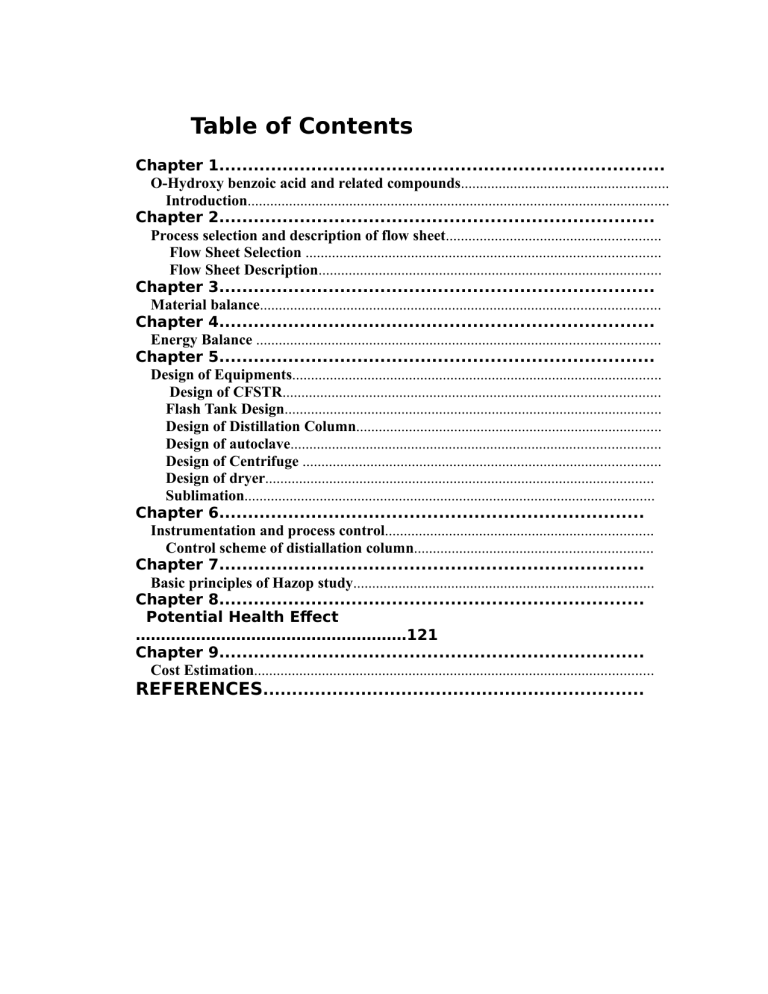

Table of Contents

Chapter 1.............................................................................

O-Hydroxy benzoic acid and related compounds.......................................................

Introduction................................................................................................................

Chapter 2...........................................................................

Process selection and description of flow sheet.........................................................

Flow Sheet Selection ..............................................................................................

Flow Sheet Description...........................................................................................

Chapter 3...........................................................................

Material balance..........................................................................................................

Chapter 4...........................................................................

Energy Balance ...........................................................................................................

Chapter 5...........................................................................

Design of Equipments..................................................................................................

Design of CFSTR....................................................................................................

Flash Tank Design....................................................................................................

Design of Distillation Column.................................................................................

Design of autoclave..................................................................................................

Design of Centrifuge ...............................................................................................

Design of dryer.......................................................................................................

Sublimation.............................................................................................................

Chapter 6.........................................................................

Instrumentation and process control.......................................................................

Control scheme of distiallation column...............................................................

Chapter 7.........................................................................

Basic principles of Hazop study................................................................................

Chapter 8.........................................................................

Potential Health Effect

………………………………………………121

Chapter 9.........................................................................

Cost Estimation..........................................................................................................

REFERENCES..................................................................

2

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter No.1

O-HYDROXY BENZOIC ACID AND RELATED

COMPOUNDS

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter 1

O-HYDROXY BENZOIC ACID AND RELATED

COMPOUNDS

Introduction

Compounds of the general structure

Where the hydroxy is ortho [69-72- 7], meta [99-06.9], or para [9996-7] are commonly known as the monohydroxybenzoic acids. Of the three acids,

the ortho isomer, salicylic acid, is by far the most important. The main importance

of salicylic acid and its derivatives lies in their antipyretic and analgesic actions

(see Analgesics, antipyretics, and anti-inflammatory agents). Natural salicylic

acid, which exists mainly as the glucosides of methyl salicylate [119-38-6] and

salicyl alcohol [90-01-7], is widely distributed in the roots, bark, leaves, and fruits

of various plants and trees. As such, their use as preparations for ancient remedies

is probably as old as herbal therapy. Hippocrates recommended the juice of poplar

trees as treatment for eye diseases. Salicyl alcohol glycosides (salicin) [138-52-3)

occur in Populous halsamifera (poplar) and Snlix helix (willow) trees. Methyl

salicylate glucosides occur in Betula (birch) and Togas (beech) trees. A more

familiar source of methyl salicylate is the leaves of Gaultheria procumbens

(wintergreen) (see also hydroxy carboxylic acids).

Free salicylic acid occurs in nature only in very small amounts. It

has been isolated from the roots, plants, blossoms, and fruit of Spirctea ulmaria,

from which its original name, acidium spiricum, was derived. Salicylic acid as

well as salicyfiltes occur in tulips, hyacinths, and violets, and in common fruits,

eg, oranges, apples, plums, and grapes, which explains the presence of salicylic

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

acid in most wines (1 – 2).

Physical Properties.

Salicylic acid is obtained as white crystals, fine

needles, or fluffy white crystalline powder. It is stable in air and may discolor

gradually in sunlight. The synthetic form is white and odorless. When prepared

from natural methyl salicylate, it may have a lightly yellow or pink tint and a

faint, wintergreenlike odor. Hydroxybenzoic acid crystallizes from water in the

form of white needles and from alcohol as platelets or rhombic prisms. pHydroxybenzoic acid crystallizes in the form of monoclinic prisms. Various

physical properties of hydroxybenzoic acids are listed in Tables 1–4.

Table 1

Physical Properties of Hydroxybenzoic Acids

Property

Value (Isomer)

Ortho

Meta

Para

Molecular weight

138.12

138.12

138.12

Melting point, oC

159

20L5-203

214.5 – 215.6

Boiling point, oC

211 swub

Density

1.443 33

4

1.473 22

29

1.497

Refractive Index

1.565

Flash point (Tag closed-cup), oC

o

20

29

1.57

Ka (acid dissociation) at 25 C

1.05

8.310-5

2.610-5

Heat of combustion, mJ/molo

3.026

3.038

3.035

Heat of sublimation, kJ/molo

95.14

To convert J to cal, divide by 4.184.

116.1

Chapter 1

Table 2

O-Hydroxy Benzoic Acid and Related Compounds

Solubilities of the Hydroxybenzoic Acids in Water, Wt %

Temperature, oC

Isomer

Ortho

Meta

Para

0

0.12

0.35

0.25

10

0.14

0.55

0.50

20

0.20

0.85

0.81

30

0.30

1.35

0.81

40

0.42

2.0

1.23

50

0.64

3.0

2.3

60

0.90

4.3

4.2

70

1.37

7.0

7.0

80

2.21

11.0

12.0

Figure 1. Reactions of the carboxyl group of salicylic acid.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Reactions. The hydroxybenzoic acids have both the hydroxyl and the

carboxyl moieties and, as such, participate in chemical reactions characteristic of

each. In addition, they can undergo electrophilic ring substitution. Reactions

characteristic of the carboxyl group include decarboxylation; reduction to

alcohols; and the formation of salts, acyl halides, amides, and esters. Reactions

characteristic of the phenolic hydroxyl group include the formation of salts,

esters, and ethers. Reactions involving form sodium salicylate. However, if

salicylic acid dissolves in the presence of alkali metals or caustic alkalies, e.g.,

excess sodium hydroxide, the disodium salt forms.

Salicylic acid can be converted to salicyloyl chloride by reaction with

thionyl chloride in boiling benzene. However, the formation of acyl halides can be

complicated by the presence of the phenolic hydroxyl. For example, the reaction

with phosphorus to arid pentachlorides is not restricted to the formation of the

acid chloride. Further interaction of the phosphorus halide and the phenolic

hydroxyl results in the formation of the phosphoric or phosphorous esters.

The formation of amides can be accomplished by the dehydration of the

ammonium salt of salicylic acid. The more common method for amides is the

reaction of the ester, acylhalide, or anhydride with an amine or ammonia. Each

step is fast and essentially irreversible.

