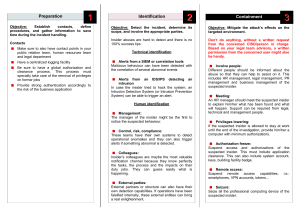

2017 Worker Safety Conference Understanding Serious Injury/Fatality Risks: How Machine Guarding Assessments, Layer of Protection Analysis, and Health and Safety Auditing Work Together to Drive a Zero Injury Culture Safety Moment Group Activity Part 1 In your facility / business if something were to happen that would critically injure or kill someone, what would it be? Write this down but don’t share it with anyone else. Safety Paradox Strong Reduction in Total Injuries Limited Progress on Fatalities Fatalities (Employee and Contractors) Recordable injury Frequency Rate (Total Injuries per 200,000 Hours worked) 5 12 10 4.6 4.1 4 2.9 8 7 6 6 2.7 2.1 2 9 8 3.1 11 9 8 3.8 3.3 3 11 2 6 6 5 4 4 1.8 1.47 1.24 2 1 0 0 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 Cargill Reportable Injury Frequency Rate 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 Cargill Fatality Cases Traditional Safety View: Herbert Heinrich Safety Triangle Fatality Lost Time Medical Aid Heinrich’s safety pyramid suggests that reducing workrelated incidents at the bottom of the pyramid will necessarily reduce the incidence or workrelated fatalities. First Aid Near Miss Our data suggests something more may be at work. New Model of Fatality Prevention: Focus on precursors with potential for serious injury Precursor A high-risk situation in which management controls are either absent, ineffective, or noncompliant and will result in a serious or fatal injury if allowed to continue. Serious Injury and Fatalities Precursor New Model Fatal Incident s Not all injuries have SIF potential Lost Time Reportable SIF & SIF Potential First Aides Injuries Near Misses Conditions Behaviors 7 Reducing injuries at the bottom of the Lost triangle does Time not necessarily Reportabl result in an e equivalent reduction of First Aides SIFs. Injuries Near Misses Conditions Behaviors Definition of Serious Injury and Fatality (SIF) Incident Incident that Results In: • Fatality • Life-threatening injury or illness • Life-altering injury or illness 8 Life-Threatening Injury/Illness Is an incident that if not immediately addressed is likely to lead to the death of the affected individual, and will usually require the intervention of internal and/or external emergency response personnel to provide life-sustaining support. Examples include, but are not limited to: • Laceration or crushing injuries that result in significant blood loss; • Injury involving damage to brain or spinal cord; • An event requiring the application of cardiopulmonary resuscitation or an external defibrillator; • Chest or abdominal trauma affecting vital organs. 9 Life-Altering Injury/Illness An incident that results in permanent impairment or loss of use of an internal organ, body function, or body part. EXAMPLES INCLUDE BUT ARE NOT LIMITED TO: • Significant head injuries; 1 0 • Spinal cord injuries; • Serious bone fractures that result in permanent impairment or loss of function; • Paralysis; • Serious burns; • Amputations; • Significant disfiguring lacerations. Definition of SIF Potential Incident Automatic Determination OR Credible Potential Any incident or exposure that meets defined automatic SIF Potential determination criteria or was • Reportable injuries; determined to have credible potential to be a fatality, life-threatening or life- • Near-misses; altering injury/illness. 1 1 This includes: • First-aid cases; • Exposing conditions. Is there credible potential that the incident could have result in a SIF injury or illness? “”1 in 100 Rule Reducing injuries at the bottom of the triangle does not necessarily result in an equivalent reduction of SIFs. New Model Fatal Incident s Not all injuries have SIF potential Lost Time Lost Time Reportable Reportabl e SIF & SIF Potential First Aides Injuries Near Misses Conditions Behaviors 13 First Aides Injuries Near Misses Conditions Behaviors Our business calls these SIF precursor activities “Lifesavers” Protein LIFEsaver SIF and SIF Potential Data FY 14/15 Contact w/ Sharp El evated Work El ectri cal Bul k Materi al H&S Mobi l e Equi pment Hot Work Li ve Ani mal Ri ggi ng / Li fti ng LOTO / Machi ne Safety Confi nd Space Hazardous Chemi cal s Excavati on / Trenchi ng Motor Vehi cl e Rai l Total s FY 15/16 32 5 27 2 22 1 18 0 15 0 12 0 10 0 144 19 7 19 0 20 1 7 0 33 0 10 1 4 1 122 Identifying Drift 1 7 Group Activity Part 2 Refer back to what you wrote down in part 1, what are you currently doing to prevent this from happening? Write this down but don’t share it with anyone else. How leaders respond to mistakes and errors shape the culture People achieve high levels of performance because of the encouragement and reinforcement received from leaders, peers, and subordinates. Punish or Learn Just Culture We Learn From Past Incidents Violations Are Rarely Malicious Leadership Response Matters