Man-made fibres

Anuncio

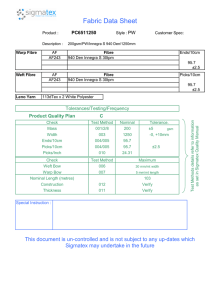

Man-made fibres Marzoli’s technology for man-made and technical fibres Man-made fibres Marzoli Index Man-made fibres p. 04 Processing of technical fibres p. 07 MARZOLI 3 VOUK Man-made fibres Marzoli’s technology for man-made and technical fibres Artificial fibres Synthetic fibres Man-made fibres can be divided in two main categories: artificial fibres and synthetic fibres. Artificial fibres are derived from natural products (in most cases cellulose) that are modified by reactive agents. Most known artificial fibres from cellulose: • • • • • • rayon or viscose; modal; lyocell; cuprammonium; acetate; triacetate. Synthetic fibres are derived from substances that are not present in nature, but instead created through chemical reactions (synthesis) from petrochemical products. Both types of fibres can be produced as a filament or can be cut at predefined lengths. When the fibre length is between 30 mm and 60 mm, the fibres are considered short or commonly called “cotton cut”, and can be processed in standard spinning mills. Most known synthetic fibres from chemical petrol products: • • • • • • • • • • acrylic; aramid (Kevlar and Nomex); vinyl chloride; modacrylic; polyamide (Nylon); polyester; polyethylene; polypropylene; polyurethane; polytetrafluoroethylene (Goretex). Synthetic fibres have been commonly used in the textile industry for several years both for apparel and for furnishing fabrics and in recent years they have evolved into new technical fibres. MARZOLI 4 VOUK Man-made fibres Marzoli’s technology for man-made and technical fibres Technical fibres In recent years textile products for technical applications in various high-tech areas have experienced great advancements. These materials are composed of natural, artificial and synthetic fibres and are capable of offering special characteristics such as mechanical, thermal, conduction, durability, resistance to flame, heat, smoke, chemicals, etc. Designed and produced based on particular needs, they are capable of performance levels that are not achievable with traditional fibres. Technical textile products are formulated by applying the manufacturer’s knowledge to the needs of the users. Together they can identify the desired characteristics of new products, the available raw materials and the most appropriate technologies to employ. One example in the architectural field is the production of fabrics used in structural frame canopies, or in the apparel and There are four basic elements that have to interact and integrate for the successful development of technical fabrics: Innovation is a strategic factor for the success of technical fabrics. Only a thorough research and development cooperation between the fabric’s user, the fibre producer and those in charge of the spinning and weaving processes can produce competitive and cutting-edge results internationally. • raw materials used to produce fibres and products with special mechanical and physical characteristics; • productive processes are influenced by the machinery manufacturers and the plant engineers; • the production of manufactured products, where the knowledge, experience and creativity of the machinery manufacturers, the spinners, the weavers and the finishing experts, all contribute to perfecting the various products; • the users always find and request new applications and innovative processes for their final products. Generally, technical fibres can be classified in two groups: furnishing industries, fabrics that offer fire-proof or anti dust-mites properties. In the field of technical textile products, natural fibres are becoming irrelevant; synthetic fibres, instead, have a huge growth potential, since they can be modified at the molecular level in order to develop the desired characteristics. Technical fibres are designed and produced with a determined end use in mind. • fibres derived from standard fibres through modifications of the productive process or their polymeric composition with the precise goal of improving certain technical characteristics. For example, high-tenacity polyester or flame resistant fibres called FR (Flame Retardant); • fibres that have been specifically studied and produced for high performance and industrial use. MARZOLI 5 VOUK Man-made fibres Marzoli’s technology for man-made and technical fibres World end-use consumption of technical texitles by application area The growth and wide distribution of technical fabrics