Esterification is frequently carried out by direct reaction of the

carboxylic acid with an alcohol in the presence of a small amount of mineral acid,

usually concentrated sulfuric or hydrochloric acid. The ester of commercial

importance is methyl salicylate. Direct esterification has the advantage of being a

single-step synthesis; its disadvantage is the reversibility of the reaction. The

equilibrium can be shifted to the right if either raw material is used in large

excess, or by selective removal of one of the products. One less frequently

employed technique is the transformation of the acid to the acid chloride followed

by alcoholysis; each step is essentially irreversible. Another method is the reaction

of the alkali salt, eg, sodium salicylate, with an alkyl or an aryl alkyl halide.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Hydroxyl. The hydroxyl group is alkylated readily by the sodium salt

and an alkyl halide (Williamson ether synthesis) (see Fig. 2). Normally, only Oalkylation is ob ring substitution includes nitration, sulfonation, halogenation,

alkylation, and acylation. The following reactions are illustrated only with

salicylic acid; however, these reactions are characteristic of all the

bydroxybenzoic acids.

Table 3 Solubilities of the Hydroxybenzoic Acids in Non aqueous Solvents,

Wt %

Solvent

Isomer

Ortho

396

0.775

Meta

327

0.010

Para

285

0.0035

28.8 38 c C

20.7 36.5c C

19.5 22.5c C

Ethanol (99 wt %)

40.6 41c C

3.9.6 65c C

38.75 67 c C

n-heptane

2.09 92.2 c C

2.0197 c C

1.5197 c C

o

Acetone at 23 C

Benzene at 25 oC

1-butanol

Methanol at 15 oC

39.87

40.38

36.22

o

Carbon tetrachloride at 25 C

0.262

Chloroform (satd in H2O) at 25 1.84

o

C

Ethanol (abs) at 21 oC

34.87

I-propanol at 21 oC

27.36

Table 4 Saturated Vapor Pressure (p) of o- and p-Hydroxybenzoic Acids

Temperature,

o

C

o-Hydroxybenzoic acid p-Hydroxybenzoic acid

p, Pab

p, Pab

95

30.9

100

48.7

105

70.1

110

104

115

153

120

220

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

125

322

130

3.03

4.59

135

649

6.94

140

10.6

145

16.1

150

23.9

155

34.6

159

47.3

B. To convert Pa to mm Hg, divide by 133.3.

Salicylic Acid

Reactions: Carboxyl. Typical decarboxylation by simple heating of a

free acid occurs with only a few types of acids. However, decarboxylation of

salicylic acid takes place readily because of the presence of the hydroxyl group,

which is electron donating (see Fig. 1). Upon slow heating, salicylic acid

decomposes to phenol and carbon dioxide; when heated rapidly, it sublimes.

Generally, the carboxyl group is not readily reduced. Lithium

aluminum hydride is one of the few reagents that can reduce an acid to an alcohol.

The scheme involves the formation of an alkoxide, which is hydrolyzed to the

alcohol. Commercially, the alternative to direct reduction involves esterification

of the acid followed by reduction of the ester.

Salicylic acid dissolves in aqueous sodium carbonate or ~odium

bicarbonate to serve. However, phenolate ions are ambident nucl~ophiles and, as

such and under certain conditions, as with the use of alkyl halides, the problem of

C- versus O-alkylation can occur. Either reaction can be made essentially

exclusive by the proper choice of reaction conditions. For example, polar solvents

favor formation of the ether, whereas nonpolar solvents favor ring substitution

(see Alkylation).

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Figure 2. Reactions of the hydroxyl group of salicylic acid.

Esters of the phenolic hydroxyl are obtained easily by the SchottenBaumann reaction. The reaction in many cases involves an acid chloride as the

acylating agent. However, acylation can also be achieved by reaction with an acid

anhydride. The single most important commercial reaction of this type is the

acetylation of salicylic acid with acetic anhydride to yield acetylsalicylic acid [5078-2] (aspirin).

Ring Substitution. In the introduction of a third group into a

disnbstituted benzene, the position the group takes depends on the groups present

(see Fig. 3). In the case of salicylic acid the hvdroxyl directs ortho and pan and

the carboxyl directs meta substitution. It is generally accepted that if both an

ortho-para and a meta director are competing for the orientation of a third group,

the ortho-para director prevails since, unlike the meta director, it activates the

ring. Specifically, the hydroxyl group is electron-donating which, on the basis of

resonance considerations, increases the

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Figure 3 Ring-substitution reactions of salicylic acid. X = halogen.

Electron density in the S and 5 positions. The electron-withdrawal

nature of the car-boxyl group decreases the electron density around the 4 and C

positions, which further enhances the electron density of the 3 and 5 positions. As

a rule, direct substitution occurs more easily in the less sterically hindered 5

position, but most often small amounts of the 3 substituted and 3,5-disubstituted

product also form. High yields of the 3-substituted salicylic acid usually can only

be prepared indirectly.

Direct halogenation of salicylic acid is generally carried out in glacial

acetic acid. As expected, the main product is the 5-halo-salicylic acid with small

quantities of the 3-halo- and 3, 5-dihalosalicylic acids.

Reaction with cold nitric acid results primarily in the formation of 5nitrosalicylic acid [96-97-9]. However, reaction with fuming nitric acid results in

decarboxylation as well as the formation of 2, 4, C-trinitrophenol [88-89-1]

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

(picric acid). Sulfonation with chlorosulfonic acid at 16O oC yields 5-sulfosalicylic

acid [56507-30-3]. At higher temperatures (1800 C) and with an excess of

chlorosulfonic acid, 3,5-disulfosalicylic acid forms. Sulfonation with liquid sulfur

trioxide in tetrachloroethylene leads to a nearly quantitative yield of 5sulfosalicylic acid (5).

Because salicylic acid contains the deactivating meta-directing

carboxyl group, Friedel-Crafts reactions (qv) are generally inhibited. This effect is

somewhat offset by the presence of the activating hydroxyl group. Salicylic acid

also reacts with isobutyl or t-butyl alcohol in 80 wt % sulfuric acid at 75 0C to

yield 5-t-butylsalicylic acid [16094-31-8]. In the case of isobutyl alcohol, the

intermediate carbonium ion rearranges to (CH3)3C+.

Miscellaneous. The Reimer-Tiemann reaction of salicylic acid with

chloroform and alkali results in the 3- and 5-formyl derivatives.

If the reaction is carried out with carbon tetrachloride, the

corresponding dicarboxylic acids form.

Alkylation involving formaldehyde in the presence of hydrogen

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

chloride is known as chloromethylation. The reagent may be a mixture of

formalin and hydrochloric acid, paraformaldehyde and hydrochloric acid, a

chloromethyl ether, or a formal. Zinc chloride is commonly employed as a

catalyst, although many others can be used. Chloromethylation of salicylic acid

yields primarily the 5-èubstituted product.

The reaction of salicylic acid with formaldehyde with catalytic amounts

of acid results in the condensation product methylene-5, 5’-disalicylic acid [12225-8].

Salicylic acid, upon reaction with amyl alcohol and sodium, reduces to

a ring-opened aliphatic dicarboxylic acid, ie, pimelic acid. The reaction proceeds

through the intermediate cyclohexanone-2-carboxylic acid.

During certain substitution reactions, the carboxyl group is often

replaced by the entering group. Au example is fuming nitric acid, which results in

the formation of trinitrophenol. Another is the bromination of salicylic acid in

aqueous solution to yield the tribromophenol derivative.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Salicylic acid couples with diazonium salts in the expected manner.

With diazotized aniline, i.e, benzenediazonium chloride, the primary product is 5phenylazosalicylic acid [314 7-53-3].

The close proximity of the carboxyl and the hydroxyl groups can be

used for beterocyclic synthesis, as in the preparation of hydroxyxanthones (6).

USES

Approximately 60% of the salicylic acid produced in the United States

is consumed in the manufacture of aspirin: this statistic has remained relatively

constant for at least the last ten years. Approximately 10% of the salicylic acid

produced is consumed in various applications, eg, foundry and phenolic resins,

rubber retarders, dyestuffs, and other miscellaneous uses. The remaining 30% is

used in the manufacture of its salts and esters for a variety of applications.

