BE WITHIN 3% OF FORK LENGTH) 2. CRACKS 3. LATCH DAMAGE 4. HEEL OF FORK (MUST BE 90% OF DIMENSION "X") 5. CARRIAGE 6. LOAD BACKREST EXTENSION 7. MAXIMUM ANGLE 93 Figure 8. Forks Check 5. Replace any damaged or broken parts that are used to keep the forks locked in position. 6. Inspect the lift chains for the correct lubrication. Use engine oil or Hyster Chain and Cable Lubricant available from your dealer for Hyster lift trucks. 7. Inspect the lift chains for cracks or broken links and pins. See Figure 9. 8. Inspect the chain anchors and pins for cracks and damage. 10 9. Inspect the chain anchors and pins for cracks and damage. 10. Make sure the lift chains are adjusted so that they have equal tension. If the chains need repair or adjustment, it must be done by authorized personnel. See Lift Chain Adjustments. 8000 SRM 552 Maintenance Procedures Every 8 Hours or Daily the operator and battery restraint systems on the E25-65XM, E25-65XM 2 models. The control lever assembly and latch are also part of the J40-65XM, J4065XM 2 operator restraint system. Each item must be checked to make sure it is attached securely, functions correctly and is in good condition. The seat belt must latch securely. Make sure the seat belt extends and retracts smoothly and is not damaged nor torn. If the seat belt cannot be pulled from the belt housing, the seat belt assembly must be replaced. Keep the belt straight so that it pulls out and retracts smoothly. Make sure the seat rails are not loose. The seat rails must lock securely in position, but move freely when unlocked. The seat rails must be securely attached to the mounting surface. 1. WORN PIN 2. CRACKS 3. EDGE WEAR (MAXIMUM 5% OF NEW) 4. 5. 6. 7. HOLE WEAR LOOSE LEAVES DAMAGED PIN CORROSION Figure 9. Lift Chains Check Safety Labels WARNING Safety labels are installed on the lift truck to give information about possible hazards. It is important that all safety labels are installed on the lift truck and can be read. Check that all safety labels are installed in the correct locations on the lift truck. See the Parts Manual or the Frame section of the Service Manual for the correct locations of the safety labels. Steering Column Latch Make sure the latch for the steering column operates correctly. The latch must NOT allow the column to move unless the latch is released. Operator Restraint System There is an indicator light on the display panel for the seat belt. The red light is ON as described in the Operating Manual. The light can help the operator remember to fasten the seat belt. The seat belt, hip restraint brackets and the seat and mounting are the parts of the operator restraint system. See Figure 10. The hood latch is also part of 1. HIP RESTRAINT BRACKETS 2. SEAT BELT 3. HOOD LATCH Figure 10. Operator Restraint System Battery Restraint System E25-65XM and E25-65XM 2 WARNING The hood and battery restraint with its latch mechanisms must operate correctly before a lift truck is operated. The battery restraint and hood frame is a heavy steel weldment that has a hinge at the front of the battery compartment. An adjustable spacer plate is used inside the battery compartment to prevent forward and backward movement of the battery. Side spacers prevent side-to-side movement of the battery of E2535XM, E40XM, E25-35XM 2, and E40XMS 2 models. 11 Maintenance Procedures Every 8 Hours or Daily The batteries of E45-65XM 2 models must fit the battery compartment width with a maximum of 13 mm (0.5 in.) clearance. Maximum movement allowed is 13 mm (0.5 in.) in any horizontal direction. The hood must be locked in the down position during operation. The battery must have the front spacer plate and side spacers correctly adjusted to prevent any horizontal movement of more than 13 mm (0.5 in.). If the unit has a seat brake, raise the seat and seat plate assembly. Use the latch handle at the rear of the hood to release the hood frame and battery restraint. See Figure 11. Raise the latch handle and slide the handle toward the right side of the truck. A spring moves the handle back to the 1. 2. 3. 4. 5. 6. HOOD SEAT LATCH ASSEMBLY BATTERY RESTRAINT AND HOOD FRAME GAS SPRING HINGE 8000 SRM 552 left. Use the lift handle by the seat to raise the hood. A gas spring and stop rod will hold the assembly in the up position. Make sure that the battery cannot move more than a total of 13 mm (0.5 in.) in any one horizontal direction. Release the stop rod by moving it to the right before lowering hood. See the label in Figure 11. Make sure the latch handle is fully to the right when closing the hood so that the latch can engage the latch piece. Make sure the hood is locked securely. Try to raise the hood using only the lift handle to make sure the hood is latched and will not move. If necessary, adjust the front and side spacer plates for the battery as shown in Figure 37. 7. 8. 9. 10. 11. 12. STOP ROD RELEASE LABEL FOR STOP ROD COUNTERWEIGHT LATCH HANDLE LIFT HANDLE BATTERY RESTRAINT WARNING LABEL Figure 11. Battery Restraint E25-65XM and E25-65XM 2 Battery Restraint System J40-65XM and J40-65XM 2 must fit the battery compartment width with a maximum of 13 mm (0.5 in.) clearance. The battery restraint is a heavy steel rod at the rear of the battery compartment. See Figure 12. An adjustable spacer plate is used inside the battery compartment to prevent forward and backward movement of the battery. The batteries for these lift trucks The hood cannot be closed unless the battery restraint is engaged. The battery restraint rod at the top rear of the battery compartment must be aligned over the edge of the battery. The handle of the battery restraint must also be in the down position to close the hood. Use the handle to move the battery 12 8000 SRM 552 Maintenance Procedures Every 8 Hours or Daily restraint rod over the edge of the battery so that the handle can be moved to the down position. can cause personal injury when the battery is connected. Never put tools or other metal on the battery. Metal on the battery can cause a short circuit and possible damage or injury. The acid in the electrolyte can cause injury. If the electrolyte is spilled, use water to flush the area. Make the acid neutral with a solution of sodium bicarbonate (soda). Acid in the eyes must be flushed with water immediately. Batteries generate explosive fumes. Keep the vents in the caps clean. Keep sparks or open flames away from the battery area. Do not make a spark from the battery connections. Disconnect the battery when doing maintenance. Make sure that the voltage and the weight of the battery are correct as shown on the nameplate. A. RETRACTED B. EXTENDED 1. BATTERY RESTRAINT WARNING LABEL 2. HOOD 3. BATTERY RESTRAINT 4. BATTERY Figure 12. Battery Restraint J40-65XM and J40-65XM 2 Battery NOTE: There can be one of two types of batteries. One type has removable cell caps. The other type has sealed cells. The sealed batteries require a different charger, the electrolyte level or specific gravity cannot be checked and water cannot be added to the electrolyte. WARNING On lift trucks other than the "XM 2" were operated with a low battery, inspect all contactors for welded contacts BEFORE you connect a charged battery, The lift truck cannot be controlled if contacts are welded. This condition Keep the battery case, top cover and the area for the battery clean and painted. Leakage from the battery and corrosion can cause a malfunction in the electric controls of the lift truck. Use a water and sodium bicarbonate (soda) solution to clean the battery and the battery area. Keep the top of the battery clean, dry and free of corrosion. Make sure the battery is charged and has the correct voltage and ampere hour rating for the lift truck. See the nameplate. Inspect the battery case, connector and cables for damage, cracks or breaks. See the battery dealer in the area to repair any damage. On batteries with cell caps, check the level of the electrolyte daily on a minimum of one cell. Add only distilled water, as necessary, to all cells that do not have the correct electrolyte level. The correct level is halfway between the top of the plates and the bottom of the fill hole. 13 Maintenance Procedures Every 8 Hours or Daily 8000 SRM 552 Hydraulic System WARNING At operating temperature the hydraulic oil is HOT. Do not permit the oil to contact the skin and cause a burn. CAUTION Do not permit dirt to enter the hydraulic system when the oil level is checked or the filter is changed. Never operate the pump without oil in the hydraulic system. The operation of the hydraulic pump without oil will damage the pump. Check the hydraulic oil level when the oil is at operating temperature, the carriage is lowered and the key is in the OFF position. The fill/dipstick cap is under the left side of the flat floor plate. Add hydraulic oil only as needed. If more hydraulic oil is added than the "FULL" level, the hydraulic oil will leak from the breather during operation. Figure 14. Hydraulic Oil Check E45-65XM and E45-65XM 2 NOTE: The dipstick for the J40-65XM, J40-65XM 2 trucks is under the hood in front of the counterweight. See Figure 15. Inspect the hydraulic system for leaks and damaged or loose components. NOTE: The dipstick/fill for the E25-35XM, E40XMS, E25-35XM 2, and E40XMS 2 trucks is under the floor plate near the left side. See Figure 13. Figure 15. Hydraulic Tank Fill and Dipstick J40-65XM and J40-65XM 2 HOW TO MAKE CHECKS WITH KEY ON WARNING 1. FILL CAP AND DIPSTICK 2. BREATHER (AGAINST FRAME) Figure 13. Hydraulic Tank Fill and Dipstick E25-40XMS and E25-40XMS 2 NOTE: The dipstick/fill for the E45-65XM 2 trucks is under the battery connector on the left side. See Figure 14. 14 FASTEN YOUR SEAT BELT! The seat belt is installed to help the operator stay on the truck if the lift truck tips over. IT CAN ONLY HELP IF IT IS FASTENED. Make sure the area around the lift truck is clear before moving the lift truck. Be careful when making the checks. Proceed carefully. 8000 SRM 552 Gauges, Horn, and Fuses 1. Check the operation of the gauges and horn. The horn will operate when the key is in any position. On both the standard and enhanced or premium display panels, the hourmeters record the hours during operation. The hours are displayed on the digital display or the LCD screen as described in the Operating Manual. 2. The battery indicator will operate as described in the Operating Manual. 