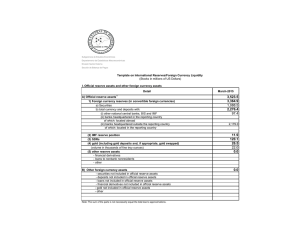

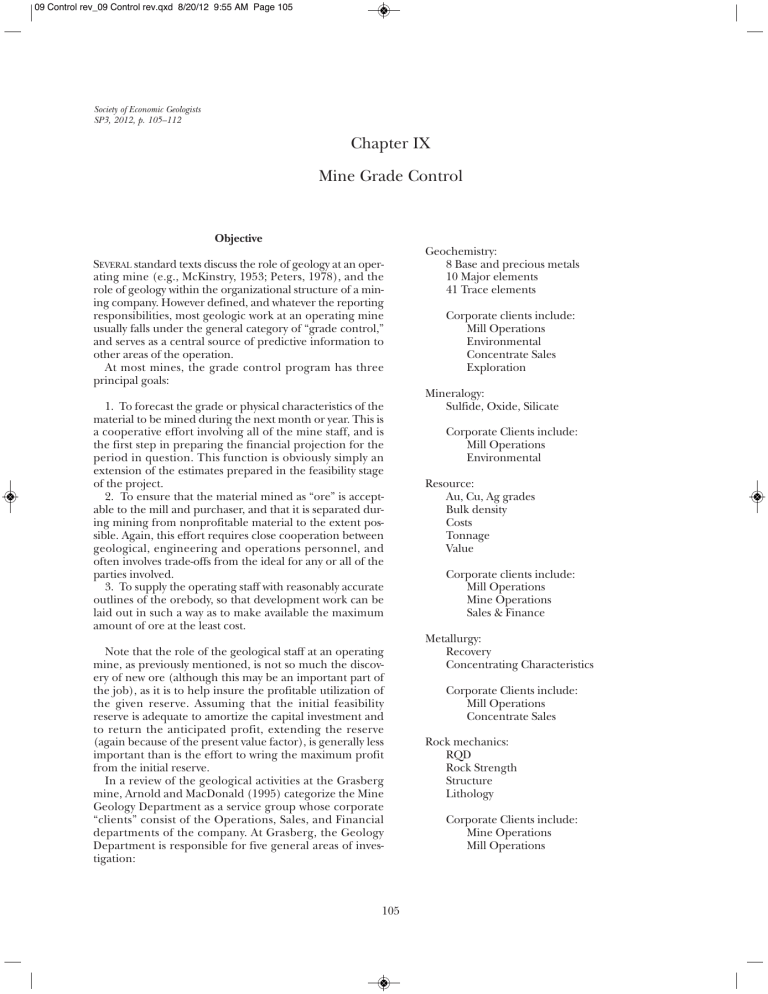

09 Control rev_09 Control rev.qxd 8/20/12 9:55 AM Page 105 Society of Economic Geologists SP3, 2012, p. 105–112 Chapter IX Mine Grade Control Objective SEVERAL standard texts discuss the role of geology at an operating mine (e.g., McKinstry, 1953; Peters, 1978), and the role of geology within the organizational structure of a mining company. However defined, and whatever the reporting responsibilities, most geologic work at an operating mine usually falls under the general category of “grade control,” and serves as a central source of predictive information to other areas of the operation. At most mines, the grade control program has three principal goals: 1. To forecast the grade or physical characteristics of the material to be mined during the next month or year. This is a cooperative effort involving all of the mine staff, and is the first step in preparing the financial projection for the period in question. This function is obviously simply an extension of the estimates prepared in the feasibility stage of the project. 2. To ensure that the material mined as “ore” is acceptable to the mill and purchaser, and that it is separated during mining from nonprofitable material to the extent possible. Again, this effort requires close cooperation between geological, engineering and operations personnel, and often involves trade-offs from the ideal for any or all of the parties involved. 3. To supply the operating staff with reasonably accurate outlines of the orebody, so that development work can be laid out in such a way as to make available the maximum amount of ore at the least cost. Note that the role of the geological staff at an operating mine, as previously mentioned, is not so much the discovery of new ore (although this may be an important part of the job), as it is to help insure the profitable utilization of the given reserve. Assuming that the initial feasibility reserve is adequate to amortize the capital investment and to return the anticipated profit, extending the reserve (again because of the present value factor), is generally less important than is the effort to wring the maximum profit from the initial reserve. In a review of the geological activities at the Grasberg mine, Arnold and MacDonald (1995) categorize the Mine Geology Department as a service group whose corporate “clients” consist of the Operations, Sales, and Financial departments of the company. At Grasberg, the Geology Department is responsible for five general areas of investigation: 105 Geochemistry: 8 Base and precious metals 10 Major elements 41 Trace elements Corporate clients include: Mill Operations Environmental Concentrate Sales Exploration Mineralogy: Sulfide, Oxide, Silicate Corporate Clients include: Mill Operations Environmental Resource: Au, Cu, Ag grades Bulk density Costs Tonnage Value Corporate clients include: Mill Operations Mine Operations Sales & Finance Metallurgy: Recovery Concentrating Characteristics Corporate Clients include: Mill Operations Concentrate Sales Rock mechanics: RQD Rock Strength Structure Lithology Corporate Clients include: Mine Operations Mill Operations 09 Control rev_09 Control rev.qxd 8/20/12 9:55 AM Page 106 106 STONE AND DUNN As noted by the authors, not all of these elements are important to each of the corporate clients—although Mill Operations may, for example, be concerned with all of these areas, the Mine Engineering group normally is less concerned with Geochemistry and Metallurgy than with those areas such as slope stability and blasting characteristics that directly influence the mining process. Similarly, the Exploration Department is less concerned with the resource or metallurgy of the existing deposit than with those areas such as Geochemistry and Mineralogy that may yield clues to the “signature” of possible new ones. In most instances, both initial resource estimates and subsequent reserve estimates are presented in some sort of block value format, in which the overall resource is subdivided into smaller units based on location, grade, mineralogy, anticipated profitability, and the like. Each block will be assigned some sort of location code, as well as the relevant data, such as tonnage, grade, vein thickness, or metallurgical recovery, from which the economic merit of the block can be derived. The blocks commonly coincide with the anticipated benches or mining levels, and, if of uniform size and shape, may include either the position of the ore/waste contact, or the proportions of ore and waste expected within the block. Resource blocks are estimated initially from exploration results, and as additional information becomes available, the blocks will be updated, and eventually move into the category of the probable or proven reserves upon which project feasibility will be based. As the mine moves toward production, proven reserve blocks will in turn become developed or operational reserves that form the basis for various production forecasts. In most instances, short-range forecasts of mine production are based on the results of detailed sampling (blast holes, development drill sampling, face or bank samples, etc.), not available at the exploration or even the feasibility stage, and may be further modified to reflect the results of reconciliations between production forecasts and actual operational results. During the progression from resource blocks to reserves and ultimately to developed or operational reserves, it is critical that a record be kept of the changes (and of the reasons therefor) in the status of individual blocks or groups of blocks. In particular, it is important to document the proportion of resource blocks that actually convert to developed reserves, in order to be able to accurately evaluate resource (or even undeveloped reserve) blocks outside the immediate mining area. Furthermore, the operational parameters of any given mine are rarely static over time, and changes in operating procedures will almost certainly have an impact on the economic evaluation of both poorly known resource areas as well as reserve blocks not yet developed in advance of actual mining. In recent years, there has been a concerted effort to improve the ore/waste selectivity through geostatistical analyses of blast hole data (although itself somewhat suspect), and to identify possible sources of bias in short-range estimation (Kwa and Mousset-Jones, 1986; Guardiano, 1990; Knudsen, 1992; Sims and Goodwin, 1992; Rossi and Parker, 1993; Rossi et al., 1993; Douglas et al., 1994; Pan, 1994; etc.), particularly in low-grade, open pit disseminated gold operations. These techniques, coupled with highly selective mining, have significantly improved the ore/waste selectivity at many of these operations, but are, unfortunately, after-the-fact approaches. The fact that even careful geostatistical analysis of sample data from blast holes at approximately 15-ft spacings still cannot guarantee a 100 percent separation of ore and waste blocks of blast hole size does not inspire confidence