There are many foundry-resin systems in use. Salicylic acid is a small

component only in the Shell process. It is used as a cross-linking agent in the

phenol—fornrnldehyde resin used as a sand core and mold binder and imparts

higher tensile strength. More recent developments have demonstrated that higher

concentrations of salicylic acid than previously used further improve cold and hot

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

tensile strength and reduce cure and machine processing time (18). The

continuing interest in energy and environmental considerations has led to the low

energy processes, which typically do not use salicylic acid. Their growth has been

somewhat limited because of the large capital expenditures required; however, the

economics is expected to shift as the cost of energy increases. Therefore, a zero or

small negative growth for salicylic acid is predicted in foundry-resin applications.

Salicylic acid has also been used in other phenolic resin applications, ie, binders

for grinding wheels, fiber glass, and brake linings (qv) (see Phenolic resins).

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter No. 2

Process Selection and Description

Of Flow Sheet

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter 2

Process Selection and Description of Flow Sheet

FIRST SYNTHESIS

Salicylic acid was first prepared by R.Piria by the fusion of salicyaldehide

with the potassium hydroxide. In 1859, a synthesis method of preparing salicylic

acid was discovered by treating the phenol with carbon dioxide in presence of

metallic sodium. However the only commercial method of manufacturing

salicylic acid until 1874 was the sponification of the methyl salicylate obtained

from the leaves of the winter green or Bark of the birch.

KOLB PROCESS

The first technically suitable process was introduced in 1874 by Kolb. It

involves the reaction of the dry sodium phenolate with carbon dioxide under

pressure and high temperature (180-200) 0C. The drawback of the process was

that the yield was not more than 50% and the separation of byproducts which

were in large quantity was difficult. Salicylic acid is manufactured by the reaction

of phenol with caustic soda and the subsequent treatment of the sodium phenolate

formed with carbon dioxide and acidifying the resultant product with the sulfuric

acid .Phenol and caustic soda are charged in equomolar proportions to a mixer.

The resulting solution is heated to a temperature of 1300C and further evaporated

to dryness in a stirred autoclave or a heated ball mill. Dry carbon dioxide gas is

absorbed and the crude product from the autoclave is dissolved in the equal

amount of water and filtered. The filtrate is precipitated and dried.To obtain pure

product, the crude sodium salicylate solution decolorized with the activated

carbon containing the zinc dust and filtered. The clarified filtrate is acidified with

the excess of sulfuric acid to precipitate the salicylic acid which is centrifuged and

dried to give the high grade salicylic acid.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

SCHMITT

Schmitt introduced the new lower temperature ranges from 1201400C which significantly increased the yield of the process. The reaction of the

carbon dioxide on the phenol forms an intermediate phenyl carbonate which

rearranges itself to give o-sodium salicylate. The Kolb-Schmitt synthesis method

is still the only industrial process in use in different modifications.

More, et al

More introduced a new step process for the carbonation of dry

sodium phenolate. The reaction is carried out in a stirred reactor. Carbon dioxide

is passed at a temperature of 1300C until 25% of the stiochiometeric amount of

the carbon dioxide is absorbed. In step 11 the temperature of the raised to

2100Cand the remaining carbon dioxide is introduced into the reactor for 5 hr. the

yield of the process was 80 to 82% and for time duration the yield was 76%.

Stopp,et al

The carbonation of the sodium salicylate is carried out in a fluidized bed reactor at

1400C and pressure of 6bar until half of the phenolate is converted to salicylate.

The resulting reaction mixture can be further carbonated in a subsequent stage at a

temperature of 2100Cand a pressure of 10 bars. The subsequent stage may be

fluidized bed reactor or stirred vessel. The yield was 85%.

Barkley et al

The sodium phenolate was cooled to 90 0C. The carbon dioxide

was passed into the autoclave; the temperature was maintained at 120 0C until the

carbon dioxide adsorption was come to an end. The temperature was raised to

induced rearrangement of the intermediate product. The temperature was kept

160-1700Cunder a carbon dioxide pressure 5 bar.

Jenson, et at

An improved method for the production of salicylic acid from phenol

with high degree of conversion and with a significant reduction in the by products

was modified by Jenson and his colleagues. The process comprises of reaction of

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

sodium phenolate with the carbon dioxide indirect single step at a temperature

above 1650C.In the Kolb carboxylation, the reaction between sodium phenolate

with carbon dioxide could advantageously takes place in single step well the

temperature at which sodium phenyl carbonate is ordinarily converted to sodium

salicylate. More particularly instead of introducing carbon dioxide below 150 0C to

produce sodium phenyl carbonate which is then in second step is converted to

sodium salicylate being held above 1650C.

Our contributions

The reaction of sodium phenolate and carbon dioxide is slowest reaction in whole

plant so every scientist focused his attention for finding the set of

thermodynamics properties that would give maximum conversion and minimum

byproduct as well as cost factor would remain under considerations along with the

safe operation.

I was personally interested in finding such data to improve the performance of the

plant used for manufacturing of salicylic acid. The autoclave present in our

department was quite unsuitable for the reaction of carbon dioxide with sodium

phenolate at different temperature and pressure. But fortunately the circumstances

for carrying the experiments in determination the kinetic data I was given

opportunity in the chemistry department lab. I performed number of experiment at

different temperature and different speed of agitation in simple conical flask.

After the result of experiment I decided batch reaction was not economical.

So I made changes in the flow diagram available in literature.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

FLOW SHEET DESCRIPTION

Preparation of Sodium Phenolate

Phenol is approximately 54% is reacted with

50%caustic soda in a CFSTR. The reaction temperature is 95-990C. The reaction

is exothermic; heat evolved from the reaction is utilized raising the temperature of

the product to 990C. Slightly excess amount of phenol is fed into the reactor

instead of caustic soda because of material of construction is greatly influenced by

the strong alkali. The reaction temperature is so high that lump formation of

sodium phenolate is out of question. Preparation of Sodium salicylate

The product of the first reactor is fed into the flash

tank where separation of water is carries out and then for any batch valve is

opened and autoclave is charged and valve of the carbon dioxide is opened at the

pressure of 8bars for the time of 5-6hrs. The reaction temperature is raised to

about 1250C.

Almost 70% conversion is achieved; carbon dioxide released is recycled back and

then utilized. Now 600Kg of phenol is added so that some sort of azeotrope is

formed and when steam is provided, this mixture is vaporized leaving the thick

slurry of sodium salicylate. The evaporated material is condensed and sent into

the continuous distillation column where separation of phenol and sodium phenate

is carried out.

Acidification tank

The product of the autoclave is thick slurry and it is

diluted with the water in the dilution tank. The solution, so obtained is charged

into the acidification tank where 40% sulfuric acid is reacted that comes from the

storage tank of sulfuric acid. Almost two hr along with agitation gives 100 app.

Conversion. In the acidification tank solid salicylic acid as well as sodium sulfate

is formed

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Purification from water (removal of water)

Removal of water is carried in two steps: in first step

centrifuge removes the large amount of water i.e. from 66 to 16 %water content.

The waste water is sent to the waste water treatment plant. The solid product that

contains salicylic acid and sodium sulfate is sent to the dryer where app. All water

content is removed.

Sublimation and crystallization

The solid product is charged into the sublimation tank

where steam is used as heating medium and vacuum is created with the help of

vacuum pump. At reduced pressure the sublimation of salicylic acid is carried out

at 760C. The vapors coming from the sublimation tank are injected into

crystallizer where condensation of vapors takes place resulting more than 99%

pure product.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter No. 3

Material Balance

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter 3

Material Balance

Reactor-1

output

input

component

NaOH

H2O

phenol

Na-Ph

total

(Kgmol)

10.65625

66.48056

11.7216

0

88.8584

Kg

426.25

1196.65

1101.83

0

2724.73

%Wt

15.64375

43.91811

40.43814

0

100

Kgmol

0.156

76.98056

1.22

10.5

88.85656

Kg

6.24

1385.65

114.68

1218

2724.57

%Wt

0.22902697

50.8575665

4.20910456

44.704302

100

Kg

6.24

35

101.16

1218

1360.4

%Wt

0.45868862

2.57277271

7.43604822

89.5324904

100

FLASH TANK

input

component

NaOH

H2O

Phenol

Na-Ph

(Kgmol)

0.156

76.98056

1.22

10.5

88.85656

output

Kg

6.24

1385.65

114.68

1218

2724.57

%Wt

0.229027

50.85757

4.209105

44.7043

100

Kgmol

0.156

1.944444

1.07617

10.5

13.67661

side stream

water-out

total

phenol

1350.65

2711.05

13.52

CO2

side stream

231

phenol

Na-Ph

side stream

600

364

Autoclave reactor-2

Addition of CO2 and reaction

input

component

NaOH

H2O

Phenol

Na-Ph

CO2

Na-Sal

(Kgmol)