Events can be avoided through an understanding of the reasons mistakes occur and lessons learned. Violations are rarely malicious, but wellmeaning behaviors, intended to get the job done. How leaders respond to mistakes and violations matters. Learn Punish Violations Non-compliant Behavior Unintentional Situational Organizational Optimizing Personal Optimizing Reckless Violations occur because a person was unaware of the rule or did not understand it or how it applied to the situation. Violations occur where a job cannot be done if the required procedures are followed. So instead of stopping “a work around” is found and the rule gets violated. Violations occur when a person chooses to violate a rule because they believe it was better for the company to do it this way. The violation was committed to improve performance or please a supervisor. Violations where the persons thought it was a better or easier way for them to do the job. Violations occur where the person violates a rule or policy and did not think about or care about the consequences. Remember . . . Concept adapted from James Reason, Sydney Dekker et al Serious Injury and Fatality (SIF) Risk Identification, Assessment and Control 23 Safety Champions SIF Hazard Identification and Task Risk Assessment Sheet Plant/department: Qualitative Risk Assessment Baseline Assessment Re-assessment Working Draft Drafted by: Nr 1 Task Hazardous event Consequences Unprotected Risk S L Risk Date: Page: Current Risk Defense Layers (Control Measures) Today Situation S L Risk Defense Layers ( Control Measures) Including the Proposed changes Serious Injury and Fatality Qualitative Risk Prioritization Matrix Task are prioritized for serious injury or fatality potential and intervention using the following risk prioritization matrix Defense Layers: Risk Reduction Allowance Independent Redundant Defense Layers Defense Layer Risk Reduction Design Changes to reduce the hazard: e.g. a process valve 12 feet high with actuator at the ground level to reduce fall exposure for operator. (Most effective/reliable defense layer) If hazard is eliminated risk is zero Engineered Safety Systems: which do not require people intervention such machine guarding well designed and engineered railing systems to prevent falls from the roof. May reduce the severity or likelihood 1-2 blocks on risk matrix depending on effectiveness. Active Safety Devices such as rail road crossing gates, fork truck speed limiters, pressure sensitive mats, sensors for speed/temperature/pressure control. May reduce severity one block on risk matrix if reliability verified. Significant Reduction In Frequency in task exposure such as from daily to annual and the frequency of exposure is continuously monitored (See below). May reduce likelihood by a maximum of one block, provided the integrity of additional deployed controls can be confirmed. Although it is recognized that task frequency may impact the type of control implemented, multiple independent defense layers from the above hierarchy must be evaluated and implemented where required. A reduction in task frequency alone is NEVER sufficient to manage the risk of a possible SIF event task! Defense Layers: Risk Reduction Allowance Independent Redundant Defense Layers Defense Layer Risk Reduction Administrative Controls: Reinforced behavior-based controls Administrative controls are defense layers which in combination can reduce the likelihood and, in the case of PPE the severity of an incident on the matrix. • • • Formal operator certification processes: Industrial truck operator licensing Formal behavior observation processes: Behavior based safety Specific disciplinary policy (e.g. Cardinal/zero tolerance safety rules) Behavior based controls • • • • Passive warning systems: Signs, warning labels Policy and procedures; Fall protection policies, confined space, lockout tagout Training programs: Lockout tagout, elevated work, task training Personal protection equipmen t Post-Event Planning: Post event planning should evaluate on-site and offsite emergency response and medical care capabilities. Basic rule is that 3 of these administrative defense layers are needed to move one block. For the purpose of this guideline it is assumed that post event planning is appropriately organized. However, if significant gaps exist, incident outcome severity would be adversely impacted, requiring the application of additional defense layers. Example: Identifying Defense Layers • • • • • • • • Design Change Engineered safety features Active safety devices Significant reduction in frequency Passive warning devices Signs Policies and procedures Training and qualification Personal Protection Most Effective Equipment Least Effective Design Safety Device Warning Device Group Activity Part 3 Refer back to what you wrote down in part 1, what types of safety assessments have you done