1 Knowledgebased integraded production management model

Anuncio

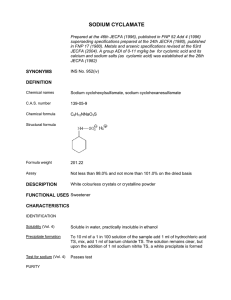

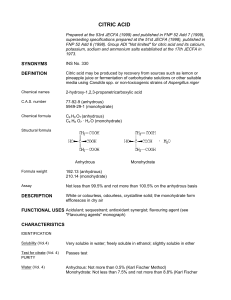

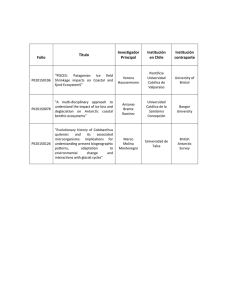

Journal of Knowledge Management Knowledge-based integrated production management model Jorge Muniz, Edgard Dias Batista Jr, Geilson Loureiro, Article information: To cite this document: Jorge Muniz, Edgard Dias Batista Jr, Geilson Loureiro, (2010) "Knowledge‐based integrated production management model", Journal of Knowledge Management, Vol. 14 Issue: 6, pp.858-871, https://doi.org/10.1108/13673271011084907 Permanent link to this document: https://doi.org/10.1108/13673271011084907 Downloaded on: 19 June 2018, At: 06:03 (PT) References: this document contains references to 46 other documents. To copy this document: [email protected] The fulltext of this document has been downloaded 2677 times since 2010* Users who downloaded this article also downloaded: Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) (2014),"An evaluation of knowledge management tools: Part 1 – managing knowledge resources", Journal of Knowledge Management, Vol. 18 Iss 6 pp. 1075-1100 <a href="https://doi.org/10.1108/JKM-11-2013-0449">https://doi.org/10.1108/JKM-11-2013-0449</a> (2014),"An evaluation of knowledge management tools: Part 2 – managing knowledge flows and enablers", Journal of Knowledge Management, Vol. 18 Iss 6 pp. 1101-1126 <a href="https://doi.org/10.1108/JKM-03-2014-0084">https://doi.org/10.1108/JKM-03-2014-0084</ a> Access to this document was granted through an Emerald subscription provided by emerald-srm:538276 [] For Authors If you would like to write for this, or any other Emerald publication, then please use our Emerald for Authors service information about how to choose which publication to write for and submission guidelines are available for all. Please visit www.emeraldinsight.com/ authors for more information. About Emerald www.emeraldinsight.com Emerald is a global publisher linking research and practice to the benefit of society. The company manages a portfolio of more than 290 journals and over 2,350 books and book series volumes, as well as providing an extensive range of online products and additional customer resources and services. Emerald is both COUNTER 4 and TRANSFER compliant. The organization is a partner of the Committee on Publication Ethics (COPE) and also works with Portico and the LOCKSS initiative for digital archive preservation. *Related content and download information correct at time of download. Knowledge-based integrated production management model Jorge Muniz, Edgard Dias Batista Jr and Geilson Loureiro Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) Abstract Purpose – This paper aims to propose a model of production management that integrates knowledge management, as a third dimension, to the production and work dimensions and to identify factors that promote a favorable context for knowledge sharing and results achievement in the production operations shop floor environment. Design/methodology/approach – The model proposed is built from opportunities identified in the literature review. Findings – The factors in the model integrate its three main components: knowledge management, production organization and work organization, providing a representation of the dynamics of the workplace and shop floor environment. Practical implications – The proposed model and its factors allow managers to better understand and to improve the organization activities, because it integrates knowledge management with the production organization and work organization components of traditional models. Jorge Muniz is Professor of Production Management and Edgard Dias Batista Jr is Professor of Information System, Statistics and Transport Planning Field, both in the Production Department, São Paulo State University, Guaratinguetá, Brazil. Geilson Loureiro is Professor of Systems Engineering at the Laboratory of Integration and Testing (LIT), Brazilian Institute for Space Research (INPE), São José dos Campos, Brasil. Originality/value – Literature acknowledges the role of knowledge as competitive advantage, but it is still dealt in an implicit way within the traditional models of production management. This paper proposes a model and factors that provide a favorable context for tacit knowledge sharing and results achievement in the production operations shop floor environment. The model explicitly integrates knowledge management with traditional models’ components. Keywords Production management, Knowledge management, Knowledge sharing, Modelling Paper type Conceptual paper 1. Introduction Traditionally, production management models are comprised of two dimensions: the technical dimension and the social dimension. The technical dimension refers to production organization, hereafter called the P-dimension, processes, activities, types and physical arrangement of equipment and to the flow of material that result in services and goods. The social dimension refers to work organization, hereafter called the W-dimension. However, knowledge management is recently gaining more attention from those subjects related to organizational sciences (Serenko and Bontis, 2004; Paiva et al., 2007), especially those related to improvement processes and incremental process innovation, more specifically in the shop floor production operations environment. Recent papers on knowledge management reinforce the need to research: Received 29 December 2009 Accepted 30 April 2010 PAGE 858 j B Factors that affect the tacit knowledge in groups within the organizations (Erden et al., 2008). B Methodologies for business improvement (Hazlett et al., 2005; Nonaka et al., 2006; Fugate et al., 2009). JOURNAL OF KNOWLEDGE MANAGEMENT j VOL. 14 NO. 6 2010, pp. 858-871, Q Emerald Group Publishing Limited, ISSN 1367-3270 DOI 10.1108/13673271011084907 B Pragmatic guidelines on how the manager can develop favorable contexts in order to encourage knowledge conversion processes within groups in the organization or within the entire organization (Nonaka et al., 2006). This paper aims to