0.156

1.944444

1.07617

10.5

12.6

output

Kg

%Wt

Kgmol

Kg

%Wt

6.24

0.325951 0.156

6.24

0.36897969

35

1.828249 1.9444

35

2.06959761

101.16

5.284162 1.07617

101.16

5.98172841

1218

63.62307 3.15

365.4

21.6065991

554

28.93857

0

0

0

0

7.35

1183.35

69.9730952

1914.4

100

1691.15

100

Addition of phenol and separation of azeotrope

input

component

NaOH

H2O

Phenol

Na-Ph

CO2

Na-Sal

(Kgmol)

0.156

1.9444

6.395319

3.15

7.35

output

Kg

6.24

35

601.16

365.4

0

1183.35

%Wt

0.284782

1.597335

27.43582

16.67617

0

54.00589

Kgmol

0.156

1.9444

0.01234

0.012069

0

7.35

Kg

6.24

35

1.16

1.4

0

1183.35

%Wt

0.50849529

2.85213707

0.09452797

0.11408548

0

96.4307542

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

2191.15

100

1227.15

100

Kg

6.24

2489.3

1.16

1.4

0

1183.35

3681.45

%Wt

0.16949843

67.617379

0.03150932

0.03802849

0

32.1435847

100

Kg

0

3033.55

1.16

1.4

1014.3

0

541.85

2.45

4594.71

%Wt

0

66.0226652

0.02524642

0.03046982

22.0753867

0

11.7929097

0

0.05332219

100

Kg

0

296.4

0.16

0.4

1014.3

0

539.5

1.225

1851.985

%Wt

0

16.0044493

0.00863938

0.02159845

54.7682622

0

29.1309055

0.06614524

100

side stream

Kgmol

Kg

0

0

152.0639 2737.15

0.01063

1

0.008621 1

0

0

0

0

2.35/142 2.35

0.0125

1.225

2742.725

%Wt

0

99.79673

0.03646

0.03646

0

0

0.085681

0.044664

100

Kg

0

2.96

%Wt

0

0.19008965

side stream

Kgmol

Kg

0

0

16.30222 293.44

%Wt

0

99.53023

Dilution tank

input

component

NaOH

H2O

Phenol

Na-Ph

CO2

Na-Sal

(Kgmol)

0.156

1.9444

0.01234

0.012069

0

7.35

output

Kg

6.24

35

1.16

1.4

0

1183.35

1227.15

%Wt

0.508495

2.852137

0.094528

0.114085

0

96.43075

100

Kgmol

0.156

138.2944

0.01234

0.012069

0

7.35

water

side input

2454.3

Acidification tank

input

component

NaOH

H2O

Phenol

Na-Ph

salicylic acid

Na-Sal

Na2SO4

(Kgmol)

0.156

138.2944

0.01234

0.012069

0

7.35

0

side input

sulfuric acid

water

output

Kg

6.24

2489.3

1.16

1.4

0

1183.35

0

%Wt

0.169498

67.61738

0.031509

0.038028

0

32.14358

0

362.6

543.9

4587.95

Centrifuge

input

component

NaOH

H2O

Phenol

Na-Ph

salicylic acid

Na-Sal

Na2SO4

sulfuric acid

Kgmol

0

168.5306

0.01234

0.012069

7.35

0

3.815845

(Kgmol)

0

168.5306

0.01234

0.012069

7.35

0

3.815845

output

Kg

0

3033.55

1.16

1.4

1014.3

0

541.85

2.45

4594.71

%Wt

0

66.02267

0.025246

0.03047

22.07539

0

11.79291

0.053322

100

Kgmol

0

16.46667

0.001702

0.003448

7.35

0

3.799296

0.0125

Drying unit

input

component

NaOH

H2O

(Kgmol)

0

16.46667

output

Kg

0

296.4

%Wt

0

16.00445

Kgmol

0

0.164444

Chapter 1

Phenol

Na-Ph

salicylic acid

Na-Sal

Na2SO4

sulfuric acid

0.001702

0.003448

7.35

0

3.8

0.0125

O-Hydroxy Benzoic Acid and Related Compounds

0.16

0.4

1014.3

0

539.5

1.225

1851.985

0.008639

0.021598

54.76826

0

29.13091

0.066145

100

0

0.003448

7.35

0

3.8

0

0

0.4

1014.3

0

539.5

0

1557.16

0

0.02568779

65.137815

0

34.6464076

0

100

0.001702

0

0

0

0

0.0125

0.16

0

0

0

0

1.225

294.825

0.054269

0

0

0

0

0.415501

100

Sublimation unit and Crystallization

input

component

NaOH

H2O

Phenol

Na-Ph

salicylic acid

Na-Sal

Na2SO4

sulfuric acid

(Kgmol)

0

0.164444

0

0.003448

7.35

0

3.8

0

output

Kg

0

2.96

0

0.4

1014.3

0

539.5

0

1557.16

%Wt

0

0.19009

0

0.025688

65.13781

0

34.64641

0

100

Kgmol

0

0.069444

0

0

7.333333

0

0

0

Kg

0

1.25

0

0

1012

0

0

0

1013.25

%Wt

0

0.12336541

0

0

99.8766346

0

0

0

100

side stream

Kgmol

Kg

0

0

0.095

1.71

0

0.4

2.3

0

539.5

0

543.91

%Wt

0

0.345829

0

0.080896

0.46515

0

109.1081

0

110

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter No.4

ENERGY BALANCE

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter 4

ENERGY BALANCE FOR THE PROJECT

REACTOR 1 ENERGY BALANE :

NaoH=10.66kgmol

+

Water=

Phenol=11.72kgmol

H2O =

100%

Conversion

at

95 C

Na-phen=

Water =

∆ HR = ∑ Hfp - ∑ H fr

= { 10.656*(-326.6) + 10.656(-258.84)}–{10.656(-165) +

10.656(-426.99)}

∆ HR = 59.247 KJ

TOTAL HEAT RQUIRED = mCp dT + ∆ HR

∆H

= (1.22*220.53KJ/Kgmol.K *

(76.98*75*5)water+(10.5*243.17*5)

0.156*78.62*5 + 59.247 KJ

= 43099 KJ

5)phenol+

+

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

ENERGY BALANCE OF AUTOCLAVE:

CO2=12.6kgmol

30 C

T=102 C

NaOH=0.156kgm

Water = 1.94 kgm

Phenol= 1.07kgm

Na-phen=10.5 //

70 %

conversion

T=125C

NaoH=0.156kgmol

Water=1.944 //

Phenol=1.07 //

Na-phen=3.15 //

Na-sal. = 7.35 //

CO2=5.25 kg

mol

T=125 C

1 ST STEP : SEPARATION OF WATER

TOTAL HEAT RQUIRED = sensible heat + latent heat

=

{ 0.156*78*7}NaOH + { 76.98*75*7}water

+{1.22*298*17}phenol+{

10.5*243*7}Na-ph

+

{1350.65*2551.6}water+

{

13.52/94

*45700

KJ/Kgmol}phenol

= 3513130.53 KJ

nd

2 STEP: ADDITION OF CO2 AND REACTION

HEAT OF REACTION = ∆HR =∑ HFP + ∑HFR

LATENT HEAT REQUIRED = (12.6* 38.65*95)CO2+ 0.156*78*78)NaoH +

(1.944*75*18)H2O + (1.07117*220*18)phenol

+(10.5*243.17*18)Na-ph

= 99310 KJ

TOTAL HEAT RQUIRED = H = Hl + ∆HR = 0

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Hl = ∆HR

Hl = ∑nHfp - ∑nHfr,

∑nHfr + Hl = ∑nHfp

7.35(-393.51* 1000) +7.35(-453*1000) = -7.35* X

X

= 859.511 KJ/gmol

X

= 904.74 KJ/gmol

5% loss so,

3rd step:

addition of phenol and separation of azeotrope

SIMPLE VACUUM SEPARATING THE COTENTS

ENERGY BALANCE OF DILLUTION TANK

Heat balance:

137*75*(T-25)

= {( 0.156*78*(125-T))NaOH +(1.944*75*(125-T))H2O

+(0.01234*220*(125-T))phenol+(7.35*257.76*(125-T))sod.sal

+(0.012069*243*(125-T))Na-phen

Therefore,

1521+18228.75+339.35+236817+3665.96+256875=T{10275–

12.168+145.8+2.7148+1894.