in block predictions based on widely spaced exploration sampling. Consider, for example, the results of blast hole sampling at the low-grade alkalic porphyry copper deposit at Ingerbelle in British Columbia. Results from blast hole drilling in an area scheduled for mining indicated that the northern part of the area to be blasted was ore, and that the southern part of the area was waste. The holes were loaded, but the explosive froze before the blast could be shot. The block was redrilled and resampled, and, mirabile dictu, the northern portion was waste, and the southern was ore! Although often considered as ground truth in reconciliation studies (especially those undertaken on a block-byblock basis), blast hole samples themselves may well introduce errors into the comparison. In most operations it is standard practice to extend blast holes below the bottom of the underlying bench in order to provide uniform fragmentation at the bench elevation. If blast holes are to be used as the primary source of grade control information, only that part of the hole actually corresponding to the bench height should be sampled, especially if there is a vertical trend in grade. Also note that the subgrade portion of the hole would otherwise be sampled twice—once by the holes drilled in the block above a particular bench elevation, and again by holes drilled on the bench itself. In addition, operational considerations may preclude collection of reliable samples from blast holes. Satisfactory sampling is particularly difficult in wet holes. Figure IX-1 illustrates the results of a series of multiple samples from the approximately two tons of cuttings from a single blast hole drilled in a low-grade copper-gold operation. The value in the solid rectangle on the histogram (0.004 oz/ton Au) represents the sample collected by a mechanical sampler on the drill rig; at this operation it would have been the value assigned to the area represented by that blast hole. Eighteen additional samples, represented by the open rectangles, were taken from opposite halves of the muck pile using various standard sampling techniques. These samples have grades ranging from 0.004 to 0.008 oz/ton Au. Those from one half of the pile averaged 0.005 oz/ton Au, and those from the opposite half averaged 0.006 oz/ton Au. Finally, all the remaining material from each half of the pile was collected, and the two roughly 1-ton bulk samples were processed and analyzed. The two results, 0.004 and 0.008 oz/ton Au, are shown on the figure by the crosshatched pattern. The bulk sample with a grade of 0.004 oz/ton Au came from the half of the pile averaging 0.005 oz/ton Au, and the sample with a grade of 0.008 oz/ton Au 09 Control rev_09 Control rev.qxd 8/20/12 9:55 AM Page 107 107 Number of Samples ORE RESERVE ESTIMATES IN THE REAL WORLD 8 6 4 2 0.004 0.005 0.006 0.007 0.008 OZ/TON Au FIG. IX-1. Histogram of multiple samples from a single blast hole. came from the half of the pile averaging 0.006 oz/ton Au. From the histogram, it would appear that a reasonable value for the block might be about 0.005 oz/ton, but that we have only a roughly one in three (8 in 21) chance of actually obtaining a single sample with this value from any given blast hole. The copper grades determined from the same set of samples showed a similar spread of values, albeit with a lower percentage variation. Published studies of grade control procedures often compare two estimation techniques, for example, two kriging techniques, using blast hole assays as an umpire to determine the “best” estimator. As discussed previously, neither estimator of the in situ reserve may be appropriate for estimating the tonnage and grade of the material actually extracted, and the reliability of blast hole samples themselves may leave much to be desired. The ultimate umpire remains the mill feed grade (Manns and Ellingham, 1992). Not only is it unbiased, but it also pays the bills. A quote from Miller and Giroux (1986, p. 270) summarizes a study of the type referred to above: Since it is impossible to prove which estimation procedure is closest to reality without tracing the estimated material through the mill, the final conclusion for the best estimation technique remains unresolved. The reliability of any grade control sampling program clearly needs to be carefully checked, not only against actual production results, but by analyzing the repeatability of the samples themselves. Again, very few reconciliations based on blast hole data take replacement dilution into account. Reconciliation of Reserve Estimates It is obvious, but unfortunate, that the true tonnage and grade of any deposit is known only after final closure of the mine. It is equally obvious that such a before-and-after comparison is of no use whatsoever in the evaluation of the property prior to mining or in mine planning during the operation. Comparison of the final production figures with estimates produced before and during the life of the operation can be useful in determining how the estimates and the evaluation might have been improved. Note, however, that any reconciliation of final production with premining reserve figures must take into account any changes in cutoff grades during the life of the operation, as well as operational changes, including changes in grade control procedures, that may have affected the economics and therefor the ultimate reserve of the operation. For this reason, a detailed reconciliation between the premining reserve estimate and final production figures may be extremely difficult. Even if produced, such detailed comparisons are seldom made available to the general public. The two papers by Crawford (2003, 2004) provide a succinct summary of the problems encountered in the reconciliation of production results with forecasts. Crawford lists three steps in the reconciliation process, any or all of which may prove problematic in practice: 1) Preproduction model to actual mine production; 2) Actual mine production to mill production; 3) Actual mill production to sales receipts. Two types of reconciliations need to be made during the course of the operation. The first are economic reconciliations over specific time periods such as the performance statistics and the cost sheet shown in Figure II-1. These compare estimated budget projections with actual costs of production and are used to track the profitability of the mining venture. The second type is a separate volume-byvolume reconciliation of tonnages and grades estimated by the mine compared to the measured production; these are used to determine the reliability of the reserve estimates. In most operations, it is standard practice to reconcile forecast and actual production on a monthly or yearly basis, and to adjust future predictions in light of empirical factors that have been found to reconcile the observed differences. Table IX-A presents the year-by-year reconciliation between TABLE IX-A. Groveland Mine: Comparison of Actual Production and Estimates 1970 1971 1972 1973 1974 Total Fe Actual Original est. After-the-fact est. Variance* 