3. Most fuses are located in the electrical compartment. Steering System WARNING Because the lift truck has hydraulic power steering, the steering can be difficult when the power steering pump is not operating. Make sure that the steering system operates smoothly and gives good steering control. Service Brakes WARNING Loss of fluid from the brake fluid reservoir indicates a leak. Repair the brake system before using the lift truck. Replace the brake fluid in the system if there is dirt, water or oil in the system. There is an indicator light on the display panel for the brake fluid level. The red light is ON as described in the Operating Manual. If the light is ON during operation, the fluid in the reservoir for the brake master cylinder is too low. Add brake fluid and check for leaks. The reservoir is under the brake pedal and floor plate. Clean the area around the fill cap so that no dirt enters the reservoir. Check the operation of the service brakes. Push on the brake pedal. The brakes must be applied before the pedal reaches the floor plate. The brake pedal must stop firmly and must not move slowly down after the brakes are applied. The brakes must apply equally to both drive wheels with no noticeable pull to either side. The service brakes are automatically adjusted as the brakes are applied when the lift truck changes directions. Maintenance Procedures Every 8 Hours or Daily NOTE: Some lift trucks are used in operations where the automatic adjusters can be slow to adjust the brake shoes. If the brakes need adjustment, operate the lift truck in forward and reverse 10 times. Apply the brake pedal firmly, but do not cause the wheels to slide. If the automatic adjusters do not adjust the brake shoes, a qualified service person must check the operation and condition of the brakes. Parking Brake There is an indicator light on the display panel for the parking brake. The red light is ON as described in the Operating Manual. If the light is ON after approximately one second, the operator is not on the seat or the key is in the OFF position. An alarm will also make a noise. ALWAYS apply the parking brake when leaving the seat. Make sure the service brakes operate correctly before checking the operation of the parking brake. Check the operation of the parking brake. The parking brake, when in good condition and correctly adjusted, will hold a lift truck with a capacity load on a 15% grade (1.5 ft rise in 10 ft). If necessary, adjust the parking brake by first making sure the lift truck cannot move (block wheels). Release the parking brake and remove the floor plates for access to the adjustment knob at the bottom of the pedal linkage. Turn the knob clockwise to increase the braking force. Some lift trucks are equipped with an additional linkage that automatically actuates a separate brake when the operator leaves the seat (seat brake). When correctly adjusted, this brake will also hold the lift truck with a capacity load on a 15% grade. If the brake does not hold the lift truck on the grade, the seat brake must be adjusted by authorized service personnel according to the procedure in the Brake section of the Service Manual. Control Levers and Pedals Check that the levers for the mast and attachment operate as described in the Operating Manual. The brake pedals are checked in the previous Service Brakes and Parking Brake paragraphs with the operation of the brakes. 15 Maintenance Procedures Every 250 Hours or Six Weeks Direction and Speed Control Pedals Check that the direction and speed control pedals operate as described in the Operating Manual. Lubricate the direction lever and accelerator pedal joints as needed. See Maintenance Schedule. 8000 SRM 552 and lower smoothly in the correct sequence. The carriage raises first, then the inner weldment and intermediate weldment (three-stage masts only). NOTE: Some parts of the mast move at different speeds during raising and lowering. Lift System Operation WARNING NEVER work under a raised carriage or forks. Lower the carriage or use chains on the mast weldments and carriage so that they cannot move. Make sure the moving parts are attached to a part that does not move. Do not try to locate hydraulic leaks by putting hands on pressurized hydraulic components. Hydraulic oil can be injected into the body by pressure. 1. Check for leaks in the hydraulic system. Check the condition of the hydraulic hoses and tubes. 3. The inner and intermediate weldments and the carriage must lower completely. 4. Raise the forks three feet, with a capacity load. The inner weldment and carriage must raise smoothly. Lower the forks. All moving components must lower smoothly. 5. With the load lowered, tilt the mast backward and forward. The mast must tilt smoothly and both tilt cylinders must stop evenly. 6. Check that the controls for the attachment operate the functions of the attachment. See the symbols by each of the controls. Make sure all of the hydraulic lines are connected correctly and do not leak. 2. Slowly raise and lower the mast several times without a load. The mast components must raise Maintenance Procedures Every 250 Hours or Six Weeks NOTE: Do these procedures in addition to the 8-hour checks. STEERING TIE RODS NOTE: Lubricate steering tie rods at 250 hours for model E25-40XMS and E25-40XMS 2 only. Lubricate the steering tie rods with multipurpose grease (see Maintenance Schedule). More frequent lubrication may be required if the lift truck operates in dirty or difficult conditions. See Figure 16. NOTE: MODEL J40-60XM SHOWN. 1. TIE ROD 2. LUBE FITTING (6) Figure 16. Lubricate Steering Tie Rods 16 8000 SRM 552 Maintenance Procedures Every 500 Hours or Three Months Maintenance Procedures Every 500 Hours or Three Months NOTE: Do these procedures in addition to the 8-hour checks. DIFFERENTIAL AND SPEED REDUCER WARNING HYDRAULIC TANK BREATHER Check and clean the hydraulic tank breather. Clean the breather when it is dirty and will not permit the easy passage of air. The breather for the E25-40XMS, E25-40XMS 2 is fastened to the truck frame to the left of the fill and dipstick cap. See Figure 13. The breather for the E45-65XM and E45-65XM 2 is fastened to the truck frame to the right of the control valve on a hose to the hydraulic tank. The breather for the J40-65XM and J40-65XM 2 is part of the fill cap and dipstick. Do not work under a raised carriage. Lower the carriage or use a chain to prevent the carriage and the inner or intermediate weldments from lowering when doing maintenance. Make sure that the moving parts are attached to parts that can not move. Check the oil level at fill plug. Add oil slowly at the fill plug. See Figure 17 for E/J40-65XM and E/J40-65XM 2. See Figure 18 for E25-40XMS and E25-40XMS 2. Fill until oil just starts to flow out the fill plug hole. Add oil only if the oil level is low. The oil must flow through the bearings to the speed reducer, so filling slowly is necessary to indicate the correct level. A. E45-65XM AND E45-65XM 2 B. J45-65XM AND J45-65XM 2 1. 2. 3. 4. DRAIN PLUG (ON BOTTOM) FILL PLUG DIPSTICK (E45-65XM AND E45-65XM 2 ONLY) (NOT USED ON LATER PRODUCTION LIFT TRUCKS) BREATHER Figure 17. Differential 17 Maintenance Procedures Every 500 Hours or Three Months 8000 SRM 552 STEERING AXLE SPINDLES Use multipurpose grease to lubricate the king pins in the steering axle. See the section the Steering Axle 1600 SRM 619 XMS (E25-40XMS, E25-40XMS 2), 1600 SRM 258 (E45-65XM, E45-65XM 2), or 1600 SRM 316 (J40-65XM, J40-65XM 2) of the Service Manual to disassemble and lubricate the king pin bearings. STEERING TIE RODS NOTE: Lubricate the steering tie rods at 500 hours for model J40-65XM only. Lubricate the steering tie rods with multipurpose grease. More frequent lubrication may be required if the lift truck operates in dirty or difficult conditions. See Lubricate Steering Tie Rods. MAST WARNING Cleaning solvents can be flammable and toxic and can cause skin irritation. When using cleaning solvents, always follow the recommendations of the manufacturer. 1. DRAIN PLUG (ON BOTTOM) 2. FILL PLUG 3. DIPSTICK 4. BREATHER Figure 18. Differential and Speed Reducer E25-40XMS and E25-40XMS 2 WHEEL NUT TORQUES WARNING Check all wheel nuts after 2 to 5 hours of operation: when new lift trucks begin operation and on all lift trucks when the wheels have been removed and installed. Tighten the nuts in a cross pattern to the correct torque value shown in the Maintenance Schedule. When the nuts stay tight for eight hours, the interval for checking the torque can be extended to 500 hours. Tighten wheel nuts as required. See Wheels, Install and tighten the nuts to the torque value shown in the Maintenance Schedule. 18 When working on or near the mast, see Safety Procedures When Working Near Mast in this section. Metal particles can fall into the eyes during the operation of the mast. Failure to remove these particles can cause eye injury. Remove metal particles that are attached to the edges of mast parts with a grinder if necessary. Always wear eye protection when using a grinder. CAUTION Do NOT use steam or high-pressure water to clean the load rollers or the lift chains. Steam and high- pressure water can remove the lubrication from the bearings in the load rollers. Water in the bearings of the sheaves and the link pins of chains can also shorten the service life of these parts. 1. Clean the mast assembly. Inspect the mast channels in the areas where the rollers travel. If there are loose particles or metal particles that are attached to the edges of mast parts, remove these particles. 8000 SRM 552 Maintenance Procedures Every 500 Hours or Three Months 2. Lubricate the sliding surfaces and the load roller surfaces along the full length of the channels as shown in Figure 19. Only apply lubricant to surfaces that are clean and dry. Only apply lubricant to the darker areas as indicated by (1) and (2). LIFT CHAINS Wear Check WARNING Do not repair a worn or damaged lift chain. Replace a worn or damaged lift chain with a new chain. If a pair of lift chains is used in the mast, both lift chains must be replaced. If a section of chain is 3% longer than a similar section of new chain, the chain is worn and must be replaced. Check the chain at a section of chain that goes over a chain sheave. If a chain scale is available, check the lift chains as shown in Figure 20. If a chain scale is not available, measure 20 links of chain. Measure from the center of a pin to the center of another pin 20 links away. Compare the length with the chart in Figure 20. Replace the chain if the length of 20 links of the worn section is more than the WEAR LIMIT. NOTE: MAST IS DIFFERENT, BUT LUBRICATION AREAS ARE THE SAME. A. UPPER LOAD ROLLERS B. LOWER LOAD ROLLERS 1. LUBRICATE STRIP BEARINGS SURFACES 2. LUBRICATE LOAD ROLLER SURFACES 3. LOAD ROLLER Figure 19. Mast Lubrication NOTE: Some applications will require more frequent cleaning and lubrication of the mast assembly. Do NOT use a lubricant-spray on the surfaces of the mast channels where the load rollers make contact. The use of the correct lubricant is important. Use multipurpose grease (Hyster Part No. 3020381) or an equivalent grease with 2% to 4% molybdenum disulfide. The load rollers and sheaves have sealed bearings that do not need additional lubrication. 