propose a model of production management that integrates knowledge management, as a third dimension, hereafter called the K-dimension, to the P and W-dimensions. In order to achieve the above-mentioned general objective, this paper has as specific objective, which is to identify factors, in the K, P and W-dimensions, that promotes a favorable context for knowledge sharing and results achievement in the production operations shop floor environment, based on literature review. In order to achieve the specific objective above, this paper is structured as following: Section 2 reviews the traditional production management models. Sections 3, 4 and 5 review models and processes of production organization, work organization and knowledge management, respectively. This leads to the K, P and W factors described in Section 6. Section 7 proposes the model. Section 8 draws conclusions. Section 9 anticipates potential further research. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) 2. Production management traditional models Traditional production management models evolved from the classic, or Taylorist model, to the socio-technical model. In the Taylorist model, scientific administration and mass production focus on production organization rationalization, seeking efficiency increase in order to obtain results, often translated in terms of quantity and cost. In the socio-technical model, Emery (1959) considers that people’s behavior at work depends on their task structure and their task content. People’s performance and feelings related to their tasks are important for their satisfaction with their jobs. Therefore, despite the fact that the social and technical dimensions are identified as separate, both should be ‘‘jointly optimized’’ for obtaining results, while developing and integrating people. This proposition is essential so that the socio-technical model cannot be considered as a social experimentation exercise, but as a way of developing more effective organizations. Both models are illustrated in Figure 1. The dashed line represents the permeability of production operations and shop floor environment to external factors, such as, market and technology aspects. The gray star that involves production organization and work organization represents the existence of a well-defined and controlled set of factors to conduct the production processes, such as standard time and best method emphasis (Taylor, 1998). The cloud involving production organization and work organization illustrates the existence of various factors related to people, such as, leadership or individual satisfaction. Those factors, although acknowledged, do not have a prescribed treatment such as the ones approached by the Taylorist model. Figure 1 Taylorist and socio-technical models of production management SOCIAL-TECHNICAL PERSPECTIVE of PRODUCTION MANAGEMENT RESULTS • Job Satisfaction • Innovation • Quality • Time • Quantity • Cost WORK ORGANIZATION PRODUCTION ORGANIZATION j j VOL. 14 NO. 6 2010 JOURNAL OF KNOWLEDGE MANAGEMENT PAGE 859 Biazzo and Panizzollo (2000) state that the differences between the socio-technical and Taylorist models are related to work organization, which, in the socio-technical model, it should be as taken an advantage for the people’s intellectual and creative capabilities, allowing continuous learning, generating recognition and social support, providing a clear relationship with social life and social values of the workers, making the visualization of the final product, ‘‘the big picture’’, possible, permitting the control on the results, minimizing hierarchical differences and group composition to be heterogeneous. The differences above also contain elements that require knowledge organization, and suggest that the P-dimension and the W-dimension are not enough for representing the increasingly important need for knowledge sharing among workers. Factors influencing knowledge sharing among workers are little understood, probably due to the emphasis on information technology (Bisalyaputra, 2004; von Krogh et al., 2000). Procedures prepared by the workers themselves in order to enhance productivity, quality, skills and understanding of the work place, attenuate the little involvement that bureaucracy can bring (Adler, 1993). Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) Knowledge management is definitely an opportunity to complement those traditional models. 3. Production organization, the P-dimension Production organization refers to processes, activities, types and physical arrangement of equipment and material flow that result in services and goods in a production system (shop floor production operations is the context of this paper). According to Biazzo and Panizzollo (2000), the post-Taylorism transformations in the automotive industry can be summarized into four models of production organization: 1. The Neo-Fordism is characterized by the introduction of advanced technologies of manufacturing in a Taylorist organizational context. 2. The Volvo Udevalla represents a break with the Fordist tradition, given the fact that it eliminates the assembly line and the ‘‘one minute job’’. 3. The Neo-Craft has been limited to the production of luxury and customized models. 