34.8 35.0 35.0 –0.2 34.7 35.2 35.2 –0.5 35.2 34.9 35.1 +0.1 34.8 34.6 35.2 –0.4 34.5 34.9 35.2 –0.7 % Magnetic Fe Actual Original est. After-the-fact est. Variance* 55.5 55.2 58.0 –2.5 58.6 53.7 60.2 –1.6 53.1 55.9 53.0 +0.1 60.7 62.7 58.5 +2.2 61.0 66.2 63.3 –2.3 % Weight Recovery Actual Original est. After-the-fact est. Variance* 42.6 42.0 42.9 –0.3 43.6 43.0 43.2 +0.4 44.3 42.8 42.8 +1.5 44.2 42.8 43.2 +1.0 44.4 42.8 43.1 +1.3 Grinding Rate (LTPH) Actual Original est. After-the-fact est. Variance* 626 610 627 –1 599 619 614 –15 612 624 626 –14 600 620 625 –25 620 621 632 –12 *Actual - After-the-fact estimate Note: “Original” estimates made in December of the preceding year. “After-the-fact” estimates made at the end of the year based on the area actually mined during the year. 09 Control rev_09 Control rev.qxd 8/20/12 9:55 AM Page 108 108 STONE AND DUNN pre- and post-mining production estimates compared with actual figures reported by the Groveland mill. Note that there is a definite tendency for the mill to report slightly lower figures for grade than even the “after the fact” mine estimate. The slight positive difference between estimated and actual weight recoveries is probably due to the use of a tonnage factor that was a little too low. The large discrepancy in the predictions of grinding rate suggests a problem with the procedures used to extrapolate test work on drill core to plant performance. Such empirical factors are usually referred to as assay adjustment, mine call factor, swell factor, dilution factor, and the like, but are simply numbers or procedures designed to force a reserve calculation to match the observed mill feed. At the Los Bronces operation, for example, blast hole grades are simply discounted by 3 percent to arrive at predicted mill feed (Godoy, 1992). Unfortunately, the reconciliation process too often dissolves into acrimony, with mill and mine each accusing the other for any shortfall in production or profitability, and both blaming the geological staff for failure to accurately predict the characteristics of the block of ground actually extracted. Even worse, this sort of factor can be determined only after the capital investment in mine and mill has been made. King et al. (1982) cites the situation at an Arizona porphyry copper operation in which it took 20 years to arrive at a satisfactory procedure for ore reserve prediction! Reconciliation of predicted vs. actual production results is often surprisingly difficult (Sides, 1992). Ore from the mine may be stockpiled before treatment, with a lag time of several days or even weeks between mining and milling. Estimates of the material to be mined are normally based on separate estimates of volume and density, while the mill feed is based on direct weight measurements (which include variable amounts of moisture). Mine production may come from several sources, with the tonnage from each only known as a volume proportion, rather than as a measured weight. Likewise, a portion of the material mined may be sent to a lean-ore stockpile, measured only by truck count and an assumed grade rather than weighed and assayed. Sampling of coarse material fed to an autogenous mill or sent to a heap leach pad is notoriously difficult. Within the mill itself, the tonnage of material reporting to tailings is usually arrived at by simply subtracting the tonnage of final product from the tonnage of crude feed, and in a surprising number of instances, the actual feed grade itself is a calculated number based on an assumed or historical unit recovery. Tailings analyses are seldom reliable in a heap leach operation, and even in a carbon-in-pulp gold operation may be influenced by a “nugget effect” caused by the escape of an occasional large but high grade fragment of carbon. Short term predictions of process recovery will be influenced by the fact that the efficiency of the processing plant itself will vary with time and maintenance schedules. Table IX-B presents an idealized list of the parameters that must be reconciled at various points in the process, together with some of the data required. In this instance, the flowsheet envisions a relatively simple operation producing a concentrate that is then sold to a custom smelter. Note that in many operations (particularly heap leach operations) where one or more of the measurements are missing, the only truly reliable figure in the entire exercise is the final smelter return. Given this situation, and in light of the difficulties mentioned above, it is highly improbable that short-term forecasts and actual production will always agree, and even after-the-fact re-estimation of blocks actually mined (vs. forecast) will usually show discrepancies. Figure IX-2 illustrates a month-by-month reconciliation between plant and mine for crude grade at the Pilot Knob operation. Although the discrepancy for any given month may be rather large, over time, these discrepancies should fluctuate PILOT KNOB PRODUCTION ESTIMATES Magnetic Fe in Plant Feed Plant Estimate – Mine Estimate 1972 1973 1974 +3.0% +2.0% +1.0% 0 -1.0% -2.0% -3.0% -4.0% -5.0% -6.0% Flotation Installed -------------Average error 1972 - mid 1974 FIG. IX-2. Pilot Knob production estimates. 09 Control rev_09 Control rev.qxd 8/20/12 9:55 AM Page 109 ORE RESERVE ESTIMATES IN THE REAL WORLD 109 TABLE IX-B. Factors to Consider in Reconciling Predicted vs. Actual Production RECONCILIATION PARAMETERS DATA REQUIRED Mine/Mill Grade Tonnage Contained metal Analyses (e xploration and development) Pit survey of area mined Tonnage Factor(s) Ore types Disposition (ore, waste, etc.) by truck count Stockpile balance (may require measured weights into and out of pile) Measured tonnage of mill feed Analysis of mill feed (including moisture) Reser ve Estimate/ Mine & Mill Grade Tonnage Contained metal Block model of reserve Pit survey of area mined Tonnage Factors Ore types Analysis of mill feed Disposition (as above) Measured mill feed rate Grinding rate Mill Feed/ Concentrate Metallurgical recovery Contained metal Reser ve Estimate/ Concentrate Metallurgical recovery Projected grind rate Mill feed grade Mill feed tonnage Mill feed moisture Concentrate(s) tonnage(s), grade(s) and moisture(s) Tailings grade Ore types, tonnages, grades Projected recoveries Measured mill feed rate Product Sales/ Concentrate Contained metal Shipping loss Projected revenue Measured weight FOB Smelter weight, grade and moisture Smelter deducts Sales price Freight cost Revenue received Reser ve Estimate/ Product Sales Projected production Projected revenue Estimated vs. actual contained metal sold Estimated vs. actual sales price Estimated vs. actual production rate around some mean value. If the average discrepancy is large enough to be significant, an adjustment factor of the type discussed above is usually applied. Note that a radical and persistent departure from the normal pattern is an indication that something is amiss—again, as at Pilot Knob early in 1974. In this instance, the mill feed grade calculated by the plant was based on historical iron unit