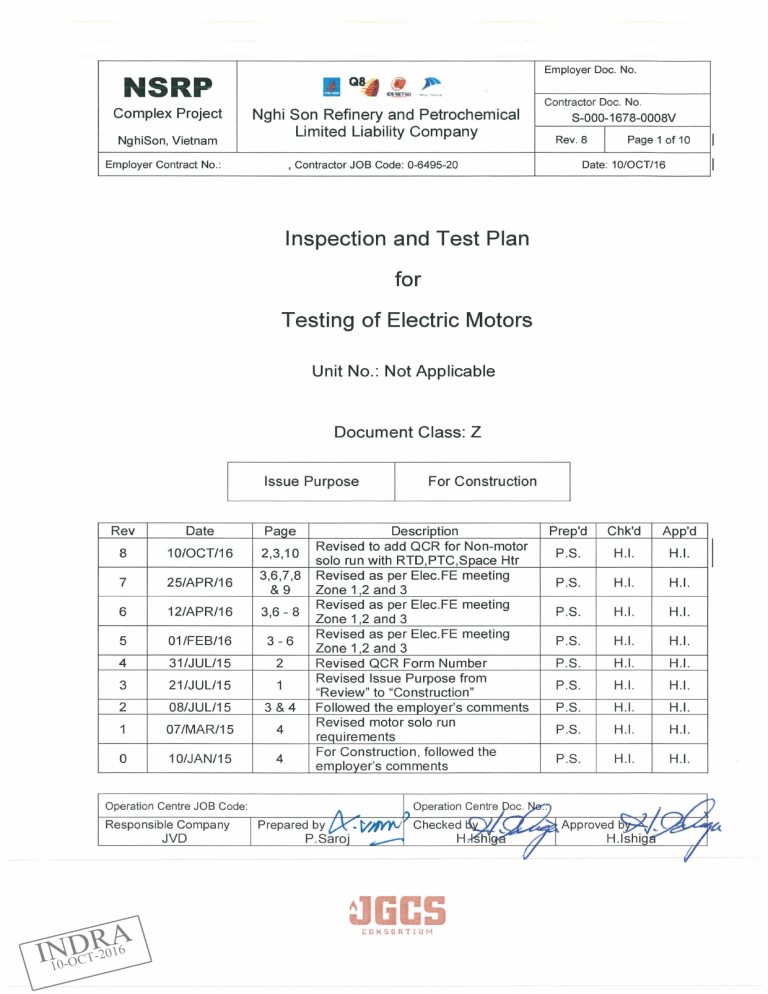

Employer Doc. No. NSRP Complex Project NghiSon, Vietnam Contractor Doc. No. Nghi Son Refinery and Petrochemical Limited Liability Company Employer Contract No.: S-000-1678-000BV Rev. 8 Page 1 of 10 Date: 10/0CT/16 , Contractor JOB Code: 0-6495-20 Inspection and Test Plan for Testing of Electric Motors Unit No.: Not Applicable Document Class: Z Issue Purpose Rev Date Page 8 10/0CT/16 2,3,1 0 7 25/APR/16 3,6,7,8 &9 6 12/APR/16 3,6-8 5 01/FEB/16 3-6 4 31/JUL/15 2 3 21/JUL/15 1 2 08/JUL/15 3&4 1 07/MAR/15 4 0 1 0/JAN/15 4 For Construction Description Revised to add QCR for Non-motor solo run with RTD,PTC,Space Htr Revised as per Elec.FE meeting Zone 1 ,2 and 3 Revised as per Elec.FE meeting Zone 1 ,2 and 3 Revised as per Elec.FE meeting Zone 1 ,2 and 3 Revised QCR Form Number Revised Issue Purpose from "Review" to "Construction" Followed the employer's comments Revised motor solo run requirements For Construction, followed the employer's comments Operation Centre JOB Code: Responsible Company JVD DR20A 16 IN CT10-O COHSDRTIUM Prep'd Chk'd App'd P.S. H.l. H.l. P.S. H.l. H.l. P.S. H.l. H.l. P.S. H.l. H.l. P.S . H.l. H.l. P.S. H.l. H.l. P.S. H.l. H.l. P.S . H.l. H.l. P.S. H.l. H.l. NSRP Complex Project Title: Employer Doc. No. Inspection and Test Plan for Testing of Electric Motors Contractor Doc. No. S-000-1678-0008V Rev. 8 Page 2 of 10 CONTENTS 1. ITP ITP No. 8000-008 Inspection and Test Plan for Testing of Electric Motors Abbreviation: H:Subcontractorisnotallowedtoproceedwiththetest/inspectionunlessawrittenreleaseisissued bytheEmployerand/orContractor.Subcontractorshallsubmitinspectionnotificationto Contractor. W:Subcontractorcanproceedwiththetest/inspectionwhenEmployerand/orContractor’sinspectoris notpresentatthenotifiedtime.SubcontractorshallsubmitinspectionnotificationtoContractor. IW:SubcontractorisrequestedtonotifyContractoroftheinitialinspectiondate/timeSubcontractor canproceedwiththetest/inspectionwhenEmployerand/orContractor’sinspectorisnotpresentat thenotifiedtime.Subsequenttest/inspectionwillnotbewitnessedunlessanydeficienciesarefound attheinitialinspection. S:SubcontractorisnotrequestedtonotifyContractor.Employerand/orContractor’sinspectorwill monitormanufacturingconditions,workmanshipandtest/inspectionduringhisvisitorperiodical inspection. R:SubcontractorisnotrequestedtonotifyContractor.Subcontractorshallperformthererequired test/inspectionandproviderelevantdocumentssuchascertificate,reportandQualityControl record.ThisdocumentsshallbesubmittedtoContractor’sinspectorforreview. I:Subcontractorshallberesponsibleforundertakingtheinspectionortestandgeneratingthe appropriatereportandrecord. 