536+2.93)}

T=

62.97 C

ACIDIFICATION TANK

HR =

nHfp - nHfr

{-96909+(9703*44)}*1000 = {3.81158*(-1384.5*1000)KJ+

7.35*(-589.5*1000)}{(-904*7.35)+(-811*3.69)+0.156*(-426)}*1000

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

HR = 93480 KJ

This much amount of heat is contained after the reaction in the system.

Now reaction temp. is 20 C

Heat balance:

Heat input = Heat out put

{3.69*137.777*5}H2SO4 +{ 30.22*75*5}water+ { 0.156*78*(63-20)}NaOH

+{138.2944*75*(63-20)}water + { 0.01234*220*43}phen + {0.0120*69*243.17*(6320)}Na-phen + {7.35*257.76*43}Na-sal

= 542097.75 KJ

This much amount is contained in the system before reaction occurs.

Now the total amount of heat that must be rejected to keep the system at 20C

= 542097.75 + 93480 = 635575.73

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter No. 5

Design of Equipments

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter 5

Design of Equipments

REACTOR DESIGN

Reactor selection

I selected the CSTR

Reactor selection criteria

1- Conversion

2- selectivity

3- productivity

4- safety

5- economics

6- availability

7- flexibility

8- compatibility with processing

9- energy utilization

10- feasibility

11- investment operating cost

12- heat exchange and mixing

Reaction

rate

Volum

e flow

rate

Volum

e of

reactor

Model

Outlet

concen

tration

Inlet

concent

ration

Contacting

pattern

Kinds of impellers

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

A rotating impeller in a fluid imparts flow and shear to it, the shear resulting from

the flow of one portion of the fluid past another. Limiting cases of flow are in the

axial or radial directions so that impellers are classified conveniently according to

which of these flows is dominant. By reason of reflections from vessel surfaces

and

obstruction by affles and other intemals, however, flow patterns in most cases are

mixed. When a close approach to axial flow is particularly desirable, as for

suspension of the solids of a slurry, the impeller may be housed in a draft tube;

and when radial flow is needed, a shrouded turbine consisting of a rotor and a

stator may be employed. Because the performance of a particular shape of

impeller

usually cannot be predicted quantitatively, impeller design is largely an exercise

of judgment so a considerable variety has been put forth by various

manufacturers. A few common types are illustrated on Figure 10.2 and are

described as follows:

a. The three-bladed mixing propeller is modelled on the marine propeller but has

a pitch selected for maximum turbulence. They are used at relatively high speeds

(up to 1800rpm) with low viscosity fluids, up to about 4000cP. Many versions are

available: with cutout or perforated blades for shredding and breaking

up lumps, with sawtooth edges as on Figure 10.2(g) for cutting and tearing action,

and with other than three blades. The stabilizing ring shown in the illustration

sometimes is included to minimize shaft flutter and vibration particularly at low

liquid levels.b. The turbine with flat vertical blades extending to the shaft is

suited to the vast majority of mixing duties up to 100,000 CP or so at high

pumping capacity. The simple geometry of this design and of the turbines of

Figures 10.2(c) and (d) has inspired extensive testing so that prediction of their

performance is on a more rational basis than that of any other kind of impeller.

c. The horizontal plate to which the impeller blades of this turbine are attached

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

has a stabilizing effect. Backward curved blades may be used for the same reason

as for type e.

d. Turbine with blades are inclined 45" (usually). Constructions with two to eight

blades are used, six being most common. Combined axial and radial flow are

achieved. Especially effective for heat exchange with vessel walls or internal

coils.

e. Curved blade turbines effectively disperse fibrous materials without fouling.

The swept back blades have a lower starting torque than straight ones, which is

important when starting up settled slurries. f. Shrouded turbines consisting of a

rotor and a stator ensure a high degree of radial flow and shearing action, and are

well adapted to emulsification and dispersion. g. Flat plate impellers with

sawtooth edges are suited to emulsification and dispersion. Since the shearing

action is localized, baffles are not required. Propellers and turbines also are

sometimes

provided with sawtooth edges to improve shear. b. Cage beaters impart a cutting

and beating action. Usually they are mounted on the same shaft with a standard

propeller. More violent action may be obtained with spined blades.

SHAFT

The shaft is vital component of the agitator and frequently limits its mechanical

performance. In addition to transmitting torque, the shaft undergoes bending, and

if not stiff enough or rigidly supported, it may vibrate badly and cause discomfort

to personnel or damage to the equipment. Therefore it must be analyzed for

combined torsional and bending stresses, deflection, and critical speed and must

be selected to meet the limiting criteria for each. Inadequately in these respects

can result in failure of the shaft by overstress, failure of the seal due to excessive

shaft bending, or failure of bearings due to wear or impact Torsional and bending

stresses calculation

COUPLINGS

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Most agitators with long overhung shaft have rigid couplings to

connect the agitator shaft and the gear reducer output shaft. The coupling facilities

shipment, installation, removal and servicing of the agitators. Although it is an

innocuous appearance block of metal, care in its design and fabrication can

contribute significantly towards the satisfactory performance of the agitator. The

reasons for this become manifest from the requirement that the rigid coupling

must meet

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

1- the coupling must be capable of transmitting the agitator torque

2- the coupling must provide at least as much rigidity as the shaft if the

critical speed of the agitator is not to be reduced .

3- the coupling must strong enough to withstand the bending moments

imposed upon it by the unbalanced hydraulic and centrifugal force.

4- The coupling must provide good alignment between the shafts being

connected

5- Because it must be assembled and disassembled in the field, frequently

under inconvenient working condition, the coupling should be relatively

easy to take apart and reassembled, and should preferably be self-aligning.

6- The coupling must be capable of taking the thrust due to weight of the

agitator.

DRAFT TUBES

A draft tube is a cylindrical housing around and slightly larger

in diameter than the impeller. Its height may be little more than the diameter of

the impeller or it may extend the full depth of the liquid, depending on the flow

pattern that is required. Usually draft tubes are used with axial impellers to direct

suction and discharge

Streams. An impeller-draft tube system behaves as an axial flow pump of

somewhat low efficiency. Its top to bottom circulation behavior is of particular

value in deep tanks for suspension of solids.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

calculations

Sodium hydroxide concentration calculation

NaOH added = 10.656 Kgmol = 426.25 Kg

Water added = 66.48 Kgmol = 1196.65 Kg

Density of NaOH =

1023.7 Kg/M3

Density of water =

997Kg/M3

Total volume of the mixture = V1+V2+dV

whereV1 is partial volume of NaOH

V2 is partial volume of water

dV is change in volume due to solubility

V

=

426.25

---------- +

1023.7

1196.65

----------997

= 1.617 M3

Reactor volume and dimensions calculations

=

=

CA0

10.656

----------1.617

6.59 Kgmol/M3

= 6.59 gmol/lit

V

Xa

-------- = --------- = 342

Fa0

- Ra

V = 0.12233*25*342

= 1.055 M3

(from graph)

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

V =

2.1

(50% reactor is filled)

prove it

:

Basic equation used for calculating reactor volume =

XA

(------------)

- rA

Vf = FA0

Vf = 1.35 m3

Vf = volume of fluid

V = 2.1 m3 (73% fill)

V = volume of vessel

D = 1.2 m

D = diameter of

vessel

H = 1.2 m

H = height of fluid

L= 1.87 m

L = length of vessel

Selection and geometry of Impeller

I selected the 300 curved, square pitched turbine blade with the

Following specifications:

S-1 =

Da/Dt

S-2 =

E/Dt

S-3 =

L/Da

S-4 =

W/Da

S-5 =

J/Dt

S-6 =

H/Dt

No. of baffles = 4

= 0.33

= 0.33

= 0.25

= 0.20

= 0.0833

= 1.00

(no clearance, not twisted but adjacent with

wall of the vessel )

Power calculation:

P =Np0(Nr3)(Da)5 = Kt (Nr3)(Da)5

= 0.34 Kw =0.45 hp

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

= 0.55 (82 % efficiency of the motor)

SHELL THICKNESS

X

=

Pri

Cc

(SE j 0.6 P)