regarding this issue? Do they focus on lower level administrative controls or higher level engineering controls? Write this down but don’t share it with anyone else. Machine Safety Eliminating SIF Events 30 CPS Enterprise Town Hall Why Machine Safety… Cross Functional/Geographical Team Identification of and 100% implementation of Machine Guarding standards established for Cargill Protein. Develop an assessment process for Grinders, whole bird chill tanks, scald tanks, surge bins and product blenders. Goals Collect data. 32 CPS Enterprise Town Hall Identify current opportunities for guarding improvements Set engineering standards for future equipment purchases. CARGILL PROTEIN EQUIPMENT RISK ASSESSMENT RECORD Machine Safety Assessments EQUIPMENT DETAILS How do plant personnel refer to this piece of equipment? Where in the plant is this equipment used? Approximately 1,400 pieces of equipment have been identified as requiring an assessment. Briefly explain how equipment is used? Which company manufactured this equipment? What are the type / model of this equipment? Do you have the OEM manual for this equipment? Has this equipment been modified from OEM specifications? If equipment has been modified, provide brief details. YES YES NO NO UNSURE As of 12/2016: were 50% complete What is the equipment’s energy source(s)? (list magnitude of energy where appropriate) By 3/2017: will be 100% complete Does this equipment require Lockout Tagout (LOTO)? If LOTO is required, provide date LOTO Procedure Review. Is use of this equipment considered a Critical Task 1. YES Date YES NO NO LEGAL AND OTHER REQUIREMENTS Is equipment covered by legal / other requirement(s) that must be maintained? If yes, list standard(s) and requirement(s). YES NO Are there any unguarded openings that a person may fall into or reach into? YES NO If yes, specifically identify these points. Example – Top of mixer is open but person could stand on mid-rail and fall into mixer. CPS Enterprise Town Hall 33 Lessons Learned So Far Mixer/blender drain/sample port accessibility Amputation exposure during sanitation when cap is removed Hazard eliminated with simple extension Lessons Learned So Far Inadequate Guarding Exposed vertical augers Group Activity Part 4 Refer back to what you wrote down in part 1, does this activity involve working with, on or near any equipment or machinery? If so, have you completed a thorough machine safety assessment? Write this down but don’t share it with anyone else. Questions so far? Understanding Serious Injury/Fatality Risks IT’S A SAFETY INSPECTOR’S WORLD? What’s in a name? Inspect or Audit īnspectiō 39 audīre noun verb a looking into to hear presence / absence effectiveness What’s the goal of auditing? Compliance or Conformance Compliance Note: The What Conformance The How Compliance is not just the rules and regulations that are placed upon us by legal entities. Singular Easier Compliance also includes Immediate Group More Difficult such as internal Interpret Results things goals that an organization sets for itself and mutual agreements between interested parties. Back to my earlier examples… How would an auditor look at these differently than an inspector? 41 Group Activity Part 5 What is your personal approach to monitoring your safety compliance? Are you more of an inspector or an auditor? What type of Safety Management System is right for your location? Formal vs. Informal – Documented or Undocumented – Complex or Simple – Registered or Unregistered Conformance to your SMS should ensure Compliance 43 How do you know if you have the right Safety Management System? It works!! 44 Group Activity Part 6 Take a minute and think about the following questions. - What type of SMS exists in my location? Do people in my location know about it? Do people in my location use it? Is my safety management system effective? What do safety management systems have to do with machine guarding assessments and layers of protection analysis? Its All About Identifying Drift 4 7 Risk Acceptance Lower Risk Higher Risk Risk Tolerance What is your risk tolerance? BRINGING IT ALL TOGETHER: DRIVING A ZERO INJURY CULTURE The Process Guide Group Activity Part 7 As we go through the next few slides, take notes about the activity you wrote down in part 1. If you can’t answer these now, you may want to figure this information out when you get back to work. Remember, its not enough that you know these answers – we have to ensure that our operations team mates know them and know how to work safely each and every day! The Process Guide The Process Guide The Process Guide The Process Guide The Process Guide The Process Guide Group Activity Part 8 Visualize using tools such as the SIF Risk Assessment Matrix, the Machine Guarding Assessment and the Safety Process Guide. How could you put these concepts to use in your own location? Thoughts and questions…