recovery. Early in 1974, the mill flowsheet was modified to meet changing customer requirements, and the previous method of calculating mill feed grade in the plant had to be revised. The geological estimate is not always wrong! A somewhat similar situation occurred at the Groveland mine, where the appearance of a sudden large discrepancy between mine and mill estimates was ultimately traced to a hidden mechanical failure in the mill. Inasmuch as the areas actually mined during a given time period are likely to be somewhat different from the areas scheduled, a single reconciliation of actual mine production to scheduled tonnage and grade is likely to be misleading as an indicator of reliability of reserve estimation. This second reconciliation, simply involves re-estimating the blocks actually mined during the period, and comparing the results with actual production. Figure IX-3 illustrates an actual reconciliation between mine and mill at a porphyry copper operation, in which the various elements responsible for the discrepancy between projected and actual results have been quantified. 09 Control rev_09 Control rev.qxd 8/20/12 9:55 AM Page 110 110 STONE AND DUNN (000) Lbs. Actual 145,344 Budget 145,155 Difference 189 Recovery -178 Sequence Difference 8,943 Tons -2,458 Cutoff Difference 9,429 Block Model Difference 5,233 Grade 2,825 Other -2,894 FIG. IX-3. Reconciliation of budget vs. actual performance. In block-by-block comparisons it is informative to examine not only the overall tonnage and grade from any particular area, but also the comparisons above and below the cutoff grade. Most estimation techniques have the effect of smoothing out the grade distributions, with the result that the grade of waste blocks is overestimated and the grade of ore blocks underestimated. An example from an actual operation is shown in the scatter diagram in Figure IX-4. The estimated grades were based on kriging exploration drill hole results and are compared to the block grades defined by blast hole samples. The grades for the entire set of blocks appear to correspond reasonably well, with the regression line (a slope of 0.96) essentially coinciding with the 45° slope on the diagram. Note, however, that roughly half of the blocks defined as waste by the blast hole samples were originally estimated to be of ore grade. The slope of a regression line of these waste blocks alone would be only 0.33. This particular estimation indicated appreciably more tonnage above cutoff than really existed. It is strongly recommended that similar scatter diagrams be plotted in the course of any comparisons, not just in reserve reconciliations. The actual distribution of points is generally more informative than the simple calculation of correlation coefficients; note that in this example the apparently high correlation coefficient is due to two highgrade pairs. Examination of the actual plots is particularly important when comparing a large number of paired data points. Figure IX-5 presents a comparison of some 3,400 individual comparisons of estimated and blast hole grades. The regression line again nearly corresponds with the theoretical 45° slope, but the correlation coefficient is only 0.74. Note the broad spread of points on both sides of the regression line, and that a significant number of blocks were misclassified (regardless of whether the estimated or the blast hole figures are considered as “correct”). Production Simulation Clearly, during the feasibility stage of any proposed mining project, it is of some importance to try to forecast the type of grade control system that will be built into the capital and operating cost structure for the proposed operation. It is not enough to simply budget for the salary of a mine geologist or geological engineer without considering the specific task that the budgeted geologist or engineer will be expected to accomplish, and the sorts of information for which the geological staff will be responsible. In general, the more inflexible the mill or processing plant, the greater the requirement for careful grade control. In many operations, the mill can physically overcome the effects of misclassification of waste for ore; only 0.60 0.50 Blast Hole Grade 0.40 Blast Hole Grade 0.30 0.20 0.10 0.60 Estimated Grade 0.50 0.40 0.30 FIG. IX-4. Estimated vs. blast hole grades. 0.20 Estimated Grade 0.10 0.00 0.00 FIG. IX-5. Comparison of estimated vs. blast hole grades. 09 Control rev_09 Control rev.qxd 8/20/12 9:55 AM Page 111 111 ORE RESERVE ESTIMATES IN THE REAL WORLD the profitability suffers. In others, a seemingly minor error may shut down the entire operation. The Cerro Matoso operation is a case in point of the latter. The smelting characteristics of the ore depend on a delicate balance between Fe, MgO, and SiO2 in the plant feed, and the profitability of the operation on the content of Ni. If the Fe-MgO-SiO2 balance is outside very narrow limits, either the metal in the electric furnace freezes solid or a superheated slag burns through the furnace wall. In such a situation, careful grade control is clearly of some interest to all concerned, and prior to project approval, it became necessary to design a grade control system that would eliminate the likelihood of a major disaster. Unfortunately, geostatistical analysis indicated that the uncertainty of prediction of slag melting temperature for individual mining blocks was too great to be acceptable. At Cerro Matoso, Hanna approached the problem through the use of production simulation, and although the details will vary, the general approach can be applied to a wide variety of deposits. 1. The first step in the simulation is the calculation of the statistics of the population of values assigned to the individual mining blocks within the overall outlines of the deposit, including the effects of both internal and replacement dilution. The population of values should include values assigned to isolated blocks of subore grade surrounded by ore-grade material. Indicator kriging should be used with extreme caution, and only if it is absolutely certain that ore and waste can be effectively separated during mining. 2. Using Monte Carlo simulation, enough blocks are drawn at random from the population to satisfy one day's mill feed. The process is repeated numerous times, the statistics of a population representing a single day of production calculated, and the percentage of this population lying outside acceptable limits estimated. Note that this procedure presupposes no effective effort at grade control during the operation, and will therefore represent a worst case situation, where production grade control is either difficult or impossible (as it often is in a true bulk mining situation). 3. Assuming that the results of step 2 indicate an unacceptably high proportion of noneconomic or otherwise inadmissible days of production, the effects of stockpiling to smooth out daily swings can be evaluated by simply repeating the evaluation using various combinations of single days of production—three days, a week, or a month (Table IX-C). If, say, an analysis of stockpiling a week’s production is adequate to smooth out the day-to-day variations, a blending system and space adequate for at least two such stockpiles can be built into the feasibility study. Note that the same amount of offgrade material will still be mined; the effects will simply be less obvious. 