3. Lubricate the pivots for the mast at the grease fittings on the pivots or the pivot pins. Use multipurpose grease. 4. If a sideshift carriage is installed, lubricate the fittings for the rollers or the sliding surfaces with multipurpose grease. Inspect the lift chains for edge wear. See Figure 9. Make sure the edge wear of the chain is not greater than 5% compared to a chain link that is not worn. FORKS WARNING Never repair damaged forks. Do not heat, weld, or bend the forks. Forks are made of special steel using special methods. Replace damaged forks. 1. Check the heel and attachment points of the forks with a penetrant or magnetic particle inspection. 2. Measure the thickness of the forks at a vertical section where there is no wear. See Figure 8. This is dimension X. Now measure the thickness at the heel of the fork. If the thickness is not more than 90% of dimension X, replace the fork. 3. Use clean engine oil as necessary to lubricate the fork guides of the carriage and the locks for the forks. 19 Maintenance Procedures Every 500 Hours or Three Months 8000 SRM 552 BRAKE FLUID WARNING Loss of fluid from the master cylinder indicates a leak. This condition can cause brake failure. The result can be material damage or personal injury. Repair the brake system before the lift truck is used. Replace the brake fluid in the system if there is dirt, water, or oil in the system. CHECK THE INDICATOR LIGHT DURING OPERATION. There is an indicator light on the display panel for low brake fluid. The red light is ON for approximately eight to ten seconds when the key is first moved to the ON position. The light comes on during operation when brake fluid is low. Pitch 12.7 mm (0.50 in.) 15.9 mm (0.63 in.) 19.1 mm (0.75 in.) 25.4 mm (1.00 in.) 31.8 mm (1.25 in.) 44.5 mm (1.75 in.) 50.8 mm (2.00 in.) Total length of Wear Limit 20 links (pitch) The maximum of new chain length of 20 links. 254.0 mm (10.0 in.) 317.5 mm (12.5 in.) 381.0 mm (15.0 in.) 508.0 mm (20.0 in.) 635.0 mm (25.0 in.) 889.0 mm (35.0 in.) 1016.0 mm (40.0 in.) 261.6 mm (10.3 in.) 327.0 mm (12.9 in.) 392.4 mm (15.6 in.) 523.25 mm (20.6 in.) 654.1 mm (25.75 in.) 915.7 mm (36.05 in.) 1046.5 mm (41.2 in.) NOTE: THE INSTRUCTIONS FOR MEASURING CHAIN WEAR ARE SHOWN ON THE CHAIN WEAR SCALE. 1. CHAIN WEAR SCALE Figure 20. Lift Chains Check 20 Check the brake fluid in the reservoir for the master cylinder. The reservoir is under the floor plate near the brake pedal. Add brake fluid as necessary. Use the brake fluid shown in the Maintenance Schedule. OTHER LUBRICATION Lubricate hinges, pins, linkages, cables, pedals, and levers as necessary. Use SAE 30 oil, multipurpose grease, or silicone lubricant-spray (Hyster Part No. 328388) as needed. See the Maintenance Schedule. SEAT BRAKE (E25-65XM AND E25-65XM 2 ONLY) Adjust the seat brake for parking as described in the section the Brake System 1800 SRM 574 (E45-65XM and E45-65XM 2) or 1800 SRM 620 (E25-40XMS and E25-40XMS 2) (of the Service Manual. Lubricate the linkage for the brake as shown in Figure 21. See the Maintenance Schedule for lubricants. 8000 SRM 552 Maintenance Procedures Every 500 Hours or Three Months • Diagrams 8000 SRM 551, (E/J40-65XM) • Diagrams 8000 SRM 622, (E25-40XMS) Additional information for the EV-T100, SR (SEM) or SP Transistor motor controllers is available in the following sections of the Service Manual: • EV-T100™ Transistor Motor Controller Description, Checks, Adjustments, and Troubleshooting 2200 SRM 581 • Transistor Motor Controllers (SR and SP) Description & Operation and Repairs & Adjustments 2200 SRM 724 • Diagrams 8000 SRM 551, (E/J40-65XM) • Diagrams 8000 SRM 622, (E25-40XMS) • Electrical Diagrams Transistor Motor Controllers (SR and SP) (SEM) 8000 SRM 742, (E25-65XM2, J40-65XM2, and N30XMH2) Contactors A. LUBRICATE 1. BEARING 2. ROD 3. BRACKET Figure 21. Lubricate Linkage for Seat Brake ELECTRICAL INSPECTION WARNING Disconnect the battery connector to prevent injury from electric shock before you make any inspections or repairs. Discharge the capacitors when you make any inspections or repairs inside of the electrical compartment. These lift trucks can have either the EV-100ZX SCR motor controller (Figure 23, Figure 24, Figure 25, and Figure 26) the EV-T100™, SR (SEM) or SP Transistor motor controllers (Figure 27, Figure 28, Figure 29, or Figure 30). These motor controllers are made for Hyster Company by the General Electric Company. Additional information for the EV-100ZX SCR motor controllers is available in the following sections of the Service Manual: • EV-100ZX™ Motor Controller Description & Operation and Repairs & Adjustments 2200 SRM 557 The contactor contacts are made of a special silver alloy. See Figure 22, Figure 23, Figure 24, Figure 27, and Figure 28. The contacts will look black and rough from normal operation. This condition does not cause problems with the operation of the lift truck. Cleaning is not necessary. DO NOT USE A FILE ON THE CONTACTS. DO NOT LUBRICATE THE CONTACTS. Always replace the contacts in sets. Check for equal spring tension if the contacts do not wear evenly. Motor Brushes CHECK THE INDICATOR LIGHT DURING OPERATION. There is an indicator light on the display panel for motor brushes on some trucks. The red light is ON for approximately eight to ten seconds when the key is first moved to the ON position. The light comes on during operation when motor brushes are worn and need to be replaced. NOTE: E25-40XMS and E25-40XMS 2: The traction motor, hydraulic pump motor, and the steering pump motor are below the battery compartment. Remove the battery and the access panel to check the motors. NOTE: E45-65XM and E45-65XM 2: The traction motor and the hydraulic pump motor are below the battery compartment. Remove the battery and the access panel to check the motors. The steering pump motor is on a vertical mount below the floor plate. Remove the floor plates for access to the steering pump motor. 21 Maintenance Procedures Every 500 Hours or Three Months NOTE: J40-65XM and J40-65XM 2: The traction motor is under the floor plate of the operator’s compartment. Remove the floor plate for access. The hydraulic pump motor and the steering pump motor are behind the battery. Open the hood for access to the motors. Many service people remove the four bolts that hold the cowl to the overhead guard when doing service work under the floor plates. This action permits the cowl and steering column to lean against the mast and gives better access to the components under the floor plate. Motor Brushes, General 1. Visually inspect the commutator and brushes every 500 hours. Make sure the surface of the commutator is good and the motor operates normally. Worn motor brushes must be replaced before they damage the surface of the commutator. Move the brush spring and remove a brush from the brush holder. When the brush wears within approximately 1.5 mm (0.60 in.) of where the brush wire joins the brush, the brush must be replaced. 2. Some lift trucks are equipped with brush wear indicators on the traction and hydraulic motors. The brush wear indicators give a signal on the LED display panel, or screen of the SEM display panel, on the instrument panel. The sensor 22 8000 SRM 552 wires for the brush wear indicators of units before the "XM 2" are an insert in the brush material when it is made. When the brush wears within 1.5 mm (0.60 in.) of the brush wire, the insulation between the sensor wire and the brush material is destroyed. The connection between the brush and the sensor wire causes the LED indicator to illuminate. The brush wear indicators will not indicate a damaged commutator nor indicate a motor malfunction. On the "XM 2" units, the brush spring makes a contact when the brush is worn to the length where it must be replaced. A status code will appear on the LCD screen as an indication that the brushes must be replaced. Visually inspect the commutator and brushes on lift trucks with brush wear indicators also. 3. Inspect the brush holders for burns or damage. Make sure the brush holder is fastened tightly to the mounts at the end of the motor. Make sure the brushes will move freely and smoothly in the brush holders. 4. Check the brush springs for damage from heat and corrosion. Replace a damaged brush spring. See the section DC Motor Maintenance 620 SRM 294 of the Service Manual, for additional information to inspect the commutator and brushes. 8000 SRM 552 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Maintenance Procedures Every 500 Hours or Three Months POWER STEERING CONTACTOR FUSE 4 (40 AMP) FUSE 6 (15 AMP) FUSE 5 (15 AMP) FUSE 3 (15 AMP) FUSE 7 (3 AMP) 1A CONTACTOR FUSE 1 (500 AMP) REGENERATIVE BRAKING CONTACTOR FIELD WEAKENING RESISTOR (SOME NORTH AMERICAN TRUCKS ONLY) 11. REVERSE CONTACTOR 12. FORWARD CONTACTOR 13. FIELD WEAKENING CONTACTOR (SOME NORTH AMERICAN TRUCKS ONLY) 14. LIFT PUMP CONTACTOR (WITHOUT SCR PUMP CONTROL ONLY) 15. FUSE 2 (325 AMP) (ON SCR PANEL WITH SCR PUMP CONTROL) 16. FUSE BLOCK Figure 22. EV-100ZX Contactor Panel for E25-40XMS 23 Maintenance Procedures Every 500 Hours or Three Months 8000 SRM 552 NOTE: MOTOR CONTROLLER WITH REGENERATIVE BRAKING, 1A BYPASS, FIELD WEAKENING, AND SCR CONTROLLER FOR HYDRAULIC PUMP MOTOR. 1. SCR CONTROL FOR HYDRAULIC PUMP MOTOR CONTROL CARD 2. TRACTION WITH REGENERATIVE BRAKING CONTROL CARD 3. POWER STEERING CONTACTOR 4. 5. 6. 7. 8. 1A CONTACTOR REGENERATIVE BRAKING CONTACTOR REVERSE DIRECTION CONTACTOR FORWARD DIRECTION CONTACTOR FIELD WEAKENING CONTACTOR Figure 23. EV-100ZX SCR Motor Controller for E45-65XM 24 8000 SRM 552 Maintenance Procedures Every 500 Hours or Three Months NOTE: MOTOR CONTROLLER WITH REGENERATIVE BRAKING, 1A BYPASS, FIELD WEAKENING, AND CONTACTOR CONTROL FOR HYDRAULIC PUMP MOTOR. 1. TRACTION WITH REGENERATIVE BRAKING AND FIELD WEAKENING CONTROL CARD 2. POWER STEERING CONTACTOR 3. 1A CONTACTOR 4. REGENERATIVE BRAKING CONTACTOR 5. 6. 7. 8. REVERSE DIRECTION CONTACTOR FORWARD DIRECTION CONTACTOR FIELD WEAKENING CONTACTOR HYDRAULIC PUMP MOTOR CONTACTOR Figure 24. EV-100ZX SCR Motor Controller for E45-65XM 25 Maintenance Procedures Every 500 Hours or Three Months Figure 25. EV-100ZX SCR Motor Controller for J40-65XM 26 8000 SRM 552 8000 SRM 552 Maintenance Procedures Every 500 Hours or Three Months Legend for Figure 25 NOTE: SCR MOTOR CONTROLLER WITH REGENERATIVE BRAKING, 1A BYPASS, FIELD WEAKENING, AND SCR CONTROLLER FOR HYDRAULIC PUMP MOTOR. 1. SCR CONTROL FOR HYDRAULIC PUMP MOTOR CONTROL CARD 2. POWER STEERING CONTACTOR 3. 1A CONTACTOR 4. REGENERATIVE BRAKING CONTACTOR 5. 6. 7. 8. REVERSE DIRECTION CONTACTOR FORWARD DIRECTION CONTACTOR FIELD WEAKENING CONTACTOR TRACTION WITH REGENERATIVE BRAKING CONTROL CARD 27 Maintenance Procedures Every 500 Hours or Three Months Figure 26. EV-100ZX SCR Motor Controller for J40-65XM 28 8000 SRM 552 8000 SRM 552 Maintenance Procedures Every 500 Hours or Three Months Legend for Figure 26 NOTE: SCR MOTOR CONTROLLER WITH REGENERATIVE BRAKING, 1A BYPASS, FIELD WEAKENING, AND CONTACTOR CONTROL FOR HYDRAULIC PUMP MOTOR. 