4. The Toyota production system or lean manufacturing is based on waste minimization, quality, teamwork, standardized processes and kaizen. Although the above listed models were observed in the context of the automotive industry, Biazzo and Panizzollo (2000) consider industry as a ‘‘microcosm’’, where the characteristics of production organization are in general ‘‘crystallized’’ and can be observed. Various models from that industry are also replicated in other industrial sectors such as mass manufacturing in electronics industry and lean manufacturing trends in aerospace industry (Murman, 2002). It is still uncertain whether those models will coexist or whether they will converge into a dominant model (Bartezzaghi, 1999; Fujimoto et al., 1997 in Biazzo and Panizzollo, 2000). The main contemporary theory lines related to production organization come from a combination of total quality management (TQM) with other theories, such as lean manufacturing. Therefore, the limits of those theories are not clear and, there is frequently an intersection among their main ideas (Berawi and Woodhead, 2005). Prasad (1995, in Herron and Braiden, 2006) identified a relationship between lean manufacturing tools and their effect on manufacturing competitiveness, on objectives improvement, on productivity, and on operations control. He highlighted 5S, standard operating procedure, problem-solving methods and quick changeover as examples of such tools. j j PAGE 860 JOURNAL OF KNOWLEDGE MANAGEMENT VOL. 14 NO. 6 2010 4. Work organization, the W-dimension Work organization refers to methods, job content and roles and responsibilities in a given production system (shop floor production operations is the context of this paper). It focuses on the social relationships among individuals and groups, their behavior, skills, capabilities, feelings and other human aspects. According to van der Zwaan (1975), it is impossible to draw limits between the technical and social dimensions. Among the various work organization models, the Swedish (semi-autonomous group) and the Japanese (enriched group) models deserve to be highlighted. Table I presents the main differences between them. This paper calls the Swedish model for work organization as semi-autonomous group and calls the Japanese model as enriched group. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) The semi-autonomous group emphasizes group autonomy and flexibility, which allows the participation of workers in the assignment and reviewing their roles and responsibilities in order to improve the local and global results of their organization. The autonomy in a semi-autonomous group may comprise work methods review, leader selection, tasks distribution, target definitions. Volvo Udevalla is an example of a factory where the semi-autonomous work organization took place (Sandberg, 1995). The enriched group is based on responsibility and multi-skills of the local management, with restricted autonomy to pre-defined roles stated by the organizational structure. Therefore, the enriched model limits workers participation on assignment and review their roles and responsibilities. In the enriched group, the worker has less autonomy than in the semi-autonomous group but more autonomy than in the Taylorist worker arrangements. Lean manufacturing groups are organized according to the enriched group model. 5. Knowledge management, the K-dimension Knowledge management refers to the management of the various knowledge conversion processes in the production system (shop floor production operations is the context of this paper). Knowledge management, as a theme, has been receiving much attention from various production management areas. This evidences its multidisciplinarity and its complexity (Alvesson and Kärreman, 2001). For example, knowledge management contributes to stimulate innovation and continuous improvement by using existing knowledge within the organization (King et al., 2008). Table I Models of work organization Swedish (semi-autonomous group) Japanese (enriched group) Semi-skilled workers with high initial training Semi-skilled workers with generally high training starting qualifications Work tied to the production cycle Highly repetitive work; cycle times around one minute on the assembly lines, around five minutes in the machining area where multi-machine work is the norm No partial autonomy for the teams through JIT design Strong hierarchical structures, group leader appointed by management, no group self regulation Work totally uncoupled from the production cycle Wholistic tasks with long work cycles (. one hour) High partial autonomy for teams through process layout De-hierarchization with elected speaker and self regulation of group affairs Source: Hancké and Rubstein in Sandberg (1995) j j VOL. 14 NO. 6 2010 JOURNAL OF KNOWLEDGE MANAGEMENT PAGE 861 According to Serenko and Bontis (2004), knowledge management is a relatively new field of the general theory of administration. Many of its concepts are still evolving (Nonaka et al., 2006; Pasternack and Viscio, 1998 in Hazlett et al., 2005). Using Kuhn’s (1996) scientific paradigm, Hazlett et al. (2005) consider knowledge with two main focuses (Figure 2): 1. Management: called the organic paradigm, based on the importance of communication and tacit knowledge. It emphasizes the people. 2. Information systems: called the computational paradigm, based on the importance of databases. It emphasizes information technology. Various organizational programs are underlined by the theme ‘‘knowledge’’, and many are backed by standards (ISO 9000, TS 16949, ISO 14000, SA 8000). However, the theme is little explored and treated modestly, marginally and implicitly in the models of production management. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) According to Nonaka (1994), new knowledge always originates in people. Nonaka rescues Polanyi’s concept of tacit knowledge, the knowledge that is personal, knowledge that cannot be objectively articulated in order to be shared with others. On the other hand, explicit knowledge is expressed in words and data that can be formally and systematically shared with other people. Nonaka presents a model based on the social and interpersonal interactions that represents the four ways of conversion between tacit and explicit knowledge (see Table II), called the SECI processes: socialization (exchange of experiences among people); externalization (record and formal availability of the knowledge for other people); combination (integrated contents explicitly available that generates new knowledge); and internalization (people acquiring the knowledge through ways already formalized and registered). Those continuous and dynamic interactions between the knowledge conversion modes result in increasing levels of knowledge, forming the so -alled Knowledge Spiral (Figure 3). Authors have defended that only the explicit knowledge can be managed, captured and kept up to date (von Krogh et al., 2000; Gilmour, 