4. In conjunction with steps 2 and 3, an educated guess may be possible as to the probable effects of a mine grade control program, especially if a test pattern of close-spaced drilling of the sort previously considered has been undertaken. If the test pattern (at less than the proposed blast hole spacing) indicates that the projectability of contacts and grades is reasonably reliable over distances equal to the blast hole spacing, it is likely that a program of blast hole sampling will, in fact, reduce (but not eliminate) the likelihood of misclassification of ore and waste. In light of the critical nature of the grade control function at Cerro Matoso, the following scheme was adopted, that although far more elaborate than necessary at many other types of operation, may nevertheless be of some interest: 1. Mining blocks of a few thousand tons each are outlined by blast hole sampling, augmented with XRF face samples during actual extraction. 2. A single day of mine production consists several individual mining blocks, each representing specific chemical TABLE IX-C. Production Simulation—Cerro Matoso; Effect of Stockpiling 1 day Stockpile 7 day Stockpile 30 day Stockpile Mean Std. Deviation 3.18% 0.30% 3.18% 0.10% 3.18% 0.04% SiO2 in slag Mean Std. Deviation 63.16 3.66 63.20 1.31 63.22 0.46 1637˚ C 70˚ C 1652˚ C 40˚ C 1654˚ C 28˚ C 92˚ C 17˚ C 4˚ C Ni Slag Melting Temperature Mean Std. Deviation Average Difference in Slag Temperature on Successive days 09 Control rev_09 Control rev.qxd 8/20/12 9:55 AM Page 112 112 STONE AND DUNN compositions required for the desired blend. The individual blocks are mined and stockpiled separately ahead of the crusher. 3. A few hundred tons are reclaimed from one of the stockpiles, crushed separately, weighed, sampled, and spread over the length of a 30-day stockpile of mill feed by a travelling stacker. The process is repeated with each of the other precrusher piles required for the day's production. 4. Based on the results of the previous day's sampling, the estimated analyses of the remaining precrusher piles may be adjusted, and the tonnages of new ore from individual mining blocks and the proportions of precrusher piles reclaimed adjusted to bring the blend in the 30-day pile into compliance with target requirements. 5. As the 30-day pile nears completion, any deviation from target requirements is adjusted using a small amount of material from one or more “specialty” stockpiles of ore with disproportionate amounts of whatever chemical element is needed to bring the final pile into balance. In this particular operation, the mine is responsible for the grade of the mill feed stockpile, and in practice, the stockpile grades very closely match the mill feed analyses. An important consideration in a predevelopment study of anticipated grade control is an honest assessment of the relative benefits of improvements in estimating technique compared with efforts to improve sampling, chemical analysis, stockpiling and the like. At Cerro Matoso, it was more cost effective to improve stockpiling (itself analyzed by a variety of statistical techniques), and to accept admittedly imperfect short-range predictions, than to spend the money on elaborate (and still imperfect) estimation techniques. Note that while geostatistical estimating techniques were essentially useless for grade control purposes at Cerro Matoso, developing an acceptable grade control system required the use of innovative statistical analysis, and could not have been done without this input. Even if geostatistical procedures are inapplicable, there is still a need for statistical mathematics! Provided that the fundamental assumptions underlying geostatistical analysis are met, and given a reasonably reliable short range variogram, Rossi and Parker (1993), propose the following general procedure to estimate the recoverable reserves of the combinations of selective mining units that constitute mining blocks or panels: 1. Develop a reserve model using ordinary kriging or a combination of ordinary and indicator kriging to give grade-tonnage curves for blocks of approximately the size and shape of possible mining panels. 2. Perform a conditional simulation, hopefully based on blast hole data, on a small grid. 3. Sample the conditional simulation, extracting a set of simulated blast holes, using the same grid used by the mine. 4. Use some form of kriging to interpolate grades on a very tight grid. 5. Assign grades to panels, defining the location of possible diglines. Note that this step may incorporate isolated points of internal dilution. 6. Compare panel grades and tonnages to reserves modelled from exploration data and develop suitable correction factors on a local to global basis. In conjunction with step 5, the effects of contact or replacement dilution can be taken into consideration, assuming the true contact has an equal probability of falling anywhere between the last ore-grade hole and the first waste hole outside the proposed digline, as previously discussed. A paper by Douglas et al. (1994) expands on this technique by including an economic function to help discriminate between material that should go the mill and material destined for the waste dump. Note that the local correction factors developed in step 6 will vary from place to place within the deposit, and that global factors likewise will not necessarily hold for a given smaller area. In particular, the amount of replacement or contact dilution will be a function of the proximity of the proposed mining block to the ore/waste contact. Factors developed for mining panels surrounded by ore-grade material will therefore differ from factors developed for panels straddling the ore/waste contact. Clearly the amount of sample data required for this sort of exercise is unlikely to be available prior to the actual development of the mining project, and the procedures as outlined are designed to improve the estimation of operational or developed reserves, and if the appropriate conditions are met, geostatistical analysis of the type proposed by Douglas et al. (1994) holds the potential to significantly improve the prediction of mill feed grades. In a situation such as the Porgera deposit previously discussed, where a very few very high-grade samples represent a disproportionate percentage of the total value of the deposit, a more reliable predevelopment simulation of a mining schedule may involve removing these samples entirely from the block model database, rather than attempting some sort of cutting procedure. Assuming that the analyses of the samples in question are valid, and that they do not represent a restricted, identifiable geologic environment, they probably represent occasional random occurrences of unusually high grade material. As such, it will be extremely difficult or even impossible to accurately predict where in the deposit similar spots are likely to occur. Consequently, a mining schedule simulated from a block model from which these samples have been removed will provide a better picture of a normal operating situation than will a model purporting to predict precisely when the proposed mining schedule will encounter one of these “hot spots.” Needless to say, the proposed operation will encounter these areas from time to time, perhaps in proportion to the frequency of such samples in the overall sample population, and such events may, in fact, represent much of the profit to be expected from the operation. However, unless the proposed operation can survive long periods of “normal” grade ore, economic viability will be in doubt. 