1. TRACTION WITH REGENERATIVE BRAKING AND FIELD WEAKENING CONTROL CARD 2. POWER STEERING CONTACTOR 3. 1A CONTACTOR 4. REGENERATIVE BRAKING CONTACTOR 5. 6. 7. 8. REVERSE DIRECTION CONTACTOR FORWARD DIRECTION CONTACTOR FIELD WEAKENING CONTACTOR HYDRAULIC PUMP MOTOR CONTACTOR 29 Maintenance Procedures Every 500 Hours or Three Months Figure 27. EV-T100 Transistor Motor Controller for J40-65XM 30 8000 SRM 552 8000 SRM 552 Maintenance Procedures Every 500 Hours or Three Months Legend for Figure 27 NOTE: TRANSISTOR MOTOR CONTROLLER FOR HYDRAULIC PUMP MOTOR AND TRACTION MOTOR WITH REGENERATIVE BRAKING, 1A BYPASS, AND FIELD WEAKENING. 1. TRANSISTOR CONTROL FOR HYDRAULIC PUMP MOTOR CONTROL CARD 2. POWER STEERING PUMP CONTACTOR 3. 1A CONTACTOR 4. L CONTACTOR 5. REGENERATIVE BRAKING CONTACTOR 6. 7. 8. 9. REVERSE CONTACTOR FORWARD CONTACTOR FIELD WEAKENING CONTACTOR TRANSISTOR CONTROL FOR TRACTION MOTOR CONTROL CARD 31 Maintenance Procedures Every 500 Hours or Three Months 8000 SRM 552 NOTE: CONTACTOR CONTROLLED HYDRAULIC PUMP MOTOR AND TRANSISTOR MOTOR CONTROLLER FOR TRACTION MOTOR WITH REGENERATIVE BRAKING, 1A BYPASS, AND FIELD WEAKENING. 1. 2. 3. 4. 5. CONTACTOR FOR HYDRAULIC PUMP MOTOR POWER STEERING PUMP CONTACTOR 1A CONTACTOR L CONTACTOR REGENERATIVE BRAKING CONTACTOR 6. 7. 8. 9. REVERSE CONTACTOR FORWARD CONTACTOR FIELD WEAKENING CONTACTOR TRANSISTOR CONTROL FOR TRACTION MOTOR CONTROL CARD Figure 28. EV-T100 Transistor Motor Controller for J40-65XM 32 8000 SRM 552 1. 2. 3. 4. 5. 6. FUSE 7 (15A) FUSE 6 (15A) FUSE 5 (15A) FUSE 3 (15A) POWER STEERING CONTACTOR FUSE 4 (POWER STEERING) (40A) Maintenance Procedures Every 500 Hours or Three Months 7. 8. 9. 10. 11. 12. LINE CONTACTOR OPENING IN COUNTERWEIGHT TRACTION MOTOR CONTROLLER FUSE 1 (TRACTION MOTOR) (500A) FUSE 2 (LIFT PUMP MOTOR) (325A) MOTOR CONTROLLER FOR LIFT PUMP MOTOR Figure 29. SR (SEM) Transistor Traction and SP Pump Motor Controllers for E25-65XM 2, J45-65XM 2, and N30XMH 2 33 Maintenance Procedures Every 500 Hours or Three Months 1. 2. 3. 4. 5. 6. 7. FUSE 7 (15A) FUSE 6 (15A) FUSE 5 (15A) FUSE 3 (15A) POWER STEERING CONTACTOR FUSE 4 (POWER STEERING) (40A) LINE CONTACTOR 8. 9. 10. 11. 12. 13. 8000 SRM 552 OPENING IN COUNTERWEIGHT TRACTION MOTOR CONTROLLER FUSE 1 (TRACTION MOTOR) (500A) CONTACTOR DRIVER MODULE FUSE 2 (LIFT PUMP MOTOR) (325A) CONTACTOR FOR LIFT PUMP MOTOR Figure 30. SR (SEM) Transistor Traction Motor Controller and Contactor Control for Lift Pump Motor for E25-65XM 2, J45-65XM 2, and N30XMH 2 34 8000 SRM 552 Maintenance Procedures Every 1000 Hours or Six Months Maintenance Procedures Every 1000 Hours or Six Months a. If either upper bearing is worn to less than 2.5 mm (3/32 in.) thickness, replace both upper bearings by driving the upper bearings out of the carriage bar. NOTE: Do these procedures in addition to the 500hour checks. LIFT CHAINS NOTE: Cleaning and lubrication can be needed more frequently in very dirty applications. See . b. If either lower bearing is worn to less than 2.5 mm (3/32 in.) thickness, replace both lower bearings by prying the lower bearings from the lower carriage bar. NOTE: To check for chain wear, see Maintenance Procedures Every 500 Hours or Three Months. Lubricate the lift chains with clean 30W engine oil or Hyster Chain and Cable Lubricant (Hyster Part No. 171350). FORKS Lubricate the fork pins and guides with clean, 20W motor oil. If the lift truck is used in dirty or difficult conditions, lubrication of the fork pins and guides may be required more frequently. Inspect the forks for wear. See Maintenance Procedures Every 8 Hours or Daily for the procedure to inspect the forks. CHECK UPPER AND LOWER BEARINGS, INTEGRAL SIDESHIFT CARRIAGE 1. Lower the carriage completely and remove the forks. 2. Remove the backrest and the lower mounting hooks from the sideshift carriage. NOTE: TWO AND THREE-STAGE FULL FREE-LIFT CARRIAGE SHOWN. 3. Use a crane with a capacity of at least 450 kg (1000 lb)to lift the outer frame away from the inner carriage. 1. 2. 3. 4. 5. 4. Clean the bearing areas. Inspect the sideshift bearings for wear as follows: UPPER BEARING LOWER HOOK LOAD ROLLER SNAP RING SIDESHIFT CYLINDER 6. 7. 8. 9. 10. LOWER BEARING SHIMS INNER CARRIAGE LUBE FITTING OUTER FRAME Figure 31. Integral Sideshift Carriage 35 Maintenance Procedures Every 2000 Hours or Yearly 8000 SRM 552 Maintenance Procedures Every 2000 Hours or Yearly Do these procedures in addition to the 1000-hour checks. HYDRAULIC SYSTEM Change Filter for Hydraulic Oil WARNING The hydraulic oil is HOT at operating temperature. Do not permit the hot oil to contact the skin and cause a burn. CAUTION Do not permit dirt to enter the hydraulic system when the oil level is checked or the filter is changed. Dirt can cause damage to components of the hydraulic system. Never operate the pump without oil in the hydraulic system. The operation of the hydraulic pump without oil will damage the pump. 1. BREATHER 2. MAIN CONTROL VALVE 3. RELIEF VALVE 4. FILTER Figure 33. Hydraulic Filter E45-65XM and E45-65XM 2 NOTE: Change the oil filter for the hydraulic system after the first 100 hours on new lift trucks. See Figure 32, Figure 33, and Figure 34. 1. On the E25-65XM and E25-65XM 2 trucks, remove the floor plates. On the J40-65XM and J40-65XM 2 trucks, open the hood for access to the filter. Clean the hydraulic filter and hoses at the filter. Figure 34. Hydraulic Filter J40-65XM and J40-65XM 2 Figure 32. Hydraulic Filter E25-40XMS and E25-40XMS 2 36 2. Loosen the hose clamp at the filter for the hose from the control valve. Lift the filter as high as possible and remove the hose from the filter. Tip the filter up to let the oil drain into the hydraulic tank. 8000 SRM 552 3. After the oil has drained, loosen the other hose clamp. On the J40-65XM and J40-65XM 2 units, remove the two screws that fasten the filter. Remove the filter. NOTE: The hydraulic oil filter has a bypass relief valve that is part of the filter. Make sure the correct replacement filter with a bypass relief valve is installed. 4. Install the new filter. Make sure the flow arrow points toward the hydraulic tank hose. Tighten the hose clamps and on the J40-65XM and J4065XM 2 units, install and tighten the two screws that fasten the filter. 5. Operate the hydraulic system and check for leaks. Change Hydraulic Oil Put the lift truck on a level surface. Lower the mast. Put a drain pan with a capacity of approximately 27 liter (29 qt) under the hydraulic tank. E25-65XM and E25-65XM 2 lift trucks. Disconnect the hydraulic hose from the hydraulic tank to the steering pump and drain the oil into the drain pan. On the J40-65XM and J40-65XM 2 trucks, turn the steering wheel for a full left turn. This action will move the right steer tire and wheel for access to the drain plug. The drain plug is in the bottom of the tank directly below the dipstick/fill cap. Remove the drain plug and drain the oil into the drain pan. When the oil has drained, connect the hydraulic hose or install the drain plug. Fill the hydraulic tank with the correct oil after the filter is installed. See the Maintenance Schedule. Maintenance Procedures Every 2000 Hours or Yearly DIFFERENTIAL AND SPEED REDUCER Drain the oil at the drain plug on the left side (right side facing the differential housing). See Figure 17 and Figure 18. The drain plug is in the differential housing near the bottom. Make sure the drain pan has a capacity of the differential and speed reducer as specified in the Maintenance Schedule. The oil drains slowly since it must flow through the bearings from the speed reducer to the differential housing. Install the drain plug after the oil has completely drained. Clean the breather in solvent. See the Maintenance Schedule for the correct lubricant. Add oil slowly at the fill plug. Fill until oil just starts to flow out the fill plug hole. Add oil only if the oil level is low. The oil must flow through the bearings to the speed reducer, so filling slowly is necessary to indicate the correct level. SERVICE BRAKES WARNING Brake linings contain fibers. Breathing the dust from these brake linings can be a cancer or lung disease hazard. Do not create dust! Do not clean brake parts with compressed air or by brushing. Use vacuum equipment approved for asbestos dust or follow the cleaning procedure in this section. When the brake drums are removed, do not create dust. Do not sand, grind, chisel, hammer, or change linings in any way that will create dust. Any changes to brake linings must be done in a restricted area with special ventilation. Protective clothing and a respirator must be used. Cleaning Procedures: WARNING Cleaning solvents can be flammable and toxic and can cause skin irritation. When using cleaning solvents, always follow the recommendations of the manufacturer. E25-65XM and E25-65XM 2 lift trucks. Remove the breather from the breather hose. Wash the breather in solvent and air dry, or replace the breather. Install the clean breather on the breather hose or pipe. J40-65XM and J40-65XM 2 lift trucks. Clean the dipstick and fill cap in solvent to clean the breather. 1. Do not release brake lining dust from the brake linings into the air when the brake drum is removed. 2. Use a solvent approved for cleaning of brake parts to wet the lining dust. Follow the instructions and cautions of the manufacturer for the use of the solvent. If a solvent spray is used, do not create brake lining dust with the spray. 3. When the brake lining dust is wet, clean the parts. Put any cloth or towels in a plastic bag or an airtight container while they are still wet. Put a "DANGEROUS FIBERS" warning label on the plastic bag or airtight container. 