seem unstoppable and is advancing even in countries that are traditionally more focused on cotton processing. • interior furnishings: rugs, carpets, draperies; • commercial furnishings: fireproof fabrics; • geotextiles: soil filtering and drainage; • civil engineering and construction: light and resistant fabrics of simple applications; Agrotech Buildtech Packtech The many uses of technical fabrics in various fields are such that making investments in technical textile production and processing plants today is not only a valid alternative to traditional spinning, but is also an important step to expanding in areas that are not as sensitive to heavy crisis that cyclically take over the global textile market. Technical fabrics can have endless applications: Sporttech Protech Clothtech Geotech Mobiltech Hometech Medtech Indutech • medical and healthcare: hospital furnishing, medical uniforms, bandages, etc; • industrial products: conveyor belts, packaging materials, food packaging, cleaning, etc; • filtration: dust filters, gas separation and purification, liquids filtration; • transport: automotive, belts, airbags, filters, soundproofing; • apparel: sport and protective, comfort, safety and accident prevenction; −− flame resistant; −− electromagnetic waves resistant; −− antimagnetic; −− UVA radiation resistant; −− cut, tear, impact resistant; −− chemicals, solvents resistant; −− thermal; −− anti-moss, water repellant, anti dust mites; −− water proof, breathable. Thanks to their variety and characteristics technical fibres are found in all productive and industrial fields and their spread will continue also in upcoming years. World end -use consumption of technical textiles, from 1995 to 2010 26 24 22 20 Million 18 Tons 16 14 12 10 1995 MARZOLI 2000 6 2005 VOUK 2010 Man-made fibres Processing of technical fibres Production technologies Marzoli knowledge in technical fibres The transformation process from fibre to yarn to fabric is comparable to the traditional process used for cotton fibres: opening, spinning, weaving, finishing, etc. Marzoli is the ideal partner for the quality and the uniqueness of its opening and blending machines, preparation and spinning. At the centre of Marzoli’s research, fibre producers, researchers and clients have actively cooperated to experiment with the various types of technical fibres in order to evaluate their spinning capabilities and the possible end results. Some fibre producers have installed selected Marzoli machines in their production departments to experiment directly on their products. Spinning Process Although technical and synthetic fibres do not require cleaning and are of uniform length, the spinning process is not at all easy or certain; rather, the choice of equipment and technology, as well as production and spinning planning, need to be appraised with care. Only with the best knowledge of the fibres to be employed one could select the right equipment to obtain the production and the quality to compete on an international level. The spinning process must be adaptable to the raw materials used in order to produce yarns that better showcase the fibre’s technical characteristics. MARZOLI Thanks to partnerships with some of the major producers of synthetic and technical yarns, Marzoli has acquired information and experience to design machines capable of powerfully yet delicately processing these fibres. Our technologists and our R&D department have actively cooperated with our customers to find the right solution for each type of raw material. 7 VOUK Man-made fibres Processing of technical fibres Opening One of the challenges of working with technical fibres is the opening of the fibrous mass without scraping, breaking, weakening the fibre. It is therefore of utmost importance to choose the correct composition of opening and blending equipment that will maximize production and quality. Marzoli’s line of equipment offers a selection among several types of openers with different types of variable speed beaters; different types Superblender B12 B12 Mixer B143L 4 cells 4 cells of carding sectors, feeding rollers and nipping points. Special finishes and, upon request, stainless steel plates are available to reduce the wear on parts in contact with the fibres. The transportation of the fibres with cage condenser instead of fans (which are used only where strictly necessary) reduces the formation of neps and curling in the opening line. High capacity blenders with pressurized air guarantee