2003). However, the same authors indicate that better results can be achieved with the existence of a favorable context, stimulated by actions that are focused on tacit knowledge sharing and people’s integration, facilitating the exchange and learning of new knowledge. This favorable context is hereafter called Ba (von Figure 2 Knowledge focuses Management (Organic Paradigm) Knowledge Information system (Computational Paradigm) Sources: Adapted from Spender and Scherer (2007); Hazlett et al. (2005) Table II Knowledge conversion process – SECI To From Tacit Explicit Tacit Explicit Socialization Internalization Externalization Combination Source: Nonaka (1994) j j PAGE 862 JOURNAL OF KNOWLEDGE MANAGEMENT VOL. 14 NO. 6 2010 Figure 3 Knowledge spiral Knowledge Level S E C I S I E C Source: Adapted from Nonaka (1994) Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) Krogh et al., 2000). When the organization formalizes and makes such actions explicit, obtaining the Ba is improved. Alvesson and Kärreman (2001) and Gourlay (2006) perform a critical analysis of Nonaka’s work. They acknowledge the comprehensiveness of the knowledge conversion processes proposed. However, they argue that Nonaka treats the subject ‘‘management’’ in a vague way and still rooted on the Taylorist idea that only the manager ‘‘adjusts the direction, selects the participants, provides the interaction environment, establishes guidance and schedule to projects and supports the innovation process’’ (Alvesson and Kärreman, 2001). Nonaka’s work is empirically founded on a product and development context. Garvin (1993) indicates the lack of prescriptive elements, mainly those related to process performance measurement and management. Despite the criticism, Nonaka’s work has been applied to empirical studies in many contexts, such as the analysis of: B organizational knowledge creation processes in the automotive industry (Vaccaro et al., 2009; Dyck et al., 2005); B influences of the adoption and use of the information on communication in organization learning (Lopez-Nicolas and Soto-Acosta, 2010); and B confirmatory factors were conducted to test Nonaka’s model with the Japanese middle managers (Nonaka et al., 1994), among others. 6. The K, P and W factors The K, P and W dimensions have relevant factors that promote the Ba for the processes of knowledge conversion in the production operations shop floor environment. Factors in the K, P and W dimensions are hereafter called the K, P and W-factors, respectively. Relevant P-factors are the use of the following tools that promote the use of worker’s knowledge and involvement. The tools contribute for the control and improvement of the daily activities of production workers. They are: problem solving methods (Garvin, 1993; Kolb, 1984); standard operating procedure (Bartezzaghi, 1999; Ohno, 1988; Spear and Bowen, 1999); 5S (Ohno, 1988); Poka Yoke (Ohno, 1988; Black, 1991) and quick changeover (Black, 1991; Shingo, 1989). Relevant W-factors are objectives, structure, communication, training, and incentives. According to Smith (2001), the most important factors for converting tacit knowledge into explicit knowledge, in the shop floor operation environment, are: objectives, communication and incentive. Worley and Doolen (2006) say that interdepartmental communication is the most common issue for converting tacit knowledge into explicit knowledge. Work j j VOL. 14 NO. 6 2010 JOURNAL OF KNOWLEDGE MANAGEMENT PAGE 863 organization models catalyze collective and individual learning, job satisfaction and productivity (van der Zwaan, 1975). Also, autonomy, in the daily routine and improvement production activities, is related to knowledge creation, storage, sharing, use and assessment. Many factors related to work organization are relevant to promote the Ba. Training, for example, cannot be separated from learning in the workplace (Darrah, 1995). Objectives represent a measurable way to relate the work of the group to the achievement of results, indicating progress, establishing priorities and justifying the claim for material and time resources to be used in problem solving and improvement projects. Structure encompasses the specification of roles and responsibilities of people in the working group, that is, group members, group leader and direct supervision, and, also, the availability of material and time resources. The formal organization of people, material resources and time allocation stimulate the initiative and the autonomy of the group members to seek support and to meet for creating, sharing, using and assessing new ideas of improvement and results gained. Barton and Delbridge (2006) state that the role of the supervisors and shop floor operators is important for continuous improvement and for the plant innovation process, and emphasizes the importance of teamwork and empowerment. They also state that supervisors must translate the company’s global objectives into objectives specifically to working groups, as a workforce motivation element. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) Communication is the process by which, ultimately, ideas and feelings are transmitted from people to people, from people to group, or from group to group (including to supporting groups, e.g. maintenance and logistics), making the social interaction necessary to knowledge management possible. Training is the skills development in production activities by emulating situations similar to working situations. Training shall provide the working groups with knowledge to action (Nonaka, 1994). Incentive is related to stimulus to carry out action, such as, to motivate shop floor operators to make suggestions for improvement in the workplace. Nakano (2007) classifies Nonaka’s ideas as analytical-constructivist, in other words, knowledge is considered as the creation process from people interaction and provides a larger range in the description, analysis and understanding of the phenomenon. Relevant K-factors are based on the work of Nonaka (1994). They are the processes of socialization, externalization, combination and internalization. The