37 Maintenance Procedures Every 2000 Hours or Yearly 4. Any cleaning cloths that will be washed must be cleaned so that fibers are not released into the air. NOTE: Some lift trucks are used in operations where the automatic adjusters can be slow to adjust the brake shoes. If the brakes need adjustment, operate the lift truck in forward and reverse 10 times. Apply the brake pedal firmly, but do not cause the wheels to slide. If the automatic adjusters do not adjust the brake shoes, a qualified service person must check the operation and condition of the brakes. CAUTION Do NOT use an oil solvent to clean the wheel cylinder. Use a solvent approved for cleaning of brake parts. Do not permit oil or grease in the brake fluid or on the brake linings. Check the brake lining and parts of the brake assembly for wear or damage. See the sections the Brake System of the Service Manual, for the removal and installation procedures of the drive wheels and hubs. If the brake linings or brake shoes are worn or damaged, they must be replaced. Brake shoes must be replaced in complete sets. Inspect the brake drums for cracks or damage. Replace any damaged parts. CONTACTORS Always replace the contacts of a contactor as a complete set. See the motor controller sections of the Service Manual for replacement and adjustment procedures. WHEEL BEARINGS Steer Wheels, Lubrication Lubricate the wheel bearings in the hubs for the steer wheels with multipurpose grease as described in the section the Steering Axle 1600 SRM 619 E25-40XMS, E25-40XMS 2, the section the Steering Axle 1600 SRM 258 E45-65XM and E45-65XM 2 or the section the Steering Axle 1600 SRM 316 J40-65XM and J40-65XM 2 of the Service Manual. Drive Wheels, Lubrication Lubricate the inner wheel bearings in the hubs for the drive wheels with multipurpose grease as described in the section Drive Axle, Speed Reducer and Differential 1400 SRM 618 E25-40XMS and E25-40XMS 2, the section Drive Axle, Speed Reducer and Differential 1400 SRM 38 8000 SRM 552 285 E45-65XM and E45-65XM 2 or the section Drive Axle, Speed Reducer and Differential 1400 SRM 575 J40-65XM and J40-65XM 2 of the Service Manual. LIFT CHAINS WARNING Cleaning solvents can be flammable and toxic and can cause skin irritation. When using cleaning solvents, always follow the recommendations of the manufacturer. Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure that the path of the compressed air is away from all personnel. Wear protective goggles or a face shield to prevent injury to the eyes. Remove the lift chains. Clean the lift chains by soaking them in a solvent that has a petroleum base for at least 30 minutes. Use compressed air to completely dry the chains when they are clean. Lubricate the lift chains by soaking them in 30W engine oil for at least 30 minutes. Remove the chains from the oil. Hang the chains for one hour so that excess oil will drain from the chains. REPLACE UPPER AND LOWER BEARINGS, INTEGRAL SIDESHIFT CARRIAGE Replace all four bearings regardless of wear. See Check Upper and Lower Bearings, Integral Sideshift Carriage for the procedure. STEERING AXLE King Pins and Rod Ends (Steering Cylinders) Lubricate the rod ends of the steering cylinder and the king pins. Use multipurpose grease. See the Maintenance Schedule for more information on lubricating these parts. OTHER LUBRICATION Lubricate hinges, levers, linkages cables and pedals as necessary. Use SAE 30 oil, multipurpose grease or silicone lubricant-spray (Hyster Part No. 328388) as needed. See the Maintenance Schedule for more lubricating information. 8000 SRM 552 Battery Maintenance Battery Maintenance HOW TO CHARGE BATTERY WARNING The acid in the electrolyte can cause injury. If electrolyte is spilled, use water to flush the area. Make the acid neutral with a solution of sodium bicarbonate (soda) and water. Acid in the eyes must be immediately flushed with water. Batteries generate explosive fumes when they are being charged. Keep fire, sparks, and burning material away from the battery charger area. Prevent sparks from the battery connections. has sealed cells. The sealed batteries require a different charger. The electrolyte level or specific gravity cannot be checked and water cannot be added to the electrolyte of these sealed batteries. Correct use of the hydrometer and proper operation of the battery charger is important. See Figure 35. Follow the instructions of the charger manufacturer. Never let the battery discharge below the minimum value given by the battery manufacturer. A fully charged battery will have a specific gravity of 1.265 to 1.310 at 25 C (77 F). See Figure 35. Never charge a battery at a rate that will raise the electrolyte temperature above 49 C (120 F). Never let a battery stay discharged for long periods. Charge batteries only in the special area for charging batteries. When charging the batteries, keep the vent caps clean. The battery charger area must have ventilation so that explosive fumes are removed. Open the hood over the battery or remove the cover if the battery has a cover. Disconnect the battery when doing cleaning and maintenance. If the lift truck has been operated with a low battery, inspect all contactors for welded contacts BEFORE you connect a charged battery. The circuit will not reset and lift truck operation cannot be controlled if the contacts are welded. CAUTION Never connect the battery charger plug to the plug of the lift truck. You can damage the traction control circuit. Make sure the charger voltage is the correct voltage and type for the battery. Sealed batteries require a different charger. Use only battery chargers approved by the battery manufacturer or dealer. CAUTION Always make sure the color in the window of the charger connector is the same as the color in the window of the battery connector. NOTE: There can be one of two types of batteries. One type has removable cell caps. The other type Specific Gravity Reading Electrolyte Temp. Correction Points Correct Value 1.210 31 C (87 F) +0.003 1.213 1.210 27 C (80 F) +0.001 1.211 1.210 25 C (77 F) 0.000 1.210 1.210 18 C (64 F) −0.004 1.206 +0.001 or −0.001 for each 2 degree C from the 25 base value. NOTE: CHECK ONLY BATTERIES THAT DO NOT HAVE SEALED CELLS. Figure 35. Check Specific Gravity 1. NORMAL CHARGE: This charge is normally given to a battery that is discharged from normal 39 Battery Maintenance 8000 SRM 552 operation. Many customers charge the battery at regular intervals that depend on use. This procedure will keep the battery correctly charged if the battery is not discharged below the limit. Always use a hydrometer to check the battery if the battery is charged at regular intervals. Frequent charging of a battery that has a 2/3 or more charge can decrease the life of the battery. The replacement battery must fit the battery area correctly. Adjust the spacer plate to prevent the battery from moving forward or backward in the battery compartment. 2. EQUALIZING CHARGE: This charge is at a low rate and balances the charge in all of the cells. The equalizing charge is normally given approximately once a month. It is a charge at a slow rate for three to six hours in addition to the regular charging cycle. Do not give an equalizing charge more than once a week. The most accurate specific gravity measurements for a charged battery will be after an equalizing charge. If the specific gravity difference is more than 0.020 between cells of the battery after and equalizing charge, there can be a defective cell. Consult your battery dealer. Make sure the battery restraint is locked in the down position before the lift truck is operated. NOTE: Many customers have battery chargers that can follow a program to automatically charge a battery according to recommendations of the battery manufacturer. Use the recommendations of the battery manufacturer for charging the battery. Also see the section the Industrial Battery 2240 SRM 1 of the Service Manual, for additional information on the charging and maintenance of a battery. HOW TO CHANGE BATTERY General WARNING Batteries are heavy and can cause an injury. Use care to avoid injury. Do NOT put hands, arms, feet, and/or legs between the battery and a solid object. Make sure the capacity of the crane and spreader bar is greater than the weight of the battery. The weight of the battery is normally shown on the battery case. The maximum battery weight is shown on the lift truck nameplate. The spreader bar must NOT be made of metal or it must have insulated straps. 40 Make sure that the battery voltage and weight of the replacement battery is correct as shown on the nameplate. Before connecting the battery, make sure the key is in the OFF position and the parking brake is set. CAUTION Batteries must be discarded according to local environmental regulations. Observe previous WARNING and CAUTION before changing batteries. Change E25-65XM and E25-65XM 2 Battery 1. E25-65XMS and E25-65XMS 2. Disconnect the battery. See Figure 36 and Figure 38. Move the connector and cables so that they will not be damaged when the battery is moved. Tilt the steering column forward and make sure the detent engages to hold the steering column. Slide the seat to the rear adjustment position. Open the hood/battery restraint as shown in Figure 36. Tilt the battery restraint and seat to the up position. Make sure the battery restraint is locked in the up position. If the truck has optional side covers, remove them. If the hood has a side door, make sure it is open. 2. E25-40XMS and E25-40XMS 2. Use a spreader bar and crane to lift the battery from the lift truck. See Figure 38. When a replacement battery is installed, make sure the battery fits the battery compartment. The battery must have the front spacer plate and side spacers correctly adjusted to prevent any horizontal movement of more than 13 mm (0.5 in.). There must be enough clearance for battery removal. See Figure 37. 8000 SRM 552 Battery Maintenance Figure 36. Open Hood E25-65XM and E25-65XM 2 3. E45-65XM and E45-65XM 2. Use a spreader bar and crane to lift the battery from the lift truck. See Figure 38. When a replacement battery is installed, make sure the battery fits the battery compartment width with a maximum of 13 mm (0.5 in.) clearance. Adjust the spacer plate to prevent the battery from moving more than a total of 13 mm (0.5 in.) forward or backward. See Figure 39. There must be enough clearance for battery removal. WARNING Correct operation of the battery restraint system requires that the battery does not move more than 13 mm (0.5 in.). Make sure the battery spacer plate is correctly adjusted. 4. If the truck has optional side covers, install them. Release the stop rod by moving it to the right before lowering hood. See the label Figure 11. Lower the hood. Make sure the latch handle is fully to the right when closing the hood so that the latch can engage the latch piece. Make sure the hood is locked securely. Try to raise the hood using only the lift handle to make sure the hood is latched and will not move. If the hood has a side door, make sure it is closed. 5. Connect the battery connector. See Figure 40. 41 Battery Maintenance 8000 SRM 552 1. BATTERY 2. SPREADER BAR 3. CRANE CHAIN Figure 38. Change Battery E25-65XM and E25-65XM 2 1. BATTERY COMPARTMENT 2. BATTERY 3. BULKHEAD 4. SPACER PLATE 5. ADJUSTMENT CAPSCREW 6. JAM NUTS A + B = 13 mm (0.5 in.) MAXIMUM Figure 37. Battery Compartment Spacer Plates E25-40XMS and E25-40XMS 2 1. BATTERY COMPARTMENT 2. BATTERY 3. BULKHEAD 4. SPACER PLATE 5. ADJUSTMENT CAPSCREW 6. JAM NUTS Figure 39. Battery Compartment Spacer Plate E/J45-65XM and E/J45-65XM 2 42 8000 SRM 552 Battery Maintenance NOTE: INDICATOR INSERT - GREEN (FOR BATTERY WITH CELL CAPS) AND GRAY (FOR BATTERY WITH SEALED CELLS). A. DIN CONNECTOR B. ANDERSON SBE CONNECTOR 1. BATTERY HALF OF CONNECTOR 2. INDICATOR INSERT FOR BATTERY VOLTAGE AND BATTERY TYPE 3. LOCK FOR CABLE TERMINALS AND INDICATOR 4. 