2. ATTACHMENT 2.1 Quality Control Report/Record Form No. QCR-8000-008A Inspection Report for Testing of Electric Motors Form No. QCR-8000-008B Inspection Report for Testing of Motor Solo Run Form No. QCR-8000-008C Inspection Report for Testing of Non-Motor Solo Run with RTD, PTC, or Space Heater A R D 0 2 N T I 10-OC 16 Employer Doc. No. NSRP Complex Project Title: Rev. 8 Contractor Doc. No. Inspection and Test Plan for Testing of Electric Motors Page 3 of 10 S-000-1678-0008V ITP No.:8000-0008 Verifying Item Activity No. Reference Acceptance Document Documents Criteria (QCR Form Inspection Mode 㻌 Remarks rd EMPLOYER 㻌 SUB CONT 3 8000-008A I W 㻌 S 㻌 8000-008A I W 㻌 W 㻌 8000-008A I W 㻌 W 㻌 No.) 1 2 3 4 5 6 Visual Check As per VENDOR DWG No Defect Winding / Insulation resistance S-000-1382-0002V IEEE test S-000-1382-0003V STD 43-2013 Space heater insulation S-000-1382-0002V IEEE resistance test S-000-1382-0003V STD 43-2013 As per DWG As per DWG 8000-008A I W 㻌 S 㻌 As per DWG 8000-008A I W 㻌 W 㻌 8000-008A I W 㻌 H 8000-008A I W 㻌 W 8000-008B I W H 8000-008C I W W Check the correct nameplate and labeling as per DWG LCS sequence test with MCC Polarization index test for 10 min. for HV motor 7 Final check of installation 8 Motor solo run test 9 As per VENDOR DWG D-000-1380-0982V 3 ~ 10 of 24 STD 43-2013 As per DWG S-000-1382-0002V Vendor recommendation S-000-1382-0003V / Remark on page 7,8 Check for Non-motor solo run S-000-1382-0002V with RTD, PTC, Space Heater S-000-1382-0003V A R D 0 2 N I 10-OCT 16 IEEE Remark on page 10 Doc No.S-000-1678-0008V_Rev.8 Contractor Job Code.. NSRP Complex Project Form No.8000-008A 0-6495-20 Page 4 of 10 INSPECTION REPORT for TESTING of ELECTRIC MOTORS QCR No. LOCATION: DWG No.: Serial No.: Motor Tag No.: System Voltage: V Rating: kW CHECK ITEMS DESCRIPTION SUBCONTR CONTR INSPECTION RESULT 1. Check correct name plate data & labelling as per DWG Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA 2. Check type of enclosure & area classification Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA 3. Remove shaft blocking & Check coupling Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA 4. Check cable phase connection is correct as per Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA 6. LCS sequence test with MCC Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA 7. Winding resistance / Insulation resistance Test Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA 8. Poralization index test for 10 min. for HV motor Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA 9. Final check of installation as per drawing Ƒ ACCEPT Ƒ NOT ACCEPTED Ƒ NA drawing and direction of rotation (CW/CCW) 5. Check proper cable installation and earthing of shield (for HV motor) inside terminal box Insulation Resistance (*1) and Polarization Index Test (*2) Test Voltage Phase to Earth (10 min.) L–E Insulation Condition : Ƒ Accept / Ƒ Not Accept / Ƒ NA Phase to Earth (1 min) L–E Polarization Index Result IR (10min) / IR ( 1 min) = Phase to Earth (1 min.) L–E Ohms : Space heater Winding Resistance Test U1 – U2 : Ohms V1 – V2 : Ohms G Ohms Ohms G W1– W2 : Ohms Test Equipment Used Sr. No. Description Model No. Calibration Due Date G G G G Remark: *1 : Test Condition and Criterria of Insulation Resistance Test ( IEEE Std 43 - 2013) Table 1 – Guidelines for