institutionalization of Nonaka’s processes as factors to create the Ba is expected to: B support socially built knowledge; B stimulate cooperation and teamwork; B emphasize the importance of transferring and transforming knowledge from personal to organizational and from tacit to explicit; and B stimulate interactive work on problems (try and error) as a learning process. Table III presents the acronyms assigned to each dimension and factor. Table III Acronyms assigned to factors and dimensions Knowledge management K-dimension Production organization P-dimension Work organization W-dimension Factor Code Factor Code Factor Code Socialization (tacit ! tacit) Externalization (tacit ! explicit) Internalization (explicit ! tacit) Combination (explicit ! explicit) SOC EXT INT CBN Problem-solving method (PSM) Standard operating procedure 5S Poka Yoke Quick change over PSM SOP 5S PY QCO Objective Structure Communication Training Incentives Personal characteristics OBJ STR COM TRN INC PCH j j PAGE 864 JOURNAL OF KNOWLEDGE MANAGEMENT VOL. 14 NO. 6 2010 7. K-PMM model – the knowledge-based and integrated production management model Traditional product management models have two dimensions, human or social, represented by the work organization is the W-dimension and a technical dimension is represented by the production organization, the P-dimension. The P and W-dimensions capture, essentially, the explicit structure and behavior of the production management system. Such a system has also a tacit structure that is progressively converted into explicit as it is better understood. Tacit knowledge exists, is important and needs to be formally included in a model of production management system, especially to model shop floor environment relationships. The knowledge conversion process acknowledges the importance of a tacit knowledge and focuses on the various processes of conversion of such knowledge into explicit and other tacit knowledge and vice versa. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) This paper proposes the K-PMM model, including a third dimension in a production management model. The K-PMM is a model of production management, focused on shop floor operations, and has three dimensions, the K, P and W dimensions. In the model it is proposed that these three dimensions must be integrated. The P, K and W dimensions of the K-PMM model were translated into factors. The factors were chosen focusing on the shop floor environment and, especially, for demonstrating the relevance of including knowledge as a third dimension of production management. The factors chosen in this work are the ones that promote the Ba, a favorable context that facilitates knowledge conversion processes. 7.1 Model justification based on a literature review Figure 4 relates papers and factors mentioned in them in order to improve the Ba. The fact that K, P and W factors are mentioned in those papers suggests that a production management model for promoting the Ba for shop floor workers should have the three K, P and W integrated dimensions. This evolves the traditional production management models presented in Section 2, adding a third dimension to them, and, reinforcing the need that these three dimensions must be integrated (Figure 5). Figure 4 Papers and factors identified in them K - Dimension Code References van der Zwaan 1975 Sandberg 1995 (Org) Emiliani 1998 Peltokorpi et al. 2007 Nonaka 1994 Garvin 1993 Bartezzaghi 1999 Bisalyaputra 2004 Nonaka et al. 2006 Easterby-Smith; 1997 Spender and Scherer 2007 Biazzo and Panizollo 2000 Emery 1959 Smith 2001 Wiig 1994 Woorley and Doolen 2006 Kulkarni et al. 2007 Ohno 1988 Shingo 1989 Spear and Bowen 1999 SOC EXT INT W – Dimension CBN OBJ STR COM TRN P - Dimension INC j PCH PSM SOP 5S QCO j PY VOL. 14 NO. 6 2010 JOURNAL OF KNOWLEDGE MANAGEMENT PAGE 865 Figure 5 Dimensions for promoting the Ba Knowledge Management (K-Dimension) Work Organization (W-Dimension) (P-Dimension) Production Organization Favorable Context (Ba) R E S U L T S Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) 7.2 Model description The K-PMM is depicted in Figure 6. The K-PMM promotes the integration of P, K and W dimensions because it is formally concerned with the tacit and explicit knowledge conversion modes, incorporating them to the procedures and assessing, by measures, their use in the shop floor knowledge identification and sharing activities. The star involving production organization and work organization represents the set of defined, controlled and integrated factors for carrying out production management in a way that creates the Ba. As in the taylorist and socio-technical models, the dashed line represents the permeability of production operations shop floor environment to external factors, such as, market, strategic and technology aspects reflected in the production processes. The inclusion of the SECI conversion process and the knowledge spiral (Nonaka, 1994), in Figure 6, formalizes the integration of knowledge management with the traditional production management model. Figure 6 highlights the need for measures and procedures, related to results or to the factors presented in Section 6, establishing a dynamic relationship of cause and effect between the factors and the obtained results. In the K-PMM, production organization focuses on the definition, management and improvement of the production processes, by the application of pragmatic tools for the critical analysis and implementation, by the operators themselves, targeting results such as Figure 6 Knowledge based production management model (K-PMM) with dimensions and factors INTEGRATED PERSPECTIVE of PRODUCTION MANAGEMENT WORK ORGANIZATION S E W-Dimension 1. Objective 2. Structure 3. Communication 4. Training 5. Incentive 6. Personal Characteristics j I C Ba PRODUCTION ORGANIZATION j PAGE 866 JOURNAL OF KNOWLEDGE MANAGEMENT VOL. 14 NO. 6 2010 RESULTS K-Dimension 1. Socialization 2. Explicitation 3. Combination 4. Internalization Measurables and Procedures P-Dimension 1. Problem Solving Method 2. Standard Operating Procedures 3. 