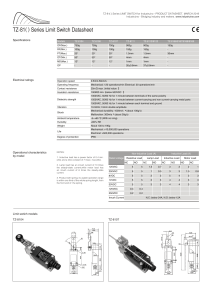

Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE Page No : 1 of 10 1. Purpose : 1. To ensure that the Washing Machine is manufactured fulfilling design specification at manufacturer's site. 2. To check the basic performance of the machine at manufacturer's site. 2. Scope and References: 1. This protocol is applicable to the Washing Machine manufactured by Talleres TACOME S.A 3. Procedure: 1. Take out photocopy of the approved protocol for the FACTORY ACCEPTANCE TEST to be carried at the manufacturer's site. 2. Carry out the below tests mentioned in Table Number 1 at manufacturer's site& mention the observation in ACTUAL column of the protocol photocopy. 3. In case of any additional information or mode of checking mention in the REMARKS column. 4. Check the basic operation of the machine. 5. In case any deviation observes during FAT, document it in Observed deviation section. 6. Ensure that corrective action taken is meeting the user requirement specification. 7. If deviation is acceptable, document in Observed Deviation section and provide proper justification. 8. If deviation does not acceptable, inform to manufacturer for necessary action. 9. If deviation is acceptable, provide final conclusion. 10. Ensure that following listed documents are provided. 1. Operational and Maintenance manual 2. Electrical / mechanical schematics diagram 3. Process and utility diagram 4. Critical Spare part list 4. Documentation All documentation work shall be completed concurrently during execution of theFAT. However the protocol does not define the sequence of the test/ documentation to be carried out. 1. Use indelible black / blue ink for the recording. 2. Fill out complete information in the format provided. 3. Do not leave any blank space. 4. Correct the wrong entry by drawing single line through incorrect data, recording the correct data and then signing and dating the change. 5. Enter “NA” in space that is not applicable. 6. During execution of the protocol any deviation must be implemented as per defined procedure. 7. During protocol execution, report shall be prepared with following details. 1. Discussion of all study in observation column. 2. FAT is successfully completed or not Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE Page No : 2 of 10 3. Conclusion 4. Recommendation, if any 5. Acceptance criteria: 1. 1. 2. 3. The Equipments shall fulfill the selection criteria & its purpose of application. The Equipments shall be as per purchase order. Accessories received shall be as per purchase order. The Equipments shall meet Pre-selected design parameters. 6. Verification Sheet: Sr. No. Item/ Parameter Expectation 1 Make Talleres TACOME S.A 2 Model Rame 7 campos 3 Capacity RAM-7-160 4 Design Should have basic four parts, Inlet system Driying system Transporting system Outlet system Electrical components 5 Inlet system - - Safety System Foulard - Emergency Stop tested - All moving parts should be suitably covered under replaceable guards or box - All electrical connections should be appropriately numbered and identified and covered with suitable guard. Pneumatic Cylinder - Technical datasheet available - Spare part ID available - Evidently new - Damage free - Technical tag available Gearbox and motor - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new Actual Remarks Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE - Weft straightener Mahlo Orthopac RVMC-15 - Scraper - Inlet platform - Upper Overfeeding - Lower Overfeeding Frame - Steel Monoblock should be assembled and damage free - Reinforced Rolling element bearings should be assembled - 3. Foulard rollers rubber covered assembled and damage free. - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new - Damage free - Inox AISI 304L Cilinders - Inox AISI 304L Scraper - Inox AISI 304L Waste Tray - Evidently new - Totally assembled - Damage free - Evidently new - Totally assembled - Damage free Overfeeding cylinder - Cover evidently new and damage free Overfeeding 1.5kW motor - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new Overfeeding cylinder - Cover evidently new and damage free Overfeeding 2.2kW motor - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new Page No : 3 of 10 Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE - - - - - Edge cylinders Side Control Panel Motorized edge opener guider Infrared edge sensors fr-55 Tensor’s guider - Fabric nailed system - Inox AISI 304L Cilinders - CW turn - Evidently new - Totally assembled - Damage free - Evidently new - Totally assembled - Damage free - Touch Panel SIMATIC HMI - Both sides placed - Inox spindle - Infrared fotoelectric sensor controlled - Evidently new - Totally assembled - Damage free - Evidently new - Totally assembled - Damage free - Evidently new - Totally assembled - Damage free Rubber wheels - Both sides placed - Rubber cover evidently new and damage free Nailed 1.1kW motor - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new Totally assembled Damage free Nailing brushes - Two brushes both side placed - Evidently new - Totally assembled Page No : 4 of 10 Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE - Unpinning watchers - Automatic chain greasing system Drying system - - - Safety System Stenter frame Air flow System - Damage free - Evidently new - Totally assembled - Damage free - Evidently new - Totally assembled - Damage free - Emergency Stop tested - All moving parts should be suitably covered under replaceable guards or box - - All electrical connections should be appropriately numbered and identified and covered with suitable guard. - 7 driying fields - Side and floor tempeture isolation - 100mm wide side and ceiling panels - Evidently new - Totally assembled - Damage free - Air flow 7.5kW motors - 2 motors placed by field - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new - Totally assembled - Damage free - Nozzles - Galvanized sheet made - Evidently new - Totally assembled - Damage free By-pass air chambers system - Technical tag available Page No : 5 of 10 boquilla Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE - - - - Burners Temperature Control Automatic fabric wide regulation Extraction - Technical datasheet available - Spare part ID available - Evidently new Air flow filters - Placed above each burner unit - Evidently new - Totally assembled - Damage free - Evidently new - Totally assembled - Damage free - - Type : RTD - - Make : Trister - - Model : PT - 100 - Wide regulation 0.75kW motors - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new - Totally assembled - Damage free General extraction - Extraction system placed at both sides of the frame - 1.5m spaced - Inner dripping tray - Extraction fan - Two 5.5kW fans placed - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new - Totally assembled - Damage free Page No : 6 of 10 Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new - Totally assembled - Damage free - 4 top nozzle - 4 bottom nozzle - 3kW helical fan - Air filters - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new - Totally assembled - Damage free - Technical tag available - Technical datasheet available - Spare part ID available - Evidently new - Totally assembled - Damage free Fabric unpinning discs - Evidently new - Totally assembled - Damage free Fabric unpinning cylinder - 1.5kW motor Transporting System - Chain Outlet System - Air cooling system - - - Weft straightener Mahlo Orthopac MFRC-15 - Technical tag available - Technical datasheet available - 15 Control Panel Spare part ID available - Evidently new - Totally assembled - Damage free Qty. 1 No. Operation : Through Auto/ ManualMode Emergency Stop Manual ON/ OFF switch Page No : 7 of 10 Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE 16 17 24 25 PLC HMI Safety Features All moving parts All electrical connections Documents Make : Siemens Model : S7 Qty. 1 No Make : Siemens Model : SIMATIC Qty. 1 No Should be suitably covered underreplaceable guards or box Should be appropriately numbered and identified and covered with suitable guard. Should be available Machine Manual MOC Certificates Should be available Calibration Certificates Should be available Test and Guarantee Certificates Should be available for Blower, motors &Filters Page No : 8 of 10 Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE 7. Observed Deviation Details of Deviation/ s : Investigation: Corrective action: Acceptable: Yes / No Deviation Approved by / Date: Page No : 9 of 10 Factory Acceptance Protocol Document No : Equipment : TACOME STENTER MACHINE Page No : 10 of 10 8. Conclusion: FAT CARRIED OUT BY: IN PRESENCE OF MANUFACTURER: Date: Date: Sign : Sign : Name:___________________________ Name:___________________________ Date: Site address : Sign : Name: ___________________________ 9. Approval Name & Designation Prepared By Checked By Approved By Department Signature Date