10 reality rev_10 reality rev.qxd 8/20/12 9:58 AM Page 113 Society of Economic Geologists SP3, 2012, p. 113–117 Chapter X Theory vs. Reality It's all very well in practice, but it will never work in theory. --French management saying THROUGHOUT the foregoing, we have stressed the fact that very few mines operate exactly as forecast, that in most instances the actual results are below original expectations, and that this fact is usually due to a failure to anticipate geologic complexities in the orebody, rather than to the computational techniques employed in the reserve estimation process. Mason (1993) has suggested that the two main reasons for incorrect reserve estimates are (1) a lack of detailed mine geology (including a fundamental geologic understanding of the deposit), and (2) “advances” in computer skills and technology. It has been pointed out to us that on occasion, a property has been brought into production simply because the company involved is anxious to become an active producer, even though the deposit in question is clearly uneconomic—a situation that seems especially prevalent with small gold occurrences. There is a legal term for this sort of action (“fraud”), and further discussion of this sordid subject is beyond the scope of this text. The intent of this chapter is not to present a detailed list of “horror stories,” but is, rather, to summarize some general observations that can be drawn from the literature. This literature contains a great many studies comparing predevelopment ore reserve projections with actual production (e.g., Section B, CIM Special Vol. 9, 1968; Blackwell and Johnson, 1986; Bryan, 1986; Clow, 1991; Birak et al., 1992; Manns and Ellingham, 1992). In many of these studies, the mine staff takes pride in the fact that the operation has produced more metal units than forecast. A study by Grenier (1964) concluded that the base metal mines reviewed produced 3.75 times the originally estimated tonnage and 1.88 times the originally estimated metal units relative to the preproduction reserves. The corresponding figures for gold mines were 1.57 and 1.08 for the less successful ones, and 11 and 8 for successful ones. A specific example is reported by Birak et al., (1992, p. 373) at the North Generator Hill gold deposit in the Jerritt Canyon district of Nevada. In this instance, block model polygons appear to underestimate mined tonnage by 14.9 percent, and to overestimate grade by 9.4 percent. Note, however, that in each of these instances, the figures indicate that the production of the additional metal units required mining a disproportionate tonnage. If the mine produced, say, 110 percent of the forecast units from 150 percent of the forecast tonnage, it means that the ore treated was lower in grade than forecast, and absent other operational factors, was not as profitable as envisioned. Due to the present value factor, additional years of operation usually do not compensate for a shortfall in grade during the early years. In addition, as we have indicated throughout this discussion, minor errors in tenor, although economically serious, may not be as catastrophic as errors in the density, metallurgical characteristics, or size, shape and location of the orebody. The realization that the metallurgical characteristics of the Groveland orebody were significantly different than those of the ore tested in the pilot plant required major modifications in the installed milling circuit. Fortunately, in this instance, the reserve was large enough to justify the conversion, but the original financial projections were obviously unrealizable. King et al. (1986) discuss a similar situation at Woodlawn. Unfortunately, in many instances, the reserve is too small to overcome the effect of the installation of an inappropriate ore treatment plant or an inappropriate mining method. By the time the problem is identified and the necessary additional equipment installed, the reserve is largely exhausted; hence the Rule of Three previously discussed. Although instances of meaningless geostatistical analysis leading to meaningless reserve estimates do occur, in our opinion, the almost universal discrepancy between estimated and realized values is due primarily to the geologic inability to accurately define the contacts between different mineral zones within the deposit (especially the contact between ore and waste) rather than to any failure of the mathematics employed in the estimation process. This geologic problem is further exacerbated by the inability of the mining operation to precisely follow the true contact between ore and waste. Together, these two problems can lead to a significant amount of replacement dilution and a corresponding reduction in the grade of the material actually mined. The problem may be simply the inability to recognize during mining a gradational (and possibly erratic) contact between ore and waste, as at the Scadding mine described by Manns and Ellingham (1992), or may be due to errors in the basic geology of the sort described by Noble (1992b), shown in Figure IV-2, and King (1986), shown in Figure X1, where the contact between ore and waste is not only erratic, but covers a much greater surface area than originally envisioned. Unless the contact is marked by a structural boundary or parting plane, as at the Orostar mine (Manns and Ellingham, 1992), some mixing of ore and waste is virtually inevitable when mining to the contact, and the amount of waste taken with the ore (both overbreak and replacement dilution) will be proportional to the sur- 113 10 reality rev_10 reality rev.qxd 8/20/12 9:58 AM Page 114 114 STONE AND DUNN 3120 N 3080 N Although there are occasional, and in our opinion “lucky” exceptions, most successful mining ventures are proven by accumulation of representative shortrange data at the feasibility stage by drilling closespaced holes or from bulk sample pits or underground workings. Conversely, most mines which have been disappointing or have failed because of reserve problems have skipped this step in their development. 