5 S 4. Poka Yoke 5. Quick change Over • Job Satisfaction • Innovation • Quality • Time • Quantity • Cost reduction in number of defects, in manufacturing time, in time of product model changeover during production, in costs, and in rework hours. The use of the P-factors enhances operators learning, by systematically seeking improvement in the production environment. Lean manufacturing and mass production were considered when selecting such factors. In order to promote the Ba integrated to the production work routine, the use of P-factors not only requires socialization, externalization and internalization of knowledge (K-factors), but also the implementation and use of the W-factors. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) In the K-PMM, work organization includes the level of autonomy at the various hierarchical levels of the people on the shop floor, for the definition, management and improvement of the production processes, in order to create opportunities for those people to develop pro-activity, learning and creativity to implement incremental innovative solutions. Attention must be given to cooperation and communication, to the incentives and training needs and to operators’ development, in order to get results for the organization and for the operators themselves. Among these results, the number of suggestions implemented; percentage of people participating in improvement projects; percentage of trained people who used, in a real work situation, the knowledge acquired; percentage of people who have a qualified substitute; percentage of people who declare themselves sufficiently motivated and satisfied can be highlighted as an example. The W-factors to promote the Ba, presented in Section 6, support the interaction between the operators and the organization, by sharing measurable objectives, by work and communication structure and by training and incentives. For the selection of those factors, two work organization models were considered: the semi-autonomous models and the enriched model. The W-factors adopted in the K-PMM contribute to organize people in order to get the best from operators’ knowledge and to obtain results. They are adequate to the production environment. It is intended, with the use of those factors, to enhance people involvement in order to get the organization objectives, systematically, by the creation, retrieving, sharing and using knowledge. The factors consider the needs of the group members when executing their routine and improvement activities, outlining: ‘‘who can help to do what’’, material and time resources availability, communication among group members and among the group and other people in the organization, training required by the various activities and by the operation of the production machinery, and incentives. The K-dimension as presented in Figure 6, promotes the integration between the P and W-dimensions, because it is formally concerned with the tacit and explicit knowledge conversion modes, incorporating them to the procedures and assessing, by measures, their use in the shop floor knowledge identification and sharing activities. Therefore, K-PMM recognizes the spontaneous and collective knowledge generation process and the workforce flexibility for the operation of shop floor machinery and for a better communication among the people involved. In Figure 6, the integration of K, P and W dimensions lead to improvement activities, such as: problem solving, kaizen projects, waste reduction, standard operation procedure elaboration and review. Those activities are the result of people’s interaction in a working group and of their knowledge application in the production environment. Kaizen improvement activities, applied continuously, incrementally and in a participative way for obtaining results, are in line with the socio-technical model. Brunet and New (2003) state that kaizen activities must be outside contractual scope. However, as mentioned in Section 6, related to the W-factors, there must be formal support (W-STR, structure) and time allocation (W-COM, communication by meetings) for improvement activities. Therefore, kaizen activities must be carried out, routinely, for improvement, without conflict with production objectives (e.g. pieces produced per day). j j VOL. 14 NO. 6 2010 JOURNAL OF KNOWLEDGE MANAGEMENT PAGE 867 8. Conclusions In the context of the shop floor production operations environment, this paper proposed a production management model which integrates knowledge management as a third dimension, hereafter called the K-dimension, to the already traditional P and W-dimensions (see Figure 7) Factors on the K, P and W-dimensions that promote a favorable context for knowledge sharing and results achievement in the production operations shop floor environment were identified based on literature review. Factors were initially identified in the literature. Those factors were presented in Section 6. Literature review (see Figure 4) showed that those factors, and therefore their corresponding dimensions, are relevant to the model and are integrated. In Section 7, a model with the three K, P and W integrated dimensions is proposed. By translating the P, K and W dimensions of the model into factors that promote a favorable context for the knowledge conversion process in the shop floor operations environment, the integration of the dimensions was demonstrated. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) The K-PMM developed is robust to different work and production organization models and to the various functions related to shop floor environment. Ongoing researches conducted by the authors in the automotive, electronics and glass industries suggest this statement. The K-PMM expands the scope of the manager over the reality of his work. This enhances the analysis of this reality and, therefore, contributes for his decision making process. 