5. 6. 7. WINDOW SHOWING BATTERY VOLTAGE WIRE FOR 12-VOLT BATTERY TAP CONNECTOR FOR 12-VOLT BATTERY TAP LOCK PINS FOR 12-VOLT CONNECTOR Figure 40. Battery Connectors for 12-Volt Battery Tap (Older Lift Trucks Only) Change J40-65XM and J40-65XM 2 Battery 1. Move the steering column to the fully forward position and make sure it is latched. Release the latch for the control lever assembly and move the assembly to the forward position. Raise the hood and seat to the fully raised position as shown in Figure 41. Raise the handle of the battery restraint rod and move the rod to the rear position. Disconnect the battery connector and move it to a position so that it will not be damaged during battery removal. Lift the side panels to remove them. 2. Use a spreader bar and crane to lift the battery from the lift truck. See Figure 41. When a replacement battery is installed, make sure the battery fits the battery compartment width with a maximum of 13 mm (0.5 in.) clearance. Adjust the spacer plate to prevent the battery from moving more than a total of 13 mm (0.5 in.) forward or backward. See Figure 39. There must be enough clearance for battery removal. 43 Battery Maintenance 8000 SRM 552 Correct operation of the battery restraint system requires that the battery does not move more than 13 mm (0.5 in.). Make sure the battery spacer plate is correctly adjusted. 3. Connect the battery connector. Move the battery restraint rod to the forward position over the edge of the battery. Move the handle to the down position. Install the side covers. Lower the hood. Move the control lever assembly fully to the rear over the hood. Make sure the latch is completely engaged. Try to raise the hood using only the lift handle to make sure the hood will not raise. A. LOCKED B. OPEN 1. 2. 3. 4. 5. BATTERY RESTRAINT HANDLE 6. BATTERY RESTRAINT ROD 7. LATCH OF HAND LEVER ASSEMBLY WARNING BATTERY CRANE CHAIN SPREADER BAR BATTERY CONNECTOR Figure 41. Change Battery J40-65XM and J40-65XM 2 44 8000 SRM 552 Lift and Tilt System Leak Check Lift and Tilt System Leak Check LIFT CYLINDERS LEAK CHECK WARNING Never allow any person under a raised carriage. Do not put any part of your body in or through the lift mechanism unless all parts of the mast are completely lowered, the key is in the OFF position and the key is removed. Before making any repairs, use chains on the mast weldments and carriage so that they cannot move. Make sure the moving parts are attached to the parts that cannot move. Do not try to find hydraulic leaks by putting your hand on hydraulic components under pressure. Hydraulic oil can be injected into the body by pressure. During test procedures for the hydraulic system, fasten the load to the carriage with chains to prevent it from falling. Keep all personnel away from the lift truck during the tests. 1. Operate the hydraulic system. Put a capacity load on the forks and raise and lower the load several times. Lower the load and tilt the mast forward and backward several times. Check for leaks. 2. Raise the carriage and load so that the rods of the main lift cylinders extend at least 60 cm (2 ft). If the carriage lowers slowly with the control valve in the NEUTRAL position, there are leaks inside the hydraulic system. The maximum speed that the carriage is allowed to lower is 50 mm (2 in.) per 10 minutes when the hydraulic oil is 30 C (90 F). If the oil temperature is 70 C (160 F), the maximum speed that the carriage can lower is 150 mm (6 in.) per 10 minutes. 3. Check the lift cylinders for internal leaks. Remove the load from the forks. Install a gate valve in the supply line between the main control valve and the mast. Put a capacity load on the forks again. Raise the carriage and load so that the rods of the main lift cylinders extend at least 2 feet. Close the gate valve. If the carriage or mast weldments lower slowly, the seals in the lift cylinders have leaks. 4. If the carriage and mast weldments do not move, open the gate valve and check for movement again. If the carriage lowers when the valve is open, check for leaks in the hydraulic lines or fittings. If no leaks are found, the main control valve can have a defect. Remove the load from the forks. TILT CYLINDERS LEAK CHECK 1. Put a capacity load on the forks. If the mast slowly tilts forward when the control valve is in the NEUTRAL position, there are leaks inside the hydraulic system. The maximum speed that the mast is allowed to tilt forward when there are internal leaks in the lift system is 13 mm (0.5 in.) per 10 minutes (measured at the tilt cylinder). The maximum speed is measured when the hydraulic oil is 30 C (90 F). If the oil temperature is 70 C (160 F), the maximum speed is 38 mm (1.5 in.) per 10 minutes. 2. If the leak rate is greater than these specifications, remove the load from the mast. Install a valve between the port at the front of the tilt cylinder and the hydraulic line. Put the load on the forks again. Close the valve. If the mast tilts slowly forward, the cylinder seals are leaking. Be sure to check both tilt cylinders. 3. If the mast does not move, open the gate valve and check for movement again. If the mast moves forward when the gate valve is open, check for leaks in the hydraulic lines or fittings. If no leaks are found, the main control valve can have a defect. Remove the load from the forks. 45 Safety Procedures When Working Near Mast 8000 SRM 552 Safety Procedures When Working Near Mast The following procedures must be used when inspecting or working near the mast. Additional precautions and procedures can be required when repairing or removing the mast. See the correct Service Manual section for the specific mast being repaired. WARNING Mast parts are heavy and can move. Distances between parts are small. Serious injury or death can result if part of the body is hit by parts of the mast or the carriage. • Never put any part of the body into or under the mast or carriage unless all parts are completely lowered or a safety chain is installed. Also make sure that the power is off and the key is removed. Put a "DO NOT OPERATE" tag in the operator’s compartment. • Be careful of the forks. When the mast is raised, the forks can be at a height to cause an injury. • Do NOT climb on the mast or lift truck at any time. Use a ladder or personnel lift to work on the mast. • Do NOT use blocks to support the mast weldments nor to restrain their movement. • Mast repairs require disassembly and removal of parts and can require removal of the mast or carriage. Follow the repair procedures in the correct Service Manual section for the mast. WHEN WORKING NEAR THE MAST ALWAYS: 1. Lower the mast and carriage completely. Push the lift/lower control lever forward and make sure there is no movement in the mast. Make sure that all parts of the mast that move are fully lowered. OR 2. If parts of the mast must be in raised position, install a safety chain to restrain the moving parts 46 of the mast. Connect moving parts to a part that does not move. Follow these procedures: a. Put the mast in a vertical position. b. Raise the mast to align the bottom crossmember of the weldment that moves in the outer weldment with a crossmember on the outer weldment. On the two-stage and freelift mast, the moving part is the inner weldment. On the three-stage mast it is the intermediate weldment. On the four-stage mast it is the first intermediate weldment. See Figure 42. c. Use a 9.4 mm (3/8 in.) minimum safety chain with a hook to fasten the crossmembers together so that the movable member cannot lower. Put the hook on the back side of the mast. Make sure the hook is completely engaged with a link in the chain. Make sure the safety chain does not touch lift chains or chain sheaves, tubes, hoses, fittings or other parts on the mast. d. Lower the mast until there is tension in the safety chain and the free-lift cylinder (freelift and three-stage masts only) is completely retracted. If running, stop the engine. Apply the parking brake. Install a "DO NOT REMOVE" tag on the safety chain(s). e. Install another safety chain [9.4 mm (3/8 in.) minimum] between the top or bottom crossmember of the carriage and a crossmember on the outer weldment. 3. Apply the parking brake. After lowering or restraining the mast, shut off the power and remove the key. Put a "DO NOT OPERATE" tag in the operator’s compartment. 8000 SRM 552 Safety Procedures When Working Near Mast Figure 42. Two-Stage, Free-Lift, Three-Stage, and Four-Stage Masts 47 Lift Chain Adjustments 8000 SRM 552 Legend for Figure 42 A. TWO-STAGE MAST B. FREE-LIFT MAST C. THREE-STAGE MAST D. FOUR-STAGE MAST 1. 2. 3. 4. 5. 6. 7. 8. OUTER WELDMENT INNER WELDMENT INTERMEDIATE WELDMENT FIRST INTERMEDIATE WELDMENT HOOK FREE-LIFT CYLINDER CROSSMEMBER CROSSMEMBER Lift Chain Adjustments WARNING When working on or near the mast, see in this section. Never allow anyone under a raised carriage. Do not put any part of your body in or through the lift mechanism unless all parts of the mast are completely lowered and the engine is STOPPED. Do not try to find hydraulic leaks by putting your hand on hydraulic components under pressure. Hydraulic oil can be injected into the body by the pressure. During test procedures for the hydraulic system, fasten the load to the carriage with chains to prevent it from falling. Keep all personnel away from the lift truck during the tests. 2. Adjust the chain anchors which support the carriage until the bottom of the fork heel is 6 ±3 mm (0.25 ±0.12 in.) above the floor level. See Figure 43. 3. See Figure 44. Adjust the chain anchors which support the carriage until the bottom of the lower carriage bar is above the floor level as shown in Table 2. Table 2. Hook Type Carriage Chain Adjustment Class II and III 82.5 ± 3 mm (3.25 ± 0.12 in.) Class IV 133.5 ± 3 mm (5.25 ± 0.12 in.) When the lift chains are correctly adjusted: • The tension will be the same on each chain of the chain set. Check tension by pushing on both chains at the same time. • The chain length will be correct. • The chains must travel freely through the complete cycle. NOTE: When the chain adjustments are complete, make sure that the threads on the nuts of the chain anchors are completely engaged. Make sure that all of the adjustment is not removed from the chain anchors. The chain anchors must be able to move on their mounting. 1. When adjusting the lift chains on forklift trucks equipped with either pin or hook forks installed, go to Step 2 . If the forklift truck is normally equipped with a hook type carriage and has an attachment without forks, go to Step 3. If the forklift truck is normally equipped with a pin type carriage and has an attachment without forks go to Step 4. NOTE: Prior to performing adjustment procedures make sure that the forklift truck is parked on a level surface and that the mast is in the vertical position. 