direct voltages to be applied during insulation resisteance test Winding rated voltage ( V ) (*a) Insulation resistance test direct voltage ( V ) < 1000 500 1000 – 2500 500 - 1000 2501 – 5000 1000 - 2500 5001 – 12000 2500 - 5000 *a: Rated line-to-line voltage for three-phase ac machines, line-to-ground voltage for single-phase machines, and rated direct voltage for dc machines or field windings. A R D 0 2 N T I 10-OC 16 Doc No.S-000-1678-0008V_Rev.8 Contractor Job Code.. NSRP Complex Project 0-6495-20 Form No.8000-008A Page 5 of 10 INSPECTION REPORT for TESTING of ELECTRIC MOTORS QCR No. Table 4 – Recommended minimum insulation resistence value at 40Ȕ (all values in MȚ) Test specimen Minimum insulation resistance Test specimen IR1 min = 100 For most ac windings built after about 1970 (form wound coils) IR1 min = 5 For most machines with random-wound stator coils and form wound coils rated below 1 kV and dc armatures NOTES 1—IR1 min is the recommended minimum insulation resistance, in megohms, at 40 rC of the entire machine winding 2—kV is the rated machine terminal to terminal voltage, in rms kV *2 : Criteria of Polarization Index Text ( IEEE Std 43-2013) If IR ( 1 min ) is greater than 5000M ohm, PI test is not required. Table 3 - Recommended minimum values of polarization index for insulation per thermal classes machine components Thermal class rating Class 130 ( B ) and above Minimum P.I. 2.0 SIGNATURE SUBCONTRACTOR CONTRACTOR EMPLOYER DATE: DATE: DATE: NAME: NAME: NAME: A R D 0 2 N T I 10-OC 16 Doc No.S-000-1678-0008V_Rev.8 Form No.8000-008B Contractor Job Code.. NSRP Complex Project 0-6495-20 Page 6 of 10 INSPECTION REPORT for TESTING of MOTOR SOLO RUN QCR No. LOCATION: DWG No.: Motor Tag No.: System Voltage: V Rated Current: A No Load Current: A Speed: r/min Running Time (if saturated): 1 hour Serial No.: Rotation Direction from NDE: / Rating: CW / kW CCW 2 hour 1. All HV motor & LV motor above 75kW: 2 hours 2. All VFD motor: 2 hours 3. Other motor: 1 hour Note : If not saturated, separated record sheet (page 9 of 9) is filled. CHECK ITEMS TIME Amb.Temp. 0 15 30 45 60 Υ Bearing Temperature DE Temp Υ No Load Current No Load Current A Vibration of Bearing Housing Velocity DE Side mm/s Top mm/s Axial mm/s NDE Side mm/s Top mm/s Axial mm/s Speed Speed r/min Rotation Direction during motor solo run test: Accept / Not Accept Space Heater Operation (if applicable): Accept / Not Accept / NA LCS Ammeter Operation (if applicable): Accept / Not Accept / NA RTD Operation (if applicable): Accept / Not Accept / NA Thermistor (if applicable): ___________ohm as record purpose A R D 0 2 N T I 10-OC 16 75 90 105 120 Doc No.S-000-1678-0008V_Rev.8 Contractor Job Code.. NSRP Complex Project 0-6495-20 Form No.8000-008B Page 7 of 10 INSPECTION REPORT for TESTING of MOTOR SOLO RUN QCR No. Test Equipment Used Sr. No. Description Model No. Remark: 1. Measurement point for bearing temperature and vibration as below. 