3320 E 3280 E Open Cut Ore Mary Kathleen – R.L. 1016 Feasibility Outline 3120 N 3080 N 3320 E 3280 E Open Cut Ore Mary Kathleen – R.L. 1016 as Mined FIG. X-1. Ore/waste contact at Mary Kathleen mine in feasibility outline and as mined; after King et al. (1986). face area of that contact. Unfortunately, errors in defining or following the ore/waste contact cannot be overcome by clever mathematical or statistical techniques applied to widely spaced sampling, a classic example of mathematical analysis exceeding the quality of the primary database (Thompson, 1992). Given this sorry state of affairs, the answer seems obvious—DRILL or SAMPLE. As was pointed out earlier, a carefully selected drilling pattern over a small area, with a hole spacing no larger than half of the proposed blast hole or production sample spacing, would have solved many of the geologic uncertainties leading either to disappointment or disaster in many of the actual case histories previously discussed. As pointed out by H.M. Parker (1994, pers. commun.): In addition to providing data on the continuity of geologic, mineralogic, or economic contacts, such close-spaced drilling and sampling is indispensable, both for proving that the deposit in question is homogeneous as assumed, and for the calculation of variograms that can be used for reliable data projection in other than the down-hole direction. Without such data, conditional simulation studies that may shed light on potential problems with both internal and replacement dilution are clearly impossible. We are, of course, aware of the time and budget constraints imposed by senior management on most development projects. In the words of the TV ad for automobile maintenance, “You can pay me now or pay me later.” “Later” may well cost several orders of magnitude more than “Now.” An excellent postmining reconciliation of the situation at the Cactus Gold mine operated by CoCa Mines during 1986–91 was presented by G.A. Hahn as part of the short course given in Denver in April 1993. His observations address many of the issues covered heretofore that we consider important in ore reserve estimation; they are summarized below with his permission, and with that of Hecla Mining Co., subsequent operators of Cactus Gold mine. The Winkler deposit at Cactus was one of several volcanic-hosted gold and silver deposits in the Middle Buttes area of southern California. The Winkler resource was originally estimated to contain 100,000 tons of mineralization grading 0.4 oz/t gold, occurring in a lens-shaped body as shown on Figure X-2a. As indicated in Table X-A, a feasibility study indicated that this high grade reserve would provide a satisfactory financial return. The operating plan envisioned mining 100,000 tons of ore and 1,300,000 tons of waste by open pit methods over a nine-month period, and processing the ore by heap leaching to produce 34,000 ounces of gold. Unfortunately, the minability of the geologic reserve was not adequately reviewed, and a mine plan was developed that envisioned bulk mining on 20-ft benches, with no attempt at selective mining. As a result, 100,000 tons of waste material with essentially zero value were taken together with the ore (Table X-A). In addition to the obvious effect on the grade, the added dilution had two important effects on the physical operation. (1) Since it was necessary to treat twice the tonnage originally envisioned, the leach pads were too small and had to be repermitted and enlarged. (2) The dilution came primarily from the clayrich alteration zone surrounding the high grade mineralization. This material seriously affected the permeability of the heap, necessitating the installation of agglomerating equipment and the retreating of the initial tonnage. 10 reality rev_10 reality rev.qxd 8/20/12 9:58 AM Page 115 115 ORE RESERVE ESTIMATES IN THE REAL WORLD X-2a Geologic Resource X-2b Minable Reserve Waste 100 feet FIG. X-2. Winkler gold deposit section: a. geologic resource; b. minable reserve. W TABLE X-A. Simplified Financial Analysis of the Winkler Deposit Mining Data Tons of Ore (1000) Waste (1000) Grade (oz/t) Mine Life (in months) Production (85 % Recovery) Gross Revenue ($M) Costs - Mining & Stripping ($M) Processing G&A Royalty Local Taxes Operating Margin less Capital Pre-Tax Profit Although total production (34,000 ounces) and total tonnage moved (1,400,000 tons) equalled the forecast figures, the economic results fell far short. At the beginning of this discussion, we stressed the fact that the purpose of any mining exercise is to make money, not ounces or pounds, and that it is very difficult to achieve a profit by treating material with zero value. In this example, however, the discrepancy in the pretax profit figures is primarily due to two factors. (1) An additional nine months of operation were required to acquire the necessary permits, expand the leach pads and solution ponds, install the necessary agglomerating equipment and reprocess the ore initially mined. As a result, General and Administrative costs increased by $1,375,000, and local property taxes increased by $150,000. (2) Due to operational changes, processing costs increased by $650,000, and capital costs increased by $750,000. In retrospect, it was found that a block model of the deposit using a cutoff of 0.02 oz/ton and 20′·20′·20′ mine cell units would have more accurately predicted the tonnage and grade of material actually mined (Figure X-2b). In part, this situation is a consequence of the fact that a small tonnage of high grade ore in a given block can support a large amount of zero-grade material before the average grade drops to the cutoff. In addition, the block size of the reserve model was similar to the size of the blast hole blocks that were used as mine control, and mining therefor essentially followed the outlines of the blocks included in the estimate. In this instance, the operation was evidently more concerned with 100 percent extraction of the ore than with the effects of replacement dilution or overbreak. TOTAL Evaluation Figures Production Figures 9 18 100 1,300 0.4 200 1,200 0.2 34,000 ounces 34,000 2,100 400 1,400 476 300 2,100 1,050 2,750 476 450 11,900 4,676 7,224 (5,250) 1,974 11,900 6,826 5,074 (6,000) (926) 10 reality rev_10 reality rev.qxd 8/20/12 9:58 AM Page 116 116 STONE AND DUNN However, the metallurgical testwork on which the original design was based quite obviously neglected to consider the possible impact of this dilution on the physical characteristics of the material that would actually be treated. In addition, there was a failure of communication between the mine planners and the geologist responsible for the reserve estimate, with the result that the selective mining necessary to achieve the grades envisioned by the geologist was not incorporated into the operating design. In summarizing a study of North American gold mining failures (defined as any project unlikely to recover its original capital cost at then-current prices), Harquail (1991) attributes the vast majority (70 percent) of failures to mistakes in ore reserve estimation—mistakes themselves attributable to the following three factors: 1. Basic mistakes a. Use of the wrong specific gravity (Ketza mine, Canamax Resources) b. Use of the wrong property