48 1. 2. 3. 4. TILT MAST FULLY BACKWARD CARRIAGE ROLLER FORK CARRIAGE ROLLER MUST NOT EXTEND MORE THAN 34 mm (1.3 in.)BELOW INNER MAST CHANNEL Figure 43. Lift Chain Adjustment, Hook or Pin Type Forks 8000 SRM 552 PMT Circuit Check 1. MAST 2. CARRIAGE 3. DISTANCE FROM FLOOR TO LOWER CARRIAGE BAR Figure 44. Lift Chain Adjustment, Hook Type Carriage 4. See Lift Chain Adjustment, Pin Type Carriage. Adjust the chain anchors which support the carriage until the center line of the fork pin is above the floor level as shown in Table 3. Table 3. Pin Type Carriage Chain Adjustment H70/80, 90 XLS 545 ± 3 mm (21.5 ± 0.12 in.) H90-110 XL 708 ± 3 mm (27.88 ± 0.12 in.) H135-155XL 907 ± 3 mm (35.75 ± 0.12 in.) 1. LOAD BACKREST 2. FORK PIN 3. DISTANCE FROM FORK PIN TO FLOOR Figure 45. Lift Chain Adjustment, Pin Type Carriage PMT Circuit Check WARNING Some malfunctions can make the traction motor run at high speed with no control by the speed controller. The PMT circuit prevents operation if these malfunctions occur. Do not operate the lift truck if the PMT circuit does not operate correctly. The Pulse Monitor Trip (PMT) circuit only functions if a fault occurs. To check the circuit, we must cause a temporary malfunction. Check the PMT circuit for correct operation as follows: 1. Raise the drive wheels and put the lift truck on blocks. See How to Raise Drive Tires in this section. Release the parking brake. 49 PMT Circuit Check WARNING Disconnect the battery connector before making any inspections or repairs. Personal injury or equipment and tool damage can occur if the battery is not disconnected. On unit before "XM 2" units, do not touch the terminals of capacitor C1 of the traction or lift control circuits. The charge on the capacitors can cause electrical shock and personal injury. Use an insulated screwdriver or jumper wire to make a short-circuit across the capacitor terminals to discharge each capacitor. This will discharge the capacitors to prevent electrical shocks. On "XM 2" units, do not touch the power terminals of the motor controllers. The charge on the capacitors can cause electrical shock and personal injury. Disconnect the battery connector and push the horn button until the horn stops making a noise to discharge the capacitors. 2. Disconnect the battery and discharge capacitor(s) C1 as previously described in the WARNING. 3. EV-100ZX Motor Controller. Disconnect the gate lead from the SCR 5 (SCR panel) for the traction circuit. The gate lead has a push-on connector on the SCR panel. Make sure that the end of the gate lead does not touch any other surface. See the section Diagrams that came with the lift truck for the location of the gate lead. EV-T100 Transistor Controller. Connect a jumper wire across the bus bars for the Contactor 1A. The logic circuit will sense a short-circuit and prevent the operation of the motor controller. 8000 SRM 552 6. Listen for the direction contactor to open. The traction system will not operate. The traction motor controller will allow two power pulses before opening the contactor. 7. When the PMT circuit disables the traction control, turn the key to the "OFF" position. If the PMT circuit does not disable the traction control, replace the control card. See the sections: • EV-100ZX™ Motor Controller Description & Operation and Repairs & Adjustments 2200 SRM 557 • EV-T100™ Transistor Motor Controller Description & Operation and Repairs & Adjustments 2200 SRM 581 8. SR (SEM) Transistor motor controller: Disconnect the battery and discharge capacitor(s) C1 as previously described in the WARNING. Disconnect one of the power leads for the motor field (F1 or F2) at the top of the SR motor controller. Make sure that the end of the F1 or F2 lead does not touch any other surface. Connect the battery. Apply the service brakes and actuate the Monotrol control pedal or the direction control lever and accelerator for slow movement in the FORWARD or REVERSE direction. The traction motor will try to run for approximately one second and then not operate. A status code 49 will appear on the LCD screen of the SEM Display Panel. 9. When the PMT circuit disables the traction control, turn the key to the OFF position. If the PMT circuit does not disable the traction control, replace the motor controller. See the sections: • Transistor Motor Controllers (SR and SP) Description & Operation and Repairs & Adjustments 2200 SRM 724 4. Connect the battery. 10. Disconnect the battery, open the electrical compartment, and discharge capacitors C1 as described in the earlier WARNING. 5. Sit on the seat to close the seat switch and turn the key to the ON position. Actuate the Monotrol control pedal or the direction control lever and accelerator for slow movement in the FORWARD or REVERSE direction. 11. Connect the gate lead, disconnect any jumper wires or connect the F1 or F2 leads. Connect the battery. Raise the drive wheels and remove the blocks. Check for normal operation of the traction motor. 50 8000 SRM 552 Wheels and Tire Maintenance Welding Repairs WARNING CAUTION Welding can cause a fire or an explosion. Always follow the instructions in the Frame section of the Service Manual if a fuel or hydraulic tank must be welded. Make sure there is no fuel, oil, or grease near the weld area. Make sure there is good ventilation in the area where the welding must be done. Do not heat, weld, or bend forks. Forks are made of special steel using special methods. Get information from your dealer for Hyster lift trucks before welding on a mast. When an arc welder is used, always disconnect the battery connector on the lift truck. This action will prevent damage to the SCR control. Connect the ground clamp for the arc welder as close as possible to the weld area. This action will prevent damage to a bearing from the large current from the welder. Some repairs require welding. If an acetylene or arc welder is used, do the procedures in the following WARNING and CAUTION. Overhead Guard Changes Do not operate the lift truck without the overhead guard correctly fastened to the lift truck. that are too big in the wrong location, can reduce the strength of the overhead guard. See your dealer for Hyster lift trucks before making any changes to the overhead guard. Do not make changes to the overhead guard by welding or drilling. Welding, or drilling holes Observe previous WARNING before doing any changes to overhead guard. WARNING Wheels and Tire Maintenance TIRES AND WHEELS E25-65XM AND E25-65XM 2 WARNING The type of tire is shown on the nameplate. Make sure the nameplate is correct for the type of tires on the lift truck. Wheels must be changed and tires repaired by trained personnel only. Always wear safety glasses. This series of lift trucks use solid rubber tires. See Figure 46. Solid rubber tires made from softer or harder material can be installed as optional equipment. The tread on the solid rubber tires can be either smooth or it can have lugs. Electric compound tires are recommended. Do not mix types of tires or tread on the lift truck. 1. SOLID RUBBER TIRE 2. WHEEL Figure 46. Tire and Wheel Remove Wheels from Lift Truck 1. Raise the lift truck as described in How to Put Lift Truck on Blocks in this manual. 2. Remove the wheel nuts or spindle nut and remove the wheel from the lift truck. Lift truck wheels are heavy. 51 Wheels and Tire Maintenance Remove and Install Tire on Wheel NOTE: Make sure the tires are installed on the wheels so that the outside edges of the tire and wheel are as shown in Figure 46. Also check the nameplate of the lift truck for the correct tire size and tread width. 1. The correct tools, equipment and a press ring must be used for each size of wheel. Use a press to push the wheel from the rim and tire. The capacity of the press must be approximately 18 to 89 kN (80,000 to 400,000 lb). For the tire sizes, see the nameplate. WARNING Check all wheel nuts after 2 to 5 hours of operation: when new lift trucks begin operation and on all lift trucks when the wheels have been removed and installed. Tighten the nuts in a cross pattern to the correct torque value shown in the Maintenance Schedule. When the nuts stay tight for eight hours, the interval for checking the torque can be extended to 500 hours. 2. When the drive wheels are installed on the lift truck, tighten the wheel nuts to the value shown in the Maintenance Schedule. 3. The steering wheels are fastened to the spindle of the steering axle with a large castle nut. Make sure the inner and outer bearings are correctly lubricated with grease. Install the inner bearing assembly and wheel on the spindle. Install the outer bearing cone and castle nut. Tighten the castle nuts of the steer wheel spindles of these units to 68 N•m (50 lbf ft) while rotating the wheel in each direction at EACH installation. Loosen the nuts 1/4 turn. Pull and push at top of wheel to check for movement (end play). If there is movement, tighten the castle nuts to 3 N•m (2 lbf ft). Install the cotter pins at the nearest alignment positions. Install the hub cap. Additional torque checks are not required. 52 8000 SRM 552 PNEUMATIC TIRES AND WHEELS J40-65XM AND J40-65XM 2 Remove Wheels from Lift Truck WARNING A solid rubber tire that is the same shape as a pneumatic tire can be installed on a wheel for a pneumatic tire. DO NOT make changes in the parts of the rim if this type of solid rubber tire is installed instead of a pneumatic tire. Changes to the parts of the rim can cause a failure of the wheel and cause an accident. The type of tire and the tire pressure (pneumatic tires) are shown on the nameplate. Make sure the nameplate is correct for the type of tires on the lift truck. WARNING Wheels must be changed and tires repaired by trained personnel only. Deflate tire completely before removing the wheel from the lift truck. If dual wheels are used, deflate both tires. Air pressure in the tires can cause the tire and rim parts to explode causing serious injury or death. Always wear safety glasses. 1. Put the lift truck on blocks as described in How to Put Lift Truck on Blocks at the beginning of this section. 2. Remove the air from the tire. Remove the valve core to make sure that all of the air is out of the inner tube. Push a wire through the valve stem to make sure that the valve stem does not have a restriction. 3. Remove the wheel nuts and remove the wheel and tire from the lift truck. Lift truck tires and wheels are heavy. See Figure 47. 