2. Criteria of bearing temperature If there is no vendor recommendation, apply the following criteria. -LV motor : Temperature rise does not exceed 80 degC -HV motor : Temperature rise does not exceed 90 degC 3. Criteria of no load current No Load Current shall be close to the value of Vendor's Motor Data Sheet. A R D 0 2 N T I 10-OC 16 Calibration Due Date Doc No.S-000-1678-0008V_Rev.8 Form No.8000-008B Contractor Job Code.. NSRP Complex Project 0-6495-20 Page 8 of 10 INSPECTION REPORT for TESTING of MOTOR SOLO RUN QCR No. 4. Criteria of vibration If there is no vendor recommendation, apply the following criteria. Shaft height means motor frame size (ex: 56, 63,࣭࣭࣭, 132, 160,࣭࣭࣭400, 450). IEC 60034-14 Table 1 – Limit of maximum vibration magnitude in displacement, velocity and acceleration (r.m.s) for shaft height H Shaft height (mm) Mounting 56 H 132 132 < H Velocity (mm/s) 280 H > 280 Velocity (mm/s) Velocity (mm/s) Free suspension 1.6 2.2 2.8 Rigid mounting 1.3 1.8 2.3 5. Criteria of speed Speed shall be close to the value of vendor's motor data sheet. 6. Check of space heater operation by clamp meter When motor operates, space heater does not operate. When motor does not operate, space heater operates. 7. Check of LCS ammeter operation Compare MCC measurement and LCS measurement . 8. Check of RTD operation Confirm to indicate temperature on MCC display. 9. Record thermistor resistance (ohm) Measure ohm by MCC display. SIGNATURE SUBCONTRACTOR CONTRACTOR EMPLOYER DATE: DATE: DATE: NAME: NAME: NAME: A R D 0 2 N T I 10-OC 16 Doc No.S-000-1678-0008V_Rev.8 Form No.8000-008B Contractor Job Code.. NSRP Complex Project 0-6495-20 Page 9 of 10 INSPECTION REPORT for TESTING of MOTOR SOLO RUN QCR No. CHECK ITEMS (If not saturated) TIME Amb.Temp. 135 150 165 180 195 210 225 Υ Bearing Temperature DE Temp Υ No Load Current No Load Current A Vibration of Bearing Housing Velocity DE Side mm/s Top mm/s Axial mm/s NDE Side mm/s Top mm/s Axial mm/s Speed Speed r/min SIGNATURE SUBCONTRACTOR CONTRACTOR EMPLOYER DATE: DATE: DATE: NAME: NAME: NAME: A R D 0 2 N T I 10-OC 16 240 255 Doc No.S-000-1678-0008V_Rev.8 Contractor Job Code.. NSRP Complex Project Form No.8000-008C 0-6495-20 Page 10 of 10 INSPECTION REPORT for TESTING of NON-MOTOR SOLO RUN WITH RTD, PTC or SPACE HEATER QCR No. LOCATION: DWG No.: Motor Tag No.: System Voltage: Serial No.: V Rating: CHECK ITEMS 1. Space Heater Operation (if applicable) : Accept / Not Accept / NA 2. RTD Operation (if applicable) : Accept / Not Accept / NA 3. Thermistor (if applicable): ___________ohm as record purpose Test Equipment Used Sr. No. Description Model No. Calibration Due Date Remark: 1. Check of space heater operation by clamp meter When motor operates, space heater does not operate. When motor does not operate, space heater operates. 2. Check of RTD operation Confirm to indicate temperature on MCC display. 3. Record thermistor resistance (ohm) Measure ohm by MCC display. SIGNATURE SUBCONTRACTOR CONTRACTOR EMPLOYER DATE: DATE: DATE: NAME: NAME: NAME: A R D 0 2 N T I 10-OC 16 kW