homogeneous final products. Fine opener B134L B134L Card C701 C701 Blending Carding When processing synthetic and technical fibres, different colours of the same fibre or fibres of different composition are often blended together. Marzoli’s high production feeders with precision scales can blend up to five different components and guarantee uniform mixes keeping blending errors below 1%. Historically, Italy has been the country of textile and fashion innovation thanks to the presence of prolific designers and researchers and it has proven itself again thanks to technical fibres. In the latest decades, several large and prestigious Italian groups have contributed to the unstoppable development of new yarns that take maximum advantage of the chemical and technical potential of the new fibres. Marzoli found itself to be the natural partner of these technical fibres pioneers and thanks to its intense dedication and its productive capabilities, has become the preferred partner for the selection of spinning equipment. Starting with the models developed in the ‘80s, Marzoli cards have adapted to the evolving attributes of technical fibres. The latest model (offering a carding area of 1.500 mm) has maintained the geometry and diameters of the carding organs that adapt well to the work required by this type of fibres. The new geometries, the large carding surface and numerous combinations of carding sectors in input and output, have allowed the new Marzoli card to increase its production rates, while guaranteeing at the same time efficient opening of the fibrous mass without fibre damage. MARZOLI 8 VOUK Man-made fibres Processing of technical fibres Spinning Technical fibres have to be spinned paying special attention to friction. Excessive friction and increase in heat can cause irreversible damage to yarn and fabrics. Roving Frames and Spinning Frames have to keep these factors into account. The correct spinning geometry, the antiballon position and the need of easy removal when required, are very important features and are characteristic of all models of Marzoli Spinning Frames. Both Marzoli roving frames and spinning frames guarantee high flexibility and can be adapted quickly to production of different types of fibres. All production parameters can be easily set using a touch screen. The cylinders can be equipped with a medium or long cradle; the spinning frame creel is extremely flexible and can be used for numerous special yarns applications. Production Rate Fibres Poli Phenil Sulfide Para-Aramid Meta ParaAramid Polyimides Polyester FR Modacrylic Length mm 51 50 50 53 60 38 Fineness Dtex 2,2 1,7 1,4 2,2 3,3 2,2 Yarn Count Ne 20 30 36 24 24 24 Card C701 Kg/h 60 55 60 58 65 60 Draw frame mt/min 450 500 500 450 450 500 Roving frame Rpm 1.000 1.100 1.200 1.100 1.100 1.100 Ring frame R.p.m. 13.000 14.000 15.000 13.000 13.000 13.200 Machines production MARZOLI 9 VOUK Man-made fibres Processing of technical fibres In the following tables we show data for some of the fibres successfully processed on Marzoli production lines. Fibre type Fineness dtex Length Fibre type Fineness dtex Length Polyester FR 3.3 60 mm Polyamide 2,2 53 mm Yarn Count Ne 24 Quality Yarn Count Ne 24 Quality U% Thin 50% Thick 50% Neps 200% RKM (cN/tex) Elong.% 12.2 38 15 25 23.5 23.00 U% Thin 50% Thick 50% Neps 200% RKM (cN/tex) Elong.% 9.0 11 15 14 22.50 22.90 Fibre type Fineness dtex Length Fibre type Fineness dtex Length Modacrylic 1,9 51 mm PoliPhenilSulfide 2,2 51 mm Yarn Count Ne 20 Quality Yarn Count Ne 20 Quality U% Thin 50% Thick 50% Neps 200% RKM (cN/tex) Elong.% 9,9 2 4 4 18.00 21,00 U% Thin 50% Thick 50% Neps 200% RKM (cN/tex) Elong.% 9,2 0 9 30 26,30 19,70 Fibre type Fineness dtex Length Fibre type Fineness dtex Length Para-Aramid 1,7 50 mm Meta Para-Aramid 1,4 50 mm Yarn Count Ne 30 Quality Yarn Count Ne 20 Quality U% Thin 50% Thick 50% Neps 200% RKM (cN/tex) Elong.% 12,0 20 45 85 65 3,5 U% Thin 50% Thick 50% Neps 200% RKM (cN/tex) Elong.% 11,5 13 270 690 19,5 18,5 MARZOLI 10 VOUK Man-made fibres Note “The text and format of this brochure can be changed any time with the change in policy matters.” MARZOLI 11 VOUK Complete Spinning System Spinning Section Short Staple Fibre - Carded Cotton - Combed Cotton - Man-made Fibres and Blends Draw Frames Combing Section Carding Section Opening Section Galileo Vi a S . Albe r t o , 10 - 250 3 6 Pa l a z z o l o s / O , B r e s c i a - I taly Tel. +39 030 7309 1 - Fax +39 030 7309 365 - [email protected] www.marzoli.it