8000 SRM 552 Wheels and Tire Maintenance A. OPTIONAL RIM ASSEMBLY B. THREE-PIECE WHEEL C. FOUR-PIECE WHEEL 1. WHEEL RIM 2. SIDE FLANGE 3. LOCK RING 4. FLANGE SEAT Figure 47. Types of Wheels for Pneumatic and Solid Pneumatic Tires Remove Wheel from Pneumatic Tire WARNING Make sure all of the air pressure is removed from the tire before a wheel is disassembled. Air pressure in the tires can cause the tire and rim parts to explode causing serious injury or death. Keep tire tools in firm contact with the wheel parts. If the tool slips, it can move with enough force to cause an injury. STEP 1. Loosen the tire bead from the side flange. STEP 2. Put the tire tool into the slot between the lock ring and wheel rim. Remove the lock ring and side flange. If there is a flange seat, remove it. 53 Wheels and Tire Maintenance 8000 SRM 552 STEP 3. Loosen the bead from the other side of the wheel rim. Remove the valve stem from the wheel. If there is a washer, keep it for installation during assembly. STEP 4. Remove the wheel rim from the tire. Install Wheel in Pneumatic Tire NOTE: There are two types of wheels used on this series of lift trucks. See Figure 47. WARNING Damage to the tire and wheel assembly and injury or death can occur if you do not do the following procedures: • Clean and inspect all parts of the wheel before installing the tire. • Do NOT use any damaged or repaired wheel parts. • Make sure that all parts of the wheel are the correct parts for that wheel assembly. • Do NOT mix parts between different types or manufacturers of wheels. • Do NOT mix types of tires, type of tire tread, or wheel assemblies of different manufacturers on any one lift truck. Do not use a steel hammer on the wheel. Use a rubber, lead, plastic or brass hammer to put parts together. Make sure that the lock ring is in the correct position. The ends of the lock ring must not touch. The clearance at the ends of the lock ring will be approximately 13 to 54 25 mm (0.5 to 1.0 in.) after it is installed. If the clearance is wrong, the wrong part has been used. 1. Clean and inspect all parts of the wheel. Paint any parts that have rust or corrosion. 2. Install a new inner tube in the tire. Used tubes and flaps can cause tire failure. 3. Apply a rubber lubricant or a soap solution to the tire bead and tube. WARNING Do not lubricate the tire bead with antifreeze or petroleum based liquid. Vapors from these liquids can cause an explosion during inflation or use. 4. Install a new tire flap. 5. Make sure the rim is the correct size for the tire. Lubricate the part of the wheel that contacts the bead and flap. 6. Install the three-piece or four-piece wheel in the tire as shown in Install Three- or Four-Piece Wheel in Pneumatic Tire. 8000 SRM 552 Wheels and Tire Maintenance Install Three- or Four-Piece Wheel in Pneumatic Tire WARNING Damage to the tire and wheel assembly and injury or death can occur if you do not do the following procedures: • Clean and inspect all parts of the wheel before installing the tire. • Do NOT use any damaged or repaired wheel parts. • Make sure that all parts of the wheel are the correct parts for that wheel assembly. • Do NOT mix parts between different types or manufacturers of wheels. • Do NOT mix types of tires, type of tire tread, or wheel assemblies of different manufacturers on any one lift truck. Do not use a steel hammer on the wheel. Use a rubber, lead, plastic or brass hammer to put parts together. Make sure that the lock ring is in the correct position. The ends of the lock ring must not touch. The clearance at the ends of the lock ring will be approximately 13 to 25 mm (0.5 to 1.0 in.) after it is installed. If the clearance is wrong, the wrong part has been used. STEP 1. Install the inner tube and the rubber flap in the tire. STEP 2. Install the wheel rim in the tire. Install the washer on the stem (if removed during disassembly). Make sure the stem of the inner tube is aligned with the slot in the rim. STEP 3. Turn over the rim and tire. Put blocks under the rim so that the rim is 8 to 10 cm (3 to 4 in.) above the floor. Install the flange seat (if used) and the side flange. Hold them in the correct position. 55 Wheels and Tire Maintenance 8000 SRM 552 STEP 4. Put the lock ring in the correct position on the rim. Add air pressure to the tire as described in Add Air to Tires. Add Air to Tires WARNING Add air pressure to the tires only in a safety cage. Inspect the safety cage for damage before use. When air pressure is added, use a chuck that fastens onto the valve stem of the inner tube. Make sure there is enough hose to permit the operator to stand away from the safety cage when air pressure is added to the tire. Do not sit or stand by the safety cage. Do not use a hammer to try and correct the position of the side flange or lock ring when the tire has air pressure greater than 20 kPa (3 psi). 1. Put the tire in a safety cage. See Figure 48. 2. Add 3 psi of air pressure to the tire. 3. Check that all wheel parts are correctly installed. Hit the lock ring lightly to make sure that it is in the seat. 4. If installation is correct, add air pressure to the tire to the specified pressure. 5. Check that all wheel parts are correctly installed. If installation is not correct, remove all of the air pressure from the tire. Remove the valve core to make sure all of the air pressure has been removed and then make adjustments. The clearance at the ends of the lock ring will be approximately 13 to 25 mm (0.5 to 1.0 in.) when the tire has the correct air pressure. 56 Figure 48. Add Air to Tires Wheels, Install WARNING Check all wheel nuts after 2 to 5 hours of operation: when new lift trucks begin operation and on all lift trucks when the wheels have been removed and installed. Tighten the nuts in a cross pattern to the correct torque value shown in the Maintenance Schedule. When the nuts stay tight for eight hours, the interval for checking the torque can be extended to 500 hours. Install the wheel on the hub. Tighten the nuts as shown in the Maintenance Schedule. 8000 SRM 552 SOLID RUBBER TIRES ON PNEUMATIC WHEELS Remove Wheels from Lift Truck WARNING Wheels must be changed and tires repaired by trained personnel only. Wheels and Tire Maintenance Always wear safety glasses. 1. Put the lift truck on blocks as described in How to Put Lift Truck on Blocks at the beginning of this section. 2. Remove the wheel nuts and remove the wheel and tire from the lift truck. Lift truck tires and wheels are heavy. Remove Solid Rubber Tire from Pneumatic Wheel NOTE: There are two types of pneumatic wheels used on these trucks. See Figure 47. WARNING Wheels must be changed and tires repaired by trained personnel only. Always wear safety glasses. WARNING Keep tire tools in firm contact with the wheel. If the tool slips, it can move with enough force to cause serious injury. STEP 1. Put the wheel rim on the bed of the press. Put the cage in position on the tire. Use the press to push the tire away from the side flange. STEP 2. Put the tire tool into the slot between the lock ring and the wheel rim. Remove the lock ring and side flange. If there is a flange seat, remove it. 57 Wheels and Tire Maintenance STEP 3. Turn the tire over. Put a support under the wheel rim. Make sure the wheel rim is at least 150 to 200 mm (6 to 8 in.) from the bed of the press. STEP 4. Put the cage in position on the tire. Use the press to push the tire from the wheel rim. 58 8000 SRM 552 8000 SRM 552 Wheels and Tire Maintenance Install Solid Rubber Tire on Pneumatic Wheel NOTE: There are two types of pneumatic wheels used on these trucks. See Figure 47. WARNING Damage to the tire and wheel assembly and injury or death can occur if you do not do the following procedures: • Clean and inspect all parts of the wheel before installing the tire. • Do NOT use any damaged or repaired wheel parts. • Make sure that all parts of the wheel are the correct parts for the wheel assembly. • Do NOT mix parts between different types or manufacturers of wheels. • Do NOT mix type of tires, type of tire tread or wheel assemblies of different manufacturers on any one lift truck. Do NOT use a steel hammer on the wheel. Use a rubber, lead, plastic or a brass hammer to put parts together. Make sure that the lock ring is in the correct position. The ends of the lock ring must not touch. The clearance at the ends of the lock ring will be approximately 13 to 25 mm (0.05 to 1.0 in.) after it is installed. If the clearance is wrong, the wrong part has been used. CAUTION Too much lubricant can cause the tire to slide and move around the wheel rim. STEP 1. Lubricate the wheel rim and the inner surface of the tire with tire lubricant or soap. STEP 2. Put the wheel rim on the bed of the press. Put the tire over the wheel rim. Put the cage in position on the tire. Use the press to install the tire on the wheel rim. 59 Wheels and Tire Maintenance 8000 SRM 552 STEP 3. Remove the cage and put the flange seat (if used), the side flange and the lock ring in position on the wheel rim. Install the cage on the tire. Use the press to push the tire onto the wheel rim so that the side flange and lock ring can be installed. STEP 4. While the cage is holding the tire on the wheel rim, install the lock ring. Use a tire tool to make sure the lock ring is in the correct position. Wheels, Install WARNING Check all wheel nuts after 2 to 5 hours of operation: when new lift trucks begin operation and on all lift trucks when the wheels have been removed and installed. Tighten the nuts 60 in a cross pattern to the correct torque value shown in the Maintenance Schedule. When the nuts stay tight for eight hours, the interval for checking the torque can be extended to 500 hours. Install the wheel on the hub. Tighten the nuts as shown in the Maintenance Schedule. 8000 SRM 552 Adhesives and Sealants Adhesives and Sealants Hyster Part No. Loctite® Part No. 360387 222 Small Screw Threadlock (Purple) 50 ml (1.7 oz) 318702* 242 Removable Threadlock (Blue) 10 ml (0.34 oz) 226414* 271 High Strength Threadlock (Red) 10 ml (0.34 oz) 318996 277 High Viscosity Threadlock (Red) 50 ml (1.7 oz) 318650 290 Low Viscosity Threadlock (Green) 0.6 ml (0.02 oz) 251099 290 Low Viscosity Threadlock (Green) 50 ml (1.7 oz) 355844* 422 SuperBonder® Adhesive 3 ml (0.1 oz) 350830 515 Gasket Eliminator (Purple) 6 ml (0.2 oz) 313022* 515 Gasket Eliminator (Purple) 50 ml (1.7 oz) 273338* 567 Pipe Sealant with Teflon® (White) 50 ml (1.7 oz) 318705 595 Super Flex® Silicone 100 ml (3.5 oz) 318701* 609 Retaining Compound 10 ml (0.34 oz) 341959 680 Retaining Compound 50 ml (1.7 oz) 226415 Primer T - Aerosol 177 ml (6 oz) 316865 Anti-Seize Compound 476 ml (1 lb) 360053-10 Chisel Gasket Remover (10 Aerosol cans per case) 318700* Loctite®, Teflon® Description Size 536 ml (18 oz) Adhesive & Sealant Kit (Contains one each of * items) Flex®, Super and SuperBonder® are registered trademarks of the Loctite Corporation. is a registered trademark of Du Pont de Nemours Co. Inc. 61 NOTES ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ 62 TECHNICAL PUBLICATIONS 8000 SRM 552 5/01 (10/99)(3/99)(9/96)(3/95)(7/94) Printed in United Kingdom