boundaries (Yuba American Gold) 2. Improper or insufficient sampling a. Widely spaced drilling leading to the interpretation of a continuous orebody that in reality is discontinuous (Cullaton Lake, Campbell Resources) b. Contaminated drilling results such as reverse circulation drilling below the water table (Cove mine, Echo Bay) c. Nonrepresentative channel or muck sampling (Magnacon mine, Flanagan McAdam) d. Incorrect cutting factor for treating reserves with a strong nugget effect (e.g., Mascot, Premier, Puffy Lake, Tartan Lake, Mt. Skukum, Ketza River, Kingston) 3. Lack of mining knowledge a. Not understanding the dilution involved in mining, especially narrow vein and placer deposits (e.g., Kettle River, Tartan Lake, Johnny Mountain, McCabe, Los Lilenas) b. Underestimating mining costs and hence using too low a cutoff for ore (e.g., Colomac, Montana Tunnels) Note that only item 2d is in any way related to the mathematical technique used in the reserve estimation process. The examples given were taken directly from the Harquail study, others have been mentioned in this discussion, and doubtless many others are available for inclusion on the list. A somewhat similar study of some 22 heap leach operations revealed a failure rate in excess of 50 percent (Kappes, 1979), prompting the following suggestions, that although aimed specifically at heap leaching projects, are nonetheless applicable to most other projects as well: 1. FIND SOME ORE. (At least three of the projects failed because the heaps were built with material that was not ore even at the projected operating costs). 2. Evaluate the metallurgical geology. 3. Perform sufficient laboratory tests. 4. Perform a field test (or pilot plant test). 5. Allow adequate time and money to begin production. A more recent study (Bullock, 2011) focusing primarily on engineering and financial shortcomings in feasibility evaluations, nonetheless includes several of the geological shortcomings discussed previously. His list of the basic causes for the failure of mineral projects to reach their projected rates of return is as follows: 1. Insufficient reliable or misstated reserves; 2. Incorrect metallurgical recovery used; 3. Overestimation off mining recovery and under estimation of mining dilution; 4. Using a higher commodity price(s) than the trend price; 5. Lack of identification of where the project’s costs lie in the seriatum of other operations of the same commodity; 6. Understated capital and/or operating cost; 7. Major items of capital cost not even considered; 8. Overoptimistic mine design or productivity 9. Overoptimistic mine development schedule and start up (learning curve) time 10. Overestimation of marketability of commodity; 11. Unpredicted variation of social/business attitude of community, state and/or national government’s reaction to the project; 12. Unidentified environmental problems; 13. Lack of experience of company and/or feasibility study contractor in developing projects, especially in a country where they have no project experience; 14. The plant does not meet design expectations; 15. Differential price inflation between commodities and consumables; 16. Differential exchange rates between home country and developing country. Of these, items #1 and #3 and, to a lesser extent, #2 have been the subject of this text. If the basic reserve data are in error, the degree of accuracy of any engineering study based on the presumed reserve is largely irrelevant. As summarized by Ranta (1992, p. 281): Proper geologic work requires a keen awareness of and ability to anticipate the technical requirements of geotechnical engineers, hydrologists, mining engineers, metallurgists, and other specialists. The same statement applies equally well in reverse: it is imperative that the other parties involved in the evaluation communicate their concerns to the geological staff responsible for gathering and recording the basic data. Far too many exploration geologists have little or no operations experience, and unless made aware of operational concerns, are almost sure to overlook features that will 10 reality rev_10 reality rev.qxd 8/20/12 9:58 AM Page 117 ORE RESERVE ESTIMATES IN THE REAL WORLD subsequently become critical to the evaluation. Very few geologists, engineers or metallurgists are clairvoyant. The best and quickest way to improve accuracy and reduce testing program costs is for geologists, mining engineers and metallurgists to talk to each other about ore types, distribution, and order of exploitation of a deposit. (Ashley and Callow, 2000) As an example of the importance of the foregoing, consider the Exotica Project. During the early 1970s, Codelco's Chuquicamata Division attempted the development of a high grade body of transported oxide copper known at that time as the Exotica deposit, now in production as Mina Sur. The reasons for the eventual failure of the project have been documented in an unusually honest assessment by Bannack (1975). Among others: 1. An incomplete geological study that translated into test samples that were not representative of the orebody. An adit was driven through the deposit in order to provide pilot plant samples, but no raises were driven to provide bulk samples representing the vertical dimension of the orebody. As a result, the ore that was tested was softer, lower in carbonate, and showed less variation in gangue mineralogy than the ore subsequently mined. 2. The plan for mine development was divorced from metallurgical testwork. Whereas the pilot plant treated an idealized mixture of ore based on the average composition and mineralogy of the deposit, mine production was planned to follow a sequential pattern 117 designed to maximize only the economics of pit development, so as to yield hard bedrock ore during the first years, together with altered ore that had been shown by testwork to be characterized by higher acid consumptions, higher extraction of impurities, and lower copper recoveries than the bedrock ore. As a result, the planned mining sequence and the testwork on the different types of ore were never combined in a study of projected cash flows. 3. The water used in the pilot plant did not correspond to the recycled water that would be used in the commercial plant, which subsequently proved to inhibit the permeability of the ore. 4. The tertiary crushing was designed open circuit without the benefit of crushing tests on representative ore samples. As a result, the new plant delivers a product that is too coarse for good copper recoveries (35% +3/8 " rather than 15% +3/8 " ). 5. The agglomerating system installed for slime control was only effective when fed with precisely measured proportions of fresh and altered ore. In practice, the mine was never able to deliver this mixture of prototypes, and instead delivered mixtures with varying degrees of alteration. We close with the quote from King et al. (1982, p. 13): …it is the geological factor that has impressed itself on us more and more as being the key deficiency where serious weaknesses in ore reserve estimation have appeared…