P

=

Pressure of system

ri

=

Radius of shell

S

=

Stress of material

Ej

=

Efficiency of joint

Cs

=

Corrosion rateik

=

101.3 7.7 1.292

0.002

160000 0.85 0.6 7.7 101.3

=

5.502 mm

X

HEAD THICKNESS

Pressure at the lease

=

gh

=

1080.46 × 9.8 × 4.43

=

46.907 KPa

Total pressure at base

=

827.697 KPa

t

=

Pi D i

2 S E j 0.2 P

827.69 1.92

2 160000 0.85 0.2 827.69

=

=

5.84 mm

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Power number, N, = Pg,/N3D5p, against Reynolds number, NRe = NDzp/p, for

several kinds of impellers: (a) helical shape (Oldshue, 1983); (b) anchor shape

(Oldshue, 1983); (c) several shapes: (1) propeller, pitch equalling diameter,

without

baffles; (2) propeller, s = d, four baffles; (3) propeller, s = 2d, without baffles; (4)

propeller, s =2d, four baffles; (5) turbine impeller, six straight blades, without

baffles; (6) turbine impeller, six blades, four baffles; (7) turbine impeller, six

curved blades, four baffles; (8) arrowhead turbine, four baffles; (9) turbine

impeller,inclined curved blades, four baffles; (10) two-blade paddle, four baffles;

(11) turbine impeller, six blades, four baffles; (12) turbine impeller with stator

ring; (13) paddle without baffles (data of Miller and Mann); (14) paddle without

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

baffles (data of White and Summerford). All baffles are of width 0.1D [after

Rushton, Costich,

and Everett, Chem. Eng. Prog. 46(9), 467 (1950)l.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Specification Sheet

Identification:

Item :

Item no:

No.required:

CFSTR ( Continuous Flow Stirred Tank Reactor)

R-01

01

Function:

Formation of sodium phenate from carbolic acid and caustic soda

Operation:

Continuous

Type:

Agitator cylindrical vessel

Design Data:

Vessel:

Working Volume

Design Volume

Temperature (Process temperature)

Design Temperature

Working Pressure

Design Pressure

Dia of Vessel

Height of vessel

Working height

Height to dia ratio

Type of head

Thickness of cylindrical protion

Thickness of bottom head

No. of baffle

Width of Baffle

Height of baffle

1.35 m3

1.86 m3

99˚C

109˚C

1 atm

1.5 atm

1.2 m

1.56 m

1.2 m

1.3

Torispherical

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Agitator:

Following specifications:

S-1 =

Da/Dt

S-2 =

E/Dt

S-3 =

L/Da

S-4 =

W/Da

S-5 =

J/Dt

S-6 =

H/Dt

No. of baffles = 4

= 0.33

= 0.33

= 0.25

= 0.20

= 0.0833

= 1.00

(no clearance, not twisted but adjacent

with wall of the vessel )

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Flash tank design

The name originate from the fact that a liquid at a pressure equal to or greater than

its bubble point pressure flashes or vaporizes, when the pressure is reduced below

its bubble point pressure producing two phase system of liquid and vapor in

equilibrium.

Basic equations used in flash calculation are

L+ V =

Ki =Yi/Xi

1 (material balance equation)

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Where Ki equilibrium constant

Yi vapor phase composition

Xi liquid phase composition

From Raults and Henry Law

YiiP = XiγiPisat

I = 1 for low to moderate pressure

γi = 1 assumption as no data is available in

literature

Zi Ki

Yi =

---------------------1+V(Ki – 1)

Zi

Xi =

----------------------1+V (Ki – 1)

for flash calculation necessary condition

P dew < P< Pbubble

Very important equation used in flash calculation

i - idew

γi - γidew

---------------γi bubble -γidew

=

---------------I bubble - idew

V-1

P – P dew

=

--------------------

Pbubble - Pdew

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

=

--------------0

- 1

P – P dew

=

----------Pbubble - Pdew

P -

P dew

V = --------------------P bubble – P dew

P bubble

=

X1P1sat +X2P2sat ……..

1

P

=

dew

-----------------Y1/P1sat+Y2/Psat …

Throttling Valves

Globe Valve is an economical throttling

valve. Its heavy duty design provides for

long service life. The in-line globe design

causes

relatively

high

pressure

drops,

however this is a desirable valve due to its

economy and reliability.

Features

1- Slow closing

2- Prevents water hammer in PVC piping

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

3- Heavy Duty Construction

4- Long service life

5-efficient throttling with minimum wire drawing or disk or seat erosion

6-available in multiports- short disk travel and fewer turn to operate, saving

time and

wear on stem and bonnet

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Jet Ejector

The two most common ejectors are operated by water or steam. The liquid

ejectors are used for creating a modest vacuum or for mixing liquids. The steam

ejectors is important in creating and holding a vacuum in a system. Ejectors have

no moving parts and operated by the action of one high pressure steam entraining

and other vapors (or liquids) at low pressure into a moving stream and thereby a

removing them from the process system at an intermediate pressure

Feature

Ejectors have the following features which make them good choice

for continuously producing economical vacuum condition.

1- They handle wet, dry or corrosive vapor mixtures

2- They develop any reasonable vacuum needed for industrial operation.

3- All sizes are available to match any small or large capacity requirement.

4- Their efficiencies are reasonable to good.

5- Have no moving parts, hence maintenance low, operation fairly constants

when corrosion is not a factor.

6- Quiet operation.

7- Stable operation within design range

8- Installation cost relatively low when compare to mechanical vacuum

pumps.

9- Space requirement is small

10- Simple operation.

Types

Ejectors may be single or multi-stage. The extra stages, with or

without inter stage condensing of steam; allow the system to operate at lower

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

absolute pressure than a single stage unit. Various combinations of series of jets

with no inter-condensing can be connected to jets with inter-condensers or after

condensers to obtain various types of the operation and steam economy.

Material of construction

Since the ejector is basically simple in construction, it is available

in many material suitable for handling corrosive vapors. Standard materials

include cast iron, meehanite, cast steel, and bronze for the body and diffusers

depending upon the pressure and temperature rating. The nozzle is usually

stainless steel or monel. Other material of construction include porcelain, carbon

graphite, impregnated graphite, synthetic resins, glass and special metal of all

types

DEMISTERS OR IMPINGENT SEPARATOR

As the descriptive name suggests, the impingement separator

allows the particles to be removed to strike some type of surface. This action is

better accomplished in pressure system where pressure drop can be taken as a

result of turbulence which necessarily accompanies the removal action. Particles

removed in stream line flow is less efficient than for turbulent flow and not be

effective if the path of travel is not properly well baffled.

There is basically three construction type for impingement separators.

1-wire mesh

2- Plates (curved, flat or special shaped)

3-packed impingement beds

A demister pad resembles a giant brillo pad with the soap. Many process plants

have discarded demister pads lying around their scrape heaps. The theory of

operation of demister is simple. Vapors and droplets of liquids strike the demister

pad with a sustainable velocity. The force of this impingement velocity causes the

tiny droplets. The heavier droplets of liquid to coalesce into large droplets.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

For knockout drum with a demister pad it apparently must have K-value of at

least

0.15 to 0.20 When a demister plugs it increases the pressure drop of the vapor, but

pressure drop cannot increase a lot because the demister will break. Demister

failure creates two problems.

1- The dislodged section of the demister pad are blown into down stream

equipment as into suction of the centrifugal wet gas compressor

2-the failed demister promotes high localized velocities. Vapors blows through the

open areas of the vessel. The remaining section of the demister pad impedes vapor

flow. The resulting high localized velocities of vapors creates more entrainment

than we could have without any demister

Steam trap

A steam trap is self actuating automatic drain valve in a steam distribution system

that performs the following functions.

1- Removal of condensate

2-Remove air or other noncondensible gases

3- Prevents or limits the loss of steam

Condensate (water) is formed when steam condenses to release latent heat. Some

heat is released in the distribution system in the form of unavoidable losses. Most

of the heat is utilized in the process equipment. Once steam has condensed, the

hot condensate must be removed immediately as it hinders effective heat transfer

from the incoming steam. By selectively purging a steam system of its condensate

and noncondensible, steam trap helps maintain high heat transfer coefficient in

equipment without losing live steam

In the recent years user interest in steam trap has closely paralleled

the increase in energy cost. High fuel cost associated with the malfunctioning trap

cannot be ignored. Spiraling cost have highlighted the need for optimum steam

trap selection and application. Experience indicates that improper selection and

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

application are the most frequent cause of the trap failure and steam loss. The

installation or the replacement of steam trap has a pay back period of as little as

three to six months.

Classification of steam trap

There are three basic type of steam traps using different physical

principle to distinguish between steam and condensate.

Thermostatic steam trap

These traps are actuated by the temperature sensitive

which operate on the basis that the steam is hotter than condensate, air, and other

noncondesibles. There are three types of thermostatic traps.