9. Further work The present paper suggests potential for developing a diagnostic tool to identify which factor should be further developed in order to get the favorable Ba. The scope extension mentioned above and the deepening of the understanding of the integration of K, P and W dimensions suggest the creation of a tool to diagnose qualitatively and quantitatively the situation of a plant that wants to promote a Ba. The K-PMM provides the basis for building a diagnostic tool for assessing the presence of the factors in a given shop floor production operation environment and orientate the formal integration of people, physical production means and knowledge. The tool would allow that the needs of the people and of the production system can be jointly met by the use of the Figure 7 Integrated P, K and W dimensions in the K-PMM Knowledge Production Work j j PAGE 868 JOURNAL OF KNOWLEDGE MANAGEMENT VOL. 14 NO. 6 2010 sources of knowledge, in a formal process, for waste reduction and other incremental improvement. Tacit knowledge can be particularly of difficult management, but the tool would enhance the creation and operation of a favorable context for the use of the operator knowledge. K-PMM was conceived for the shop floor production operations environment, where direct work force is predominant, with focus on the application of experience and skills of operators in the assembly line of the automotive sector. As future work, it is also proposed the analysis of the application of the K-PMM in other sectors, such as the electrical-electronic and chemical, and also in areas with more specialized workforce, not completely automated, such as maintenance and tooling groups. References Adler, P.S. (1993), ‘‘Time and motion regained’’, Harvard Business Review, Vol. 71 No. 1, pp. 97-108. Alvesson, M. and Kärreman, D. (2001), ‘‘Odd couple: making sense of the curious concept of knowledge management’’, Journal of Management Studies, Vol. 38 No. 7, pp. 995-1018. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) Bartezzaghi, E. (1999), ‘‘The evolution of production models: is a new paradigm emerging?’’, International Journal of Operations & Production Management, Vol. 19 No. 2, pp. 229-50. Barton, H. and Delbridge, R. (2006), ‘‘Delivering the ‘learning factory’? Evidence on HR roles in contemporary manufacturing’’, Journal of European Industrial Training, Vol. 30 No. 5, pp. 385-95. Berawi, M.A. and Woodhead, R.M. (2005), ‘‘Application of knowledge management in production management’’, Human Factors and Ergonomics in Manufacturing, Vol. 15 No. 3, pp. 249-57. Biazzo, S. and Panizzollo, R. (2000), ‘‘The assessment of work organization in lean production: the relevance of the worker’s perspective’’, Integrated Manufacturing Systems, Vol. 11 No. 1, pp. 6-15. Bisalyaputra, K. (2004), ‘‘Knowledge transfer as sustainable competitive advantage’’, International Engineering Management Conference Proceedings of IEEE, pp. 536-40. Black, J.T. (1991), The Design of the Factory with a Future, McGraw-Hill, New York, NY. Brunet, A.P. and New, S. (2003), ‘‘Kaizen in Japan: an empirical study’’, International Journal of Operations & Production Management, Vol. 23 No. 12, pp. 1426-46. Darrah, C.N. (1995), ‘‘Workplace training, workplace learning: a case study’’, Human Organization, Vol. 54 No. 1, pp. 31-41. Dyck, B., Starke, F.A., Mischke, G.A. and Mauws, M. (2005), ‘‘Learning to build a car: an empirical investigation of learning organization’’, Journal of Management Studies, Vol. 42 No. 2, pp. 387-416. Easterby-Smith, M. (1997), ‘‘Discipline of organizational learning: contributions and critiques’’, Human Relations, Vol. 50 No. 9, pp. 1085-113. Emery, F. (1959), Characteristics of Socio-technical Systems, Document No. 527, Tavistock Institute, London. Emiliani, M.L. (1998), ‘‘Lean behaviors’’, Management Decision, Vol. 36 No. 9, pp. 615-31. Erden, Z., von Krogh, G. and Nonaka, I. (2008), ‘‘The quality of group tacit knowledge’’, Journal of Strategic Information Systems, Vol. 17 No. 1, pp. 4-18. Fugate, B.S., Stank, T.P. and Mentzer, J.T. (2009), ‘‘Linking improved knowledge management to operational and organizational performance’’, Journal of Operations Management, Vol. 27 No. 1, pp. 247-64. Garvin, D.A. (1993), ‘‘Building a learning organization’’, Harvard Business Review, Vol. 71 No. 4, pp. 78-90. Gilmour, D. (2003), ‘‘How to fix knowledge management’’, Harvard Business Review, Vol. 81 No. 10, pp. 1-2. Gourlay, S. (2006), ‘‘Conceptualizing knowledge creation: a critique of Nonaka’s theory’’, Journal of Management Studies, Vol. 43 No. 7, pp. 1415-36. j j VOL. 14 NO. 6 2010 JOURNAL OF KNOWLEDGE MANAGEMENT PAGE 869 Hazlett, S.A., McAdam, R. and Gallangher, S. (2005), ‘‘Theory building in knowledge management: in search of paradigms’’, Journal of Management Inquiry, Vol. 14 No. 1, pp. 31-42. Herron, C. and Braiden, P.M. (2006), ‘‘A methodology for developing sustainable quantifiable productivity improvement in manufacturing companies’’, International Journal of Production Economics, Vol. 104 No. 1, pp. 143-53. King, W.R., Chung, T.R. and Haney, W.H. (2008), ‘‘Knowledge management and organizational learning’’, International Journal of Management Science, Vol. 36 No. 2, pp. 167-72. Kolb, D.A. (1984), Experiential Learning: Experience as the Source of Learning and Development, Prentice-Hall, Englewood Cliffs, NJ. Kuhn, T.S. (1996), The Structure of Scientific Revolutions, 3rd ed., The University of Chicago Press, Chicago, IL (originally published in 1962). Kulkarni, U.R., Ravindran, S. and Freeze, R. (2007), ‘‘A knowledge management success model: theoretical development and empirical validation’’, Journal of Management Information Systems, Vol. 23 No. 3, pp. 309-47. Lopez-Nicolas, C. and Soto-Acosta, P. (2010), ‘‘Analyzing ICT adoption and use effects on knowledge creation: an empirical investigation in SMEs’’, International Journal of Information Management (in press). Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) Murman, E.M. (2002), Lean Enterprise Value: Insights from MIT’s Lean Aerospace Initiative, MIT, Cambridge, MA. Nakano, D. (2007), ‘‘Reframing knowledge management: a study of perspectives and related processes’’, Proceedings of the International Conference in Birmingham, England, 2006. Nonaka, I. (1994), ‘‘A dynamic theory of organizational knowledge creation’’, Organization Science, Vol. 5 No. 1, pp. 14-37. Nonaka, I., Von Krogh, G. and Voelpel, S. (2006), ‘‘Organizational knowledge creation theory: evolutionary paths and future advances’’, Organizational Studies, Vol. 27 No. 8, pp. 1179-208. Nonaka, I., Byosiere, P., Borucki, C.C. and Konno, N. (1994), ‘‘Organizational knowledge creation theory: a first comprehensive test’’, International Business Review, Vol. 3 No. 4, pp. 337-51. Ohno, T. (1988), Toyota Production System: Beyond Large-scale Production, Productivity Press, New York, NY. Paiva, E.L., Roth, A.V. and Fensterseifer, J.E. (2007), ‘‘Organizational knowledge and manufacturing strategy process: a resource-based view analysis’’, Journal of Operations Management, Vol. 26 No. 1, pp. 115-32. Peltokorpi, V., Nonaka, I. and Kodama, M. (2007), ‘‘NTT DoCoMo’s launch of IMode in the Japanese mobile phone market: a knowledge creation perspective’’, Journal of Management Studies, Vol. 44 No. 1, pp. 50-72. Sandberg, A. (Org.) (1995), ‘‘Enriching production: perspectives on Volvo’s Uddevalla plant as an alternative to lean production’’, MPRA Paper No. 10785, September 26, available at: http://mpra.ub.unimuenchen.de/10785/ Serenko, A. and Bontis, N. (2004), ‘‘Meta-review of knowledge management and intellectual capital literature: citation impact and research productivity ranking’’, Knowledge and Process Management, Vol. 11 No. 3, pp. 185-98. Shingo, S. (1989), Study of the Toyota Production System: From an Industrial Engineering Viewpoint, Productivity Press, New York, NY. Smith, E.A. (2001), ‘‘The role of tacit and explicit knowledge in the workplace’’, Journal of Knowledge Management, Vol. 5 No. 4, pp. 311-21. Spear, S. and Bowen, H.K. (1999), ‘‘Decoding DNA of the Toyota Production System’’, Harvard Business Review, Vol. 77 No. 5, pp. 97-106. Spender, J.C. and Scherer, A.G. (2007), ‘‘The philosophical foundations of knowledge management: editors’ introduction’’, Organization, Vol. 14 No. 1, pp. 5-28. Taylor, F.W. (1998), The Principles of Scientific Management, Dover, New York, NY. j j PAGE 870 JOURNAL OF KNOWLEDGE MANAGEMENT VOL. 14 NO. 6 2010 Vaccaro, A., Veloso, F. and Brusoni, S. (2009), ‘‘The impact of virtual technologies on knowledge-based processes: an empirical study’’, Research Policy, Vol. 38 No. 8, pp. 1278-87. van der Zwaan, A.H. (1975), ‘‘The socio-technical systems approach: a critical evaluation’’, International Journal of Production Research, Vol. 13 No. 2, pp. 149-63. von Krogh, G., Ichijo, K. and Nonaka, I. (2000), Enabling Knowledge Creation: How to Unlock the Mystery of Tacit Knowledge and Release the Power of Innovation, Oxford University Press, New York, NY. Wiig, K.M. (1994), Knowledge Management: The Central Management Focus for Intelligent-acting Organizations, Schema Press, Arlington, TX. Worley, J.M. and Doolen, T.L. (2006), ‘‘The role of communication and management support in a lean manufacturing implementation’’, Management Decision, Vol. 44 No. 2, pp. 228-45. Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) About the authors Jorge Muniz is Professor of Production Management at São Paulo State University (UNESP), Brazil. He holds a doctorate research at the Production Department, São Paulo State University (UNESP) and a Master in Production Engineering, São Paulo University (USP). He has worked for many years in the Brazilian automotive industry in production management assignments. Jorge Muniz is the corresponding author and can be contacted at: [email protected] Edgard Dias Batista Jr is Professor of Information System, Statistics and Transport Planning Field at the Production Department, São Paulo State University (UNESP), Brazil. He holds a doctorate title in Computation and System Engineering, Federal University of Rio de Janeiro (COPPE/UFRJ) and a Master in System Analysis and Application, National Space Research Institute (INPE), Brazil. He has been a consultant in public transport planning department for the government. Geilson Loureiro is a Professor of Systems Engineering at INPE (Brazilian Institute for Space Research) and ITA (Technological Institute of Aeronautics). He works also as a consultant to global Brazilian companies such as EMBRAER and VALE. He worked as a post doctoral associate at Massachusetts Institute of Technology (MIT) in the NASA Concept of Exploration and Refinement project for deriving system of systems architectures for human and robotic solar system exploration. Geilson has already published two books on complex systems concurrent engineering. To purchase reprints of this article please e-mail: [email protected] Or visit our web site for further details: www.emeraldinsight.com/reprints j j VOL. 14 NO. 6 2010 JOURNAL OF KNOWLEDGE MANAGEMENT PAGE 871 This article has been cited by: Downloaded by Universidad del Norte At 06:03 19 June 2018 (PT) 1. Agus Pramusinto, Erwan Agus Purwanto. Case Study 2: Toward Surabaya Cyber City: From GRMS to e-Sapawarga (2004– 2014) 55-83. [Crossref] 2. Uma MageswariS.D., S.D. Uma Mageswari, SivasubramanianR. Chitra, R. Chitra Sivasubramanian, DathT.N. Srikantha, T.N. Srikantha Dath. 2017. A comprehensive analysis of knowledge management in Indian manufacturing companies. Journal of Manufacturing Technology Management 28:4, 506-530. [Abstract] [Full Text] [PDF] 3. Kherbouche Asma, Megnounif Abdellatif. 2016. A New Model for the Impact of Knowledge Management on University Performance. Part 1: Theoretical Development. Journal of Information & Knowledge Management 1650041. [Crossref] 4. Michelle Liu, Pramila Rao. 2015. A comparative perspective of knowledge management via social media: India and China. The Learning Organization 22:2, 93-114. [Abstract] [Full Text] [PDF] 5. Wangwei Chu, Yingguang Li, Changqing Liu, Wenping Mou, Limin Tang. 2014. A manufacturing resource allocation method with knowledge-based fuzzy comprehensive evaluation for aircraft structural parts. International Journal of Production Research 52:11, 3239-3258. [Crossref] 6. Davi Nakano, Jorge Muniz Jr, Edgard Dias Batista Jr. 2013. Engaging environments: tacit knowledge sharing on the shop floor. Journal of Knowledge Management 17:2, 290-306. [Abstract] [Full Text] [PDF]