1-

Liquid expansion

2-

Balanced pressure

3-

Bimetallic

Mechanical steam trap

These traps operate on the difference of density between

steam and condensate. The two important type of mechanical steam traps are

1- ball float

2- bucket

Thermodynamic steam trap

These traps are operates on the facts that flash steam is

produced when pressure is reduced on the hot condensate. The release of flash

steam causes the discharge to close. There are the following further types.

1- Disk type

2-

Piston type

3-

Lever type

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

FLASH CALCULATION

data

temperature

v.p.of waterKPa

v.p.of

phenol

Kpa

v.p.of

100

101.33

fluid composision

name

composition

water

0.87

3.51

phenol

Na-

0.0137

PheKPa

2.07

Phe

0.1182

Pbubble Kpa

Pdew Kpa

88.45

14.36

Na-

vapor

0.856391

liquid

0.143609

composition

0.975529

0.00729

0.0139688

1.028442

comp.

0.0220693

0.051924

0.871002

0.945

KPRESURE Kpa

25

component

water

phenol

Na-Phe

values

4.053

0.1404

0.0828

Yi

0.9786

0.007089

0.014361

1

Total mole for 25-ton per day = 88.85656*25 = 2221.4 Kgmol

Total moles in tank

=

Total weight

= 318.995(0.9*116+0.061*94+0.02818)

=

318.995 Kgmol

35293.41 Kg

Weight required for 1.5-batch of autoclave = 35293.41/4 = 8823.35 Kg

Average density = 0.90*1258+0.061*1023+0.028*994

=

1222.25 Kg/m3

Xi

0.028531

0.061549

0.9099

1

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Filled volume

= 7.2174 m3

% fill

total volume

= 45 %

= 16 m3

L = 5m , D = 2m

Some more specifications

Height of liquid

=

Height of inlet pipe

=

Height of demister pad =

Thickness of demister pad =

Material of demister pod

=

Height of outlet

=

Steam pressure

=

DESIGN OF DISTILLATION COLUMN

The detailed process design of the carbolic acid column is given below. The

pictorial Representation of the column is given in fig. The feed to the column is a

mixture of carbolic acid and sodium phenolate. The compositions of the

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

components are given below. The top and bottom product, both are the required

products used in reactor one and in autoclave (second reactor).

I. Thermodynamics: The primary requirement while designing mass transfer

contact equipment is the

Thermodynamic equilibrium data. The data required is in the Vapor-Liquid

Equilibrium

(VLE) data for the carbolic acid and sodium phenolate system. The X-Y curve is

shown in the fig. To

Develop the VLE data, a model was used.

yi pt =

i xi Pi sat --------------------------(1)

Where,

yi = mole fraction of component “i” in vapor.

pt = total system pressure.

i = activity coefficient of component “i” in

liquid.

xi = mole fraction of component “i” in liquid.

Pi sat = saturation vapor pressure of component “i”.

The equilibrium vapor pressure was evaluated using correlations given in

literature. The correlation was based on the critical properties of the components.

The two components carbolic acid and sodium phenolate form a highly non-ideal

system. To accommodate this nonideality, an activity coefficient term was used

for the liquid phase. The activity coefficient was evaluated using the UNIFAC

model. Since the evaluation of the VLEdata is highly iterative, an algorithm was

developed which was solved using a computer program. The gas phase was

assumed to be ideal. This is a valid assumption since the column is at 1

atmosphere pressure (760 mm Hg. abs.). The boiling points of the two

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

components require the column to be operated at 1 atmosphere. The operating

pressure was chosen to be 760 mm Hg (abs).

The following questions must be answered before going into detailed design of

the distillation column

1- what column is selected packed or tray column ?

Answer

Tray column would be better choice in situation facing due to the following

reasons

1- stage efficiency can be determined experimentally in packed column

because

ŋ =f(type and sizing of packing, fluid rates, fluid properties, column diameter,

operating temperature and pressure, extent of liquid dispersion……)

Where as a number of correlations are available for tray

column efficiency discussed by the famous authors. Coulson and Richardson,

Ludwig, Perry, Peter and Timmerhaus, conceptual design of distillation

column and more…..

2-tray column can be designed over a wide range without flooding

3-total dry weight of the tray column is less than the packed column

4-design information for tray column id readily available as compared to

packed column. This made path of working easy for me when I decided tray

column

5-if chances of foam formation are more then packed column would be given

preference, but in situation facing me no foam formation (surface tension at

different temperature and pressure would dictate foam formation criteria)

6- Thermal expansion chances can be easily handled with tray column instead

of packed column.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

7- Equilibrium Data for large compounds as well as my compound are

available in literature and this data is more reliable for tray column instead of

packed column

What type of tray is selected sieve tray, bubble cap, or valve tray ?

Answer

I decided sieve tray because of the following reasons

1- Manufacturing cost is low

2-operating cost is low

3-simple to construct

4-minmum entrainment as compare to bubble cap and valve tray

5-less pressure drop as compare to other

6-most commonly used

Glossary of notations used:

F = molar flow rate of Feed, gm

D = molar flow rate of Distillate, gmol/hr.

W = molar flow rate of Residue, gmol/hr.

xF = mole fraction of phenol in liquid/Feed.

yD = mole fraction of phenol in Distillate.

xW = mole fraction of phenol in Residue.

MF = Average Molecular weight of Feed, g/gmol

MD = Average Molecular weight of Distillate, g/gmol

MW = Average Molecular weight of Residue, g/mol

RRm = Minimum Reflux ratio

RR = Actual Reflux ratio

LR = Molar flow rate of Liquid in the Enriching Section, gmol/hr.

VR = Molar flow rate of Vapor in the Enriching Section, gmol/hr.

LS = Molar flow rate of Liquid in Stripping Section, gmol/hr.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Vs = Molar flow rate of Vapor in Stripping Section, gmol/hr.

q = Thermal condition of Feed

ρl = Density of Liquid, kg/m3.

ρg = Density of Vapor, kg/m3.

ql = Volumetric flow rate of Liquid, m3/s

qv = Volumetric flow rate of Vapor, m3/s

l = Viscosity of Liquid, cP.

Tl = Temperature of Liquid, 0K.

Tv = Temperature of Vapor, 0K.

II. Preliminary calculations:

Feed = 9915 gmol/h

xF = 0.67, MF = 101.16g/gmol.

D = 6783.89gmol/hr, xD = 0.97, MD = 94.66g/gmol.

W=3131.1gmol/hr, xW = 0.02, MW =115.56g/mol.

Basis: 1 Hour Operation.

From the graph

Rm = 1.5

Let, R= 2.1 *Rm

estimated )

RR= 1.5×2.0= 3.2

Number of Ideal trays = 17

Number of Ideal trays in Enriching Section = 8

Number of Ideal trays in Stripping Section = 9

Now, we know that,

RR = R/ D

=> R =RR×D

i.e., R= 3.2*6783.89 = 21705gmol/h

L= Liquid flow rate on the Top tray = 21705gmol/h

VR= L + D

(from trial this value is

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

= (R+1)*D = 4.2*6783.89mol/hr = 28488.6gmol/h

VR = Gas flow rate in the Enriching Section = 28488.6gmol/h

Since feed is Liquid, entering at bubble point,

q= (HV-HF) / (HV-HL) = 1

Now,

Slope of q-line = q/ (q-1) = 1/ (1-1) = 1/0 = .

Now we know that,

LS = F + L R

LS = 9915+21705.6=31619.6 gmol/h

Therefore, liquid flow rate in the Stripping Section = 31619.6 gmol/h

Also, we know that,

VS = [(q-1) ×F] + VR

VS = [(1-1) ×F] + VR

VS = VR = = 28488.6gmol/h

Therefore, the flow rate of Vapor in the Stripping Section = = 28488.6gmol/h

IV. Design Specification:

Tray Hydraulics

The design of a sieve plate tower is described below. The equations and

correlations are borrowed from the 6th and 7th editions of Perry’s Chemical

Engineers’ Handbook, plant design and economics by Peter and Timmerhaurse,

ludwick, unit operation of chemical engineering by McCabe and Smith, Coulson

and Richardson’s book, separation techniques by C.G. King The procedure for

the evaluation of the tray parameters is iterative in nature. Several iterations were

performed to optimize the design.

The final iteration is presented here.

1. Tray Spacing, (ts):

Let ts = 457mm (18in).

2. Hole Diameter, (dh):

Let dh = 5 mm.

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

3. Hole Pitch (lp):

Let lp = 3× dh

i.e., lp = 3×5 = 15 mm.

4. Tray thickness (tT):

Let tT = 0.6× dh

i.e., tT = 0.6×5 = 3 mm.

5. Ratio of hole area to perforated area (Ah/Ap):

Refer fig 6.3Now, for a triangular pitch, we know that

Ratio of hole area to perforated area (Ah/Ap) = ½ (/4×dh2)/ [(√3/4) ×lp2]

i.e., (Ah/Ap) = 0.90× (dh/lp)2

i.e., (Ah/Ap) = 0.90× (5/15)2

i.e., (Ah/Ap) = 0.1

Thus,

(Ah/Ap) = 0.1

6. Plate Diameter (Dc):

The plate diameter is calculated based on the flooding considerations

L/G { g/ l}0.5 = 0.11

Now for,

L/G { g/ l}0.5 = 0.11 and for a tray spacing of 457 mm.

We have from the flooding curve, ---------- (fig.18.10, page 18.7, 6th edition

Perry.)

(Plant design and economics by Peter and

Timmerhaus)

Flooding parameter,

Now,

Csb, flood = 0.07 m/s.

Unf = Csb, flood × (σ/ 20) .0.2 [( l - g) / g] 0.5---- {eqn. 18.2, page

18.6,

6th edition

Perry.}

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

(Plant design and economics by Peter and

Timmerhaus)

Where,

Unf = gas velocity through the net area at flood, m/s (ft/s)

Csb, flood = capacity parameter, m/s (ft/s, as in fig.18.10)

σ= liquid surface tension, mN/m (dyne/cm.)

l = liquid density, kg/m3 (lb/ft3)

g = gas density, kg/m3 (lb/ft3)

Now, we have,

σ= 28.57 dyne/cm.

ρl = 1023 kg/m3.

ρg = 2.52 kg/m3.

Therefore,

Unf = 0.07× (28.57/20)0.02 *[987-2.52)/ 2.52]0.5

i.e., Unf = 4.87 ft/s = 1.49 m/s.

Let

Actual velocity, Un= 0.8×Unf

i.e., Un = 1.19 m/s

Now, volumetric flow rate of Vapor

qo = 28488.6*94.5 / (3600×2.52*1000) = 0.3 m3/s.

Net area available for gas flow (An)

Net area = (Column cross sectional area) - (Down comer

area.)

An = Ac - Ad

Thus,

Net Active area, An = qo/ Un = 0.3/1.119 = 0.252 m2.

Let Lw / Dc = 0.75

Where, Lw = weir length, m

Dc = Column diameter, m

,

θc = 2×sin-1(Lw / Dc) = 2×sin-1 (0.75) = 97.180

Ac =(3.14/4) × Dc2= 0.7854×Dc2 , m2

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

And,

θc = angle

Ad = [(/4) × Dc2 × (θc /3600)] - [(Lw/2) × (Dc/2) ×cos (θc /2)]

Ad = [0.7854× Dc2 × (97.180/3600)]-[(1/4) × (Lw / Dc) × Dc2 × cos

(97.180)]

Ad = (0.2196× Dc2) - (0.1241× Dc2)

Ad = 0.0955×Dc2, m2

Since,

An = Ac -Ad

0.252 = (0.7854×Dc2) - (0.0955× Dc2)

i .e., 0.6895× Dc2 = 0.252

Dc2 = 0.252/ 0.6895 = 0.365

Dc = 0.6 m

Take Dc = 0.635 m

Since Lw / Dc = 0.75,

Lw = 0.75× Dc = 0.75×0.635 = 0.476 m.

Therefore, Lw = 0.476 m.

Ac = 0.7854×0.6352 = 0.316 m2

Now,

Ad = 0.0879×0.635 = 0.0354 m2

An = Ac - Ad

An =0.316-0.0354

An = .2806 m2

7. Perforated plate area (Ap):

Active area (Aa)

Aa = Ac - (2×Ad)

Aa = 0.316- (2×0.0354)

Aa = 0.245 m2

Lw / Dc = 0.476/ 0.635 = 0.75

θc = 97.18 0.

θc = angle

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

θ1=180 0 - 97.18 0 = 82.82 0

θ1 =

angle

Acz = 2× Lw× (thickness of distribution)

= 5 – 20% of Ac

Where Acz = area of calming

zone, m2

Acz = taking 10% of Ac = 0.02833

Also,

Awz = {(Л/4)Dc2 (ά/3600)}-{Л/4× (Dc-0.05)2× ά/3600}

Where Awz = area of waste periphery, m2

i.e., Awz = 2 – 5 % of Ac, taking 2% of Ac,

i.e., Awz = 0.0.0057 m2

Now,

Ap = Ac - (2×Ad) - Acz – Awz

Ap = 0.2833 – 2*0.0354 - 0.02833 - 0.0.0057 =0.1784 m2

Thus, Ap = 1.720 m2

8. Total Hole Area (Ah):

Since,

Ah / Ap = 0.1

Ah = 0.1× Ap

Ah = 0.1× 0.1784 =0.01784m2

Thus, Total Hole Area = 0.01784 m2

Now we know that,

4*Ah = nh × (.Лdh2)

Where nh = number of

holes.

nh = (4×0.01784)/ (.3.14×0.0052)

⇒nh = 909

Therefore, Number of holes = 909.

9. Weir Height (hw):

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Let hw = 45 mm.

10. Weeping Check

All the pressure drops calculated in this section are represented as mm head of

liquid on the plate. This serves as a common basis for evaluating the pressure

drops.

Notations used and their units:

hd = Pressure drop through the dry plate, mm of liquid on the plate

uh = Vapor velocity based on the hole area, m/s

how = Height of liquid over weir, mm of liquid on the plate

hσ= Pressure drop due to bubble formation, mm of liquid

hds= Dynamic seal of liquid, mm of liquid

hl = Pressure drop due to foaming, mm of liquid

hf = Pressure drop due to foaming,

Df = Average flow length of the liquid, m

Rh = Hydraulic radius of liquid flow, m

uf = Velocity of foam, m/s

(NRe) = Reynolds number of flow

f = Friction factor

hhg = Hydraulic gradient, mm of liquid

hda = Loss under down comer apron, mm of liquid

Ada = Area under the down comer apron, m2

c = Down comer clearance, m

hdc = Down comer backup, mm of liquid

Calculations:

Head loss through dry hole

hd = head loss across the dry hole

hd = k1 + [k2× (ρ g/ρl) ×Uh2] --------- (eqn. 18.6, page 18.9, 6th

edition Perry)

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

where Uh =gas velocity through

hole area

k1, k2 are constants

For sieve plates

k1 = 0 and

k2 = 50.8 / (Cv)2

where Cv = discharge coefficient, taken from fig. 18.14, page 18.9, 6th edition

Perry).

Now,

(Ah/Aa) = 0.01784/ 0.245 m2 = 0.073

also tT/dh = 3/5 = 0.60

Thus for (Ah/Aa) = 0.07993 and tT/dh = 0.60

We have from fig. edition 18.14, page 18.9

6th Perry.

Cv = 0.730

k2 = 50.8 / 0.7302 = 95.3275

Volumetric flow rate of Vapor at the top of the Enriching Section

qt = 0.3 m3/s.

Velocity through the hole area (Uh):

Velocity through the hole area at the top = Uh, = qt /Ah

= 0.3/0.01784 = 16.8 m/s

Velocity through hole area should be minimum because at low gas flow rate

weeping is

observed.

Now,

hd, = k2 [ρg/ρl] (Uh )2

= 95.3275(2.91/1011) 16.82

hd, top = 85.24 mm clear liquid. -------(minimum at top)

Chapter 1

O-Hydroxy Benzoic Acid and Related Compounds

Head Loss Due to Bubble Formation

hσ = 409 [σ/ (ρldh)] --- (eqn. 18.2.a, page 18.7, 6th

edition Perry)

where σsurface tension, mN/m

(dyne/cm)

dh =Hole diameter, mm

ρl = average density of

liquid in the

section,

kg/m3

= (987+1141)/2

= 1064 kg/m3

hσ=409 [17.4565 /(777.92 x5)]

hσ= 2.714 mm clear liquid

Height of Liquid Crest over Weir:

how = 664_)w [(q/Lw)2/3]-----------( eqn. 18.12.a, page 18.10,

6thedition Perry

q

= liquid flow rate at top, m3/s

= 17747.8/

(3600788.86)

= 6.24910-3 m3/s

q = 99.05 gal/min(or

GPM).

Lw = weir length = 1.425 m = 4.675 ft